Patents

Literature

65 results about "Craquelure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Craquelure (French: craquelé, Italian: crettatura) is a fine pattern of dense cracking formed on the surface of materials. It can be a result of drying, aging, intentional patterning, or a combination of all three. The term is most often used to refer to tempera or oil paintings, but it can also develop in old ivory carvings or painted miniatures on an ivory backing. Recently, craquelure has been proposed as a way to authenticate art.

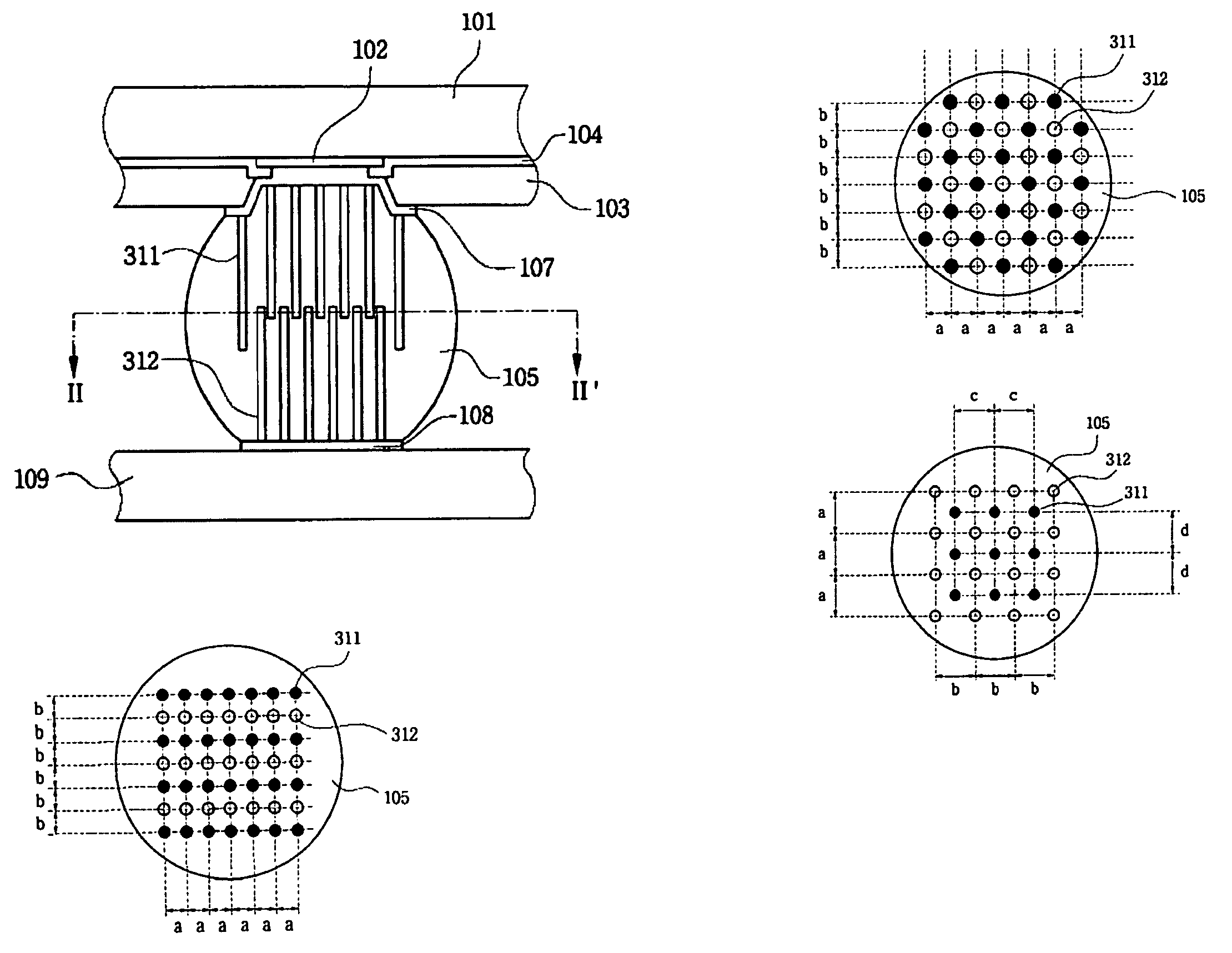

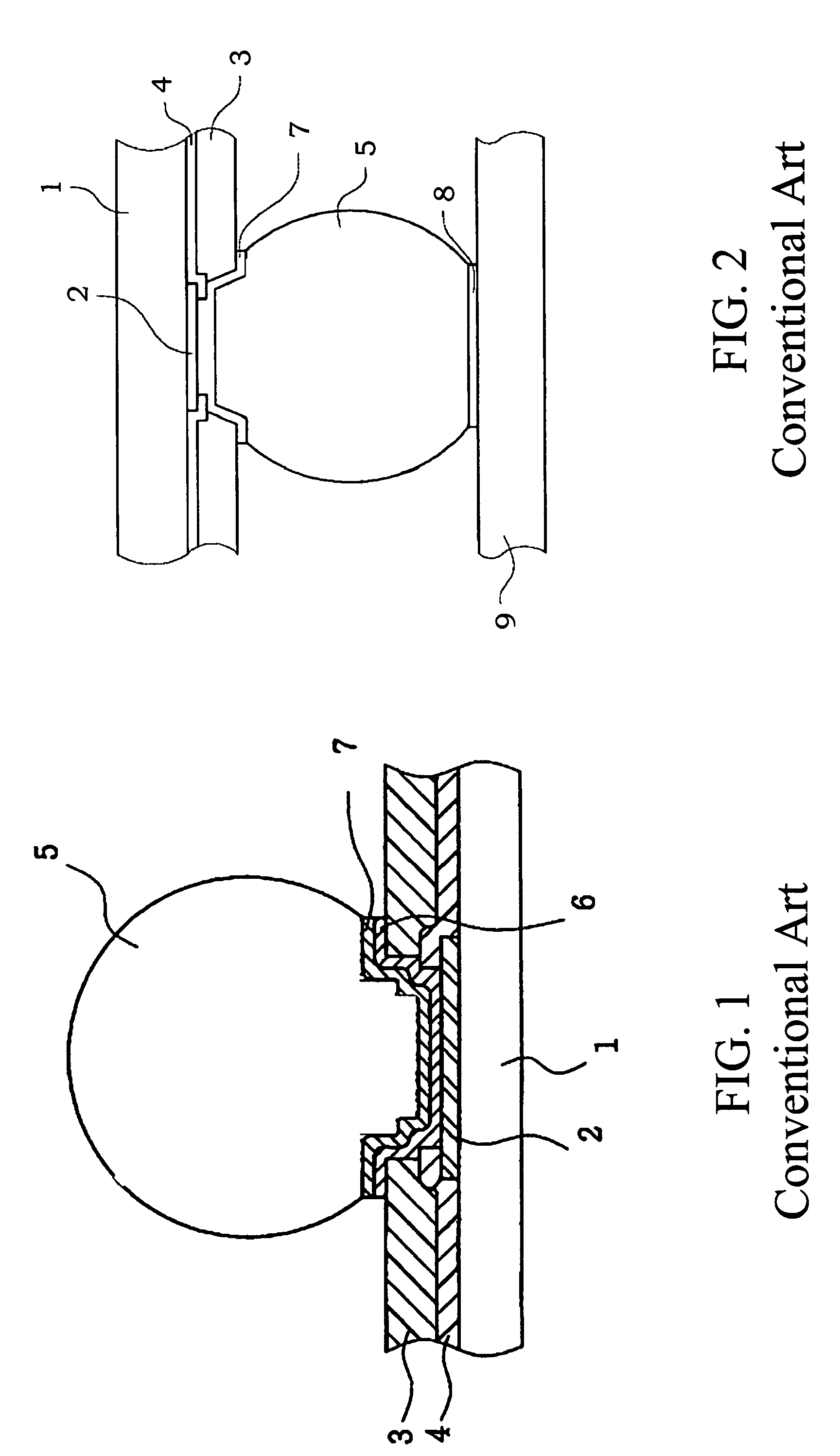

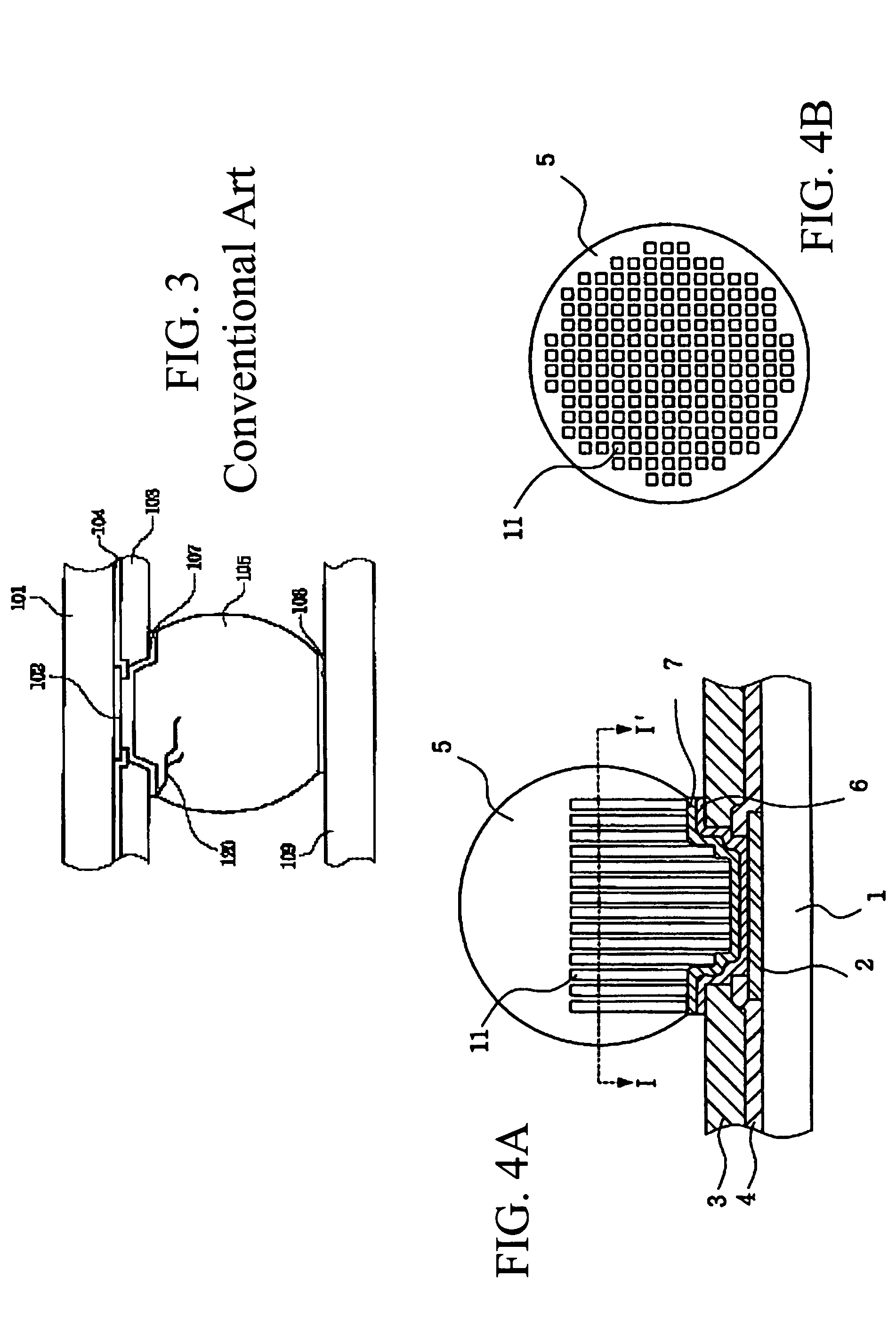

Reinforced solder bump structure and method for forming a reinforced solder bump

A reinforced solder bump connector structure is formed between a contact pad arranged on a semiconductor chip and a ball pad arranged on a mounting substrate. The semiconductor chip includes at least one reinforcing protrusion extending upwardly from a surface of an intermediate layer. The mounting substrate includes at least one reinforcing protrusion extending upwardly from a ball pad, the protrusions from both the chip and the substrate being embedded within the solder bump connector. In some configurations, the reinforcing protrusion from the contact pad and the ball pad are sized and arranged to have overlapping under portions. These overlapping portions may assume a wide variety of configurations that allow the protrusions to overlap without contacting each other including pin arrays and combinations of surrounding and surrounded elements. In each configuration, the reinforcing protrusions will tend to suppress crack formation and / or crack propagation thereby improving reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

