Double-degree-of-freedom sand blasting treatment device for submarine suspended pipeline

A degree of freedom and pipeline technology, applied in construction, infrastructure engineering and other directions, can solve the problems of uncontrollable whether the sand bag hits the pipeline, backward construction methods, time-consuming and labor-intensive, etc. The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

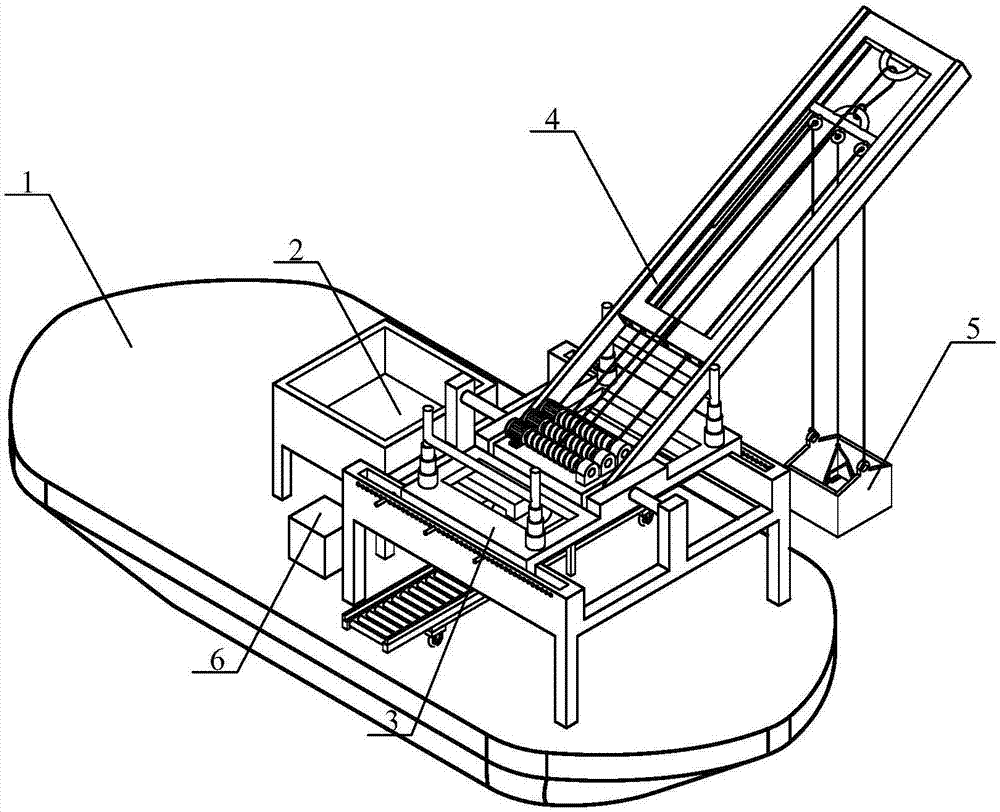

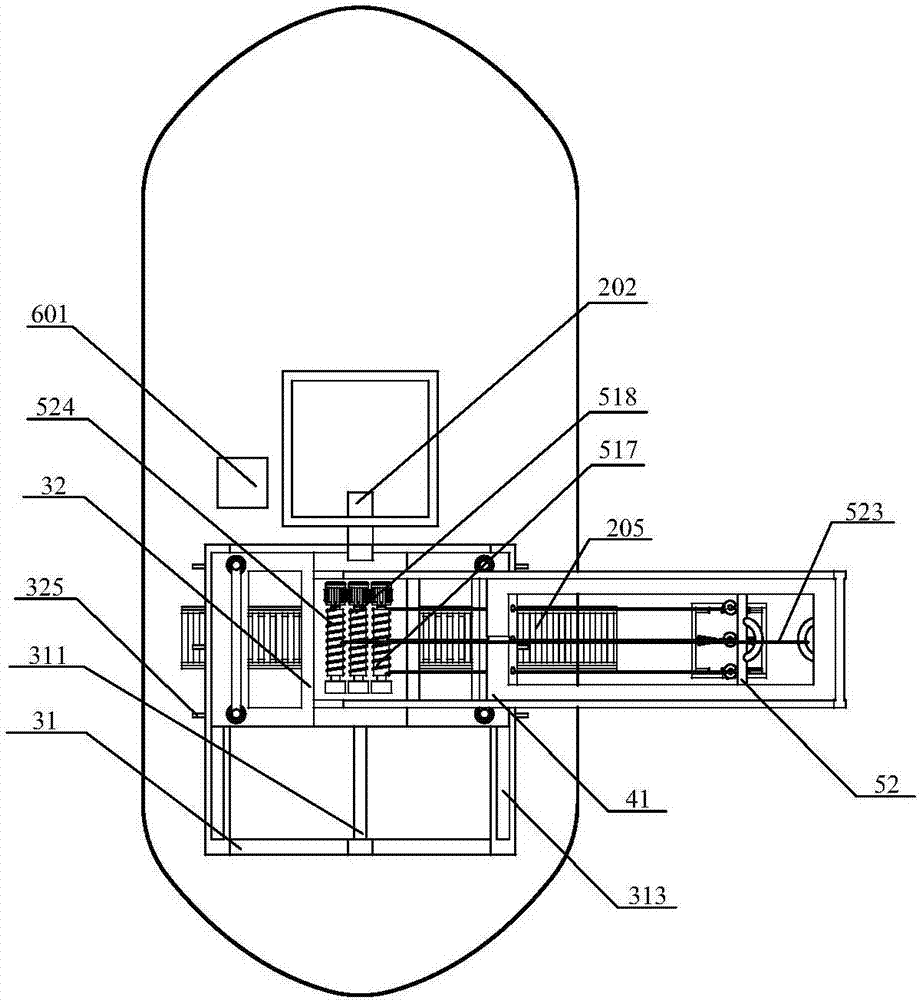

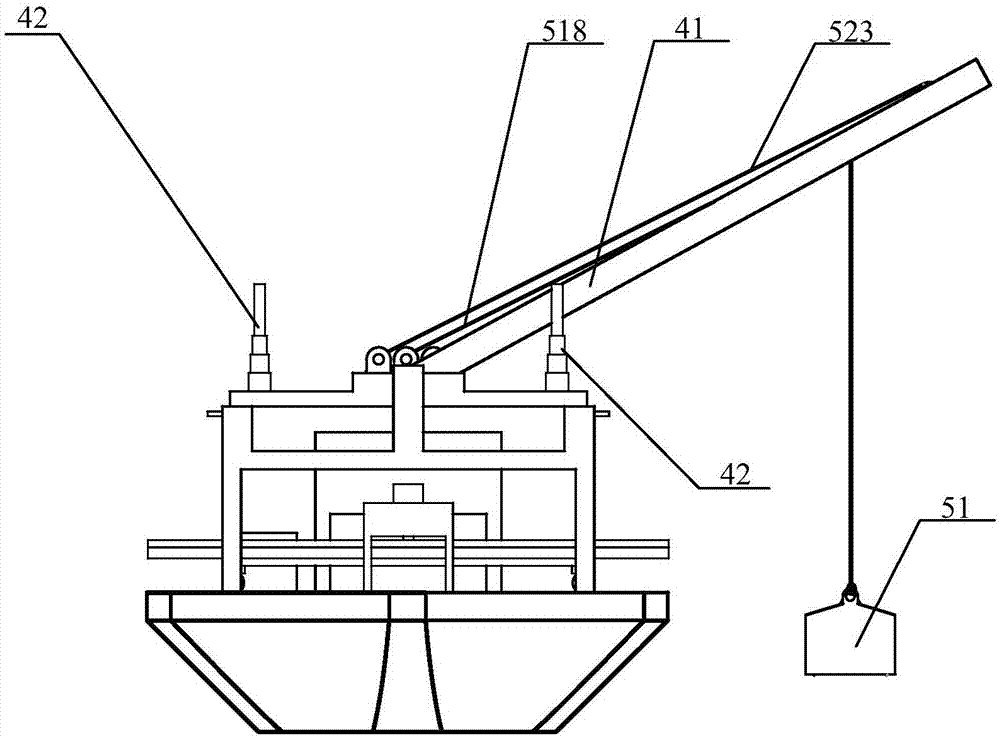

[0021] Figure 1 to Figure 8 As shown, the double-degree-of-freedom sand blasting device for suspended submarine pipelines is installed on the barge 1, including: packing structure 2, longitudinal feeding structure 3, transverse feeding structure 4, hoisting structure 5 and control structure 6; among them: packing structure 2 Complete the work of packing the sand into bags, the longitudinal feeding structure 3 and the horizontal feeding structure 4 carry out construction positioning and horizontal and vertical continuous construction control, the hoisting structure 5 completes the transfer of sand bags from the barge 1 to the suspended part of the submarine pipeline, and the control structure 6 Provide power supply and construction control for the whole device.

[0022] like figure 2 and Figure 4 As shown, the packing structure 2 is located in the middle of the deck of the barge 1, including: a sand storage area 201, a sand suction device 202, a sand transport square pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com