Patents

Literature

1351results about How to "Speed up development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and Method for Programmatic Management of Distributed Computing Resources

ActiveUS20090271472A1Speed up developmentSpeeding up deliveryMultiple digital computer combinationsProgram controlExternal connectionWeb server

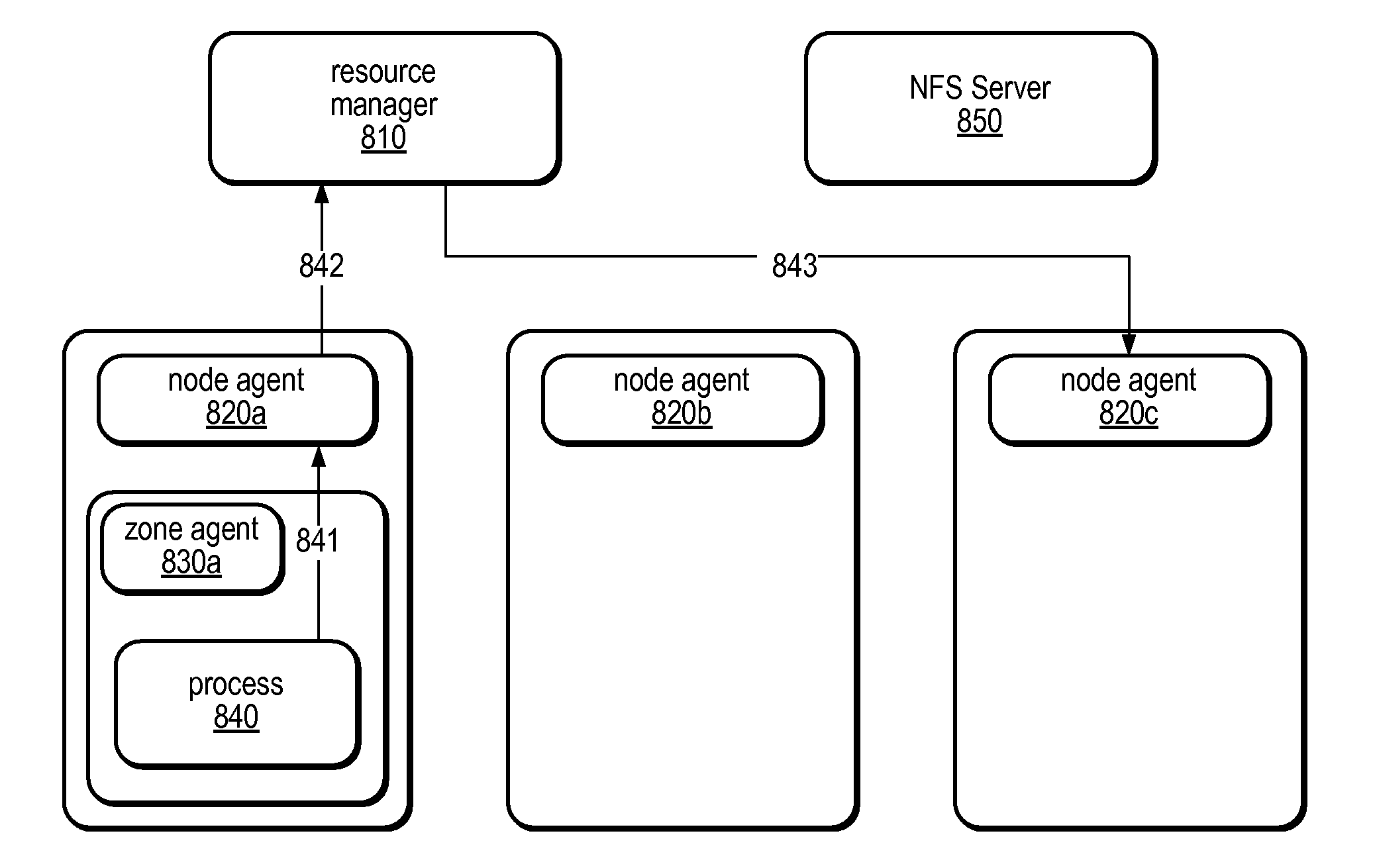

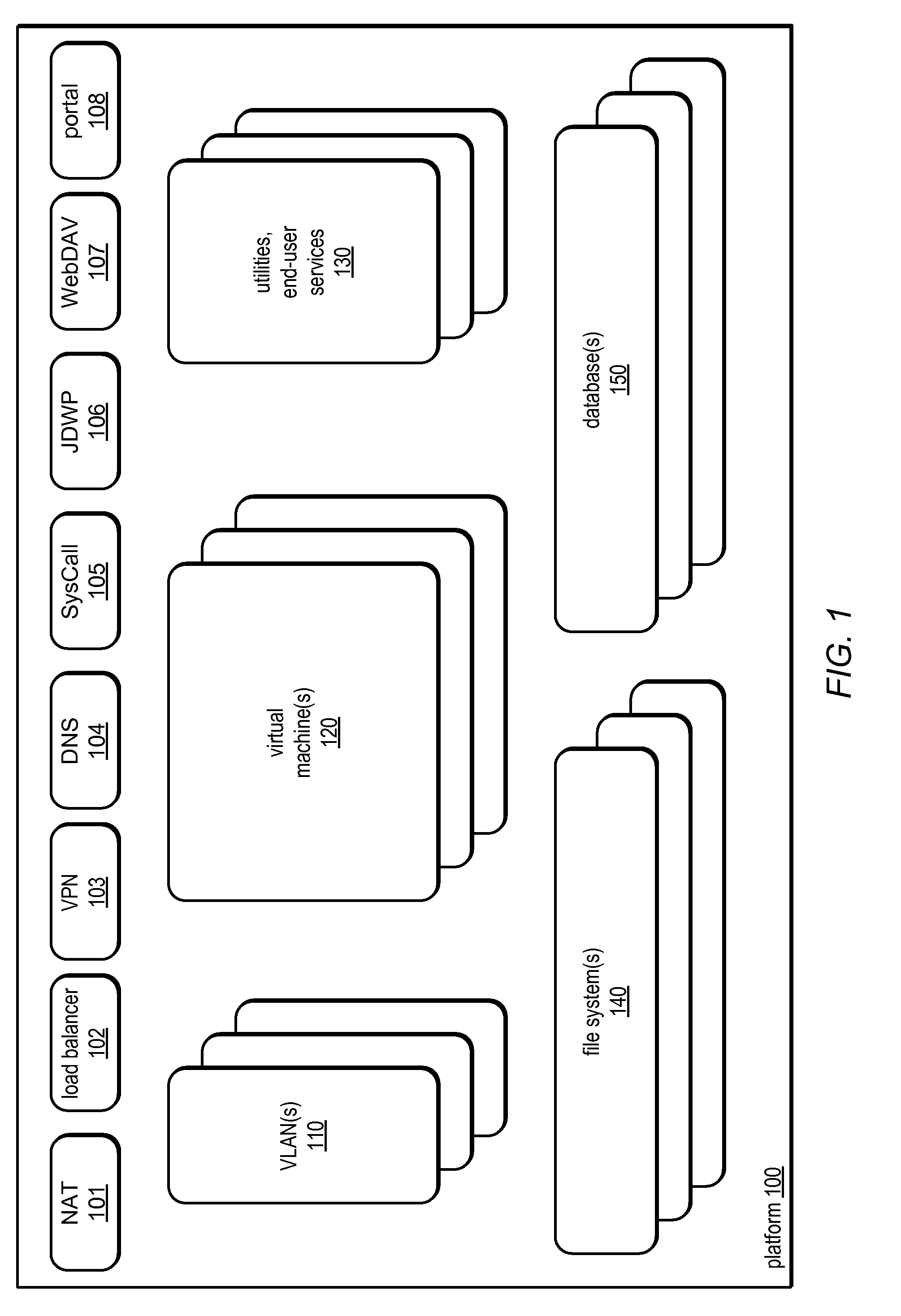

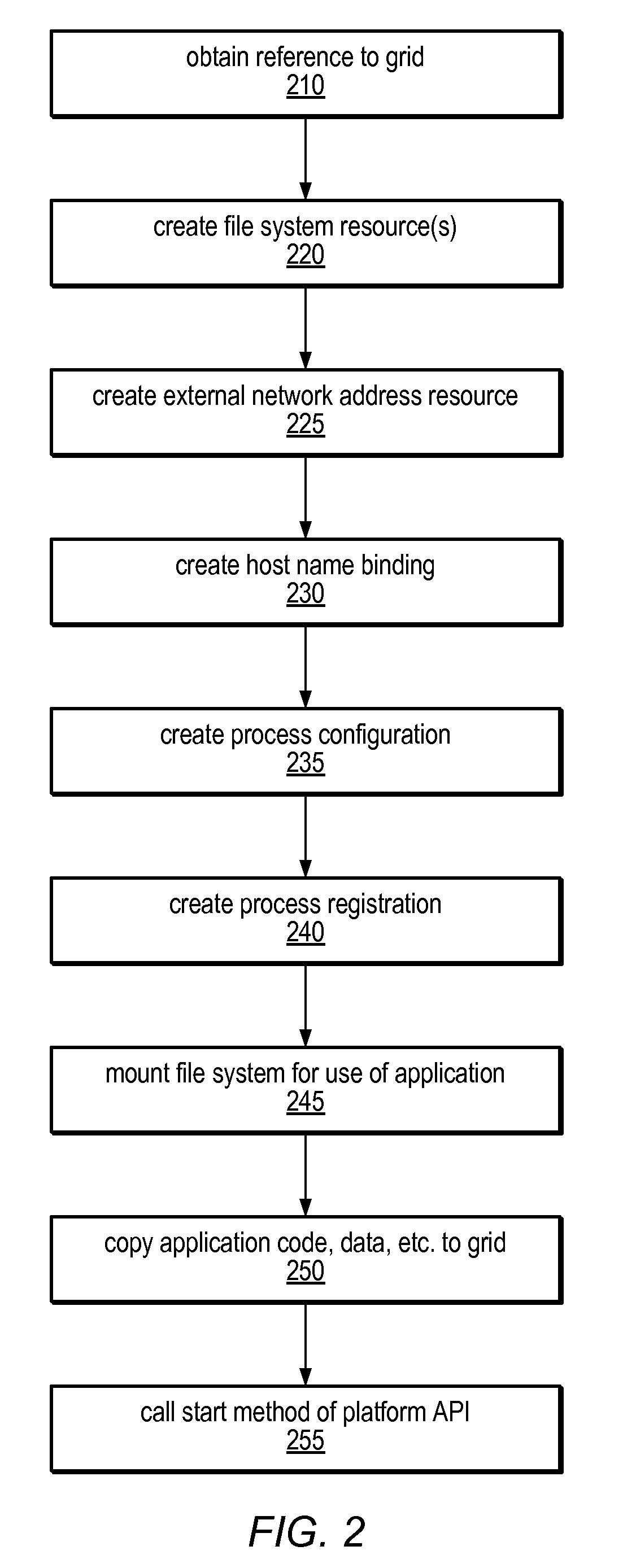

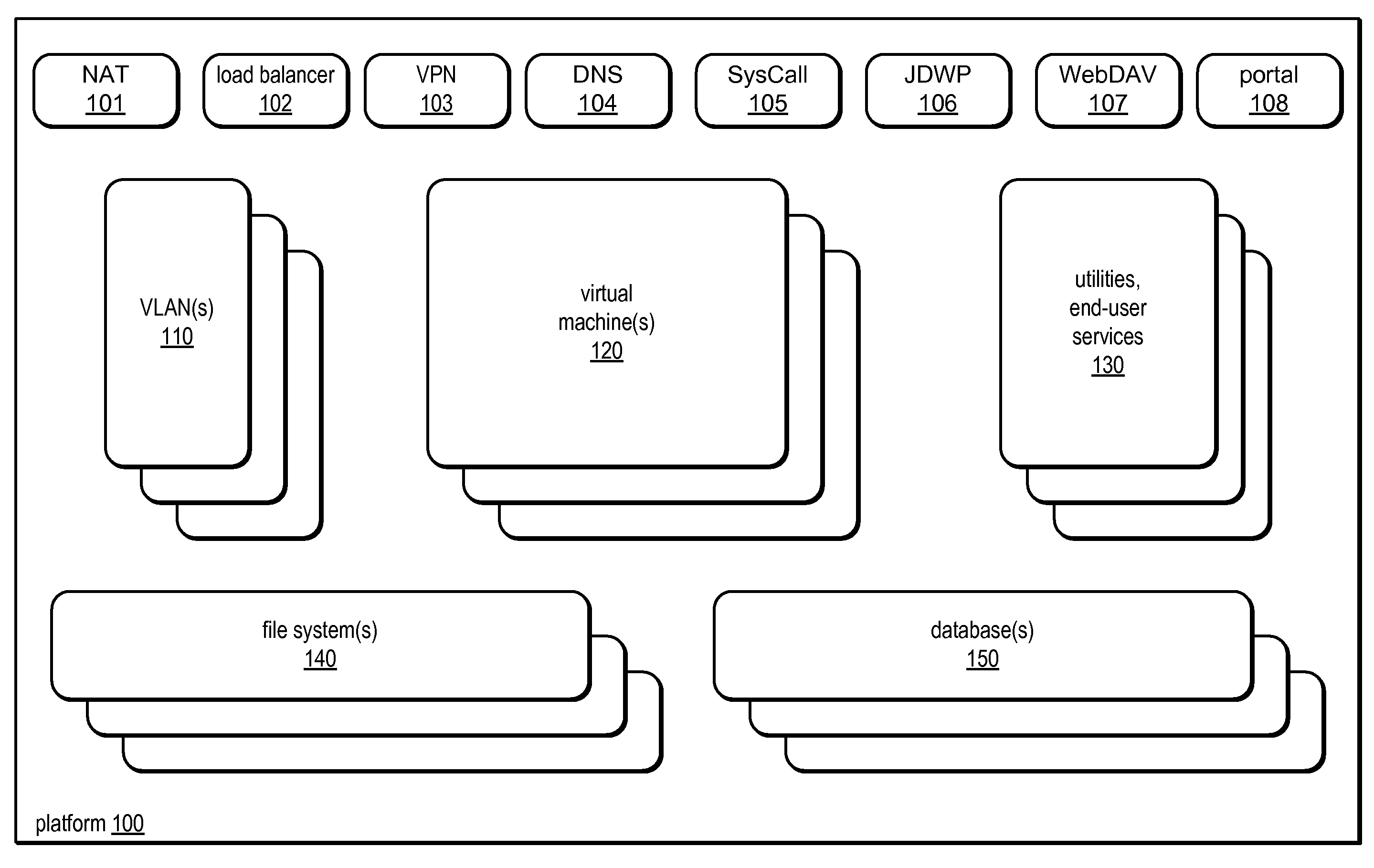

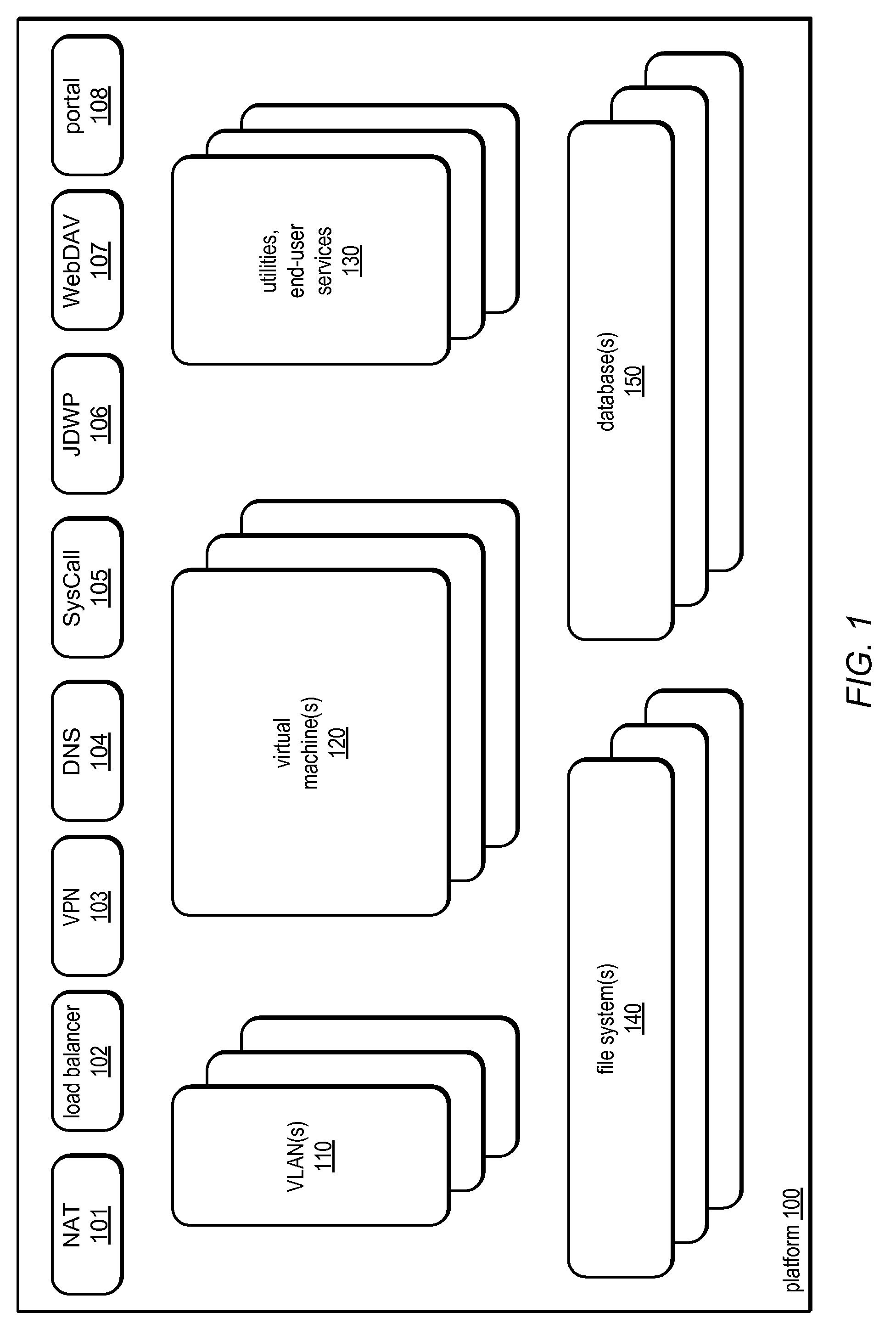

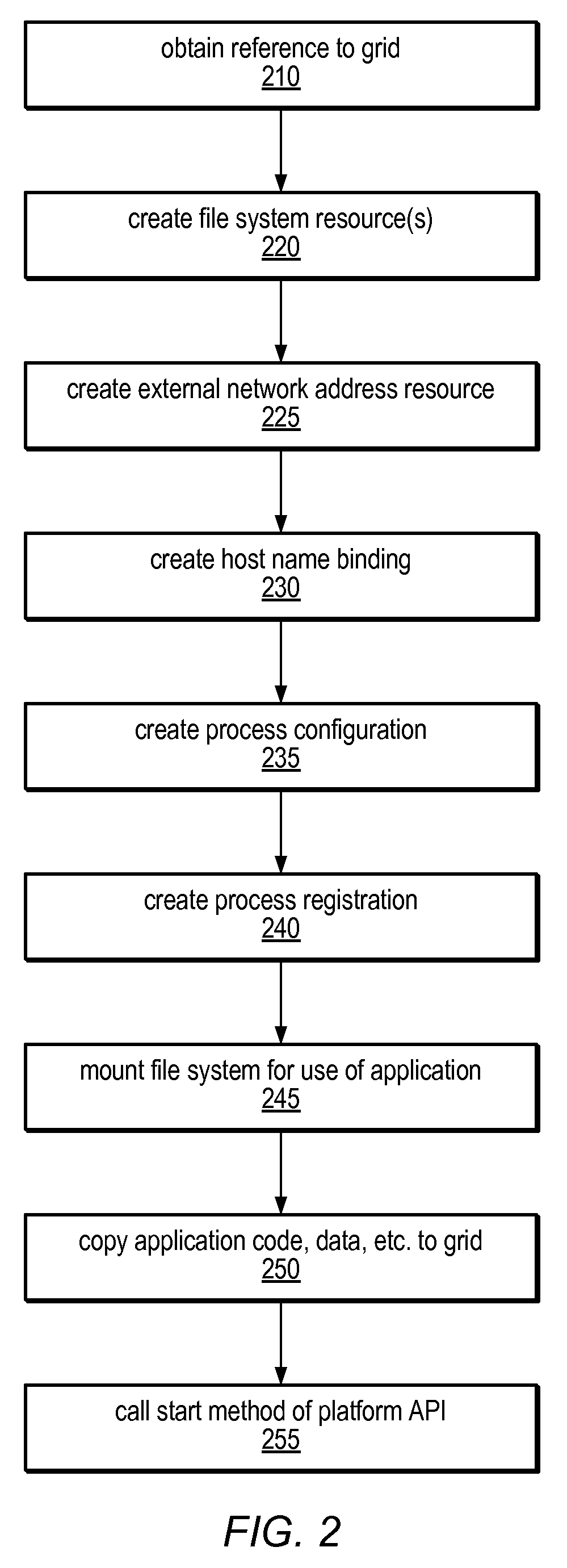

Systems and methods for providing a development and deployment platform for Software as a Service (SaaS) providers are disclosed. The platform may provide an application programming interface (API) through which customers may configure virtualized grids of language-level virtual machines (VMs), networks, and storage resources. A grid may be horizontally scalable and programmatically configurable by a customer and / or customer code. The platform may allow dynamic scaling of resources (up