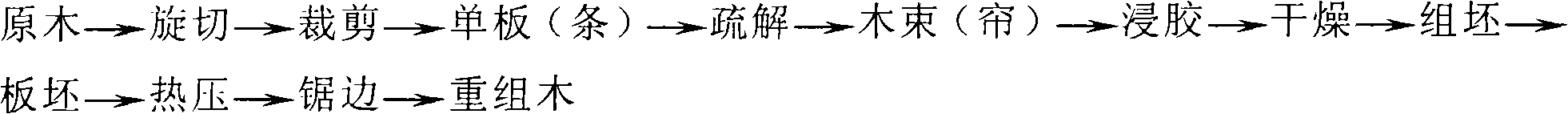

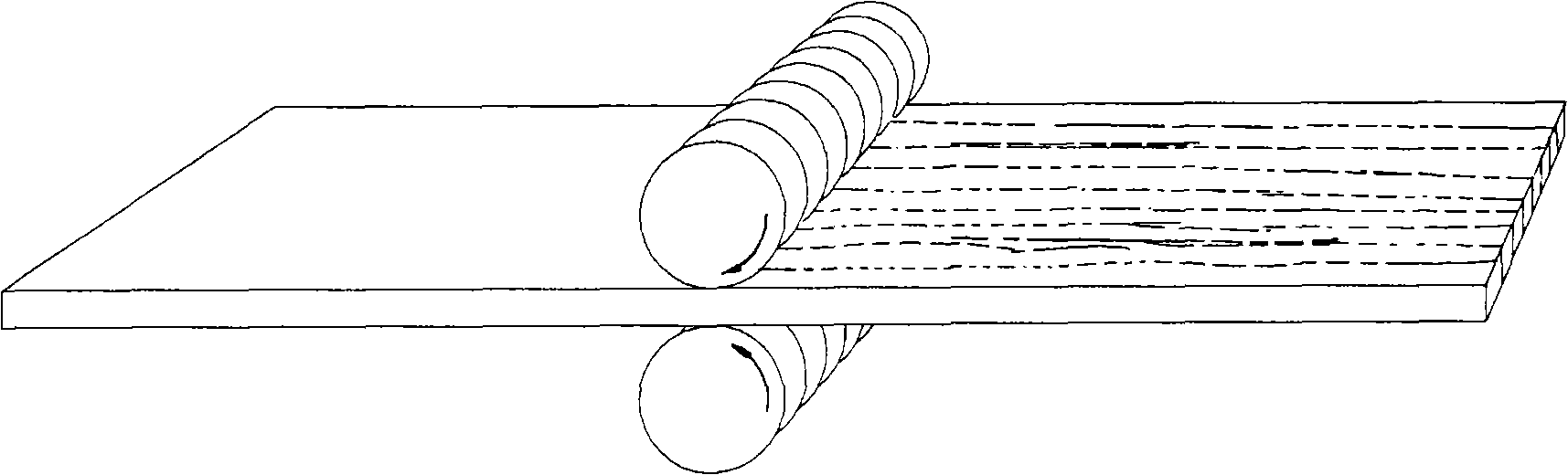

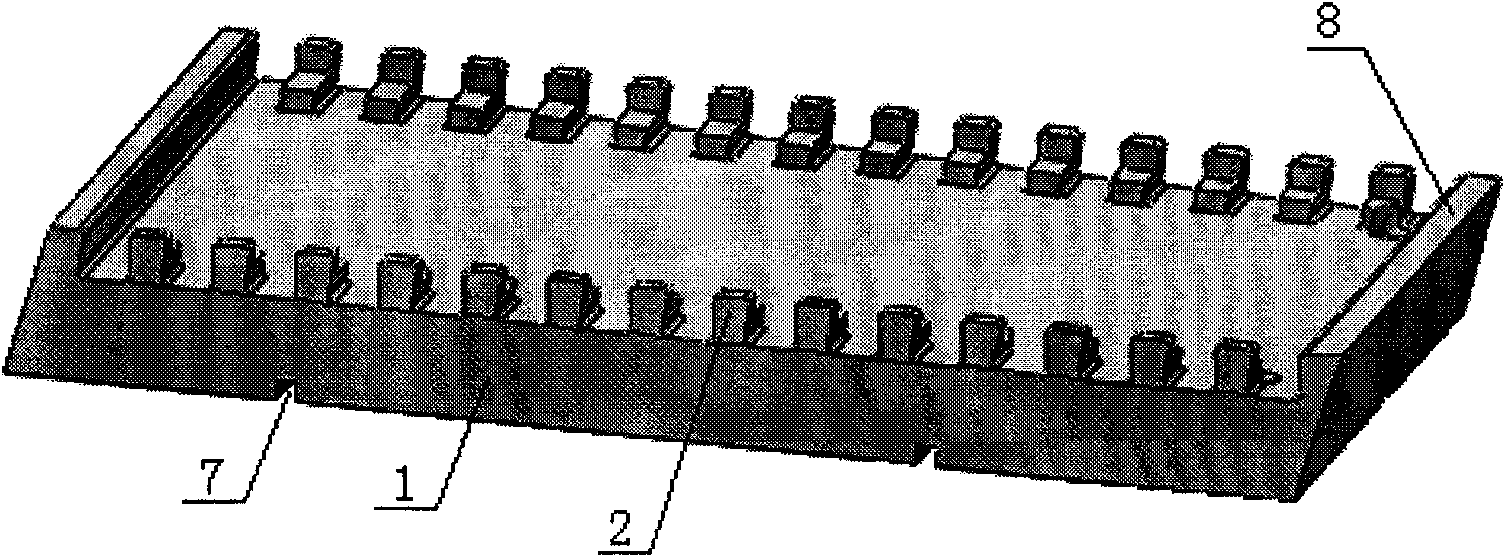

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

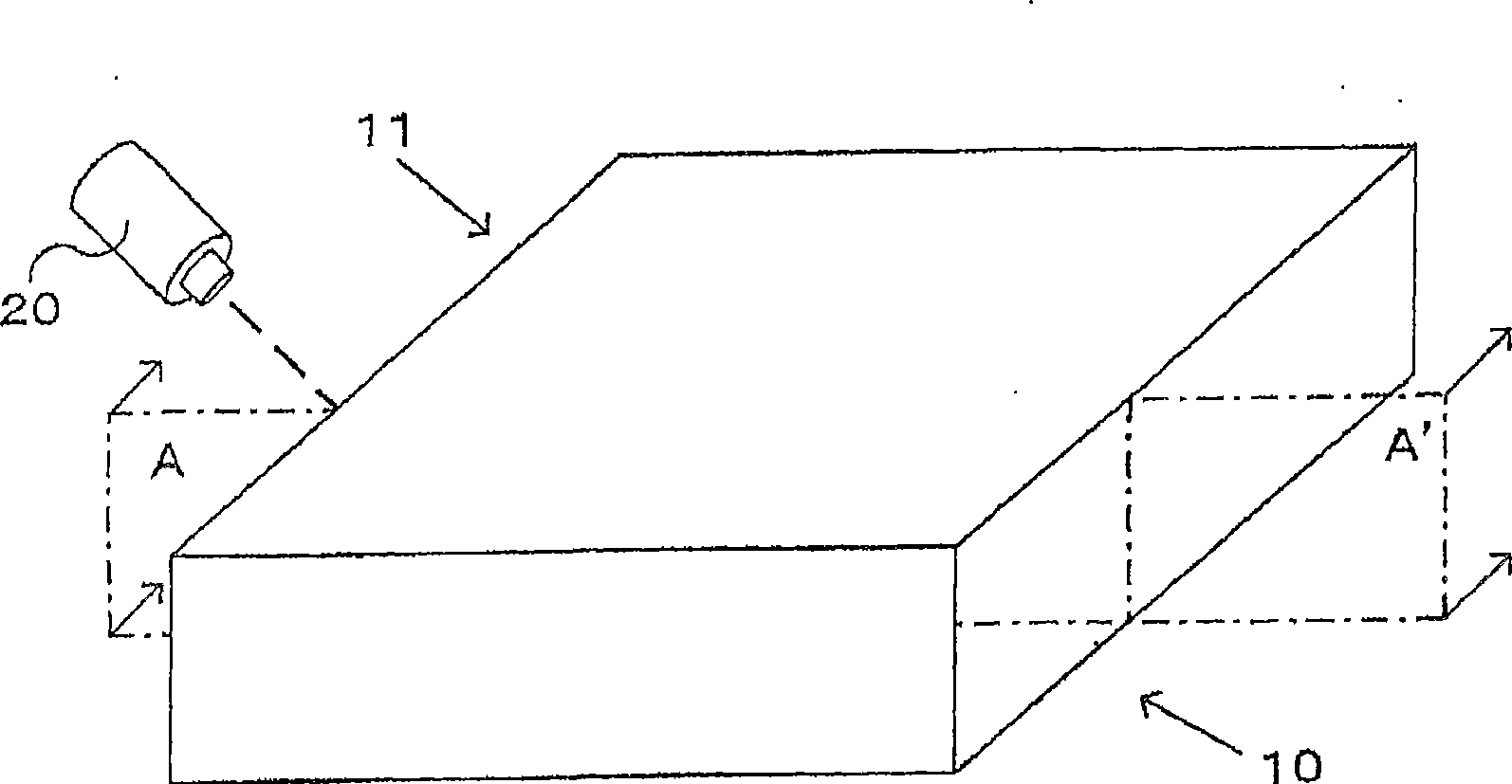

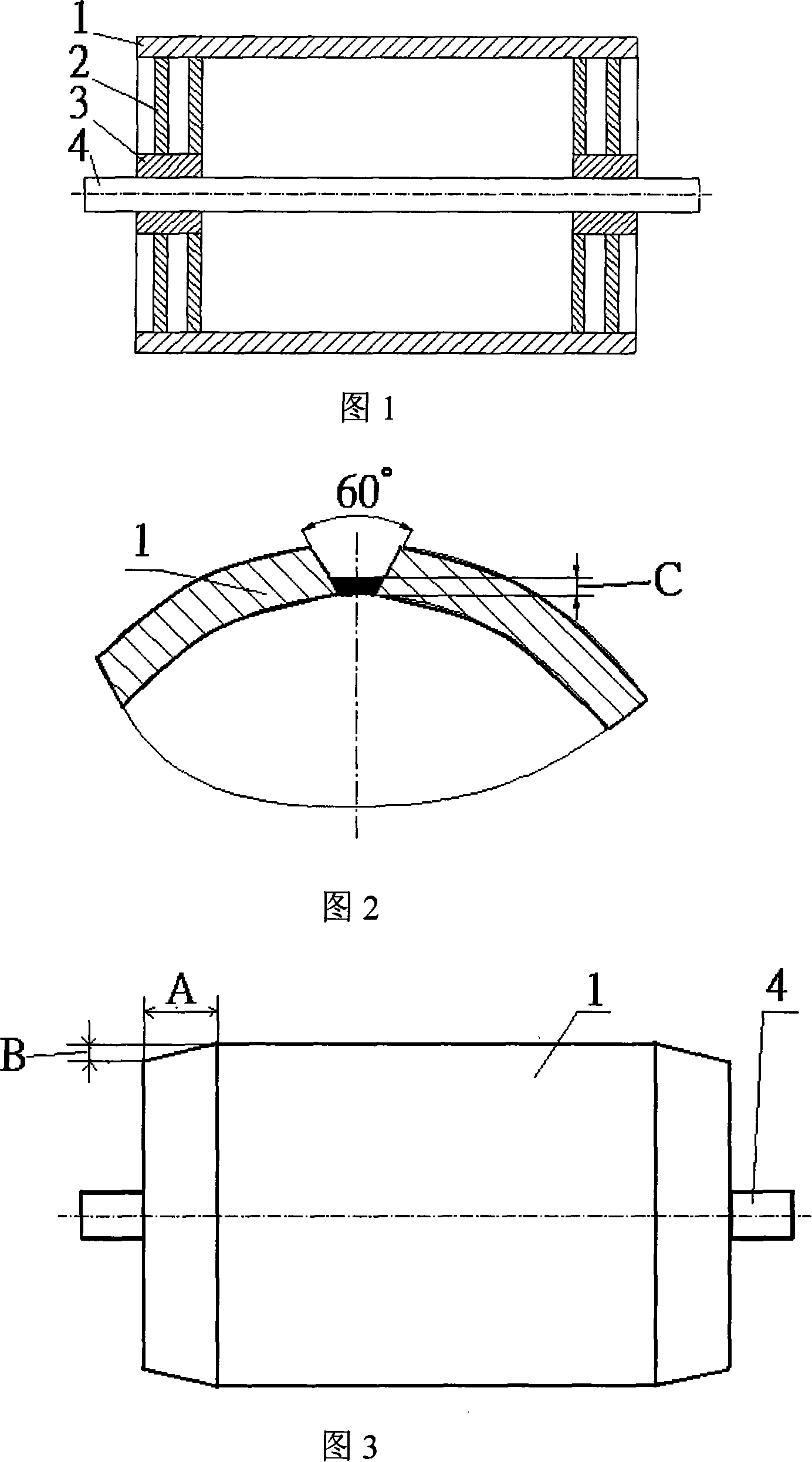

Chamfering method for brittle substrate

InactiveCN101386466AStretch Direction AdjustmentAdjust shapeFine working devicesGlass severing apparatusStress distributionWavelength

The invention provides a chamfering method for brittle material substrate, which can form small depression for chamfering processing surface. A thermal stress distribution field which can control cracks in the substrate is formed by using a laser source with absorptivity of 0.05 to 0.95 relative to the substrate (10), irradiating laser near a edge line (11), forming temperature distribution in the substrate through a laser absorption region (14) from the edge line to inner part of the substrate, extending the cracks through thermal stress distribution in the substrate generated by the temperature distribution, and adjusting extension direction of the cracks.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Method for preparing casting titanium and titanium-aluminum base alloy porous ceramic mould shell

InactiveCN101104195AQuality improvementReduce residual strengthFoundry mouldsFoundry coresHigh pressurePorous ceramics

Disclosed is a preparation method of a porous ceramic shell of cast titanium and titanium aluminum alloys, relating to the melt mould precise casting field. The invention solves the problem that cracks are caused when the thin-walled titanium and the titanium aluminum alloys castings are solidified and shrunk due to the large residual intensity of the present shell of cast titanium and titanium aluminum alloys. The method is as following: firstly, wax mould pressing; secondly, coating and hanging four surface layers, and the manufacturing processes of each layer are that coating and hanging coatings of the surface layer, sprinkling zirconic sand, drying in the room temperature, and then the next layer is coated and hung; thirdly, coating and hanging two transitional layers, whose differences from coating and hanging the surface layers lie in that each coated and hung transitional layer comprises a high polymer and a back coating of water latex, and bauxite sand of 50 to 70 orders is sprinkled; fourthly, coating and hanging four to eight reinforcing layers, whose differences from hanging and coating the transitional layers lie in that the bauxite sand of 30 to 40 orders is sprinkled; fifthly, coating and hanging the coatings of an outer layer , which will be dried in the room temperature; sixthly, dewaxing by high pressure steam; seventhly, roasting the shell. The invention can be widely applied in the manufacturing of the shell of titanium and titanium aluminum alloys castings for the national defense and domestic use.

Owner:HARBIN INST OF TECH

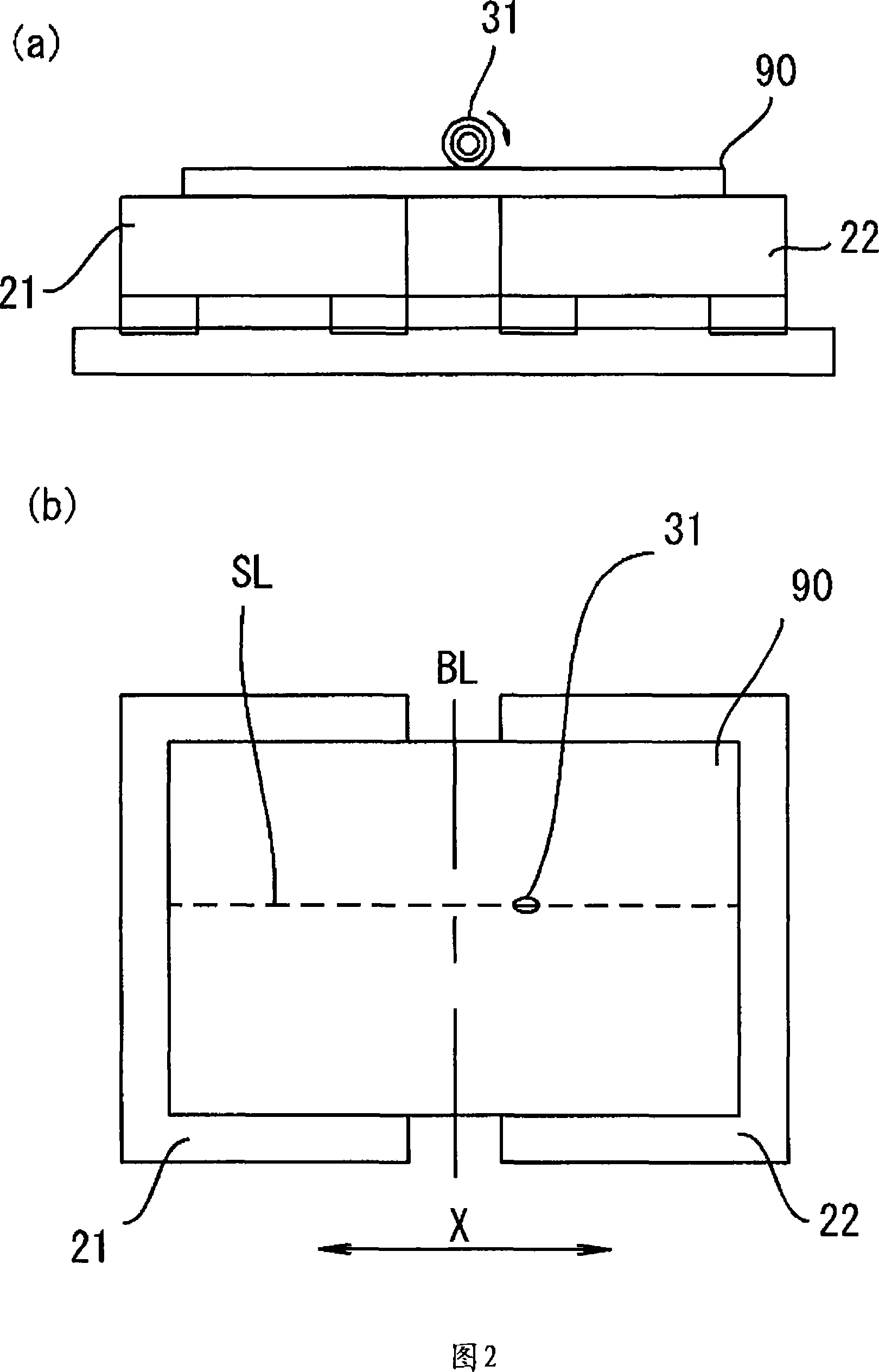

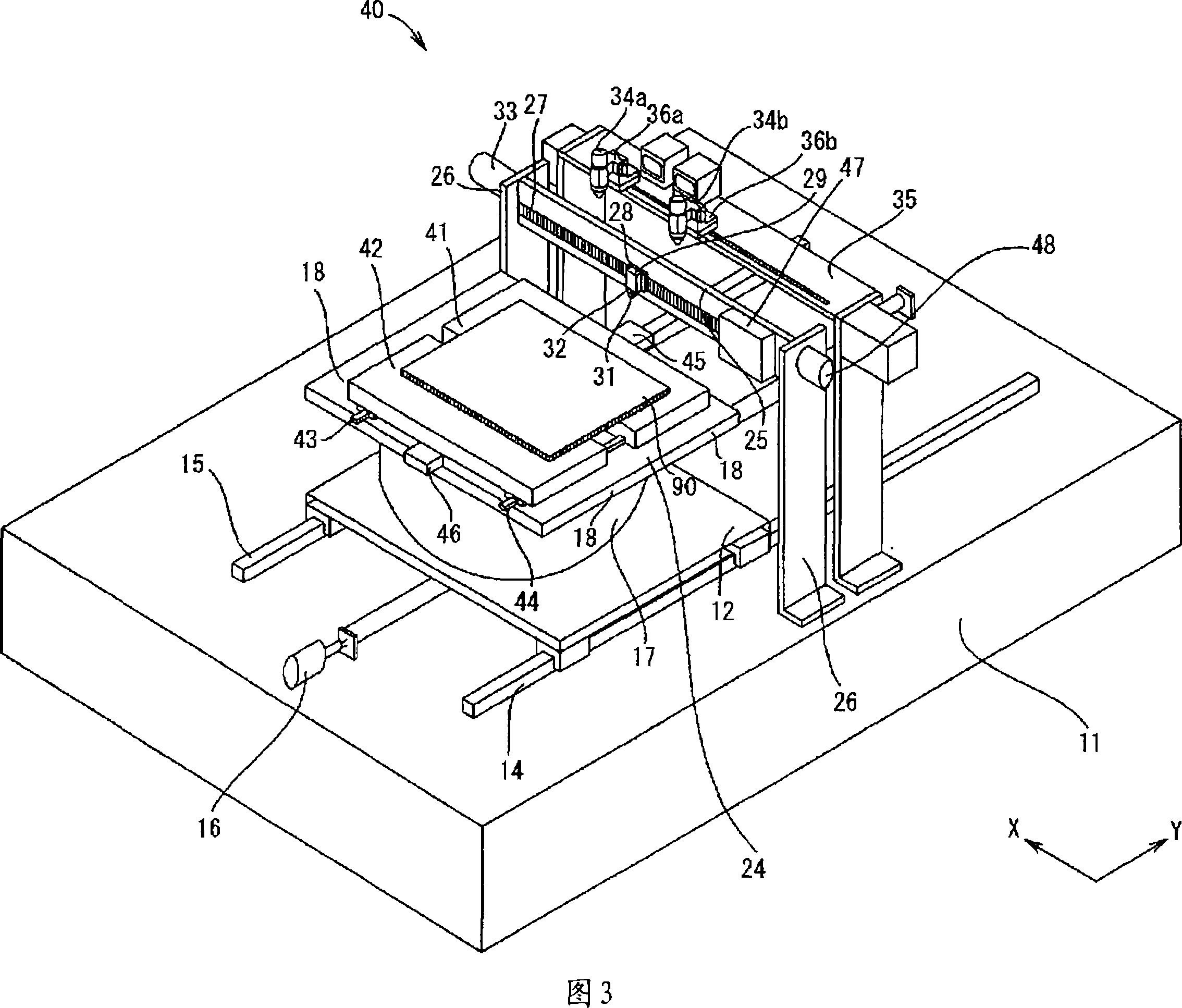

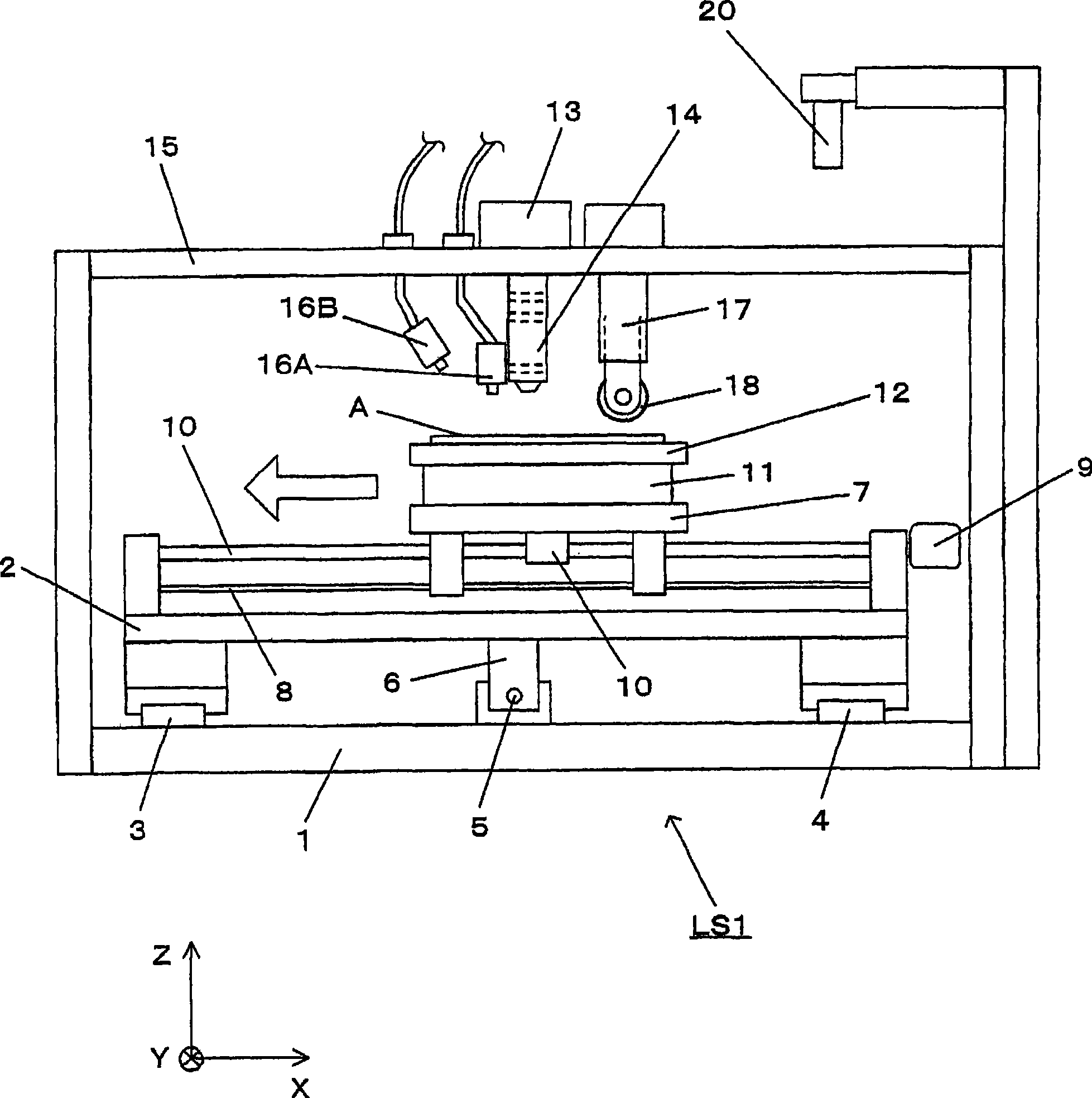

Method and apparatus for scribing brittle material board and system for breaking brittle material board

InactiveCN101068666AEasy to crimp and turnAvoid it happening againConveyorsWorking accessoriesEngineeringVacuum pump

According to the inventive method and apparatus for scribing brittle material board and system for breaking brittle material board, generation of uncontrollable unnecessary cracks in unspecified directions is prevented during scribing process of a brittle material board. A mother glass board (90) is provided on the surface of a first holding table (21) and a second holding table (22). When the mother glass board is fixed on the first holding table (21) and the second holding table (22) by being sucked from a suction hole by a vacuum pump and the like, nonuniform internal stress existing in the mother glass board (90) is adjusted in a specific direction for scribing, by moving the first holding table (21) and / or the second holding table (22) a minute distance along a prescribed direction.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Crackle lacquer, preparing method thereof and spraying method for the same

InactiveCN101210129ANatural textureImprove the three-dimensional effectPretreated surfacesCoatingsLacquerMetallurgy

The invention relates to a crack lacquer. According to the portion by weight, the lacquer comprises the following components that: 11 to 40 percent of thermoset acrylics, 4 to 20 percent of no-light powder, 0.5 to 26 percent of auxiliary, 2.7 to 33 percent of mixed solvent, and 5 to 15 percent of paint; the crack lacquer has natural grain, good three-dimensional effect and even cracks; the crack effect is beautiful with excellent aging resistance, water resistance and stability; the preparation technique of the crack lacquer of the invention is simple, and the spraying method of the crack lacquer is as follows: priming lacquer is firstly sprayed so as to ensure that the priming lacquer is matched with the crack lacquer; in the spraying process, the temperature difference between the bottom of the crack lacquer and a bottom layer is generated by adopting the high solidity and the high speed of the volatilization of the solvent of the crack lacquer; the priming lacquer of the crack lacquer is cracked by means of the strain of a lacquer film; the greater the color difference between the priming lacquer and the crack lacquer, the better the three-dimensional effect of the crack lacquer and the more obvious the aesthetic perception of the decoration.

