Patents

Literature

221results about "Textile treatment dyeing devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

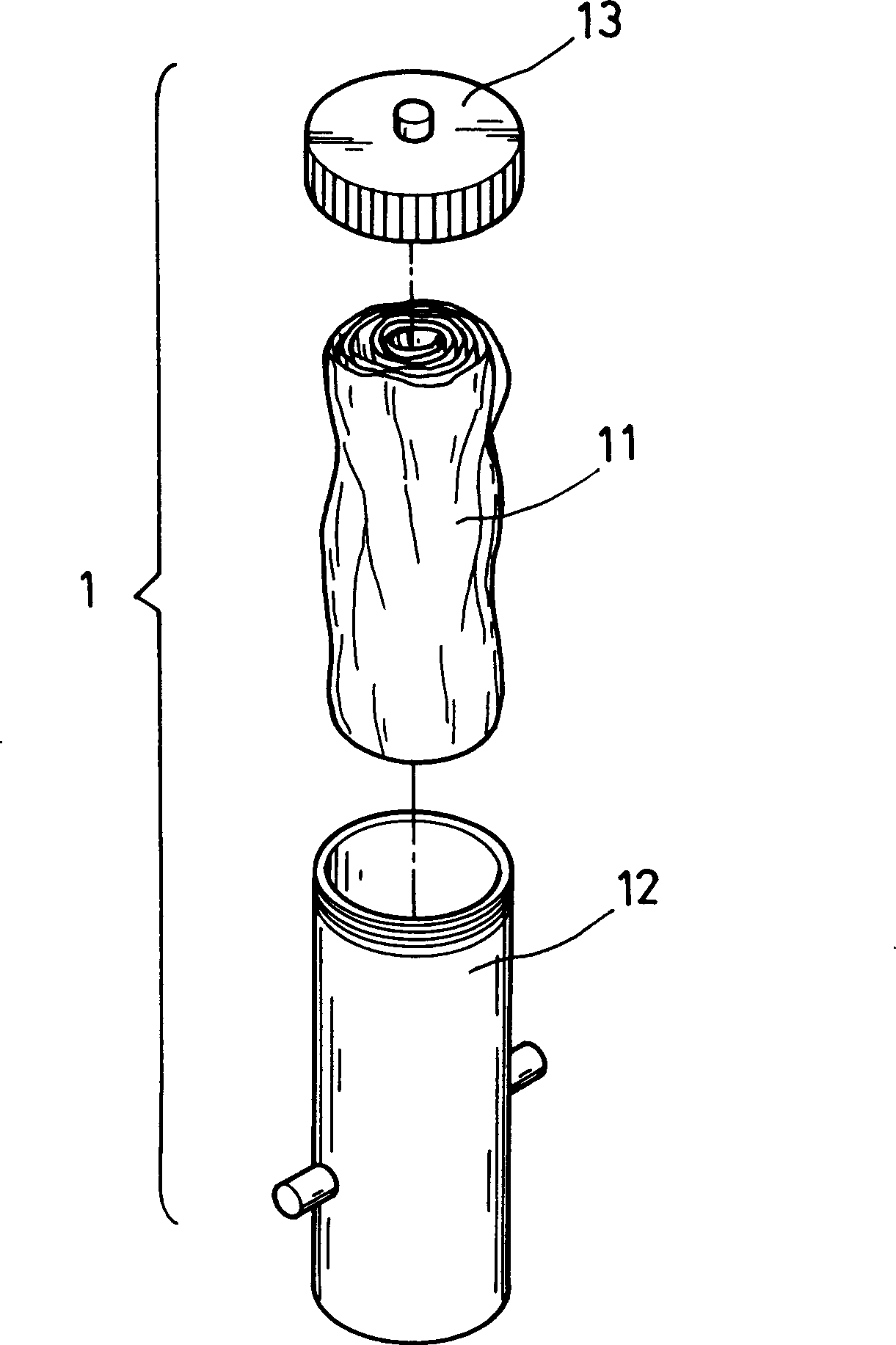

Novel sample dyeing machine

InactiveCN101603260AReduce installationImprove the operating environmentTextile treatment dyeing devicesTextile treatment machine arrangementsState of artThermal energy

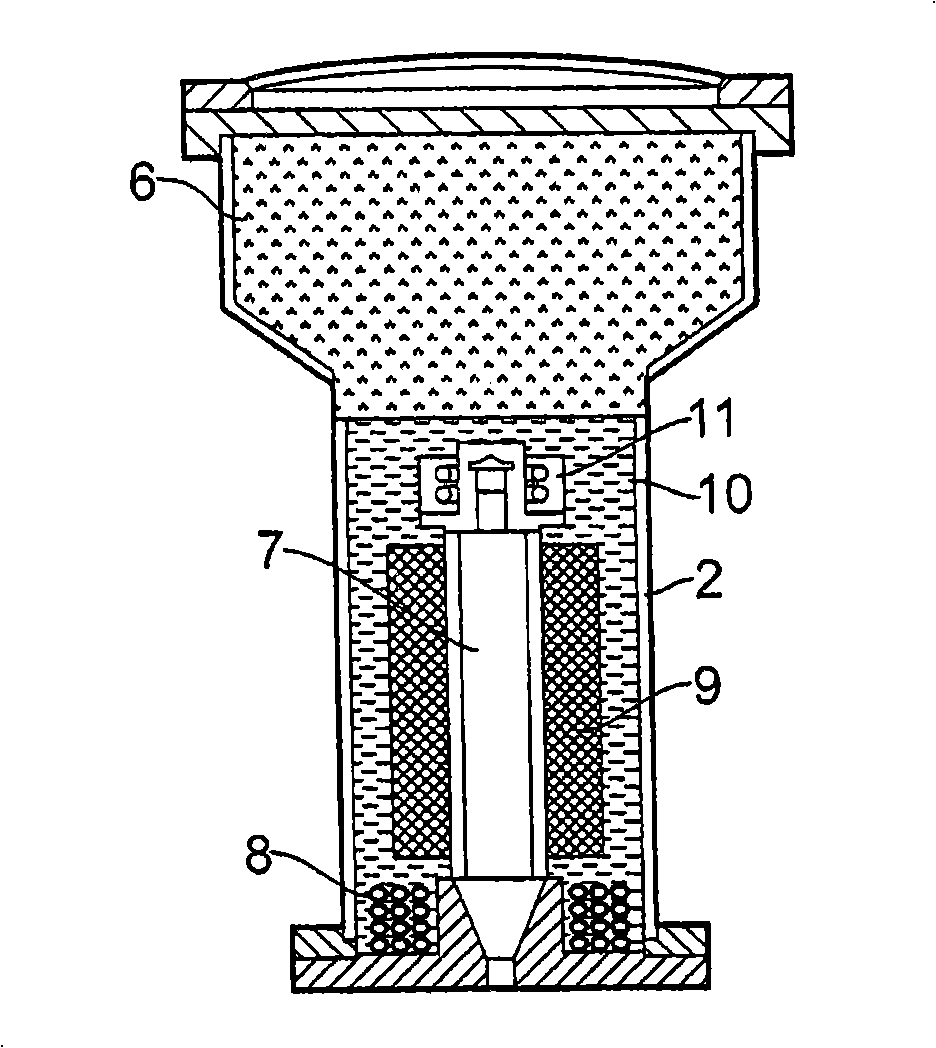

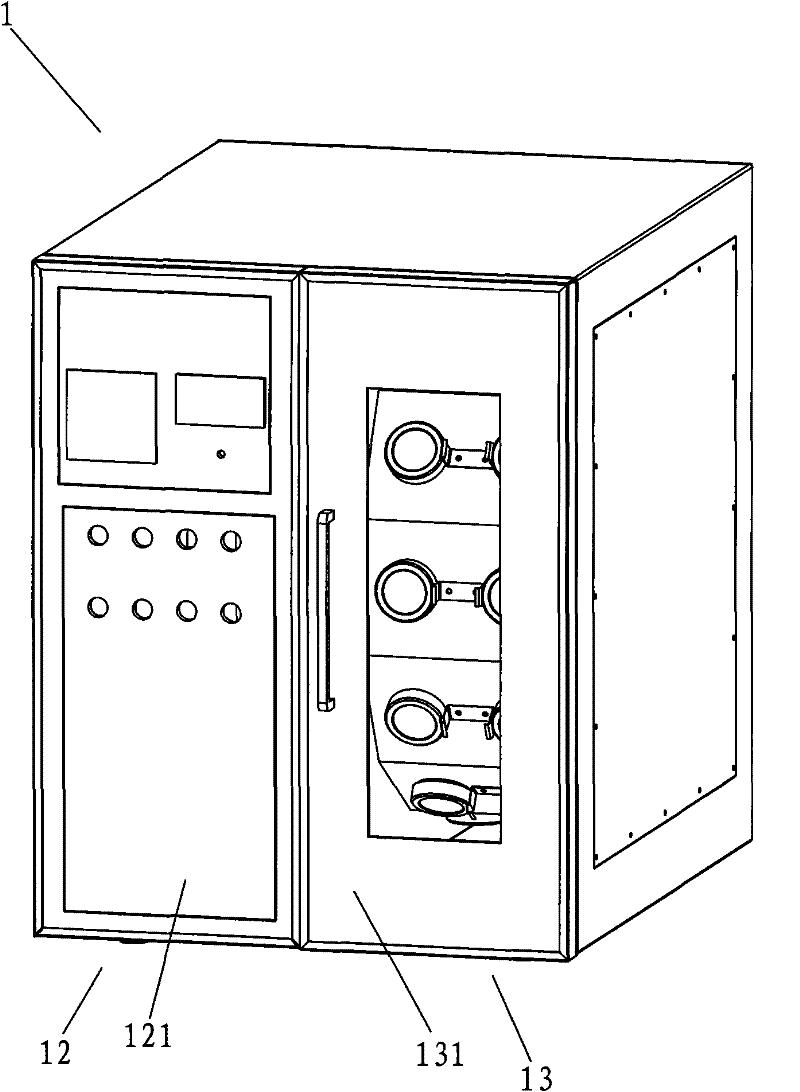

The invention discloses a novel sample dyeing machine. The machine comprises a rotary frame arranged in a cylinder, a plurality of sample cups and a plurality of sample cup sleeves, wherein the rotary frame is closed and filled with a solid heat-conducting medium in which a heating device is arranged; the sample cup sleeves are fixed on the rotary frame and buried in the solid heat-conducting medium, and openings of the sample cup sleeves are exposed out of the rotary frame; and the sample cups are fixed in the sample cup sleeves respectively in a mode of being movably taken out. In the machine, the solid heat-conducting medium is used for heat conduction, and the sample cups are not contacted with a heat carrier directly, so that the pollution caused by taking glycerin as the heat carrier does not occur, and the glycerin is not consumed; compared with the prior art, the machine has the advantages of keeping the original operating habits, improving the proofing operation environment, and saving energy, along with environmental protection; the machine adopts the solid heat-conducting medium for heat conduction, and no pressure is generated in the rotary frame; moreover, the wind cooling way is adopted for cooling, so that the assembly of pipes is saved, and the machine can be used after connecting to a power supply.

