Fast proofing method for cold pad batch dyeing

A cold pad heap dyeing and fast technology, applied in the direction of dyeing method, dyeing device for processing textile materials, processing of textile materials, etc., can solve the problems of difficult color matching and poor production practicability, and achieve uniform color and meet normal production. The effect of proofing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

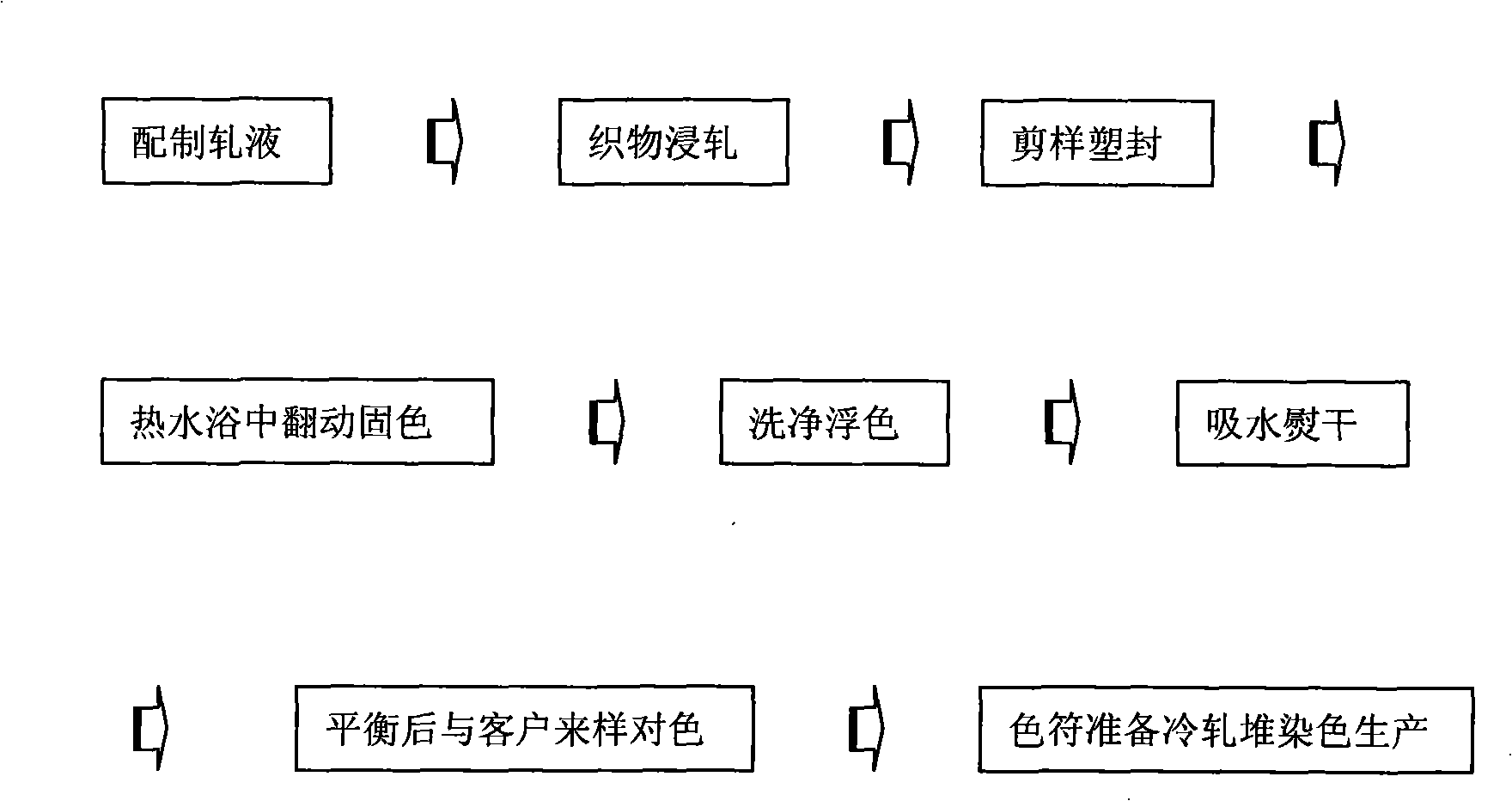

Image

Examples

Embodiment 1

[0012] Dye formula: remazol 3RS yellow 8.35g / l, remazol 3BS red 1.8g / l, remazol CA blue 2.63g / l;

[0013] Alkaline formula: pure minus 10-30g / l, soaking soda 30-50g / l.

[0014] Fabric: Silk cotton.

[0015] Before padding, mix the dyeing solution and lye in a ratio of 3-5:1-2, dip the fabric for 2-5 seconds, and roll it with a padding car, with a pressure of 2-5kg / cm 2 , speed 5-25 m / min. Cut a piece of fabric after padding, place it flat in a plastic bag, seal it after removing the air, fix it on a mechanism and place it in a water bath at 40-75°C for 40-80 minutes (or by hand). Take out the fabric, wash the unfixed dye with hot water, warm water and cold water respectively, then squeeze dry, dry the cloth to absorb water, gradually iron dry, balance at room temperature, and match the color.

Embodiment 2

[0017] Dye formula: remazol H-X black 10g / l, remazol RGB navy blue 36g / l, Jincheng HF-GD red 23.5g / l

[0018] Alkali formula: pure water 30-50g / l, bubble alkali 70-100g / l.

[0019] Fabric: Silk 02 Crepe Chine

[0020] Before padding, mix the dyeing solution and lye in a ratio of 3-5:1-2, dip the fabric for 2-5 seconds, and roll it with a padding car, with a pressure of 2-5kg / cm 2 , speed 5-25 m / min. Cut a piece of fabric after padding, place it flat in a plastic bag, seal it after removing the air, fix it on a mechanism and place it in a water bath at 40-75°C for 40-80 minutes (or by hand). Take out the fabric, wash the unfixed dye with hot water, warm water and cold water respectively, then squeeze it dry, dry the cloth to absorb water, iron it gradually, balance the room temperature, and check the color.

Embodiment 3

[0022] Dye formula: remazol H-X black 10g / l, remazol RGB navy blue 36g / l, Jincheng HF-GD red 23.5g / l

[0023] Alkaline formula: pure minus 30-50g / l, soaking soda 70-100g / l.

[0024] Fabric: silk striped

[0025] Before padding, mix the dyeing solution and lye in a ratio of 3-5:1-2, dip the fabric for 2-5 seconds, and roll it with a padding car, with a pressure of 2-5kg / cm 2 , speed 5-25 m / min. Cut a piece of fabric after padding, place it flat in a plastic bag, seal it after removing the air, fix it on a mechanism and place it in a water bath at 40-75°C for 40-80 minutes (or by hand). Take out the fabric, wash the unfixed dye with hot water, warm water and cold water respectively, then squeeze it dry, dry the cloth to absorb water, iron it gradually, balance the room temperature, and check the color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com