Owner:海宁市盐官工业投资有限公司

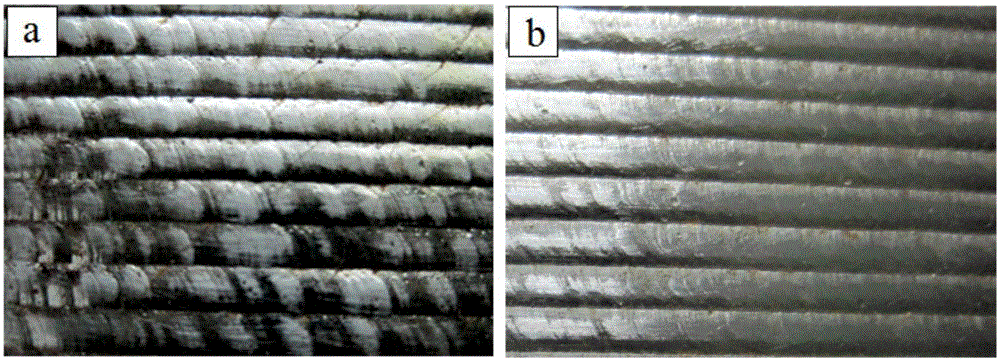

Manufacturing technology of novel hobbing cutter with laser cladding WC wear-resistant coating

ActiveCN103737273AImprove wear performanceInhibit sheddingMetallic material coating processesNumerical controlHobbing

The invention relates to a manufacturing technology of a novel hobbing cutter with a laser cladding WC wear-resistant coating. The manufacturing technology comprises the following steps: (1) manufacturing the hobbing cutter with a forging method, wherein the hobbing cutter is made of alloy steel; (2) carrying out peel removal cleaning treatment on surfaces to be machined of the intertooth space of an alloy cutter; (3) using a transverse flow CO2 laser, taking a numerical control machine tool as a workbench, and carrying out cladding wear-resistant strengthening treatment on the intertooth space of a cutter ring cutter, wherein the thickness of the WC cladding layer is 1.5-2.5mm; (4) carrying out performance detection on a composite coating. A laser surface cladding technology is adopted, and the tissues of a cladding coating mainly consist of carbides and a supersaturated solid solution superfine casting-state structure, wherein spherical tungsten carbide ceramics are of ultra-high hardness and uniformly distributed on a binding phase with extremely high hardness level, and also achieves an inhibition effect on abrasion, and the grinding resistance between hobbing cutter edges can be effectively improved; the binding phase is good in tenacity and high in strength, the formation of cracks can be effectively reduced, and the wear resistance and corrosive resistance of the hobbing cutter is improved, and the service life of the hobbing cutter is prolonged.

Owner:江苏点金激光科技有限公司

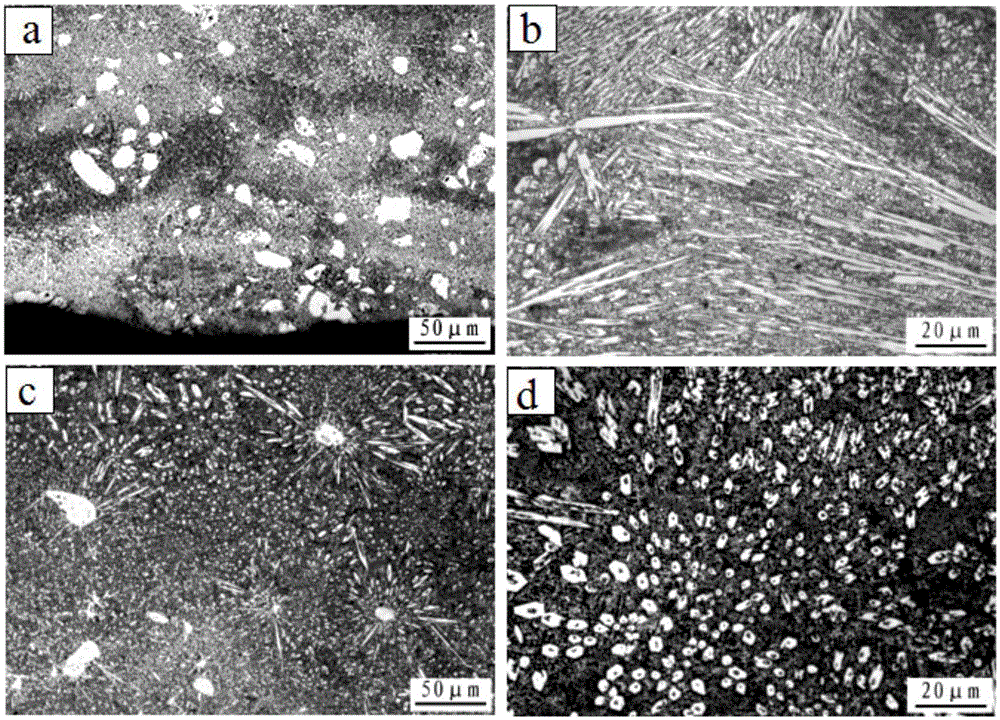

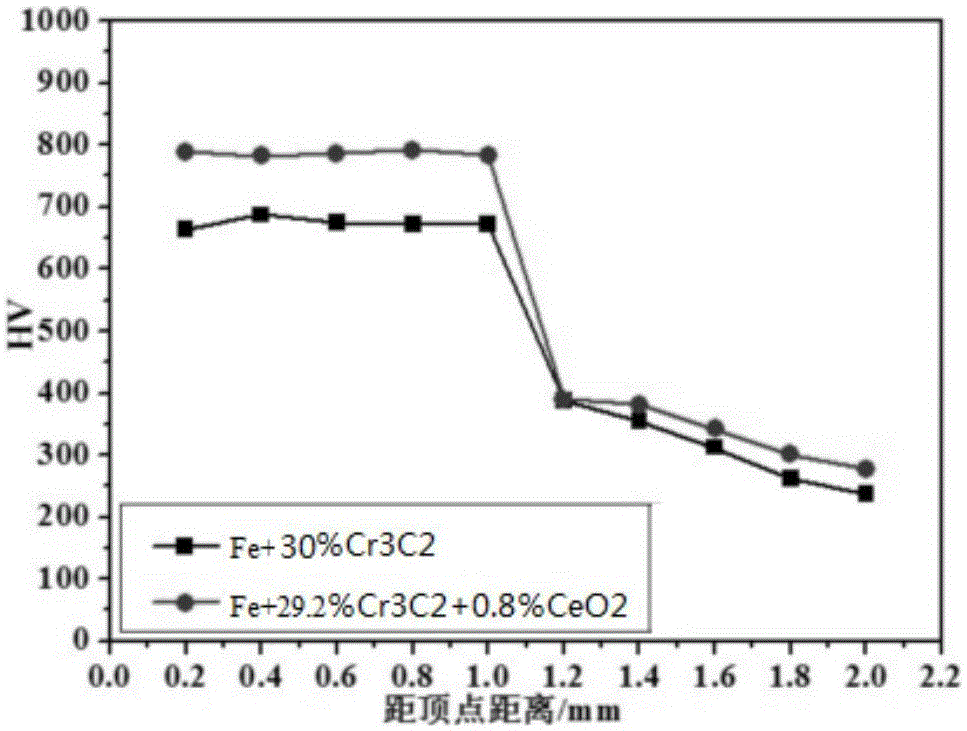

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

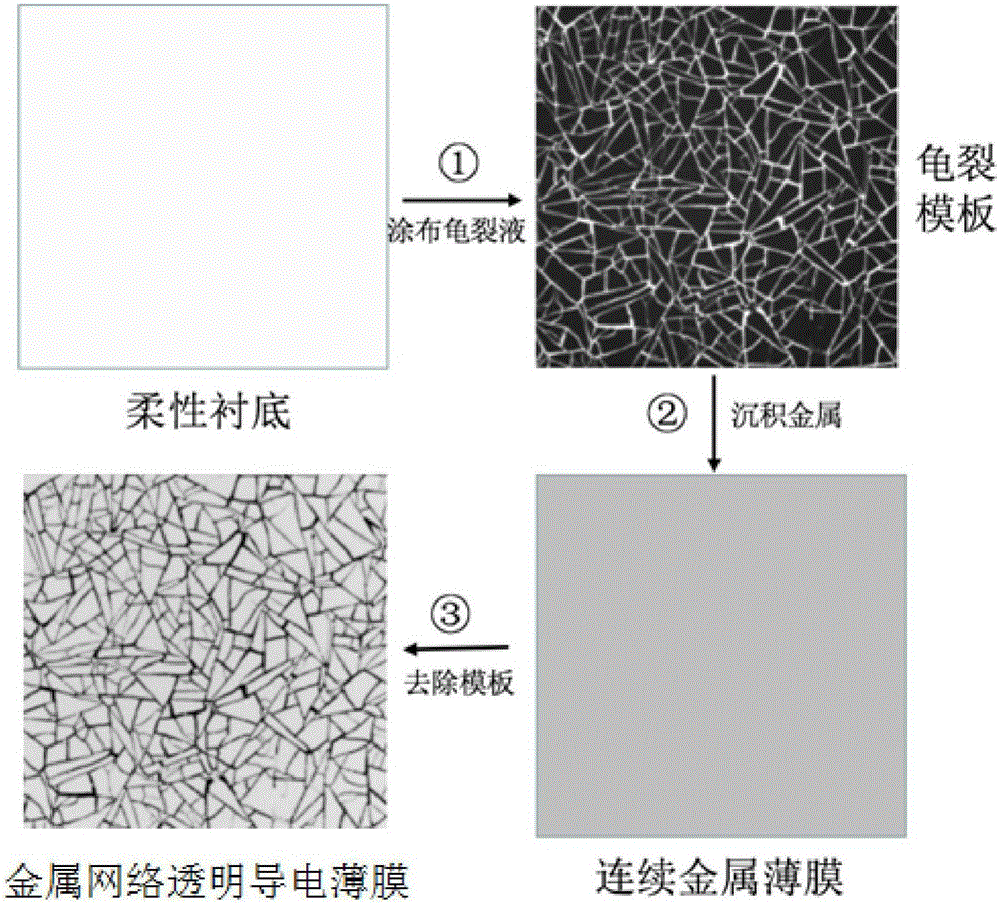

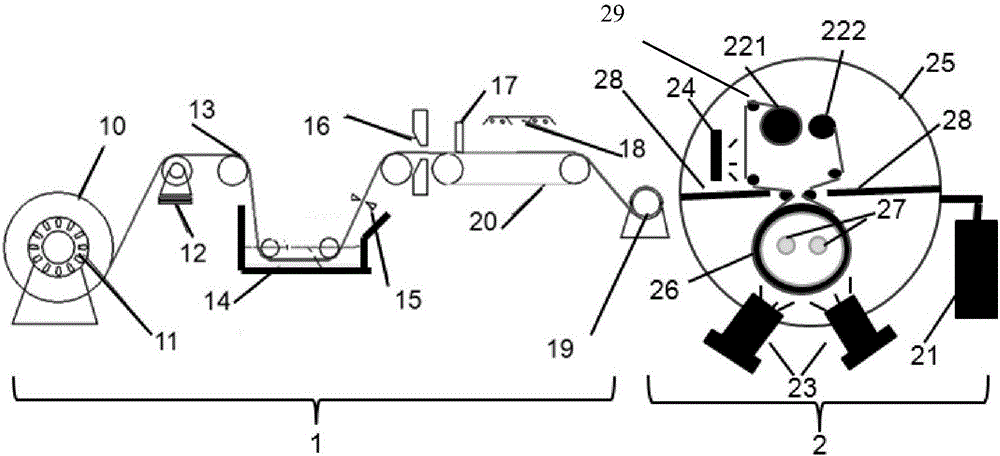

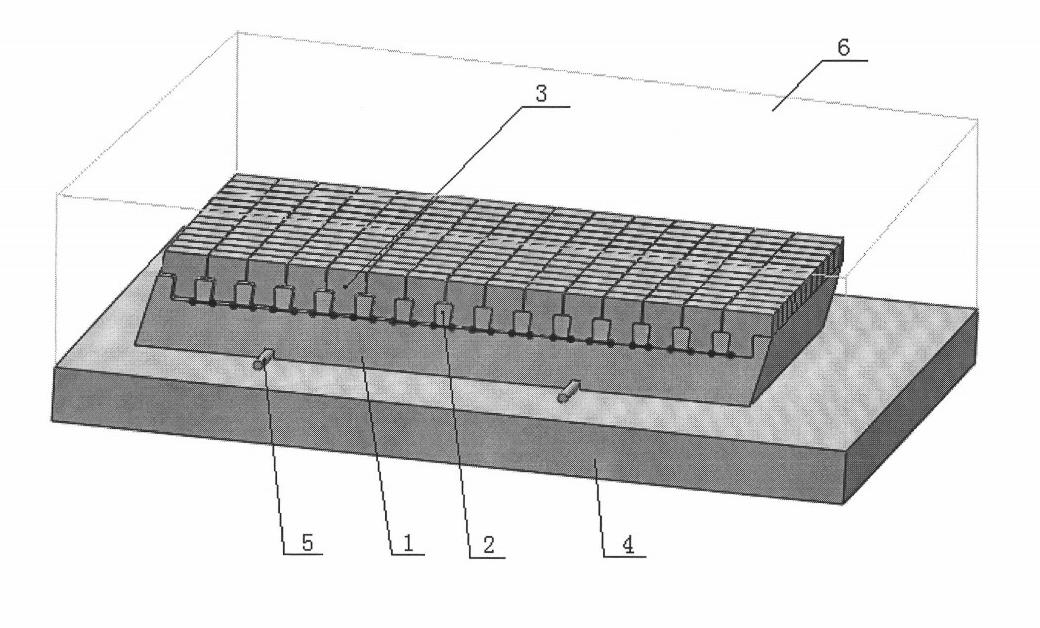

Method and apparatus for continuous production of flexible micro-nano metal network transparent conductive film

ActiveCN106244989AImprove uniformityImprove transmittanceVacuum evaporation coatingSputtering coatingEngineeringVacuum pump

The invention discloses a method and apparatus for continuous production of a flexible micro-nano metal network transparent conductive film. The method comprises the steps of: continuously conveying a flexible substrate to undergo pre-cleaning, air drying, atmospheric pressure plasma cleaning, cracking liquid coating and heating in order, thus forming a craquelure template on the flexible substrate; placing the flexible substrate in a vacuum chamber and performing vacuum pumping on the vacuum chamber; subjecting the flexible substrate to secondary plasma cleaning, then coating a compact metal film, and filling the craquelures on the craquelure template with a metal film material in the process so as to obtain a flexible micro-nano metal network transparent conductive film semi-finished product; releasing vacuum, taking out the semi-finished product from the vacuum chamber, and removing the craquelure template from the flexible substrate, thus obtaining the product. The method and apparatus provided by the invention realize continuous and large-area production of the flexible micro-nano metal network transparent conductive film. The film coating mode is suitable for industrial automatic continuous magnetron sputtering production lines, can greatly shorten the production cycle, and substantially improves the productivity.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

