Patents

Literature

129results about How to "Speed up the debugging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Financial trading system

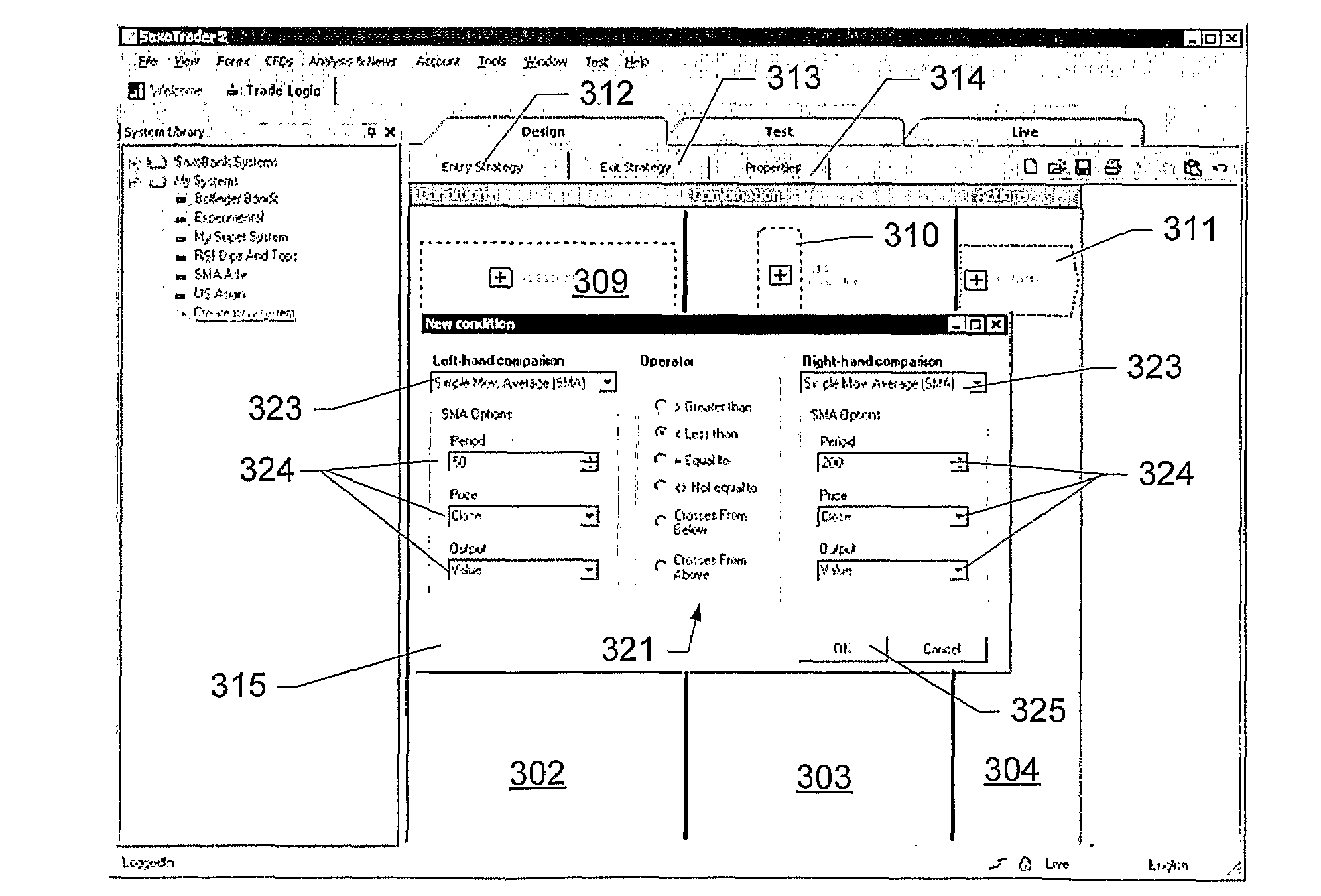

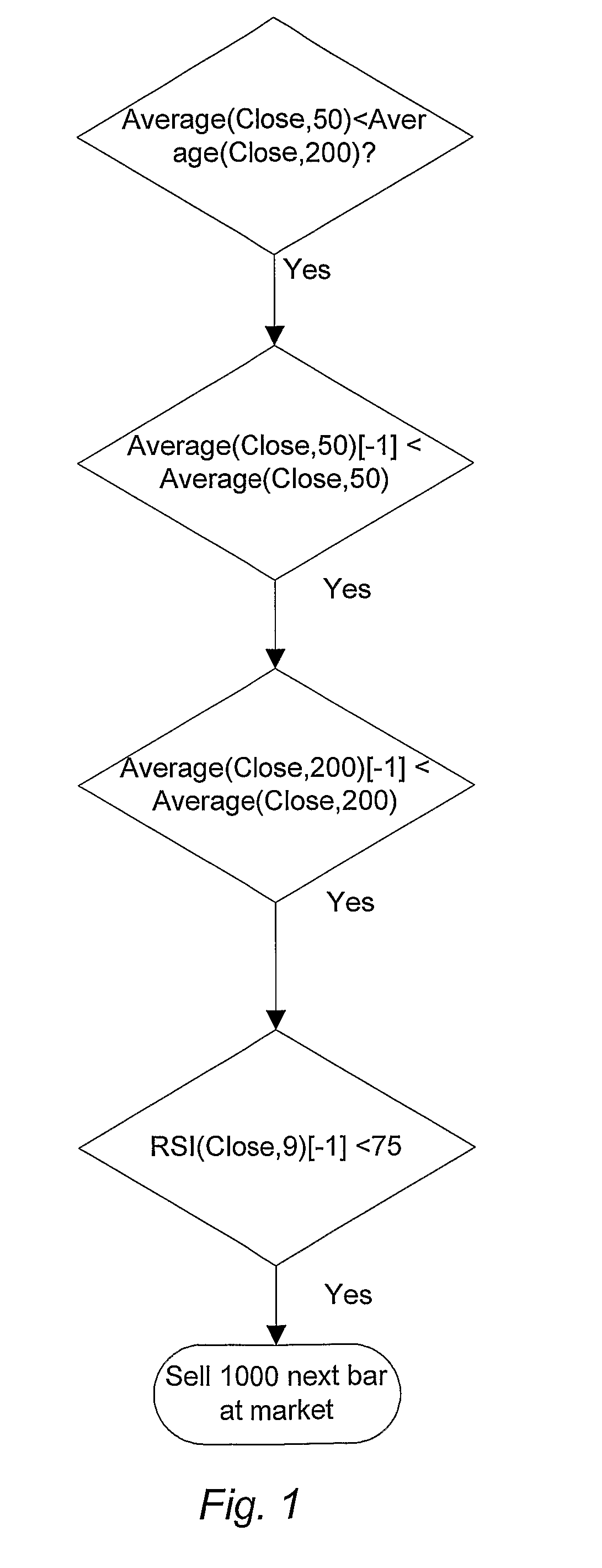

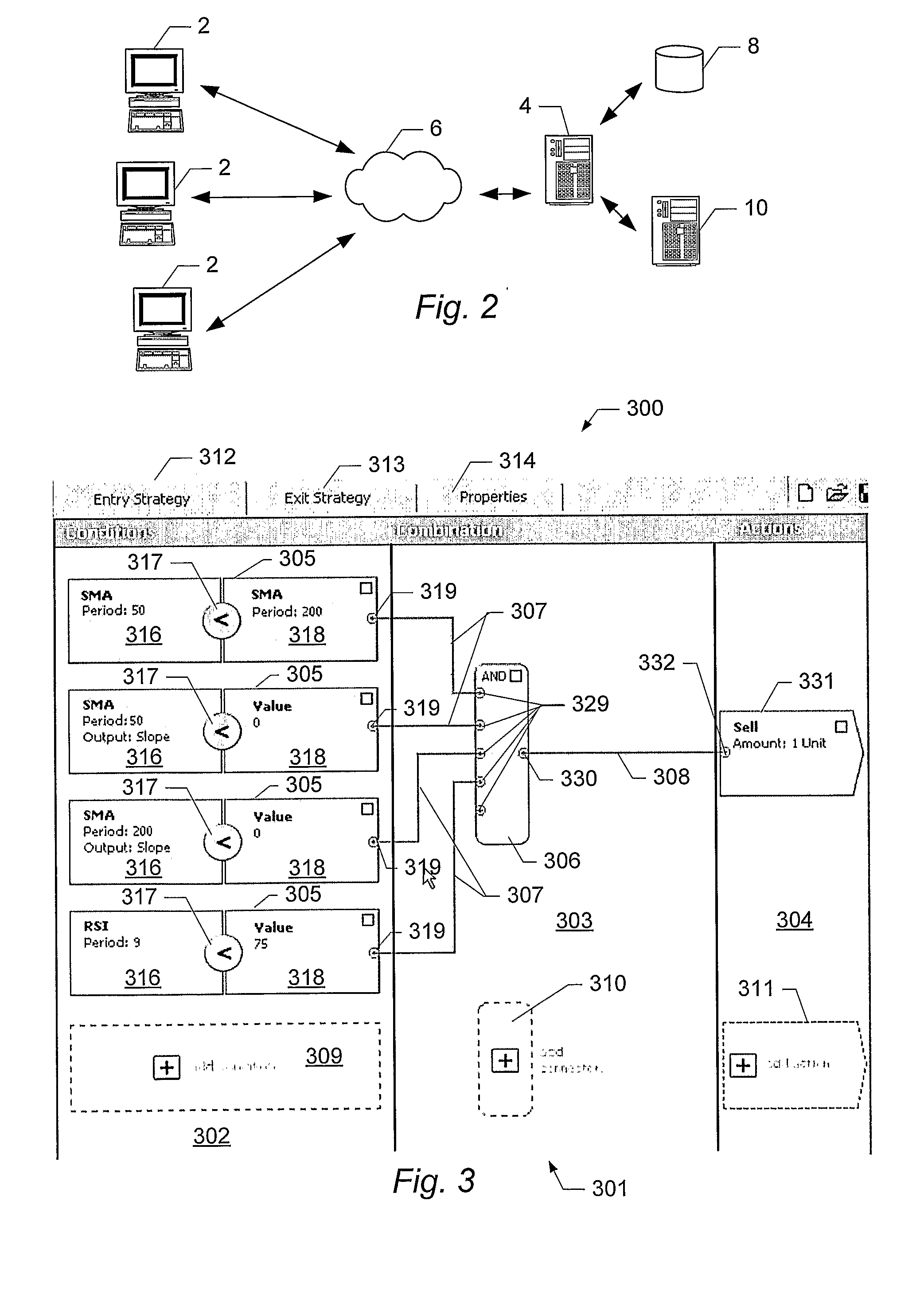

InactiveUS20100057600A1Improve organizationEasy to useFinanceVisual/graphical programmingGraphicsGraphical user interface

Disclosed is a computer-implemented system for facilitating generation of a computer-executable financial trading strategy, the system being adapted to provide a graphical user interface for defining a financial trading strategy by arranging interconnectable building blocks into a diagram on a drawing pane provided by the graphical user interface, each building block representing a functional system component of the financial trading strategy; wherein the system includes a plurality of types of functional system components, wherein the drawing pane includes a corresponding plurality of sub-panes, and wherein the system is configured to provide functionality for a user-controlled placement of building blocks into the sub-panes corresponding to the respective types of building blocks.

Owner:SAXO BANK

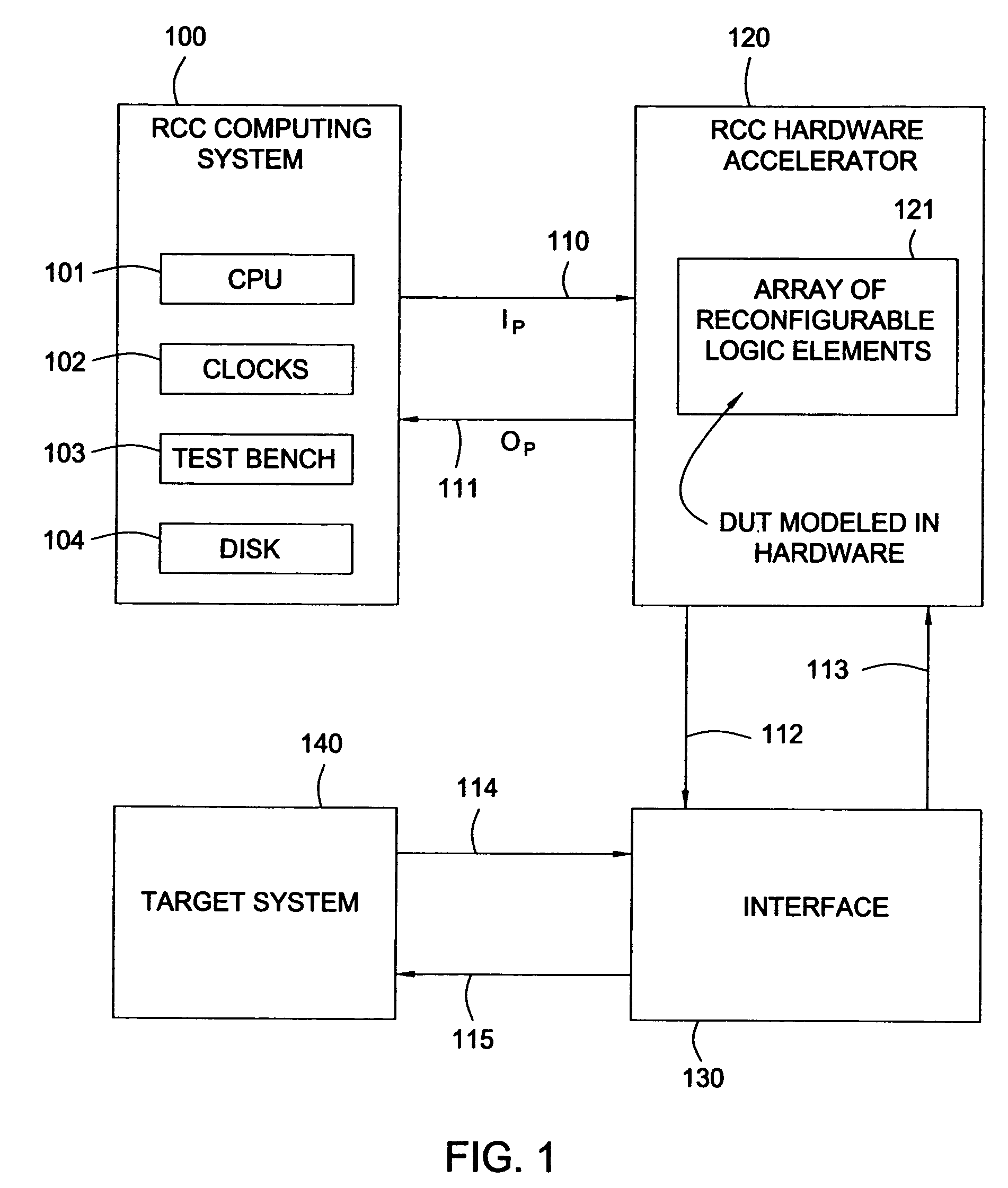

VCD-on-demand system and method

InactiveUS7480606B2Speed up the debugging processReturn quicklyAnalogue computers for electric apparatusAnalogue computers for nuclear physicsTest benchParallel simulation

In the VCD-On-Demand system, the EDA tool has the following attributes: (1) RCC-based parallel simulation history compression and recording, (2) RCC-based parallel simulation history decompression and VCD file generation, and (3) On-demand software regeneration for a selected simulation target range without simulation rerun. When the user selects a simulation session range, the RCC System records a highly compressed version of the primary inputs from the test bench process. The user then selects a narrower region, the simulation target range, within the simulation session range for a more focused analysis. The RCC System dumps the hardware state information of the hardware model into a VCD file. The RCC System then allows the user to proceed directly to view the VCD file from the beginning of the simulation target range without having to rerun the entire simulation from the beginning of the simulation session range.

Owner:CADENCE DESIGN SYST INC

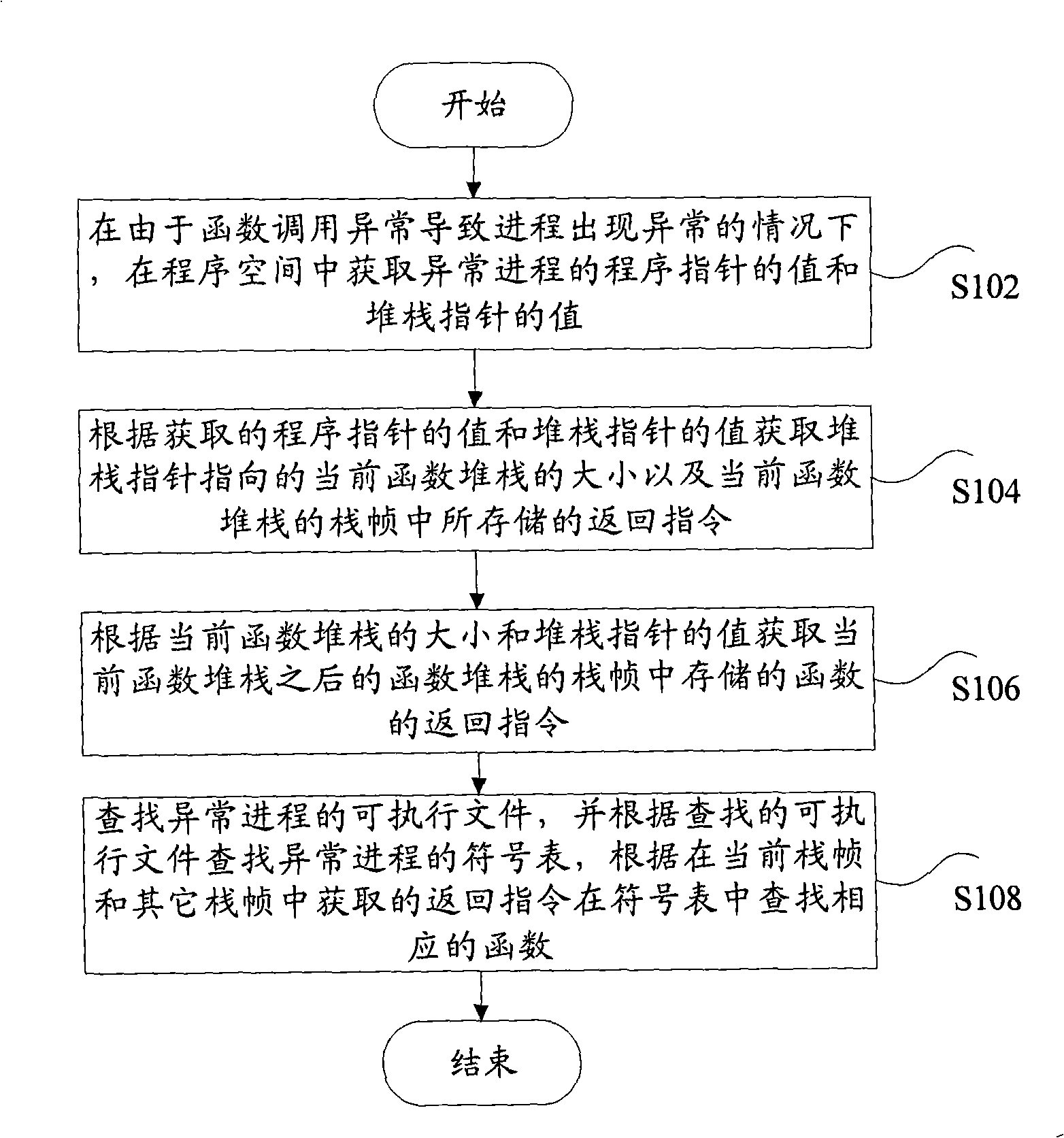

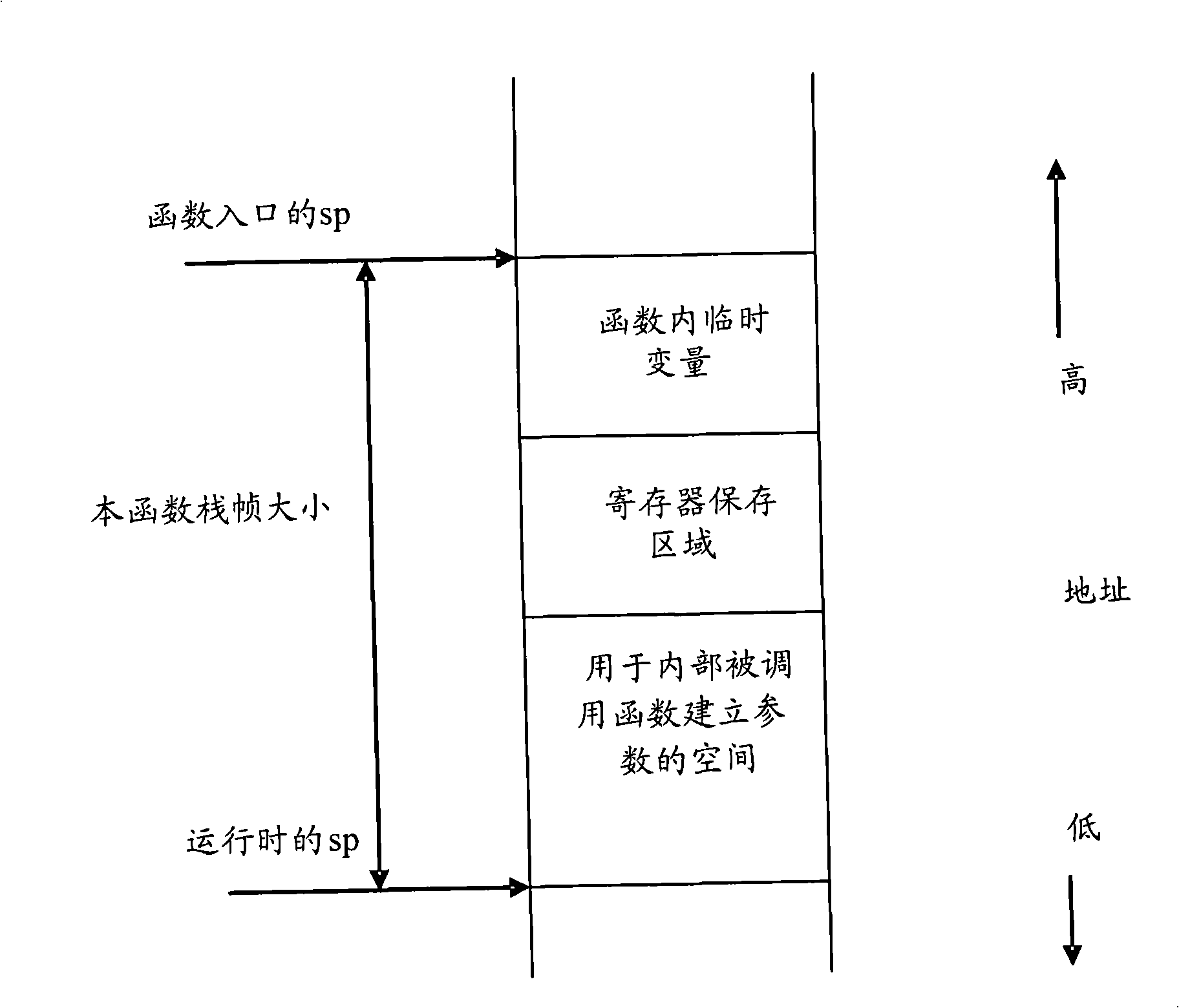

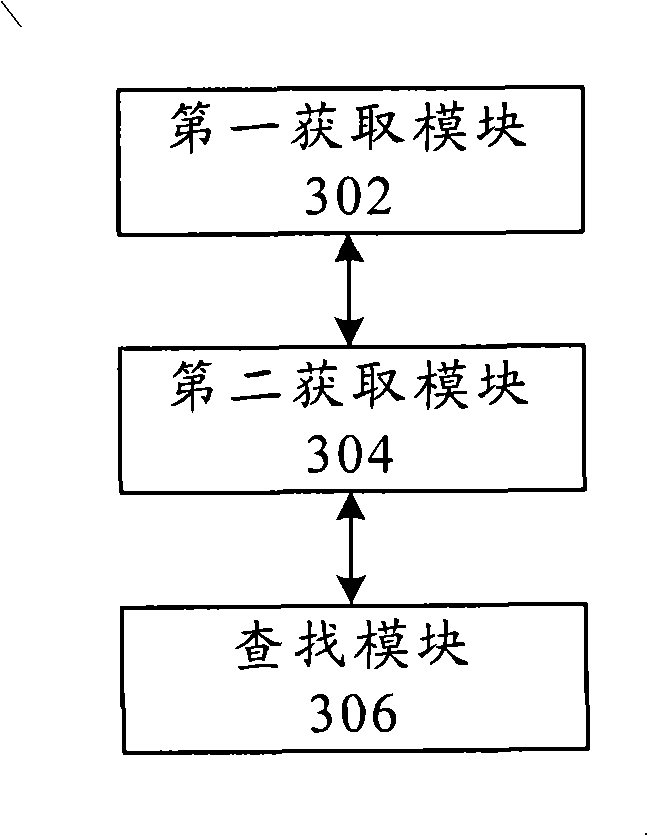

Fault locating method and device

ActiveCN101261603AEasy to operateOperation results are intuitiveSoftware testing/debuggingComputer scienceEmbedded system

The invention discloses a fault positioning method, and the method comprises that: when in abnormality of the process due to the abnormality of the functional call, the value of a procedure pointer and the value of a stack pointer during the abnormal process are obtained in a procedure space; the size of the current function stack which is pointed by the stack pointer and a return command which is stored in a stack frame of the current function stack are obtained according to the value of the procedure pointer and the value of the stack pointer; the return command of a function which is stored in the stack frame of a function stack after the current function stack is obtained according to the size of the current function stack and the value of the stack pointer; an executable file of the abnormal process is searched, a symbol table of the abnormal process is searched according to the searched executable file, and the corresponding function is searched in the symbol table according to the return commands which are obtained in the current stack frame and other stack frames. In addition, the invention further discloses a fault positioning device.

