Patents

Literature

36results about How to "Reliable technical solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kubernetes-based high-availability method and device for deploying a harber mirror image warehouse

ActiveCN109684420AHigh availability deploymentAvoid exceptionDatabase distribution/replicationDatabase modelsPoint of entryHigh availability

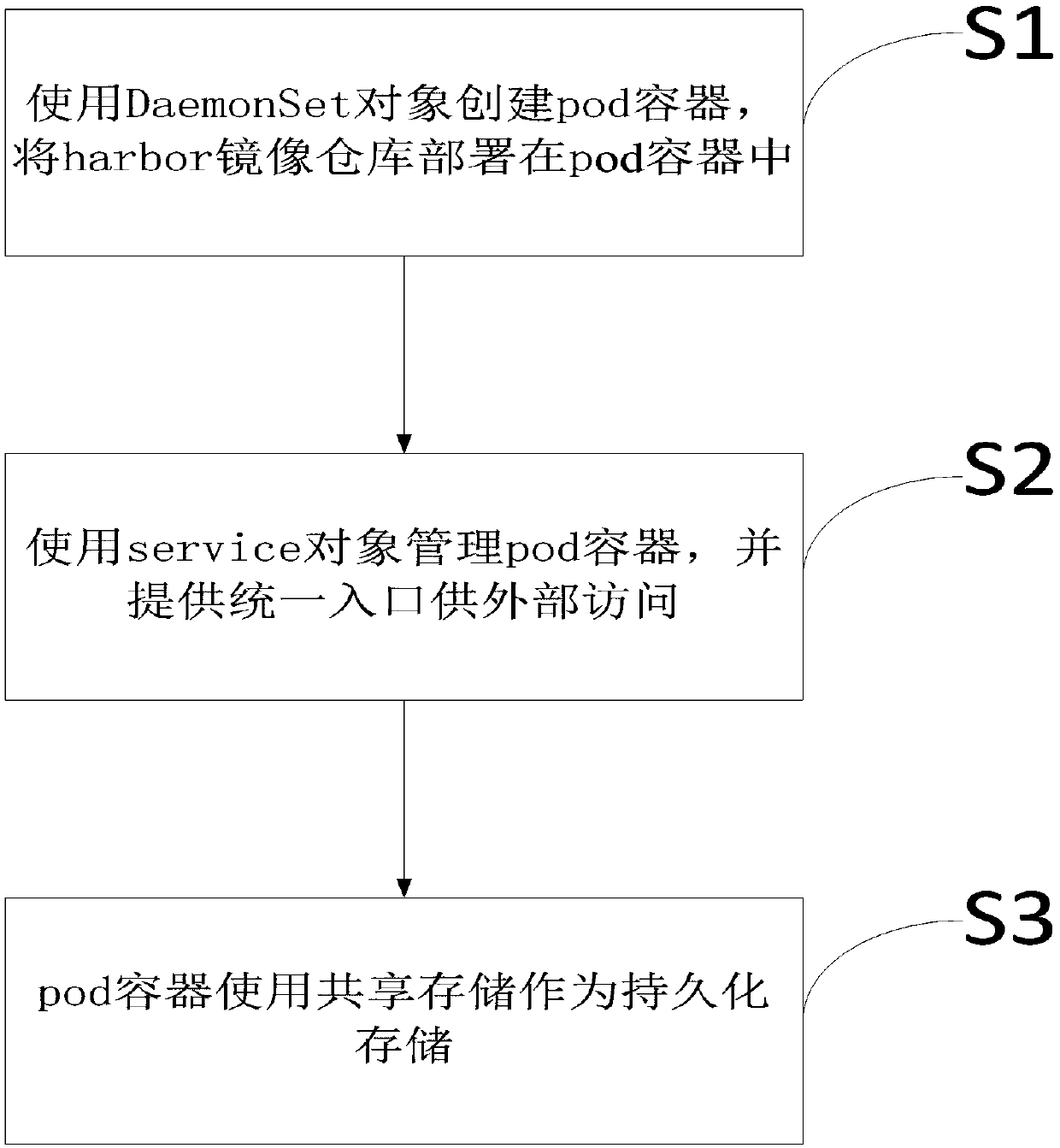

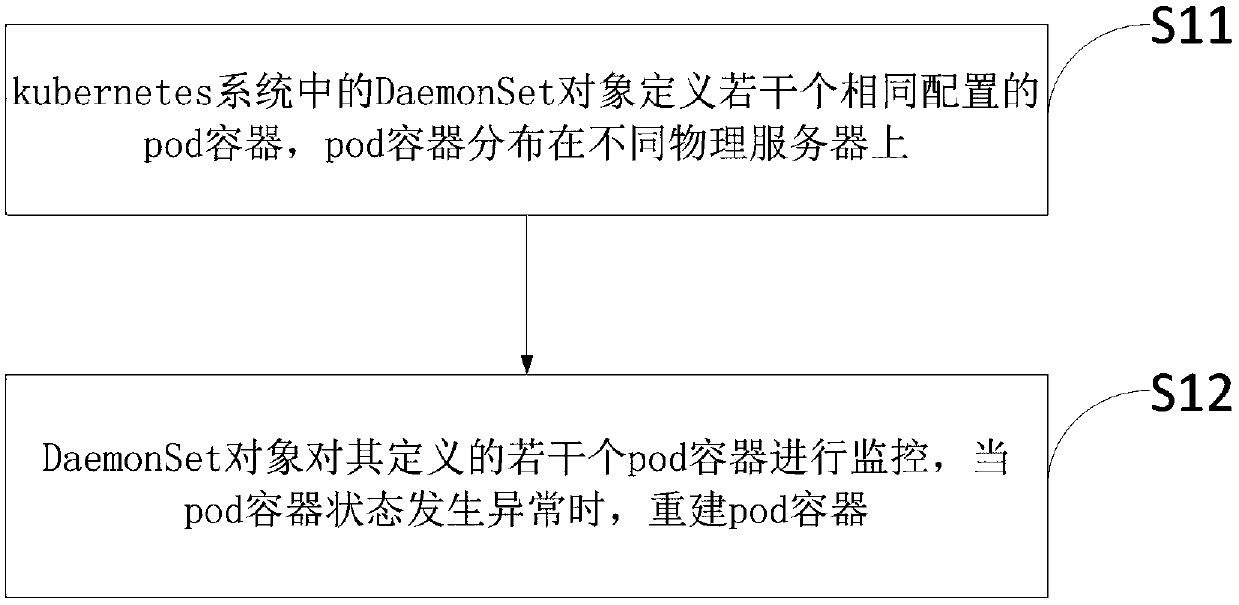

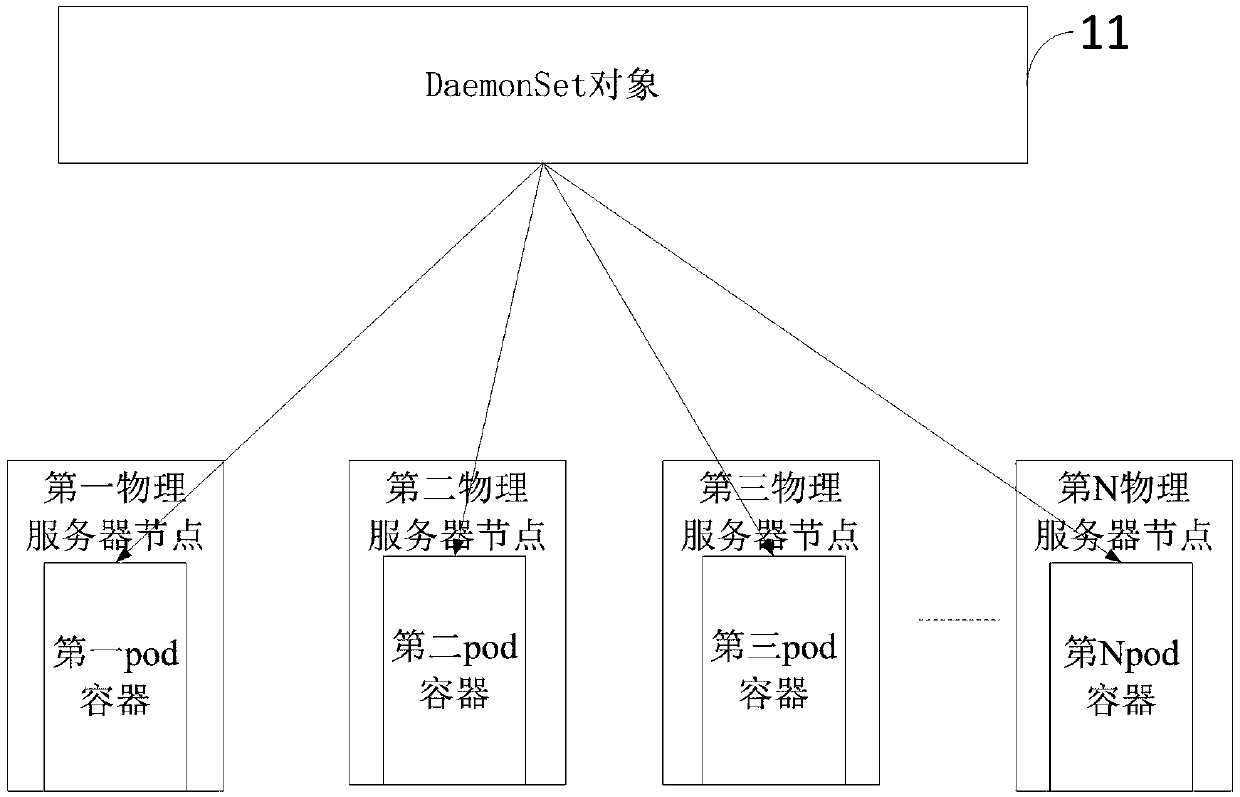

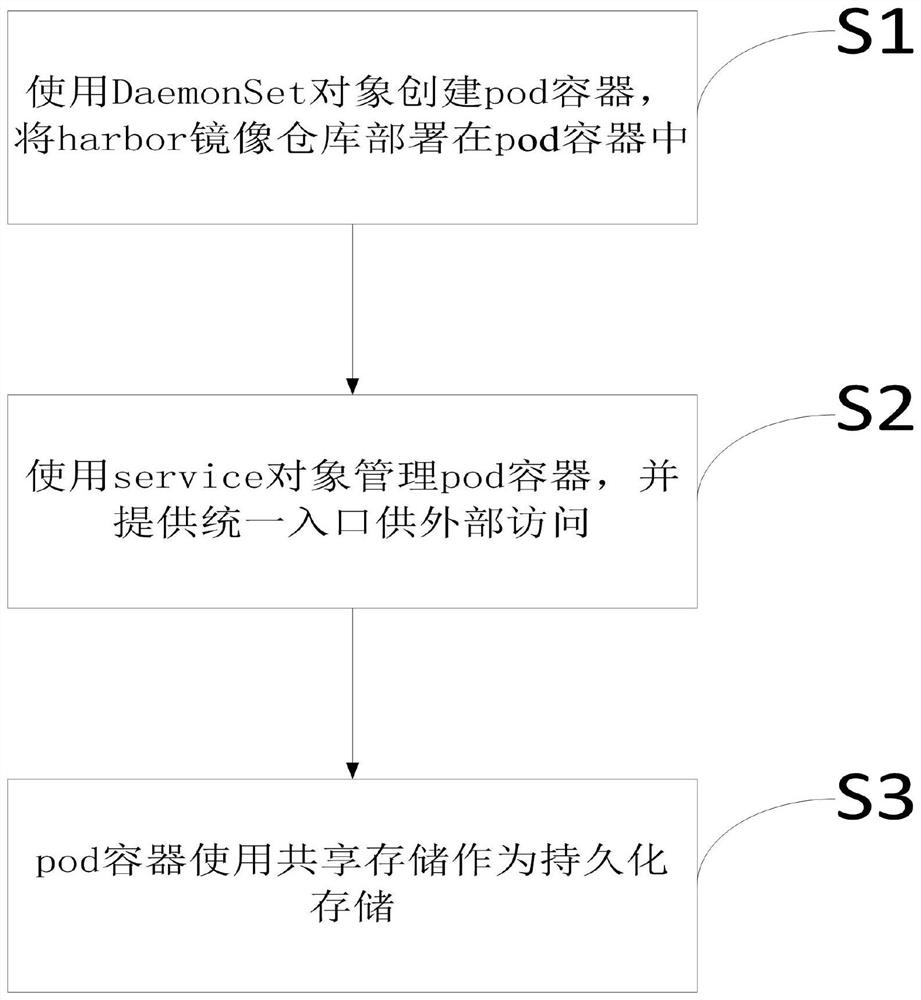

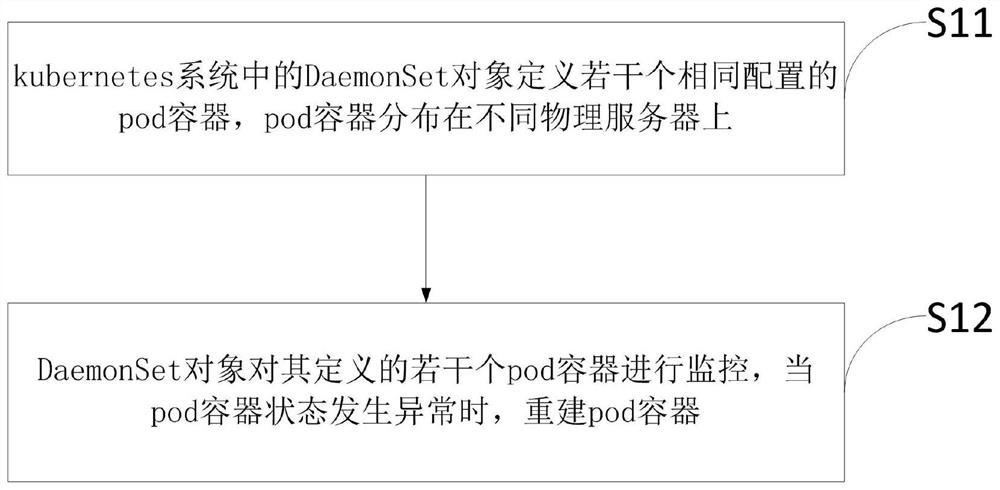

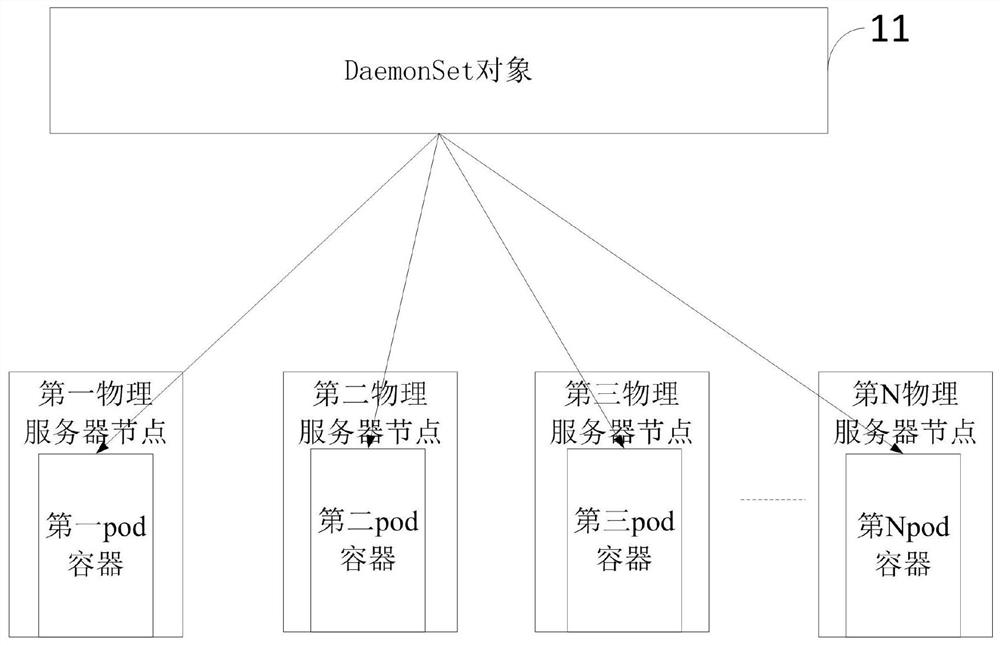

The invention aims to solve the problems existing in the prior art of high-availability deployment of a harber warehouse. The invention innovatively provides a kubernetes-based method and a kubernetes-based device for deploying a harber mirror image warehouse with high availability. The method comprises the following steps of: creating a harbor service container by using a DaemonSet object; The method comprises the following steps: deploying a harber mirror image warehouse in a pod container; the service object is used for managing the pod container; According to the method, the shared storageis used as the main storage, a unified entrance is provided for external access, and the pod container uses the shared storage as the persistent storage, so that the high-availability deployment of the harber mirror image warehouse can be realized, the problems that data synchronization often causes abnormity or data loss and the like are avoided, the operability is high, the method is simple, feasible and reliable, and the working efficiency is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

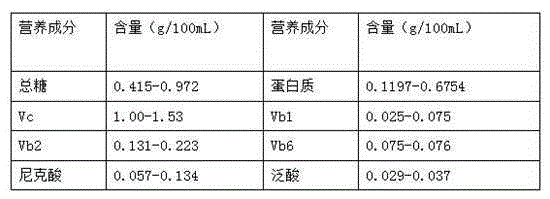

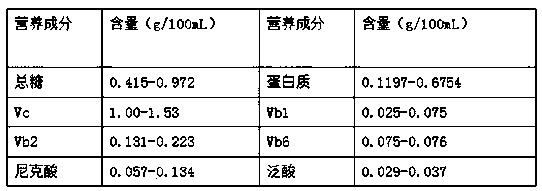

Production method of fermented fruit and vegetable juice and Chinese rice wine composited function beverage

ActiveCN105249100ALong flavorFlavor substances, these flavors lastAlcoholic beverage preparationFood ingredient functionsBiotechnologyNutrition

The invention discloses a production method of a fermented fruit and vegetable juice and Chinese rice wine composited function beverage. The production method comprises steps as follows: fermented fruit and vegetable juice and fermented fruit and vegetable Chinese rice wine are prepared; the fermented fruit and vegetable Chinese rice wine, the fermented fruit and vegetable juice and water are mixed in a volume ratio being (7-10): (3-6): (1-1.5); degassing, sterilizing and filling are performed after mixing, and a finished product is obtained. The fermented fruit and vegetable juice and Chinese rice wine composited function beverage produced with the method can overcome defects of uncomprehensive nutrition and absence of a healthcare function of the fermented fruit and vegetable Chinese rice wine as well as low content of vitamin B of the fermented fruit and vegetable juice, produces unique fermentation flavor, has more comprehensive and more balanced nutrition and gastrointestinal healthcare efficacy, is suitable for people of all ages and is a novel nourishing beverage.