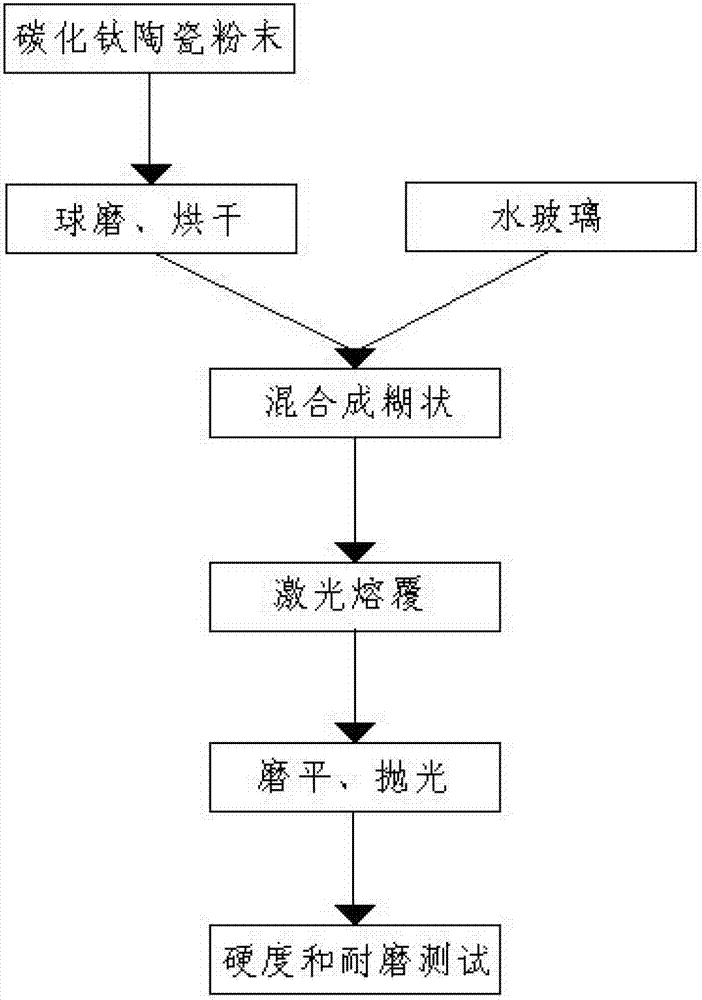

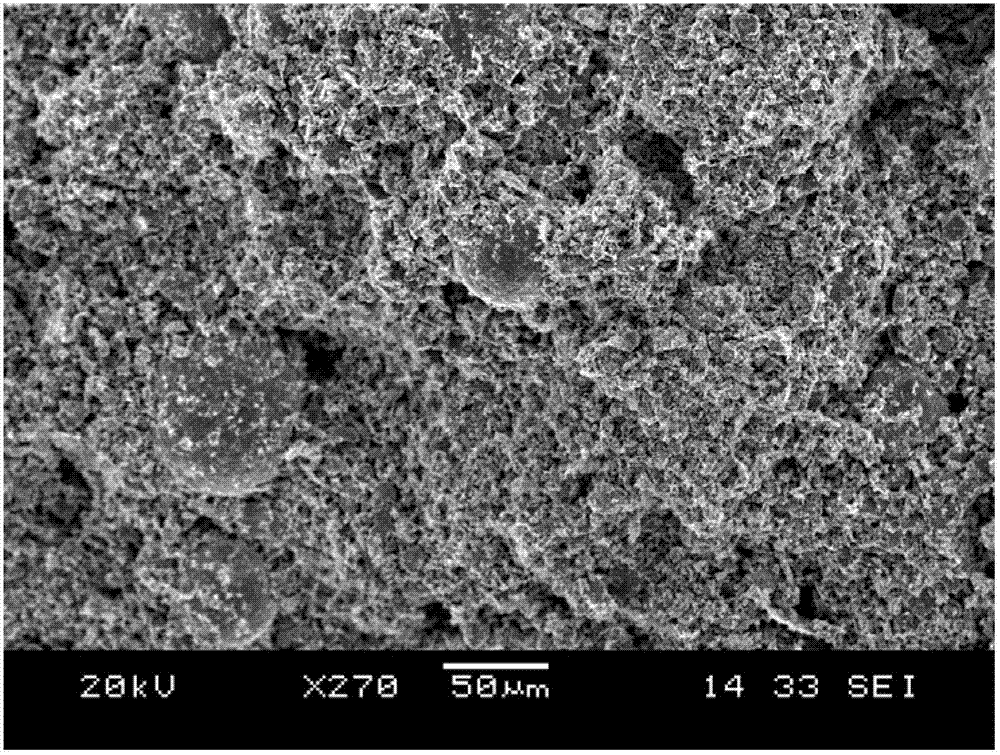

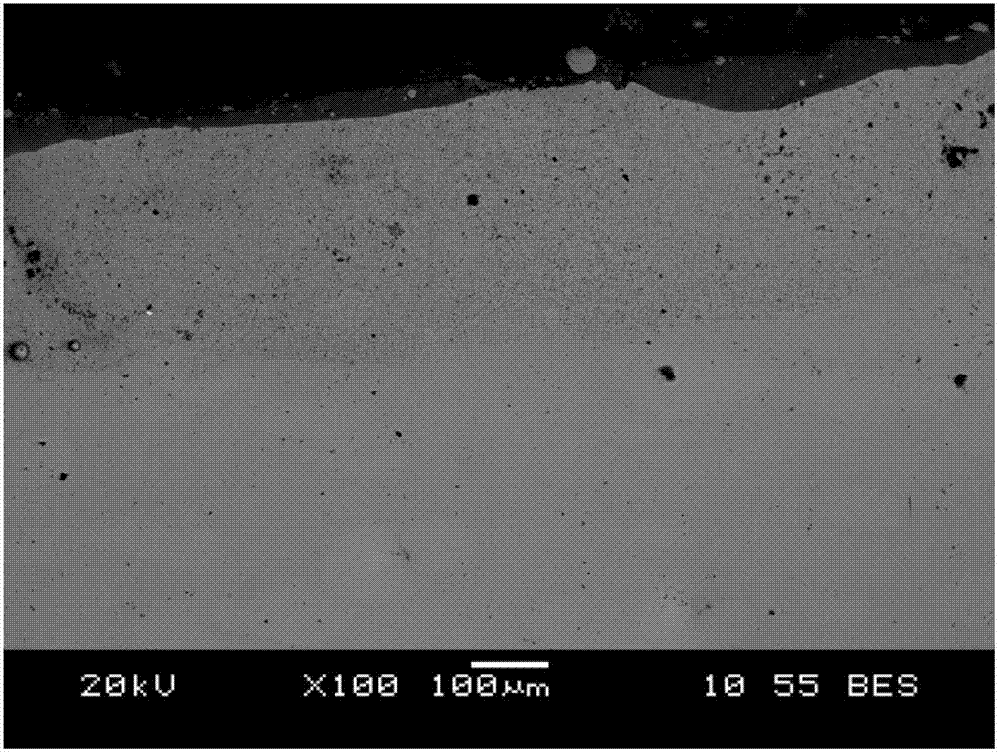

Titanium carbide metal ceramic powder and method for laser cladding of powder

InactiveCN102962447AImprove wear resistanceHigh hardnessMetallic material coating processesHardnessTitanium carbide

The invention relates to the technical field of metal surface treatment, and specifically discloses a titanium carbide metal ceramic powder and a method for laser cladding of the powder. The titanium carbide metal ceramic powder consists of titanium carbide, lanthanum oxide and nickel 60. The method comprises the following steps of: putting the titanium carbide ceramic powder in a ball mill to be ball-milled for 15 hours to 20 hours, and drying the ball-milled powder; mixing the dried powder and water glass into a paste powder; coating the paste powder onto the surface of a test block to be clad to be flatly pressed, and drying naturally; cladding the dried paste powder on the test block by using a pulsed laser machine; flatly grinding the clad test block, carrying out the polishing treatment of the clad surface, and then cleaning with anhydrous ethanol; and carrying out the hardness test and the wear test of the test block. The cladding layer obtained from the invention has the advantages of strong high temperature resistance, strong wear resistance, high hardness, compact and uniform structure, uniform thickness, grain refinement, few pores and cracks, good surface quality and the like.

Owner:SHANTOU UNIV

Reflective crack relief pavement interlayer with improved load bearing capacity and method for designing interlayer

ActiveUS20050022696A1Prevent moistureSlow deteriorationIn situ pavingsSingle unit pavingsPolymer modifiedRoad surface

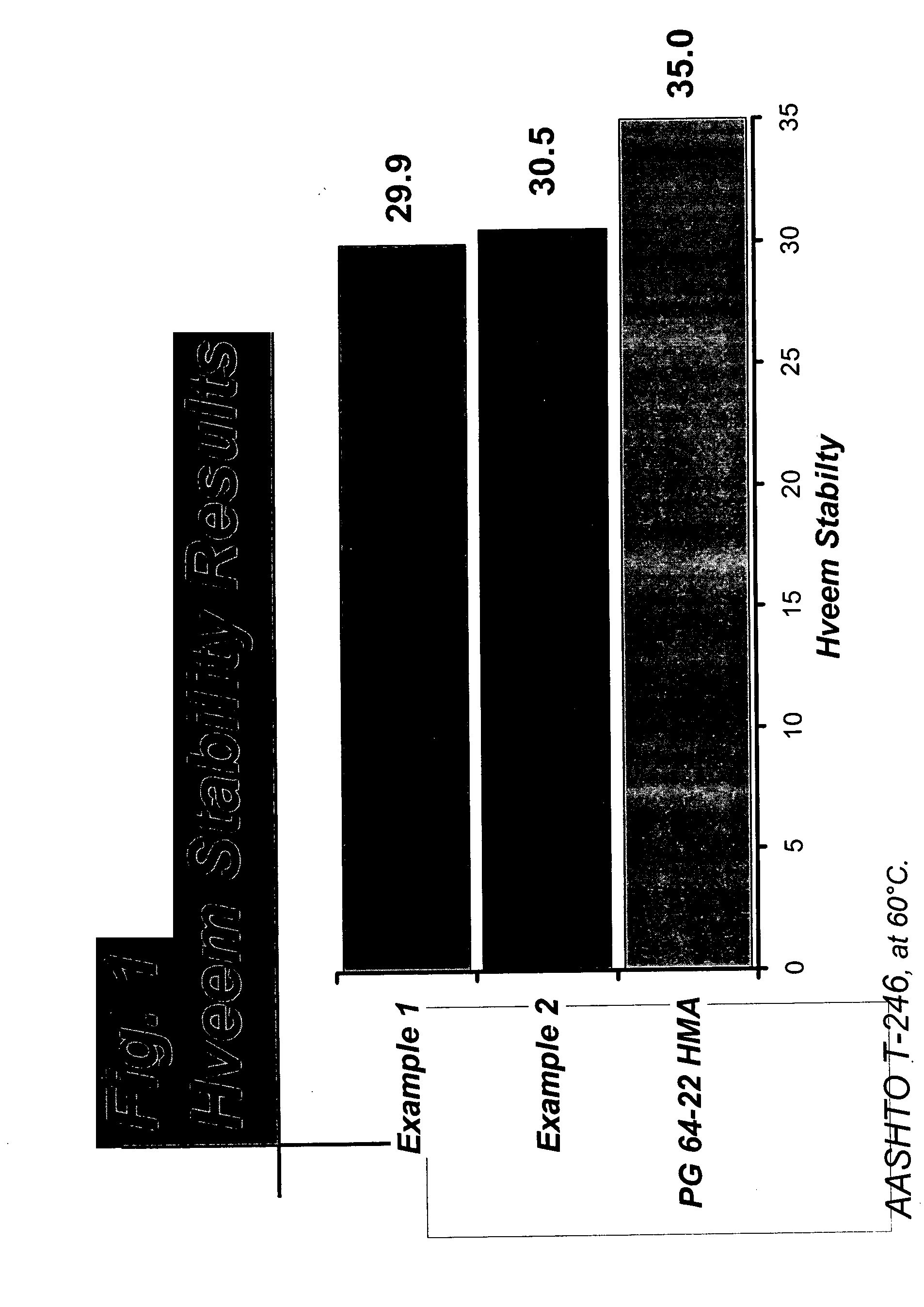

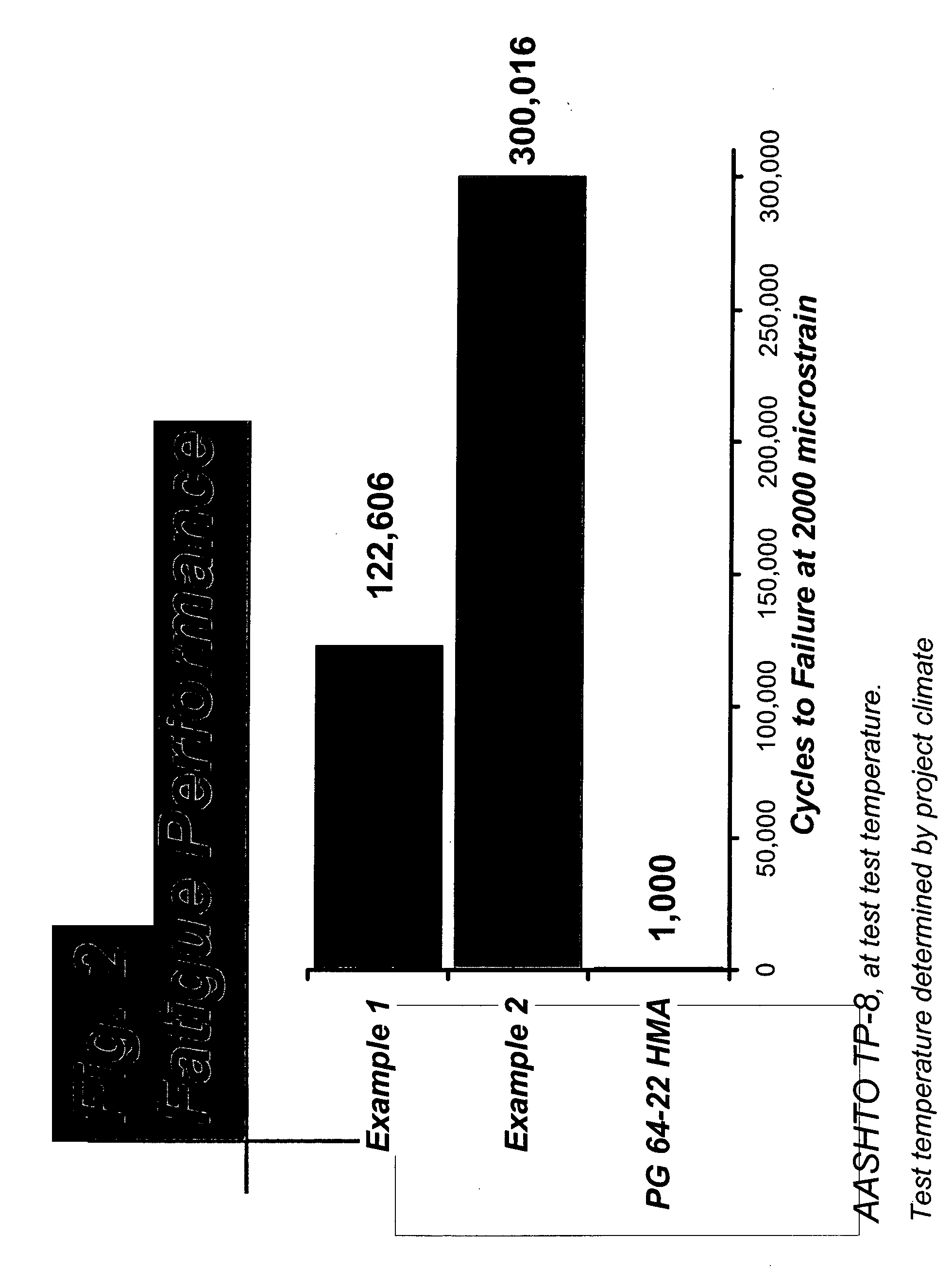

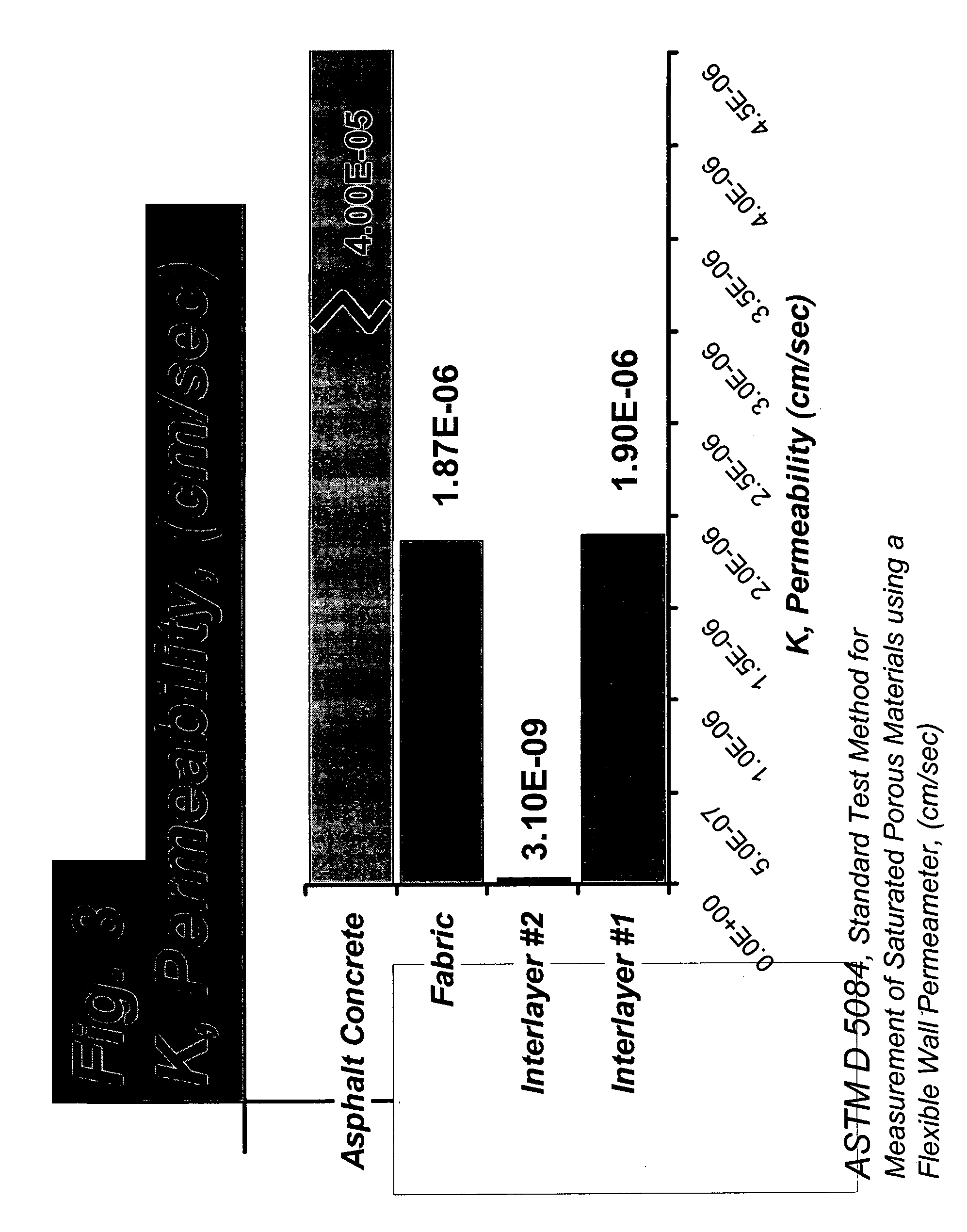

A highly strain tolerant, substantially moisture impermeable, reflective crack relief interlayer is provided. The interlayer includes a polymer modified asphalt binder mixed with a dense fine aggregate mixture containing a substantial amount of manufactured sand. The interlayer mix is designed using a fatigue test and a stability test. Preferably, a hot mix asphalt overlay that is compatible with the interlayer, as well as the demands of local traffic and climate, is placed over the interlayer so that a protected, smooth paved surface is provided. The interlayer may delay the first appearance of cracks and the severity of cracks for several years compared with traditional hot mix overlays and extend pavement service life.

Owner:ARRMAZ PROD INC

Manufacturing method of surface-quenching chromium-plating winded-welding roller

InactiveCN101134277AAvoid crackingGuaranteed depth uniformityFurnace typesHeat treatment process controlManufacturing cost reductionSand blasting

The present invention discloses surface quenched chrome plated wound and welded roller making process, which includes the steps of hot winding, bottoming welding and processing bevel, coarse turning, surface quenching, semi-finish turning, assembling welding, finish machining and post-treatment. The process of the present invention is suitable for making roller of 500-1200 mm diameter, 25 mm wall thickness and 2050-2200 mm length, and roller surface is treated through quenching, sand blasting to roughen and chrome plating. The present invention has the advantages of saving in material, low making cost and short production period.