Owner:SHISHI TAIRUI PRECISION MACHINERY

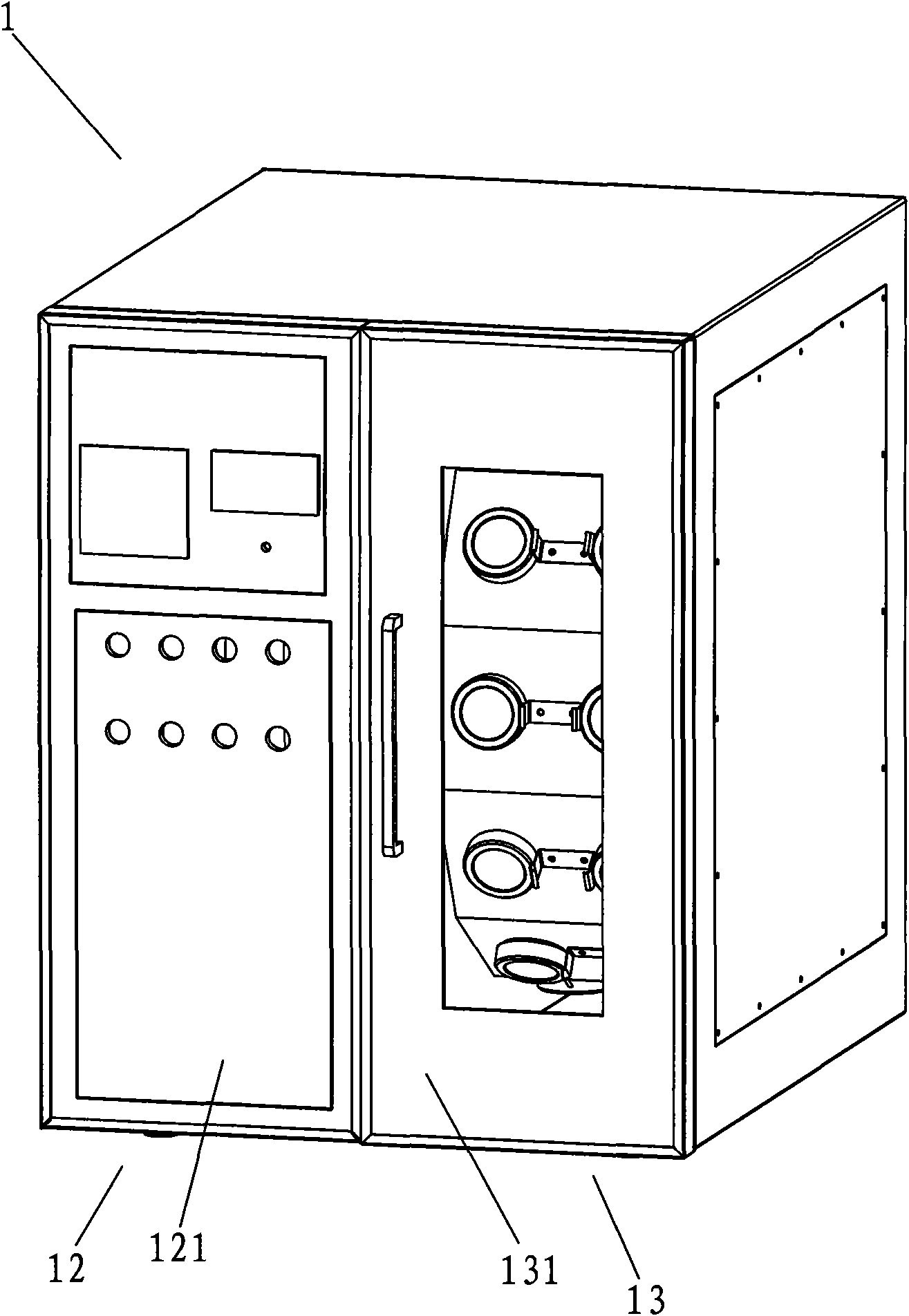

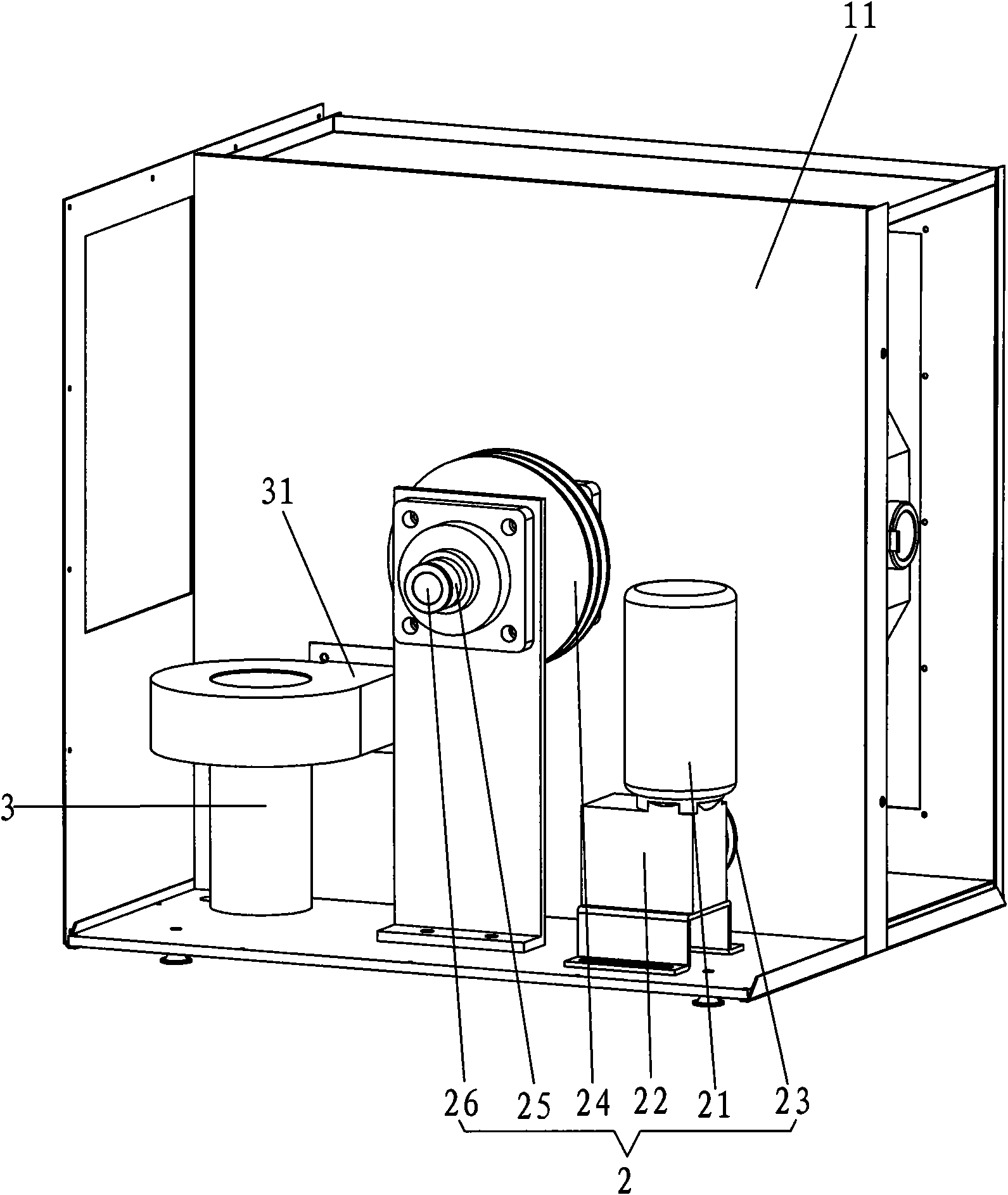

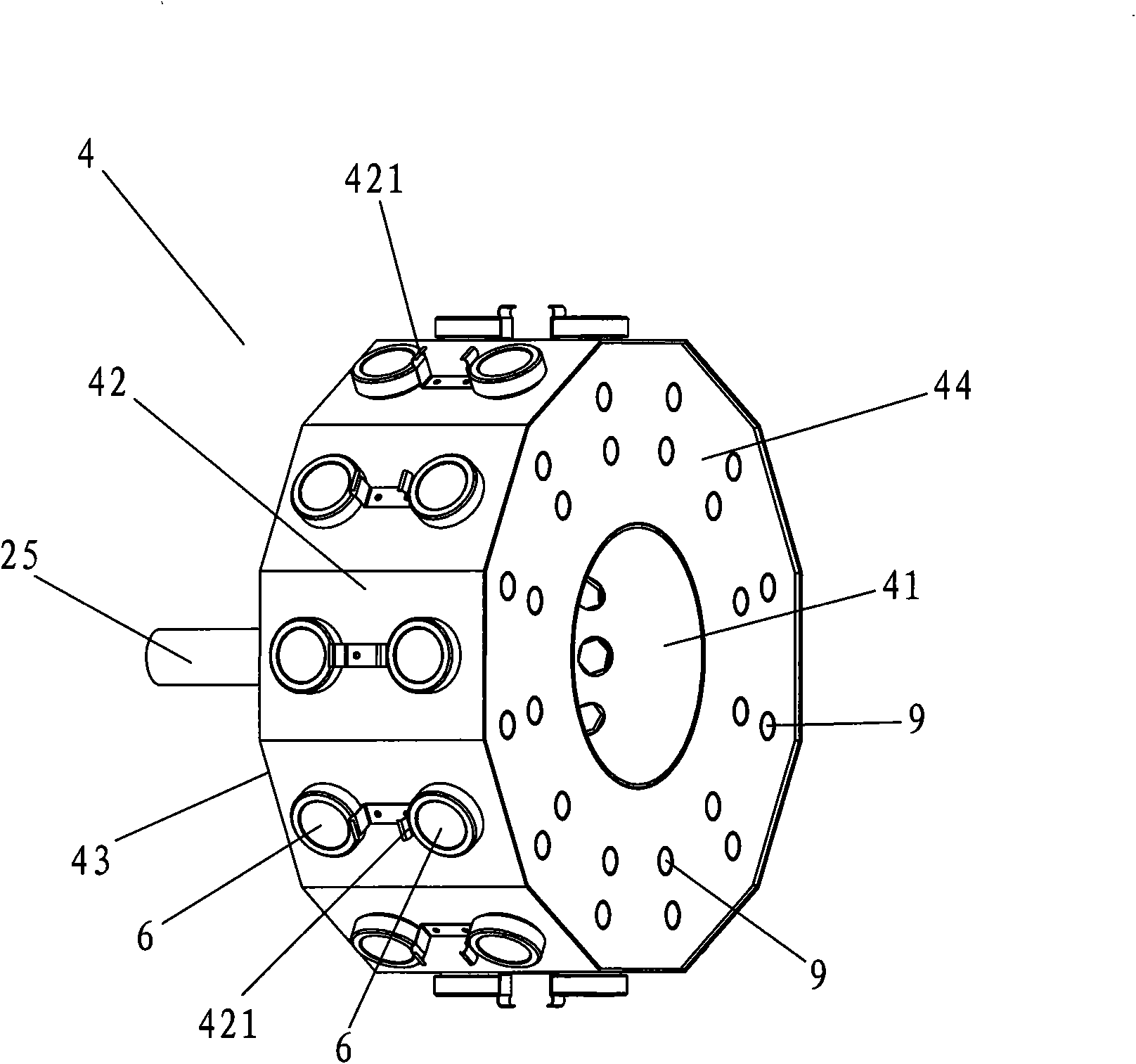

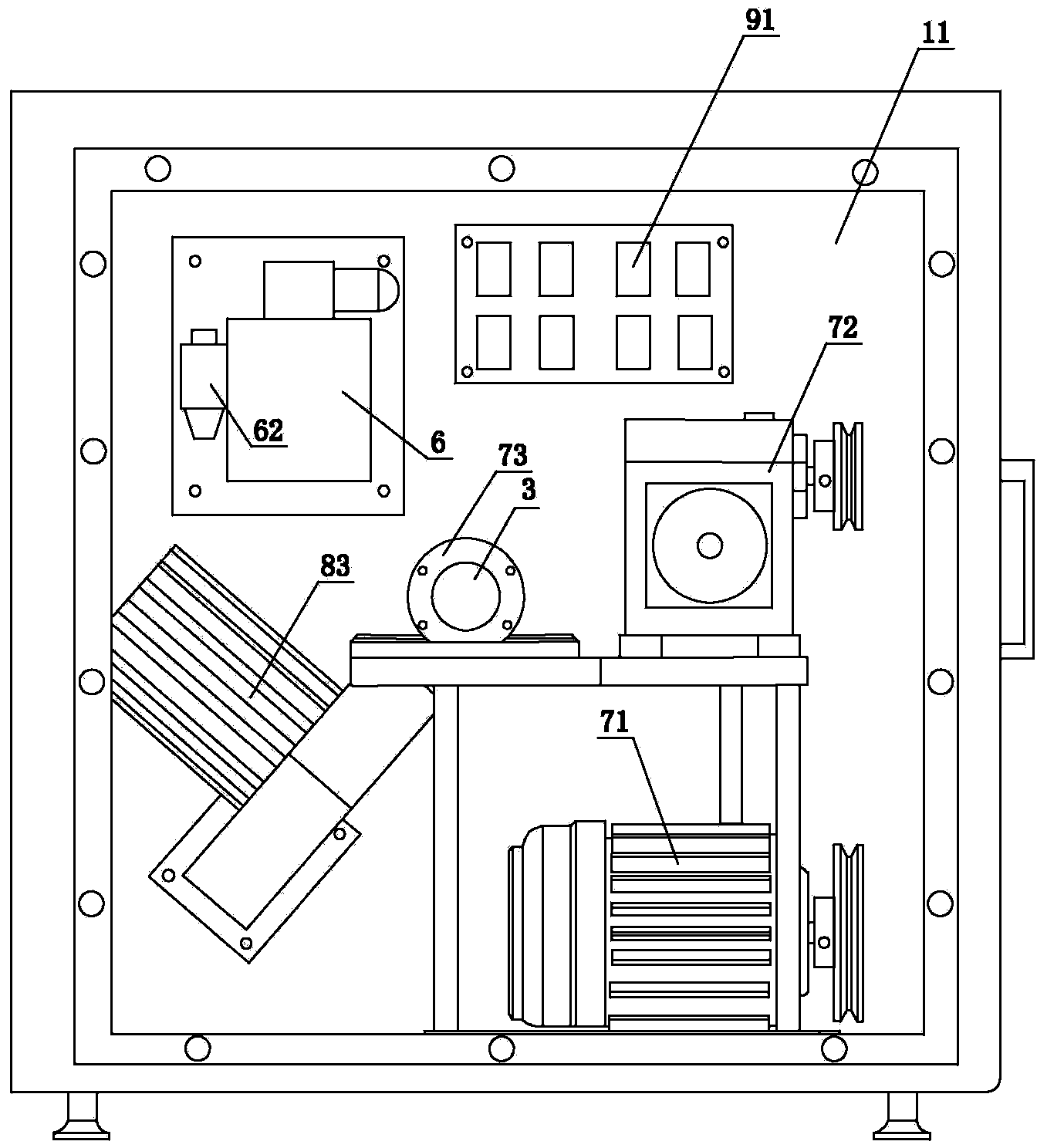

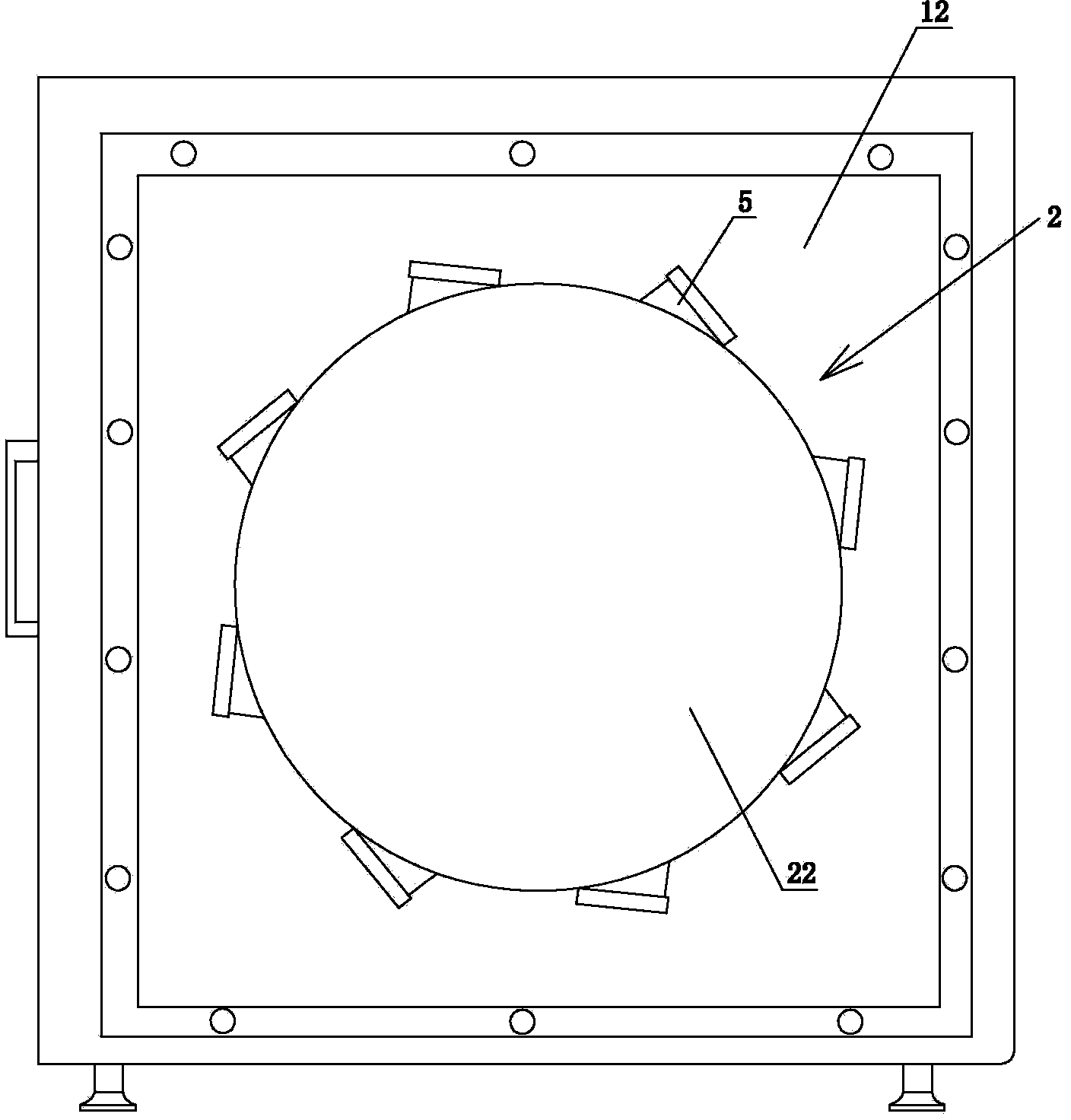

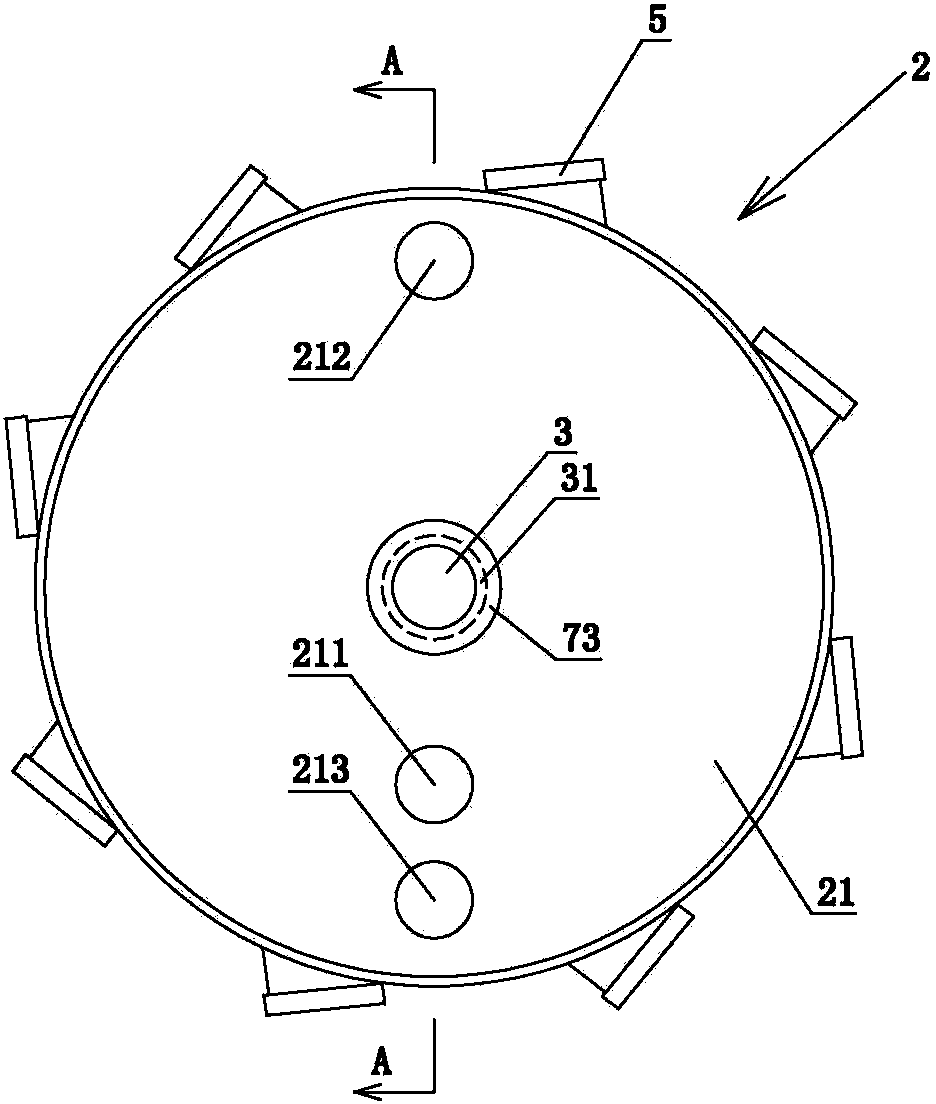

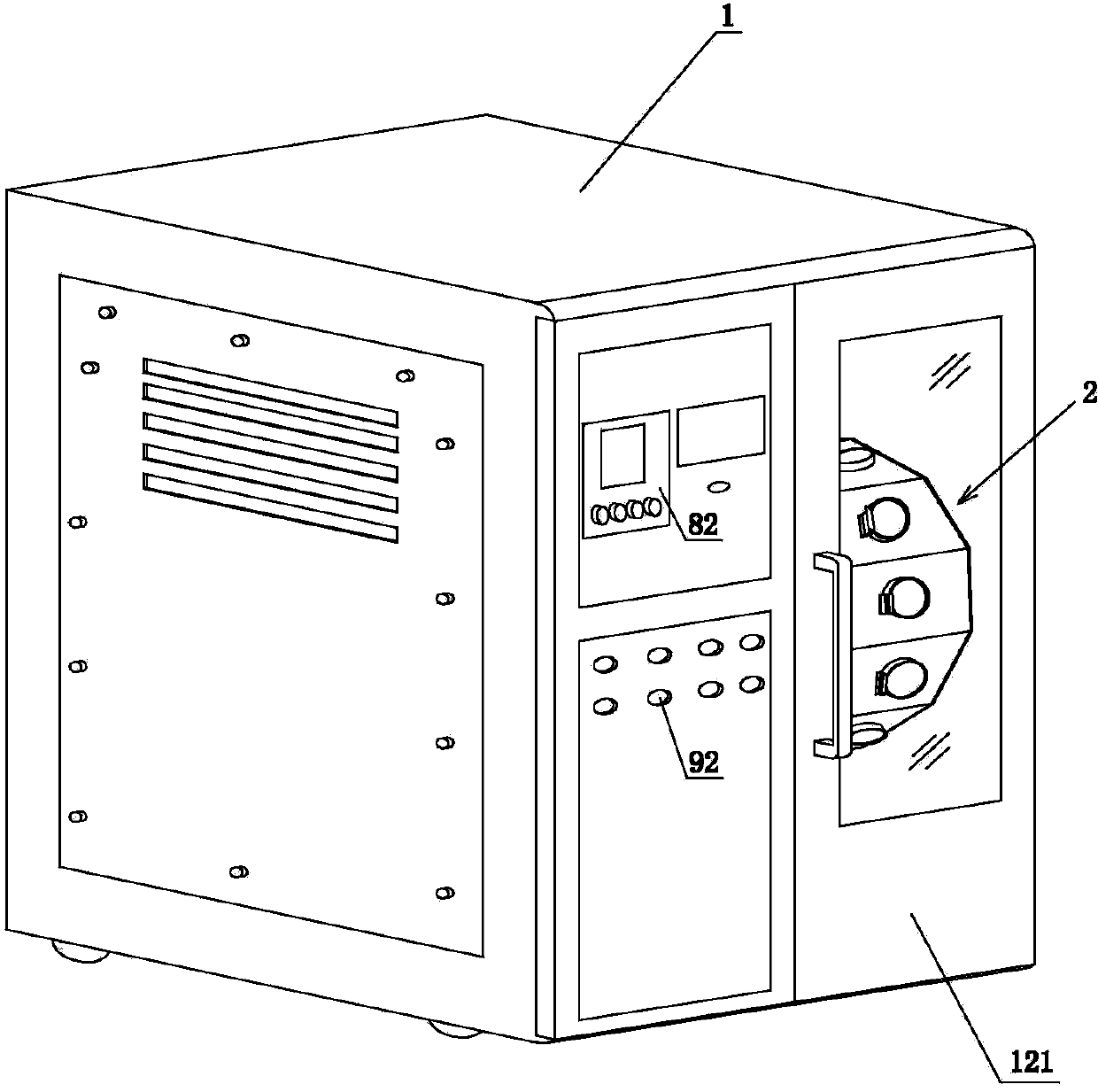

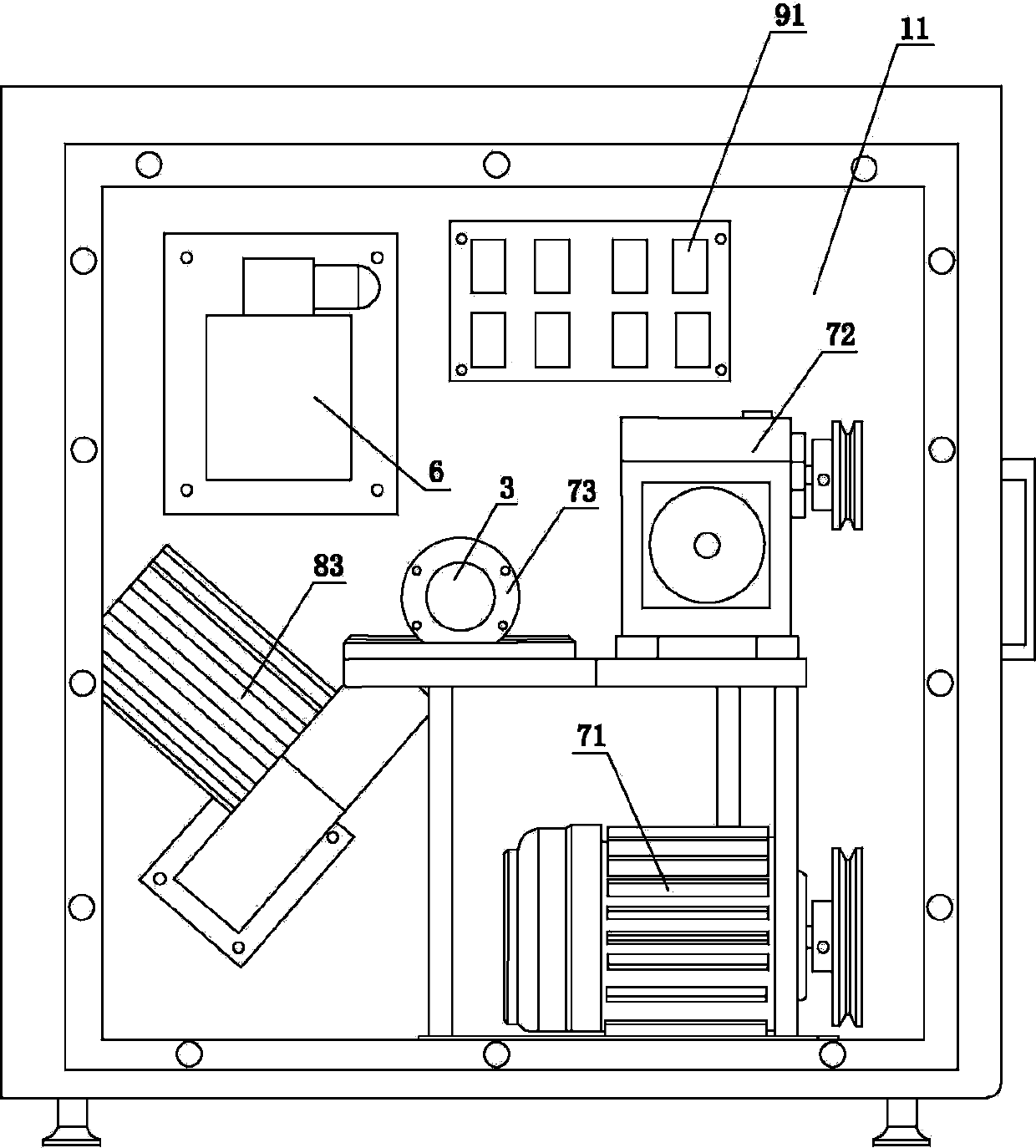

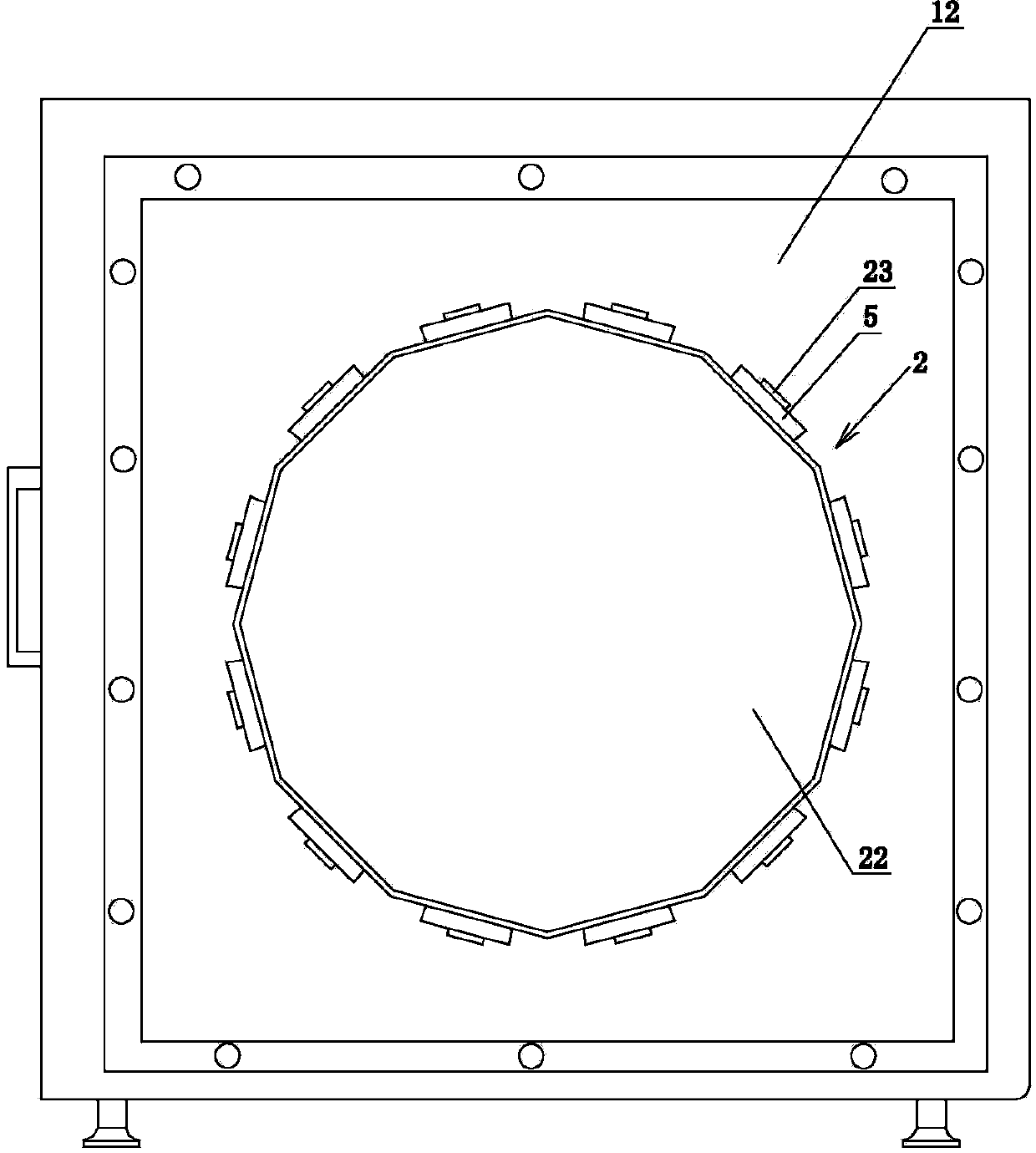

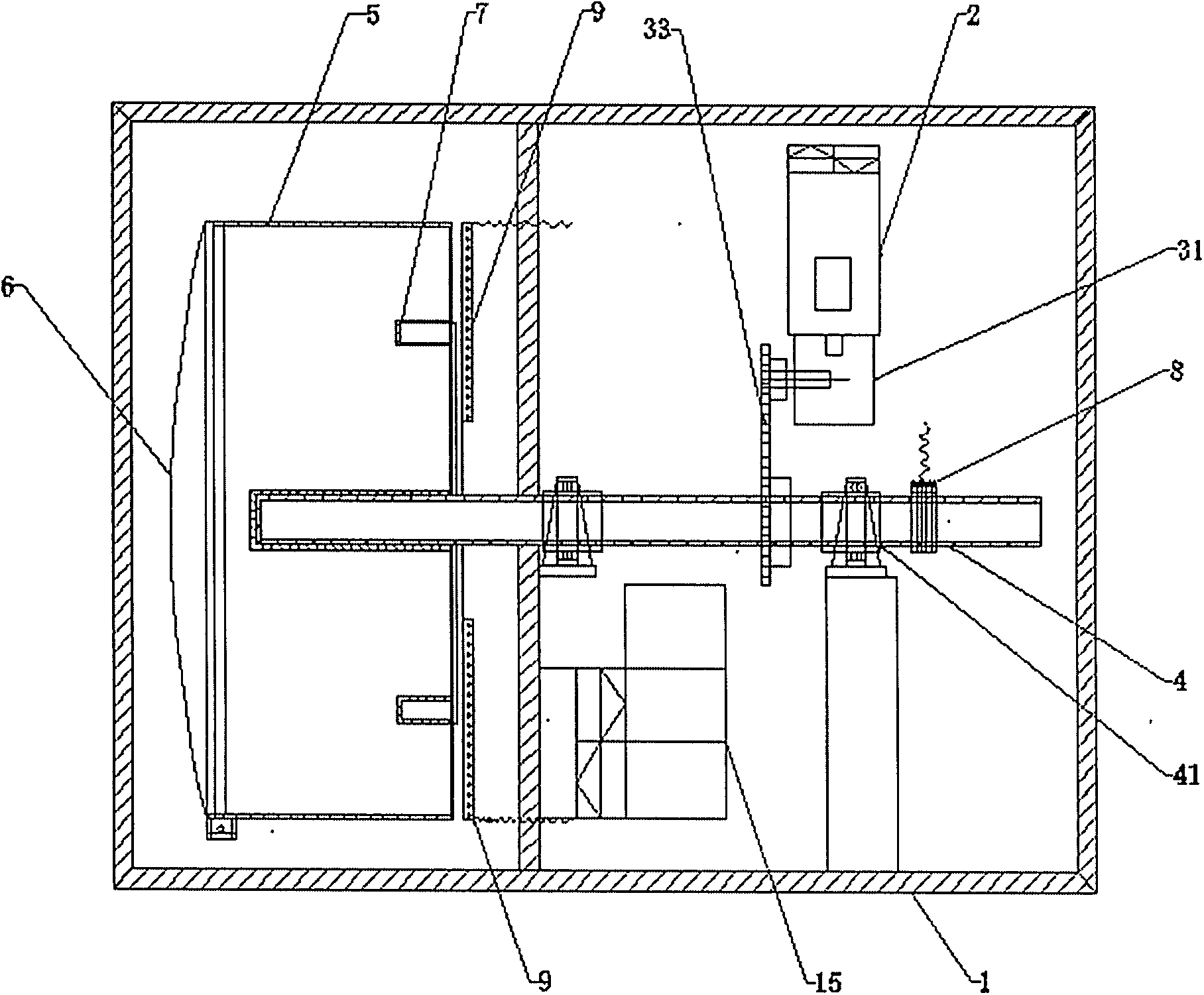

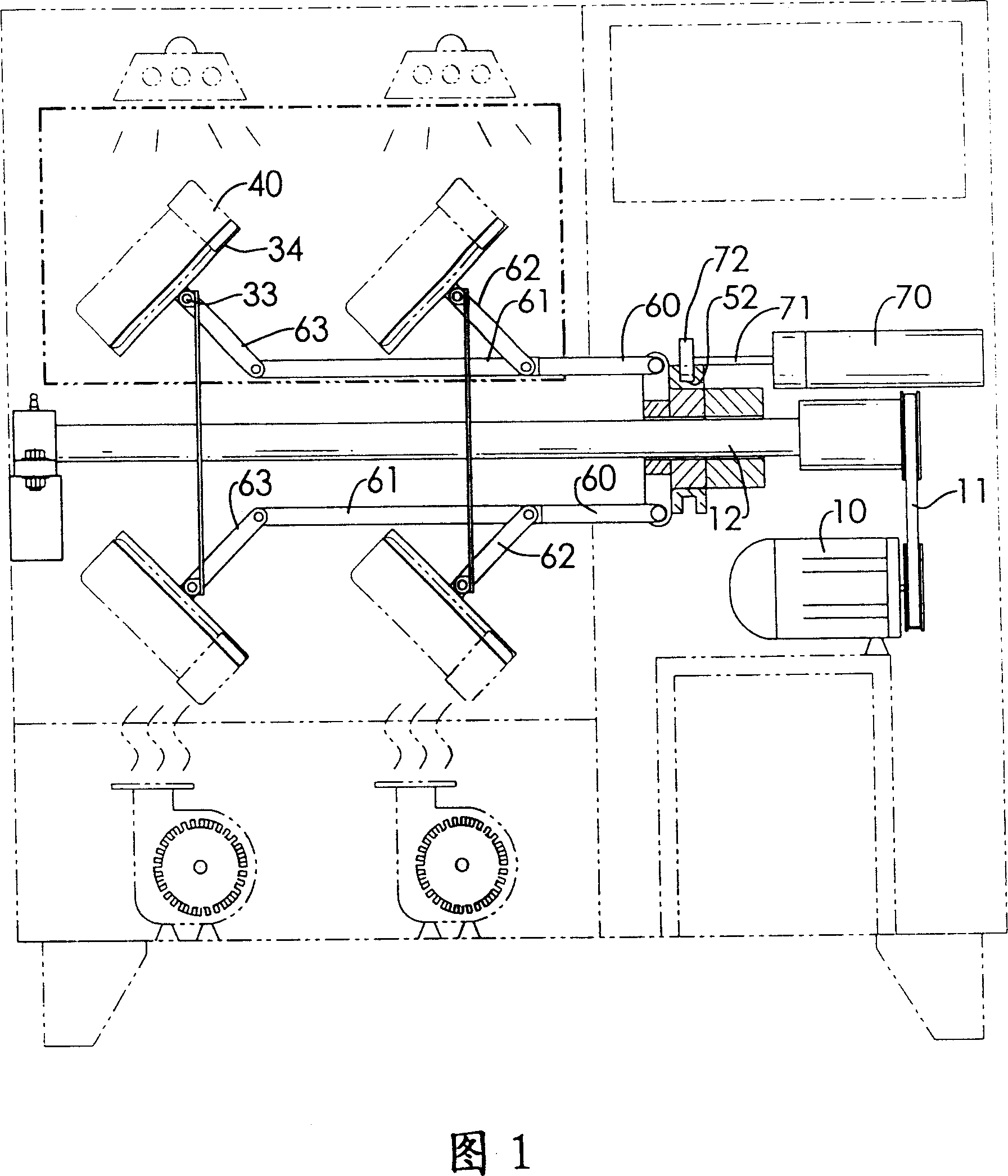

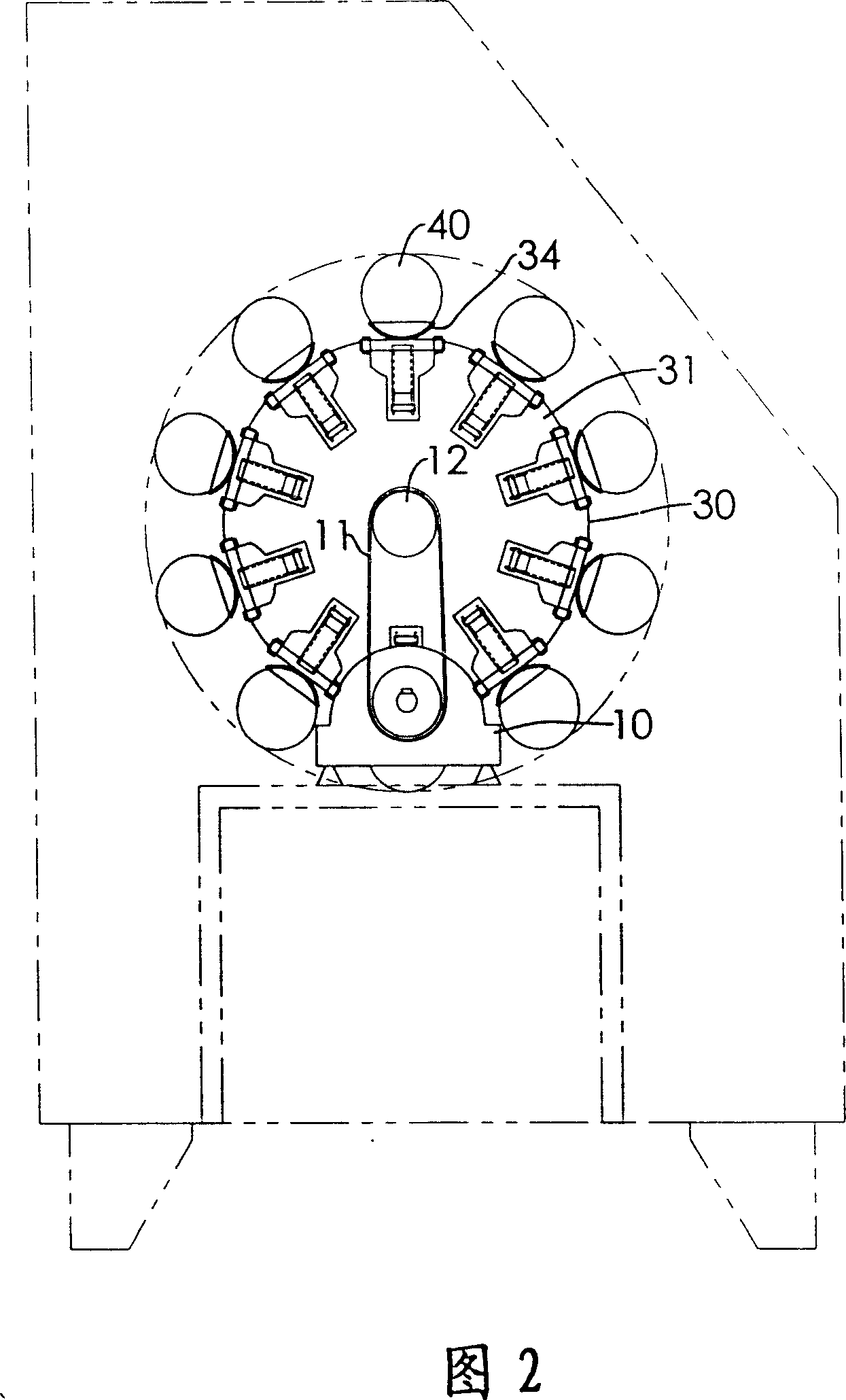

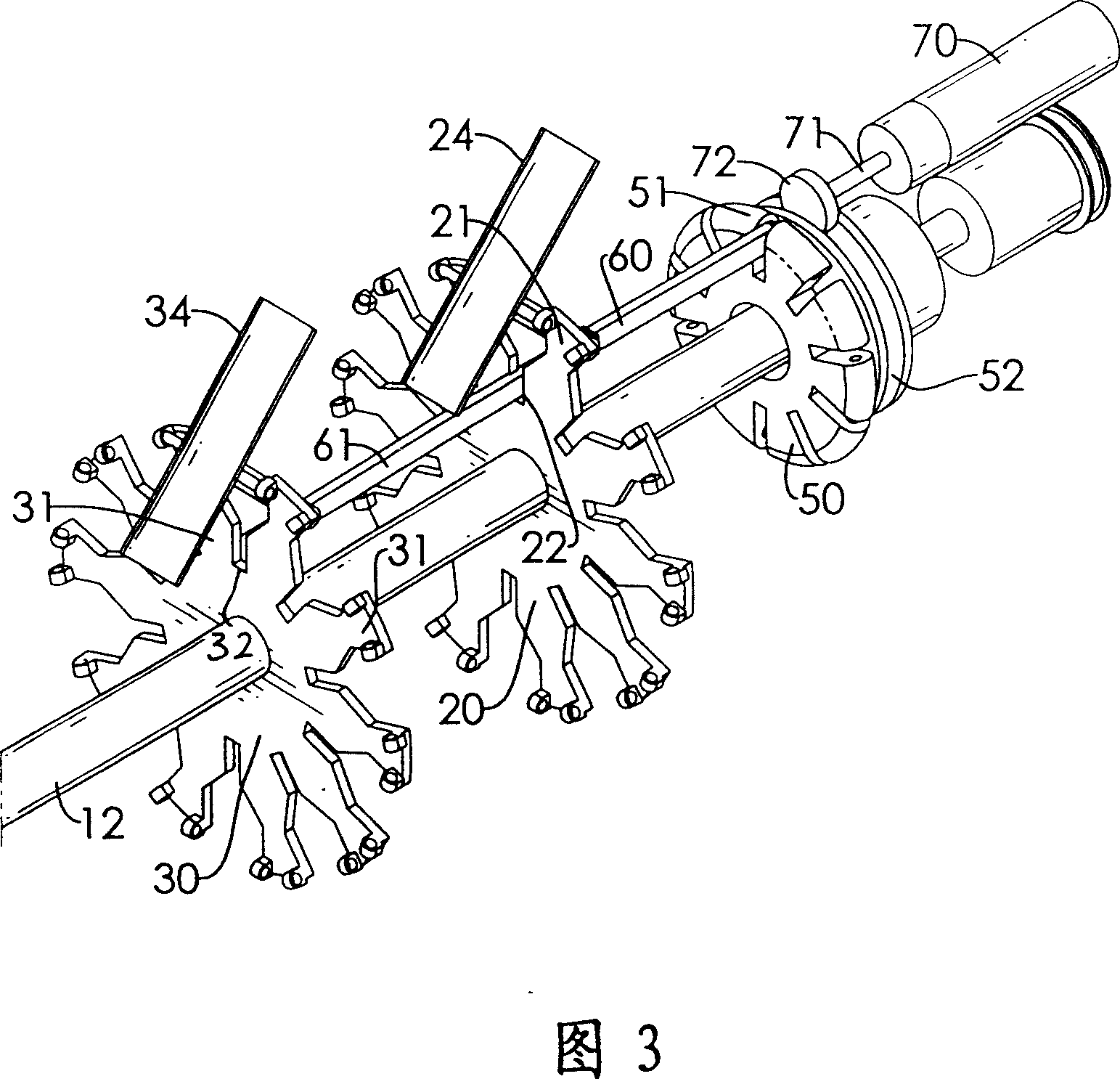

Recirculating air heating type laboratory color dyeing machine

ActiveCN103757848AReduce manufacturing costReduce consumptionTextile treatment dyeing devicesTextile treatment machine arrangementsEngineeringLaboratory facility

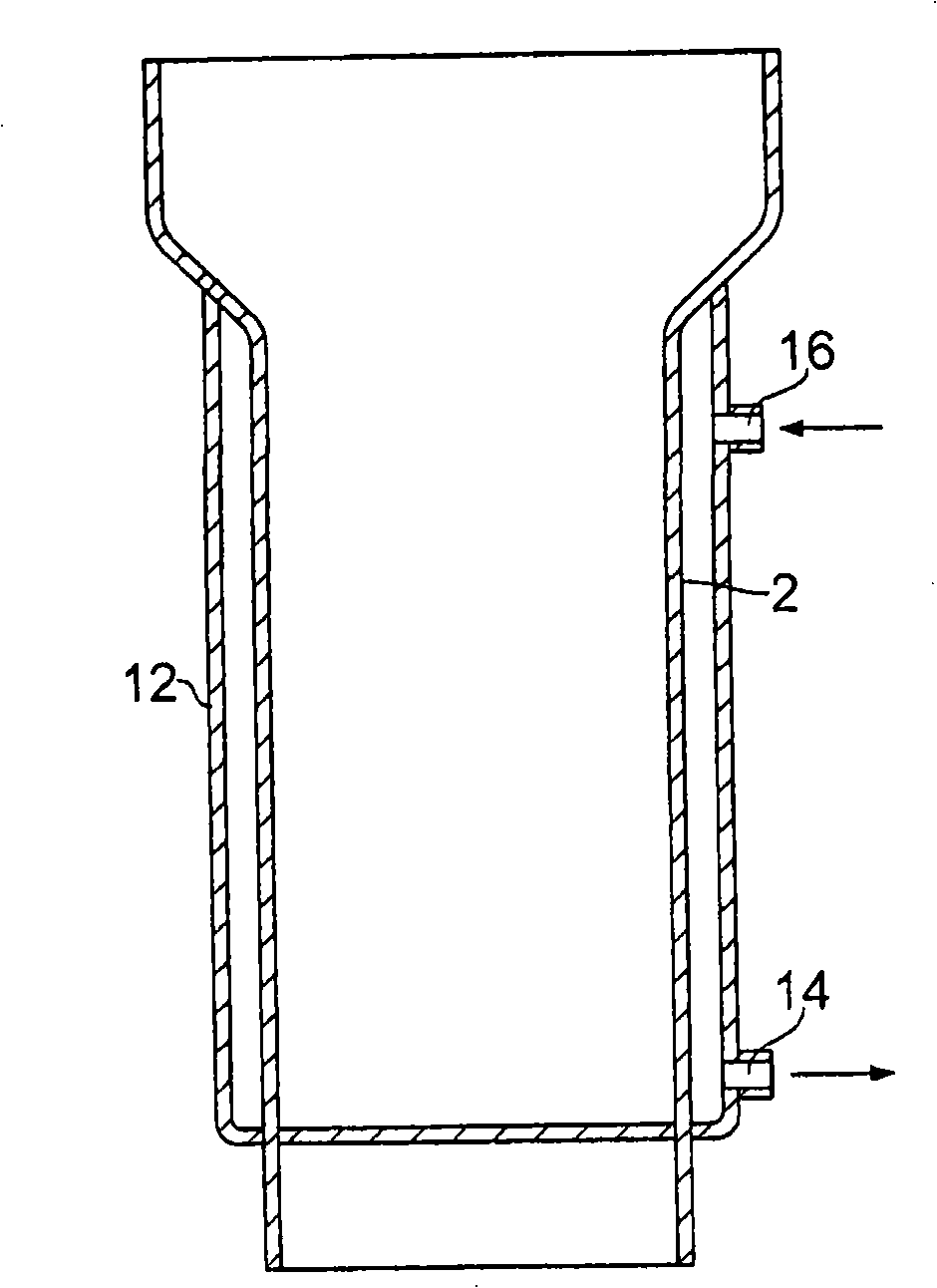

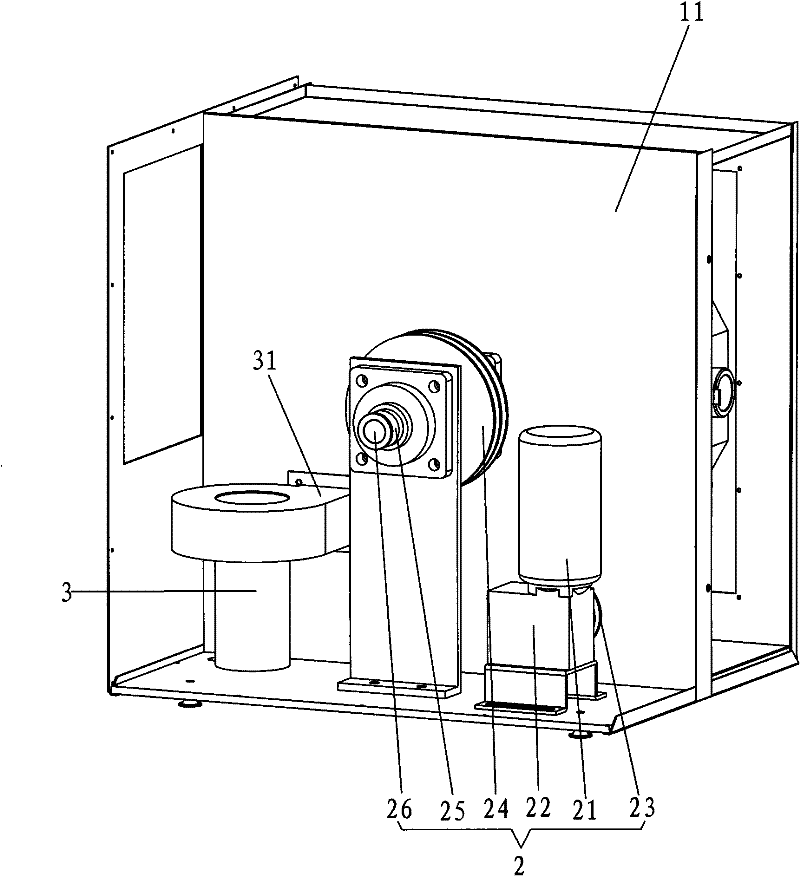

A recirculating air heating type laboratory color dyeing machine comprises a box body, a hollow rotating disc arranged in the box body and a rotating shaft connected with the rotating disc. A plurality of dyeing cup sleeves are evenly distributed on the outer peripheral face of the rotating disc, a dyeing cup is sleeved with each dyeing cup sleeve, a left end cover is arranged on the left end face of the rotating disc, a right end cover is arranged on the right end face of the rotating disc, one end of the rotating shaft penetrates through the left end cover to be fixedly connected with the right end cover, and the other end of the rotating shaft is connected with a transmission mechanism, a bearing is arranged on the rotating shaft, the left end cover is fixedly connected to an outer ring of the bearing, an air heater is arranged on the left side of the rotating disc, an air outlet of the air heater is connected with a hot air pipe, an air input hole is formed in the lower portion of the left end cover, one end of the hot air pipe penetrates into the air input hole and faces to the lateral wall of a corresponding dyeing cup sleeve, a hot air recovery device is arranged on the air heater, and an air inlet of the hot air recovery device is connected with a recovery pipe, a recovery hole is formed in the upper portion of the left end cover, and the other end of the recovery pipe penetrates through the recovery hole to be located in the rotary disc.