Owner:广西轻工业科学技术研究院有限公司

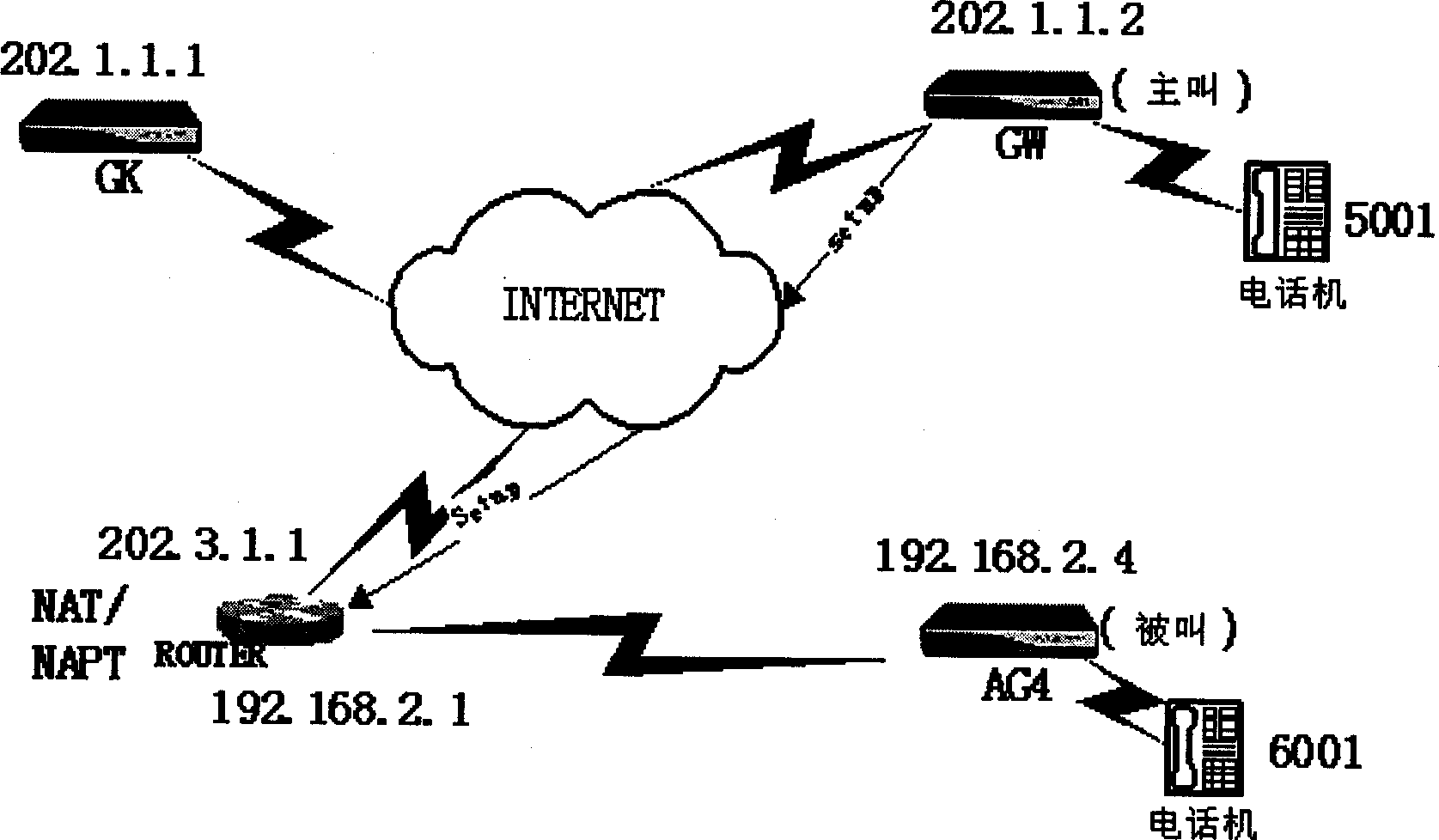

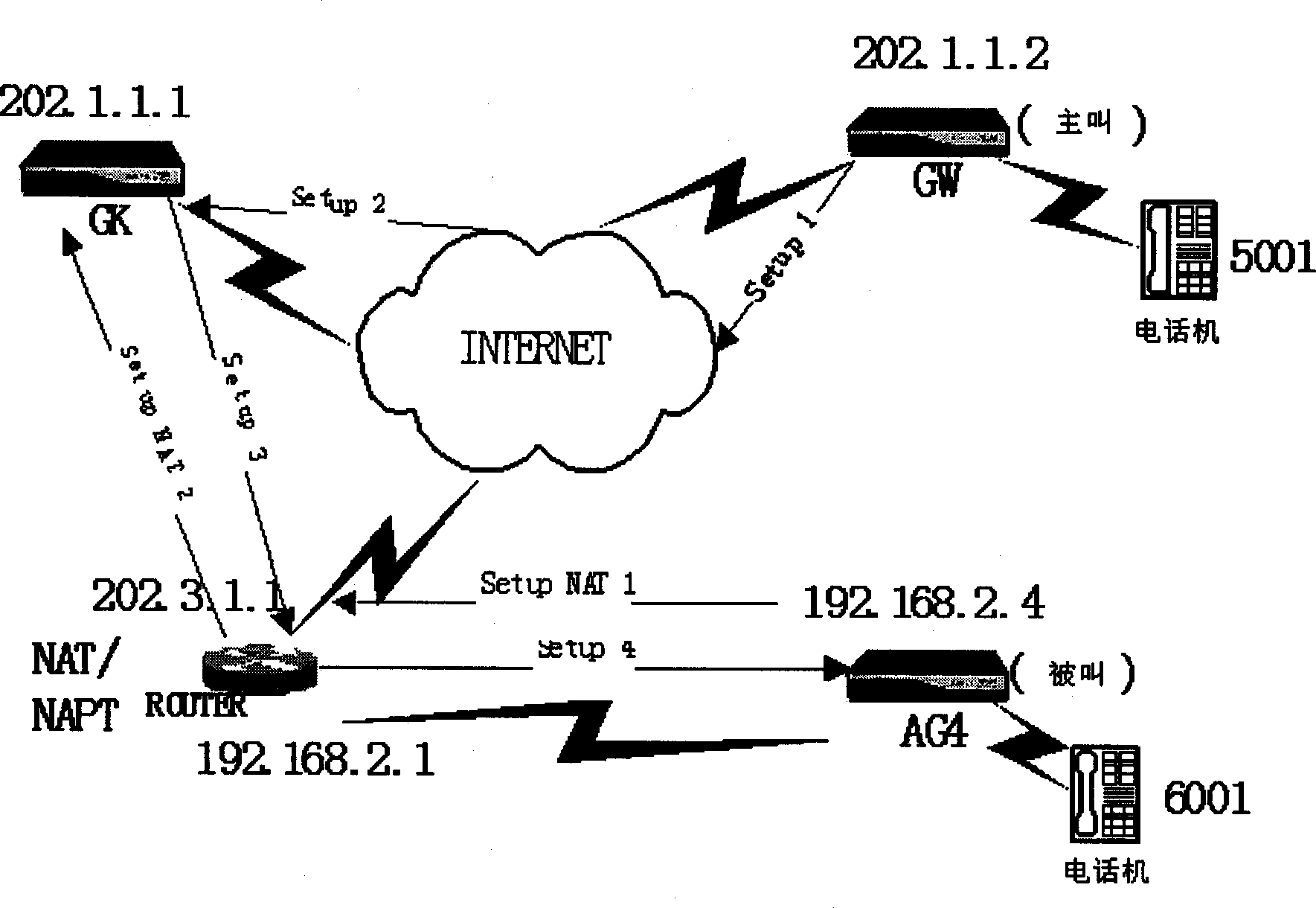

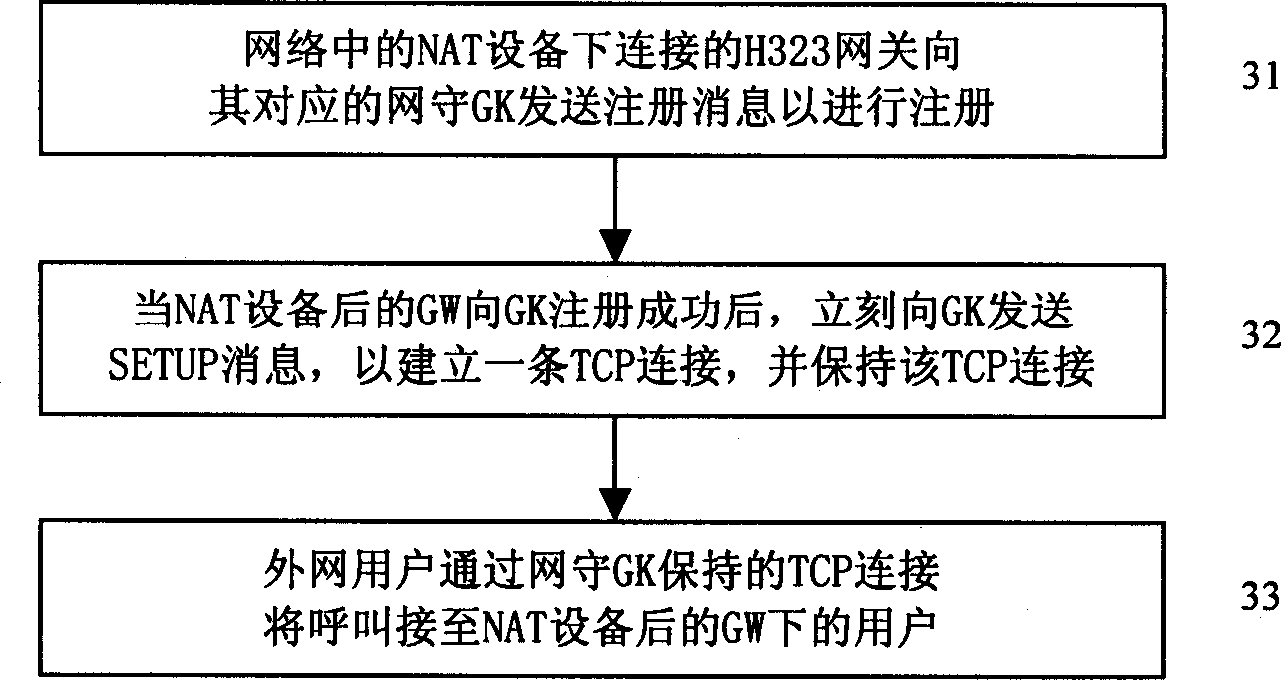

Method for realizing external network user crossing NAT equipment

InactiveCN1767509AReliable technical solutionData switching by path configurationNetwork connectionsTelecommunicationsComputer science

Owner:BEIJING JIAXUN FEIHONG ELECTRIC CO LTD

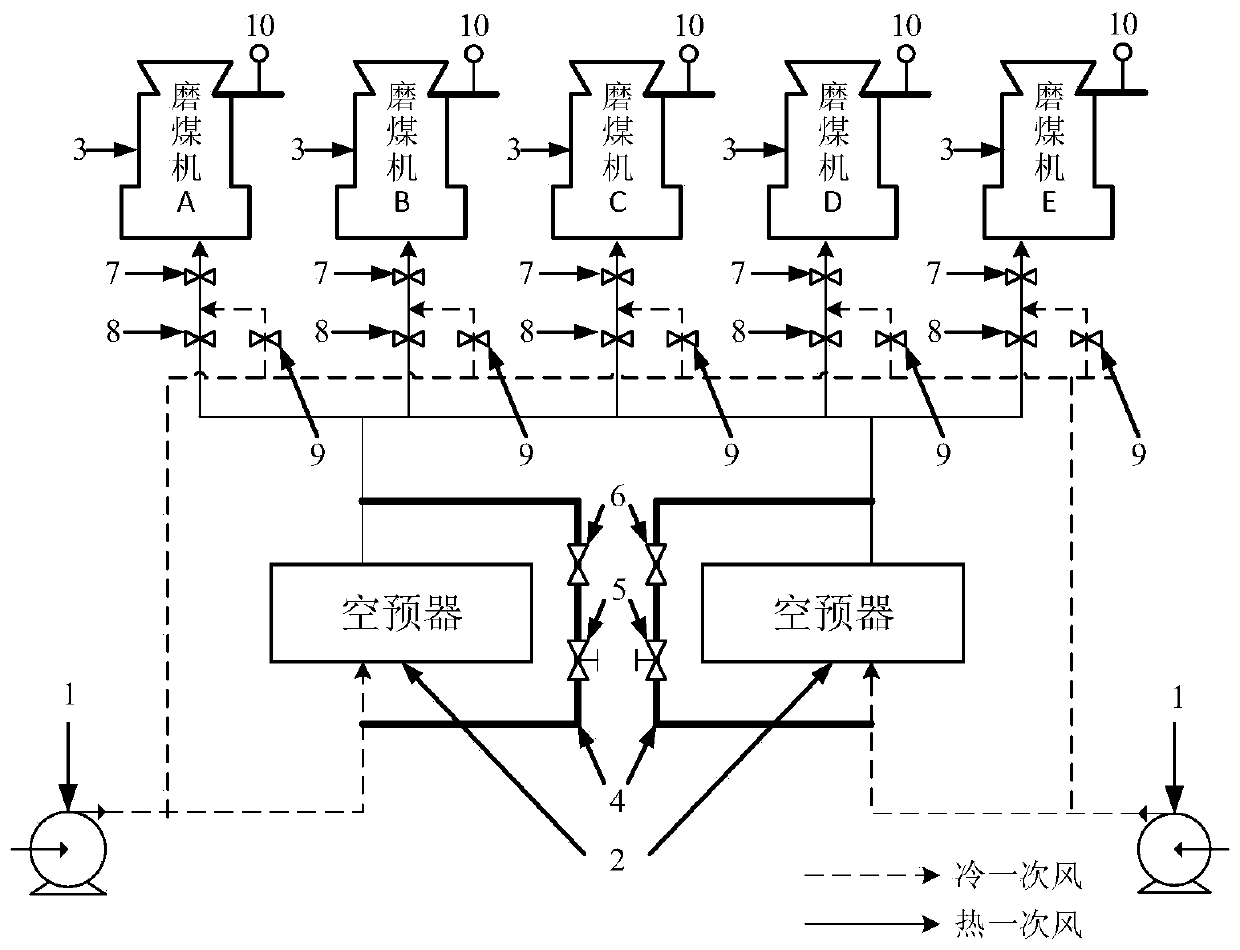

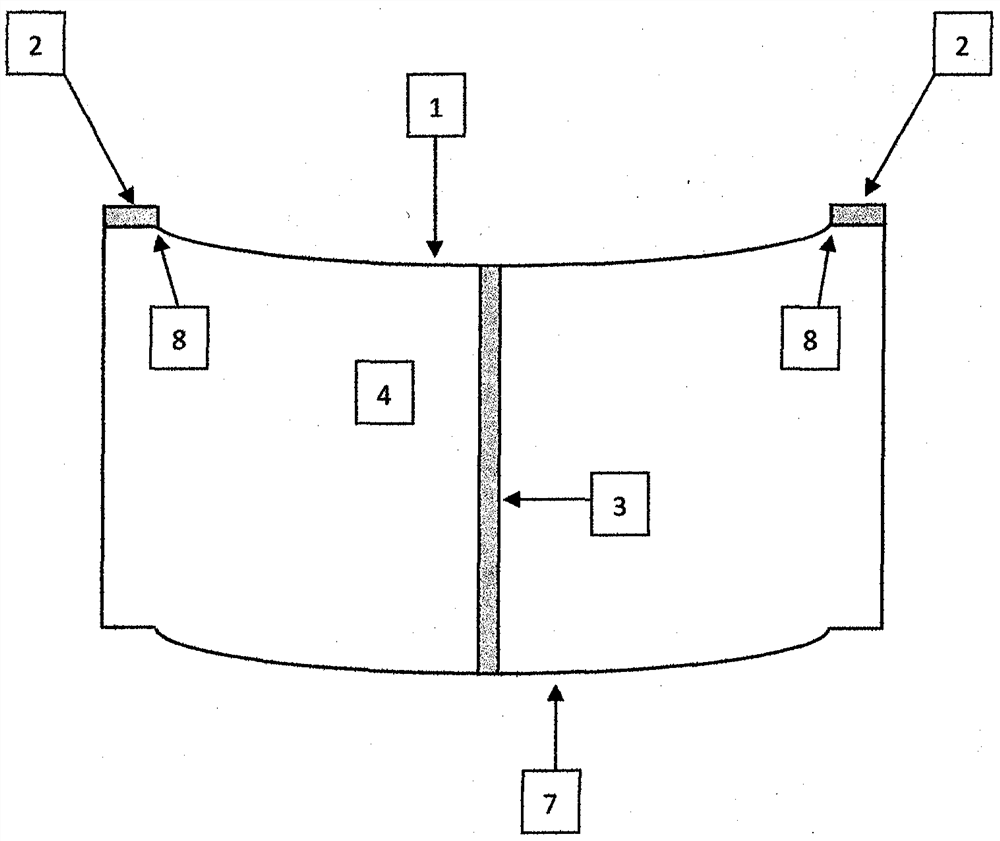

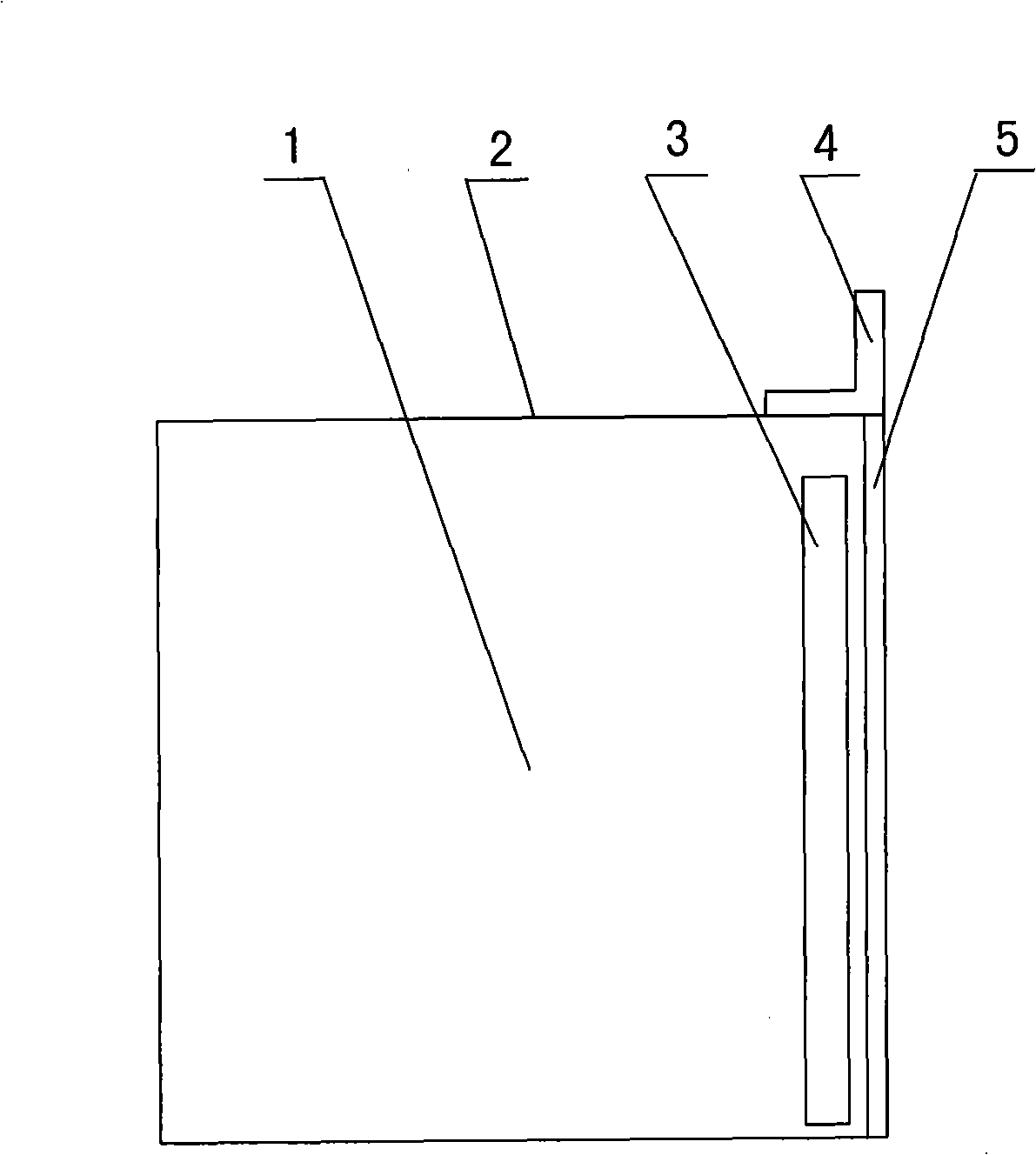

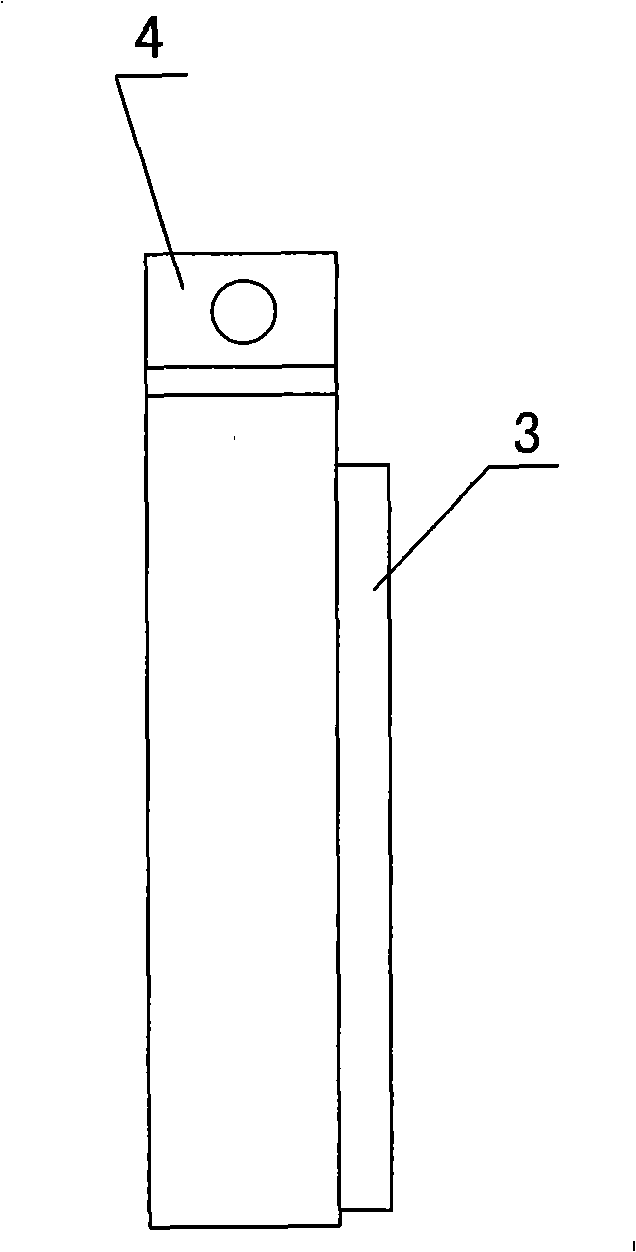

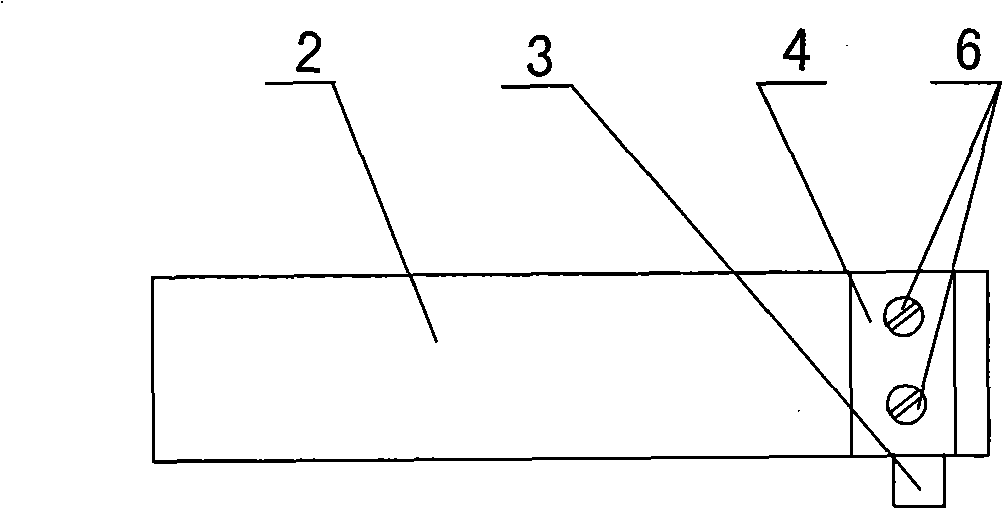

System for improving outlet temperature adjustment flexibility of coal mill

PendingCN111359765AReduce the ratio of primary air to hot airGuaranteed temperatureGrain treatmentsAir preheaterCold air

The invention discloses a system for improving the flexibility of outlet temperature adjustment of a coal mill. The system comprises a primary air fan (1), an air preheater (2), the coal mill (3) anda bypass cold air pipeline (4), wherein the outlet of the primary air fan (1) is divided into two paths, one path is communicated with the inlet of the coal mill (3), the other path is communicated with the inlet of the air preheater (2), the outlet of the air preheater (2) is communicated with the inlet of the coal mill (3), and the bypass cold air pipeline (4) is communicated between the inlet and the outlet of the air preheater (2). The bypass air pipelines are additionally arranged on the front pipeline and the rear pipeline of the primary hot air side of an original air preheater, so thatthe primary air volume entering the air preheater for heating is adjustable, when the moisture of coal for actual combustion is low, the primary air volume entering the air preheater is reduced through the arranged bypass air channels, the primary air-hot air ratio of the inlet of the coal mill is reduced, and the outlet temperature of the primary air-powder mixture is ensured to meet the designrequirement.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

Raisin tree seed wine and production method thereof

InactiveCN106398973AFull of nutritionGood curative effectAlcoholic beverage preparationYeastTremella

The invention discloses raisin tree seed wine and a production method thereof. The raisin tree seed wine is produced from the following raw materials in parts by weight: 50-80 parts of raisin tree seed, 5-10 parts of barbary wolfberry fruit, 3-5 parts of tremella, 5-10 parts of citruslimon slice, 15-25 parts of crystal sugar and 4-8 parts of activated yeast. The invention provides a brewing method of the raisin tree seed wine which is rich in nutrition, rich in taste and mellow in fruit flavor, has effect of expelling wind-damp, has good treatment effect for rheumatoid arthritis, and also has effects of sobering up, soothing the nerves, relieving thirst and restlessness, resisting oxidation, lowering blood pressure and the like.

