Patents

Literature

41results about How to "Uniform crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

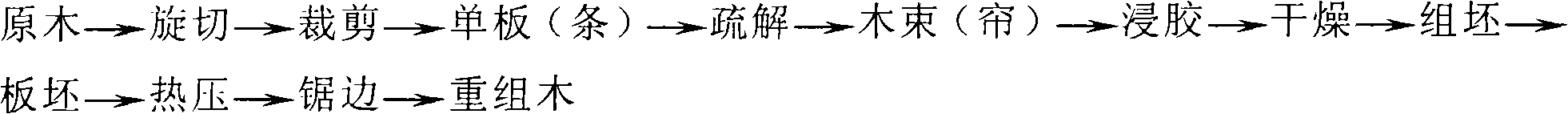

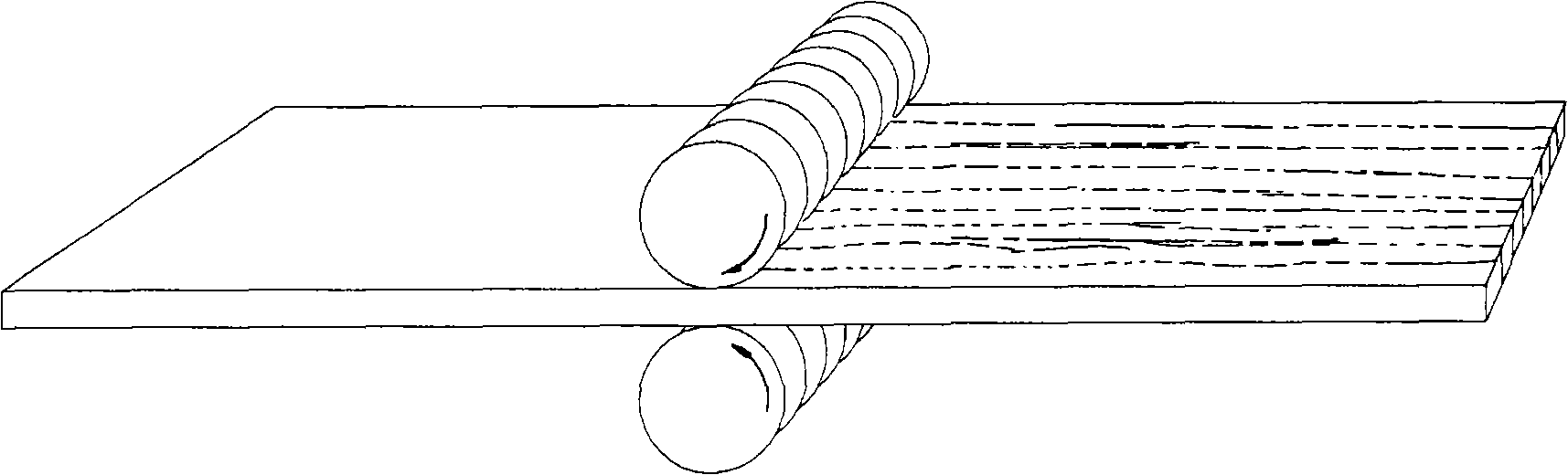

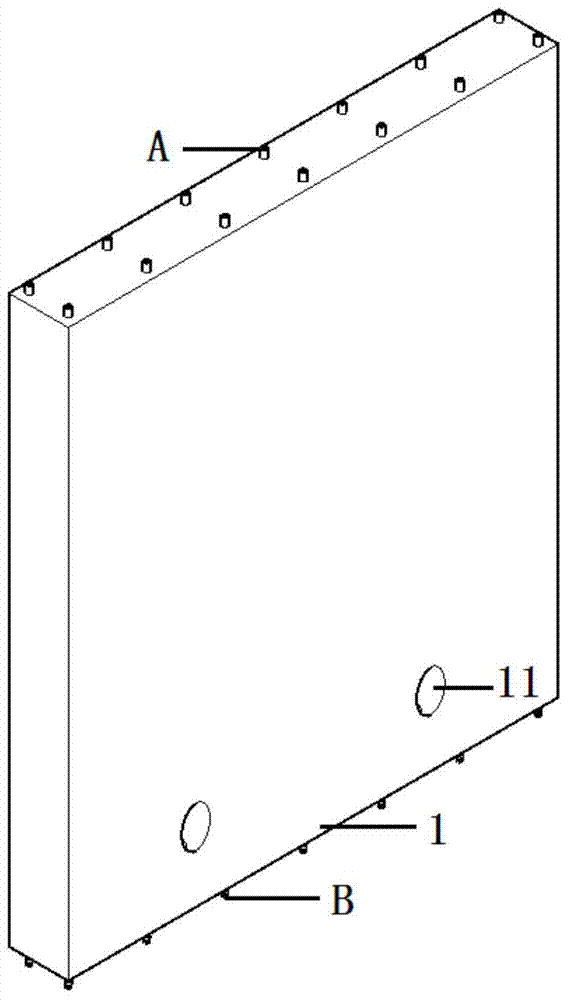

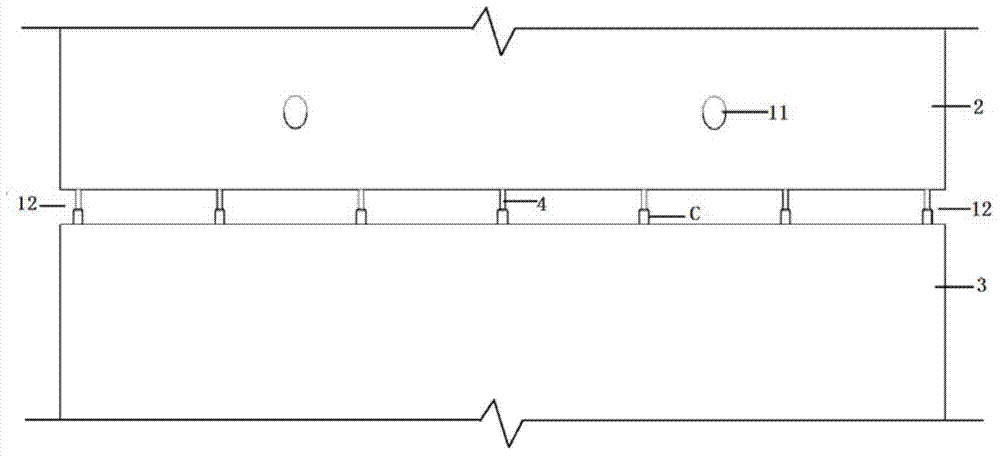

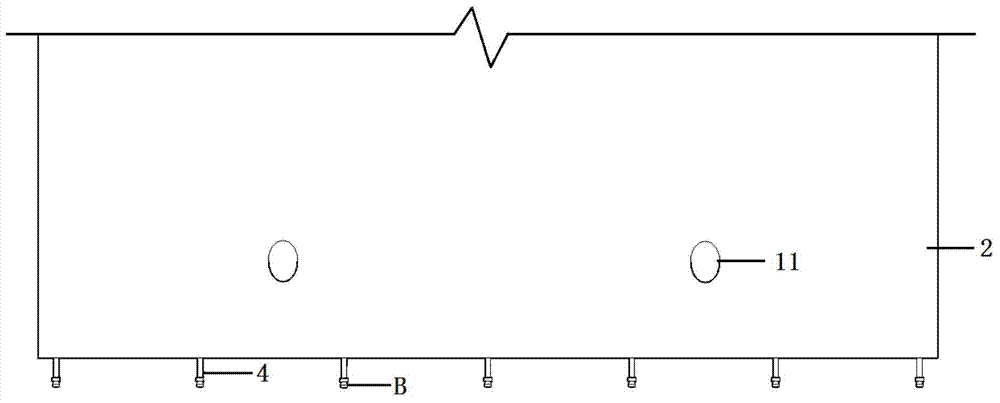

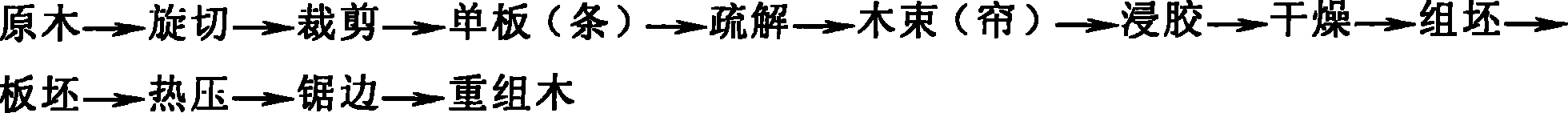

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

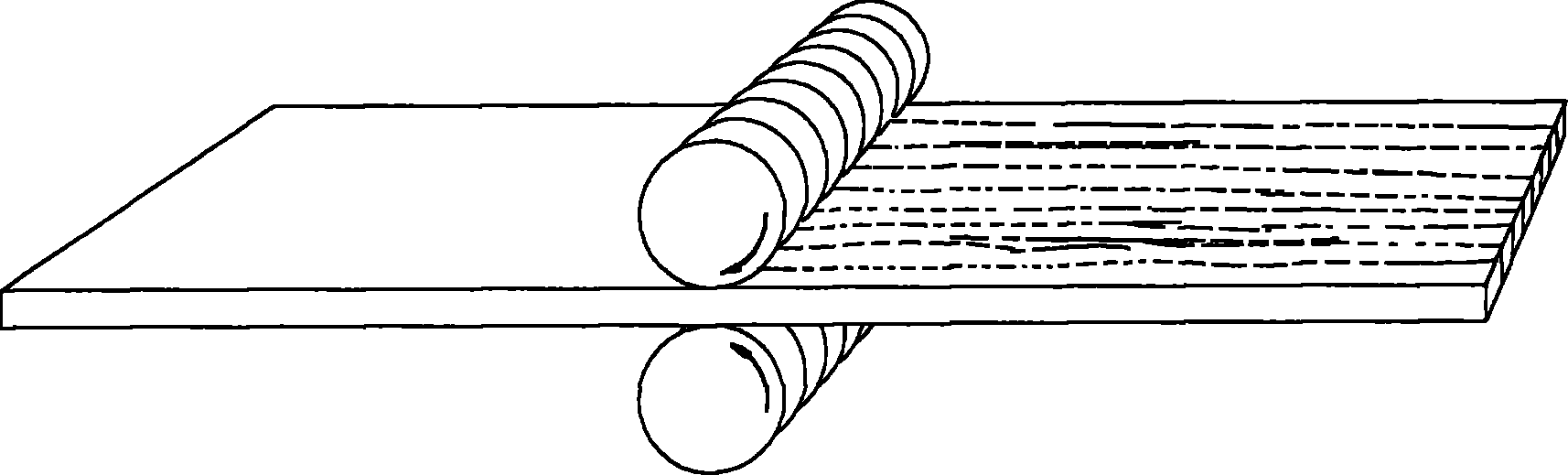

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

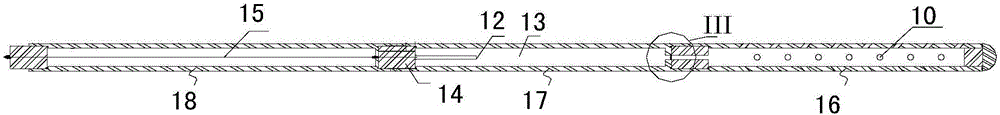

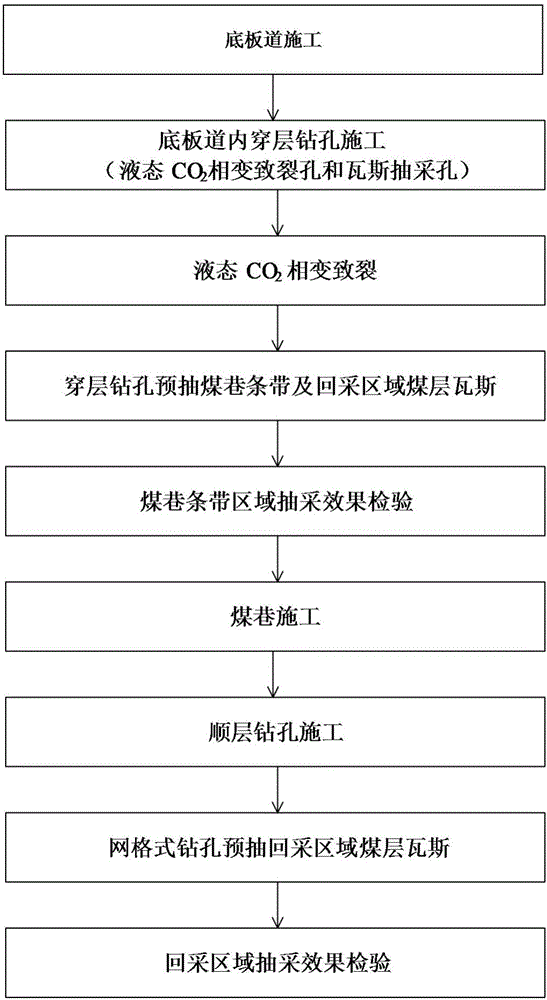

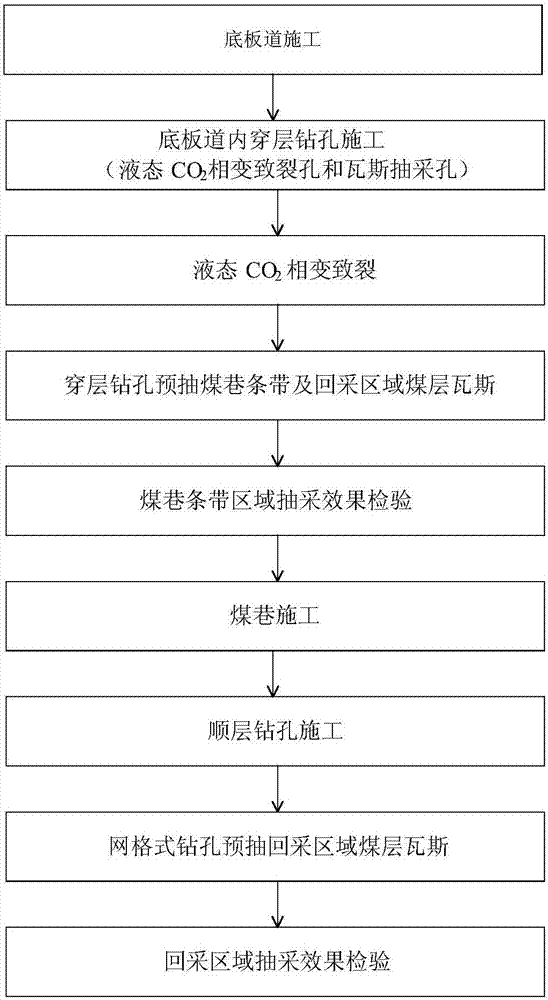

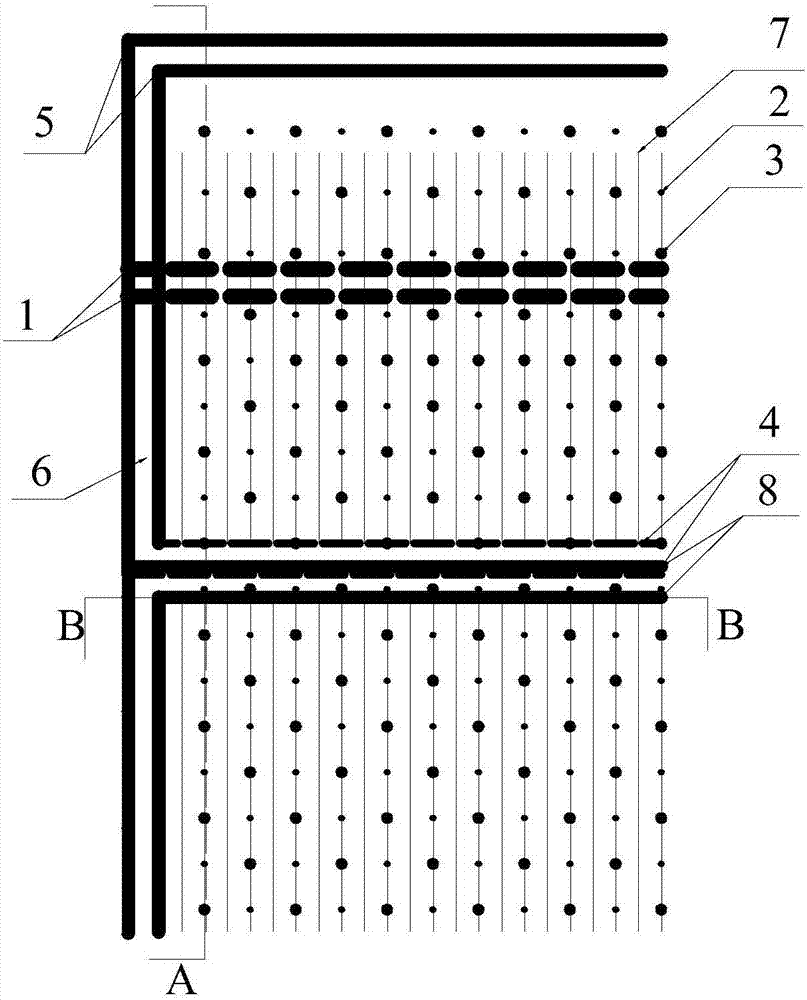

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

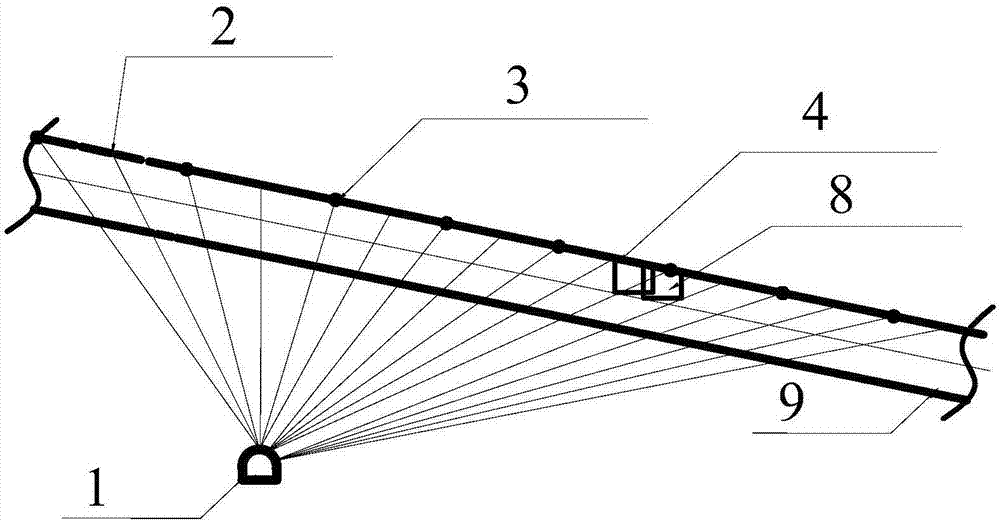

Precast concrete member connected by straight thread and pier head lock anchor grouting sleeve, and method for assembling same

The invention relates to a precast concrete member connected by a straight thread and a pier head lock anchor grouting sleeve, and a method for assembling the precast concrete member, belonging to the technical field of constructional engineering assembly concrete structures. The method of connecting by the straight thread and the pier head lock anchor grouting sleeve is adopted; one end of a reinforcing steel bar is processed into the straight thread (6), and the other end of the reinforcing steel bar is processed into a pier head (5); the inner wall of the end with smaller diameter of a connecting sleeve is processed into a thread (9) which is connected with the reinforcing steel by the straight thread (6) and is used for transmitting force; the inner wall of the end with larger diameter of the connecting sleeve is processed into a thread (16) which is connected with a matched plug ring (10) by an external thread (17); after grouting is carried out through a grouting hole, the original way that the tensile force of the reinforcing steel bar of a prefabricated part connected by grouting is transmitted mainly by bonding is changed by the reinforcing steel bar through lock anchor extrusion and bonding force transmission among the pier head of the reinforcing steel bar, the plug ring, grouting material and the sleeve. The safety and economical efficiency of the connection of the novel precast concrete member are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

