Compositions and methods for dying natural fibers with natural dyes to ensure color (hue and shade)-match consistency

a technology of natural fibers and dyes, applied in the direction of dyeing process, liquid/gas/vapor treatment of definite length materials, instruments, etc., can solve the problem of eluded artisan dyeing from batch to batch, the most difficult to achieve consistent hue and shade matching, and prior art attempts to solve this problem between batches have failed. problem, to achieve the effect of ensuring color (hue and shade)matching consistency, reducing dye waste, and enhancing dye penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

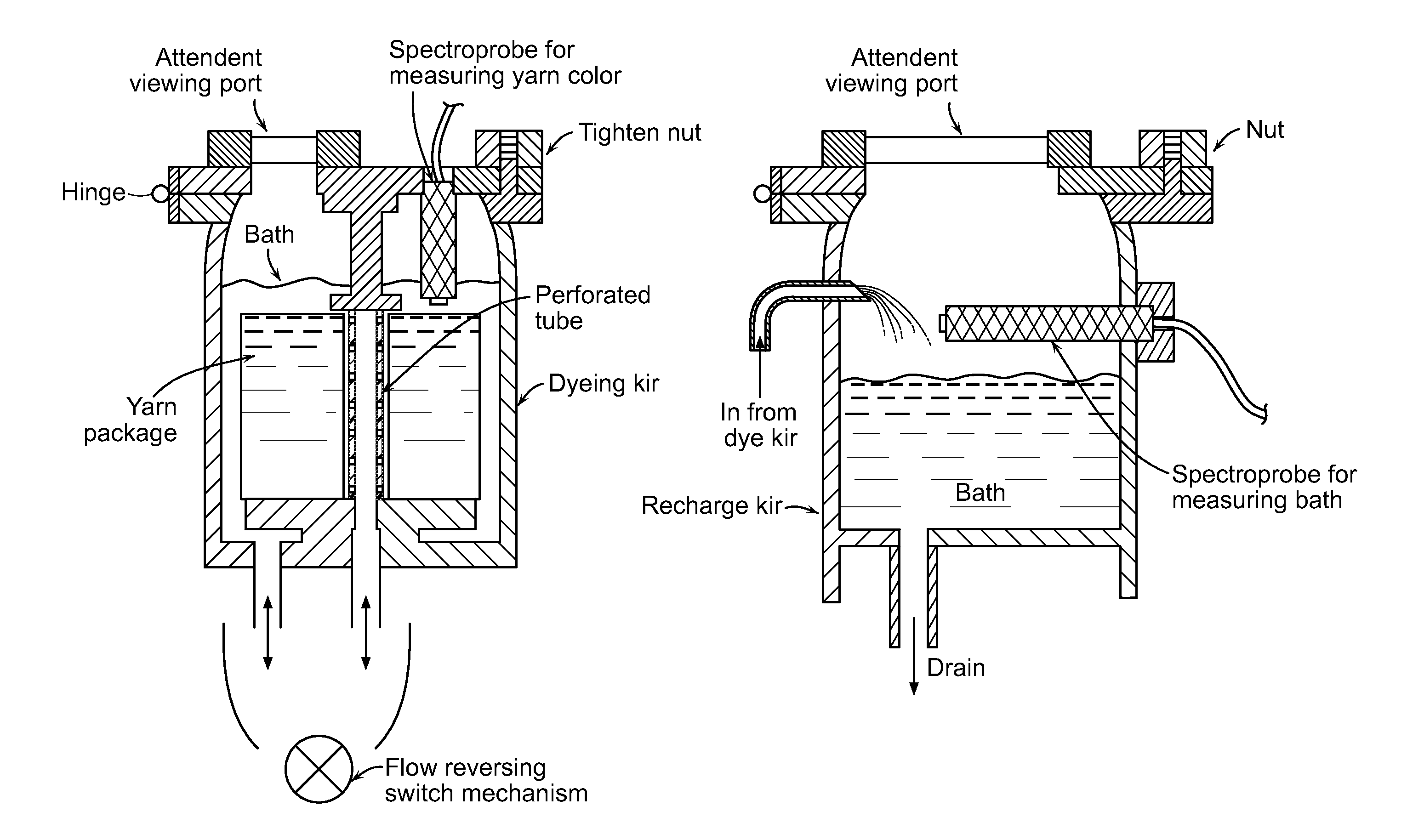

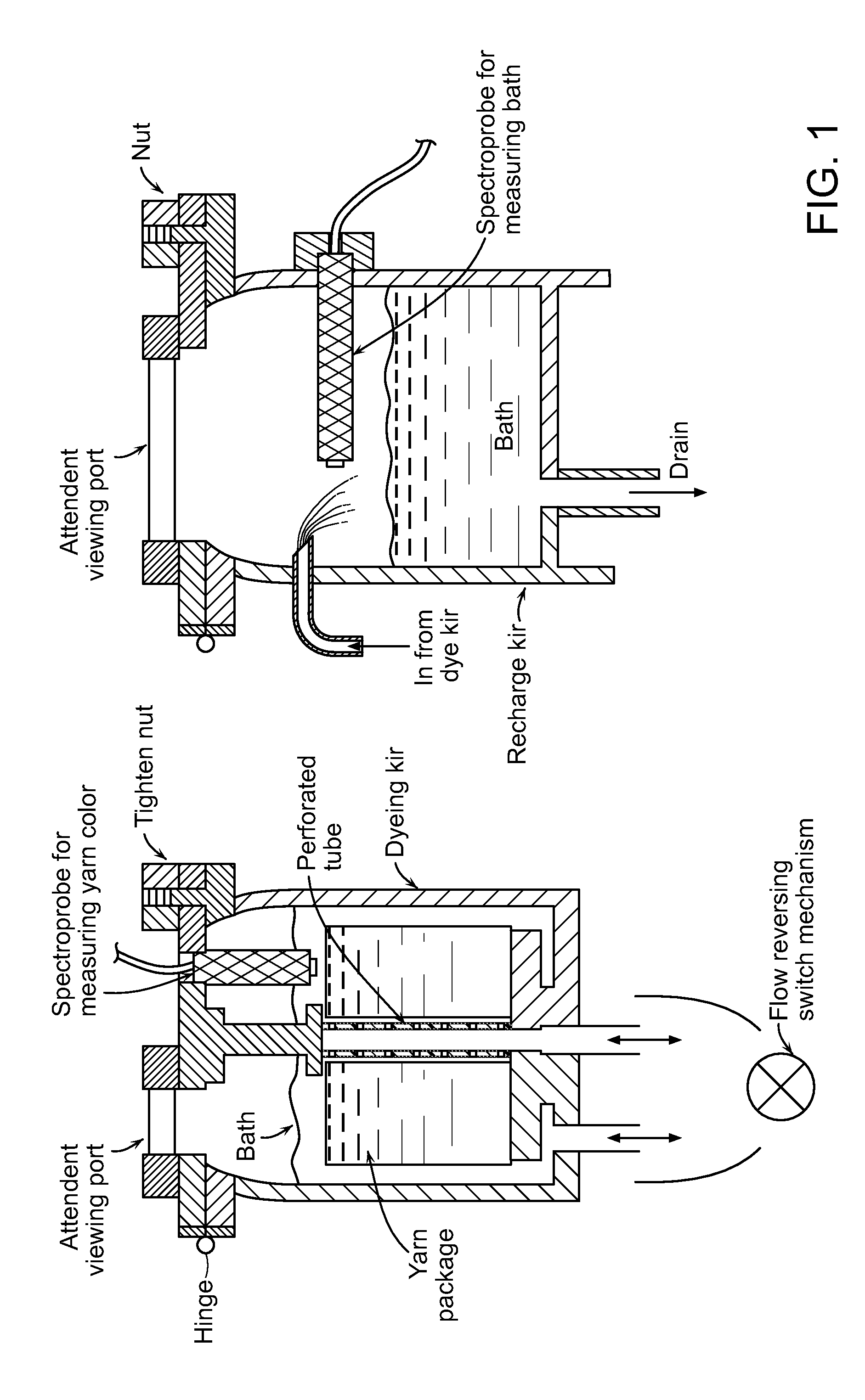

Method used

Image

Examples

example 1

Dyeing Chocolate (Brown) Color

[0034]This example provides one specific procedure used to mordant and dye wool yarn. One of ordinary skill in the art, when provided with the teachings of this specification, will be able to modify the procedure with regard to other dye colors and fibers (materials).[0035]Prepare dyeing vat by adding clean water at ˜190° F.[0036]Add mordant chemicals per formula based on % of WOG[0037]15% Aluminum Sulfate[0038]6% cream of tartar[0039]Add material to be dyed[0040]Contact material with mordant solution for ˜60 min while maintain temperature at ˜190° F.