Owner:MCC SFRE HEAVY IND EQUIP

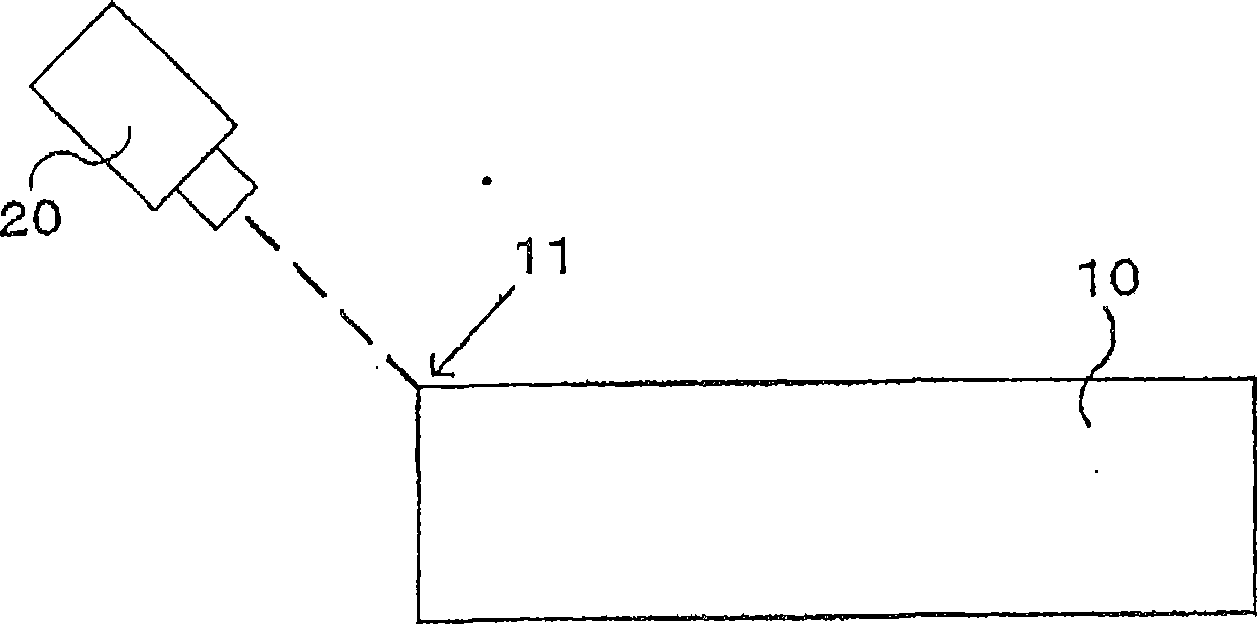

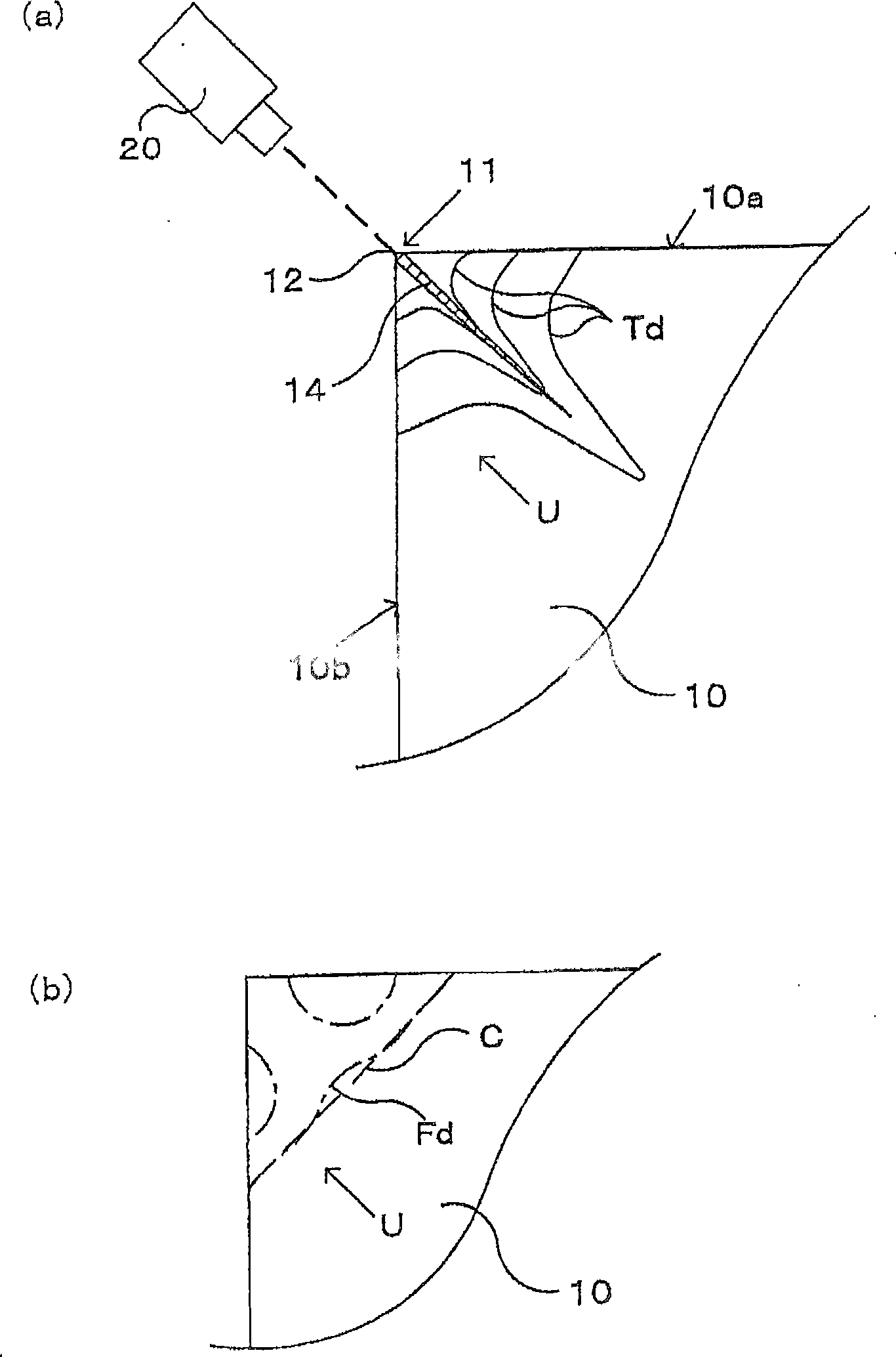

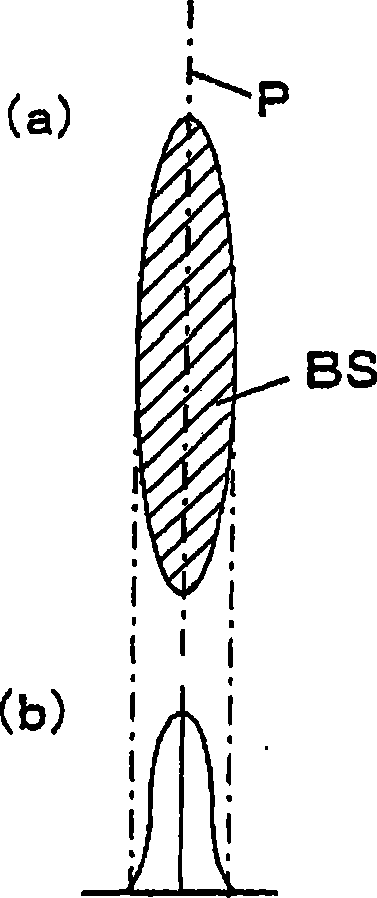

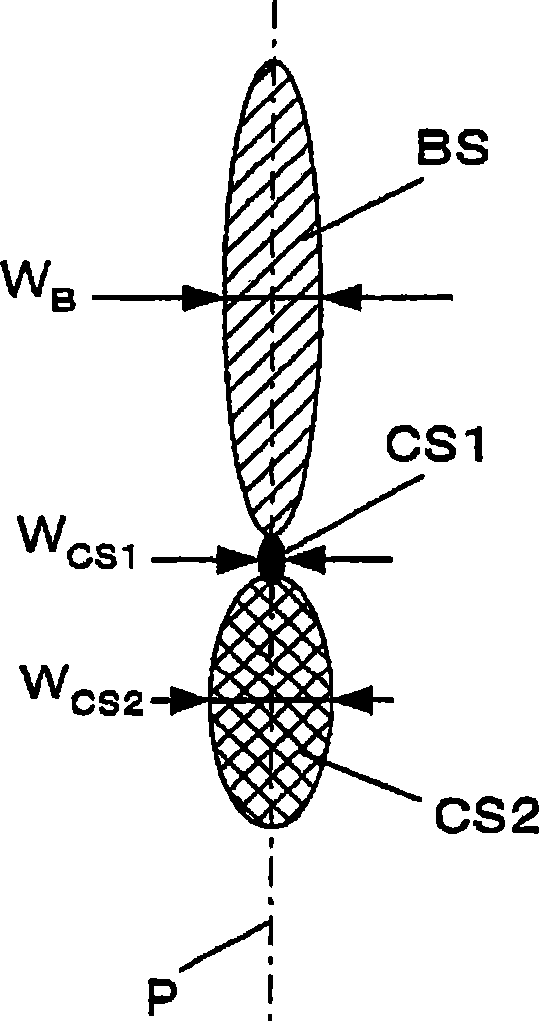

Processing method of brittle material substrate

InactiveCN101396771ASemiconductor/solid-state device manufacturingFine working devicesEngineeringCraquelure

The present invention provides a method for processing substrate made of brittle material. A crackle which penetrates into the inner part of substrate can be reliably formed at the correct position along a preset dividing line. The method for processing substrate made of brittle material uses a heating step and a cooling step for forming the crackle. The heating is executed with a mode that the beam spot (BS) moves relatively along the preset dividing line (P) according to the heating step. The cooling is executed with a mode that the cooling spot moves relatively along the track for scanningthe beam spots according to the cooling step. The cooling step comprises the following procedures executed sequentially: (a) a first cooling procedure for relatively moving the first cooling spot (CS1) which is reduced to smaller than the width of beam spots along with the beam spot thereby extending the shallow crackle (S2); and (b) a second cooling procedure for relatively moving the second cooling spot (CS2) which is extended to larger than the width of the beam spot along with the track for scanning the first cooling point, thereby penetrating the shallow crackle formed beforehand in the thickness direction of substrate.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Electromagnetic stirring laser cladding repairing method for cracks of ultra-high strength steel undercarriage component

InactiveCN107723701ACrack Defect RepairLow costMetallic material coating processesSurface cleaningStress relief

The invention belongs to the technical field of laser material additive manufacturing and repairing, and relates to an electromagnetic stirring laser cladding repairing method for cracks of an ultra-high strength steel undercarriage component. The electromagnetic stirring laser cladding repairing method is mainly used for repairing the surface cracks on the undercarriage component. The electromagnetic stirring laser cladding repairing method comprises the steps that (1) a material used for laser cladding repairing is prepared; (2) surface cleaning is conducted before repairing; (3) electromagnetic stirring assists laser cladding repairing; (4) machining is conducted; (5) nondestructive testing is conducted; and (6) repairing is finished after stress relief annealing is conducted. Accordingto the electromagnetic stirring laser cladding repairing method for the cracks of the ultra-high strength steel undercarriage component, the average tensile strength of direct laser cladding repairing is 1424.3 MPa, the average extension rate is 11.5%, the average impact toughness is 478 KJ / m<2>, and the average microhardness of repaired metal is 464.6 HV; and the average tensile strength of electromagnetic stirring assisted laser cladding repairing is 1466.7 MPa, the average extension rate is 15.1%, the average impact toughness is 665 KJ / m<2>, and the average microhardness of the repaired metal is 491.4 HV. Deformation of the component is controllable after repairing, the repaired part is free of defect, the repair area is better in room-temperature plasticity and impact toughness, and the service life of the undercarriage component is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Elastic true stone lacquer

The invention relates to the technical field of building coating, in particular to an elastic true stone lacquer. The elastic true stone lacquer comprises the following components in parts by weight: 80-120 parts of water, 3-6 parts of film-forming additive, 100-200 parts of elastic emulsion, 1-3 parts of thickening agent and 500-800 parts of natural color sand. Because of adopting the above technical scheme, the invention takes natural color sand in the natural world as a basis raw material which is matched with elastic emulsion and various auxiliaries to be mixed to prepare the elastic true stone lacquer. The elastic true stone lacquer serves as the decorative layer of building walls, has vivid stone-like effect, has certain elasticity and favorable flexible crimpiness, prevents chapping, can be freely designed and applied and can freely be designed and constructed at any position of the building; and the elastic paint film thereof has the characteristics of filling fine cracks and can fill up wall body cracks because of expansion caused by heat and contraction caused by cold, and coating durability can last more than 10 years.

Owner:上海雅达特种涂料有限公司 +1

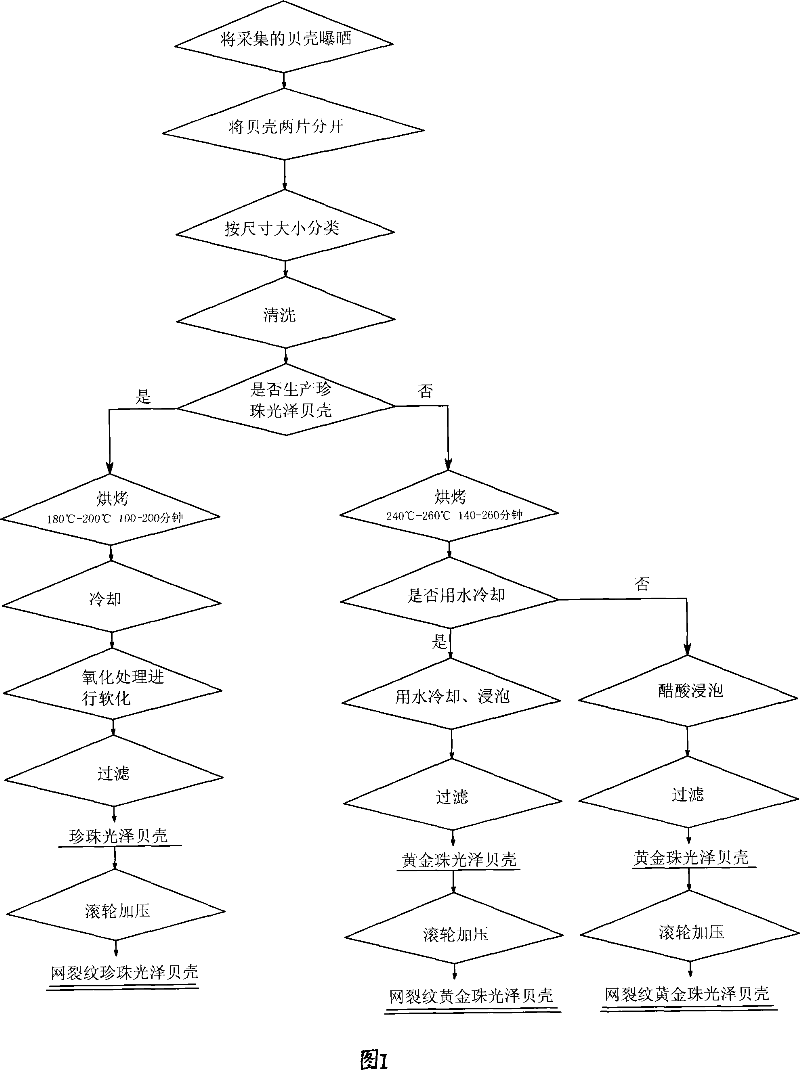

A shell softening method for making the shell surface generate better pearly luster and golden pearly luster

InactiveCN101037073ABeautify lifeImprove living qualityDecorative surface effectsArtistic surface treatmentEngineeringWarming process

The invention discloses a method of softening the shell, which can make the shell surface of better pearl gloss and gold pearl gloss, the beneficial effects are that: insolating the collecting shell in the sun while separating and sorting the two slices of the shell; being divided the CaCo3 structure by the warming process; bleaching the shell by the oxidant, and softing the column edge layer of the shell; warming the crystal of the CaCo3 in the shell to loose by baking, controlling the different temperatures and warming times to obtain the shell of pearl gloss and gold pearl gloss; mechanical pressing the shell of pearl gloss and gold pearl gloss to generate netty crack and obtain the netty crack shells of pearl gloss and gold pearl gloss. The softing netty crack shells of pearl gloss and gold pearl gloss can be used for manufacturing decorative materials which can beautify the people's life and improve the standard of living.