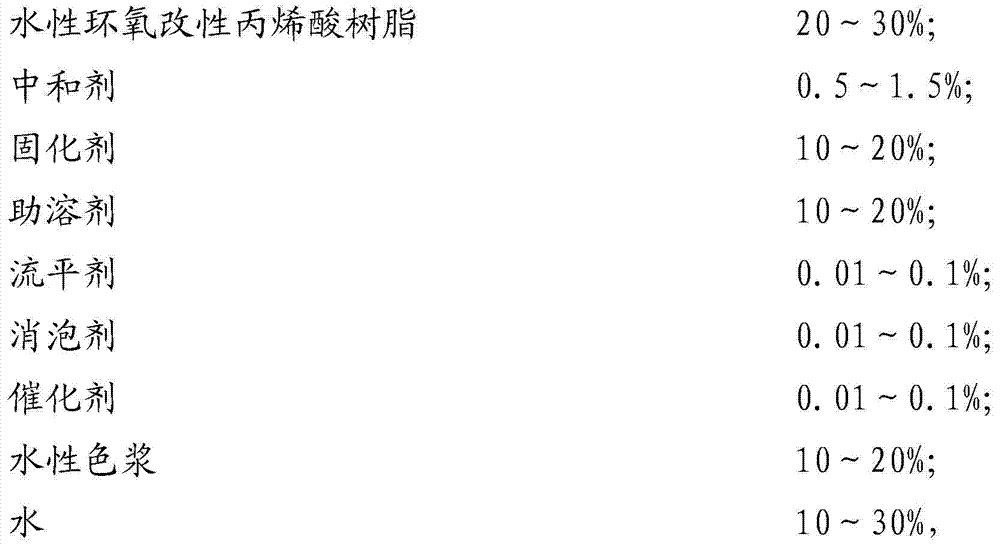

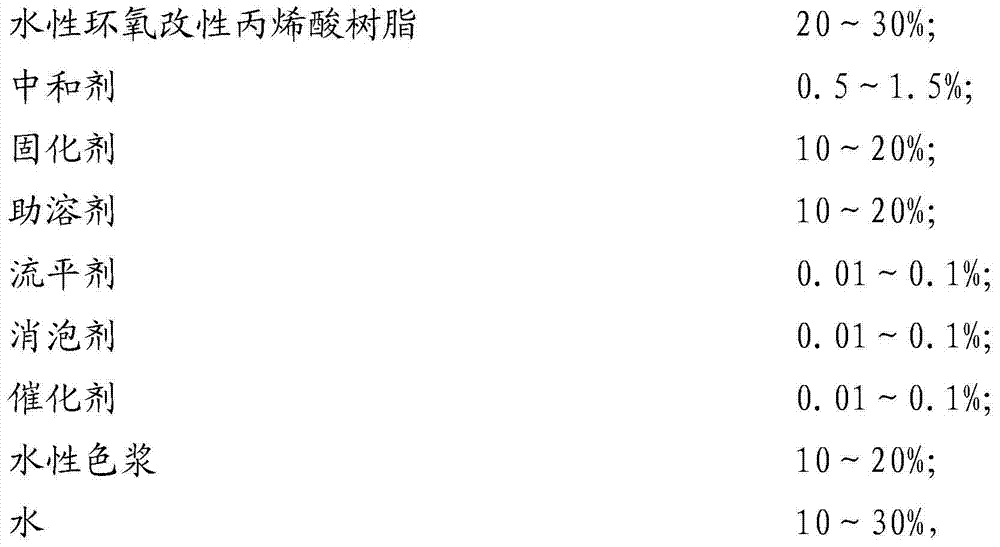

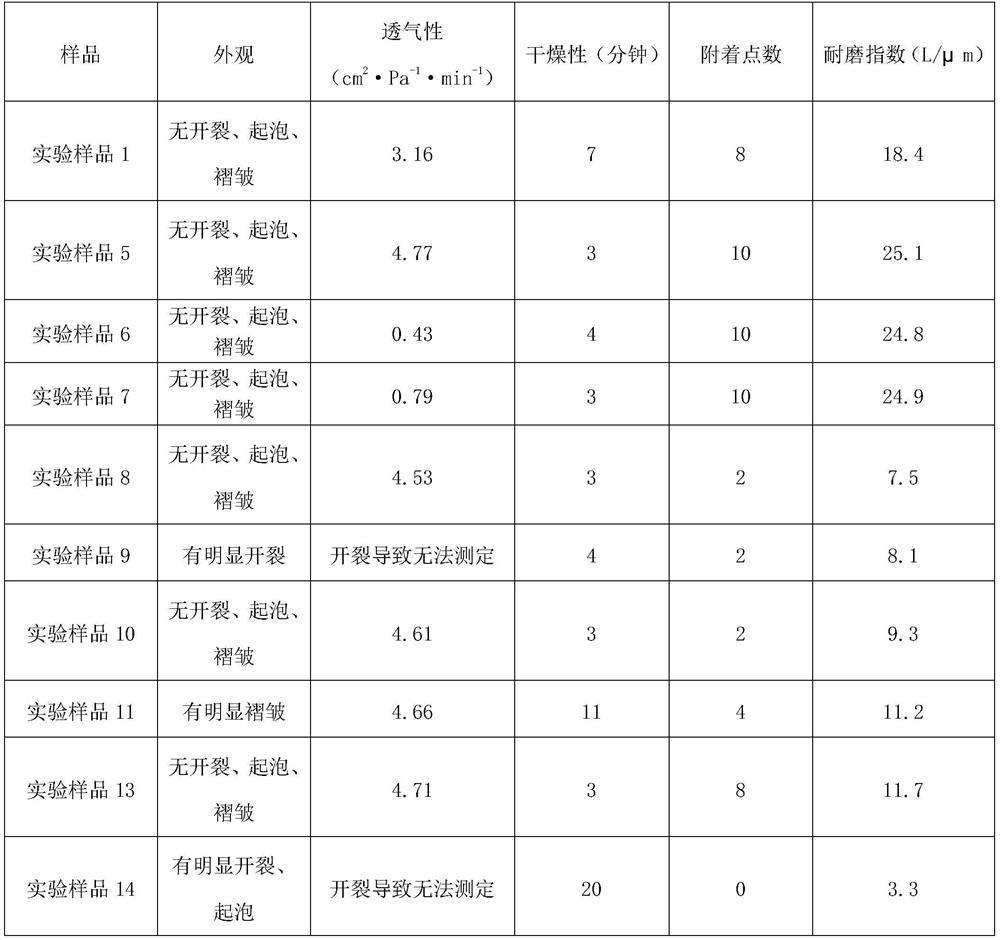

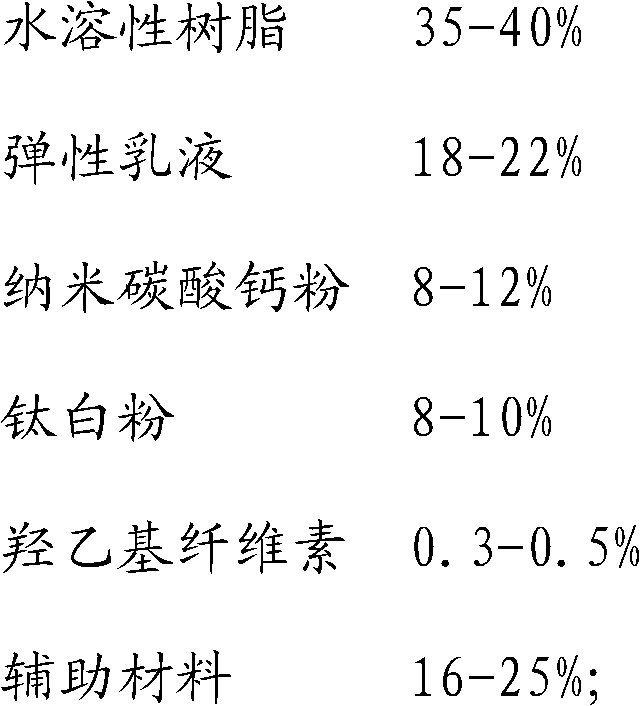

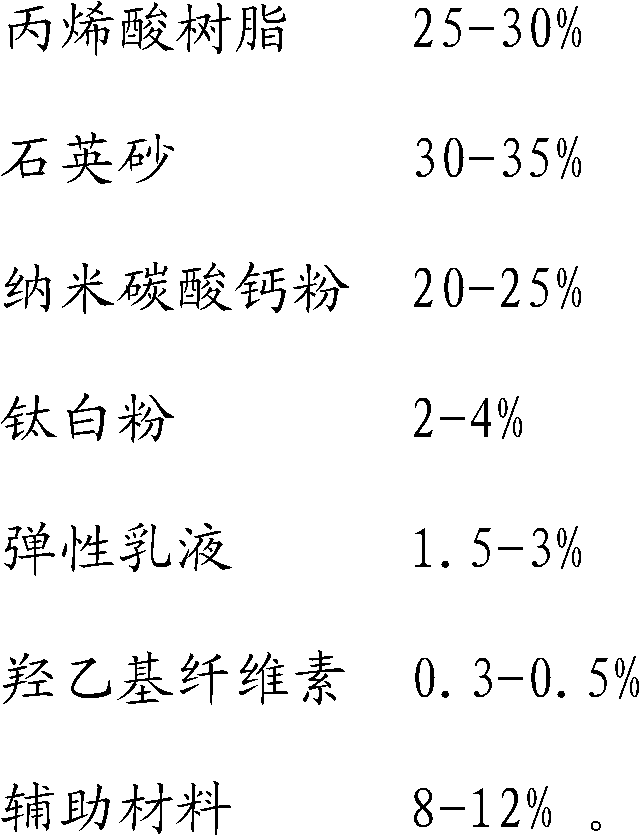

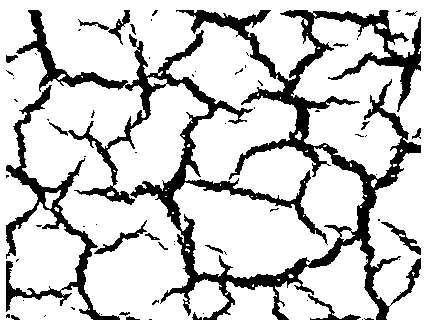

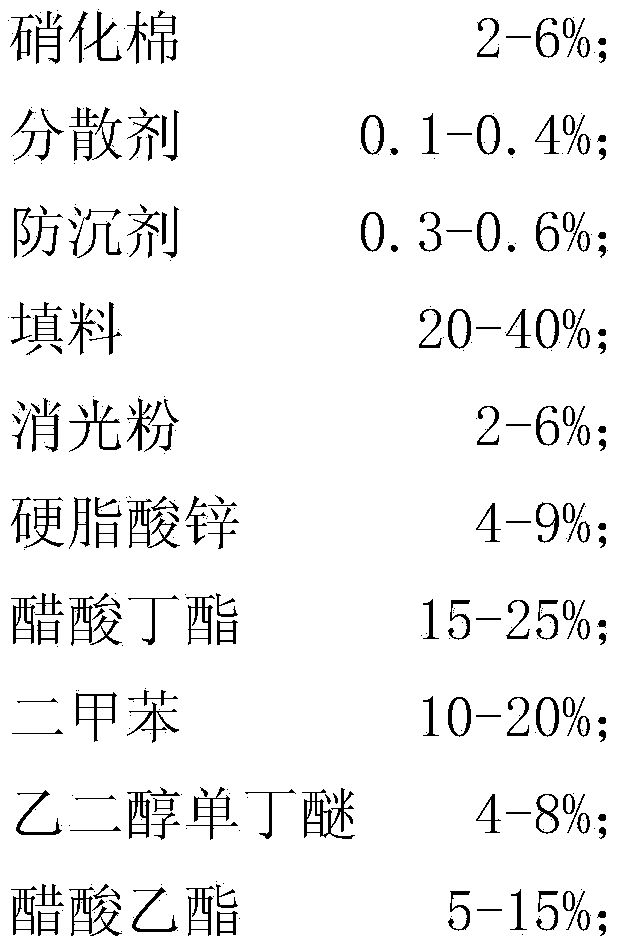

Environment-friendly water-based crack lacquer and application method thereof

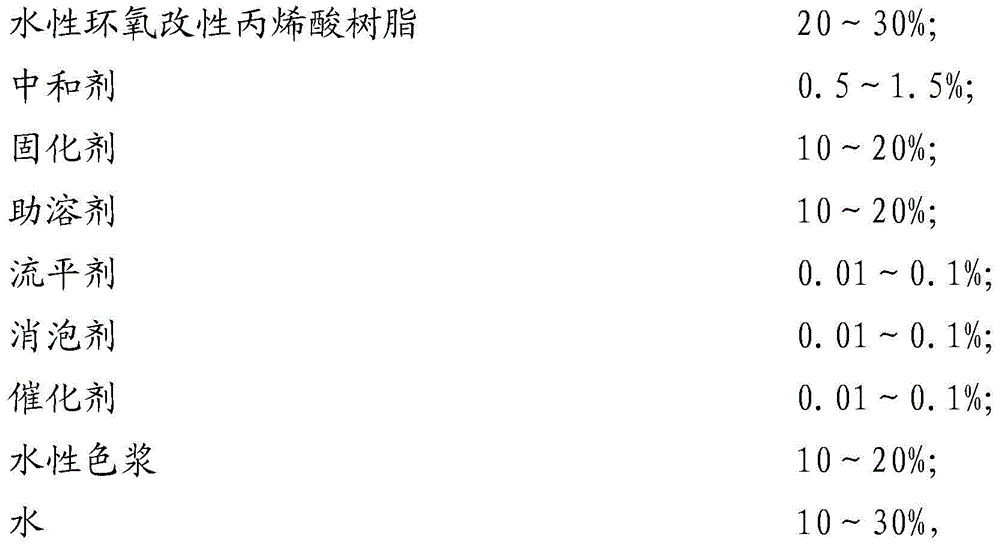

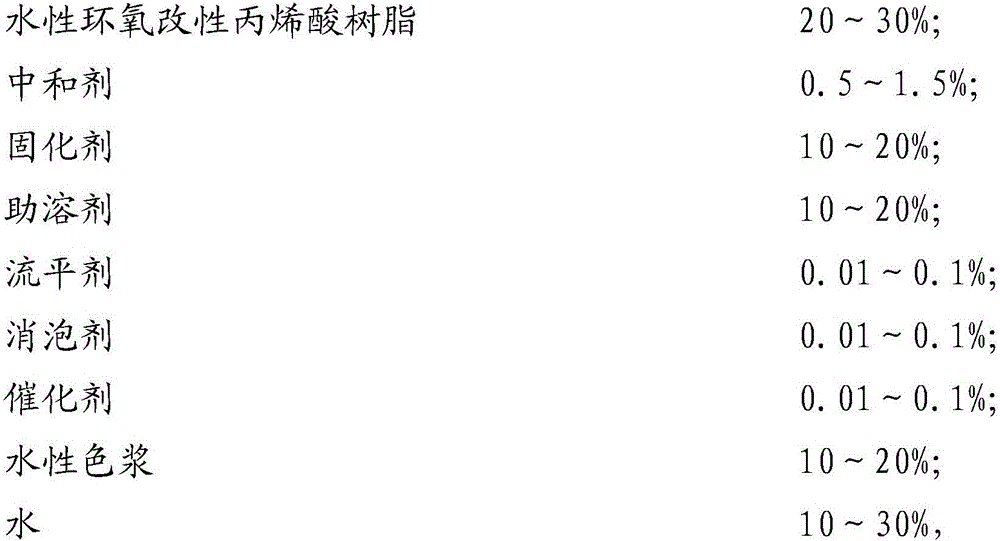

The invention discloses an environment-friendly water-based crack lacquer and an application method thereof. The n environment-friendly water-based crack lacquer comprises a water-based crack primer and a water-based crack finishing coat; the water-based crack primer is prepared from such components in percentage by weight as 20-30% of water-based epoxy modified acrylic resin, 0.5-1.5% of neutralizer, 10-20% of curing agent, 10-20% of cosolvent, 0.01-0.1% of flatting agent, 0.01-0.1% of defoamer, 0.01-0.1% of catalyst, 10-20% of water-based color paste and 10-30% of water; the water-based crack finishing coat is prepared from such components in percentage by weight as 60-80% of styrene-acrylic emulsion, 1-2% of neutralizer, 15-40% of water-based color paste and 0.01-0.1% of water-based crack agent. Compared with the correlation techniques, the environment-friendly water-based crack lacquer has the beneficial effects of high environmental friendliness and safety performance, excellent decoration effect and strong adhesion.

Owner:湖南天氟新材料有限公司

Precast concrete members connected by locking and anchoring pier heads and grouting variable diameter sleeve, prefabricated concrete member and manufacturing method of prefabricated concrete member

InactiveCN104264909AReduce the overall heightReduce the overall diameterWallsBuilding reinforcementsRebarPrecast concrete

The invention provides precast concrete members connected by locking and anchoring pier heads and grouting a variable diameter sleeve, a prefabricated concrete member and a manufacturing method of the prefabricated concrete member, belonging to the technical field of prefabricated concrete structures in architectural engineering. A sleeve connection method for transferring forces based on extrusion and bonding is adopted, a pier head (5) and a pier head (6) are processed at the two ends of rebars, one end of a connecting sleeve (7) adopts the sleeve inner diameter smaller than the outer diameter of the rebar pier head (6) at the corresponding end, a plugging ring (10) with an inner diameter smaller than the outer diameter of the rebar pier head (5) at the corresponding end is adopted at the other end of the connecting sleeve, and the rebars transfer forces by utilizing locking and anchoring extrusion and bonding among the pier heads, the plugging ring, the grouting materials and the sleeve through sleeve grouting, thus changing the previous mode that the pull of the rebars of the precast concrete members connected through grouting is mainly transferred through bonding. The safety and economy of connection of the novel precast concrete members are improved to some extent.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

Prefabricated concrete member, assembled concrete member and fabricating method through straight thread and nut locking anchor grouting sleeve connection

The invention discloses a prefabricated concrete member, an assembled concrete member and a fabricating method through straight thread and nut locking anchor grouting sleeve connection and belongs to the technical field of assembled concrete structures of constructional engineering. A method of straight thread and nut locking anchor grouting sleeve connection is applied, one end of a reinforcing steel bar is machined to form a straight thread (6), a nut (5) is connected with the other end of the reinforcing steel bar, the inner wall of a small-diameter end of a connecting sleeve is machined to form a screw thread (9) so as to be connected with the reinforcing steel bar through the straight thread (6) to transmit force, the inner wall of a large-diameter end of the connecting sleeve is machined to form a screw thread (16) so as to be connected with a matched blocking ring (10) through an external thread (17), after grouting through a grouting hole (8), the pulling force of the reinforcing steel bar is transmitted through locking anchor extruding and cementation among the reinforcing steel bar nut, the blocking ring, a grouting material and the sleeve, and traditional methods that pulling forces of reinforcing steel bars of prefabricated members through grouting connection are mainly transmitted through cementation are changed. According to the prefabricated concrete member, the assembled concrete member and the fabricating method through straight thread and nut locking anchor grouting sleeve connection, the connection of the novel prefabricated concrete member is improved in terms of safety and economical efficiency.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

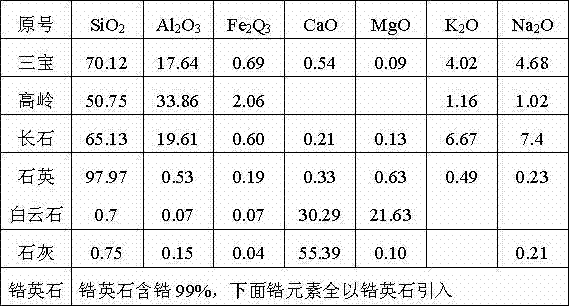

Method for manufacturing official kiln imitated crackle glaze ceramic product

The invention discloses a formula of an official kiln imitated crackle glaze material, wherein a small deal of zirconite is introduced to the formula, and through the reasonable matching ratio of all components, the glaze material is wide in adaptability, good in heat stability as well as gentle and jade-like in glazing color. The invention also discloses a method for manufacturing an official kiln imitated crackle glaze ceramic product by using the official kiln imitated crackle glaze material, wherein the ball milling fineness of the glaze material is mastered, and the ceramic blank biscuit firing and glaze firing times, temperature and glaze applying thickness are controlled, so that large official kiln crackle pieces appear after a glazing surface is subjected to thermal expansion and cold shrinkage. The method has the characteristics of science, reasonability, easiness for implementation, high rate of finished products, good ceramic quality, clear, simple, unsophisticated and elegant crackle pieces and uniform glaze layer crackles and can form the visual artistic effect that the jade-like stone is as thick as accumulated fat.