Owner:ZTE CORP

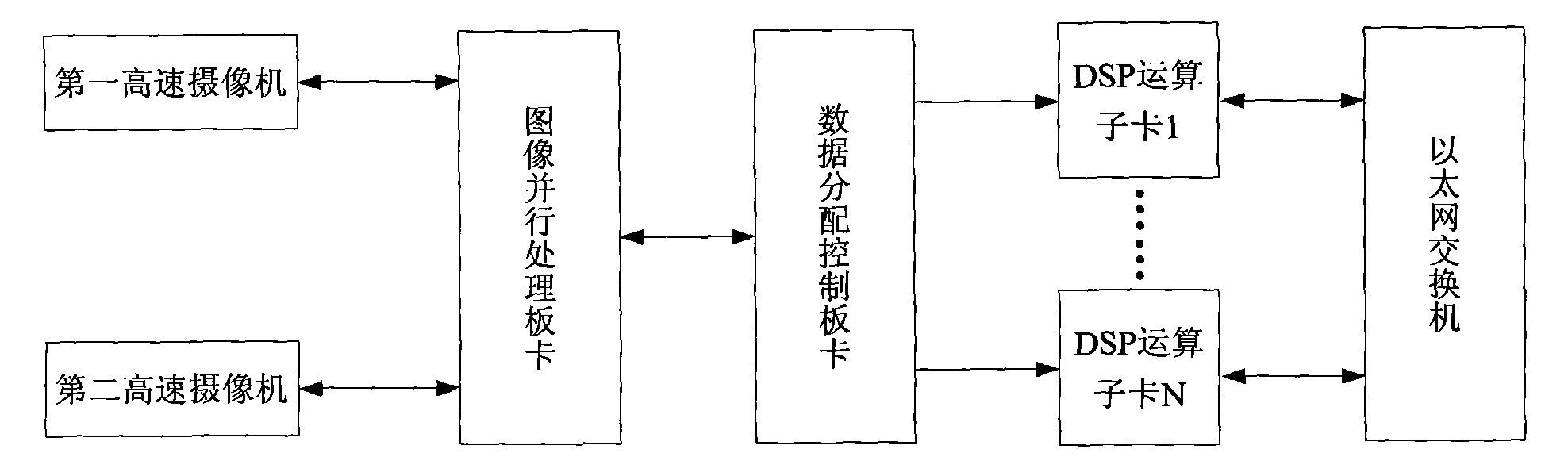

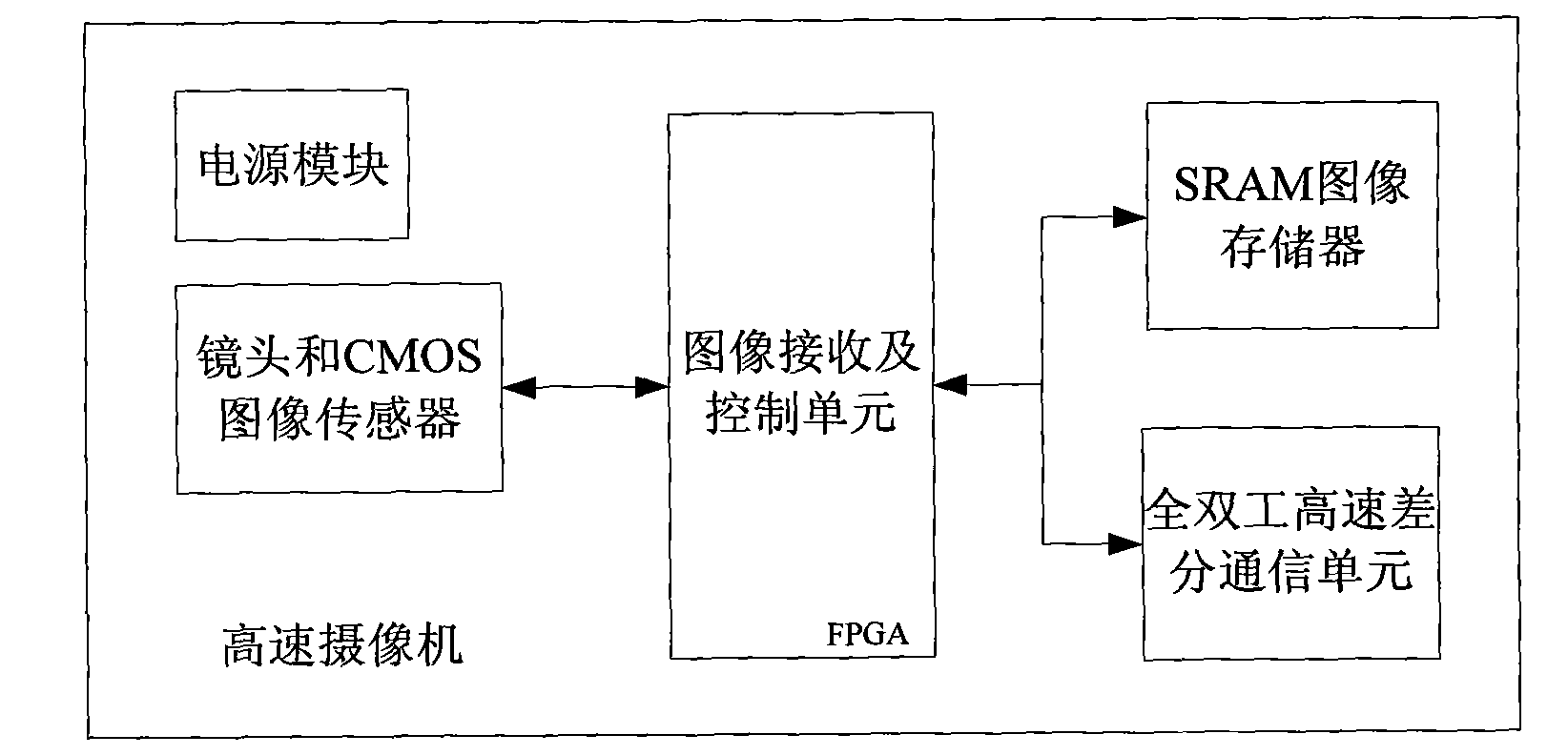

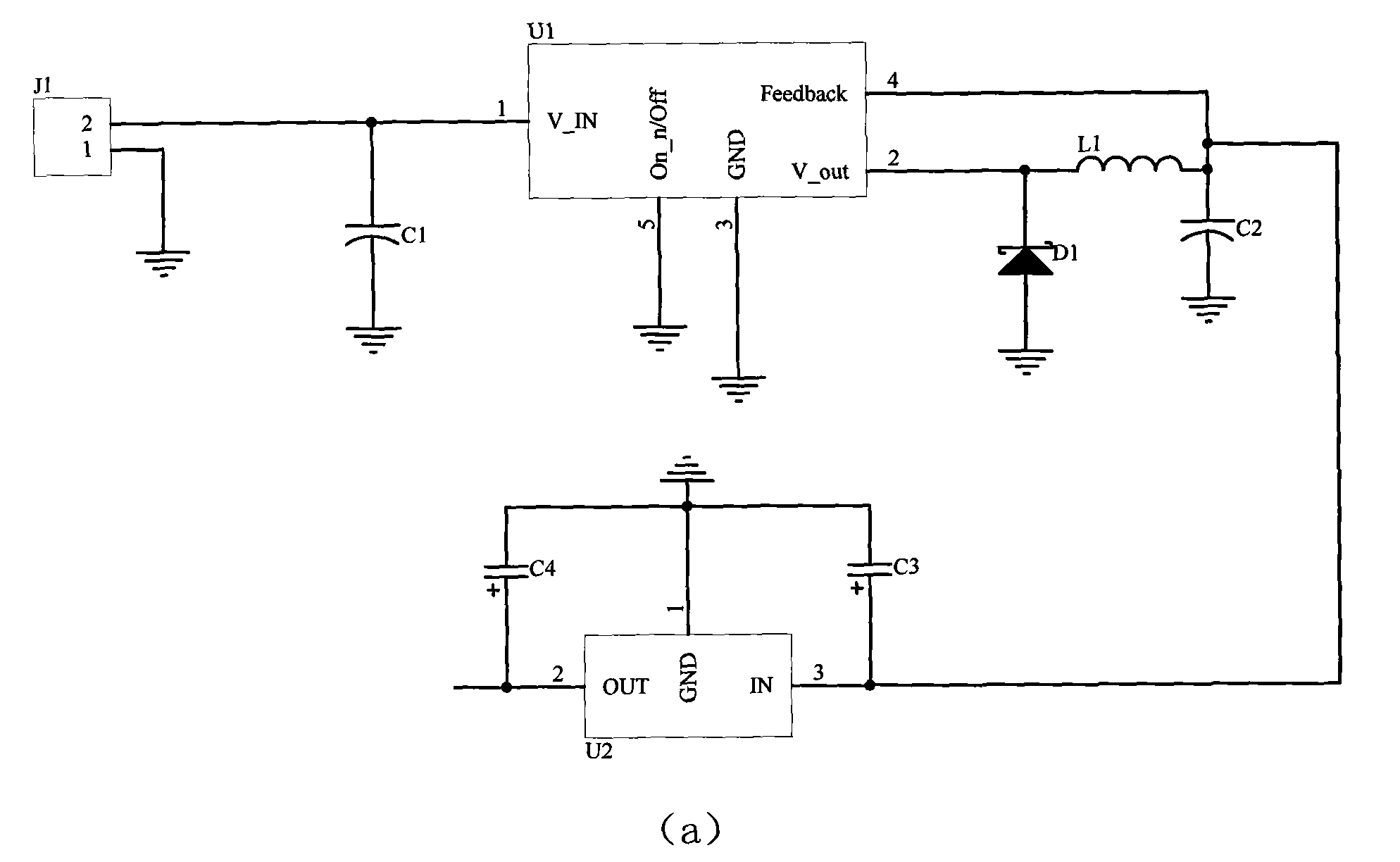

Geometric correction and disparity extraction device of binocular camera

InactiveCN101916429AGive full play to one's own advantagesFast operationTelevision system detailsColor television detailsDigital signal processingDistribution control

The invention discloses a geometric correction and disparity extraction device of a binocular camera, which comprises two high-speed cameras, an image parallel processing board, a data distribution control board, a plurality of DSP (Digital Signal Processing) operation daughter cards and an Ethernet switch. Images acquired by the high-speed cameras are transmitted to the image parallel processing board for real-time geometric correction, the results are distributed to the data distribution control board and one group of DSP operation daughter cards for real-time processing, and the processing results are summarized by the Ethernet switch and transmitted to receiving equipment. Different disparity extraction methods and the advanced application of binocular stereoscopic vision are realized by updating software on the DSP operation daughter cards. The invention has the advantages of high processing speed, strong real-time performance, small size, low power consumption, strong extendibility and strong flexibility; the cameras have adjustable base distance and convenient onsite debugging; and the processing process of the DSP operation daughter cards can be changed through the Ethernet or a USB flash drive.

Owner:ZHEJIANG UNIV

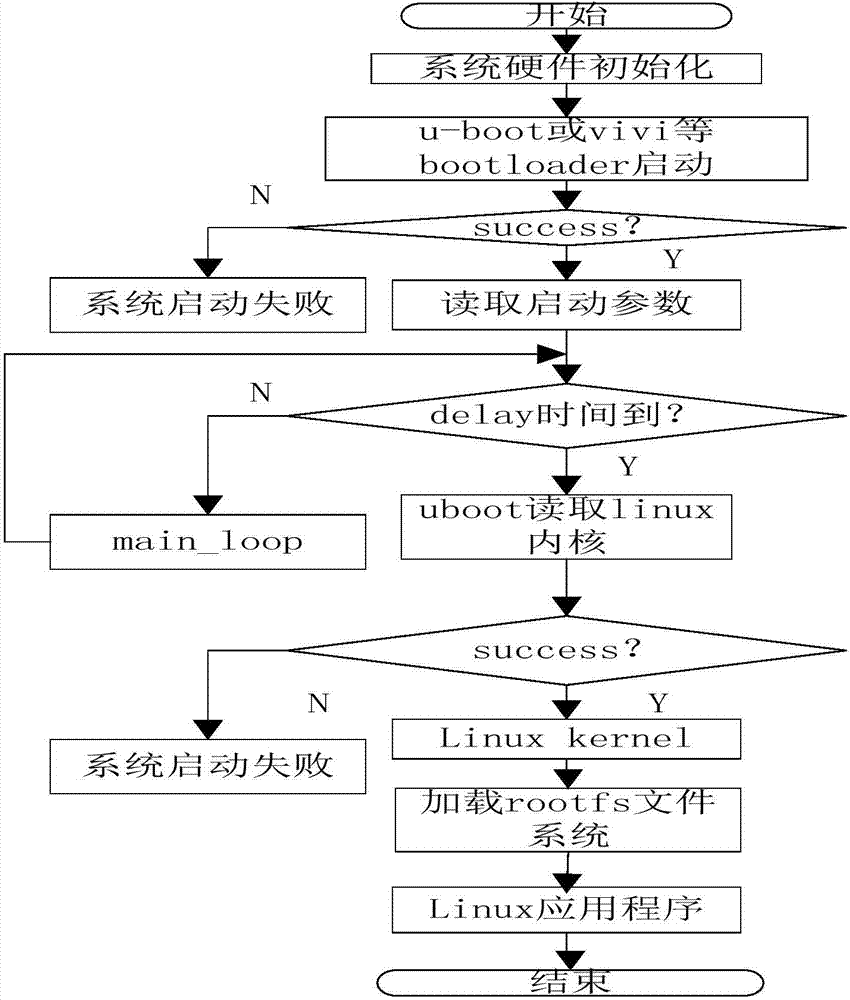

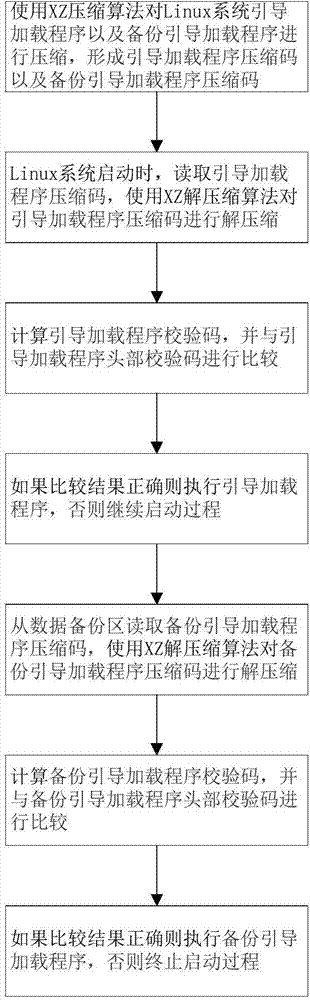

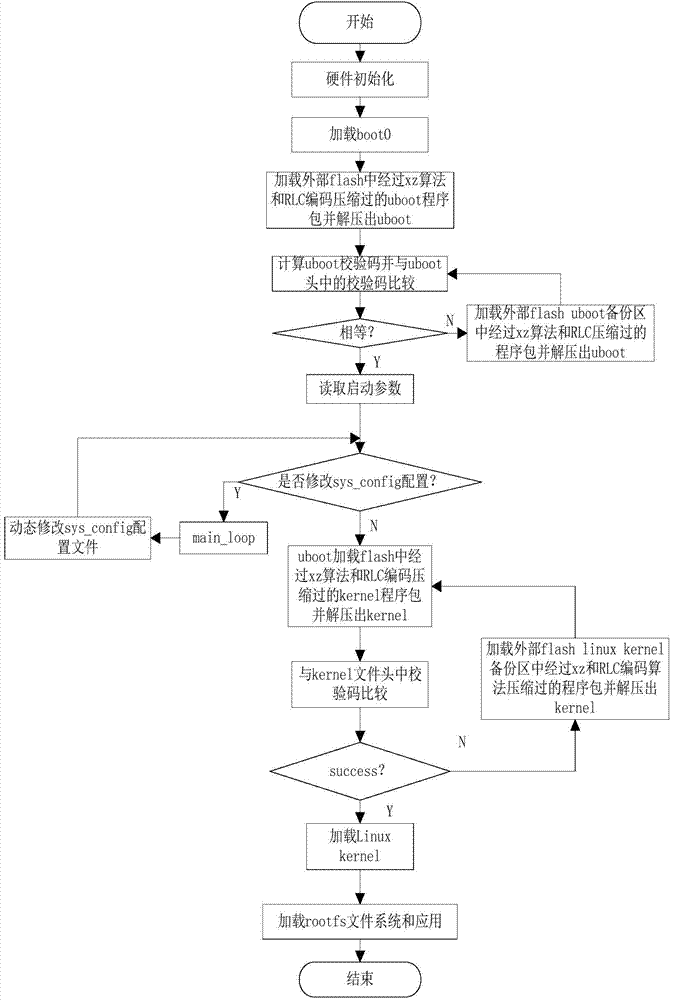

Rapid and safe starting method for embedded Linux system

InactiveCN104778060AIncrease the compression ratioImprove experienceProgram loading/initiatingRedundant operation error correctionGNU/LinuxComputer science

The invention discloses a rapid and safe starting method for an embedded Linux system. The method comprises the following steps: A1, compressing a Linux system bootstrap loader and a backup bootstrap loader by using an XZ compression algorithm to form a bootstrap loader compression code and a backup bootstrap loader compression code; A2, during starting of the Linux system, reading the bootstrap loader compression code, and decompressing the bootstrap loader compression code by using the XZ decompression algorithm; A3, calculating a bootstrap loader check code, and comparing the bootstrap loader check code with a bootstrap loader head check code; A4, if a comparison result is correct, executing the bootstrap loader, otherwise executing a step A5; A5, reading the backup bootstrap loader compression code from a data backup region, and decompressing the backup bootstrap loader compression code by using an XZ decompression algorithm; A6, calculating a backup bootstrap loader check code, and comparing the backup bootstrap loader check code with a backup bootstrap loader head check code; A7, if a comparison result is correct, executing the backup bootstrap loader, otherwise terminating the starting progress.

