Continuous dyeing sample plate

A prototype machine and frame technology, applied in the field of bleaching, dyeing, printing and finishing, can solve the problems of great variation in dyeing effect and disjointed dyeing process, and achieve the effects of low cost, simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

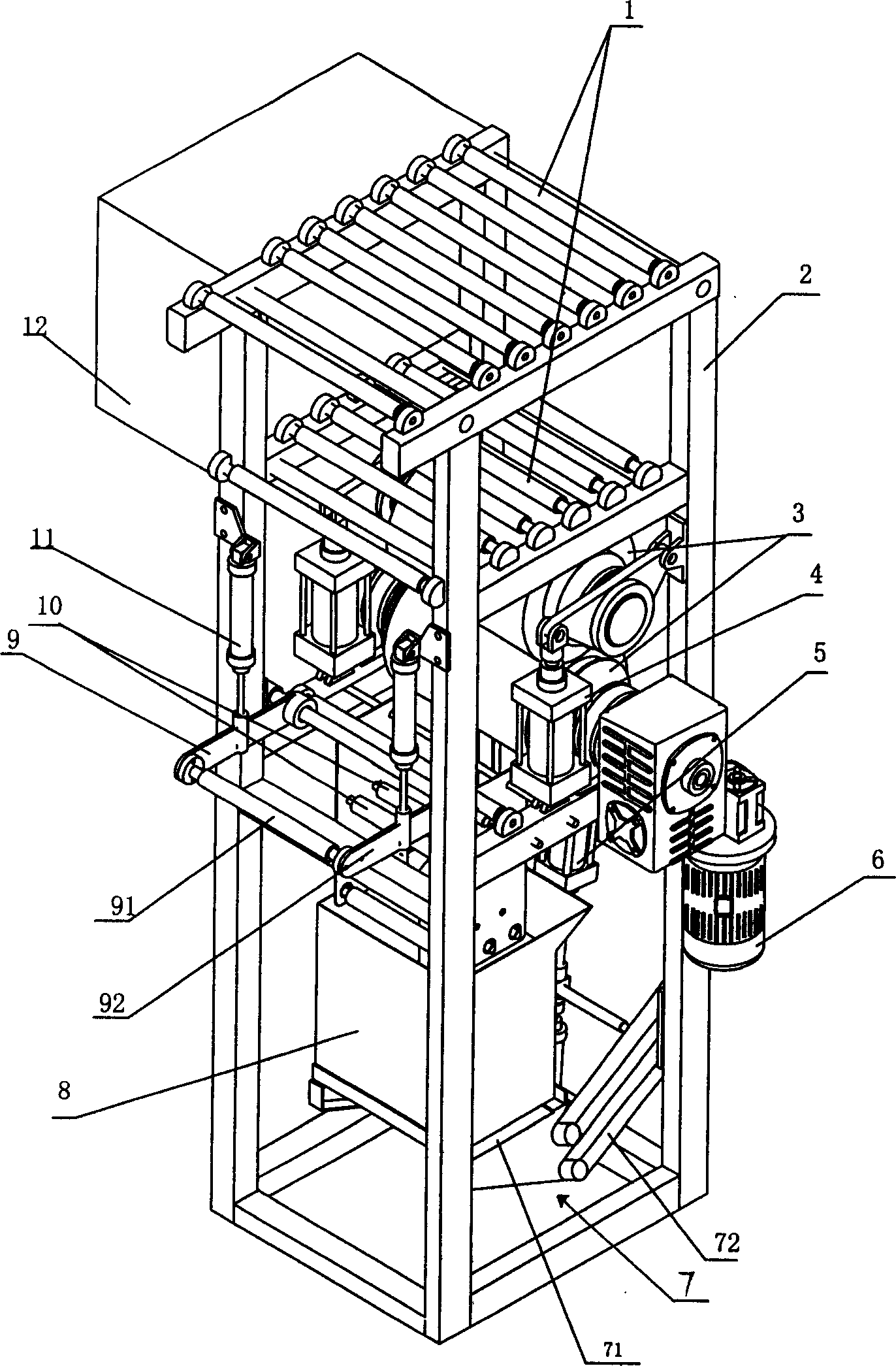

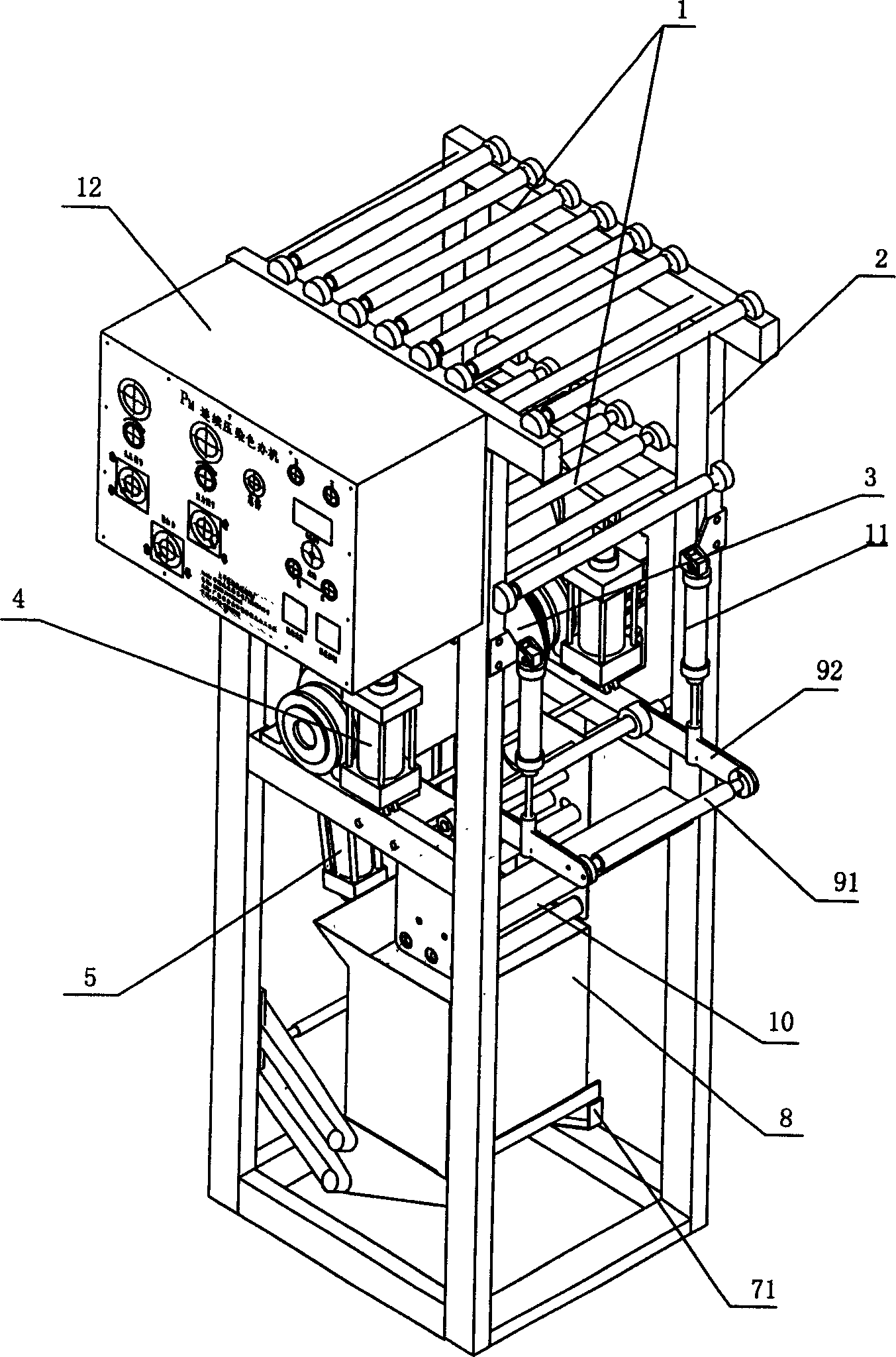

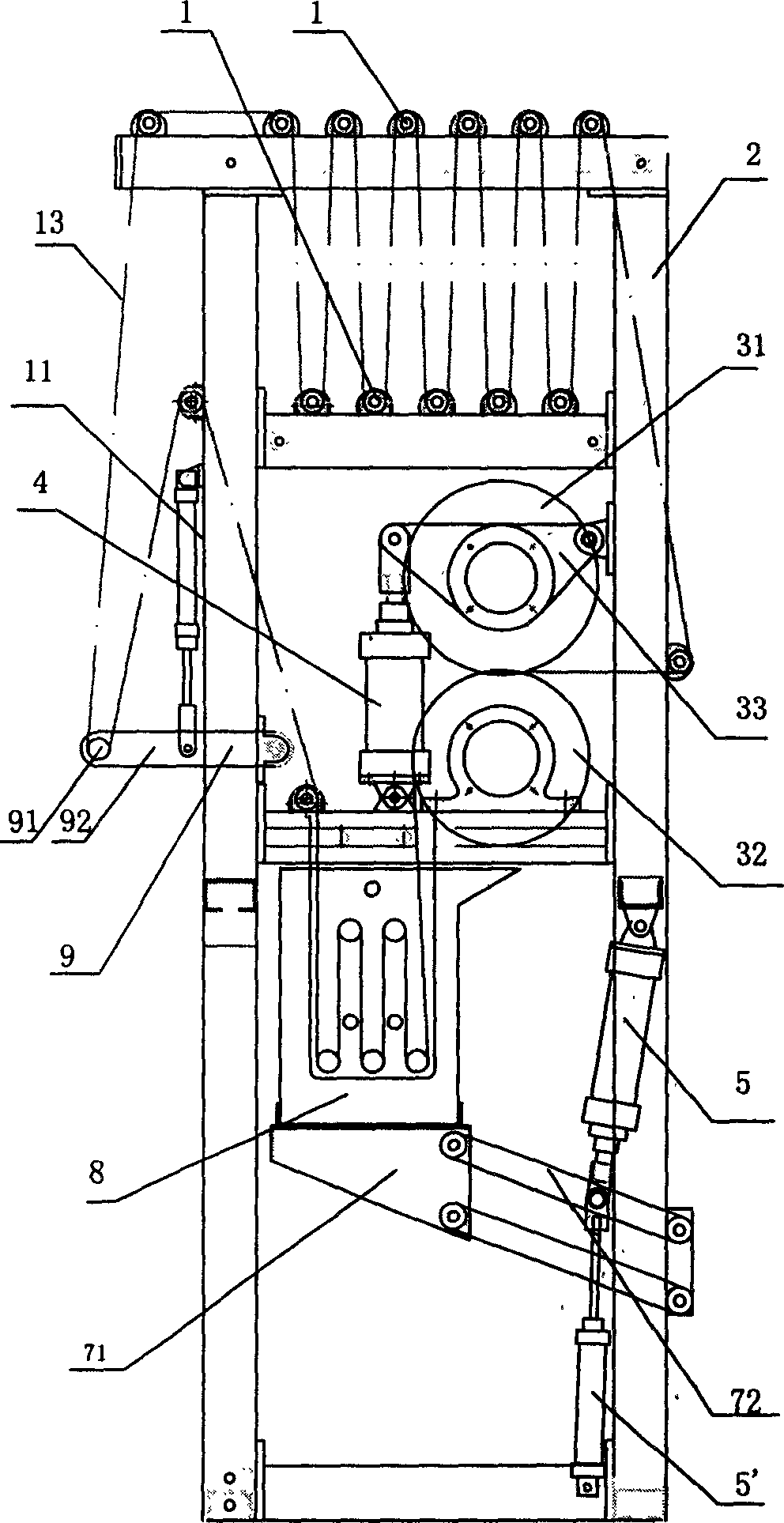

[0020] Depend on Figure 1-Figure 4 As shown, the continuous dyeing sample machine of the present invention includes a frame 2, a pressing roller 3 arranged on the frame 2, a stroke roller group 1, a dyeing vat 9, a dyeing roller group 10, a control device 12, and an oxidation stroke roller group 1 arranged side by side. Set on the upper part of the frame 2, the oxidation stroke drum group is made of stainless steel. There are 15 rollers in this embodiment, all of which are installed on the frame with small bearing seats. The same; the frame 2 is a metal frame, which is used to install all the above-mentioned components; the rolling roller 3 is arranged in the middle section of the frame 2; The bearing seat is fixed on the frame, which is the active roller of this machine; the rubber roller 31 covered with rubber is installed in a pair of lever-type pressing arms 33 with bearing seats, and the fulcrum of the pressing arm 33 is fixed on the frame 2 The other end is pushed up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com