Owner:汤秋影

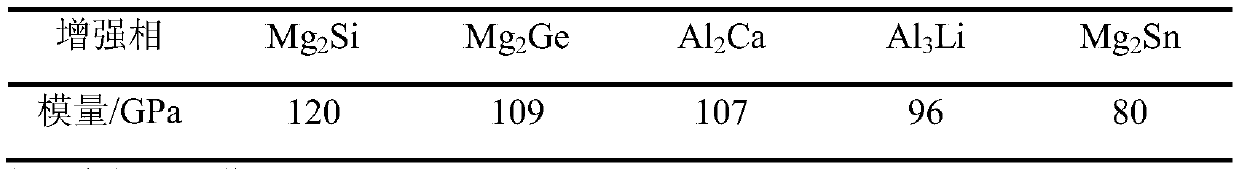

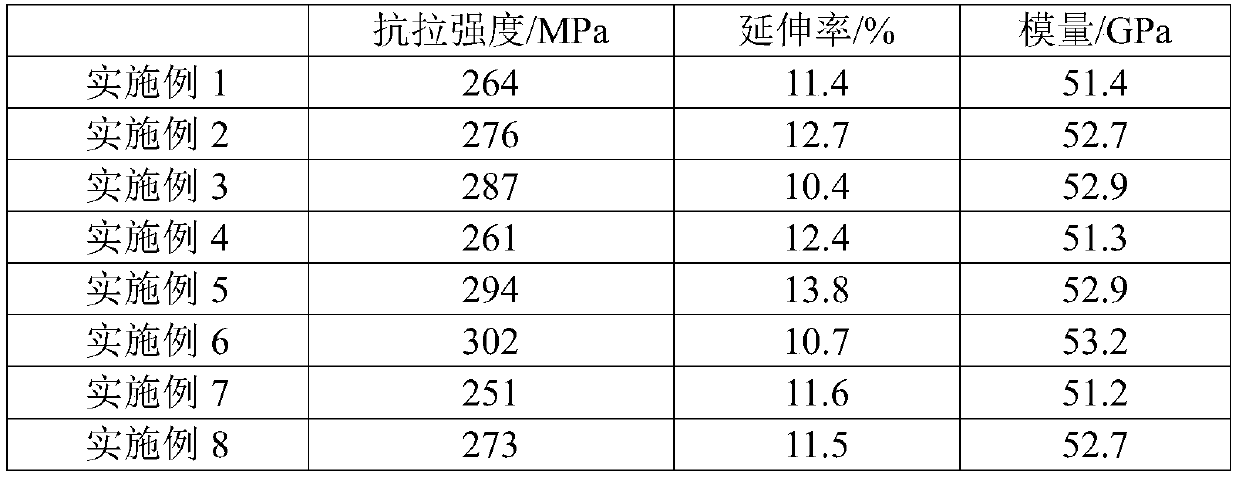

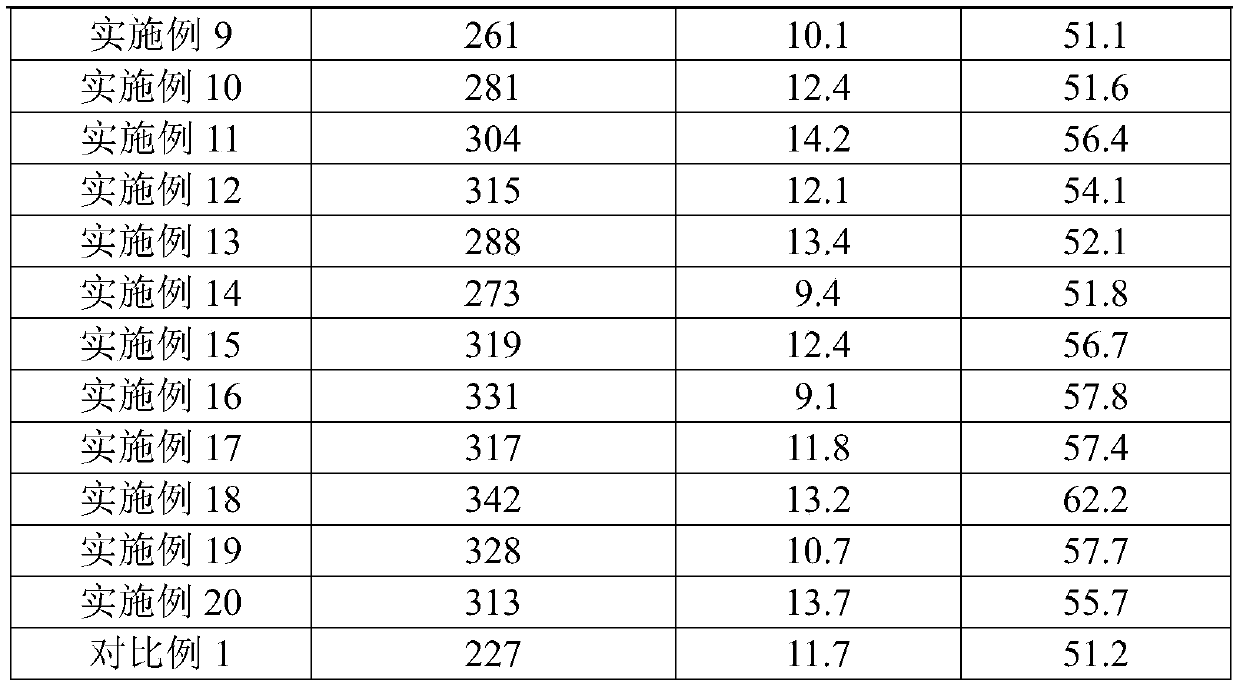

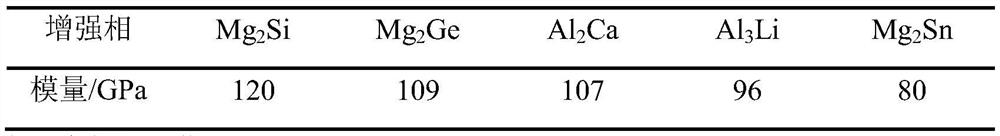

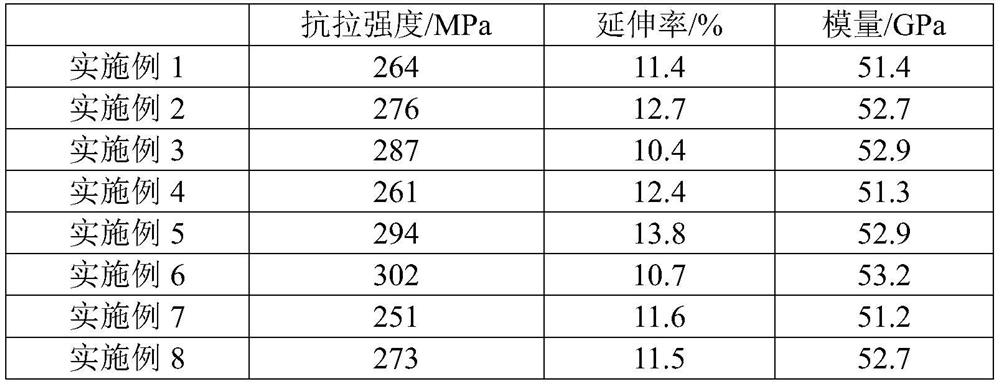

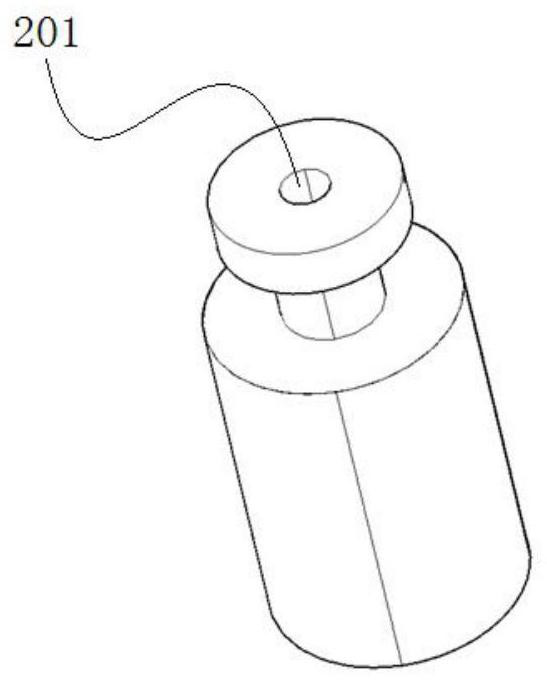

High-strength high-toughness high-modulus deformed magnesium alloy and preparation method thereof

The invention discloses a high-strength high-toughness high-modulus deformed magnesium alloy and a preparation method thereof. The high-strength high-toughness high-modulus deformed magnesium alloy iscomposed of the following elements of, by mass, a% of Al, b% of one of La, Ce and Pr or b% of a mixture of several of the La, the Ce, the Pr, c% of Mn, a total of d% of one or several of RE rare earth elements Gd, Y, Sm, Nd, Er, Eu, Ho, Tm, Lu, Dy and Yb, a total of e% of one or several of Si, Ge, Ca, Li, Sn, Zn and Sb, a total of less than 0.2% of impurities and the balance Mg, wherein the a, the b, the c, the d and the e meet the requirements that the a is greater than or equal to 3.5 and less than or equal to 6.0, the b is greater than or equal to 0.5 and less than or equal to 4.5, the c is greater than or equal to 0.01 and less than or equal to 1.0, the d is greater than or equal to 0.01 and less than or equal to 2.5, and the e is greater than 0 or less than or equal to 4.0. A raw material are preheated, melted and cast to obtain a magnesium alloy cast ingot, the magnesium alloy cast ingot undergoes hot extrusion or hot forging or hot rolling to obtain the magnesium alloy deformedpiece, the method is simple, the process stability is good, and the controllability is high.

Owner:SHANGHAI JIAO TONG UNIV +2

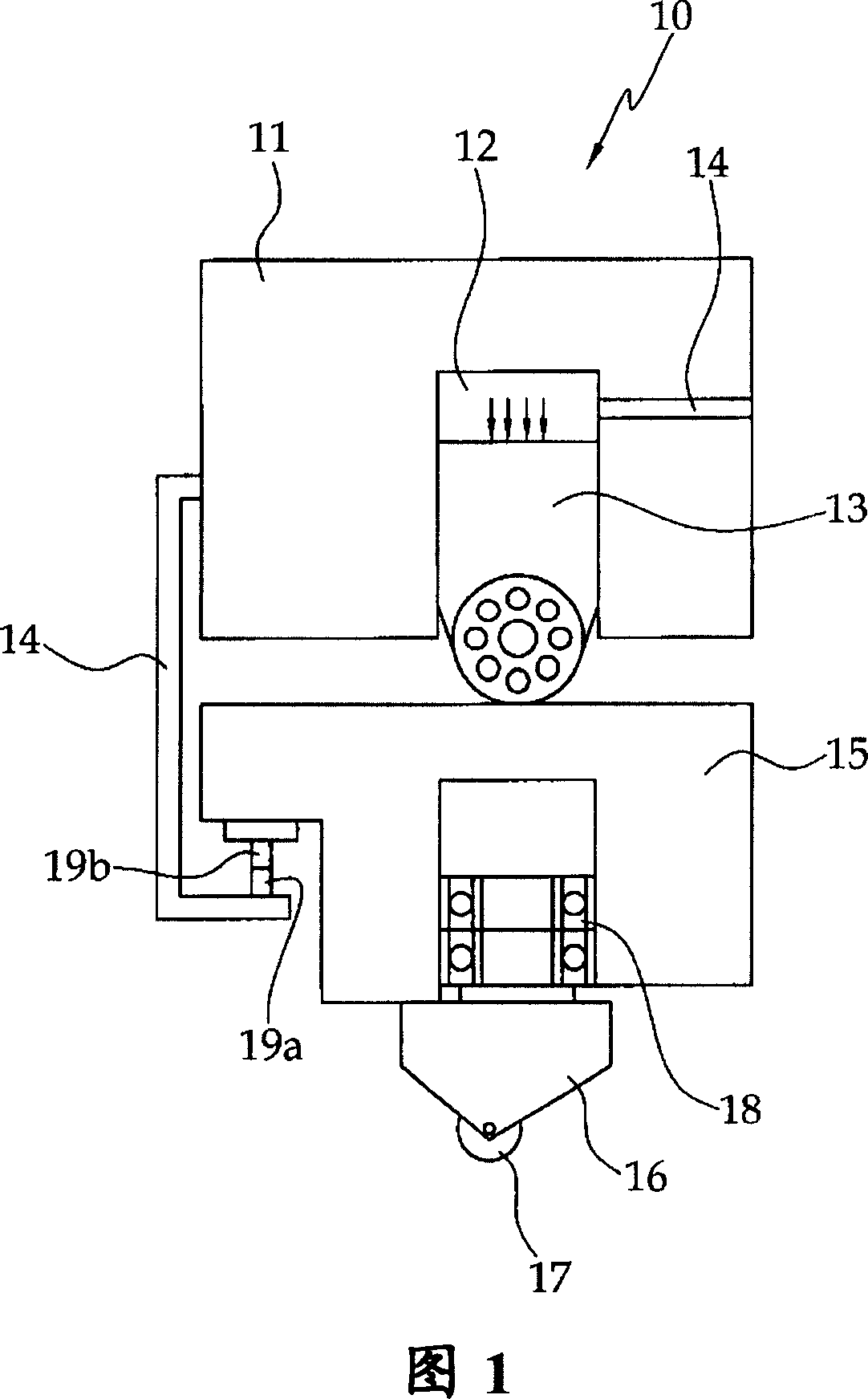

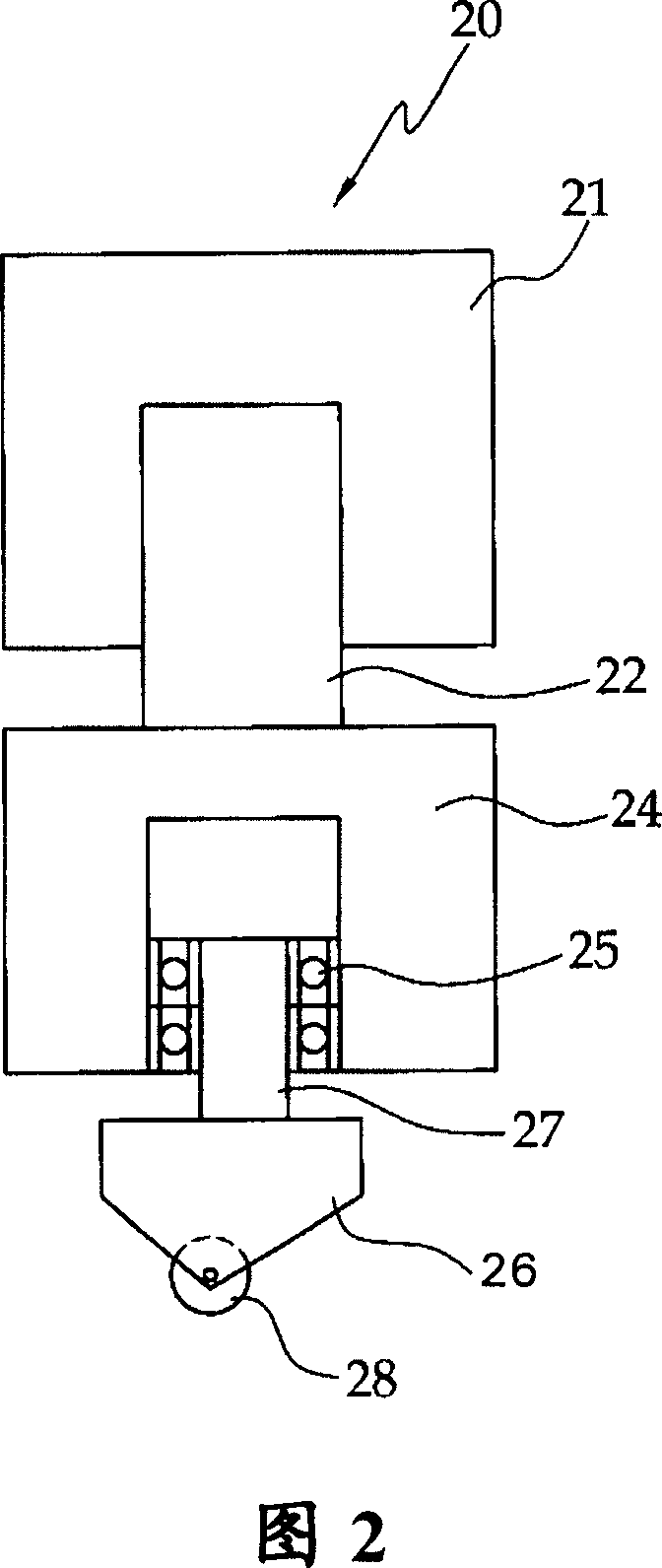

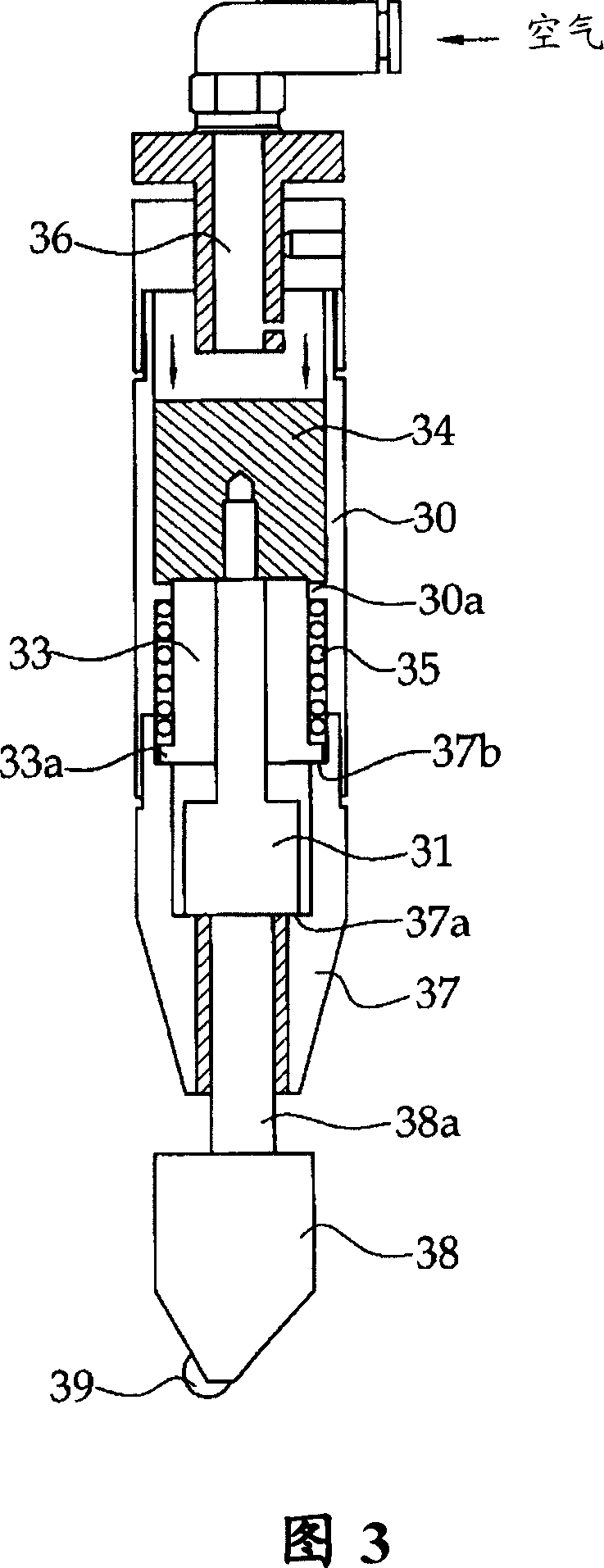

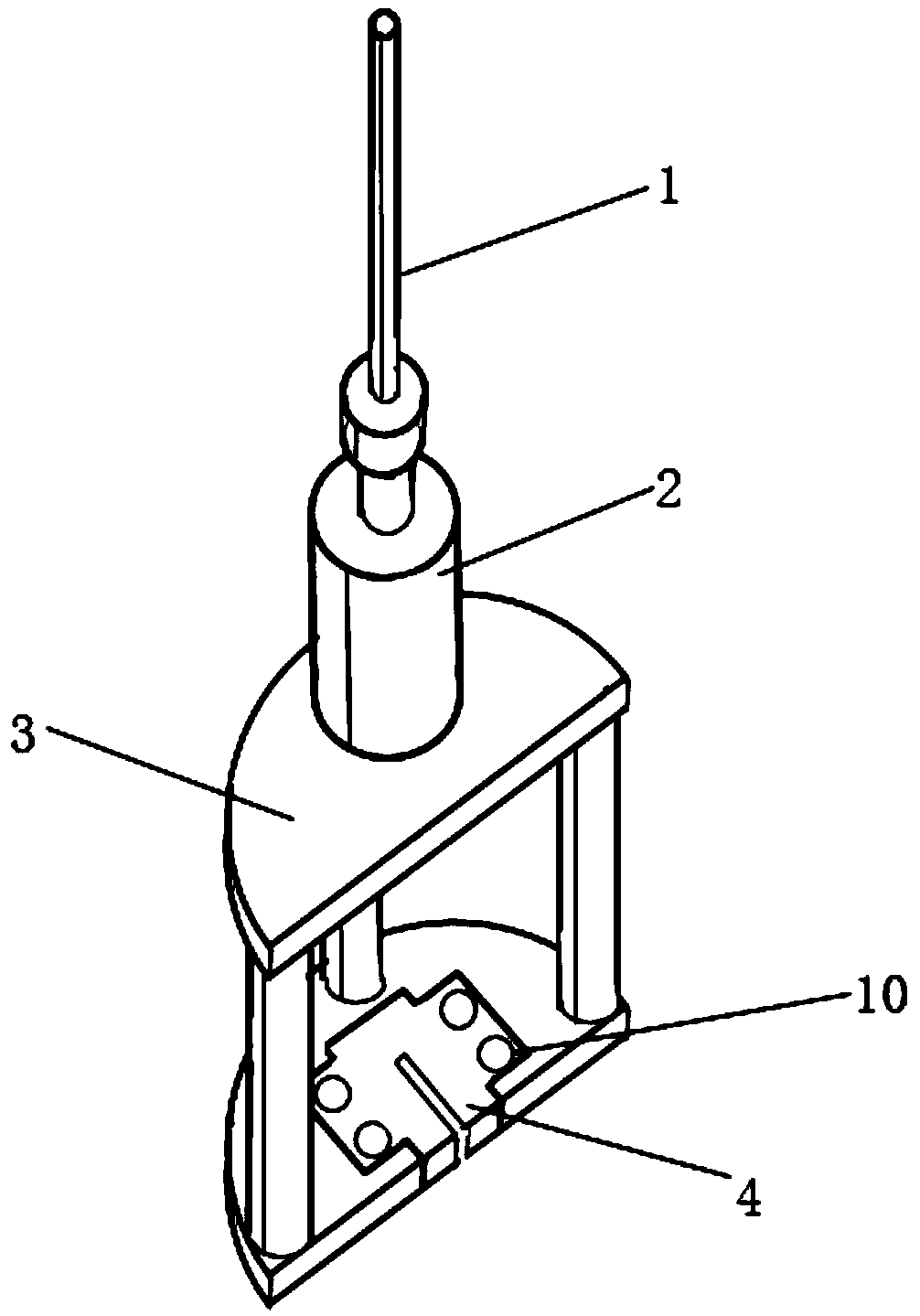

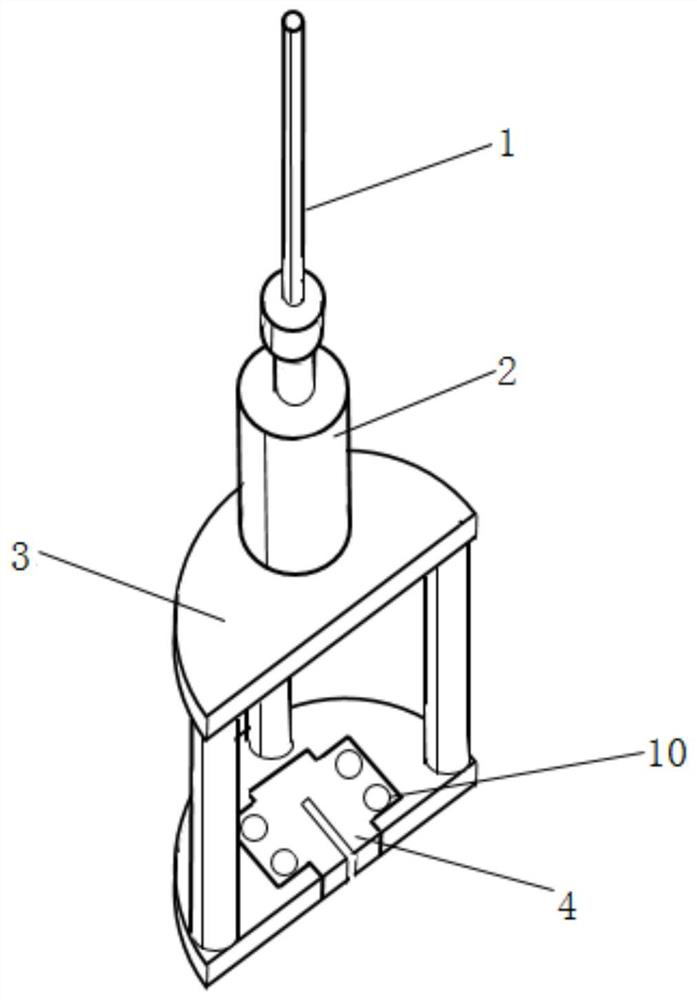

Scriber for controlling pressure by magnetic force

InactiveCN1958489AUniform crackUniform pressurePlaning/slotting machinesGlass severing apparatusMagnetic tension forceEngineering

The invention provides a scriber employing magnetic force to control pressure which can apply pressure uniformly onto a substrate in a right condition. The scriber comprises a first magnet connected with a wheel which is used for making a crack on substrate; a second magnet for generating a predefined repulsive force opposite to the first magnet; and a head part, in which the first and second magnets are movable. For the reason that the magnet is between the head part and the wheel holder, the pressure applied on wheel holder can be uniformly maintained by magnetic repulsive force, so that an effect of maintaining uniform crack depth can be obtained.

