Patents

Literature

61results about How to "Reduced carrying capacity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

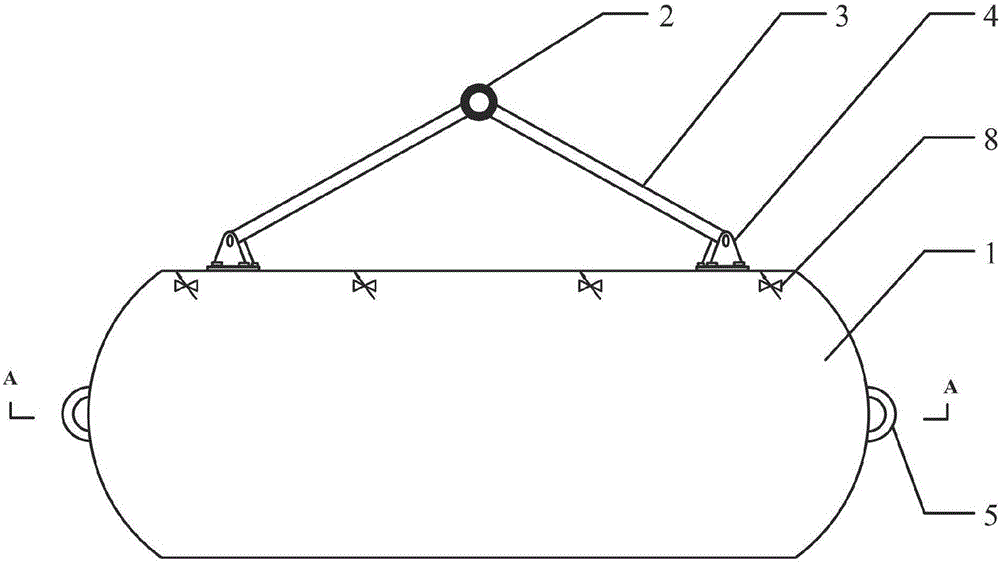

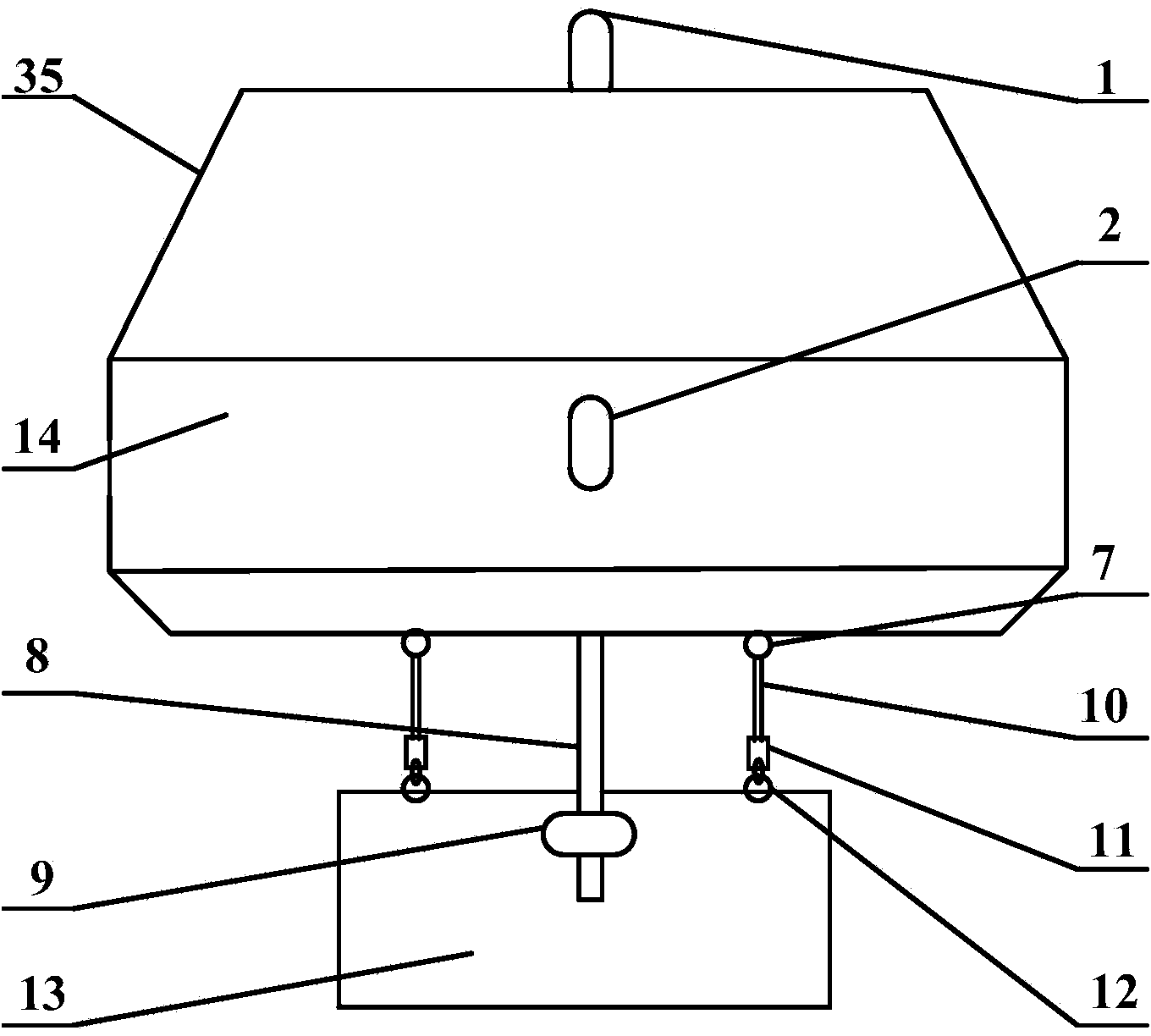

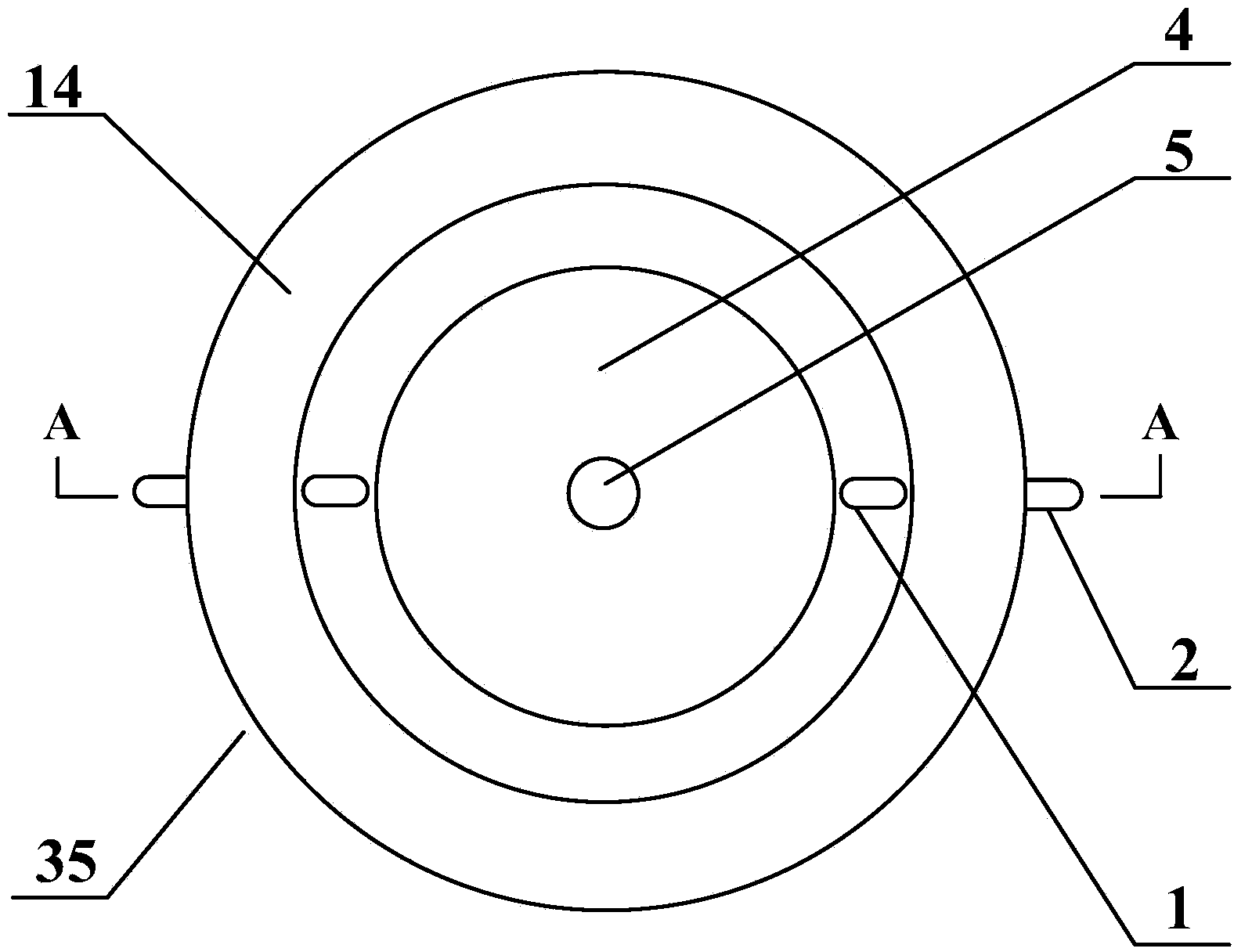

Buoyancy-adjustable device and method for auxiliary installation of underwater equipment

InactiveCN103754340AWithstand small tensionReduced carrying capacity requirementsUnderwater equipmentPull forceBuoy

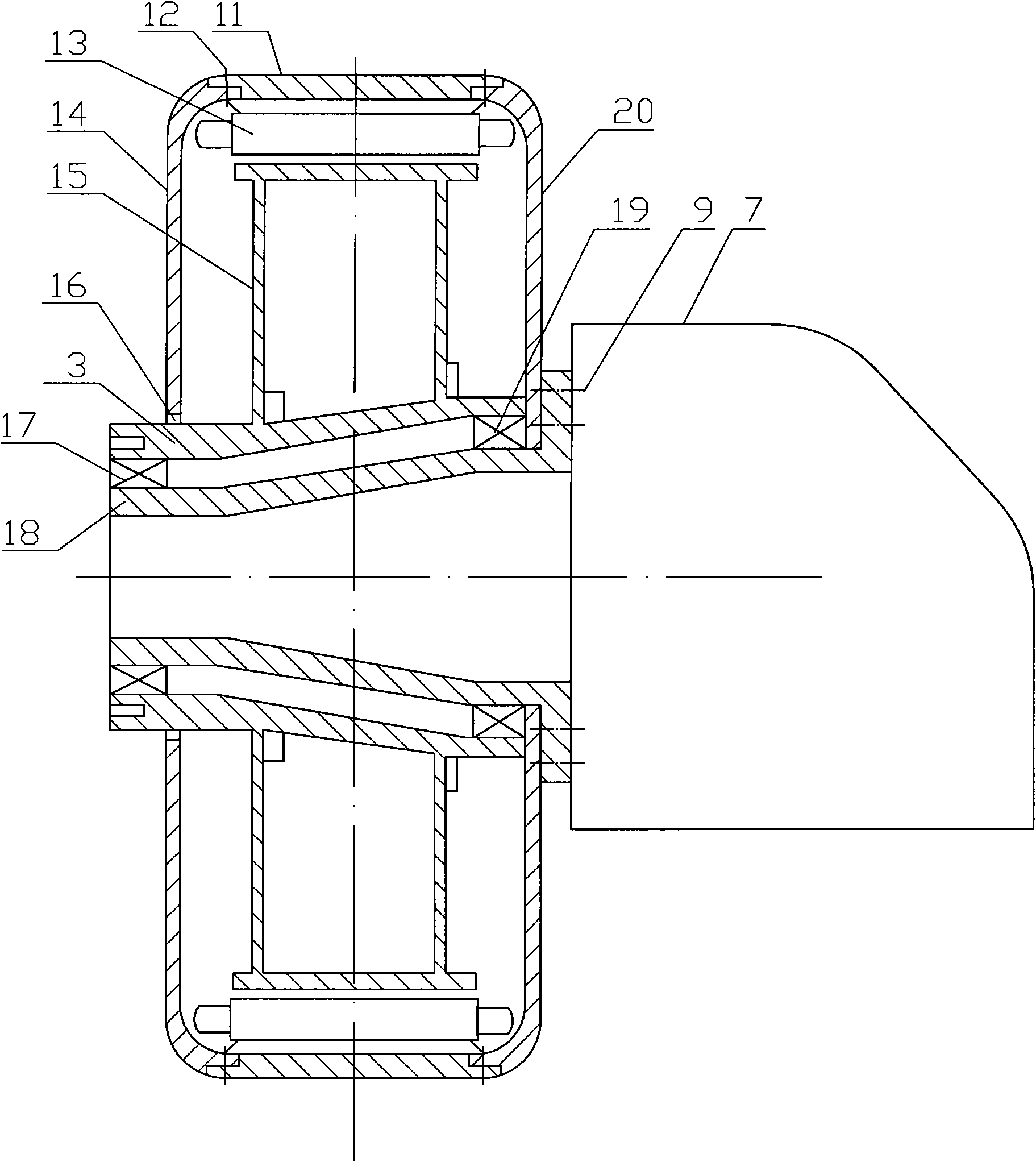

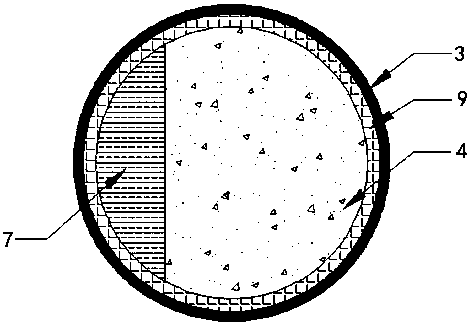

The invention belongs to the field of marine engineering and particularly relates to a buoyancy-adjustable device and a method for auxiliary installation of underwater equipment. The buoyancy-adjustable device for auxiliary installation of underwater equipment comprises a buoy, a top lifting lug, a side lifting lug, a bottom lifting lug, a lifting cable, a locating rod and a hydraulic shackle, wherein the main body of the buoy is cylindrical, and conic surfaces are formed at the upper end and the lower end of the buoy; the buoy is made of a solid buoyancy material; the top lifting lug, the side lifting lug and the bottom lifting lug are arranged at the top of the buoy; a funnel-shaped guide-in cone, a cylindrical guide-in hole and a gyro-shaped balance weight cabin are sequentially arranged in the axial direction of the buoy from the top to bottom, the funnel-shaped guide-in cone and the gyro-shaped balance weight cabin are communicated through the cylindrical guide-in hole, three oblique water ducts which are communicated with the exterior are arranged at the bottom of the balance weight cabin, and the three water ducts are uniformly distributed in the circumference direction. Small pull force is applied on an installation rope in the installation process, and the buoyancy material which is used as the material of main body of the auxiliary installation device can endure deep water pressure and is suitable for deep water installation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

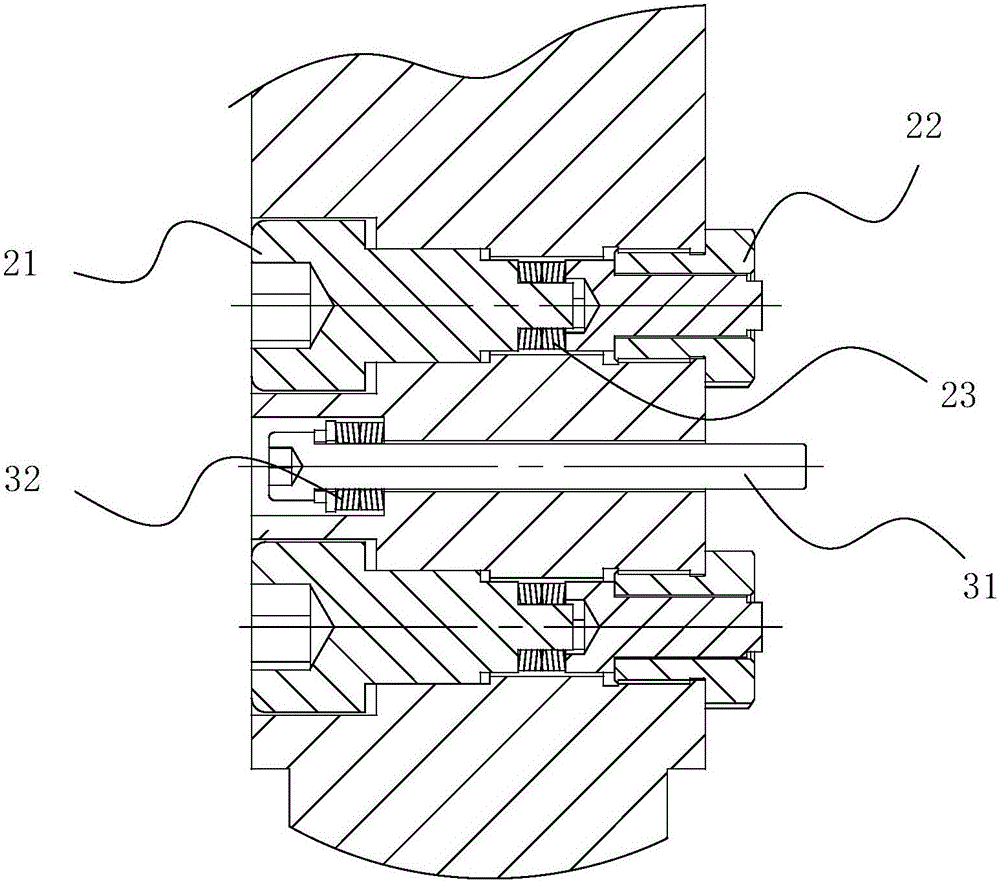

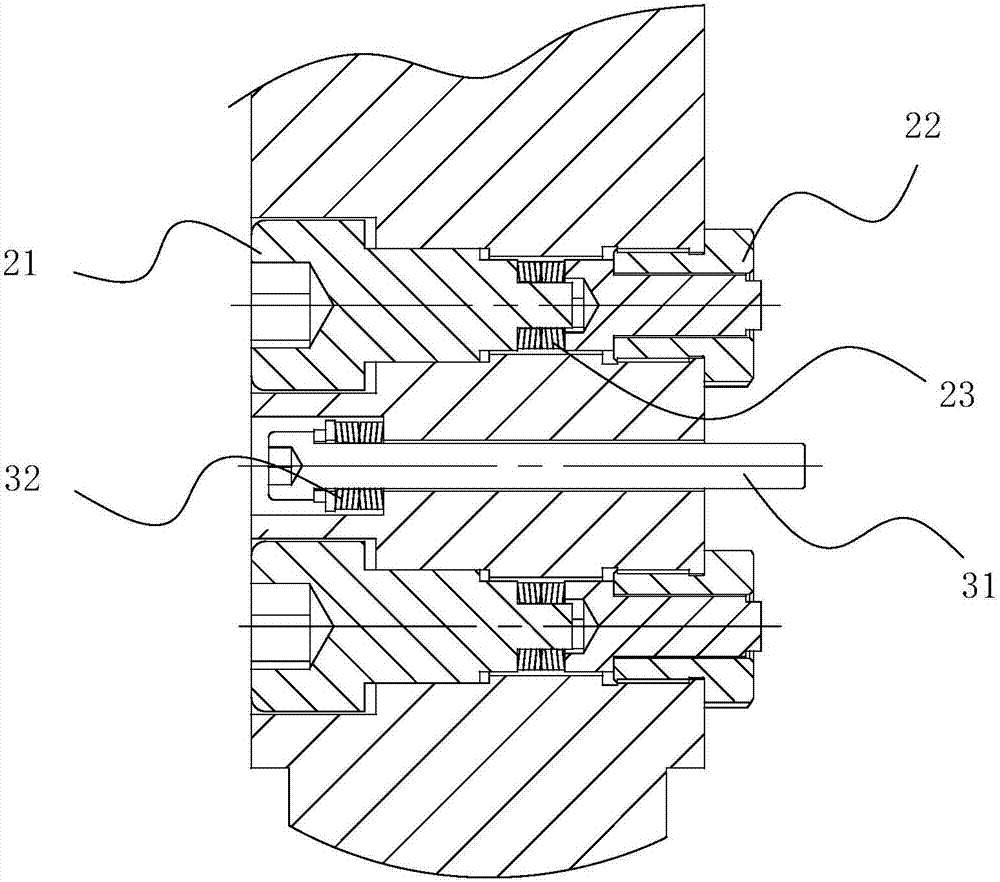

Megawatt-stage direct-drive internal rotor permanent-magnetic wind power generator set

InactiveCN101639042AEnsure personal safetySimple structureMachines/enginesWind motor combinationsElectric generatorStator

The invention discloses a megawatt-stage direct-drive internal rotor permanent-magnetic wind power generator set which comprises a wind wheel, a paddle-distance changing system, a permanent-magnetic generator, an engine room, an engine base and a yawing system, wherein the permanent-magnetic generator comprises a casing, a stator, a front end lid, a rotor, a back end lid and a rotor rotation support mechanism, the rotor rotation support mechanism comprises a movable shaft, a bearing I, a fixed shaft and a bearing II, the movable shaft and the fixed shaft are hollow, the movable shaft is sheathed outside the fixed shaft, one end between the movable shaft and the fixed shaft is provided with the bearing I, and the other end is provided with the bearing II. The rotor is fixed on the movable shaft, the movable shaft is connected with the wind wheel, and the fixed shaft is connected with the engine room and the engine base. The hollow fixed shaft can provide a passage from the engine room and the engine base to a wheel hub for equipment maintenance personnel and ensures the human safety. The bearing has low bearing capacity, and the end lid of the bearing side of the generator and the fixed shaft are simultaneously connected with the engine room and the engine base to achieve the aim that the end lid bears the stator load of the generator and the fixed shaft bears the load of the rotor and the wind wheel.