and down) to match changing demands, by allowing customers and / or customer code to programmatically alter their own system level structure at runtime, through the API. The grid may be accessed by both on-grid and off-grid processes, through internal and external connectivity resources provided by the platform. The platform may provide common utilities for end-user services, deployment operations, and development tasks (e.g., debugging), and may include frameworks and macro-components (e.g. web servers). The platform may host long-running Internet-based services and / or one-shot computational services.

Owner:ORACLE INT CORP

System and method for programmatic management of distributed computing resources

ActiveUS7886021B2Speed up developmentSpeeding up deliveryMultiple digital computer combinationsProgram controlWeb serviceStructure of Management Information

Systems and methods for providing a development and deployment platform for Software as a Service (SaaS) providers are disclosed. The platform may provide an application programming interface (API) through which customers may configure virtualized grids of language-level virtual machines (VMs), networks, and storage resources. A grid may be horizontally scalable and programmatically configurable by a customer and / or customer code. The platform may allow dynamic scaling of resources (up and down) to match changing demands, by allowing customers and / or customer code to programmatically alter their own system level structure at runtime, through the API. The grid may be accessed by both on-grid and off-grid processes, through internal and external connectivity resources provided by the platform. The platform may provide common utilities for end-user services, deployment operations, and development tasks (e.g., debugging), and may include frameworks and macro-components (e.g. web servers). The platform may host long-running Internet-based services and / or one-shot computational services.

Owner:ORACLE INT CORP

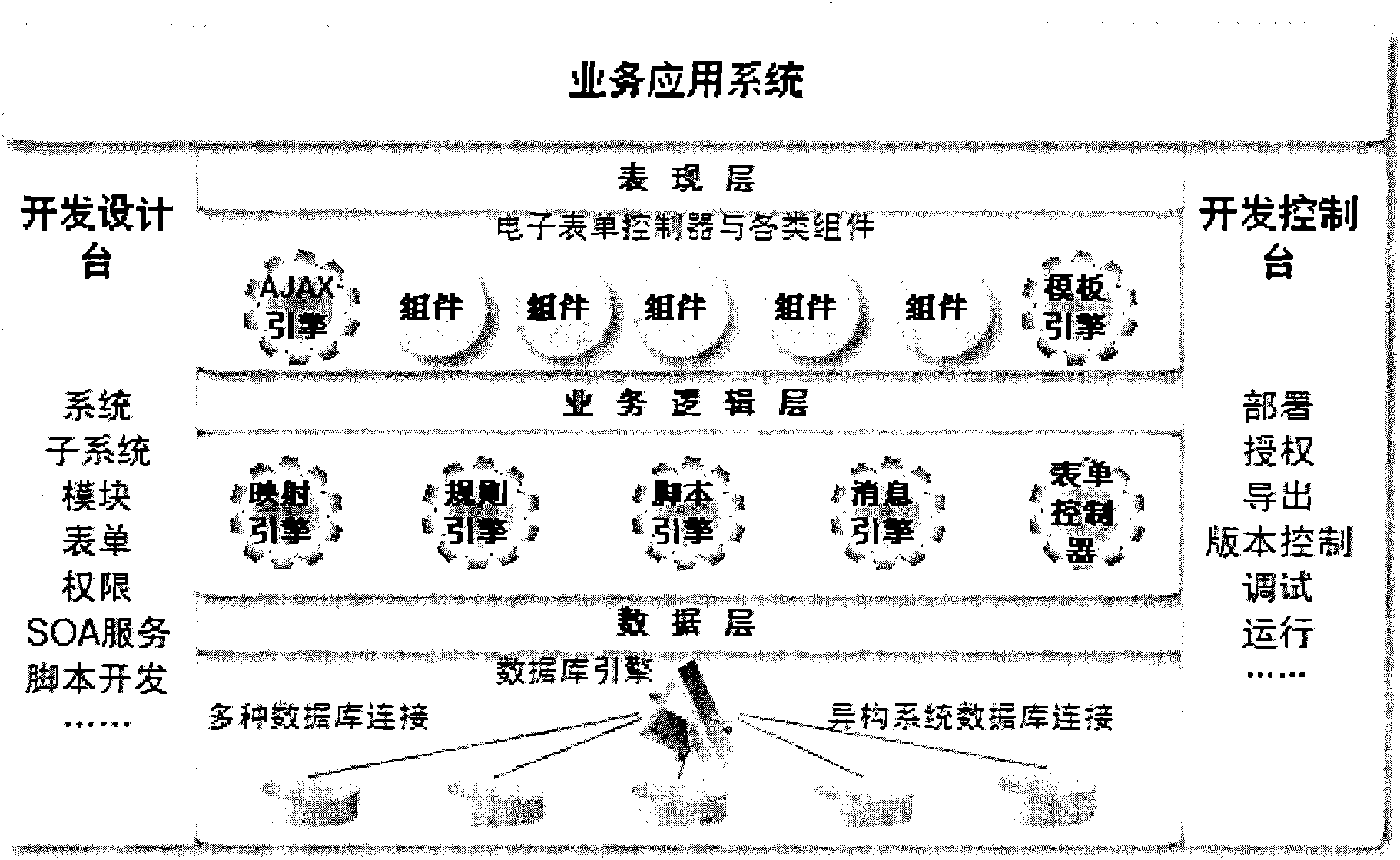

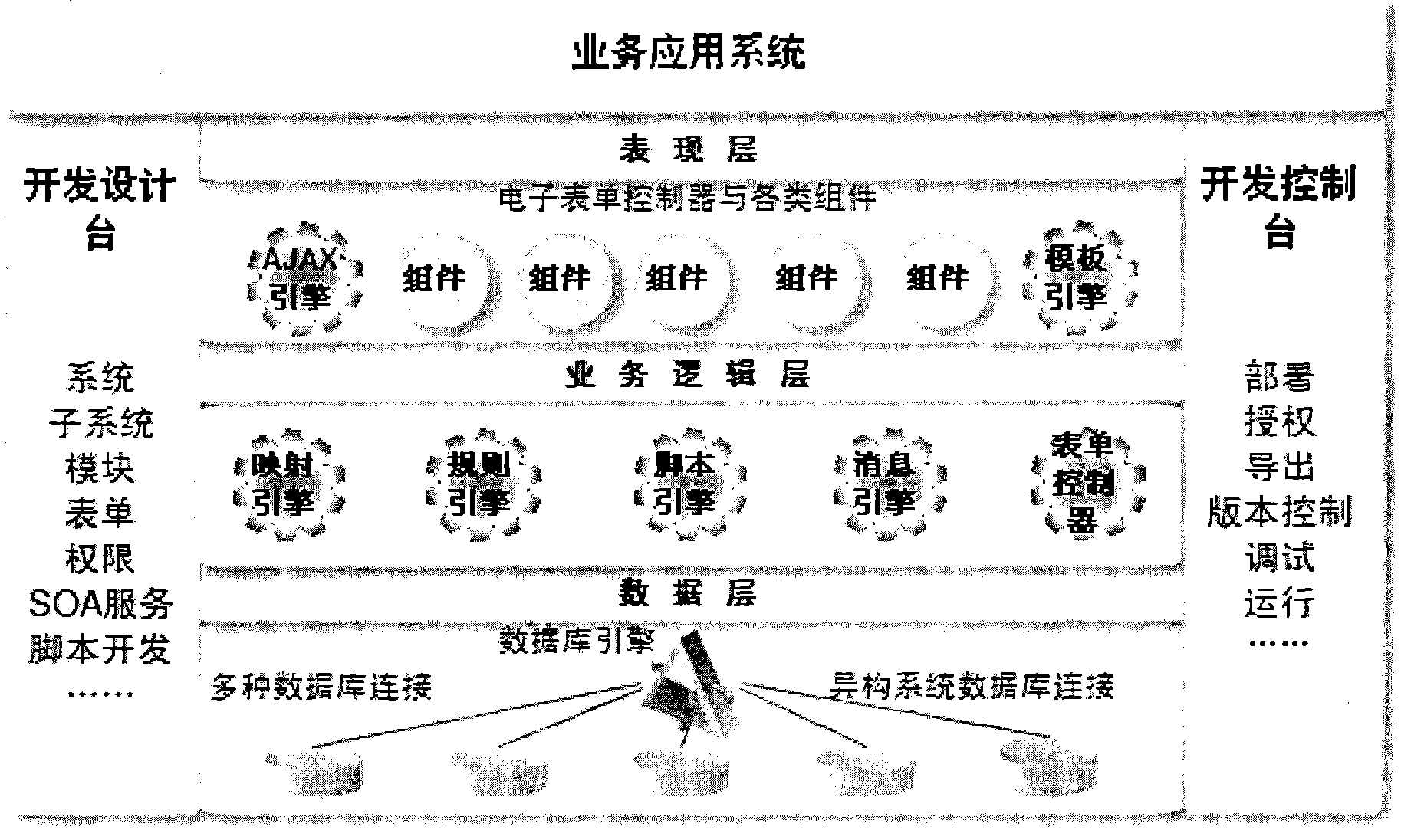

Technical implementation method for application development through electronic form