Owner:SHISHI TAIRUI PRECISION MACHINERY

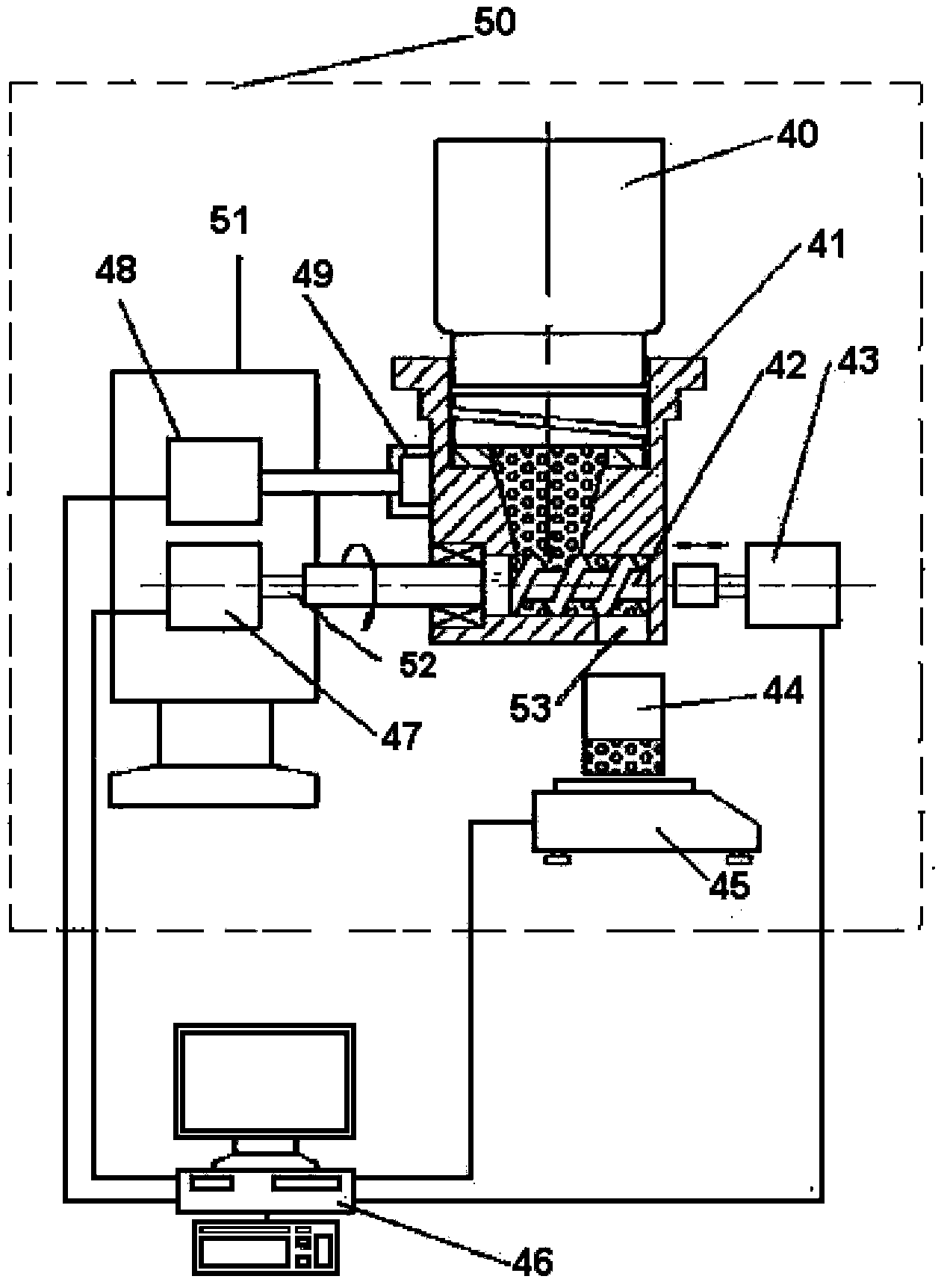

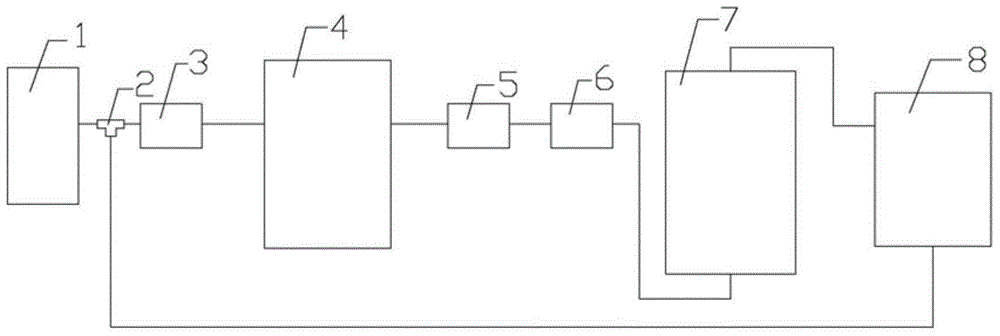

Sample dyeing machine for supercritical CO2 dyeing and dye weighing system

InactiveCN103422288AAccurate weighingSave waterTextile treatment dyeing devicesTextile treatment machine arrangementsWater sourceCo2 storage

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

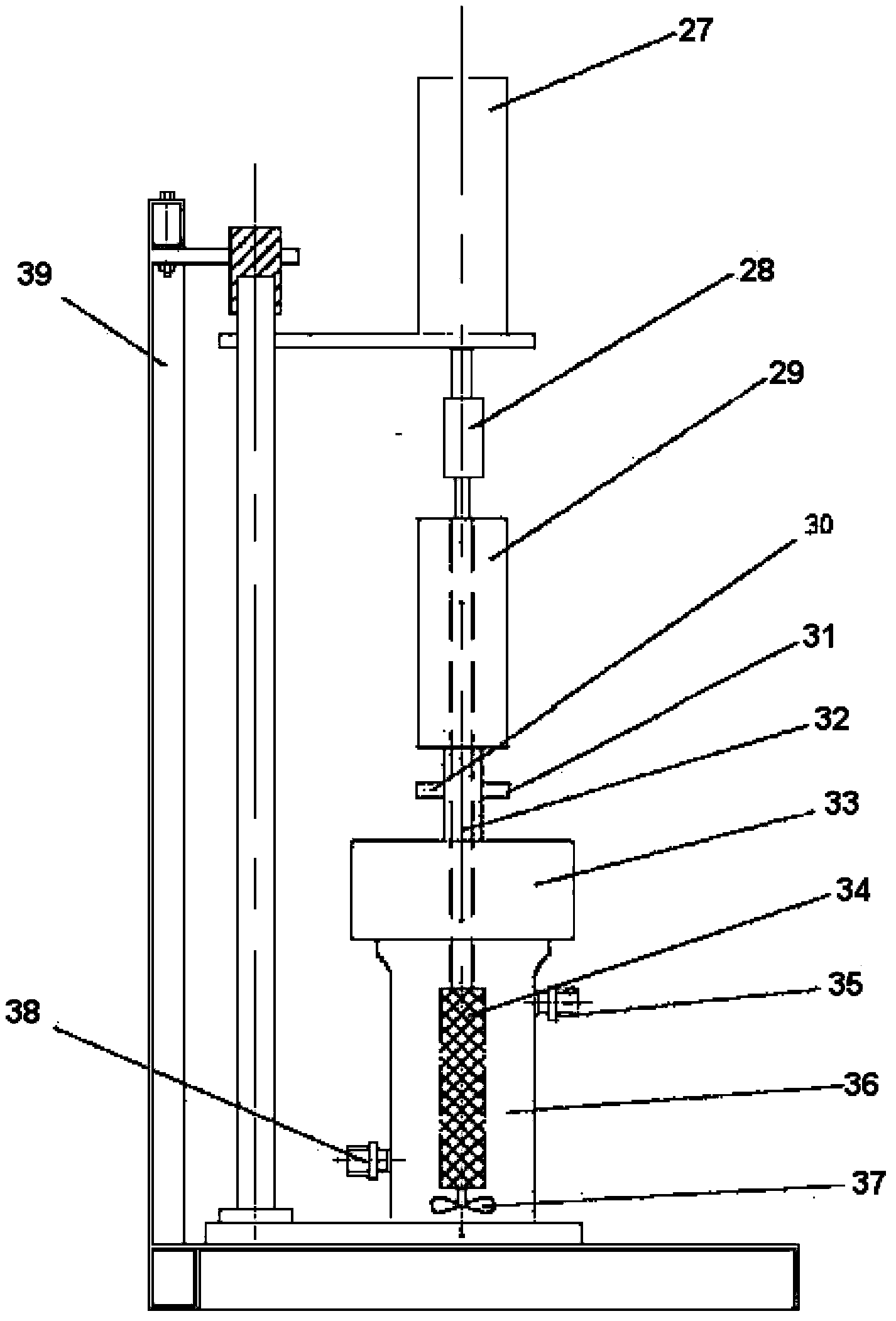

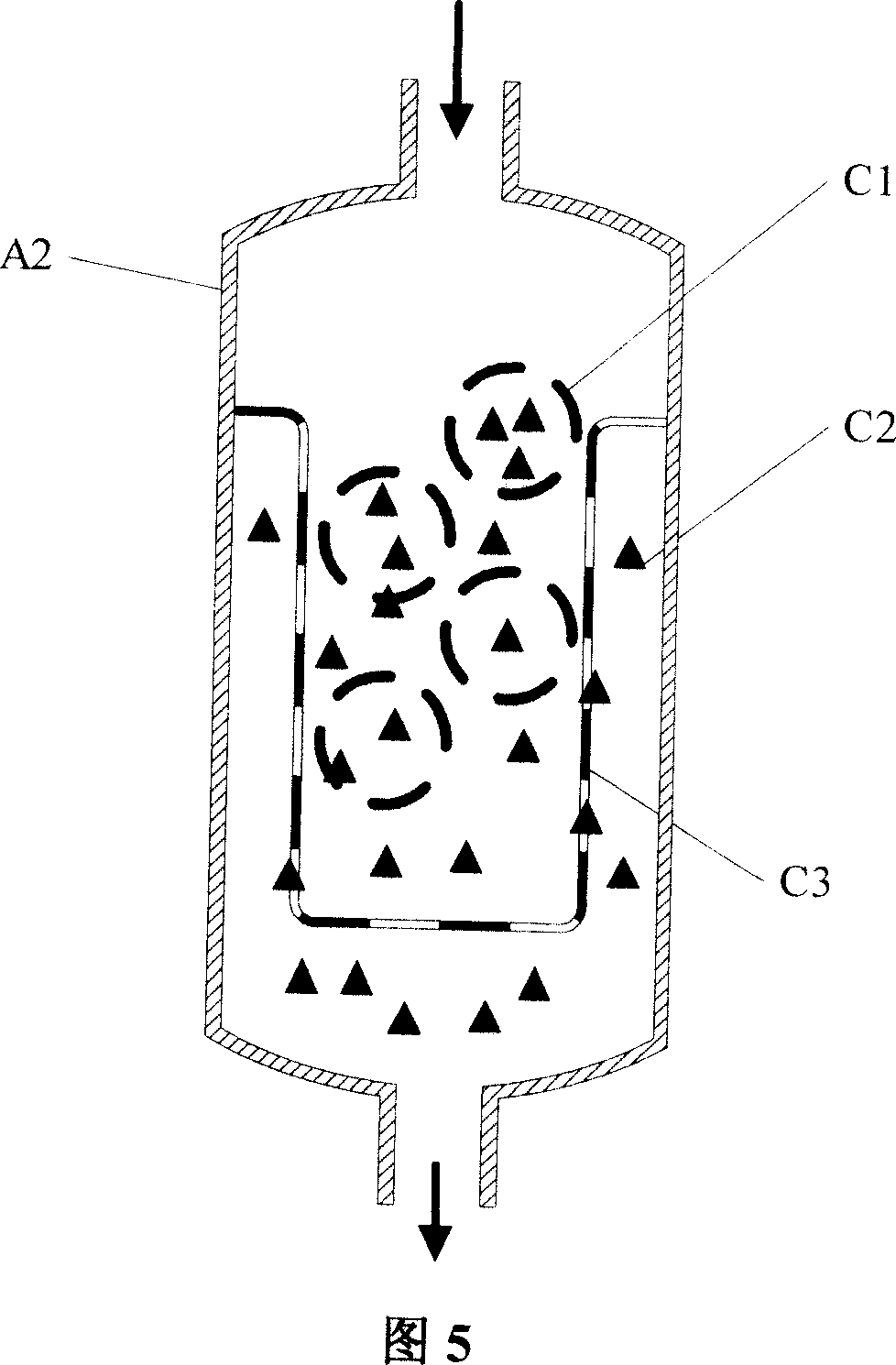

Supercritical carbon dioxide fluid proofing device and dyeing method

ActiveCN105040325AEfficient retentionImprove solubilityTextile treatment dyeing devicesTextile treatment machine arrangementsGas solidEngineering

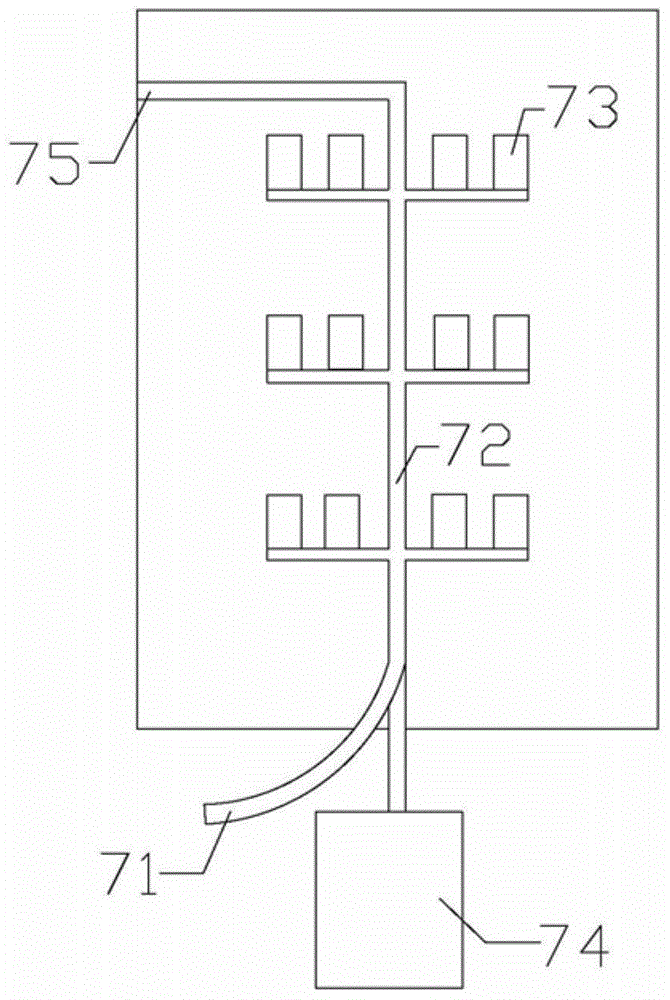

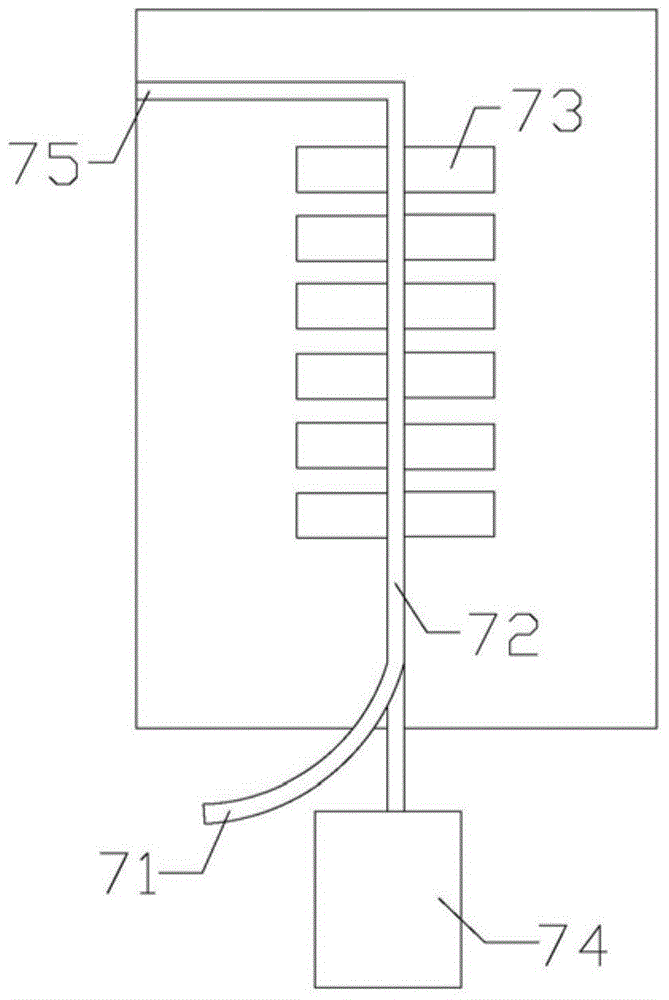

The invention relates to a supercritical carbon dioxide fluid proofing device and a dyeing method and belongs to the technical field of spinning. The device comprises a dyeing kettle, the dyeing kettle comprises a sample unit supporting rack, multiple sample units and a motor, the sample unit supporting rack is arranged inside a cylinder body of the dyeing kettle, the motor passes through the dyeing kettle in a sealed mode and is connected with the sample unit supporting rack, the multiple sample units are arranged on the sample unit supporting rack, a channel used for allowing the carbon dioxide fluid to flow into the sample units is formed inside the sample unit supporting rack, and the sample units comprise a gas-solid separating membrane, a porous partition plate I, a dye chamber, a porous partition plate II, a sample chamber and a detachable sealing cover II in sequence from near to far at a carbon dioxide fluid inlet and outlet of a detachable sealing cover I. The supercritical carbon dioxide fluid proofing device and the dyeing method have the advantage of putting forward the supercritical carbon dioxide fluid proofing device for the first time.

