Supercritical carbon dioxide fluid proofing device and dyeing method

A carbon dioxide, supercritical technology, used in solvent dyeing, textile material dyeing equipment, textile material processing equipment configuration, etc., to achieve the effect of increasing the dispersion effect, increasing the dispersing and dissolving state of dyes, and improving the quality of proofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

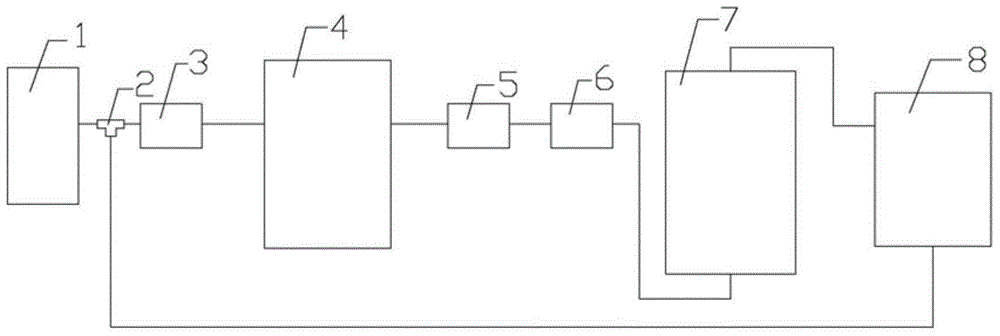

[0028] A supercritical carbon dioxide fluid sampling device, the device includes a carbon dioxide storage tank 1, a three-way valve 2, a condenser 3, a carbon dioxide circulation tank 4, a high-pressure pump 5, a carbon dioxide heat exchanger 6, a dyeing kettle 7, and a separation kettle 8, The carbon dioxide storage tank 1 is connected to the inlet I of the three-way valve 2, and the outlet of the three-way valve 2 passes through the condenser 3, the carbon dioxide circulation tank 4, the high-pressure pump 5, the carbon dioxide heat exchanger 6, the dyeing kettle 7, the separation Kettle 8 is connected to inlet II of three-way valve 2;