Owner:DONGGUAN TCI TANG CHEN GRAFT & GIFT

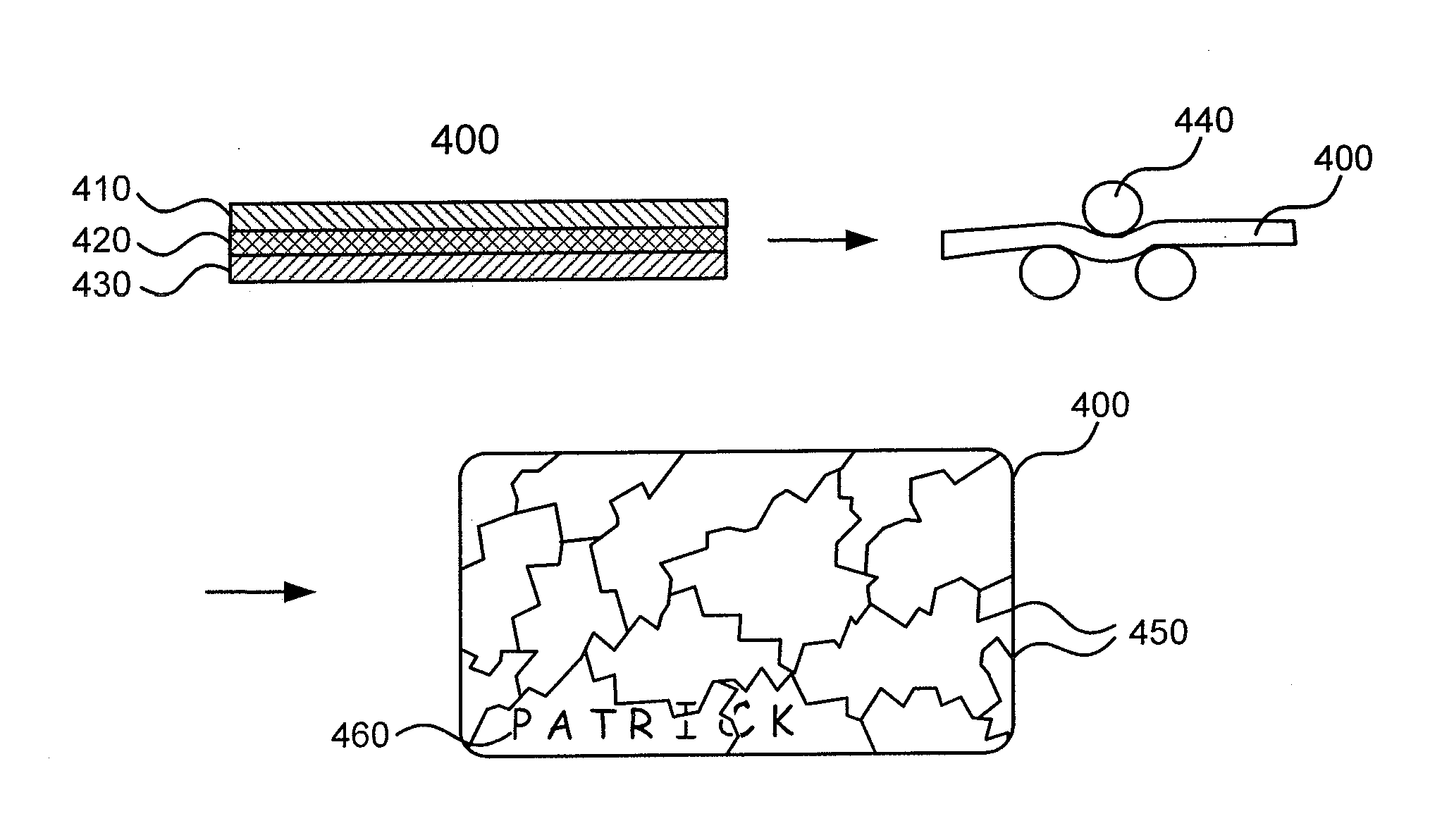

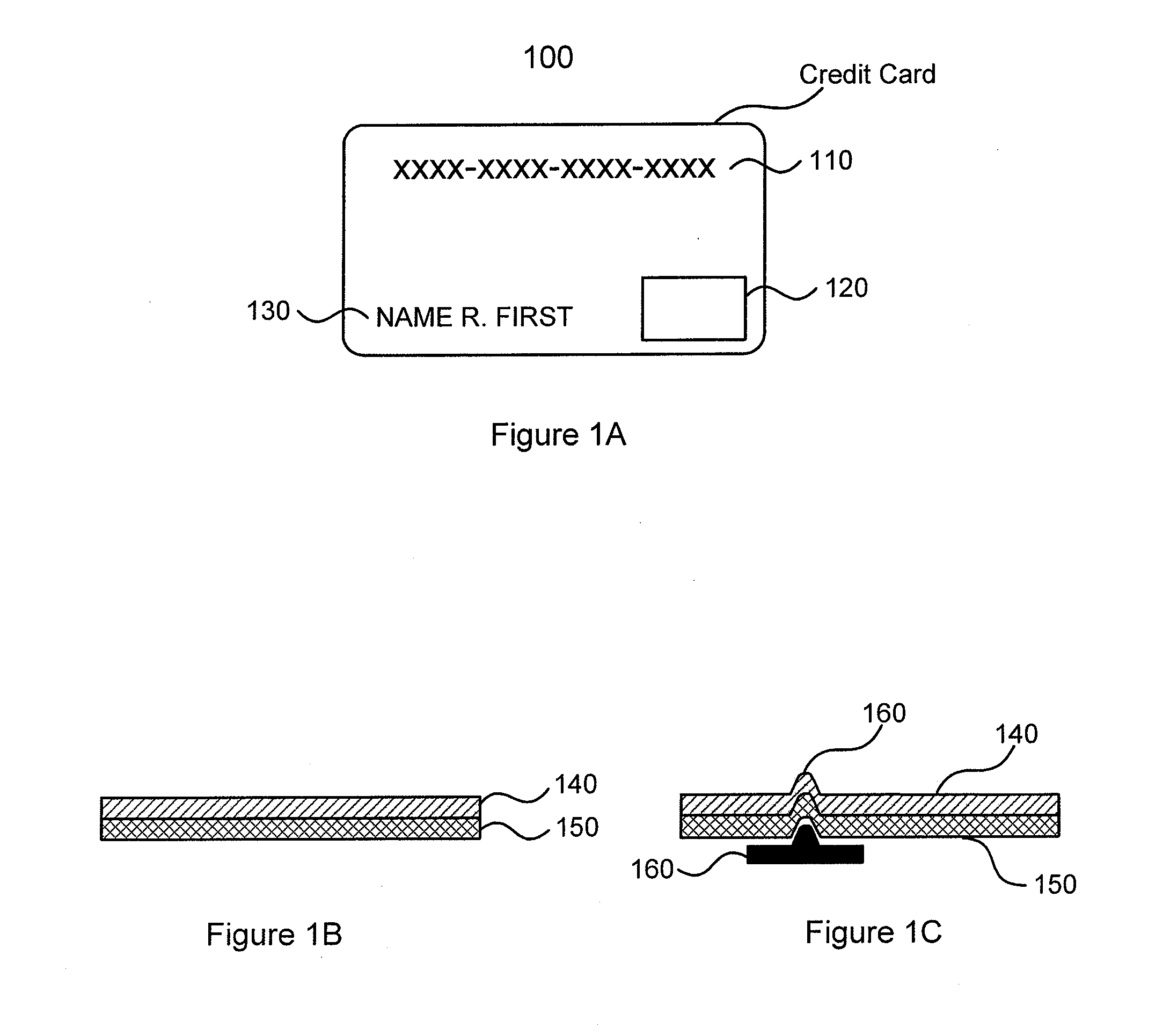

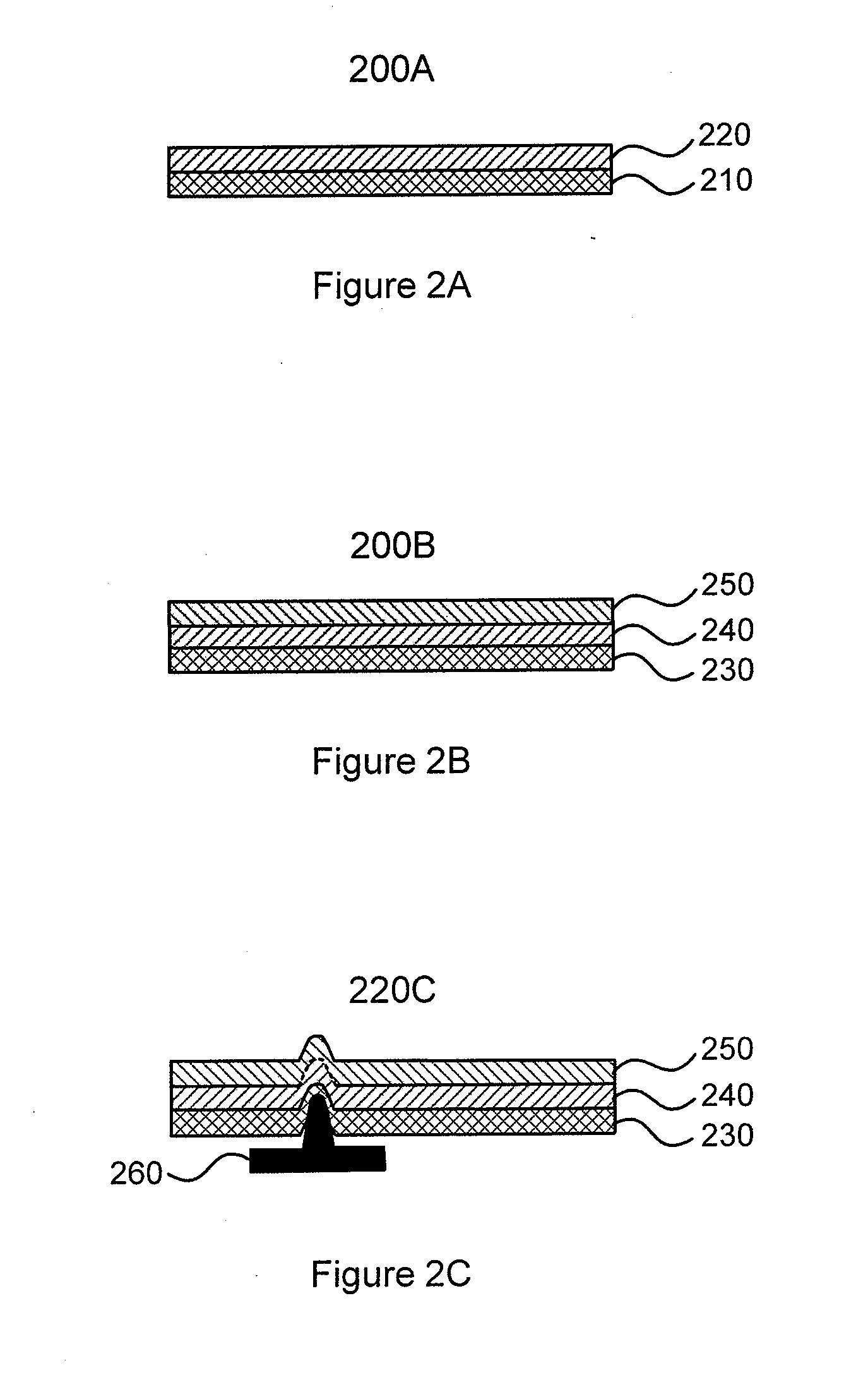

Crack embossing using diamond technology

A portable consumer device having a substrate layer, a protective layer and a diamond-based brittle material layer having an intentionally created unique fissure or cracked patterns or crystal zone boundaries and systems and methods for making and using same are disclosed. The diamond-based brittle material layer includes a diamond material. The unique random fissure or cracked pattern and crystal zone boundaries, or the electromagnetic signature based thereon, of the brittle material layer are detected and used to authenticate the portable consumer device.

Owner:VISA INT SERVICE ASSOC

Microstructural gypsum mould preparation method

The invention provides a microstructural gypsum mould preparation method, and relates to a gypsum mould preparation method. The microstructural gypsum mould preparation method aims at solving the problems that gypsum moulds with dozens of micrometers to hundreds of micrometers of formation structures are unlikely to be prepared by a conventional gypsum formation method, the prepared gypsum moulds have poor surface smoothness and air hole defects, and defects such as cracking or formation of microcracks are easily caused in the follow-up drying process of the gypsum moulds. The microstructural gypsum mould preparation method comprises the following steps of: step one. preparing a retarder water solution; step two. preparing gypsum slurry; step three. removing gas from the gypsum slurry; step four. carrying out pouring and ultrasonic treatment; step five. allowing to stand; step six. drying at a room temperature; and step seven. carrying out gradual drying to obtain the microstructural gypsum mould. A microstructural gypsum mould prepared by the method has the advantages that the frequency of cracking and formation of cracks is reduced, and the rejection rate is remarkably reduced and is 0%-4%. The microstructural gypsum mould preparation method can be obtained.

Owner:HARBIN INST OF TECH

Wax printing manufacture technology

InactiveCN104420097ARich layersRich expressivenessTextile parts treatmentWaxManufacturing technology

The invention discloses a wax printing manufacture technology. A technology flow comprises the following steps: pre-processing, applying wax, dyeing, dewaxing and rinsing. When a wax flake is subjected to dip dyeing in a dye vat, certain 'wax seals' are broken due to folding, so that natural cracks, which are usually called 'icy veins', are generated. Sometimes, the 'icy veins' need to be made according to requirements, and the 'icy veins' cause a wax printing pattern to show richer layers and own a natural and unique style. The wax-printing 'icy veins', which are similar to the cracked glaze' of enamel, own artistic effects, the size and the moving direction of the cracks can be controlled by people, so that a description object can be presented appropriately and has distinctive characteristics. If a flower-shaped mouth with multiple color layers needs to be dyed, a color separation wax sealing way can be adopted, and expressive force is richer.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Dyeing technology for wood veneer/batten

ActiveCN105946078AEnsure color consistencyMeet needsWood compressionWood treatment detailsWood veneerManufacturing technology

The invention belongs to the technical field of wood veneer / batten manufacturing, and particularly relates to a dyeing technology for a wood veneer / batten. The dyeing technology solves the problem that the existing technology is not reasonable in design and the like. The dyeing technology for the wood veneer / batten comprises the following steps that A, separation is conducted; B, kiering is conducted; C, dyeing is conducted; D, water is removed; F, drying is conducted; and F, post-treatment is conducted. The dyeing technology has the beneficial effects that firstly, removing resin oil, a mineral line, spots, cracks and the like is the purpose of kiering, the color required by a customer is achieved, the color of the wood veneer is whiter and whiter, and the hand feeling is more comfortable and softer; secondly, the technology is simple and easy to control; thirdly, the quality and structural stability of products are improved, and practicability is higher; and fourthly, the dyeing quality is improved.

Owner:JIASHAN JIUSHUN WOOD CO LTD

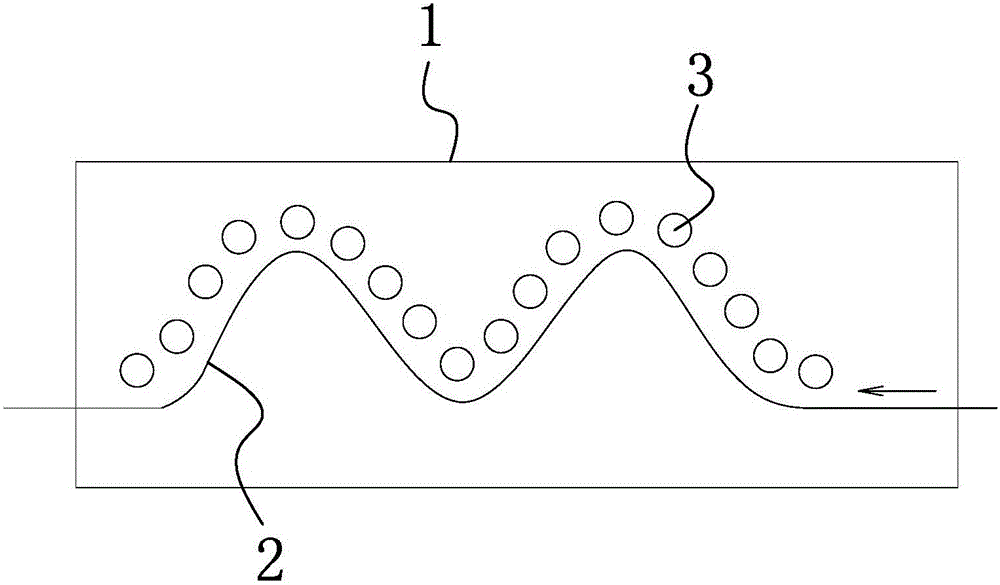

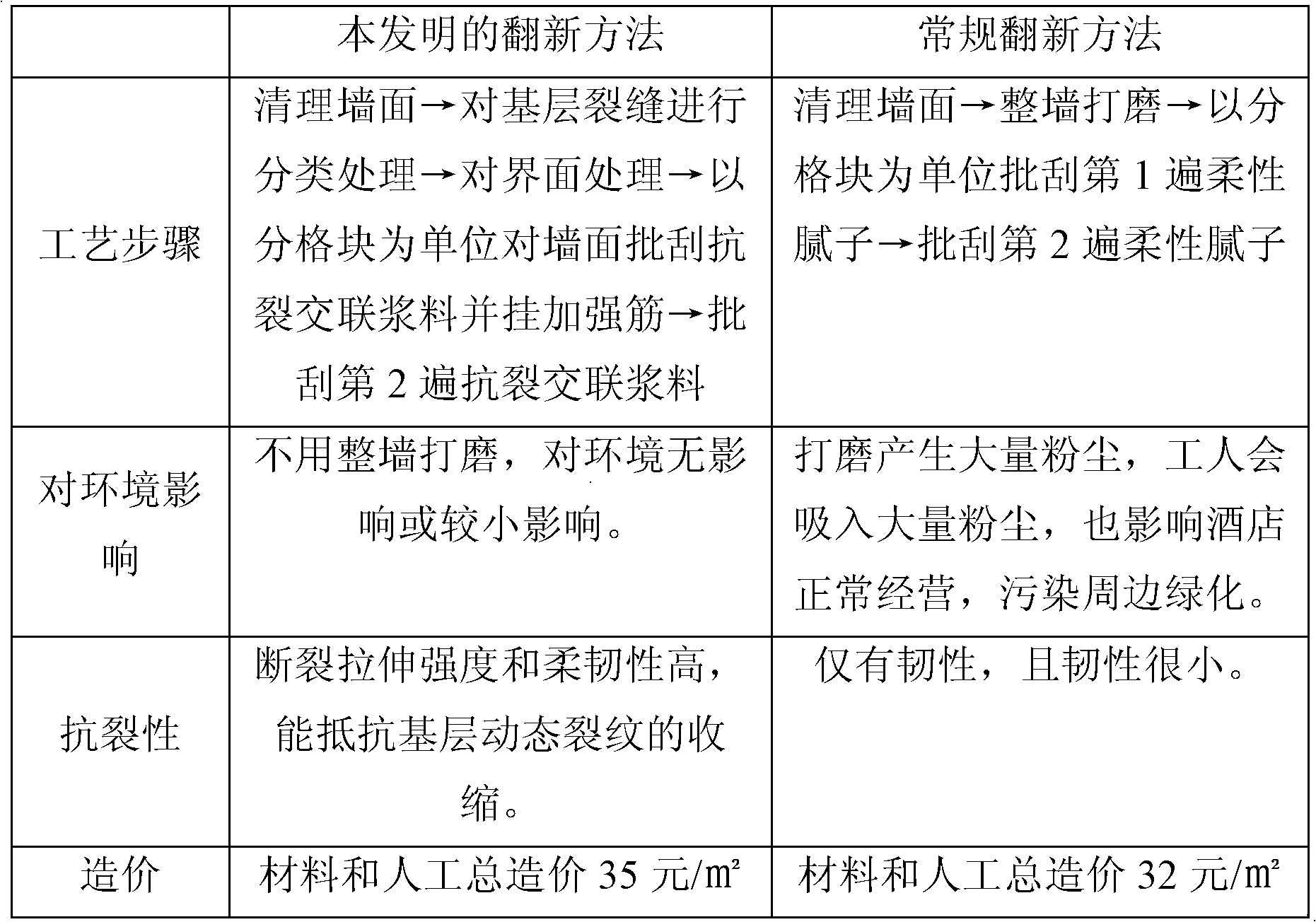

Method for renovating outer wall coated with fluorocarbon paint

The invention relates to a method for renovating an outer wall coated with fluorocarbon paint, comprising the following steps: (1) cleaning a wall face: cleaning up paint films of the wall face in saltpetering, pulverization, peeling and blistering; (2) classifying cracks of a base layer: for less than 1mm of a craquelure, polishing along the craquelure; for regular cracks and craquelures with more than 1mm, making a V-shaped groove along the cracks; processing the V-shaped groove by a bonding agent, plaster and a crack repairing agent to the V-shaped groove and two sides of the V-shaped groove and embedding an anti-crack cloth; (3) treating an interface of an old fluorocarbon paint base layer: evenly mixing the bonding agent with quartz sand and Portland cement, and roller-painting; (4) scraping anti-crack crosslinking slurry in batch on the wall face based on division blocks as units, and further hanging reinforcing ribs: after coating the anti-crack crosslinking slurry on the wall face, pressing the reinforcing ribs into the slurry; and (5) scraping the anti-crack crosslinking slurry in batch for the second time: making the total thickness of a dry film of the anti-crack crosslinking slurry be at least 1.5mm.

