Novel reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

A new type of reinforced concrete technology, applied to building components, building structures, floor slabs, etc., can solve the problems of poor structural integrity, large steel consumption, self-heavy, etc., and achieve improved integrity, strong earthquake resistance, and improved ductility. anti effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

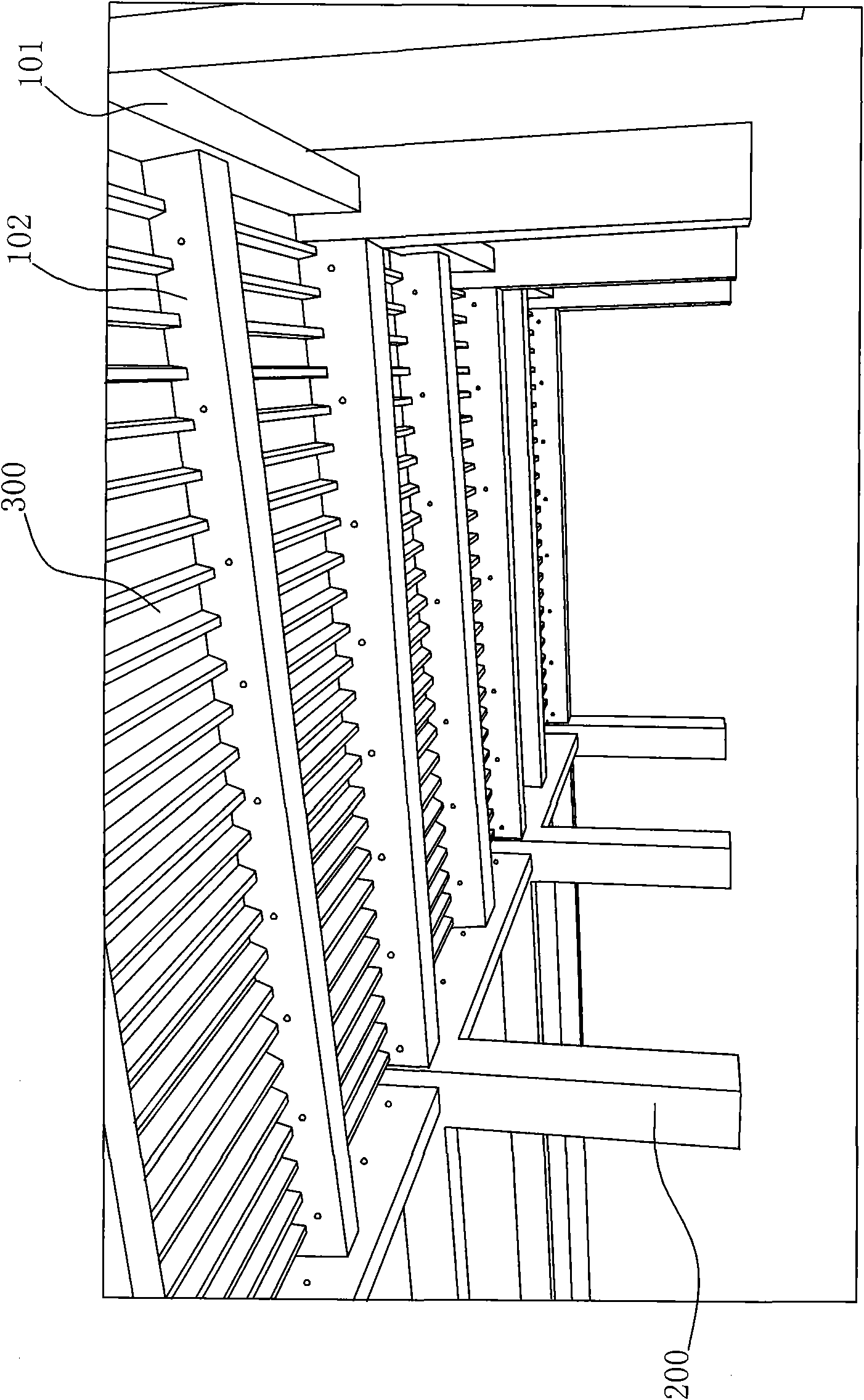

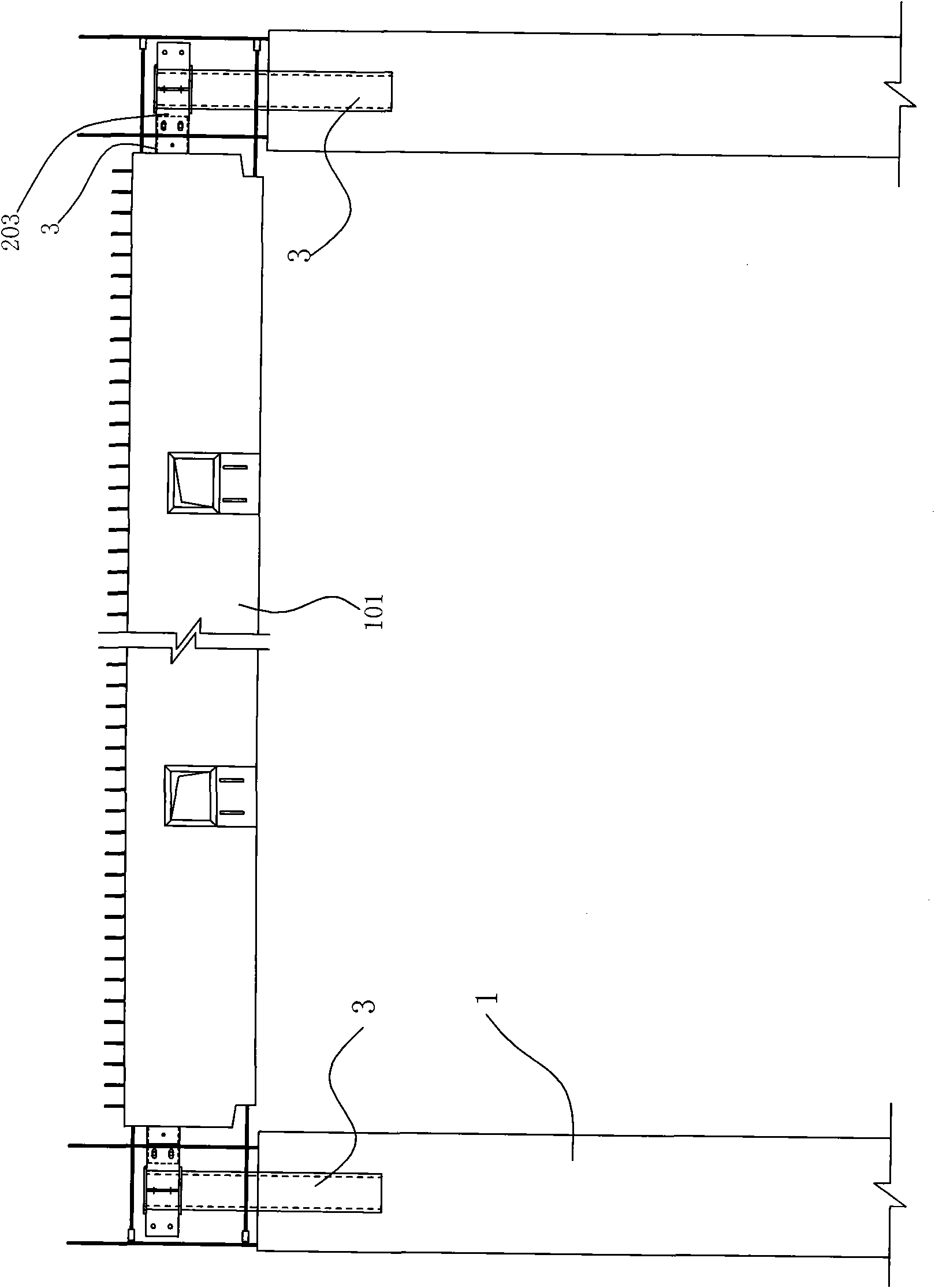

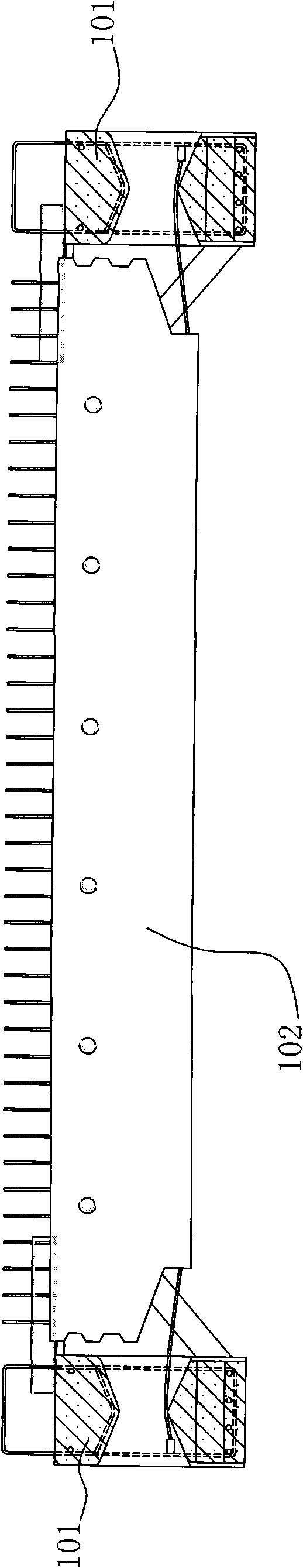

[0058] see Figure 1 to Figure 4 , an embodiment of a novel reinforced concrete prefabricated monolithic house structure system given in the present invention, including a floor 300, a laminated beam 100 supporting the floor 300, and columns 200 and / or shear walls, the laminated Composite beam 100 is divided into main beam 101 and secondary beam 102, and described main beam 101 is used for connecting described column 200 and / or shear wall, and described secondary beam 102 is connected on described main beam 101, and described composite The beam includes a prestressed prefabricated beam and a cast-in-place part, wherein the prestressed prefabricated beam includes a beam body 1 and a prestressed steel strand 2 embedded in the beam body 1 as a main reinforcement, and at least one end of the beam body 1 is set There is a section steel 3 suitable for connecting with the external structure, part of the section steel 3 is embedded in the beam body 1, and the rest is exposed at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com