Dyeing method of cotton yarns

A dyeing method and yarn technology, which is applied in the field of textile printing and dyeing, can solve problems such as high difficulty, dyes cannot effectively penetrate yarn fibers, and unstable quality, and achieve the effects of improving diffusion performance, improving dyeing permeability, and increasing dyeing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 32

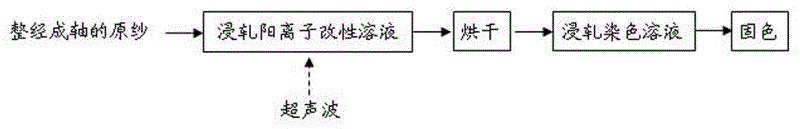

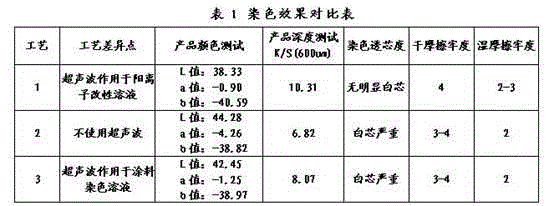

[0014] The production process of the present embodiment 32s / 2 pure cotton dyed yarn is as figure 1 As shown, the main process conditions are as follows:

[0015] 1. Padding cationic modification solution. The 32s / 2 pure cotton raw yarn that has been warped into a shaft is directly immersed in the cationic modification solution in the rolling tank without scouring process or pretreatment process with scouring effect, and is rolled by a rolling machine, in this way Two dipping and two rolling. The composition of cationic modification solution is: cationic modifier CL-200 20g / L purchased from Guangzhou Xiangzhong Textile Chemical Co., Ltd., non-ionic penetrant AG-310 3g / L purchased from Guangdong Lingjie Manufacturing Chemical Co., Ltd. , soda ash 8g / L.

[0016] The ultrasonic wave is turned on 3 minutes before the yarn enters the rolling groove, and lasts until it is turned off after dyeing. Ultrasonic frequency is 40kHz, power density is 0.5W / cm 2 . The temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com