Fast changing fixture for six-axis air floating grinding machine

A quick-change fixture and air flotation technology, which is applied in the direction of grinding workpiece supports, can solve problems such as unfavorable machine tool accuracy, affecting part processing, and affecting processing efficiency, and achieves the effects of easy use, improved installation accuracy, and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

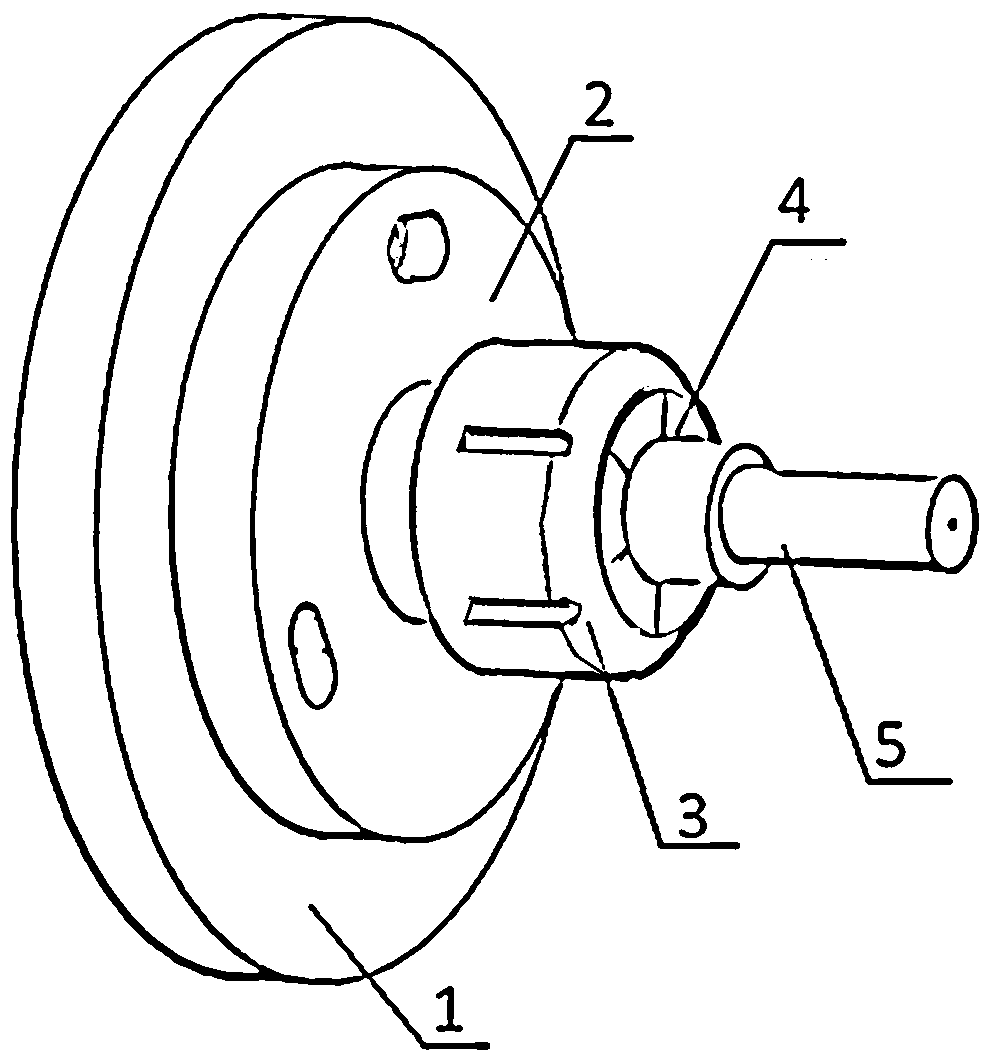

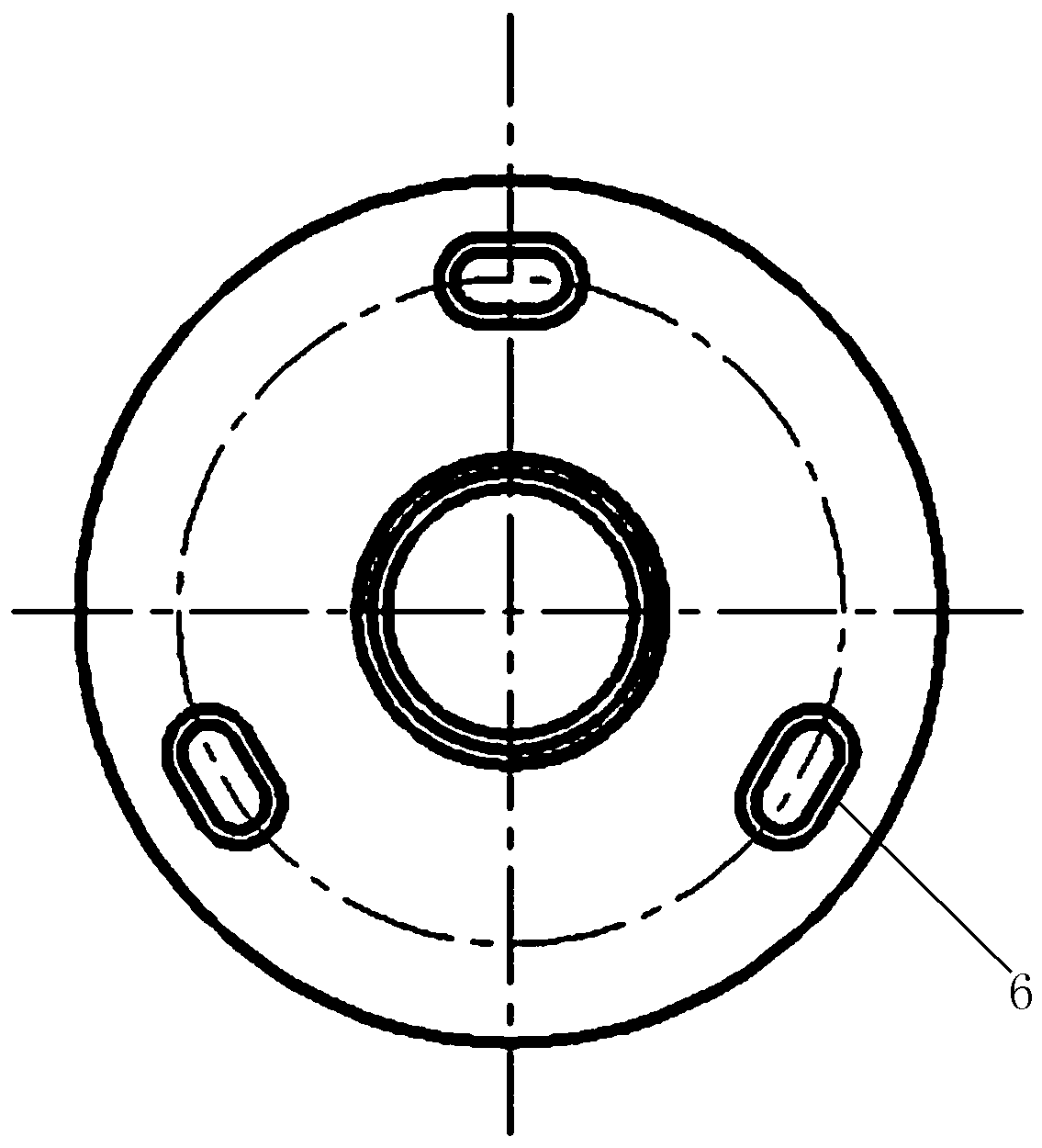

