Precast concrete member connected by straight thread and pier head lock anchor grouting sleeve, and method for assembling same

A technology of prefabricated concrete and prefabricated components, which is applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of low reliability, loss of life and property, and unexperienced problems, so as to reduce the amount of steel and grouting, Saving of life and property damage, reduction of height and diameter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

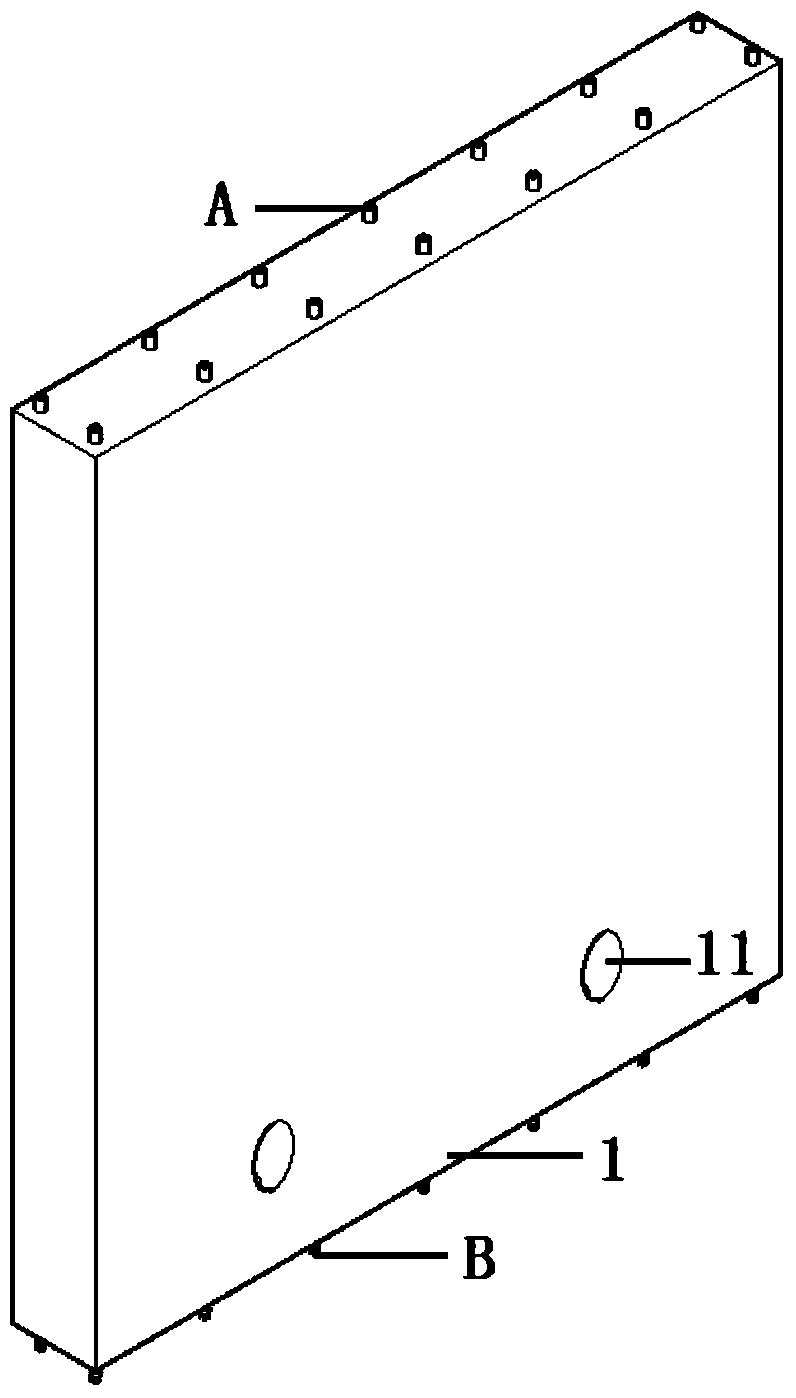

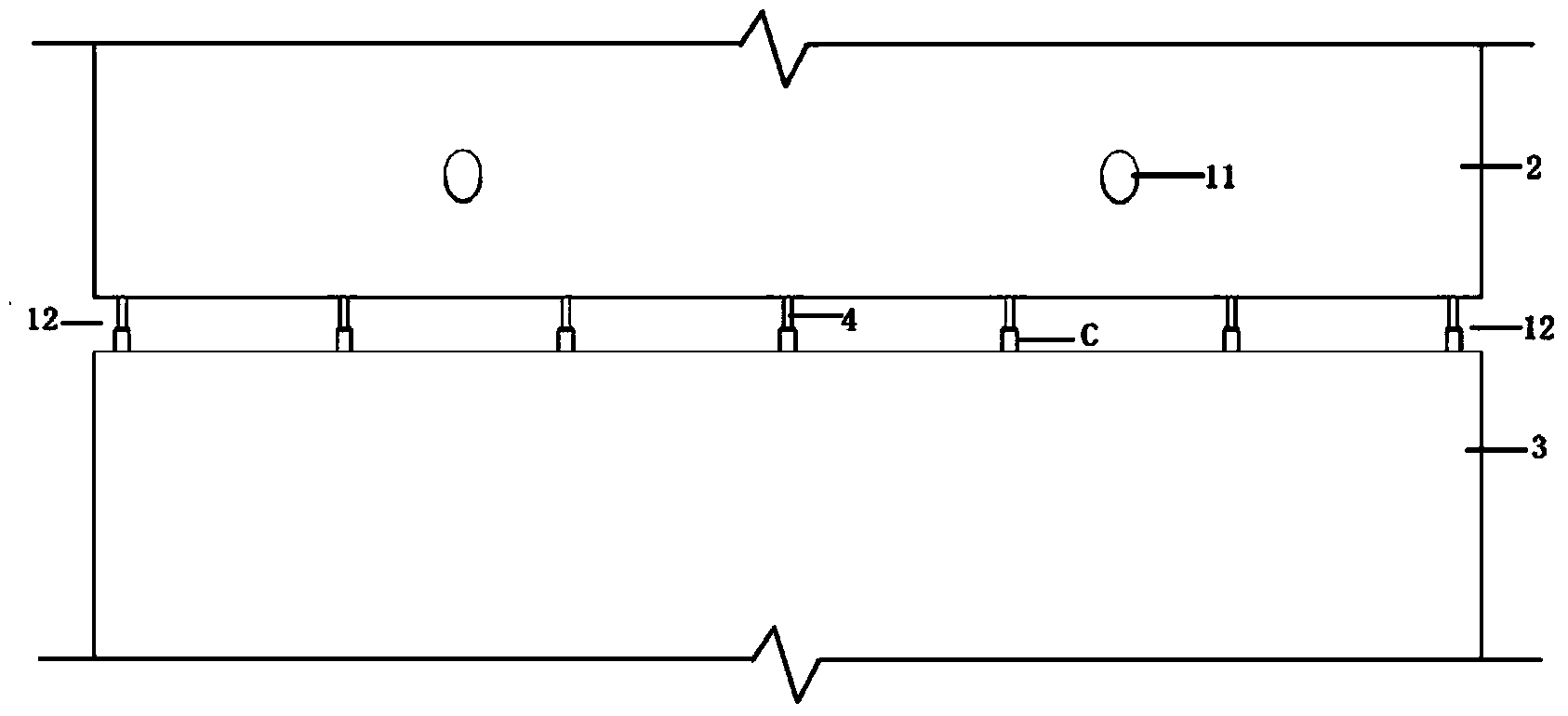

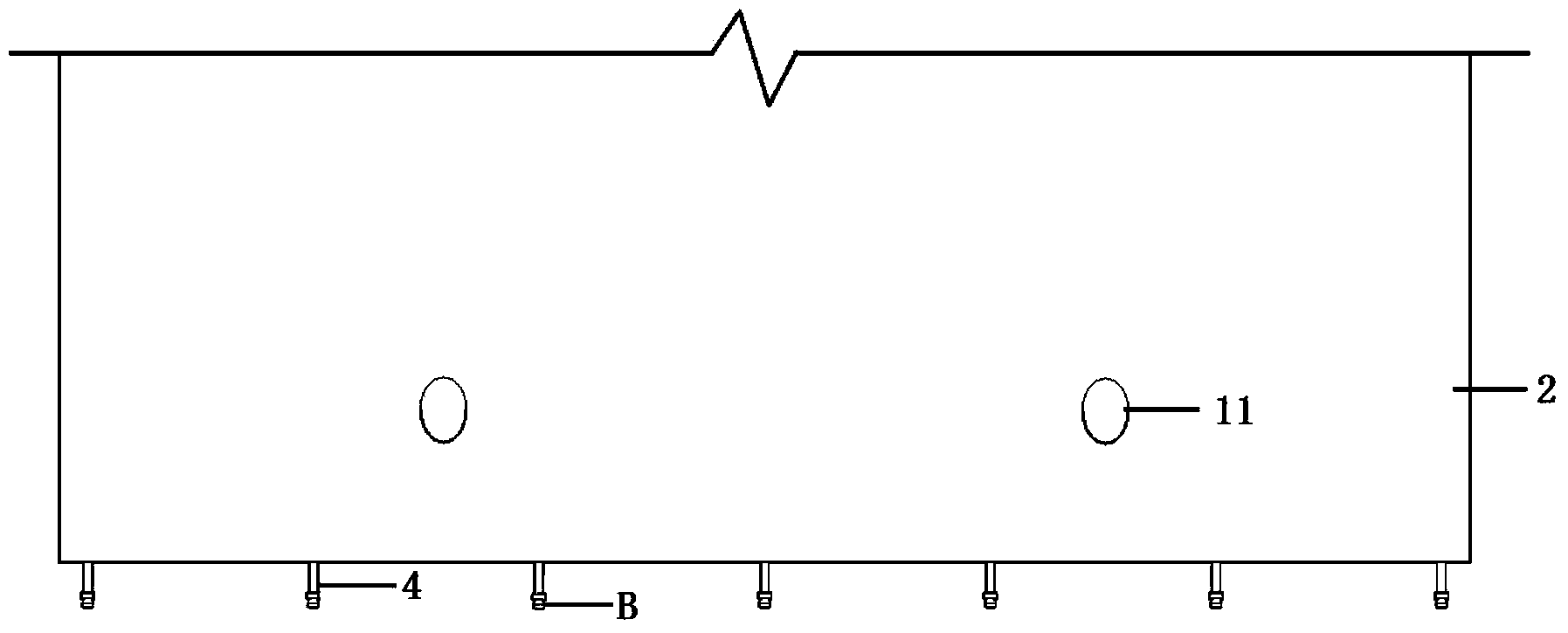

[0038] Such as Figure 1 to Figure 13 As shown, the assembled concrete shear wall connected with the straight thread and the pier head lock anchor grouting sleeve is composed of prefabricated concrete shear wall connected by the pier head lock anchor grouting