Owner:ALLWINNER TECH CO LTD

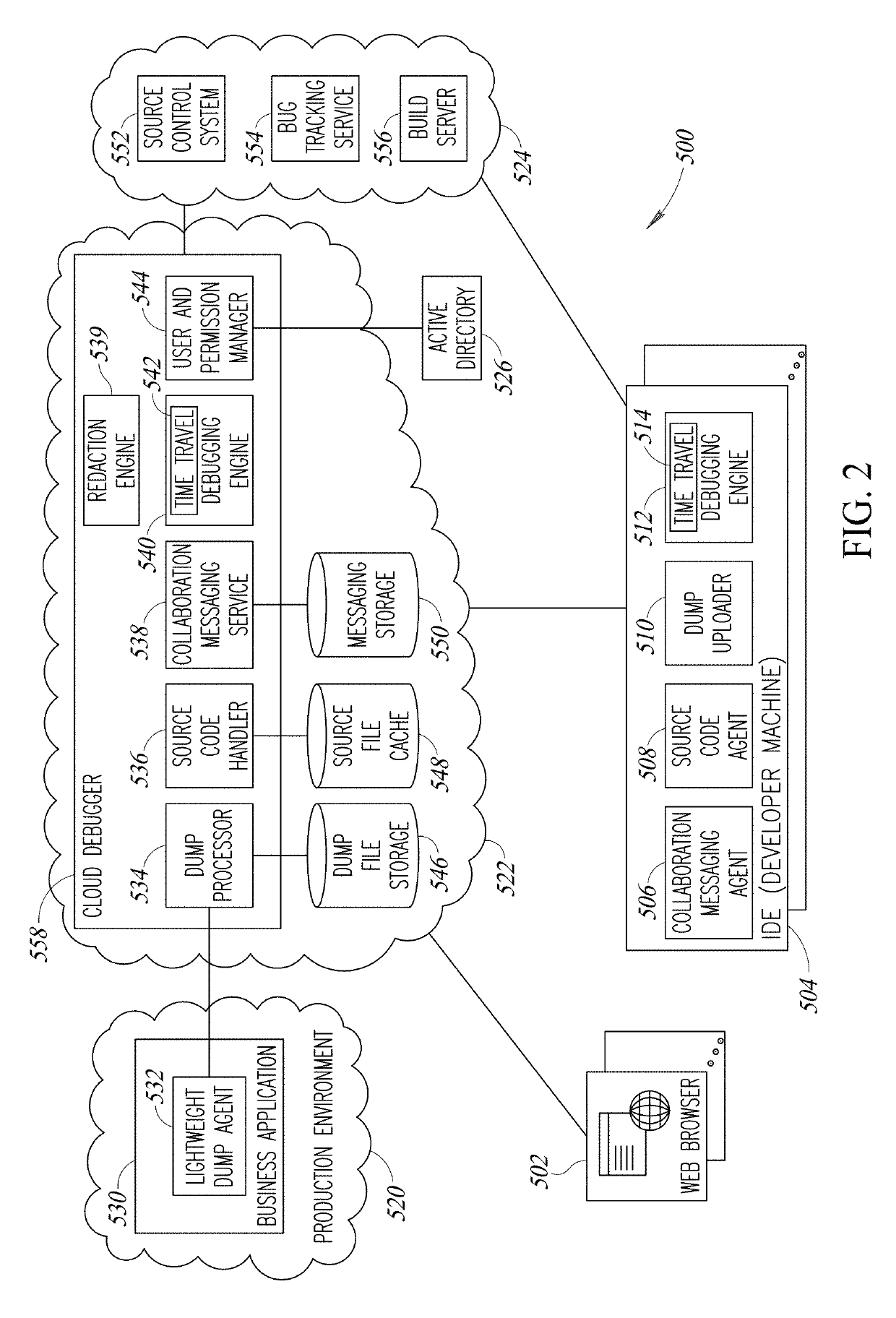

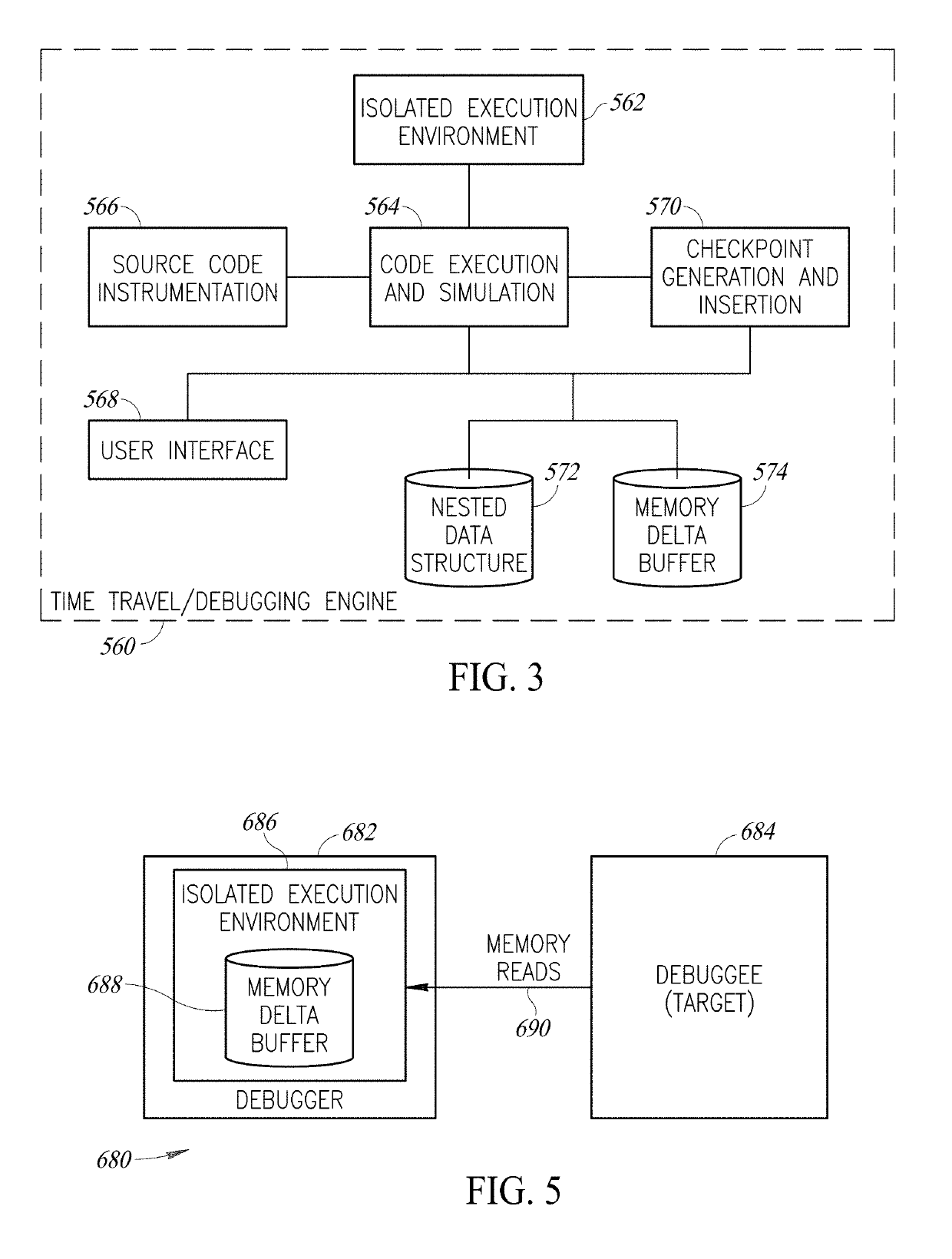

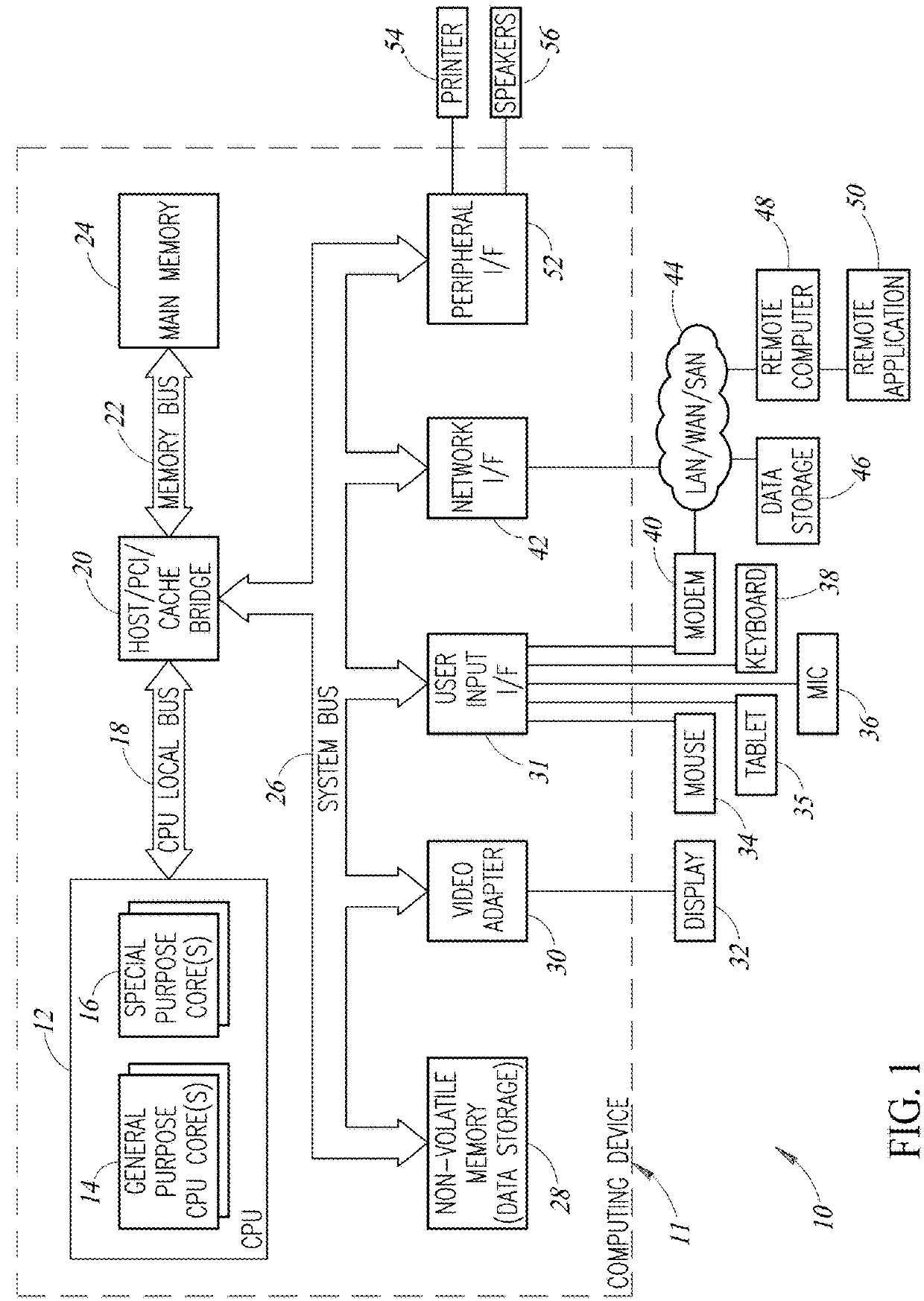

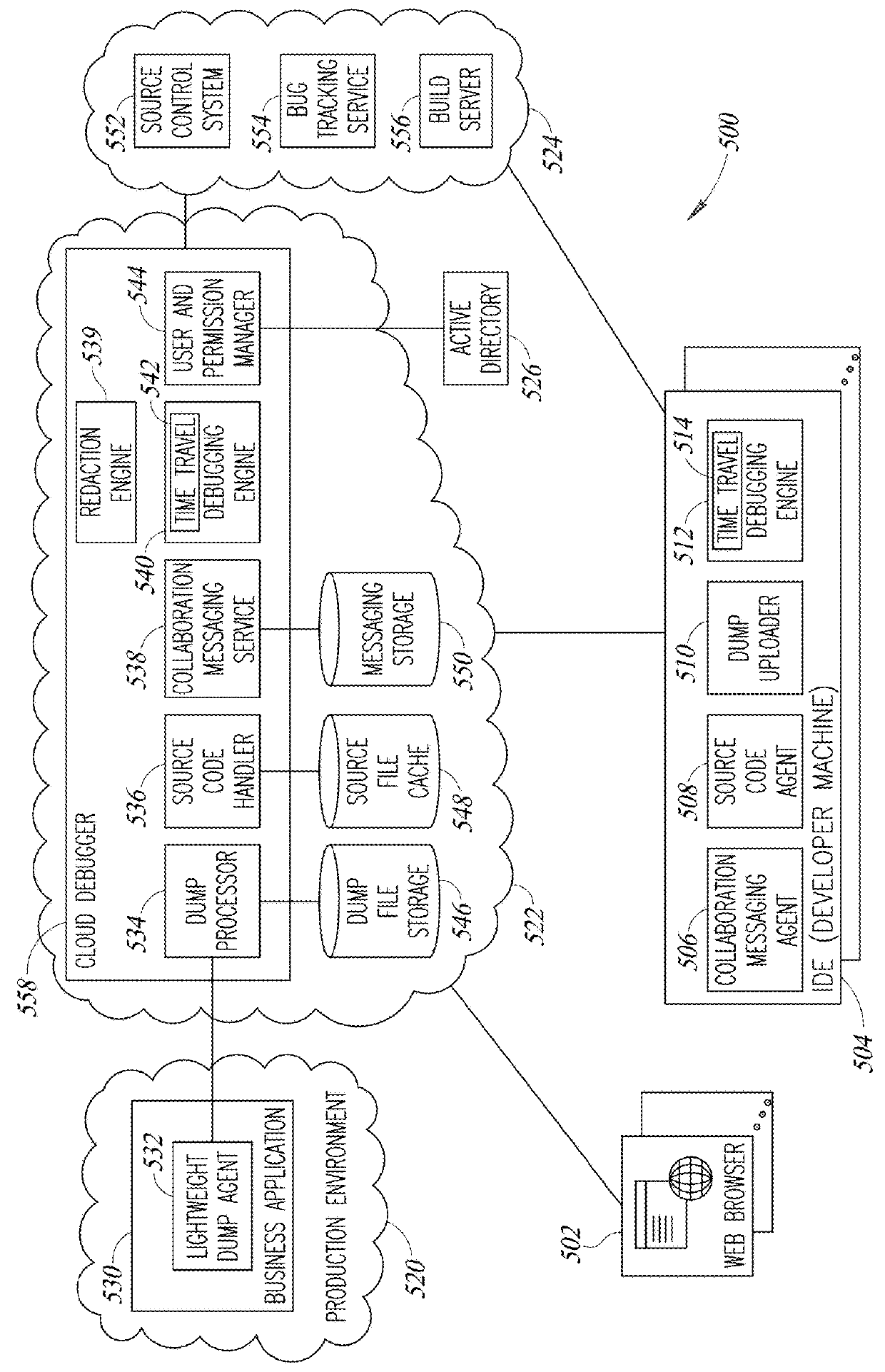

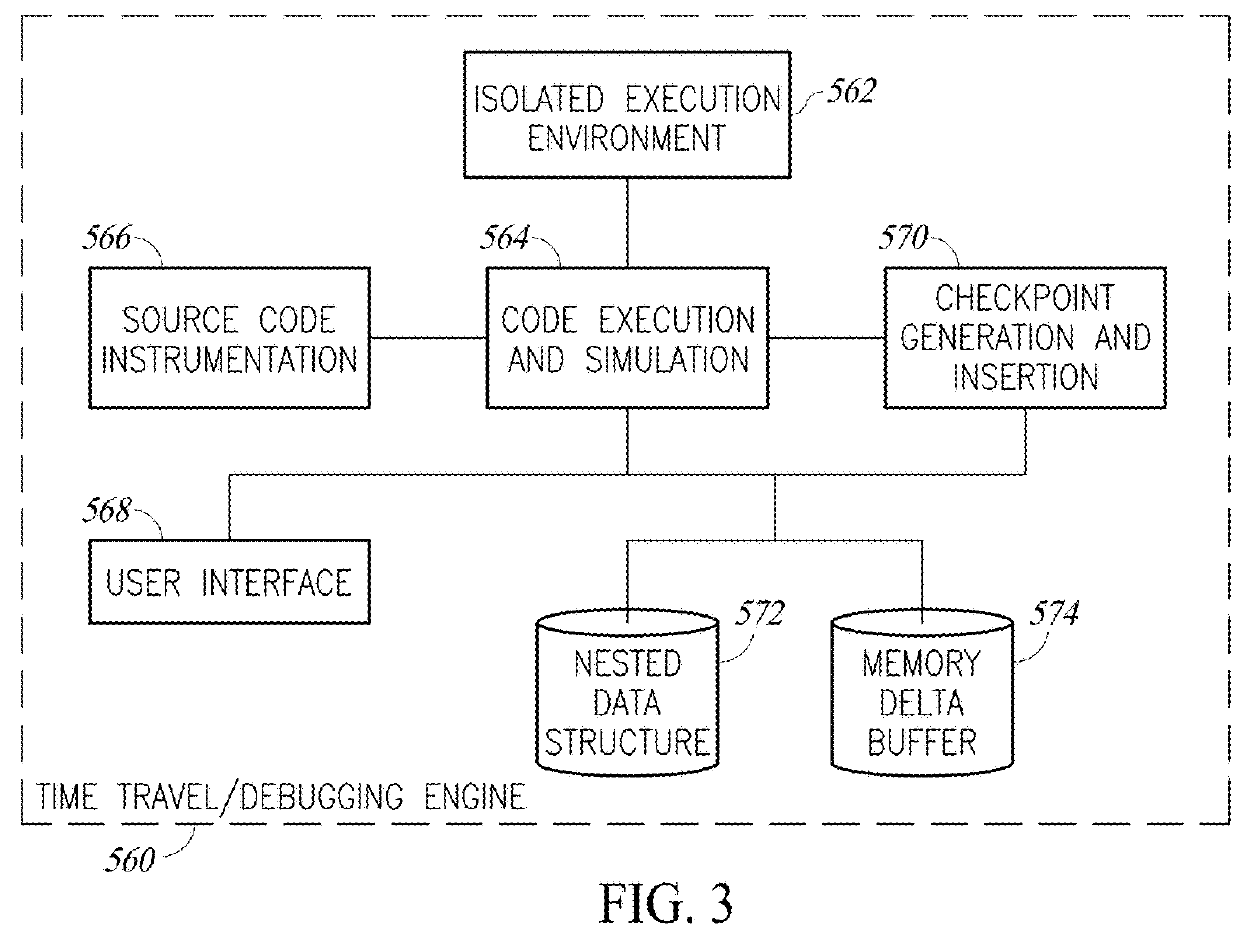

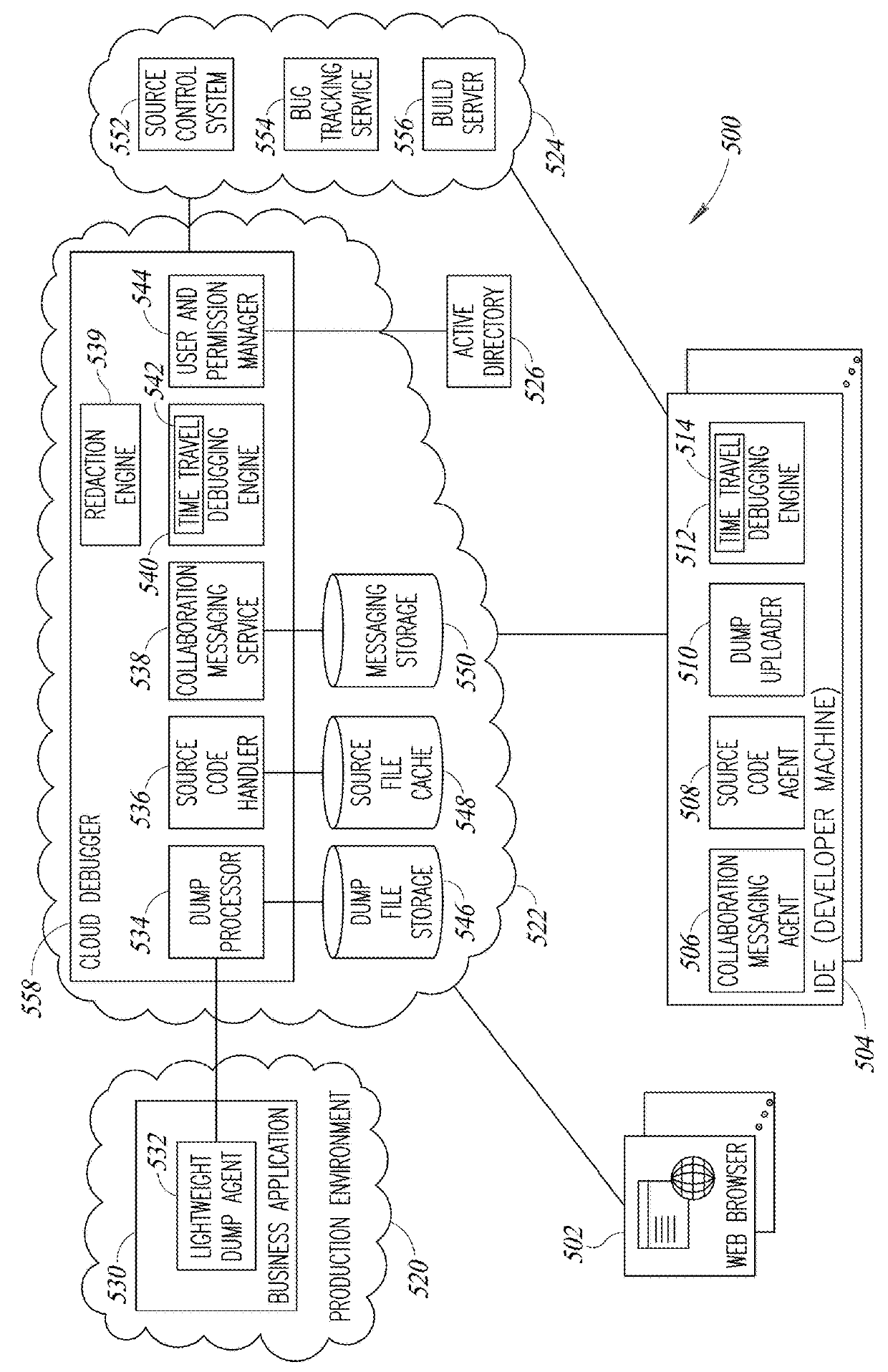

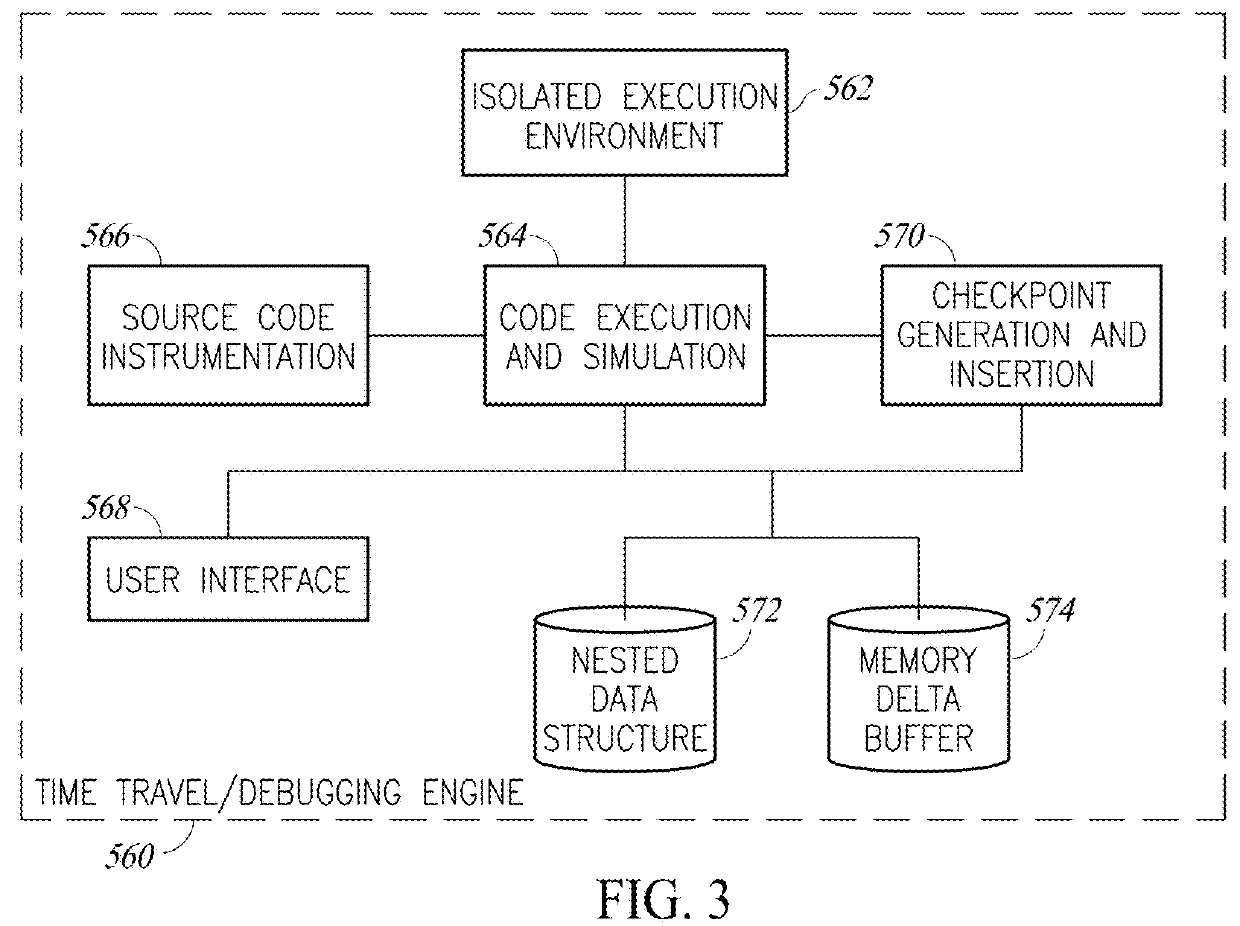

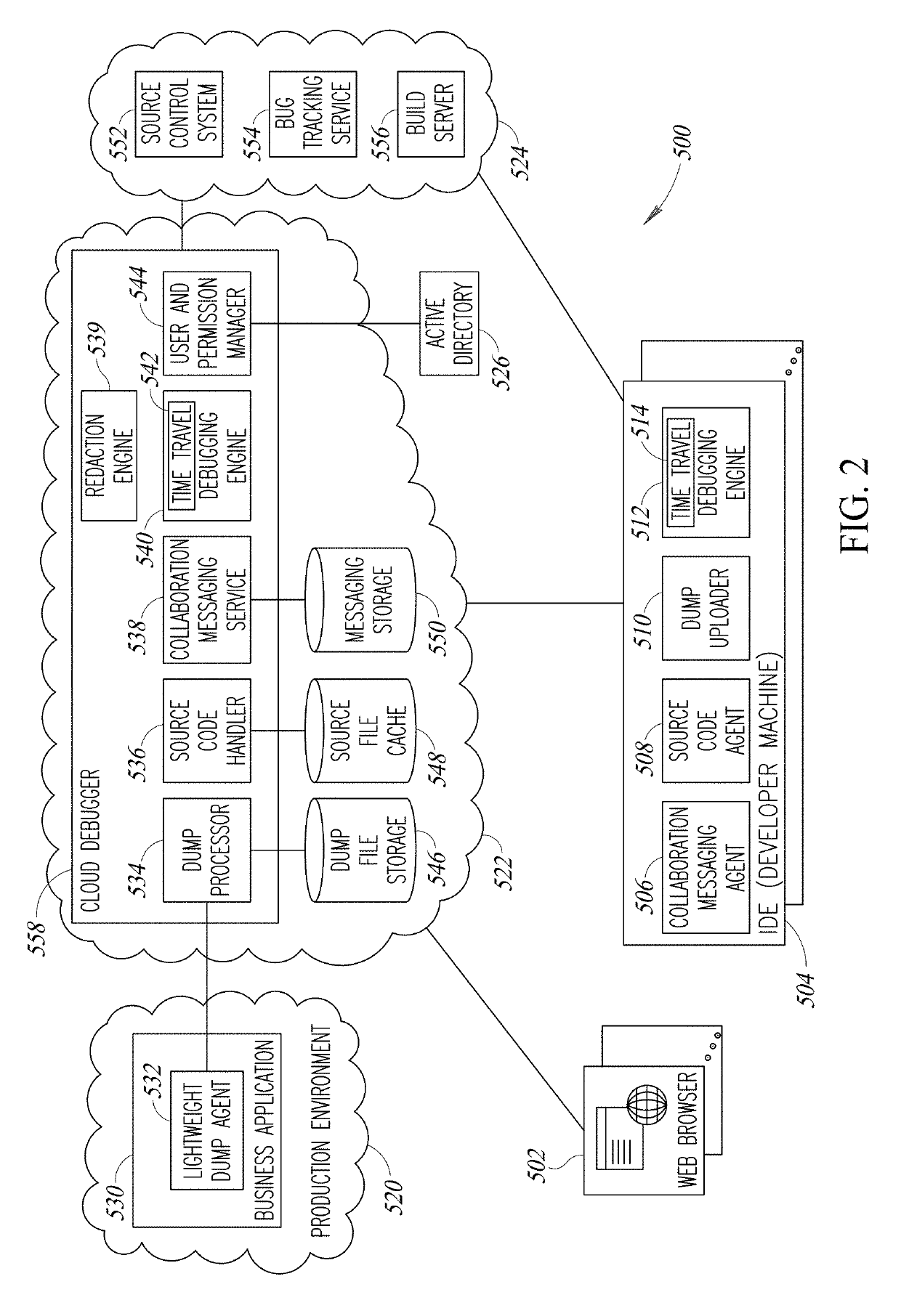

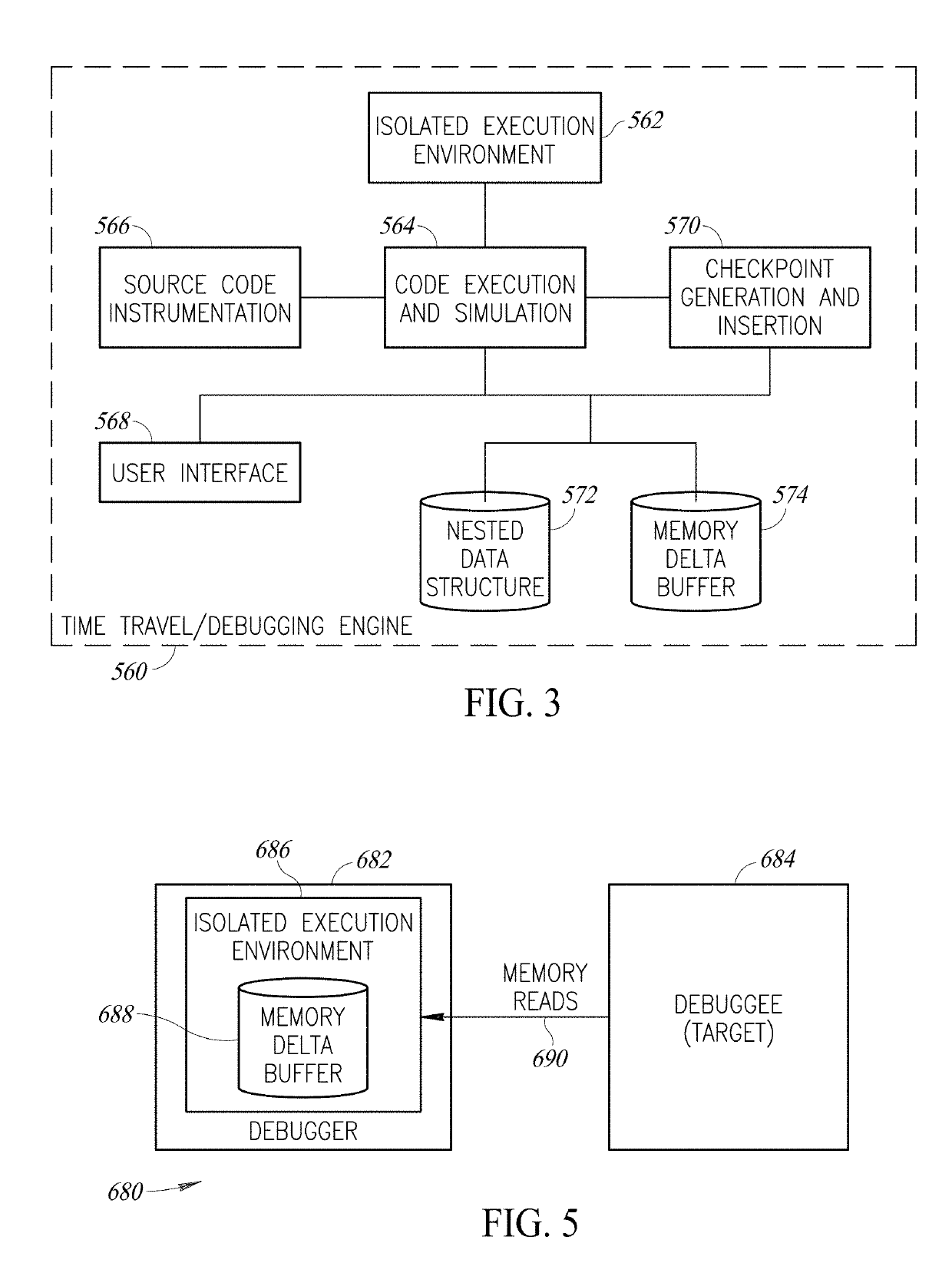

Time Travel Source Code Debugger Incorporating Redaction Of Sensitive Information

ActiveUS20190213355A1Easy to changeSpeed up the debugging processDecompilation/disassemblyDigital data protectionHead-up displaySource code

A novel and useful system and method of time traveling source code debugging including several advanced capabilities that significantly improve the source code debugging process. Upon hitting a breakpoint or opening a dump file, the debugger travels to the future which can be altered by a user by modifying code on the fly (live coding) and receiving immediate feedback to validate bug fixes. Visual annotations including values of variables and expressions are provided as a heads up display effectively flattening time and space. A pivoting capability allows a user to switch the execution context of the code at any time. Point in time links that store the state of the debugging session can be created and activated. An asynchronous collaboration and messaging system enables multiple participants to share a debugging session. An optional redaction capability is also provided for obscuring or replacing sensitive private information.