Owner:DALIAN POLYTECHNIC UNIVERSITY

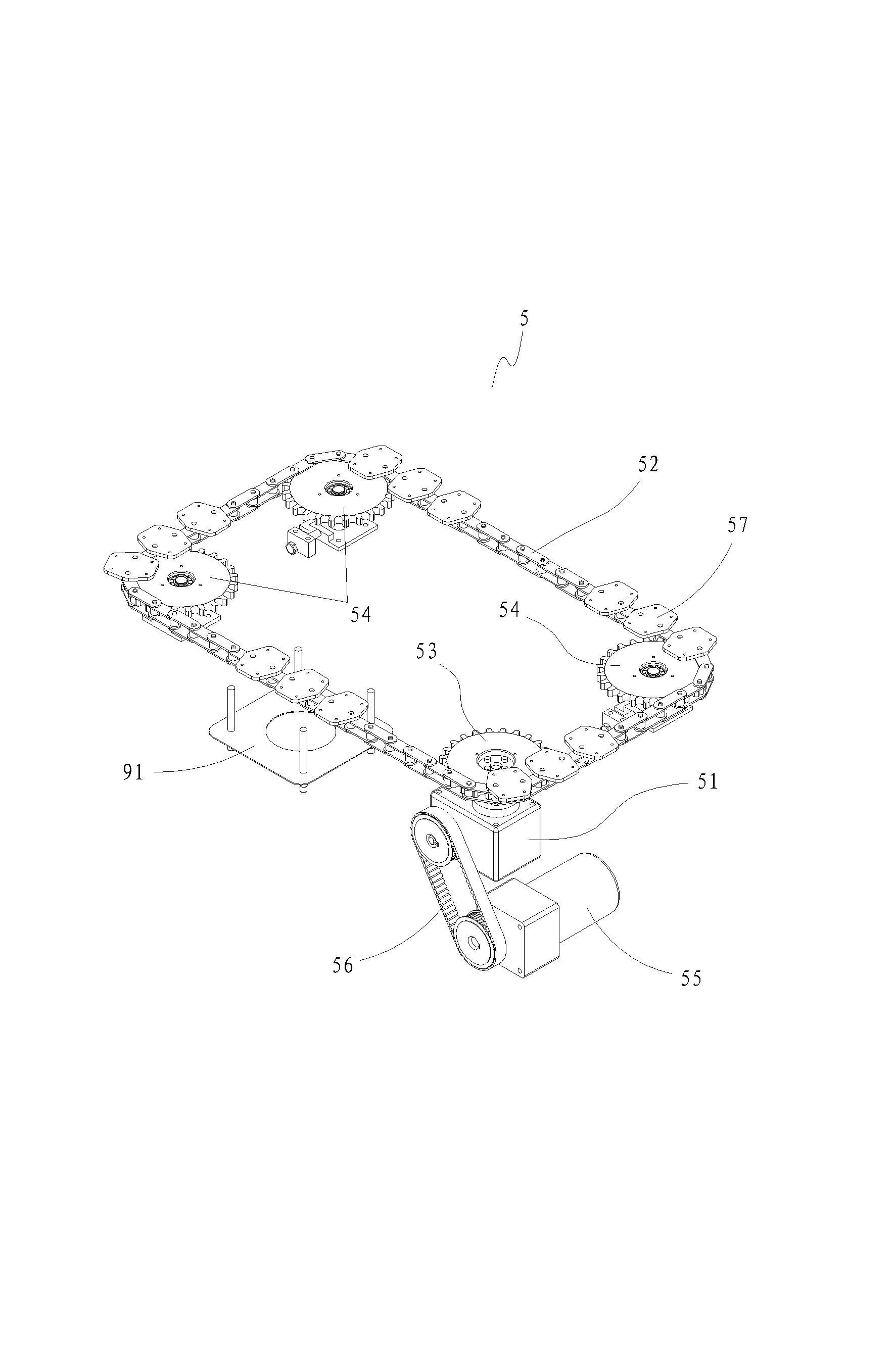

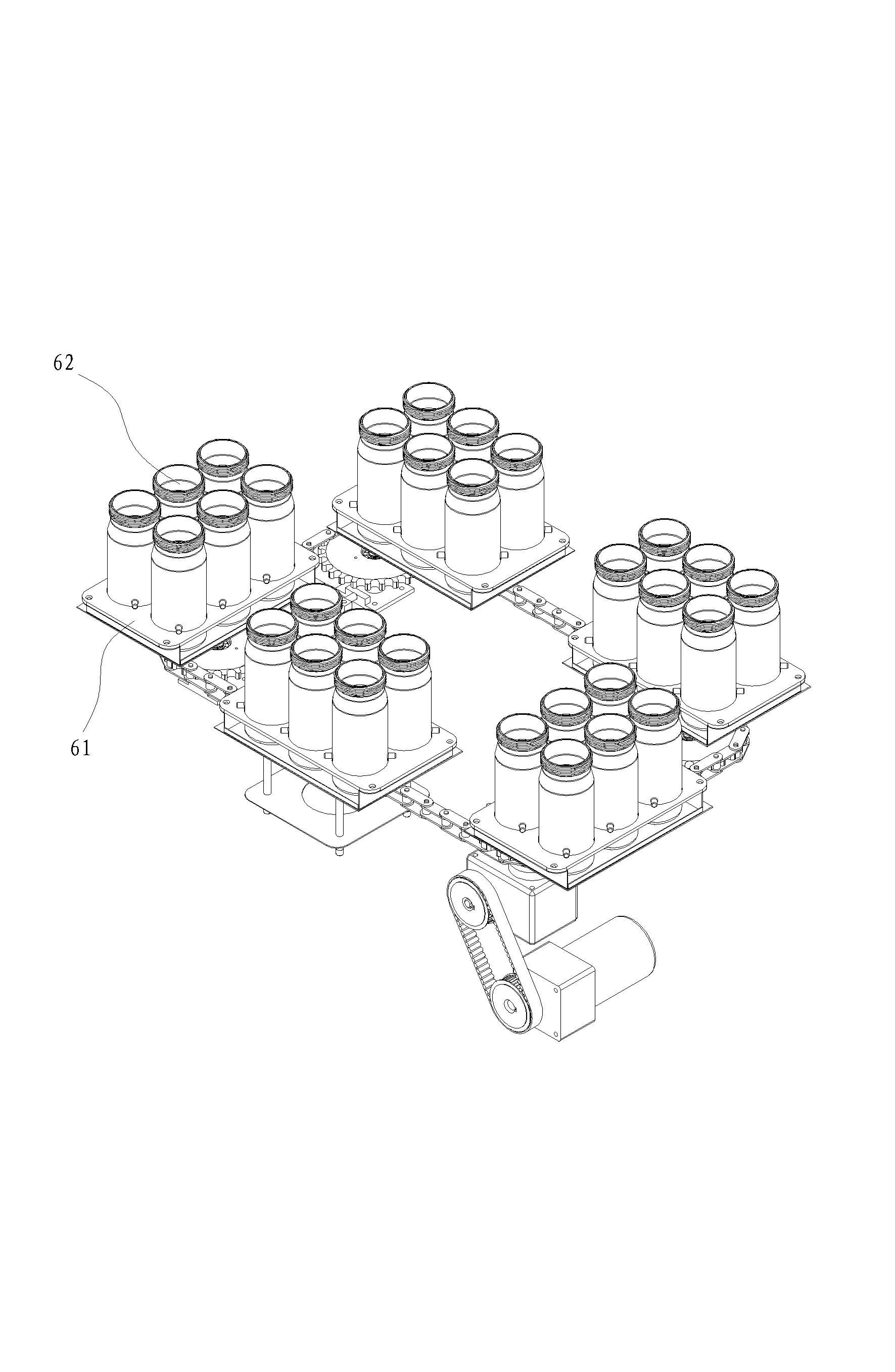

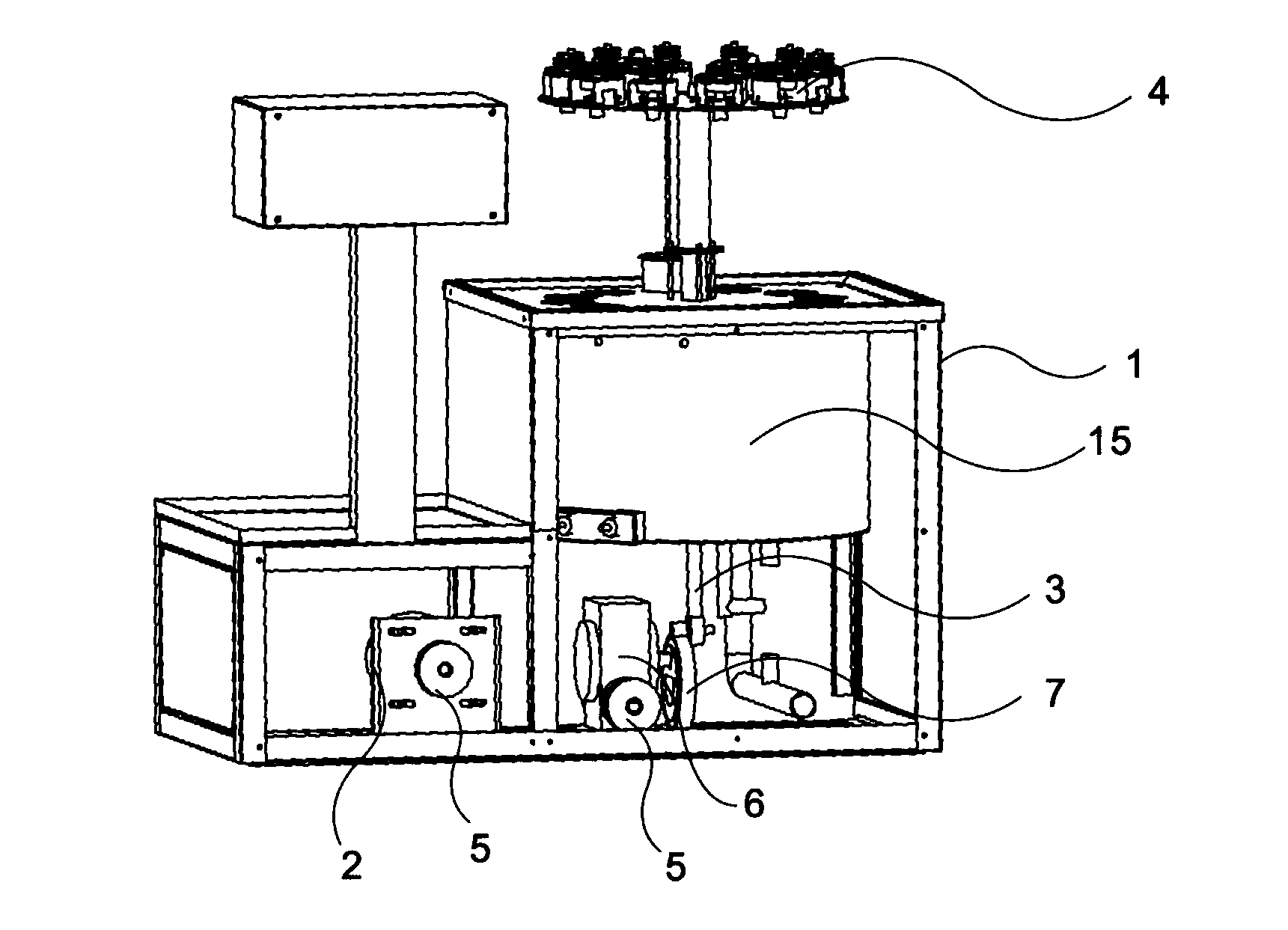

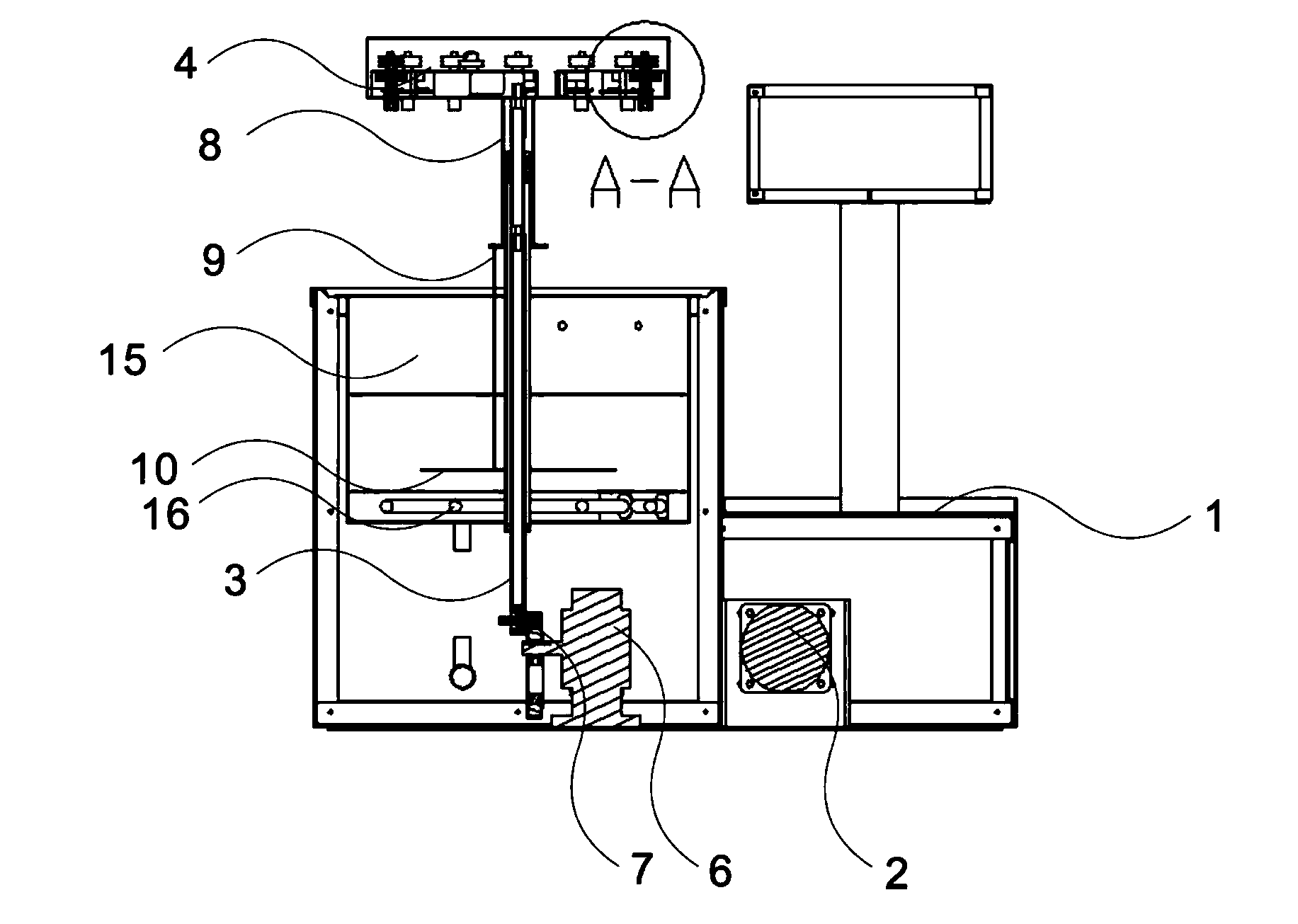

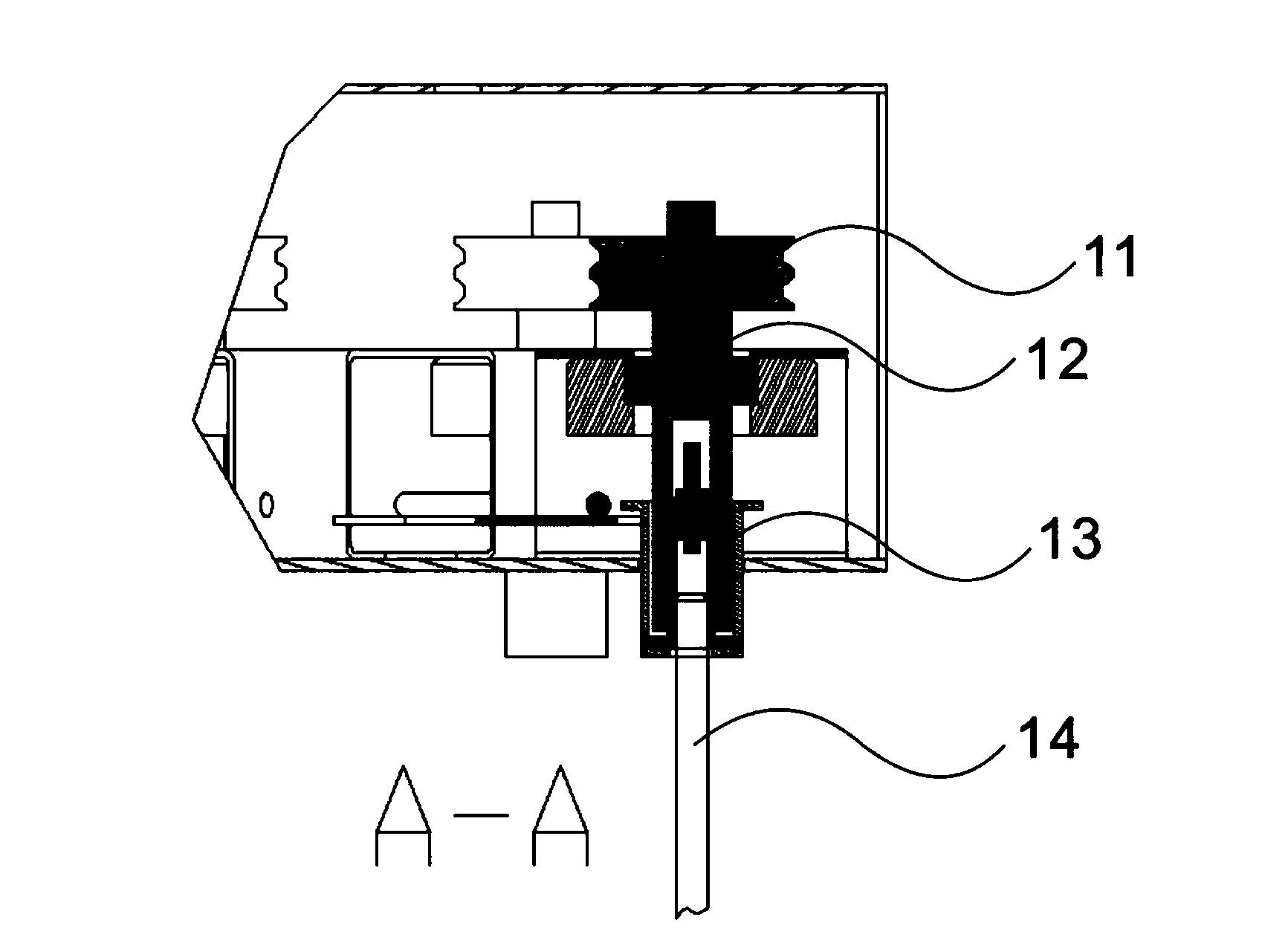

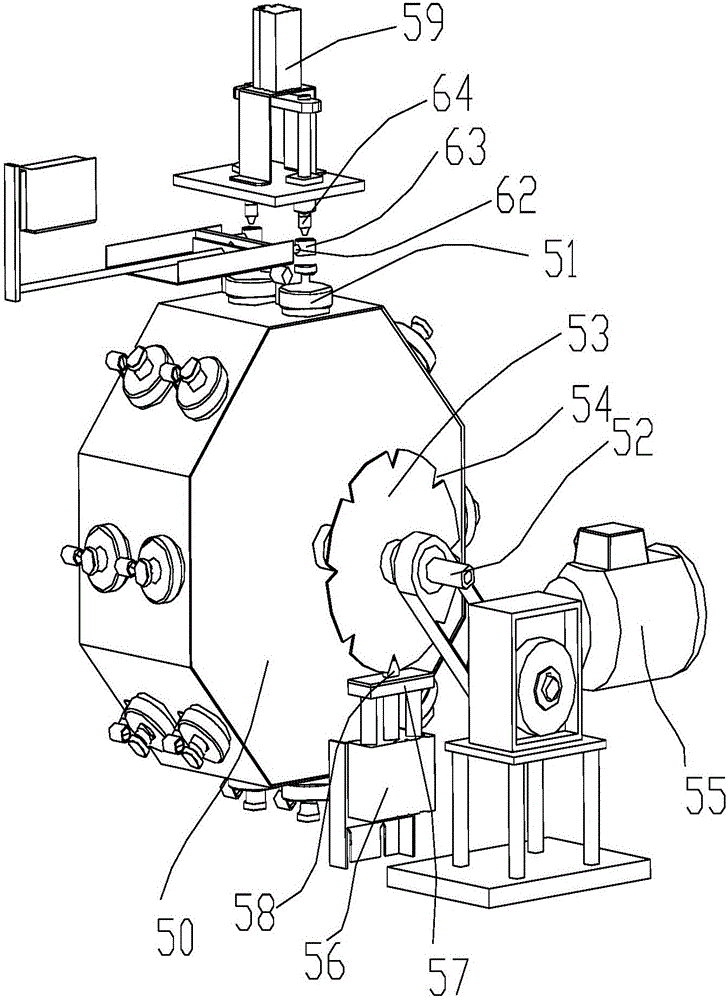

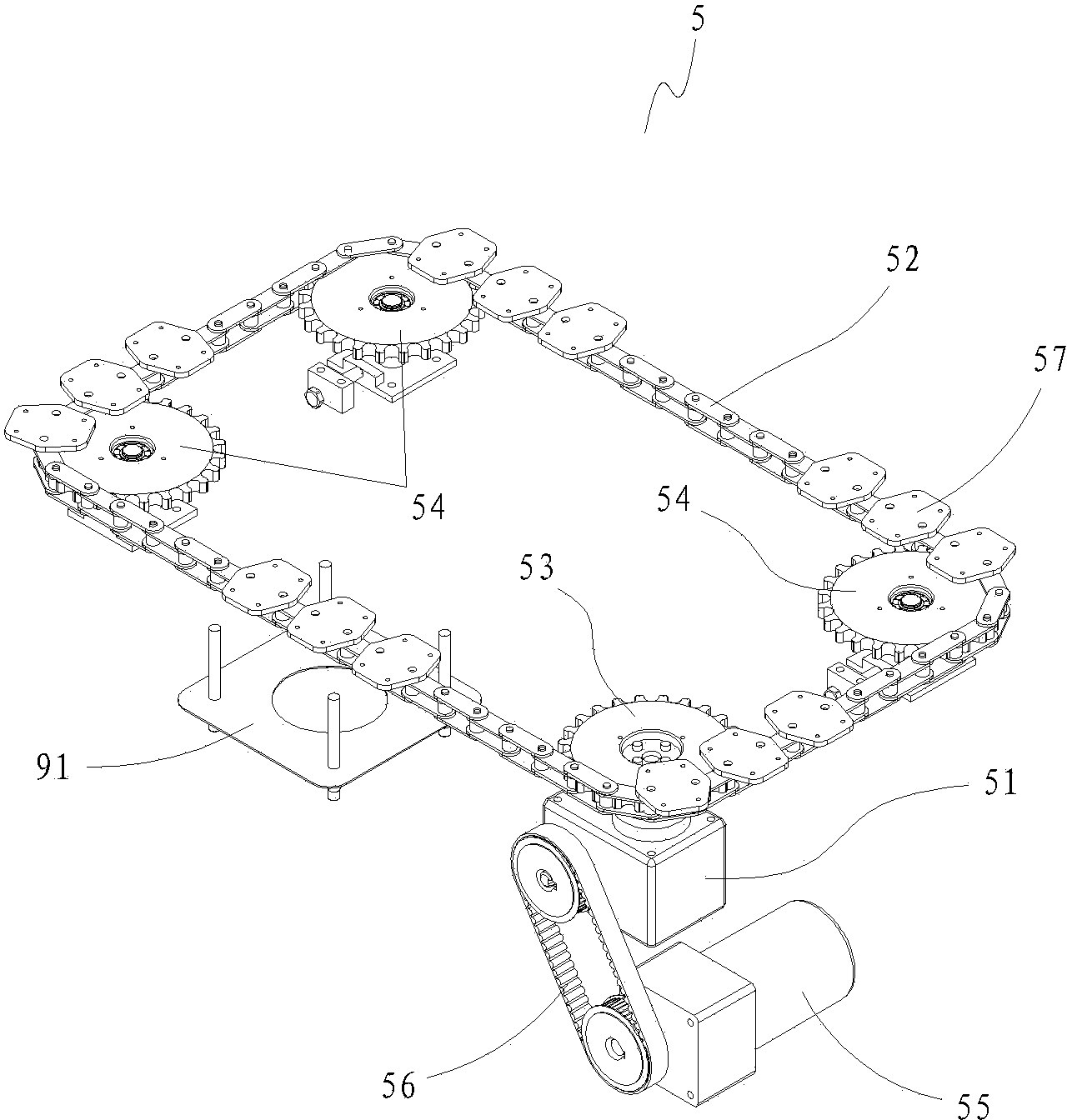

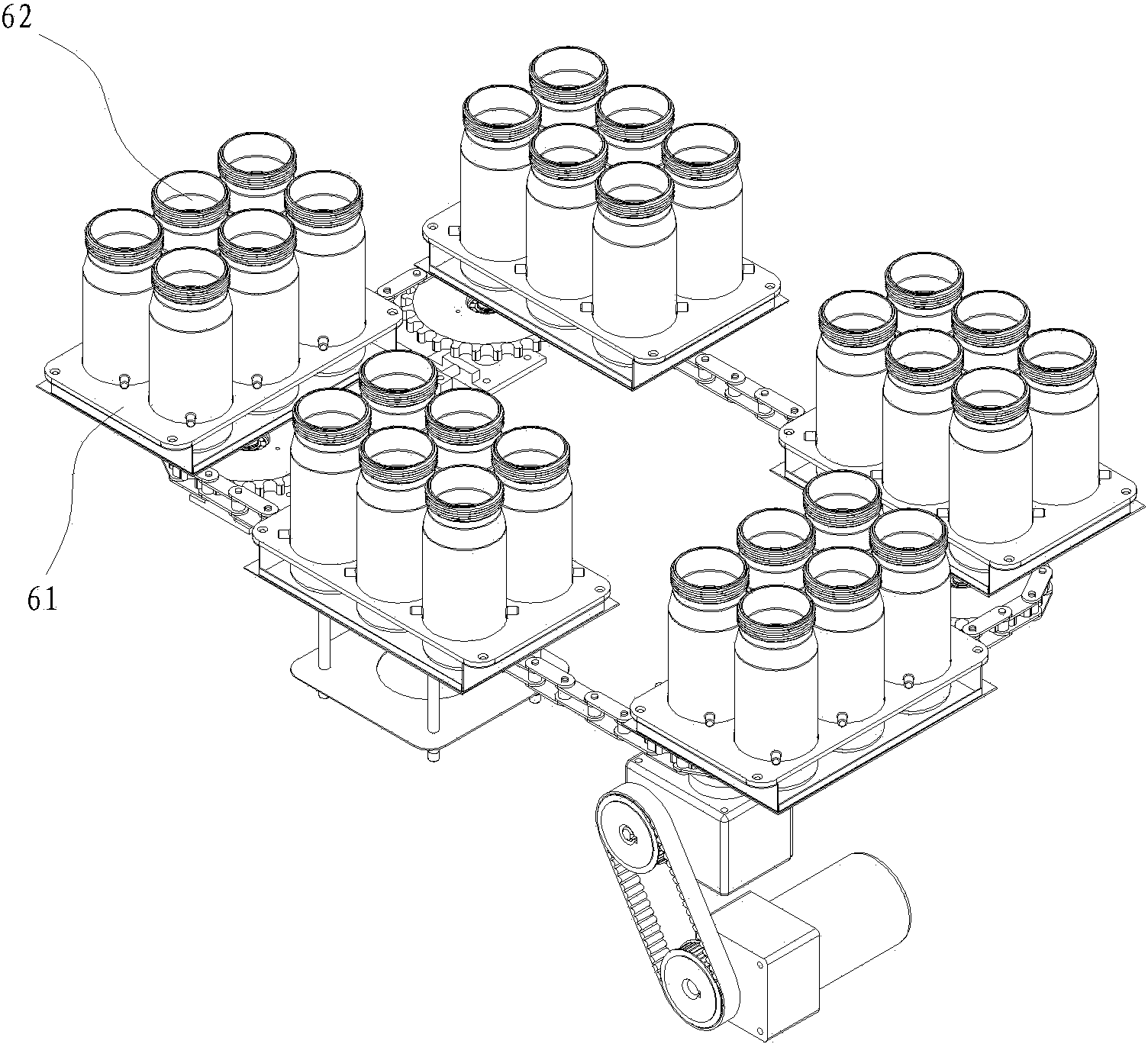

Printing and dyeing dropping machine

ActiveCN102587065ASolve the positioning problemPrecise positioningTextile treatment dyeing devicesBottleManipulator

The invention discloses a printing and dyeing dropping machine, which comprises a bench provided with a liquid extracting area and a liquid distributing area, wherein the liquid extracting area contains a plurality of mother liquid bottles, and the liquid distributing area is positioned on one side of the liquid extracting area. A three-axis manipulator is arranged above the liquid extracting area, a positioning mechanism is arranged on the liquid extracting area, and a turntable mechanism is arranged on the liquid distributing area and is connected with a divider to precisely control a steel cup on the turntable mechanism to be matched with an outlet of a liquid distributing mechanism in a positioned manner. An injector can be precisely positioned by a positioning sleeve and an acrylic positioning plate, perpendicularity of the injector can be kept, and the problem of positioning in dye dropping is solved. When liquid is distributed, a turntable-type circulating structure is used for weighing and liquid distributing operations. When a motor stops rotating, the cup can be precisely transferred to a next cup position by the aid of the limit function of the divider, and positioning deviation of the cup and the liquid distributing mechanism due to movement inertia is avoided.

Owner:厦门瑞比精密机械有限公司

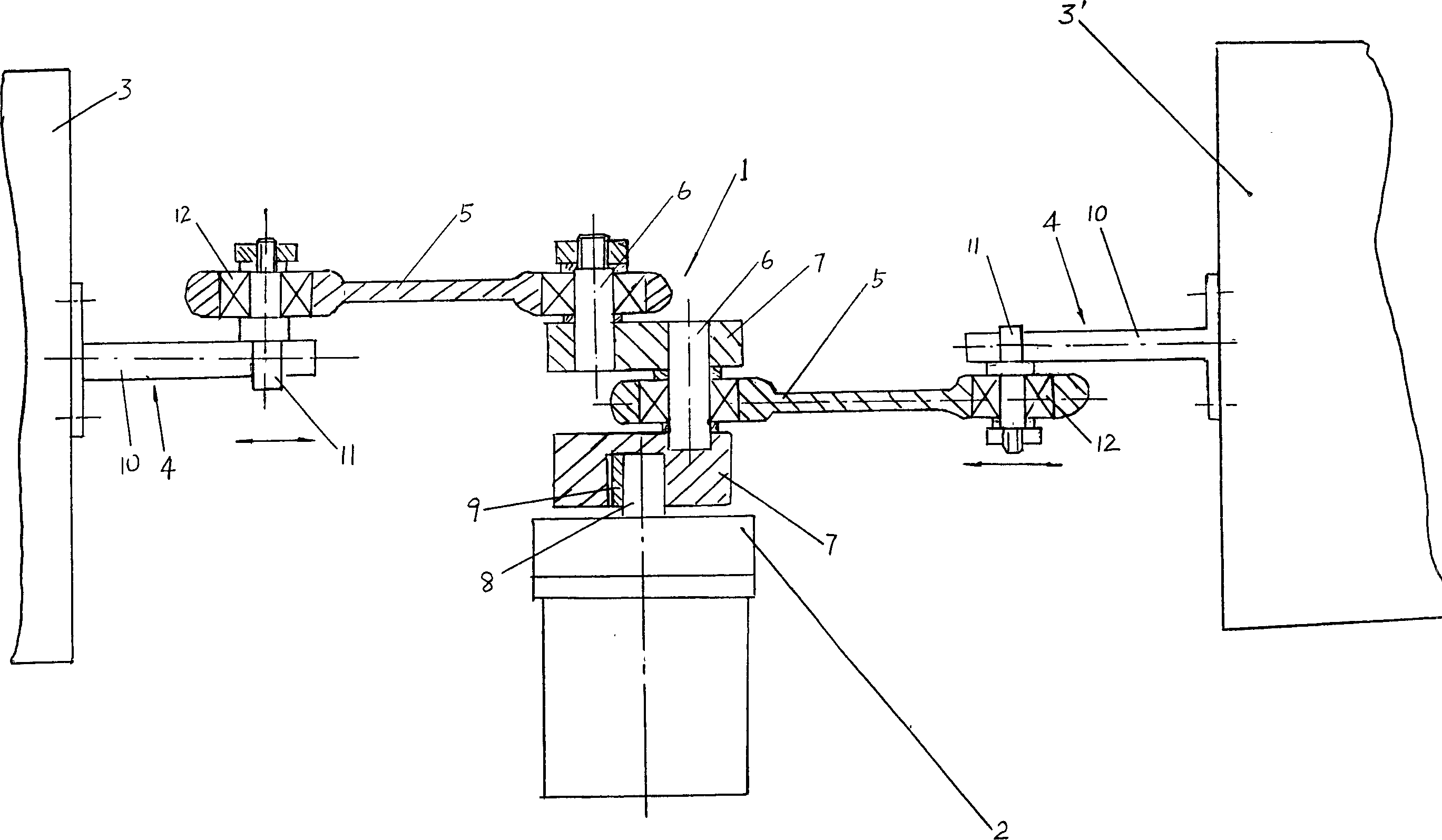

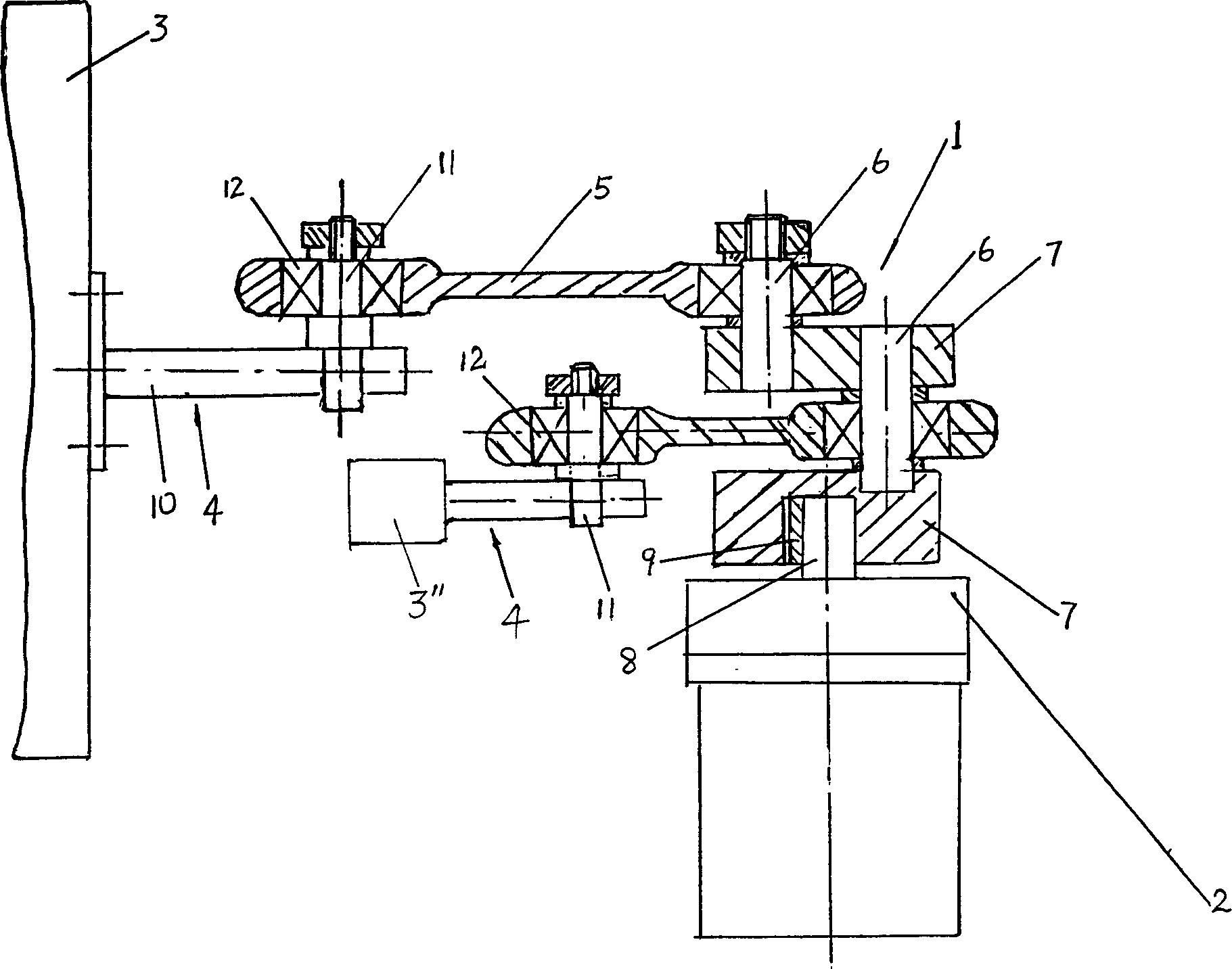

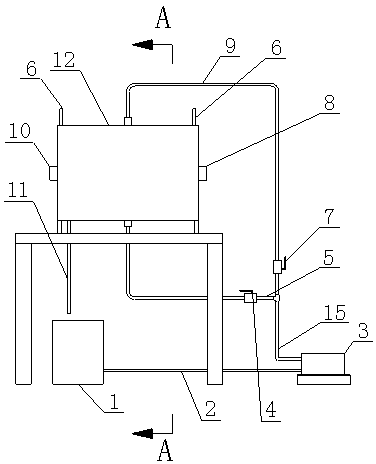

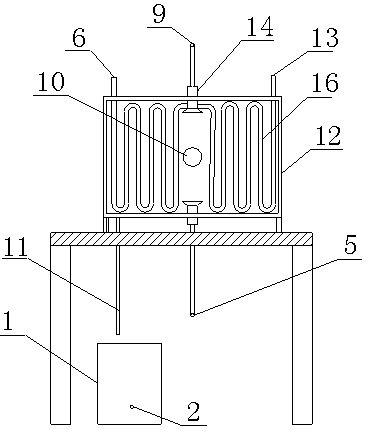

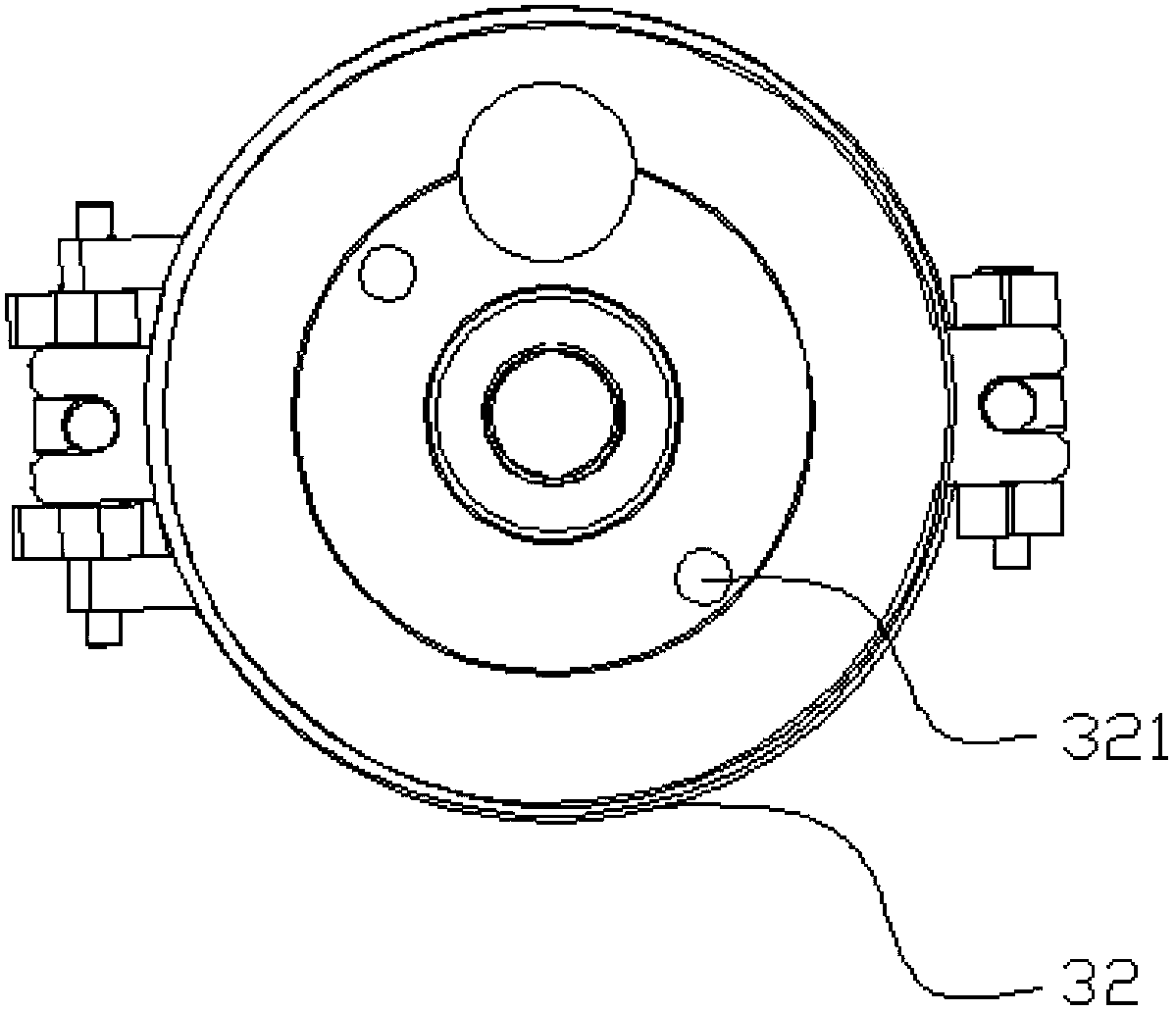

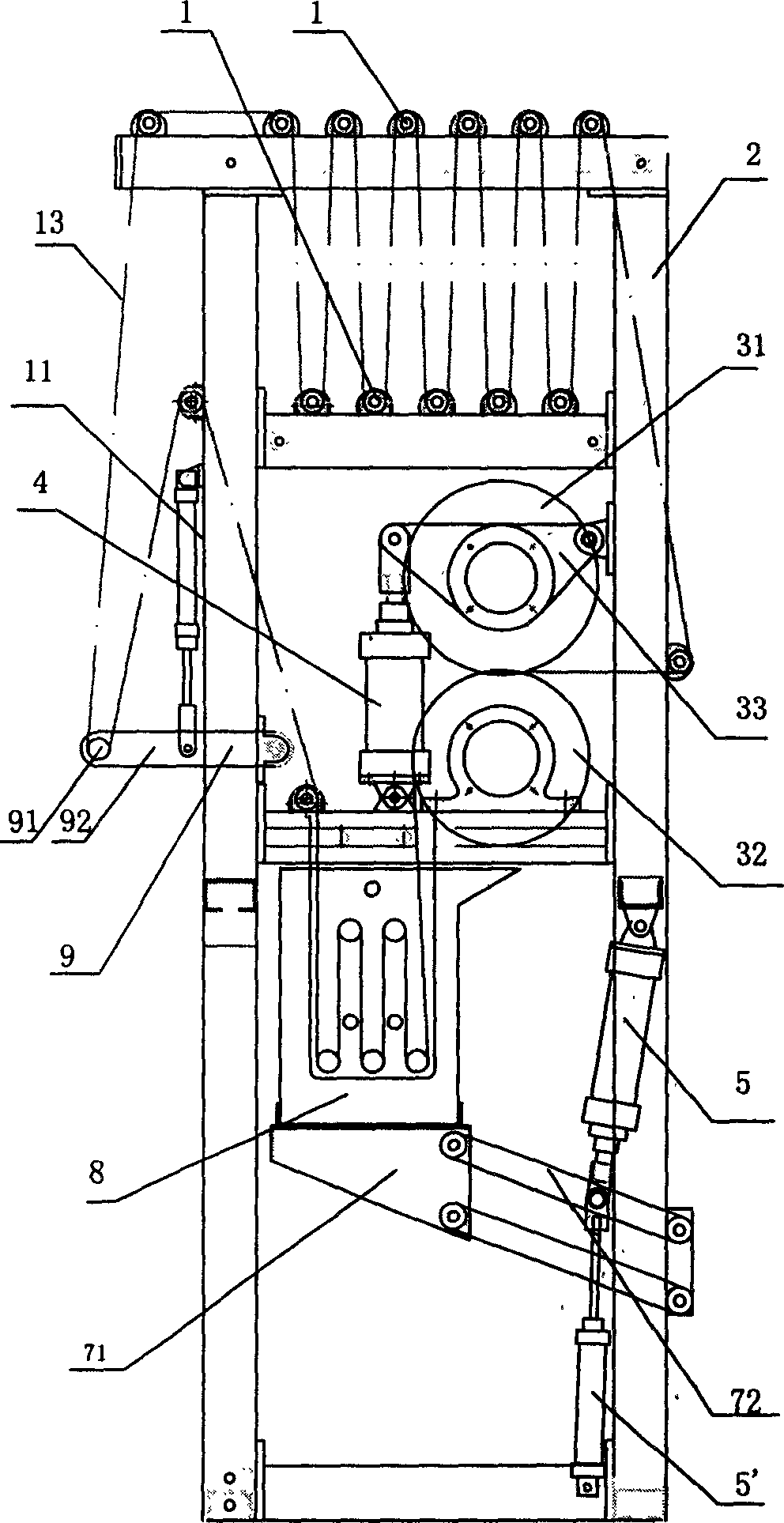

Balance oscillating dyeing machine

InactiveCN1676732AReduce noiseStable jobTextile treatment dyeing devicesVibration treatmentEngineeringWork time

This invention discloses a kind of balanced concussion coloring machine which can keep the apparent force almost in balance when the crank mechanical linkage is working which can drive the concussing box moving. So the vibration is small while the jar is low and the abrade is small. As a result, we can substantially elongate the machine's non-accident working time and using life length. It includes the crank mechanical linkage (1), concussion box(3), and (3) whose reciprocation is driven by (1) is linked with (1) and is fixed on one side of (1). The invention's characters are that not only does (1 has (3) on its side, but also it has another concussion box(3`) or (3``)on the other side to balance the apparent force of (1). (3),(3') and (3``) are linked with one end of the connection bar(5) of (1), while the other end is linked with the crank(6) corresponding to (1).

Owner:张同生

Wind-heat dyeing color tester

ActiveCN103741418AReduce manufacturing costReasonable designTextile treatment dyeing devicesTextile treatment machine arrangementsHeat conductingPulp and paper industry

A wind-heat dyeing color tester comprises a box, a hollow rotating disk and a rotary shaft, wherein the rotary shaft is connected with the rotating disk which is arranged in the box. A plurality of dyeing cup sleeves are uniformly distributed on the periphery of the rotating disk, an opening of each dyeing cup sleeve is exposed outside the rotating disk, a dyeing cup is sleeved in each dyeing cup sleeve, the left end face of the rotating disk is provided with a port, and an end cover is fixedly arranged on the right end face of the rotating disk. One end of the rotary shaft is connected with the end cover while the other end of the rotary shaft is connected with a transmission mechanism, a hot air pipe is connected onto a hot air blower which is arranged on the left side of the rotating disk, and an air outlet of the hot air pipe faces the side walls of the dyeing cup sleeves. The dyeing cups are heated by hot air instead of using conduction oil as a heat-conducting medium for heating, so that production cost is greatly saved for enterprises. Moreover, according to repeated experiments, electric energy consumed by the hot air blower is less than that consumed by heating the conduction oil, so that energy consumption is reduced.

Owner:SHISHI TAIRUI PRECISION MACHINERY

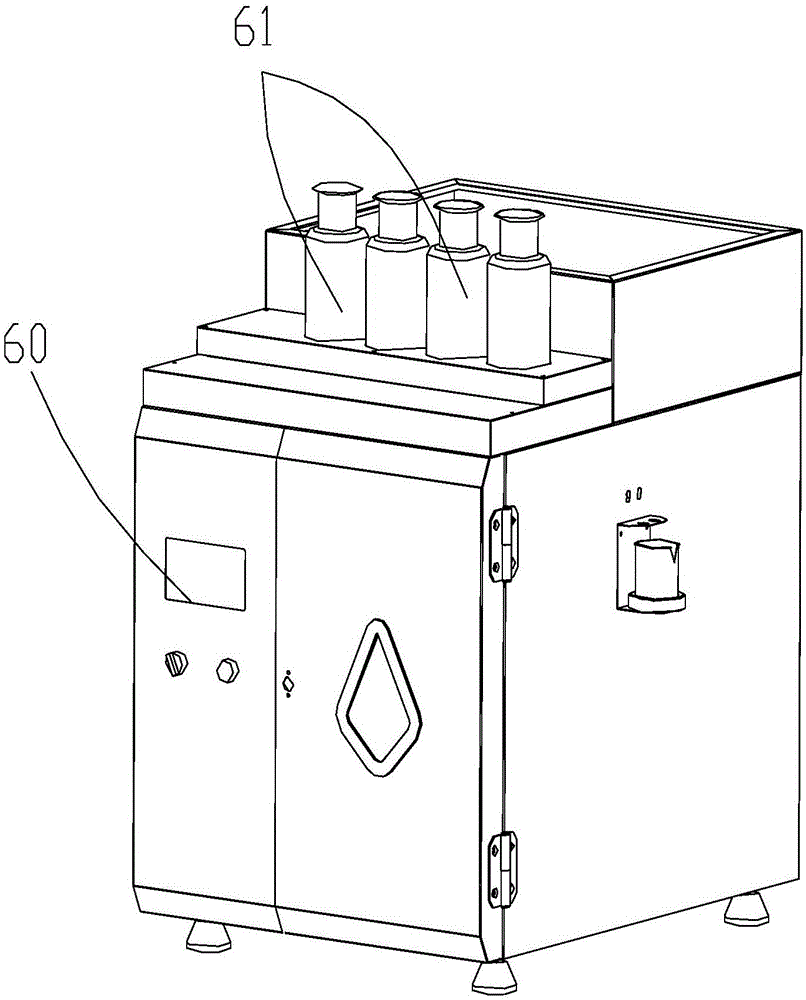

Lifting type hand sample machine

InactiveCN104278466AUniform dyeingSimple structureTextile treatment dyeing devicesTextile treatment machine arrangementsMechanical engineeringDyeing

The invention discloses a lifting type hand sample machine which comprises a machine body and a speed regulating motor. The speed regulating motor is arranged at the lower portion of the machine body and drives a lifting shaft to vertically move through a lifting transmission mechanism, the lifting shaft is fixedly connected with a suspension rod lifting rotation disc, and the suspension rod lifting rotation disc is arranged at the top of the lifting shaft and moves with the lifting shaft synchronously and vertically. The problem that an existing hand sample machine is uneven in dyeing and an existing stirring mode enables the surfaces of fabrics to be coarse, draped and adhered is solved, and the lifting type hand sample machine is simple in structure, convenient to use, ensures even fabric dyeing and saves manpower.

Owner:LONGCOLOR TEXTILE EQUIP

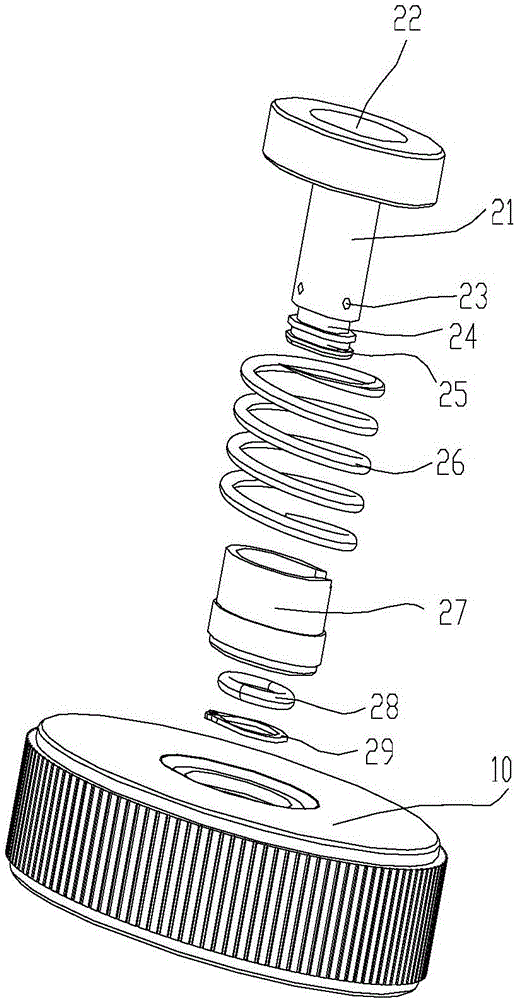

Color testing machine capable of achieving automatic charging and using method thereof

ActiveCN105970529AImplement auto-joinReduce human errorTextile treatment dyeing devicesEngineeringHuman error

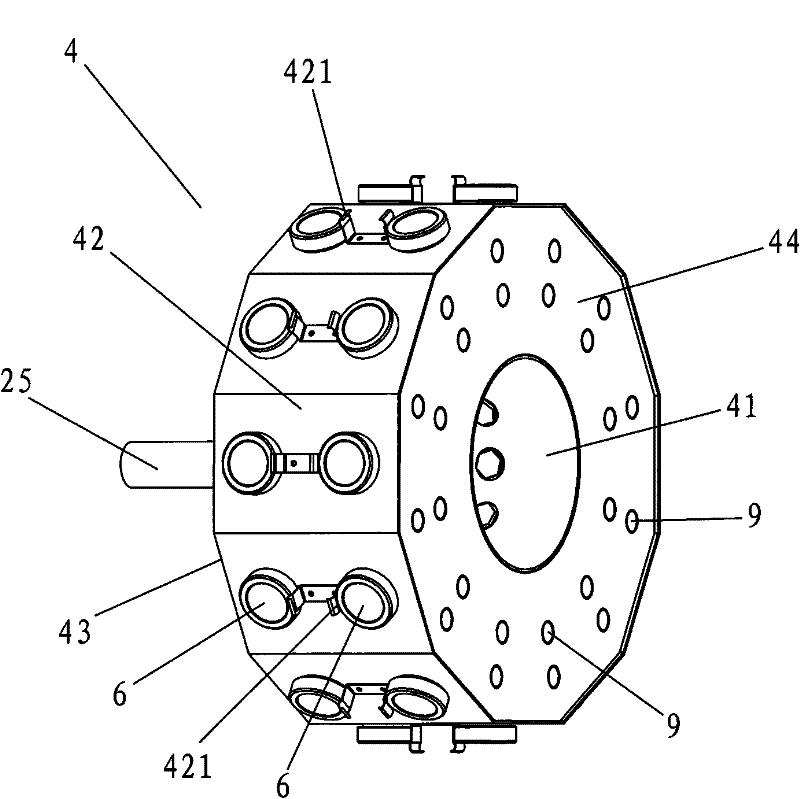

The invention discloses a color testing machine capable of achieving automatic charging. The color testing machine comprises a shell, a rotating mechanism, dyeing cups, an auxiliary charging mechanism and a data processor; a containing cavity is formed in the shell; the rotating mechanism comprises a rotating cage and a power mechanism, the rotating cage is a three-dimensional component formed by drawing a n-regular polygon, and the side walls of the rotating cage are each provided with internally-concaved containing grooves; the dyeing cups are arranged in the containing grooves; each cup lid comprises a movable shaft which can vertically move, and each movable shaft is provided with a charging port and discharging ports; each material injecting cup is provided with holes and connected with the bottom wall of the corresponding cup lid; cup bodies are connected with the cup lids in a matched mode; when the movable shafts are pressed, the discharging ports of the movable shafts enter the material injecting cups; the auxiliary charging mechanism comprises a flow pump and a first air cylinder, the flow pump is connected with sample charging needles which are opposite to the charging ports, and the first air cylinder is used for pushing the movable shafts; the rotating mechanism and the auxiliary charging mechanism are both controlled by the data processor. According to the color testing machine capable of achieving automatic charging, automatic auxiliary charging is achieved, human errors are reduced, and dyeing defects cannot be generated.

