Short-cut nitrification coupled anaerobic ammonia oxidation denitrification reactor

An anammox and short-range nitrification technology, which is applied in the field of short-range nitrification coupled with anammox denitrification reactors, can solve problems such as the restriction of synchronous metabolic reaction, and achieve the improvement of short-range nitrification rate, saving investment and operation cost, and restoring sedimentation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

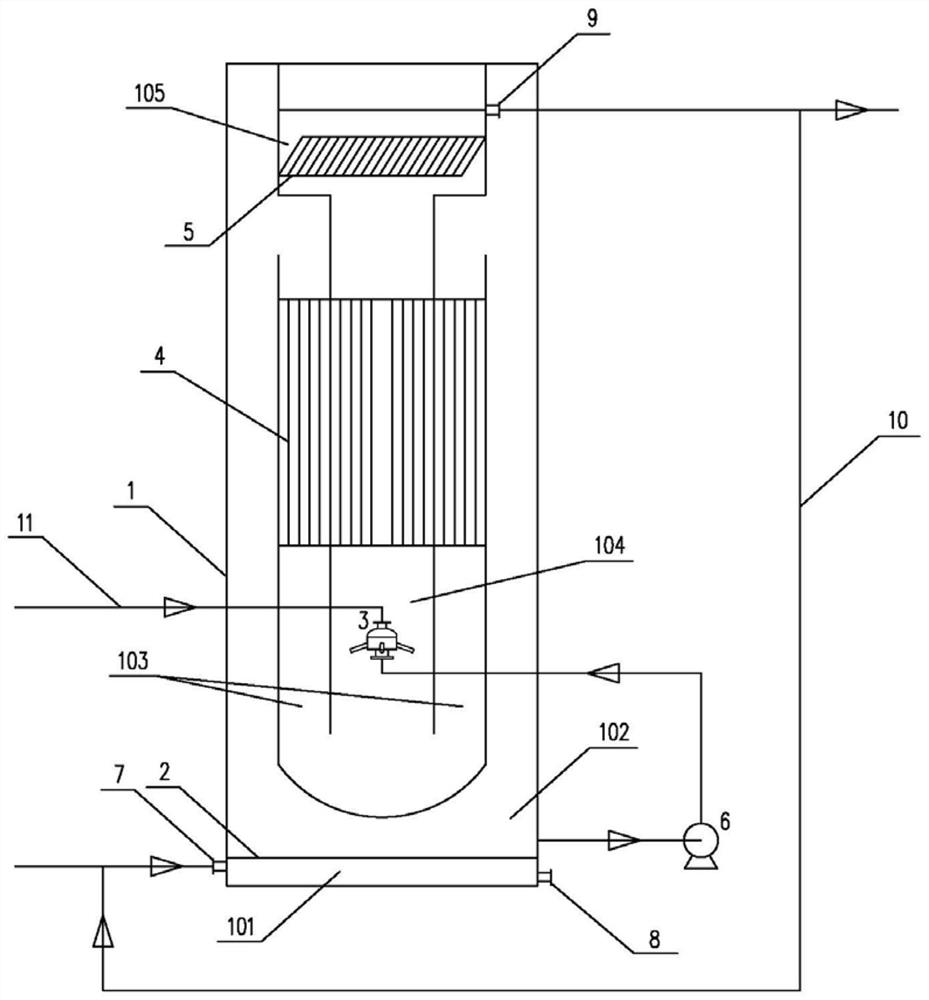

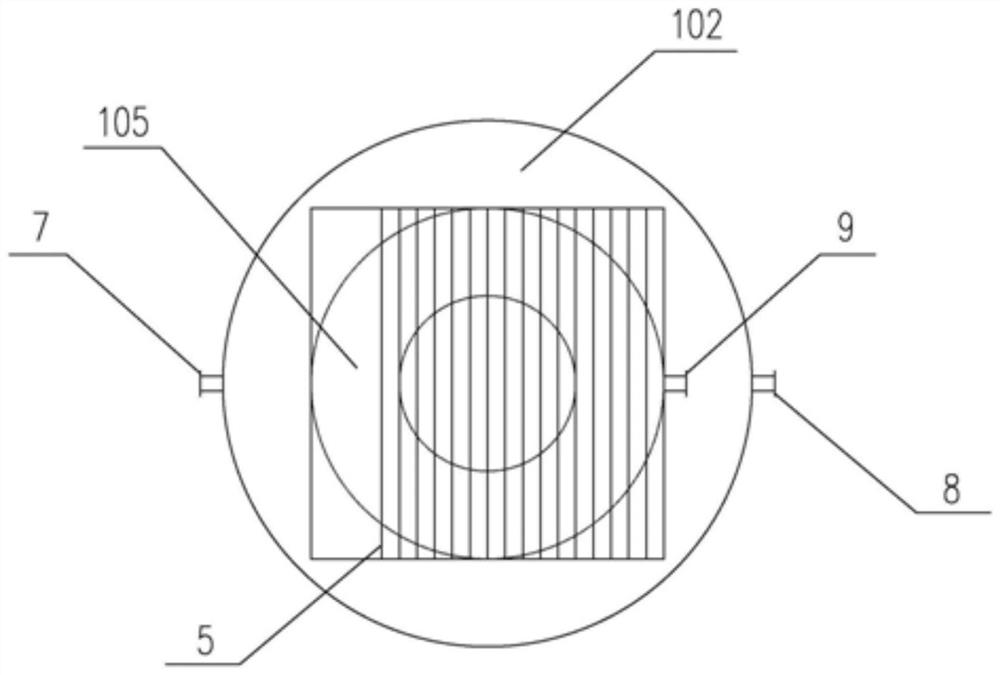

[0029] Such as figure 1 and figure 2 As shown, the short-path nitrification coupled anammox denitrification reactor includes a tank body 1, a water distributor 2, a jet aerator 3, an enzyme floating packing 4, an inclined plate separator 5 and an external circulation pump 6.

[0030] Wherein, the tank body 1 includes a mixing zone 101, an anaerobic zone 102, an anoxic zone 103, an aerobic zone 104, and a solid-liquid separation zone 105, and a water inlet 7 and a sludge discharge port 8 are provided on the side wall near the bottom;

[0031] The anaerobic zone 102, the anoxic zone 103 and the aerobic zone 104 are all biochemical reaction zones, which are separated in the tank body 1 by a cylindrical inner tank with an upper opening and a lower opening, and are all located in the mixing zone 101 above;

[0032] The mixing zone 101 is located at the bottom of the tank body 1, with a water distributor 2 inside, and communicates with the outside world through the water inlet 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com