Owner:OZCODE LTD

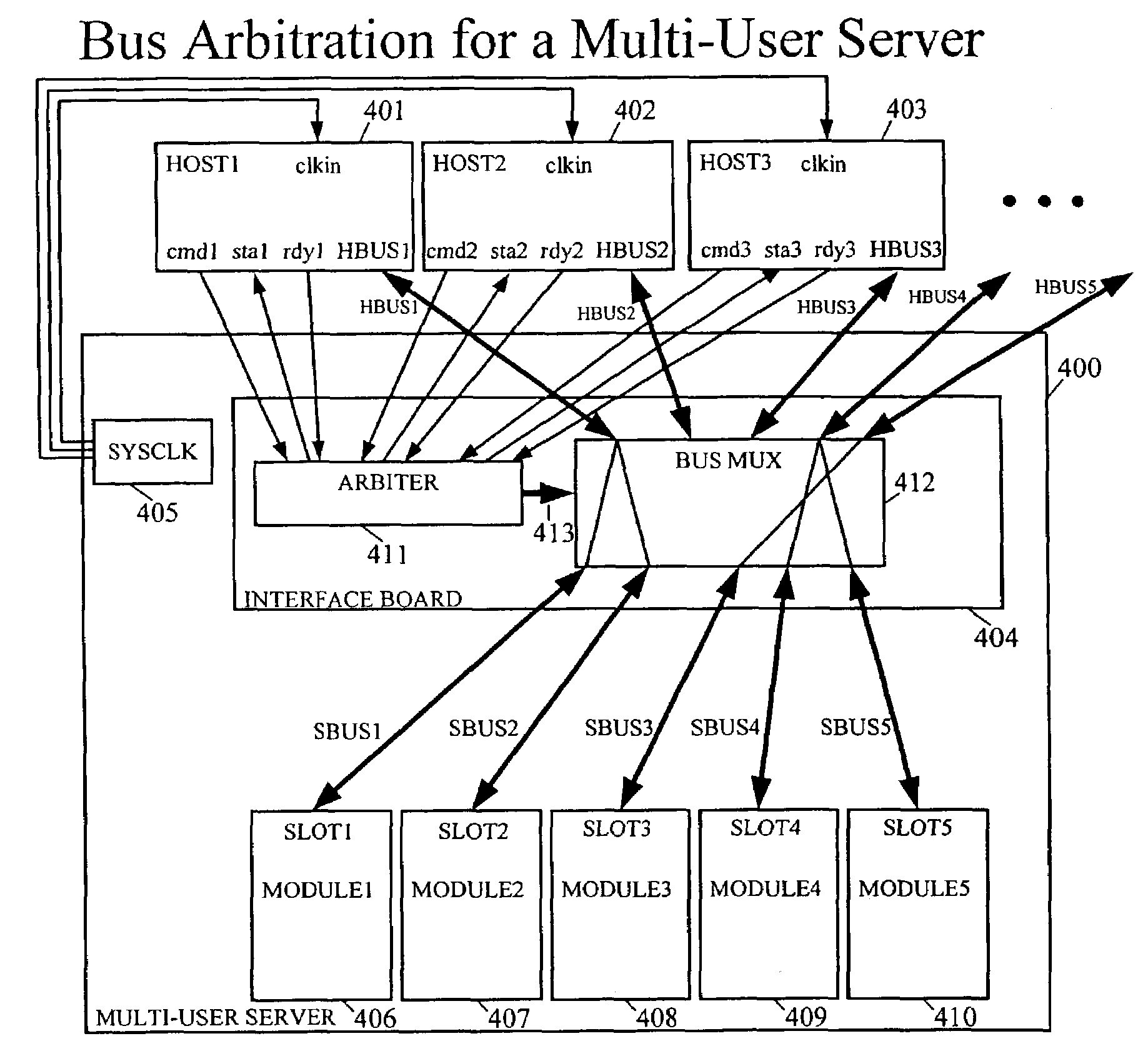

Multi-user server system and method

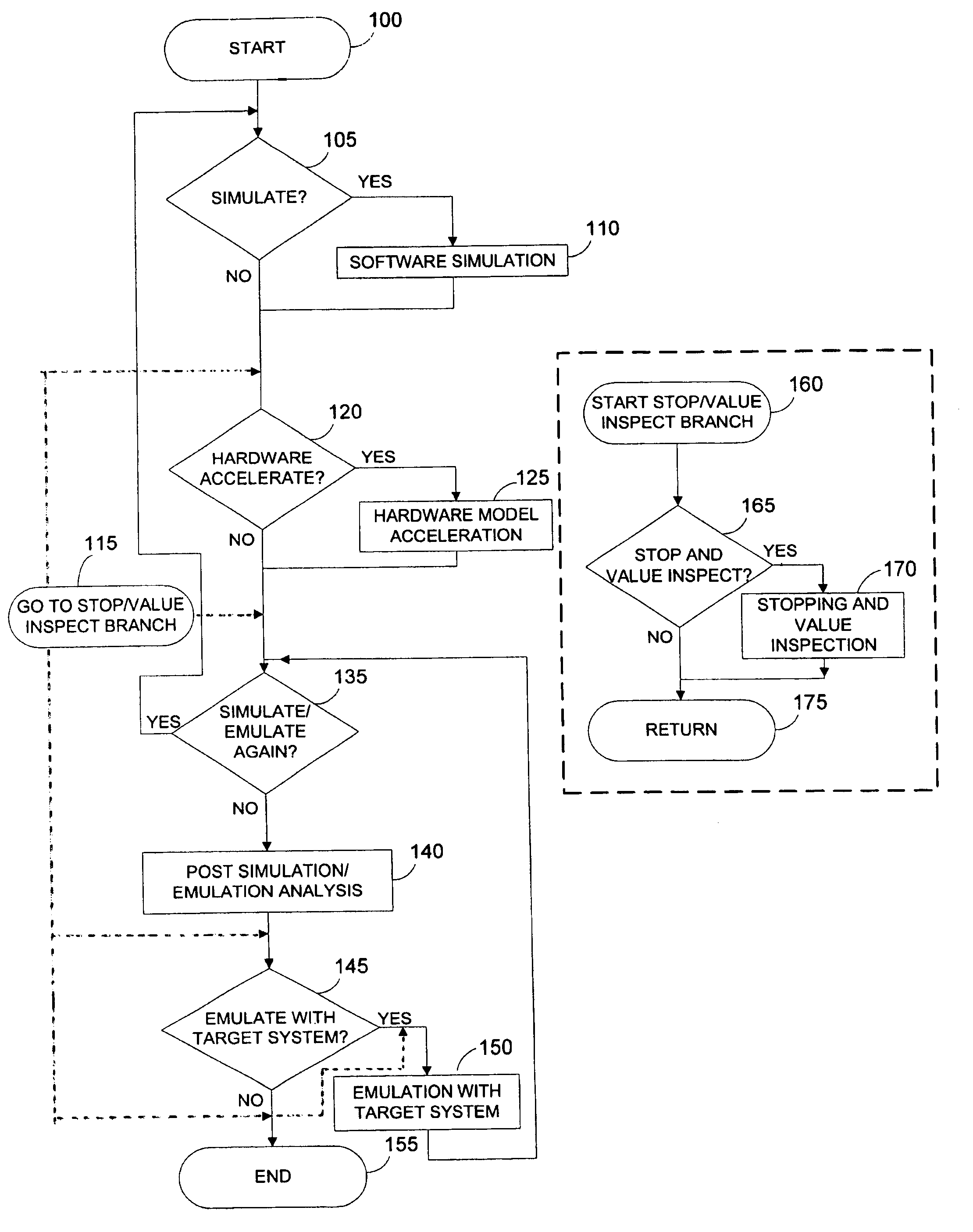

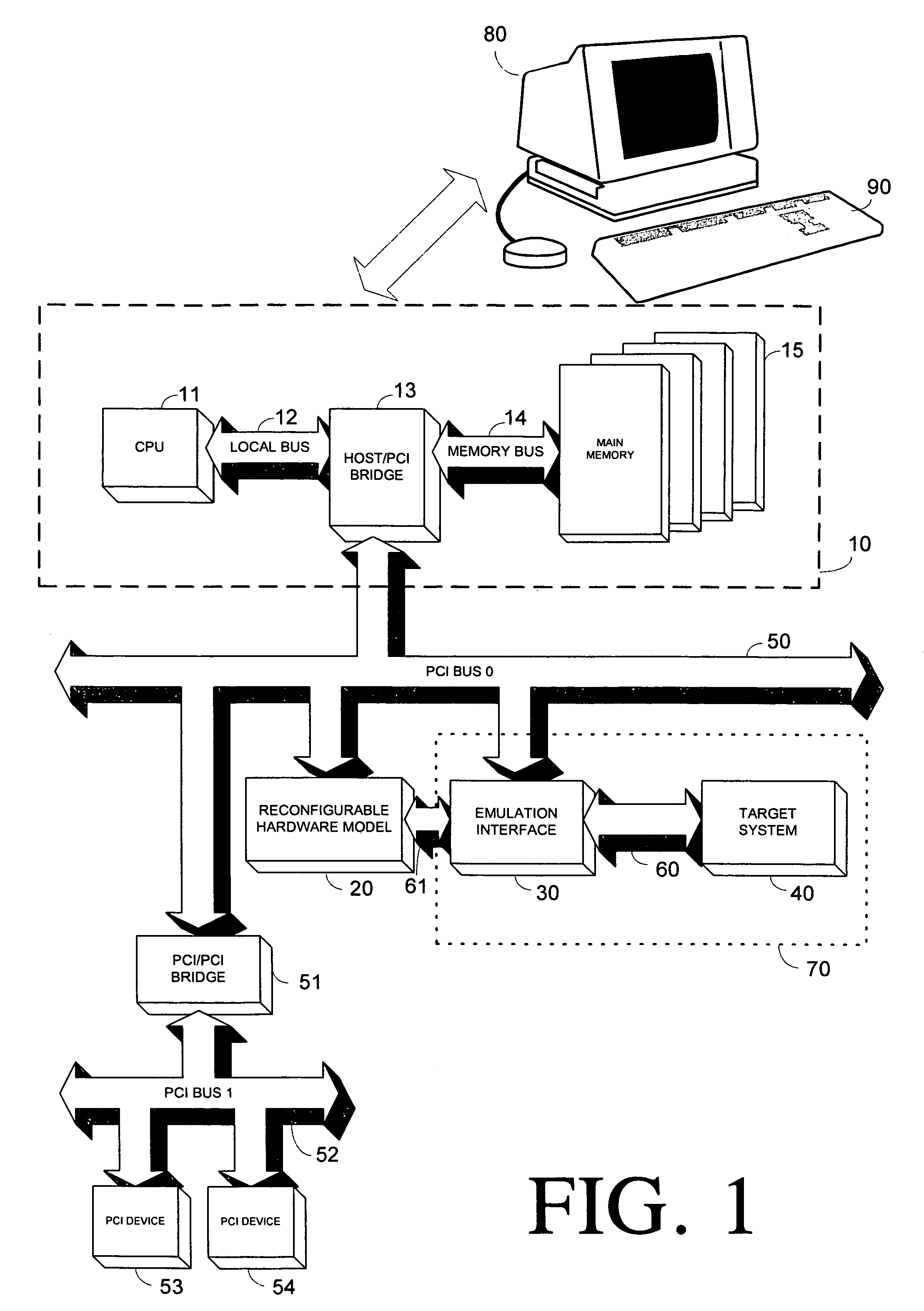

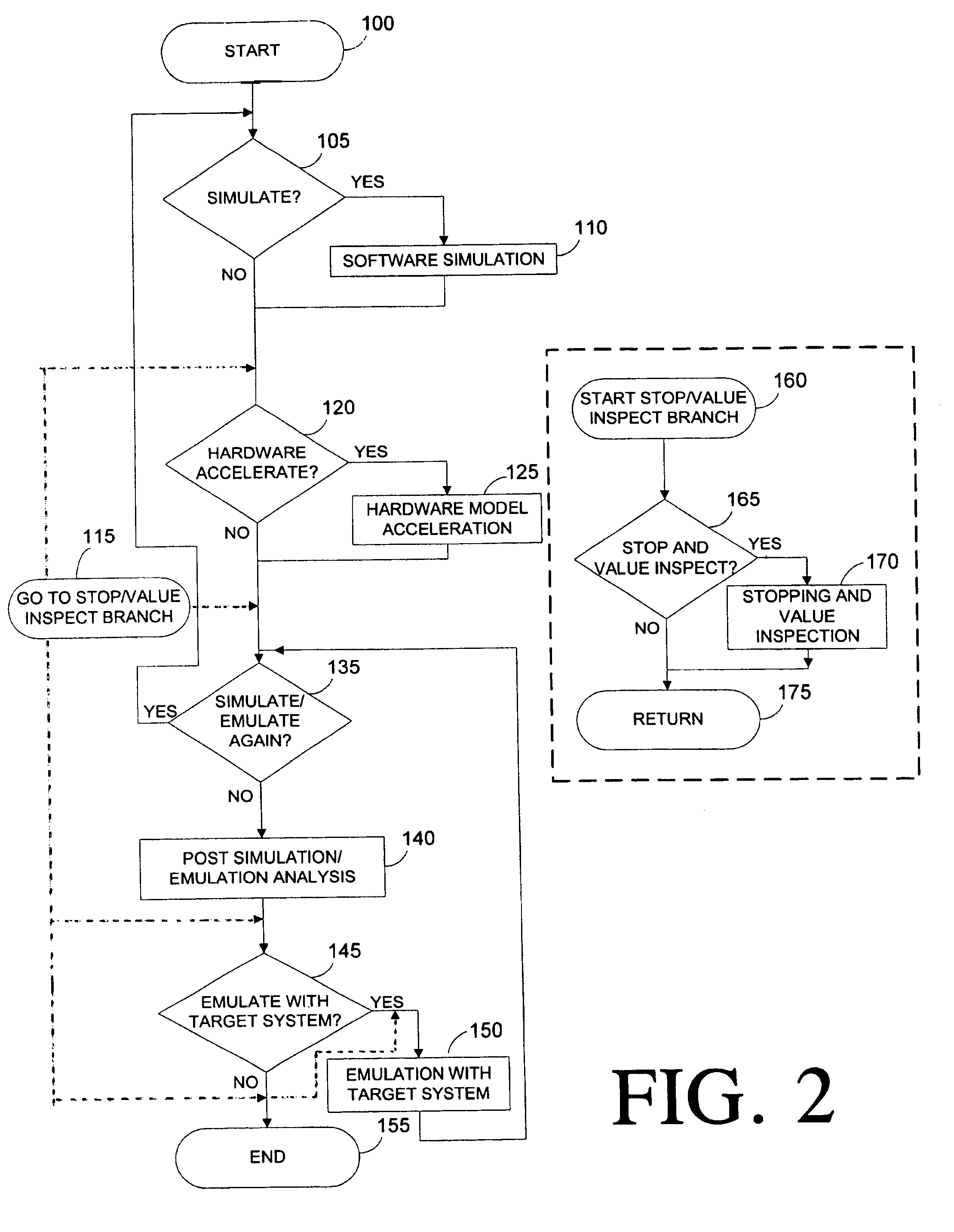

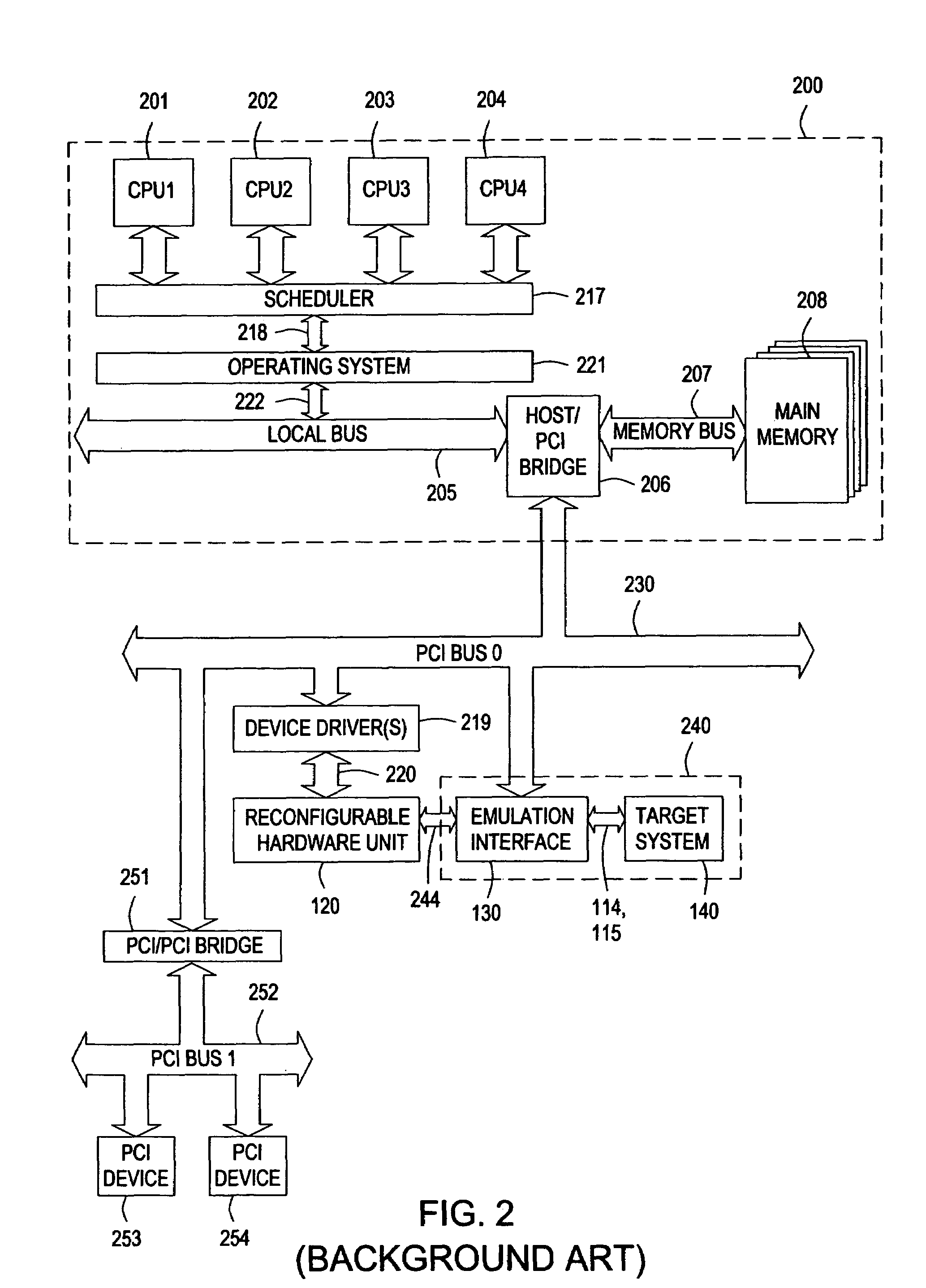

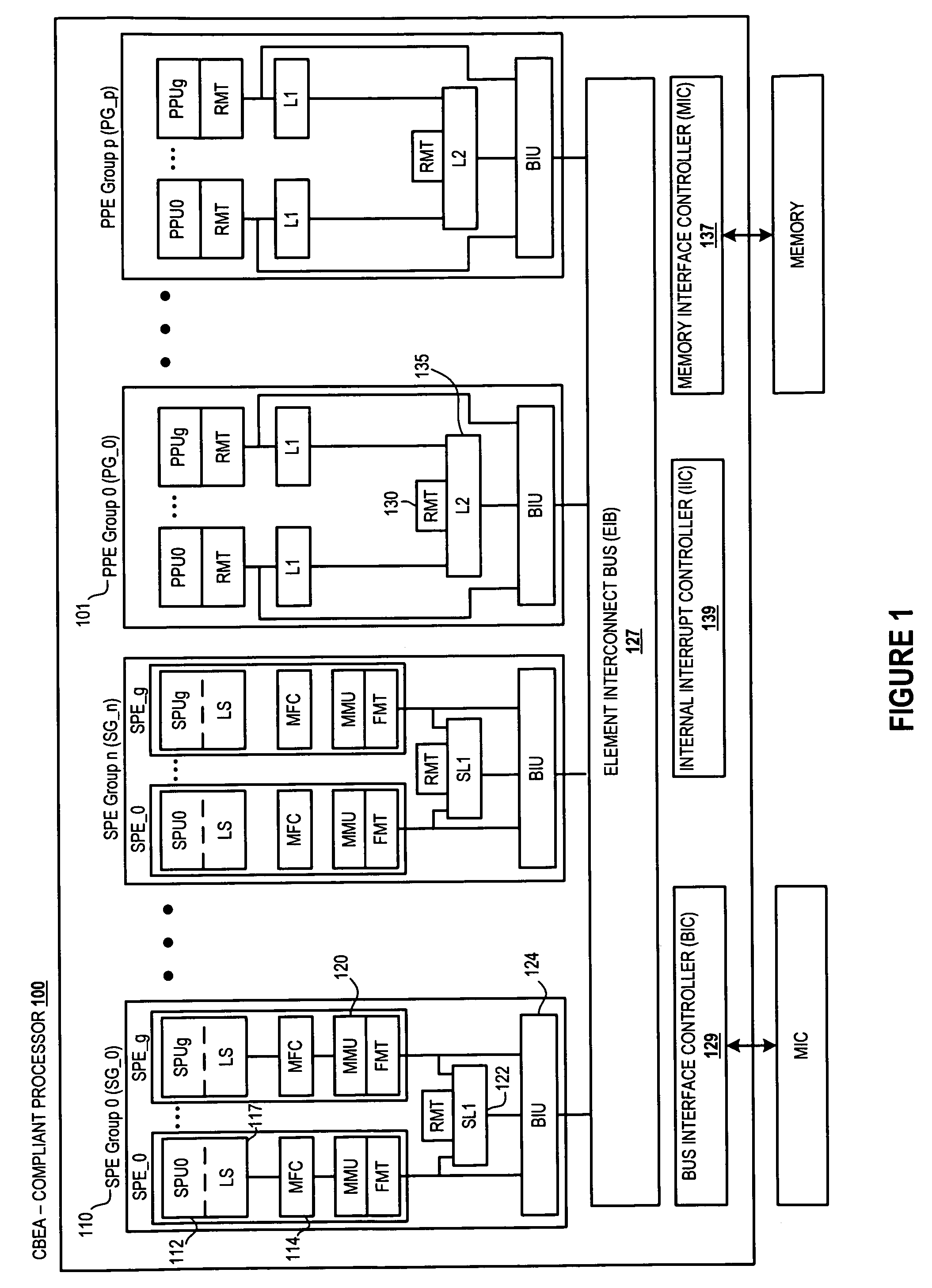

ActiveUS7505891B2Speed up the debugging processReduce processCAD circuit designSoftware simulation/interpretation/emulationMultiplexerFpga chip

The multi-user server technology allows multiple host stations to configure, load, and execute multiple jobs in a reconfigurable hardware unit for emulation purposes, simulation acceleration purposes, and a combination of emulation and simulation in a concurrent manner. The reconfigurable hardware unit includes a plurality of hardware resources (e.g., FPGA chips on slot module boards) for modeling at least a portion of one or more user design. The server includes a bus arbiter for deciding which one of the host stations will be coupled to the hardware resources via the bus multiplexer. The plurality of hardware resources includes slot modules, which includes one or more boards of FPGA chips. An arbitration decision is made to assign a particular slot(s) to a particular host. A host and its respective assigned slot(s) can communicate with each other while other hosts and their respective assigned slot(s) communicate with each other.

Owner:CADENCE DESIGN SYST INC

Time Travel Source Code Debugger Incorporating Pivoting Ability

ActiveUS20190213101A1Easy to changeSpeed up the debugging processDecompilation/disassemblyPlatform integrity maintainanceHead-up displayRotation function

A novel and useful system and method of time traveling source code debugging including several advanced capabilities that significantly improve the source code debugging process. Upon hitting a breakpoint or opening a dump file, the debugger travels to the future which can be altered by a user by modifying code on the fly (live coding) and receiving immediate feedback to validate bug fixes. Visual annotations including values of variables and expressions are provided as a heads up display effectively flattening time and space. A pivoting capability allows a user to switch the execution context of the code at any time. Point in time links that store the state of the debugging session can be created and activated. An asynchronous collaboration and messaging system enables multiple participants to share a debugging session. An optional redaction capability is also provided for obscuring or replacing sensitive private information.

Owner:OZCODE LTD

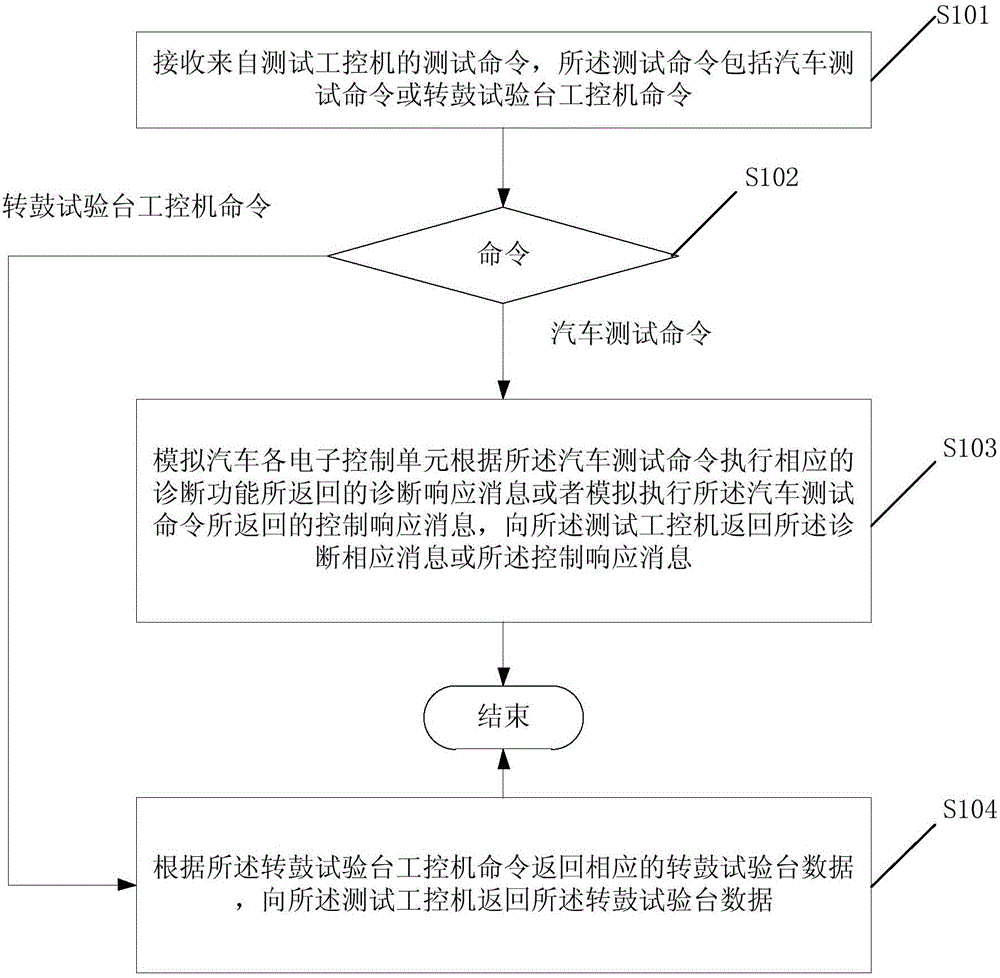

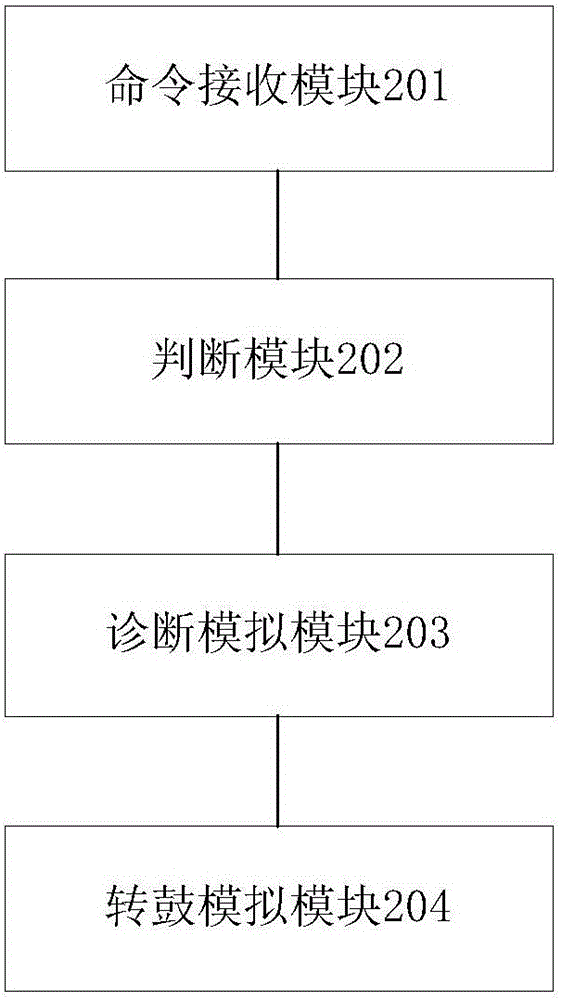

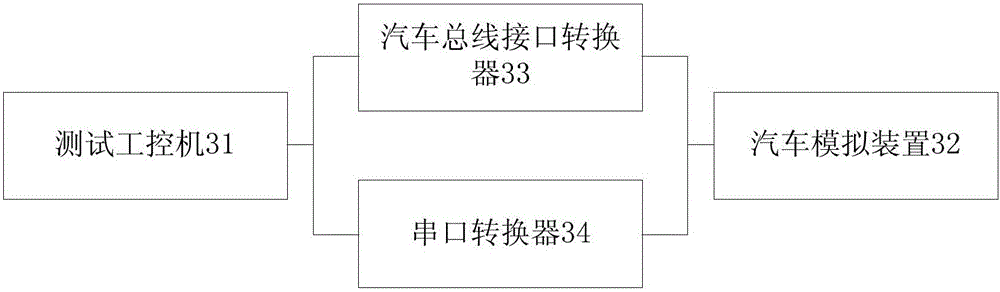

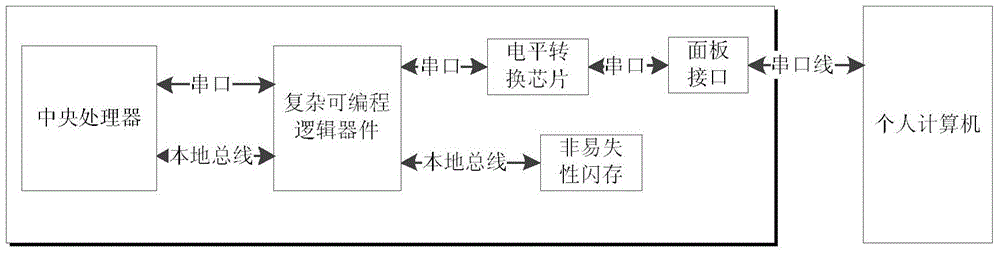

Automobile simulation method and device, and automobile test simulation system

ActiveCN106053098ASpeed up commissioning workSpeed up the debugging processVehicle testingPersonal computerChassis dynamometer

The present invention discloses an automobile simulation method and device, and an automobile test simulation system. The method comprises: receiving a test command from a test industrial personal computer, wherein the test command includes an automobile test command or a chassis dynamometer industrial personal computer command; if the automobile test command is received, executing a simulation step, and if the chassis dynamometer industrial personal computer command is received, executing a chassis dynamometer simulation step; performing a diagnosis simulation step including simulating each electric unit of the automobile to execute the diagnosis response message returned back by the corresponding diagnosis function or simulating the control response message returned back by executing the automobile test command according to the automobile test command, and returning back corresponding message to the rest industrial personal computer or controlling the response message; and performing a drum simulation step including returning back corresponding chassis dynamometer data according to the chassis dynamometer industrial personal computer command, and returning back the chassis dynamometer data to the test industrial personal computer. Various required signals are supplied to the test system GATS for debugging so as to accelerate the debugging work of the GATS.

Owner:SAIC GENERAL MOTORS

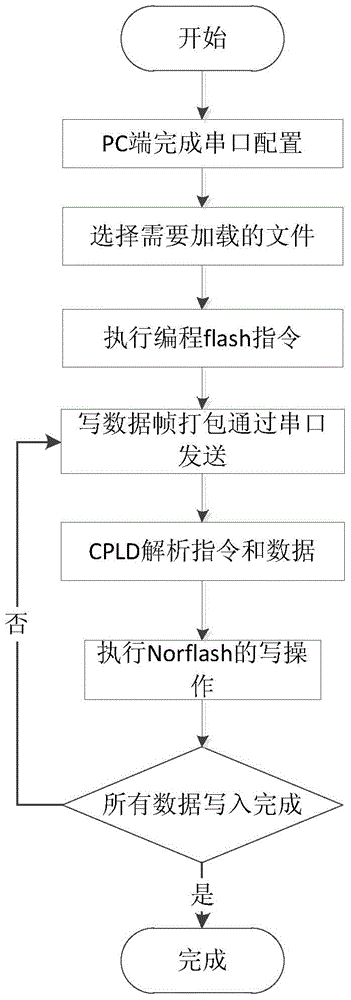

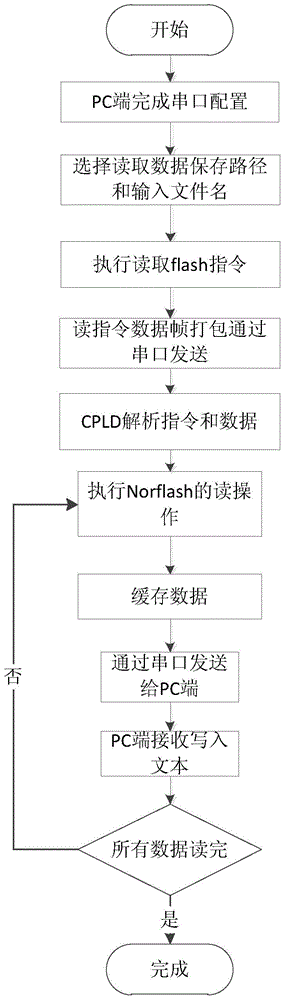

System and method for loading PowerPC system guide file through serial port

ActiveCN104133705ASimple loading processProgramming Speed GuaranteedProgram loading/initiatingPowerPCLogic implementation

The invention discloses a system and method for loading a PowerPC system guide file through a serial port. The method includes the steps of circuit board design of a loading scheme, logic implement of a CPLD and design of loading software of a PC end; after the requirements of the three modules are met, the file is sent to the CPLD through the serial port through the loading software at the PC end, and the file is programmed to a Norflash through the logic in the CPLD so that the system guide file loading can be completed. The invention provides the simple system loading method. The logic of Norflash programming is achieved on the CPLD instead of achieving a programming algorithm on the software of the PC end, and therefore the programming speed is ensured; meanwhile, due to the scheme, the software at the PC end can be quietly easily developed by reading the file to be loaded and then sending the file through the serial port according to the well-defined packaging data frame in the frame format. In addition, the system replaces a special simulator and a special programming environment, the loading process of the system guide file is simplified, and the debugging efficiency in the early period is improved.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

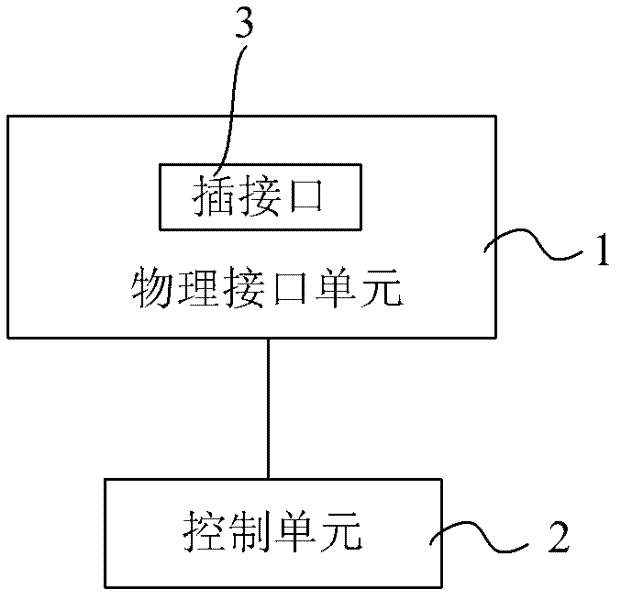

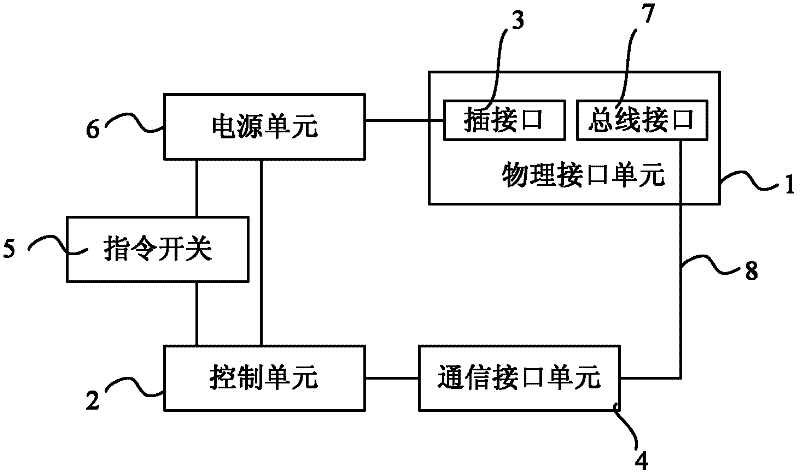

Board card test device

The invention discloses a board card test device, which comprises a physical interface unit and a control unit, wherein an inserting connection hole is formed in the physical interface unit; an insertion core of a board card to be tested is inserted into the inserting connection hole; the control unit is connected with the physical interface unit and used for testing the board card to be tested according to a test program which is locally set; and the control unit is in data communication with the board card to be tested in the test process. The board card test device can be used for testing whether the communication of the board card is normal. The board card test device is easy to operate and particularly applicable to a debugging scene of a railway vehicle so as to test the board card in a network monitoring system in the railway vehicle before energization; complicated equipment is not required; and a simple and effective scene test tool is provided for elimination of faults of the board card before the energization of the network monitoring system.