Owner:广州市鸿通机械有限公司

Textile mini-type dyeing machine

InactiveCN103668834ASimple heatingSave materialTextile treatment dyeing devicesTextile millSmall sample

The invention discloses a textile mini-type dyeing machine, relates to a dyeing machine and provides a dyeing machine used for dyeing small samples or medium samples. Heat-conduction media are not needed, materials are saved, and the heating efficiency is high. The textile mini-type dyeing machine is provided with a machine frame, a motor, a transmission device, a rotating shaft, a dyeing roller, a temperature sensor, an electric slip ring, an electric heater and a control circuit; an electric control chamber and a dyeing chamber are formed in the machine frame, the motor is arranged in the electric control chamber of the machine frame, the motor is connected with the transmission device, the transmission device is connected with the rotating shaft, the rotating shaft is connected with the machine frame in a rotating mode, the dyeing roller comprises a roller body and a roller cover, the dyeing roller is a closed pressure container, the dyeing roller is arranged in the dyeing chamber of the machine frame, a thermometer hole is formed in the roller body of the dyeing roller, the temperature sensor is arranged in the thermometer hole formed in the dyeing roller, one end of the rotating shaft extends into the dyeing chamber and is connected with the dyeing roller, the electric slip ring is arranged on the rotating shaft, a temperature sensor lead is electrically connected with the control circuit through the electric slip ring, and the electric heater is arranged at the outer side of the roller body of the dyeing roller and electrically connected with the control circuit.

Owner:赢世科技(厦门)有限公司

Compositions and methods for dying natural fibers with natural dyes to ensure color (hue and shade)-match consistency

InactiveUS20150218748A1Improve dye penetrationAccurate hueTextile treatment dyeing devicesLiquid/gas/vapor treatment of definite length materialsNatural fiberNatural dye

This invention discloses novel and nonobvious compositions and methods suitable for the dyeing of natural fibers with natural dyes that ensure shade-match consistency.

Owner:RAMBLERS WAY FARM

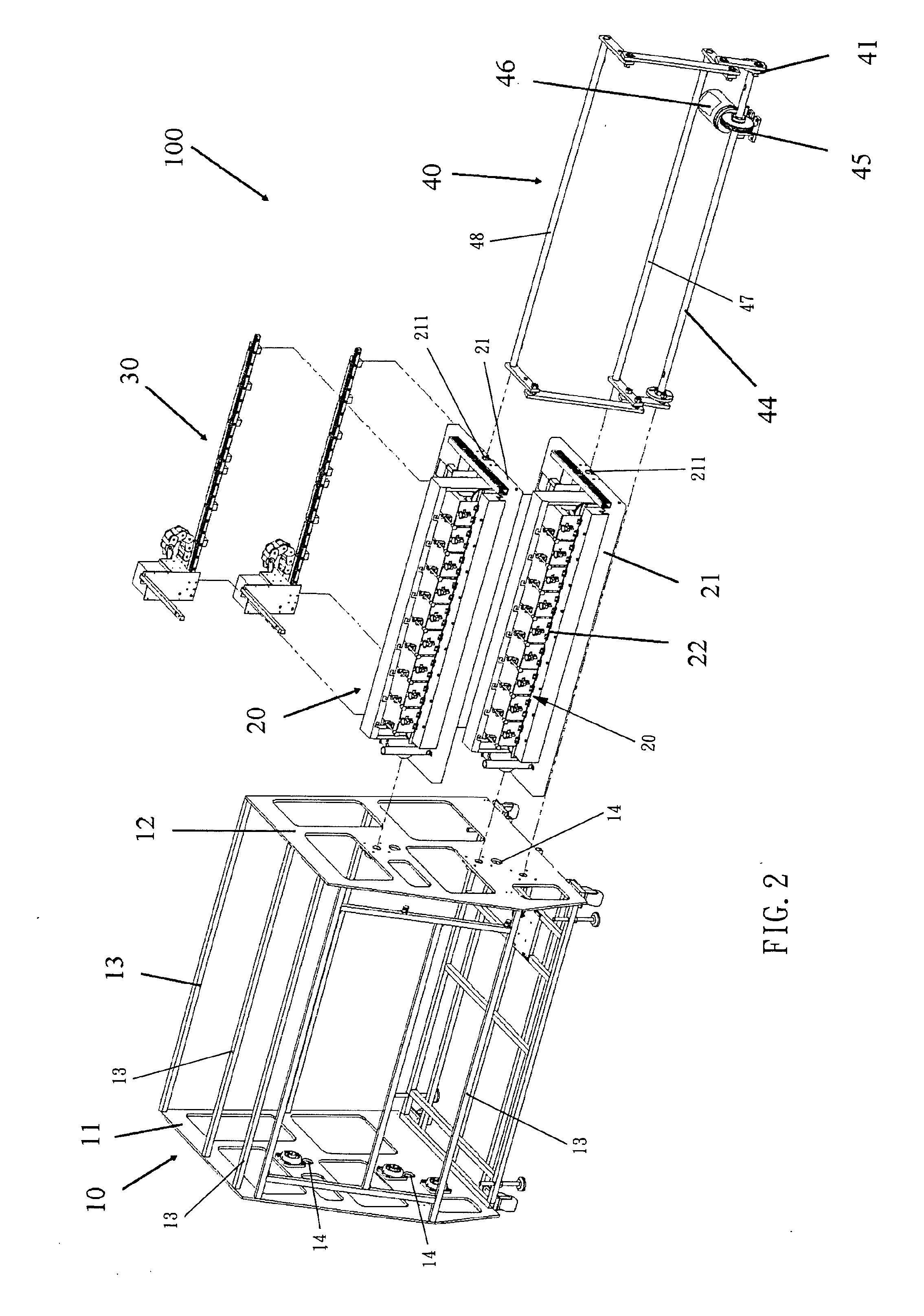

Printing and dyeing dropping machine

ActiveCN102587065BSolve the positioning problemPrecise positioningTextile treatment dyeing devicesBottleManipulator

The invention discloses a printing and dyeing dropping machine, which comprises a bench provided with a liquid extracting area and a liquid distributing area, wherein the liquid extracting area contains a plurality of mother liquid bottles, and the liquid distributing area is positioned on one side of the liquid extracting area. A three-axis manipulator is arranged above the liquid extracting area, a positioning mechanism is arranged on the liquid extracting area, and a turntable mechanism is arranged on the liquid distributing area and is connected with a divider to precisely control a steel cup on the turntable mechanism to be matched with an outlet of a liquid distributing mechanism in a positioned manner. An injector can be precisely positioned by a positioning sleeve and an acrylic positioning plate, perpendicularity of the injector can be kept, and the problem of positioning in dye dropping is solved. When liquid is distributed, a turntable-type circulating structure is used for weighing and liquid distributing operations. When a motor stops rotating, the cup can be precisely transferred to a next cup position by the aid of the limit function of the divider, and positioning deviation of the cup and the liquid distributing mechanism due to movement inertia is avoided.

Owner:厦门瑞比精密机械有限公司

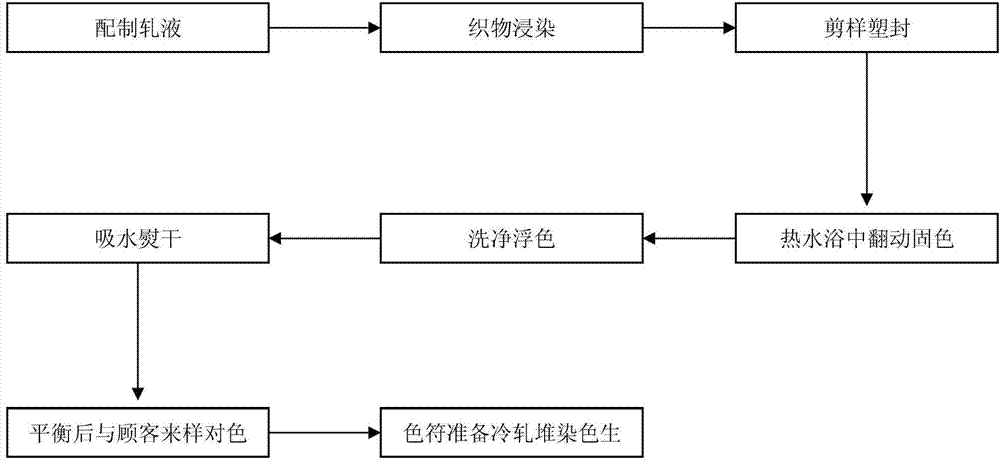

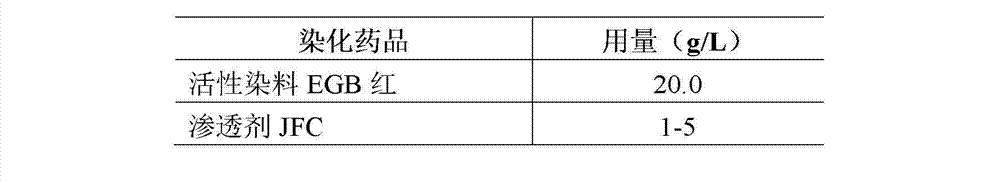

New rapid proofing method for cold pad batch dyeing

ActiveCN102787462AEasy to operateProcess equipment requirements are simpleTextile storage in wounded formTextile treatment dyeing devicesWater bathsThermal insulation

The invention relates to a new rapid proofing method for cold pad batch dyeing. The method comprises the following steps of: (1) preparing the reactive dye pad dyeing solution which is consistent with the production formulation of a large sample, and using up reactive dye, penetrant solution and reactive dye cold pad batch alkaline agent which are mixed together in 40-90 minutes; (2) according to the soaking time and mangle expression which are consistent with the large sample production, alternately soaking and rolling a small cotton sample; (3) rolling the pad dyed small cotton sample along a glass rod which has the same breadth as the small cotton sample, putting the rolled small cotton sample into a plastic hermetic bag which is matched with the small cotton sample, extracting the gas in the plastic bag, and keeping tight; (4) slightly putting the plastic hermetic bag which contains the small cotton sample into a water bath of 20-40 DEG C to be banked up for 20-60 minutes in a thermal insulation manner, pulling the hermetic bag out, and putting the hermetic bag into a water bath of 40-70 DEG C to be banked up for 5-30 minutes in a thermal insulation manner, pulling the hermetic bag out, and taking the dyed cotton fabric out; and (5) according to the dyeing which is consistent with the technology of the large sample production, matching the colors of the small dyed cotton sample. The method has the following beneficial effects that the method is simple to operate, the requirements on the technological equipment are low, the proofing colors can be accurately produced by corresponding to the colors of the large sample, and delta E (DE) is not more than 1 according to color measurement committee (CMC).

Owner:ZHEJIANG YIDE CHEM

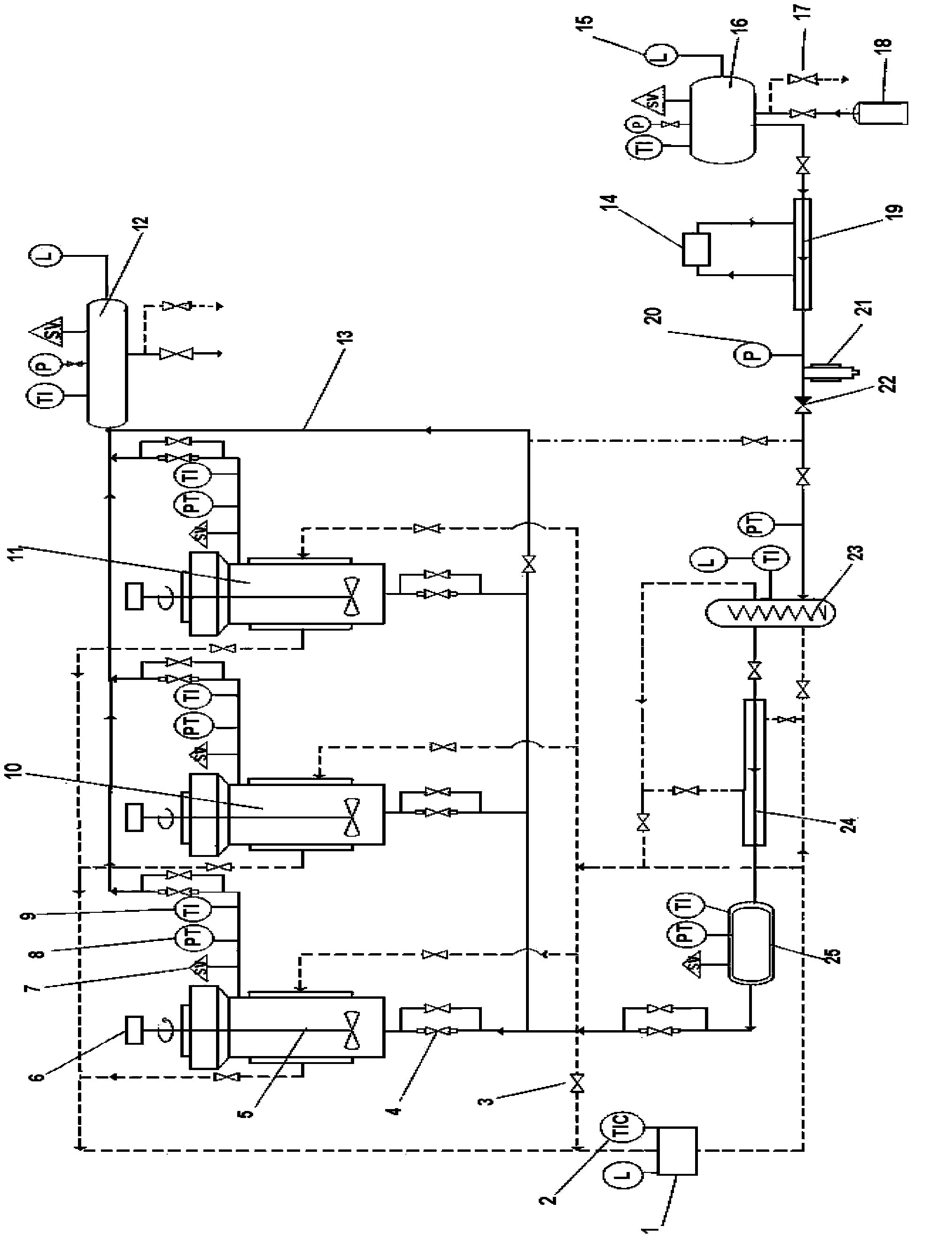

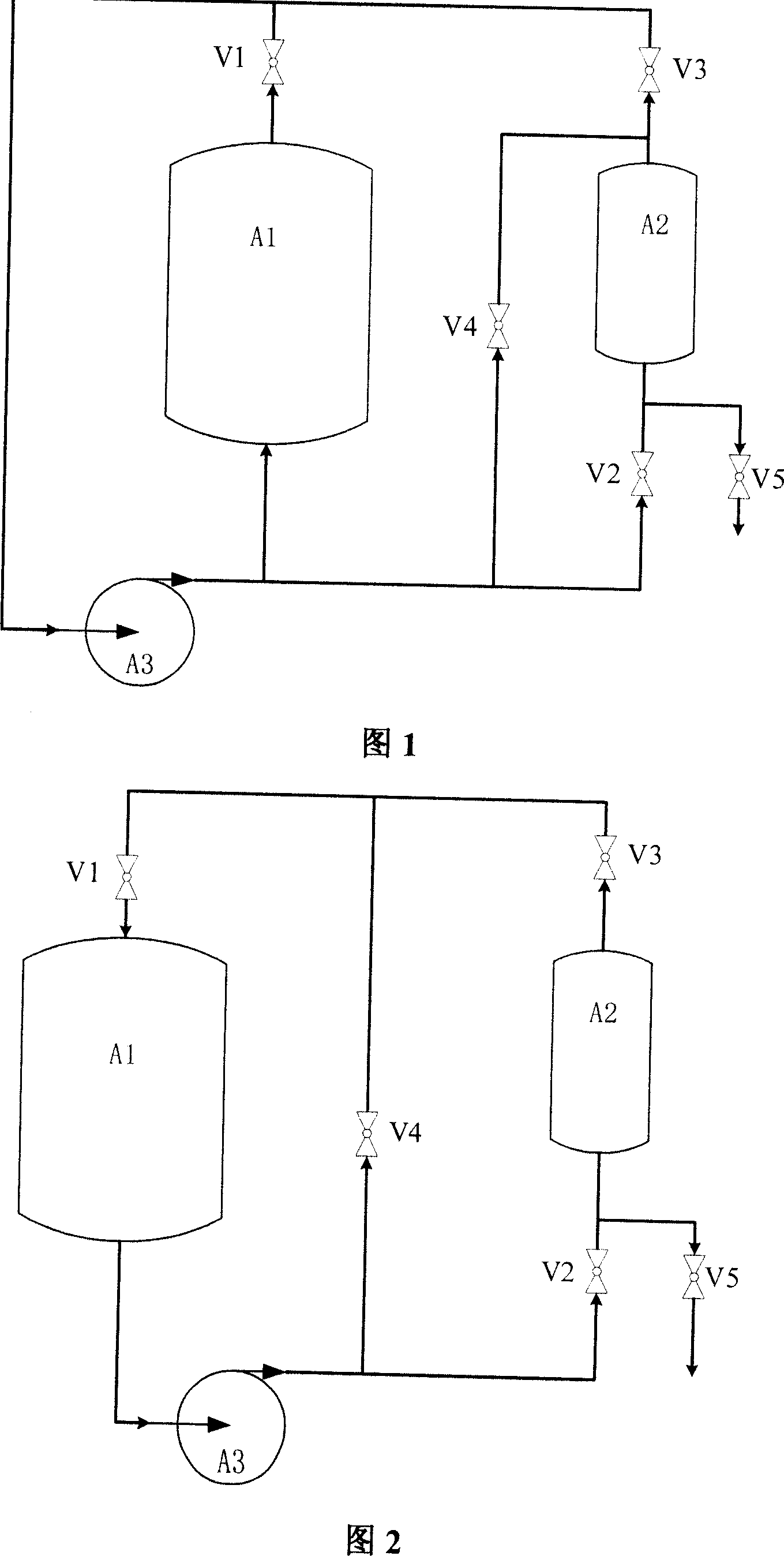

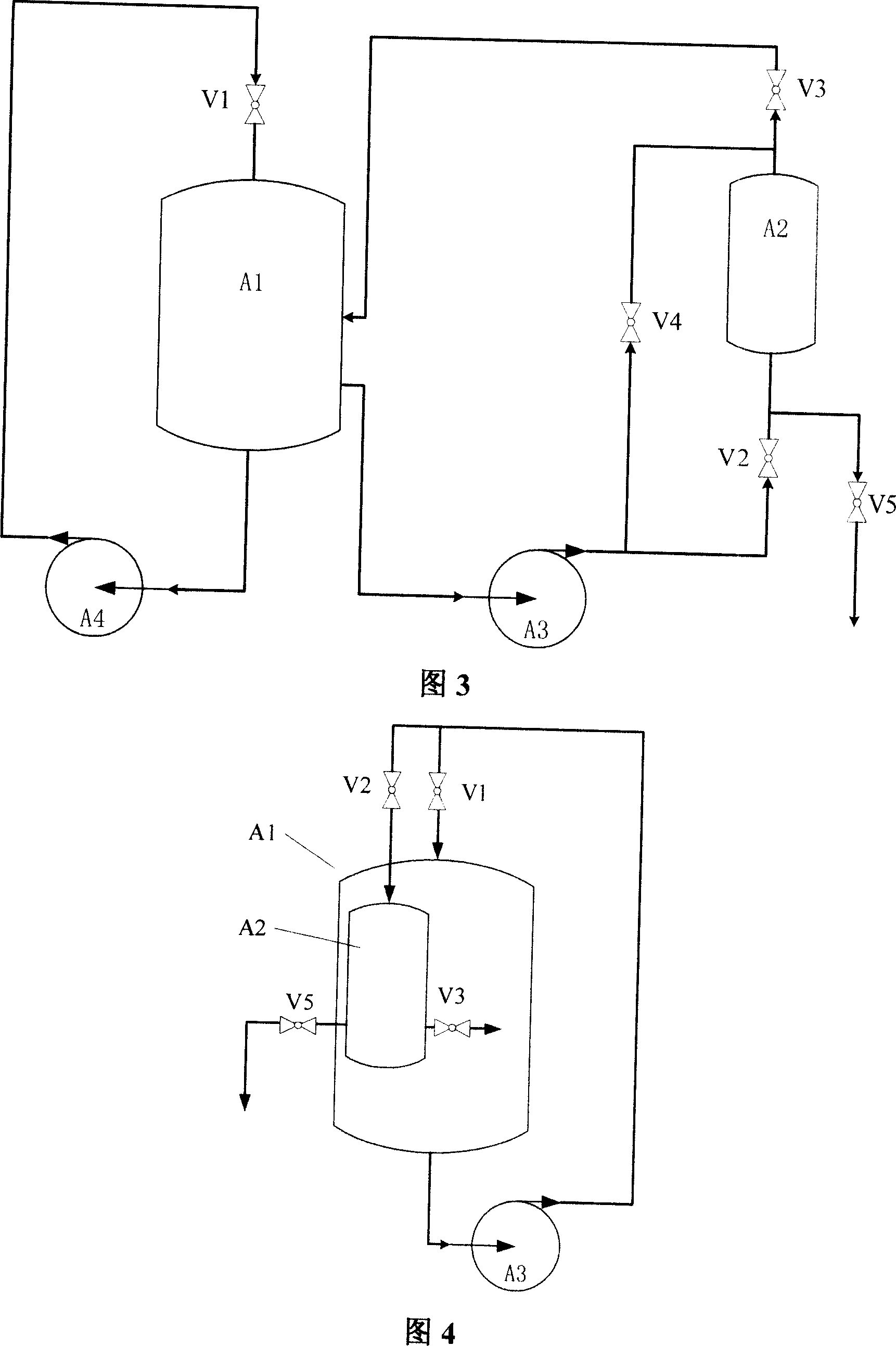

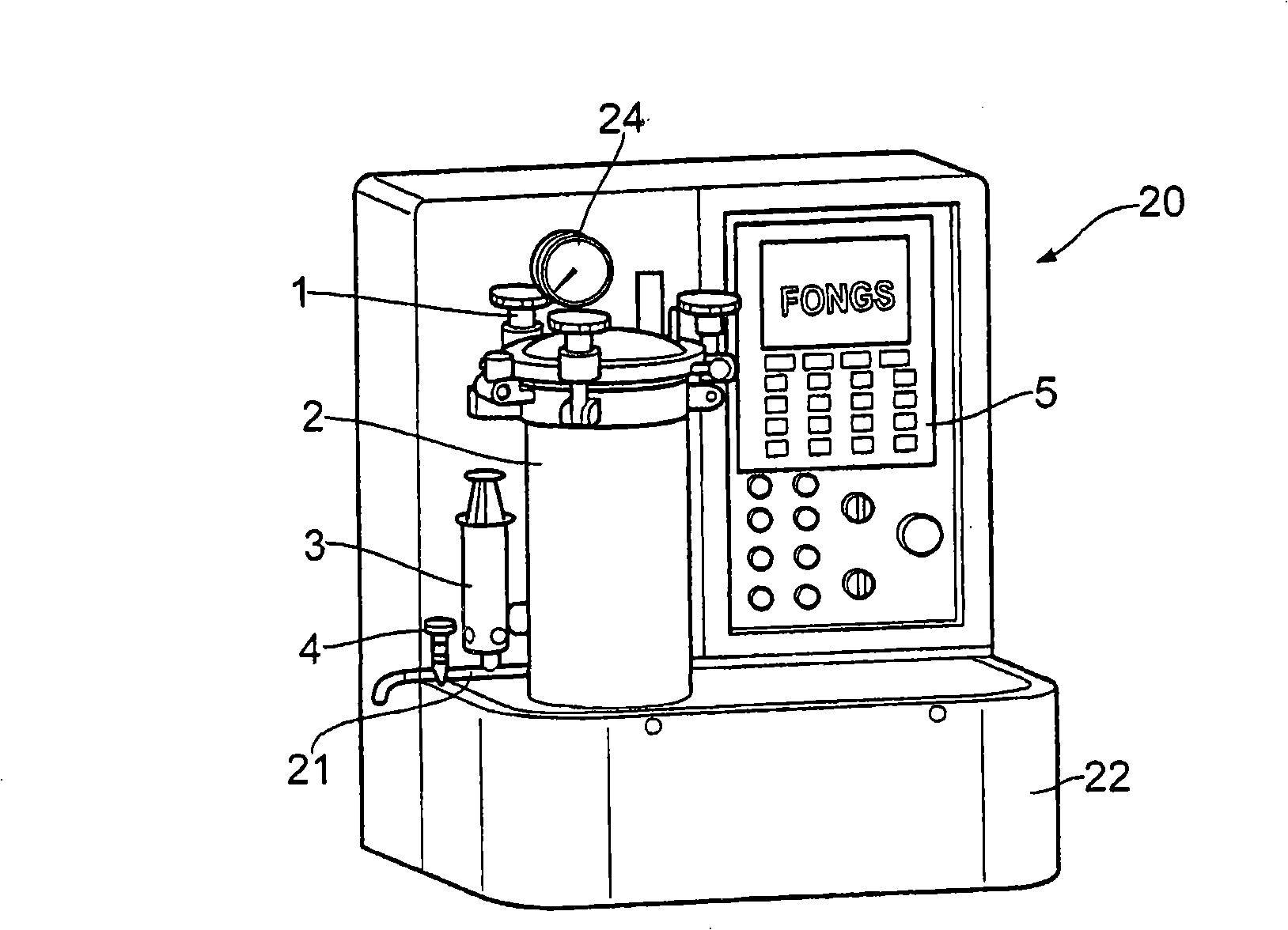

Dyeing hand sample machine and dyeing method thereof

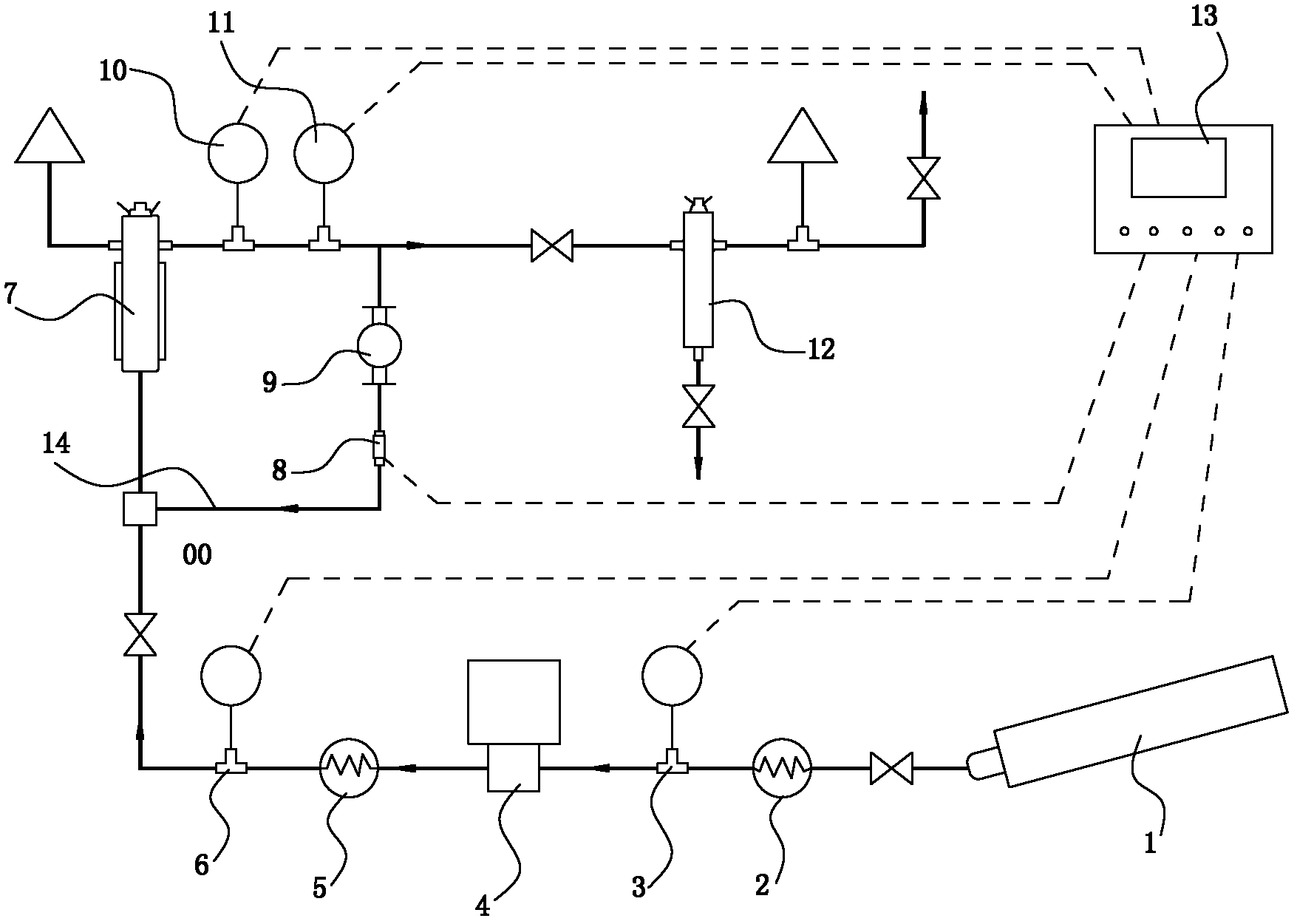

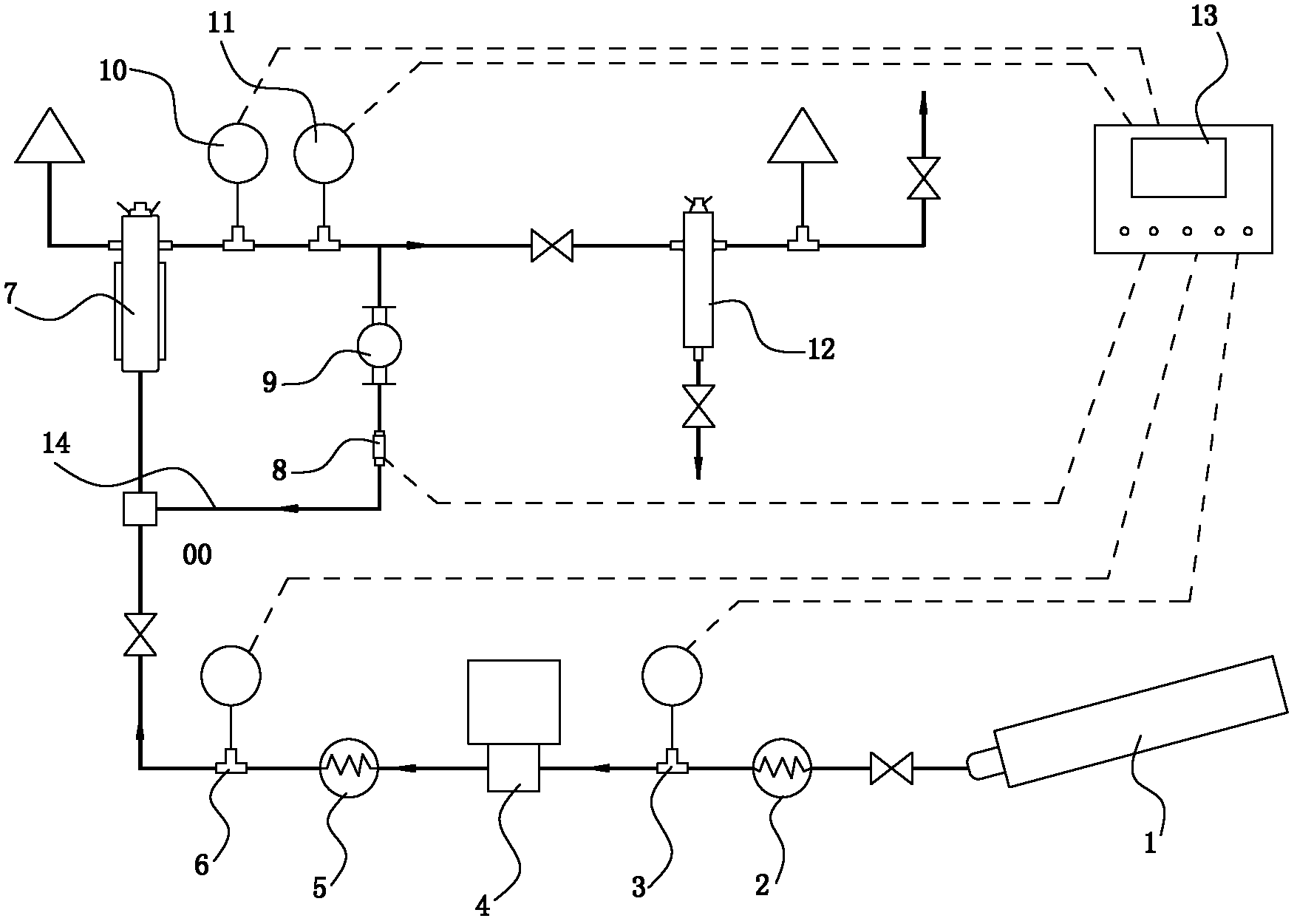

ActiveCN102535068AEasy to operateReduce pollutionTextile treatment dyeing devicesDyeing processEngineeringHigh pressure

The invention discloses a dyeing hand sample machine comprising a dyeing kettle, a front end pipeline, a rear end pipeline, a dye recovering tank, a cold water thermostatic bath, a carbon dioxide high-pressure pump and a pressure reducing device, wherein the front end pipeline and the rear end pipeline are respectively communicated with the dyeing kettle; a carbon dioxide input port, the cold water thermostatic bath and the carbon dioxide high-pressure pump are arranged on the front end pipeline; a hot oil thermostatic bath is arranged between the carbon dioxide high-pressure pump and the dyeing kettle; the pressure reducing device is arranged on the rear end pipeline; the dye recovering tank is positioned at the rear end of the pressure reducing device; a recycling pipe, through which the front end pipeline is communicated with the rear end pipeline, is arranged between the front end pipeline and the rear end pipeline; and a recycling bump or a compressor is arranged on the recycling pipe. The dyeing hand sample machine has the advantages of complete functions, simplicity in operation and very high sample making speed, thereby filling a gap in the production of the supercritical dyeing industry.

