Sample dyeing machine for supercritical CO2 dyeing and dye weighing system

A supercritical, CO2 technology, applied in solvent dyeing, dyeing equipment for textile materials, textiles and papermaking, etc., to save water resources, ensure quality, and reduce pollution

Inactive Publication Date: 2013-12-04

THE HONG KONG RES INST OF TEXTILES & APPAREL

View PDF9 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are currently no sim

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

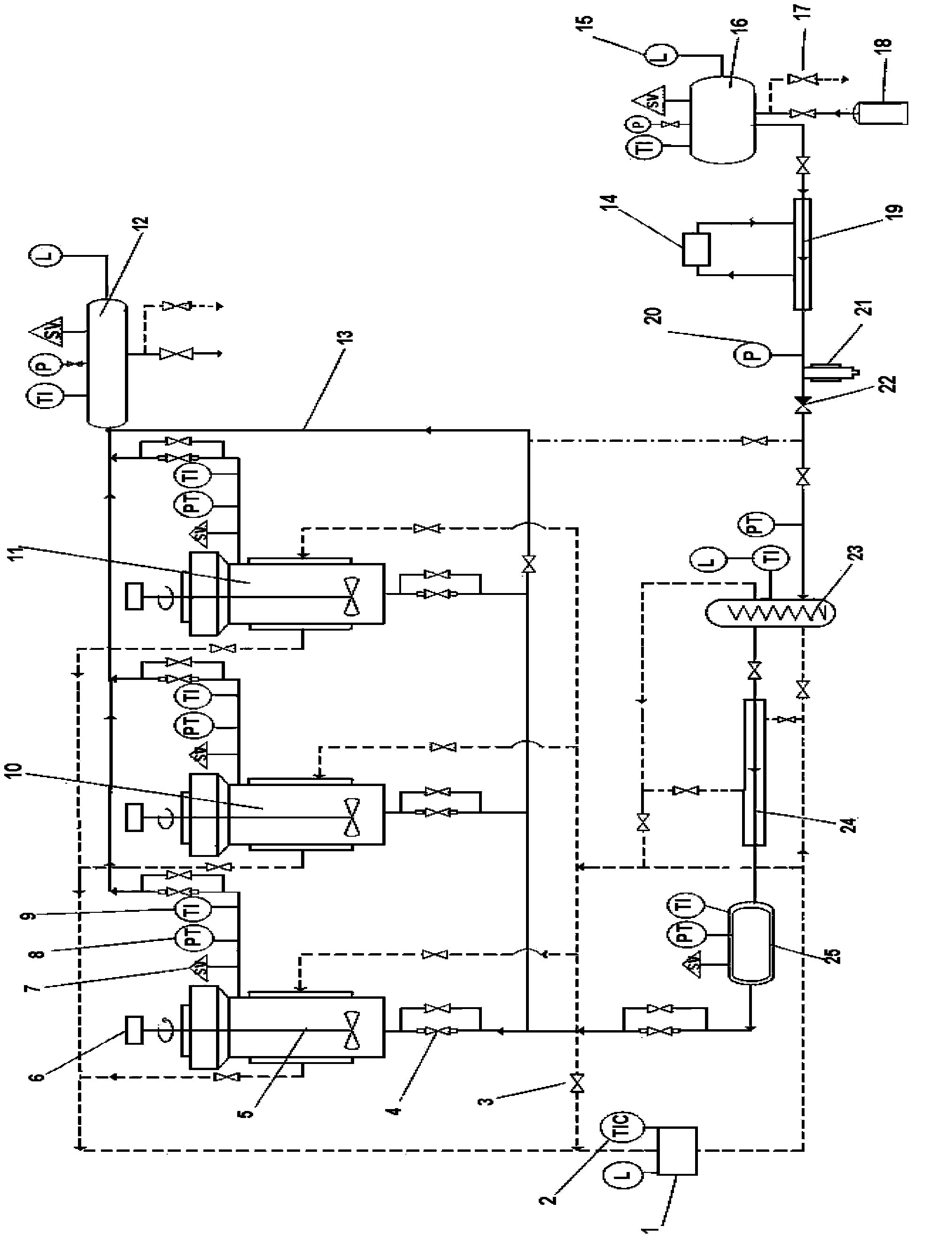

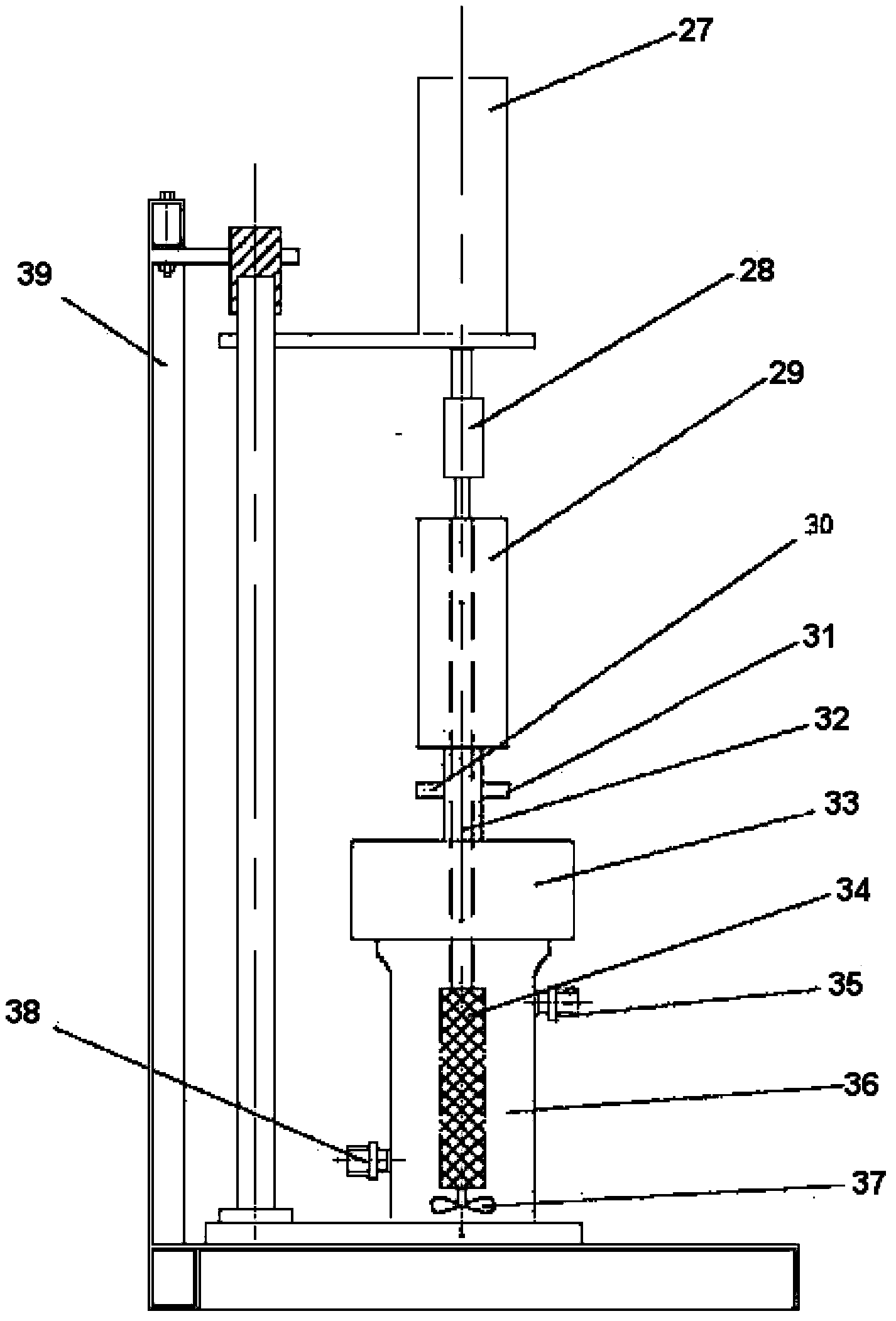

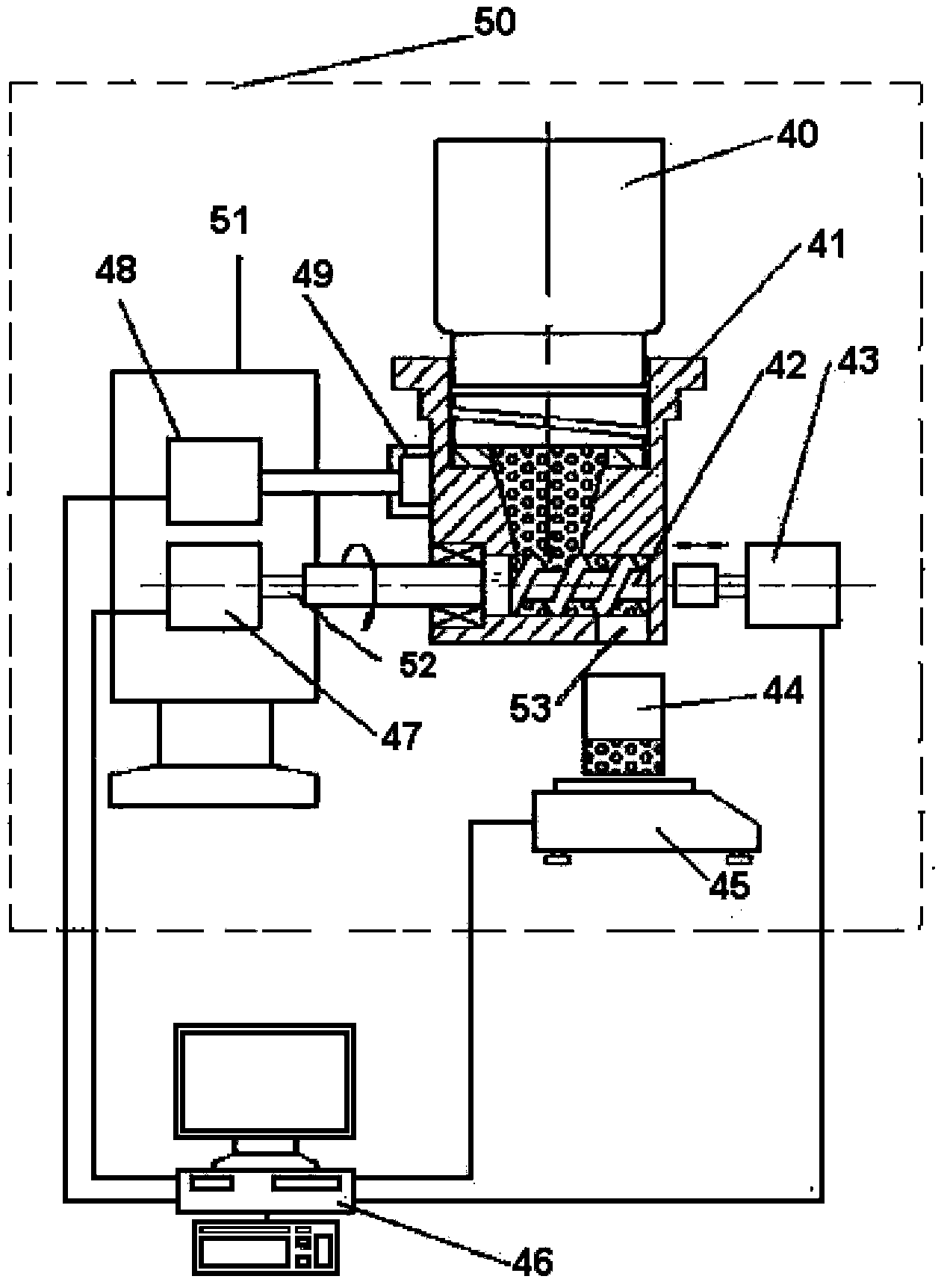

The invention discloses a sample dyeing machine for supercritical CO2 dyeing and a dye weighing system. The machine comprises a CO2 cylinder, a CO2 storage tank, a CO2 pump, a heat exchanger, a high-pressure storage tank, three or more parallel dyeing kettles, an exhaust storage tank, a jacketed pipe, and a hot oil furnace. The CO2 is communicated with the CO2 storage tank. An outlet of the CO2 storage tank is communicated