Owner:CHINA CNR CORPORATION

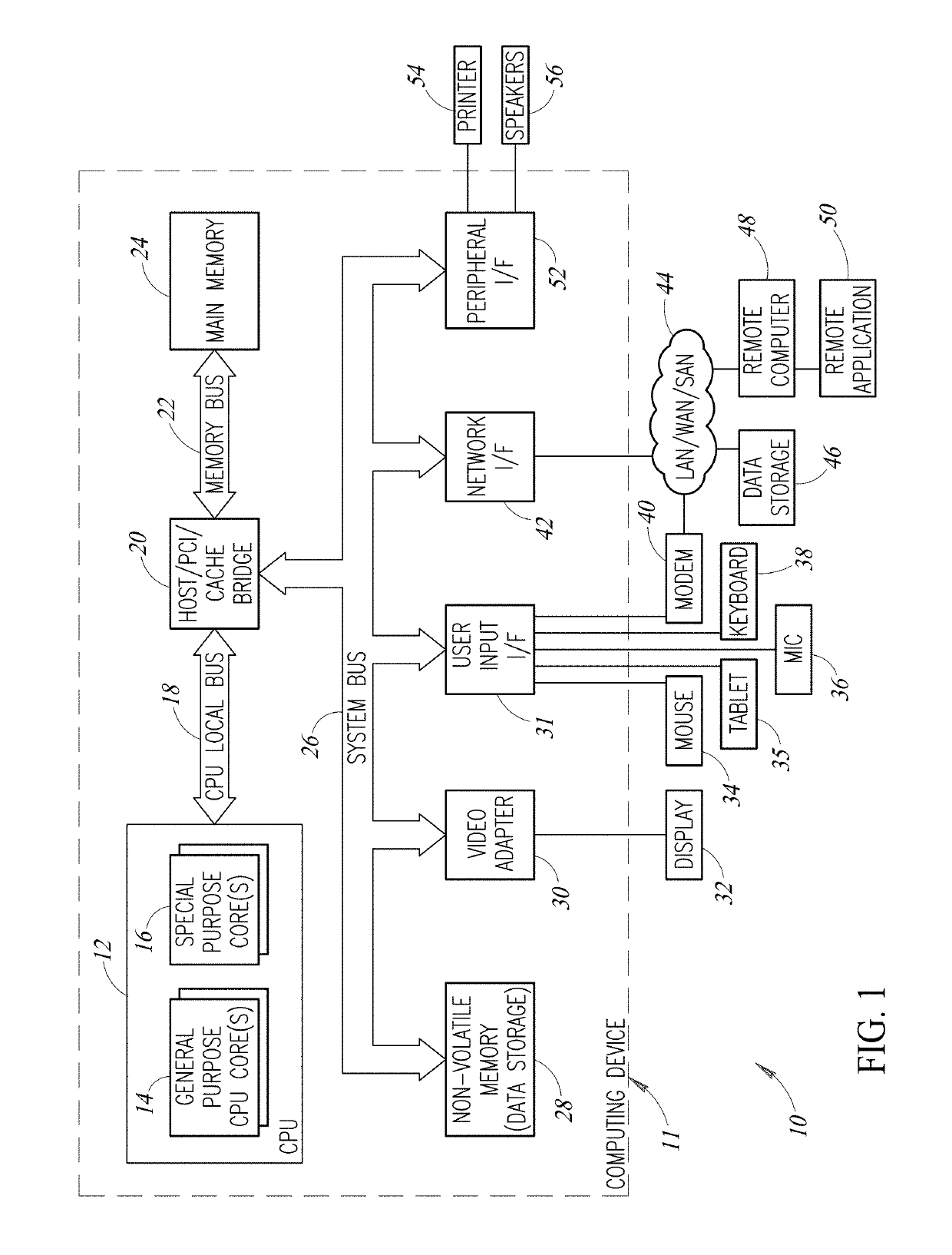

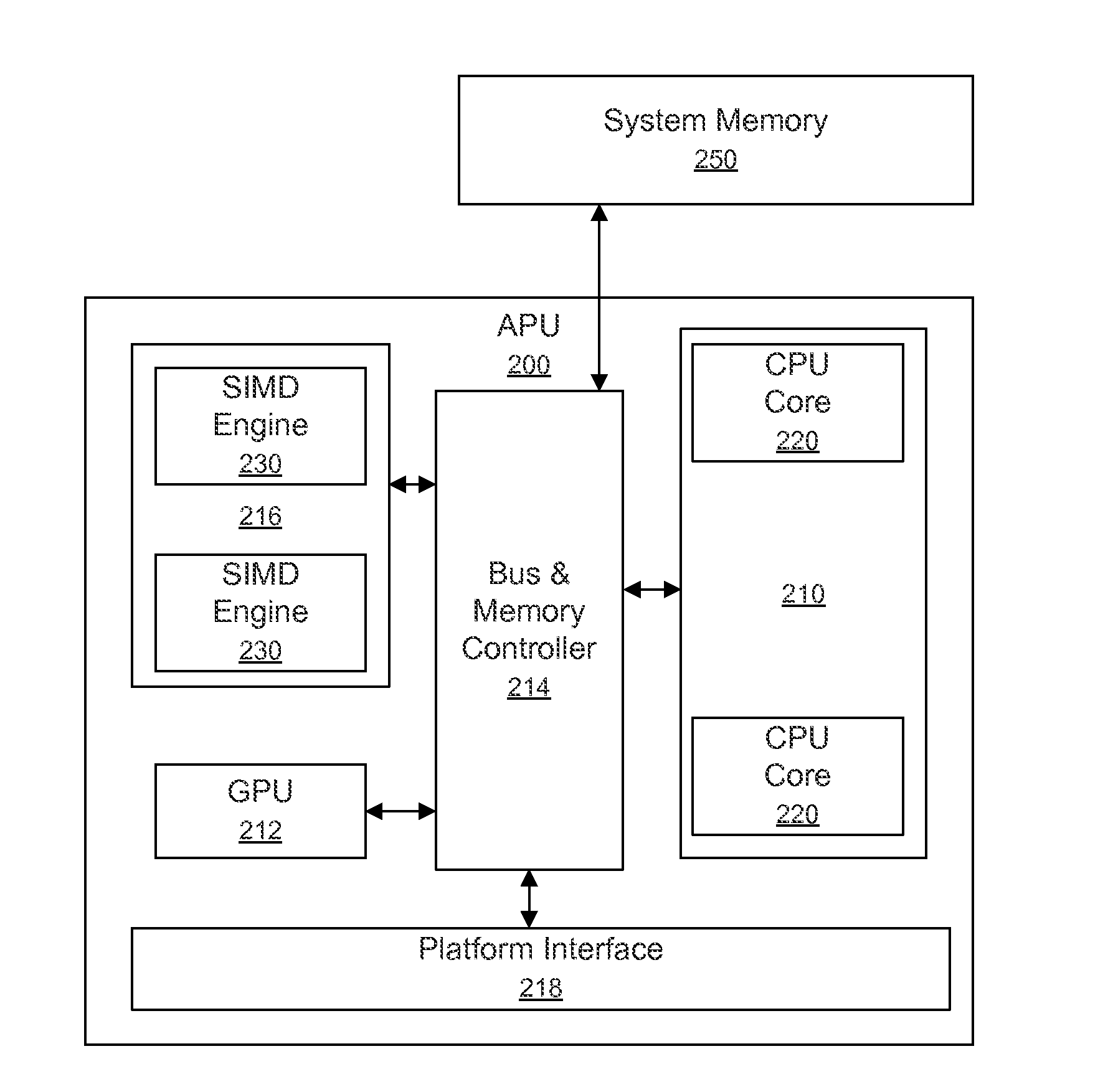

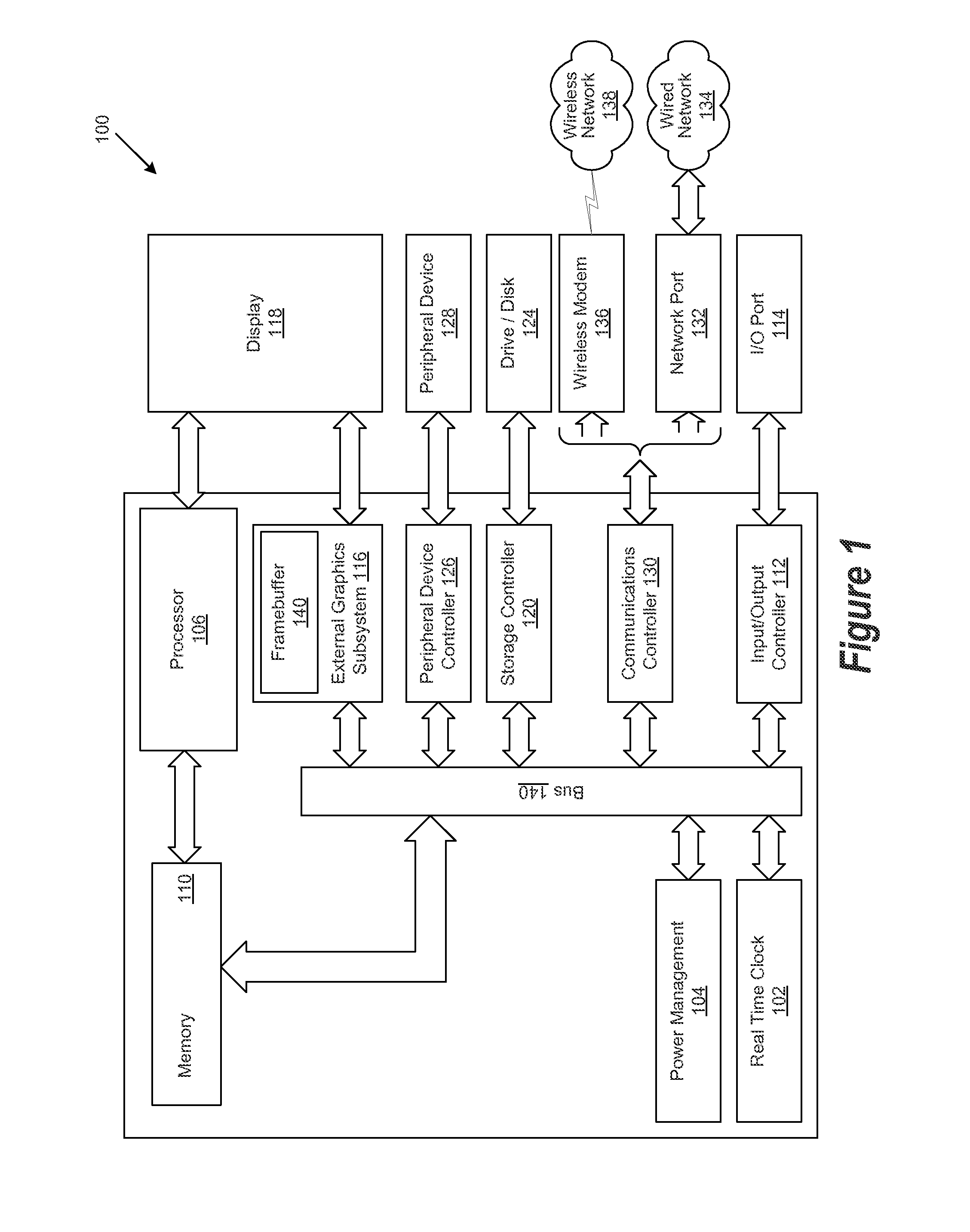

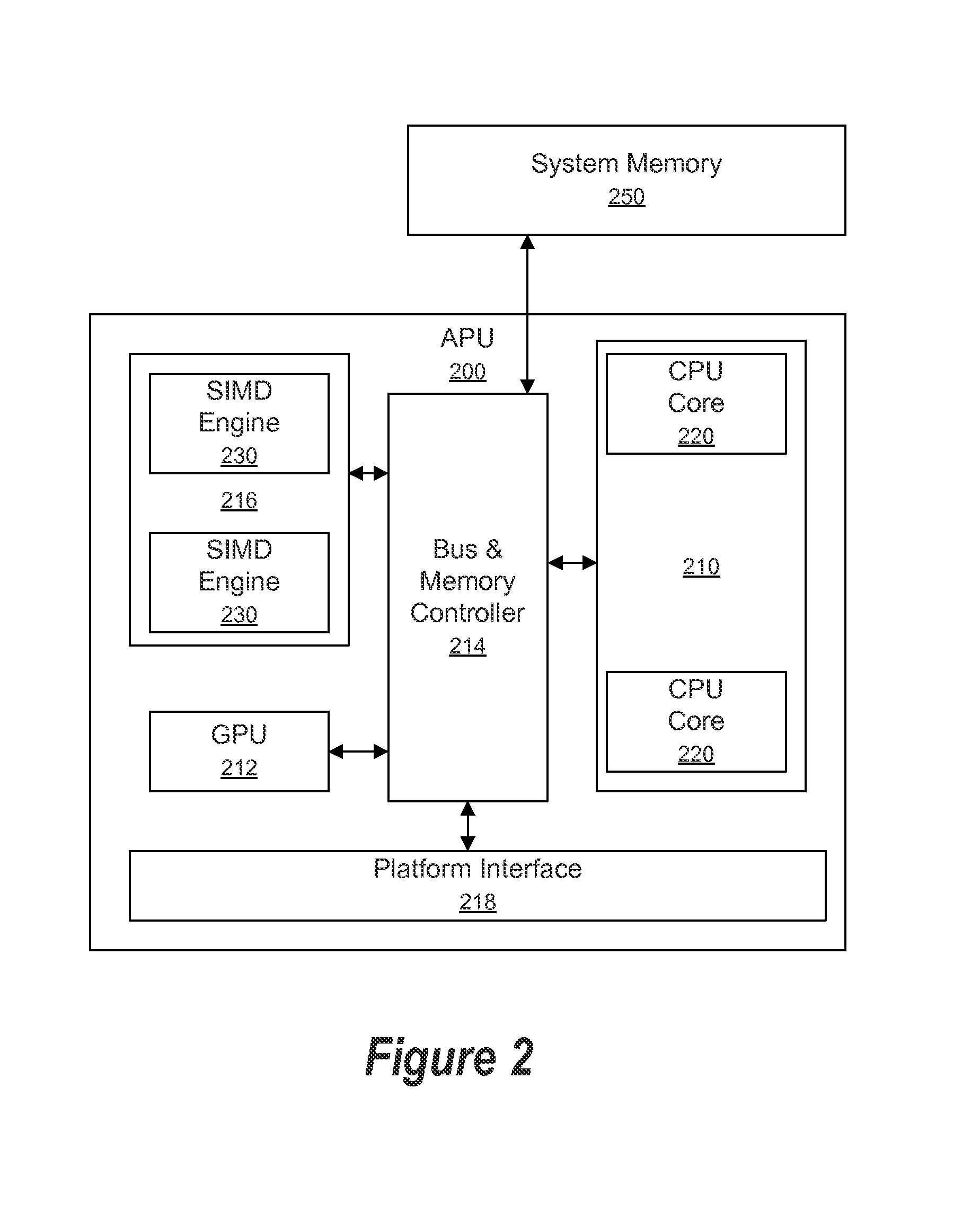

Accelerated Processing Unit Debugging Using a Graphics Processing Unit Centric Debug Core

ActiveUS20130159771A1Speed up the debugging processPerformanceError detection/correctionComputational scienceGraphics

An Accelerated Processing Unit (APU) comprising a central processing unit (CPU) core portion and a graphics processing unit (GPU) core portion coupled to the CPU core portion. The GPU core portion includes a GPU core and a dedicated GPU debugging core, the dedicated GPU debugging core enabling performance of GPU centric debug functions.

Owner:ATI TECH INC

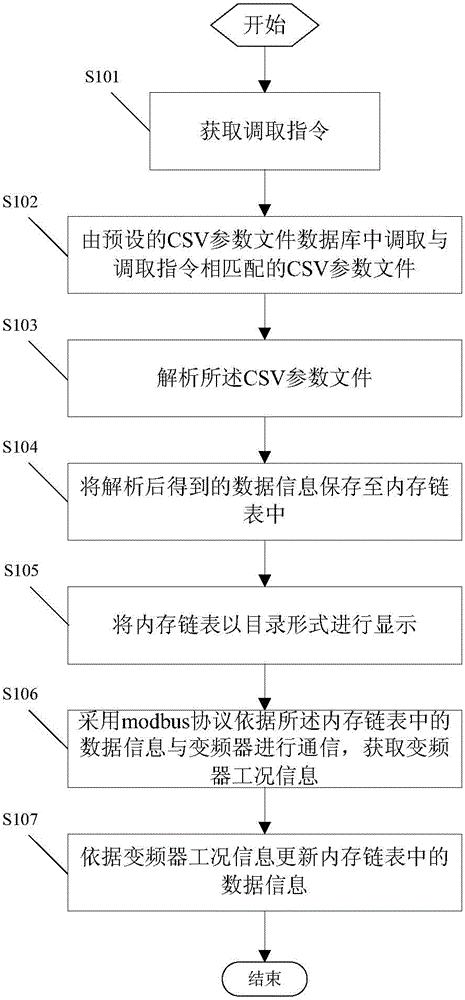

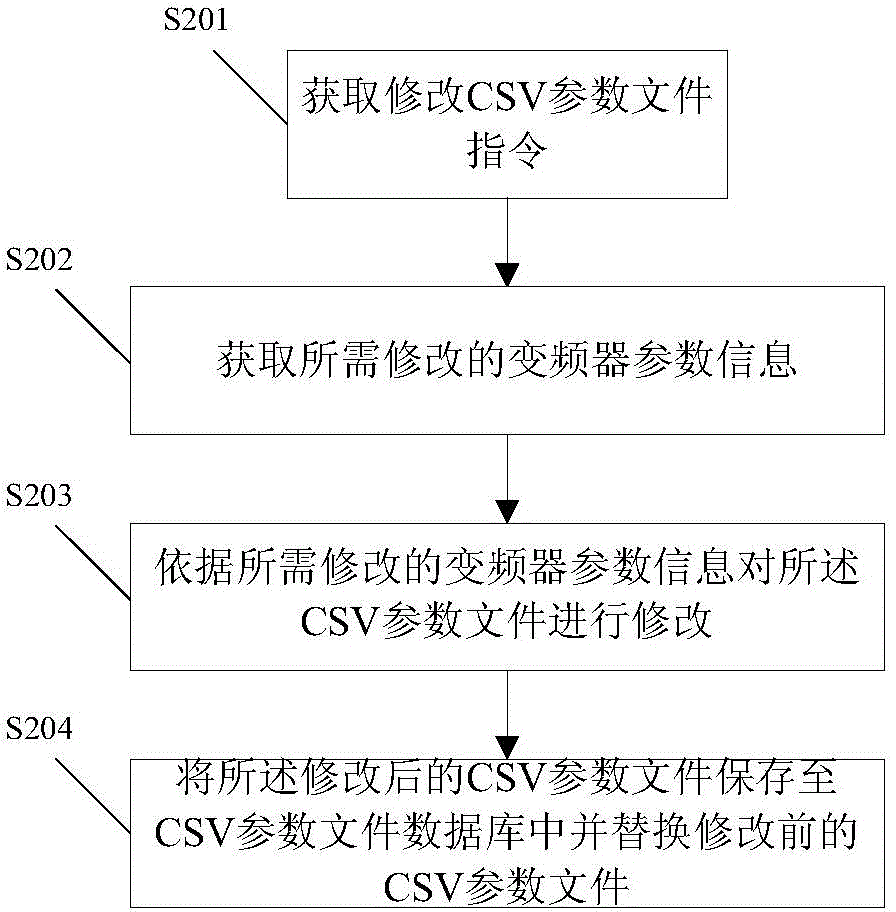

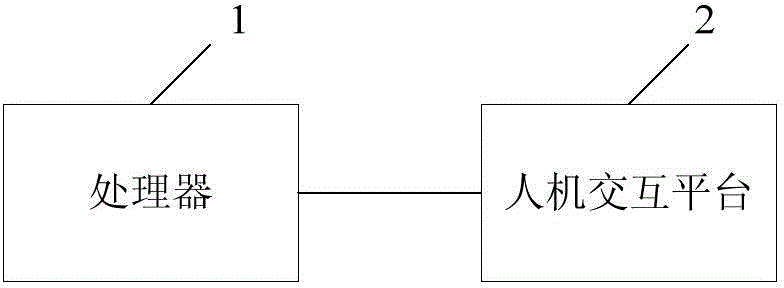

Frequency converter monitoring method and system

ActiveCN104536398ASpeed up the debugging processSpeed up developmentTotal factory controlProgramme total factory controlFrequency changerModbus

The invention discloses a frequency converter monitoring method. The frequency converter monitoring method comprises the steps that a CSV parameter file is called from a CSV parameter file database according to a calling instruction and is analyzed, data information obtained after analysis is stored to an internal storage chain table and displayed in a catalog mode, communication with a frequency converter is carried out through a modbus protocol according to the data information in the internal storage chain table, the working condition information of the frequency converter is obtained, and the data information in the internal storage chain table is updated. Due to the fact that the CSV parameter file is an editable file, when the functions of the frequency converter are modified according to needs of a user, a developer only needs to edit the original CSV parameter file again and modify or add or cancel data content in the original CSV parameter file according to the modification of the frequency converter and does not need to develop or compile the whole CSV parameter file, and therefore field debugging and the integrated development progress are improved.

Owner:SHENYANG YUANDA POWER ELECTRONICS TECH +2

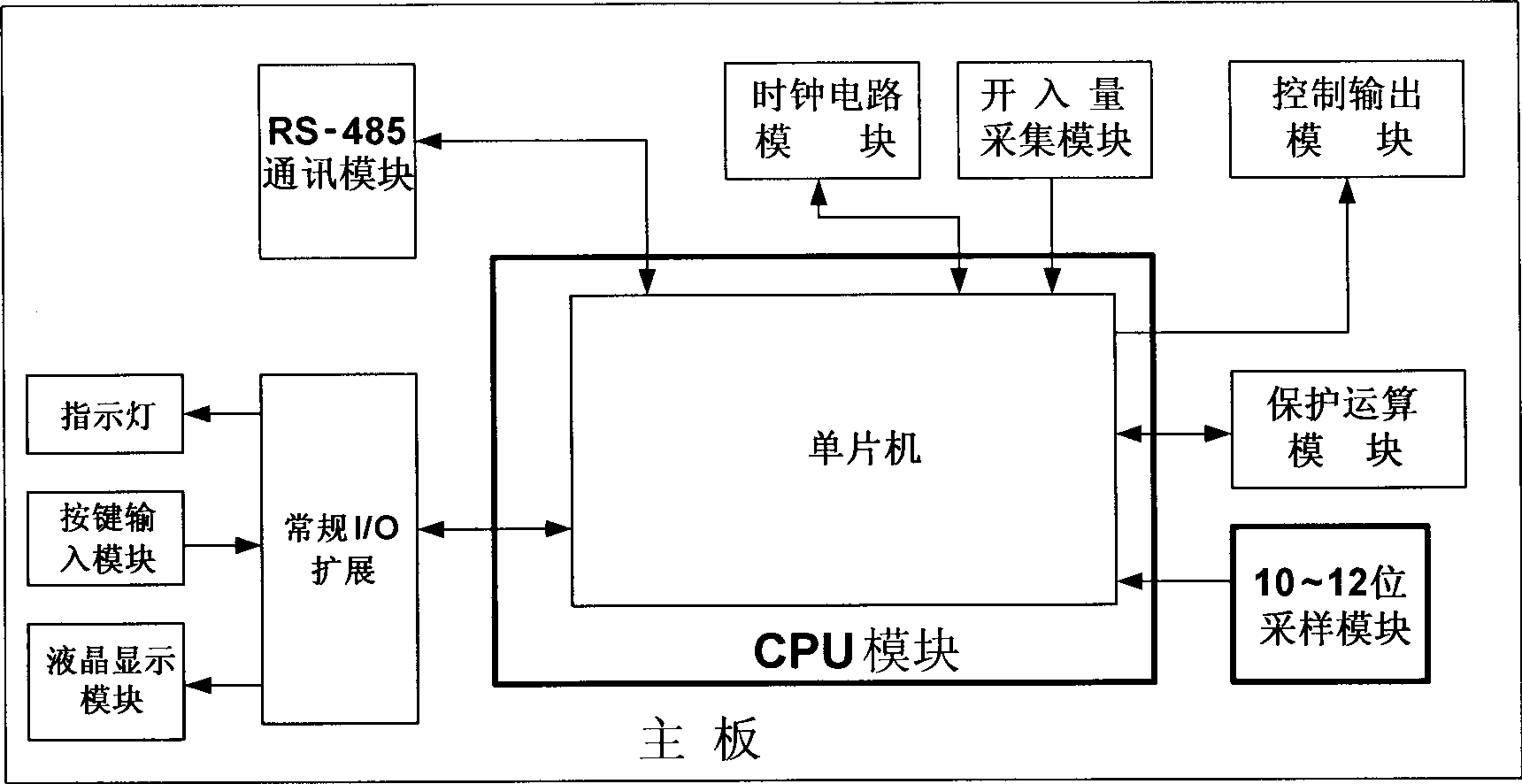

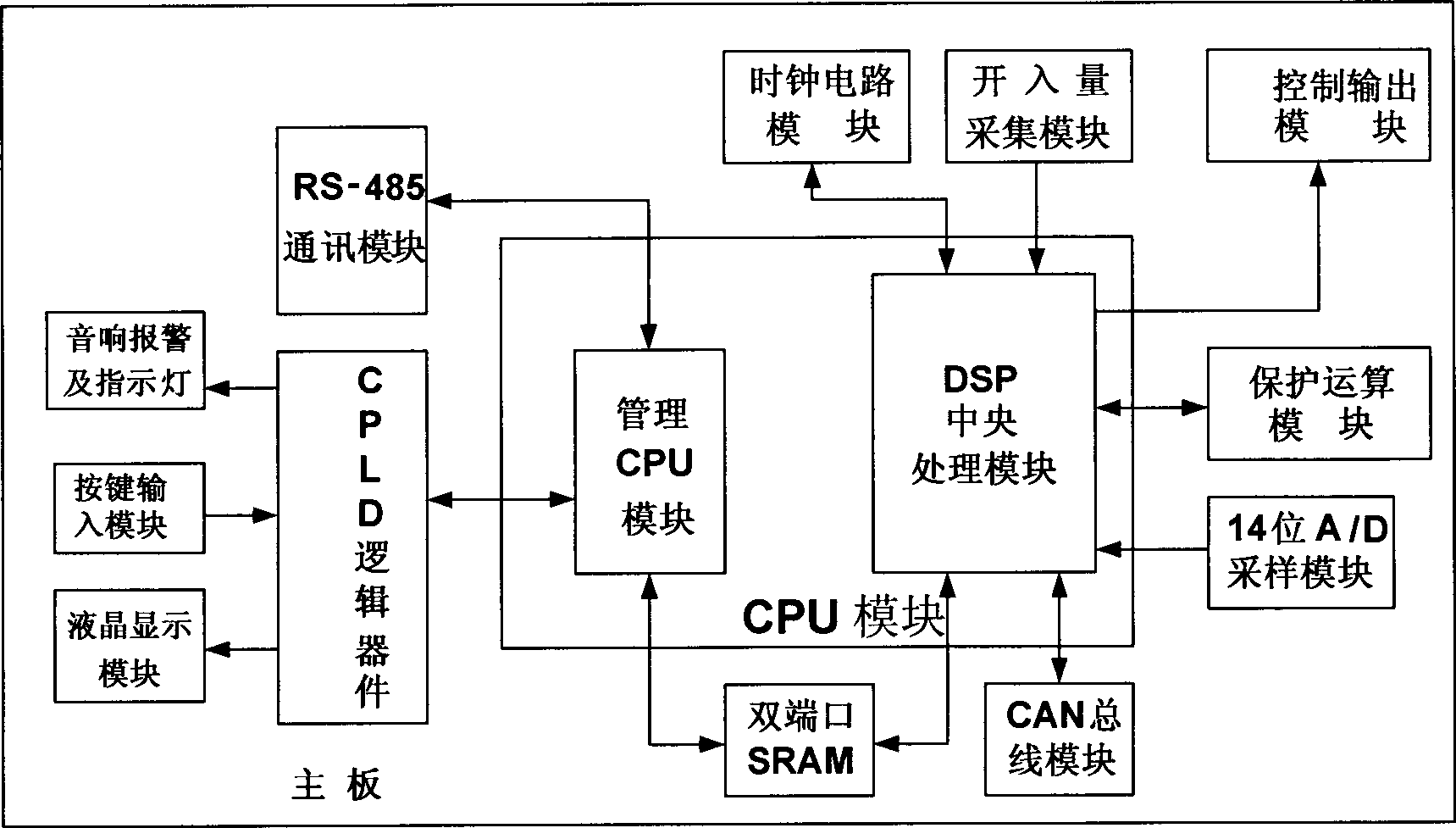

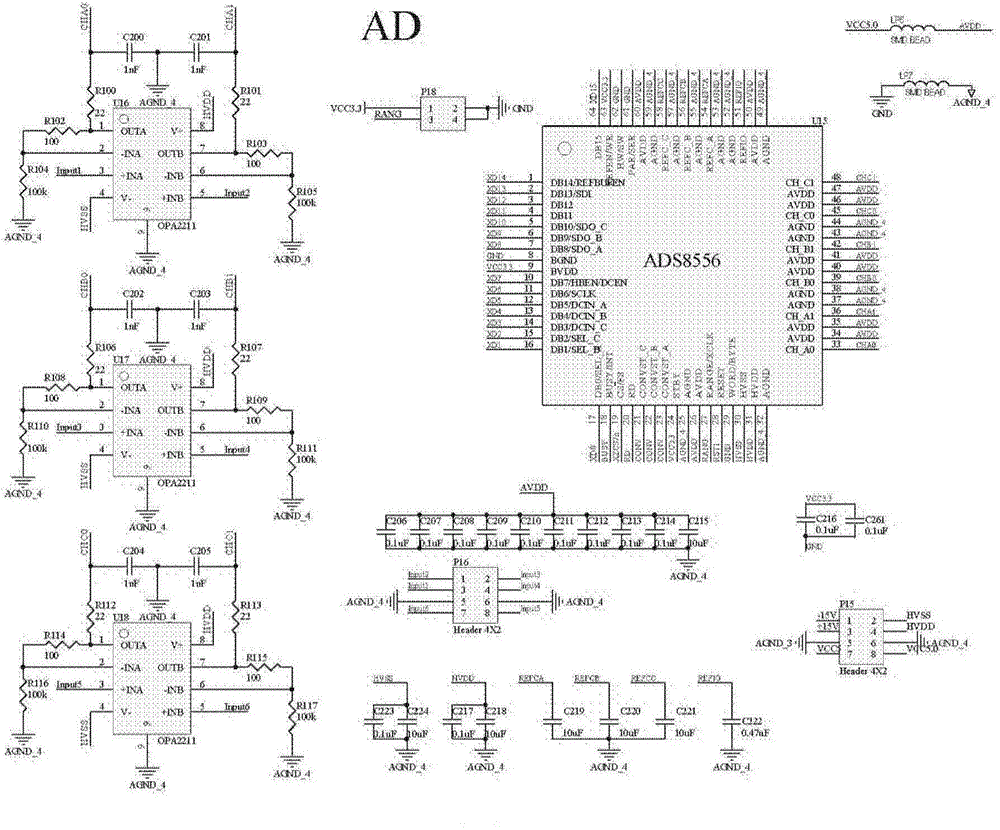

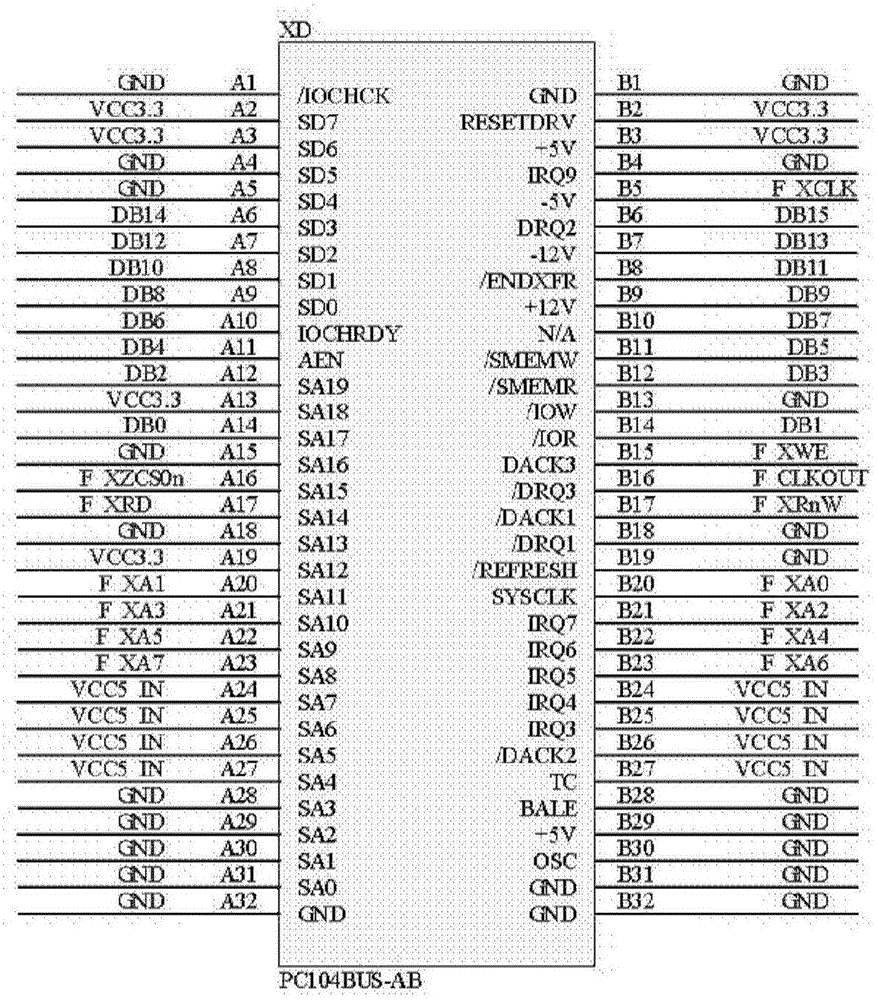

Mainboard using 32-bit DSP as kernel for microcomputer protection device

InactiveCN101373891AImprove performanceImprove efficiencyEmergency protective arrangements for automatic disconnectionElectric digital data processingMicrocomputerInformatization

The invention discloses a mainboard of a microcomputer protective device, which takes a 32-bit DSP as a core and mainly comprises a CPU module and a 14-bit sampling module connected with the CPU module. A double-port SRAM, a CPLD logic device, a CAN bus module and a communication module are also arranged in the mainboard; the CPU module comprises a CPU management module and a DSP central processing module; the CPU management module, the double-port SRAM and the DSP central processing module are sequentially connected through bidirectional buses; at the same time, the CPU management module is also connected with the CPLD logic device and the communication module, and the sampling module and the CAN bus module are also connected with the DSP central processing module. A modular circuit with multiple functions is also arranged in the mainboard, such as a warning device, a display module, a clock module, etc. The mainboard has the advantages of strong function, high processing speed, high informatization level, convenient data sharing, good stability, etc., and is mainly used in the microcomputer protective device.

