Method and apparatus for dyeing and sampling soft bag

A soft, bag body technology, applied in the direction of processing textile material dyeing devices, processing textile material carriers, etc., can solve problems such as easily dyed flowers or wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

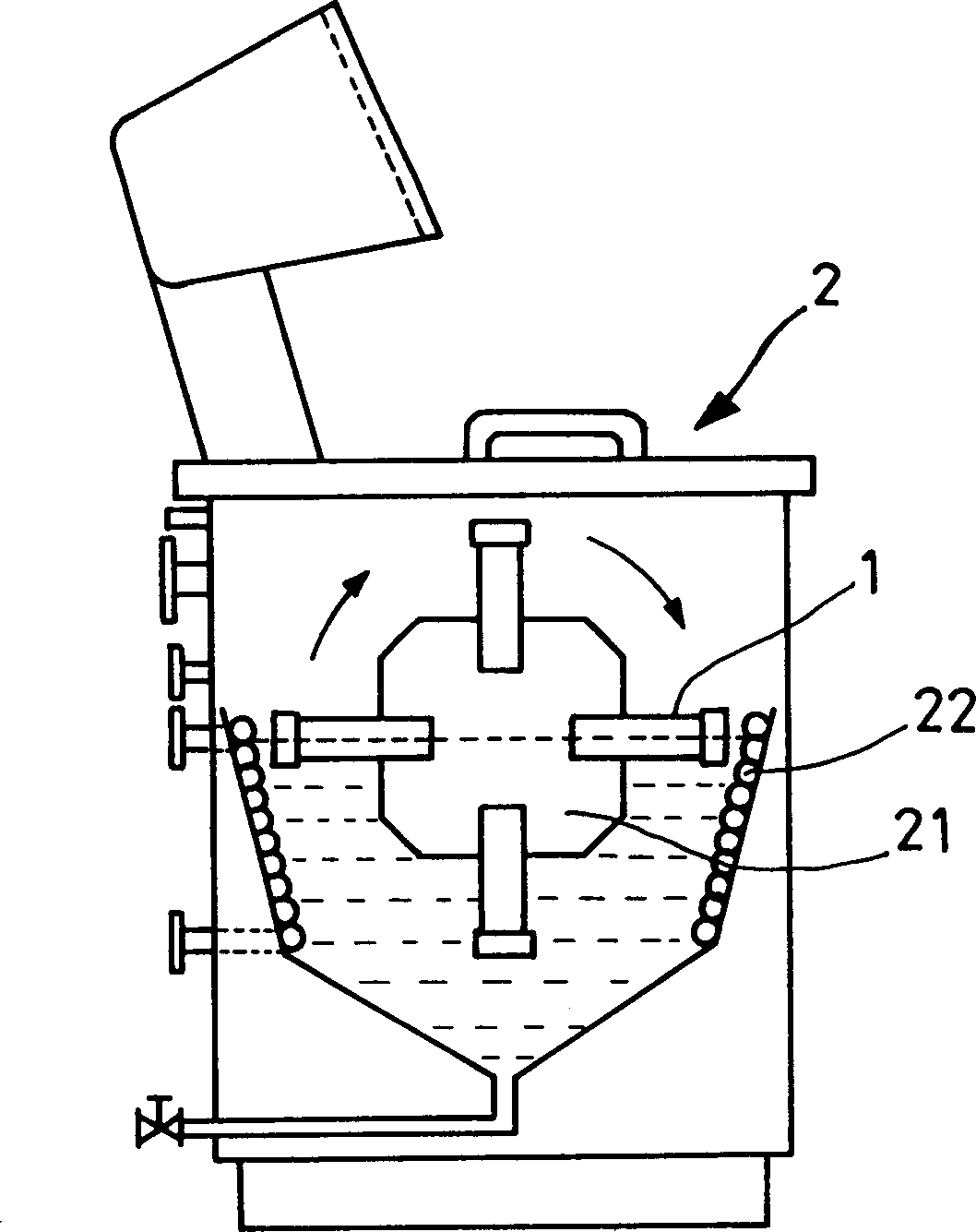

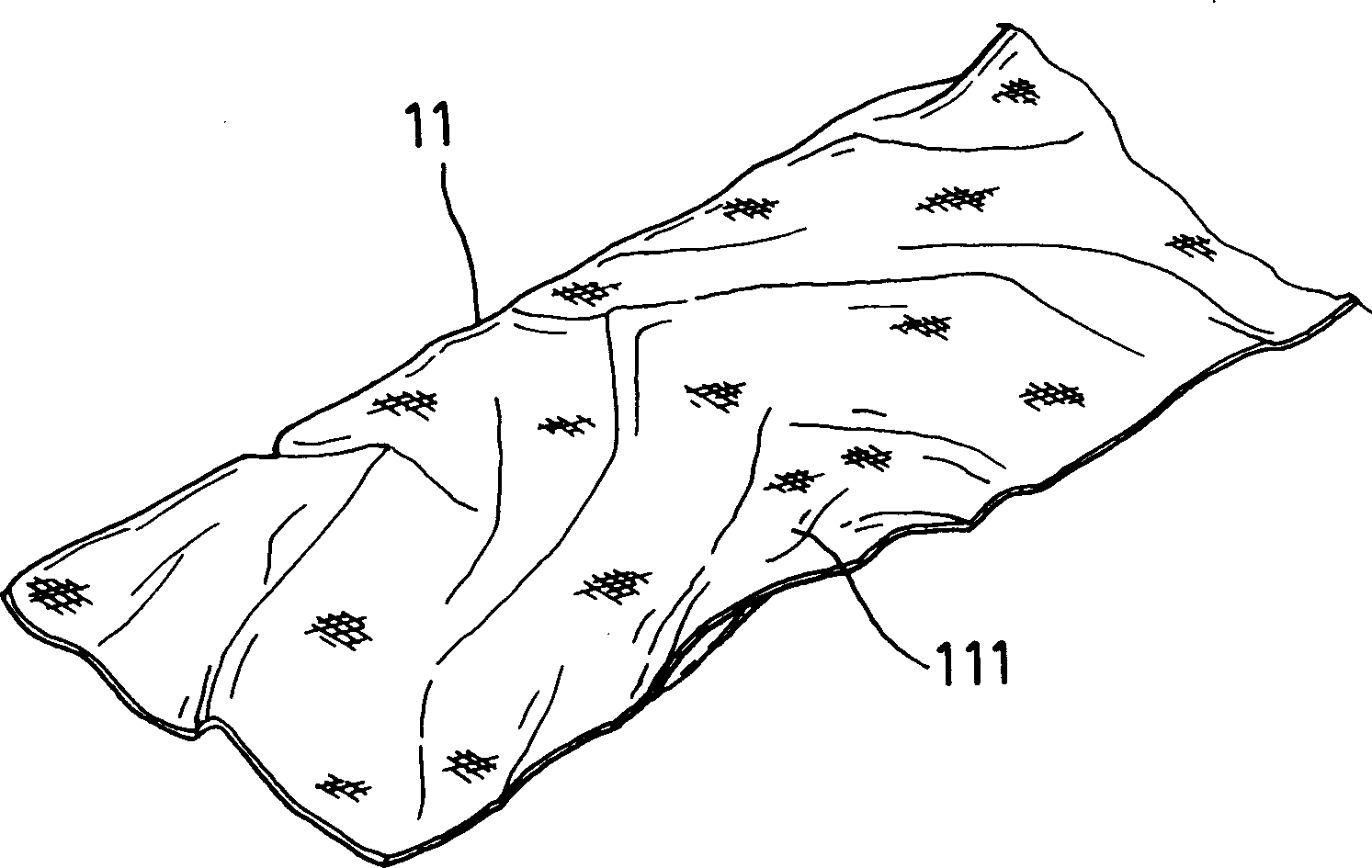

[0030] Referring to Figure 4, the method for dyeing and proofing a soft bag body of the present invention, the implementation steps are first to flatten the fabric 10 to be dyed and place it in a soft waterproof bag body 30. The bag body 30 can be heat-resistant. The bottom end of the bag is pre-closed 31, and then the required dye L is injected into the bag body 30 according to the predetermined dip bath ratio to make it as Figure 5 As shown in the state; then the open end 32 of the bag body 30, approximately at the position shown by the dotted line, is heat-melted to be closed, or directly folded at the dotted line without heat-melting, and then clamped and fixed by tools such as clamps or pressing plates , Constitute a sealed dyeing proofing bag 3 to keep the dye solution in the bag; the structure of the clamp or the pressing plate will be described later.

[0031] Refer to Figure 6 , Figure 7 As shown, Figure 6 Shows that the proofing bag 3 baths are relatively high, about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com