sleeve in the cast-in-place zone; the prefabricated concrete shear wall described here The components are the upper wall and the lower wall.

[0039] The assembled concrete member that the straight thread is connected with the pier head lock anchor grouting sleeve includes the vertical reinforcement 4 of the upper wall, the vertical reinforcement 13 of the lower wall, the vertical reinforcement 4 of the upper wall and the vertical reinforcement 13 of the lower wall Connected to each other through the sleeve 7; the upper end of the sleeve 7 is provided with an internal thread 16, and the side of the sleeve 7 is provided with a grouting hole 8; the ends of the vertical reinforcement 4 of the upper wall and the vertical rein...

Embodiment 2

[0050] Such as Figure 14-15 As shown, in this embodiment, the prefabricated concrete beams connected with the pier head lock anchor grouting sleeve, the assembled concrete beams and the practice are similar to those in Example 1, and can be referred to Figure 1-9 . The prefabricated components are prefabricated concrete beams: a prefabricated beam 18 on one side and a prefabricated beam 19 on the other side, and the prefabricated beam 18 on one side and the prefabricated beam 19 on the other side are connected by a sleeve 7 . The difference is that there is no need to set construction holes in the prefabricated beam 18 on one side and the prefabricated beam 19 on the other side, and the concrete is directly poured between the prefabricated beam 18 on one side and the prefabricated beam 19 on the other side to form a cast-in-place belt 12; One side of the end also has a plugging pad; a grouting hole and a grouting hole will be set on the sleeve 7 tops placed horizontally, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com