Owner:成都瑞科电气有限公司

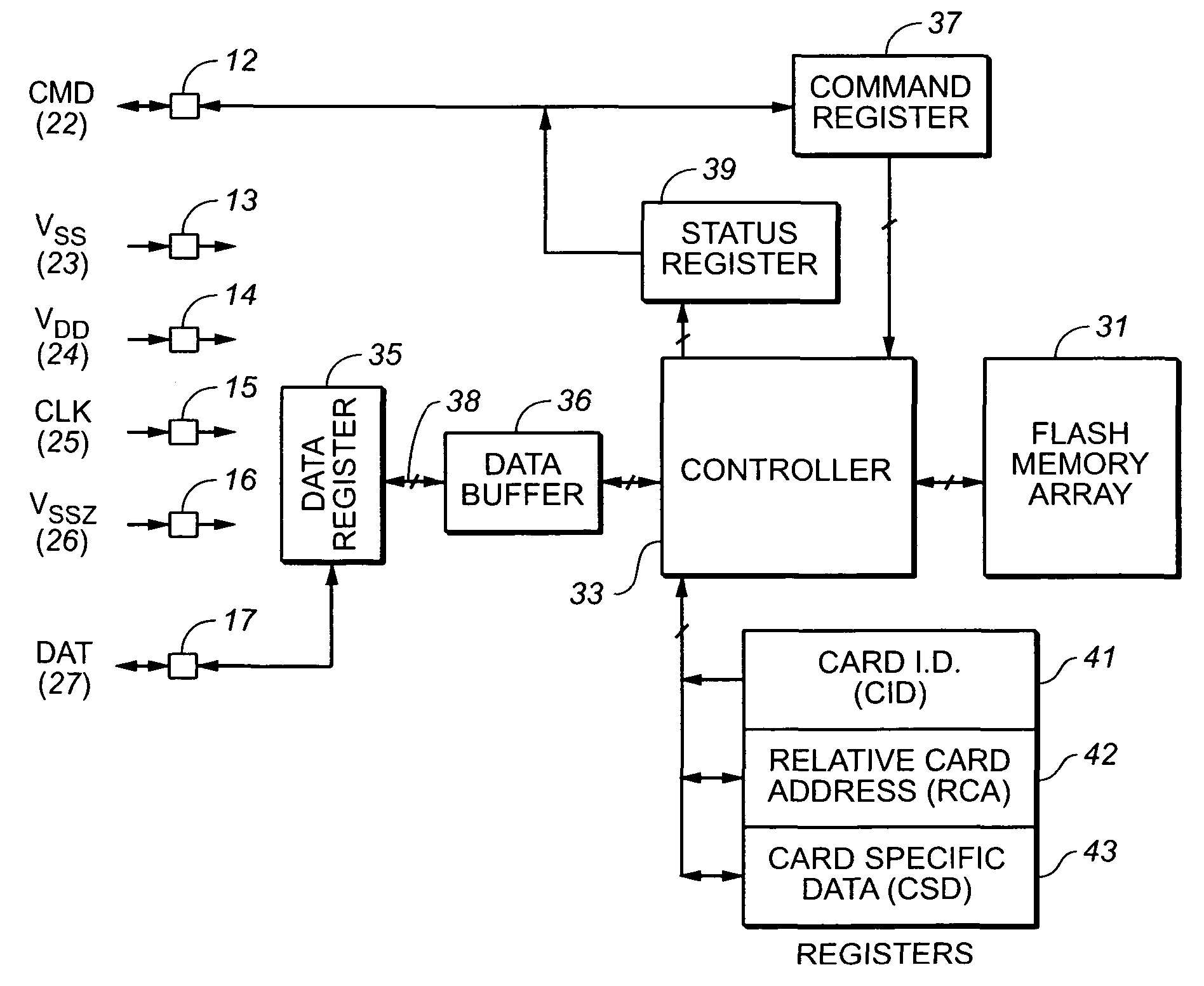

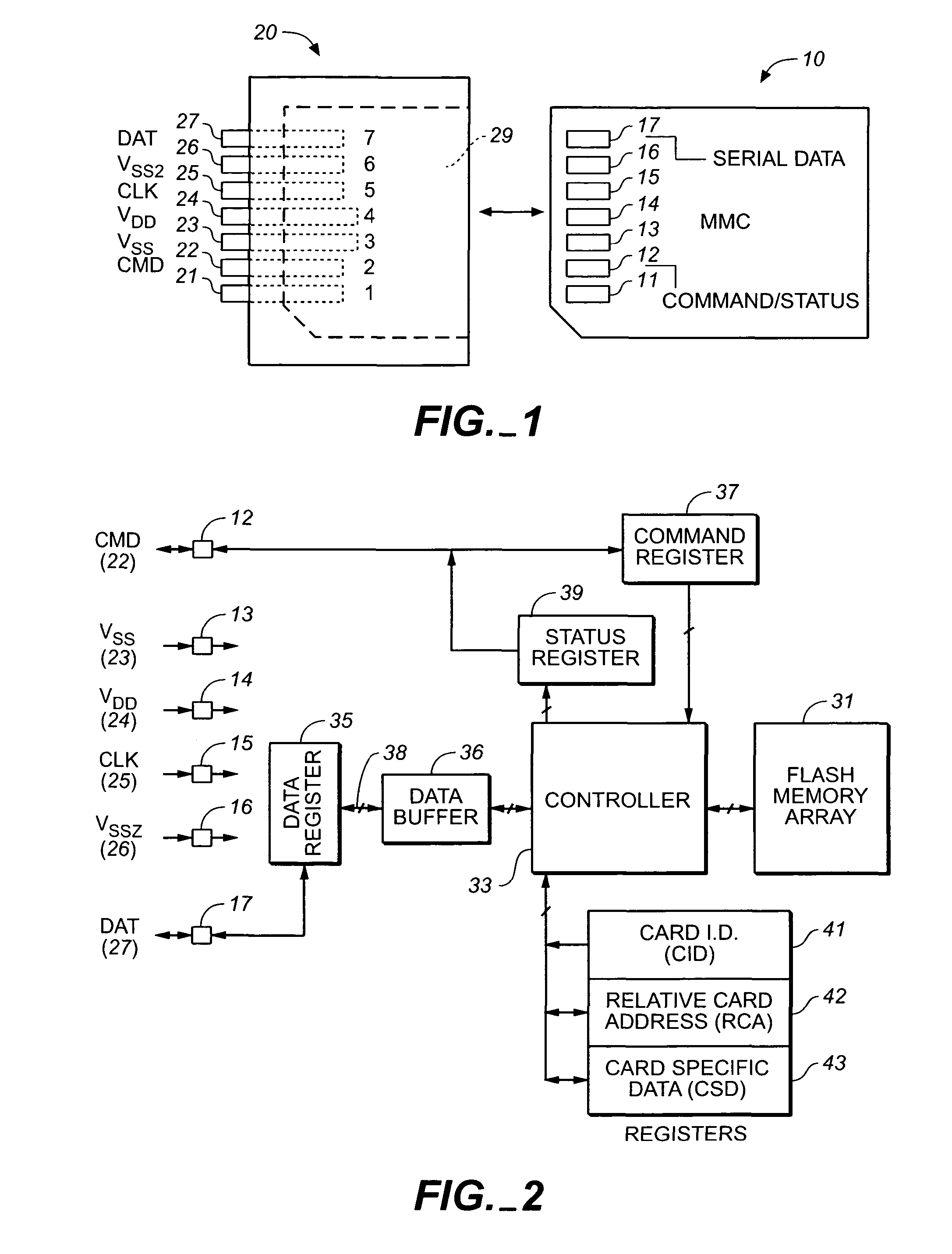

Non-volatile memory system with self test capability

ActiveUS7814377B2Fast and easy waySpeed up the debugging processElectronic circuit testingError detection/correctionMemory systemsHandshake

In a non-volatile memory system, test data may be retrieved by means of a circuit without the help of firmware. The circuit is triggered into action when it detects an abnormality in the processor or host interface. In such event, it formats the self test or status signals from the various blocks in the non-volatile memory system controller and sends a test message to the outside world without the assistance of the system processor or interface controller. When implemented in memory systems with multiple data lines, only one of the data lines may be utilized for such purpose, thereby allowing the testing to be performed while the system is still performing data transfer. Preferably, the system includes the test mode communication controller, which can select between a test channel and a host interface channel for the test message transfer so that the same testing may be performed when the memory system is in the test package as well as in an encapsulated package. The test message is transmitted repeatedly and the test message is structured so that it is easier for the receiver host to decipher the message without a handshake with the memory system. A communication controller preferably detects whether any of the communication channels is not used by the controller of a non-volatile memory system for sending signals and sends diagnostic signals through such channel.

Owner:SANDISK TECH LLC

Laser spot trajectory extracting and displaying device and method

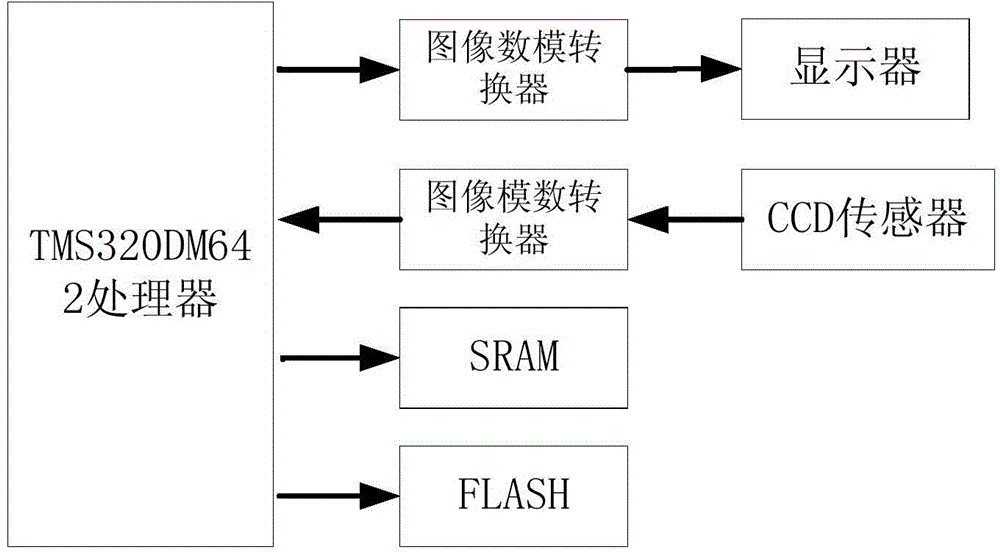

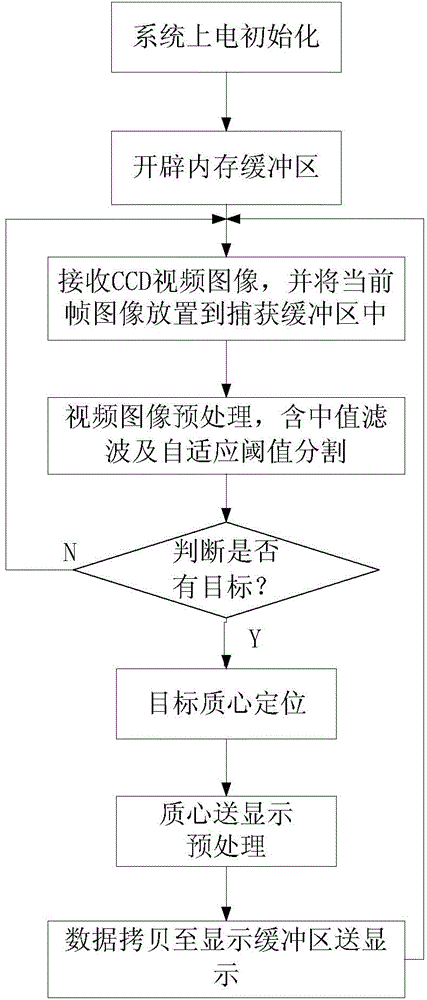

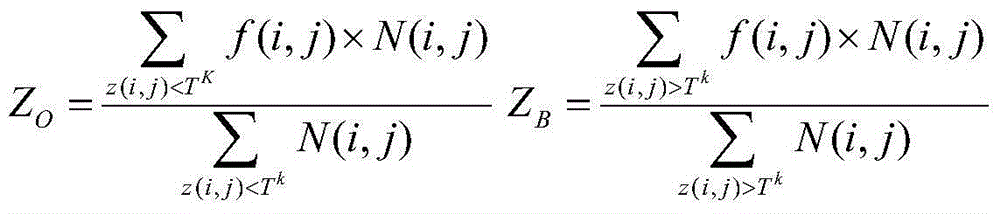

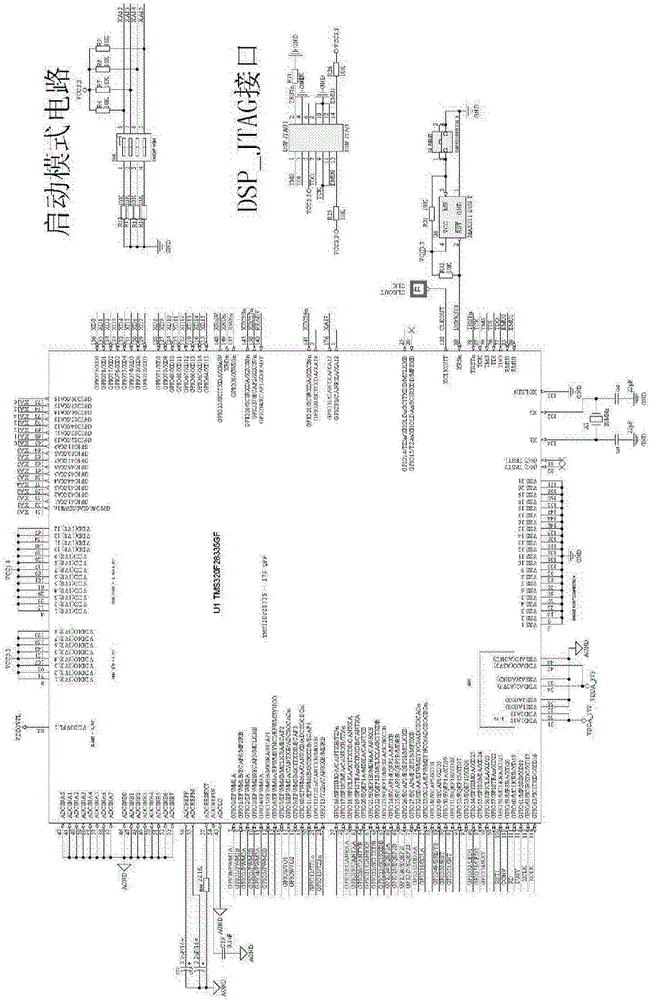

InactiveCN104410811ASpeed up the debugging processImprove efficiencyClosed circuit television systemsLaser scanningDisplay device

The invention discloses a laser spot trajectory extracting and displaying device and method, wherein the device includes an image processor, an ADC image analog-digital converter, a DAC image analog-digital converter, a display, a CCD sensor, a storage module; an analog signal output from the CCD sensor is converted into a digital signal by the ADC image analog-digital converter, and the signal is transmitted to an image processor for image processing. The processed image is converted into a PAL or NTSC standard analog television signal by the DAC image analog-digital converter, and then output by the display. The storage module is connected to the image processor for increasing storage space of the image processor. The invention has an advantage of being convenient in use. The device and method can collect and display quickly the trajectory of the laser spot, and thus further determines whether the laser scan trajectory of a device complies with a predetermined trajectory. The invention may improve greatly laser processing and debugging of a laser performance equipment and the factory acceptance efficiency.

Owner:HUBEI ENG UNIV

Communication control circuit for laser tracker

ActiveCN104898466AVarious forms of communicationEnhanced operational status monitoringProgramme control in sequence/logic controllersDecompositionTroubleshooting

The invention discloses a communication control circuit for a laser tracker, which comprises a digital signal processor, an acquisition module, a communication module, and a signal driving module. The control part of the digital signal processor of the communication control circuit only shoulders closed-loop control of the outermost layer position, and speed control and current closed-loop control are realized by the communication module in outer servo driving. In addition, the communication control circuit of the invention also adopts a modular design, and a testability design and an extensibility design are introduced. The circuit of the invention has complete integrated functions, the control part only shoulders closed-loop control of the outermost layer position, computational burden and real-time performance are reduced after decomposition, and hardware foundation is laid for adopting advanced control algorithm and improving the control frequency; monitoring on operation states of each module and the overall body is enhanced, and the debugging efficiency and the troubleshooting efficiency are improved; and the servo system which does not have a high real-time performance requirement can be directly used a current, speed and position three-closed loop integrated control and communication unit.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

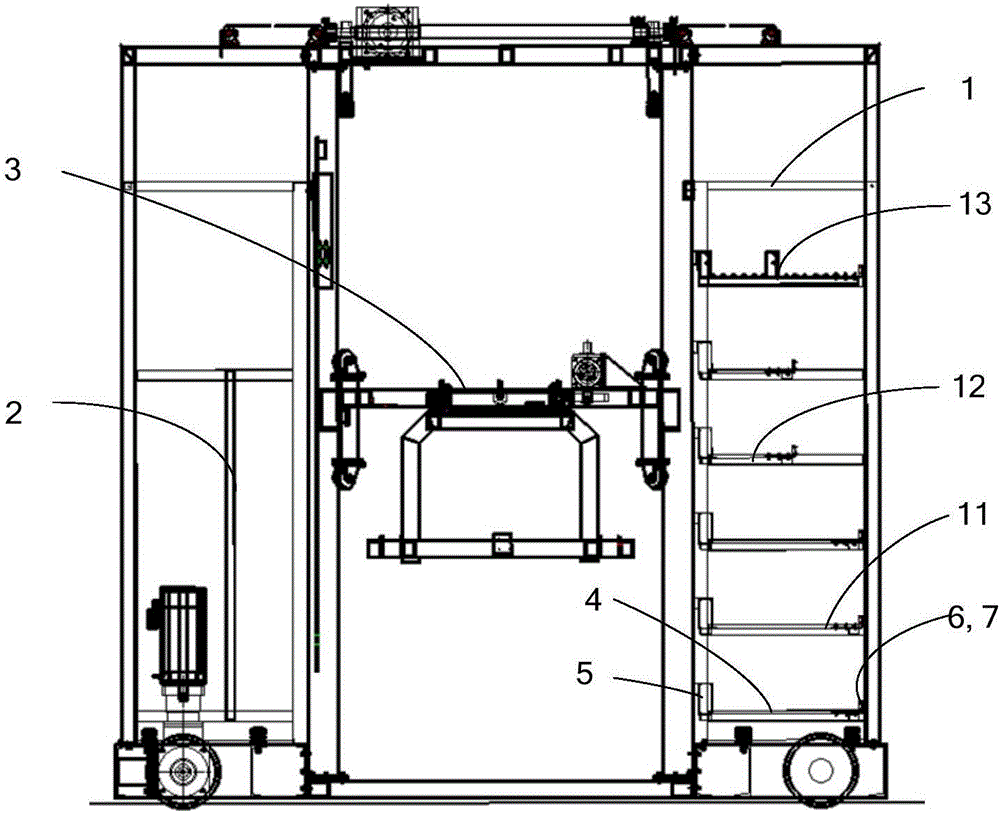

Battery replacing robot with temporary battery storage rack and battery replacing method of battery replacing robot

InactiveCN106515679AAvoid back and forth motionShorten the timeElectric propulsion mountingVehicle servicing/repairingElectricityElectrical battery

The invention belongs to the field of the battery replacement of an electric vehicle, and relates to a battery replacing robot with a temporary battery storage rack and a battery replacing method of the battery replacing robot. The battery replacing robot disclosed by the invention comprises a battery replacing robot body and a temporary battery storage rack located on one side of the battery replacing robot body; the temporary battery storage rack comprises a plurality of racks for big batteries, racks for small batteries and racks for big and small batteries, which are arranged layer by layer in the vertical direction. According to the battery replacing robot and the battery replacing method thereof disclosed by the invention, the temporary battery storage rack is arranged in the battery replacing robot body, and a fully-charged battery is stored in the temporary battery storage rack in advance; during replacement of the battery of a vehicle, the depleted battery is taken out and placed into a vacant space in the temporary battery storage rack; the fully-charged battery in the temporary battery storage rack is taken out and put into the vehicle; and therefore, the back and forth movement of the battery replacing robot between the vehicle and charging equipment is avoided, a lot of time is saved, and the efficiency of battery replacement is enhanced.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

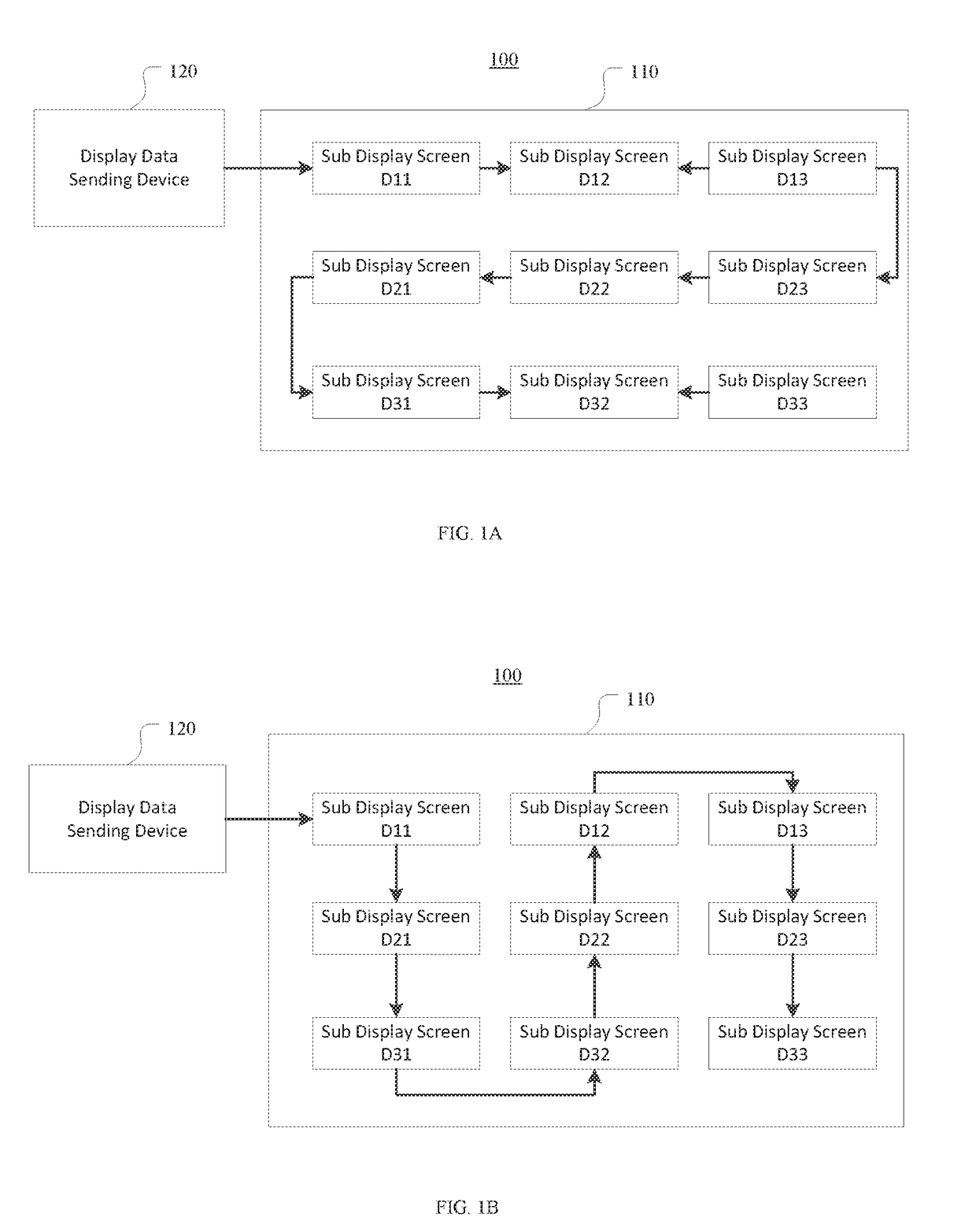

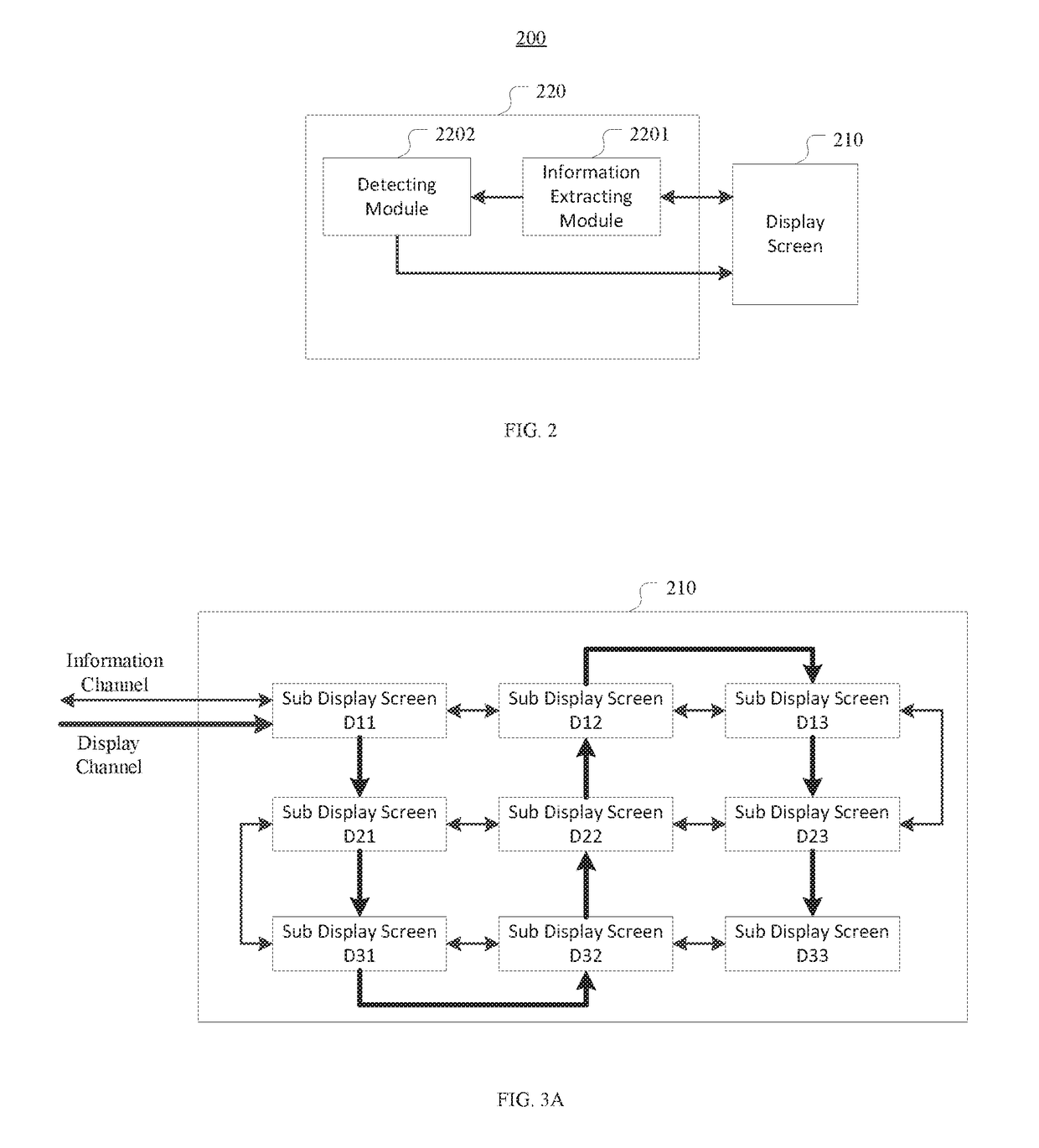

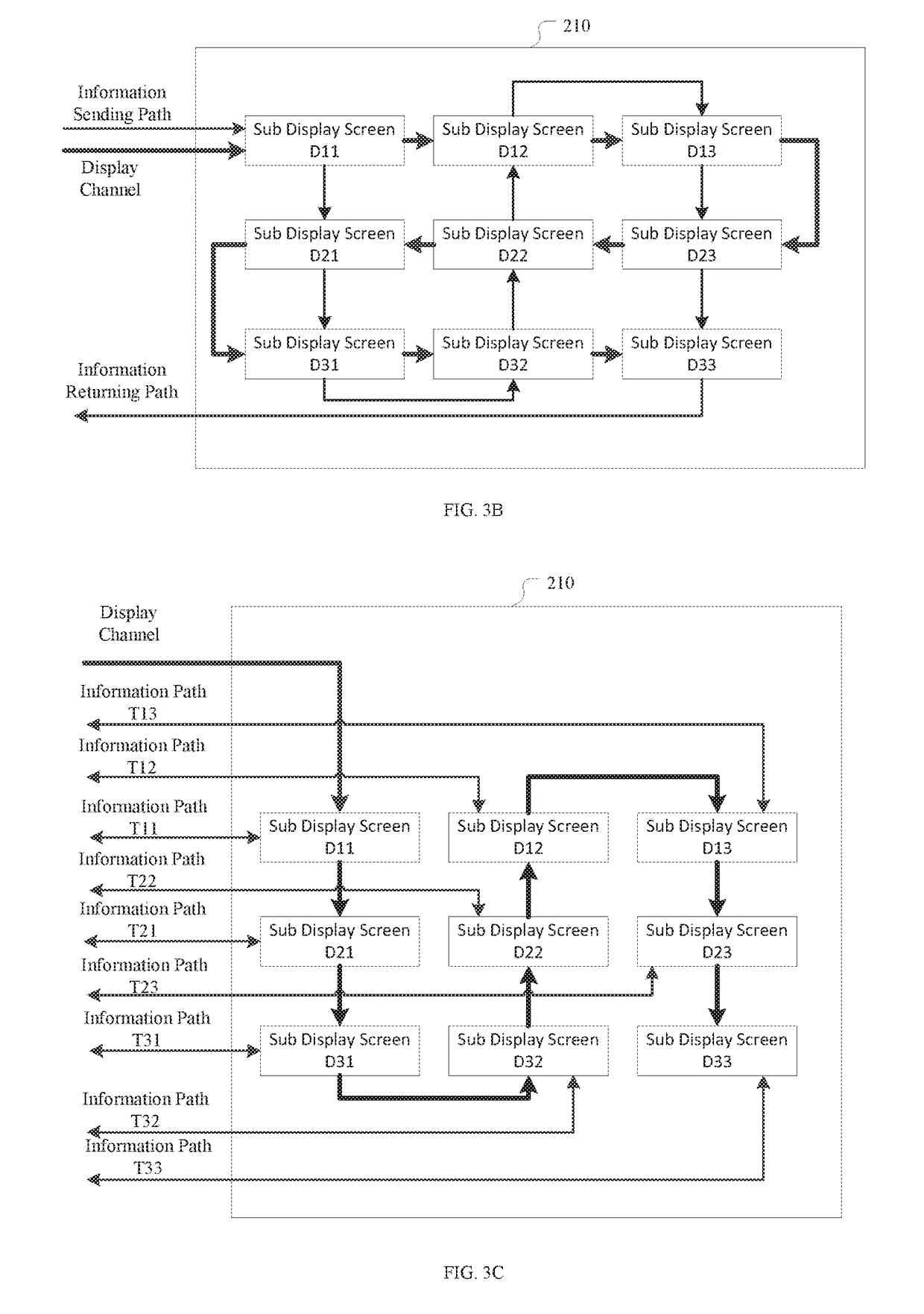

Display Apparatus and Display Control Method

ActiveUS20190065133A1Improve the display effectSpeed up the debugging processStatic indicating devicesSelective content distributionComputer engineering

