Print cloth sample making process and color fixer

A production method and fabric swatch technology, applied in transfer printing method, processing textile material dyeing device, printing and other directions, can solve the problem of steam fixing without fixing device, etc., to achieve convenient and fast plate making, flexible and convenient use, and save money. and time-wasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Making documents: Take a picture with a digital camera, transfer it to a microcomputer and save it as a PHOTOSHOP image file, and modify, process, render, etc. edit the image as needed, and quickly get several basically determined documents;

[0023] Cloth pretreatment and printing: Mix sodium alginate, urea, sodium bicarbonate and water to form a high-viscosity water slurry, apply the water slurry to the cloth by any known method such as silk screen printing, dipping, and roller coating, and then Dried and cut into the maximum width that the printing device can handle, it can be printed on the machine.

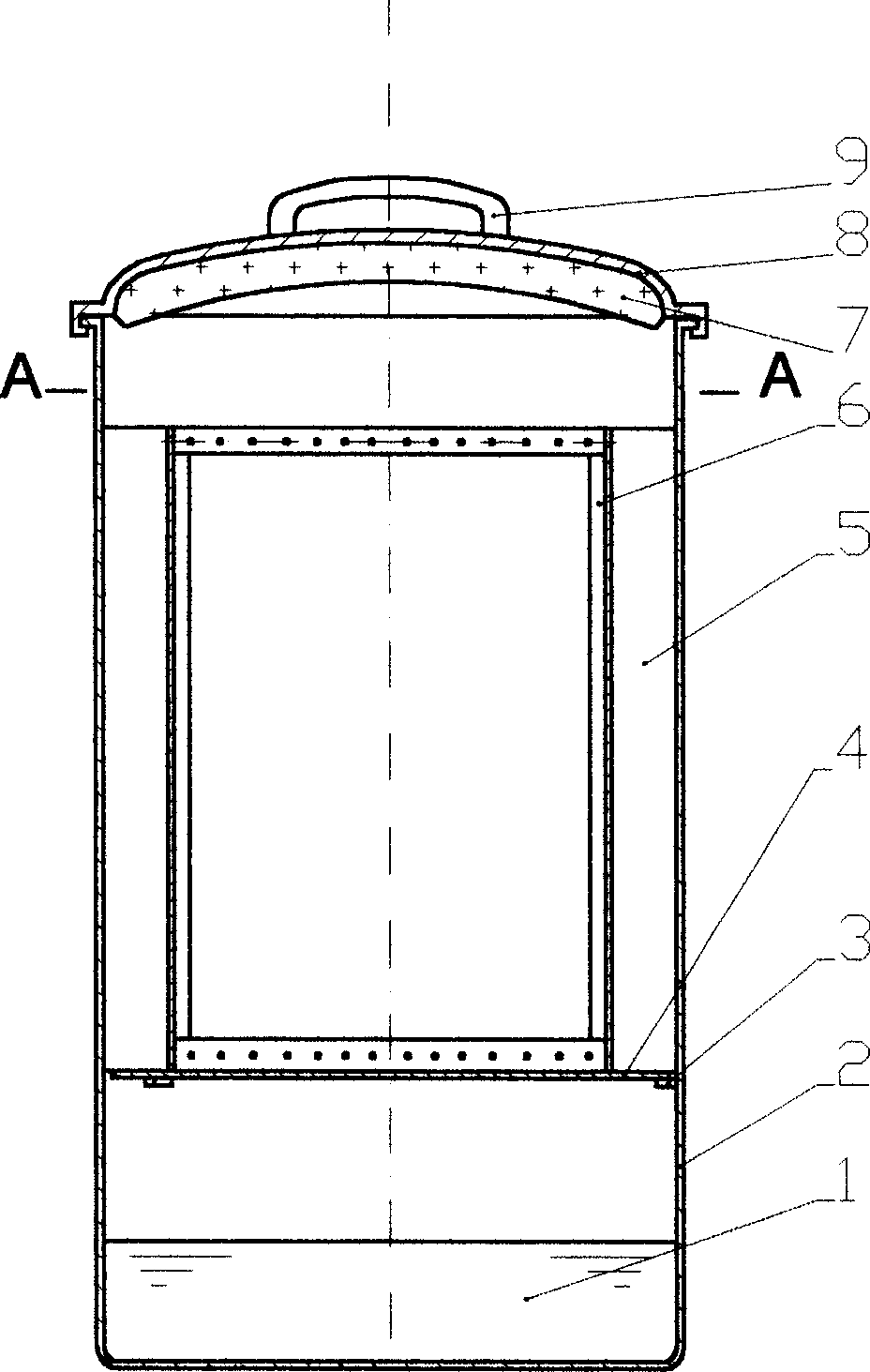

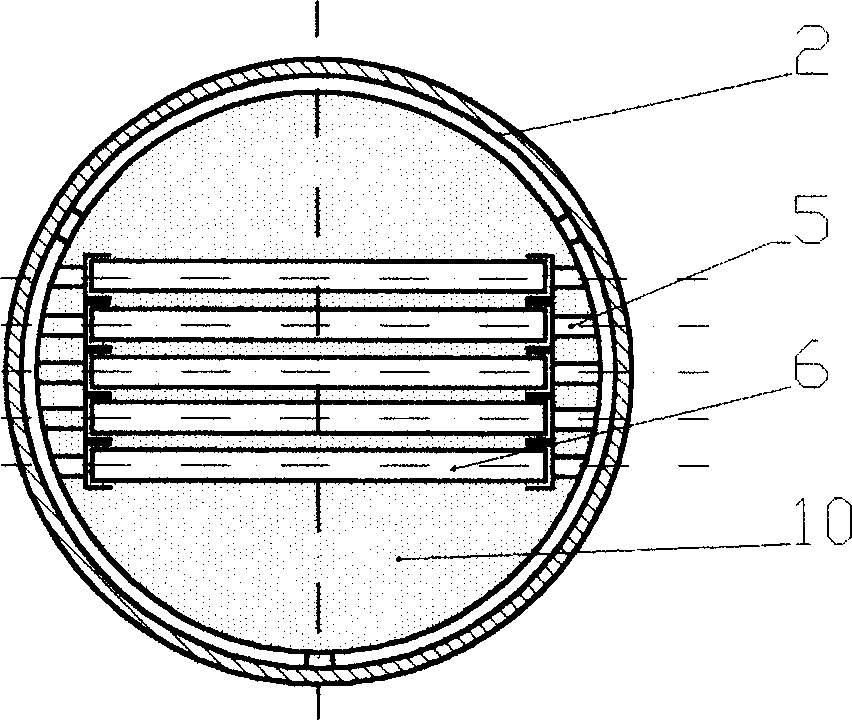

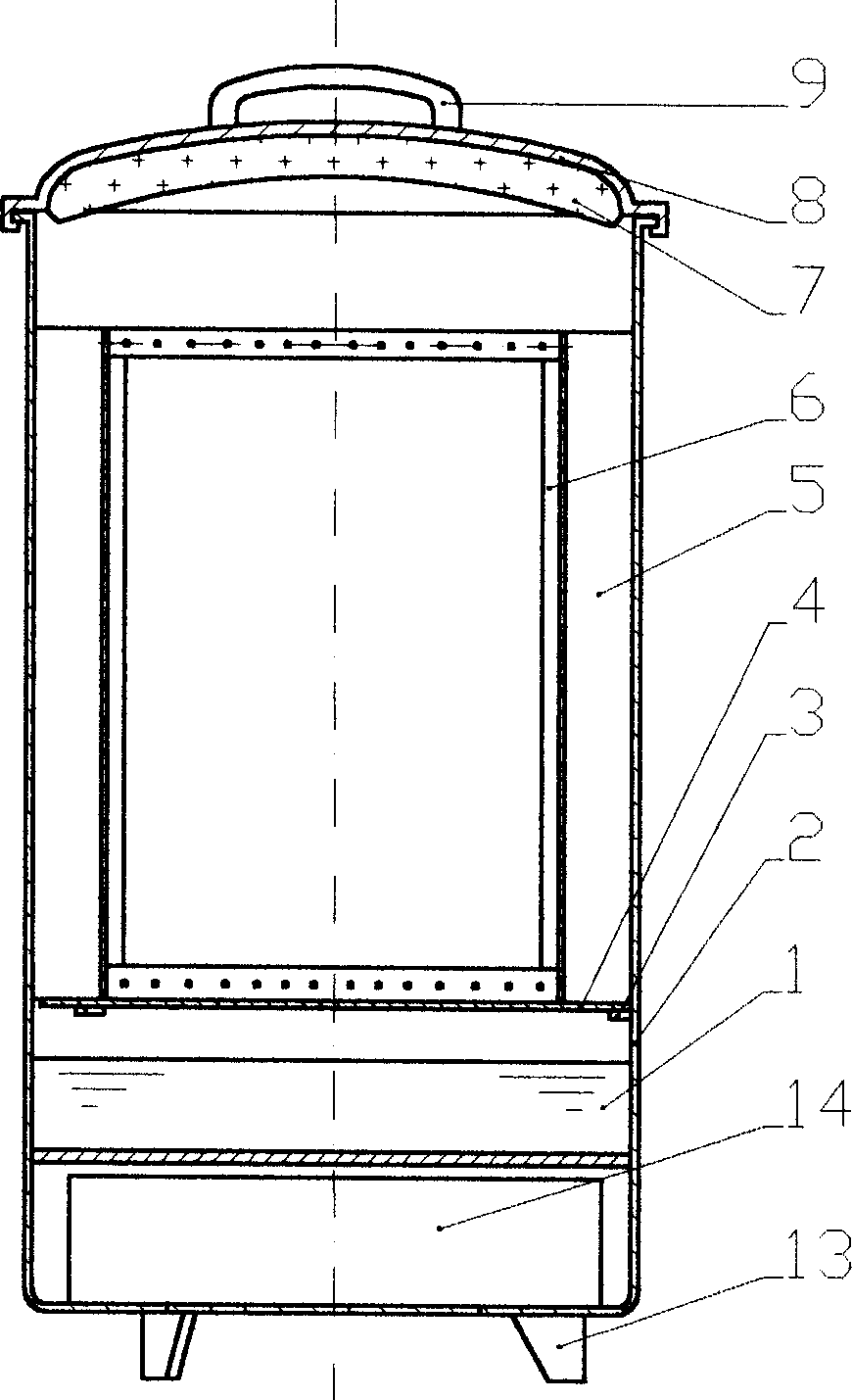

[0024] Color-fixing treatment: fix the printed cloth samples on the frame of the color-fixing device provided by the invention, a batch can be three to five sheets, and carry out color-fixing treatment in the color-fixing device for about half an hour.

[0025] Washing and drying: After the cloth sample comes out of the steam room, wash it with clean water and dry it. ...

Embodiment 2

[0032] Making documents: directly adopt a very satisfactory picture document, and save it as a picture file after slightly cutting the format size in the picture software;

[0033] Cloth pretreatment and printing: Mix sodium alginate, urea, sodium bicarbonate and water to form a high-viscosity water slurry, apply the water slurry to the cloth by any known method such as silk screen printing, dipping, and roller coating, and then Dried and cut to the maximum width that the printing device can handle, the image is printed with a printer onto transfer paper, which is then transferred to fabric using known thermal transfer methods.

[0034] Color-fixing treatment: Fix the printed cloth samples on the frame of the color-fixing device as described below. A batch of three to five pieces can be fixed in the color-fixing device for about half an hour.

[0035] Washing and drying: After the cloth sample comes out of the steam room, wash it with clean water and dry it.

[0036] The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com