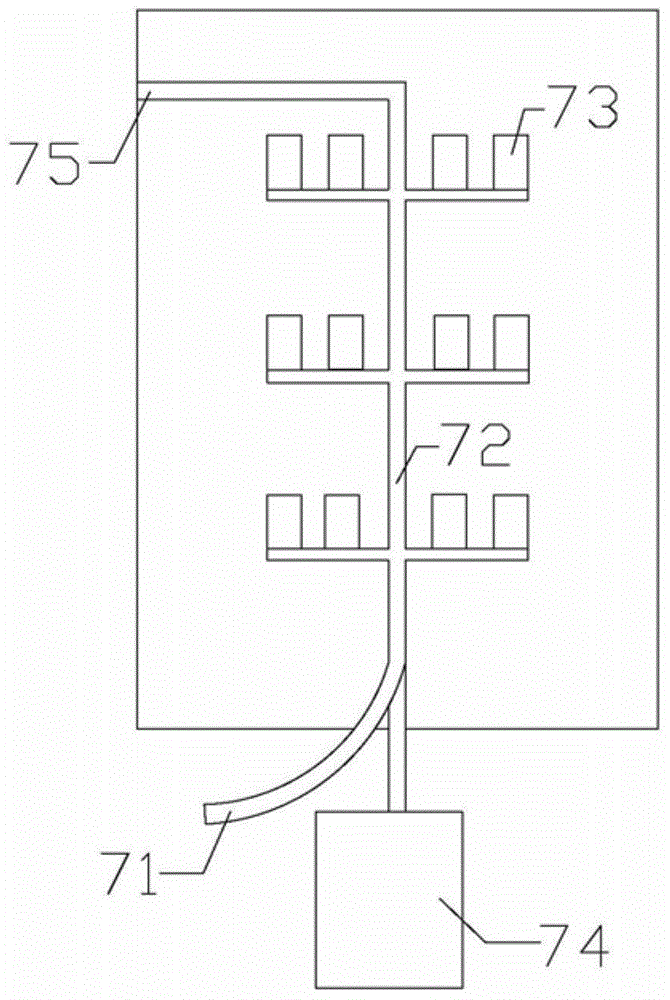

[0029] Described dyeing still 7 comprises sample unit supporting frame 72, 12 detachable sample units 73, motor 74 that different quality dyes are housed, and described sample unit supporting frame 72 is arranged in the cylinder body of dyeing still 7, and described motor 74 seals pass through the dyeing kettle 7 and are connected to the sam...

Embodiment 2

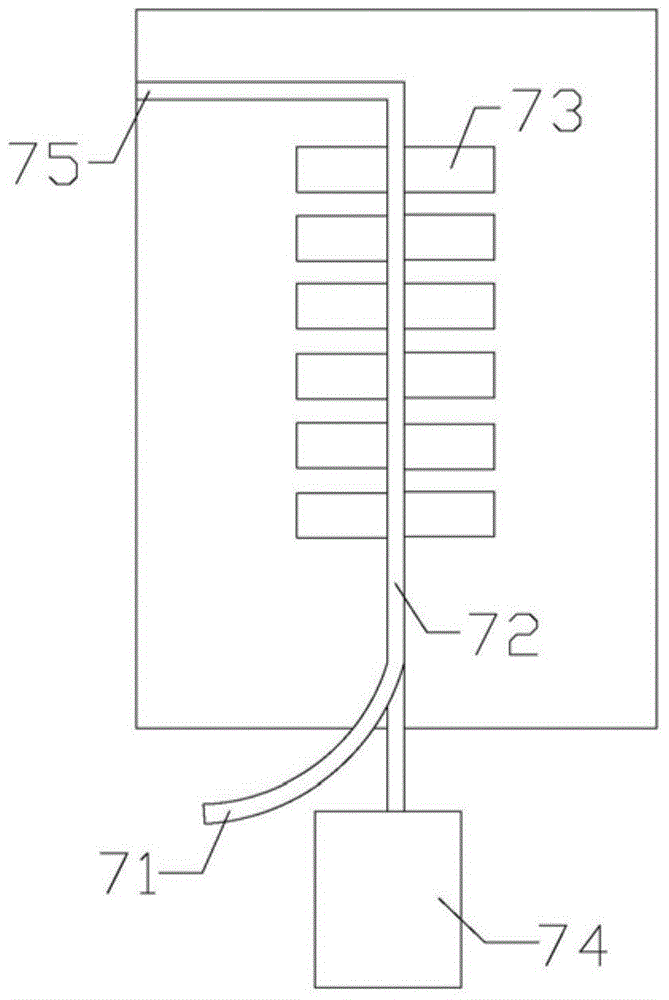

[0031] A supercritical carbon dioxide fluid sampling device, the difference from Embodiment 1 is that the 12 sample units 73 are horizontally arranged on the sample unit support frame 72 .

Embodiment 3

[0033] A dyeing method utilizing the device described in embodiment 1, said method comprising the following steps:

[0034] ① Switch the three-way valve I2 to the inlet I, and the carbon dioxide in the carbon dioxide storage tank 1 is cooled to liquid carbon dioxide by the condenser 3 and stored in the carbon dioxide circulation tank 4;

[0035] ②During dyeing: the carbon dioxide in the carbon dioxide circulation tank 4 is transported to the carbon dioxide heat exchanger 6 through the high-pressure pump 5, and the carbon dioxide is heated to a supercritical state. The carbon dioxide fluid flows into the channel of each sample unit 73, and then passes into the sample unit 73. From the inlet and outlet of the detachable sealing cover I731, the carbon dioxide fluid passes through the gas-solid separation membrane 732 and the porous partition plate I733 to reach the dye chamber 734. The critical carbon dioxide fluid reaches the sample chamber 736 through the porous partition plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com