Owner:华小平 +1

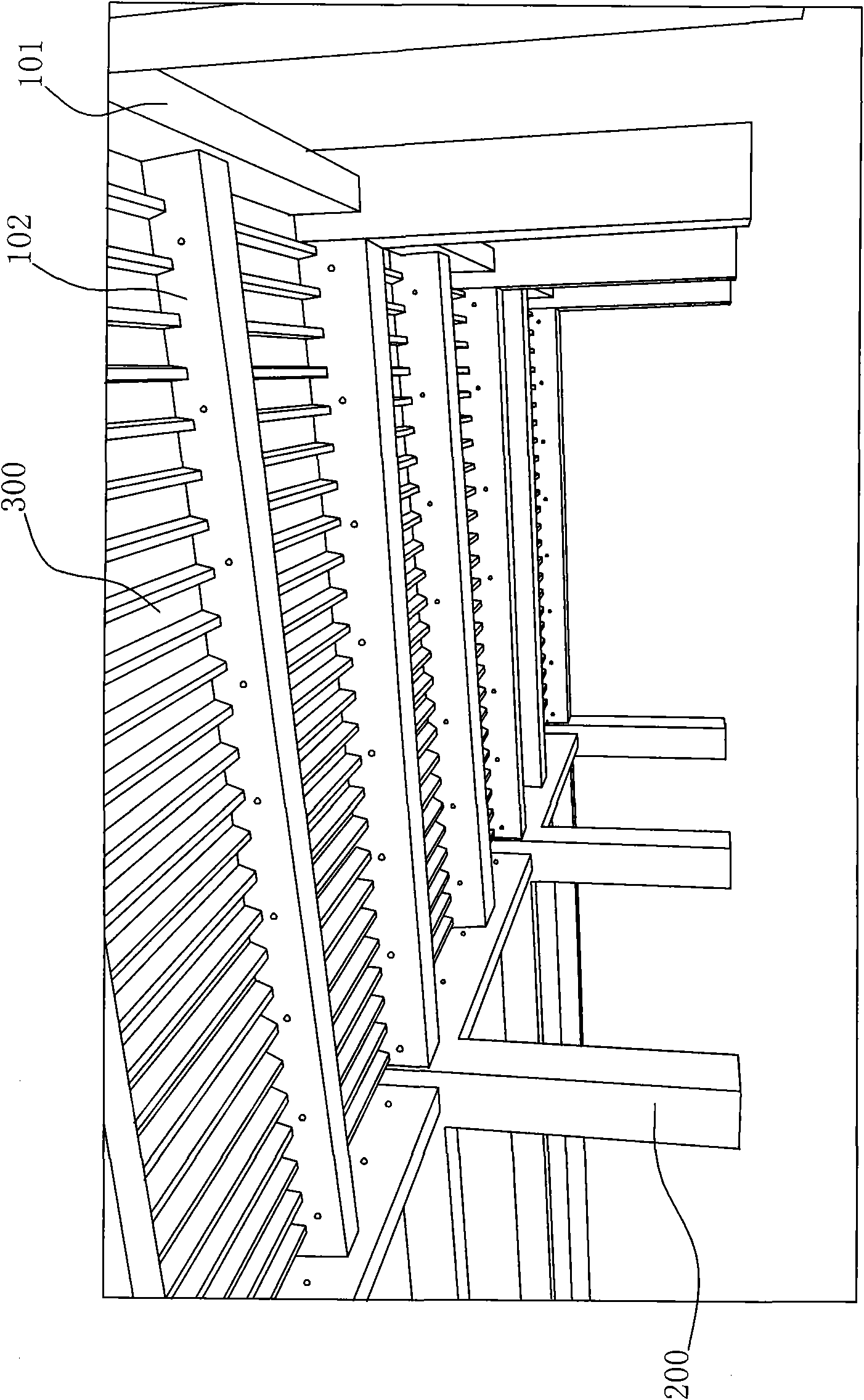

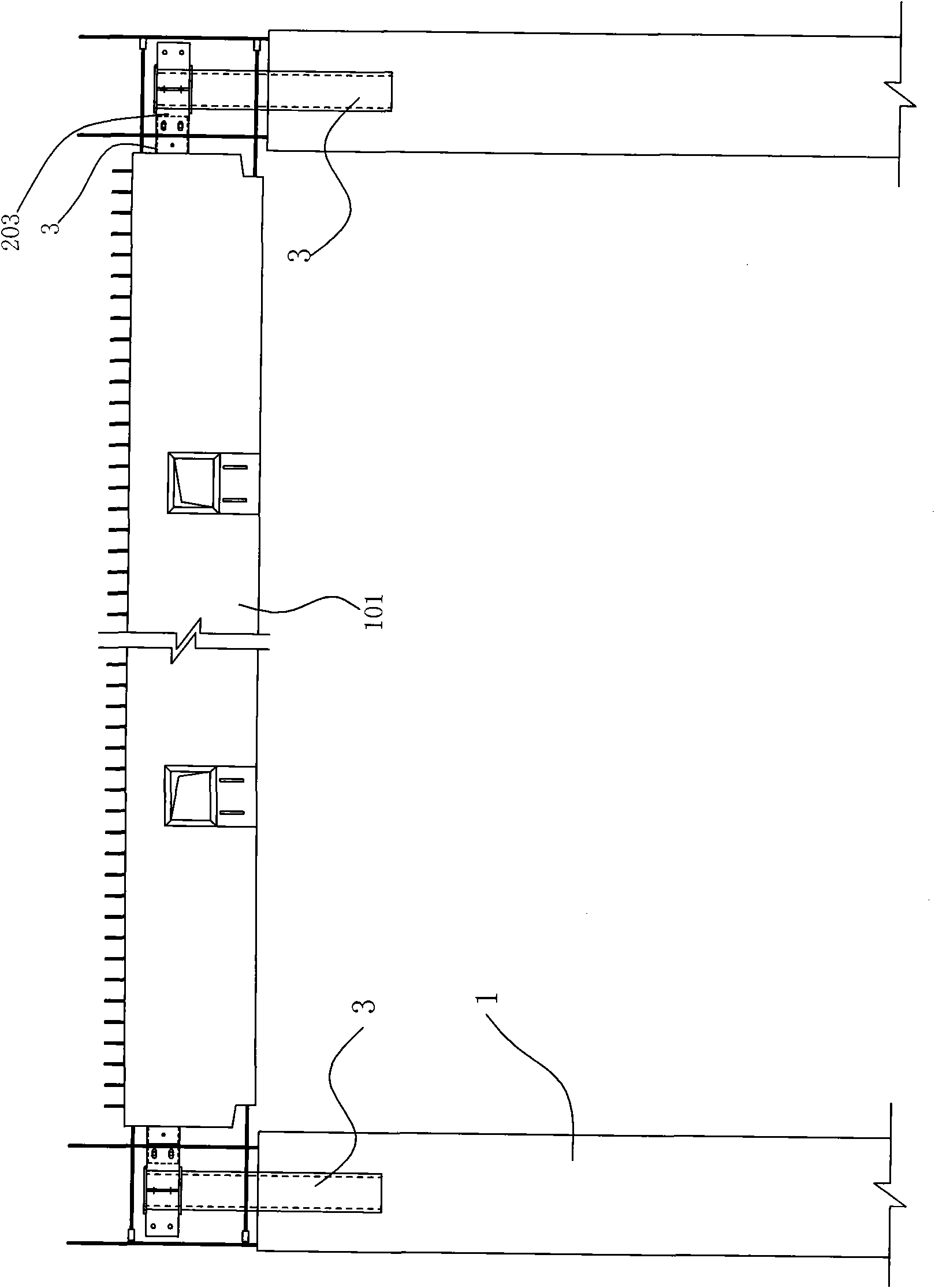

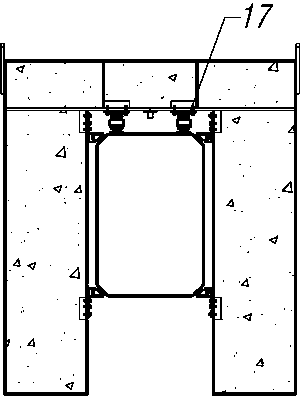

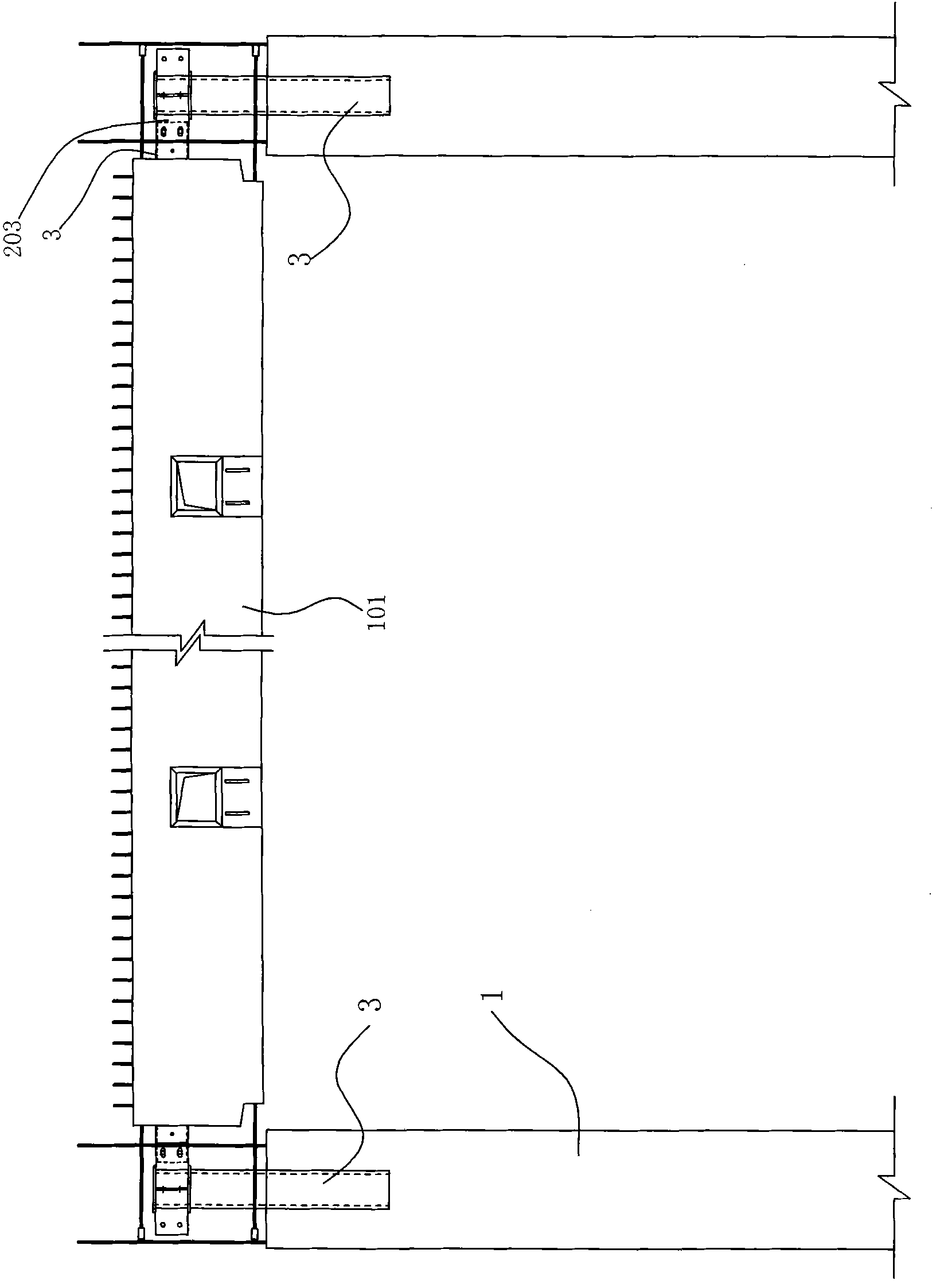

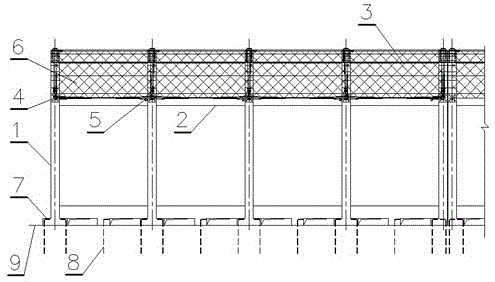

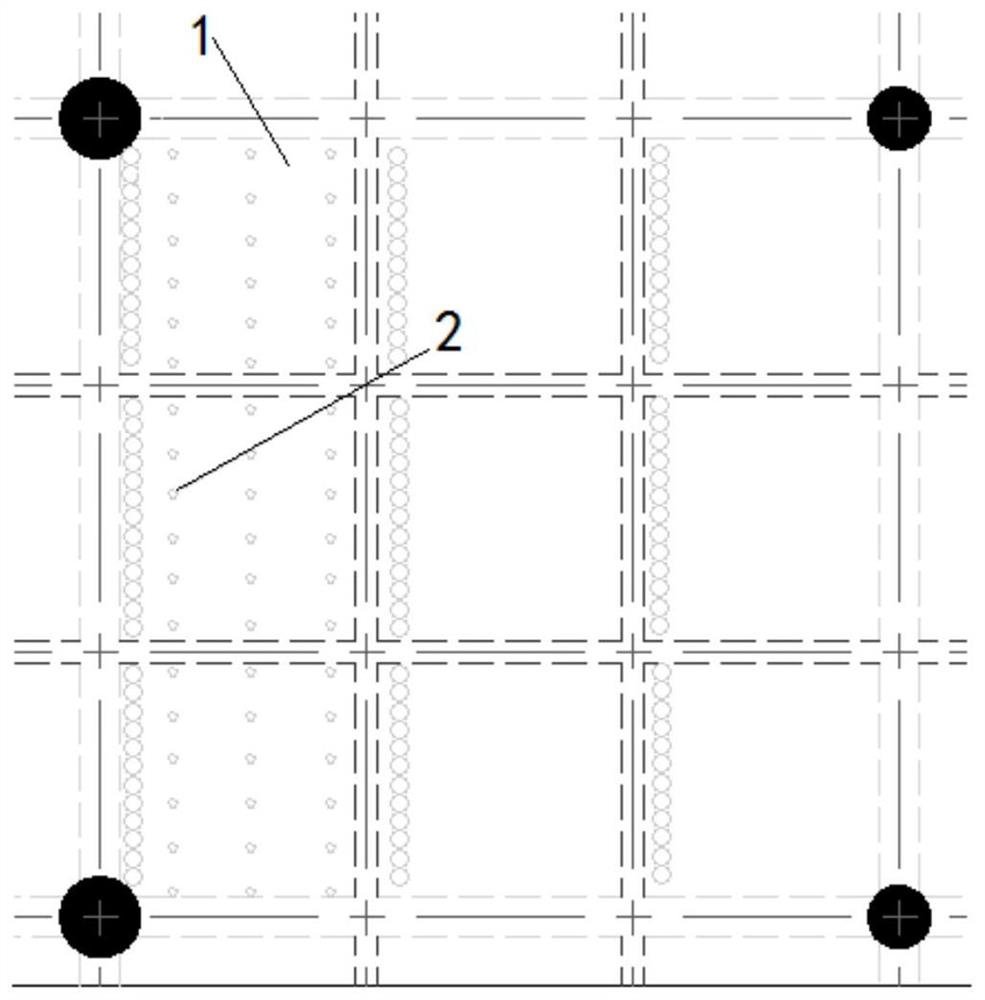

Novel reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386AReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

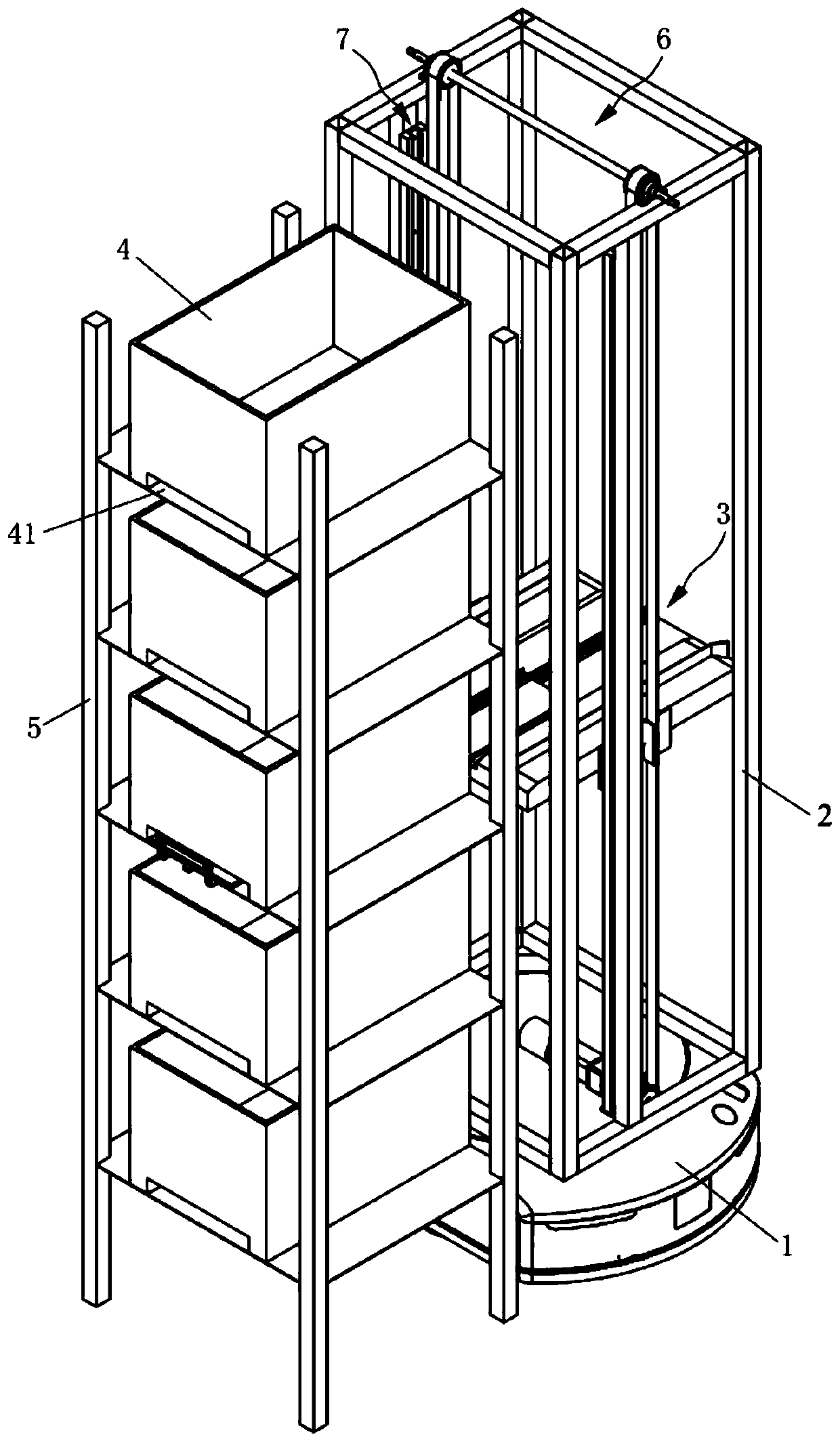

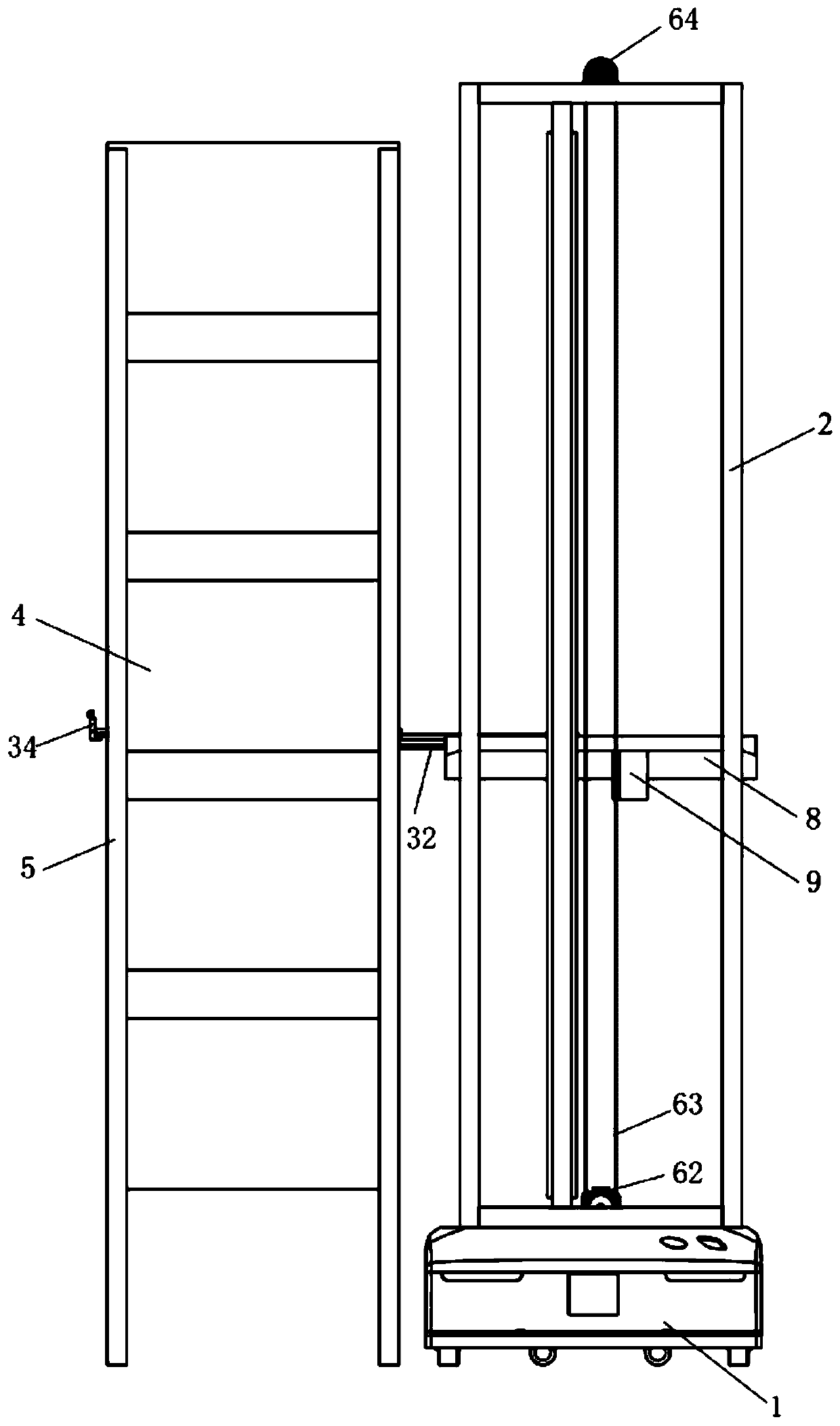

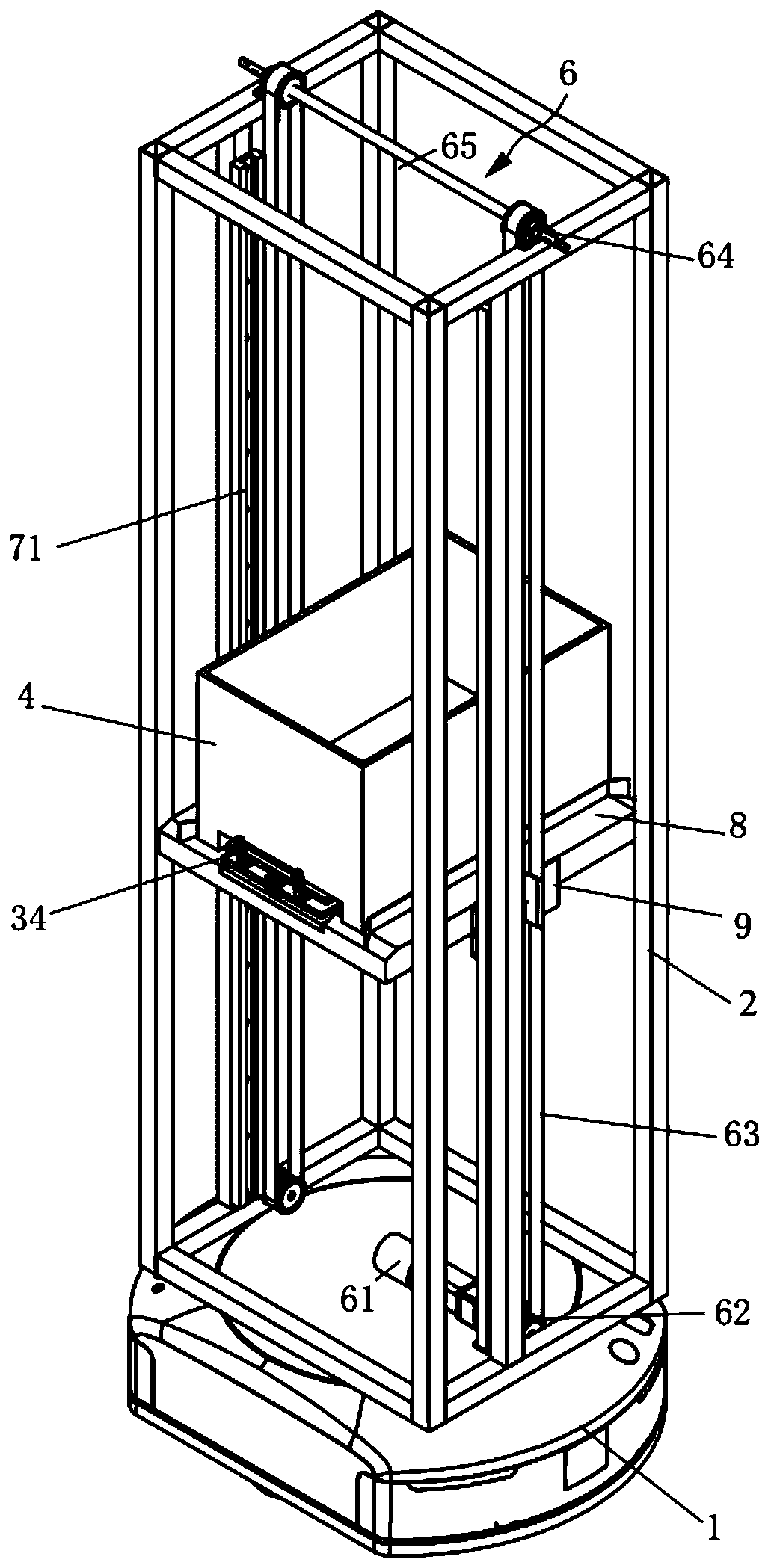

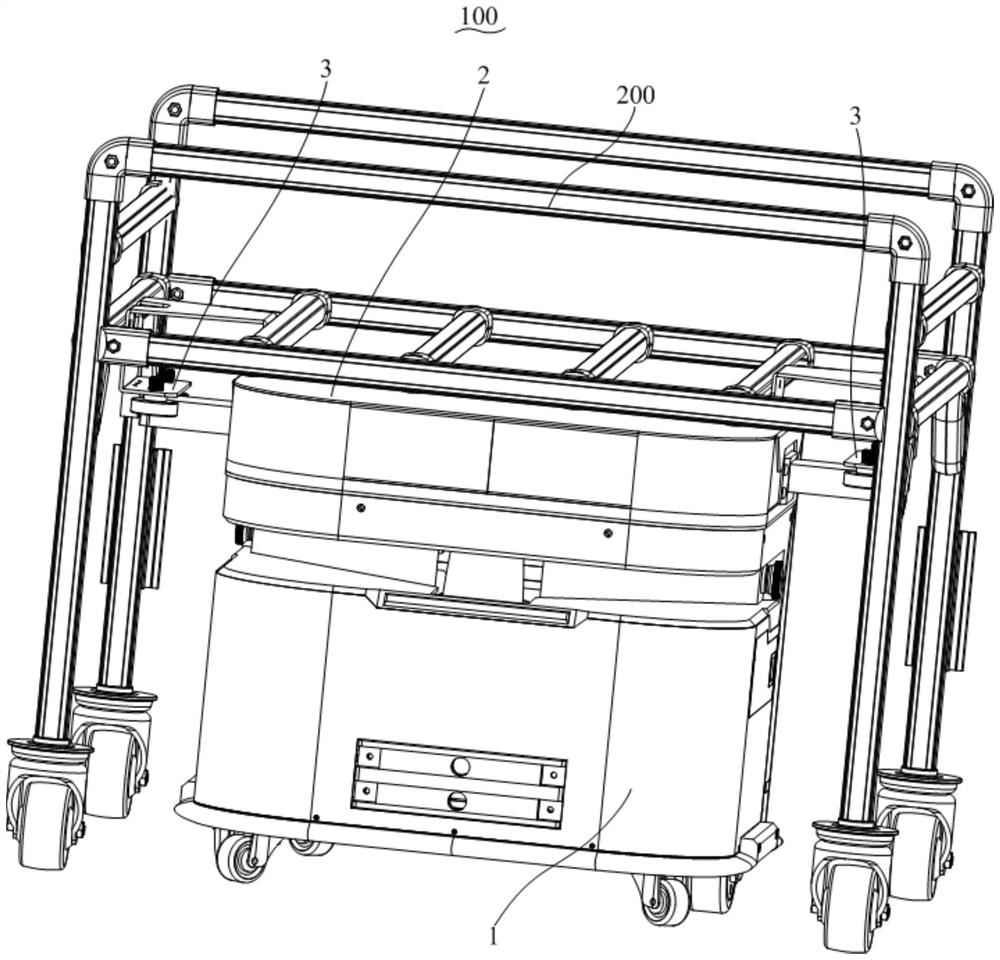

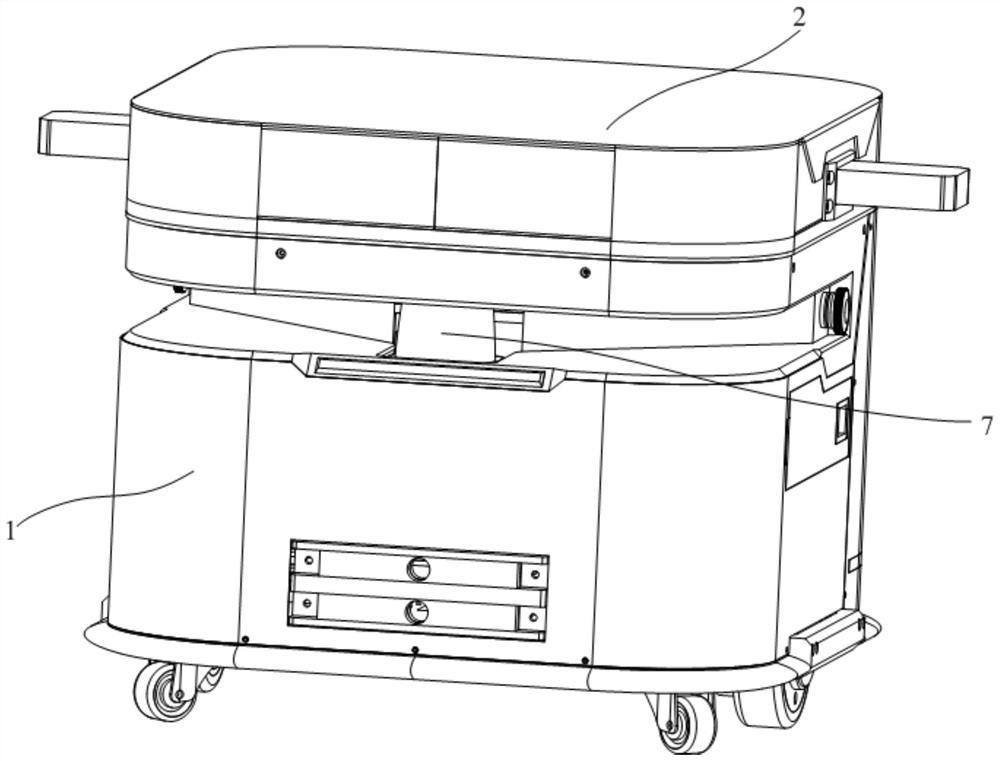

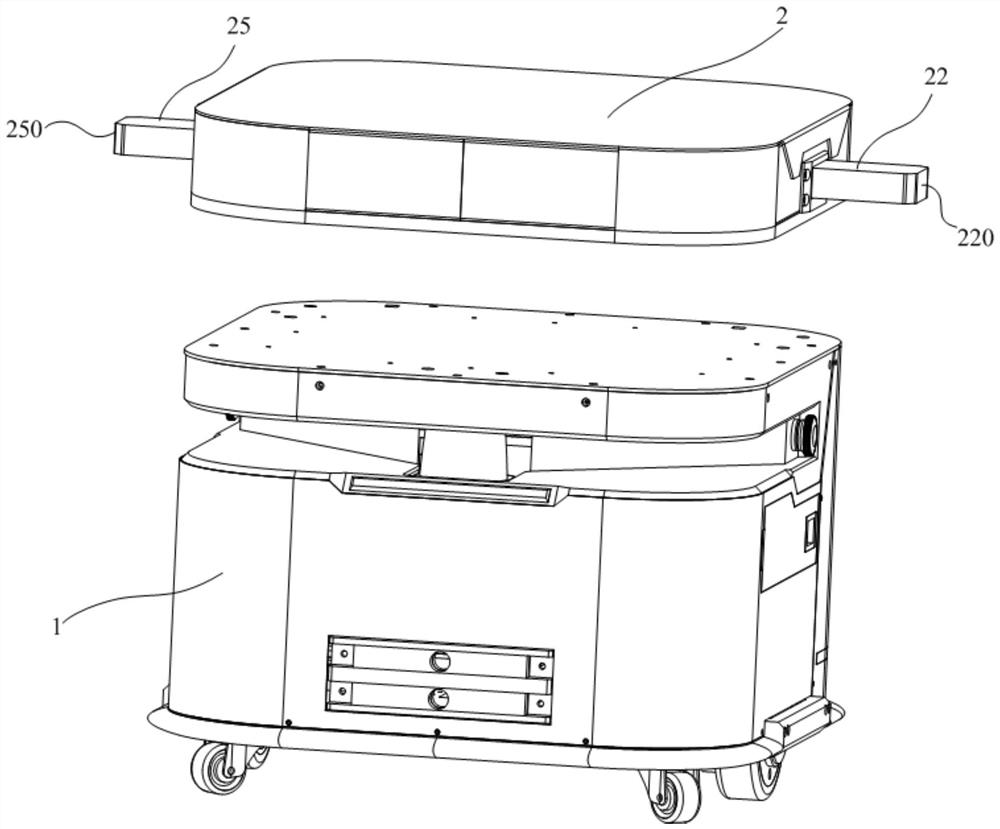

Carrying robot

PendingCN109941652AReduced stiffness requirementsImprove stabilityStorage devicesEngineeringFriction force