with the CO2 pump. An outlet of the CO2 pump is communicated with the heat exchanger. An outlet of the heat exchanger is communicated with the high-pressure storage tank. An outlet of the high-pressure storage tank is communicated with the dyeing kettles. An outlet of every dyeing kettle is communicated with the exhaust storage tank. The jacketed pipe is disposed outside the dyeing kettles and outside a pipeline between the heat exchanger and the high-pressure storage tank. The hot oil furnace heats the heat exchanger, the jacketed pipe and the dyeing kettles through a heat circulation pipeline. The machine and the system can be used with the early developed supercritical CO2 dyeing equipment and have the advantages that water sources are saved, production cost is reduced, process conditions of large-scale production are simulated and dyes are added accurately.

Description

technical field [0001] The invention relates to the field of anhydrous dyeing, in particular to a supercritical CO 2 Color sample puncher and dye weighing system for dyeing. Background technique [0002] Traditional textile dyeing mainly uses water as the medium, which not only consumes a lot of water resources, but also has problems such as large environmental pollution, high energy consumption, and high processing costs. At present, many countries and regions have tightened environmental protection regulations, making the traditional dyeing and finishing industry face difficulties. In order to solve the problem of water pollution caused by the textile dyeing and finishing industry, the Hong Kong Productivity Council began to develop supercritical carbon dioxide water-free dyeing process in 2005. Recycled industrial carbon dioxide can be used as a carrier to carry dyes to dye textiles in a supercritical state. The feature of this technology is that no water is used in th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B9/02D06B23/10D06B23/20

CPCD06B19/00D06B23/10

Inventor 莫崧鹰陈声泉谢志强

Owner THE HONG KONG RES INST OF TEXTILES & APPAREL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com