Owner:陈志刚

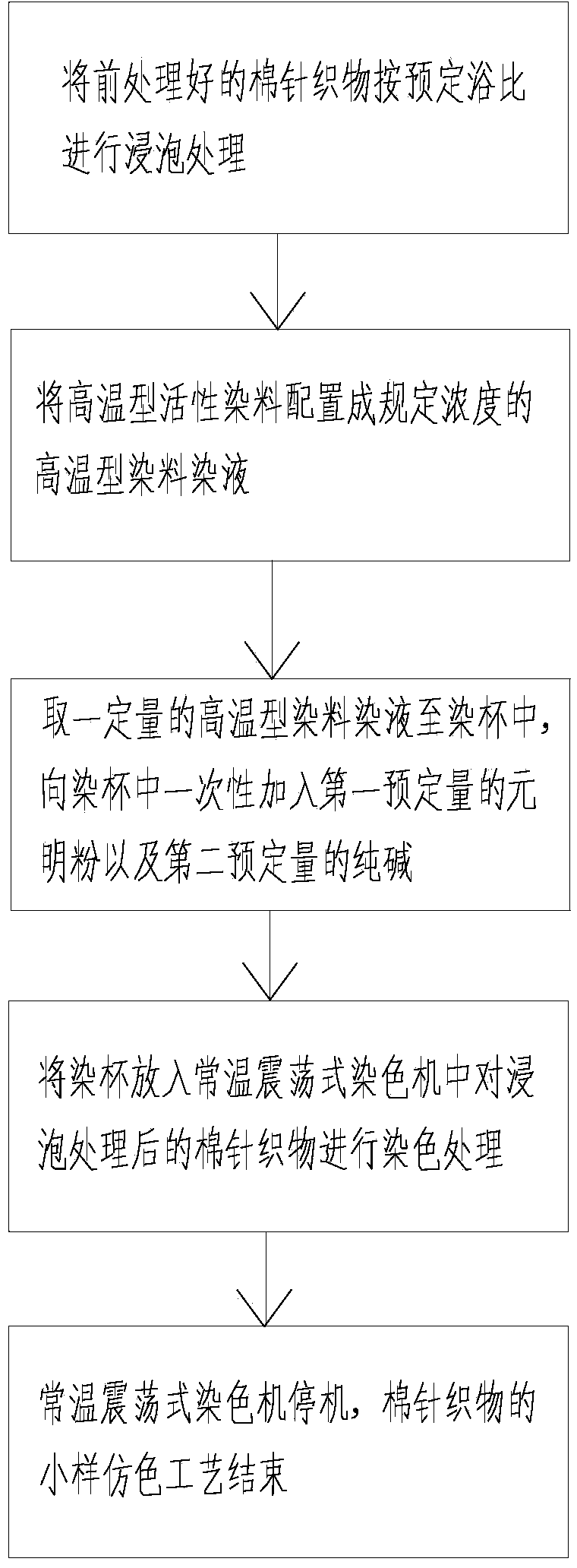

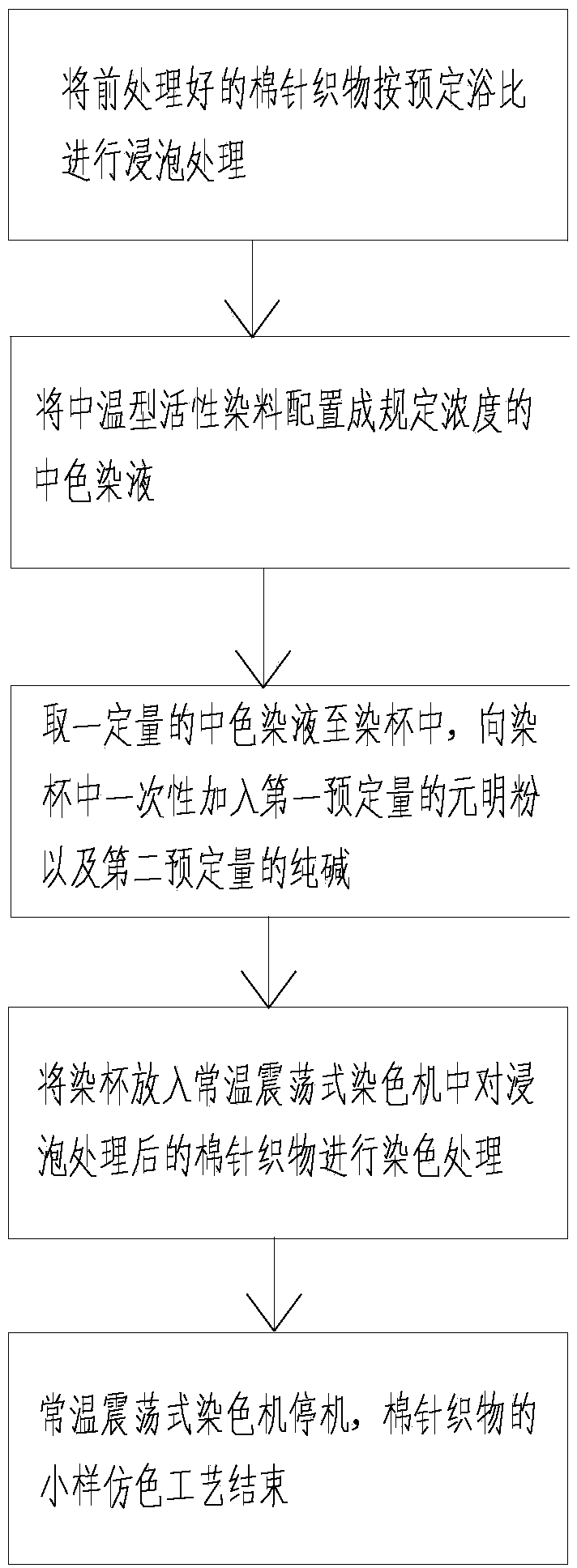

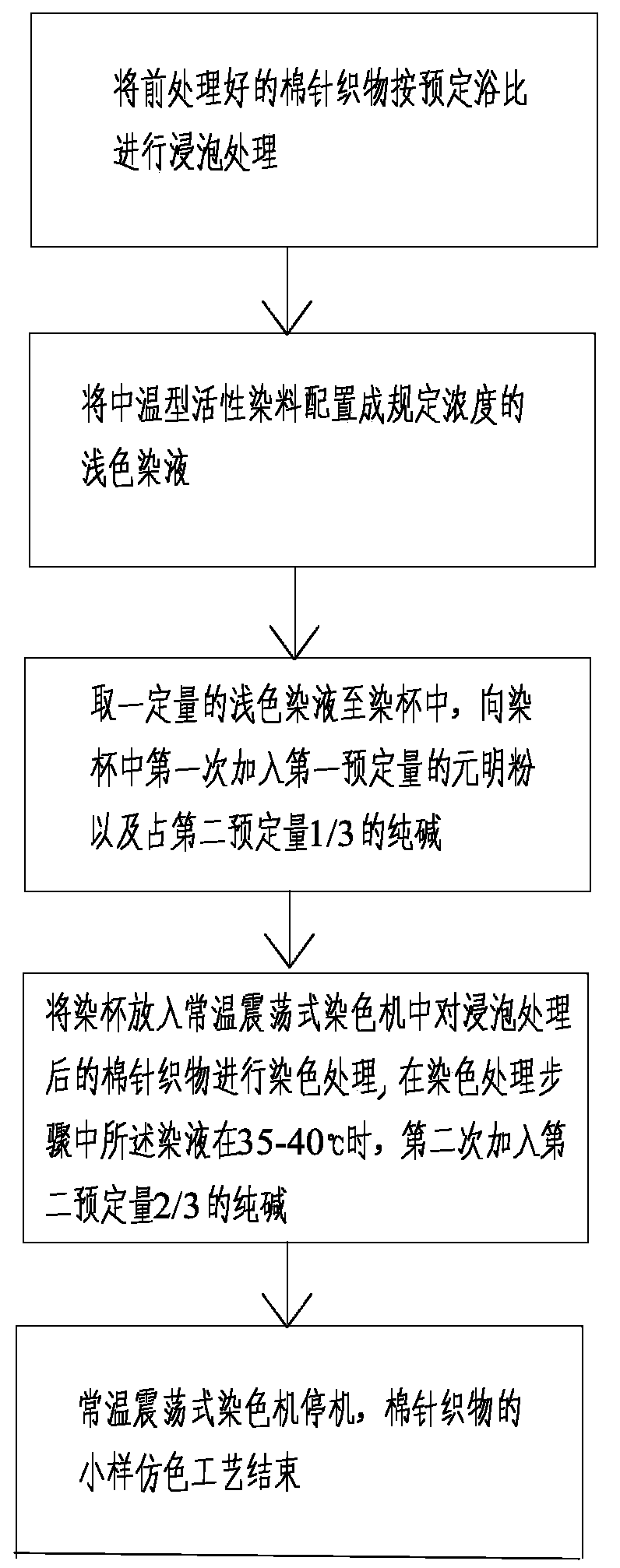

Hand sample color imitation process for cotton knitted fabric

ActiveCN103924462AGood reproducibilityImprove one-time success rateTextile treatment dyeing devicesDyeing processDark colorHue

The invention discloses a hand sample color imitation process for cotton knitted fabric. The hand sample color imitation process is mainly designed to overcome the defect that the reproducibility of the color phase of a hand sample and the color phase of a bulk sample is low due to a traditional hand sample dyeing process. The hand sample color imitation process for the cotton knitted fabric comprises the steps of hand sample soaking treatment, dyeing liquid preparation, additive adding and dyeing treatment. In the step of additive adding, anhydrous sodium sulphate of a first preset amount and sodium carbonate of a second preset amount are added to high-temperature dye liquor or neutral color dye liquor or dark color dye liquor at one time, or the anhydrous sodium sulphate of the first preset amount and the sodium carbonate one third of the second preset amount are added to light color dye liquor for the first time. In the step of dyeing treatment of the light color dye liquor, when the dye liquor is 35 DEG C to 40 DEG C, the sodium carbonate of two thirds of the second preset amount is added for the second time. The reproducibility of the dyeing hand sample and bulk sample of the cotton knitted fabric can be effectively improved, the one-time success rate of bulk sample dyeing is improved, and production cost is lowered.

Owner:JIHUA 3543 KNITTING CLOTHING

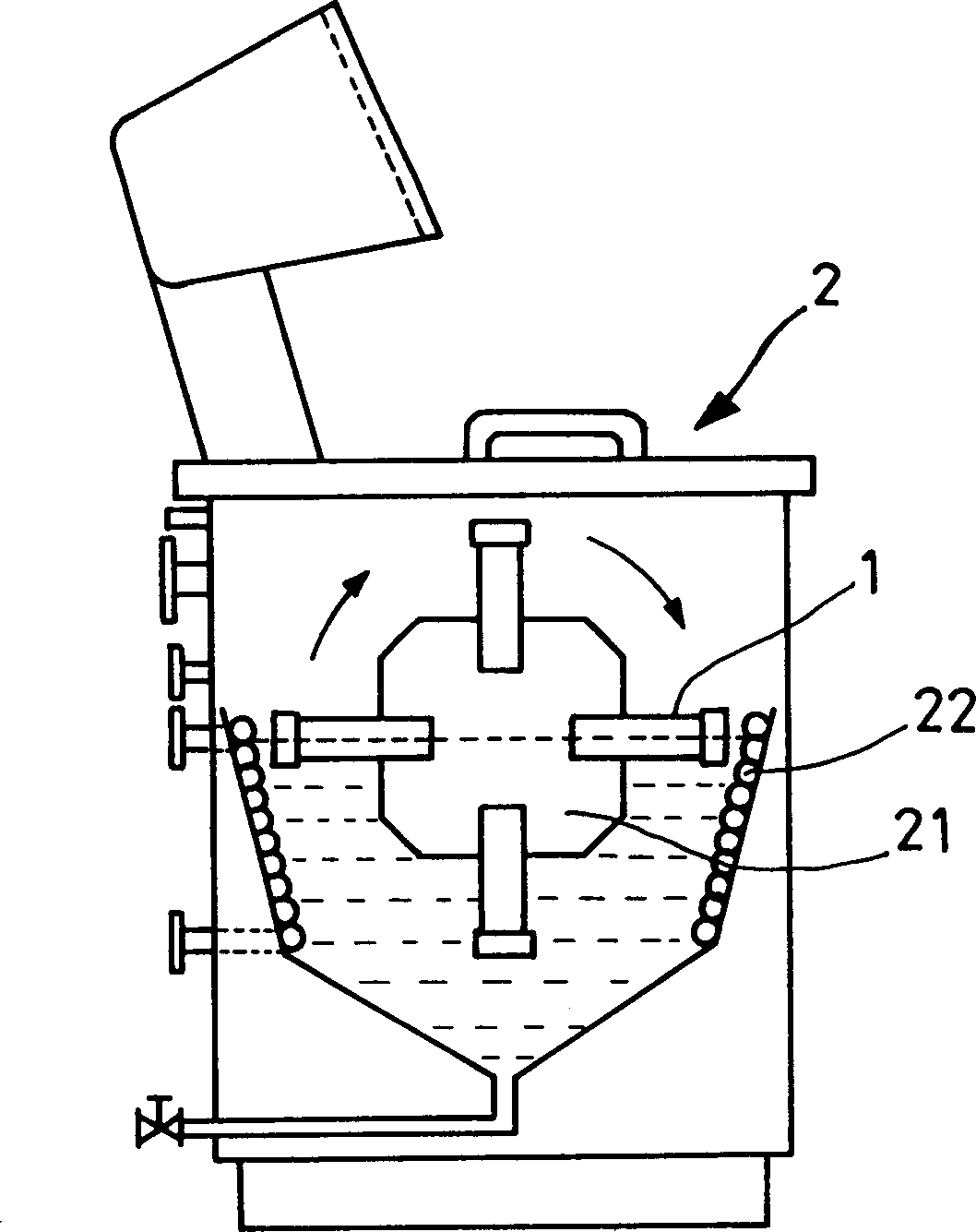

Novel yarn dyeing device

InactiveCN103696190AIncrease temperatureTake advantage ofTextile treatment dyeing devicesTextile treatment machine arrangementsYarnTextile technology

The invention relates to a novel yarn dyeing device, and belongs to the technical field of textile. The novel yarn dyeing device comprises a dyeing box, a dye feeding pipe, a dye pump, a lower dye discharging pipe, a yarn outlet, an upper dye discharging pipe, a yarn inlet, a dye recycling pipe, a dyeing box and a dye header pipe. Two spraying heads are arranged on the novel yarn dyeing device; yarns passing through the dyeing box can be uniformly dyed; and the dye can be recycled and sufficiently utilized by the dye box of the device. Steam pipes are arranged on the inner side of the dye box, so that the temperature of the dye box can be increased. In addition, the device is simple in structure and small in occupied area; continuous production can be realized; a small amount of yarns can be experimentally dyed; the production cost is saved; and the work efficiency is improved.

Owner:JIANGSU GOLD IRON MAN AUTOMATION TECH

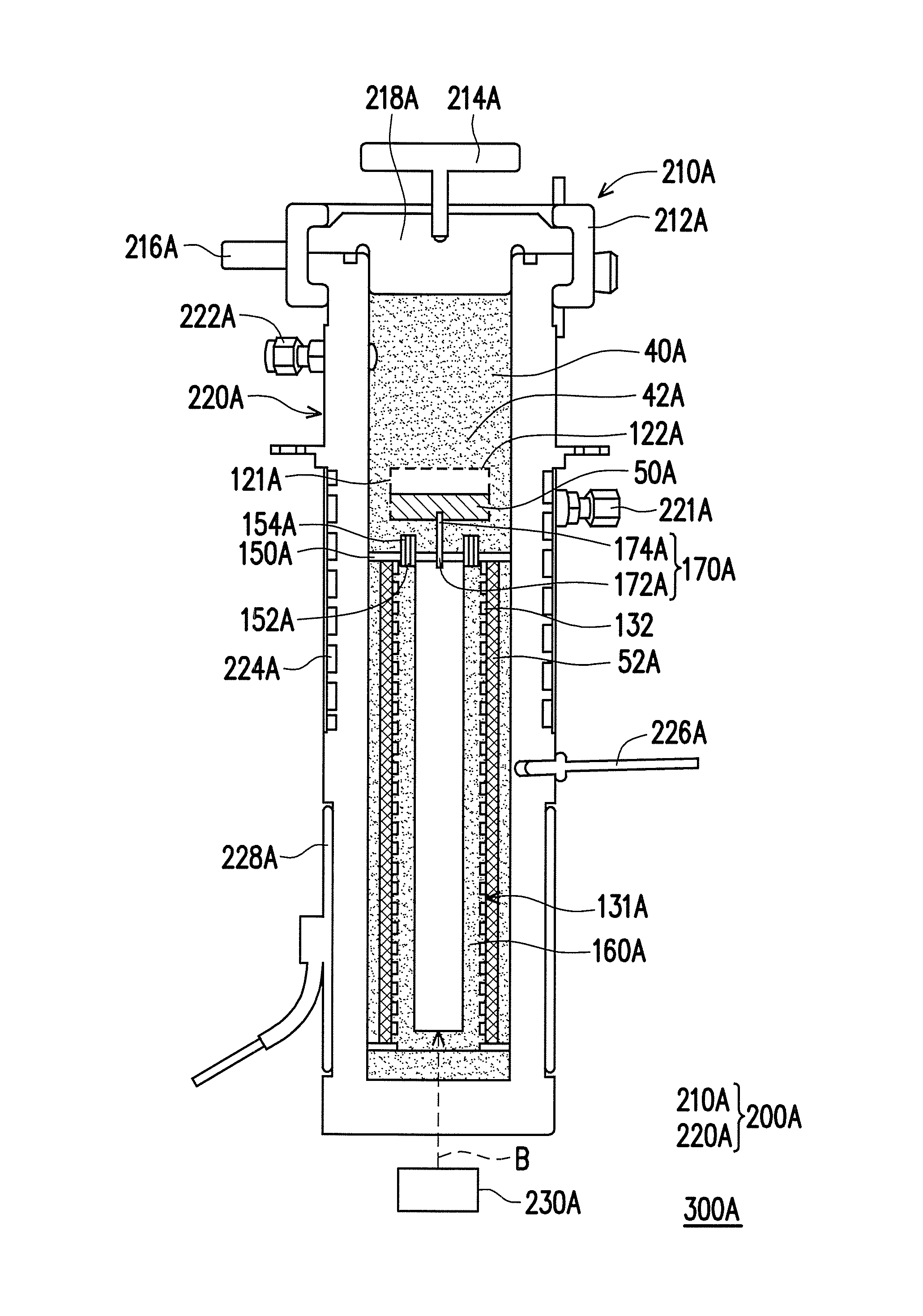

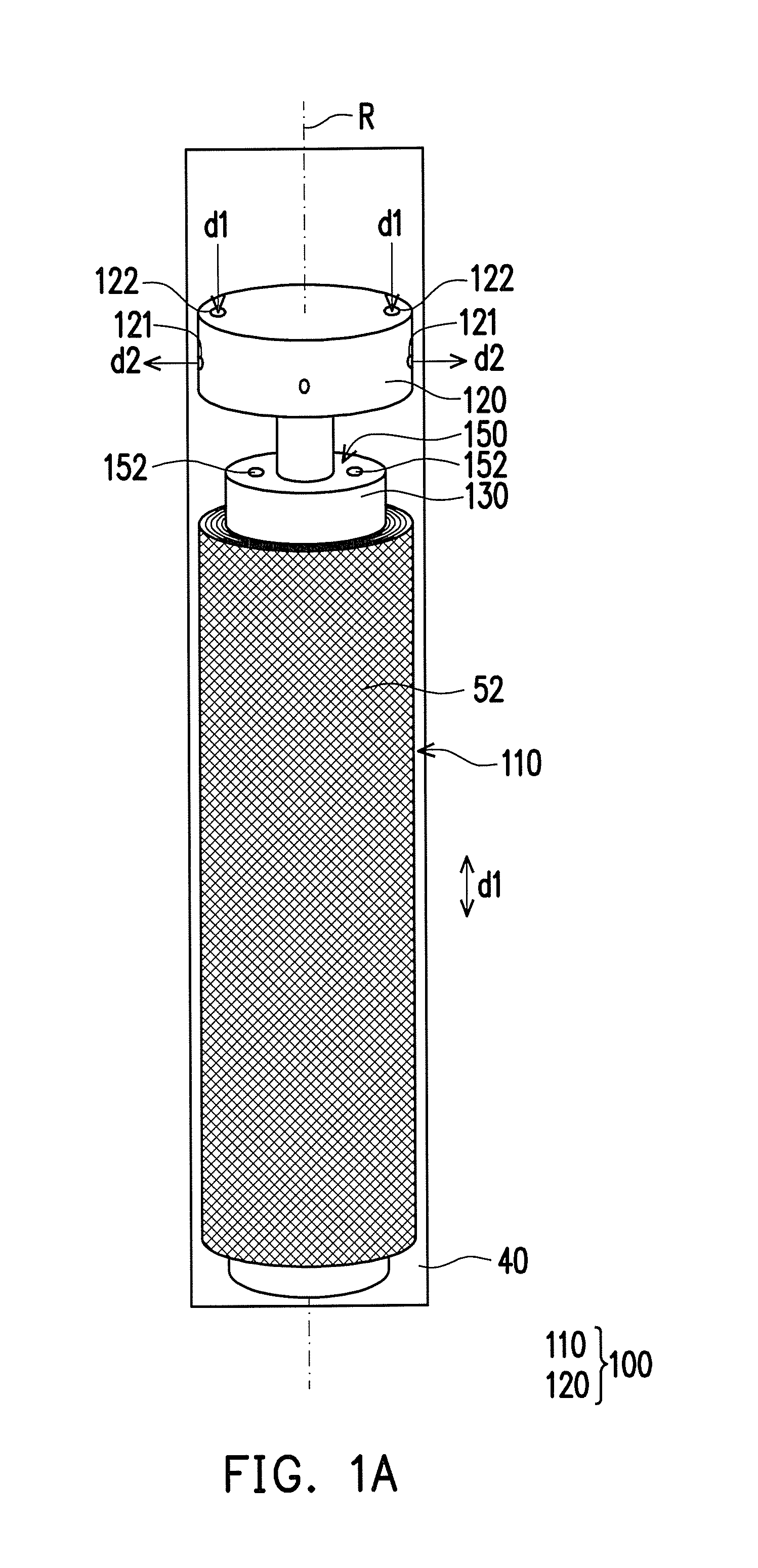

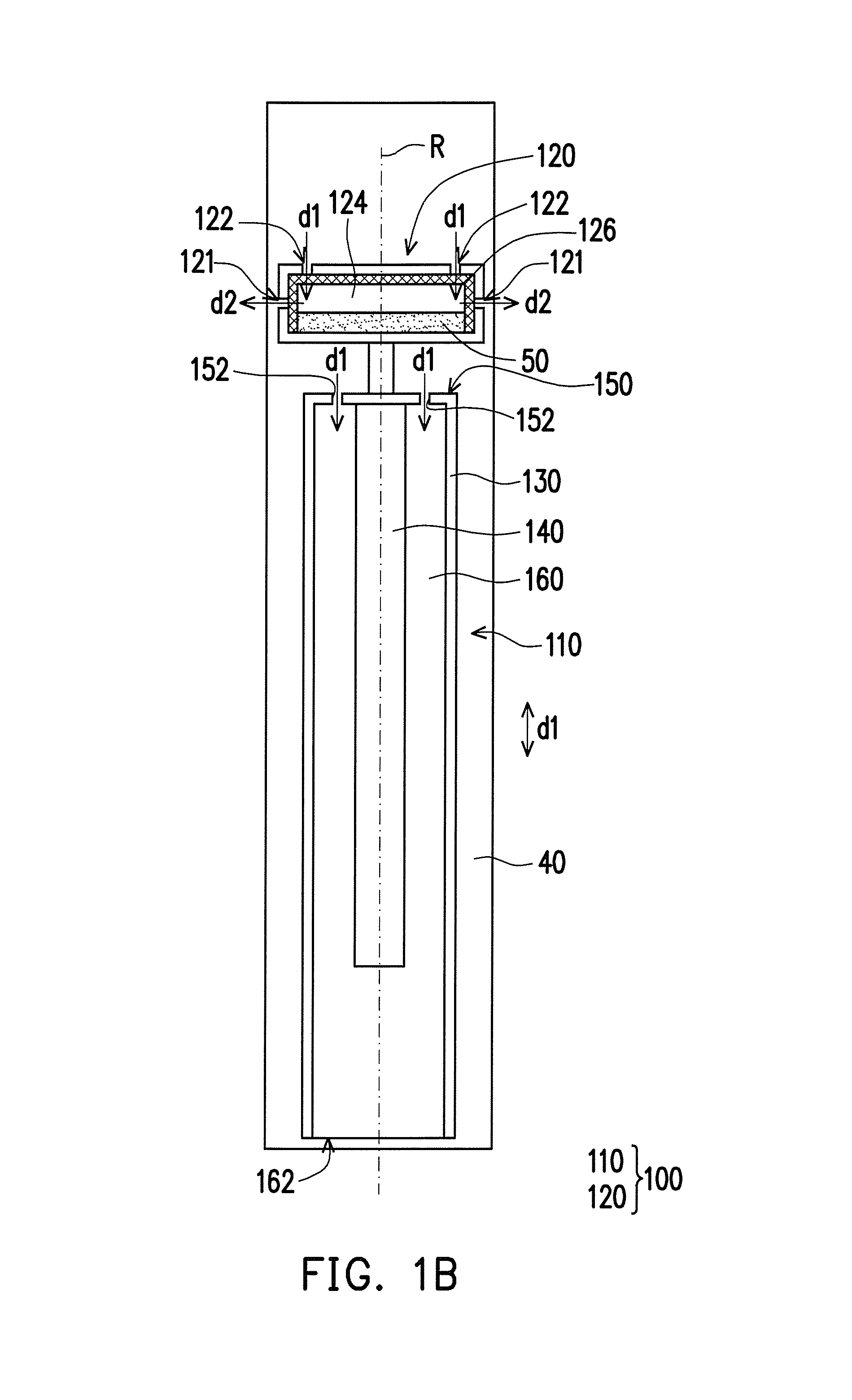

Dyeing device and dyeing apparatus

ActiveUS20160244902A1Improve dyeing effectHigh pressure spaceTextile treatment containersTextile treatment dyeing devicesFiberEngineering

A dyeing device adapted to move in a high pressure space having a fluid is provided. The dyeing device includes a magnetic dyeing shaft and a dye mixing chamber connected to the magnetic dyeing shaft. The magnetic dyeing shaft is configured to make a fiber product wind thereon, and the dye mixing chamber is configured to store dye, and the dye mixing chamber is adapted to let the fluid in the high pressure space flow through. A dyeing apparatus including the dyeing device is also provided.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

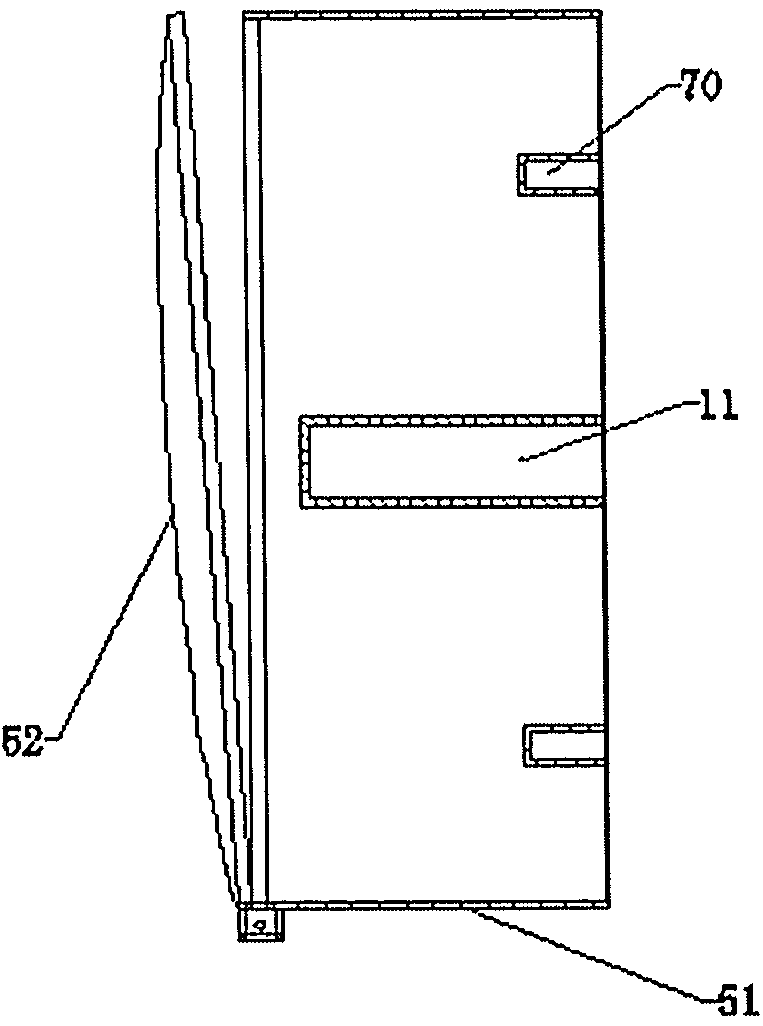

Cloth support of color testing machine

InactiveCN103541175APrecise Control of ColorFully contactedTextile treatment dyeing devicesTextile treatment carriersFiberPulp and paper industry

The invention discloses a cloth support of a color testing machine. The cloth support of the color testing machine comprises a plurality of cloth supporting plates, a vibrating spear, a plurality of connecting assemblies and two end plates located at the two ends of each cloth supporting plate. The two ends of each cloth supporting plate are connected with corresponding end plates through the connecting assemblies respectively, all the cloth supporting plates are arranged in the circumferential direction in sequence, no space is reserved between adjacent cloth supporting plates, and the vibrating spear is not connected with the rest of the components of the cloth support of the color testing machine and can move freely in the cloth supporting plates. In the dyeing process of cloth, the cloth support of the color testing machine will rotate synchronously along with the rotation of the equipment, the vibrating spear moves on a guide rod to beat the cloth supporting plates due to the gravity action in the rotating process, the beaten cloth supporting plates generate vibration to enable the cloth winding the outer sides of the cloth supporting plates to make sufficient contact with dyes, the dyes can effectively permeate in cloth fibers, and thus the effects of accurately controlling the color of the cloth and improving the quality of color testing can be achieved.