InactiveCN102063306ARapid Visual DevelopmentReduce the amount of developmentSpecific program execution arrangementsOperational systemElectronic form

The invention discloses a technical implementation method for application development through an electronic form. The electronic form technique integrates data acquisition and presentation functions into a whole; an electronic form system is divided into an interface representation layer, a service logic layer and a data exchange layer; and the electronic form technique reduces the development programming codes by over 90 percent in comparison with the traditional development mode, the development efficiency is improved by one order of magnitude in comparison with the traditional mode, the configured design concept and the development mode are improved, the agility of a service system is greatly promoted, data sharing and application integration are realized by adopting service-oriented architecture (SOA) loose coupling application integration technology, different bottom-layer operating systems and databases can be spanned, and the application system has good compatibility and mobility.

Owner:夏春秋

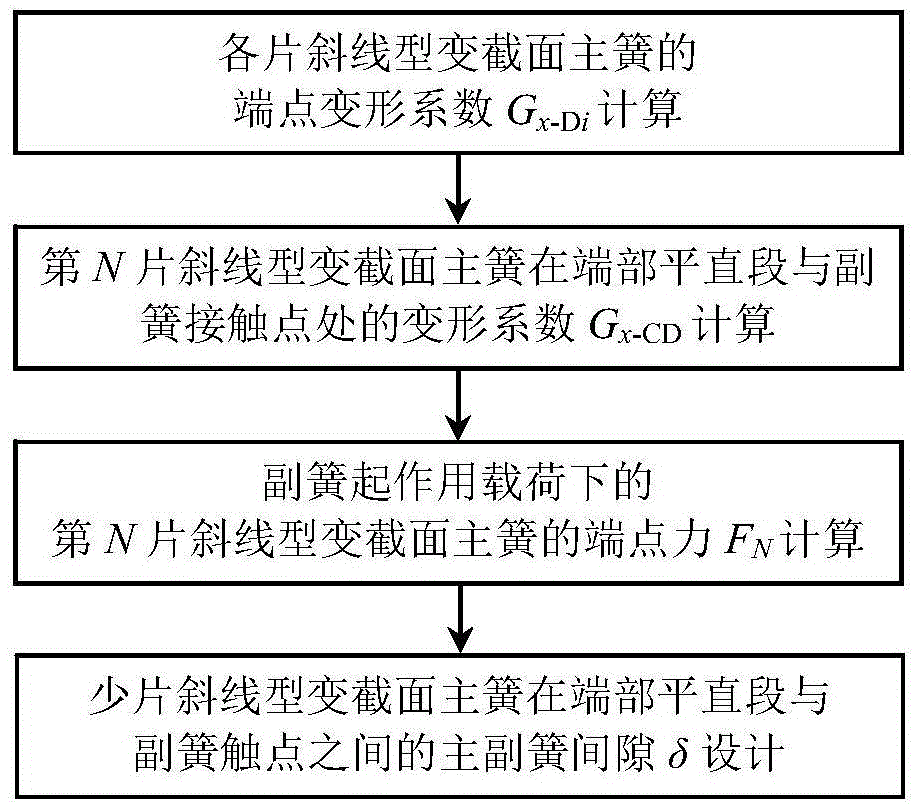

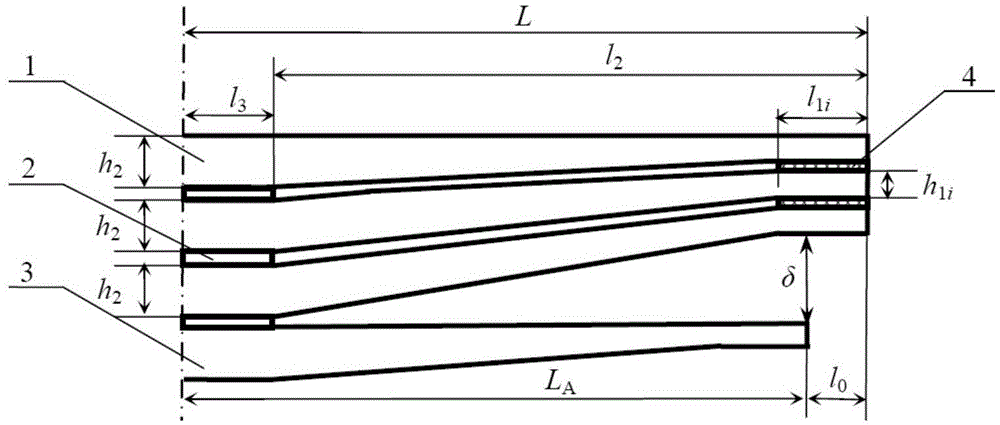