Owner:上海天补科技有限公司

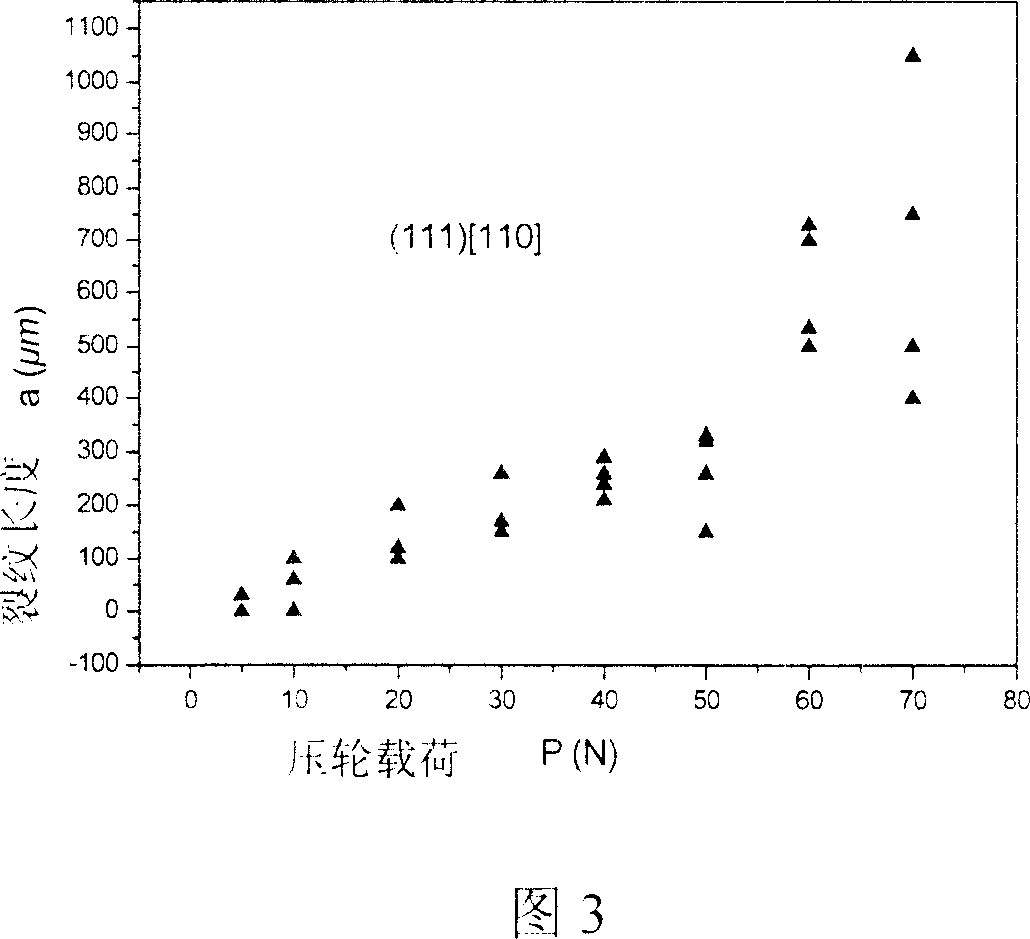

Prefabricated method for thin film microcrack and special apparatus for the same

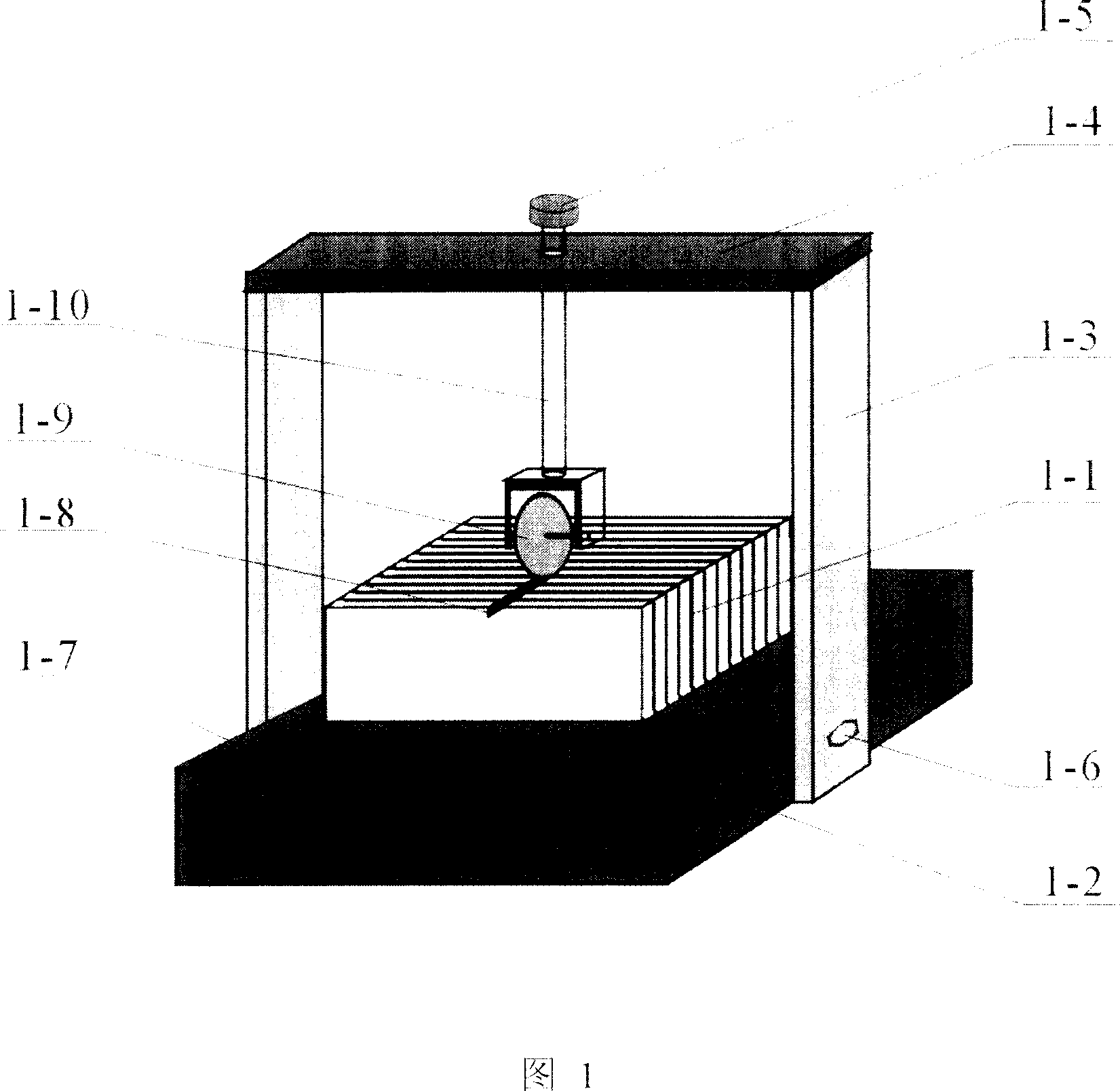

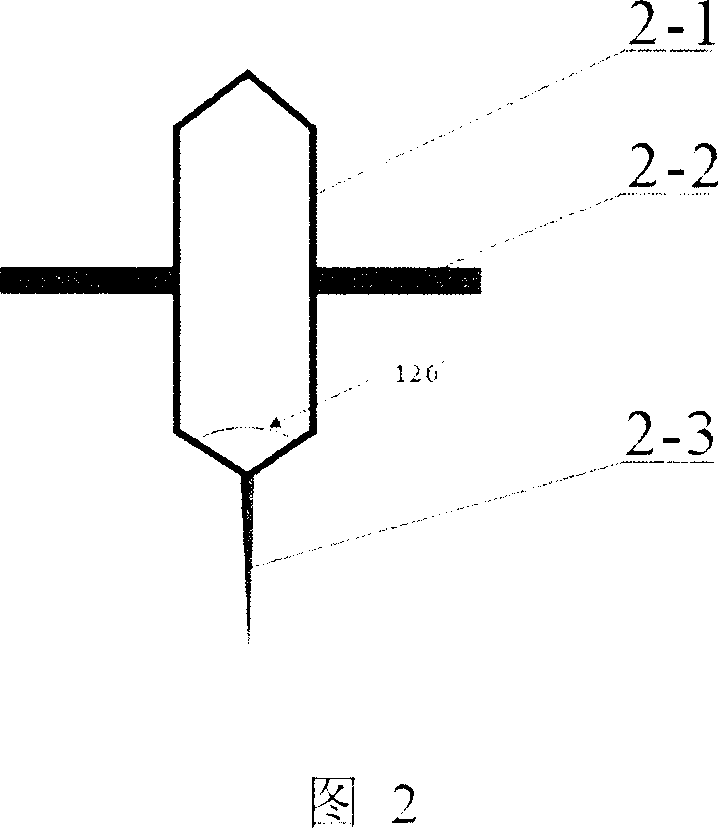

InactiveCN1919719AThe surrounding stress field is simpleImprove residual stressDecorative surface effectsForce measurementFilm materialSilicon

The invention discloses a film material micro-cracking preparing method and specific device, which comprises the following steps: fixing film material on the polishing surface of silicon single-wafer, cutting the silicon single-wafer with film material into piece sample, adhering multiple piece samples into block sample with the direction of piece samples consistent, setting film material between two silicon single-wafers, falling the pressurized wheel on one side of micro-crack, making the surface with micro-crack in the whole sliding course to generate micro-crack under the trace. The device is composed of objective table, force gauge, pressurized wheel fixing beam, load adjusting button and pressurized wheel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

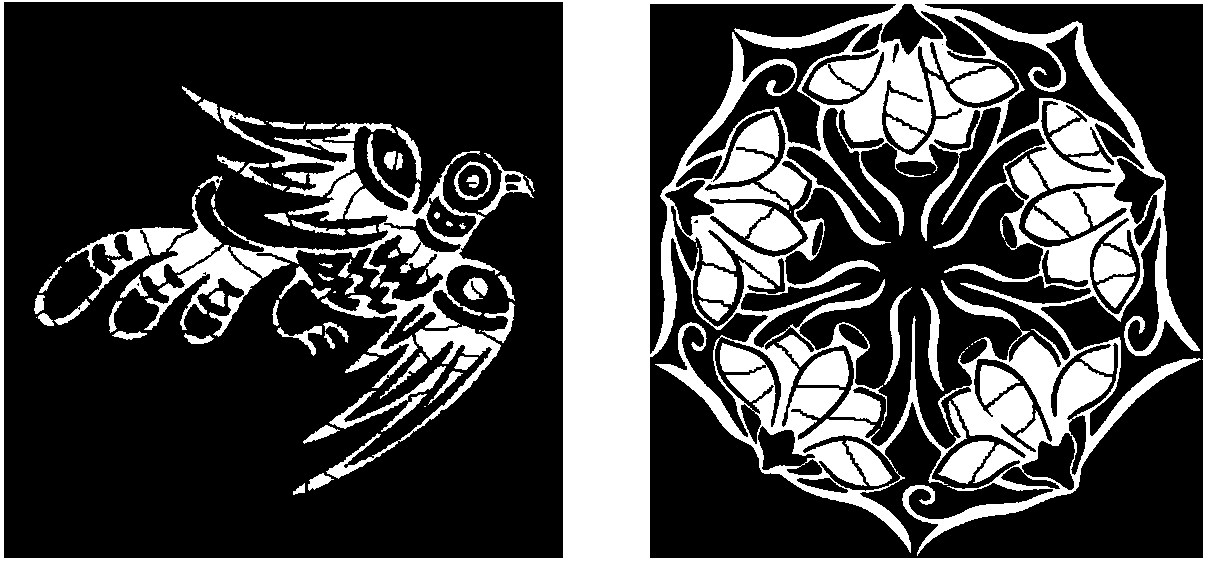

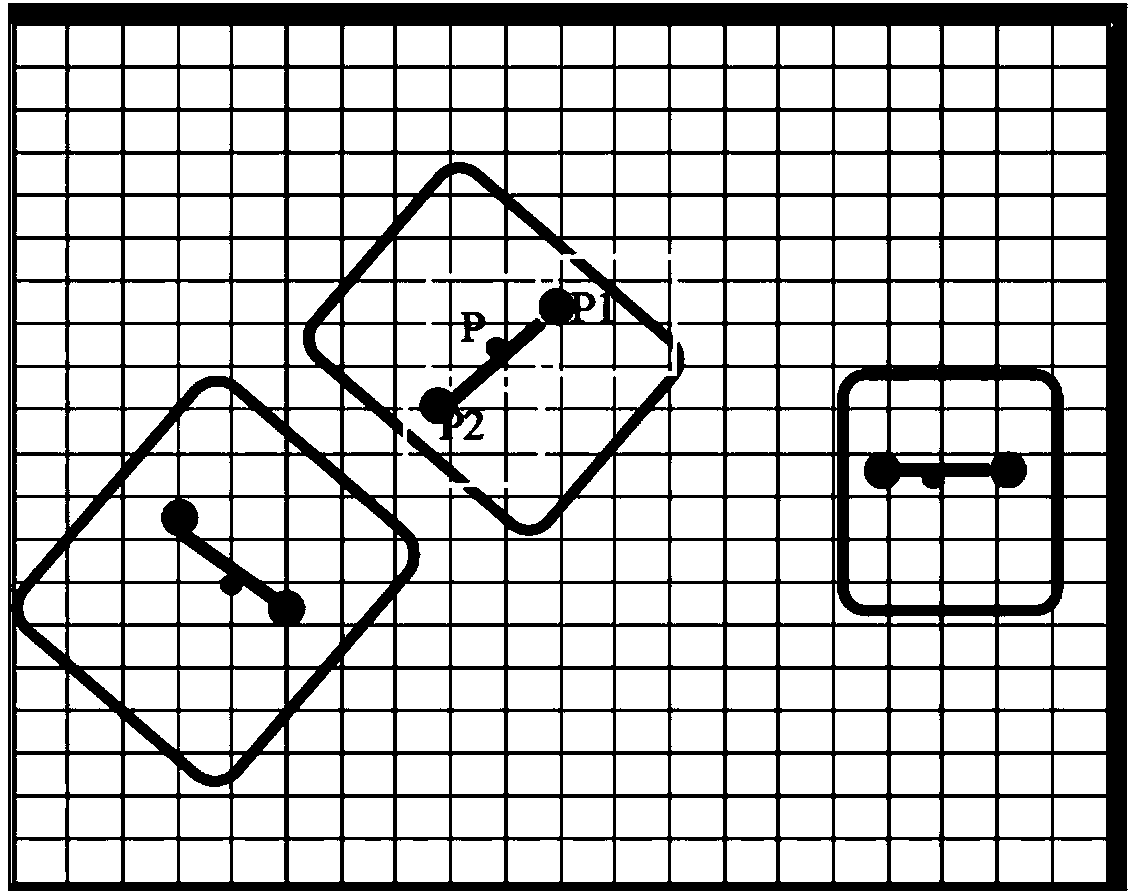

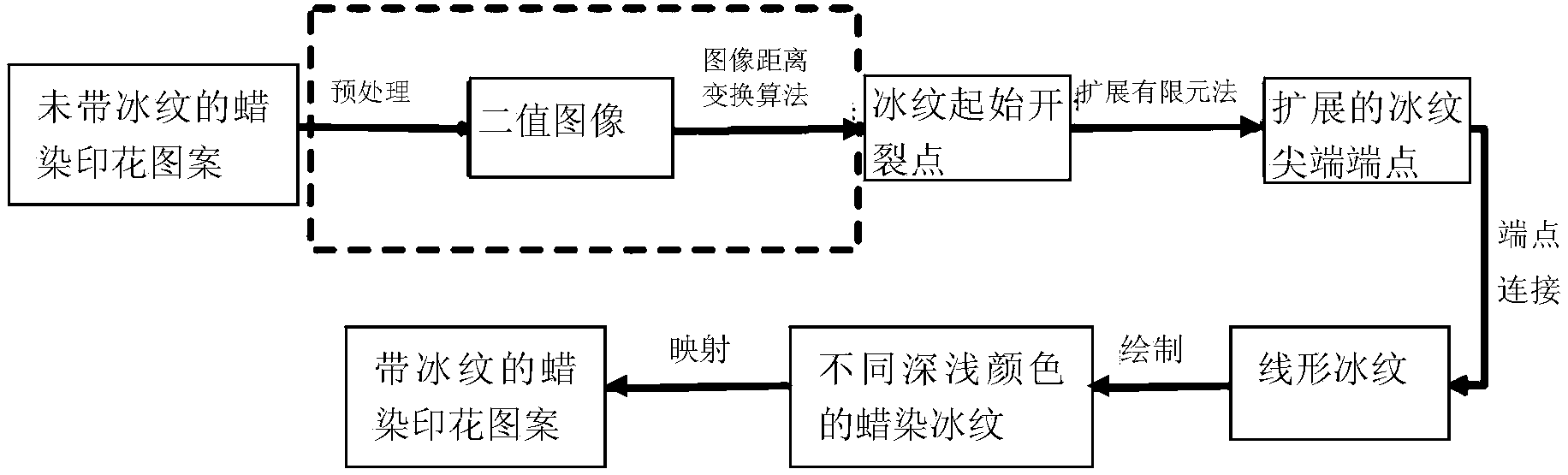

Wax printing stamping pattern emulation method with ice vein effects

ActiveCN103870645AImprove the operating environmentLow costSpecial data processing applicationsVeinRandom method

The invention relates to digital image processing, and provides a wax printing stamping pattern emulation method with ice vein effects so that the positive effects are realized in the aspects of protection, recording and inheritance of the ancient art. The method has the technical scheme that the wax printing stamping pattern emulation method with ice vein effects comprises the following steps of 1, initial cracking veins determination: a random method is adopted for determining the initial cracking veins; 2: ice vein expansion process simulation: the ice vein cracking process is simulated on the basis of a two-dimensional crack fracture expansion finite element solving method according to Griffith fracture criterions in fracture mechanics, the initial cracking vein expansion process is simulated, further, the end point information of the point end of the ice veins after the expansion in each step is obtained, and after a series of end points of the ice vein point end are obtained, the end points are connected into continuous and smooth flow line ice veins; 3, ice vein drawing: wax printing ice veins with different shade colors can be generated. The method is mainly applied to digital image processing and wax printing occasions.

Owner:TIANJIN UNIV

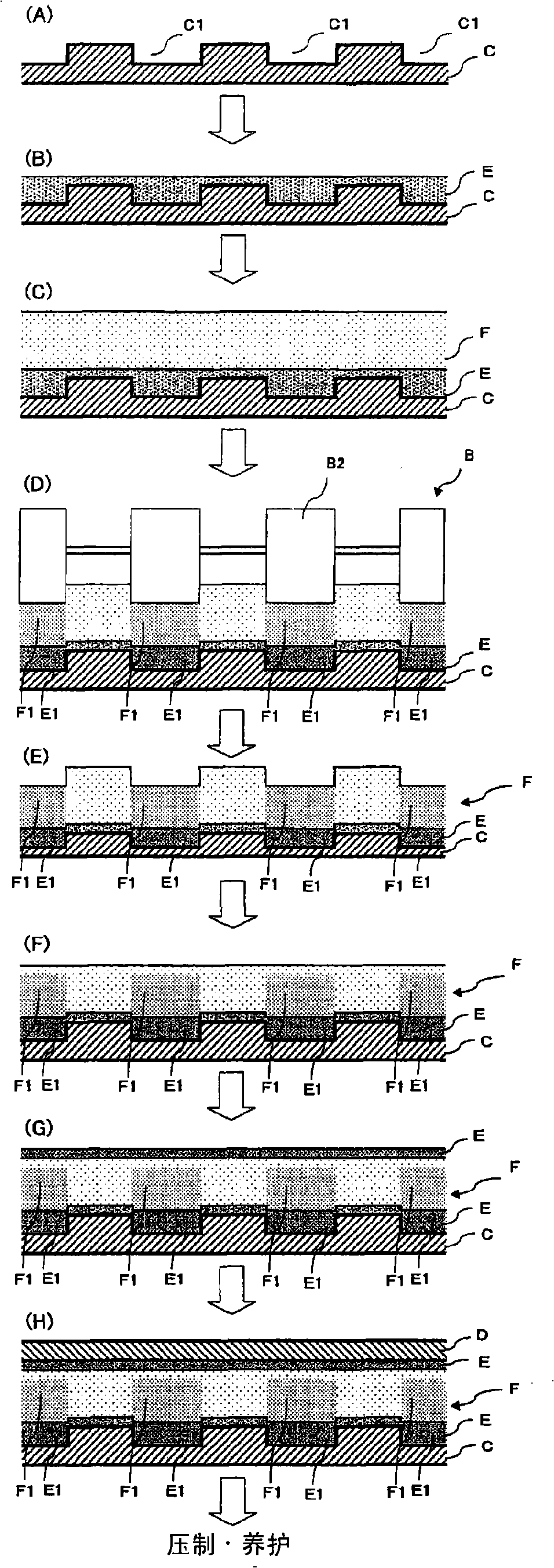

Wood cement board

ActiveCN101550743AAvoid crackingIncrease inhalationConstruction materialSolid waste managementCement boardMaterials science

Provided is a wood cement board that has a pattern of acute-angled and deep recesses and projections on its surface, and that tends not to cause cracking during a hardening and curing process, a drying process, a transportation process and so on. The wood cement board has a pattern of recesses and projections on its surface, in which the distance from the apex of the projections to the rear face is 9 mm or more, and the distance from the apex of the projections to the base point of the recesses is 2 mm or more, and is equal to or less than half the distance from the apex of the projections to the rear face. The average specific gravity of the wood cement board as a whole, and the specific gravities of the projections and the recesses are each 1.1 or more, and the difference between the specific gravity of the projections and the specific gravity of the recesses is less than 0.1.

Owner:NICHIHA CORP

Wood floor surface coating processing method

InactiveCN102641836AClear textureEnhance the sense of naturePretreated surfacesCoatingsWater basedLacquer

The invention provides a wood floor surface coating processing method which comprises the following steps: first layer colored paint is sprayed on a pretreated wood floor, the spraying weight is 140-240 g / m<2>, and then the wood floor is heated and dried, and is also smoothly polished; water-based crackle paint is then sprayed, the spraying weight is 80-150g / m<2>, and then the wood floor is subjected to hot drying at the temperature of 50-150 DEG C to generate cracks; second layer colored paint is sprayed on the wood floor, the spraying weight is 60-110 g / m<2>, and then the wood floor is heated to be dried; subsequently, the surface of the wood floor is polished, so that the second layer colored paint on the convex surface of the wood floor is removed, the color of the first layer colored paint is exposed, and the color of the second layer colored paint is maintained in the inner and concave surfaces of the cracks; and prime paint and wear-resistant finish paint are finally coated on the wood floor and are also dried, so the wood floor finished product is obtained. The surface textures of the wood floor processed by the wood floor surface coating processing method are criss-cross, changeful, well-proportioned and have three-dimensional and artistic aesthetic feeling, and furthermore, the special classical decorative effect is achieved.