Owner:TOP ENG CO LTD

High-purity quartz sand preparation process

The invention provides a high-purity quartz sand preparation process. The high-purity quartz sand preparation process comprises the steps of carrying out artificial mineral processing according to themass of quartz ore raw materials by breaking through a traditional quartz sand process mode; washing the quartz ore raw materials with flowing water; crushing the quartz ore raw materials into quartzore particles by using a cone crusher; heating the quartz ore particles and then cooling the same; filtering out the quartz ore particles from water and then air-drying the quartz ore particles; grinding the quartz ore particles into quartz coarse sand, screening out the quartz coarse sand of which the grain size is smaller than the set mesh number in a process of grinding quartz ore particles, and adding fine quartz ground sand in the quartz coarse sand and grinding the mixture; filtering out quartz ground sand, impurities and quartz sand with over-small grain size in the ground quartz coarse sand; carrying out pulse dust removal on the filtered quartz coarse sand to obtain quartz coarse sand without dust; carrying out magnetic separation on the quartz coarse sand without dust; carryingout color sorting on the magnetically separated quartz coarse sand by using a color sorting machine; and carrying out microwave irradiation on the magnetically separated quartz coarse sand.

Owner:福建省吉康新型建材有限公司

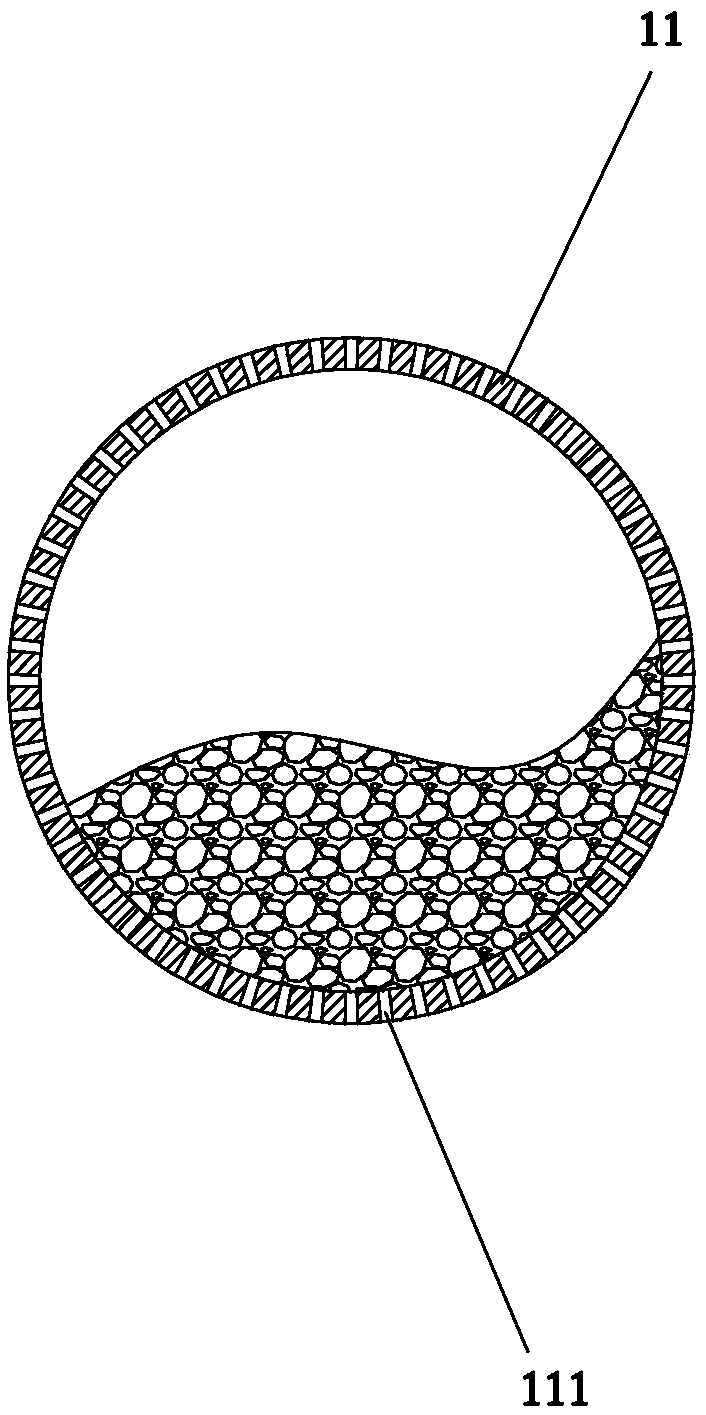

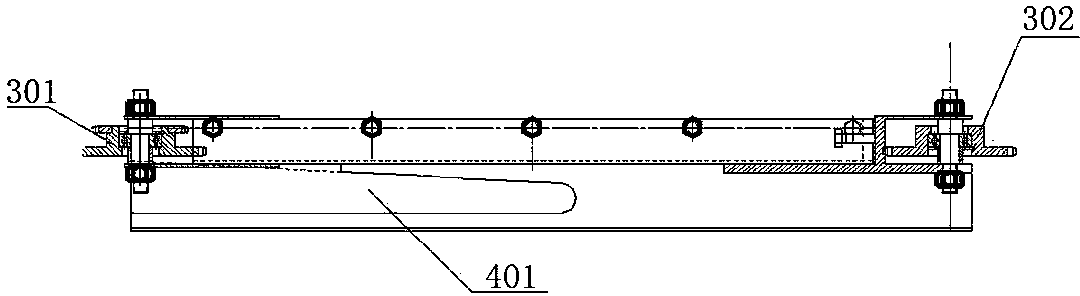

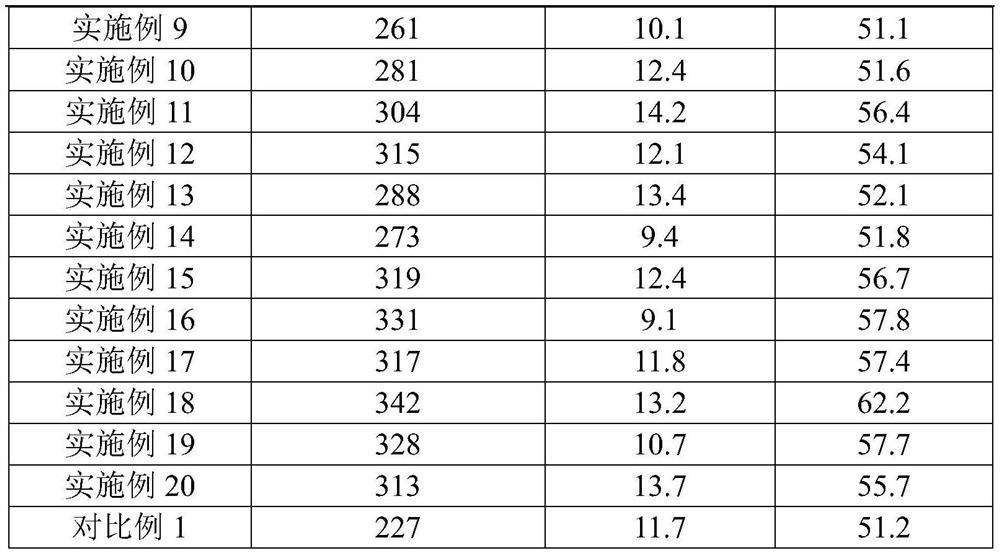

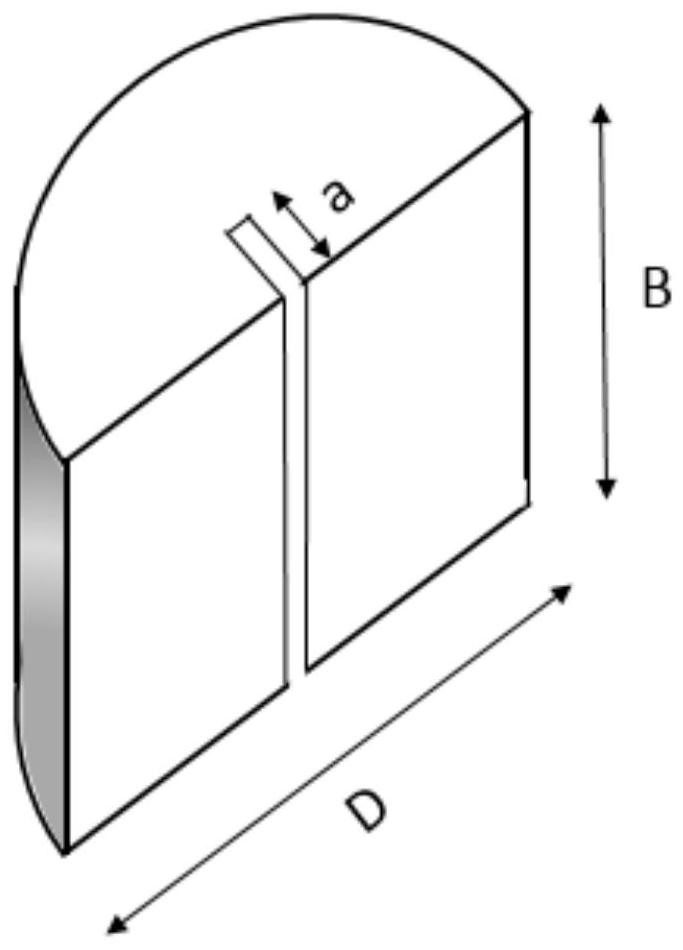

NSCB (notched semi-circular bend) specimen preparation device for testing I-type fracture toughness of compacted clay and use method thereof

ActiveCN109459290AIntegrity guaranteedUniform crackPreparing sample for investigationType fractureSpecimen preparation

The invention provides an NSCB (notched semi-circular bend) specimen preparation device for testing I-type fracture toughness of compacted clay and a use method thereof. The device comprises a specimen-making container and a compacting device, wherein the specimen-making container comprises a container side edge baffle plate I, a container side edge baffle plate II, a crack precast cushion block,a container base and a container bounding framework; the compacting device comprises a compacting rod, a compacting hammer, a compacting plate and a crack cushion block cap. During testing, an earth material is put in the specimen-making container, and the compacting plate stretches into the specimen-making container. The use method of the device comprises the steps of selecting the crack precastcushion block, installing the specimen-making container, preparing the earth material, performing cyclical compacting and the like. By adopting the device, the preparation of the NSCB specimen can berealized, a crack can be precast without generating disturbance to the specimen, so that the integrity of the specimen is guaranteed and the crack is enabled to be uniform.

Owner:CHONGQING JIAOTONG UNIVERSITY

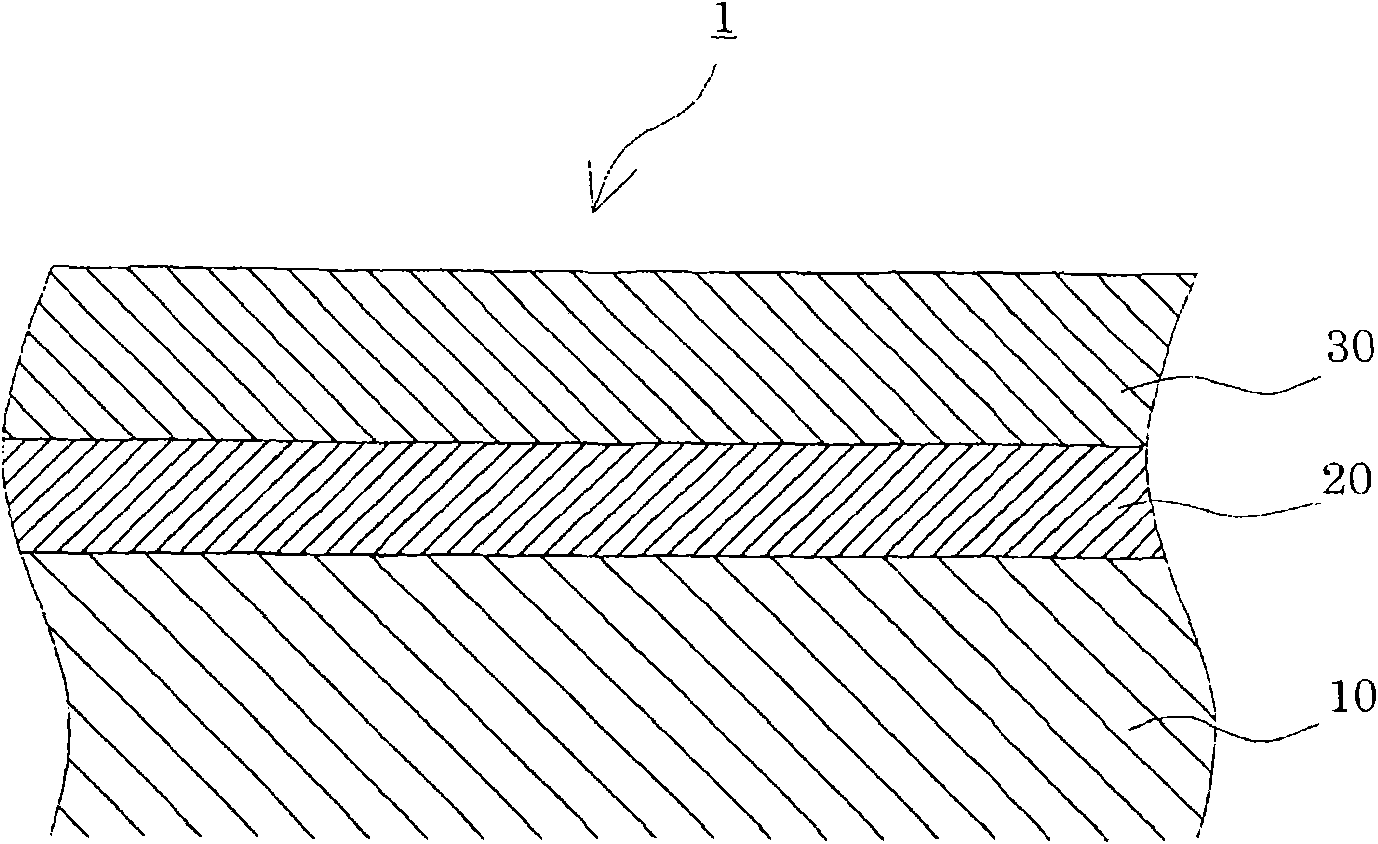

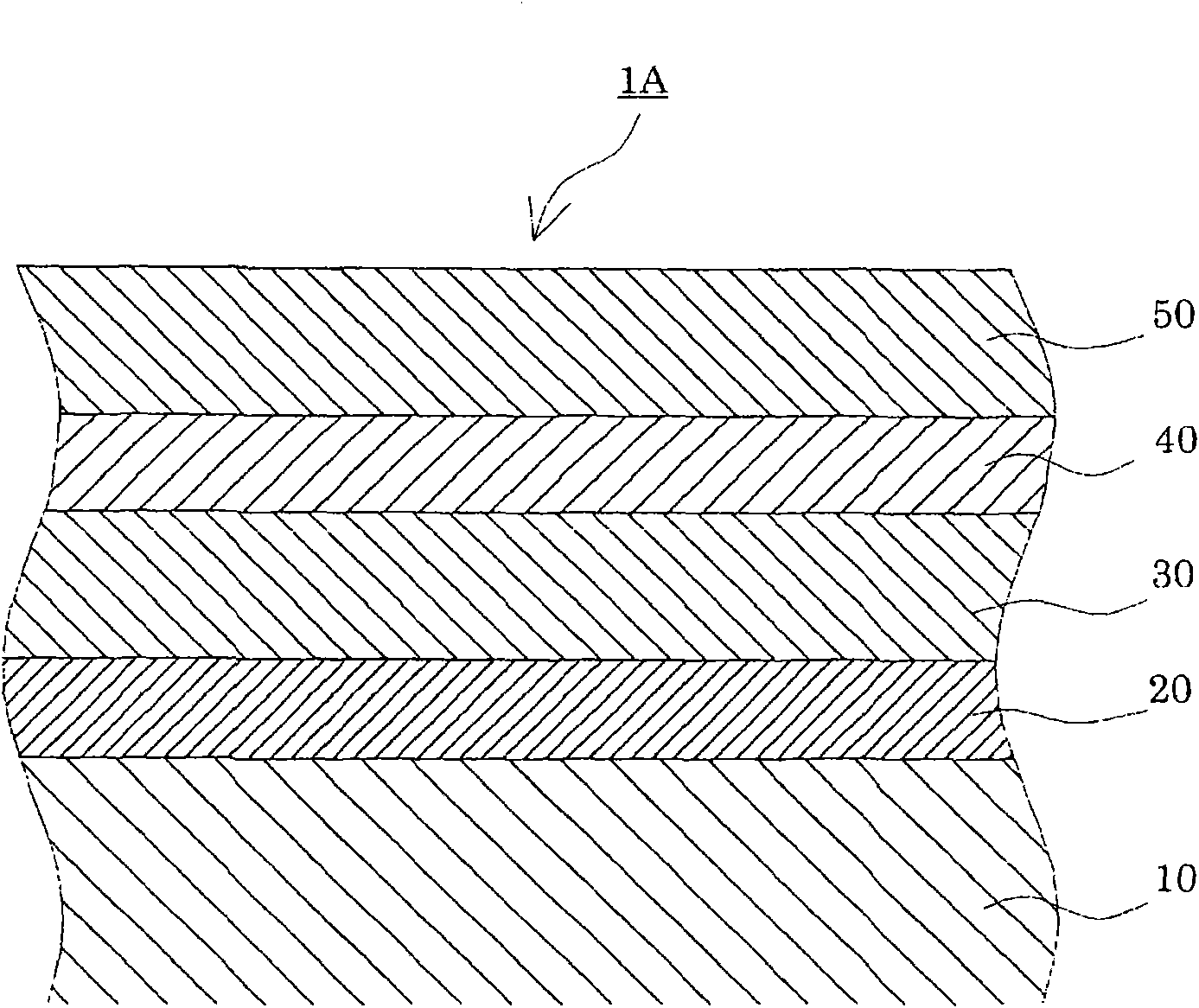

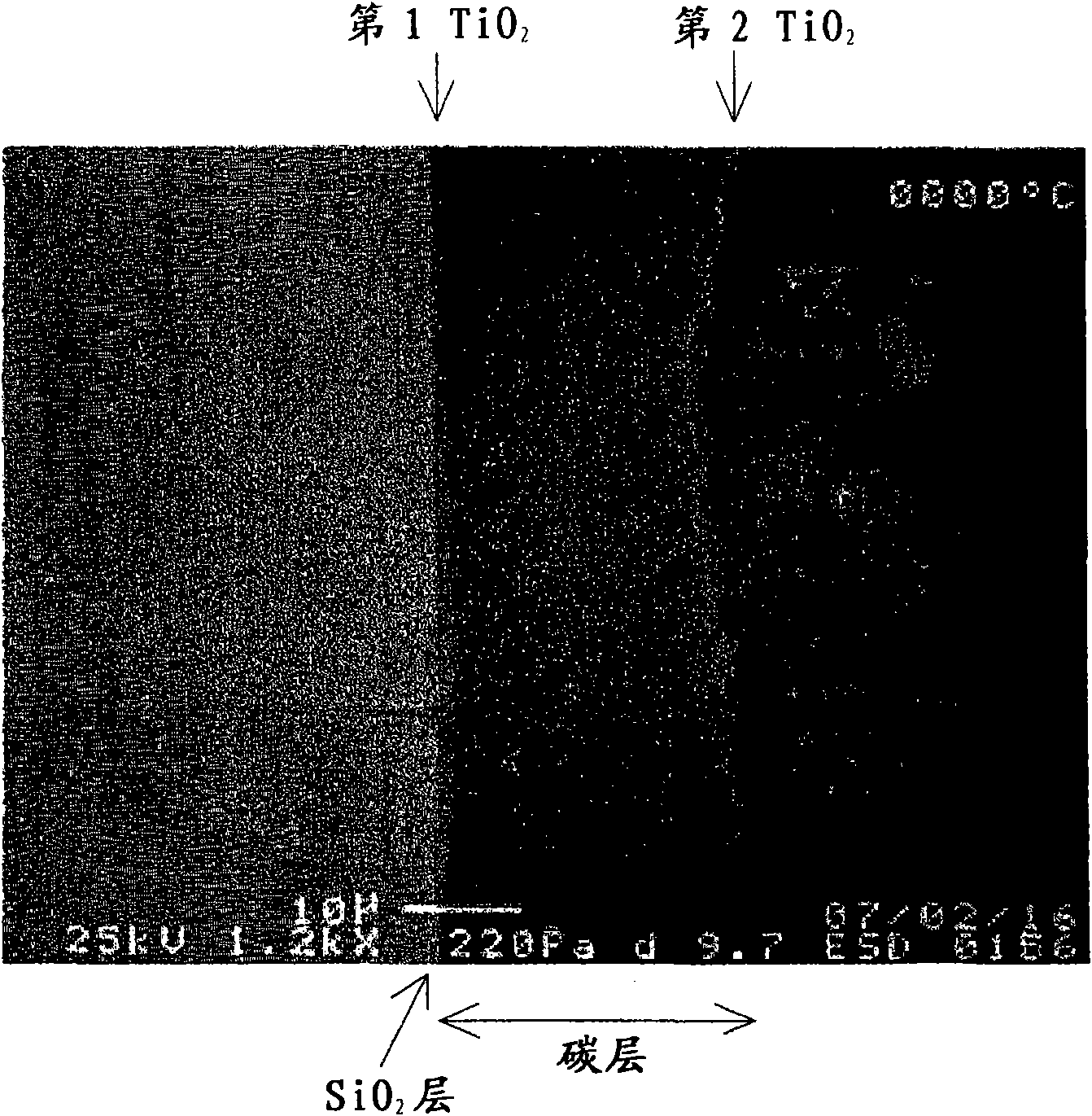

Method of preventing sulfide corrosion, high-temperature member with resistance to sulfide corrosion, and method of repairing heat-transfer tube