Owner:无锡阳博印染机械设备有限公司

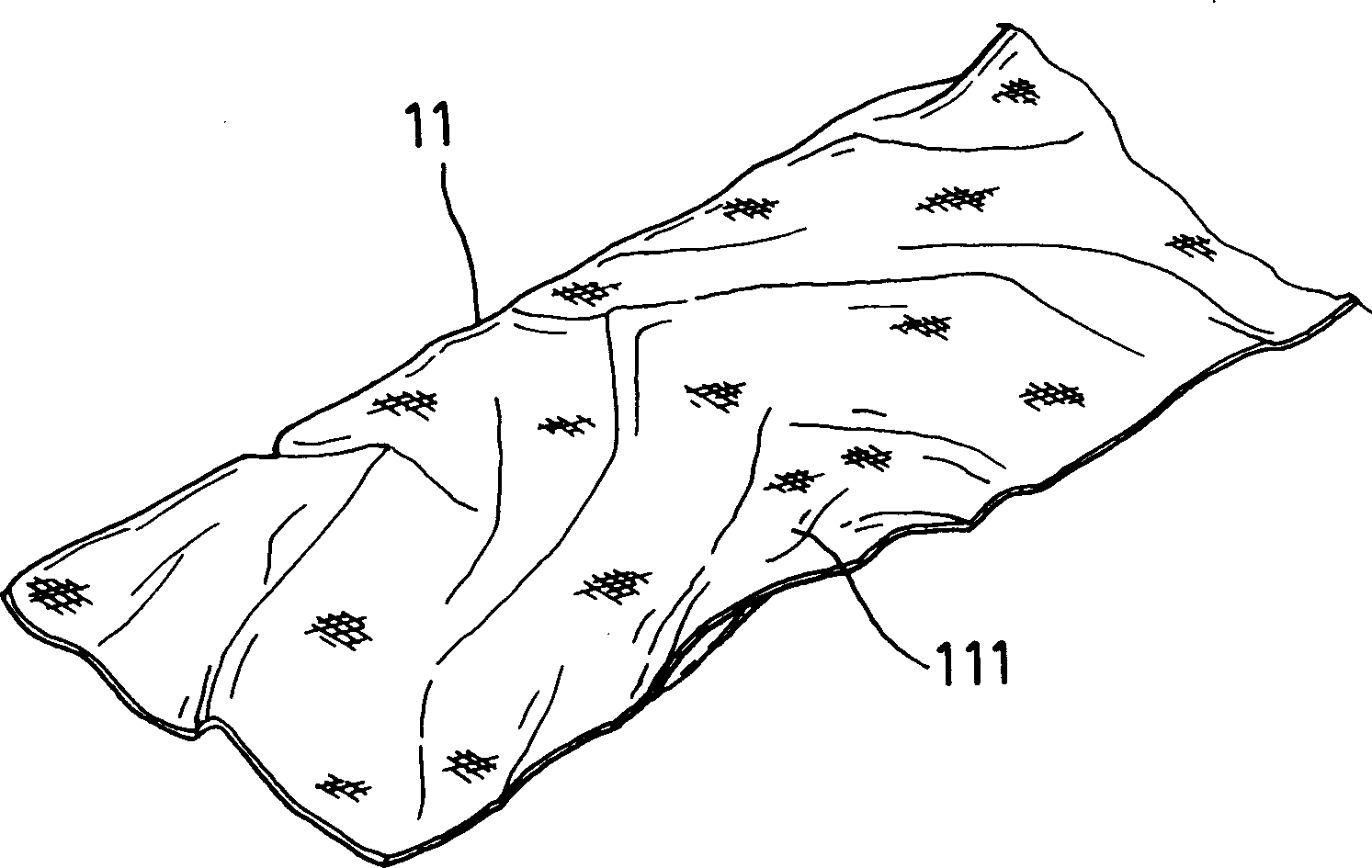

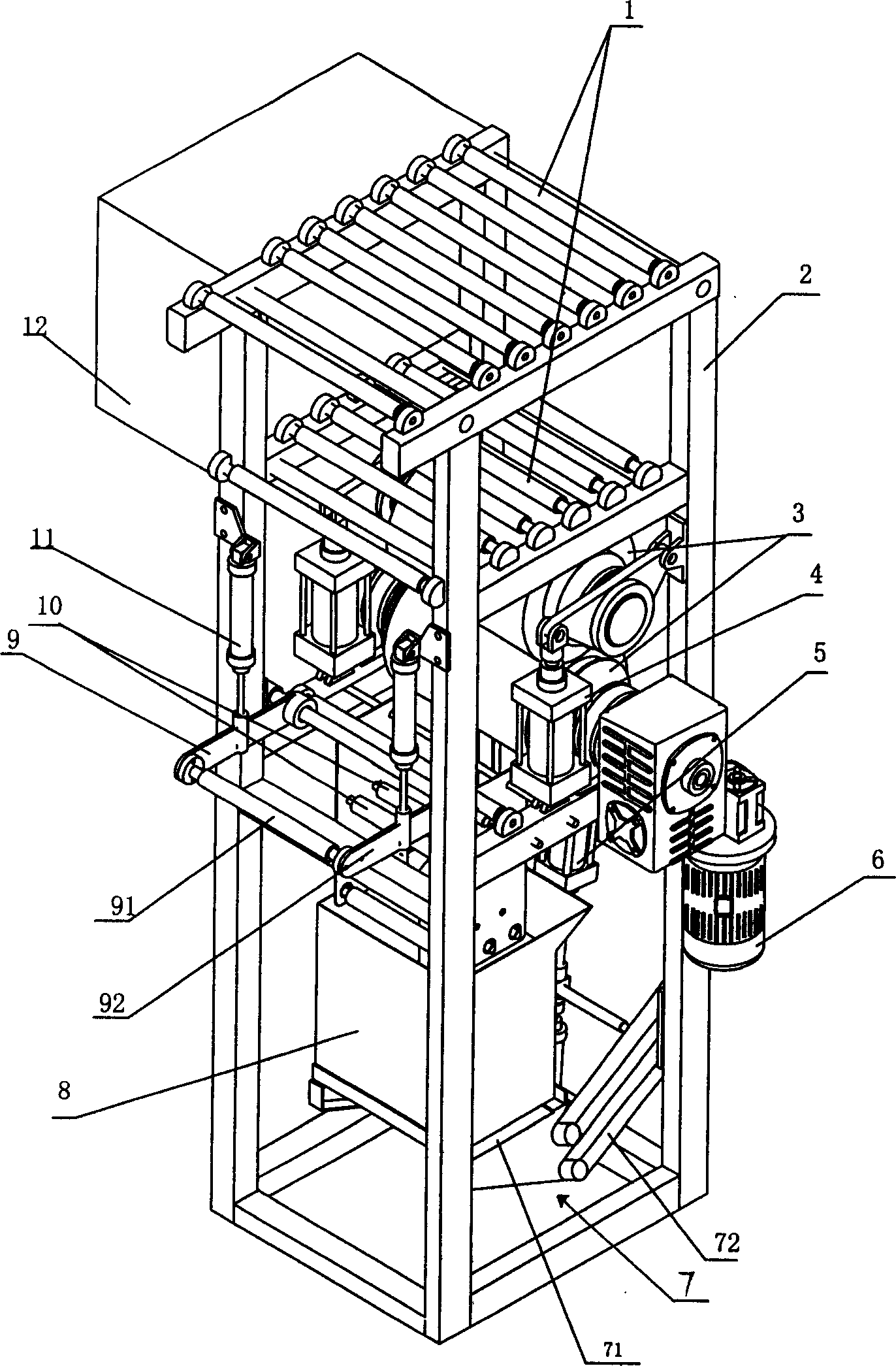

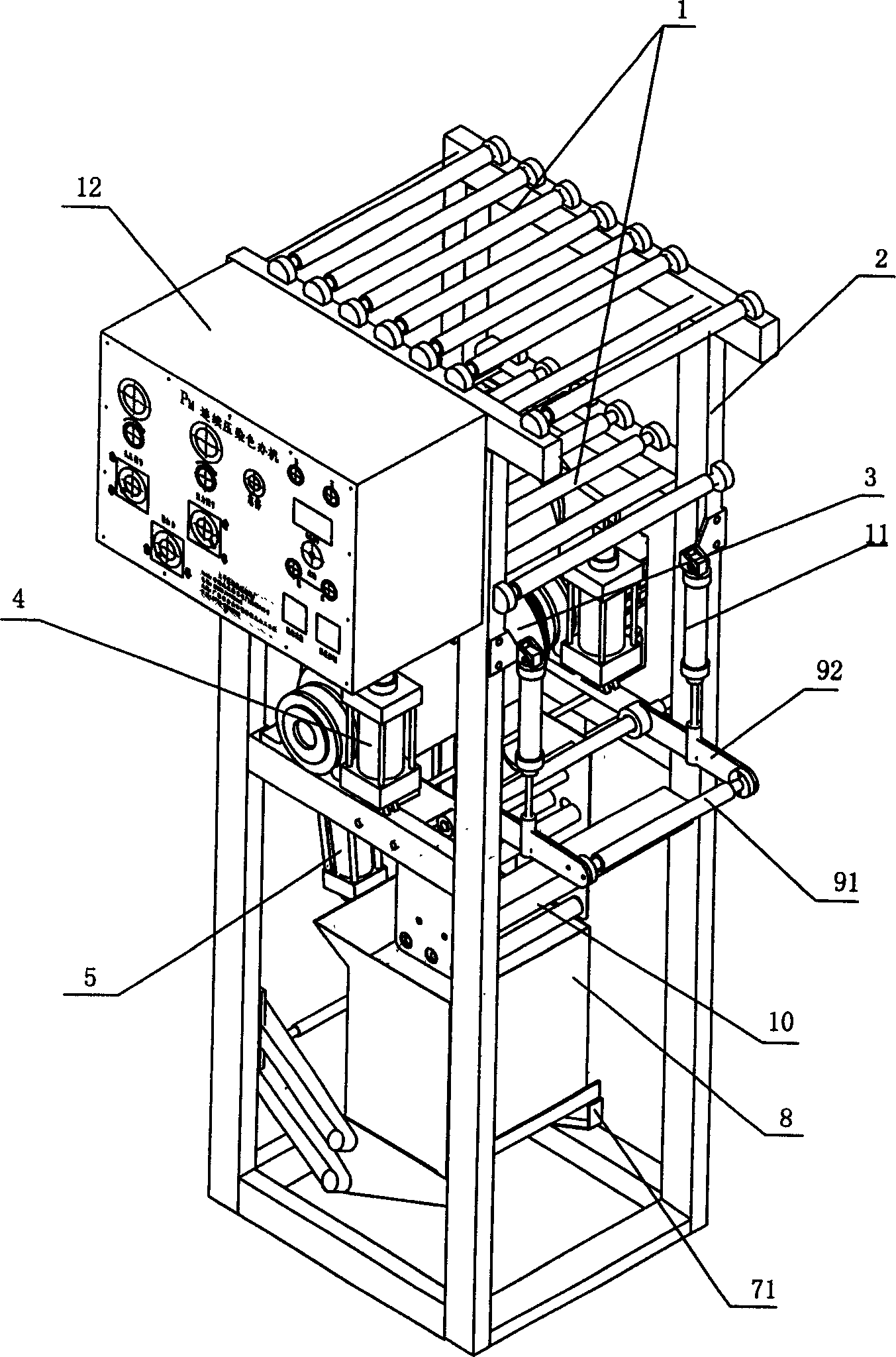

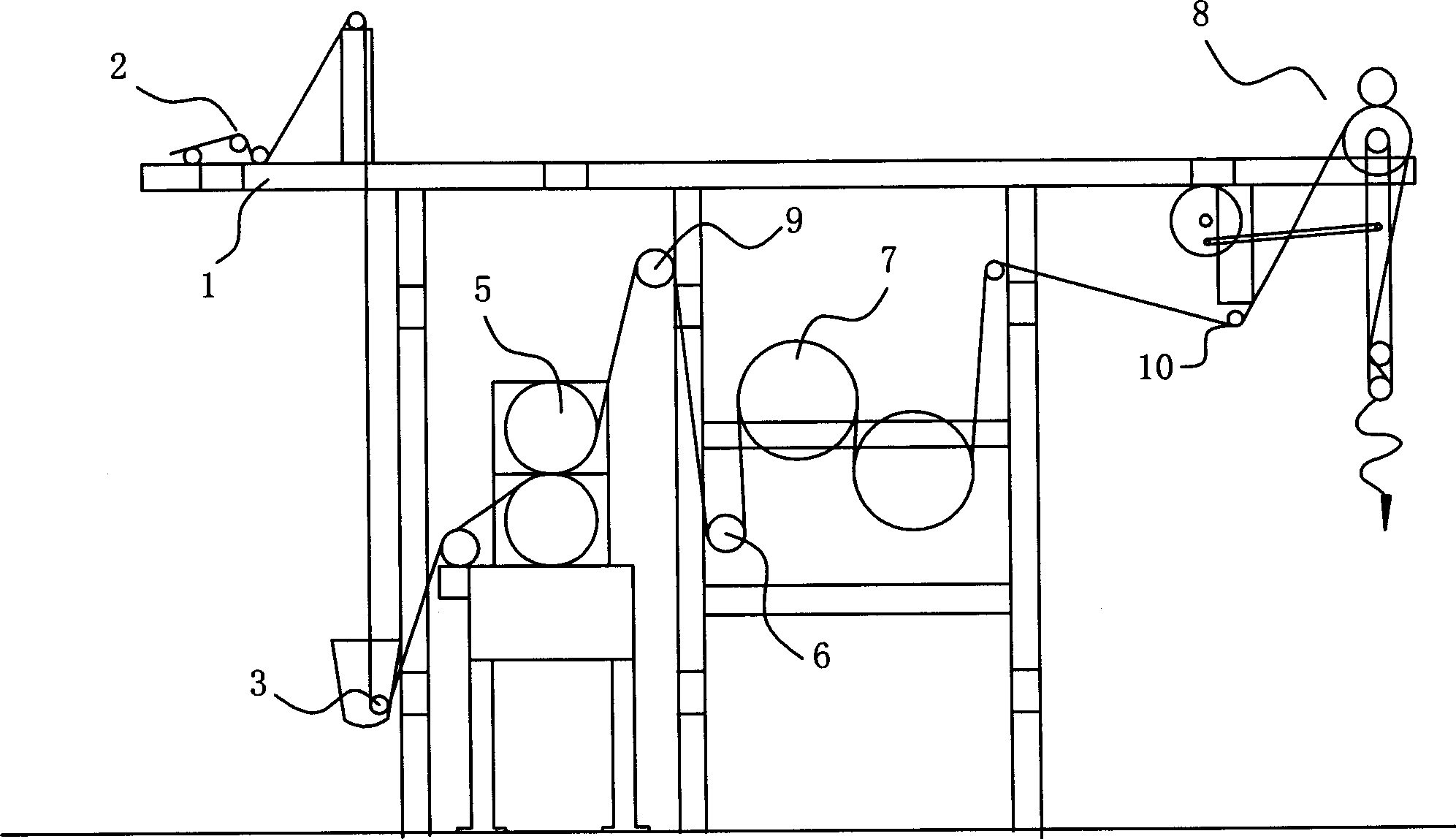

Method and apparatus for dyeing and sampling soft bag

InactiveCN1521299ALow priceReduce negative impactTextile treatment dyeing devicesTextile treatment carriersFiberYarn

The dyeing and striking-off process with soft bag includes the following steps: setting spread cloth or yarn to be dyed inside one soft waterproof bag; injecting dye solution in proper amount into the bag; sealing the mouth of the bag to maintain the dye solution inside the bay and to form dyeing and striking-off bag; stretching the dyeing and striking-off bag with some fixture, and turning and driving the bag to make the dye solution flow inside the bag to penetrate cloth fiber for homogeneous dyeing. The dyeing and striking-off apparatus includes dyeing and striking-off bag, bearing stage for the bag to be set on and fixed, and dyeing machine with support frame, spraying unit, sliding unit, driving unit, hot water tank, cold water tank and airtight door. The present invention has the advantages of homogeneous dyeing, saving in dye solution, low cost and no pollution.

Owner:许 云鹏

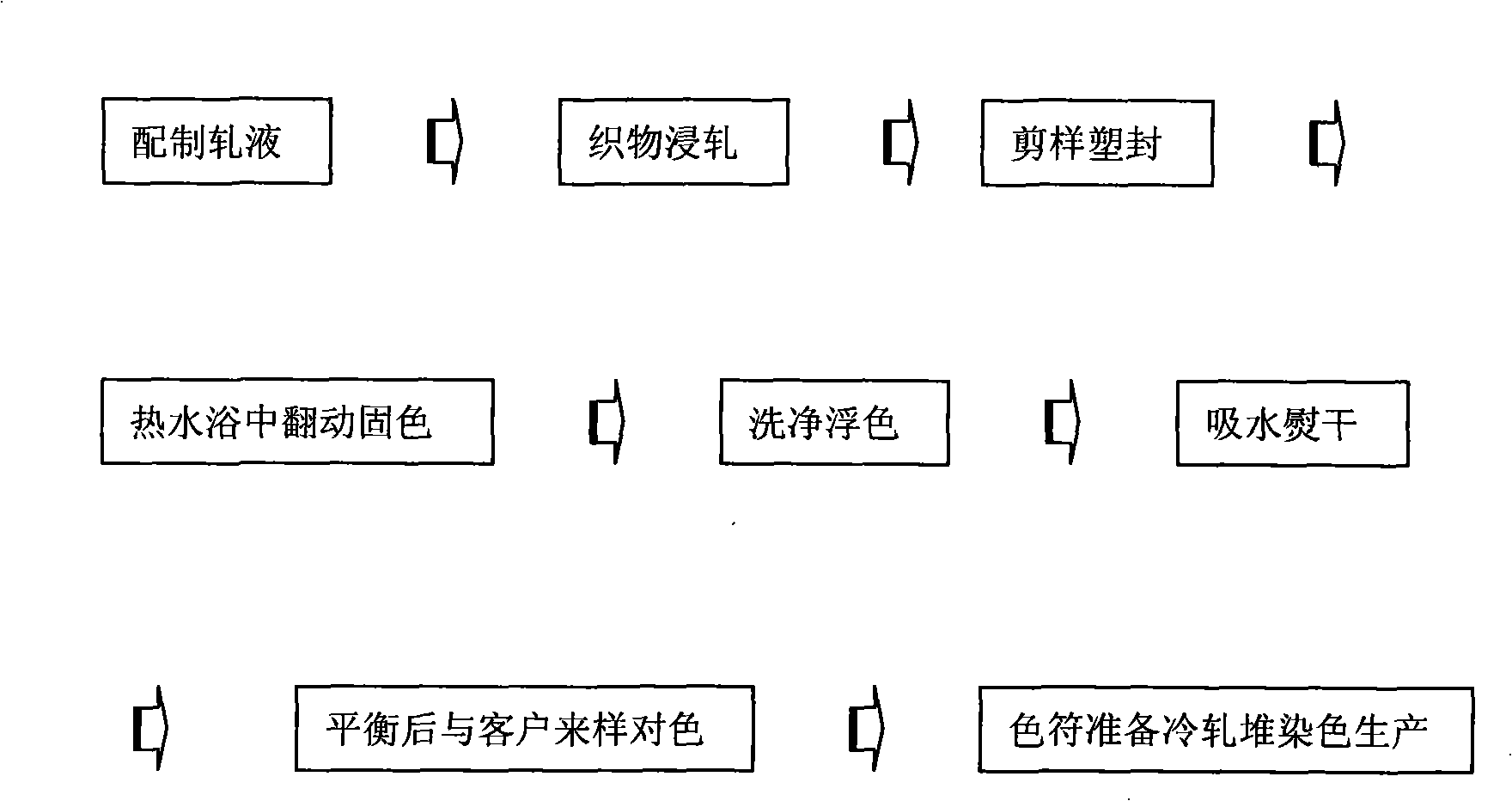

Fast proofing method for cold pad batch dyeing

ActiveCN101275351AUniform colorMeet normal production proofing requirementsTextile treatment dyeing devicesDyeing processDyeingColor difference

The invention discloses a quick fent method for cold rolling pile dyeing. The quick fent method for cold rolling pile dyeing is characterized by including the following steps: mangling make-up; fabrics slop padding; sample shearing plastic packaging; flipping fixation in hot-water bath; washing floating color; water absorption iron dry; balance color. Compared with the present technology, the invention have the following advantages: 1, the fent hand sample has uniform colors, positive and negative color difference CMC(2,1)DE is less than 1; the color is the same with that of the pile setting method, (which is close to or achieves 5 grade rated by the color changing cendre sample card according to the GB250-1984, ISO 105-02 1984 assessment,) which can be used in thicker cotton type fabrics, or can be used in relative thin fabrics such as silk brocade cloth. 2, the process can be completed in 2 hours from mangling make-up to color sample output, which satisfies the fent requirement of the regular production.

Owner:ZHEJIANG SILK TECH +1

Continuous dyeing sample plate

InactiveCN1786323AEasy to useSimple structureTextile treatment dyeing devicesPulp and paper industryDyeing

The invention discloses a continuous dyeing template machine. It includes framework, roll compacting roller, course roller group, dyeing vessel, dyeing roller group, and controller. The roll compacting roller is set power setting. The dyeing vessel is set at the bottom of the dyeing roller group. The features are that the framework is set a dyeing vessel elevating platform. Rubber surfaced roller of the roll compacting roller is connected to elevating drive. The advantages of the dyeing template machine are simple structure, low cost, and high efficiency.

Owner:梅秉枢

Micro capsule no-aids free water washing dyeing process and device

A microcapsule dyeing technology and apparatus without assistant and water washing is disclosed. Said apparatus is a by-pass linked to an ordinary high-temp and -pressure dyeing machine. Said by-pass consists of a microcapsule dye extractor, the water inlet and outlet tubes connected to microcapsule dye extractor and dyeing machine, and the valve for controlling the release of dye. The residual microcapsule can be easily separated from dyeing liquid.

Owner:SHANGHAI WOODGE TEXTILE TECH

Rolling water drying machine

InactiveCN1786321AImprove drying effectReasonable designTextile treatment dyeing devicesTextile treatment machine arrangementsSteam pressureElectric machinery

The invention discloses a water mangling and drying machine. It is made up of distribution box, three ac frequency conversion electric machineries, cloth entering holder, cloth entering guide roller, steeping roller, breadth staying roller, air pressure laminating pressure roller, tension roller, two drying pots, guide cloth output cloth falling roller. The air pressure laminating pressure roller is connected to steam pressure. The tension roller is connected to tension gauge. The two drying pots are connected to electric heater unit. The advantages of the invention are simple operation, and good drying effect. It can fully satisfy various fabrics laminating drying full width and full width padding bottoming.

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD

Device for testing color

The present invention relates to a color-testing machine. Said color-testing machine mainly includes the following several portions: rotating shaft, first rotary disk, second rotary disk, supporting frames, color-testing cups, pushing disk, pushing-pulling lever or pushing-pulling block, first connecting bar, second connecting bar, third connecting bar and fourth connecting bar. Said invention also provides the connection mode of all the above-mentioned portions. Said invention also provides the working principle of said color-testing machine and its concrete operation method.

Owner:陈昱仁 +1

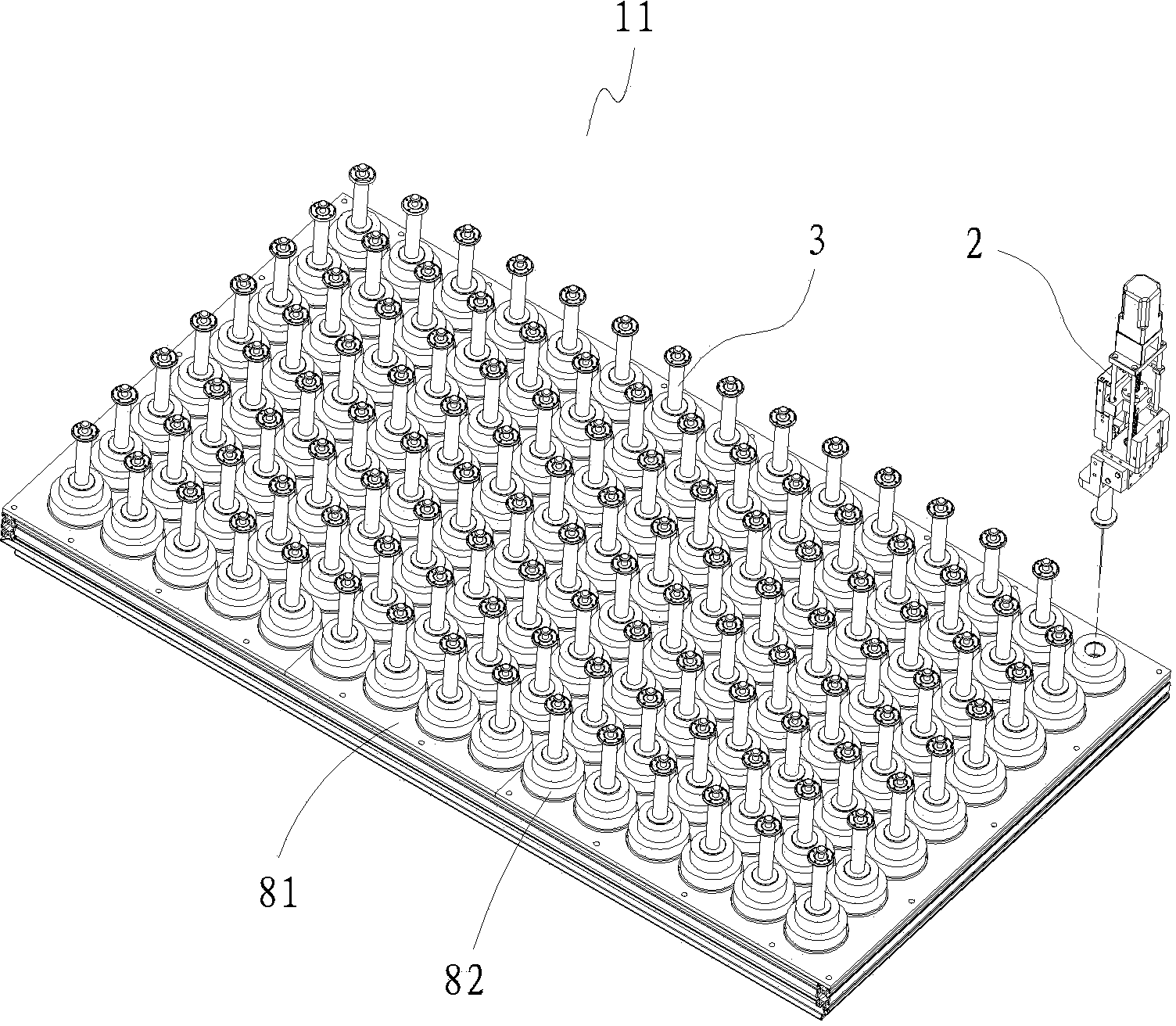

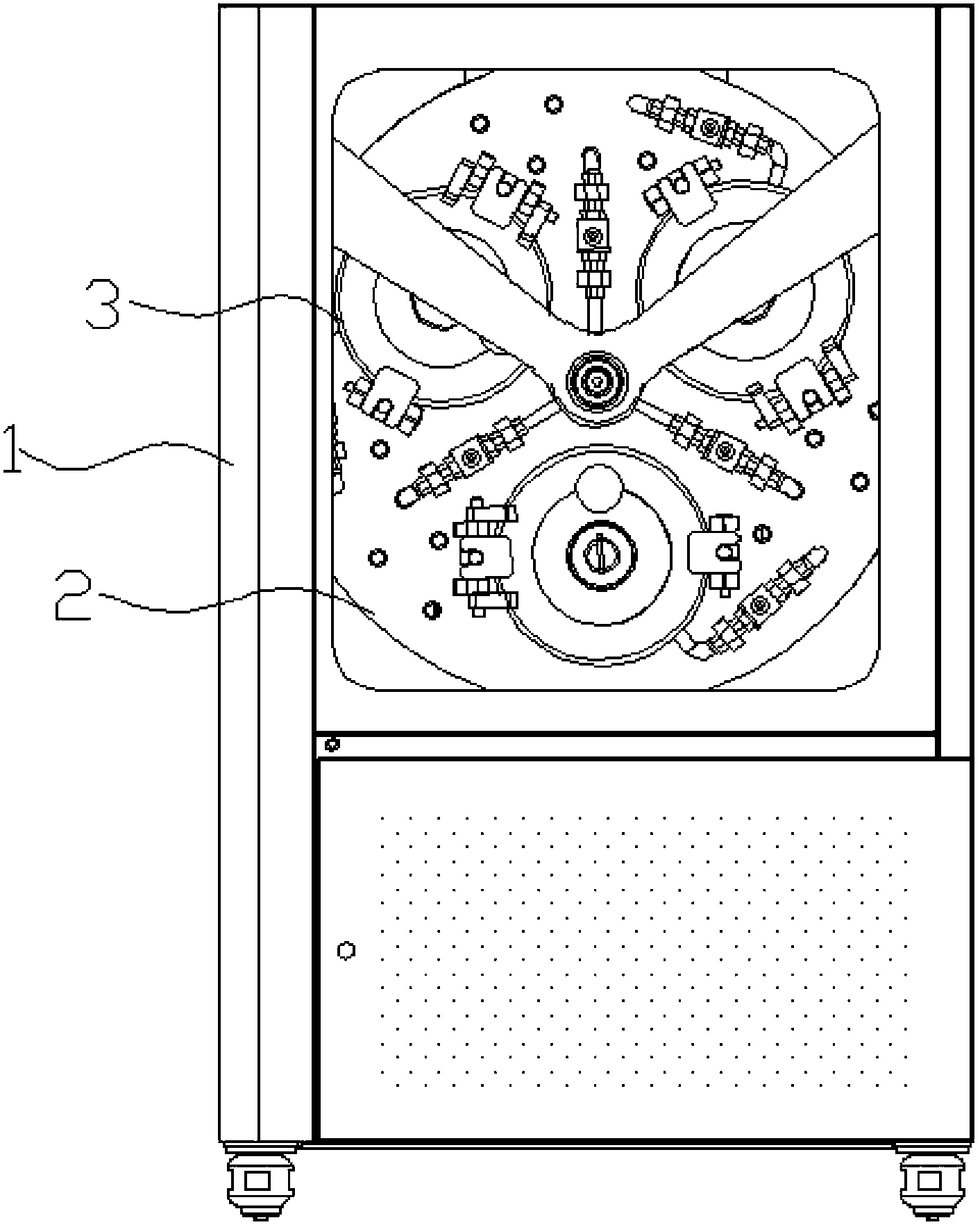

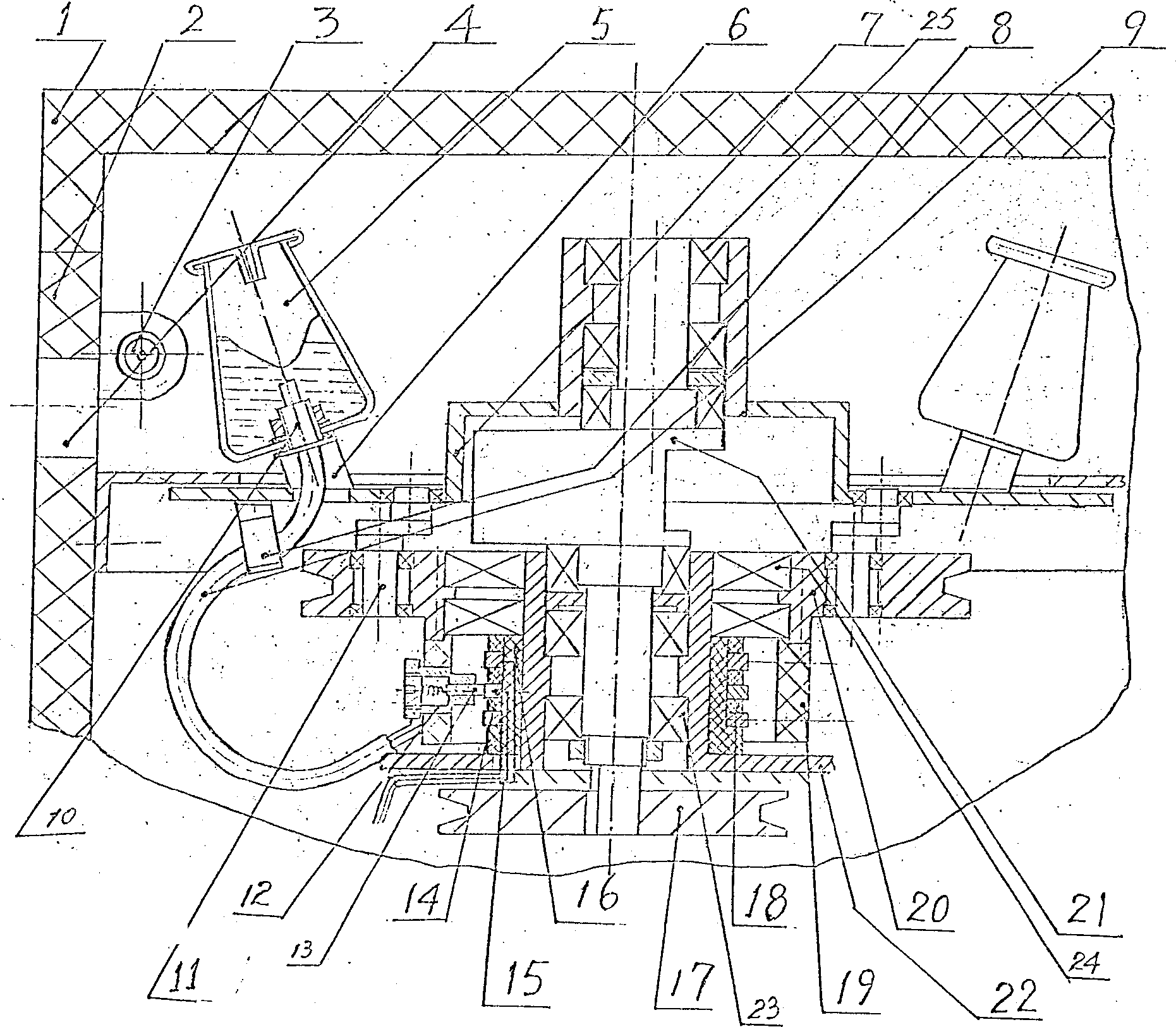

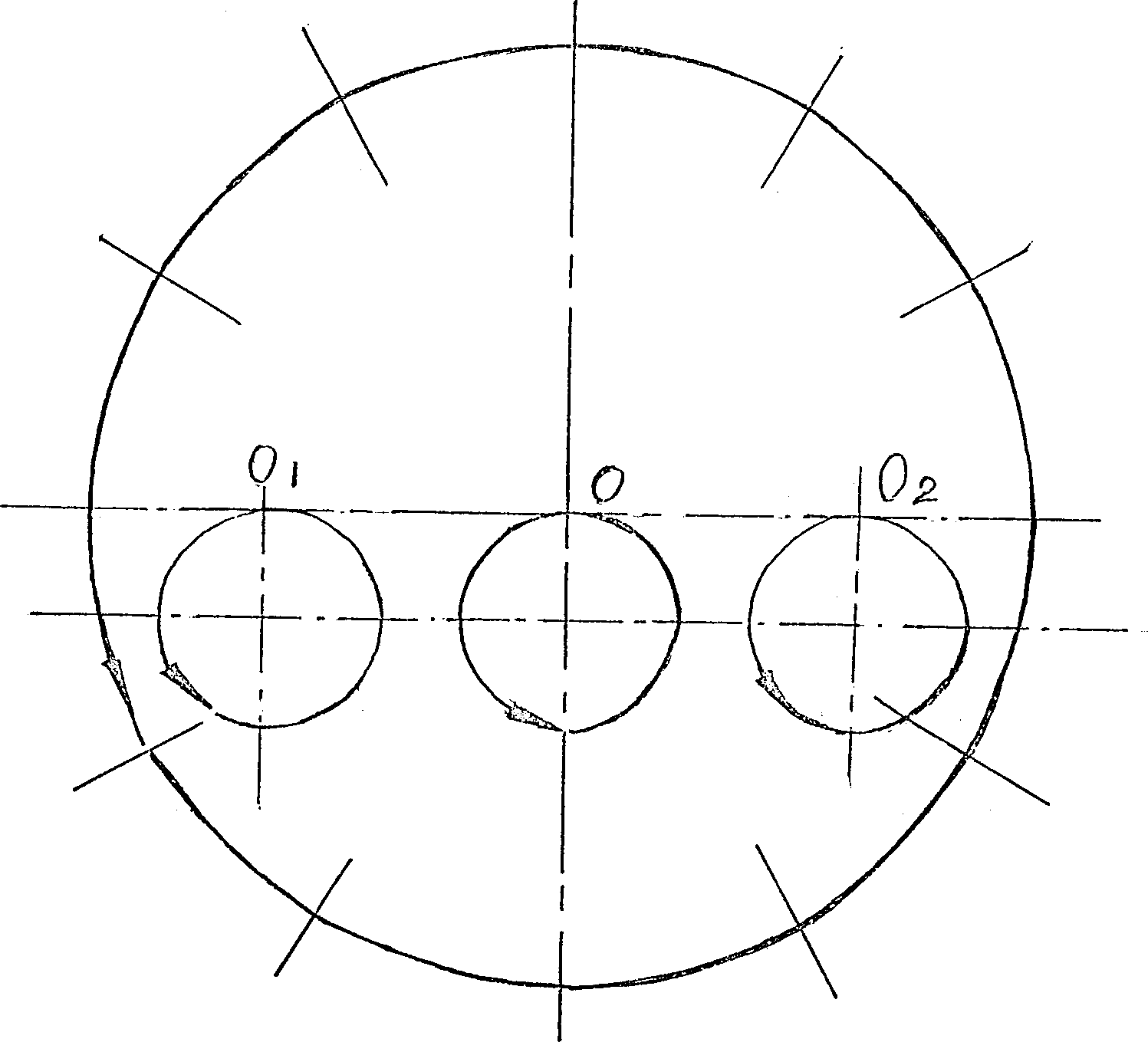

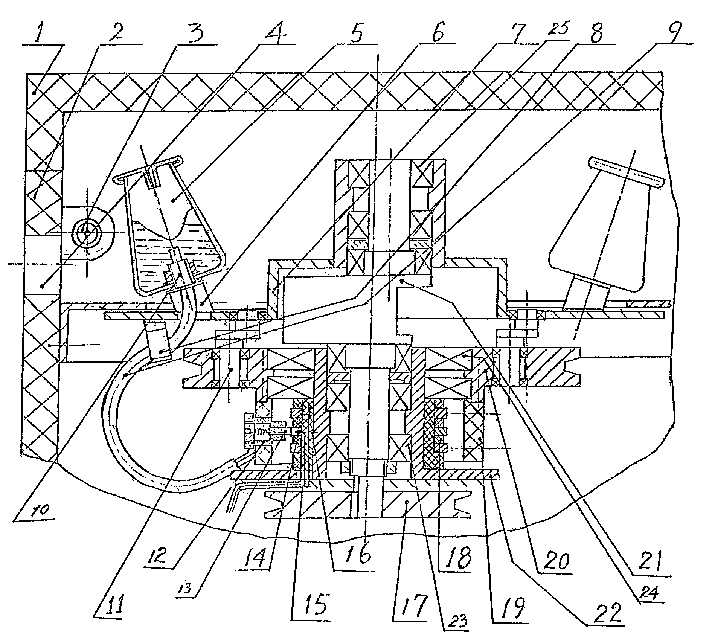

Circular translational sample-dyeing machine

InactiveCN1399029ASolve feeding difficultiesEasy to dropTextile treatment dyeing devicesLow noiseTemperature control

The circular translational dyeing machine features the infrared heaters distributed on the inner wall of the frame; built-in mechanical transmission machanism with main crankshaft fixed on the frame, the first transmission part mounted to the end of the main crankshaft, the second transmission part mounted, on the fixing frame and connected to the driven crankshaft and dyeing cup fixing plate; dyeing cups distributed on the plate; and temperature sensors connected to the temperature emasuring and controlling circuit inside the dyeing cups. It has the advantages of small vibration, low noise, high temperature control precision, high automation, etc. and may be used widely in dyeing smaple in textile dyeing and finishing trade.