[0041]Drain mordant solution; keep material wet[0042]Add dye per formula based on % of WOG[0043]2.5% Logwood[0044]10% Cutch[0045]0.5% Madder[0046]1% calcium carbonate[0047]Maintain temperature of ˜190° F.[0048]Run dyeing process until spectrophotometer readings indicate target color and shade are obtained (approx. 30 minutes).[0049]drain dye solution[0050]Add 3% solution of iron salts (ferrous sulfate) at ˜...

example 2

Other Dye Colors

[0054]The general procedure outlined above in Example 1 can be used with minor modification with regard to other dye colors. One of ordinary skill in the art, provided with the teachings of this specification, will be able to adapt the procedure above without undue experimentation. Dye formulations for numerous other colors are provided below. All percents are approximate within ±20% and may be modified by one of skill in the art as desired. For example, different lots of dye or dye from different suppliers may require minor adjustments in the amounts of dye used. All formulas are based on percent of WOG (weight of goods) to be dyed unless otherwise noted. Mordant formulas are also noted below. Other dye formulations can be developed by one of ordinary skill in the art when provide with the teachings of this specification

Sage

[0055]Mordant[0056]15% Aluminum Sulfate[0057]6% Cream of Tartar[0058]Dye[0059]1.5% Hermatine HS or Logwood[0060]3.5% Fustic or Osage

French Madde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com