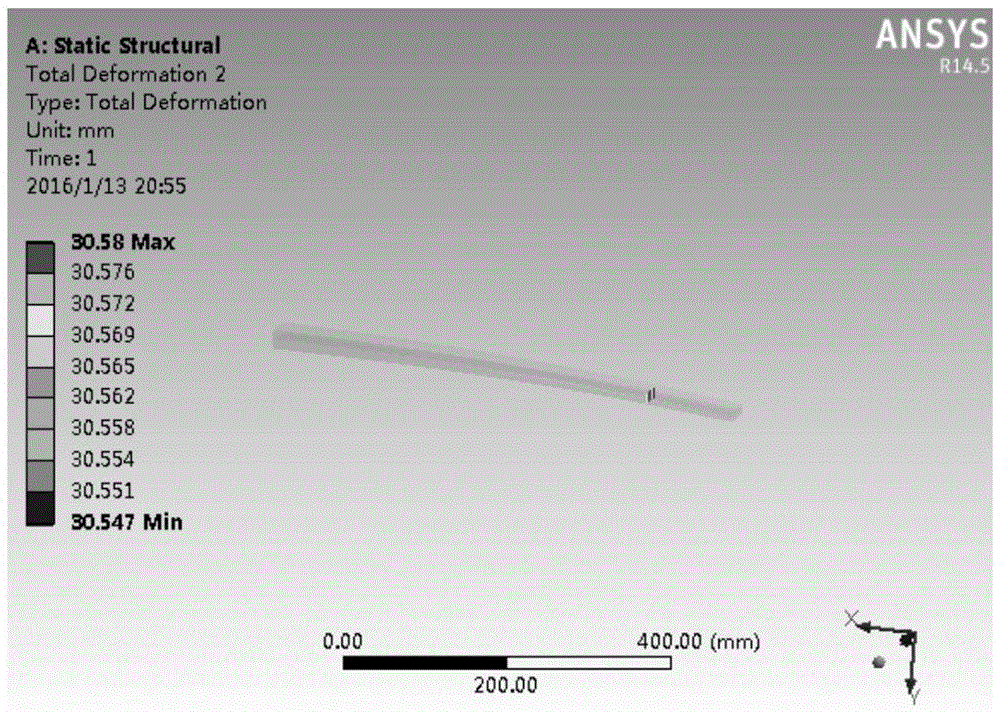

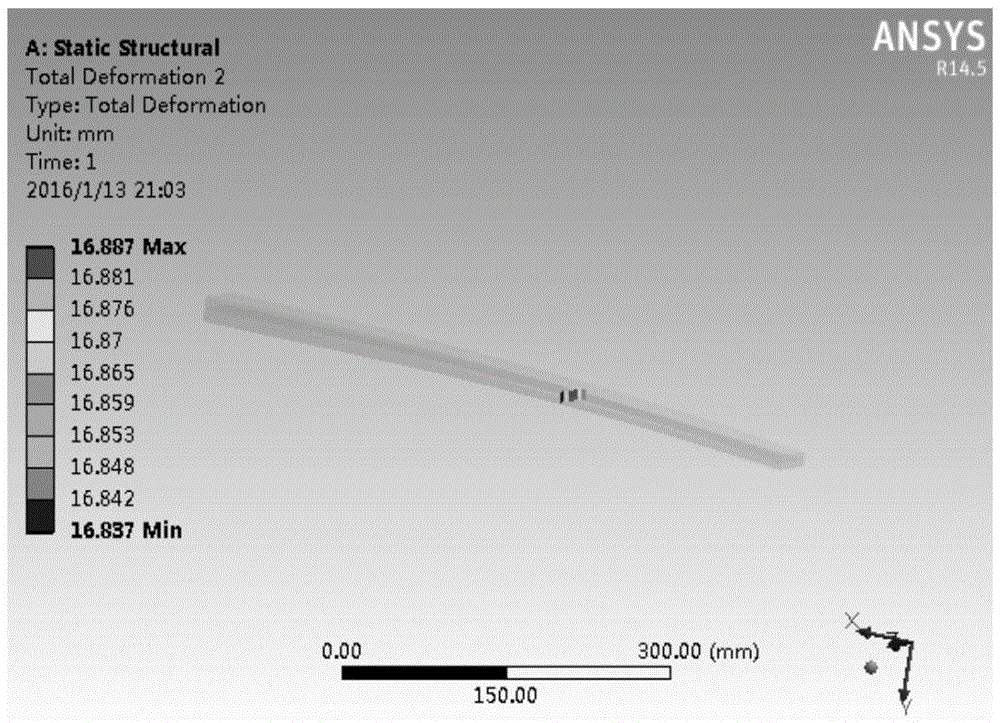

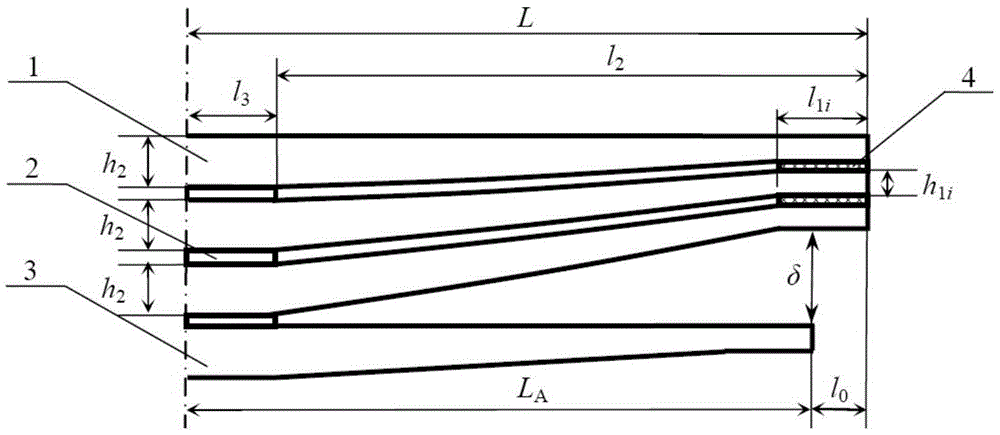

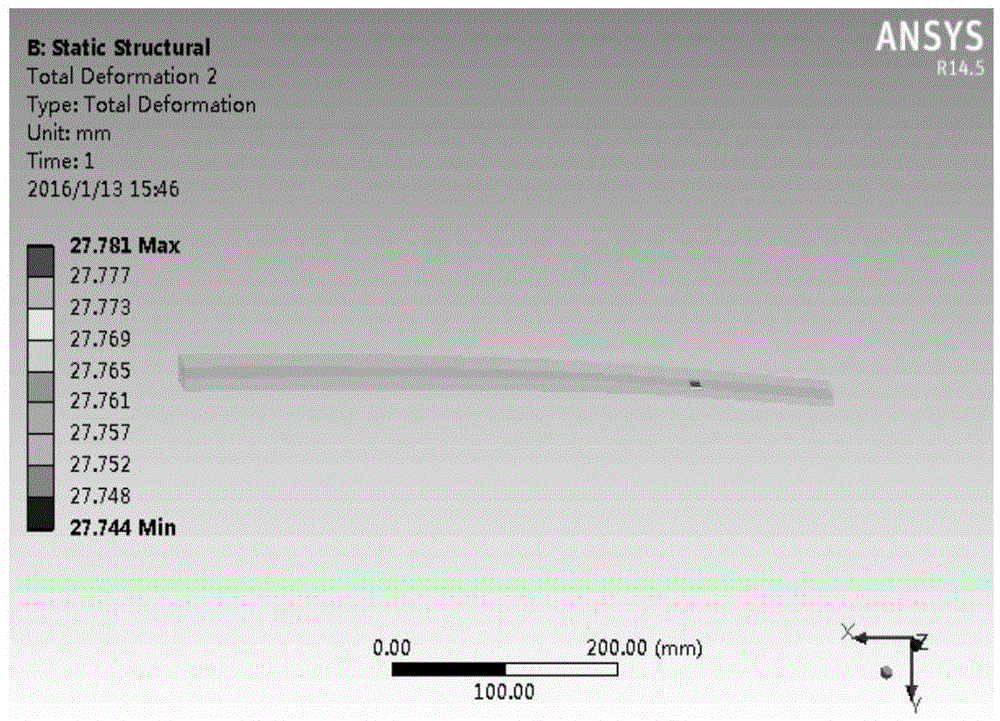

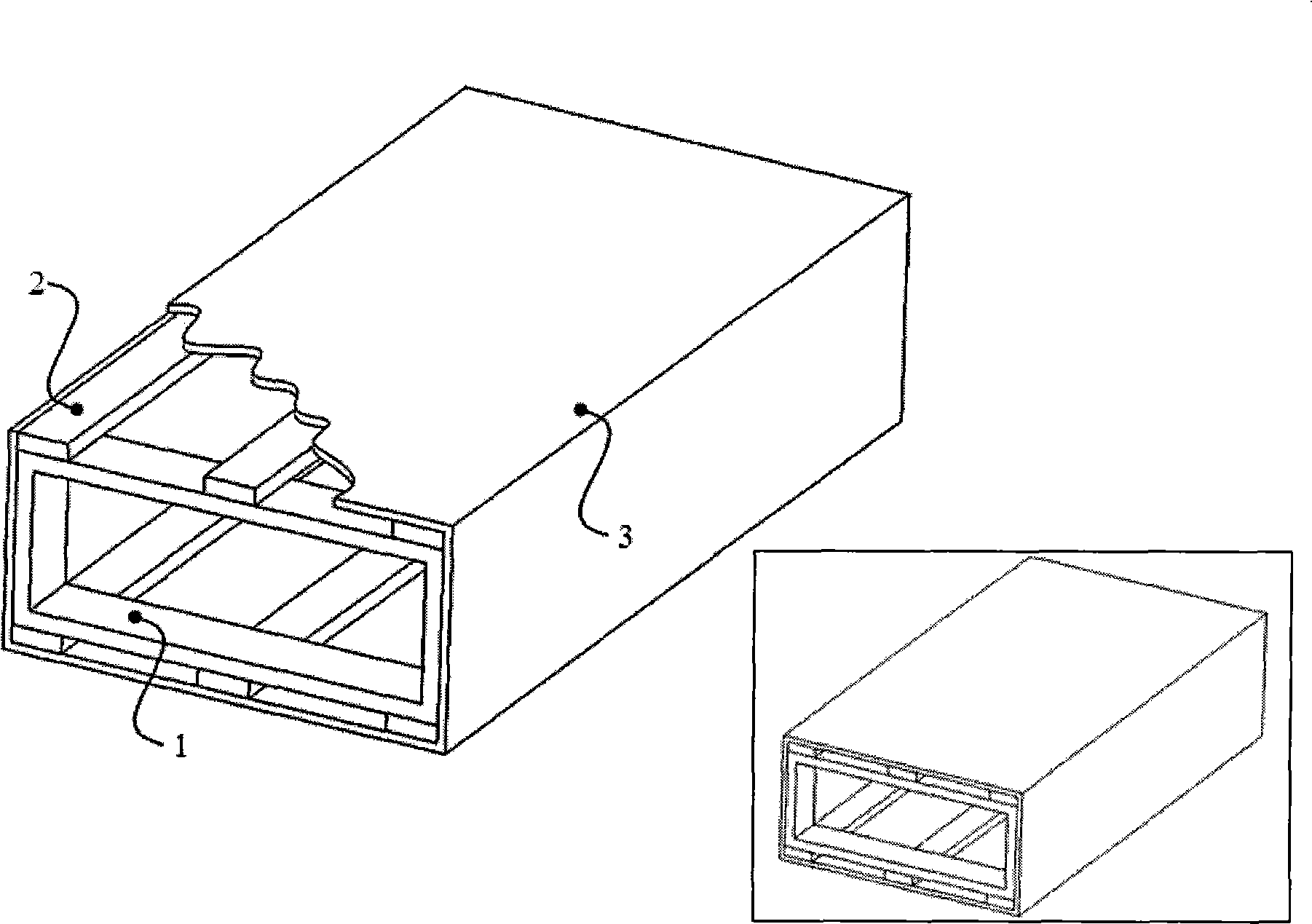

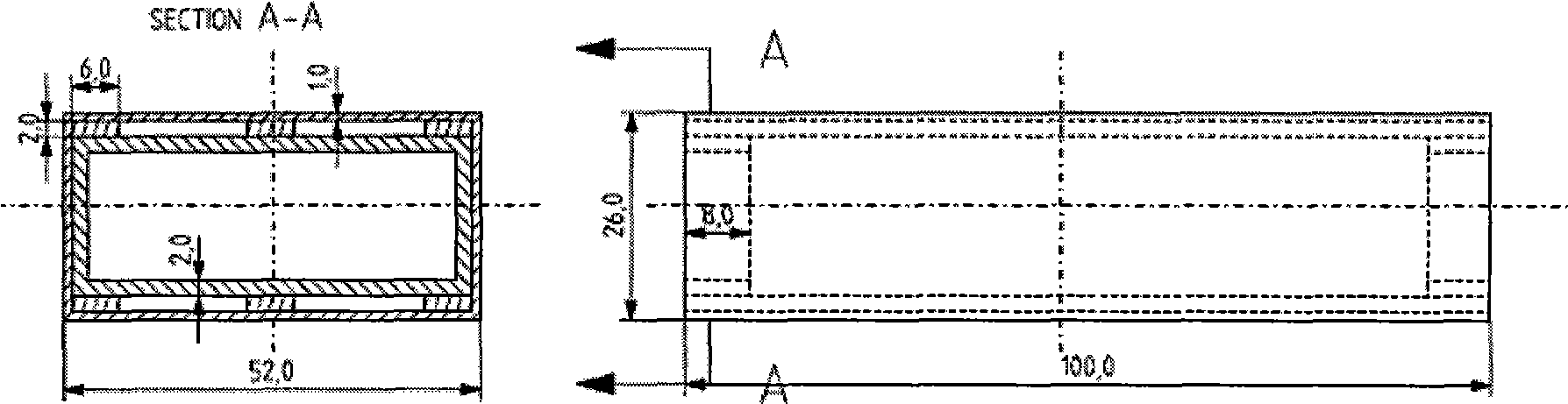

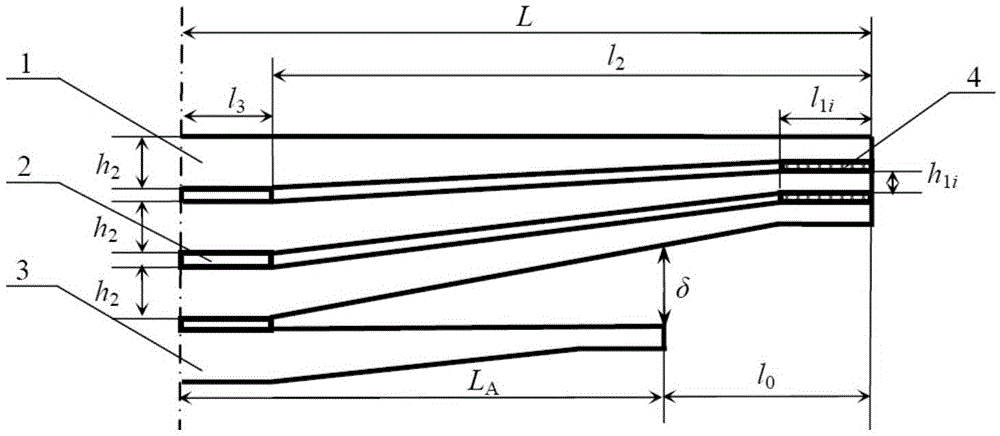

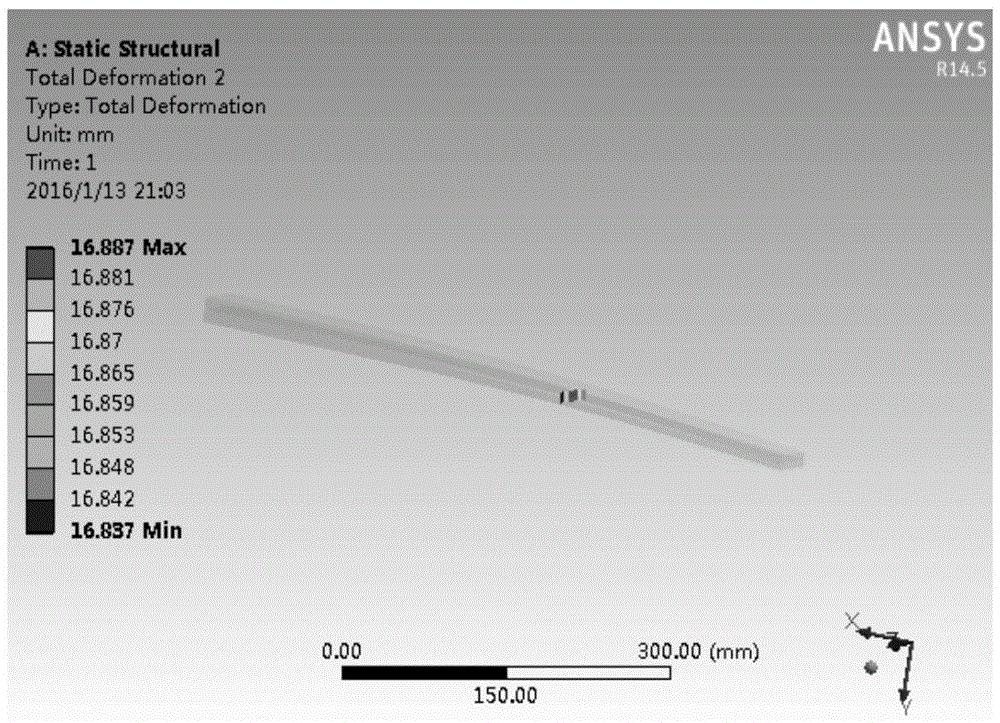

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

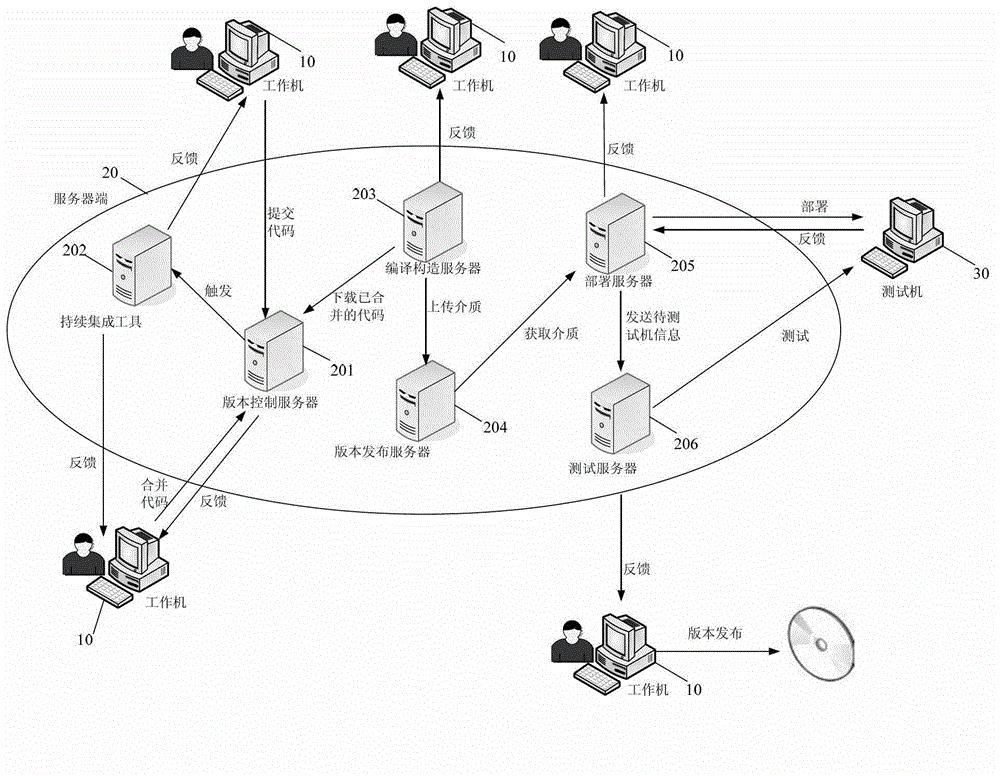

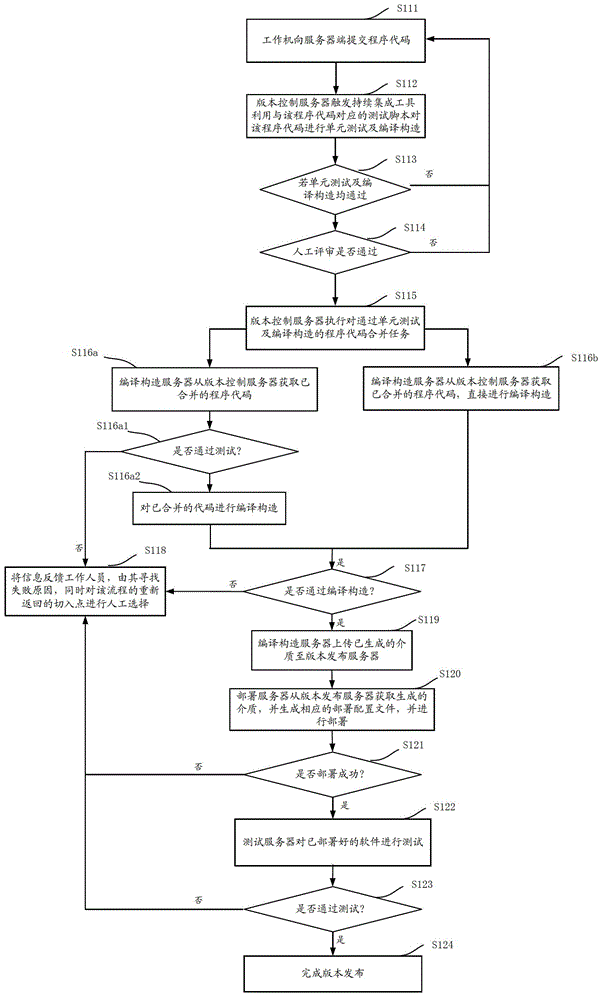

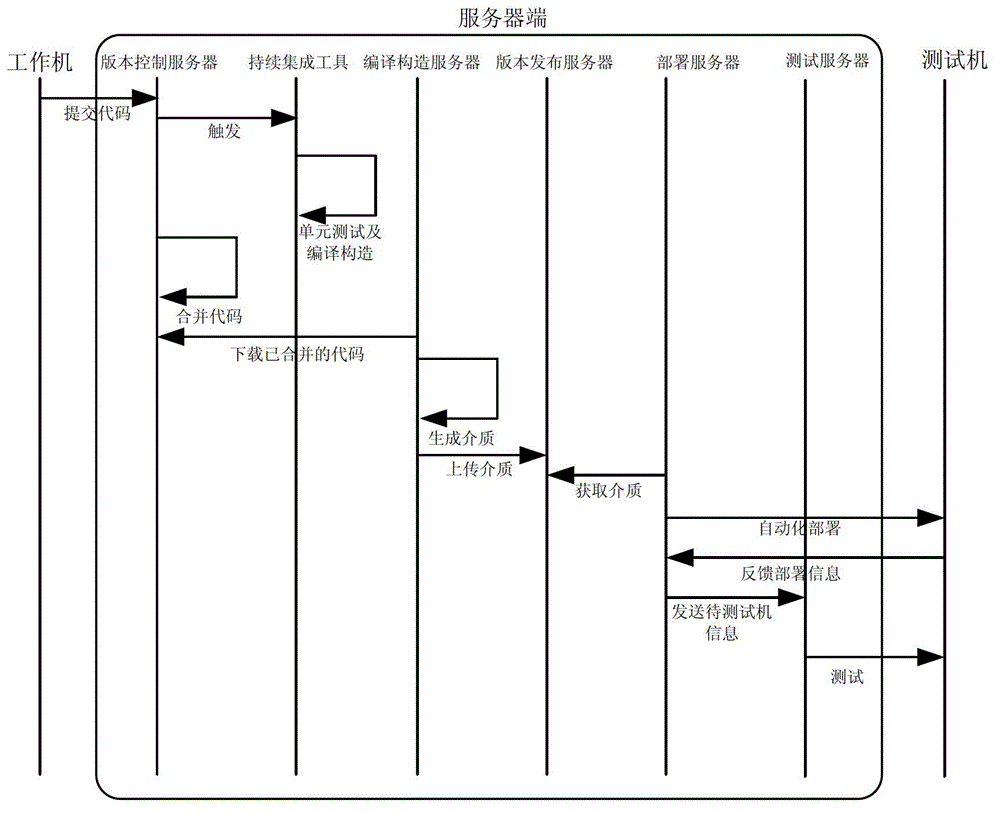

Software integrating method and system oriented to cloud computing software research and development process