The invention discloses a carrying robot and belongs to the technical field of warehousing robots. The carrying robot comprises a movable base, an object carrier, a telescopic assembly and a shiftingfinger, wherein one end of the telescopic assembly is connected with the object carrier, and the other end of the telescopic assembly is connected with the shifting finger; the shifting finger is configured to have a first position which is no higher than the upper surface of an upper fork and a second position which is higher than the upper surface of the upper fork; and under the action of the telescopic assembly, the shifting finger can penetrate through the lower part of a to-be-transferred object to abut against the back surface of the to-be-transferred object, and drag the to-be-transferred object into and out of the object carrier. The carrying robot only needs to overcome the friction force acting on the to-be-transferred object in the dragging process when the to-be-transferred object is transferred, the rigidity requirement for the telescopic assembly is reduced, and the design difficulty and the manufacturing cost are favorably reduced; and the shifting finger penetrates through the lower part of the to-be-transferred object and then abuts against the back surface of the to-be-transferred object, so that the stability when the to-be-transferred object is dragged is improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

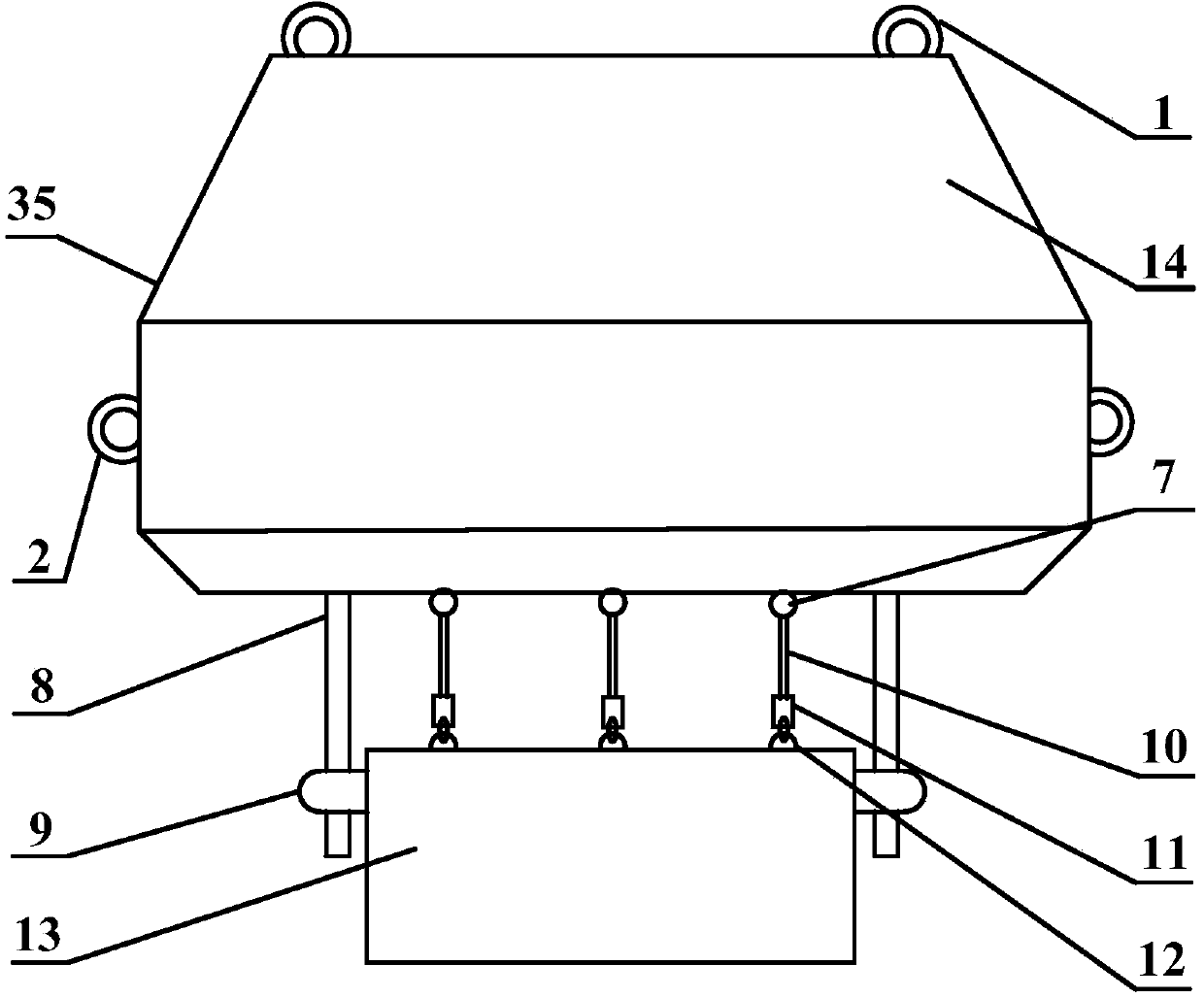

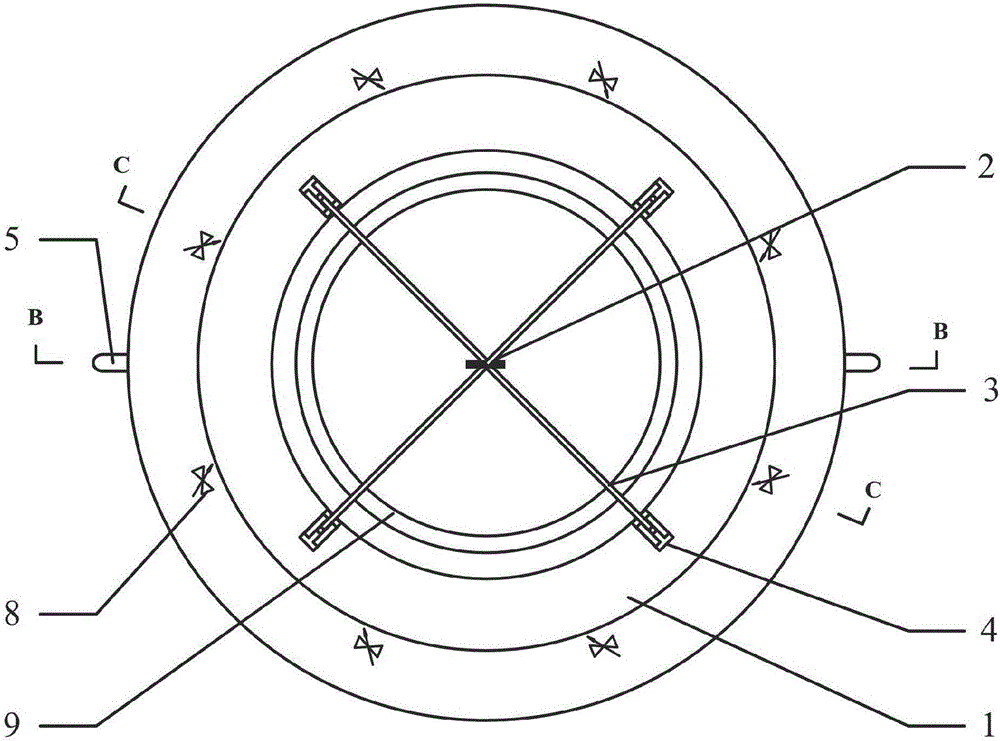

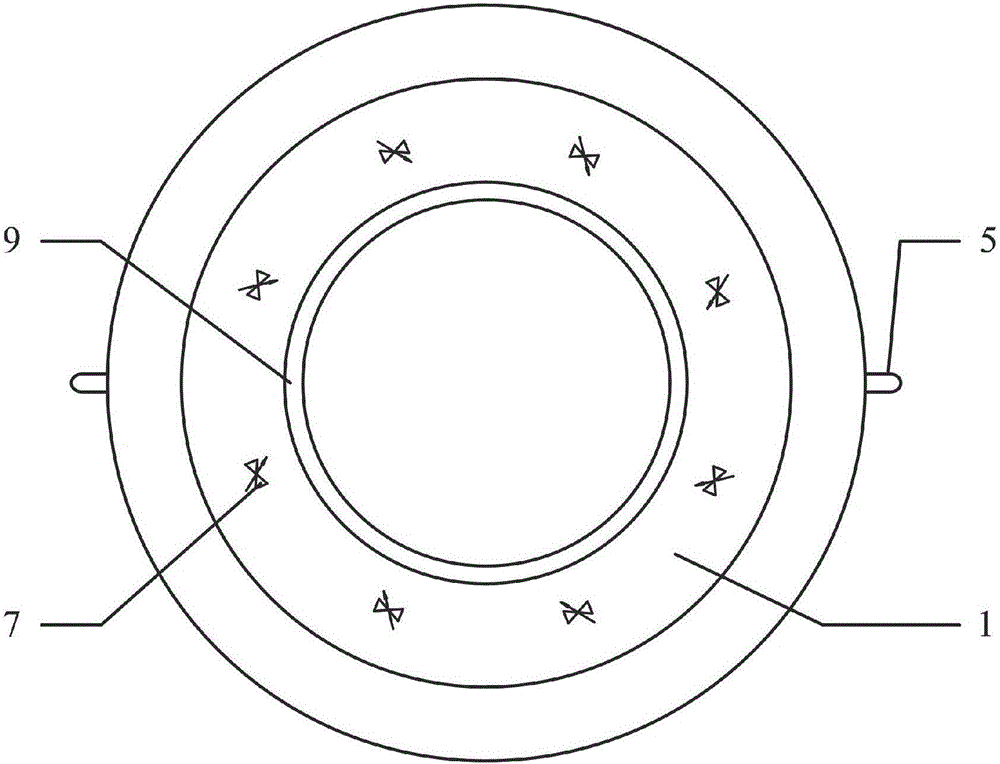

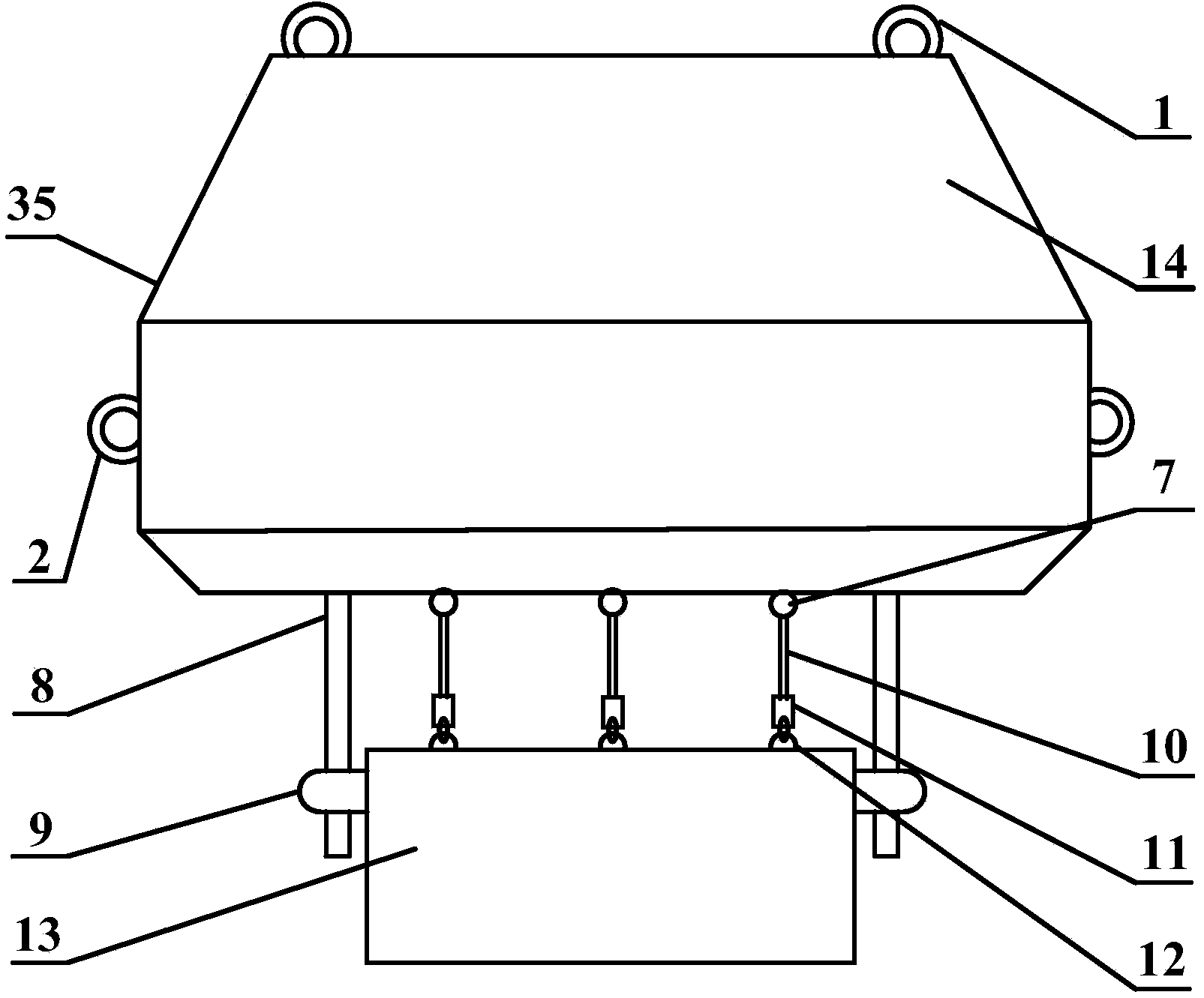

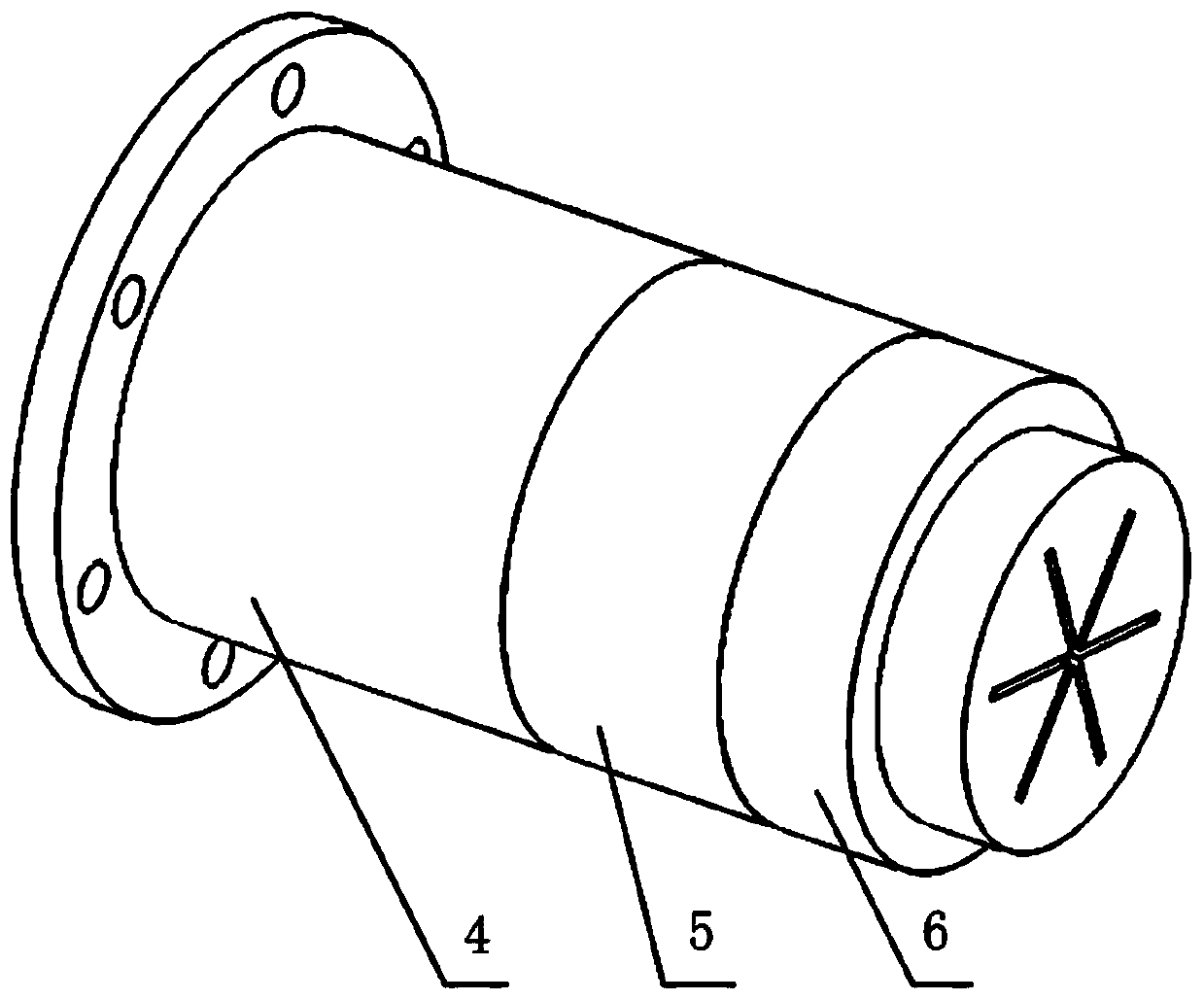

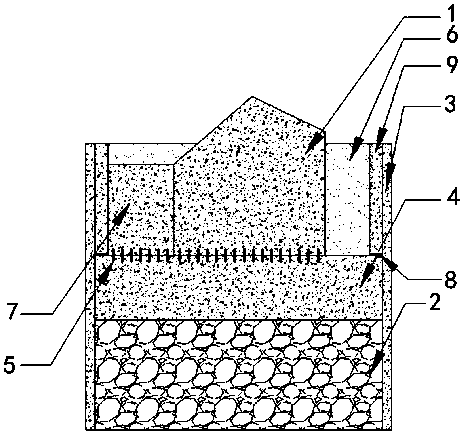

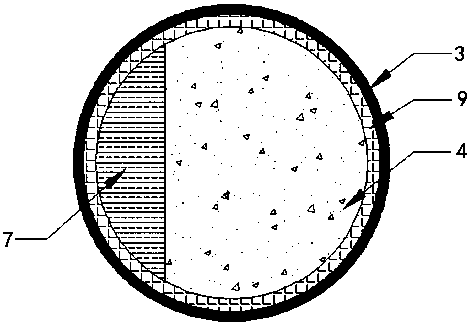

Water-gas replacement type underwater equipment auxiliary installation device and method

ActiveCN105775078AWithstand small tensionLow costLoad-engaging elementsUnderwater equipmentExhaust valveMarine engineering

The invention belongs to the technical field of ocean engineering and particularly relates to a water-gas replacement type underwater equipment auxiliary installation device and method. The water-gas replacement type underwater equipment auxiliary installation device comprises a main body, hinged supports, brackets, a bracket lifting ring, lifting lugs, ballast tanks, water inlet valves and exhaust valves. The water-gas replacement type underwater equipment auxiliary installation device is characterized in that the four hinged supports are arranged on the top surface of the main body and uniformly distributed in the circumferential direction; one bracket is connected to each hinged support; the top ends of all the brackets are all connected with the bracket lifting ring; the eight same ballast tanks are uniformly distributed in the main body and independent from one another; and the bottom of each ballast tank is provided with one water inlet valve, and the top of each ballast tank is provided with one exhaust valve. According to the water-gas replacement type underwater equipment auxiliary installation device and method, the tensile force borne by installation cables in the installation process is small, the main body of the auxiliary installation device is made of steel, the deep water pressure can be borne, and the cost is low, so that the auxiliary installation device is suitable for deep water installation; and no large-area deck ships needs to be employed to transport underwater equipment, and the underwater equipment can be dragged to the installation position at a port by a transport ship in a wet mode.

Owner:无锡市弘泰检测科技有限公司

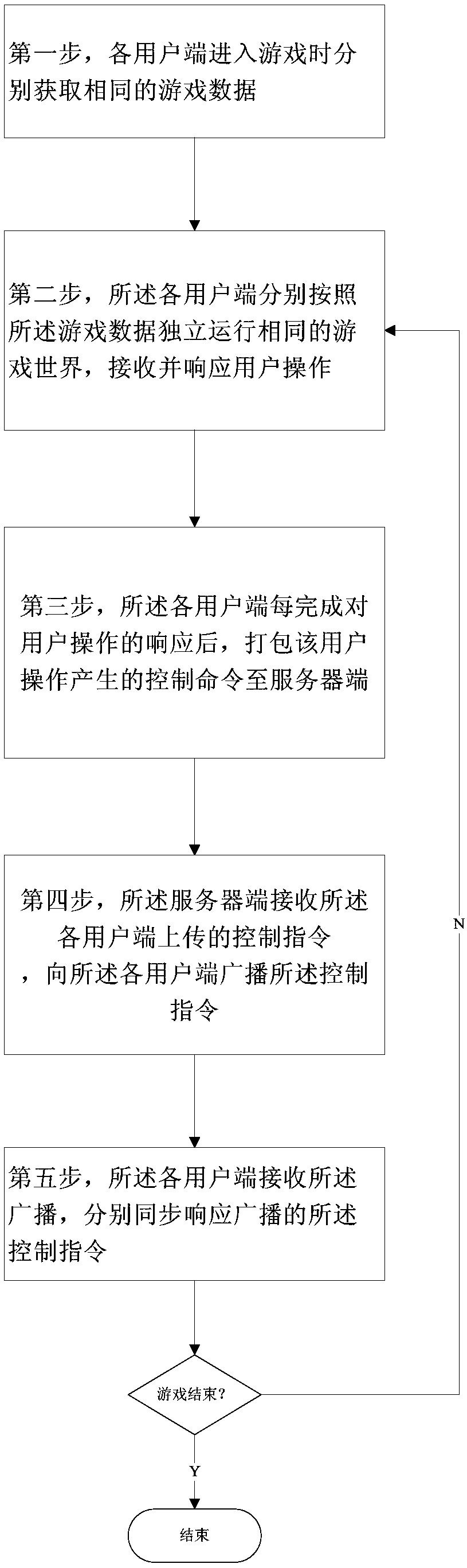

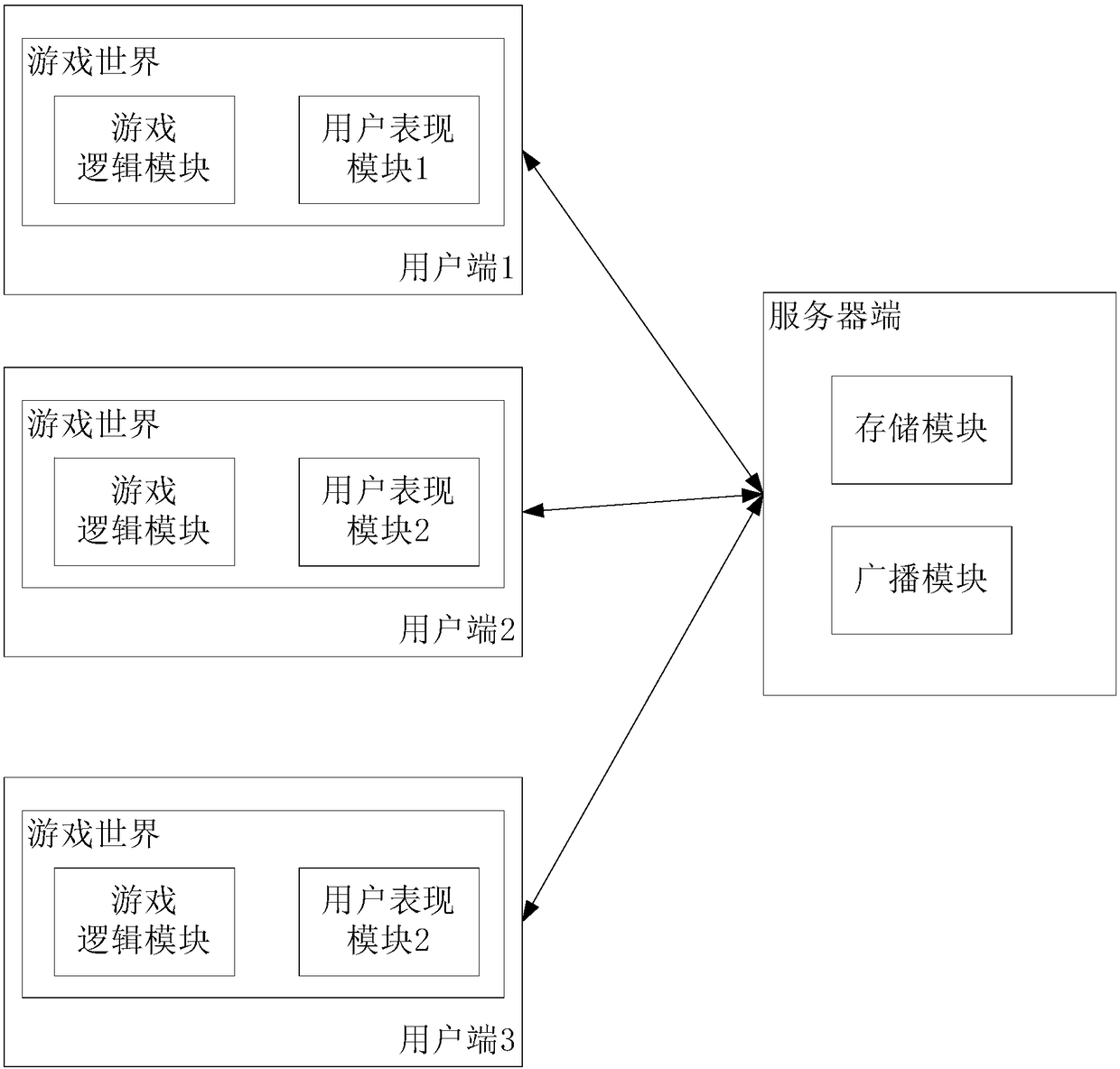

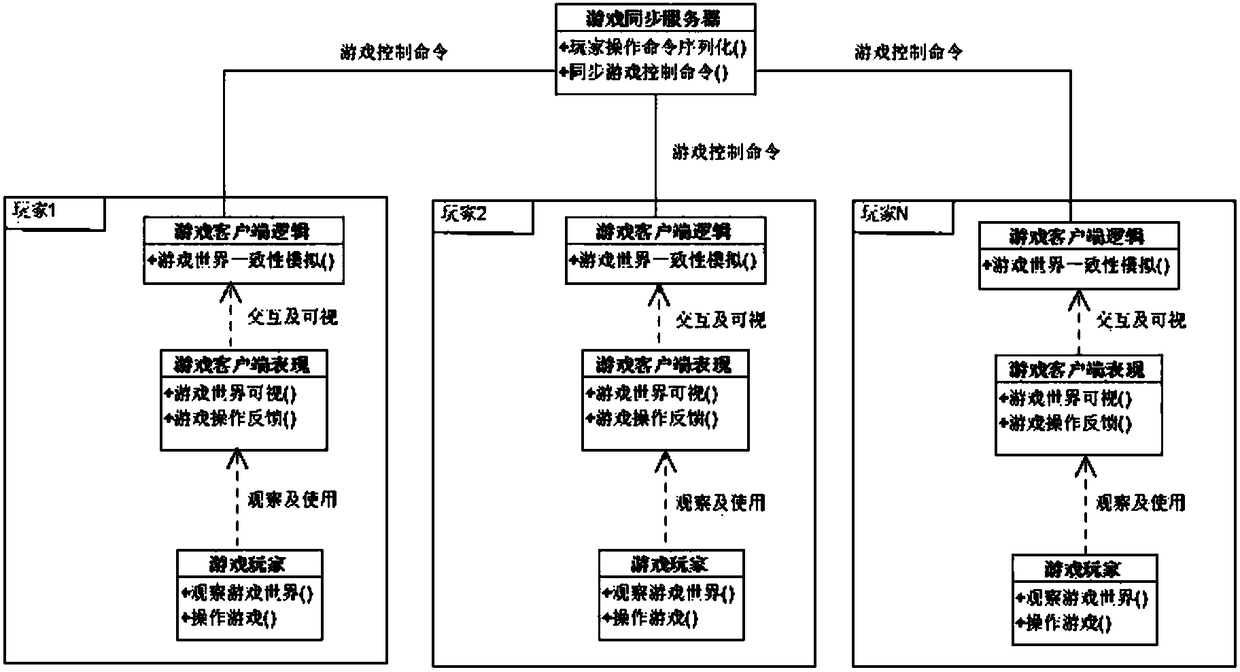

Peer-to-peer computing based game interactive method and system for multi-user scenario

InactiveCN108379833AGreatly load levelAchieve interactionVideo gamesPeer to peer computingHuman–computer interaction

The invention discloses a peer-to-peer computing based game interactive method and system for a multi-user scenario. The peer-to-peer computing based game interactive method comprises the following steps of: uploading a control instruction generated in a user operation process to a server, broadcasting the control instruction through the server, receiving the control instruction of the user whilereceiving data broadcasted by the server through each user side, independently and synchronously operating a complete game world according to the control instruction, thereby realizing interaction andsynchronization among the user sides. A server side of the peer-to-peer computing based game interactive device only store and broadcast game data, and therefore, a peer-to-peer computing technologyprovided by the invention does not bring higher requirements on network and cpu consumption under the multi-user scenario, and can greatly improve user bearing level. Moreover, user experience is realized by a relatively independent user presentation module in each user side. While improving user experience, the peer-to-peer computing based game interactive method reduces requirements on bearing ability of the server, so that cost at the game operation stage is reduced.

