A gel slug isolation well control method

A gel and wellbore technology, applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., to achieve novel technical ideas, reliable technical solutions, and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A gel slug isolation well control method, it comprises the following steps:

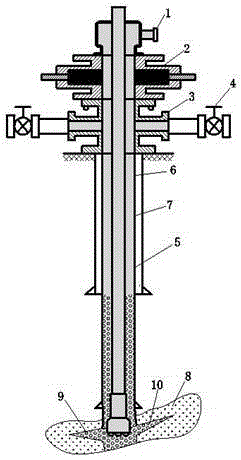

[0030] S1. When drilling in a complex wellbore situation where spills and leaks coexist (such as fractured reservoirs, that is, reservoirs 8 with fractures 9, leakage, and gas overflow 10), first implement throttling and exhaust, and plugging while drilling; If the pressure bearing capacity meets the requirements of the heavier drilling fluid, use the heavier drilling fluid to throttle and kill the well, restore and rebuild the wellbore pressure balance relationship, see figure 1 ;

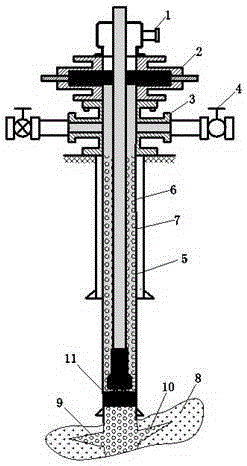

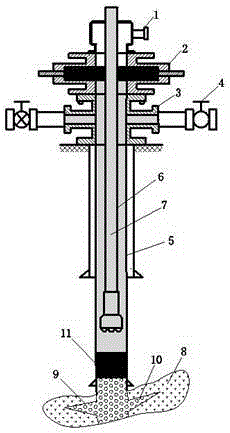

[0031] S2. If plugging while drilling is unsuccessful, resulting in dirty wellbore exhaust and pressure bearing capacity not meeting the requirements of heavier drilling fluid, use throttling circulation to inject gel until a gel slug 11 is formed in the lower part of the wellbore. Isolate the wellbore, block the upward movement (upward channeling) of oil and gas, and effectively control the complex leakage at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com