New process of manufacturing cemented carbide and a product obtained thereof

A cemented carbide and hard technology, which is applied in the field of manufacturing cemented carbide, can solve the problems of reducing the toughness of sintered products and not being solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

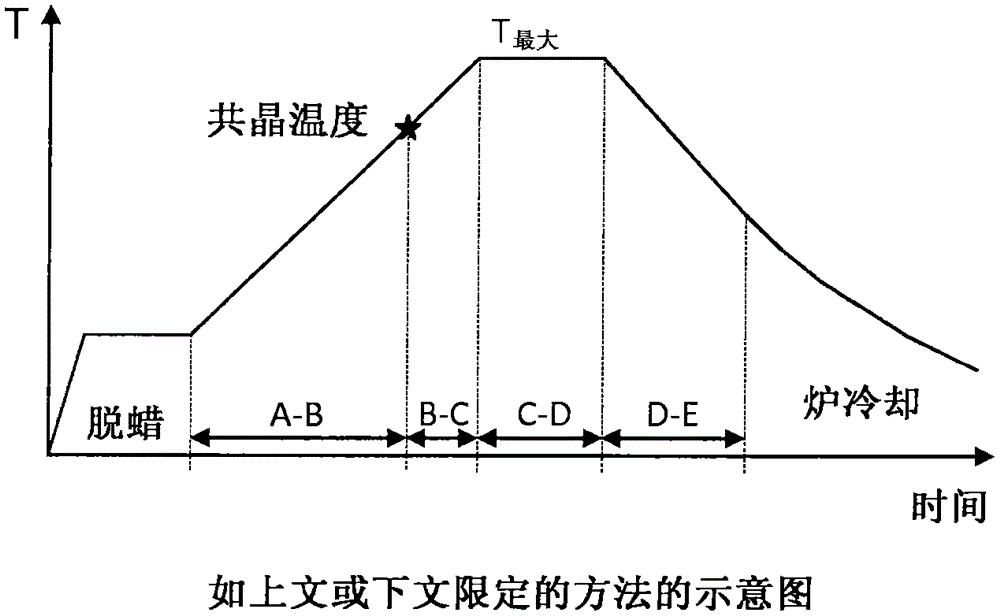

Method used

Image

Examples

Embodiment 1

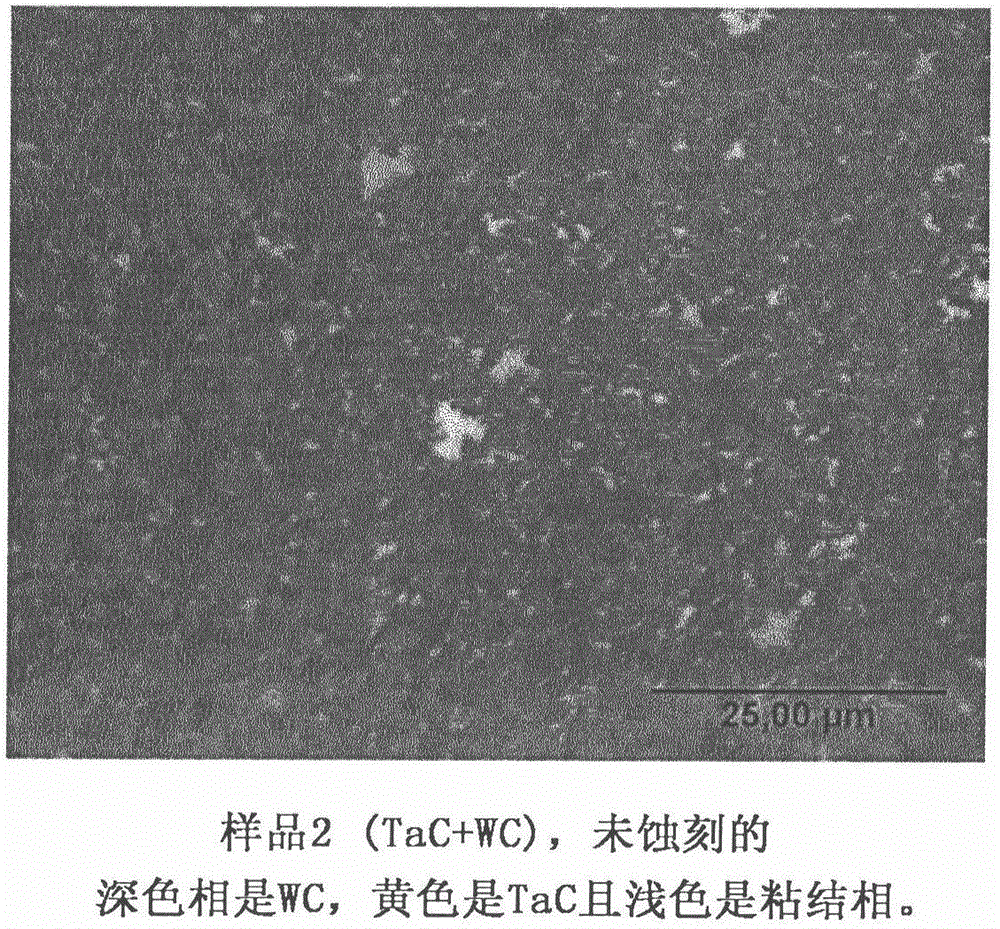

[0076] composition

[0077] Using ThermoCalc software [J.-O.Andersson, T.Helander, L.Hoglund, P.Shi, and B.Sundman, Thermo-Calc & DICTRA, computational tools formaterial science, Calphad, 2002: 26 (2): 273 -312] Determination of composition. The standard is that the carbon activity in the fcc+MC+WC region is 0.5 in a liquid at 1410° C. and a Co composition of 6 wt%.

[0078] Table 1. Composition of pre-alloyed raw materials and reference raw materials in % by weight. Values are provided by powder manufacturer Wolfram Bergbau.

[0079] powder

C (wt%)

Ta (wt%)

Cr(wt%)

Grain size (μm)

(W, Ta)

6.16

0.8439

4.35

(W, Cr)

6.13

0.6499

3.85

WC

6.15

4.25

[0080]Samples are listed in the table below. Each sample has a reference with the same Ta or / and Cr content. Furthermore, pure samples of WC+Co were fabricated without any added carbides.

[0081] (W, Ta)C+CoWC+TaC+C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com