InactiveCN103336688AReduce integration riskImprove development qualityTransmissionSpecific program execution arrangementsSoftware development processTest script

The invention discloses a software integrating method and system oriented to a cloud computing software research and development process. The method comprises the following steps that a working machine submits program codes to a server side; the server side is triggered to perform unit test and compiling construction on the received program codes by using a test script which corresponds to the received program codes after receiving the program codes submitted by the working machine; the server side execute a task of combining the program codes passing unit test and compiling construction; the server side acquires the combined program codes, and performs test and compiling construction or performs compiling construction directly to generate a file to be installed; the server side generates a corresponding deployment configuration file, deploys a tester and installs software; the server side tests the deployed software, and returns a test result; and a software version is issued for the software passing the test.

Owner:CHINA STANDARD SOFTWARE

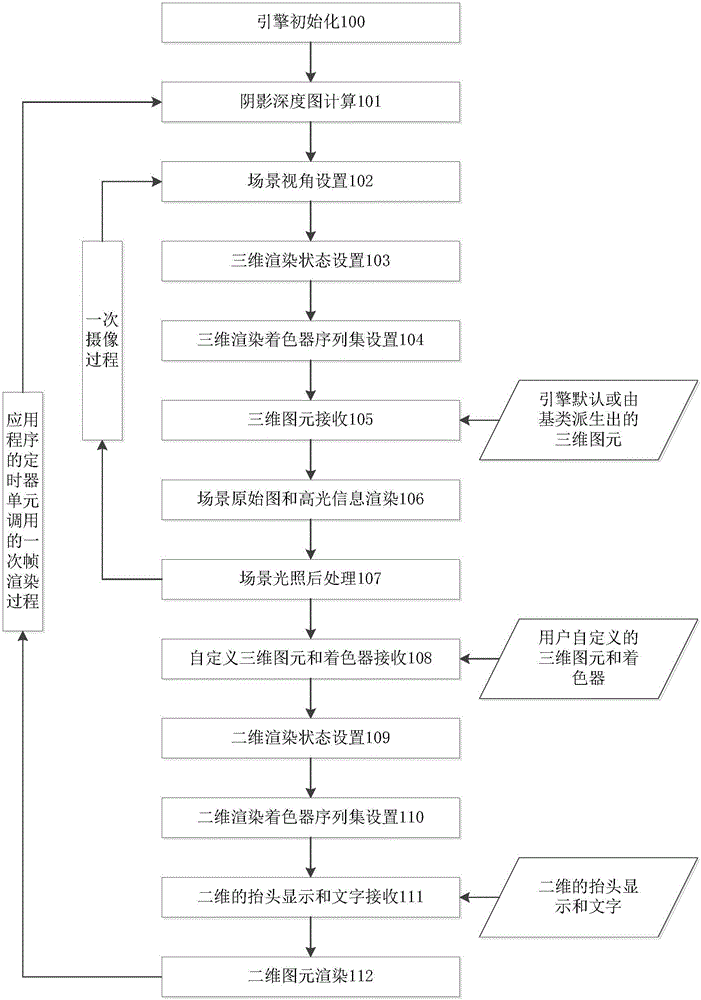

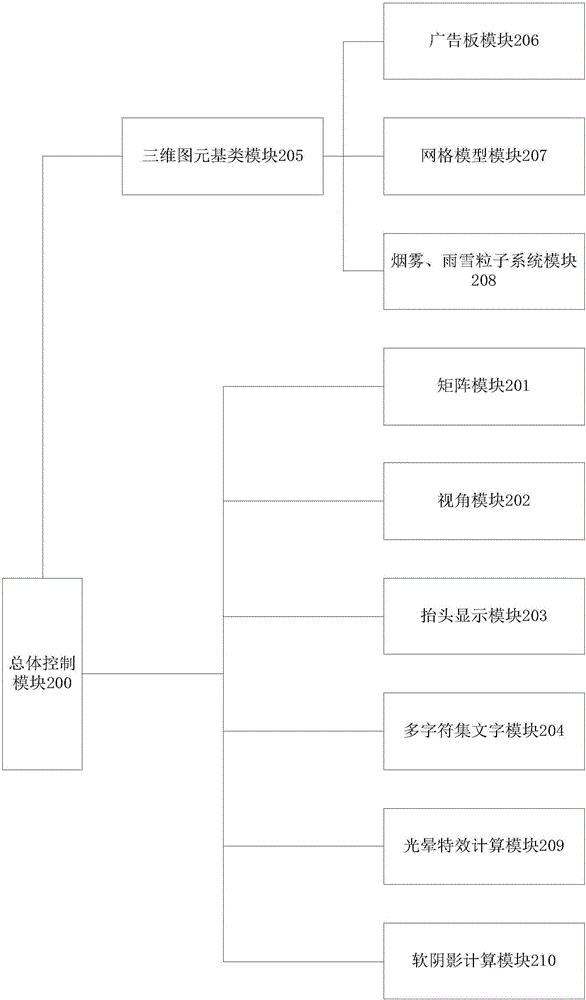

Direct3D 11-based 3D graphics rendering engine

ActiveCN106056661ALower the thresholdReduce development costs3D-image renderingHead-up displayGraphics

The invention discloses a Direct3D 11-based 3D graphics rendering engine, which comprises a master control module and a plurality of functional sub modules, wherein the functional sub modules comprise a matrix module, a view point module, a head-up display module, a multi-character set word module, a 3D primitive base class module, a poster board module, a mesh model module, a smoke and rain and snow particle system module, a halo special effect calculation module, and a soft shadow calculation module. According to the default rendering process for each frame, the soft shadow module is firstly called, and with the illumination direction as the view point, the depth information of each primitive in the rendering scene is calculated; then, with the sight line of eyes of an observer as the angle, each primitive in the scene is rendered to the surface, an original scene view is obtained, highlight information is obtained at the same time, and the actual lighting effects of each pixel point is obtained according to the depth information and the illumination calculation result; and finally, in combination with the first sum depth information and the highlight information, highlight aura special effect post-processing on the illumination is carried out on the original scene view, and the final single-frame rendering graph is obtained.