Owner:黄文庆

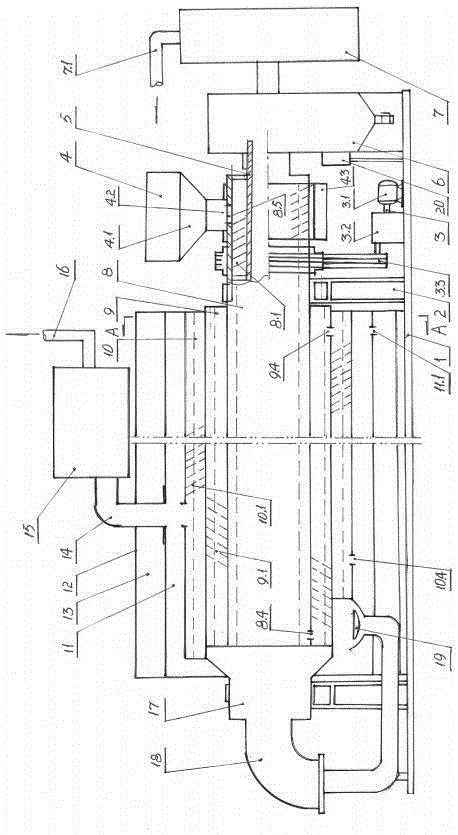

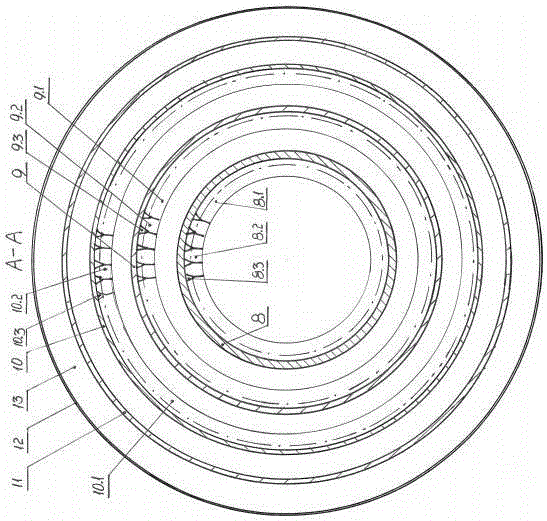

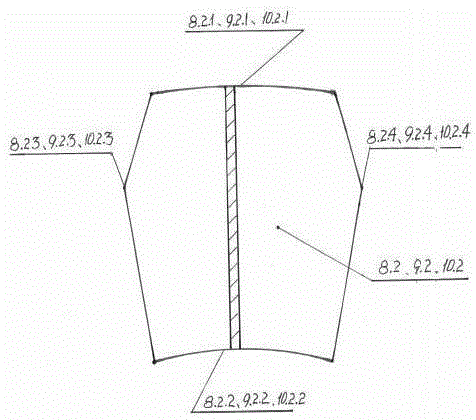

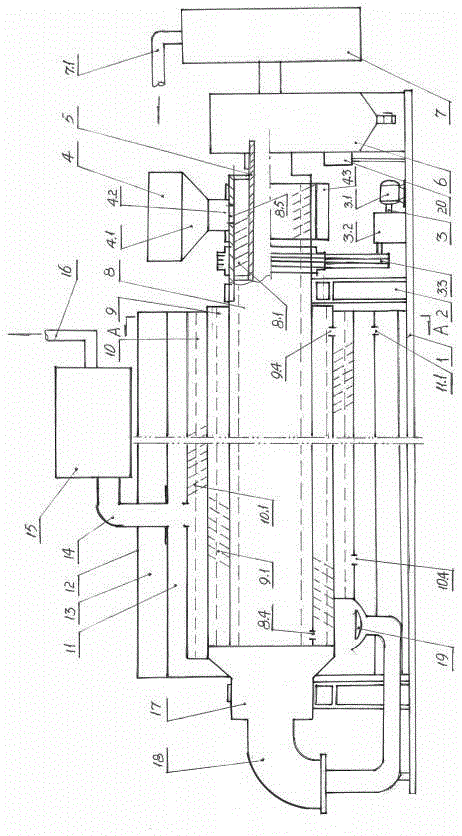

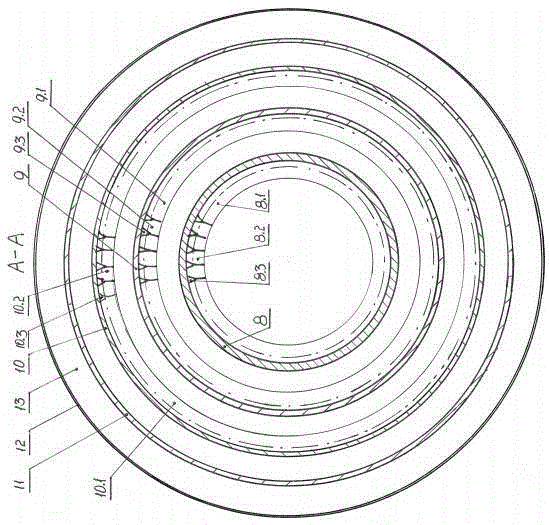

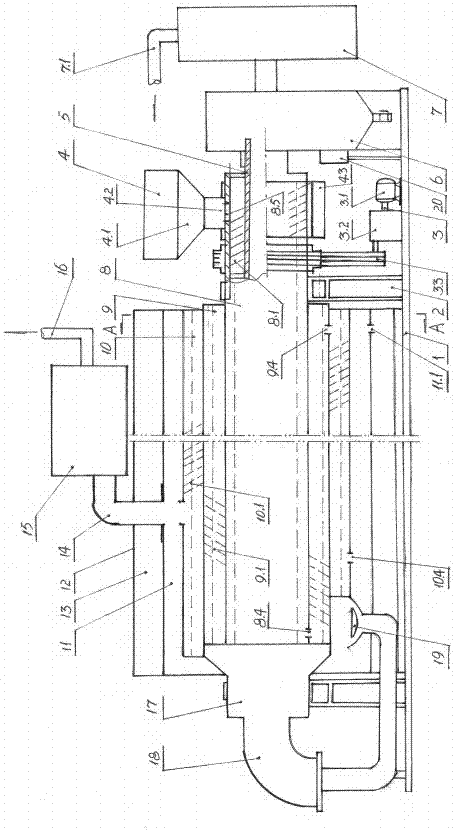

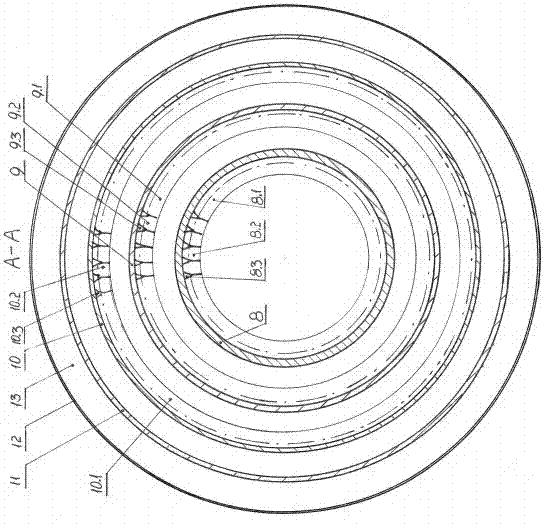

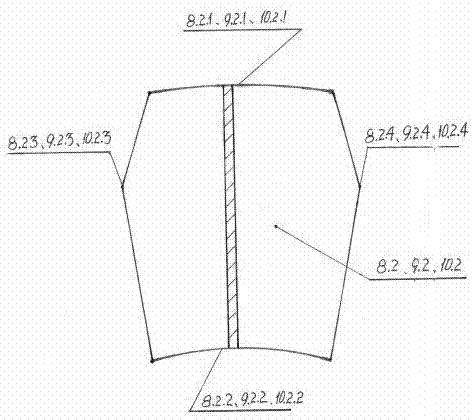

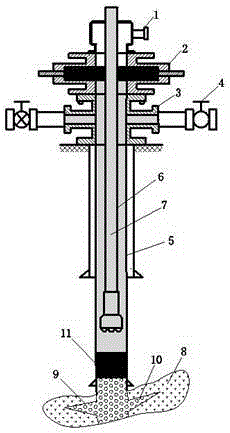

Sludge treatment device

ActiveCN105217907AOvercome secondary pollutionAlleviate the contradiction between sludge output and sludge treatment capacity lagSludge treatmentHeavy metalsEngineering

The invention discloses a sludge treatment device, and belongs to the technical field of sludge treatment. According to the technical scheme, the sludge treatment device comprises a machine base, a sludge treatment drum, a power driving mechanism, an output pipeline and a machine cover. The sludge treatment device is characterized in that the sludge treatment drum at least composed of three spiral barrels is included, the spiral barrels comprise the heavy metal treatment drum, the carbonization drum and the fixed carbon combustion drum which are coaxially installed into a whole in a sleeving mode from inside to outside, the spiral lines of the inner sides of barrel bodies are oppositely arranged, the barrel walls at the tail ends of the spiral lines are provided with discharge holes, and the two ends of the sludge treatment drum are each provided with a support device. Compared with the prior art, the sludge treatment device has the advantages of being novel, reliable in technical scheme, free of secondary pollution, high in investment efficiency and capable of rapidly achieving effects and has the outstanding substantive features and significant improvement.

