Printing and dyeing dropping machine

A technology of dripping machine and mother liquor, which is applied in textile processing machine accessories, dyeing devices for processing textile materials, textiles and papermaking, etc. It can solve problems such as low efficiency, inclination or inaccurate positioning of syringes, and affecting the normal operation of the liquid extraction process, etc. , to achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

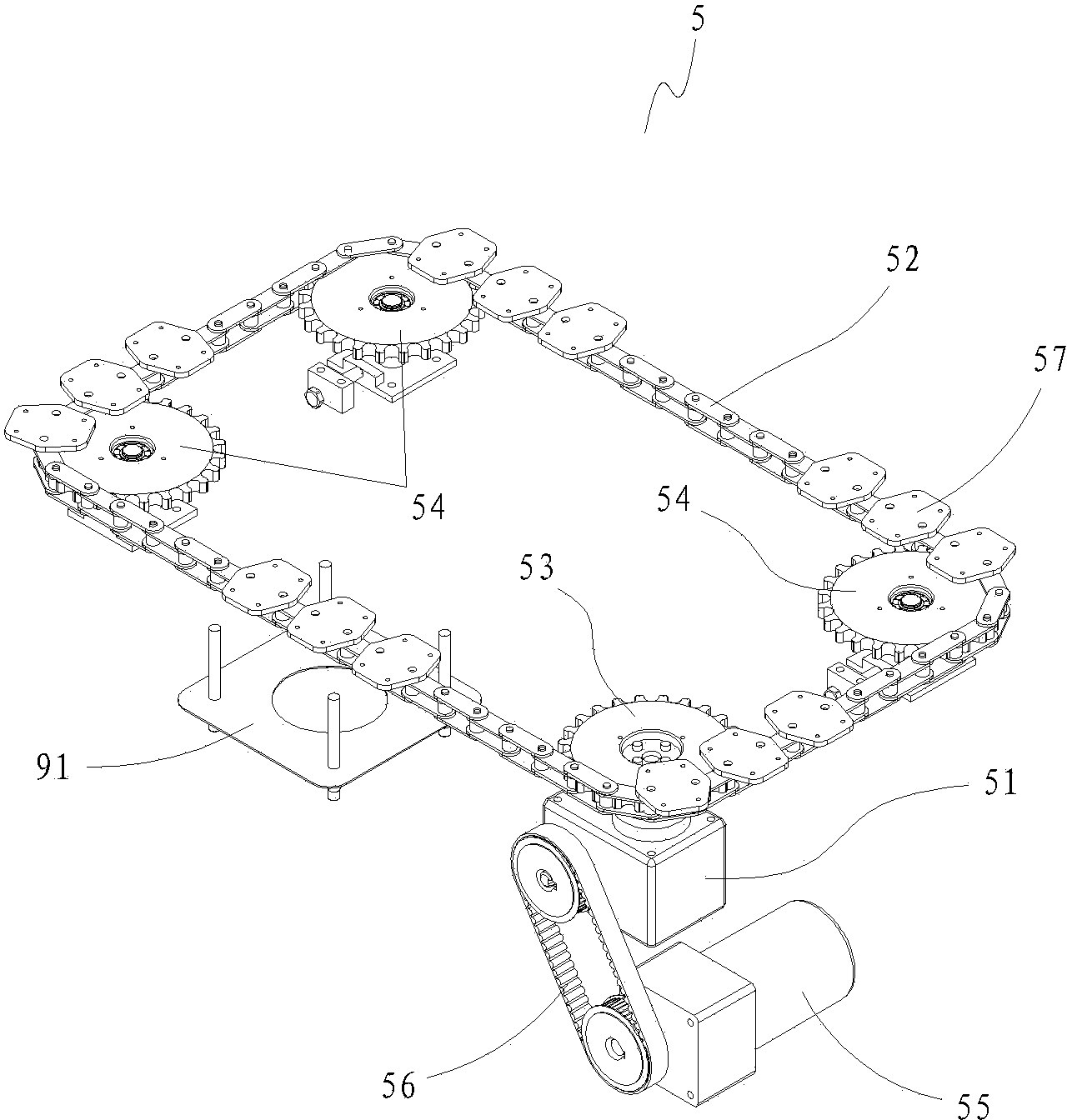

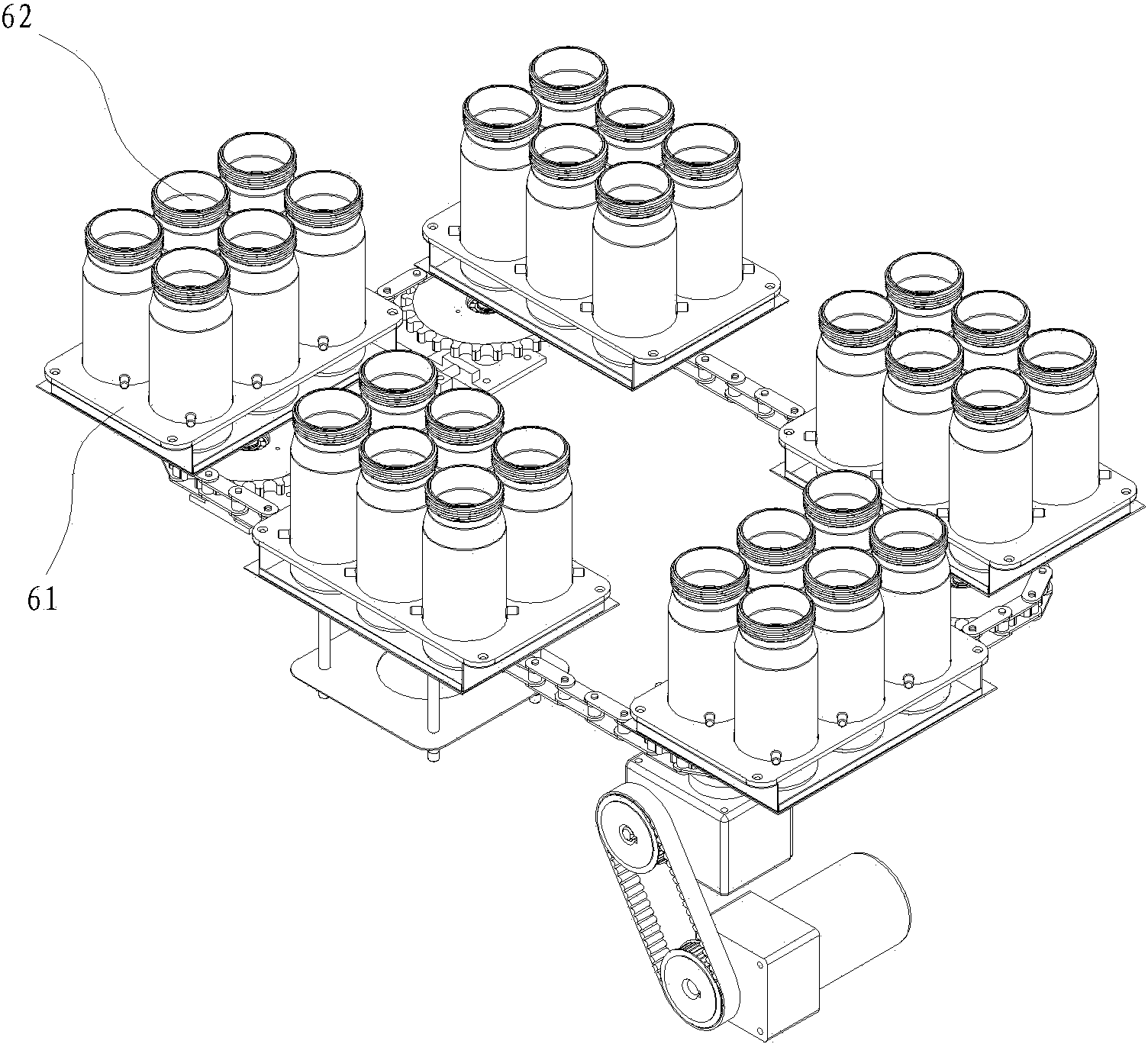

[0030] Example: see Figure 1 to Figure 5 , a printing and dyeing machine, comprising:

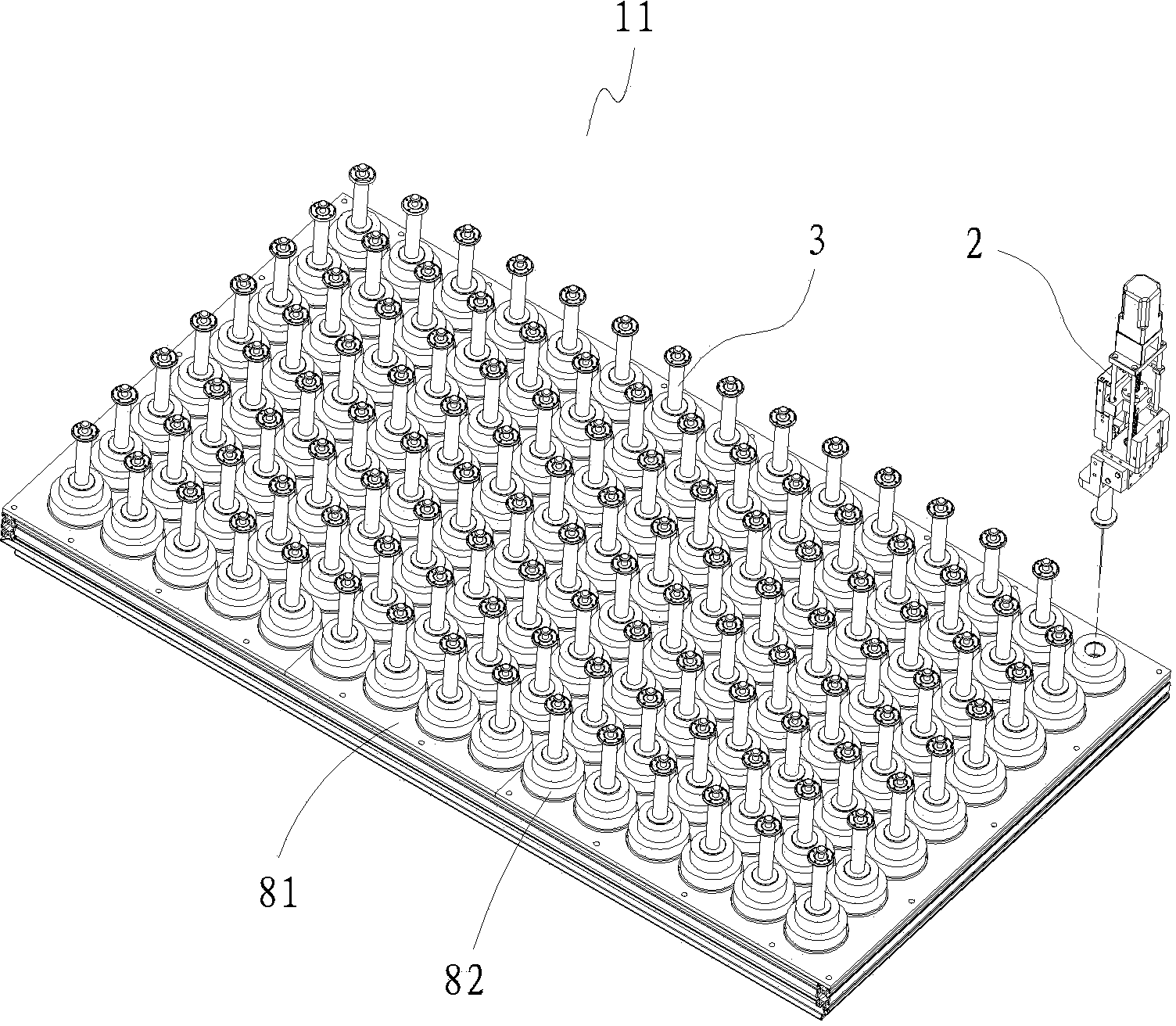

[0031] Machine 1, which has a liquid taking area 10 for accommodating multiple mother liquid bottles and a liquid dispensing area 11 located on one side thereof, a three-axis manipulator 2 is arranged above the liquid taking area, and the manipulator cooperates with a syringe 3 to transfer the mother liquid to the dosing area and insert the syringe back into the corresponding mother solution bottle 4;

[0032] The liquid taking area 10 is provided with a positioning mechanism, and the positioning mechanism has a plurality of positioning holes, and a mother liquid bottle 4 is placed in each positioning hole, and each mother liquid bottle is equipped with a syringe 3, and the three-axis manipulator 2 holds one of the syringes Or play it back to the corresponding mother solution bottle based on the positioning hole where the mother solution bottle is located;

[0033] The liquid dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com