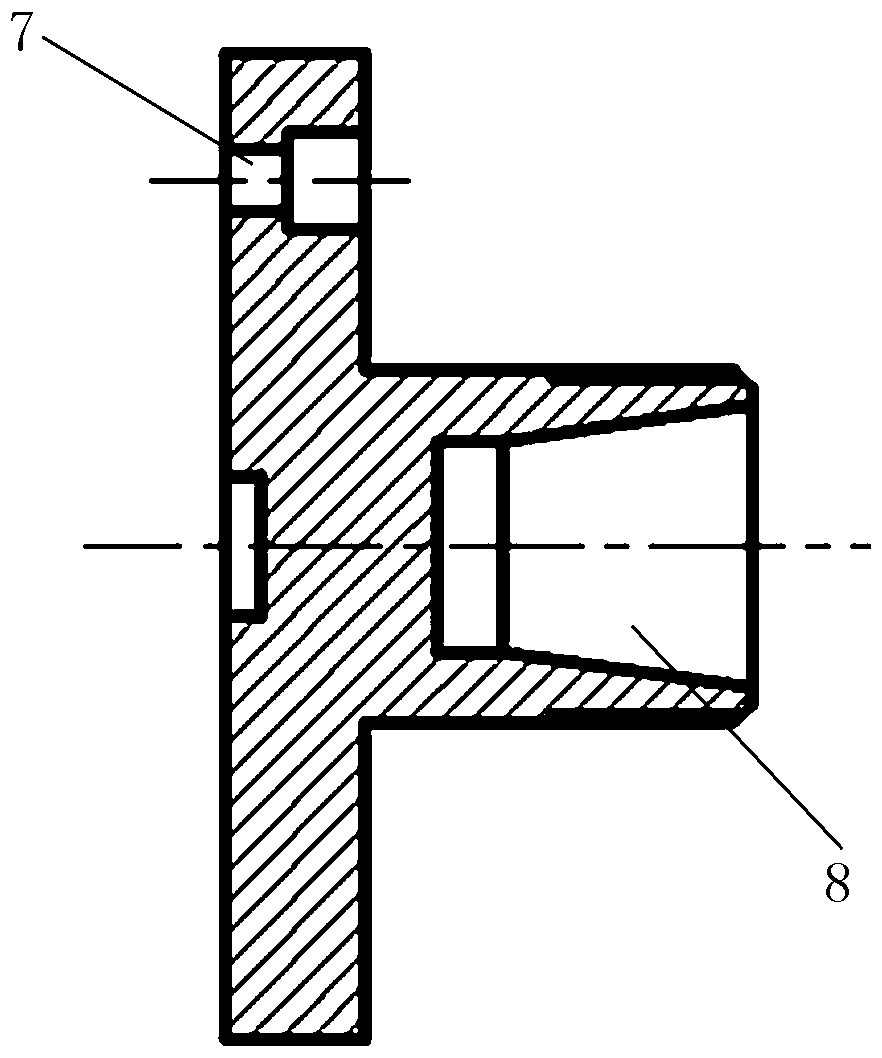

[0021] The six-axis air-floating grinder quick-change fixture includes a cylindrical machine tool spindle 1 and a faceplate fixture 2 threadedly connected to it. The faceplate fixture 2 is provided with three waist-shaped grooves 6, and a countersink hole 7 is provided in the waist-shaped groove. The faceplate fixture 2 and the machine tool spindle 1 are locked by three M8 hexagon socket head screws; the center of the faceplate fixture 2 is provided with an internal taper hole 8, and the inclined surface at one end of the circlip 4 fits with the internal taper hole of the faceplate fixture 2 to limit the circlip 4 Move in the axial direction, and apply pressure to the circlip 4 to shrink the inner hole of the circlip 4; the inner hole of the other end of the circlip 4 is in clearance with the clamped workpiece 5, and the circlip and the clamped workpiece are fixed by line contact; The back cap 3 is sleeved on the outside of the circlip and is threadedly connected with the facep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com