Soft coal rock sample preparation system and method

A sample preparation system and a technology for soft coal rock, applied in the field of coal rock property testing, can solve the problems of difficult to achieve sampling effect, easy to break, low success rate, etc., and achieve the effects of simple structure, good integrity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

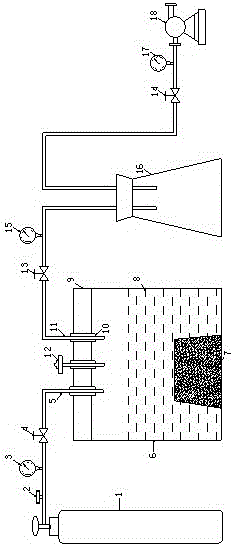

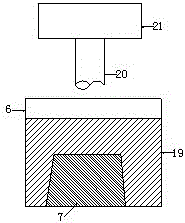

[0030] like figure 1 As shown, a soft coal rock sample preparation system includes a wooden box 6 provided with a box cover 9. The box cover 9 is provided with holes and connected to a liquid nitrogen treatment system and a vacuum system through pipelines. The liquid nitrogen treatment system includes a liquid inlet valve 4, a first pressure gauge 3, a liquid nitrogen tank shut-off valve 2 and a liquid nitrogen tank 1 connected in sequence through a liquid inlet pipeline 5; valve 12. The vacuum pumping system includes a first valve 13 , a second pressure gauge 15 , a buffer tank 16 , a second valve 14 , a vacuum gauge 17 and a vacuum pump 18 connected in sequence through an outlet pipeline 11 . The liquid inlet pipeline 5 and the gas outlet pipeline 11 pass through the box cover 9 and extend into the wooden box 6, and the joints of the liquid inlet pipeline 5, the gas outlet pipeline 11 and the box cover 9 are all sleeved with sealing sleeves 10 .

[0031] In the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com