Sand bag stacking construction device for submarine suspended pipeline treatment

A construction device and sand bag technology, which is applied in the direction of pipeline laying and maintenance, transportation and packaging, pipes/pipe joints/fittings, etc., can solve the problem of inability to ensure that sand bags fall accurately to the suspended place, time-consuming, labor-intensive construction, and a lot of time and effort. Manpower and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

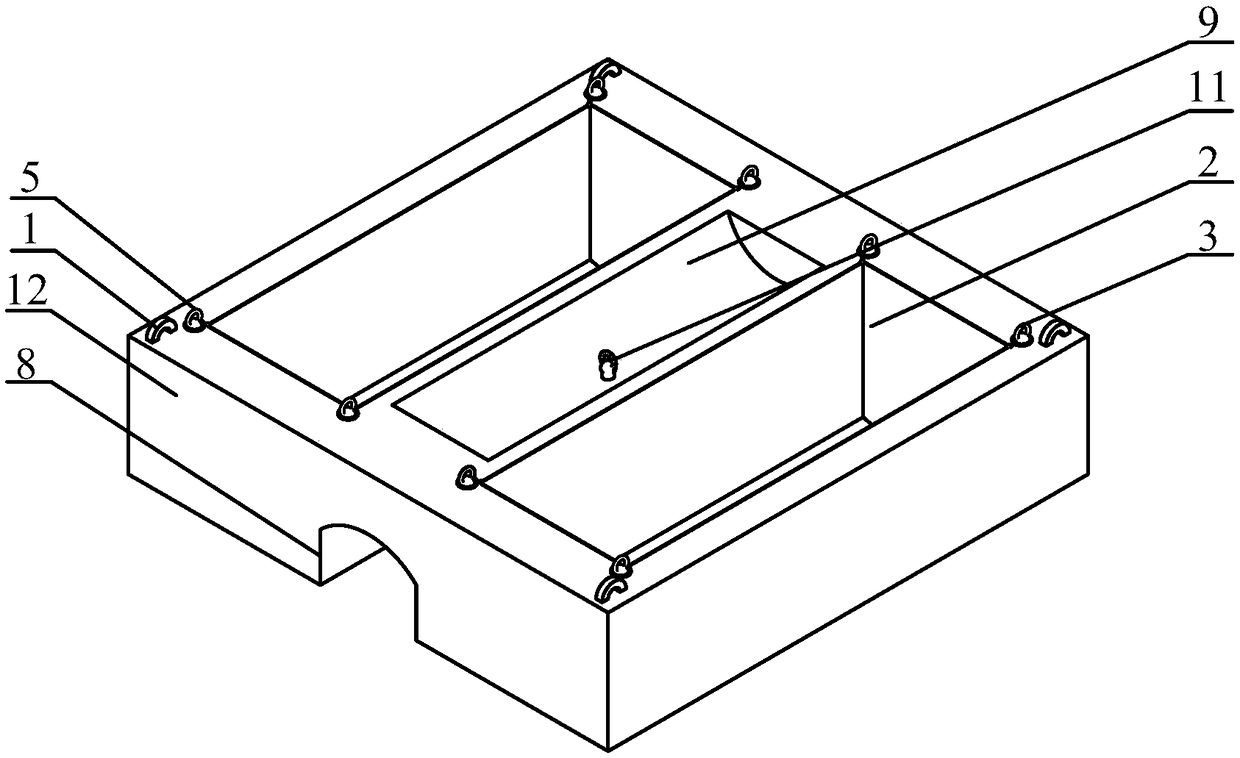

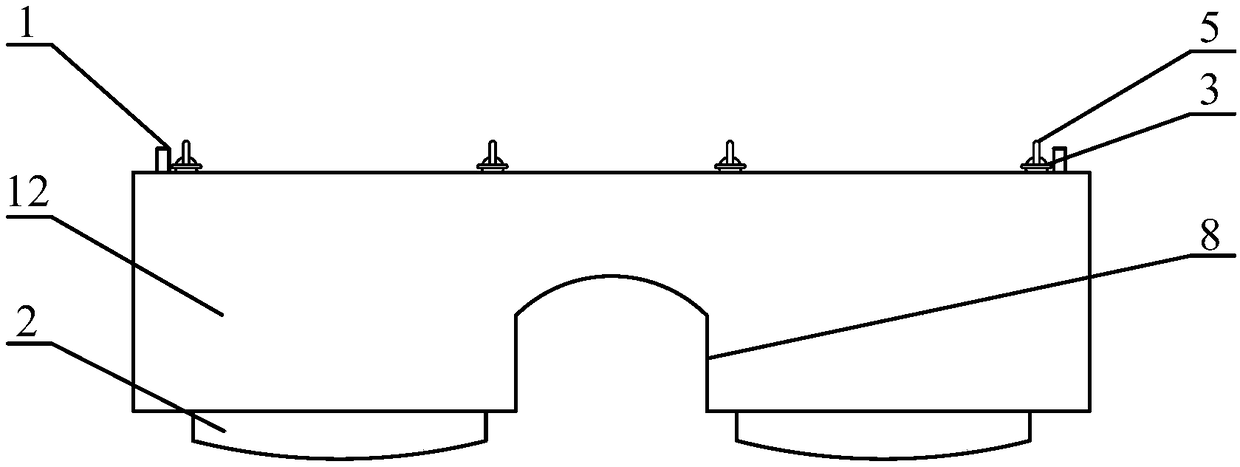

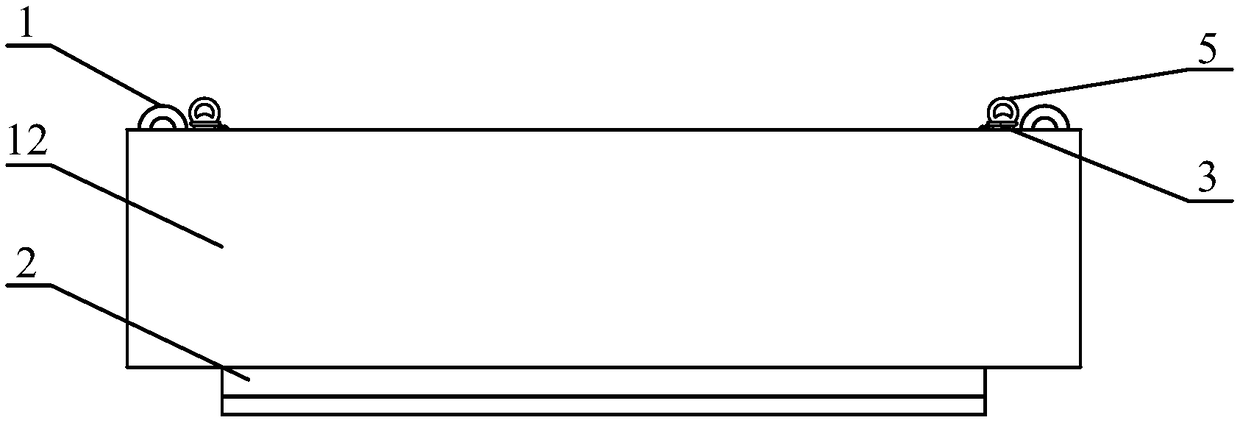

[0026] Such as Figure 1 to Figure 7 As shown, the sand bag stacking construction device for the treatment of submarine suspended pipelines includes: floating body 12, lifting lug 1, container bag 2, lifting ring 3, top pin hole 4, top pin 5, sand bag bin 6, sand bag 7, concave Groove 8, bearing bin 9, bearing bin pin hole 10, bearing bin pin 11.

[0027] The main body of the floating body 12 is a cuboid made of solid buoyant material with strong pressure resistance; the solid buoyant material can be buoyant materials such as chemical foam composite material, microsphere foam composite material or light synthetic composite material.

[0028] Four lifting lugs 1 are arranged on the top of the floating body 12; the four lifting lugs 1 are respectively located on the four corners of the top surface, and are symmetrical to the two center lines of the rectangle on the top surface. The lifting lug 1 is used to connect the hook of the land crane, thereby hoisting the sandbag stackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com