Owner:徐明好

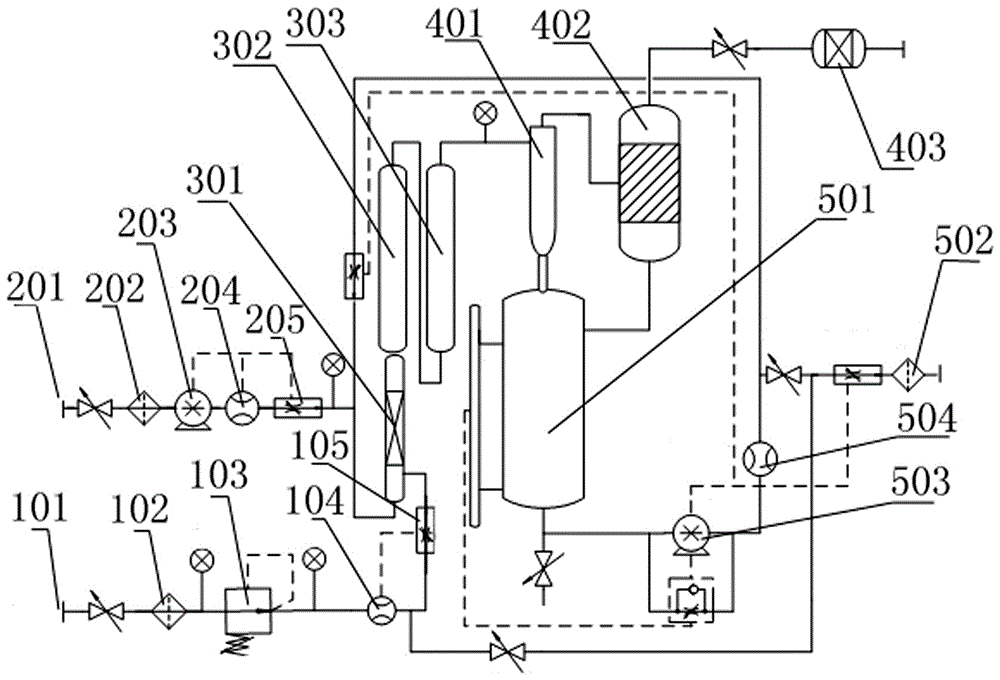

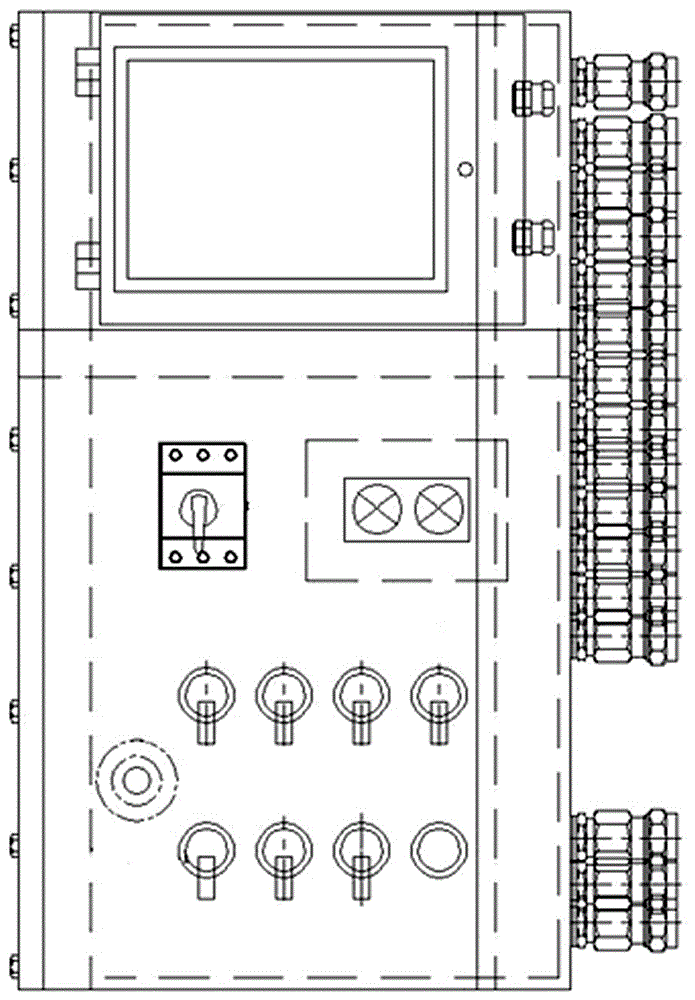

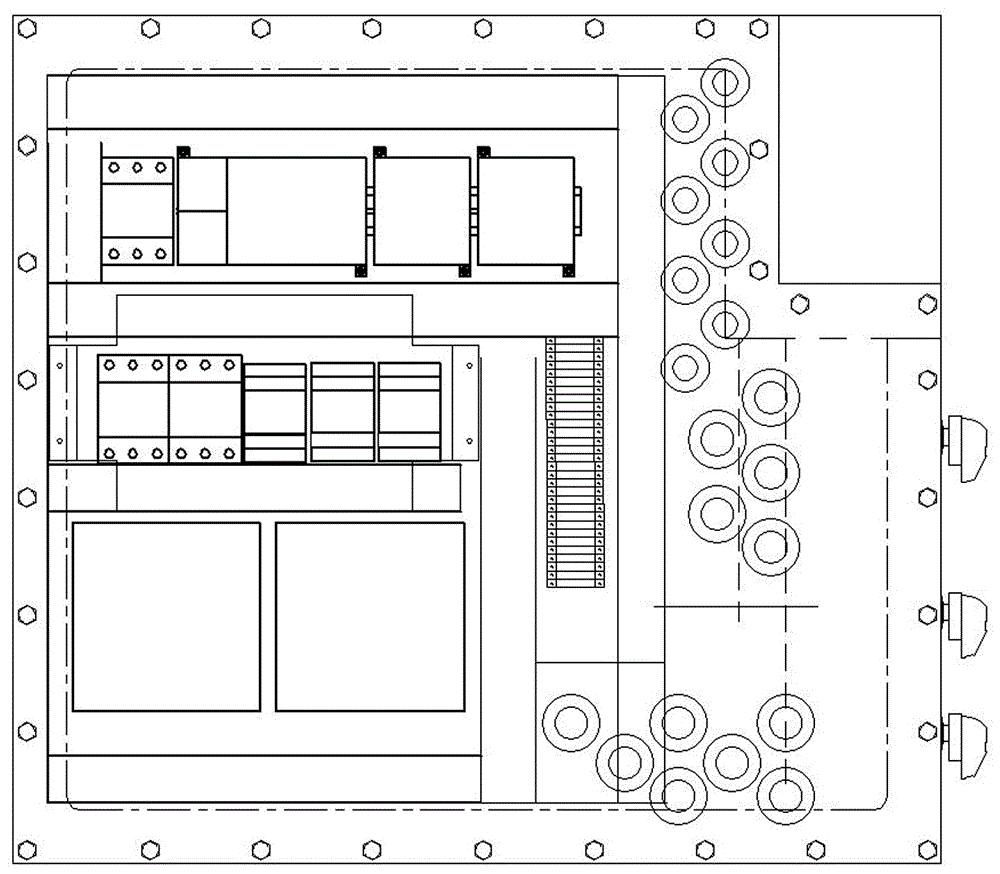

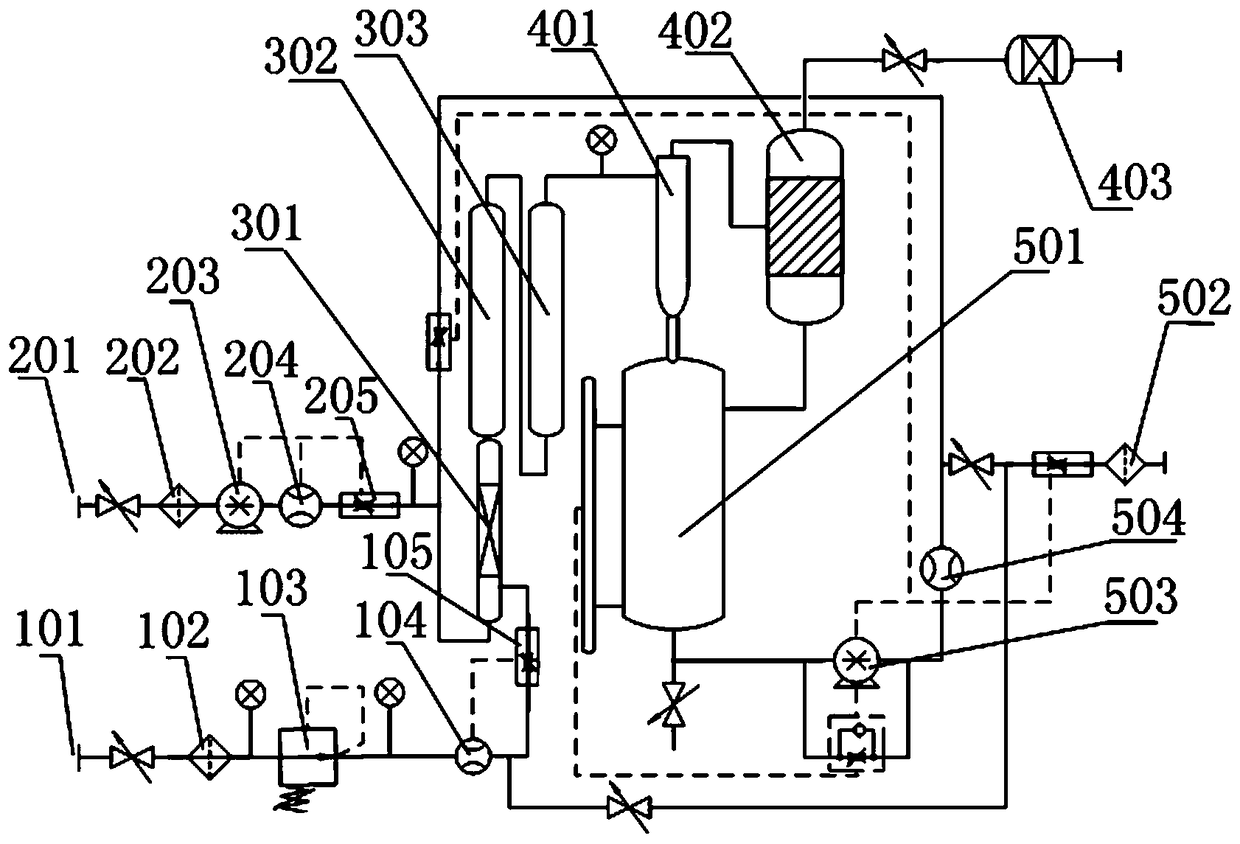

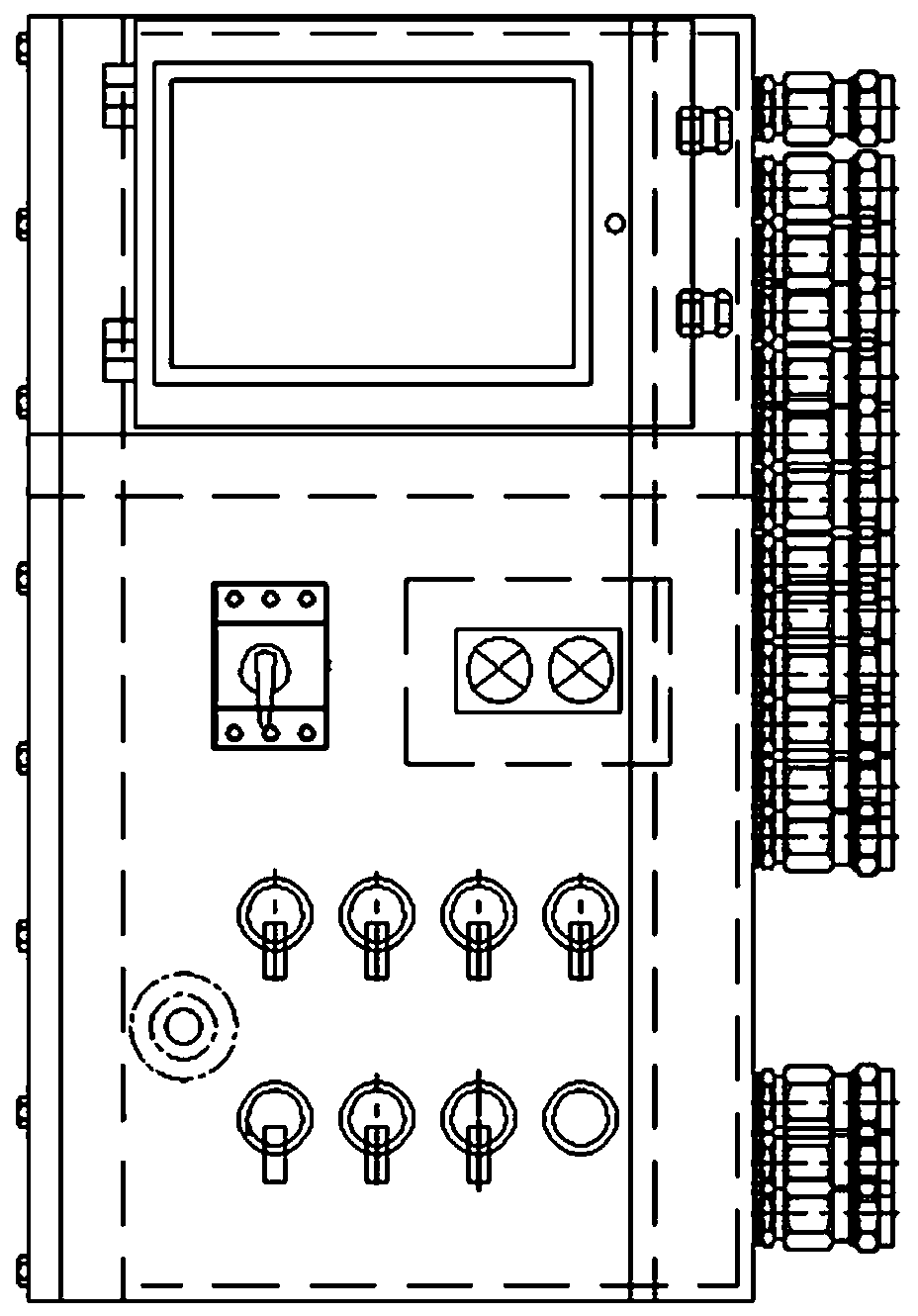

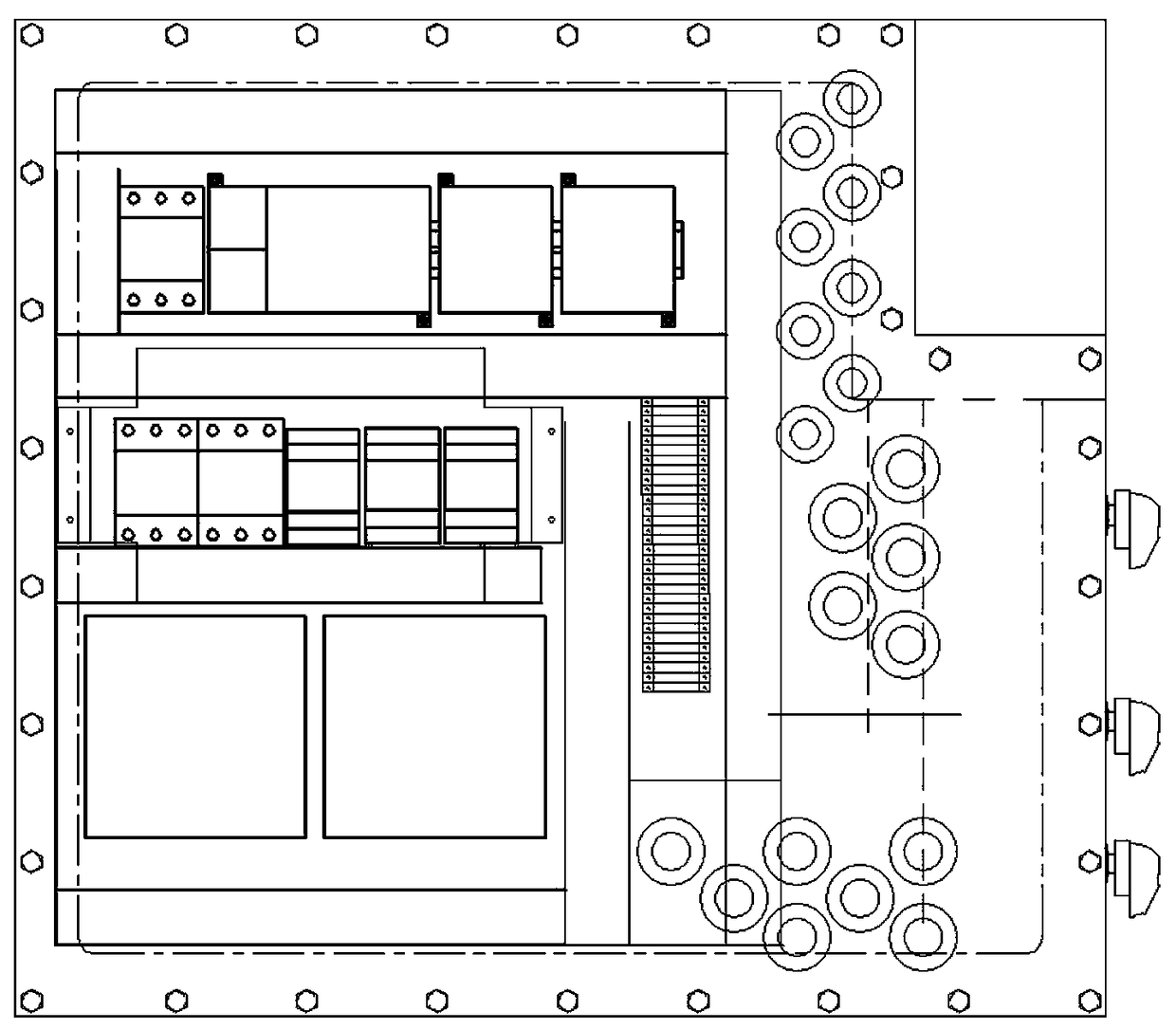

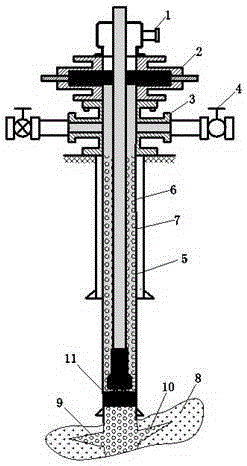

Anti-explosion fuel oil dehydration and deoxidizing device

ActiveCN106390527AIncrease contact areaImprove separation efficiencyLiquid degasificationLiquid separationAutomatic controlFuel oil

The invention relates to an online fuel oil dehydrating and deoxidizing device, particularly relates to an anti-explosion fuel oil dehydrating and deoxidizing device, and belongs to the technical field of comprehensive guarantee. The device comprises an air inlet pipeline system, an oil inlet pipeline system, an oil-gas mixing system, an oil-gas separating system, a petroleum product conveying system and an automatic control system, wherein a gas-liquid static mixer II is additionally arranged in the oil-gas mixing system. By additionally arranging the gas-liquid static mixer II, the contact area between a fuel and nitrogen is increased, so that the total quantity of fuel oil treated in the periodic time of the replacement reaction is increased, and the separation efficiency of water and the fuel oil and the separation efficiency of oxygen and the fuel oil are improved; by rapidly separating the fuel oil and nitrogen, an online, rapid and high-flow dehydrating and deoxidizing function is realized. By virtue of an anti-explosion design, the reliability and safety of the device are improved, and the demands of different customers are met.

Owner:SHENYANG AEROSPACE XINGUANG GRP

Designing method of sludge processing apparatus and apparatus thereof

ActiveCN105347634AAlleviate the contradiction between sludge output and sludge treatment capacity lagReliable technical solutionSludge treatmentWater contentHeavy metals

The invention discloses a designing method of a sludge processing apparatus and an apparatus thereof, which belong to the technical field of sludge processing. The designing method of the sludge processing apparatus comprises an integral design of an engine base, a sludge processing roller, a power drive mechanism, an output pipeline and an engine cover as well as a concrete design of each component, the designing method is characterized in that according to the different heavy metal contents in the sludge, the modified sludge with water content being 25-30% is placed in three different sludge processing rollers in order, quantitative glucose powder is added for mechanical stirring at uniform speed for propulsion, and three technical steps of heavy metal and dehydration / denitrification treatment, carbonization treatment and fixed carbon combustion treatment are carried out under normal pressure condition at temperature of 100-450 DEG C. Compared with the prior art, the designing method and the sludge processing apparatus have the advantages of novel and reliable performance, and no secondary pollution; waste can be changed into valuables, and sludge harmlessness treatment is realized, and the designing method and the sludge processing apparatus realize protrude substantiality characteristic and obvious progress for resource processing.

Owner:徐明好

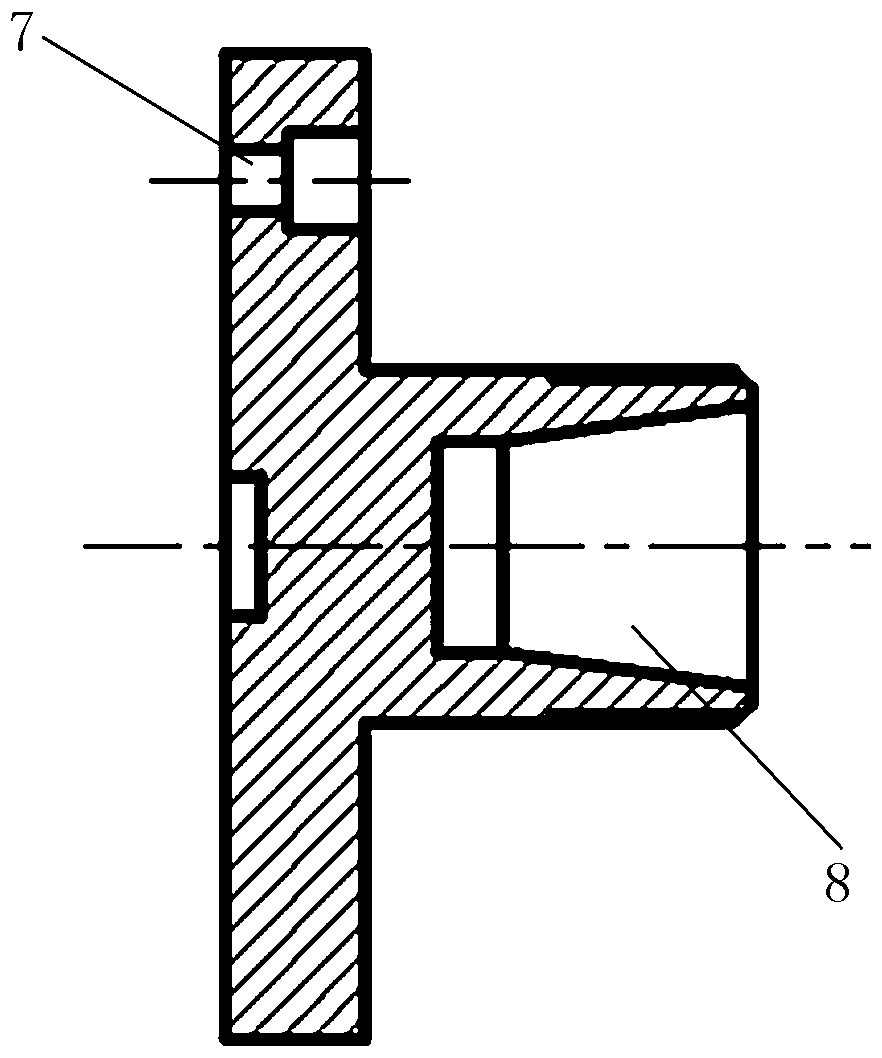

Fast changing fixture for six-axis air floating grinding machine

PendingCN109333353AAchieve installationGuaranteed accuracy requirementsGrinding work supportsLathe faceplateMachine parts

The invention relates to a fast changing fixture for a six-axis air floating grinding machine. According to the structure of the fast changing fixture, a machine tool spindle and a disc chuck clamp are connected in a fastened mode through bolts to fix the position of the disc chuck clamp; a back cap is connected with the disc chuck clamp through threads;the back cap and a clamping spring are fixedin a clearance fit mode; and a machined part and a clamping spring inner hole are fixed in a clearance fit mode. By adjusting and disassembling the connecting bolts between the disc chuck clamp and the machine tool spindle, fast installation, alignment and replacement of the machined part and the machine tool spindle are guaranteed.

Owner:SHENYANG AEROSPACE XINGUANG GRP

Water cushion pond filling and drainage system capable of generating electricity

ActiveCN103556611BImprove the operating environmentReduce energy consumptionWater-power plantsHydro energy generationElectricityWater diversion

The invention relates to a plunge pool water filling and discharging system capable of generating electricity, aiming at providing a plunge pool water filling and discharging system which is capable of generating electricity, is convenient to overhaul, safe, reliable and easy in running and maintenance, and can reduce energy consumption. The invention has the technical scheme that the plunge pool water filling and discharging system capable of generating electricity is provided with a dam, a plunge pool, an auxiliary weir and a downstream river channel, wherein a drainage gallery of the auxiliary weir is internally provided with a water pumping energy storage power generation plant; the plant is internally provided with a reversible type water pump hydroelectric generating set; under the working condition of a water pump, a water inlet of the reversible type water pump hydroelectric generating set is communicated with the plunge pool by a pipeline I buried in the auxiliary weir, and a water outlet is communicated with the downstream river channel by a pipeline II buried in the auxiliary weir; a mountain body at one side of the auxiliary weir is provided with a regulating reservoir used for converging the mountain earth surface water seepage of the both sides of the plunge pool and the leakage water of the dam, the plunge pool and an underground plant; the regulating reservoir is higher than the water level of the downstream river channel; the regulating reservoir is communicated with the pipeline II by a water diversion power generation pipeline. The plunge pool water filling and discharging system is suitable for the hydraulic and hydroelectric engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