Owner:张同生

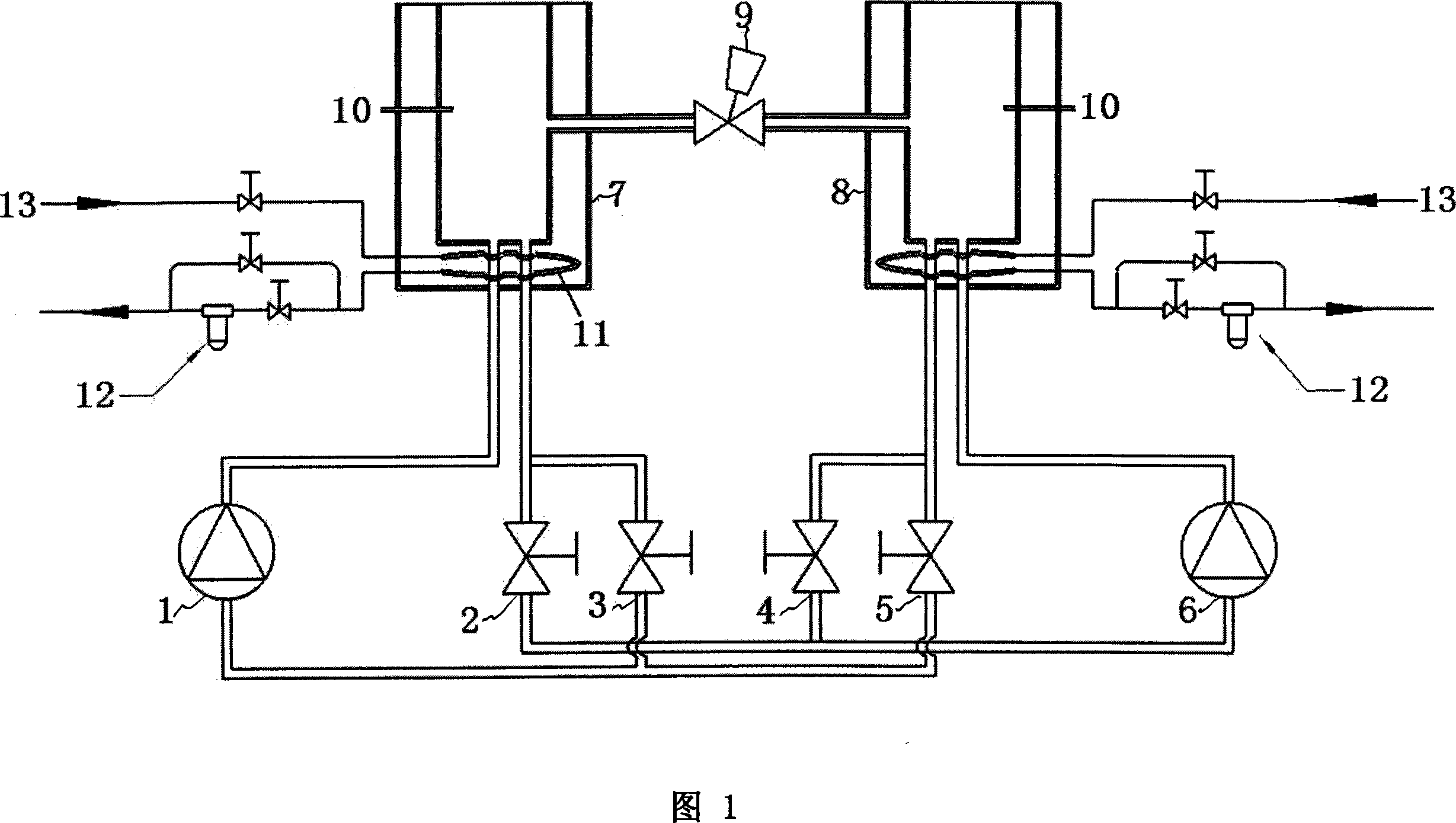

Double-bladder type dyeing machine

The invention relates to a double-liner type dyeing machine, which comprises a draining valve, a steam inlet opening, a circulation pump, and a pneumatic three-way valve. The dyeing machine is characterized in that the inner layers of two dyeing vessels are connected through a communicating valve, two dyeing vessels are both double-layered, the outer layers of vessel bodies are provided with heating coil pipes, the inner layers of the vessel bodies of two dyeing vessels are respectively and mutually connected with the circulation pump through a pipeline, and the pneumatic three-way valve is respectively arranged in pipeline loops outside the two vessel bodies. A dye liquor heating way is changed along with the change of the temperature through the heating water of the outer layers; two vessels are connected, the dyeing can be performed in a single vessel, and also the vessels are connected to dye bobbin yarns with the same colors.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Print cloth sample making process and color fixer

InactiveCN1417404AAvoid demandEasy to modifyTextile treatment dyeing devicesTransfer printing processEngineeringMechanical engineering

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

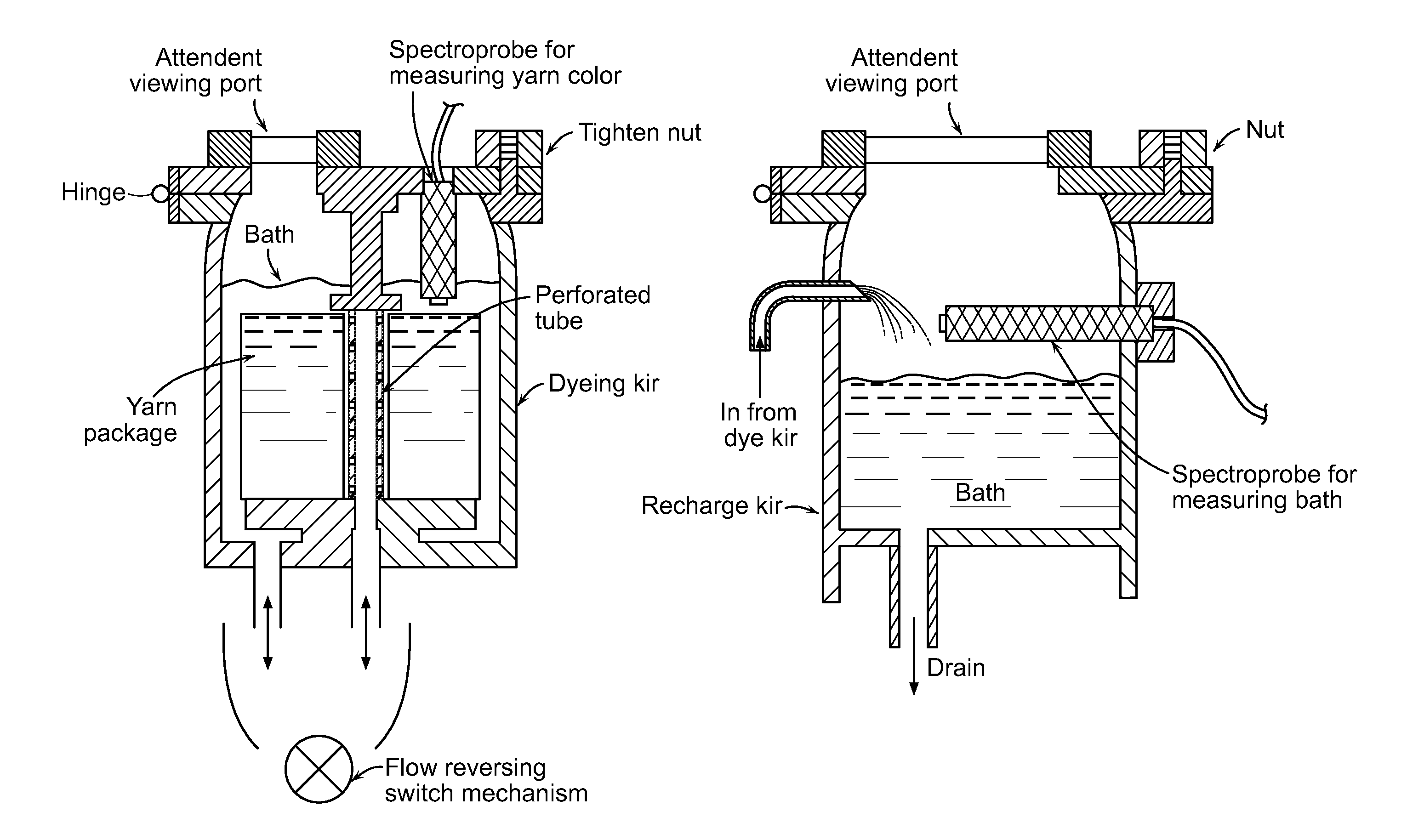

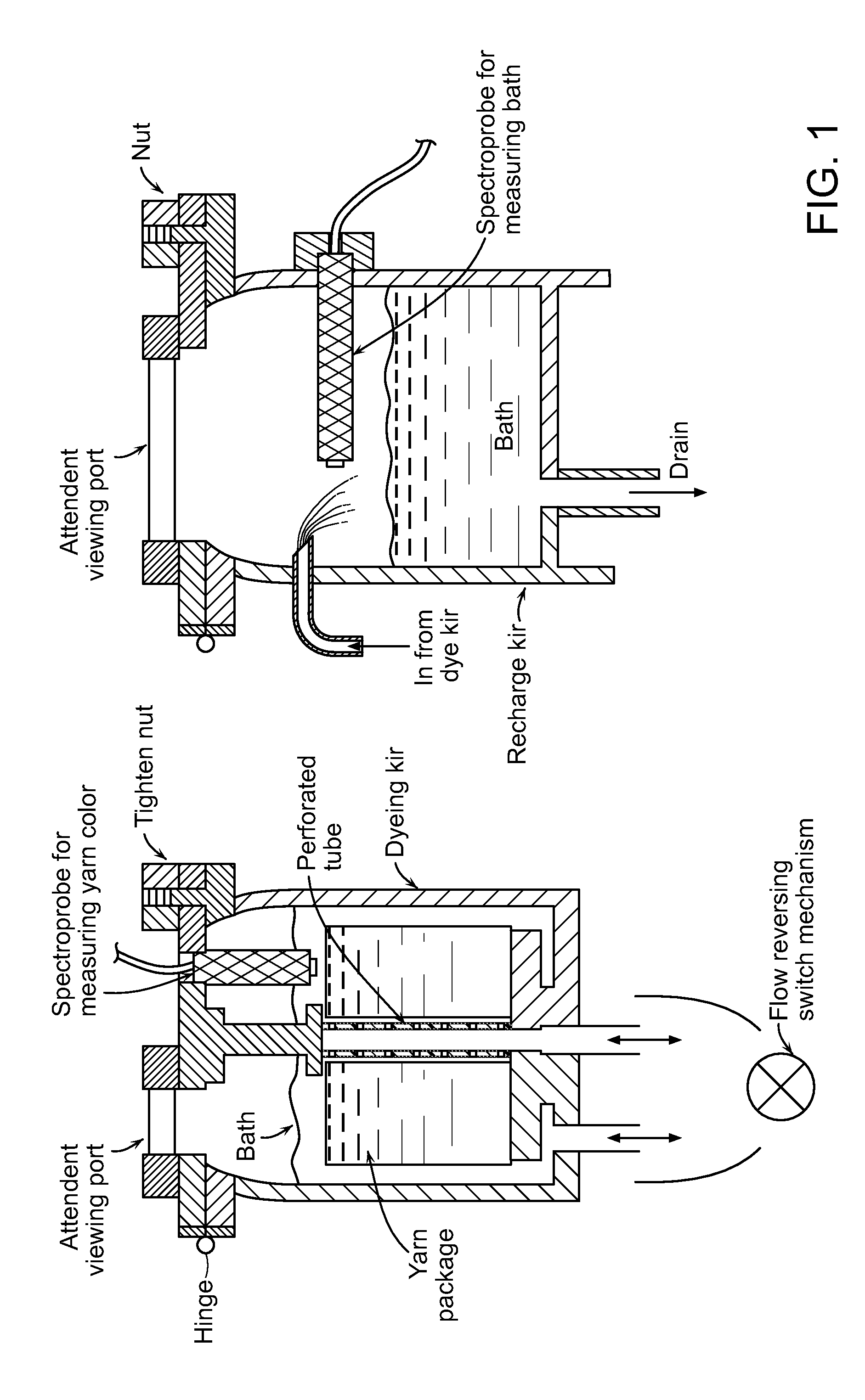

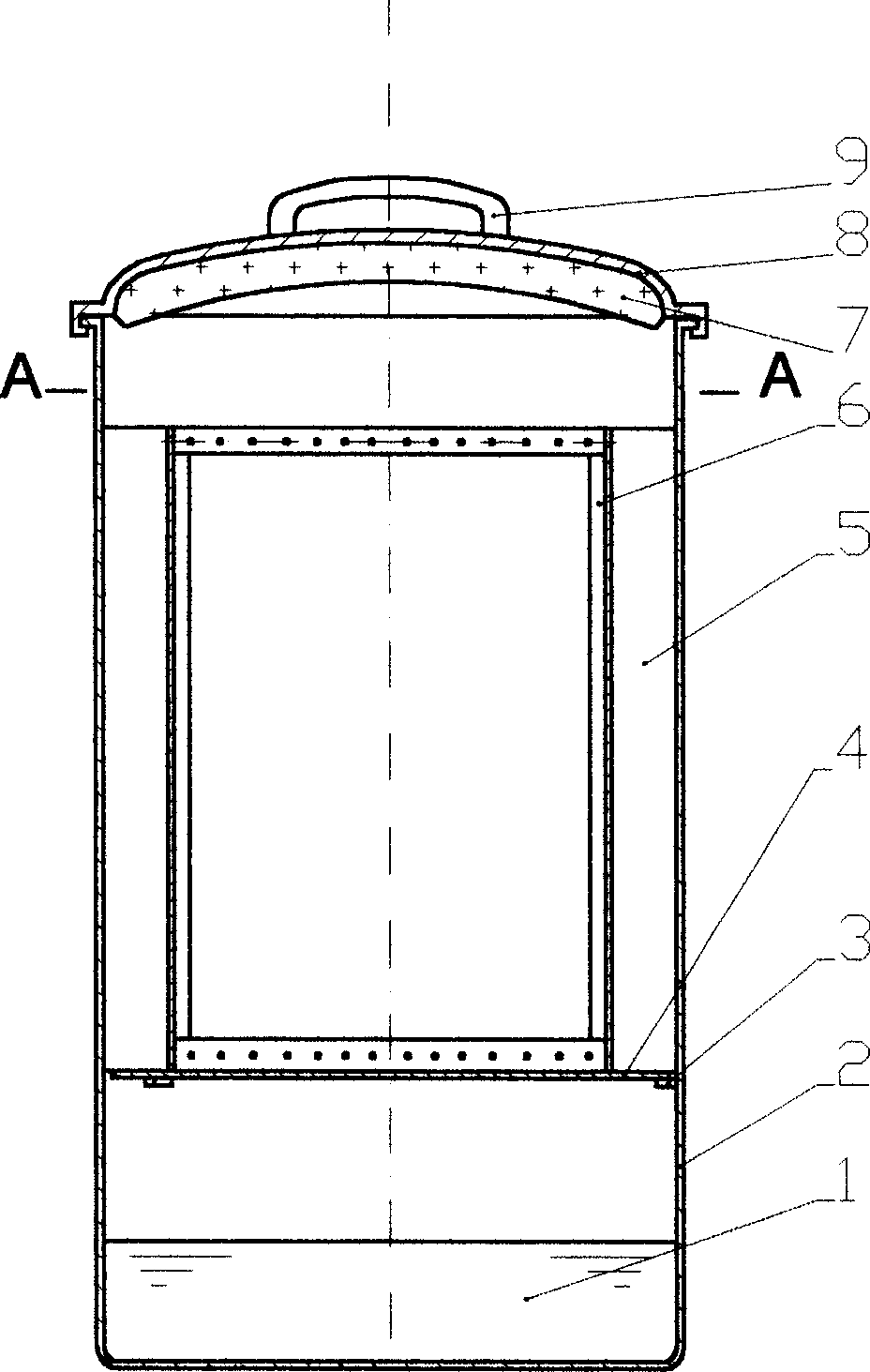

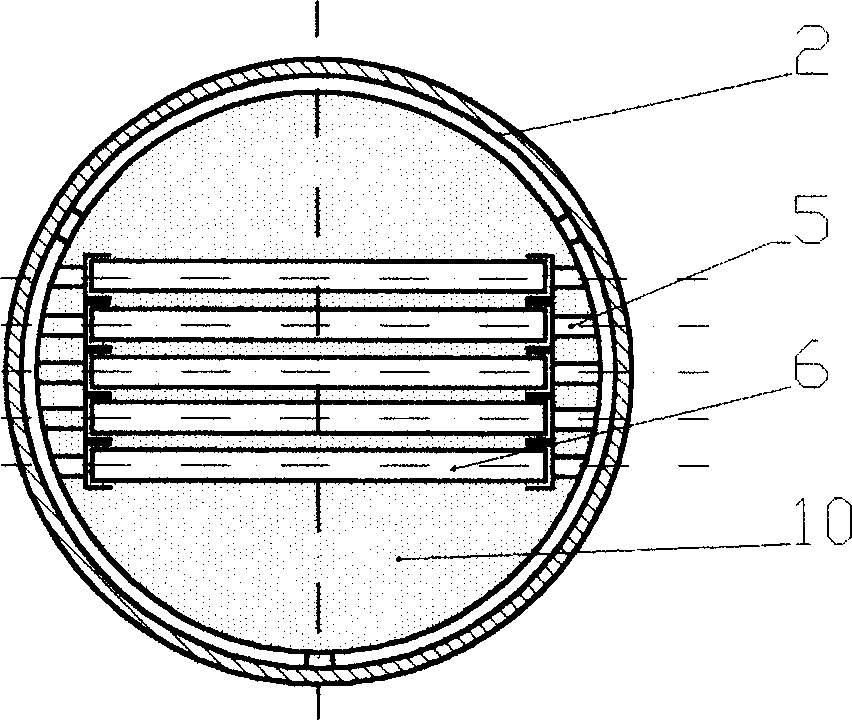

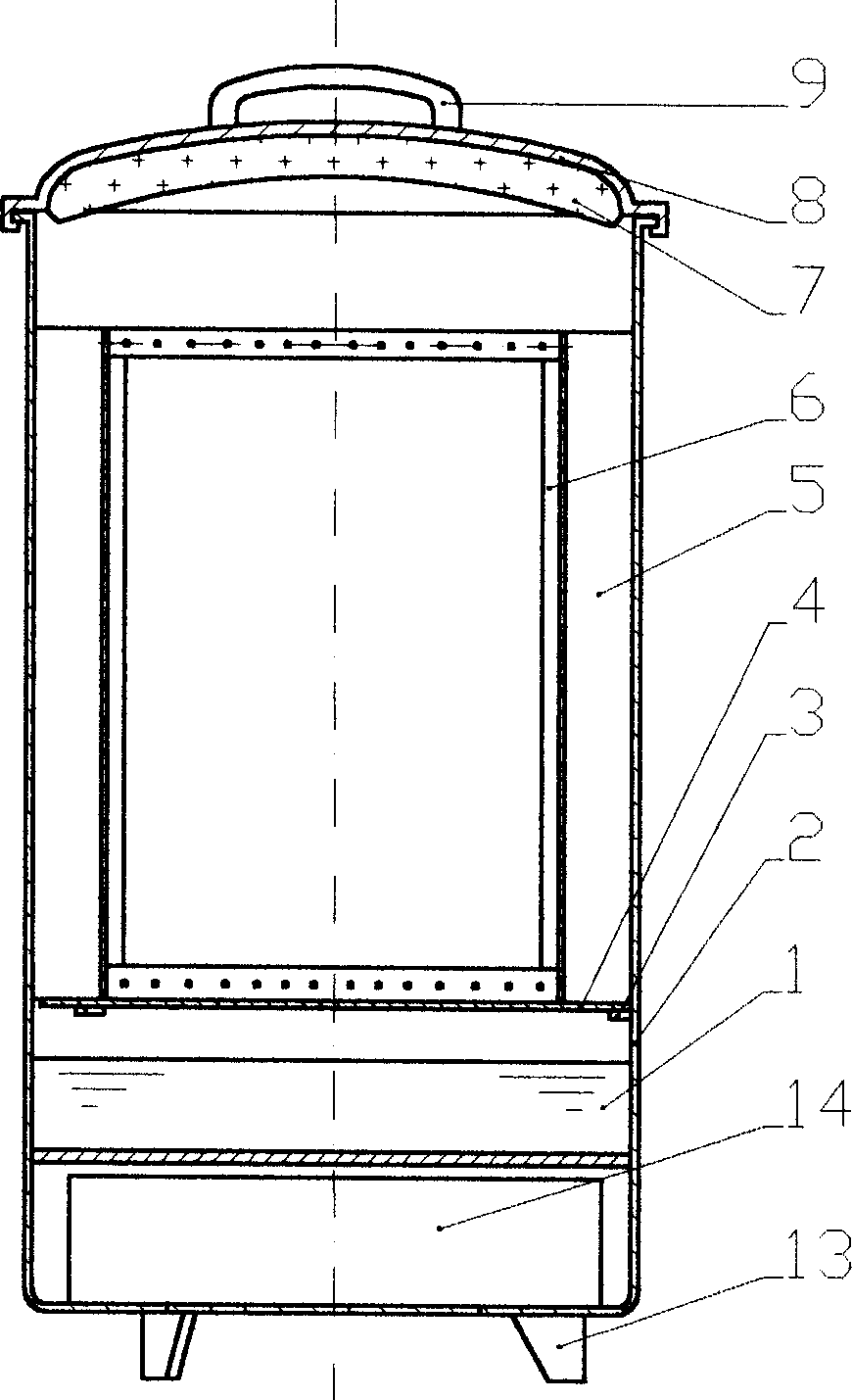

Sample package dyeing machine

InactiveCN101302690ASave spaceSave energyTextile treatment containersTextile treatment dyeing devicesSingle sampleYarn

A dyeing machine (2) for dyeing a sample yarn package (9) comprises a kier (2), a spindle (7) mounted in the kier for supporting a sample yarn package, and a dye liquor circulation system (25) operable to circulate dye liquor through the sample yarn package with inside-to-out and outside-to-in flow directions, the kier and the spindle configured to accommodate a single sample yarn package with a weight less than 1.2 kg, and the machine having an operating volume such that a single sample yarn package weighing less than 1.2 kg can be dyed using a liquor ratio of substantially 1:6.

Owner:FALMER INVESTMENTS LTD

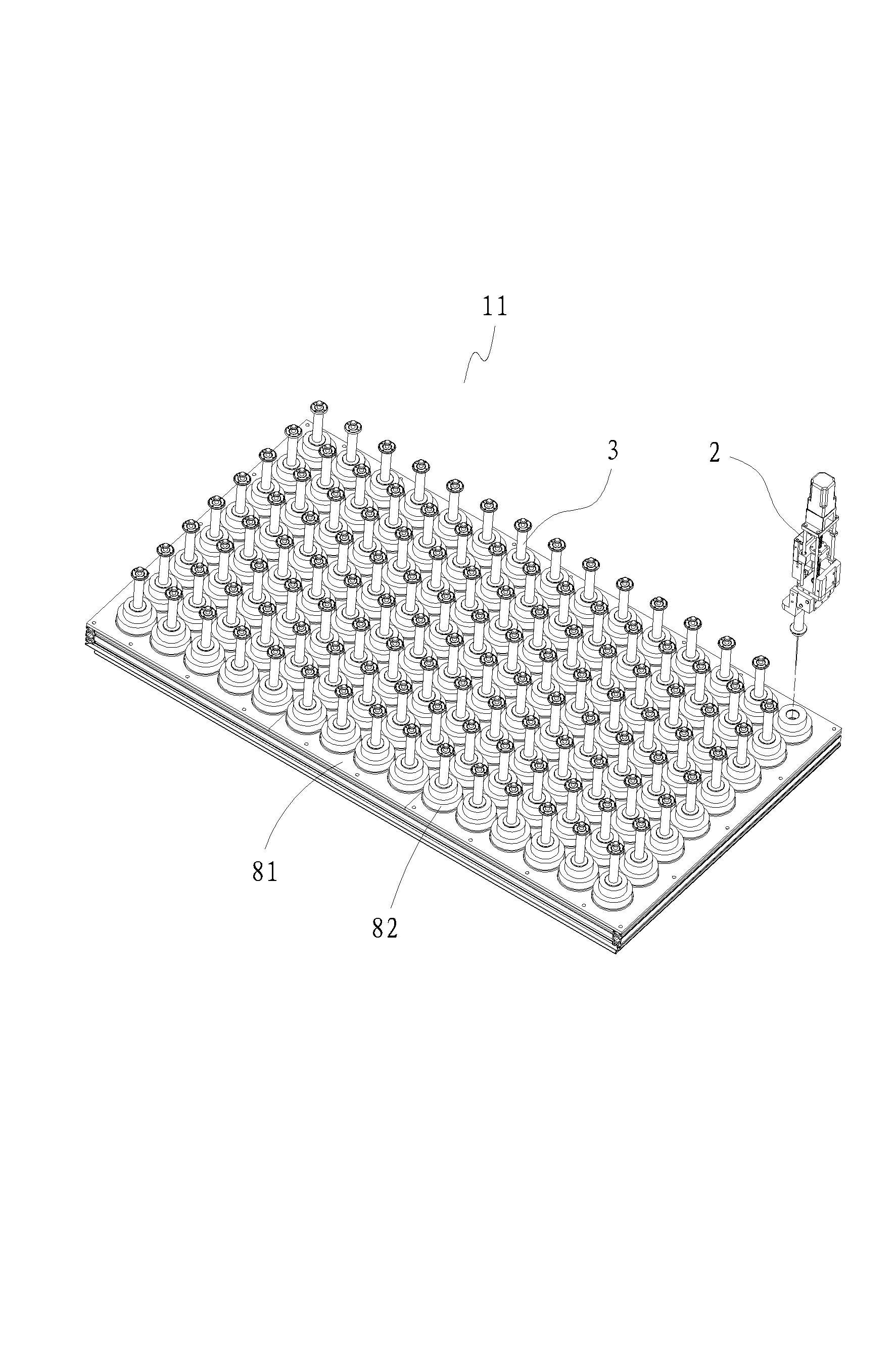

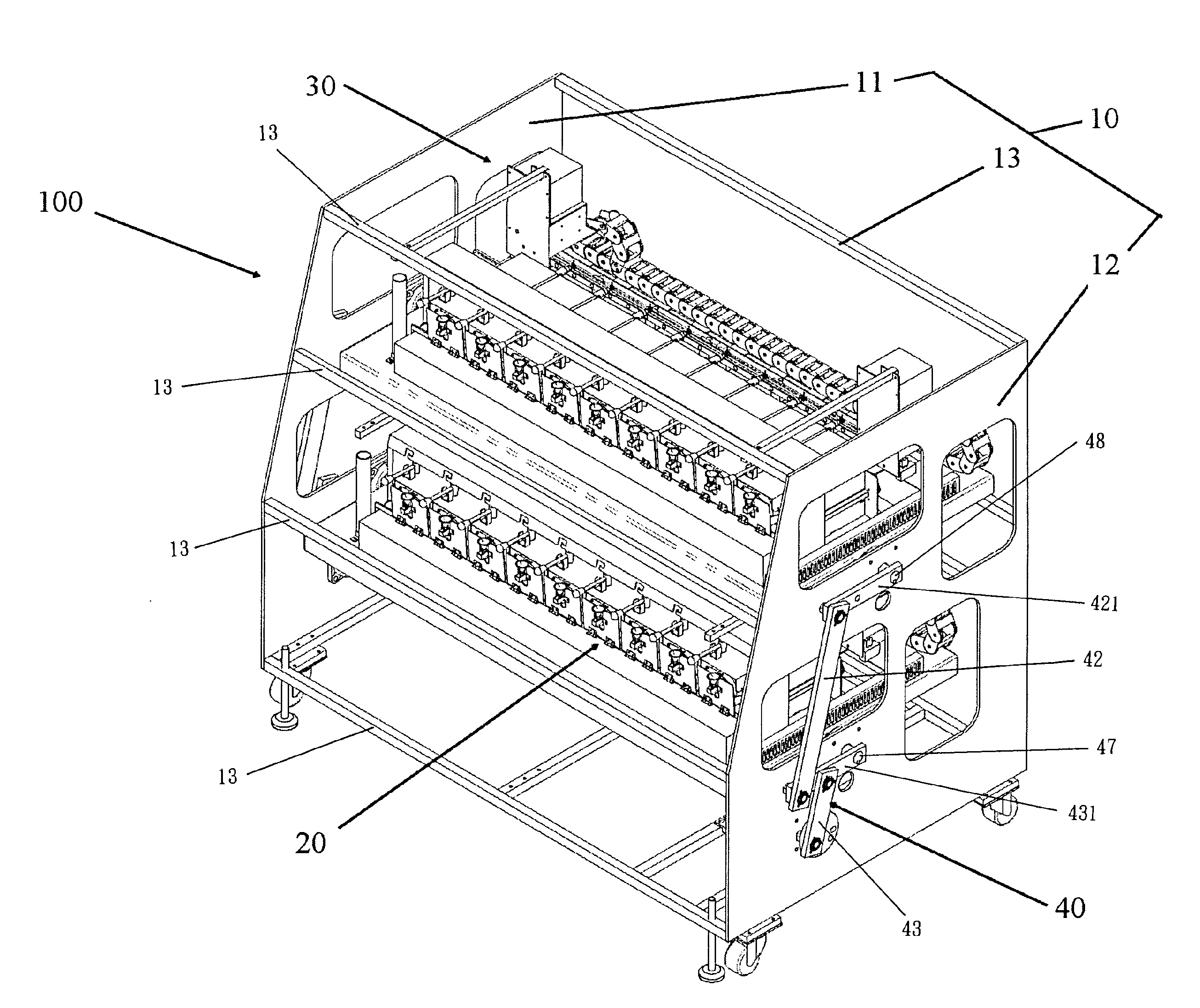

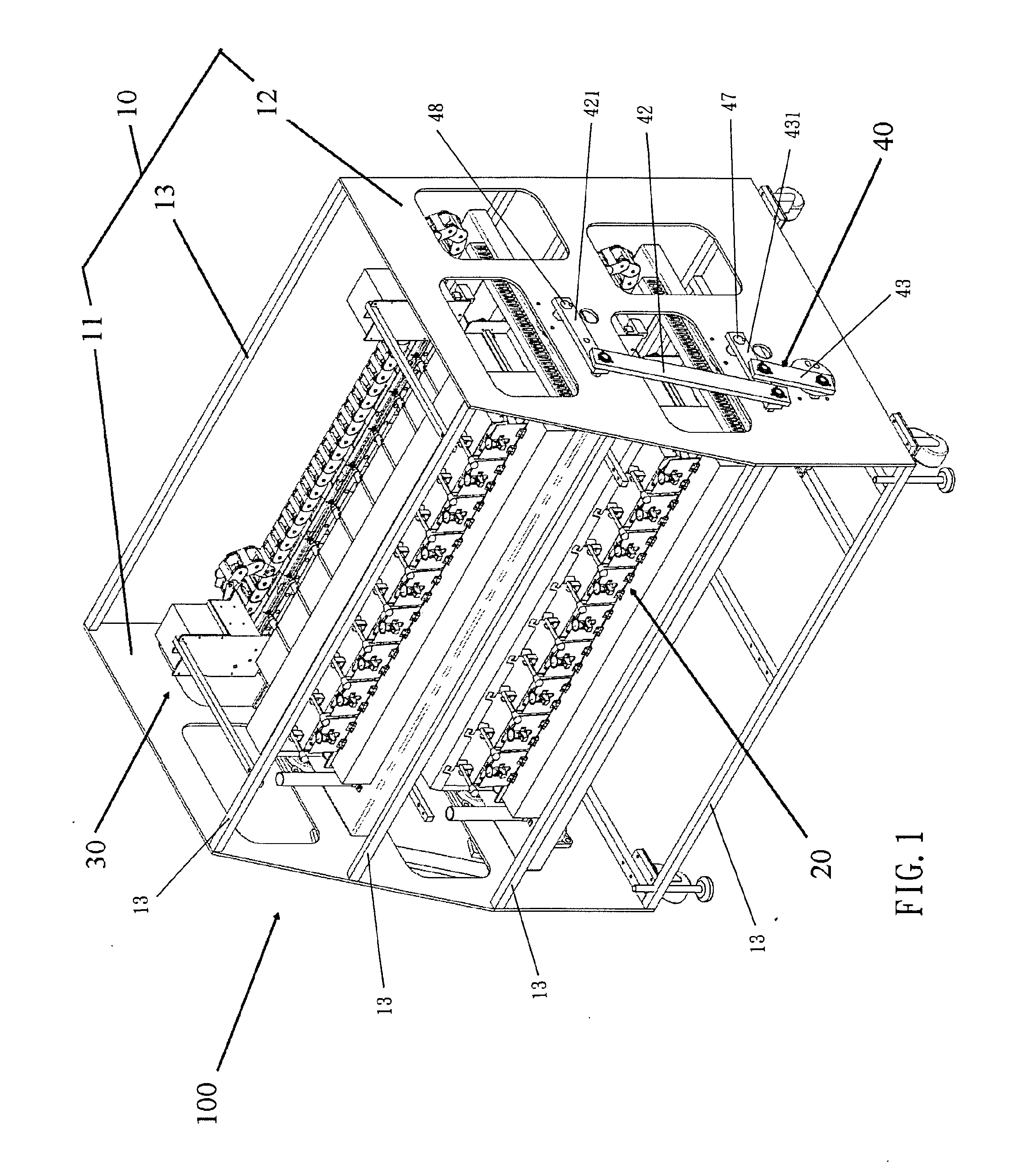

Multi-container dyeing machine with individual container temperature control and quantitative chemical-feeding control

InactiveUS20110247371A1Easy to controlAvoid wrinklesTextile treatment dyeing devicesWashing apparatusTemperature controlFrame based

A multi-container dyeing machine includes a machine frame base, a heating and cooling module having multiple temperature-controlled heating and cooling devices each consisting of a housing, a container, a heating unit, a temperature sensor, a transmission wheel and an electric fan and a mounting plate mounted in the machine frame base to carry the temperature-controlled heating and cooling devices, an automatic quantitative feeder for selectively feeding an auxiliary agent to the containers of the temperature-controlled heating and cooling devices selectively without interrupting the machine and a swinging mechanism controllable to tilt the mounting plate of heating and cooling module and the temperature-controlled heating and cooling devices.

Owner:LOGIC ART AUTOMATION

Novel sample dyeing machine

InactiveCN101603260BReduce installationImprove the operating environmentTextile treatment dyeing devicesTextile treatment machine arrangementsEnvironmental resistanceThermal energy

The invention discloses a novel sample dyeing machine. The machine comprises a rotary frame arranged in a cylinder, a plurality of sample cups and a plurality of sample cup sleeves, wherein the rotary frame is closed and filled with a solid heat-conducting medium in which a heating device is arranged; the sample cup sleeves are fixed on the rotary frame and buried in the solid heat-conducting medium, and openings of the sample cup sleeves are exposed out of the rotary frame; and the sample cups are fixed in the sample cup sleeves respectively in a mode of being movably taken out. In the machine, the solid heat-conducting medium is used for heat conduction, and the sample cups are not contacted with a heat carrier directly, so that the pollution caused by taking glycerin as the heat carrier does not occur, and the glycerin is not consumed; compared with the prior art, the machine has the advantages of keeping the original operating habits, improving the proofing operation environment, and saving energy, along with environmental protection; the machine adopts the solid heat-conducting medium for heat conduction, and no pressure is generated in the rotary frame; moreover, the wind cooling way is adopted for cooling, so that the assembly of pipes is saved, and the machine can be used after connecting to a power supply.

Owner:SHISHI TAIRUI PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com