ActiveCN101636524AAvoid crackingReduce crackingSolid state diffusion coatingLiquid/solution decomposition chemical coatingCarbon layerTitanium metal

A method of sulfide corrosion prevention by which a base is protected from sulfide corrosion; and a high-temperature member which has excellent resistance to sulfide corrosion. Also provided is a method of repairing a cracked heat-transfer tube which comprises: forming a silicon oxide layer on the surface of the base; applying a titanium-containing coating fluid containing titanium metal or a titanium compound to the silicon oxide layer and thermally oxidizing the coating to form a first titanium oxide layer; forming a carbon layer on the first titanium oxide layer; and applying a titanium-containing coating fluid to the carbon layer and thermally oxidizing the coating to form a second titanium oxide layer, whereby the base is protected or repaired with the silicon oxide layer, first titanium oxide layer, carbon layer, and second titanium oxide layer.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

Precast concrete component and assembly concrete component connected with pier head locking anchor grouting straight sleeve and production method thereof

InactiveCN104264788AReduce the overall heightReduce the overall diameterBuilding reinforcementsPull forceRebar

The invention provides a precast concrete component and an assembly concrete component connected with a pier head locking anchor grouting straight sleeve and a production method thereof and belongs to the technical field of construction engineering assembly concrete structures. A method of sleeve connection based on extrusion and binding force transfer is adopted and a pier head (5) and a pier head (6) are machined at two ends of steel bars respectively; the sleeve inner diameter of one end of a connecting sleeve (7) is smaller than the outer diameter of the corresponding end of steel bar pier head (6); the inner diameter of the other end of the connecting sleeve is large and the other end of the connecting sleeve is provided with threads; a blocking ring (10) is connected with the connecting sleeve, wherein the inner diameter of the blocking ring (10) is smaller than the outer diameter of the corresponding end of steel bar pier head (5); the locking anchor extrusion and binding force transfer among the steel bar pier heads, the blocking ring, the sleeve and grouting materials is utilized through the steel bars due to the sleeve grouting and accordingly the mode that the steel bar tension of the previous grouting connection precast component is mainly transferred through bonding is changed. According to the production method, the safety and the economy of the connection of the novel precast concrete component are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

Crackle lacquer, preparing method thereof and spraying method for the same

InactiveCN101210129BNatural textureImprove the three-dimensional effectPretreated surfacesCoatingsLacquerMetallurgy

Owner:海宁市盐官工业投资有限公司

Recombination wood and manufacturing method thereof

ActiveCN101357470BIncrease productivityIncrease profitDomestic articlesFlat articlesPulp and paper industryRetting

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method solves the problem that wood bunch is irregular; the utilizing rate of wood and production efficiency of wood bunch are increased; defibering process is simplified and energy consumption for defibering is lowered. The process ensures that the cracks on the wood bunch shades and wood bunches are even and that the dipping of wood bunchshades or wood bunches is even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in manufacturing wood bunches from raw wood directly by the prior art, and the boards, the surface is very smooth and the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material, are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

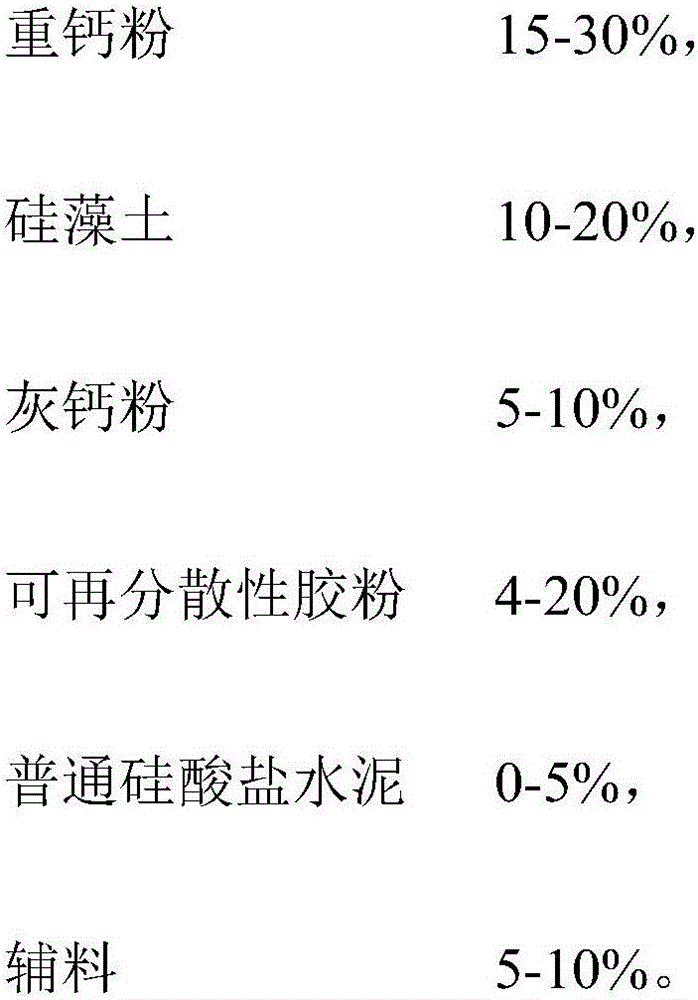

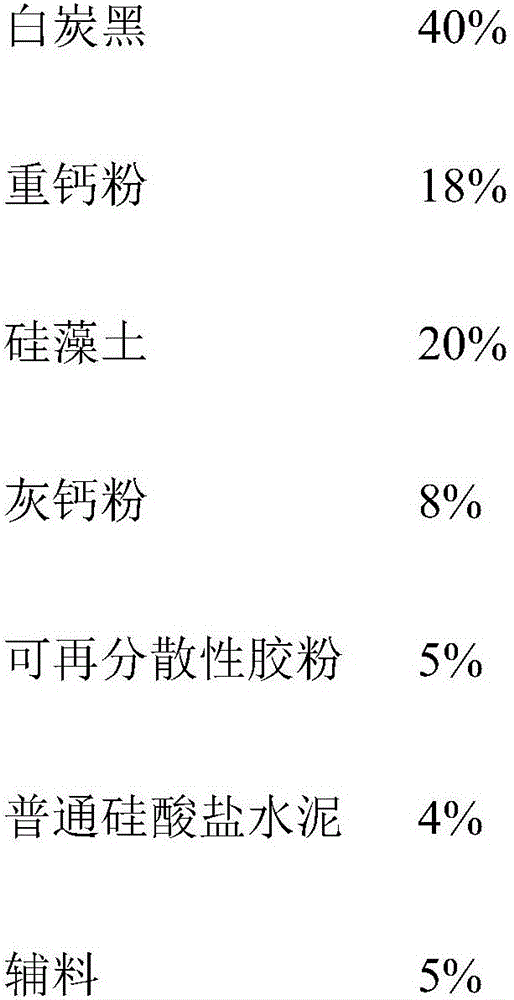

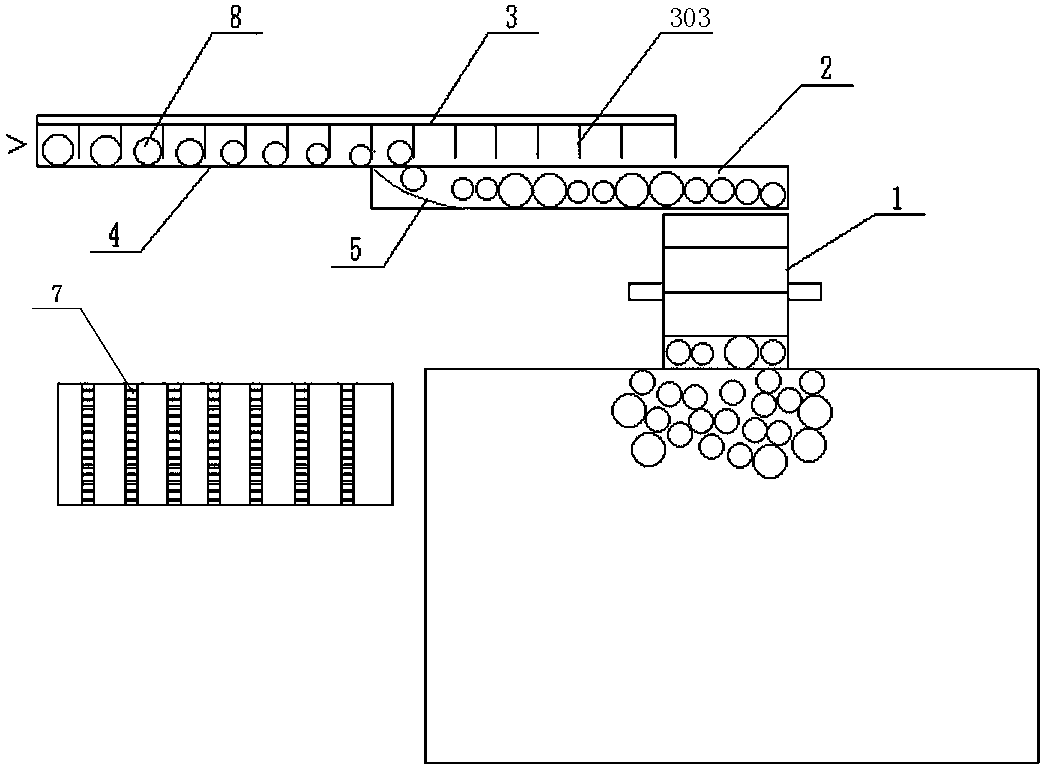

Dry powder crackle coating and construction method

The invention discloses a dry powder crackle coating and a construction method thereof. The coating is prepared from components in percentage as follows: 30%-50% of white carbon black, 15%-30% of heavy calcium powder, 10%-20% of diatomite, 5%-10% of ash calcium powder, 4%-20% of redispersible rubber powder, 0-5% of ordinary Portland cement and 5%-10% of auxiliary materials. Meanwhile, the invention further discloses the construction method of the dry powder crackle coating. The crackle effect is formed by adopting clear water as a solvent and combining a printing roller with concave-convex patterns. The crackle coating prepared with a formula and the construction method has natural crackle texture, good stereo effect and uniform crackles. Raw materials in the formula are natural inorganic materials and convenient to transport, the clear water is adopted as the solvent, the problem of pollution caused by traditional crackle paint is solved, and the coating is healthy and environment-friendly. The bottom and the surface of the dry powder crackle coating are made of the same material, and the preparation and construction processes are simple and convenient to operate.

Owner:JILIN PROVINCE LANSHE DIATOM NEW MATERIALS

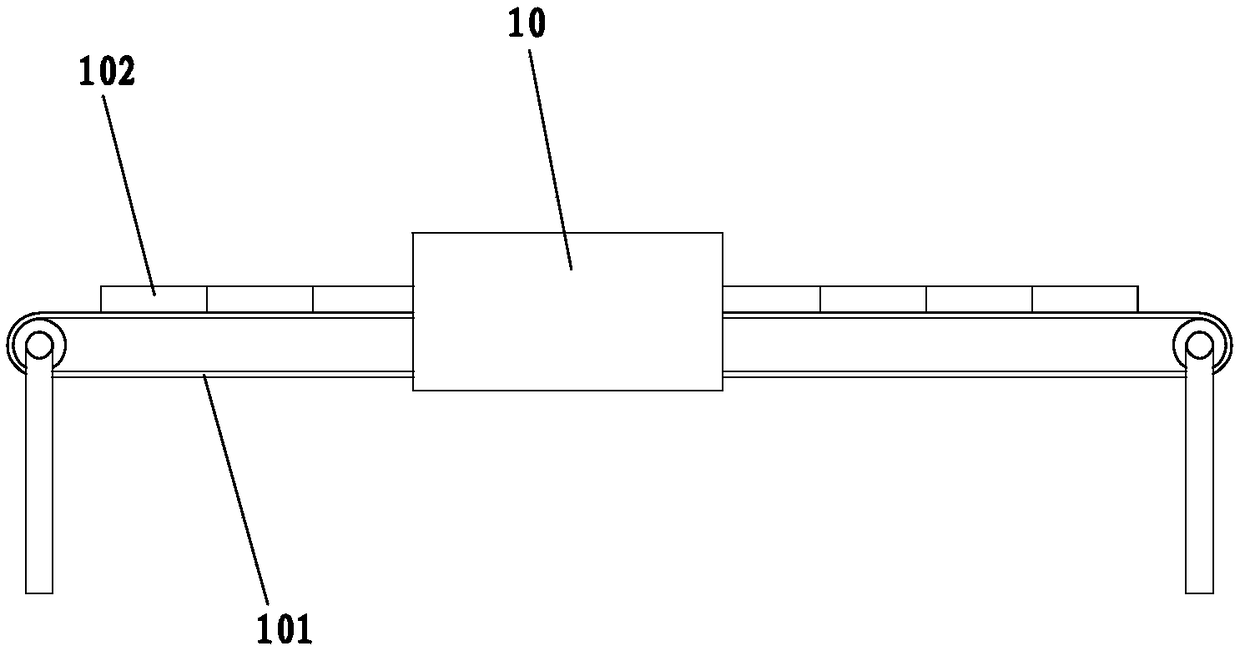

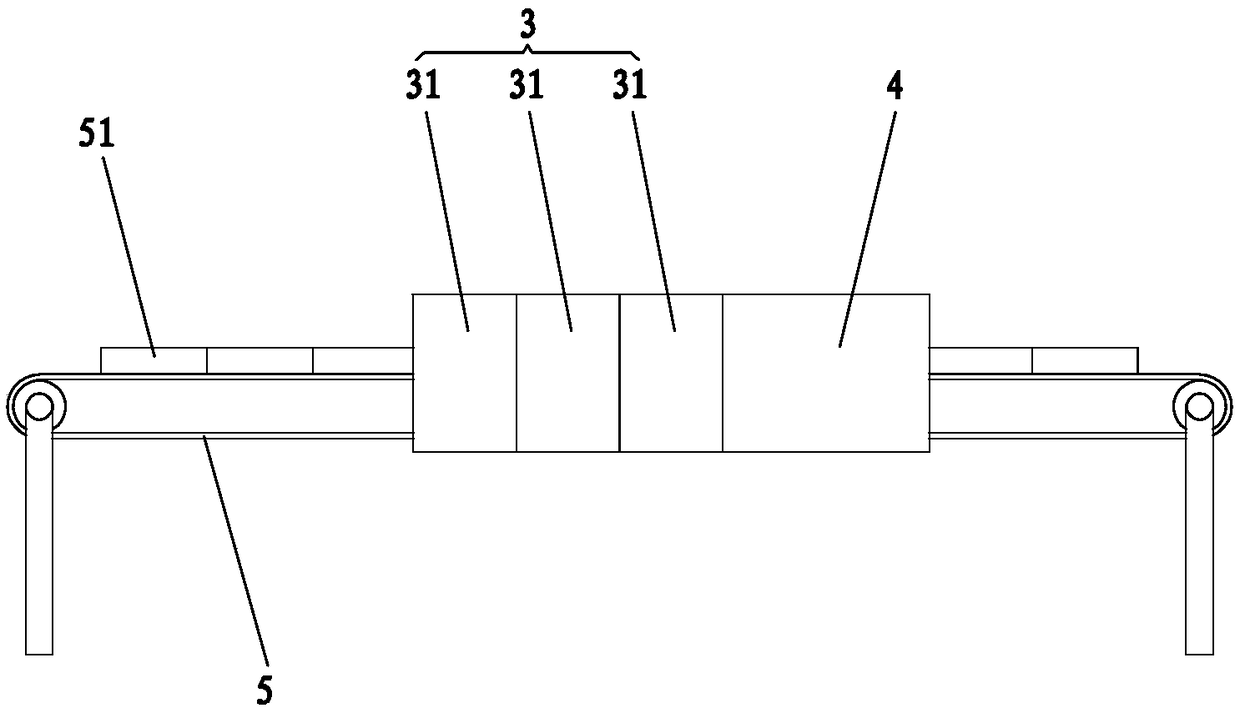

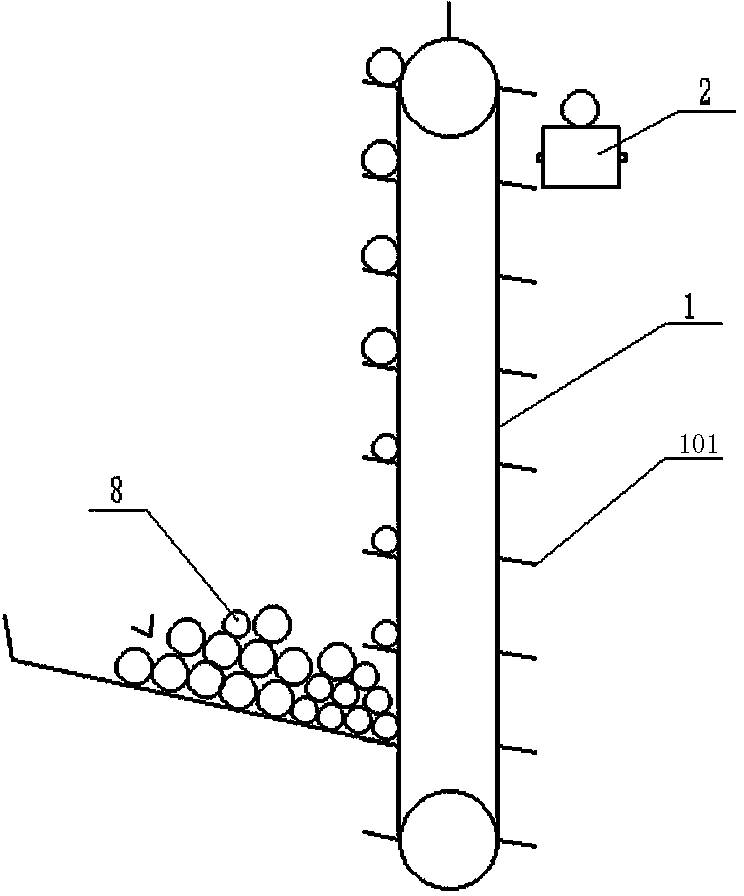

Walnut shell breaking device

InactiveCN104256856AIncrease productivityIncrease breaking speedHuskingHullingWalnut NutConveyor belt

The invention relates to a walnut shell breaking device. Lifting plates in an angle with a belt are fixed on the surface of the belt of a vertical lifting device at intervals, and the rear end of a horizontal conveyor belt is overlapped on the vertical lifting device. A push plate feeding machine is arranged before the horizontal conveyor belt and is parallel to horizontal conveyor belt, and push plates are arranged on the surface of a chain of the push plate feeding machine at intervals. An oblique-opening leakage groove is horizontally arranged below the push plate feeding machine; an oblique-opening leakage port of a gradually increasing width is formed on the bottom of the oblique-opening leakage groove, and a shell breaking mechanism is arranged below the oblique-opening leakage groove. Walnuts correspondingly fall into the shell breaking mechanism through the oblique-opening leakage port according to the size, and are ground under the action of a fixed knife and a movable knife, so that shells of the walnuts are broken. The sorting and the shell breaking of walnuts are integrated on one device, the production efficiency is increased, the shell breaking speed is quicker, equidistant teeth are uniformly distributed on the working surface of the movable knife and corresponded with the fixed knife, so that the walnuts are more ground, and furthermore uniform cracks are more easily formed on the walnut and high kernel exposure rate is guaranteed.