Owner:SNAIL GAMES

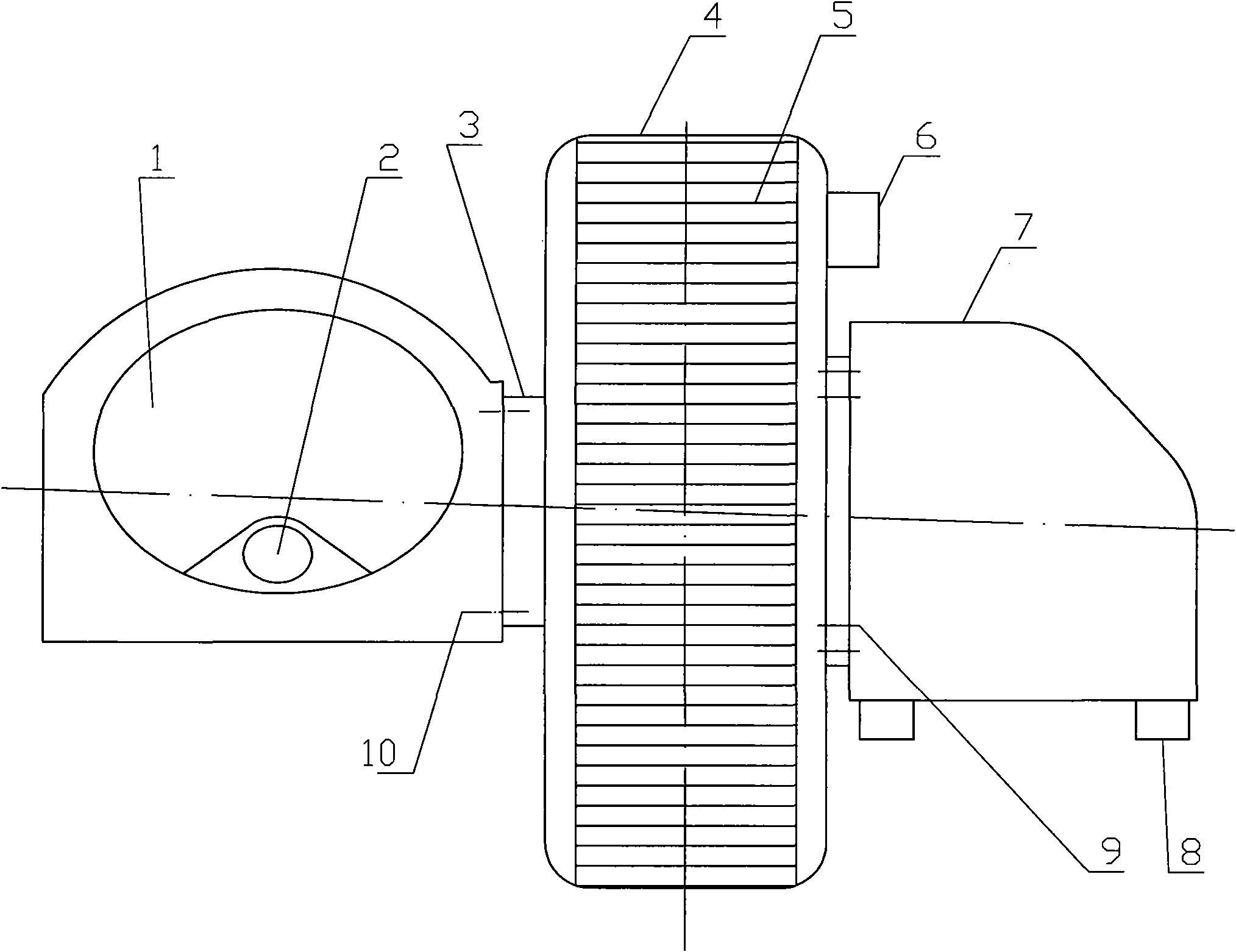

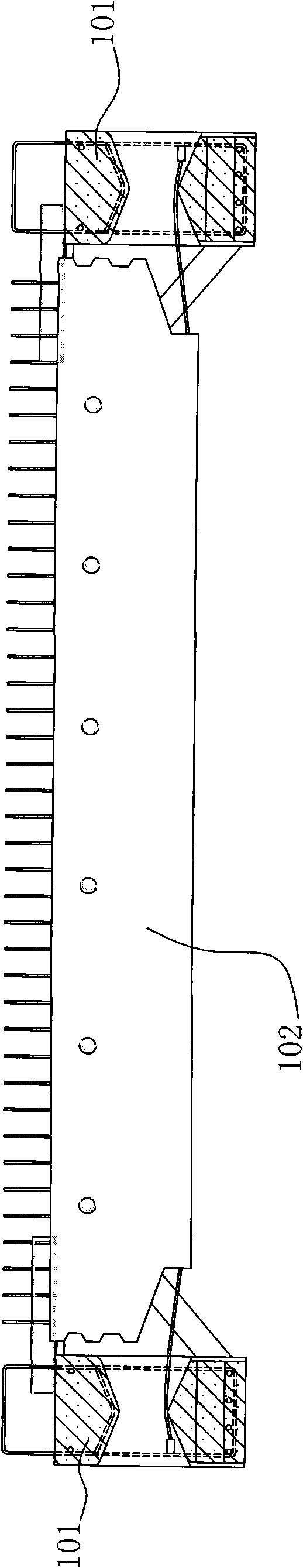

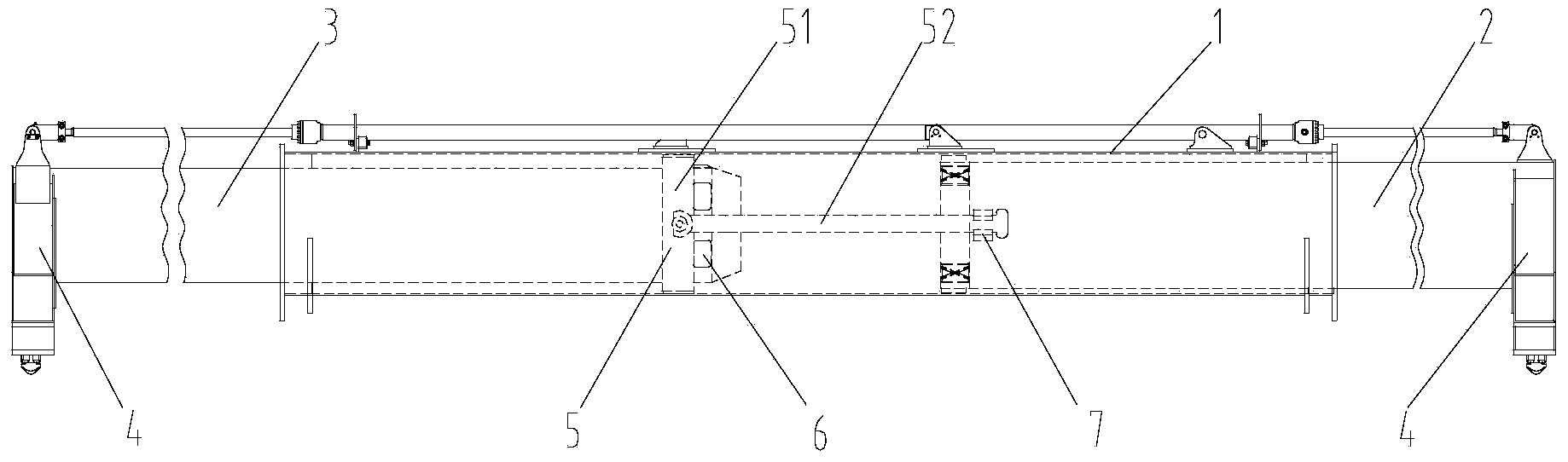

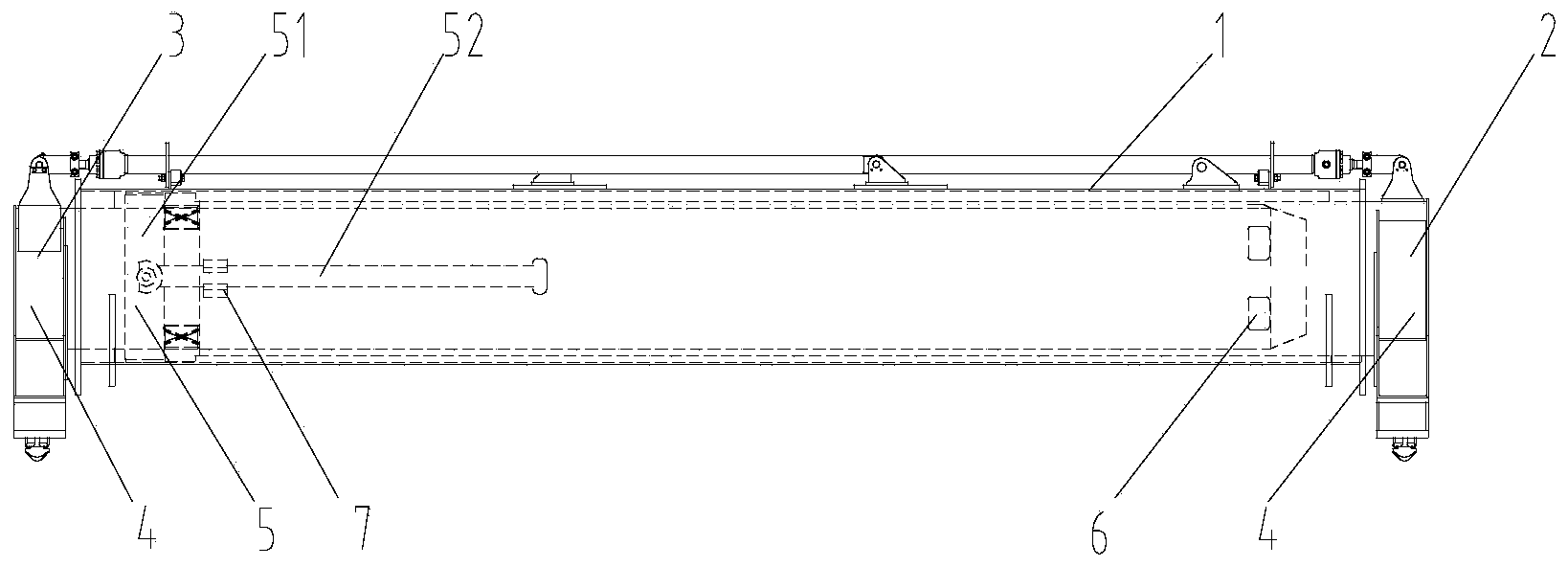

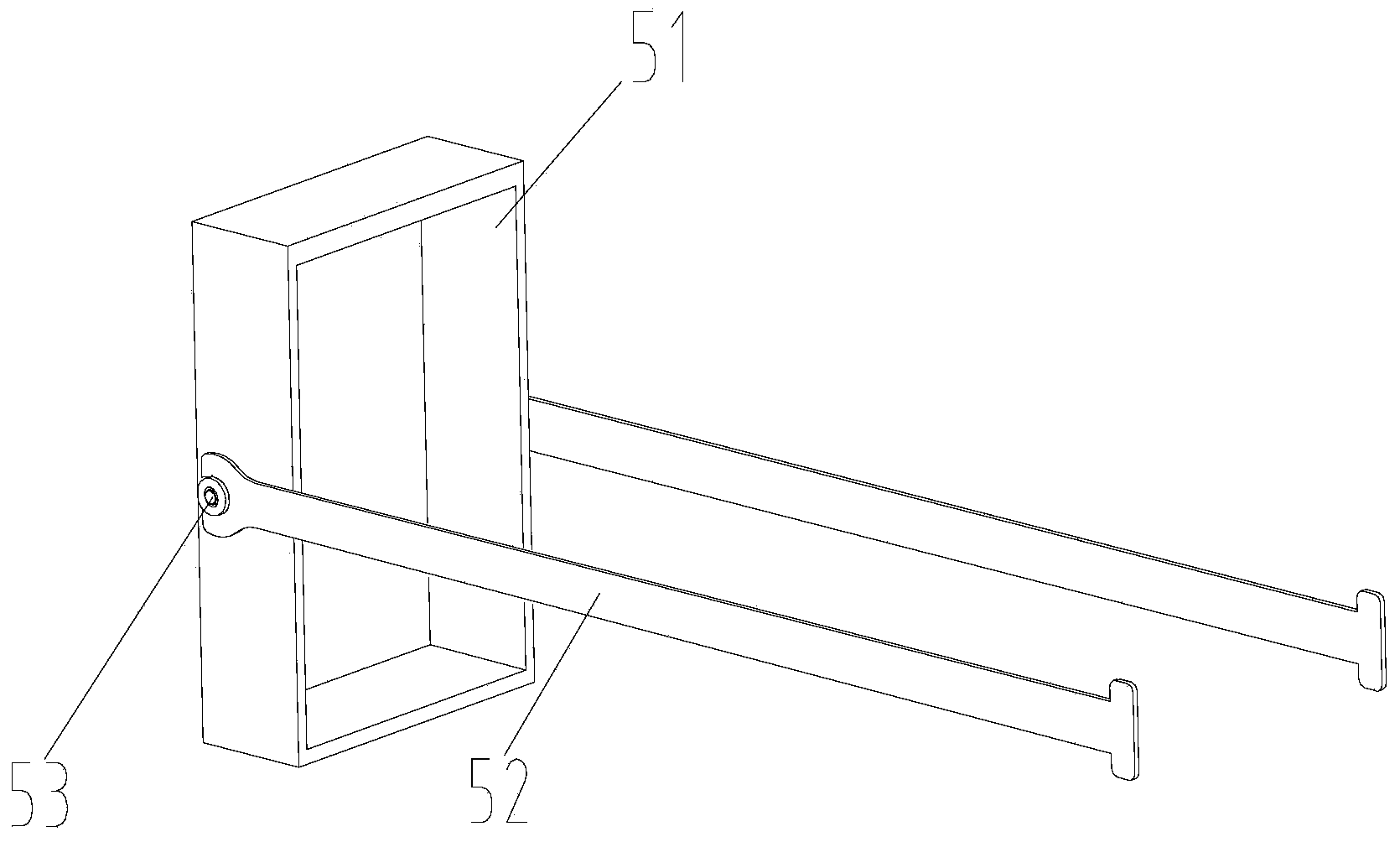

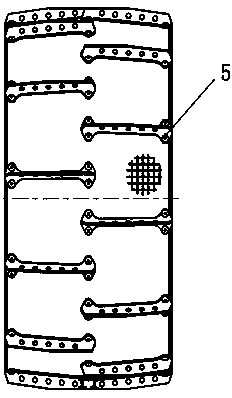

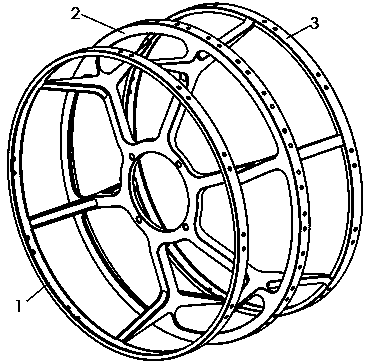

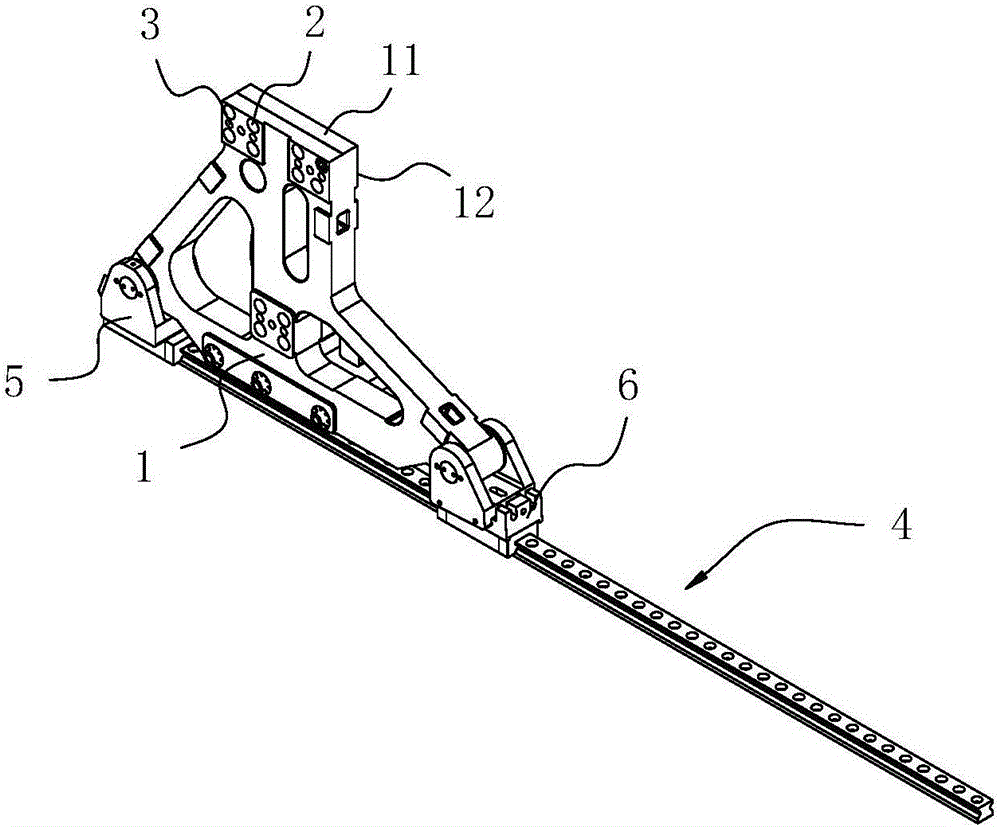

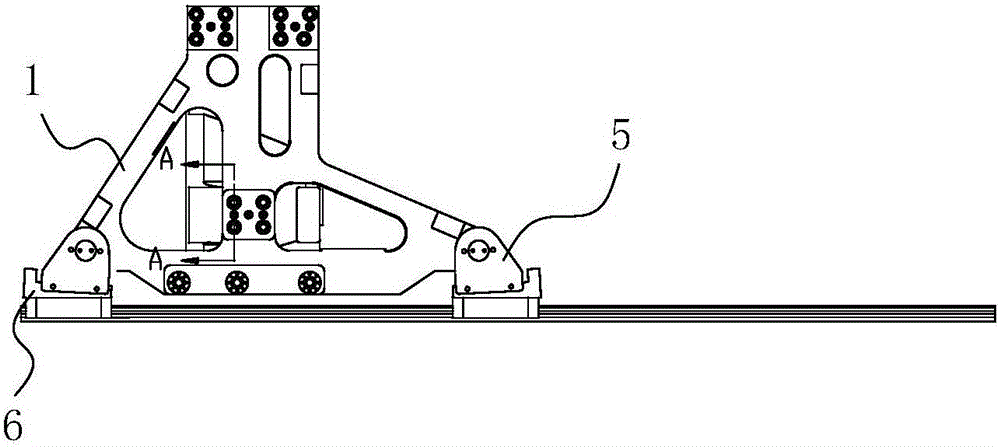

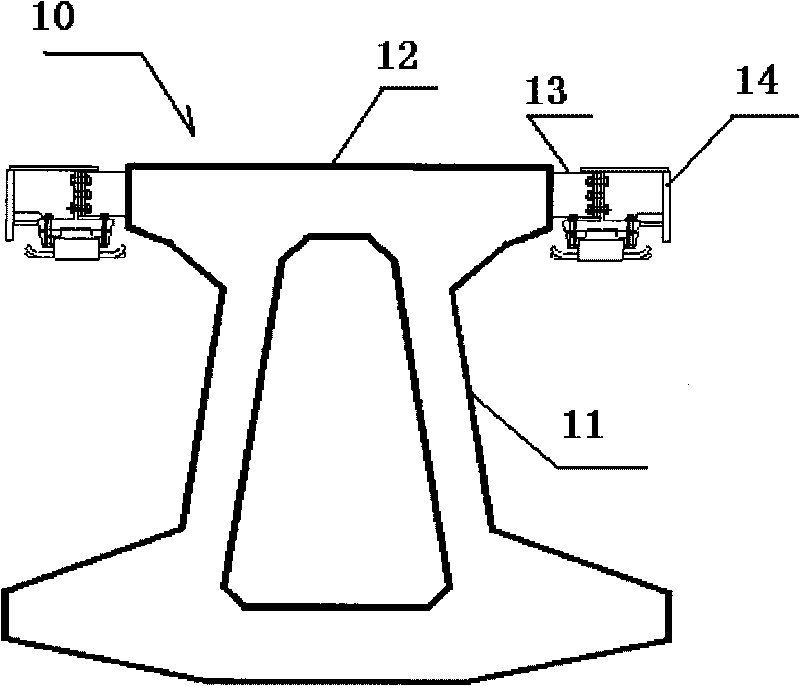

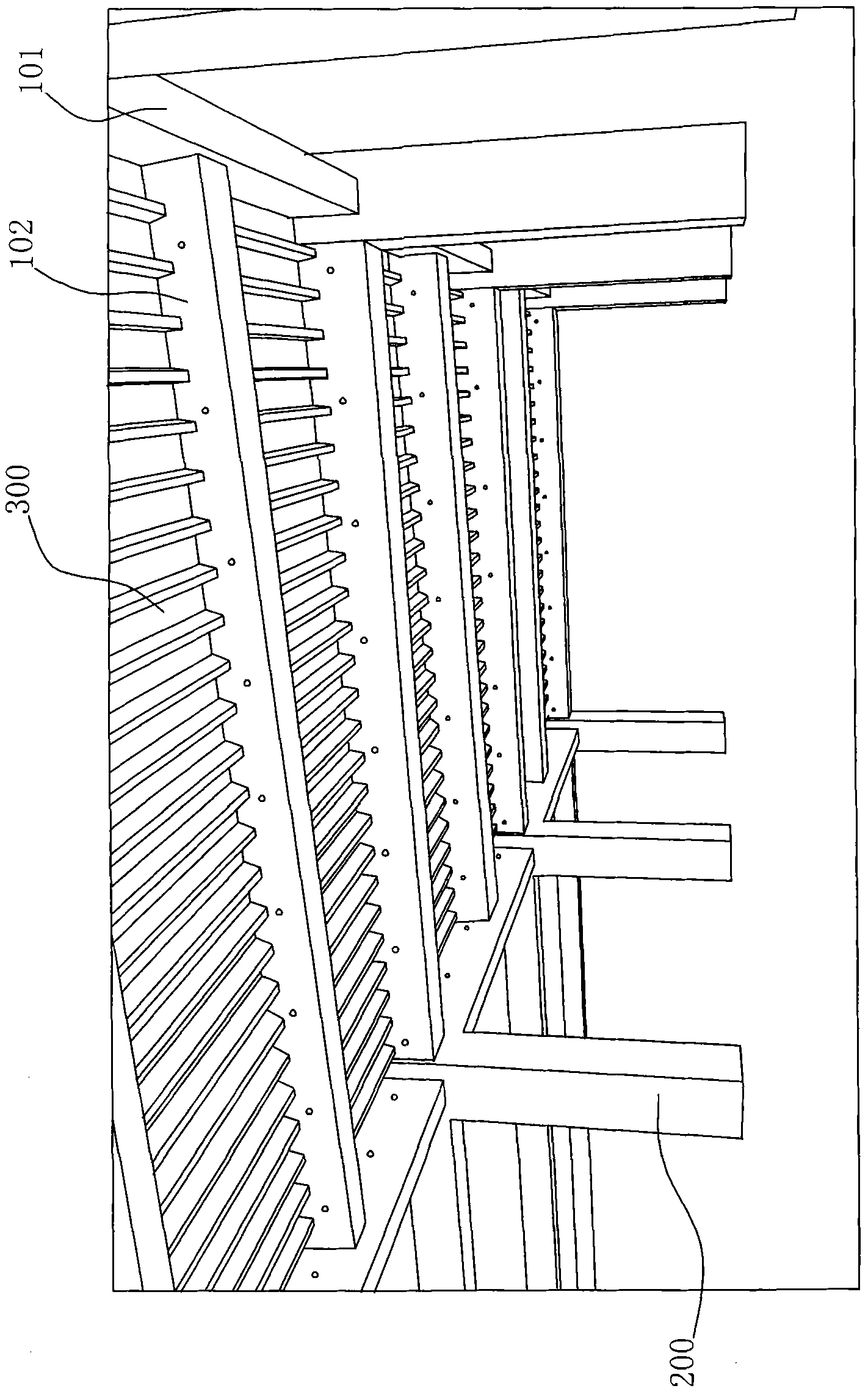

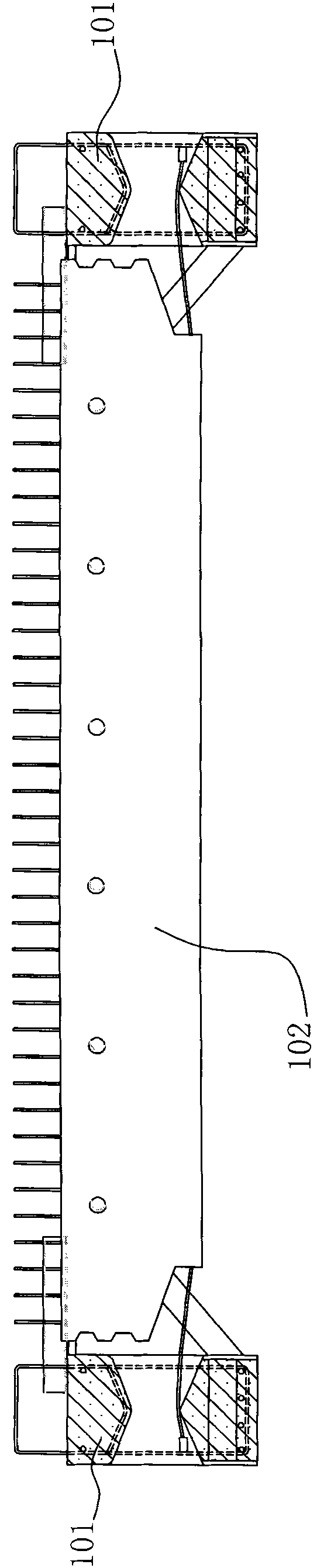

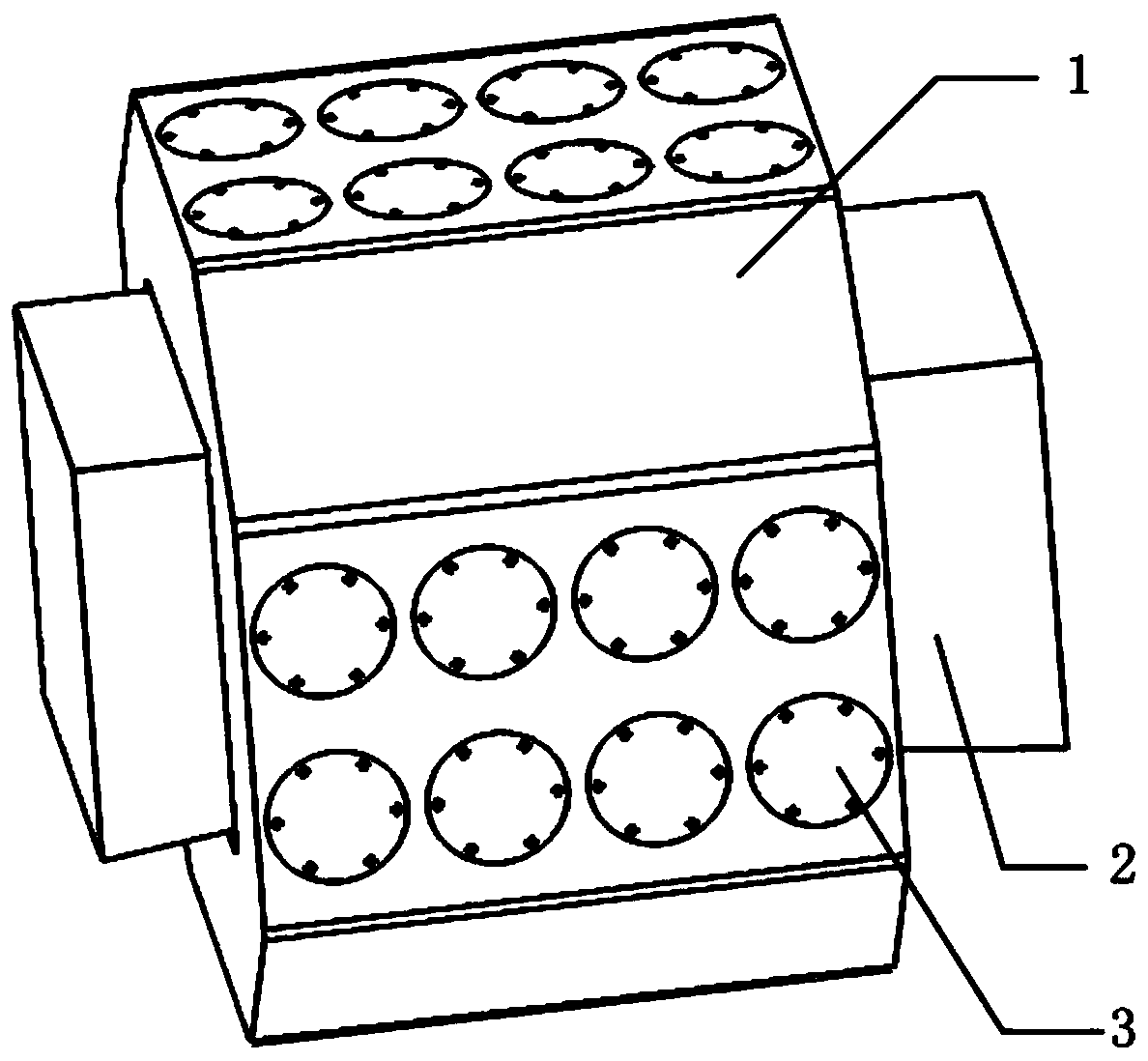

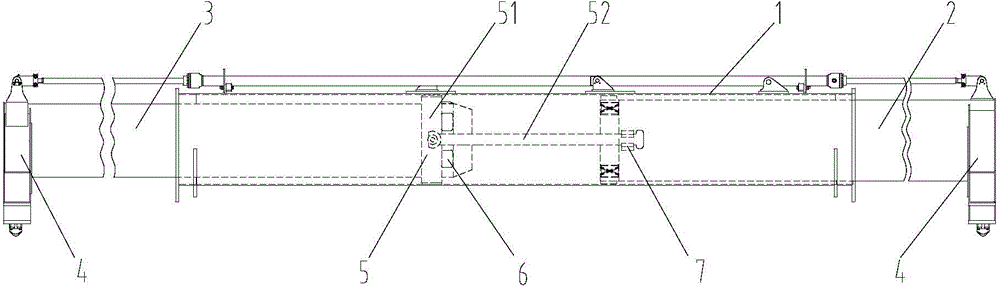

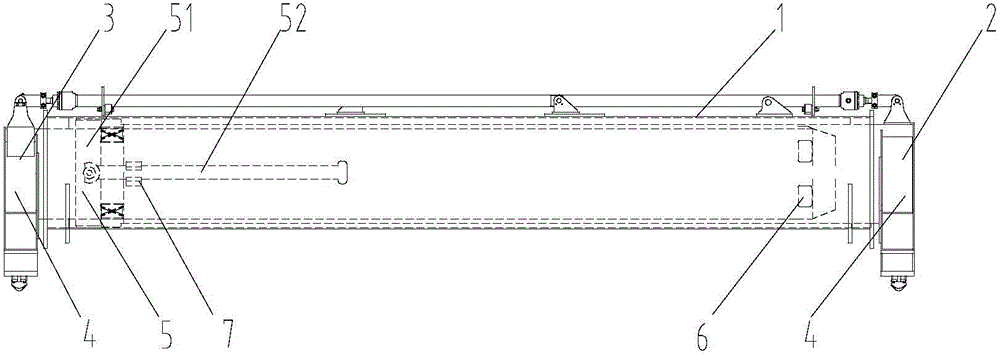

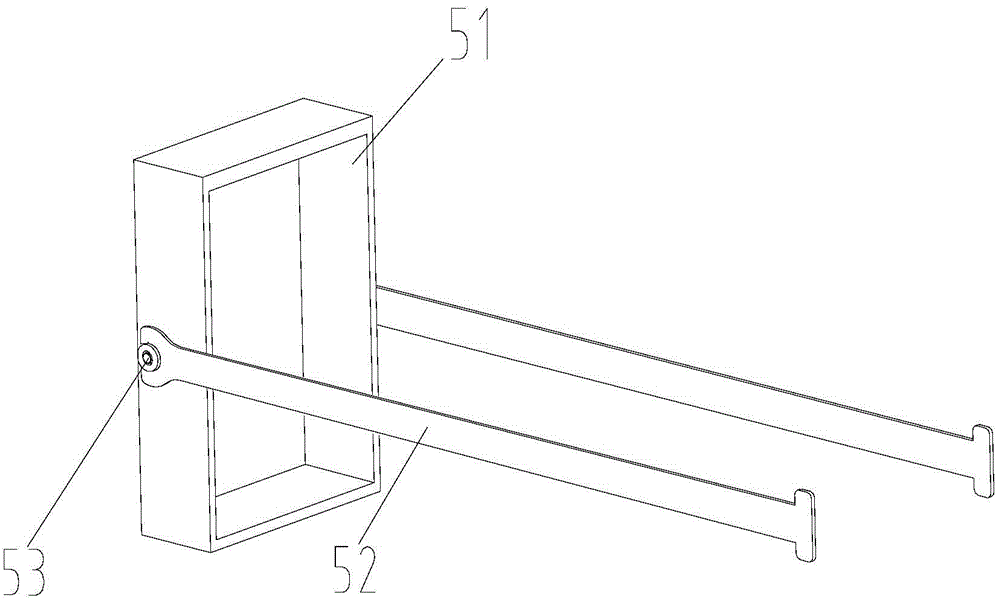

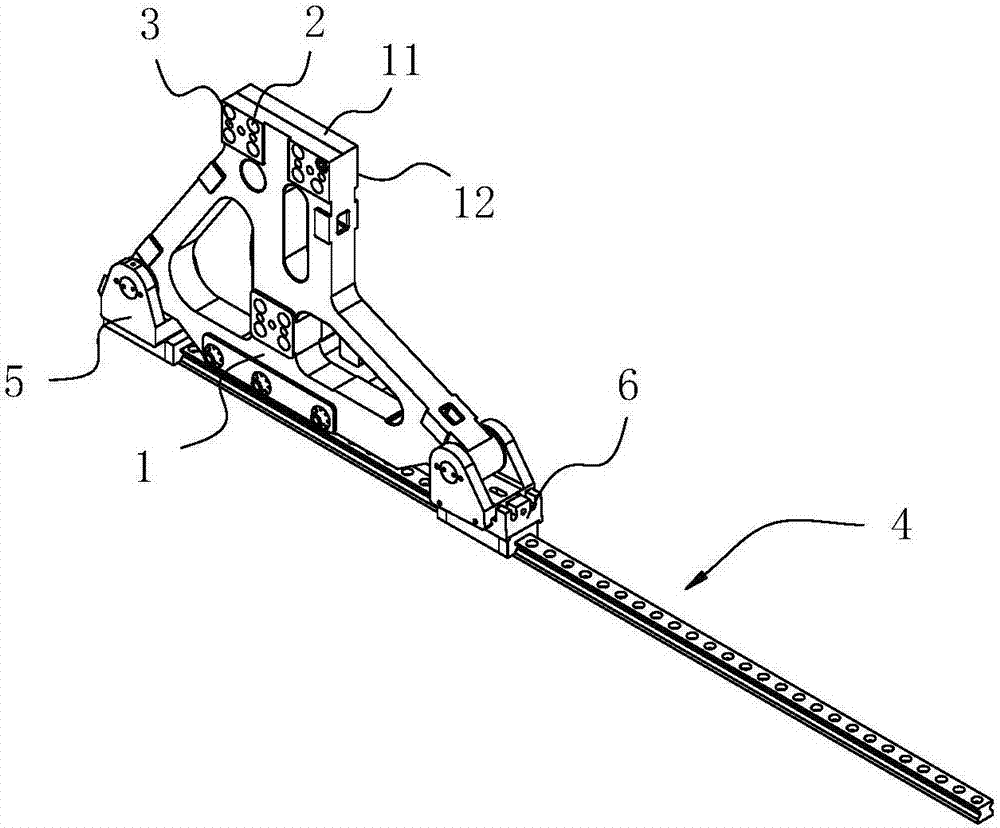

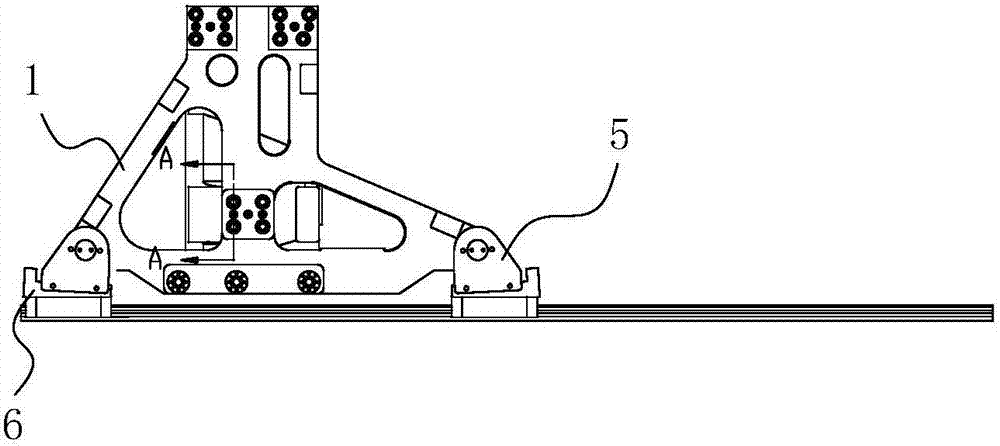

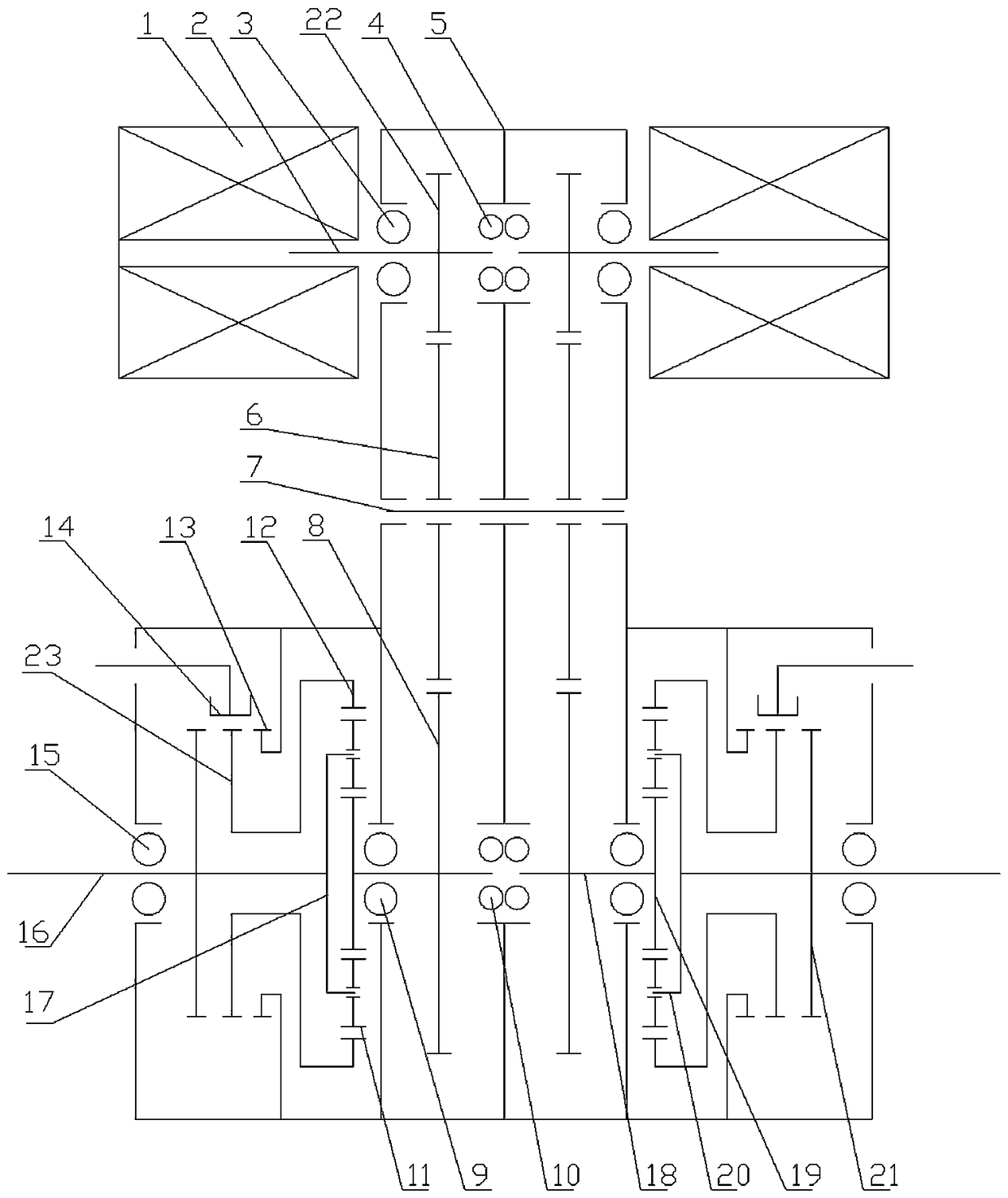

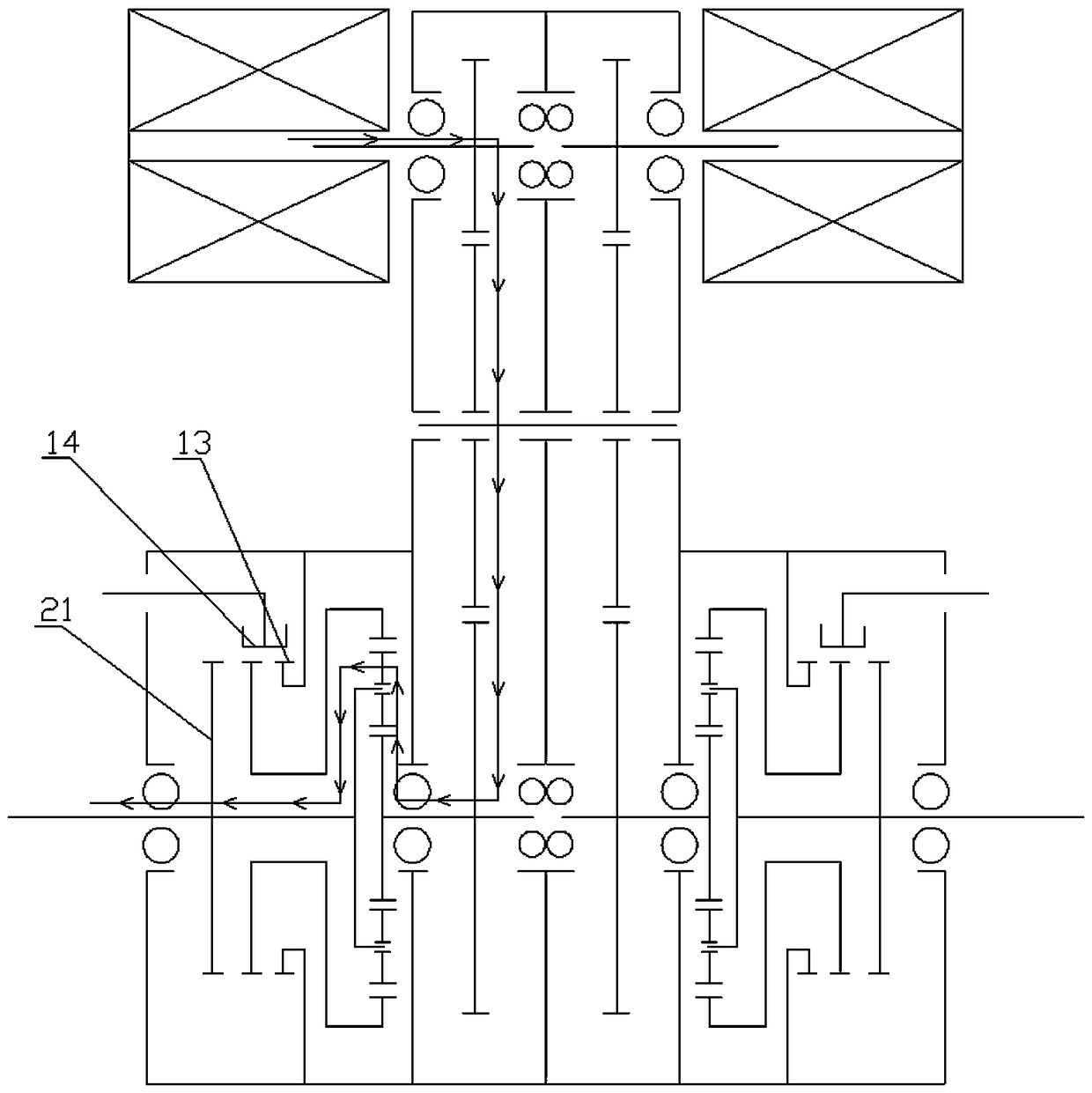

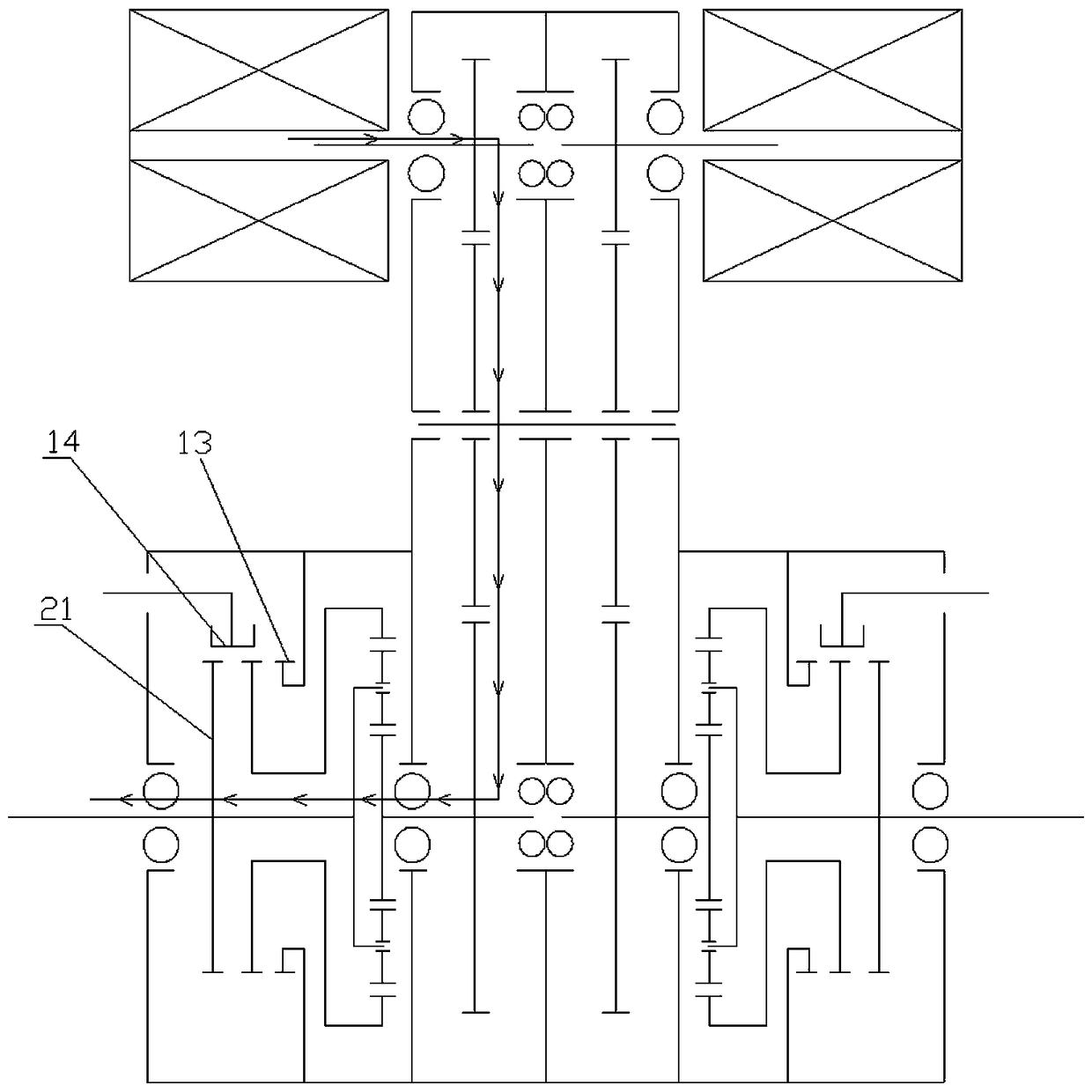

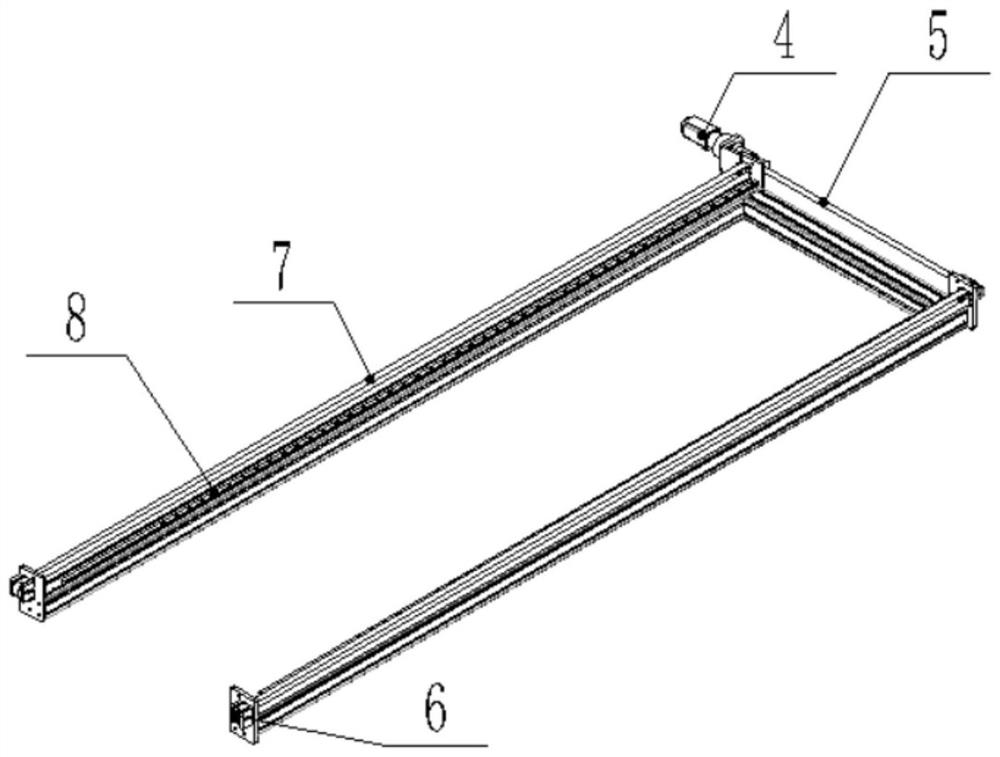

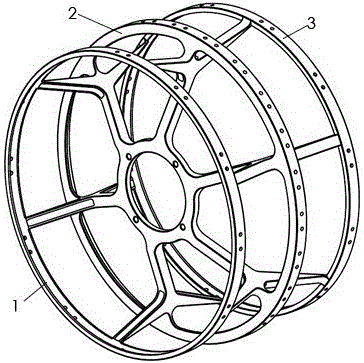

Single-girder hanger and reach stacker

The invention provides a single-girder hanger which comprises a girder (1), a large telescopic beam (2), a small telescopic beam (3), cross beams (4), a follow-up supporting mechanism (5), a first limiting mechanism (6) and a second limiting mechanism (7), wherein the large telescopic beam (2) and the small telescopic beam (3) are located in the girder (1), and the small telescopic beam (3) is nested in the larger telescopic beam (2); the cross beams (4) are located at free ends of the large telescopic beam (2) and the small telescopic beam (3); one end of the follow-up supporting mechanism (5) is connected with the large telescopic beam (2), the other end of the follow-up supporting mechanism (5) is nested on the small telescopic beam (3), the outer wall of the follow-up supporting mechanism (5) is propped against the inner surface of the girder (1), and the inner wall of the follow-up supporting mechanism (5) is propped against the outer surface of the small telescopic beam (3); the first limiting mechanism (6) is located at the fixed end of the small telescopic beam (3); and the second limiting mechanism (7) is located on the large telescopic beam (2). According to the single-girder hanger, the follow-up supporting mechanism is arranged between the girder and the telescopic beams, follow-up supporting for the small telescopic beam is realized, and supporting moment arms of the two telescopic beams are prolonged, so that the stress condition of a mechanical structure is improved, the requirement for carrying capacity of a mechanical material is reduced, the carrying capacity of the single-girder hanger is improved, and the single-girder hanger can lift a heavy load container weighing up to 20 ft.

