Recombination wood and manufacturing method thereof

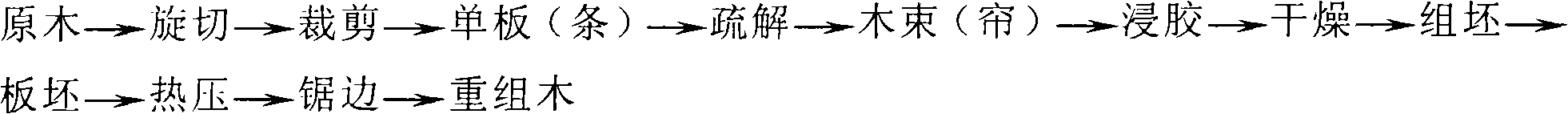

A technology for recombining wood and manufacturing methods, which is applied in the direction of manufacturing tools, flat products, and other household appliances, and can solve problems such as reduced production efficiency, uneven glue application, and low utilization of wood, and achieves solutions to irregular wood bundles and simplified Effect of deflagging process and reducing energy consumption of deflagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

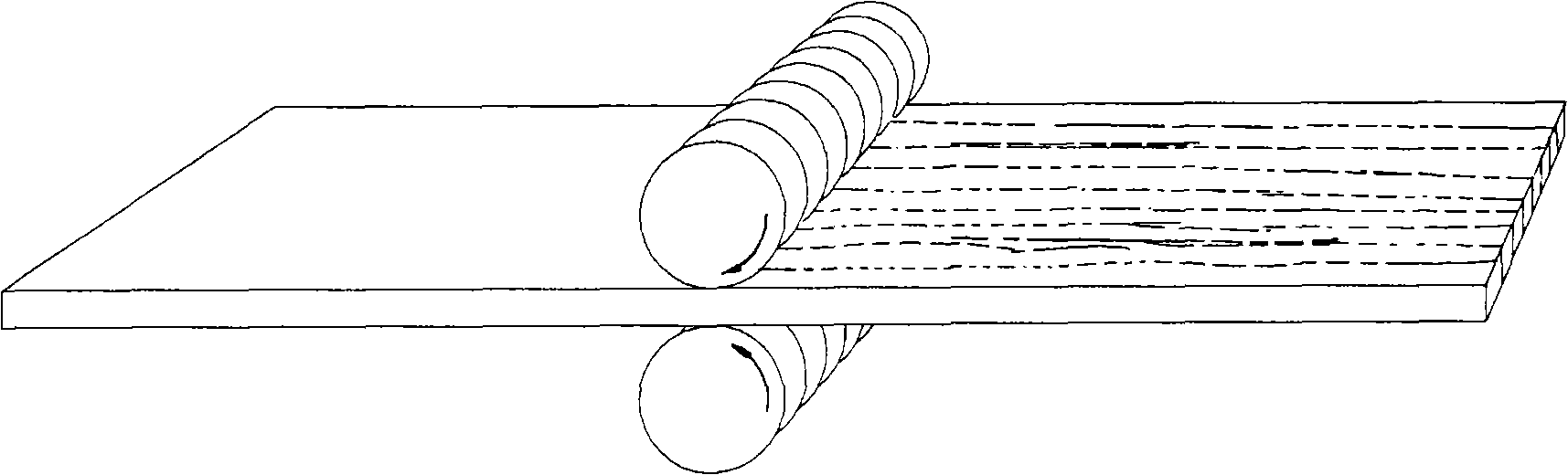

[0082] Rotary cut eucalyptus (eucalyptus urophylla), poplar (poplar tomentosa), Chinese fir (Chinese fir), pine (larch) and other wood to form veneers with a thickness of 4.0mm, and cut the veneers into certain The width of the veneer is 120-1220mm, and the veneer is extruded by the upper and lower extrusion rollers to form a wood beam curtain with point cracks or line cracks (or point cracks and line cracks). The extrusion rollers used can be a pair of extrusion rollers with helical convex teeth, or a pair of annular tooth extrusion rollers with linear convex teeth, or a pair of extrusion rollers with point-shaped convex teeth. Roll to obtain the number of visible cracks intersected by any horizontal straight line and the linear and / or point cracks formed by defrosting in the cross-sectional direction of the wood beam curtain between 5-15 / cm.

[0083] Put the decomposed wood beam curtain in the impregnation treatment tank (vacuum tank), and then pump it into the vacuum tank w...

Embodiment 2

[0090] Rotary cut eucalyptus (eucalyptus urophylla), poplar (populus tomentosa), fir (Chinese fir), pine (larch) and other wood to form a veneer, the thickness of which is 6.0mm, and the veneer is cut into 10 by a cutting machine. - 120mm wide veneer strips, after the above-mentioned thinning, form wooden beams with point cracks or line cracks (or point cracks and line cracks). The extrusion rolls used are as Figure 5 , Figure 5a The annular tooth-shaped extrusion roller provided with linear convex teeth is shown as having annular convex teeth in the circumferential direction, and several annular convex teeth are arranged in parallel in the axial direction of the extrusion roller. Put the decomposed wood bundles and adhesive (20-35% solid content) in the impregnation treatment tank, pressurize to 0.20-0.80MPa after sealing, keep the pressure for 3-5min, open the treatment tank after releasing the pressure, and take out the dipping treatment tank wooden beams after. Take o...

Embodiment 3

[0095] The poplar waste veneer of the plywood, the thickness is 2mm; the plate clone wood veneer at the bottom of the container, the thickness is 2mm; the waste veneer Douglas fir veneer of the laminated veneer lumber, the thickness is 4mm; After cutting into veneer strips with a width of 10-30mm, use such as Figure 5 , Figure 5a A pair of extruding rollers in the shape of a circular tooth with linear convex teeth extrudes the veneer once, and then uses such as Figure 6 , Figure 6a A pair of extrusion rollers with point-shaped protruding teeth as shown squeezes the veneer once, so that any horizontal straight line L in the cross-sectional direction on the wood beam curtain intersects the linear and / or point-shaped cracks formed by defrosting The number of visible cracks is between 2-10 / cm. Decompose it to form wood bundles with point cracks or linear cracks (or point cracks and linear cracks), place the deflated wood bundles in a phenolic resin glue tank with a solid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com