Owner:GUANGDONG YIHUA TIMBER IND

Brick inlaying method for fully covered thermal inlaid brick cooling wall

The invention relates to the technical field of blast furnace cooling wall manufacture, in particular to a brick inlaying method for a fully covered thermal inlaid brick cooling wall. The brick inlaying method is characterized in that: inlaid bricks are inlaid into a wooden mould and then a sand mould is made, and the brick inlaying method comprises the specific steps of: 1) pasting fireproof asbestos paper onto the side face and the bottom face of each inlaid brick; 2) placing the inlaid bricks onto the wooden mould, making the inlaid bricks close to one another and putting a movable block into a hollow part at the dovetail-shaped bottom of each inlaid brick; 3) embedding the wooden mould into a sand box and firmly connecting the wooden mould with the sand box; and 4) filling moulding-sand resin sands into the sand box, turning the sand box and taking out the wooden mould after the moulding sands are solidified, and retaining the inlaid bricks in the sand mould. The brick inlaying method has the advantages that: 1) gaps among the inlaid bricks are eliminated, so cracks on the inlaid bricks caused by the entered metal solution can be avoided, and the quality and the qualification rate of the product are improved; and 2) the side face of the exposed part of each inlaid brick cannot be pasted by the metal, so the later processing work is reduced and the production efficiency is improved.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

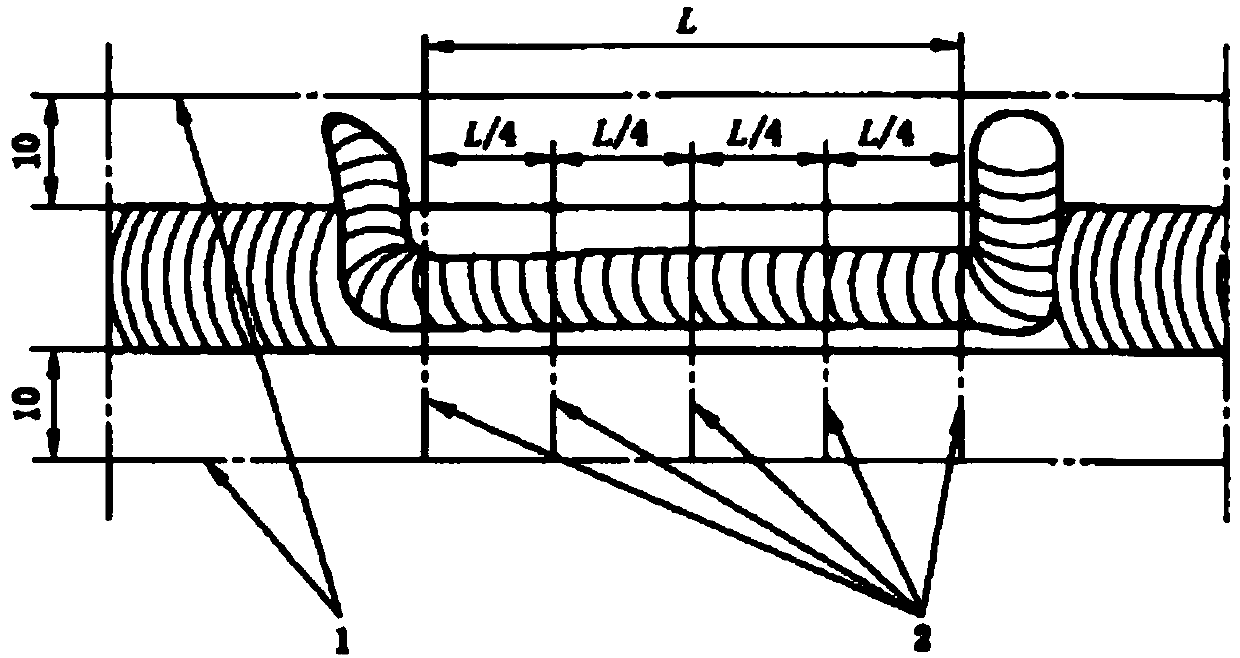

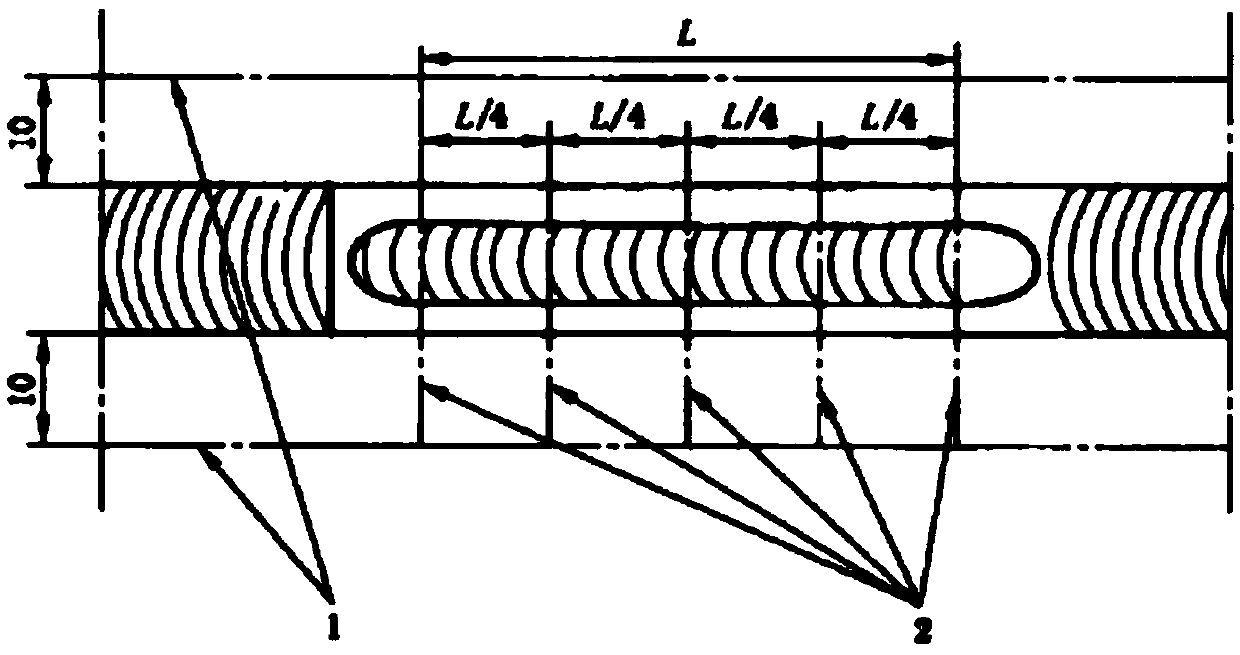

Method for detecting welding cracks of inclined Y-shaped groove

InactiveCN109520858AReduce the risk of oversizingImprove efficiencyPreparing sample for investigationArc welding apparatusEngineeringAssembly structure

The invention relates to a method for detecting welding cracks of an inclined Y-shaped groove. The method comprises the following steps: (1) selecting an appropriate welding material; (2) optimizing processing morphology of the groove; (3) performing preweld cleaning; (4) test piece splicing; (5) welding and restraining the weld joint; (6) preheating a testing weld before welding; (7) welding thetesting weld; (8) post-weld treatment; (9) performing weld coloring; and (10) assessment of the crack. The step (2) comprises the following sub-step: preparing samples 1 and 2, wherein the assembly structure of the sample 1 is a wedge surface which is in a longitudinal symmetry manner and mutually presents a tip top, and the assembly structure of the sample 2 is as follows: the two sides are in the shape of a wedge surface which is in a longitudinal symmetry manner and mutually presents a tip top, the middle is a slope extending up and down, the relatively upper wedge surface of the slope wholly sinks in parallel, and the sinking depth is consistent with the standard required post-weld inclined Y root gap. In addition, the method disclosed by the invention directly adopts a coloring snap or bend breaking method, and the surface crack rate, root crack rate and section crack rate can be intuitively measured.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

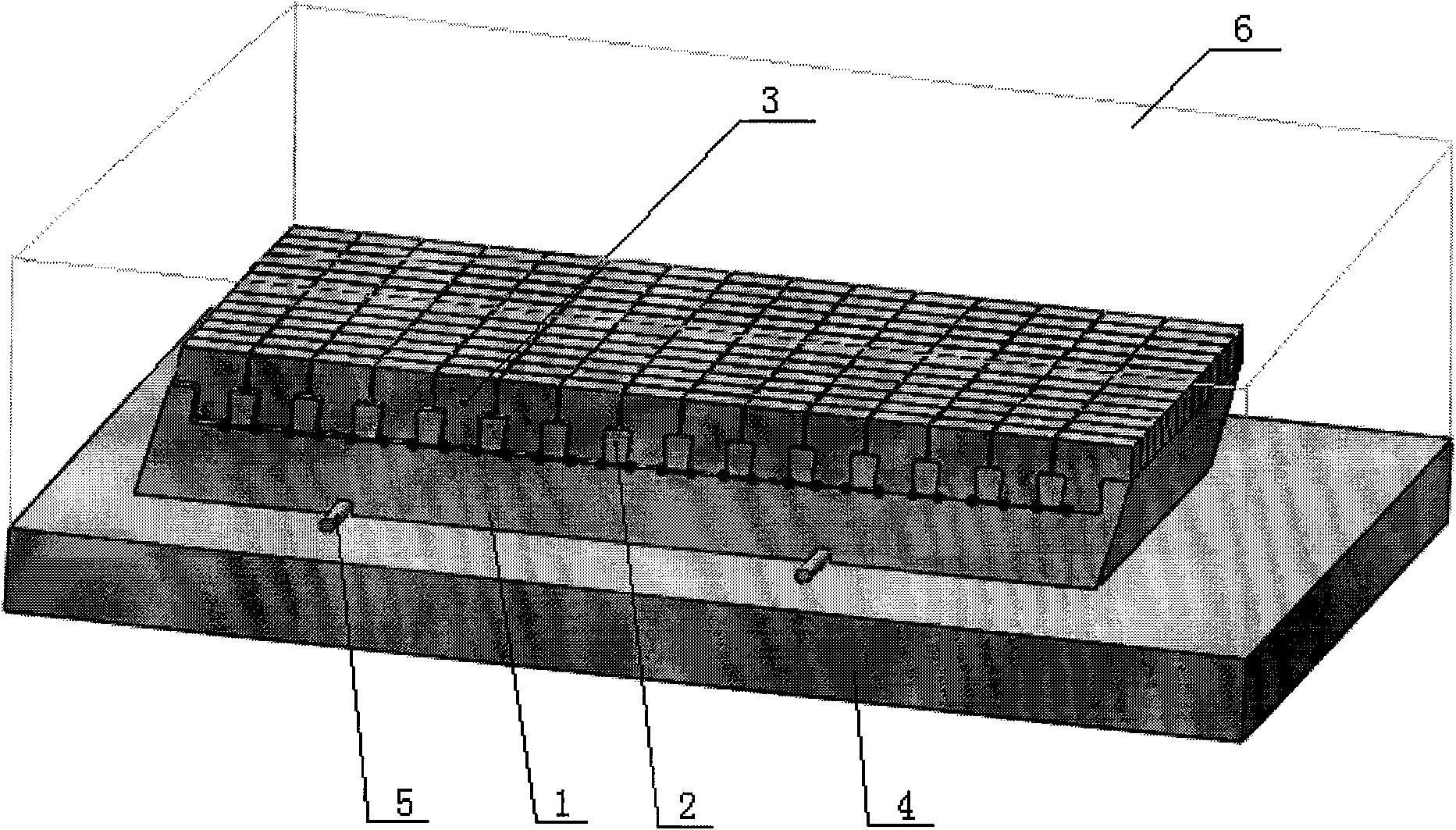

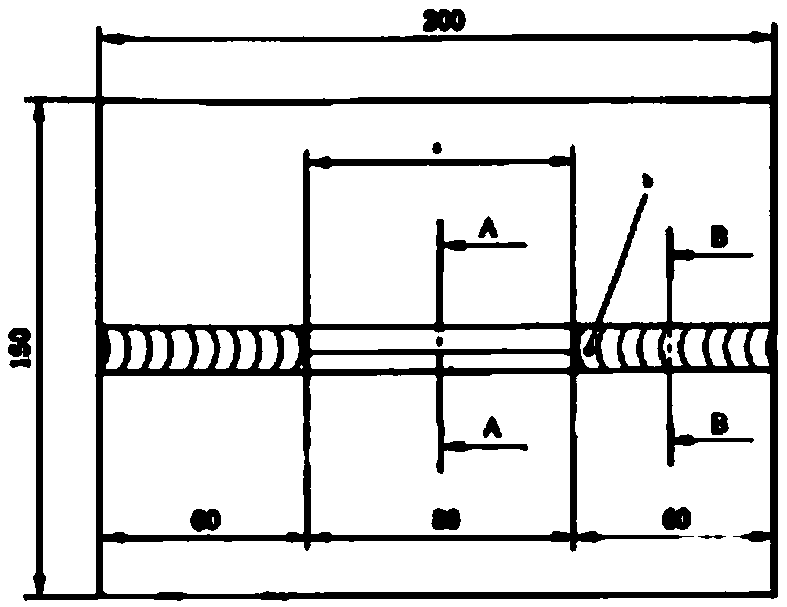

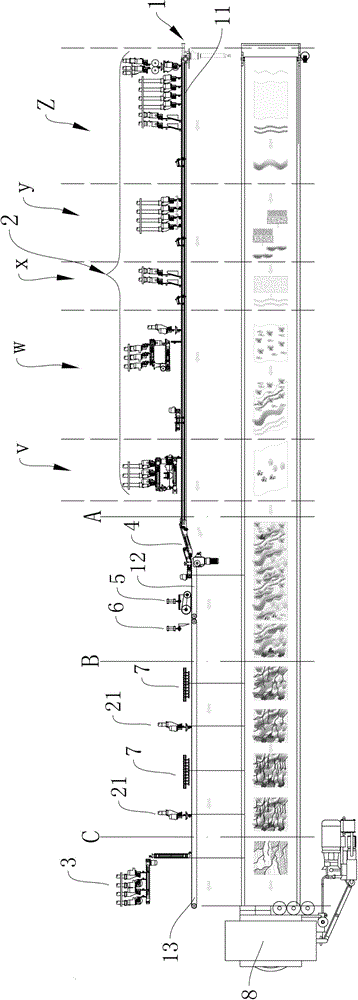

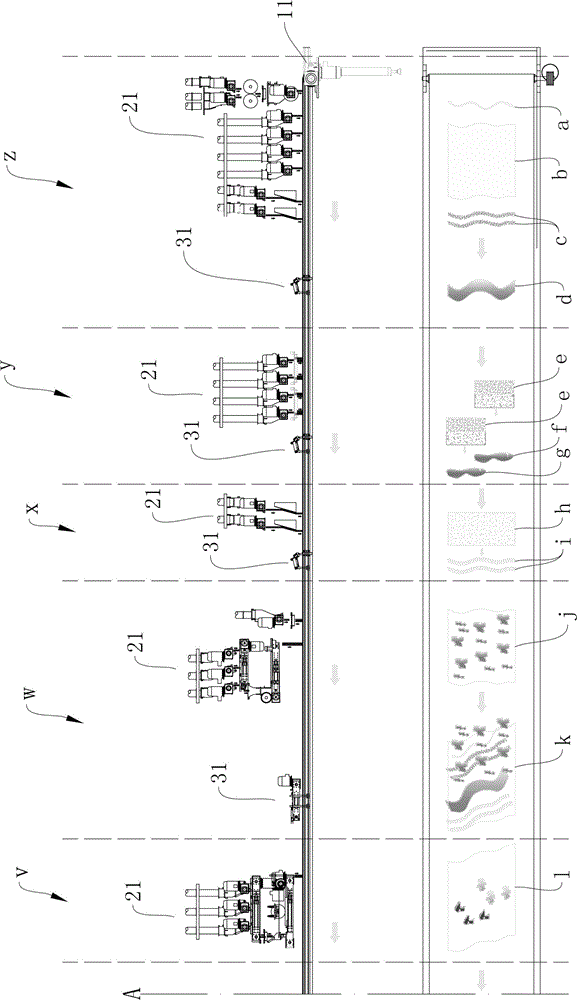

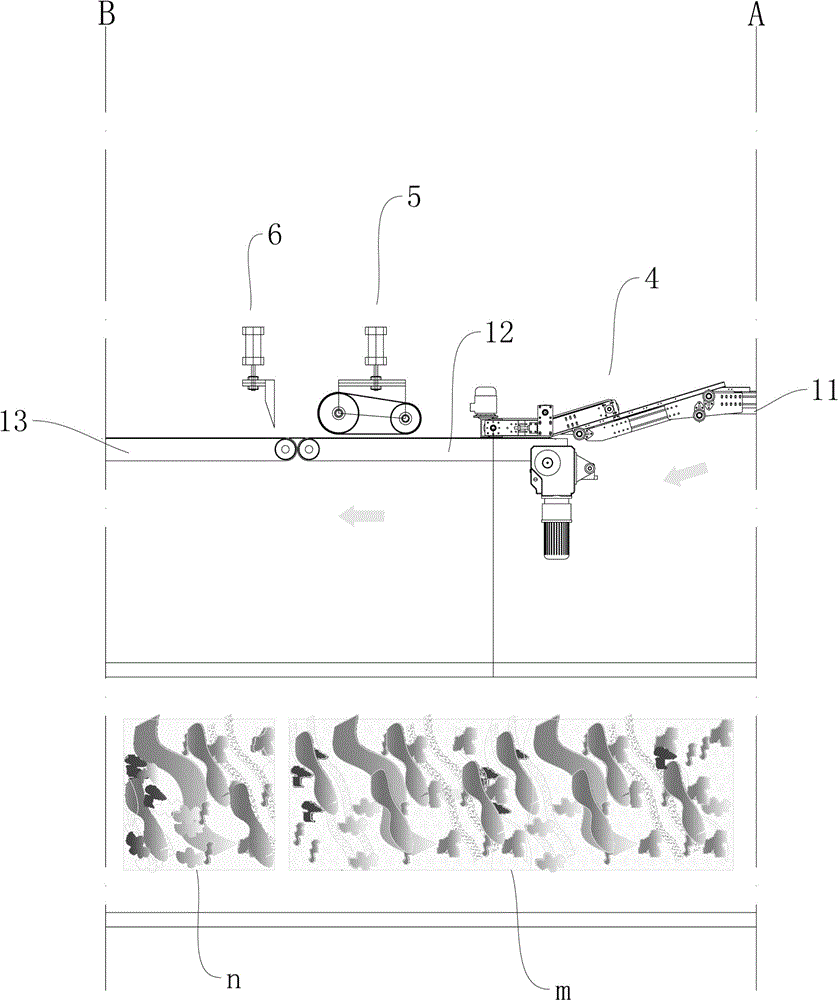

Forming production process for whole-body ceramic polished tile

ActiveCN106671263ARich texture colorRealistic texture colorCeramic shaping plantsFeeding arrangmentsLife qualityWhole body

The invention relates to a forming production process for a whole-body ceramic polished tile. According to the forming production process, a conveyer belt device, a front distribution device, a powder shape correction device, a rear distribution device, a material pile slope arrangement device, a grinding device, a cutting device, a craquelure generation device, a stamping forming device and the like are scientifically, reasonably and orderly controlled to operate orderly and systematically according to well designed process steps, so that the produced tile product has the characteristics of hardness, abrasion resistance and durability of common whole-body ceramic polished tiles and has rich, realistic and bright textured patterns and colors of glazed tiles. The forming production process is a brand new and revolutionary production process which replaces a production process for existing polished tile and glazed tile products, meets increasingly high life quality requirements of people, and can be used for producing the ceramic polished tile product with the texture effect of natural stone and whole-body textures consistent from inside to outside.

Owner:佛山市高明贝斯特陶瓷有限公司 +2

Insulation external wall repair technology

The invention relates to the technical field of external wall repair, in particular to an insulation external wall repair technology. According to the insulation external wall repair technology, whena small amount of superficial shallow cracks appear in a finish coat, a reinforcing agent is injected into the cracks, the strength of the finish coat around the cracks is enhanced, and then adhesivemortar is injected into the cracks to repair the cracks; when a large amount of craquelure appears in a facing, the finish coat is remade, anti-cracking fibers are added to a finish coat material, andthe anti-cracking ability of the finish coat is improved; and when cracks appear in an insulation layer, the cracks are filled with fitting pieces after crack expanding, and the sufficient elastic space is provided for thermal expansion or contraction of the insulation layer. According to the insulation external wall repair technology, the repair way is convenient, the repair cost is low, and after repair, the service life of an insulation wall can be obviously prolonged.

Owner:上海忠辰建设集团有限公司

Method for repairing wall crack of building

The invention provides a method for repairing a wall crack of a building. Firstly, impurity removal and wall surface shoveling are carried out on the position, where the crack is generated, of the wall surface, then puttying is carried out, a bottom material is applied, and an adhesive is applied on the cleaned outer wall surface; then smaller holes and crack are filled up, and drying is carried out for more than 12 hours; then fine mesh gauze is used for binding the crack, the fine mesh gauze is roller-coated with a waterproof binder, and finally, after roller-coating of a primer is completed, finish paint is sprayed. If an empty drum is generated on the wall surface, repairing padding is injected into the empty drum of the wall crack, and after an empty drum groove is filled and leveledup, a crack-sealer is used for leveling the empty drum and the wall surface. The method for efficiently and rapidly repairing the wall crack has the advantages that the manpower can be effectively saved, the construction period is not delayed, the repairing effect of the crack is good, and the empty drum cannot be generated and the calcimine cannot peel off after repairing is completed.

Owner:新昌县鼎绑机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com