Circular translational sample-dyeing machine

A translation type, dyeing machine technology, applied in the field of dyeing machines, can solve the problems of affecting the quality of dyeing samples, difficult temperature control, troublesome operation, etc., and achieve the effects of high temperature control accuracy, low operation noise, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

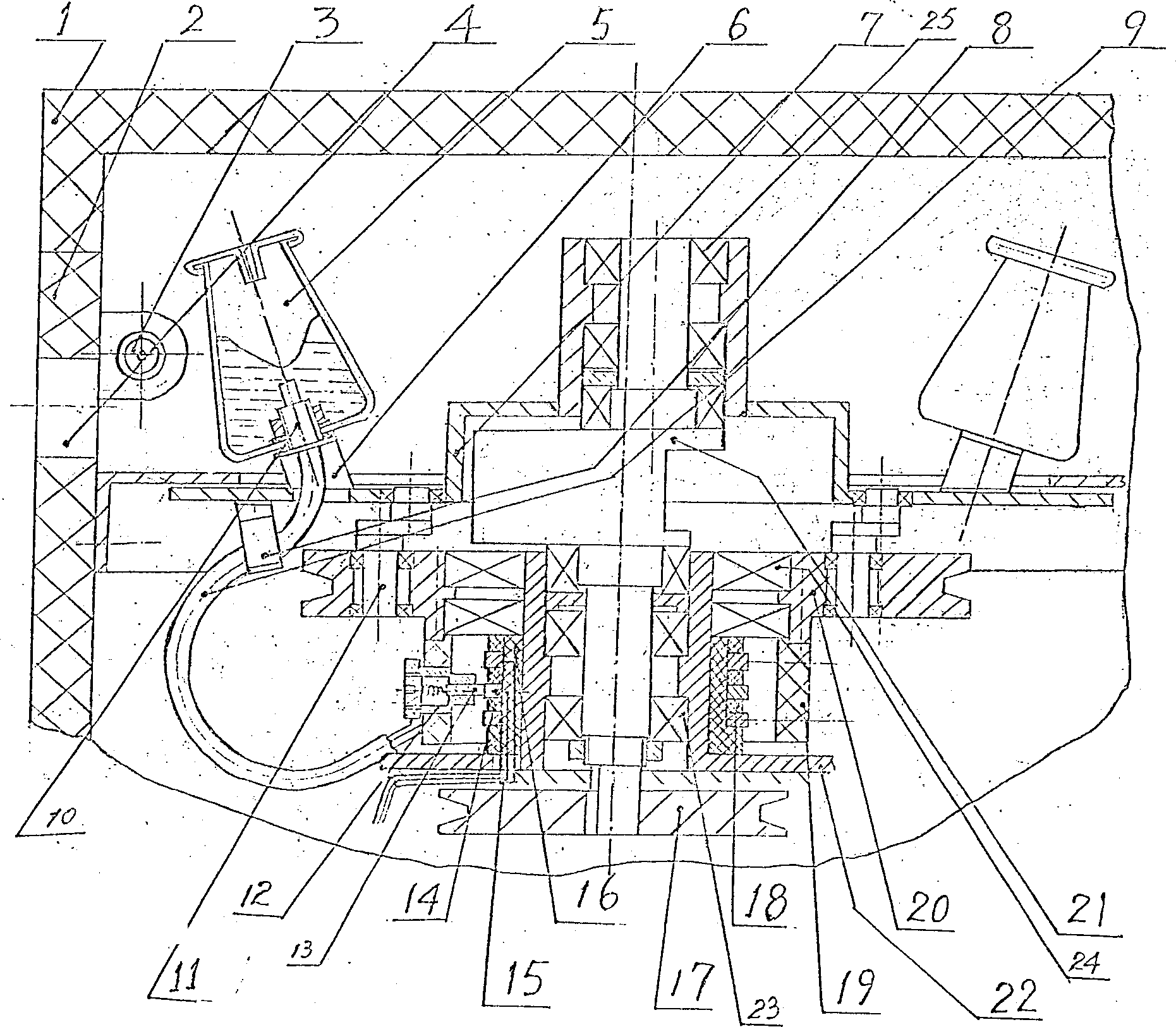

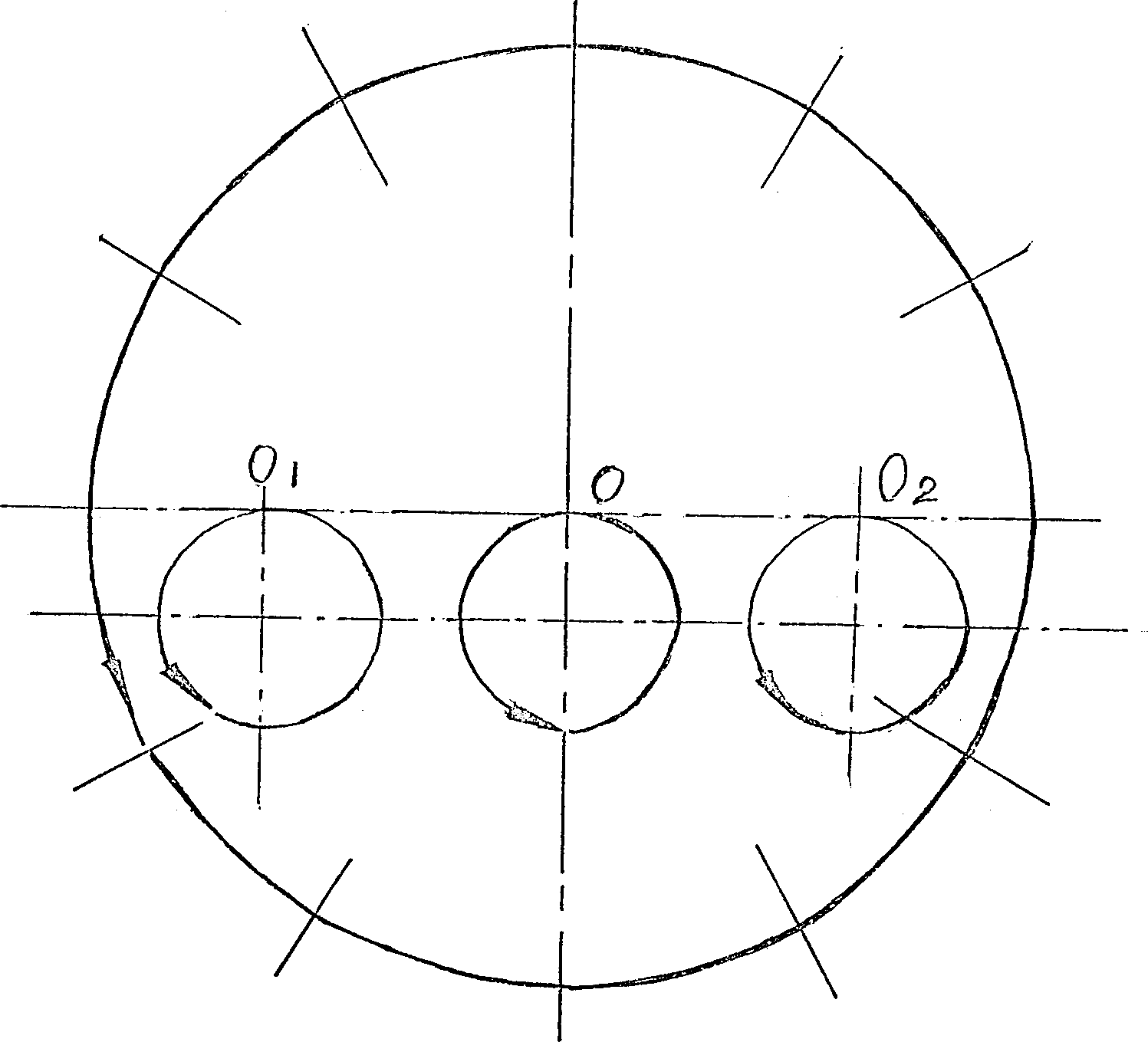

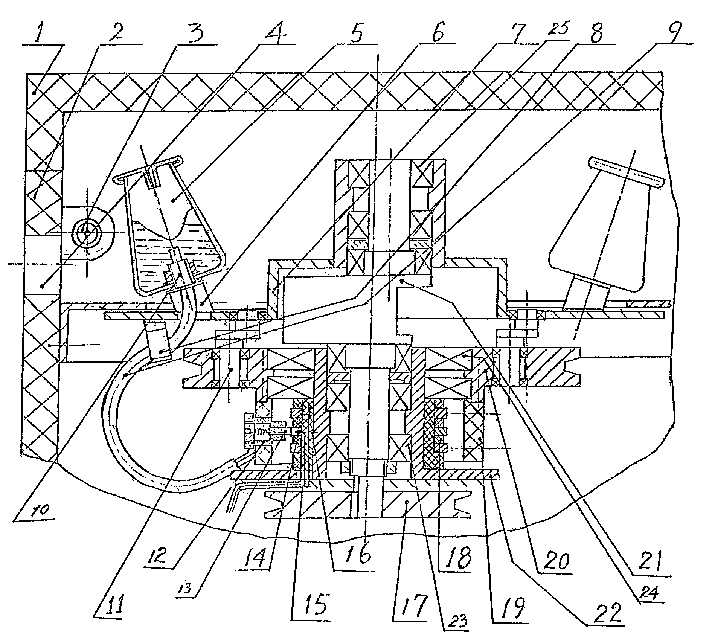

[0012] Such as figure 1 , figure 2 As shown, the body of the present invention includes a machine cover 1, a lower body 2, a dyeing cup 5, an infrared heater 3, a temperature sensor 10 and a mechanical transmission mechanism; device 3, the infrared heater is at least one, and there can be multiple; the lower body 2 also has a dyeing cup forced cooling air duct hole 4 to connect with the air duct; the mechanical transmission mechanism is fixed in the body, with The main crankshaft 21 with the same radius of curvature of gyration, the driven crankshaft 11 and its transmission components are composed, wherein the main crankshaft 21 is fixed in the lower body 2 through the support bearing 23 mounted thereon and the fixed frame 22 installed thereon; Crankshaft 21 stretches out the first transmission part 17 is equipped with at one end outside fixed frame 22, and this transmission part can be belt pulley, gear, sprocket etc., and the second transmission part 20 is housed near the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com