Owner:SANY MARINE HEAVY IND +1

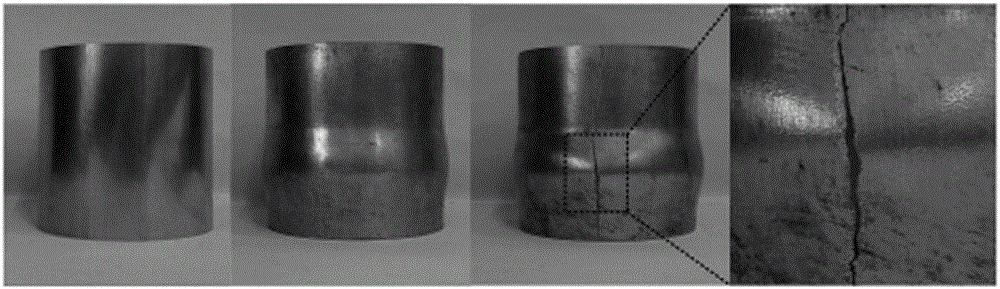

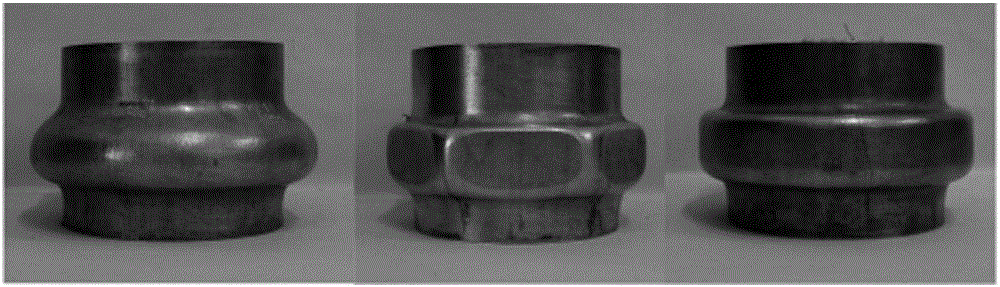

Solution treatment and granular medium cold forming method for high-strength aluminum alloy pipe fitting

ActiveCN105964722ASimple process controlLow input costFurnace typesProcess efficiency improvementSolid particleArtificial aging

Disclosed is a solution treatment and granular medium cold forming method for a high-strength aluminum alloy pipe fitting. Forming of complex parts from a high-strength aluminum alloy extruded pipe at a room temperature is realized through the process of solution treatment, granular medium pressure forming and artificial aging. The process is easy and convenient to control, the input cost is low, product design is flexible, energy consumption is low, production efficiency is high, the size of a target workpiece is precise, and high use strength and stability are achieved. After a pipe blank is subjected to solution treatment, the strength and hardness are lowered, the plasticity is remarkably improved, parts in complex shapes can be formed only at the room temperature, and the bearing capacity requirement for equipment is low. The strength of the formed pipe fitting is low, the strength of the pipe fitting can be recovered to the original state through artificial aging, and the service life of the target pipe fitting is prolonged. Solid granular media are stable in chemical property, environmentally friendly, free of pollution and reusable, and have the characteristic of uneven distribution of internal pressure, and the use strength of the formed pipe fitting is guaranteed while the plastic processing capacity of the pipe blank is improved.

Owner:YANSHAN UNIV

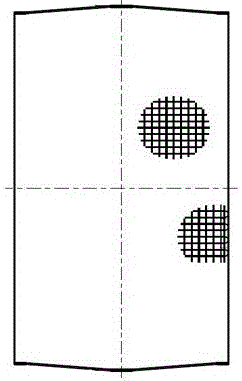

High-performance screen wheel

A high-performance screen wheel comprises a rim structure, a screen tread and pawls. The rim structure comprises a first rim, a second rim and a third rim which are coaxial; the second rim is arranged between the first rim and the third rim, radiuses of the first rim and the third rim are the same, the radius of the second rim is larger than that of the first rim and the third rim, and the three rims are connected and reinforced by reinforcing ribs. The screen tread is of a metal mesh structure covering the outer surface of the rim structure. The pawls are metal strips arranged on the screen tread and fixedly connected with the rim structure. The wheel is light and small, has simple structure and has low requirements for installation space and carrying capacity. When applied to a lunar rover, the light screen wheel has good trafficability on lunar soil of the soft lunar surface.

Owner:SHANGHAI AEROSPACE SYST ENG INST

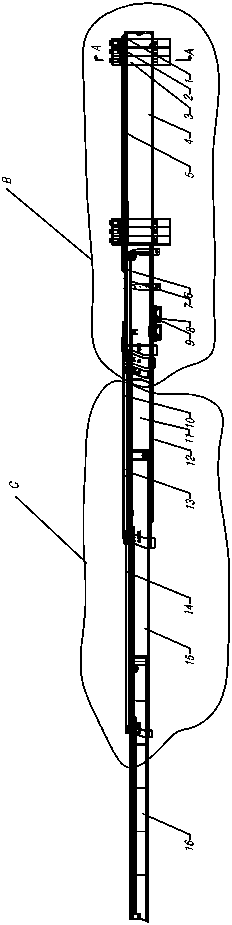

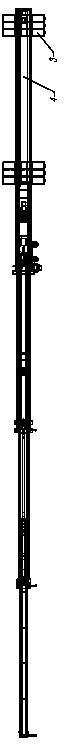

Multi-arm automatic balancing mechanism of window cleaning machine

InactiveCN104224035AMeet mooringReduced carrying capacity requirementsWindow cleanersBalancing machineGear wheel

The invention relates to a multi-arm automatic balancing mechanism of a window cleaning machine. The multi-arm automatic balancing mechanism of the window cleaning machine comprises a plurality of arms and a balancing device, wherein the plurality of arms comprise a reducing motor, a gear rack, a gear, four traction chains, a fixed arm, a second arm, a third arm and a fourth arm; the reducing motor is installed at the bottom of the fixed arm, the gear rack is installed at the bottom of the second arm, an output shaft of the reducing motor is connected with the gear rack through the gear, the independent fixed arm, the second arm, the third arm and the fourth arm are serially connected through the four traction chains to form an integral body, and the balancing device is installed on the fixed arm; the balancing device comprises a counterweight, a traveling wheel, a first chain, a first sprocket, a second chain and a second sprocket, the traveling wheel is arranged on the counterweight, the first sprocket is installed at the tail part of the fixed arm, one end of the first chain is connected onto the counterweight, the other end of the first chain is wound through the first sprocket and then is connected with the tail part of the second arm, the second sprocket is installed at the front part of the fixed arm, one end of the second chain is connected onto the counterweight and the other end of the second chain is wound through the second sprocket and then is connected with the tail part of the second arm. The multi-arm automatic balancing mechanism of the window cleaning machine has the advantages that the overall structure of the window cleaning machine is reduced, the weight is reduced, the running performance and the safety are higher, and the space for stopping the machine is minimized.

Owner:SHANGHAI POINT HIGH RISE EQUIP

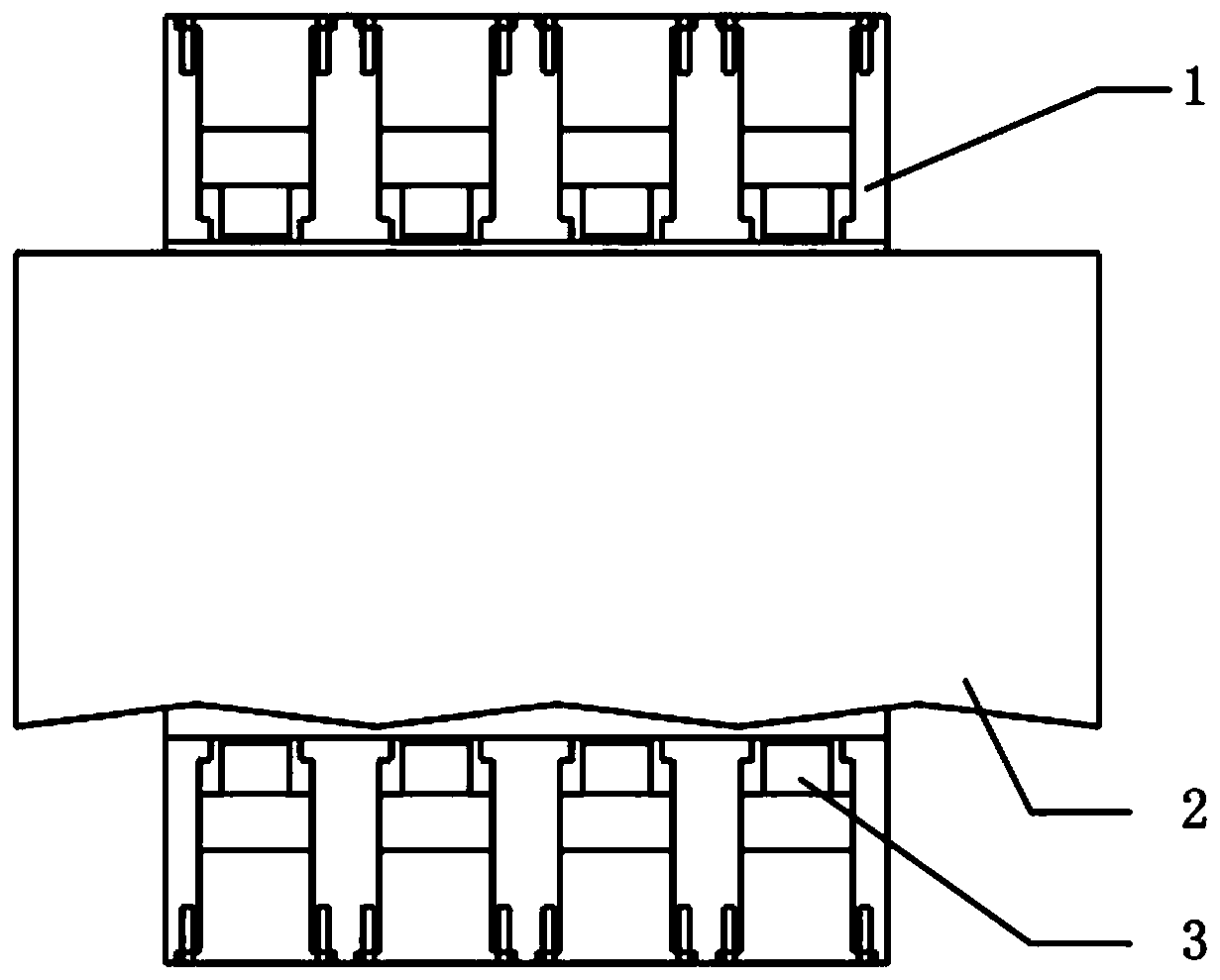

Sliding foot assembly and movable mold plate supporting structure using same

The invention discloses a sliding foot assembly. The sliding foot assembly comprises sliding foot bodies, wherein each sliding foot body is provided with a first supporting end face and a second supporting end face perpendicular to each other. The sliding foot bodies are provided with elastic supporting assemblies which make contact with supported pieces and are used for supporting the supported pieces directly. One end of each elastic supporting assembly protrudes out of the surface of the corresponding second supporting end face, and the other end of each elastic supporting assembly is fixedly connected with the corresponding sliding foot assembly. The invention further discloses a movable mold plate supporting structure using the sliding foot assembly. Due to the arrangement of the elastic supporting assemblies, the mold locking deformation force transmitted to linear guide rails is greatly lowered, an ultra-large type machine can also be designed to be in linear guide rail guiding supporting, and the ultra-large type machine can achieve high-speed, high-efficiency and stable control production.

Owner:BORCH MACHINERY

Buoyancy-adjustable device and method for auxiliary installation of underwater equipment

InactiveCN103754340BWithstand small tensionReduced carrying capacity requirementsUnderwater equipmentPull forceBuoy

The invention belongs to the field of marine engineering and particularly relates to a buoyancy-adjustable device and a method for auxiliary installation of underwater equipment. The buoyancy-adjustable device for auxiliary installation of underwater equipment comprises a buoy, a top lifting lug, a side lifting lug, a bottom lifting lug, a lifting cable, a locating rod and a hydraulic shackle, wherein the main body of the buoy is cylindrical, and conic surfaces are formed at the upper end and the lower end of the buoy; the buoy is made of a solid buoyancy material; the top lifting lug, the side lifting lug and the bottom lifting lug are arranged at the top of the buoy; a funnel-shaped guide-in cone, a cylindrical guide-in hole and a gyro-shaped balance weight cabin are sequentially arranged in the axial direction of the buoy from the top to bottom, the funnel-shaped guide-in cone and the gyro-shaped balance weight cabin are communicated through the cylindrical guide-in hole, three oblique water ducts which are communicated with the exterior are arranged at the bottom of the balance weight cabin, and the three water ducts are uniformly distributed in the circumference direction. Small pull force is applied on an installation rope in the installation process, and the buoyancy material which is used as the material of main body of the auxiliary installation device can endure deep water pressure and is suitable for deep water installation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

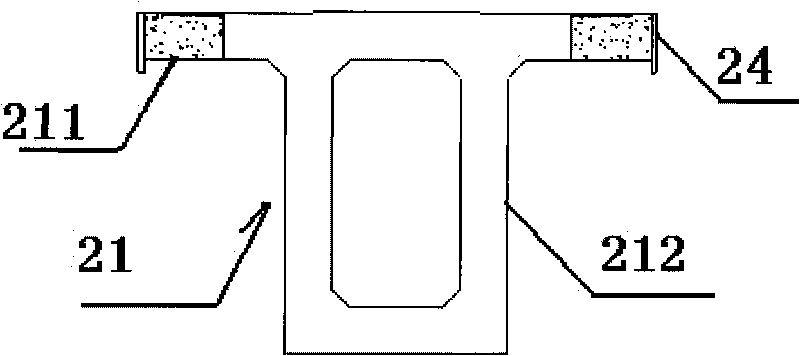

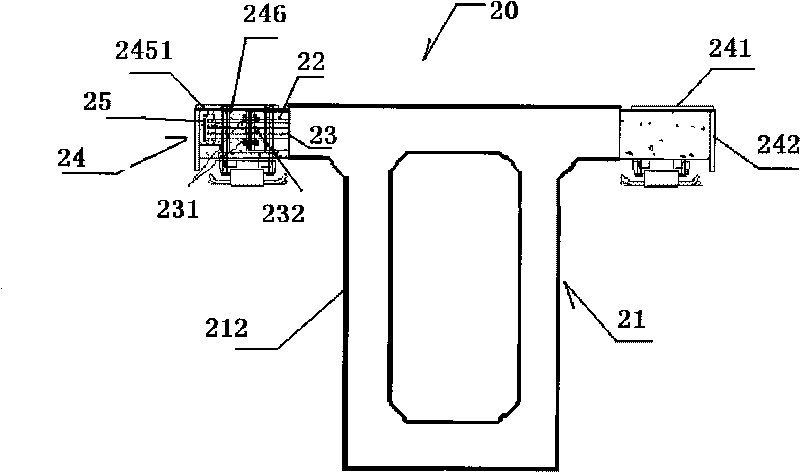

Post-pouring functional zone combined track beam

The invention relates to a post-pouring functional zone combined track beam, comprising a support beam and steel functional components. The lower part of the support beam is provided with a webplate, and two sides of the upper wing edge of the webplate are provided with post-pouring functional zones; a transverse dowel bar and a connecting piece respectively extend out of cantalevers at two sides of the upper wing edge of the support beam extend; two sides of the support beam are respectively provided with the steel functional components; the transverse dowel bar is inserted into the steel functional components; the connecting piece of the support beam is firstly connected with the steel functional components, and then concrete is poured and filled among the steel functional components and in the steel functional components, and a post-pouring functional zone is formed after solidification. In the invention, the functional zones finally become an integer, thereby the purpose of rigidity utilization is realized, the weight of the beam is reduced, and the difficulty for transportation is reduced. Simultaneously, a gap does not exist in the longitudinal direction and the transverse direction of the track beam after formation so that the function of reducing operation noise is also achieved.

Owner:TONGJI UNIV

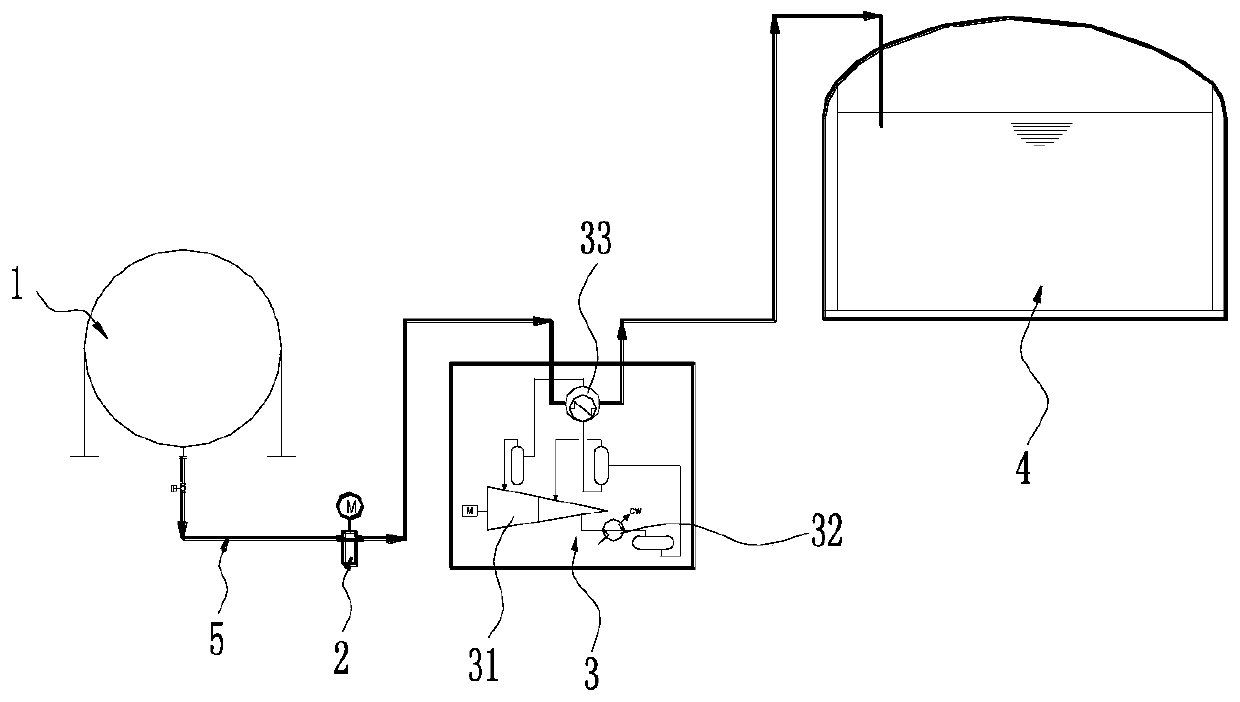

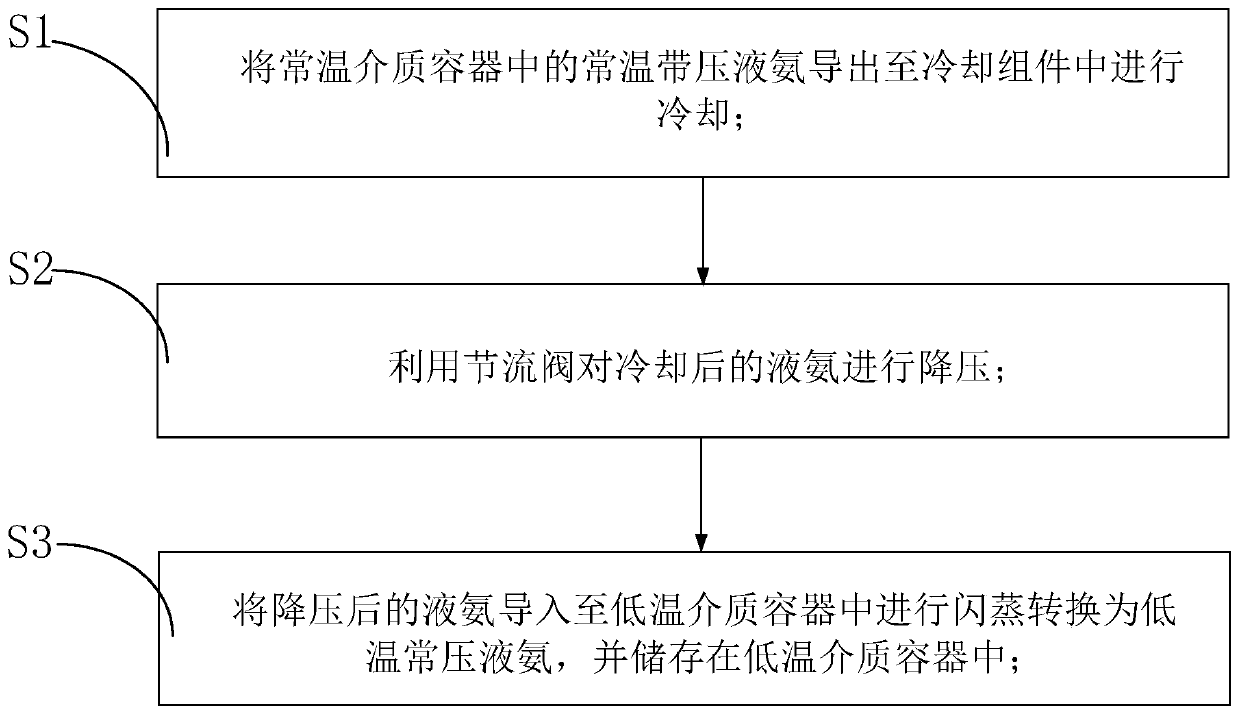

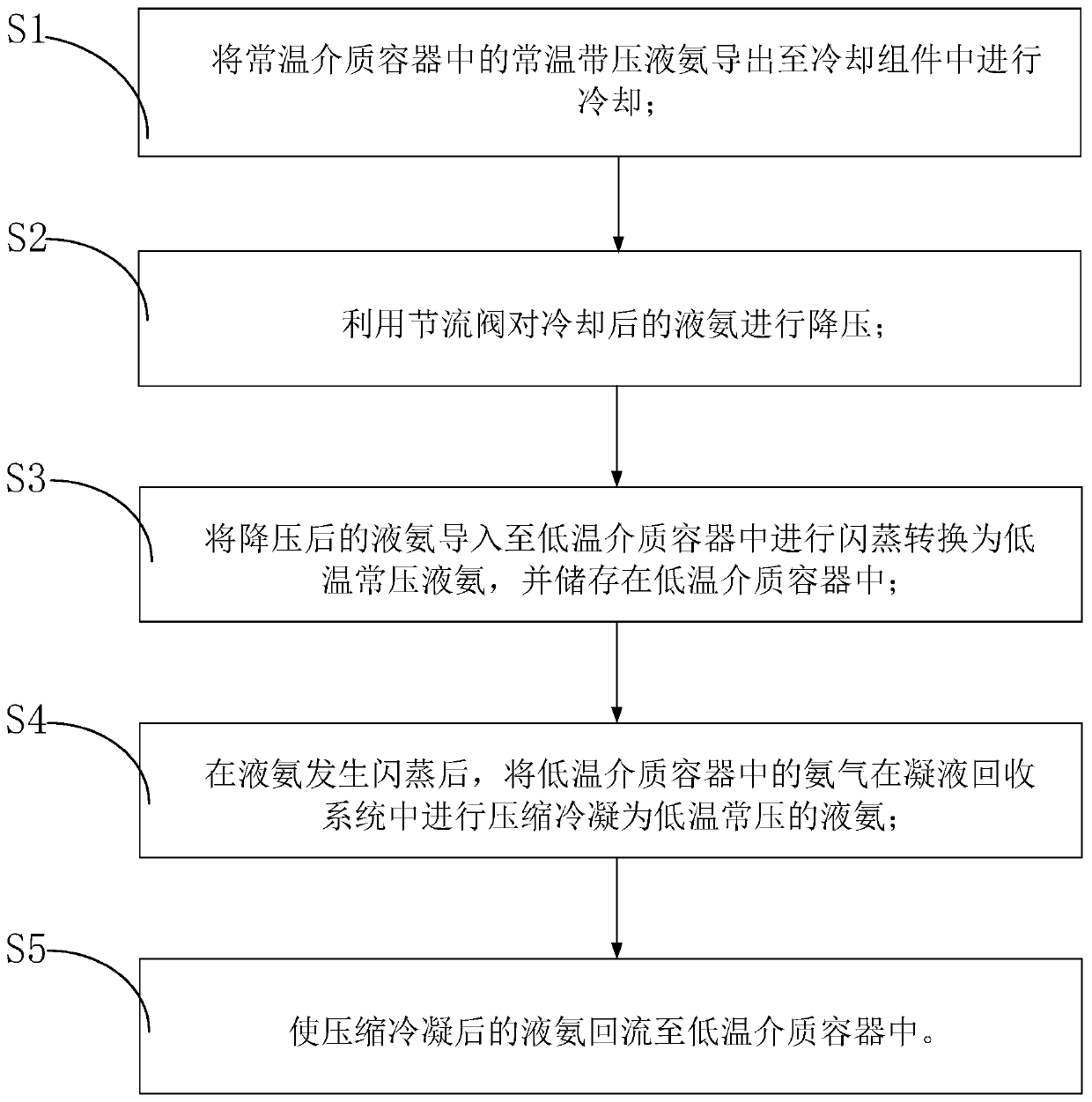

Liquid ammonia conversion equipment and liquid ammonia conversion method

PendingCN110005945AReduce storage costsReduced carrying capacity requirementsFluid transferredPressure vesselsBoiling pointThrottle

The invention relates to the technical field of chemical production, in particular to liquid ammonia conversion equipment and a liquid ammonia conversion method. The liquid ammonia conversion equipment comprises a constant temperature medium container, a cooling assembly, a throttling valve and a low temperature medium container. The constant temperature medium container is used for storing liquidammonia with a pressure at a constant temperature; the cooling assembly is used for cooling the liquid ammonia in the constant temperature medium container and is connected to the constant temperature medium container through a pipeline; the throttling valve is connected to the cooling assembly through a pipeline for reducing the liquid ammonia output by the cooling assembly to constant pressureand the temperature of the liquid ammonia reduced in pressure is higher than a corresponding boiling point of the liquid ammonia at the constant temperature to flash the liquid ammonia; the low temperature medium container is connected to the throttling valve through a pipeline and providing a flash space for the liquid ammonia at the reduced pressure as well as storing the low-temperature constant pressure liquid ammonia. The low-temperature constant pressure liquid ammonia is stored by the low temperature medium container, the low temperature medium container is relatively low in demand on carrying ability and relatively low in engineering investment, and the storage cost of the liquid ammonia is relatively low.