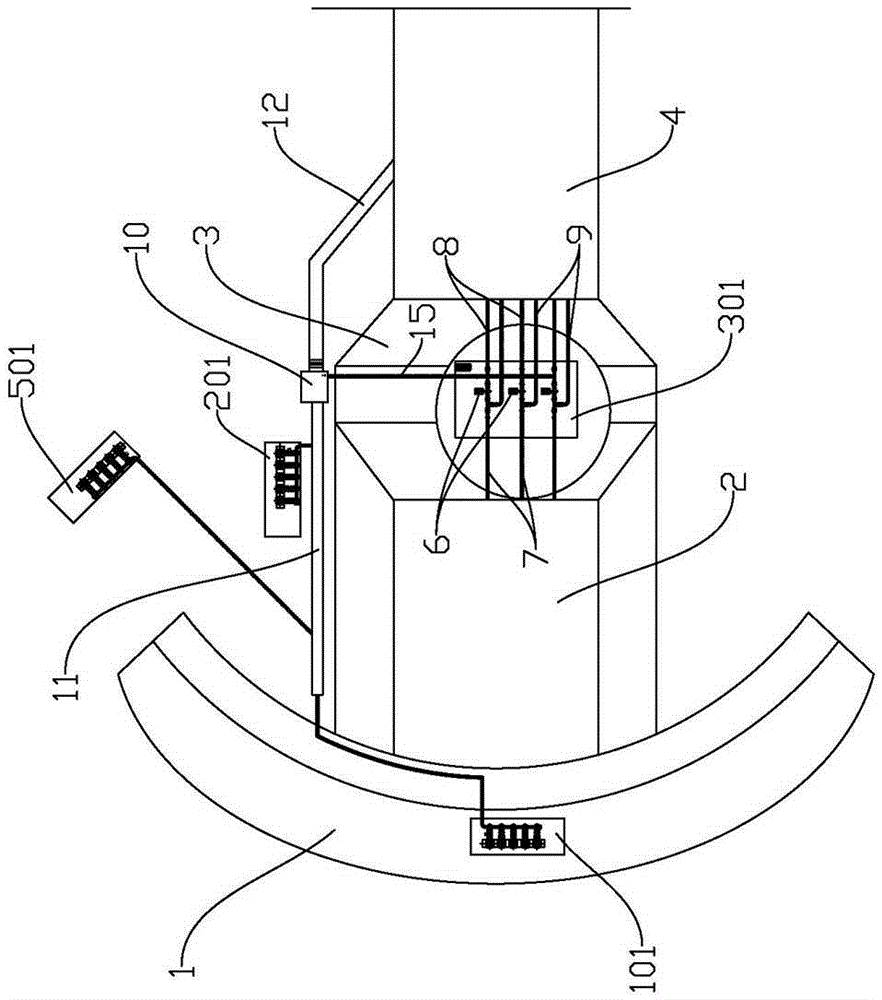

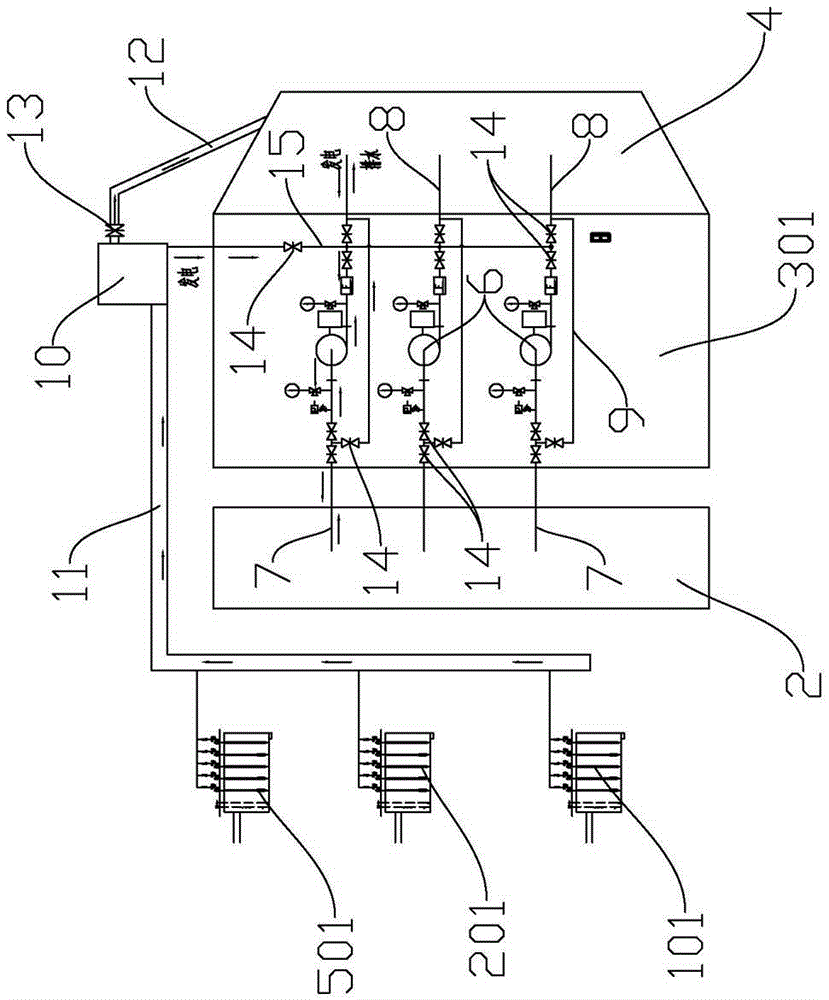

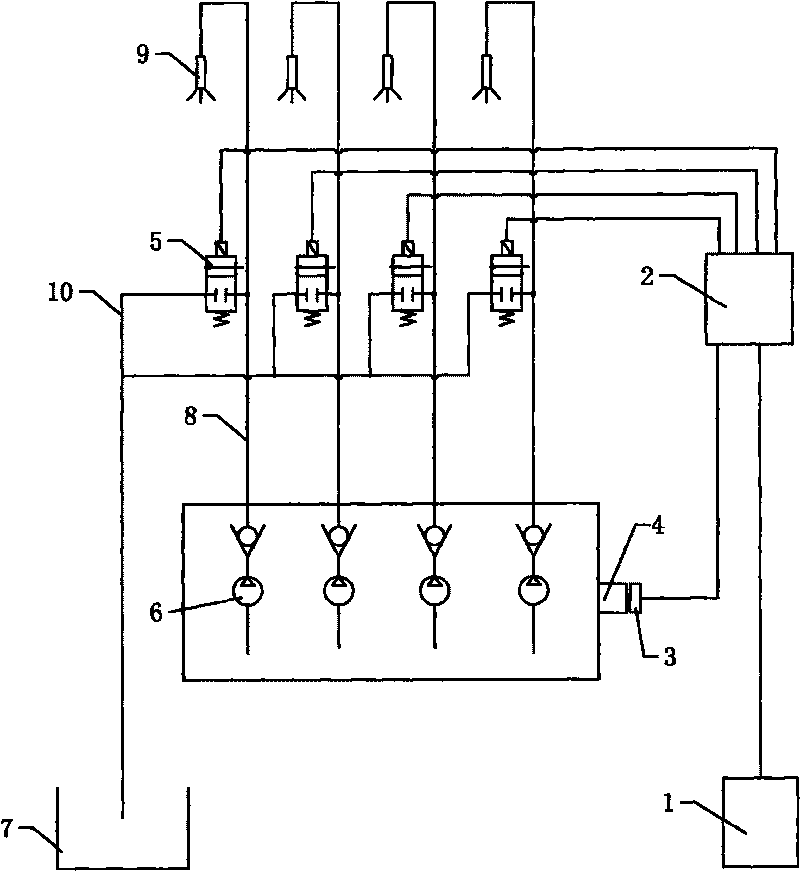

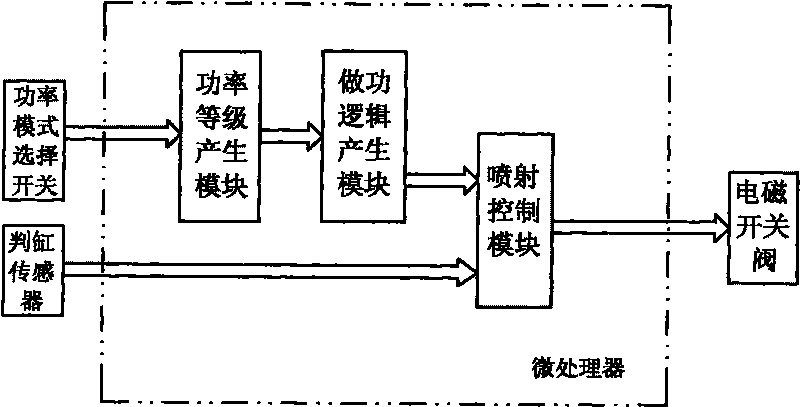

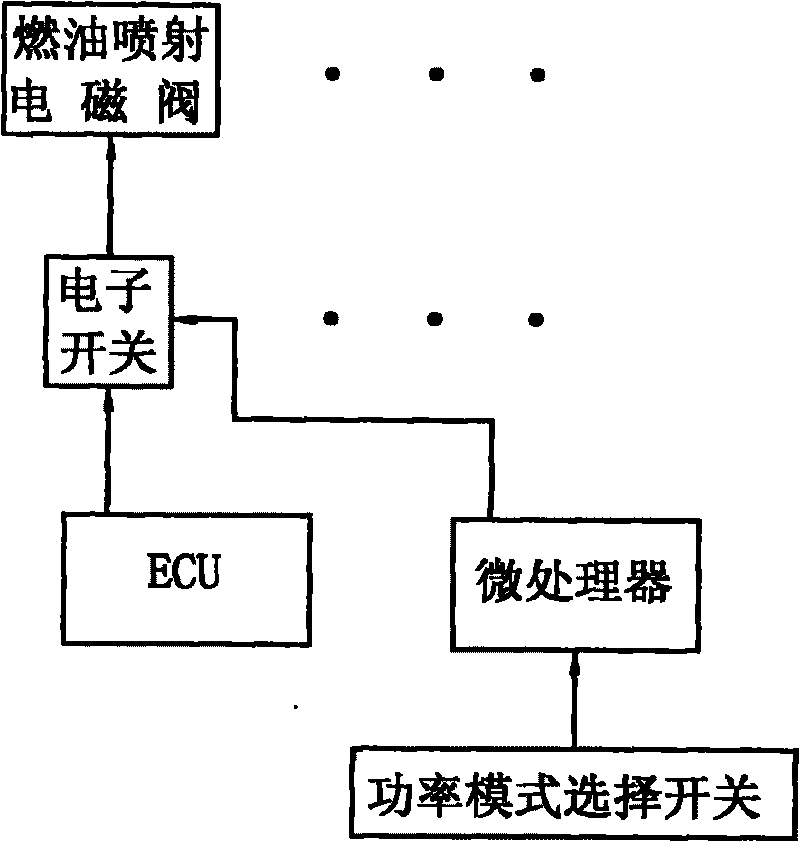

Variable-power running control device for self-propelled harvester

InactiveCN101696661AUniform wearRunning balanceElectrical controlMachines/enginesFuel tankPower level

The invention discloses a variable-power running control device for a self-propelled harvester, which is suitable for a harvester with an engine having a mechanical fuel injection system. The variable-power running control device has the main technical concept that the variable-power running control device for the self-propelled harvester is provided with a power mode selection switch, an electromagnetic switch valve, a cylinder detection sensor and a micro-processor; the electromagnetic switch valve is arranged in an oil return bypass between a high-pressure oil pipe of the fuel injection system and an oil tank; and the micro-processor is provided with a power level generating module, an acting logic generating module and an injection control module. After making little alteration on the technical scheme, the variable-power running control device for the self-propelled harvester is also suitable for the harvester having the engine with an electrically-controlled fuel injection system. Under the situation that rated power of the engine is far higher than running load of the harvester, the variable-power running control device is capable of making cylinders of the engine do work alternately so as to flexibly lower the power level of the engine and to run the engine in a high-frequency state with a lower fuel consumption rate. Therefore, the oil-saving effect is obvious.

Owner:潍坊威度电子科技有限公司

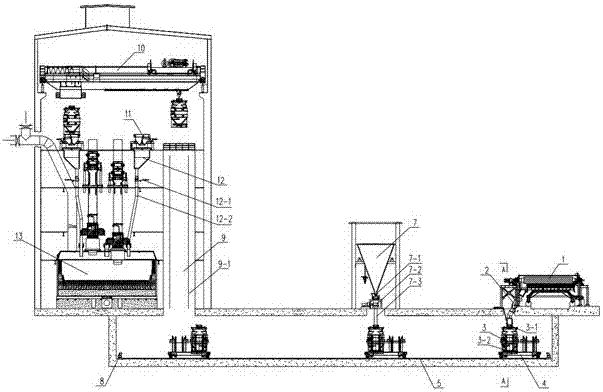

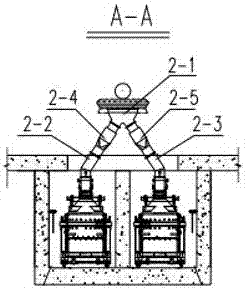

Device and method for hot charging rotary hearth furnace direct-reduced pellets into furnaces

PendingCN107354261AReduce lossesHigh degree of automationHearth type furnacesReciprocating motionEconomic benefits

The invention provides a device and method for direct reduction of pellets in a rotary hearth furnace and hot loading into the furnace. The rotary hearth furnace at the beginning of the transport track, the batching bin at the middle of the transport track, the lift shaft at the end of the transport track, the bridge crane on the top of the lift shaft, the material bell and the mineral heat below the bridge crane travel Furnace, the material bell is connected to the submerged arc furnace through the furnace bottom silo. In the present invention, the high-temperature pre-reduced pellets of the rotary hearth furnace are directly discharged into the heat-insulating closed material tank and transported to the bottom material bin of the submerged arc furnace, and uninterrupted circular transportation can be formed through multiple tracks to realize the pre-reduced balls of the rotary hearth furnace. The pellets are continuously added to the submerged arc furnace for smelting, which is not easy to be oxidized during transportation, and the heat loss is small, which can reduce the overall energy consumption and improve economic benefits. At the same time, the technical solution is simple, reliable, highly automated, compact in production, and easy to implement.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

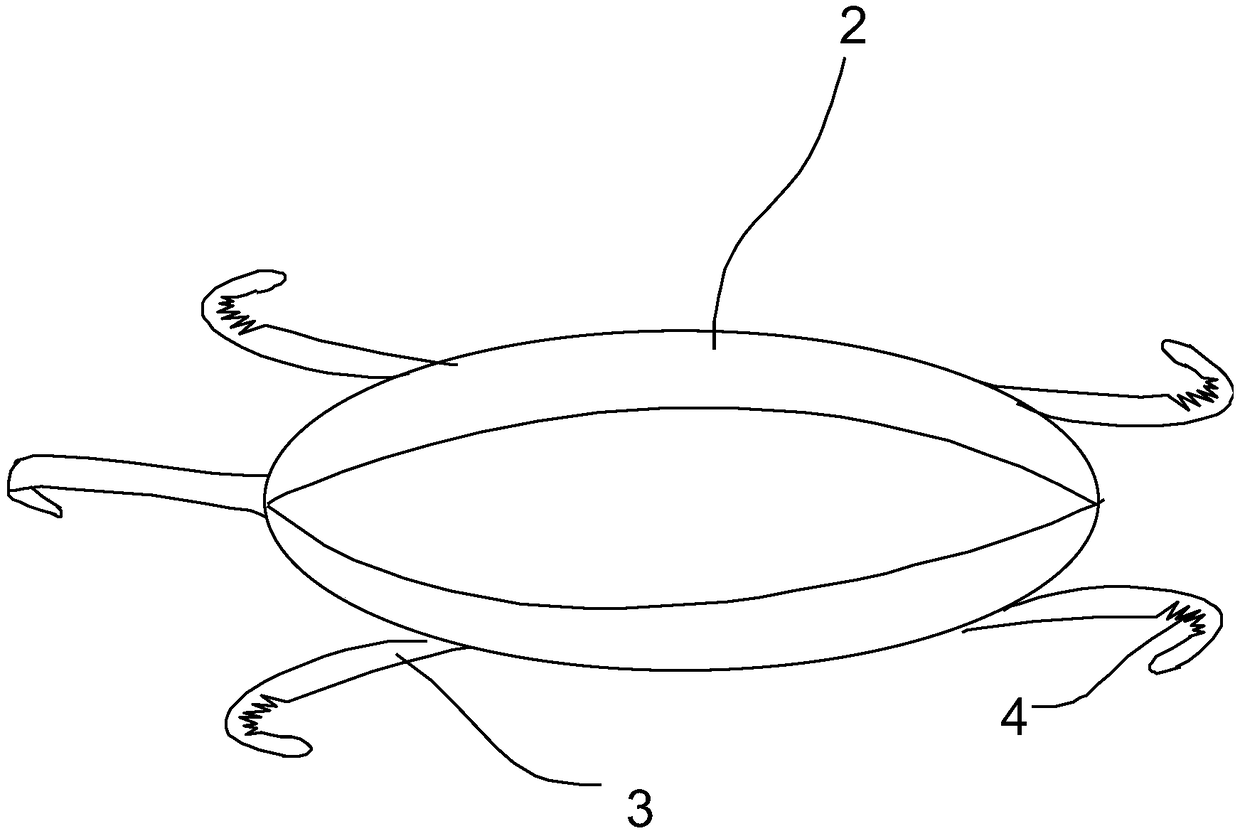

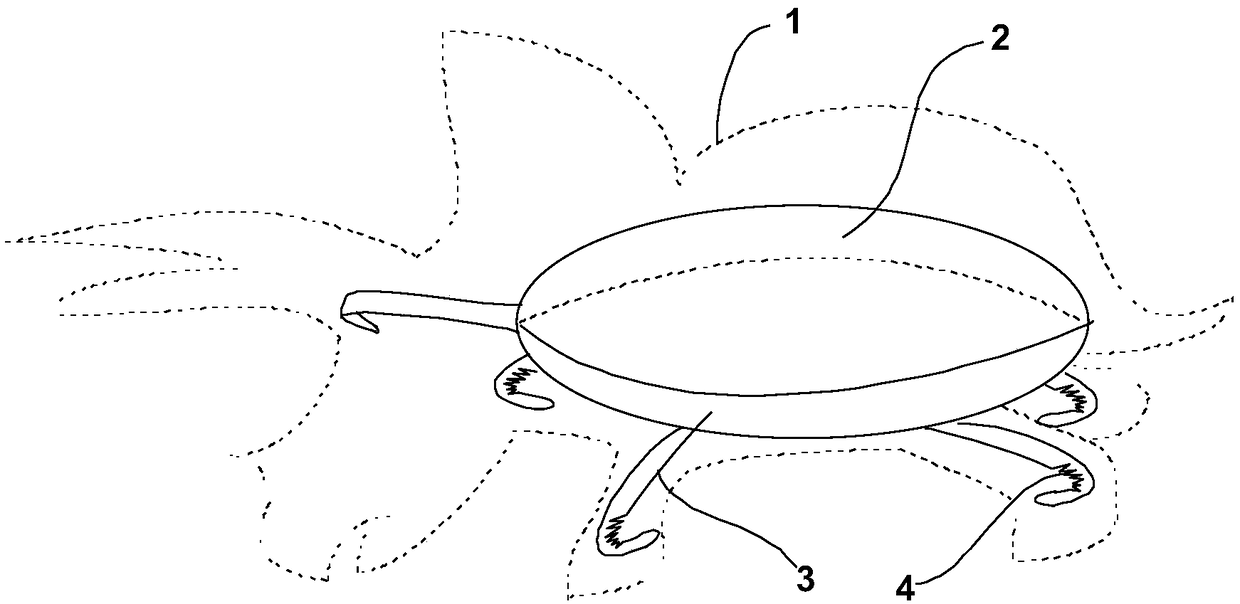

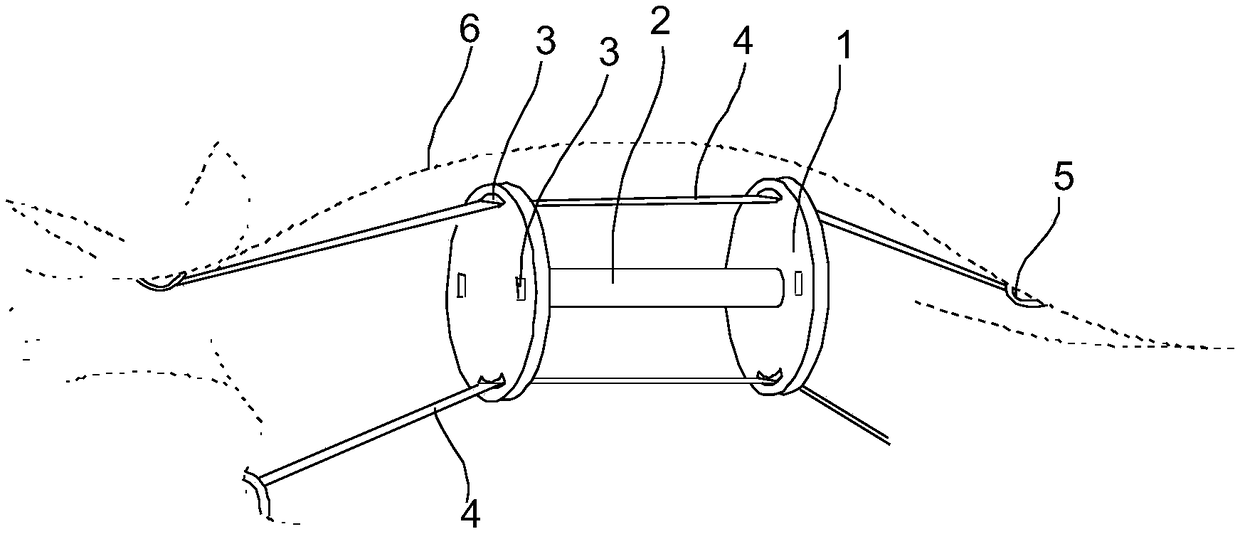

Movable pet biting toy

InactiveCN108684570ASimple technical solutionReliable technical solutionTaming and training devicesBitingEngineering

The invention discloses a movable pet biting toy comprising a toy body and a deformation drive mechanism; the toy body comprises at least one biting part and at least one deformation part; the deformation drive mechanism comprises a biting airbag and a deformation airbag; the biting airbag and the deformation airbag are respectively matched with the biting part and the deformation part; the bitingairbag is connected with the deformation airbag through air; the deformation force of the deformation airbag is greater than the pressure of biting the airbag. The technical solution of the present invention has the following beneficial effects: through the design of the biting airbag and the deformation airbag, when the pet bites, the deformation part will act correspondingly with the action ofthe pet, and an interaction effect with the pet. The technical scheme of the invention is simple and reliable; and the interaction function with the pet can be obtained by improving the existing pet toy.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

