Megawatt-stage direct-drive internal rotor permanent-magnetic wind power generator set

A technology of wind power generating set and inner rotor, which is applied in the direction of wind motor combination, wind engine, and wind engine consistent with the wind direction, etc. It can solve problems such as poor ventilation and heat dissipation, and achieve personal safety. Good effect of wind energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

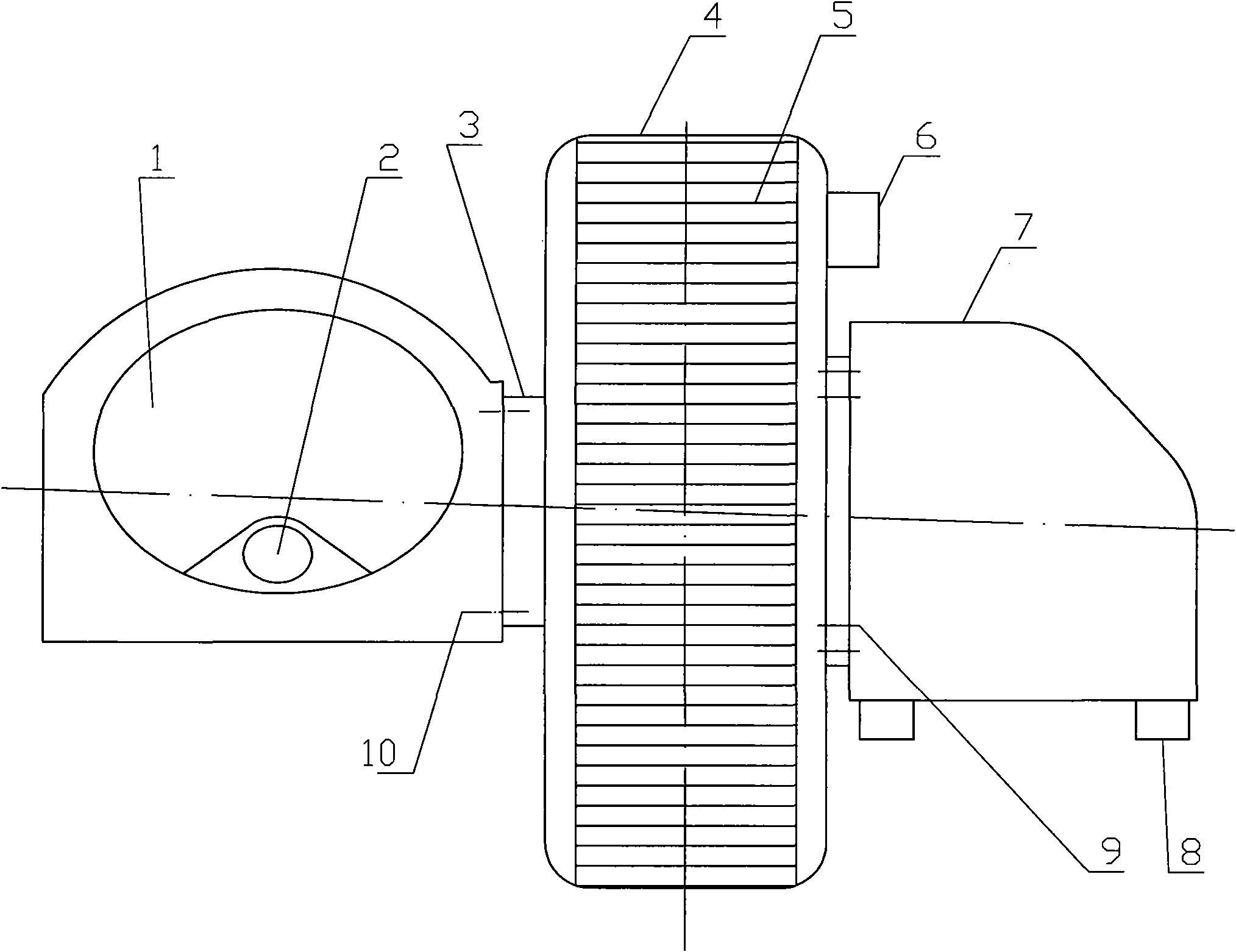

[0014] Such as figure 1 A specific embodiment shown includes a wind rotor 1 , a pitch control system 2 , a permanent magnet generator 4 , a nacelle base 7 and a yaw system 8 .