Owner:CHIPONE TECH BEIJINGCO LTD

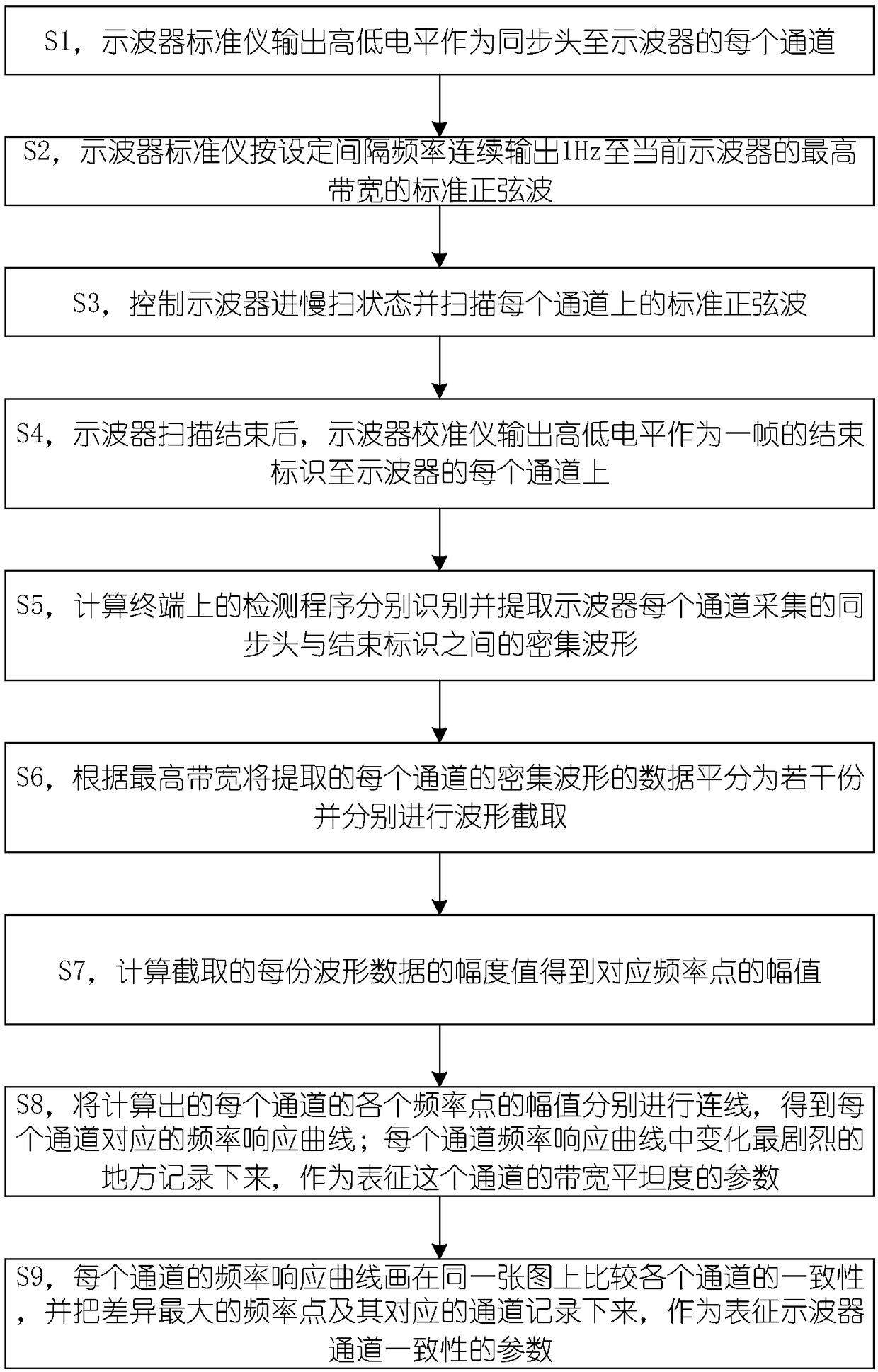

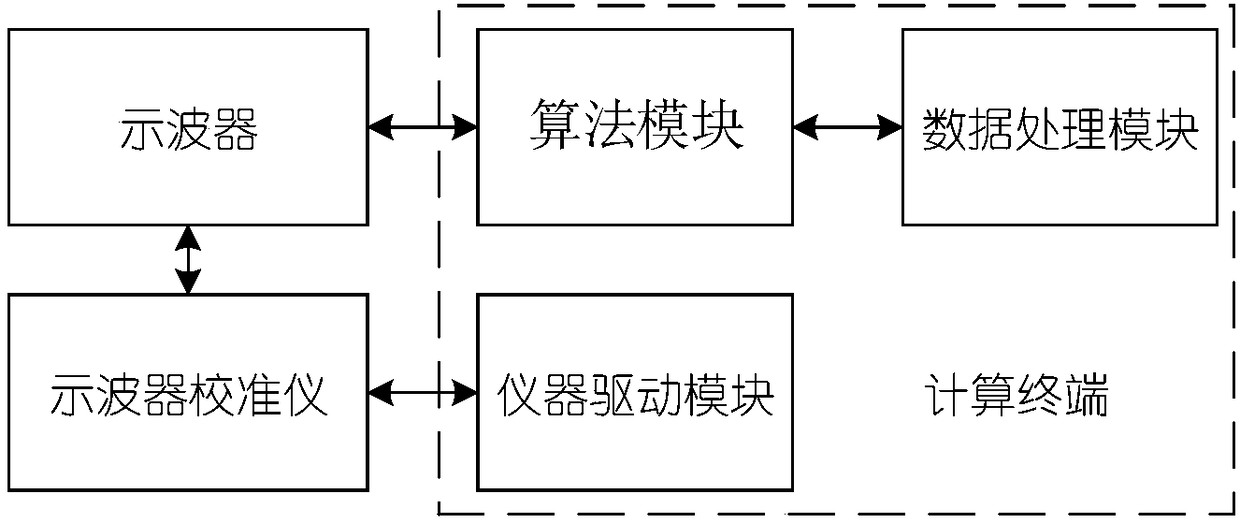

Method and system for detecting bandwidth flatness and consistency of multichannel digital oscilloscope

ActiveCN108107394ASpeed upShorten development timeElectrical measurementsHigh- and low-levelSine wave

The invention discloses a method and system for detecting the bandwidth flatness and consistency of a multichannel digital oscilloscope, and the method comprises the following steps: S1, enabling an oscilloscope standard instrument to output high and low levels to all channels; S2, enabling the oscilloscope standard instrument to continuously output standard sine waves from 1Hz to the maximum bandwidth; S3, enabling the oscilloscope to scan the standard sine wave of each channel; S4, enabling the oscilloscope standard instrument to output an end identification to each channel; S5, enabling a detection program to extract the intensive waveform data collected by each channel of the oscilloscope; S6, dividing the data of the intensive waveform into a plurality of parts, and carrying out the waveform interception; S7, calculating the amplitude of each part of waveform data; S8, connecting the calculated amplitudes of all frequency points of all channels, and obtaining a corresponding frequency response curve; S9, comparing the consistency of all channels on the same image, and recording the frequency point with the maximum difference and the corresponding channel as oscilloscope consistency parameters. The method speeds up the circuit bandwidth debugging, and shortens a product research and development time.

Owner:FUJIAN LILLIPUT OPTOELECTRONICS TECH

Time Travel Source Code Debugger Incorporating Point In Time Links

ActiveUS20190213102A1Increase heightEasy to changeDecompilation/disassemblyPlatform integrity maintainanceHead-up displaySource code

A novel and useful system and method of time traveling source code debugging including several advanced capabilities that significantly improve the source code debugging process. Upon hitting a breakpoint or opening a dump file, the debugger travels to the future which can be altered by a user by modifying code on the fly (live coding) and receiving immediate feedback to validate bug fixes. Visual annotations including values of variables and expressions are provided as a heads up display effectively flattening time and space. A pivoting capability allows a user to switch the execution context of the code at any time. Point in time links that store the state of the debugging session can be created and activated. An asynchronous collaboration and messaging system enables multiple participants to share a debugging session. An optional redaction capability is also provided for obscuring or replacing sensitive private information.

Owner:OZCODE LTD

Time Travel Source Code Debugger Incorporating Live Coding Ability

ActiveUS20190227904A1Easy to changeSpeed up the debugging processDecompilation/disassemblyNon-redundant fault processingHead-up displayRotation function

A novel and useful system and method of time traveling source code debugging including several advanced capabilities that significantly improve the source code debugging process. Upon hitting a breakpoint or opening a dump file, the debugger travels to the future which can be altered by a user by modifying code on the fly (live coding) and receiving immediate feedback to validate bug fixes. Visual annotations including values of variables and expressions are provided as a heads up display effectively flattening time and space. A pivoting capability allows a user to switch the execution context of the code at any time. Point in time links that store the state of the debugging session can be created and activated. An asynchronous collaboration and messaging system enables multiple participants to share a debugging session. An optional redaction capability is also provided for obscuring or replacing sensitive private information.

Owner:OZCODE LTD

Water-feeding pump system driven by high-speed synchronous motor

ActiveCN103147955ANo lossImprove transmission efficiencyPump installationsPositive-displacement liquid enginesSynchronous motorFluid coupling

The invention discloses a water-feeding pump system driven by a high-speed synchronous motor, and relates to an efficient, energy saving and speed governing electric water-feeding pump system which is used in a large and medium-sized thermal power generating unit. The water-feeding pump system comprises a low rotational speed front-mounted pump, a low rotational speed front-mounted pump motor, an intermediate frequency variable-frequency power supply, a high-speed synchronous motor, a high rotational speed water-feeding pump and a static excitation device, wherein the high-speed synchronous motor is driven by the intermediate frequency variable-frequency power supply; the rotational speed is steplessly adjustable in a range from 60 rpm to 6,000 rpm; and the high-speed synchronous motor and the high rotational speed water-feeding pump are in direct connection through opposite wheels. Problems that an existing speed governing electric water-feeding pump adopts speed governing operation of a speed increase gear and a hydrodynamic coupler, the transmission loss is large, the response speed is slow, the adjusting dead zone is large, impact of starting on station service buses is obvious and the like are solved. The comprehensive transmission efficiency of the water-feeding pump system driven by the high-speed synchronous motor is higher than that of a steam feed pump system remarkably, heat consumption of a steam turbine generator unit is reduced remarkably, and the net coal consumption rate of the generator unit is decreased.

Owner:章礼道

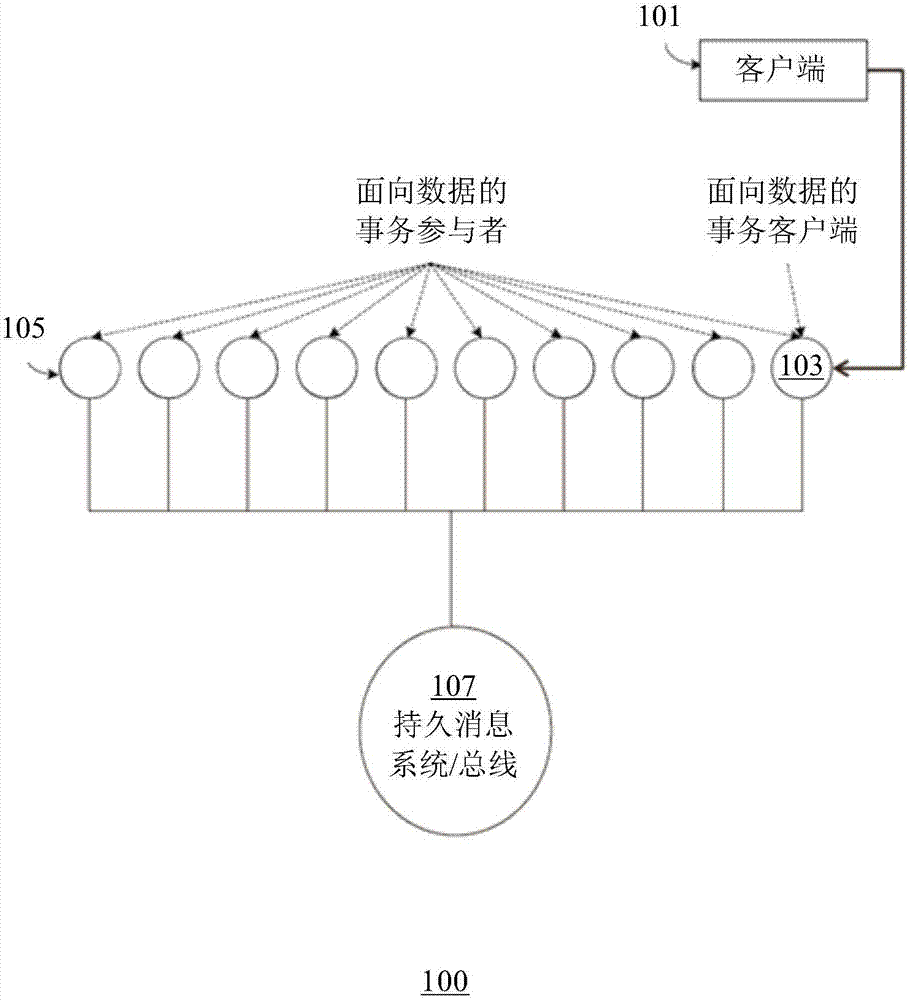

System for high-throughput handling of transactions in data-partitioned, distributed, relational database management system

ActiveCN107113341AImprove performanceImprove throughputRelational databasesTransmissionMessage deliveryRelational database management system

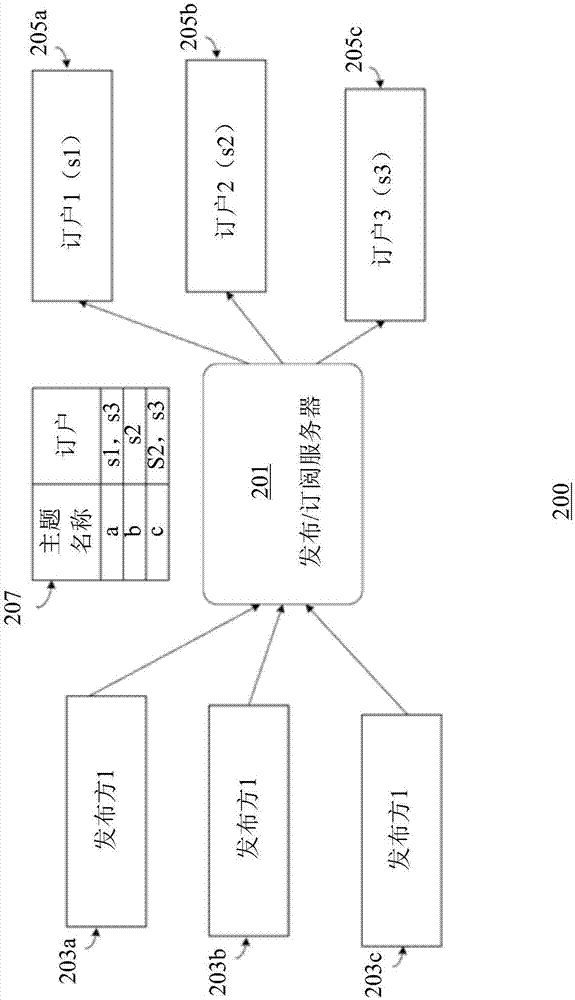

The invention discloses a system for high-throughput handling of transactions in a data-partitioned, distributed, relational database management system. A topic-based messaging architecture (including schema, protocols, naming conventions, etc.) is used in a distributed data-oriented OLTP environment. The topic-based messaging architecture is implemented as a type of publication-subscription ("pub-sub") messaging pattern. In one or more embodiments of the topic-based system, messages are published to "topics" or named logical channels. Subscribers in a topic-based system will receive all messages published to the topics to which they subscribe, and all subscribers to a topic will receive the same messages. The publisher is responsible for defining the classes of messages to which subscribers can subscribe. The topic-based messaging interface improves the scalability of a distributed database management system and provides a robust mechanism for message delivery.

Owner:HUAWEI TECH CO LTD

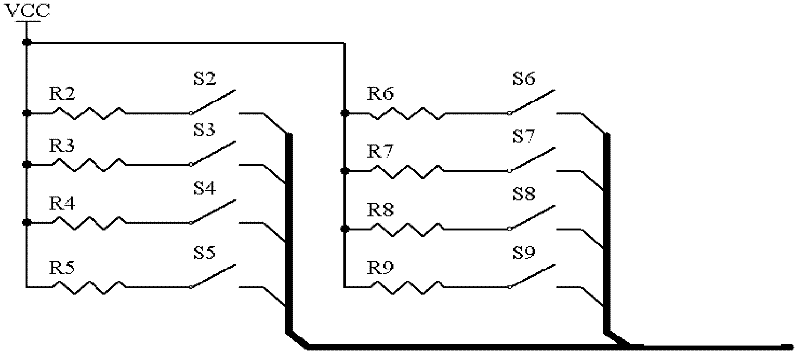

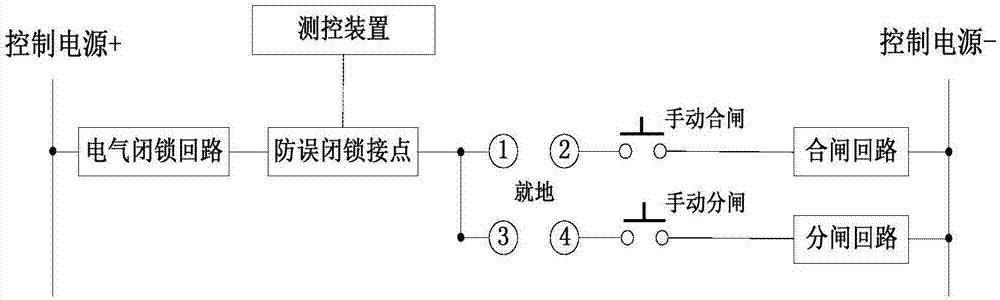

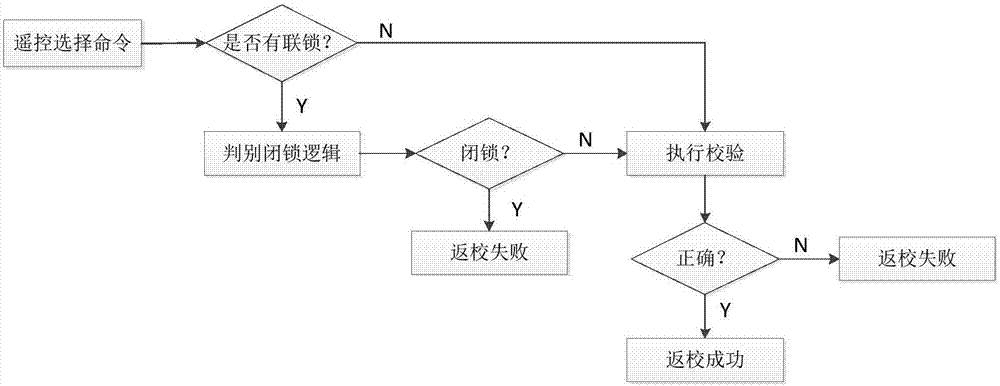

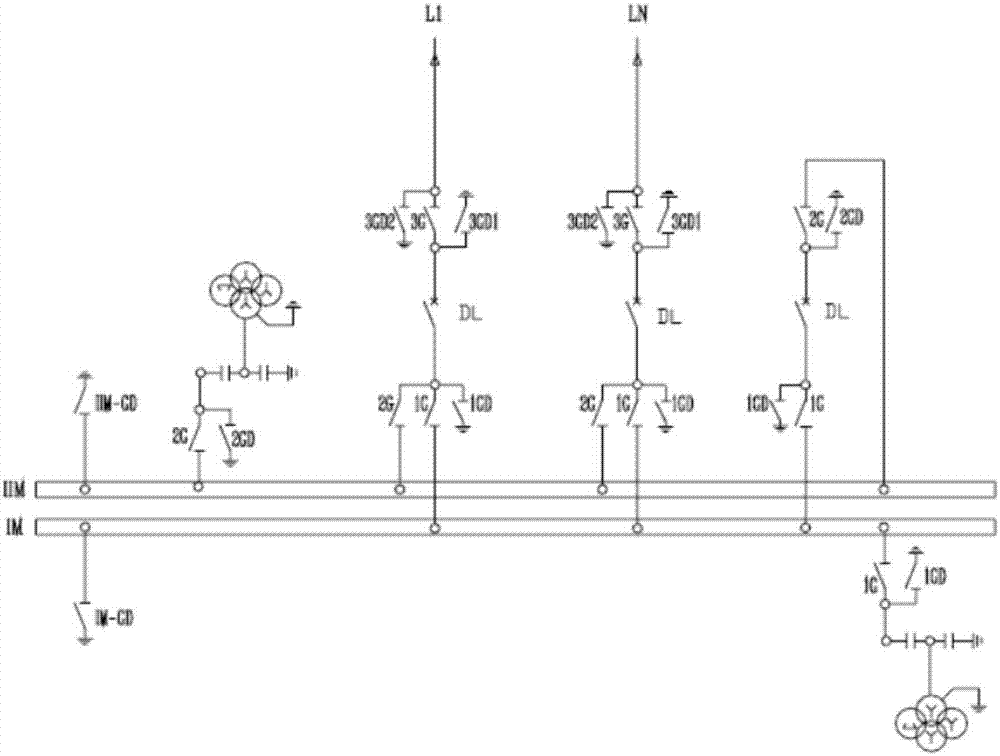

Measurement and control device and misoperation-preventive locking logic display method thereof

ActiveCN107482772ASpeed up the debugging processReal-time discriminationCircuit arrangementsInformation technology support systemEmbedded systemEngineering

The present invention relates to a measurement and control device and a misoperation-preventive locking logic display method thereof, which belong to the technical field of power system protection and automation. The method of the invention firstly determines the misoperation-preventive locking logic according to a misoperation-preventive logic rule base; then, the determined misoperation-preventive locking logic is loaded into the measurement and control device; the measurement and control device identifies the received misoperation-preventive locking logic and marks it with an OR gate logic, and the corresponding logical expression is split into at least two parallel sub-logical expressions; and finally the contents of the sub-logical expressions obtained are graphically displayed. The method of the invention can display the blocking logic diagram in real-time on the measurement and control device so as to make the engineer intuitively, conveniently and real-time determine whether the blocking logic result reflects the actual working condition of the equipment layer and to facilitate the debugging progress of the automation project of a substation.

Owner:XUJI GRP +3

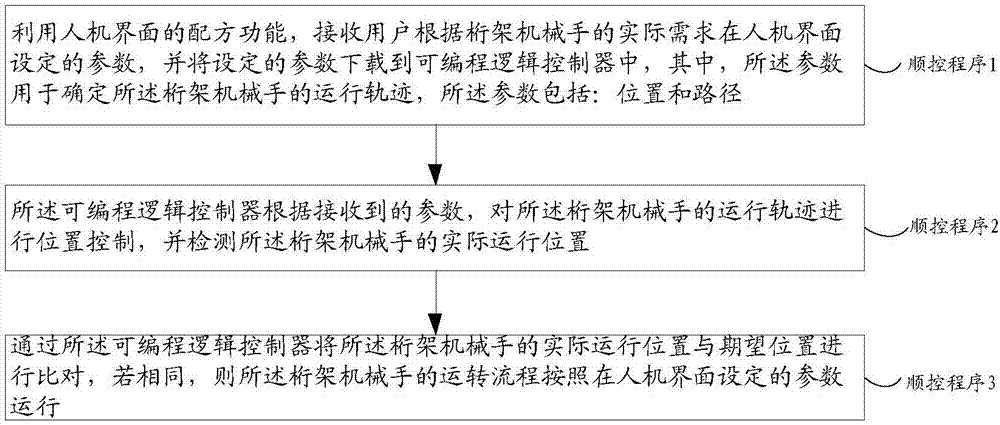

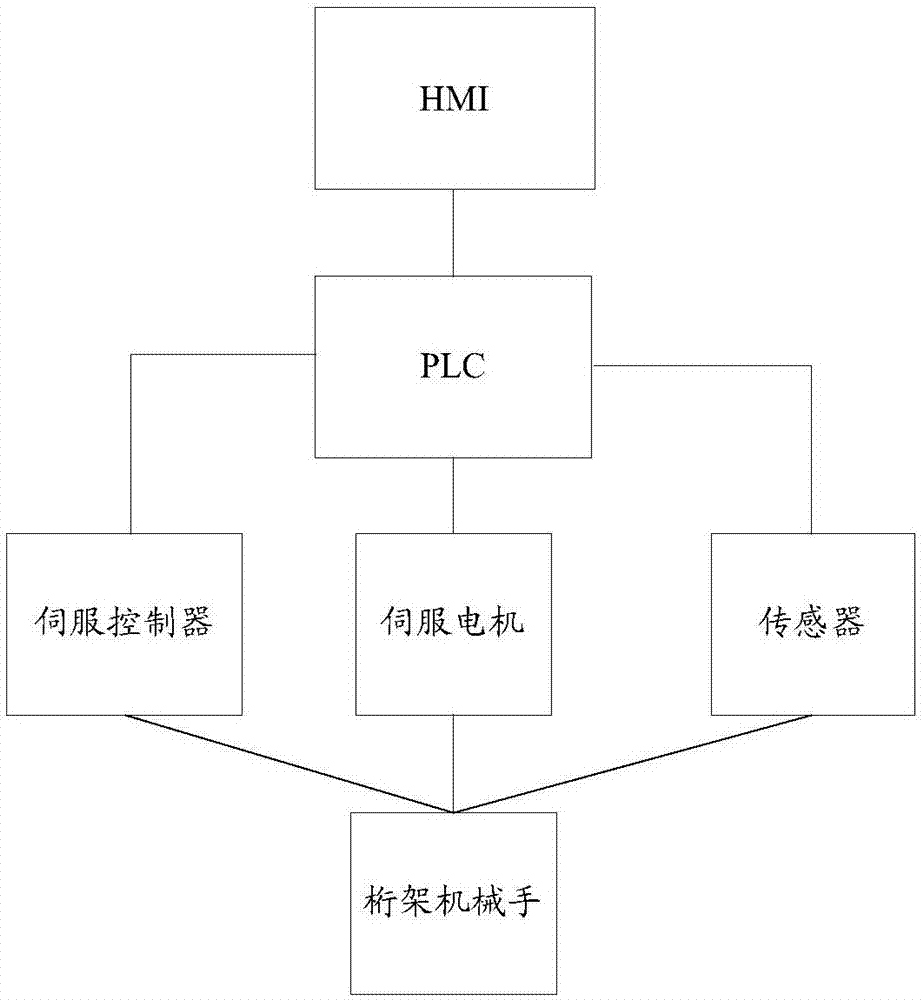

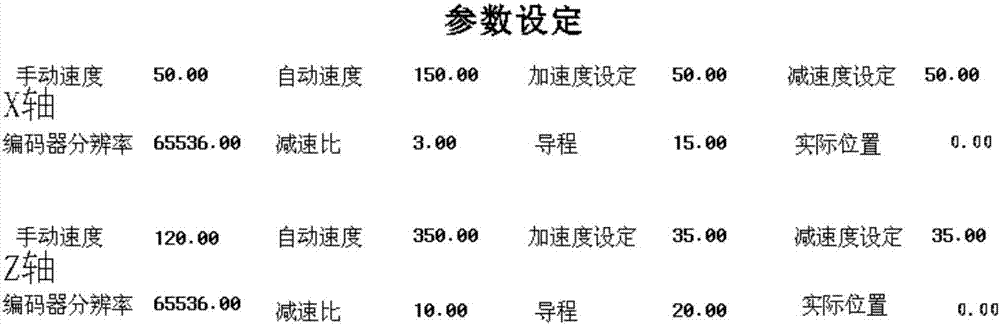

Visual programming method and operation system of truss mechanical arm

InactiveCN107378951ASpeed up the debugging processReduce commissioning costsProgramme-controlled manipulatorProgrammable logic controllerManipulator

The invention provides a visual programming method and operation system of a truss mechanical arm. The debugging progress of the truss mechanical arm can be accelerated, and the debugging cost of the truss mechanical arm can be reduced. The method comprises the steps that by means of the recipe function of a human machine interface, parameters set by a user on the human machine interface according to the actual need of the truss mechanical arm are received, the set parameters are downloaded into a programmable logic controller, and the parameters are used for determining the operating track of the truss mechanical arm and comprise positions and paths; the programmable logic controller carries out position control over the operating track of the truss mechanical arm according to the received parameters, and the actual operating position of the truss mechanical arm is detected; and the actual operating position of the truss mechanical arm and the expected position are compared through the programmable logic controller, and if the actual operating position of the truss mechanical arm and the expected position are the same, the operating process of the truss mechanical arm operates according to the parameters set on the human machine interface. The visual programming method and operation system of the truss mechanical arm relate to the technical field of automation equipment.