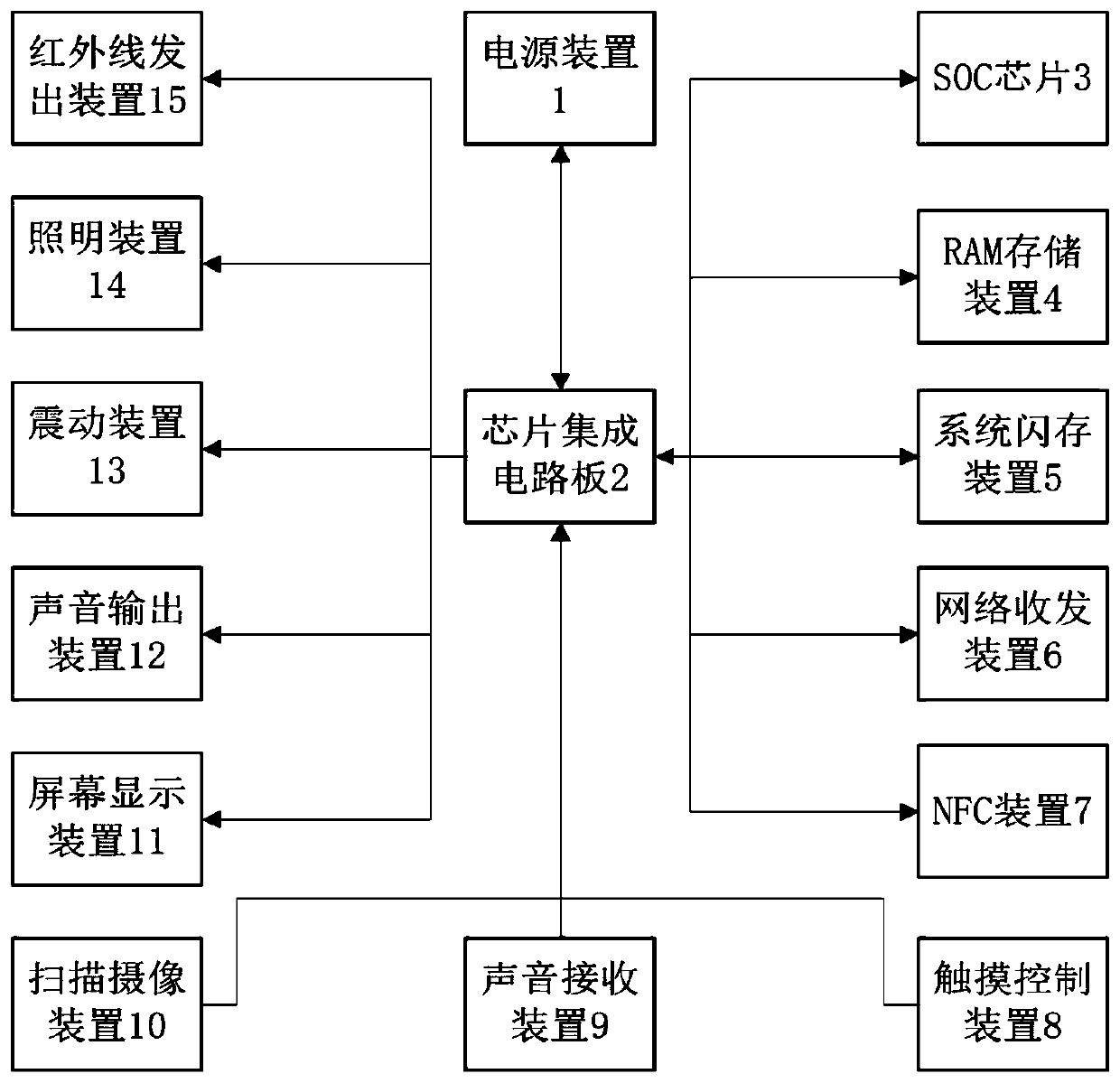

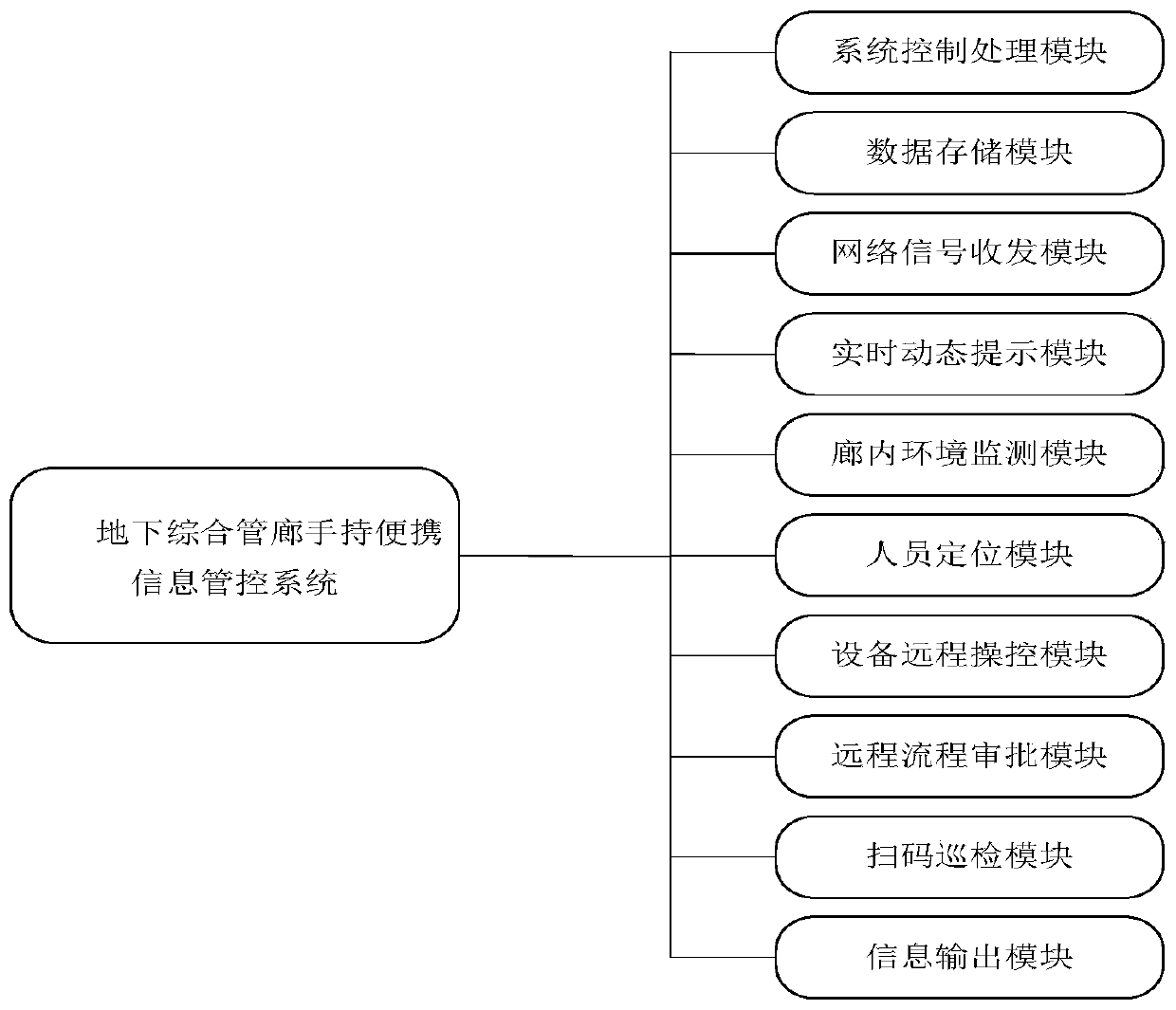

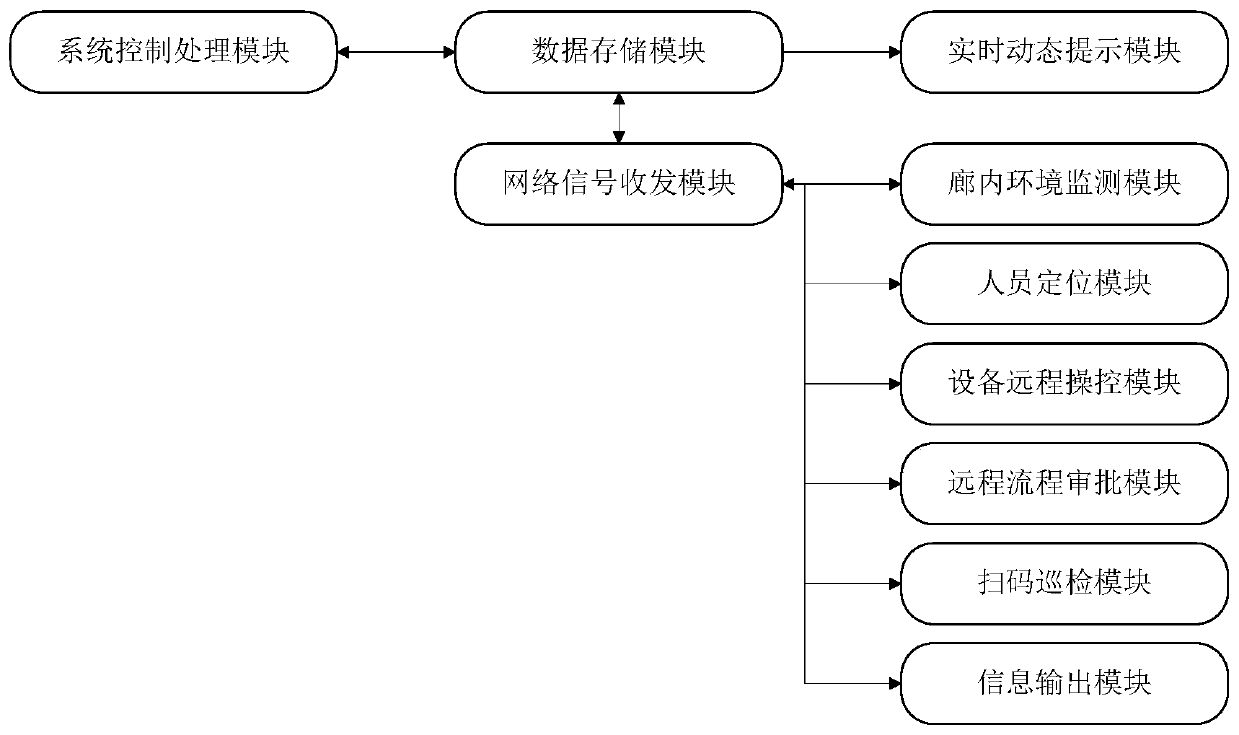

Handheld portable information management and control system for underground comprehensive pipe gallery

PendingCN110188900AEffective controlEasy to controlChecking time patrolsOffice automationElectricityRemote control

The invention belongs to the technical field of underground pipe gallery control, and relates to a handheld portable information management and control system for an underground comprehensive pipe gallery. The main structure module comprises a network signal receiving and transmitting module, a real-time dynamic prompt module, an in-corridor environment monitoring module, a personnel positioning module, an equipment remote control module, a remote flow approval module, a code scanning inspection module and an information output module. The system control processing module is in bidirectional electric information connection with the data storage module; the data storage module is in electric information connection with the real-time dynamic prompting module; the network signal receiving andtransmitting module is in bidirectional electrical information connection with the data storage module; the in-corridor environment monitoring module, the personnel positioning module, the equipmentremote control module, the remote process approval module, the code scanning inspection module and the information output module are in bidirectional electric information connection with the network signal receiving and transmitting module; the design concept is scientific, the technical scheme is advanced, the control principle is reliable, operation and use are convenient, real-time controllability is good, and the application environment is friendly.

Owner:QINGDAO WACOSOFT TECH

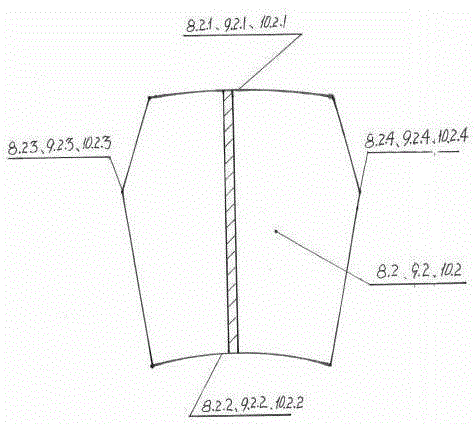

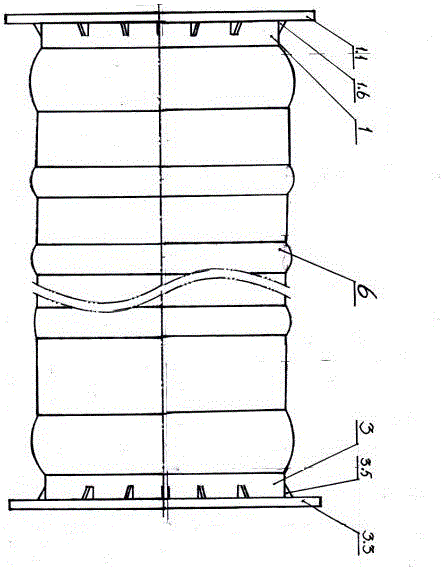

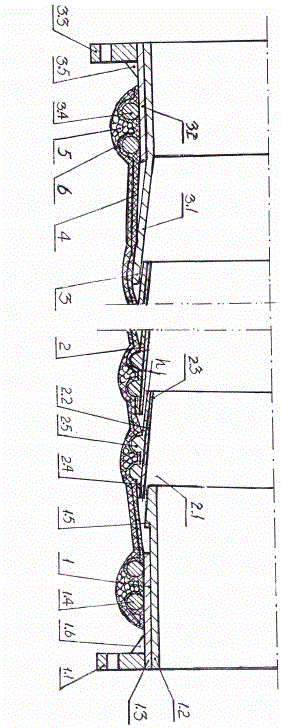

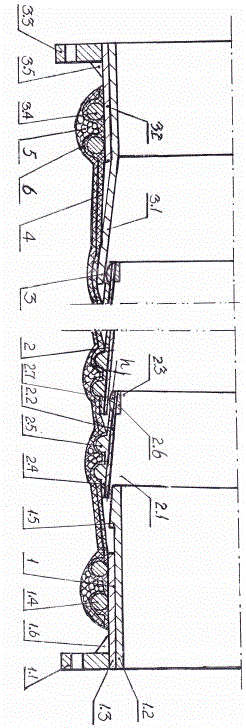

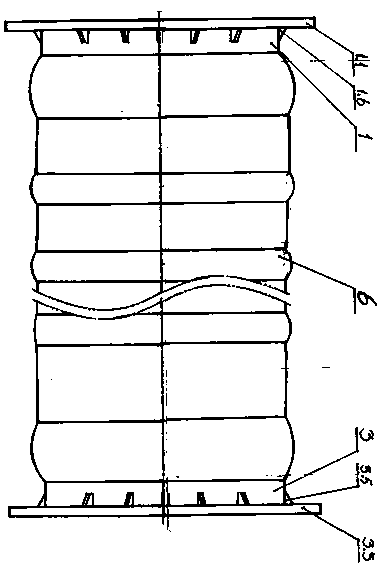

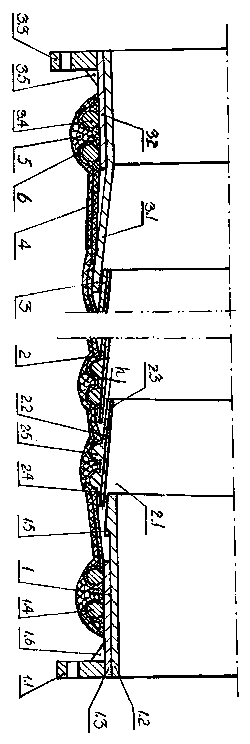

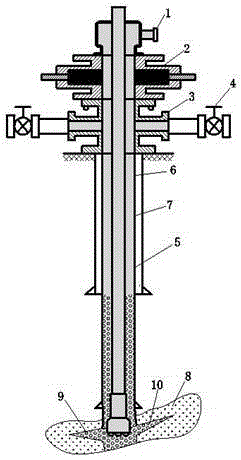

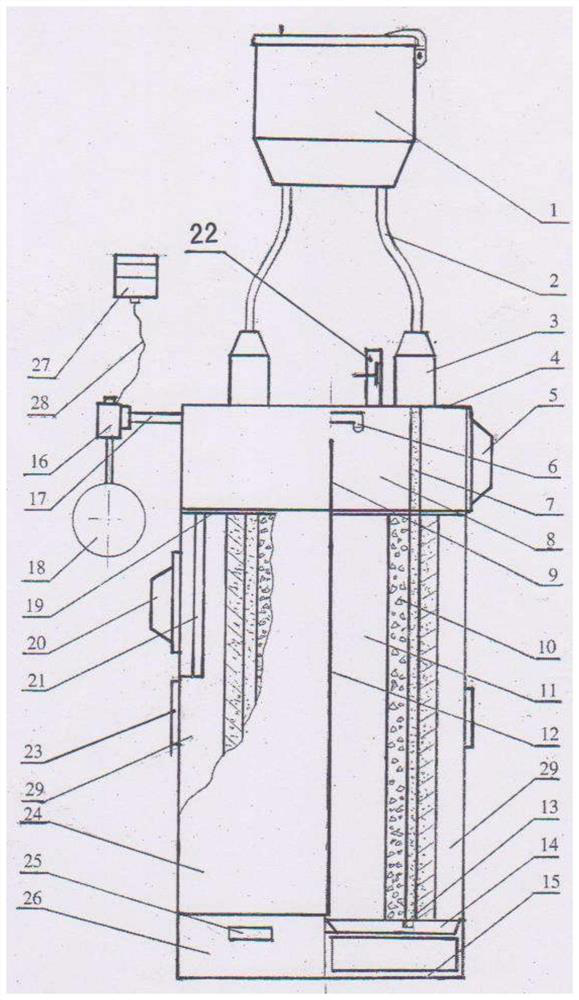

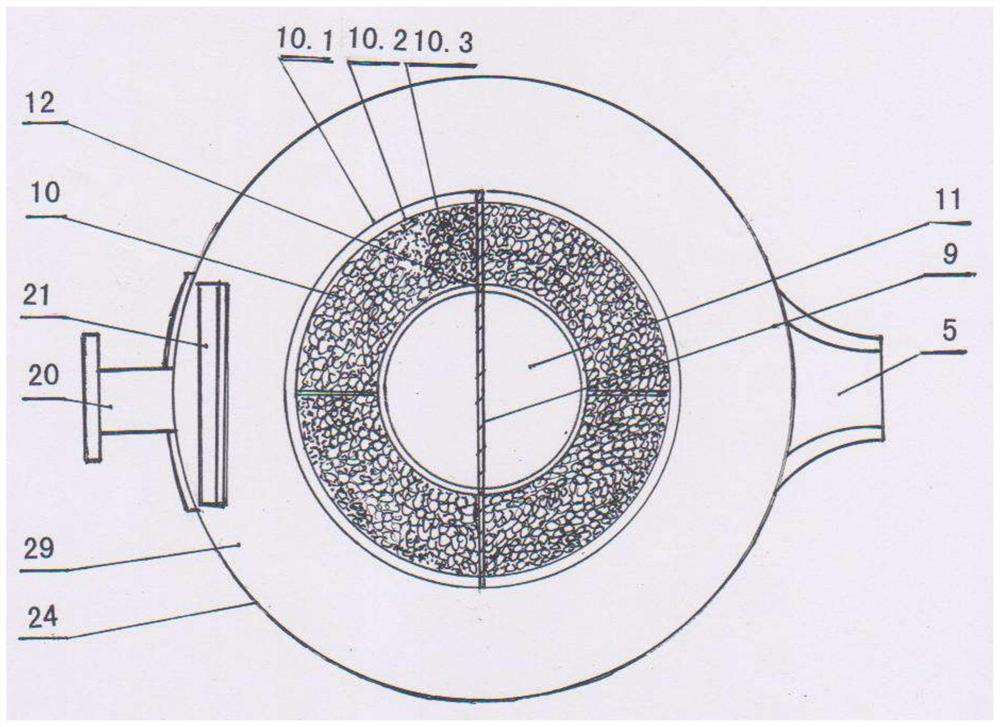

Full-armor mud discharging pipe, production method and special device of full-armor mud discharging pipe

The invention discloses a full-armor mud discharging pipe, a production method and a special device of the full-armor mud discharging pipe and belongs to the technical field of dredging engineering equipment. According to the technical scheme, the full-armor mud discharging pipe comprises a pipe body and a connecting and fastening layer combined to the outer side of the pipe body; the full-armor mud discharging pipe is characterized in that an inlet end joint pipe, tapered pipes and an outlet end joint pipe are sequentially assembled into a whole in an armored manner to form the pipe body and are each at least formed by combing an inner steel pipe layer and an outer steel pipe layer, and at least two annular locating and fastening rings are arranged on the outer side wall of each outer steel pipe layer; and each connecting and fastening layer is sequentially wrapped with a strengthened elastic material layer, a multi-layer steel fastening layer and an elastic material layer. Compared with the prior art, the full-armor mud discharging pipe, the production method and the special device have remarkable improvements and the prominent substantive distinguishing features that the technical scheme is reliable, the bending requirement for adjusting the direction of the mud discharging pipe is met, and the wear resistance of the full-armor mud discharging pipe can be close to that of a metal composite mud discharging pipe, and the use performance of the metal mud discharging pipe is improved comprehensively.

Owner:姜考成

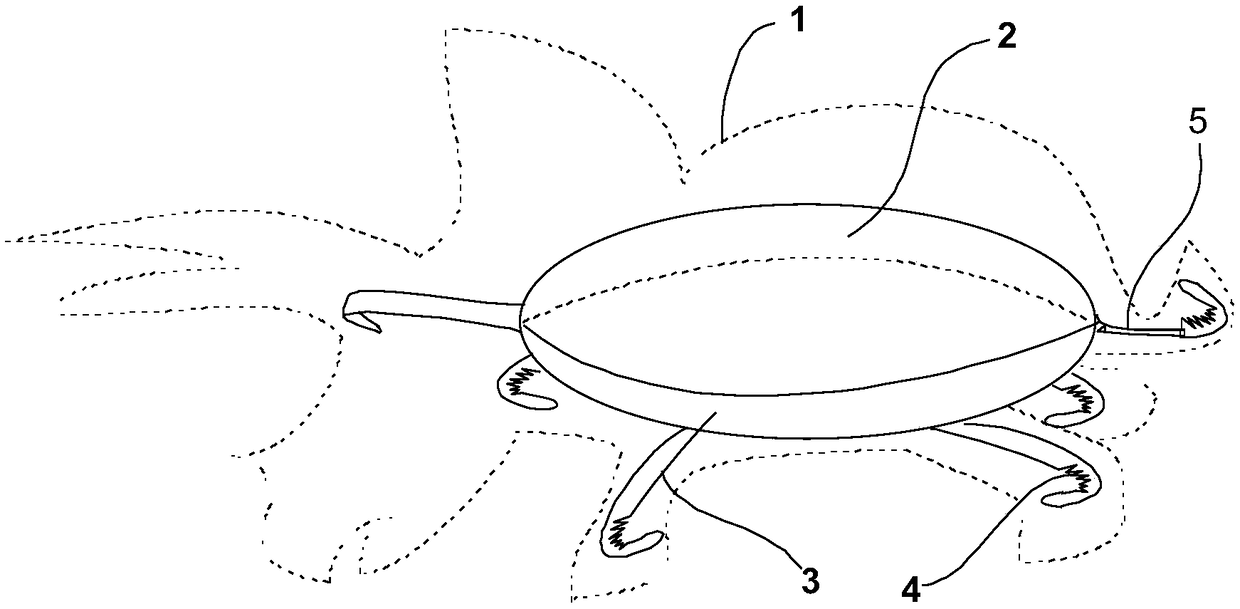

Biting toy capable of interacting with pets

PendingCN108684569ASimple technical solutionReliable technical solutionTaming and training devicesEngineeringCompanion animal

The invention discloses a biting toy capable of interacting with pets comprising an unpowered drive mechanism and a toy main body; the toy main body comprises at least one deformation part and at least one biting part; the unpowered drive mechanism comprises at least one support for supporting the biting part; the support at least comprises two projecting support parts and at least one connectingpart which connects the support parts; an edge of the support part is provided with through holes along the axial direction of the connecting part; an elastic member movably penetrates the through hole; two ends of the elastic member are connected to the deformation part of the toy main body. According to the invention, by the connecting of the biting part and the deformation part, when the toy isbite by pets, the biting part will deform and press the elastic member or flexible member between the two through holes so that the elastic member or flexible member shortens to drive the deformationpart to deform. As the pet moves accordingly, it interacts with the pet.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

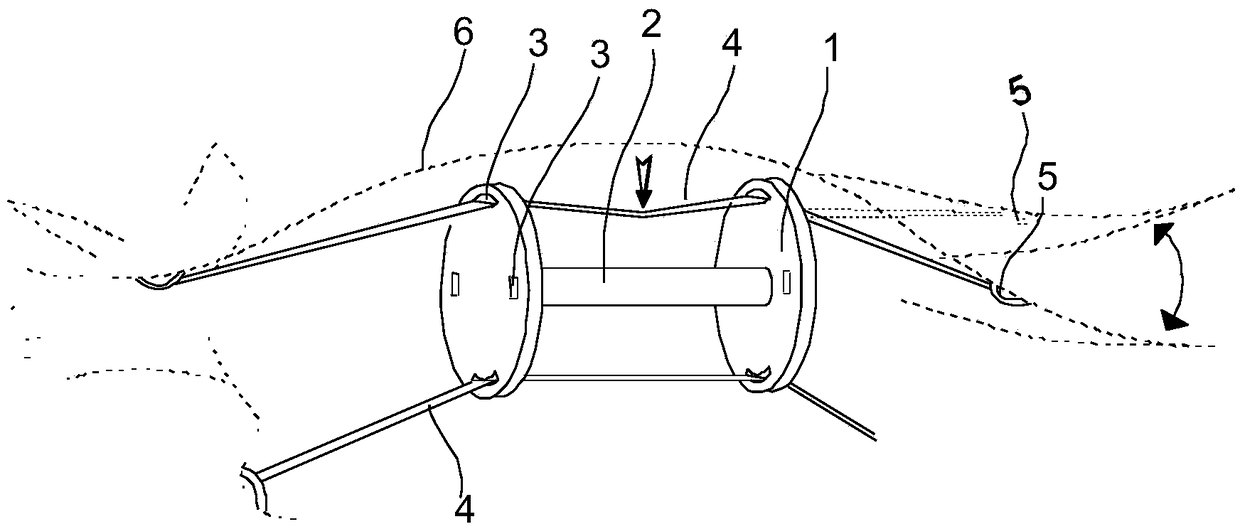

Gas pipeline cleaning equipment for inner floating top storage tank

InactiveCN109665227AAvoid disturbanceAchieve two-phase separationLarge containersControl valvesCheck valve

The invention discloses gas pipeline cleaning equipment for an inner floating top storage tank. The gas pipeline cleaning equipment includes a gas-liquid separation tank, a liquid level transmitter, avalve group, and a controller, wherein the top of the gas-liquid separation tank is connected to the tops of a swept pipeline and the inner floating top storage tank through a first pipeline and a second pipeline, the bottom of the gas-liquid separation tank is connected to the bottom of the inner floating top storage tank through a third pipeline, the liquid level transmitter is used for detecting the liquid level of the gas-liquid separation tank and transmitting the liquid level to the controller, the valve group comprises a first control valve, a second control valve, a third control valve and a check valve, the first control valve is arranged on the first pipeline, the second control valve is arranged on the second pipeline, the third control valve and the check valve are arranged onthe third pipeline, the third control valve is close to the gas-liquid separation tank, the check valve is close to the inner floating top storage tank, and the controller is used for receiving the liquid level and controlling the open and close of the first control valve, the second control valve and the third control valve according to the liquid level. The gas pipeline cleaning equipment can effectively achieve two-phase separation of gas and liquid and avoid the disturbance of the pipeline cleaning gas to the liquid phase.

