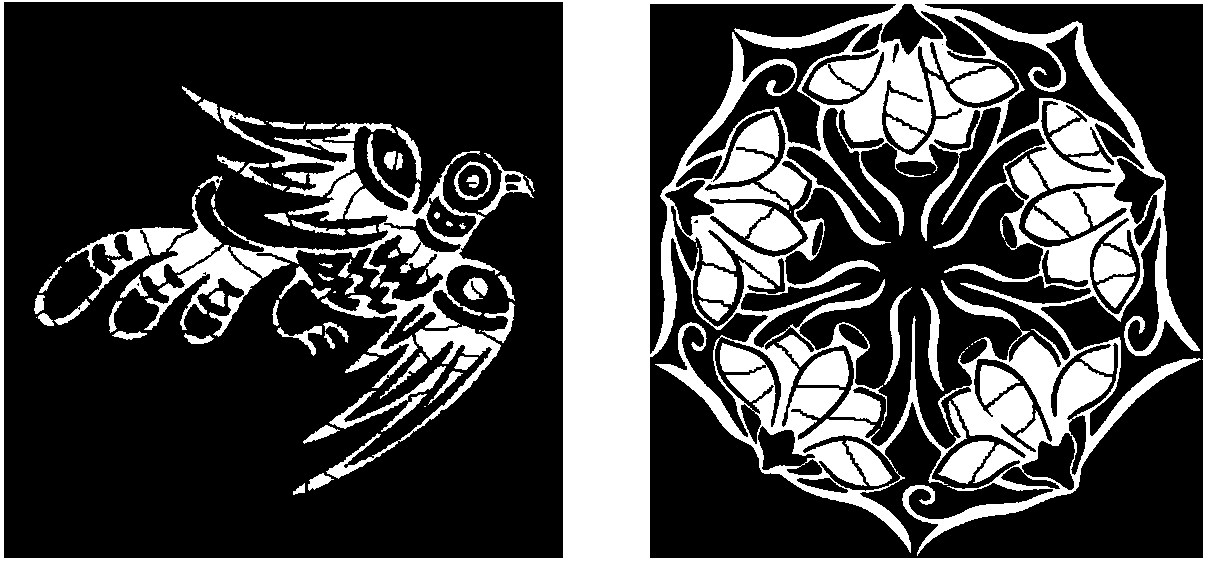

Wax printing stamping pattern emulation method with ice vein effects

A simulation method, the technology of ice pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

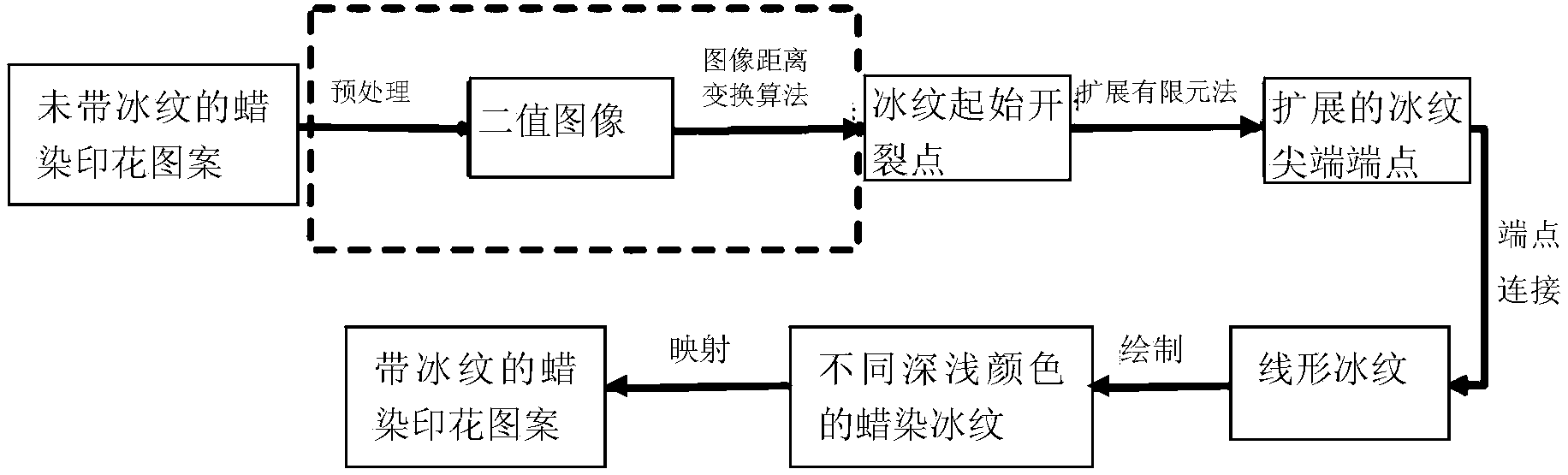

[0058] The present invention proposes a batik printing pattern simulation method with ice pattern effect, which mainly includes the following steps:

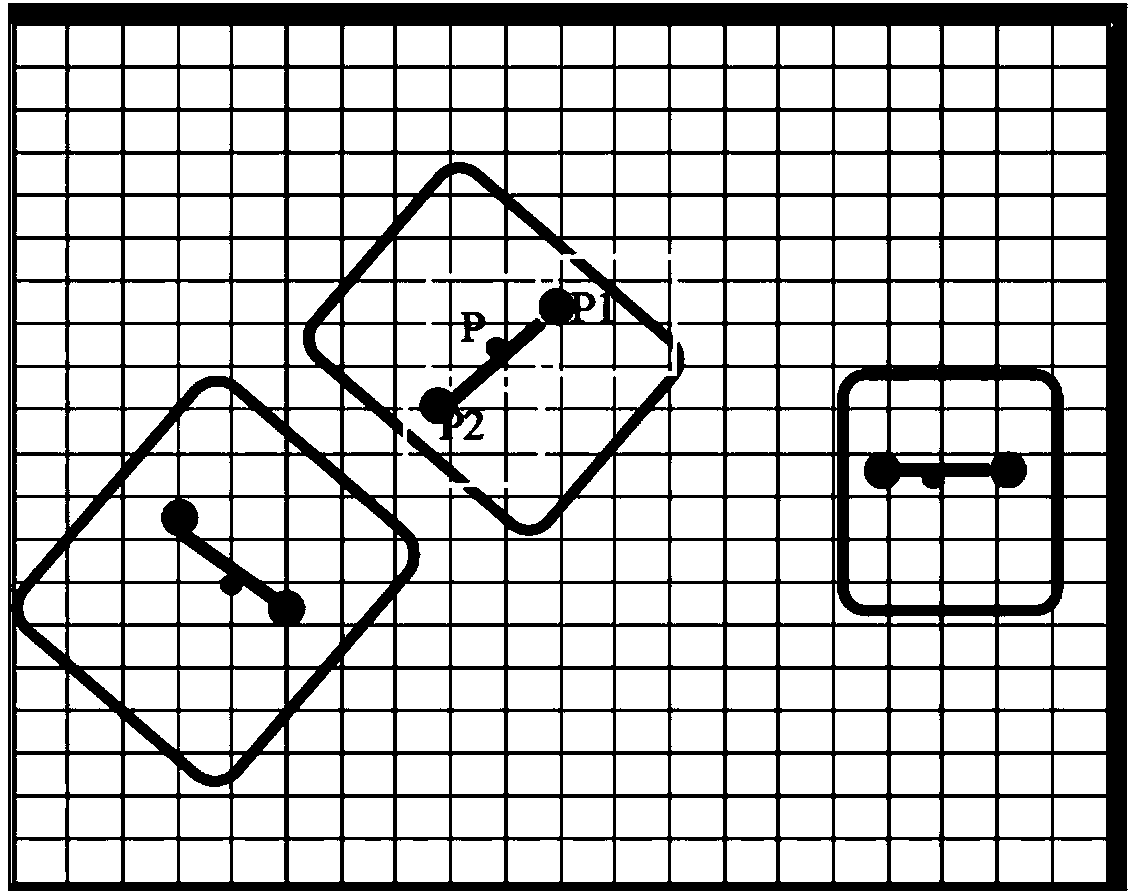

[0059] 1) Determination of the initial cracking ice pattern. The ice pattern not associated with the pattern is not affected by the batik pattern because the cracking position is not affected by the batik pattern. The present invention uses a random method to determine the initial cracking ice pattern, that is, records the position information of the tip of the initial ice pattern. In order to get some meaningful batik printing patterns with ice patterns, the effect of ice patterns with relatively regular distribution is mainly considered.

[0060] 2) Simulation of ice pattern expansion process. Based on the Griffith fracture criterion in fracture mechanics, the extended finite element method to solve the two-dimensional crack fracture simulates the cracking process of ice cracks, simulates the process of ice crack expansion at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com