A glue coating method with symmetrically arranged double glue heads

A symmetrical arrangement and gluing technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of gluing time to be improved, gluing method inefficiency, and four frame time-consuming problems, so as to reduce gluing The effect of process time, low drive power demand, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

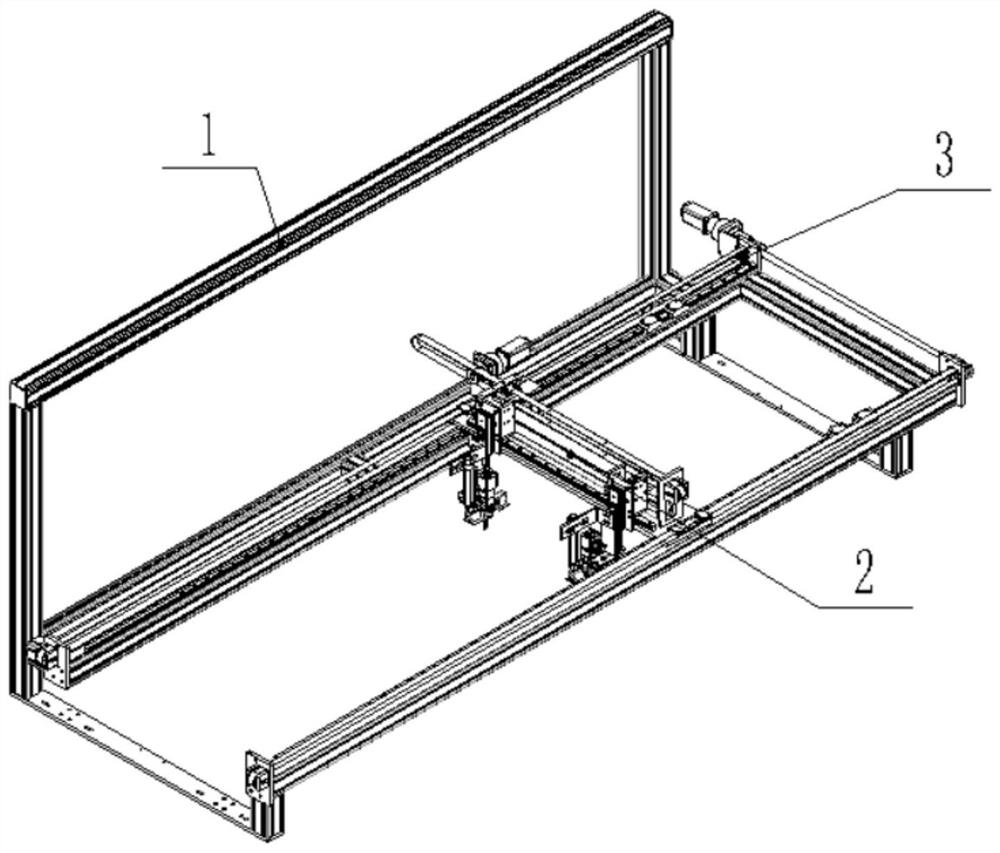

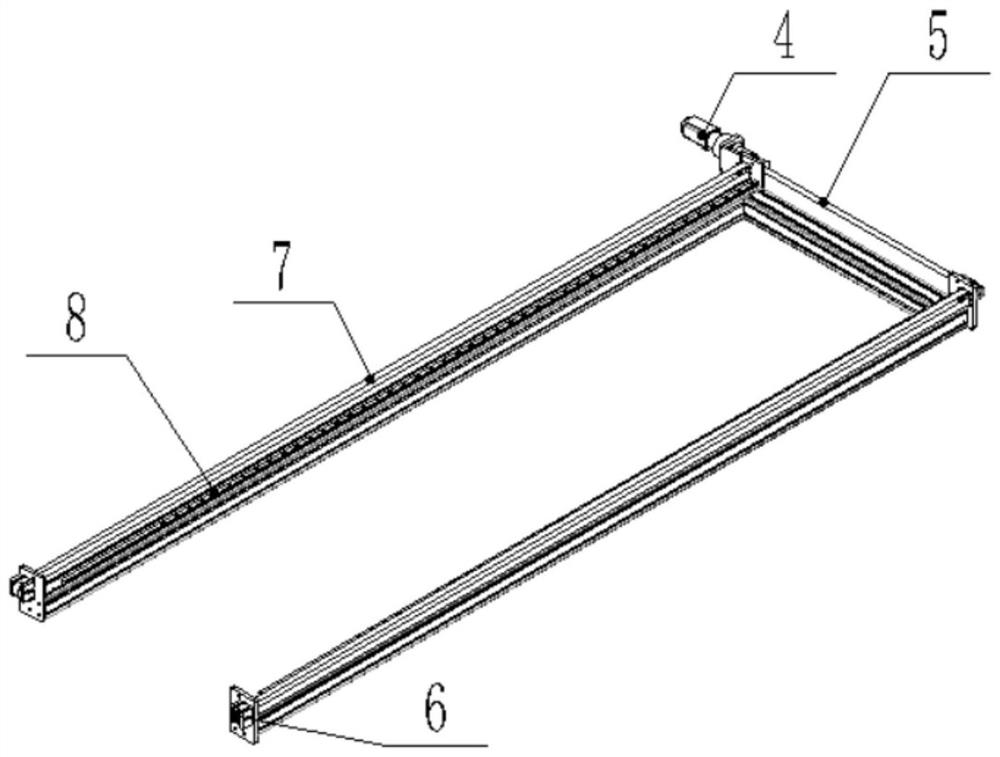

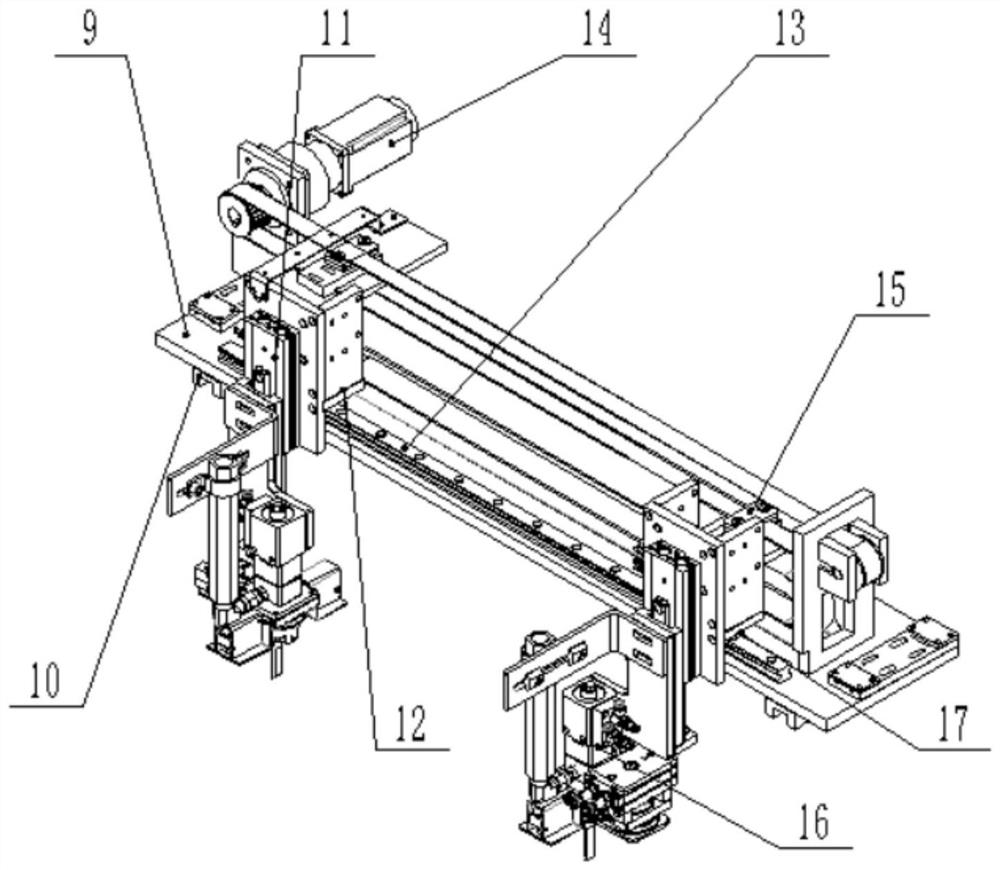

[0033] Such as figure 1 , 3 , 4 and 6, a symmetrically arranged double glue head glue coating method, as follows:

[0034] Step 1. Place two short frames and two long frames side by side on the bottom of rack 1, and arrange them vertically in the order of long frame, short frame, short frame and long frame; The head 16 is all connected to the glue supply system (the glue supply system is the prior art, no more repeated description).

[0035] Step 2: The horizontal device 3 drives the vertical base 9 to translate horizontally, and at the same time, the vertical servo motor 14 fixed on the vertical base 9 drives the two gluing units to translate vertically through the belt transmission mechanism, so that the two gluing units are reset to the initial position The horizontal device 3 and the vertical servo motor 14 are jointly driven to realize fast walking in a diagonal lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com