Owner:SINOPEC ENG +1

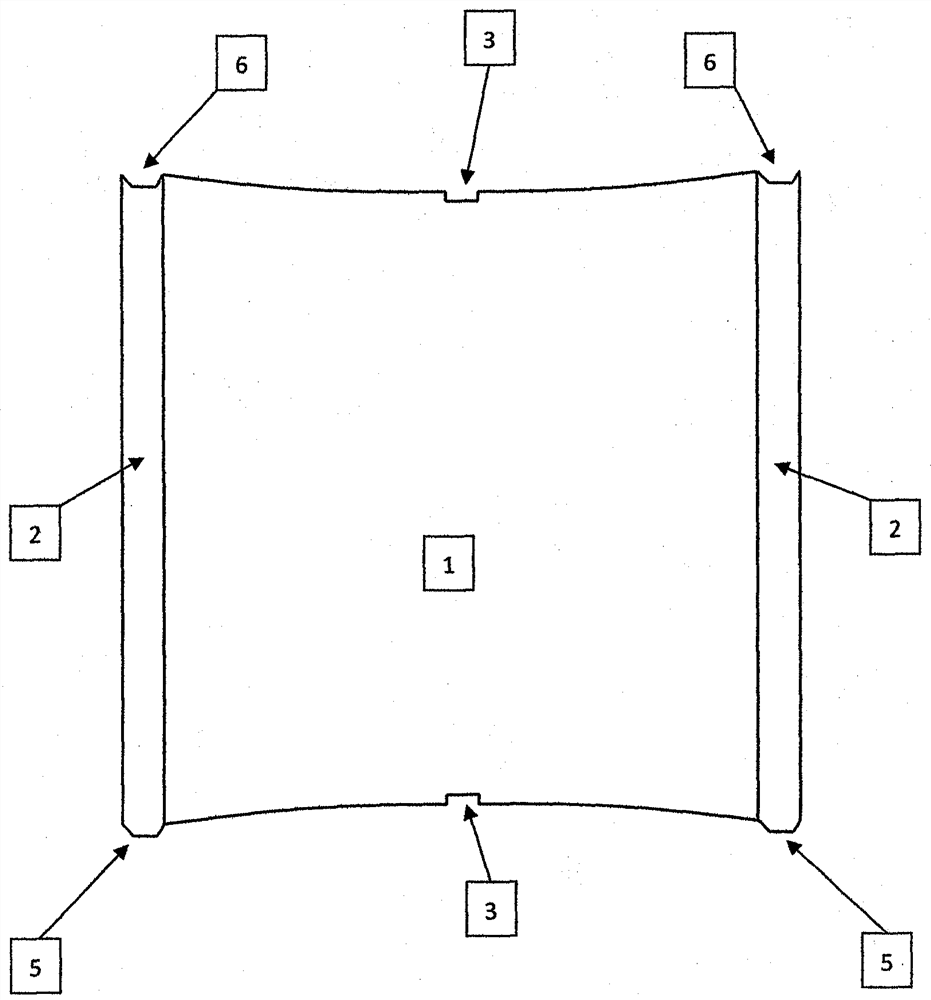

Automatic wall building machine using special wall bricks

PendingCN111926987AMeet the requirements of the processFully automatedBuilding componentsBuilding material handlingBrickArchitectural engineering

The invention relates to the technical field of building engineering automation, and discloses an automatic wall building machine using special wall bricks. The special wall bricks are cuboids and have concave top surfaces, convex bottom surfaces, two flat long side surfaces and two concave wide side surfaces; grasping grooves of mechanical claws of the automatic wall building machine are formed in the two wide side surfaces; the automatic wall building machine comprises a wall building system, a brick supply system, a grouting system, a positioning and ranging system, a power supply system and a PLC system; the PLC system moves a plurality of mechanical arms and mechanism claws of the wall building system, with the help of the positioning and ranging system, the mechanical claws extend into the grasping grooves and grasp the special wall bricks in the brick supply system, and then the special wall bricks are built on a wall body; and the PLC system starts a mortar pump of the groutingsystem, an electric valve at a nozzle outlet is opened, and a mortar pipe is used for grouting mortar in a mortar storage tank in the concave parts at the top surfaces of the special wall bricks andvertical gaps at transverse connections of the special wall bricks. According to the automatic wall building machine, the degree of automation is high, and the practicability is high.

Owner:邓生毛 +1

A sludge treatment device

Owner:徐明好

Plastic bag cutting sealed household electrical appliance

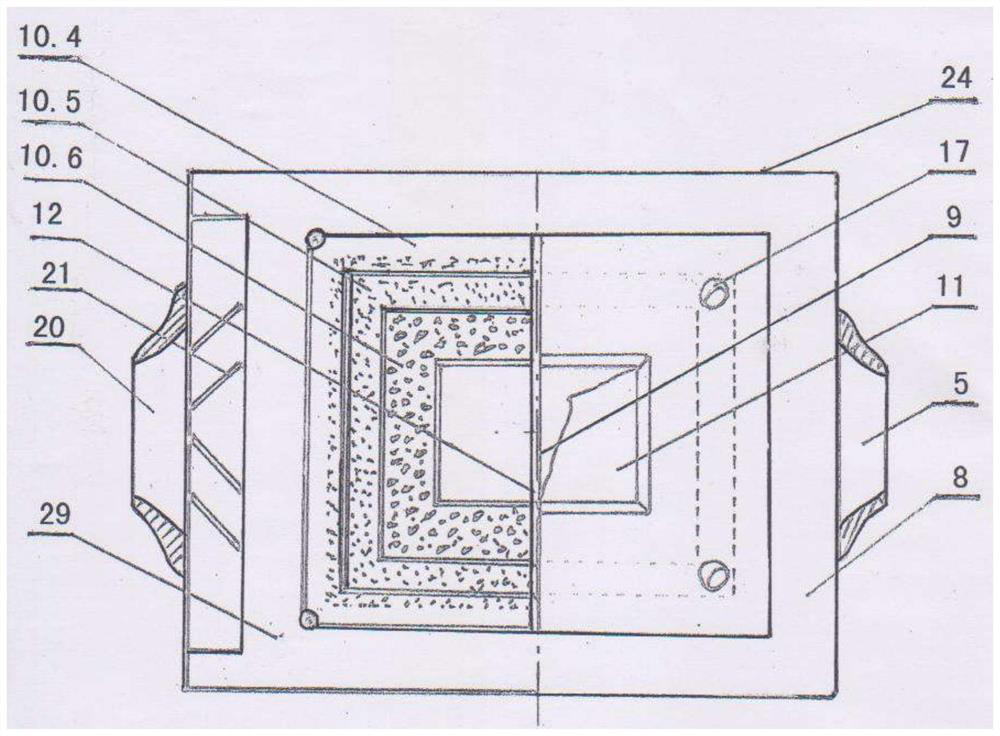

InactiveCN101314262ASolve cutting problemsSolve the sealing problemBox making operationsPaper-makingHome appliancePlastic bag

The present invention discloses a domestic electric appliance for incising and sealing a plastic bag. In order to solve the problems of incising and sealing of the long cylindrical plastic bag, the present invention adopts a technical proposal that: the electric appliance comprises a pedestal, an actuating mechanism and a heating circuit. The electric appliance is characterized in that A. in the pedestal, a base (1) is arranged; the rear lateral surface of the base (1) is fixedly screwed with an L-shaped angle iron (4);The right lateral surface of the base (1) is fixedly screwed with an incising lower strip (5);The upper surface of the base (1) is fixedly screwed with a heating body (3); B. in the actuating mechanism, a sealing pressing strip (8) and a cutting knife (7) are arranged; a round hole at the front end part of the actuating mechanism is rotationally connected with a round hole on the L-shaped angle iron (4);The rear end part of the actuating mechanism is provided with a handle; when the actuating mechanism is downwardly rotated, incising is first to performed, and then pressure is generated; C. in the heating circuit, power is transmitted to a heating cord (RL) to heat, and then the heat is transmitted to the heating body (3).The electrical appliance has the advantages that the electrical appliance can conveniently and simultaneously incise and seal the long cylindrical plastic bags.

Owner:SHANGHAI SONGJIANG NO 2 SENIOR HIGH SCHOOL

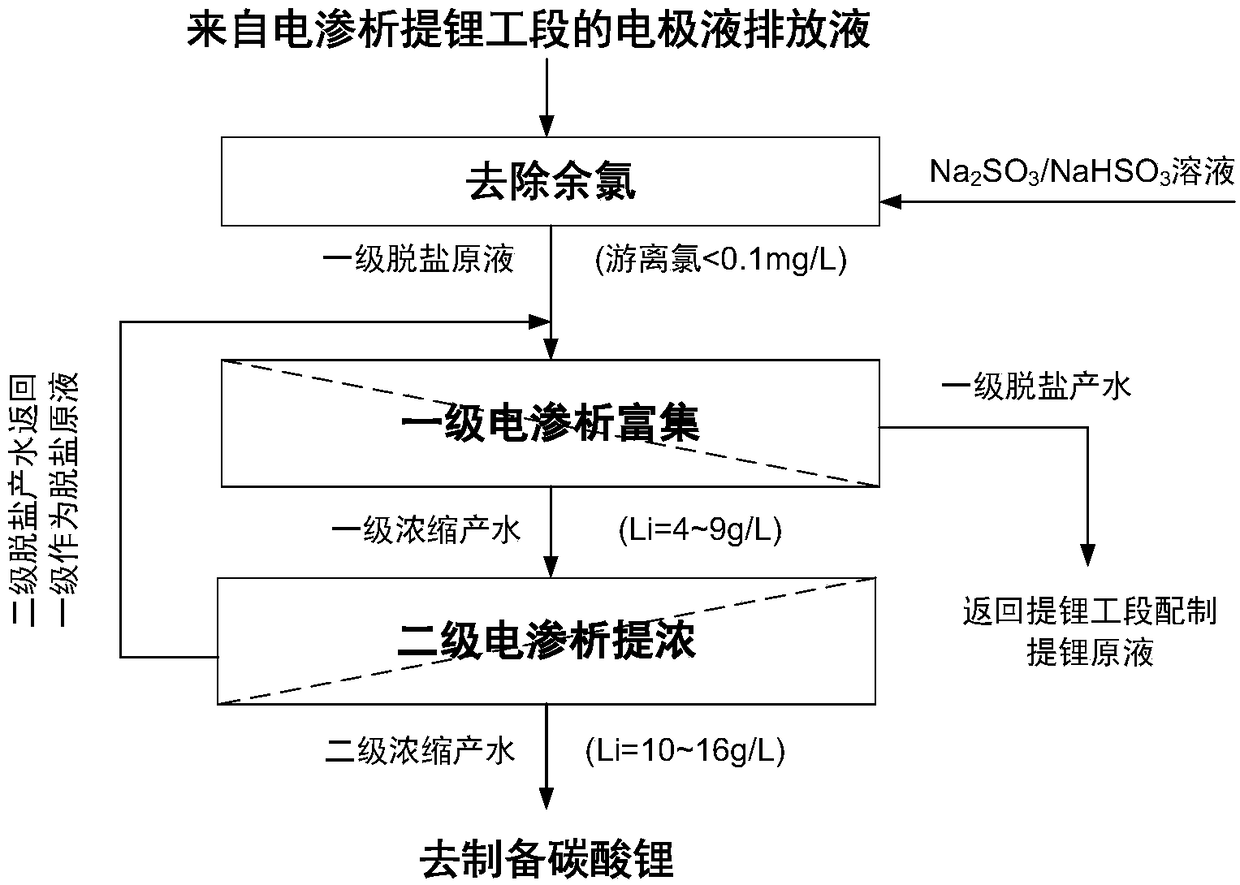

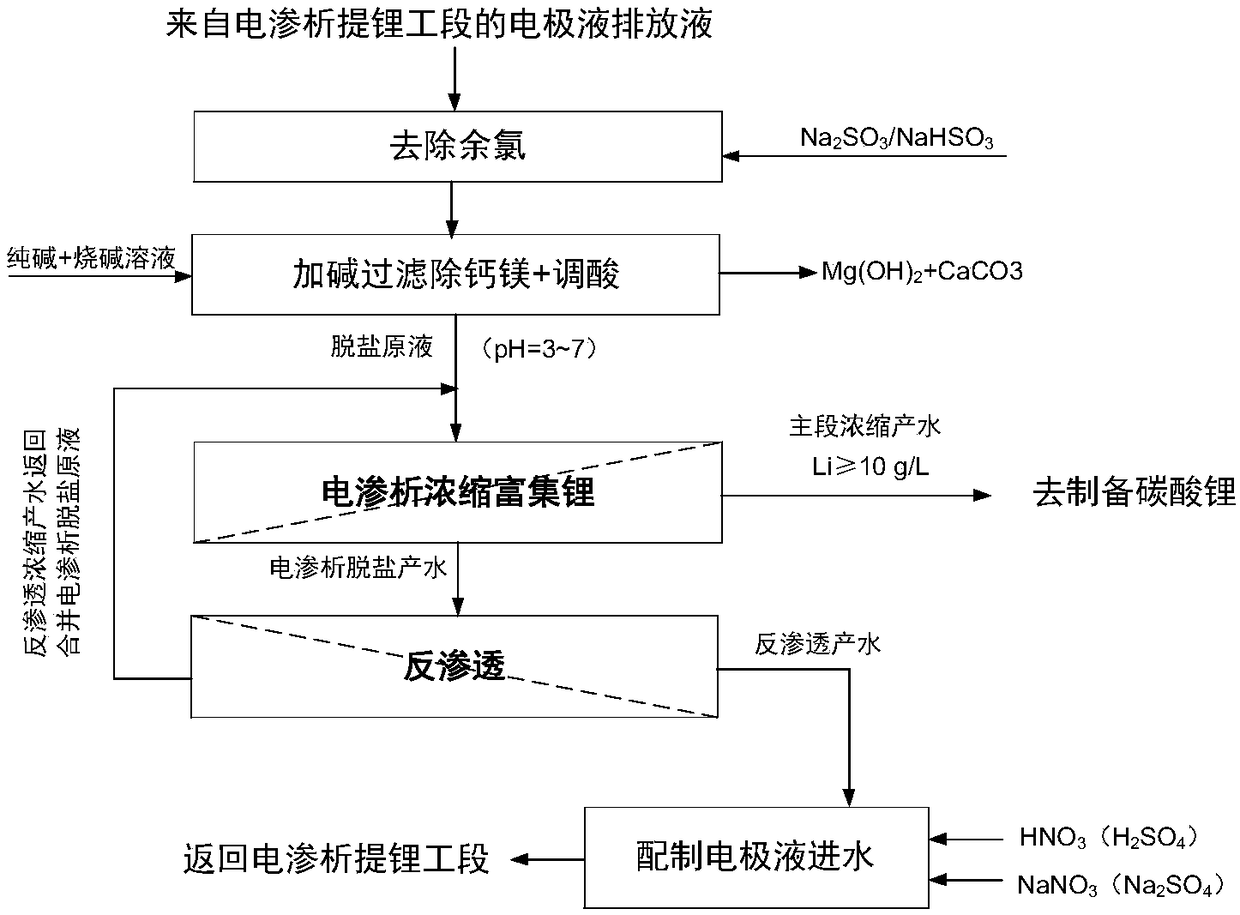

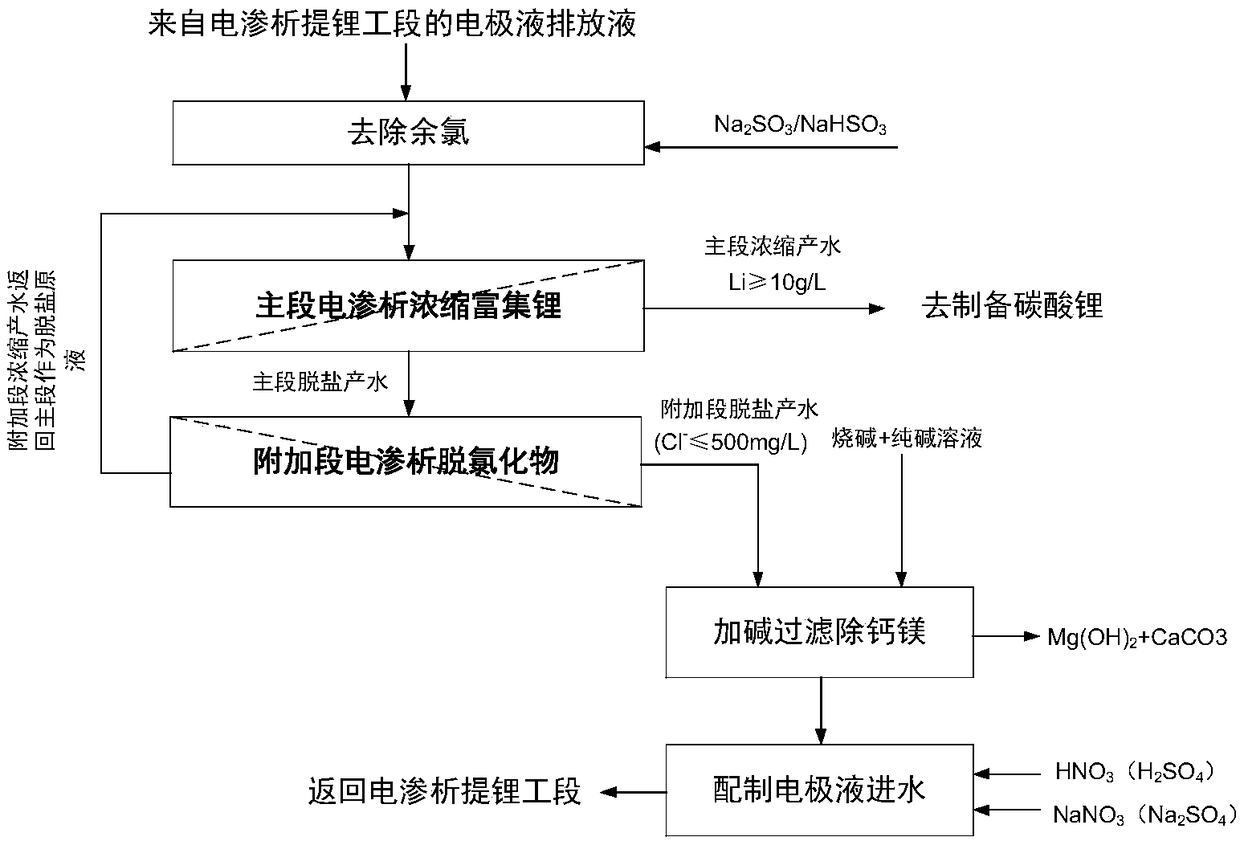

A method for recovering electrode discharge liquid in the electrodialysis lithium extraction process of high-magnesium solution

ActiveCN106365183BReduced electrodialysis operating costsSmall footprintGeneral water supply conservationDispersed particle separationRecovery methodHigh magnesium