Owner:CIMC ENRIC ENGINEERING TECHNOLOGY CO LTD

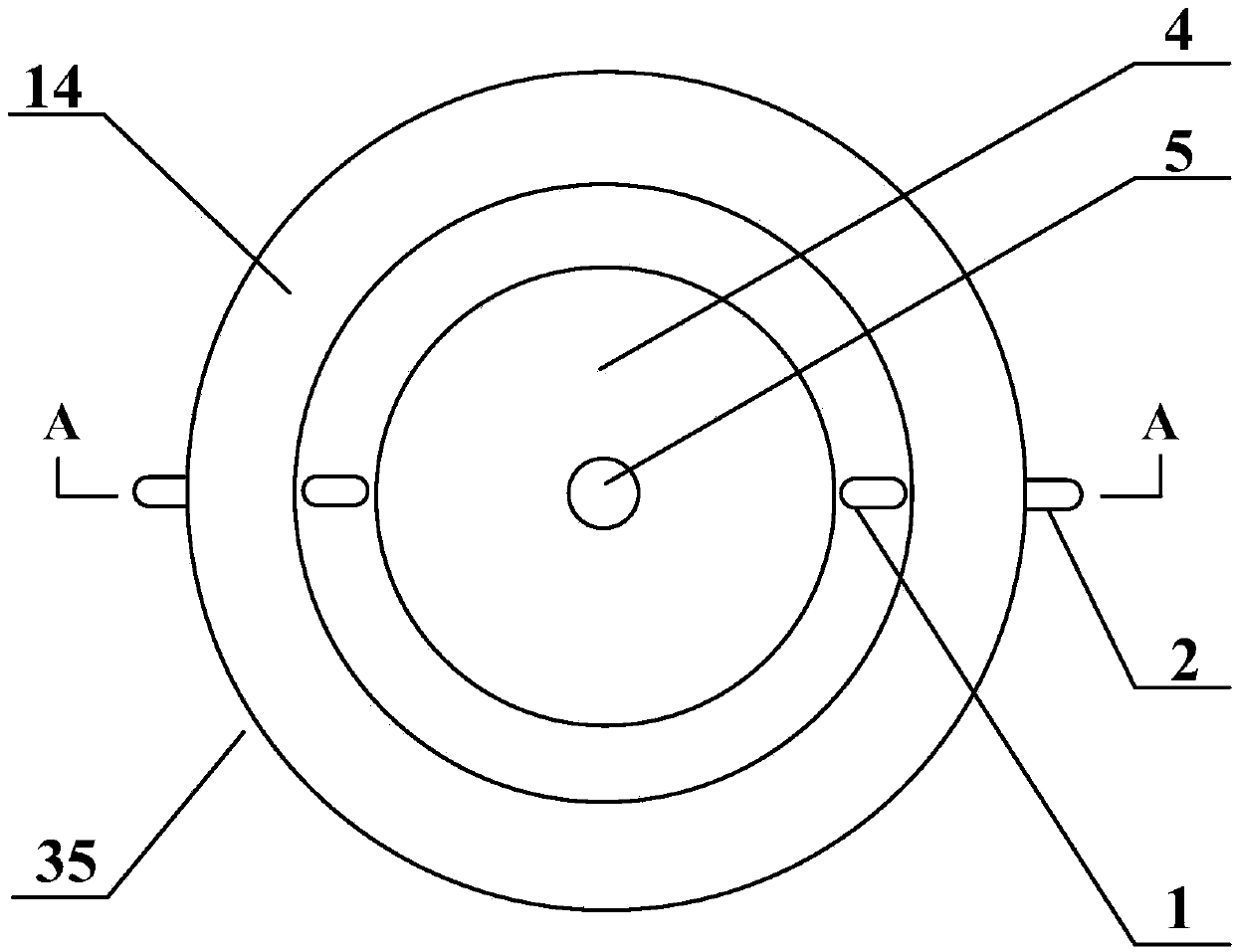

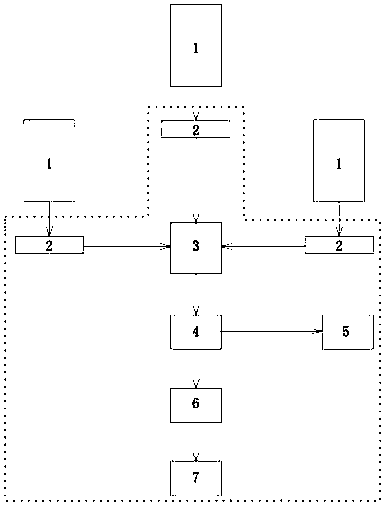

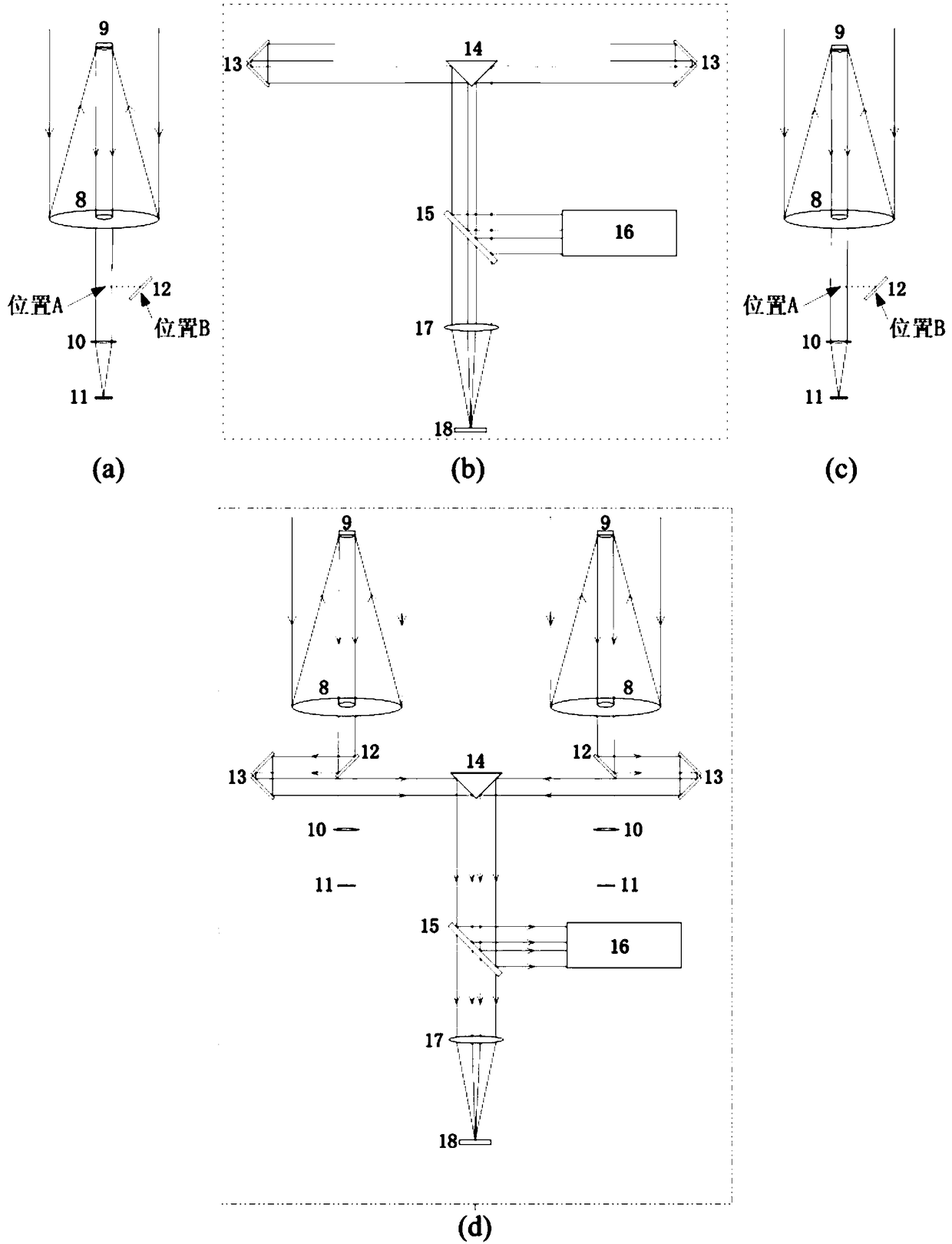

Space-reconfigurable remote sensing camera based on synthetic aperture technology

InactiveCN108955640ASmall sizeReduced carrying capacity requirementsPicture taking arrangementsPhysicsImage resolution

The invention discloses a space-reconfigurable remote sensing camera based on a synthetic aperture technology. The space-reconfigurable remote sensing camera comprises a plurality of remote sensing camera modules (1) and a synthetic aperture assisting system, and the synthetic aperture auxiliary system comprises a synthetic aperture inphase corrector module (2), a synthetic aperture beam combinermodule (3), a synthetic aperture beam splitter module (4), a synthetic aperture inphase detector module (5), a synthetic aperture imaging and focusing module (6) and a synthetic aperture imaging detector module (7). Every remote sensing camera module can be in a separate working mode, or can be spatially reconstructed to form a synthetic aperture working mode. When high-resolution imaging of earthis not required, every remote sensing camera is in the separate working mode; and when high-resolution imaging of earth is required, the remote sensing cameras spatially reconstruct around the synthetic aperture assisting system to form the synthetic aperture working mode. The space-reconfigurable remote sensing camera can realize the imaging resolution of an equivalent large-aperture remote sensing camera.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386BReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

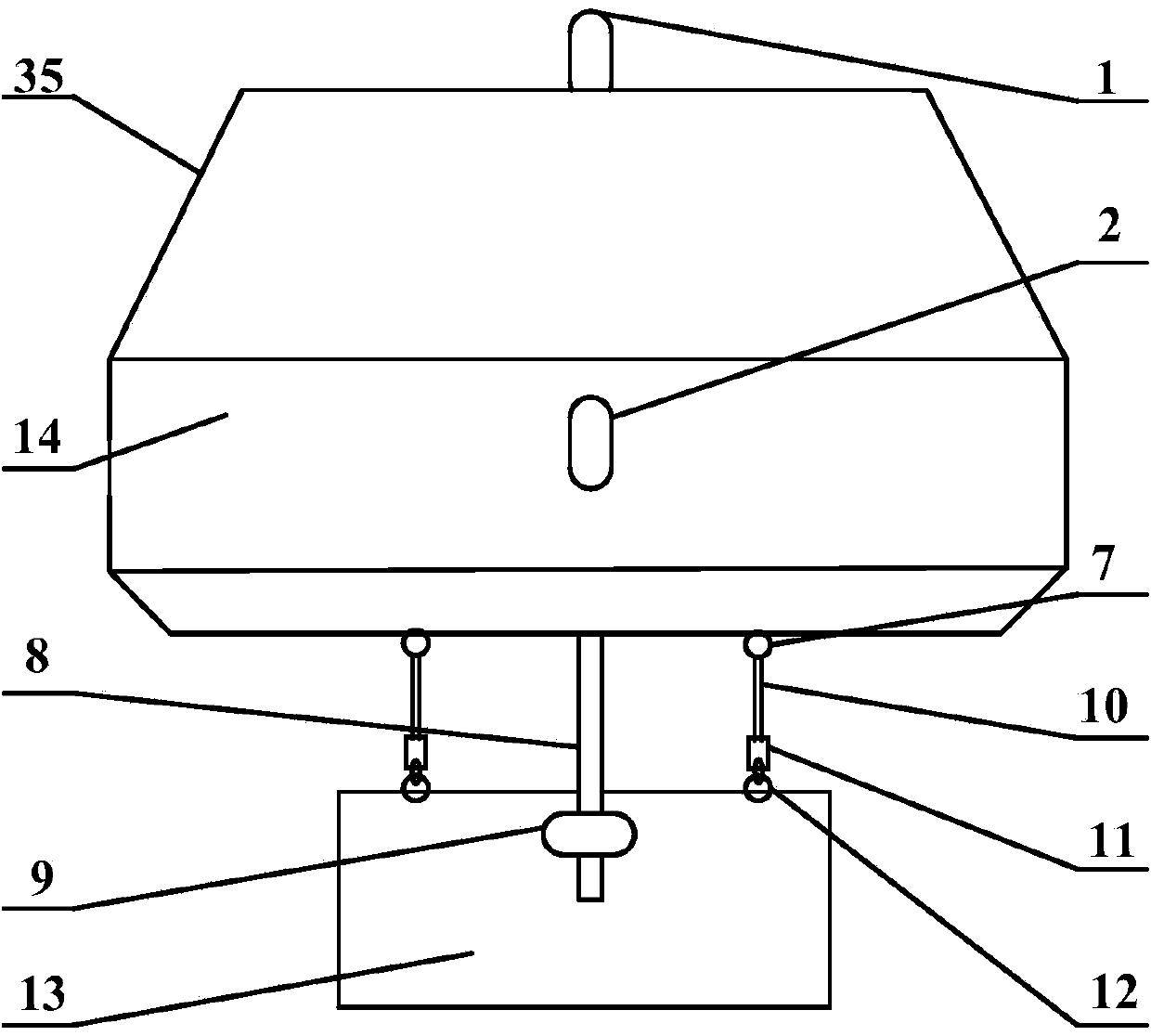

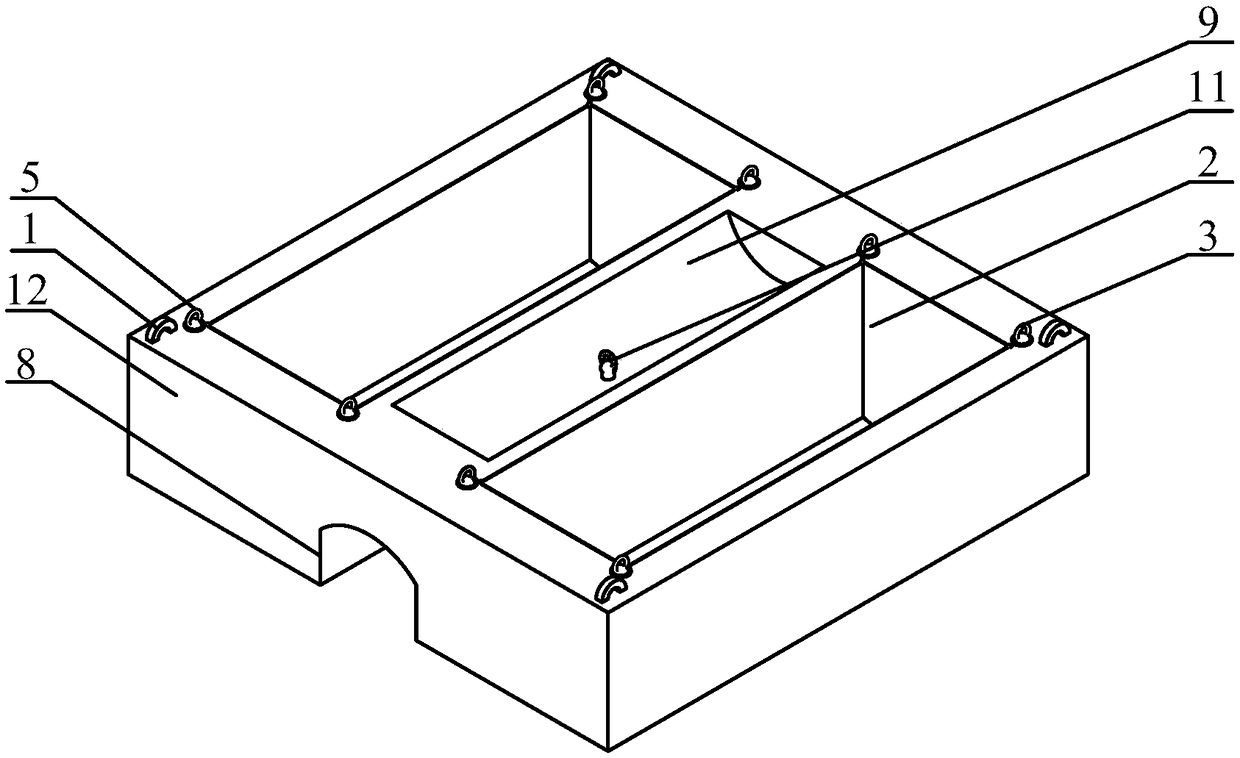

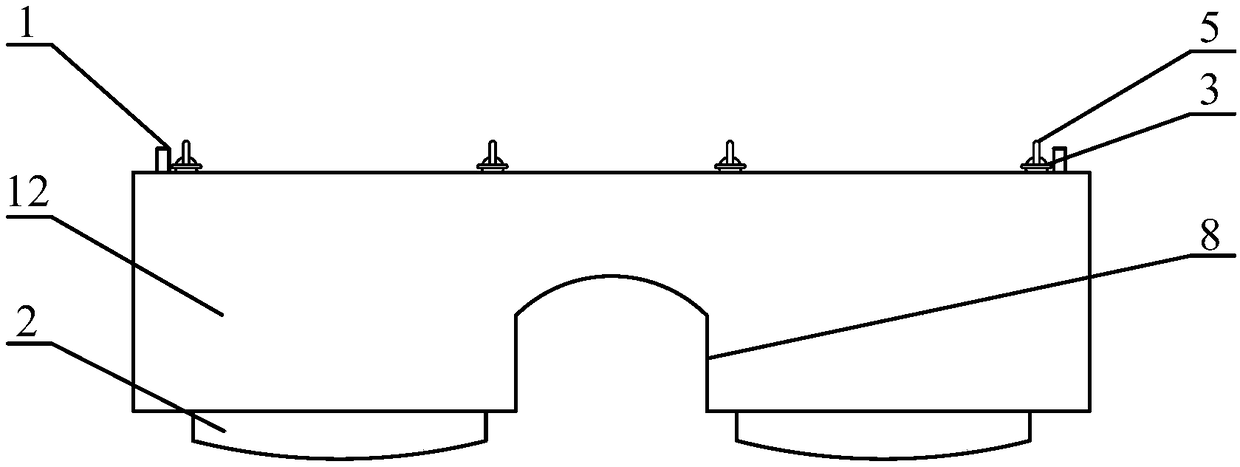

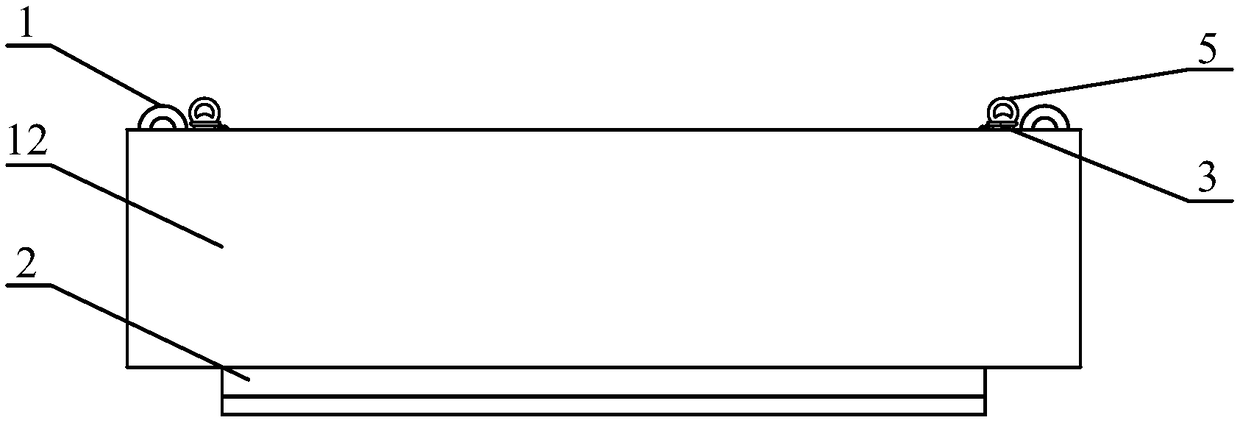

Sand bag stacking construction device for submarine suspended pipeline treatment

ActiveCN109237124AControllable landing positionScientific and effective constructionPipe laying and repairUnderwater equipmentSubmarineEngineering

The invention belongs to the field of ocean engineering, and in particular, relates to a sand bag stacking construction device and a construction method for seabed suspended pipeline treatment, whichis used for treating the submarine suspended pipeline. The sand bag stacking construction device for treating the seabed suspended pipeline comprises a floating body, a lifting lug, a container bag, hanging ring, a top pin hole, a top pin, a sand bag bin, a sand bag, a groove, a weight bearing bin, a weight bearing bin pin hole and a weight bearing bin pin; the floating body main body is a cuboidand is made of a solid buoyancy material; four corners of the top of the floating body is provided with up-lifting lugs, and the center of the bottom of the floating body is provided with an arch-shaped groove; the center of the top of the floating body is provided with a semi-cylindrical weight bearing bin, and the center of the bottom of the floating body is provided with a weight bearing bin pin hole; the two sides of the weight bearing bin are provided with two sand bag bins for placing container bags; four corners of the sand bag bin are provided with top pin holes for fixedly connectingthe top pins of the lifting ring; by using the device, the underwater landing place of the sand bag can be accurately located, the sand bag can be neatly stacked, and the problem of the submarine pipeline suspension can be accurately and efficiently addressed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

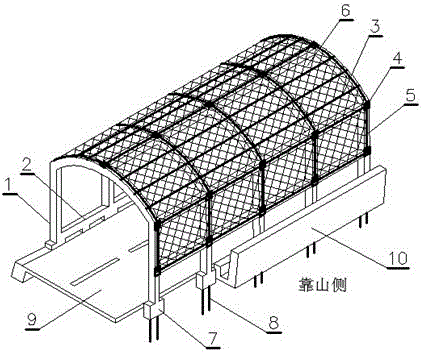

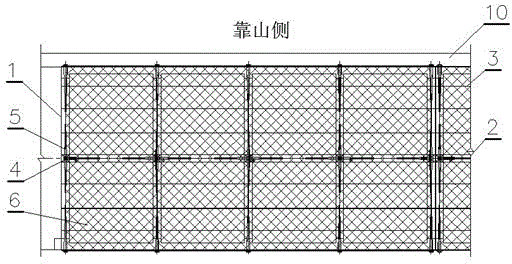

Protective structure for preventing rockfall dangers at high and steep slope of mountain road

ActiveCN102966052BReduce weightIncreased durabilityProtective constructionSafety netReinforced concrete

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Ultrasonic suspension guide rail with high positioning precision

ActiveCN109898944AExtend your lifeIncrease limit speedPower-operated mechanismWing suspension devicesTransducerEngineering

The invention discloses an ultrasonic suspension guide rail with high positioning precision. A transducer bracket is of an annular structure and sleeves a guide rail body, and a gap is formed betweenthe inner circumferential face of the transducer bracket and the periphery of the guide rail body; a plurality of piezoelectric transducers arranged at different positions in the direction of the guide rail body are mounted around the upper part, the lower part and the two sides of the transducer bracket correspondingly, through holes communicating with the gap from the exterior are formed in theside wall of the transducer bracket, and the piezoelectric transducers are mounted in the through holes; and rear end covers of the piezoelectric transducers are fixed into the through holes, the tailends of amplitude-change poles are fixedly connected with the rear end covers through ceramic piezoelectric patches, snowflake-shaped grooves are formed in the end faces of the front ends of the amplitude-change poles, and the front ends of the amplitude-change poles serve as the tail ends of the piezoelectric transducers. Frictional wear is reduced, the sound intensity of ultrasonic waves is adjusted according to the distance between the bracket and the bottom of the guide rail, and thus force enabling the guide rail to move in the circumferential direction is generated.

Owner:ZHEJIANG UNIV

Single-girder hanger and reach stacker

ActiveCN103523664BIncrease the support armRealize the lifting operationRunwaysEngineeringStructural engineering

The invention provides a single main beam spreader, comprising a main beam (1); a large telescopic beam (2) and a small telescopic beam (3) located inside the main beam (1); the small telescopic beam (3) is set on the large Inside the telescopic beam (2); the beam (4), located at the free ends of the large telescopic beam (2) and the small telescopic beam (3); also includes: a follow-up support mechanism (5), one end of which is connected to the large telescopic beam (2) , the other end is set on the small telescopic beam (3), the outer wall of the follow-up support mechanism (5) is in contact with the inner surface of the main beam (1), and the inner wall of the follow-up support mechanism (5) is in contact with the outer surface of the small telescopic beam (3). connected; the first limit mechanism (6) located at the fixed end of the small telescopic beam (3); the second limit mechanism (7) located on the large telescopic beam (2). The single main girder spreader provided by the present invention realizes the follow-up support for the small telescopic beam by setting a follow-up support mechanism between the main girder and the telescopic beam, and extends the supporting arm of the two telescopic beams, thus improving the mechanical structure The stress conditions reduce the load-bearing capacity requirements of mechanical materials, improve the load-bearing capacity of the single main girder spreader, and realize the lifting operation of heavy-duty containers above 20ft.

Owner:SANY MARINE HEAVY IND +1

Traction robot and traction equipment

PendingCN112829854AReduced carrying capacity requirementsImprove reliabilityVehiclesAutomated guided vehicleMoving parts

The invention relates to the technical field of traction, and particularly discloses a traction robot and traction equipment. The traction robot comprises an automatic guide vehicle and a traction device; the traction device comprises a device body, a first moving part, a driving mechanism for driving the first moving part to reciprocate along a first track, a first guiding part arranged on the device body along a second track, a first moving inserting part movably arranged on the first guiding part and provided with a first clamping and inserting part, a first connecting rod rotationally connected with the first moving inserting part and the first moving part, a second guide partarranged on the device body along a third track, a second moving inserting part movably arranged on the second guide part and provided with a second clamping and inserting part, and a second connecting rod rotationally connected with the second moving inserting part and the first moving part; the second track and the third track are symmetrically arranged on the two opposite sides of the first moving part in a spaced mode, and the first clamping and inserting part and the second clamping and inserting part can be matched with a clamping structure of a material carrier in a clamping and inserting mode. The traction robot and the traction equipment have good traction performance.

Owner:SHENZHEN YOUIBOT ROBOTICS CO LTD

A sliding foot component and a dynamic template support structure using the same

The invention discloses a sliding foot assembly. The sliding foot assembly comprises sliding foot bodies, wherein each sliding foot body is provided with a first supporting end face and a second supporting end face perpendicular to each other. The sliding foot bodies are provided with elastic supporting assemblies which make contact with supported pieces and are used for supporting the supported pieces directly. One end of each elastic supporting assembly protrudes out of the surface of the corresponding second supporting end face, and the other end of each elastic supporting assembly is fixedly connected with the corresponding sliding foot assembly. The invention further discloses a movable mold plate supporting structure using the sliding foot assembly. Due to the arrangement of the elastic supporting assemblies, the mold locking deformation force transmitted to linear guide rails is greatly lowered, an ultra-large type machine can also be designed to be in linear guide rail guiding supporting, and the ultra-large type machine can achieve high-speed, high-efficiency and stable control production.

Owner:BORCH MACHINERY

Double-input and double-output wheel-sided transmission assembly

PendingCN108297683AReduced carrying capacity requirementsLow costMotor depositionControl devicesDrive motorVariator

The invention discloses a double-input and double-output wheel-sided transmission assembly which comprises a transmission shell. Power input shafts, power output shafts and planetary mechanisms are symmetrically arranged on the left side and the right side of the transmission shell correspondingly; one ends of the two power output shafts externally extend out of the transmission shell for drivingleft wheels and right wheels correspondingly; the other ends of the two power output shafts are fixedly connected with planetary frames correspondingly; the power output shafts are provided with output shaft gears, low-gear teeth are fixed to the transmission shell, high-low-gear tooth seats are arranged between the output shaft gears and the low-gear teeth, and the high-low-gear tooth seats are fixedly connected with gear rings of the planetary mechanisms; the high-low-gear tooth seats are engaged with sliding sleeves, sun wheel input shafts are provided with sun wheel input gears, and sun wheels are engaged with planetary wheels; one ends of the two power input shafts externally extend out of the transmission shell for being connected with driving motors; and the power input shafts are provided with input shaft gears, and the input shaft gears are engaged with the sun wheel input gears through idle wheels. The double-input and double-output wheel-sided transmission assembly is high in efficiency and low in cost.

