Gas pipeline cleaning equipment for inner floating top storage tank

An internal floating roof storage tank and gas technology, applied in the directions of containers, packaging, transportation and packaging, can solve problems such as poor safety, waste of materials and energy, and achieve the effects of avoiding disturbance, high degree of automation and simple technical solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

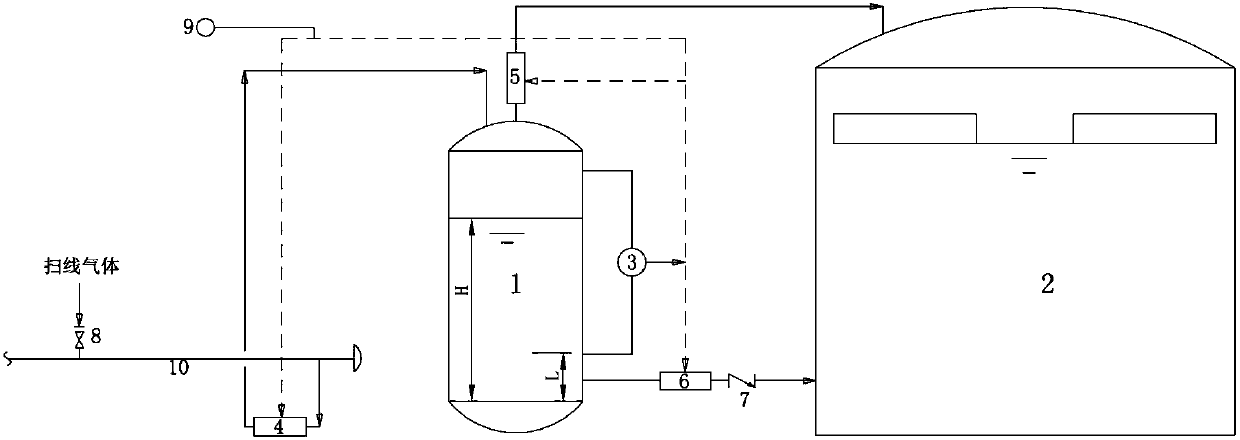

[0051] figure 1 A schematic structural view showing a gas line sweeping device for an internal floating roof storage tank according to an exemplary embodiment of the present invention, as shown in figure 1 As shown, gas sweeping equipment for internal floating roof tanks includes:

[0052] The gas-liquid separation tank 1, the top of the gas-liquid separation tank 1 is connected to the top of the swept line pipeline 10 and the inner floating roof storage tank 2 through the first pipeline and the second pipeline respectively, and the bottom of the gas-liquid separation tank 1 is connected to the top of the gas-liquid separation tank 1 through the third pipeline connected to the bottom of the inner floating roof storage tank 2;

[0053] A liquid level transmitter 3, the liquid level transmitter 3 is used to detect the liquid level of the gas-liquid separation tank 1 and transmit the liquid level to the controller (not shown);

[0054] The valve group, the valve group includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com