Owner:FENYANG CHENGYI DEV CO LTD

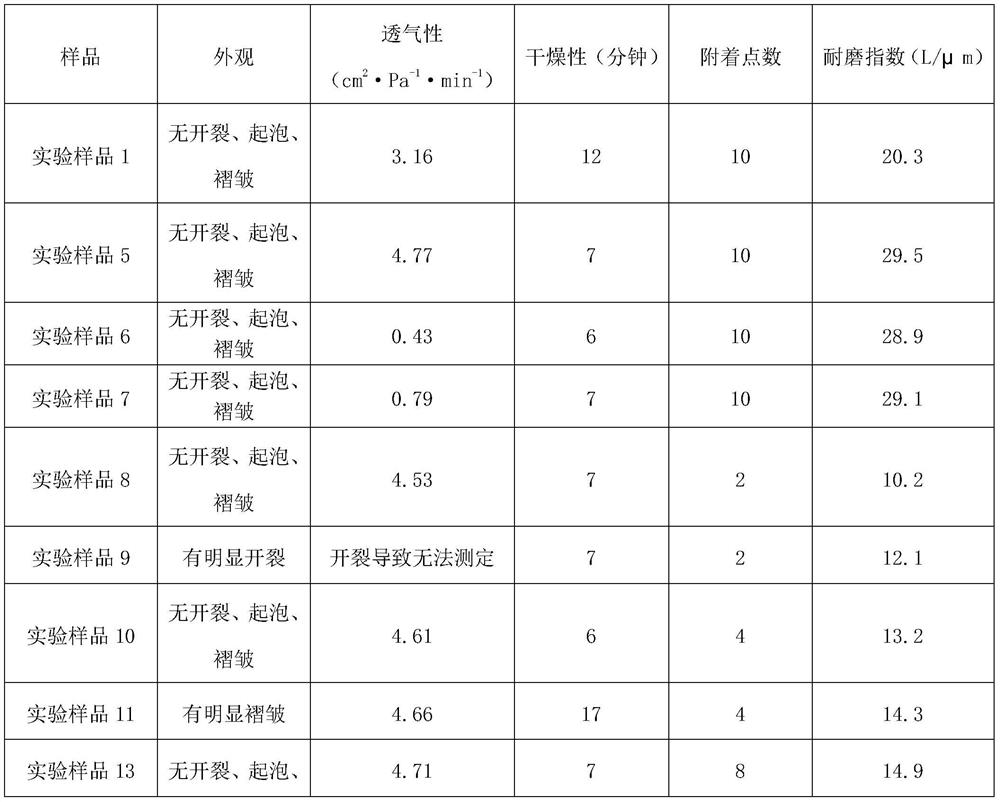

A kind of multifunctional coating for casting and preparation method thereof

ActiveCN110625061BPrevent sticky sandPrevent shrinkageFoundry mouldsFoundry coresPolystyreneLost-foam casting

The invention provides a multifunctional coating for casting and a preparation method thereof and particularly relates to the technical field of casting coatings. The method comprises the steps that firstly, a polystyrene fused solution is adopted for firing a compound, quartz sand powder and bentonite wrap the compound in batch in sequence, a wrapping compound is prepared, then powder of plasterof paris, sweet wormwood herb wax, trehalose and zinc oxide crystal whiskers are added to the wrapping compound, and the multifunctional coating for casting is prepared. The coating can be simultaneously used for two processes of lost foam casting and V-method casting, after coating is completed, cracks, bubbles and wrinkles do not exist, and the multifunctional coating for casting has the advantages of being resistant to wear, high in drying speed, adhesive force and air permeability and the like. The sand burning, shrinkage porosity and pore defects of a casting can also effectively prevented. The other aim of the invention is to provide the preparation method of the multifunctional coating for casting. The method is easy to operate, stable in process and suitable for large-scale production, and parameters can be controlled.

Owner:柳州市一乐科技有限公司

A kind of oil painting canvas with crack and preparation method thereof

InactiveCN103213452BHigh artistic valueUniform crackLayered productsOther artistic work equipmentsOil paintCraquelure

The invention discloses an oil painting canvas with flaws. The oil painting canvas comprises a base fabric, a priming coat and a floating coat from bottom to top, wherein the priming coat is formed by the way that priming coat coating liquid is coated on the base fabric and is dried; and the floating coat is formed by the way that floating coat coating liquid is coated and is dried after the base fabric is coated on the priming coat. With the adoption of the oil painting canvas with the flaws, and the manufacturing method thereof, after the priming coat, the floating coat and a face coating are coated on the base fabric of an oil painting, the surface of the base fabric of the oil painting has uniform and natural flaws, three-dimensional aesthetic feeling and art beauty of the oil painting created by applying the oil painting base fabric are improved, and artistic value of the oil painting is further improved.

