Group vision machine assisted assembly method and model system

An assembly method and visual machine technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as difficulty in adapting to production models, low production efficiency, and large floor space, so as to save investment in production equipment and Occupies space, improves production efficiency, and has good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

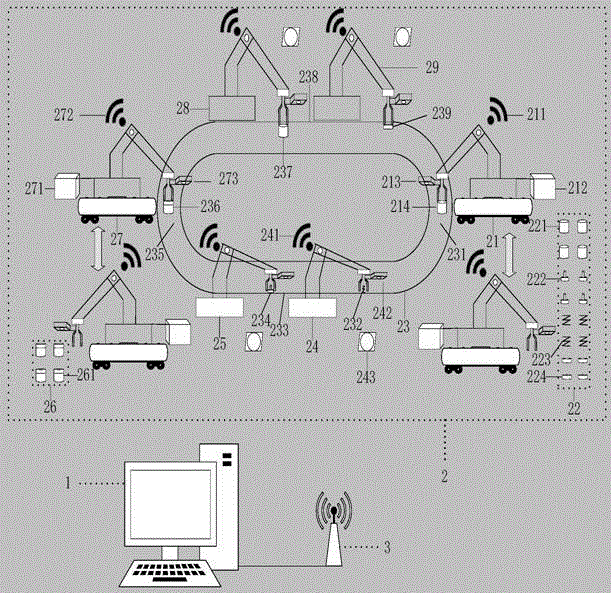

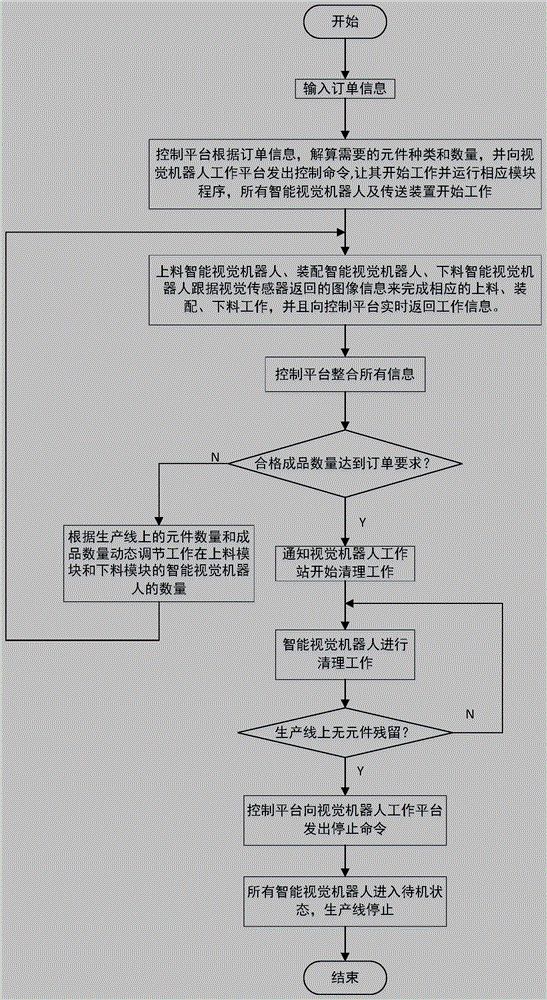

[0023] Such as figure 1 As shown, the group vision machine collaborative assembly model system of the present invention includes a control platform 1, a vision robot workstation 2, and a wireless module 3 responsible for communication between the control platform 1 and the vision robot workstation 2. The control platform 1 integrates the vision robot workstation 2 and sends back work information, and send control commands to the visual robot work platform 2 according to the integrated work information.

[0024]The visual robot workstation 2 includes a component storage area 22, a material loading area 231, an assembly area 233, an assembly area 238, a blanking area 235, and a finished product storage area 26, wherein the component storage area 22 places four kinds of components 221, 222, 223, 224, the loading area 231 and the unloading area 235...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com