Designing method of sludge processing apparatus and apparatus thereof

A technology of sludge treatment and design method, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve air and environmental pollution, the overall technical route of national sludge treatment and disposal is not clear enough, Problems such as failure to be dealt with properly can achieve the effect of no secondary pollution, alleviating the contradiction between sludge production and sludge treatment capacity lag, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

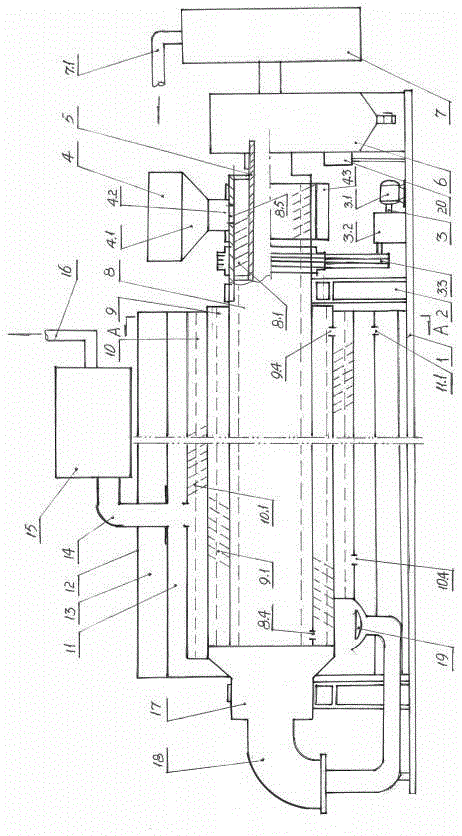

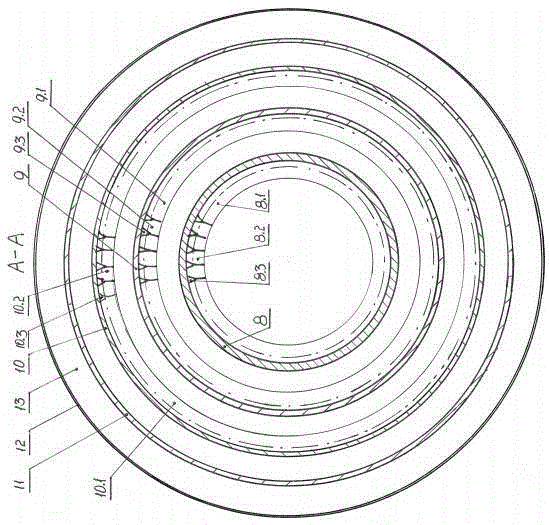

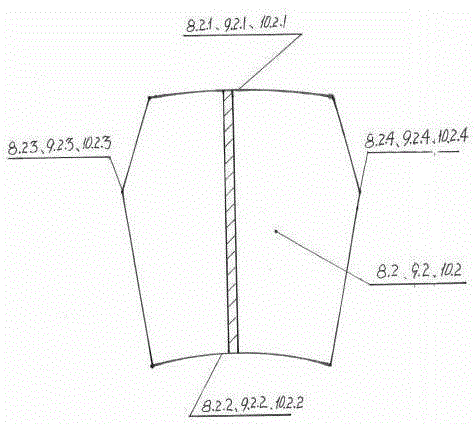

[0033] The design method of a sludge treatment device in Example 1 of the present invention includes the overall design of the machine base, the sludge treatment drum, the power drive mechanism, the output pipeline, the machine cover and the specific design of each component. The design method of the above-mentioned sludge treatment device is to add a certain amount of glucose powder to the modified sludge with a water content of 25-30% according to the difference in heavy metal content in the sludge, and then add a certain amount of glucose powder under normal pressure and different temperatures. Under the same conditions, three sludge treatment drums are passed through three sludge treatment drums in sequence, and three process steps are carried out in the process of mechanical stirring and uniform rotation of heavy metals, dehydration and denitrification treatment, carbonization treatment, and fixed carbon combustion treatment; the treated sludge meets the requirements of the...

Embodiment 2

[0045] The design method of a sludge treatment device in Example 2 of the present invention includes the overall design of the machine base, the sludge treatment drum, the power drive mechanism, the output pipeline, the machine cover, and the specific design of each component. The design method of the above-mentioned sludge treatment device is to add a certain amount of glucose powder to the modified sludge with a water content of 25-30% according to the difference in heavy metal content in the sludge, and then add a certain amount of glucose powder under normal pressure and different temperatures. Under the same conditions, three sludge treatment drums are passed through three sludge treatment drums in sequence, and three process steps are carried out in the process of mechanical stirring and uniform rotation of heavy metals, dehydration and denitrification treatment, carbonization treatment, and fixed carbon combustion treatment; the treated sludge meets the requirements of th...

Embodiment 3

[0057] The design method of a sludge treatment device in Example 3 of the present invention includes the overall design of the machine base, the sludge treatment drum, the power drive mechanism, the output pipeline, the machine cover and the specific design of each component. The design method of the above-mentioned sludge treatment device is to add a certain amount of glucose powder to the modified sludge with a water content of 25-30% according to the difference in heavy metal content in the sludge, and then add a certain amount of glucose powder under normal pressure and different temperatures. Under the same conditions, it passes through three sludge treatment drums in turn, and performs three process steps of heavy metal and dehydration and denitrification treatment, carbonization treatment, and fixed carbon combustion treatment during the process of mechanical stirring and uniform rotation of the drums; the treated sludge meets the national standards. The standard for agr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com