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

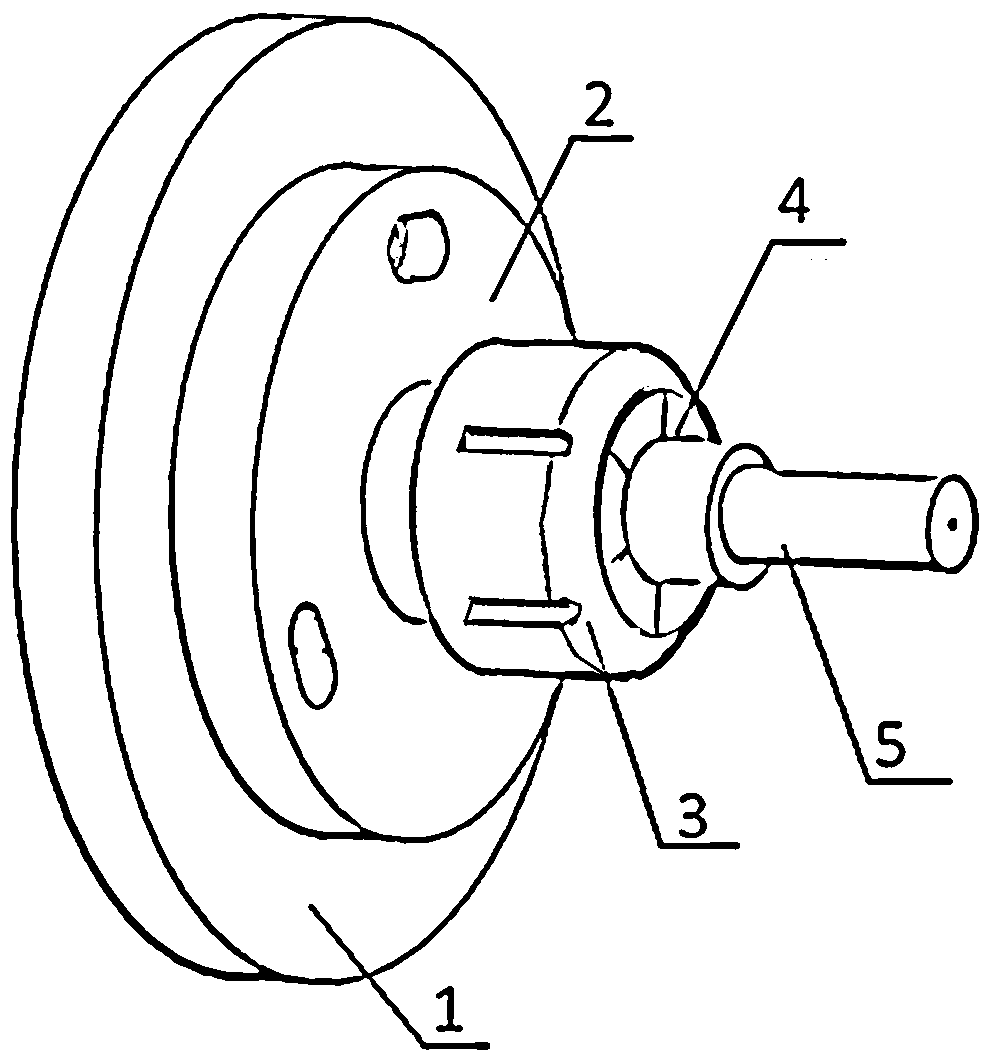

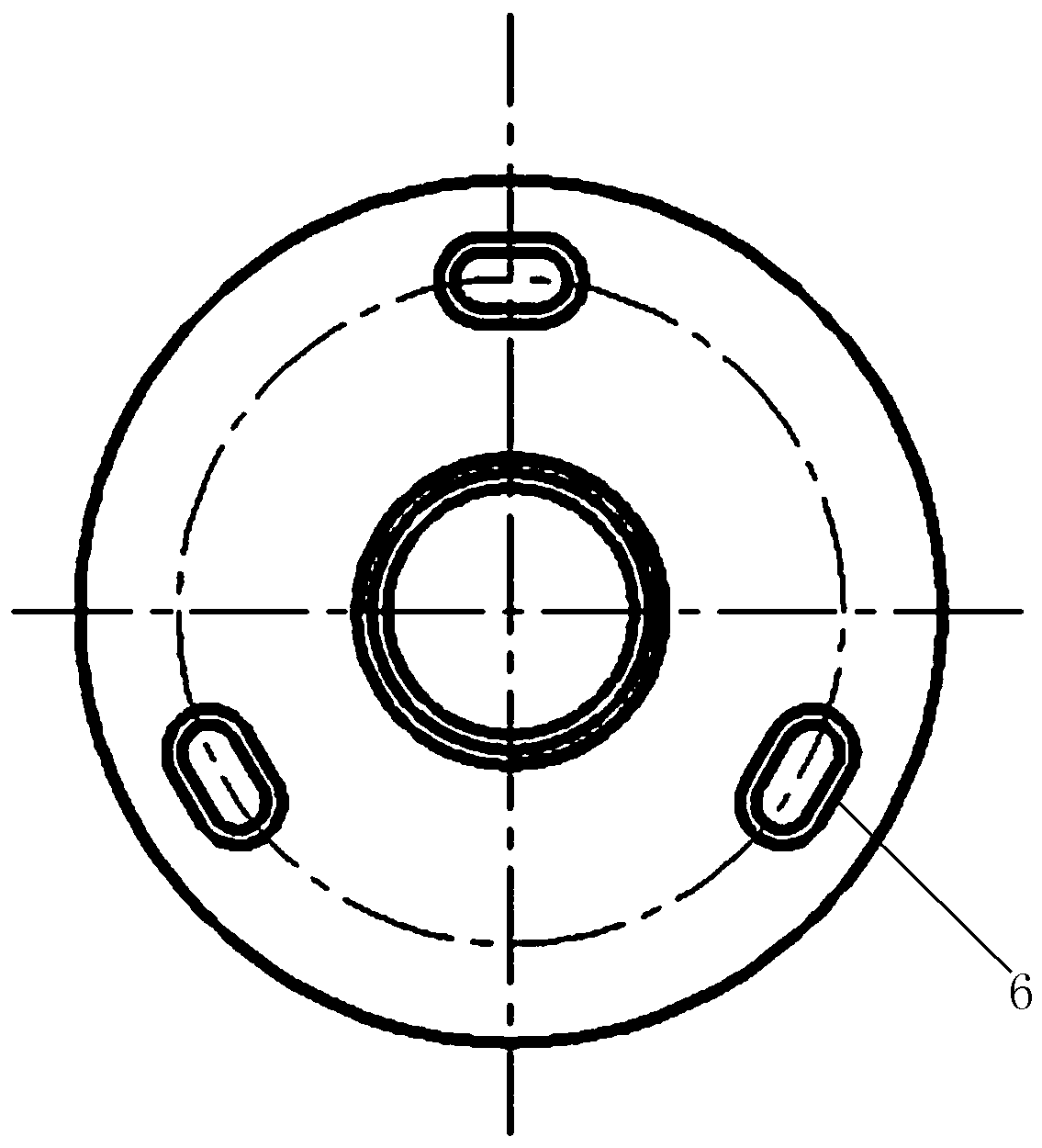

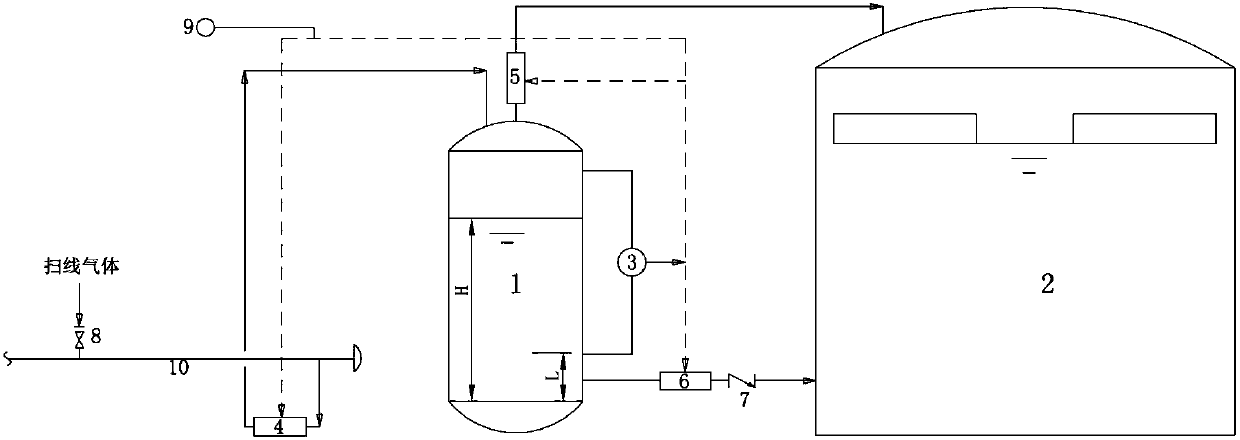

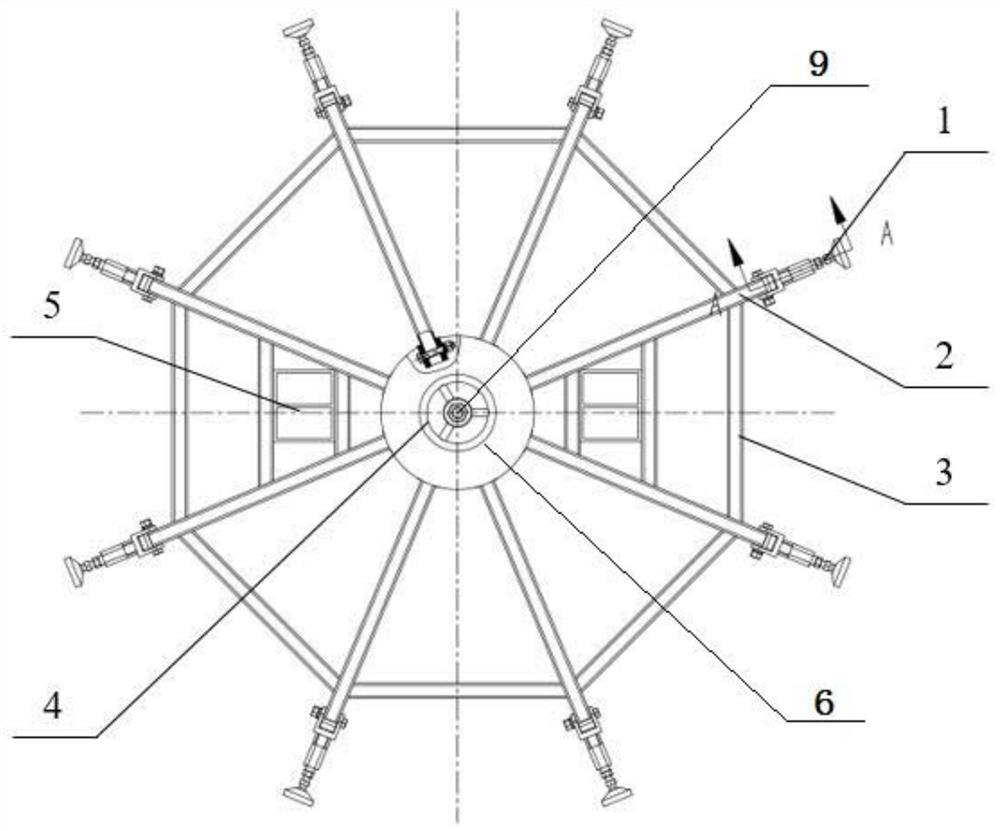

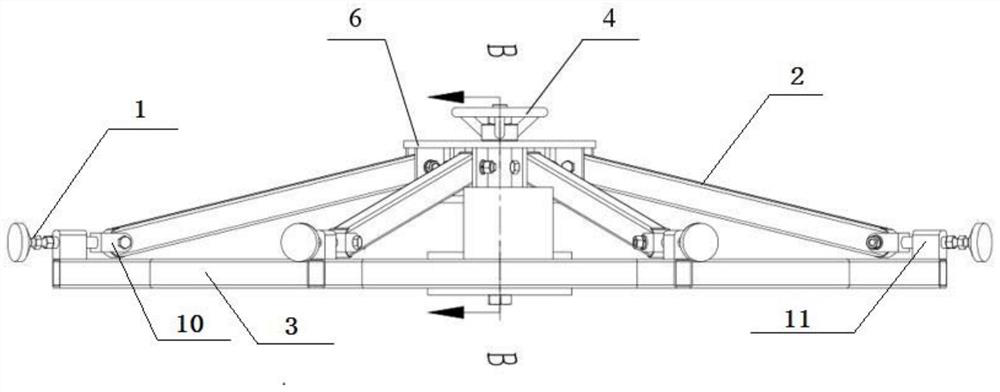

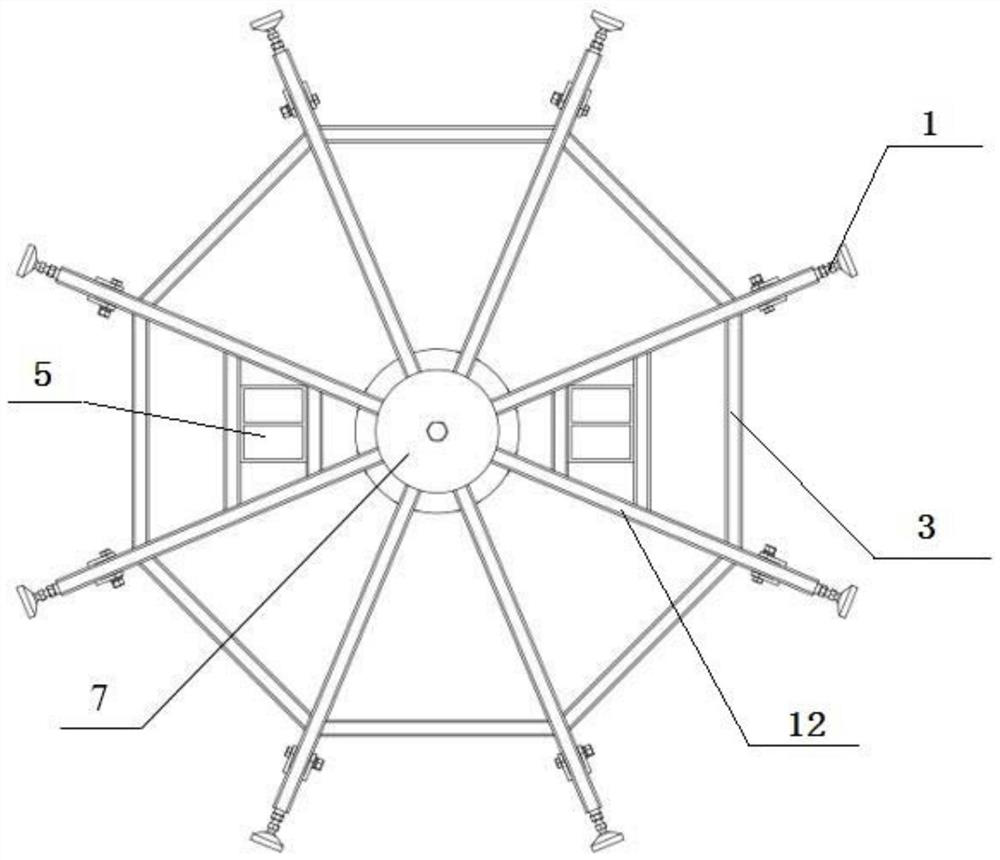

Wind power blade root shrinkage prevention device and using method

ActiveCN109367075BPrevent shrinkageNo wear and tearDomestic articlesStructural engineeringMechanical engineering

The invention provides a wind power blade root anti-shrinkage device, and relates to the technical field of wind power blade manufacturing. The wind power blade root anti-shrinkage device comprises asupport, supporting feet, mounting arms, a mounting disc and a center shaft mounted on the support. The mounting arms are arranged on the periphery of the mounting disc. The supporting feet connectedwith blade roots in an abutting manner are hinged to the mounting arms. The supporting feet are mounted on the support and move in the radial direction of the blade root circle. The mounting disc is mounted on the center shaft in a sleeving manner and moves in the axial direction of the center shaft. A limiting part for limiting the position of the mounting disc is arranged on the center shaft. The invention further provides an application method of the device. After the blade roots are placed in the wind power blade root anti-shrinkage device, the supporting feet are adjusted manually and arein contact with the inner walls of the blade roots, the position of the mounting disc on the center shaft is adjusted, and the mounting arm drives the supporting feet to move in the radial directionof the blade root circle till the supporting feet are connected with the inner walls of all the blade roots in the abutting manner. The wind power blade root anti-shrinkage device is stable in structure, convenient to operate and high in practicality, anti-shrinkage treatment can be carried out on the blade roots of various different types, and the blades cannot be damaged.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Production method of fermented fruit and vegetable juice and glutinous rice wine composite functional beverage

ActiveCN105249100BLong flavorGood health effectAlcoholic beverage preparationFood ingredient functionsBiotechnologyNutrition

The invention discloses a production method of a composite functional beverage of fermented fruit and vegetable juice and fermented glutinous rice. By preparing fermented fruit and vegetable juice and fermented fruit and vegetable sweet fermented glutinous rice, the obtained fermented fruit and vegetable sweet fermented glutinous rice, fermented fruit and vegetable juice and water are prepared according to the ratio of 7‑10:3‑ The volume ratio of 6:1-1.5 is used for blending; after blending, degassing, sterilizing and filling are carried out to obtain the finished product. The fermented fruit and vegetable juice and sweet fermented rice composite functional drink produced by the present invention can make up for the incomplete nutrition and lack of fermented fruit and vegetable sweet fermented glutinous rice. Health function and the disadvantage of low B vitamin content in fermented fruit and vegetable juice, which forms a unique fermented flavor, has more comprehensive and balanced nutrition and gastrointestinal health effects, and is suitable for all ages. It is a new type of nourishing drink.

Owner:广西轻工业科学技术研究院有限公司

A method and device for deploying a harbor mirror warehouse with high availability based on kubernetes

ActiveCN109684420BGuaranteed downtimeReliable technical solutionDatabase distribution/replicationDatabase modelsData synchronizationHigh availability

In order to solve the problems existing in the prior art of high-availability deployment of harbor warehouses, the present invention innovatively proposes a method and device for high-availability deployment of harbor mirror warehouses based on kubernetes, uses DaemonSet objects to create harbor service containers, and deploys harbor mirror warehouses In the pod container, the service object is used to manage the pod container and provide a unified entrance for external access. The pod container uses shared storage as persistent storage, which can not only realize the high-availability deployment of the harbor mirror warehouse, but also avoid frequent exceptions in data synchronization Or data loss and other issues, the operability is strong, simple and reliable, and the work efficiency is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Pavement maintenance robot

PendingCN114561858ASystematicImprove integrityMixing operation control apparatusPretreatment controlSocial benefitsPavement maintenance

The invention relates to automatic road construction equipment, and discloses a robot for discovering and maintaining a damaged road surface. The pavement maintenance robot comprises a walking system, a positioning detection system, a crushing system, a concrete pouring system, an alarm system, a power supply system, a control system and the like. According to the invention, the work of finding and maintaining the damaged road surface can be automatically, systematically and comprehensively completed, the maintenance cost can be saved, and the maintenance road occupation time is reduced. The method has wide application prospects and remarkable economic benefits and social benefits.

Owner:函鼎科技(成都)有限公司

Explosion-proof fuel oil dehydration and deoxygenation device

ActiveCN106390527BIncrease contact areaImprove separation efficiencyLiquid degasificationLiquid separationAutomatic controlPetroleum product

The invention relates to an online fuel oil dehydrating and deoxidizing device, particularly relates to an anti-explosion fuel oil dehydrating and deoxidizing device, and belongs to the technical field of comprehensive guarantee. The device comprises an air inlet pipeline system, an oil inlet pipeline system, an oil-gas mixing system, an oil-gas separating system, a petroleum product conveying system and an automatic control system, wherein a gas-liquid static mixer II is additionally arranged in the oil-gas mixing system. By additionally arranging the gas-liquid static mixer II, the contact area between a fuel and nitrogen is increased, so that the total quantity of fuel oil treated in the periodic time of the replacement reaction is increased, and the separation efficiency of water and the fuel oil and the separation efficiency of oxygen and the fuel oil are improved; by rapidly separating the fuel oil and nitrogen, an online, rapid and high-flow dehydrating and deoxidizing function is realized. By virtue of an anti-explosion design, the reliability and safety of the device are improved, and the demands of different customers are met.

Owner:SHENYANG AEROSPACE XINGUANG GRP

Inductance Defect Identification Method

ActiveCN109444148BComprehensive data collectionImprove detection accuracyOptically investigating flaws/contaminationUsing optical meansSynthetic dataIndustrial engineering

The invention discloses an inductance defect identification method, which collects the size attribute of the inspection surface, the outer edge damage attribute, the rust surface attribute, the crack attribute, the concave-convex attribute, and the exposed copper attribute of the key inspection surface through all the inspection positions, and the rest except the rust surface attribute There are multiple collections of data for a single attribute, and intelligent identification is carried out based on all the collection data of the key detection surface, and the defect classification and sorting of the detection inductor is carried out, or intelligent identification is carried out according to the order of the collection data of the key detection surface, and the good and bad products of the detection inductor are carried out. Classification and sorting of good products. The invention collects comprehensive data on the key detection surface of the inductance, the collected data is relatively comprehensive, and the detection precision is high. It can achieve more detailed screening and sorting, and can screen out inductors that are easy to reprocess, reducing the waste of resources. It has detailed screening classification mode and high-speed screening mode to meet different needs. It can also realize the detection of special requirements for special inductance. The overall technical scheme is reliable, easy to realize and implement.

Owner:昆山市泽荀自动化科技有限公司

A gel slug isolation well control method

InactiveCN103711452BReduce security risksIncrease success rateSealing/packingWell drillingEngineering

The invention discloses a gel plug packing well control method. The well control method includes the following steps that S1, a gel plug is built in a wellbore when spillage together with complicated wellbore conditions appear; S2, throttling circulating exhaust is performed on packed upper portion of the wellbore; S3, preparatory work for boring stopping and leaking stoppage is performed in safe operation time provided by wellbore packing; S4, the gel plug is broken to remove the wellbore packing, and leaking stoppage operation is performed by the adoption of an extrusion method; S5, weighted drilling fluid is used for throttling well killing. The well control method has the advantages that due to wellbore packing through the gel plug and removal of wellbore packing through gel breaking, a brand new choice is provided for processing the complicated wellbore conditions; the gel plug blocks an oil-gas shifting-up channel, in this way, overflow is effectively controlled to be located in the bottom hole, the safe operation time is provided for leaking stoppage and well killing, and safety risks of well control are reduced; the technical thought is novel, the technical scheme is reliable, and the well control method is beneficial for forming a practical engineering technology.

Owner:SOUTHWEST PETROLEUM UNIV

Design method of a heavy-duty diesel vehicle exhaust fine dust treatment device

The invention discloses a design method of a heavy-duty diesel vehicle exhaust fine dust treatment device, and relates to the technical field of air dust removal and purification. The design method of the heavy-duty diesel vehicle exhaust fine dust treatment device of the present invention is: on the basis of inheriting the basic principle of existing bag-type fiber dust filter design, the heavy-duty diesel vehicle exhaust fine dust treatment device of the present invention is designed as The metal cloth bag structure with sand and gravel particles as the filter medium for exhaust gas and dust disposal enables the tail gas and dust to be treated to be trapped during the advancing process, forming a dense ash filter layer on the surface of the sand particles in the dust disposal and filtration wall, and the dust filter The thickness of the layer is controlled according to the needs, which will further trap the fine particles in the dust, so that the treated tail gas dust can meet the requirements of the National VI emission standard. Compared with the prior art, the present invention has outstanding substantive features and remarkable progress of novel technical scheme, reliable technology, no secondary pollution, energy saving and emission reduction, safety and environmental protection.

Owner:徐功波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com