Owner:QIJIANG GEAR TRANSMISSION

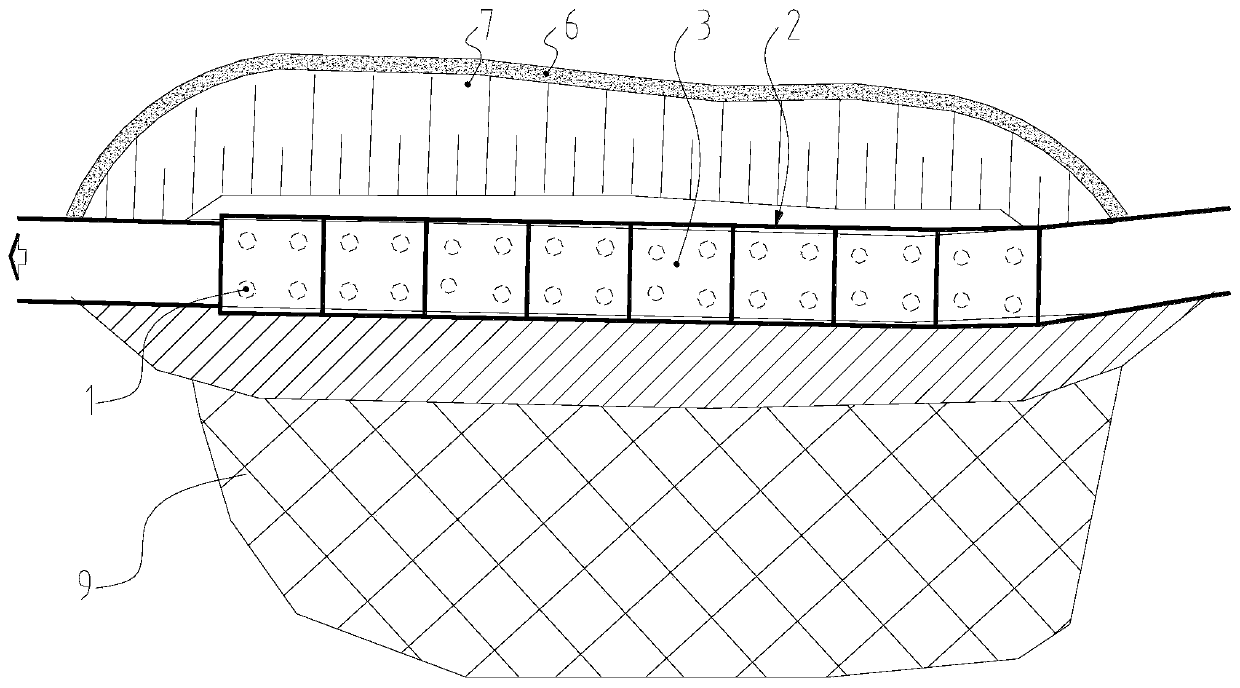

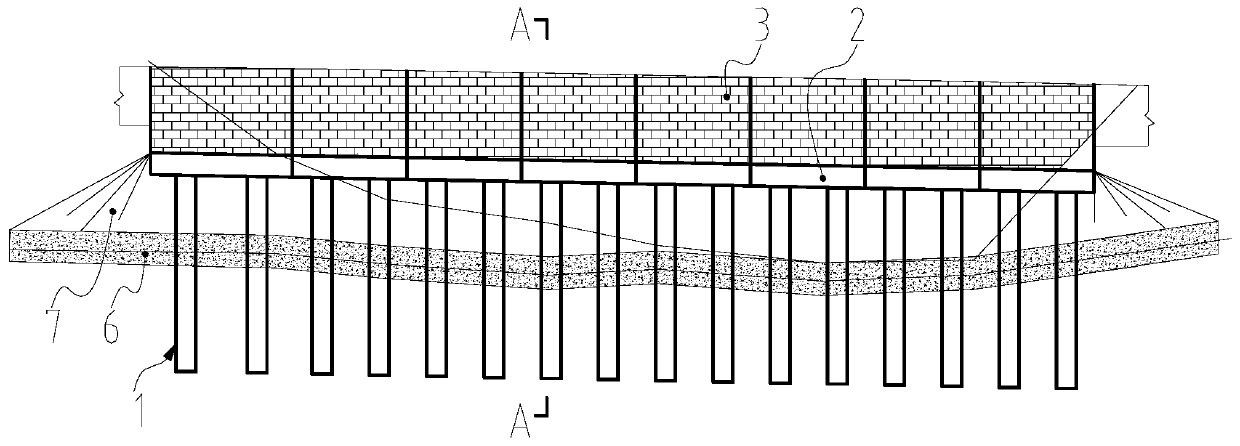

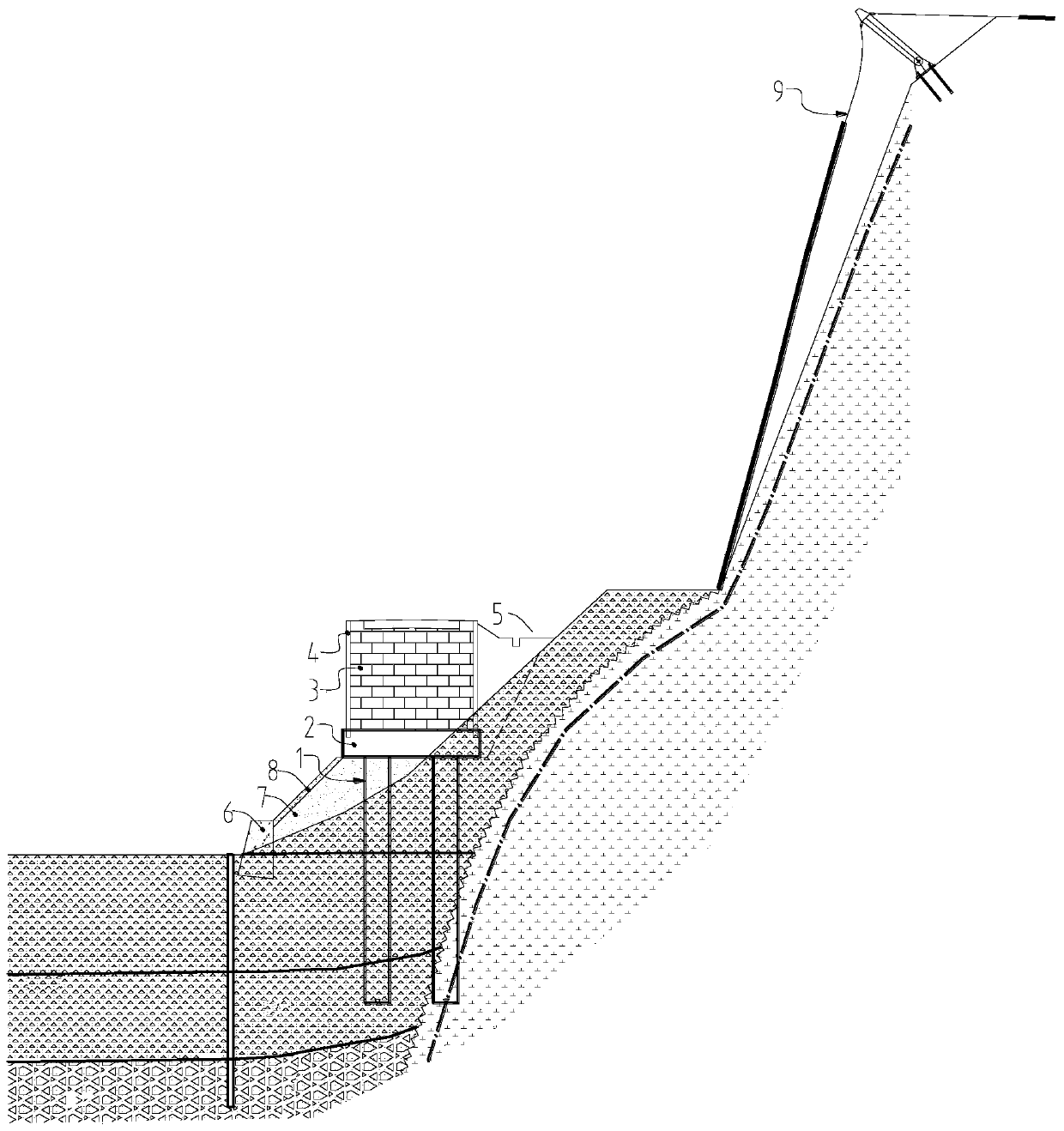

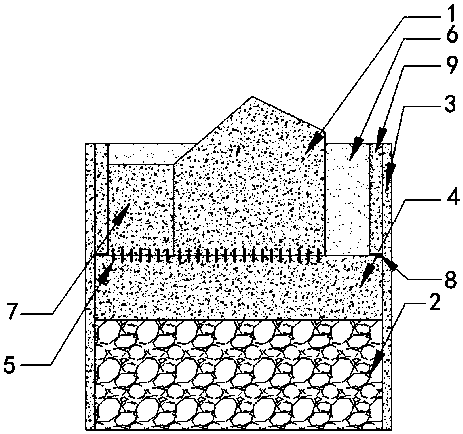

Disaster prevention mountainous steep slope road section light high-fill embankment structure and construction method

ActiveCN109811607AImprove disaster resilienceSolve the problem of roadbed fillingRoadwaysExcavationsReinforced concreteRiver routing

The invention discloses a disaster prevention mountainous steep slope road section light high-fill embankment structure and a construction method, belongs to the field of roads and aims to improve thedisaster prevention and reduction capability of a mountainous steep slope and a high-fill road section, and improve structural security of a key road section with mountainous traffic facilities and the capability of rapid traffic recovery under disaster conditions. The structure comprises a reinforced concrete pile foundation, a reinforced concrete bearing platform and a light soil roadbed, wherein the reinforced concrete pile foundation is buried in a bearing stratum; the reinforced concrete bearing platform is supported at the top end of the reinforced concrete pile foundation and connectedwith the reinforced concrete pile foundation; the light soil roadbed is filled and constructed on the reinforced concrete bearing platform. By adopting the structure, a road section that only a bridge can be constructed generally is changed into a roadbed structure mode, and an existing damaged bridge is repaired by using the structure, so that the stability of a steep slope embankment is improved, influence of a roadbed structure close to a river upon a river channel is avoided, and difficulties in roadbed filling of steep slopes, roads close to rivers and highfill road sections can be effectively solved, meanwhile, the area occupation is reduced, and by adopting the light high-fill embankment structure, the traffic insurance capability of a road section is greatly improved, and the whole service life periodic cost is reduced.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Large-span arch bridge foundation

ActiveCN107842032AImprove lateral load carrying capacityReduced carrying capacity requirementsFoundation engineeringArch-type bridgeBridge engineeringArch bridge

The invention belongs to the technical field of bridge engineering and particularly relates to a large-span arch bridge foundation comprising an arch seat and a bearing layer used for supporting the arch seat. The large-span arch bridge foundation further comprises support parts. The support parts are arranged on the periphery of the bearing layer and are used for supporting the bearing layer in the transverse direction. Through the foundation structure, the transverse bearing capacity of the large-span arch bridge foundation is promoted substantially, and the size of the support parts is determined according to the magnitude of the transverse load applied to the bearing layer in actual construction. Due to arrangement of the support parts, the transverse bearing capacity of the foundationstructure is improved, then the requirement for the bearing capacity of the bearing layer is lowered so that the excavation depth of the foundation can be reduced in actual construction, constructioncost is lowered, the construction period is shortened, and the large-span arch bridge foundation can be suitable for more geological conditions. On the other hand, greater support capacity can be improved, and then the large-span arch bridge foundation can be suitable for construction of a large-span or even super-large-span arch bridge.

Owner:GUANGXI UNIV +1

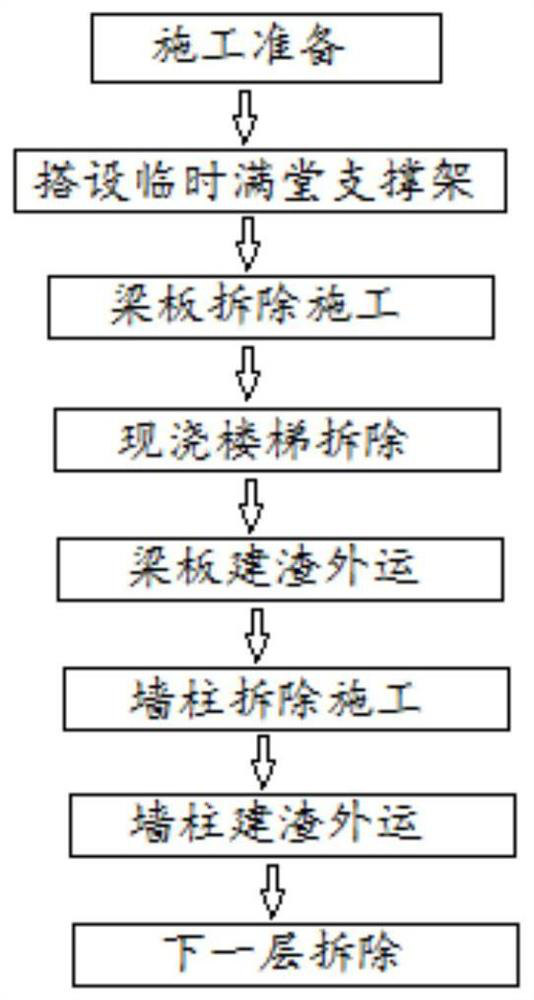

Static breaking construction method for reinforced concrete structure

PendingCN114541807AReduce pollutionReduced carrying capacity requirementsClimate change adaptationBuilding repairsReinforced concreteArchitectural engineering

The invention provides a static breaking construction method for a reinforced concrete structure. The static breaking construction method comprises the steps of construction preparation, temporary full space supporting frame erecting, beam and slab dismantling construction, cast-in-place stair dismantling, beam and slab building slag outward transporting, wall column dismantling construction, wall column building slag outward transporting, next-layer dismantling and the like. According to the method, the full-space supporting frame is erected on the lower portion of the demolition area, the demolition object is hoisted in time, the requirement for the bearing capacity of the structure to be demolited can be greatly lowered, the construction safety coefficient is increased, and meanwhile potential safety hazards caused by structural vibration can be reduced.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

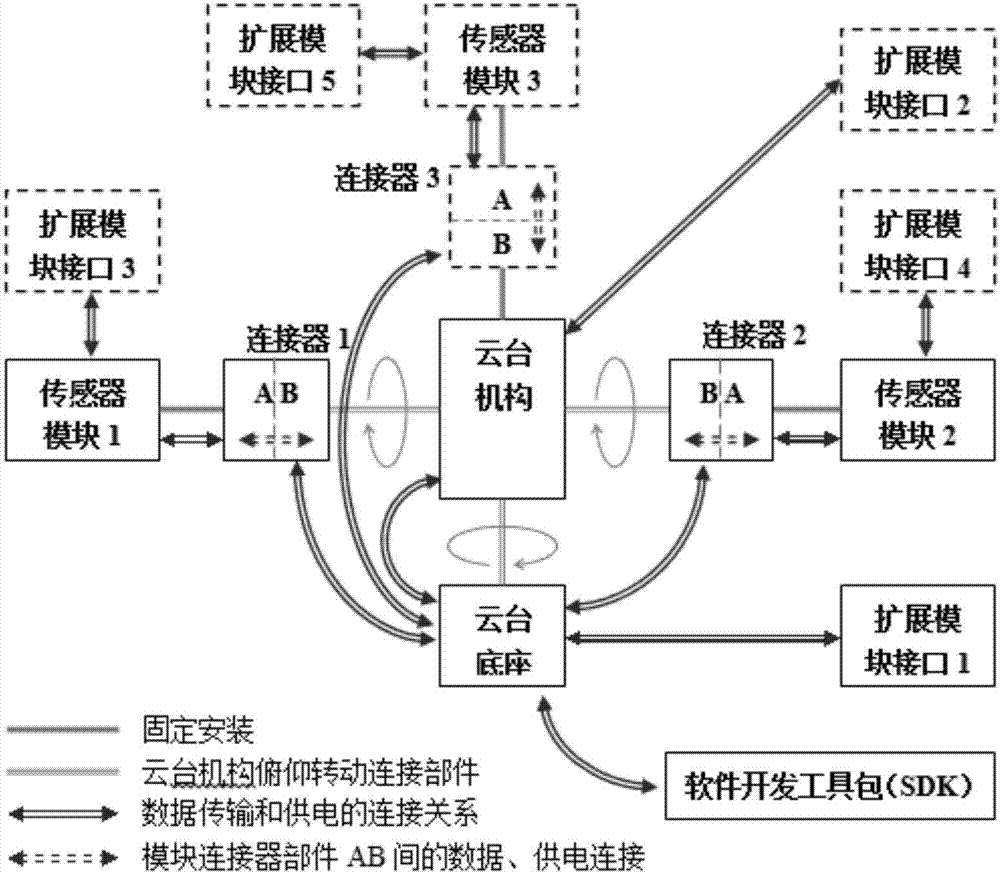

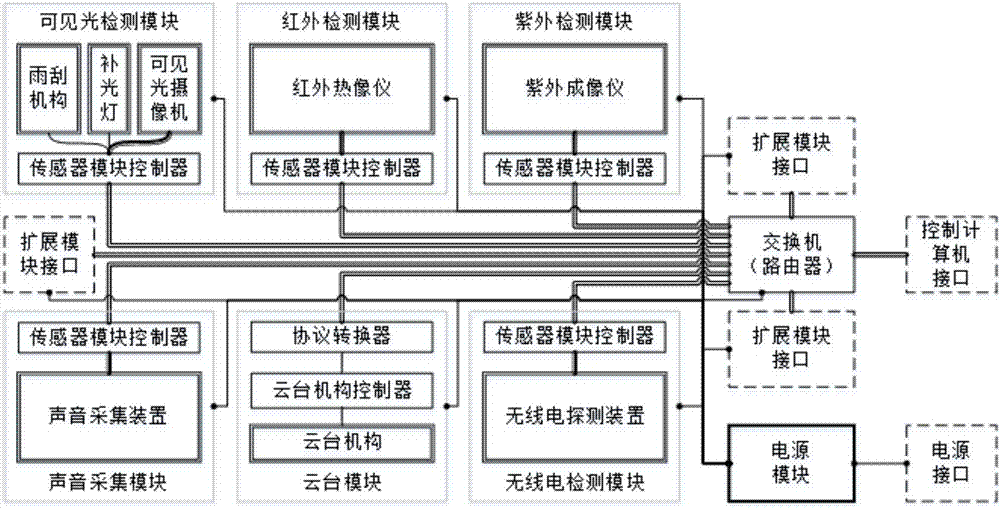

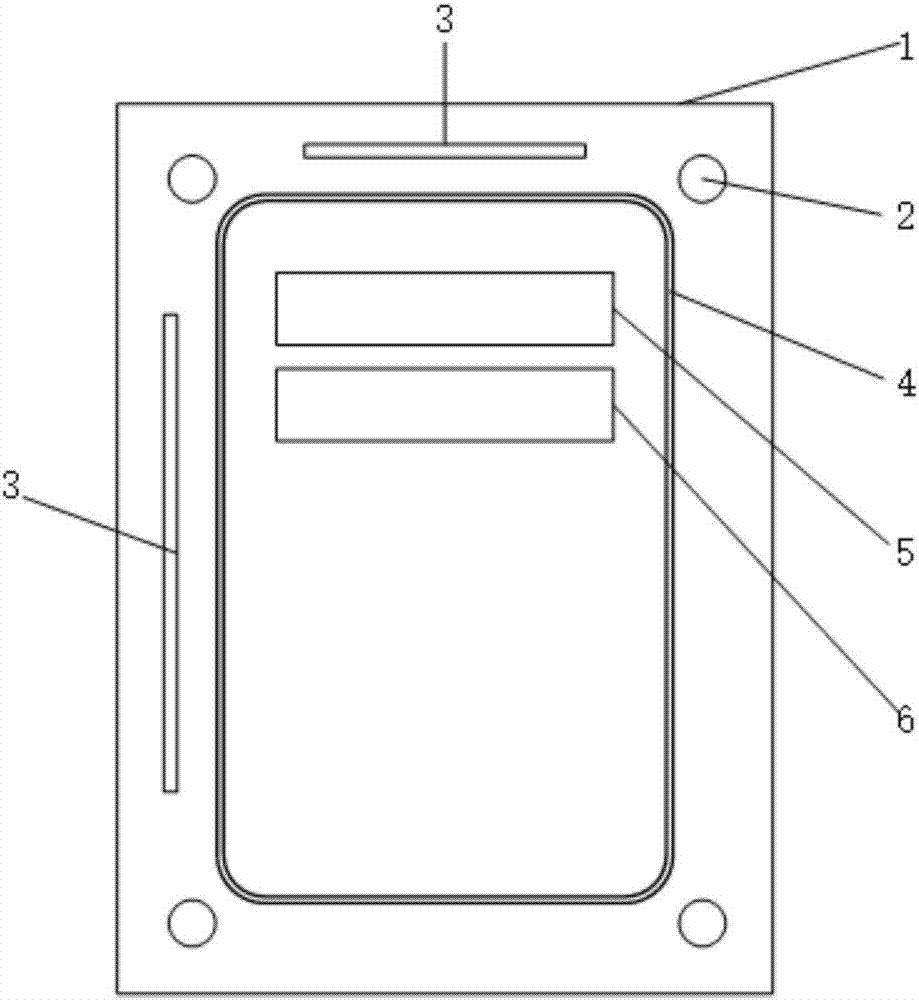

Cloud desk system with changeable sensors

InactiveCN107168128ALower replacement costsImprove reusabilityProgramme control in sequence/logic controllersEngineeringDesk

The embodiments of the invention disclose a cloud desk system with changeable sensors. The system herein includes: a cloud desk module, at least two sensor modules and a connector. The cloud desk module includes: a cloud desk mechanism, a cloud desk mechanism controller and a protocol converter. The connector includes: a first connector part and a second connector part. The first connector part and the second connector part can be detachably connected. The cloud desk mechanism is connected to the at least two sensor modules through the connector. The cloud desk mechanism and the cloud desk mechanism controller are connected. The cloud desk controller and the protocol converter are connected.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

A construction method suitable for the foundation of long-span arch bridges

ActiveCN107761541BImprove carrying capacityReduced carrying capacity requirementsBridge structural detailsBridge erection/assemblyBridge engineeringLong span

The invention belongs to the technical field of bridge engineering, and particularly relates to a construction method suitable for a large-span arch bridge foundation. The construction method for thelarge-span arch bridge foundation comprises the following steps: A, trench excavation: excavating trenches in the ground corresponding to arch bridge foundation supporting pieces, wherein the lower parts of the trenches are positioned in a bearing stratum; B, supporting piece pouring: pouring concrete in the trenches excavated in the step A, and hardening the concrete to obtain the supporting pieces; C, foundation pit excavation: excavating a soil layer above the bearing stratum to the bearing stratum; D, foundation plate pouring: pouring concrete in a foundation pit formed in the step C to obtain a foundation plate; and E, arch seat pouring: after the foundation plate in the step D is hardened, pouring an arch seat on the foundation plate. According to the construction method, on one hand, the excavation depth can be reduced, and the foundation structure of the foundation is suitable for geology of which a covering layer is thick; and on the other hand, the bearing capacity of the foundation can be greatly improved, and thus, the foundation structure is suitable for a foundation of the large-span arch bridge.

Owner:GUANGXI UNIV +1

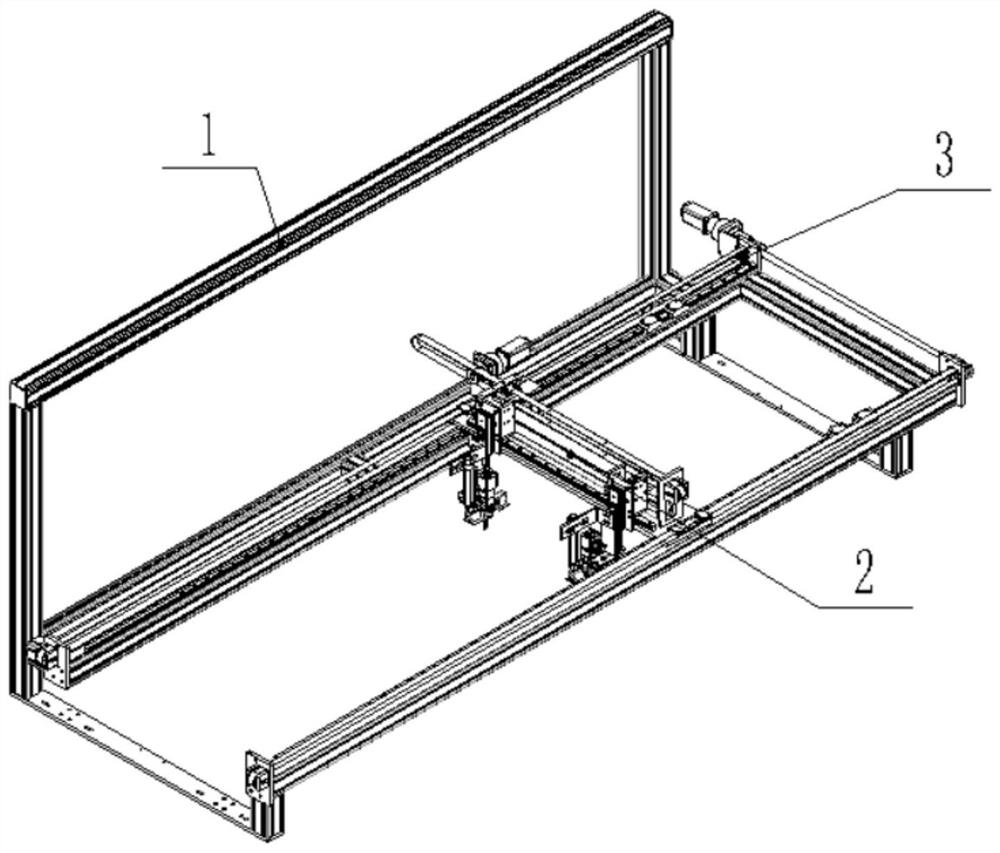

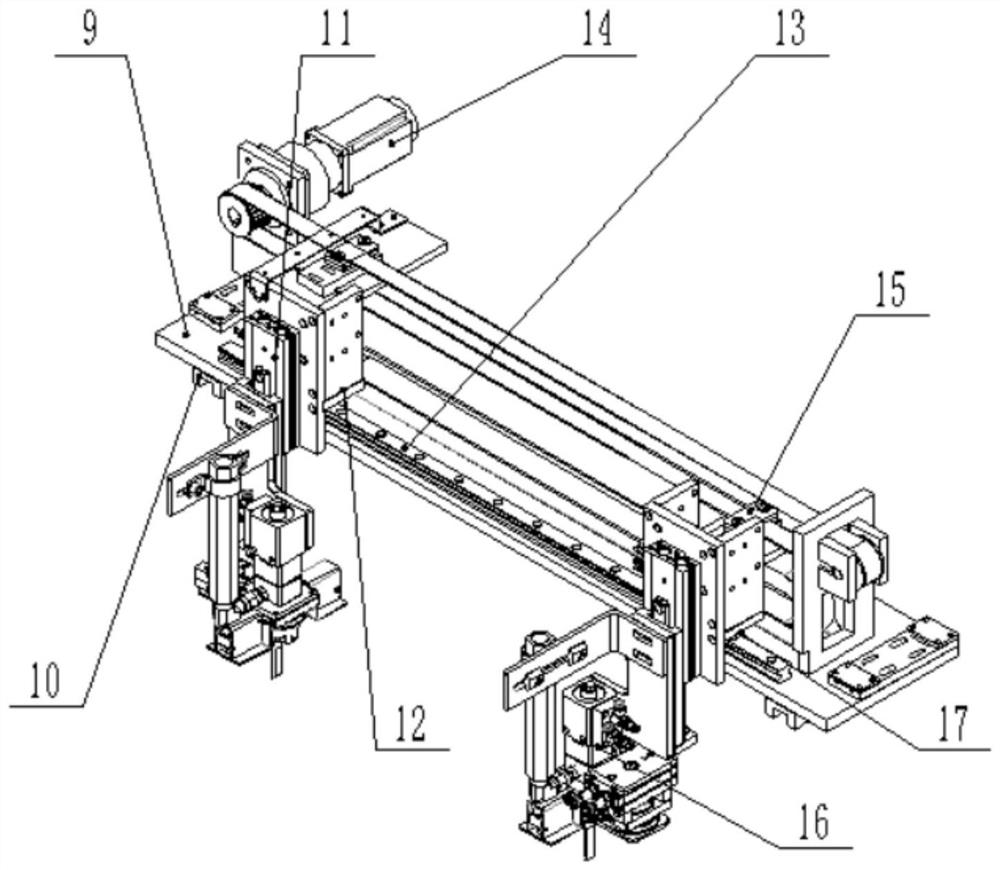

A glue coating method with symmetrically arranged double glue heads

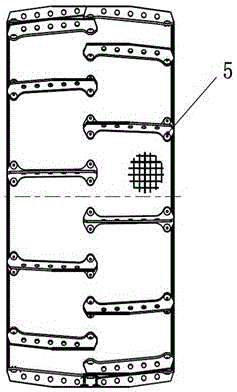

ActiveCN112934611BAvoid defects that require waiting timeImprove efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a gluing method with symmetrically arranged double gluing heads. It has become an urgent need to design a gluing method and device that can improve gluing efficiency, gluing effect, simple and precise control, and meet process requirements. The horizontal device of the present invention drives the longitudinal base of the longitudinal device to move along the direction of gluing, and the longitudinal servo motor drives the two gluing units respectively placed on the upper and lower belt sections of the synchronous belt to move symmetrically towards or against each other. The cylinder drives the glue applicator to move in the direction of the plumb weight, realizing the three-dimensional movement of the two glue applicators. The invention utilizes the symmetrical opposite or opposite movement characteristics of two gluing units placed on the upper and lower belt sections of the synchronous belt, and can most effectively realize the frame sorting and gluing work of "long, short, short, long" due to process requirements, Moreover, the power source is less, the cost is lower, the control method is simple, and the precision is high. It is convenient to disassemble and maintain when a certain gluing unit fails, while the other gluing unit can still perform gluing operations.

Owner:上海盛普流体设备股份有限公司 +1

A high-performance screen wheel

Owner:SHANGHAI AEROSPACE SYST ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com