Owner:莆田市集友艺术框业有限公司

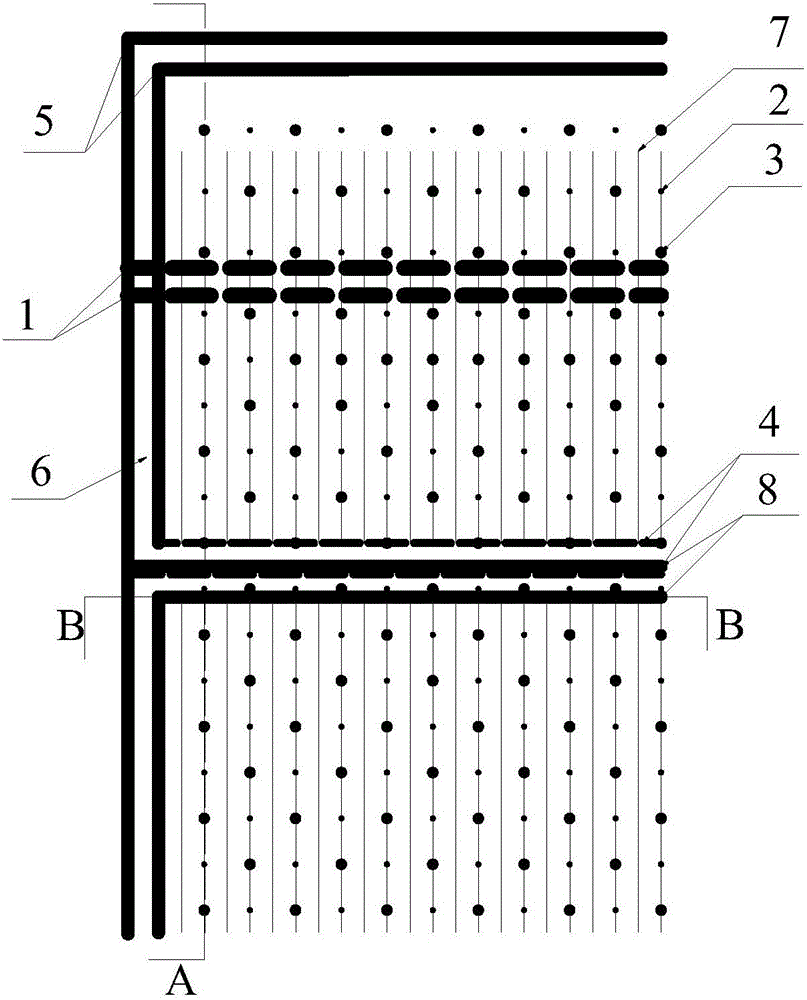

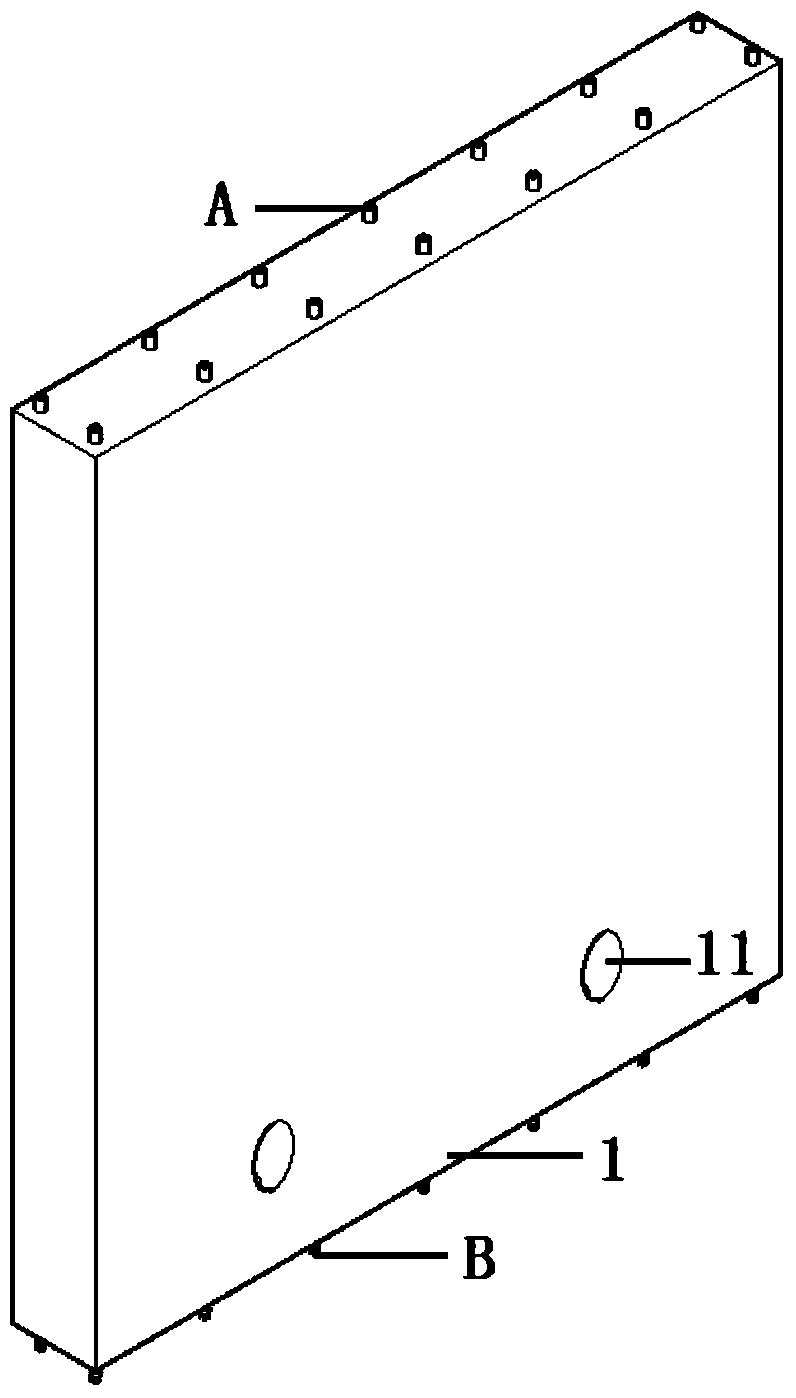

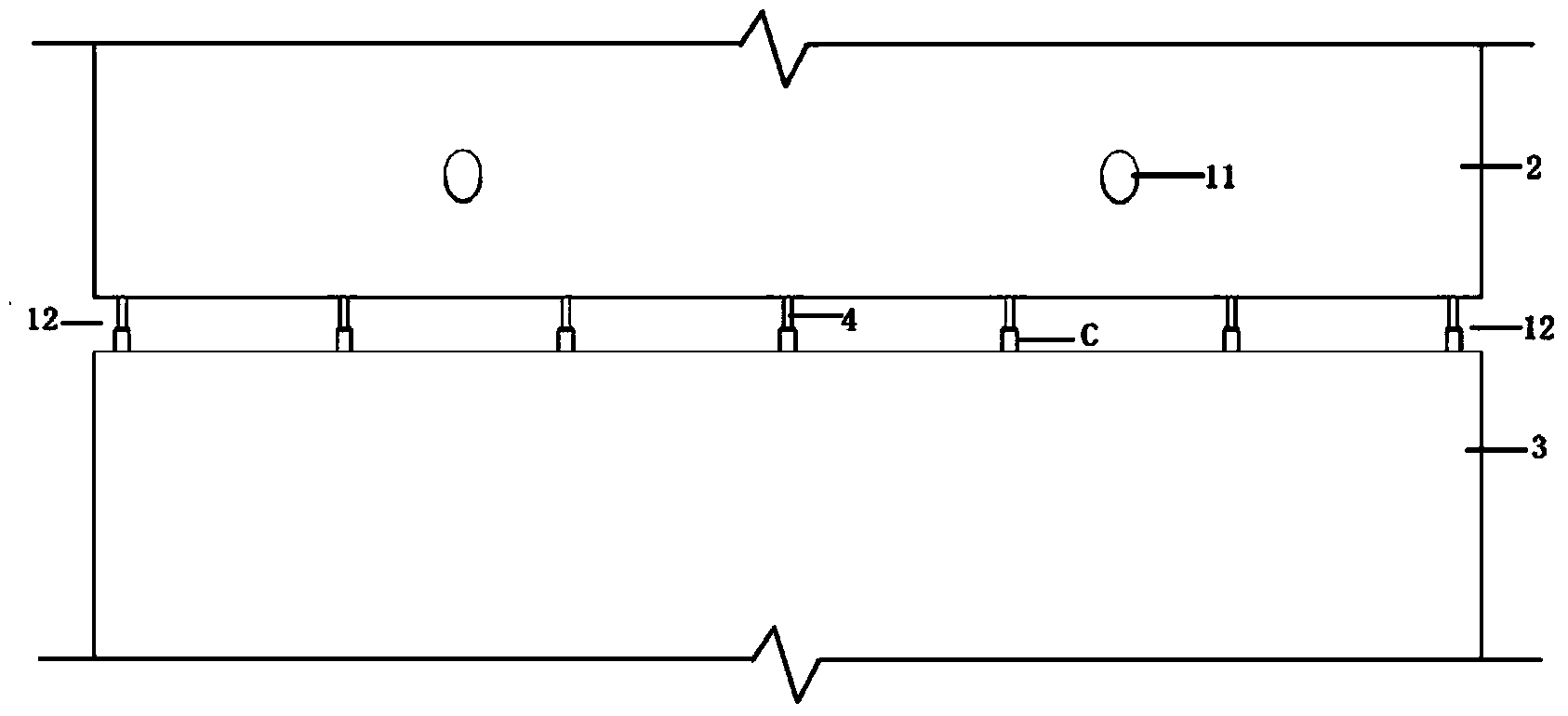

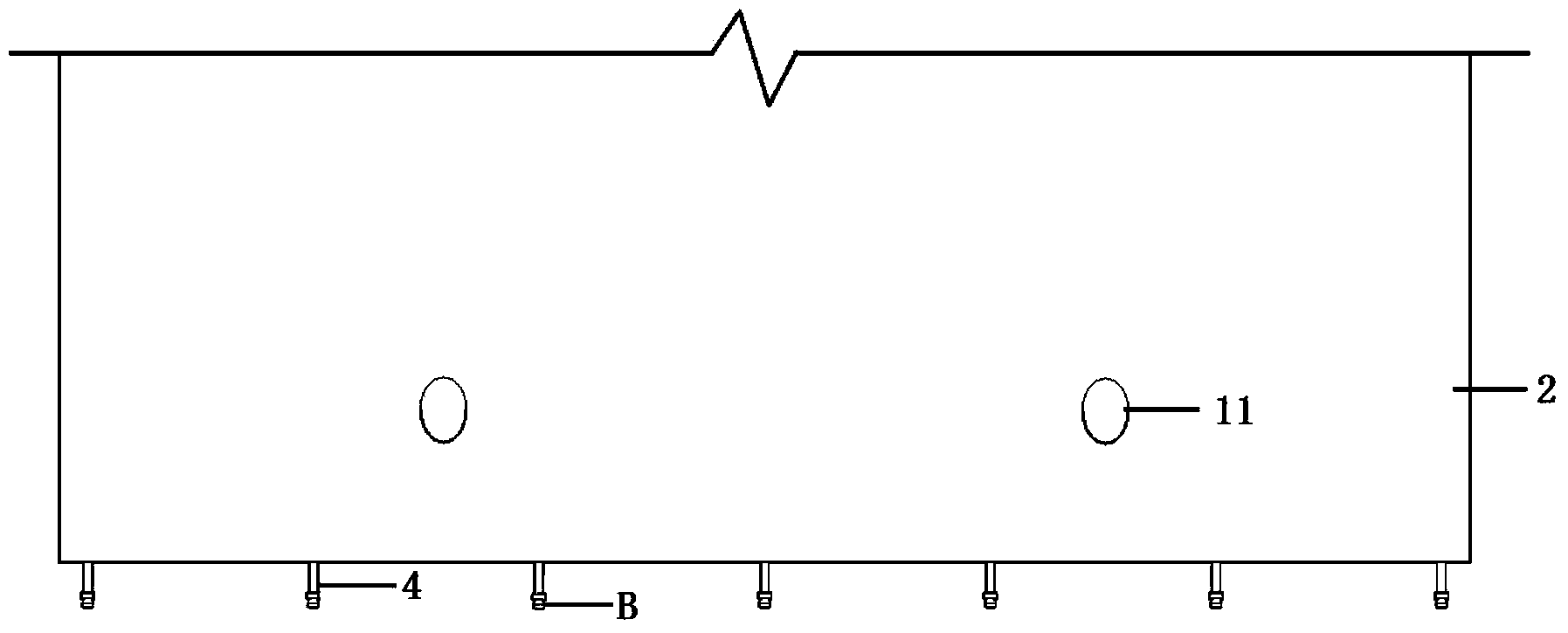

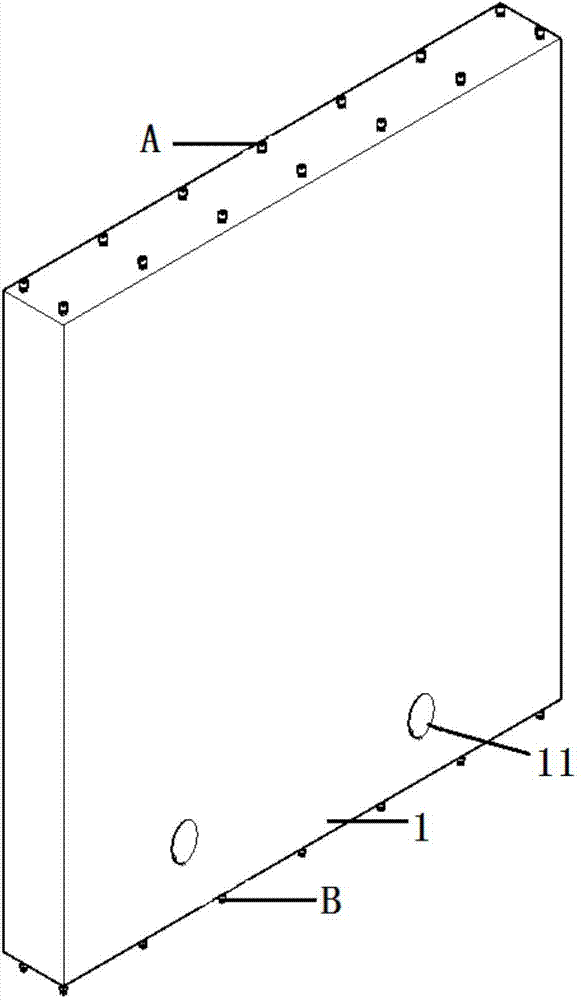

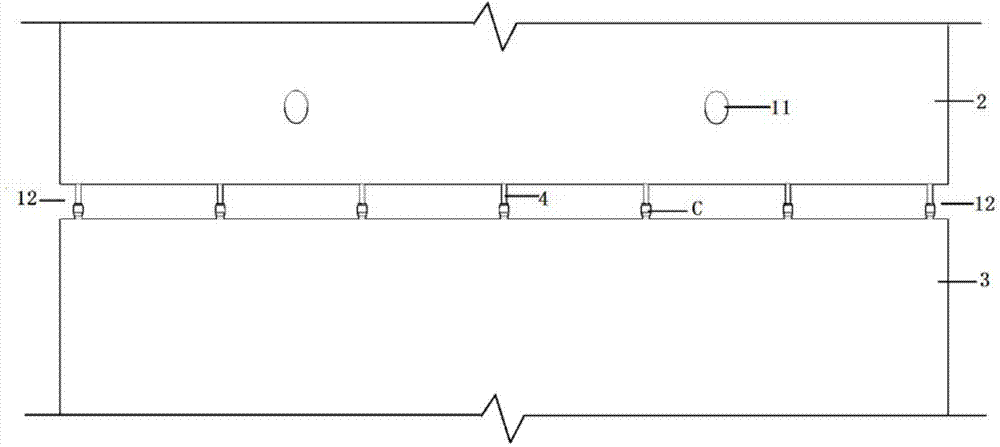

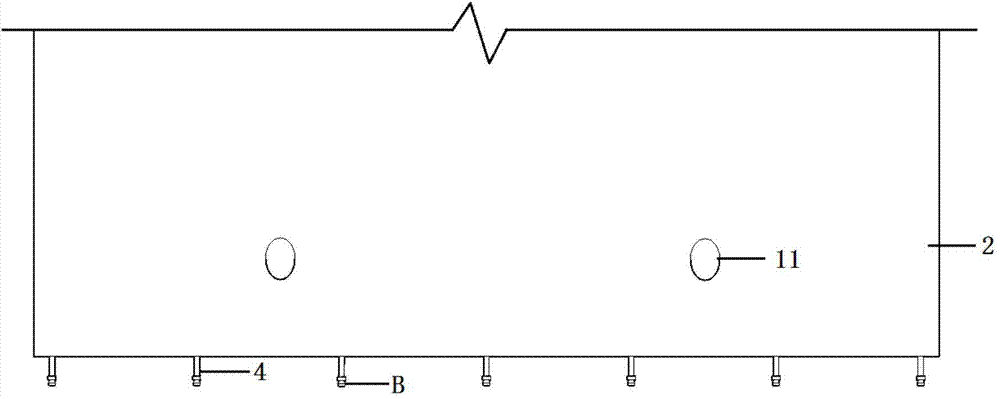

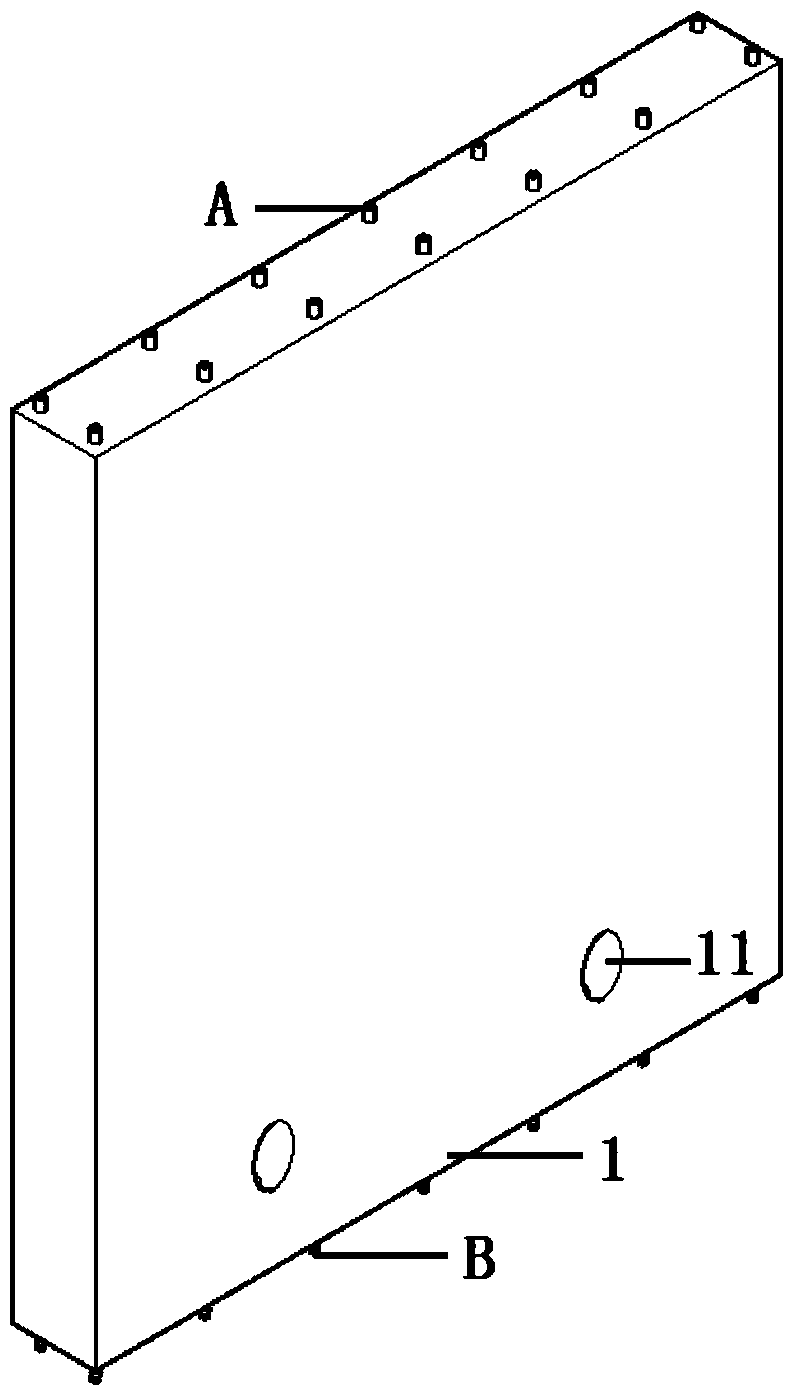

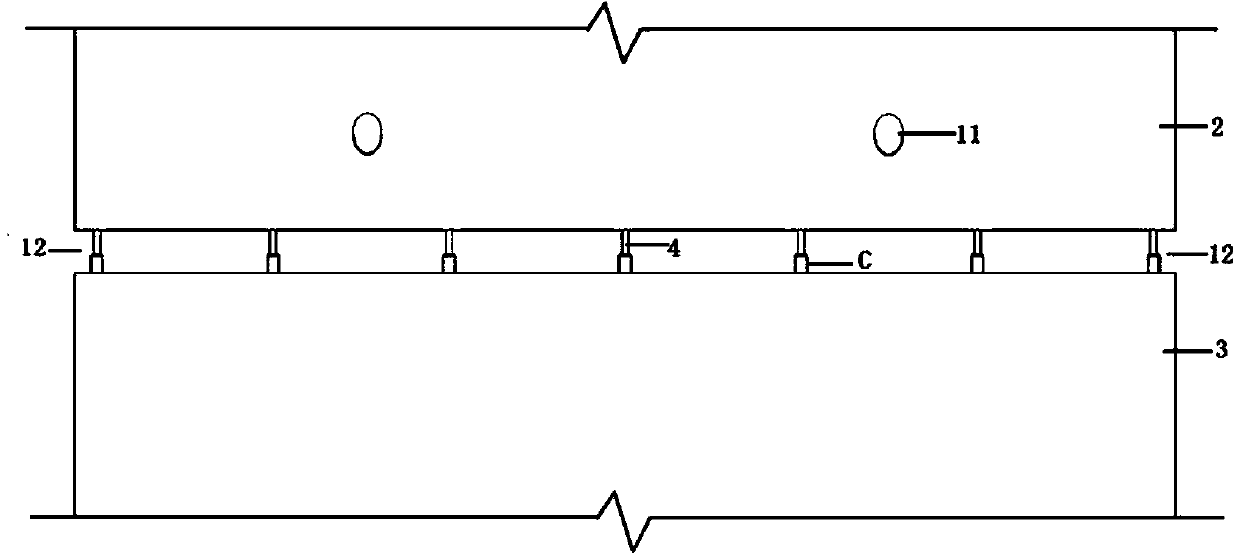

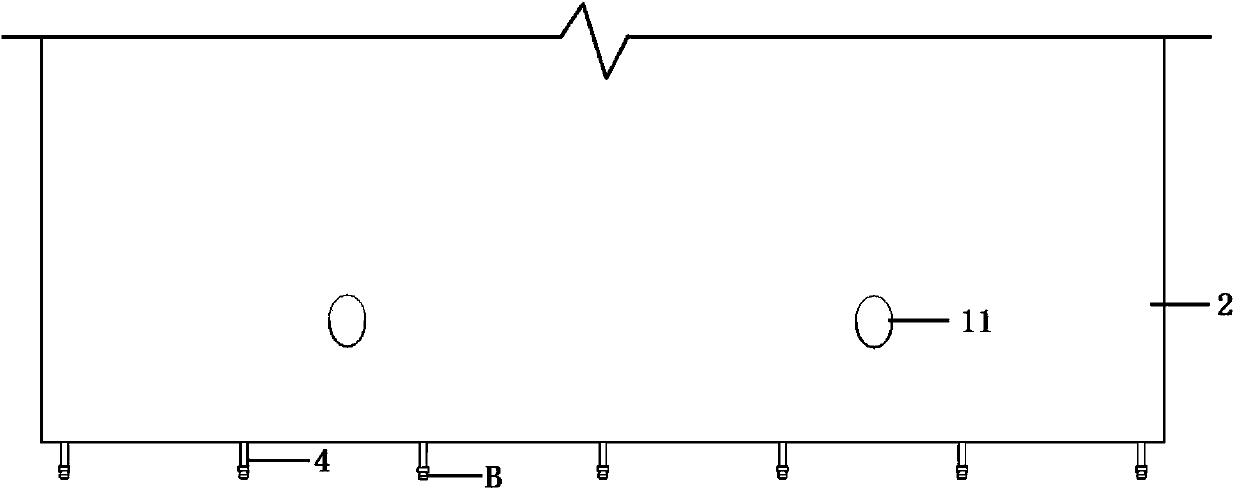

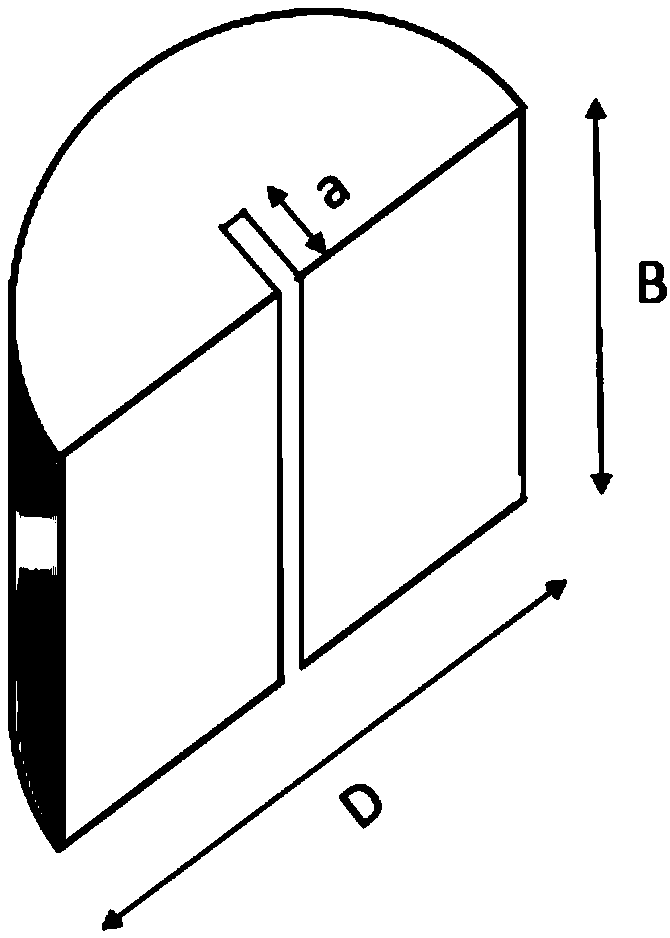

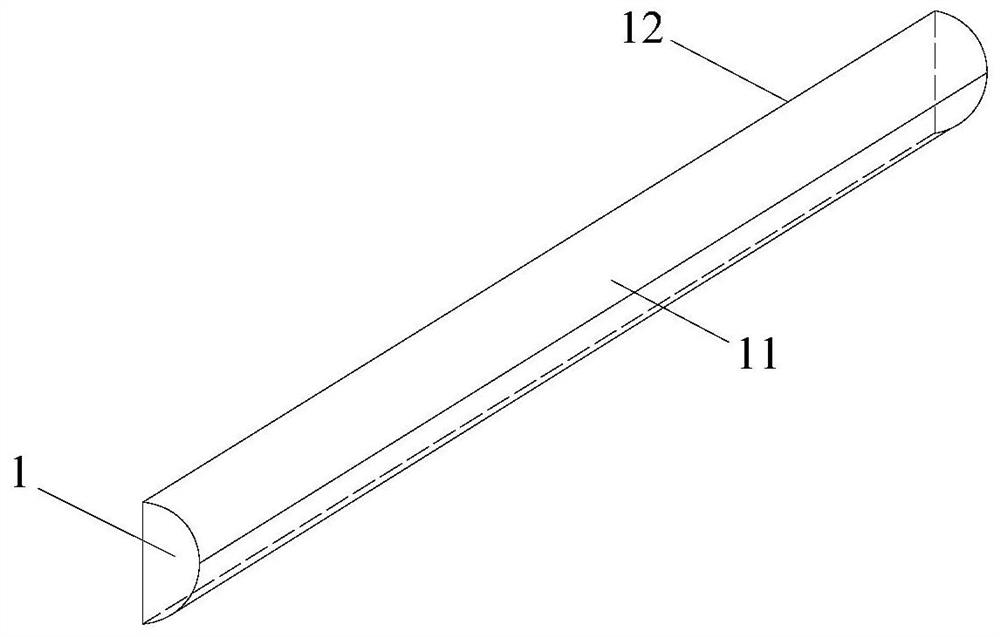

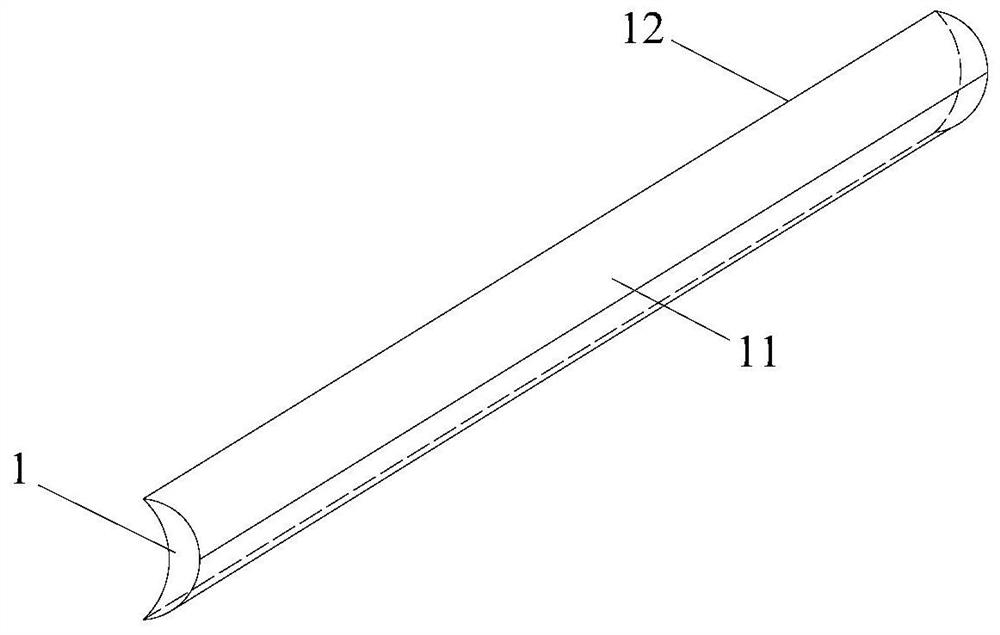

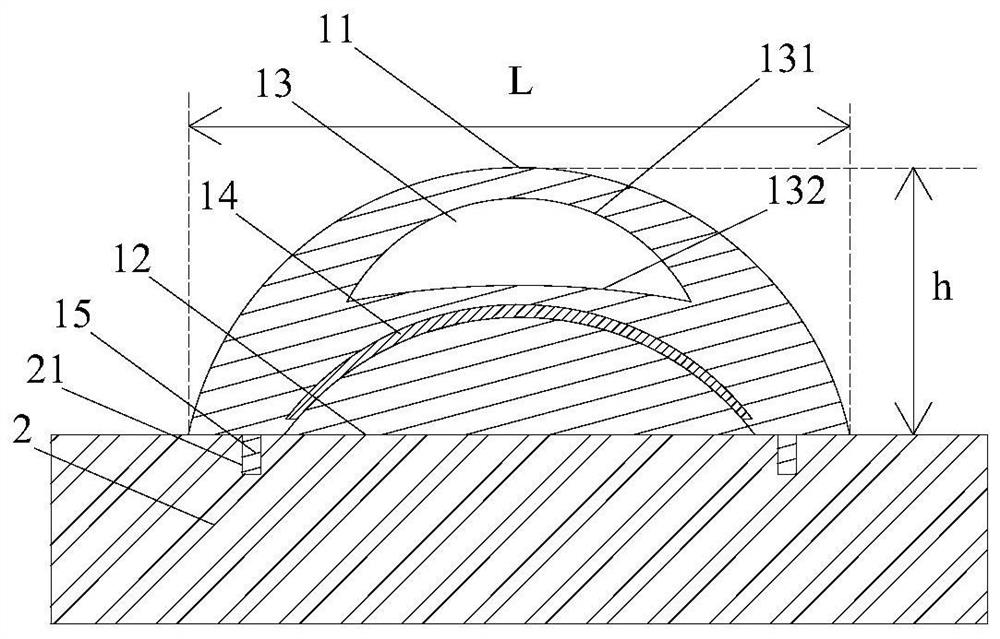

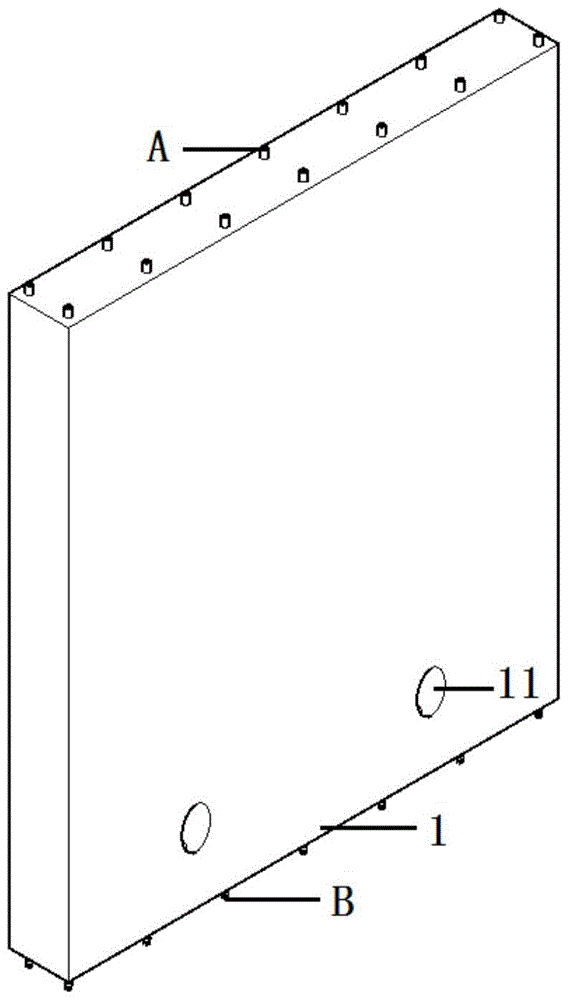

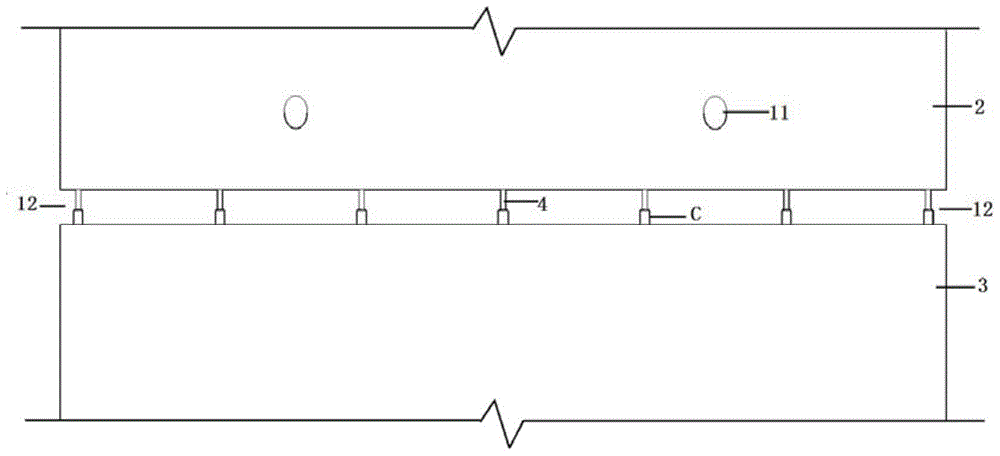

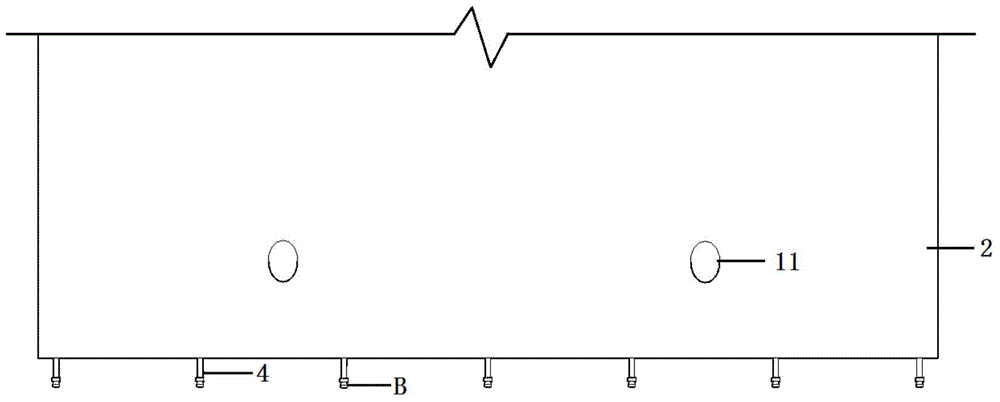

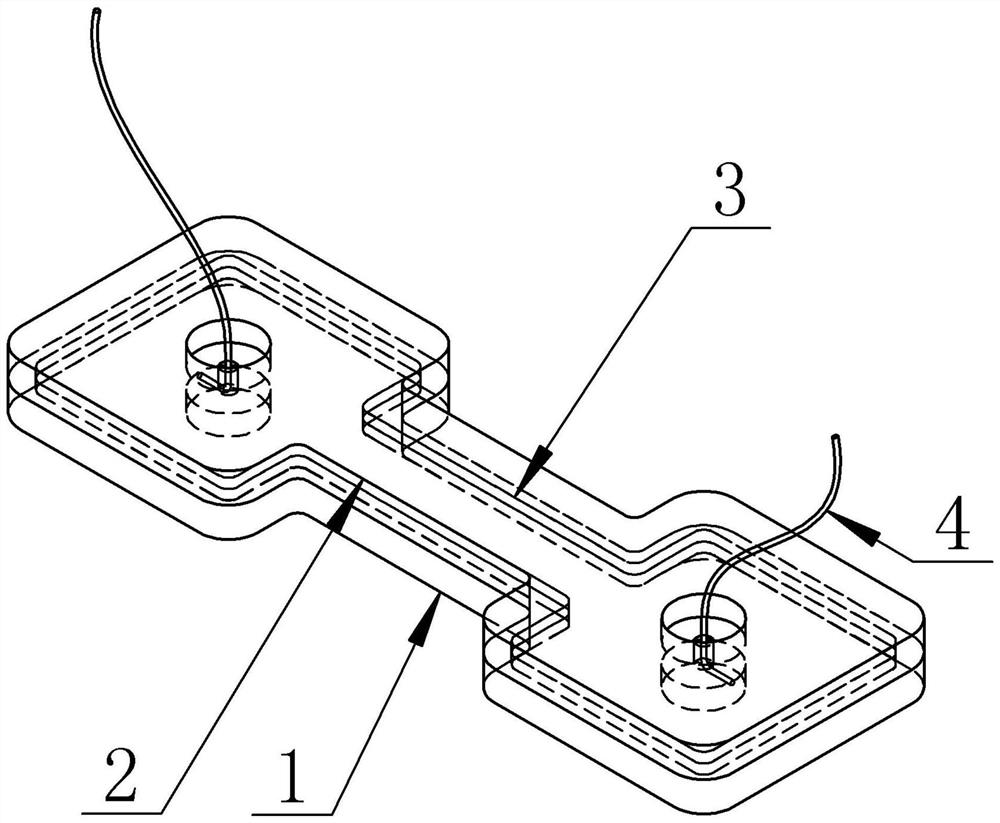

Crack Inducing Members and Crack Inducing Structures

ActiveCN112267344BGood for stress reliefGuaranteed beautyPaving detailsClassical mechanicsEngineering

The invention relates to a concrete crack induction structure, and discloses a crack inducer. The crack inducer (1) is columnar, and the crack inducer (1) has an upper bottom surface (11) of the inducer and a lower bottom surface of the inducer ( 12), the upper bottom surface (11) of the inducer is an outwardly convex arc surface, and the lower bottom surface (12) of the inducer is a plane or an arc surface concave toward the upper bottom surface (11) of the inducer . The invention also discloses a crack induction structure. The crack inducer of the invention can form cracks with smaller width on the concrete pavement, and the cracks produced are relatively uniform, thereby ensuring the aesthetics of the concrete pavement and driving comfort.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of high strength toughness high modulus deformation magnesium alloy and preparation method thereof

The invention discloses a deformed magnesium alloy with high strength, toughness and high modulus and a preparation method thereof, which is composed of the following elements in terms of mass percentage: a% of Al, b% of one or more of La, Ce, and Pr Mixed, c% of Mn, a total of d% of RE rare earth elements Gd, Y, Sm, Nd, Er, Eu, Ho, Tm, Lu, Dy, Yb one or more elements, a total of e% One or several elements in Si, Ge, Ca, Li, Sn, Zn, Sb, the total amount of impurities is less than 0.2%, and the balance is Mg; a, b, c, d and e satisfy 3.5≤a≤6.0 , 0.5≤b≤4.5, 0.01≤c≤1.0, 0.01≤d≤2.5 and 0

Owner:SHANGHAI JIAOTONG UNIV +2

A kind of nscb sample preparation device for testing the i-mode fracture toughness of compacted clay and its application method

ActiveCN109459290BIntegrity guaranteedUniform crackPreparing sample for investigationType fractureClassical mechanics

The invention provides an NSCB sample preparation device for testing the I-mode fracture toughness of compacted clay and a use method thereof. The device includes a sample preparation container and a compactor. The sample preparation container includes a container side baffle I, a container side baffle II, a crack prefabricated spacer, a container base and a container constraint frame. The compactor includes a compacting rod, a compacting hammer, a compacting plate and a crack spacer cap. During the test, earth materials were placed in the sample preparation container. The compaction plate extends into the sample preparation container. The use method of the device includes the steps of selecting prefabricated pads for cracks, installing sample preparation containers, installing compactors, disposing soil materials, and cyclic impacting. The device can realize the preparation of straight groove semicircular bending samples, and can ensure the prefabrication of cracks without disturbing the samples, which can not only ensure the integrity of the samples but also make the cracks uniform.