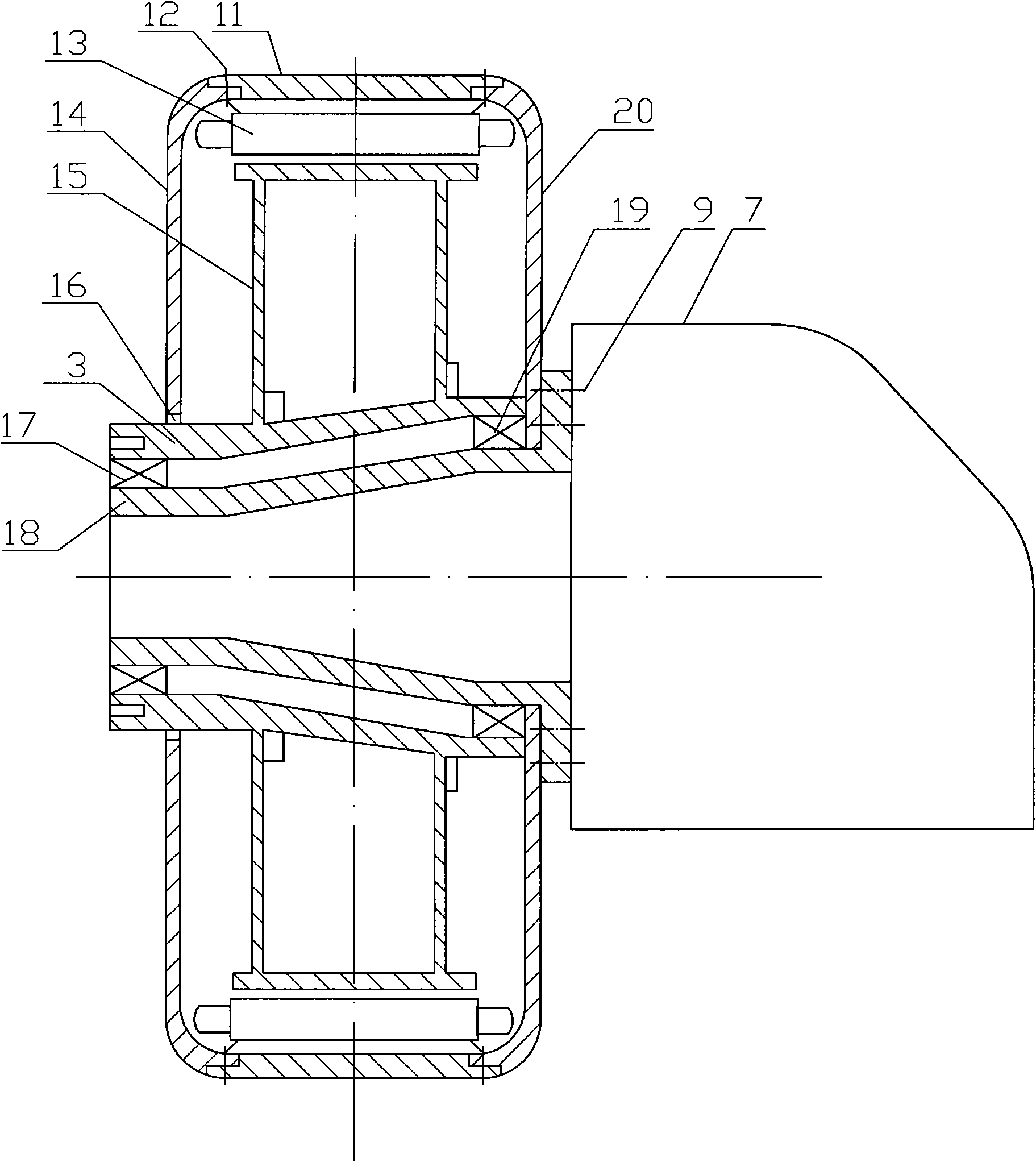

[0015] Such as figure 2 As shown, the permanent magnet generator 4 includes a casing 11, a stator 13, a front end cover 14, a rotor 15, a rear end cover 20 and a rotor rotation support mechanism, the front end cover 14 is fixed on the front end of the casing 11 by bolts III12, and the rear end cover 20 is fixed on the rear end of the casing 11 by bolts III12. The casing 11 is provided with cooling ribs 5 , and the rear end cover 20 is provided with a cooling fan 6 . The stator 13 and the rotor 15 are disposed inside the casing 11 . The rotor rotation support mechanism includes a moving shaft 3, a bearing I17, a fixed shaft 18 and a bearing II 19, the moving shaft 3 and the fixed shaft 18 are conical hollow shafts, the moving shaft 3 and the fixed shaft 18 are inserted in the casing 11, and the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com