Owner:北京隆庆智能激光装备有限公司

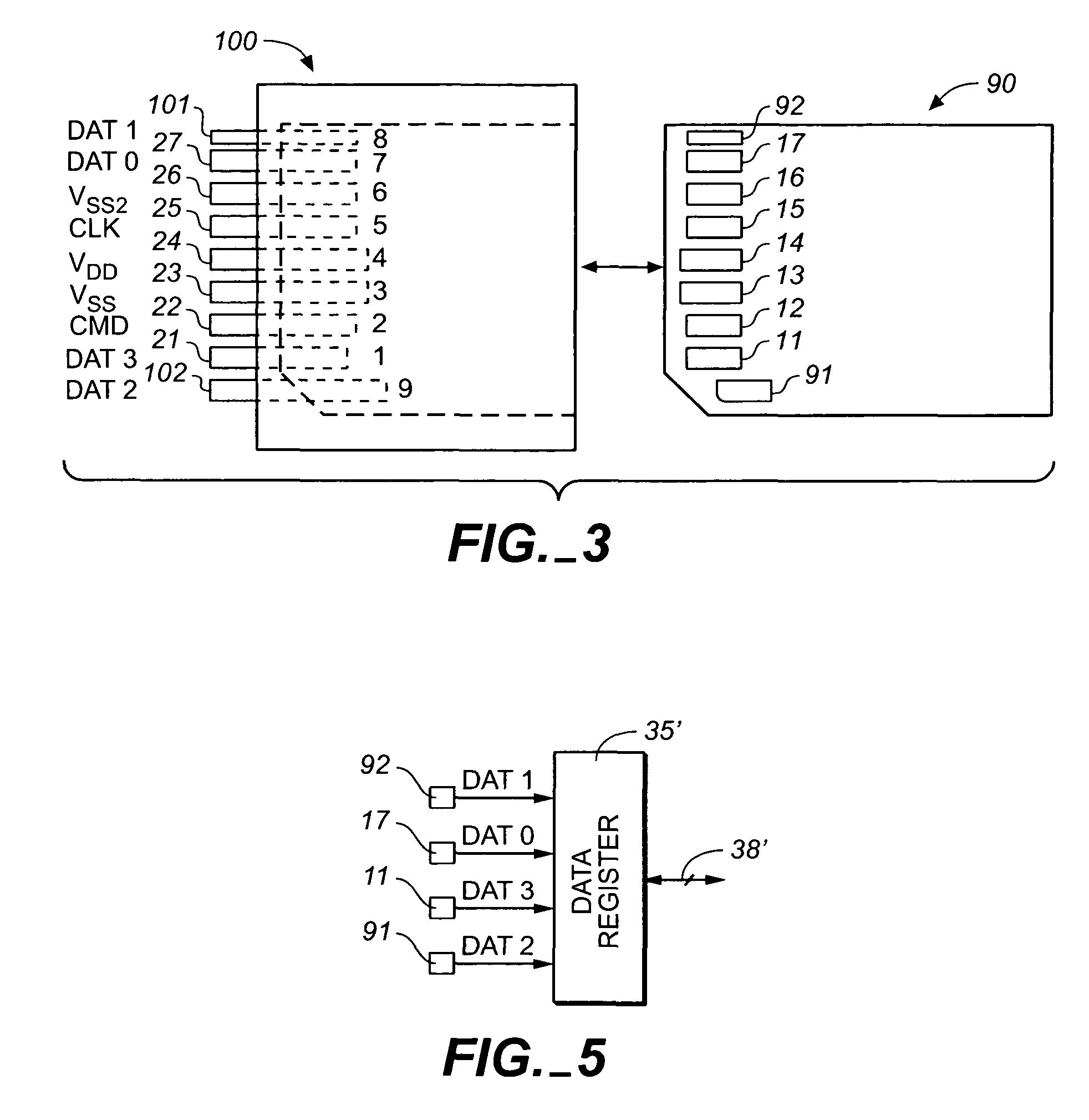

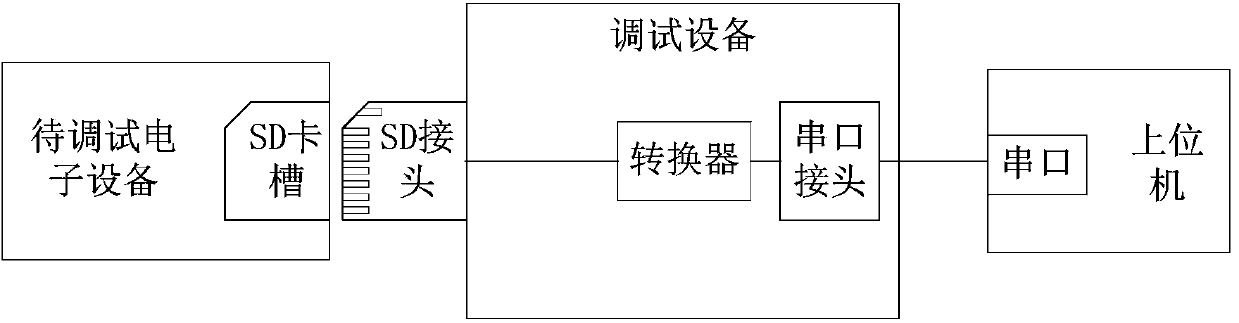

SD card slot based debugging equipment, system and method

InactiveCN103810068ATroubleshoot test debugging issuesAvoid disassemblyDetecting faulty computer hardwareProblem solveData conversion

The invention provides an SD card slot based debugging equipment, system and method, wherein the debugging equipment comprises a converter, an SD connector and a serial port connector, the converter is used to convert the data received from the SD connector into the serial port data and output the serial port data from the serial port connector, meanwhile, the converter is used to convert the data received from the serial port connector into the SD data and output the SD data from the SD connector, and the SD connector is used for being inserted into an SD card slot. According to the invention, the problem of abnormal test debugging of the whole machine occurring before starting a system server is solved, the disassembly is avoided, and the debugging speed and the problem solving speed are increased.

Owner:FUZHOU ROCKCHIP SEMICON

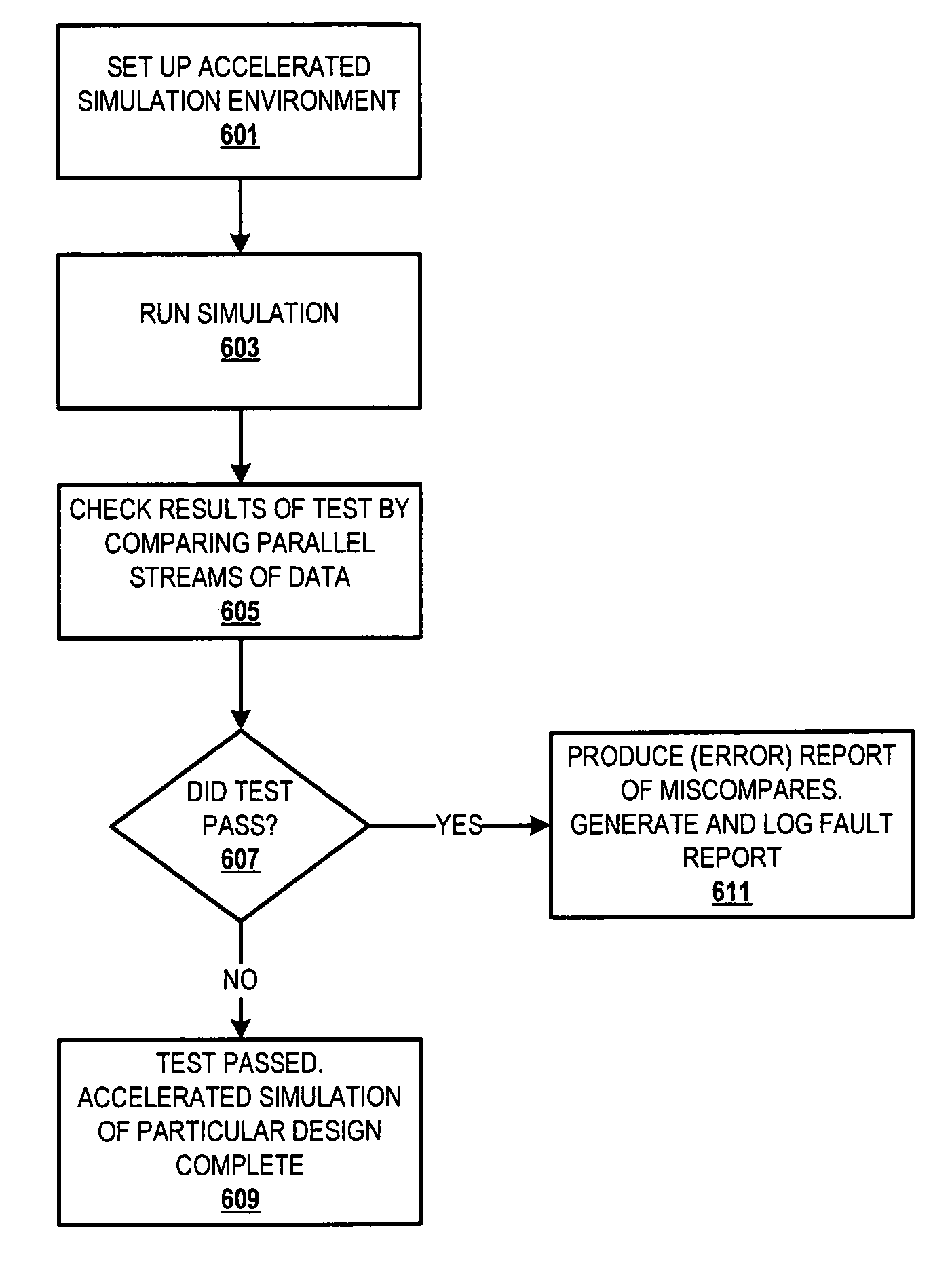

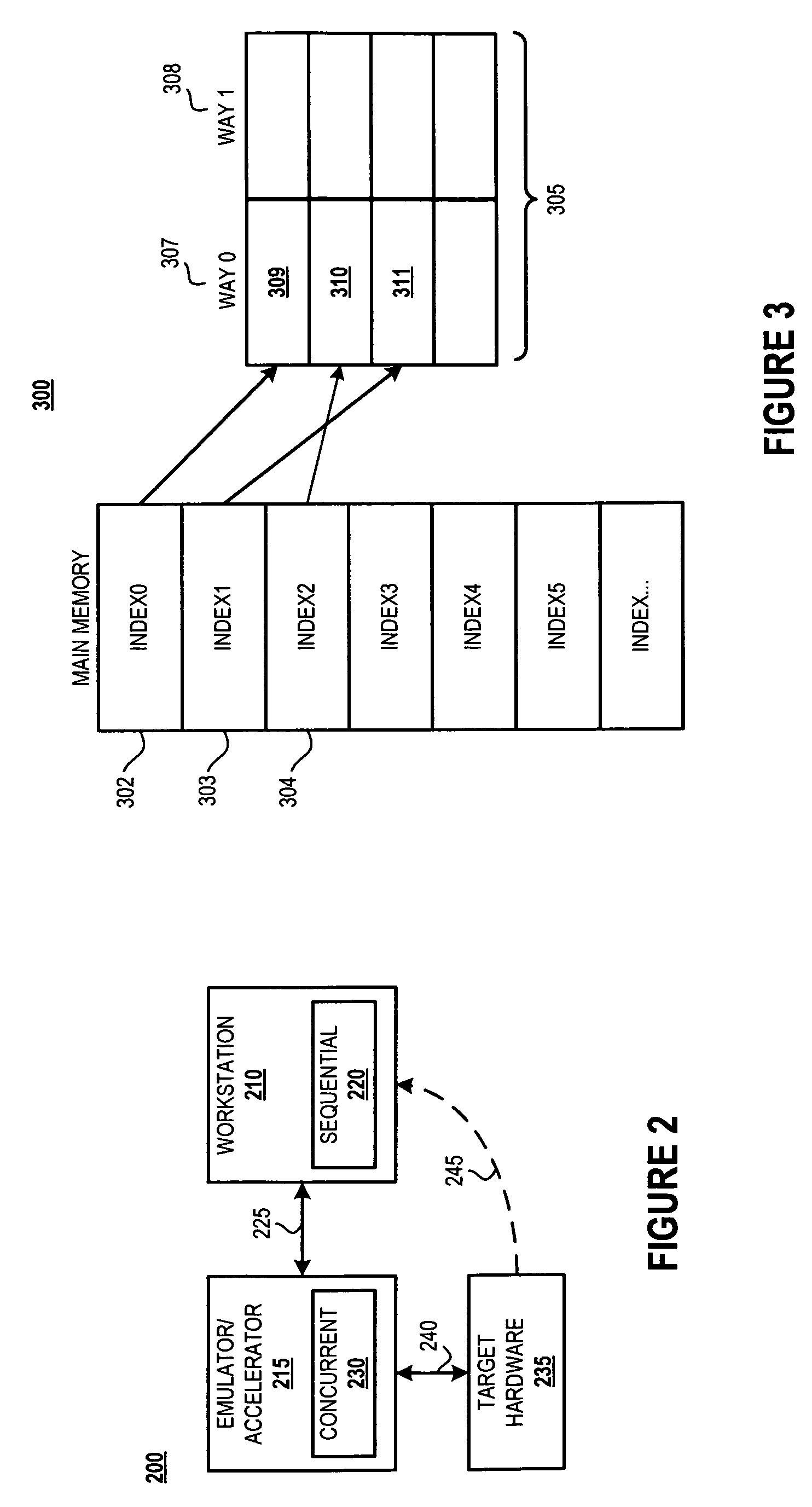

Accelerated simulation and verification of a system under test (SUT) using cache and replacement management tables

ActiveUS7756695B2Speed up the debugging processData augmentationComputer aided designSoftware simulation/interpretation/emulationDirect entryLocking mechanism

Owner:TWITTER INC

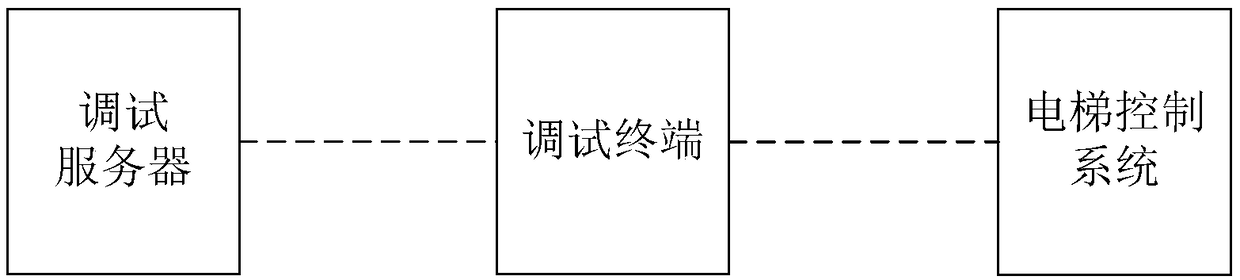

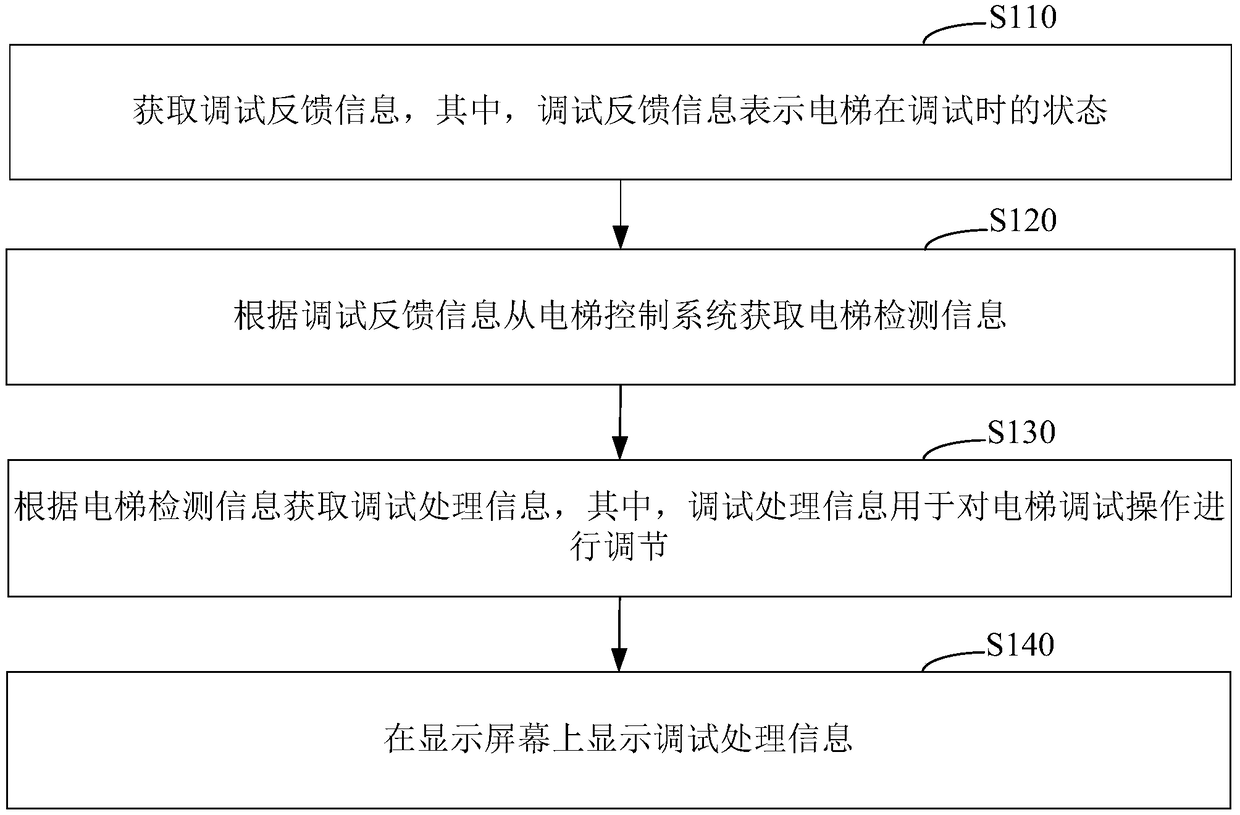

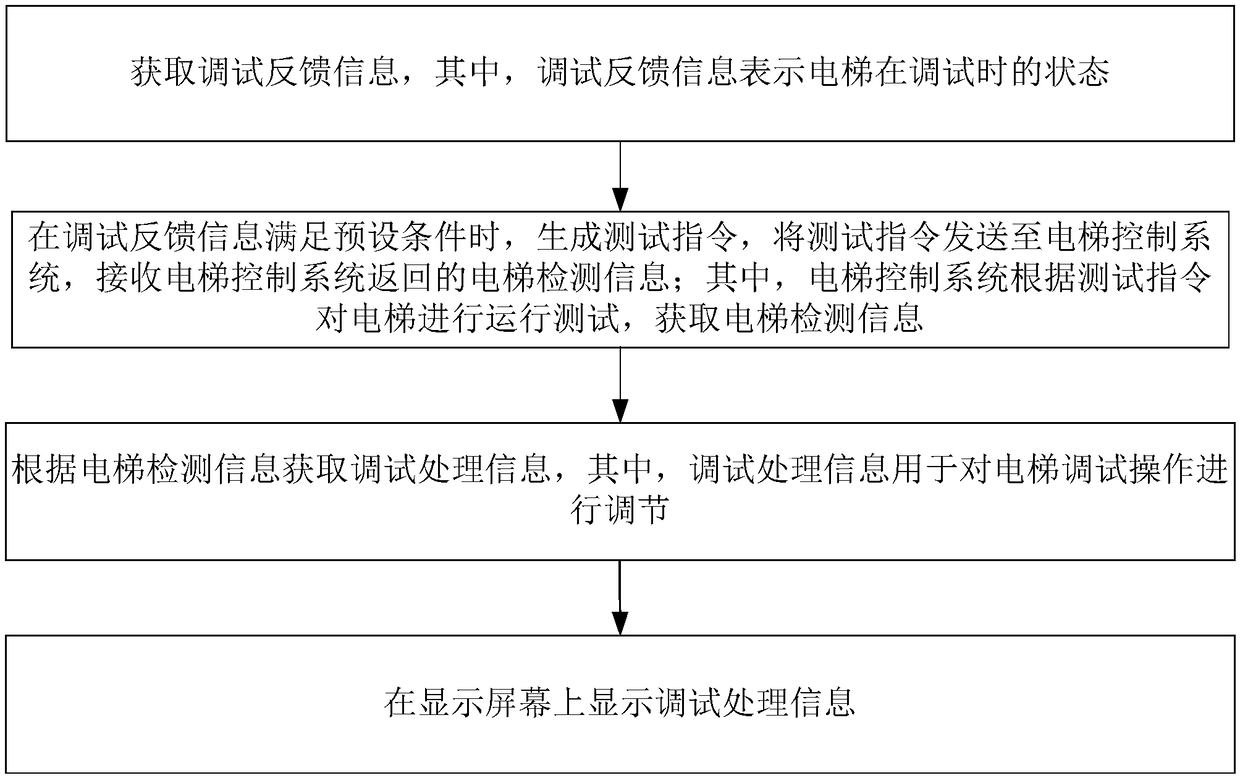

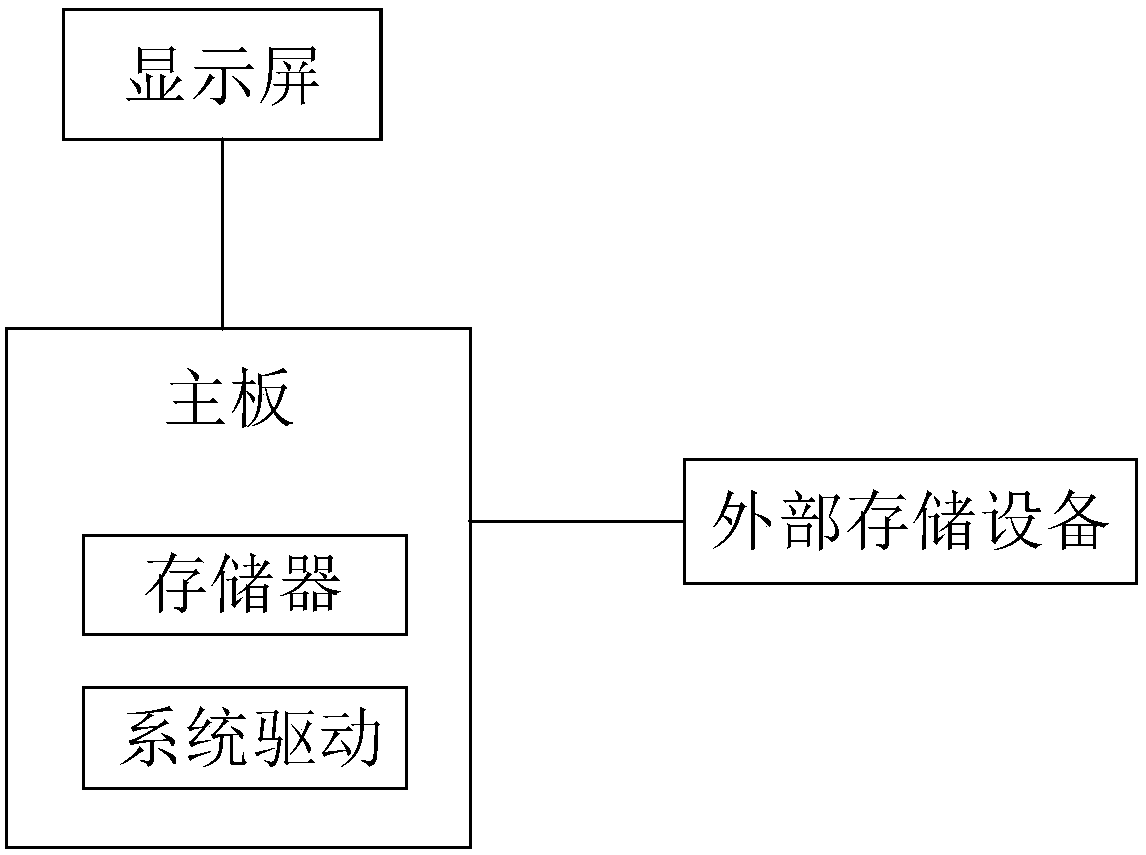

Elevator debugging information processing method and system, readable storage medium and debugging equipment

ActiveCN108910642ASpeed up the debugging processImprove debugging efficiencyElevatorsInformation processingControl system

The invention relates to an elevator debugging information processing method and system, a readable storage medium and debugging equipment, and belongs to the technical field of elevators. In the elevator debugging process, debugging feedback information can be obtained, and the debugging feedback information represents the elevator debugging state; according to the debugging feedback information,elevator detection information is obtained from an elevator control system, the elevator detection information is analyzed to obtain debugging processing information, the debugging processing information is displayed on a display screen and used for adjusting elevator debugging operation, elevator debugging workers can be guided to discover problems appearing in the elevator debugging process intime, adjusting suggests for debugging operation are provided, debugging work in the elevator site is facilitated, the elevator debugging schedule is accelerated, and the elevator debugging efficiencyis improved.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

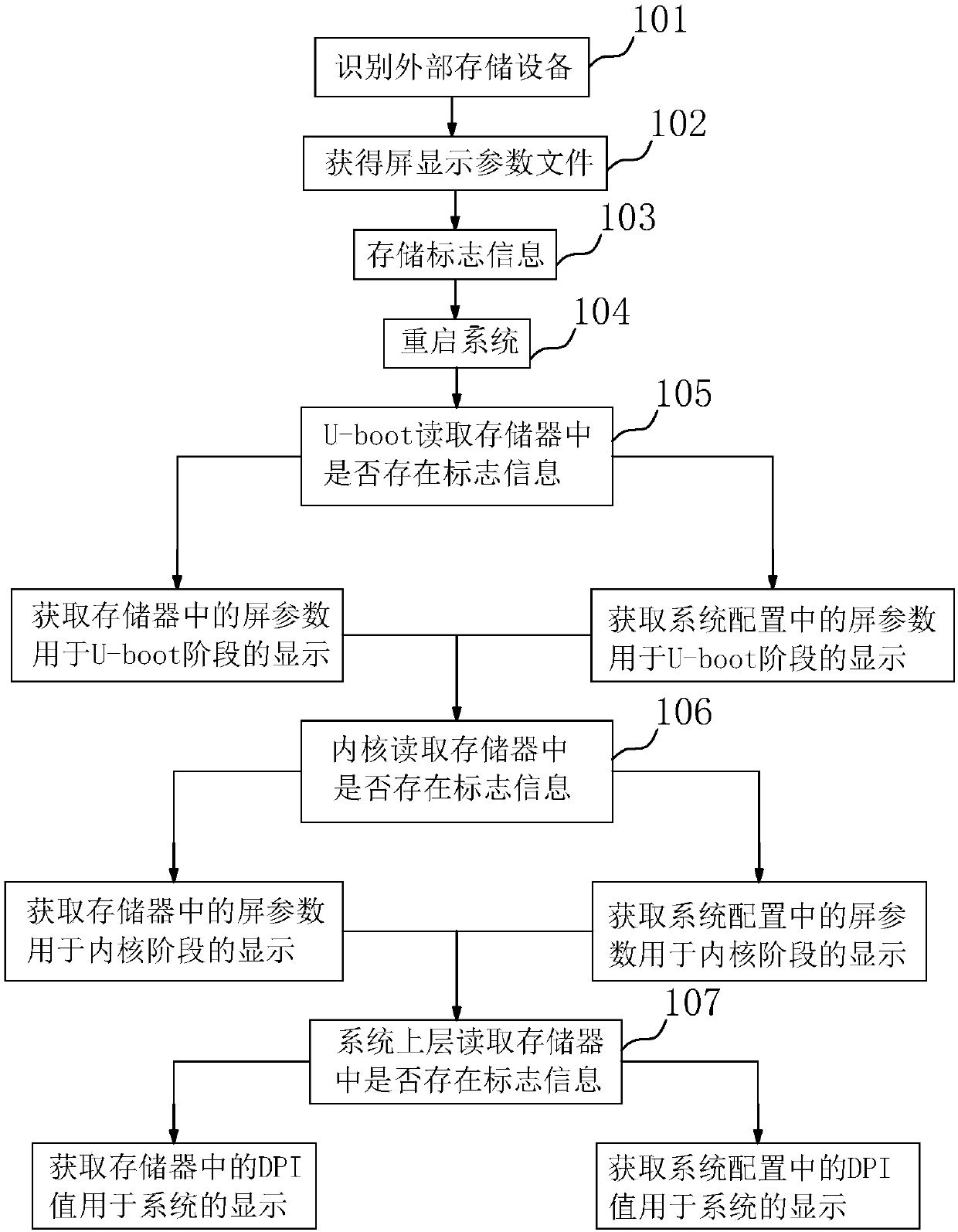

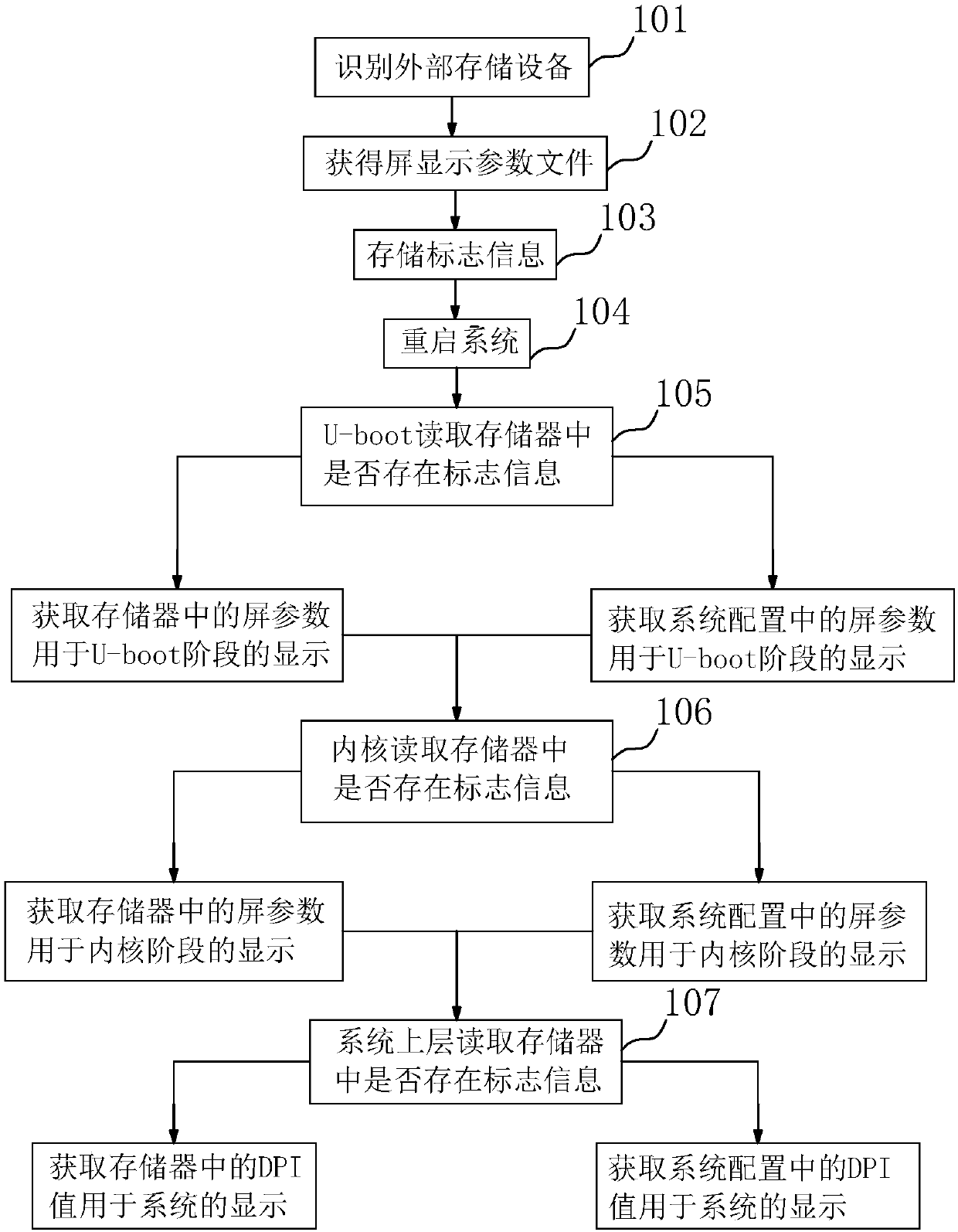

Display system and method of display screen

InactiveCN109976687AShorten the timeSpeed up developmentDigital output to display deviceExternal storageImage resolution

The invention relates to a display system and method of a display screen, and the method comprises the steps: obtaining a screen display parameter file from an external storage device; storing mark information used for indicating restarting to be displayed by the screen display parameter file; and after restarting, displaying in the screen display parameter file according to the mark information.Through the process, if the screen parameter file needs to be modified, the content in the screen display parameter file can be directly modified, the processes of re-modifying codes, compiling and packaging system software, burning a system and the like are not needed, display screens with different resolutions can be adapted, the time is saved, the development and debugging progress of productsis accelerated, and the production efficiency is improved.

Owner:深圳市雍慧电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com