A construction method suitable for the foundation of long-span arch bridges

A construction method and large-span technology, applied in the field of bridge engineering, can solve the problems of small lateral bearing capacity of pile group foundation, small lateral load transmitted to the foundation, and unsuitable pile group foundation, etc., so as to improve bearing capacity and reduce construction costs. Costs, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

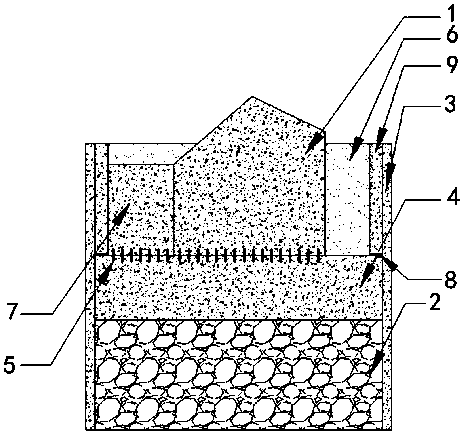

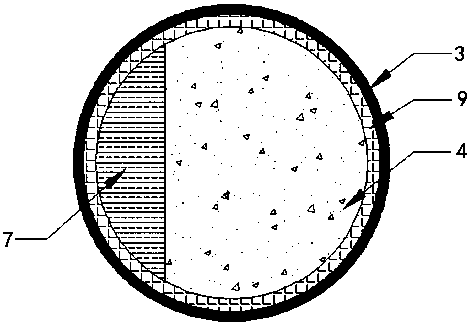

[0067] Example 1, such as figure 1 and 2 Shown:

[0068] A long-span arch bridge foundation, including an abutment 1 and a bearing layer 2 for supporting the abutment 1, and also includes a support 3, which is arranged on the periphery of the bearing layer 2, the The supporting member 3 is used to support the bearing layer 2 in the lateral direction.

[0069] The basic structure of the present application is provided with the support member 3 for supporting the force-bearing layer 2 in the lateral direction, thereby greatly improving the lateral load-bearing capacity of the foundation of the application. The size of the support member 3 is based on the actual construction. Determine the magnitude of the lateral load on layer 2. Due to the setting of the support member 3, the lateral bearing capacity of the foundation structure is improved, thereby reducing the requirement for the bearing capacity of the bearing layer 2. Therefore, in actual construction, the excavation dept...

Embodiment 2

[0091] Embodiment 2: as figure 1 and 2 Shown:

[0092] A construction method applicable to the foundation of a long-span arch bridge, comprising the following steps:

[0093] A, trench excavation: excavate a trench on the ground corresponding to the arch bridge foundation support 3, and the lower part of the trench is located in the bearing layer 2;

[0094] B. Pouring support 3: pour concrete in the trench excavated in step A, and obtain support 3 after hardening;

[0095] C. Excavation of the foundation pit: Excavate the soil layer above the bearing layer 2 until the bearing layer 2;

[0096] D, pouring base plate 4: pouring concrete in the foundation pit formed in step C to obtain base plate 4;

[0097] E. Pouring the abutment 1: After the base plate 4 in step D is hardened, pour the abutment 1 on the base plate 4.

[0098] In the construction method of the present application, by excavating the trench, the lower part of the trench is located in the bearing layer 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com