Owner:CHONGQING JIAOTONG UNIVERSITY

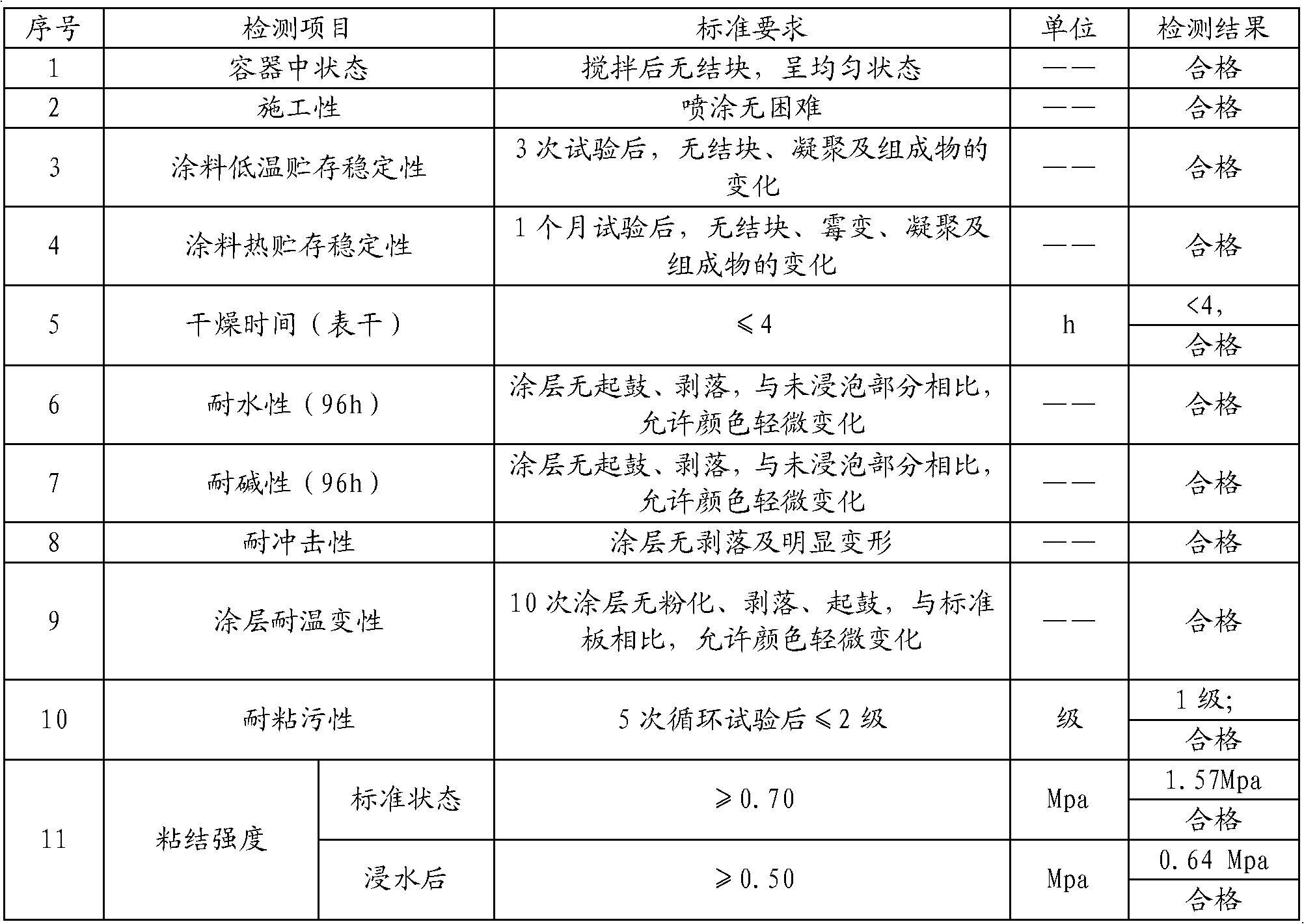

Water-based crack sandstone paint and preparation method thereof

Owner:佛山市南海万磊建筑涂料有限公司

Preparation method of plant modified water-based crackle lacquer

The invention discloses a preparation method of plant modified water-based crackle lacquer and belongs to the technical field of coating preparation. Lotus root and soybeans are fermented, a fermented supernatant fluid is obtained and then mixed with garcinia cambogia juice to obtain a mixture; then the mixture and natural resin of peach gum are mixed for modification to obtain a product, and epoxy resin is modified under the action of a microorganism through the product to obtain modified epoxy resin; and finally, the modified epoxy resin, water-based color paste and other raw materials are blended to obtain base coat, finishing coat is prepared through fluorocarbon resin, and the crackle lacquer can be obtained through combination of the base coat and the finishing coat. The epoxy resin is modified through amino acid in the fermented fluid of the lotus root and soybeans and hydroxycitric acid in garcinia cambogia under the action of the microorganism, various active groups in the epoxy resin are added, the base coat is prepared through the modified epoxy resin so that the chemical bonding force between the crackle lacquer and a base body can be increased, accordingly the attachment force of the crackle lacquer is increased, after curing of the base coat, excellent alkali resistance and attachment force are achieved, extremely low VOC and good flexibility are also achieved, the phenomenon that a lacquer face falls off after cracking of the crackles is avoided, and the application prospects are wide.

Owner:周荣

Low gas permeability coal seam liquid phase co 2 Phase change fracturing anti-reflection mesh gas drainage method

ActiveCN106194244BLarge amount of extractionEnsure safe productionFluid removalGas removalProcess engineeringPhase change

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Crack paint and preparation method thereof

The invention relates to the technical field of solvent-type wood paint, and especially relates to a crack paint which is easy to construct and which can provide beautiful cracks. The crack paint comprises components of, by weight: 75-90% of a crack paint mother liquor, and 10-25% of a color paste. The invention also discloses the preparation method of the crack paint. The method specifically comprises the preparation of the crack paint mother liquor and the mixing of the crack paint mother liquor and the color paste. With the formula disclosed in the invention, the crack paint which is easy to construct and which can provide beautiful cracks assists in solving defects such that over-thin cracks, non-cracking surface, non-uniform crack sizes, and paint falling after cracking of existing crack paints. With the crack paint provided by the invention, crack patterns with various colors can be formed by spraying. The crack paint is advantaged in easy-cracking wet film, uniform cracks, no color separation, no falling, beautiful patterns, and the like.

Owner:SHANGHAI CARPOLY PAINT

Prefabricated concrete components, assembled concrete components and methods of pier head lock anchor grouting straight sleeve connection

InactiveCN104264788BReduce the overall heightReduce the overall diameterBuilding reinforcementsArchitectural engineeringRebar

The invention provides a precast concrete component and an assembly concrete component connected with a pier head locking anchor grouting straight sleeve and a production method thereof and belongs to the technical field of construction engineering assembly concrete structures. A method of sleeve connection based on extrusion and binding force transfer is adopted and a pier head (5) and a pier head (6) are machined at two ends of steel bars respectively; the sleeve inner diameter of one end of a connecting sleeve (7) is smaller than the outer diameter of the corresponding end of steel bar pier head (6); the inner diameter of the other end of the connecting sleeve is large and the other end of the connecting sleeve is provided with threads; a blocking ring (10) is connected with the connecting sleeve, wherein the inner diameter of the blocking ring (10) is smaller than the outer diameter of the corresponding end of steel bar pier head (5); the locking anchor extrusion and binding force transfer among the steel bar pier heads, the blocking ring, the sleeve and grouting materials is utilized through the steel bars due to the sleeve grouting and accordingly the mode that the steel bar tension of the previous grouting connection precast component is mainly transferred through bonding is changed. According to the production method, the safety and the economy of the connection of the novel precast concrete component are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

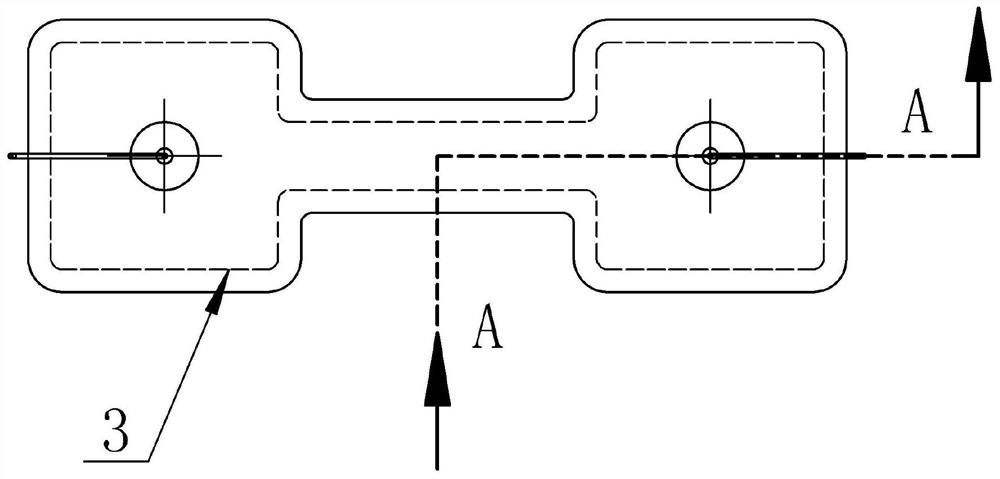

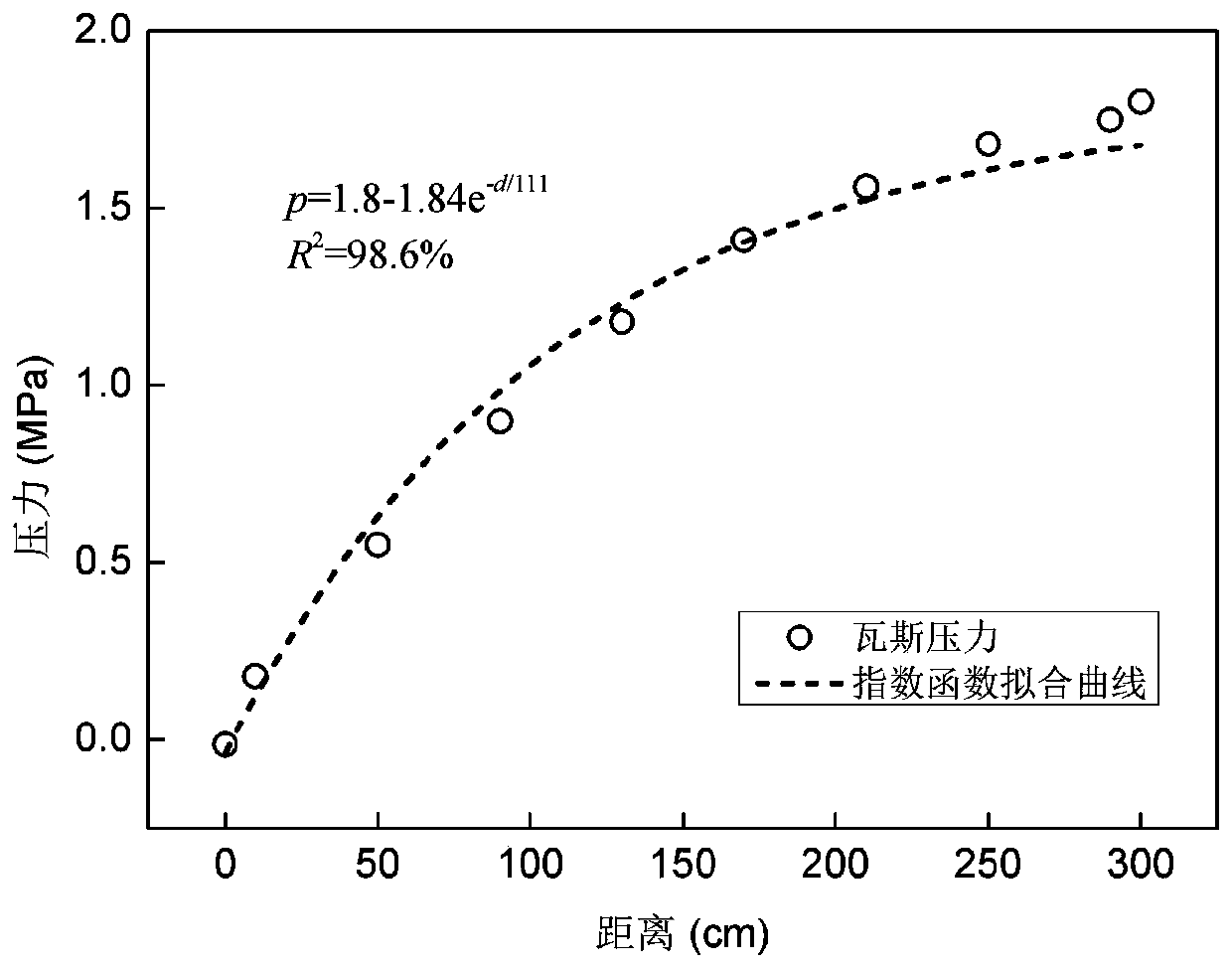

Resistance-type flexible carbon fiber strain sensor and manufacturing method thereof

ActiveCN113551588AHigh sensitivityImprove controllabilityElectrical/magnetic solid deformation measurementCarbon fibersFiber strain

The invention relates to the technical field of flexible sensors, and particularly discloses a resistance-type flexible carbon fiber strain sensor and a manufacturing method thereof. The structure of the resistance-type flexible carbon fiber strain sensor comprises an upper protection layer, a sensitive element and a lower protection layer which are sequentially stacked from top to bottom; wires are respectively connected with left and right ends of the sensitive element; and the sensitive element is made of carbon fiber prepreg cloth. The resistance-type flexible carbon fiber strain sensor has the advantages of strong elasticity, high sensitivity, strong controllability, strong anti-interference capability, adjustable sensitivity and working range, and low manufacturing difficulty.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

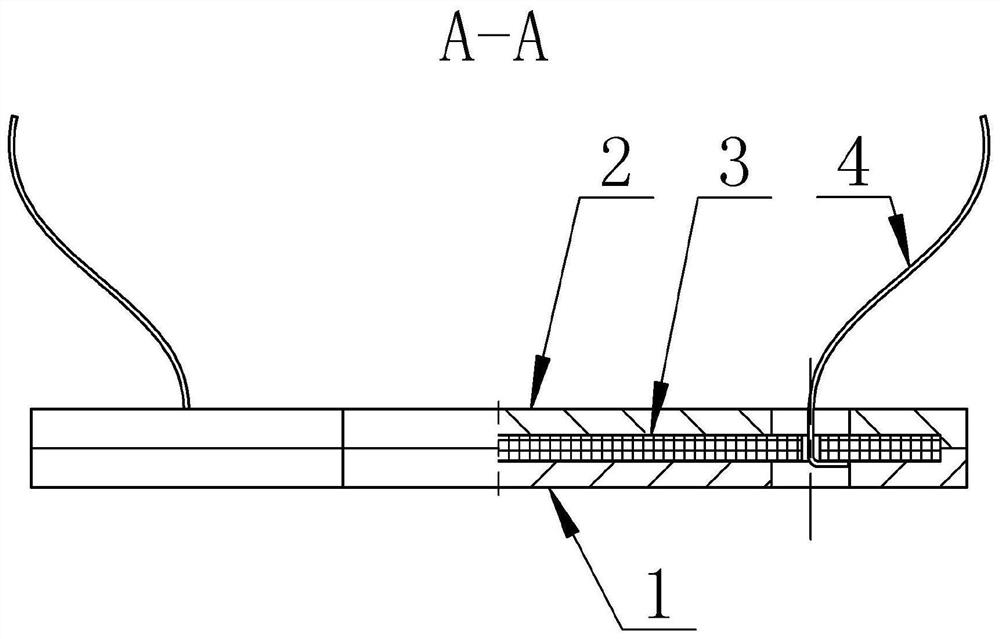

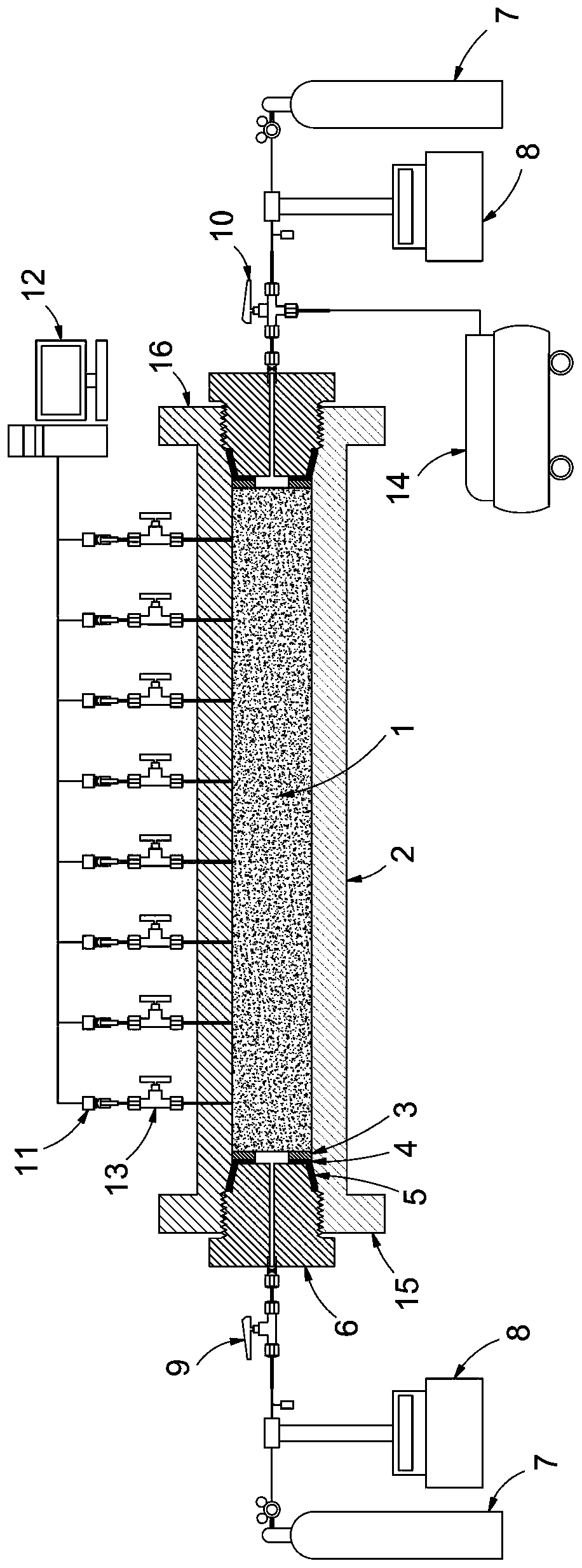

A measuring device and measuring method for the effective impact radius of a gas drainage borehole

ActiveCN110219699BAvoid prolonged exposureThere is no problem of long exposure timeMining devicesGas removalThermodynamicsMechanical engineering

The invention discloses a measuring device and method for the effective influence radius of a gas extraction drilled hole. The measuring device comprises a coal core gripper, a gas injection part, a gas simulation extraction part and a pressure testing part. According to the measuring device and method, operation that a coring drilled hole is constructed in an original coal seam, then coal core samples are collected and determined in a laboratory is only needed, operation that a series of gas extraction drilled holes and pressure observation drilled holes are constructed in the coal seam is not needed, the engineering quantity is greatly lowered, and the testing success rate is higher than that of a traditional measuring method; the coal quality of the coal core samples, holes and facturesare relatively even, the error brought by gas geological occurrence change to measuring can be avoided, the coal core samples are sealed in the coal core gripper, thus the problem of long exposing time is avoided, and the measuring accuracy rate is high; and tracking and monitoring of the intermediate process that does not reach the extraction time can be achieved, thus the measuring accuracy canbe ensured, and the measuring result can provide theoretical basis and data supporting for reasonable arrangement of the gas extraction drilled hole of the coal seam.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com