Owner:钱进 +3

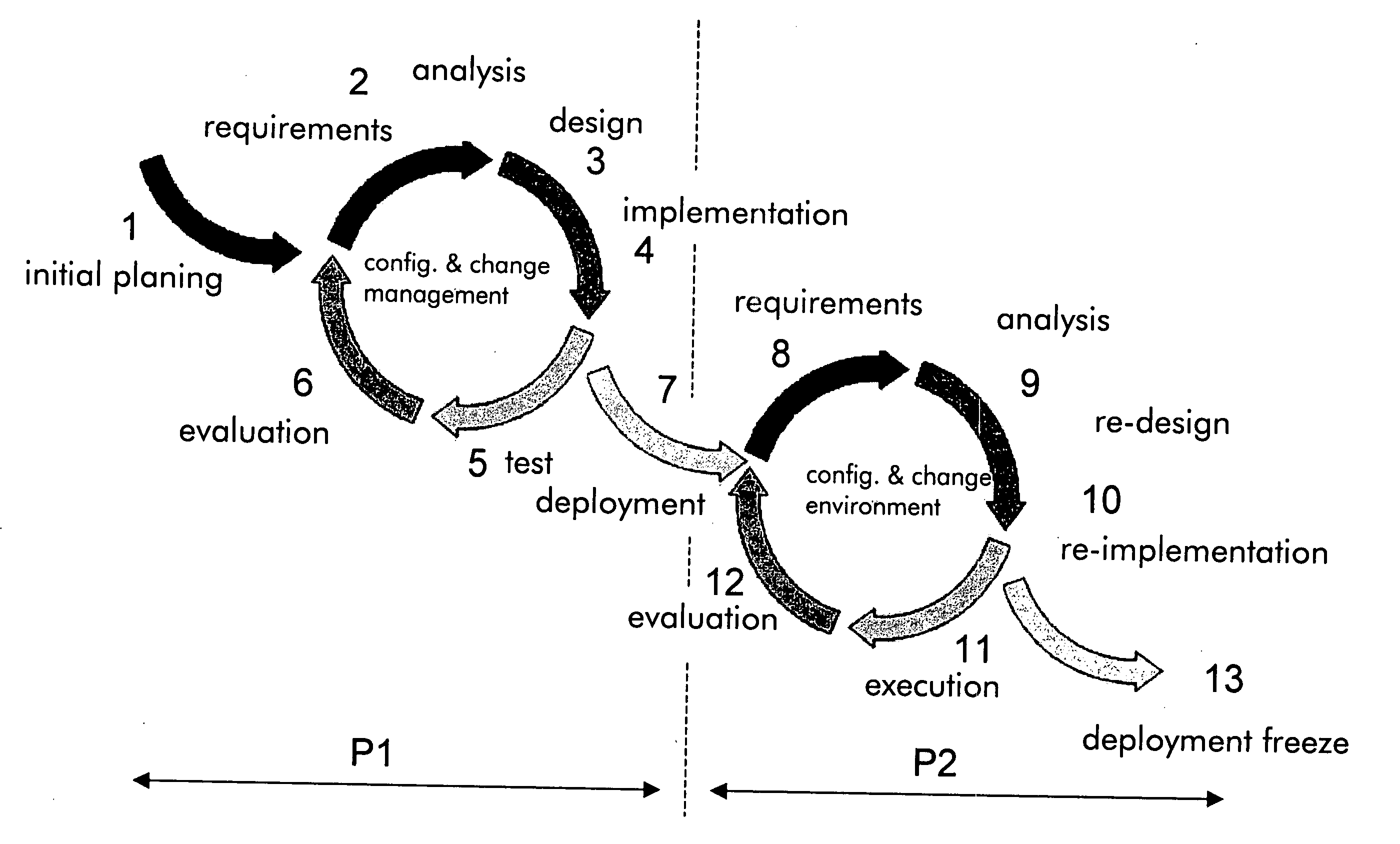

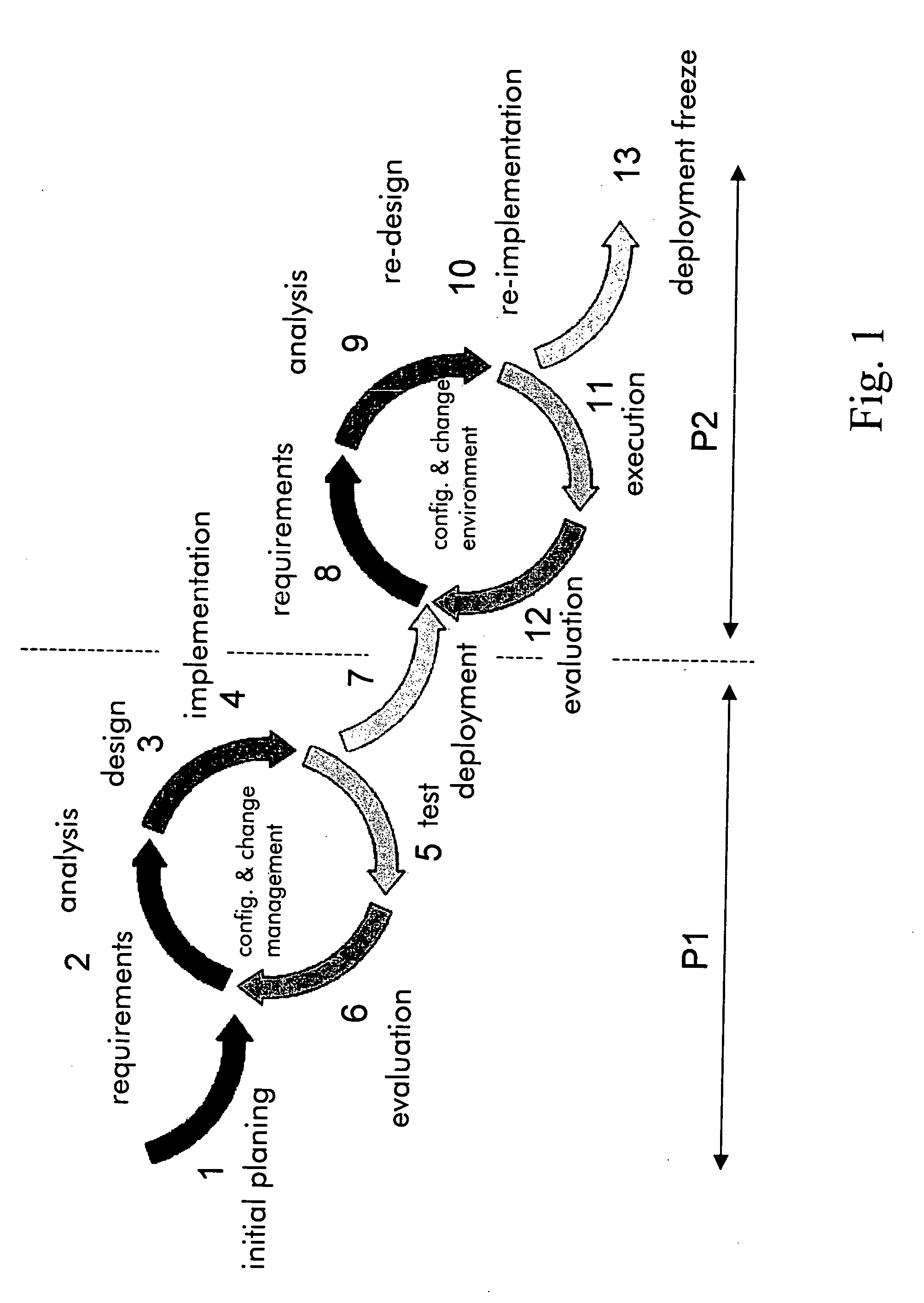

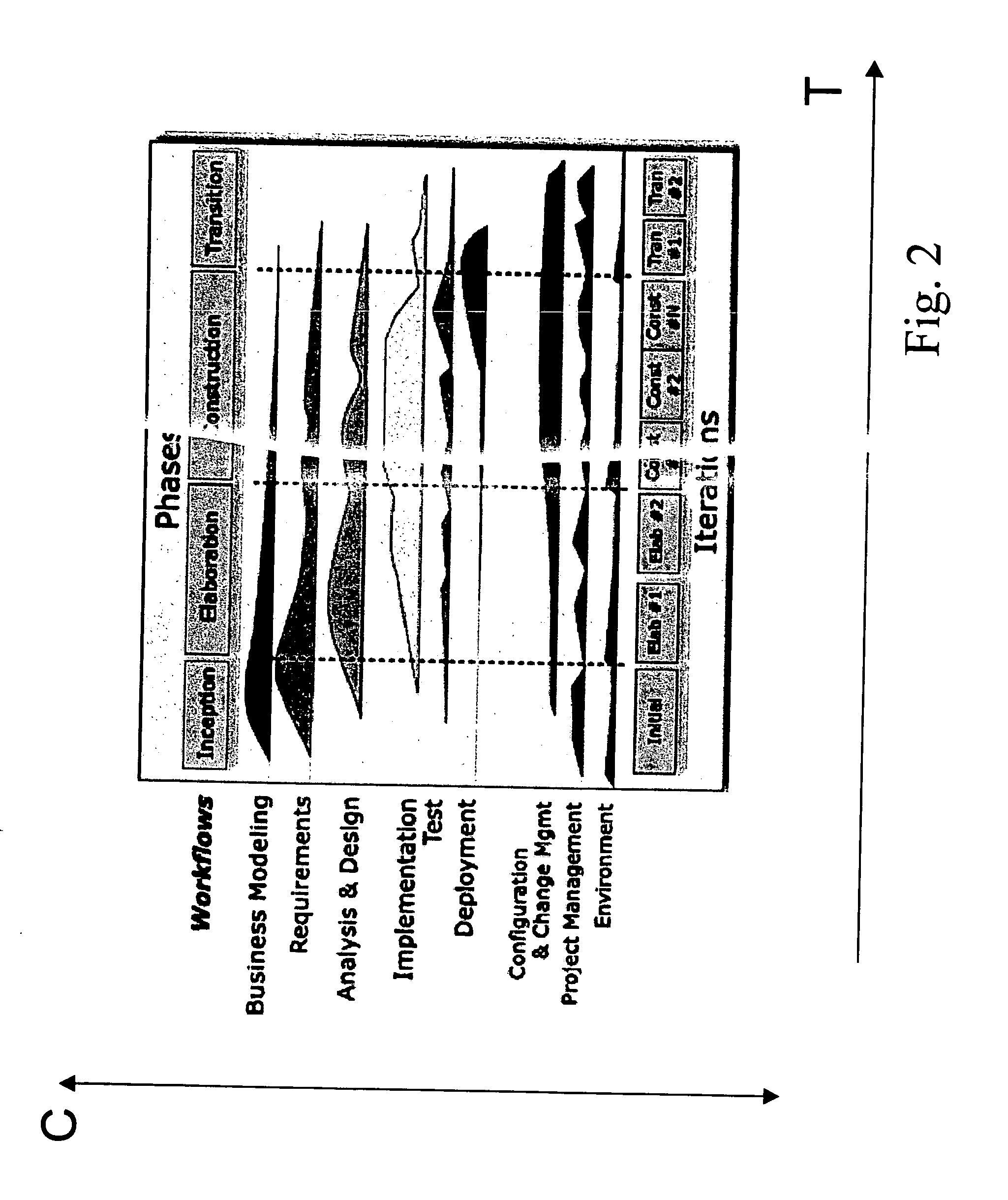

Adaptive evolutionary computer software products

InactiveUS20070033659A1Less development workSpeed up developmentDigital data processing detailsSoftware engineeringBehavioral analyticsParallel computing

The invention concerns a method for automatically adapting a computer program product to an environment, the computer program product comprising executable parts and data parts, the method comprising the steps of configuring the computer program product for the environment and executing the software in the environment. Furthermore the method comprises the steps of observing effects of the execution, i.e. metering the behavior, of the executable parts, analyzing the inter-relation of the observed effects with the software, and modifying executable parts based on rules in order to reduce undesirable observed effects like in-efficiency or failure. The present invention relates also to the automatically adapting computer program product, and a method for manufacturing the automatically adapting computer program product.

Owner:PIECE FUTURE PTE LTD

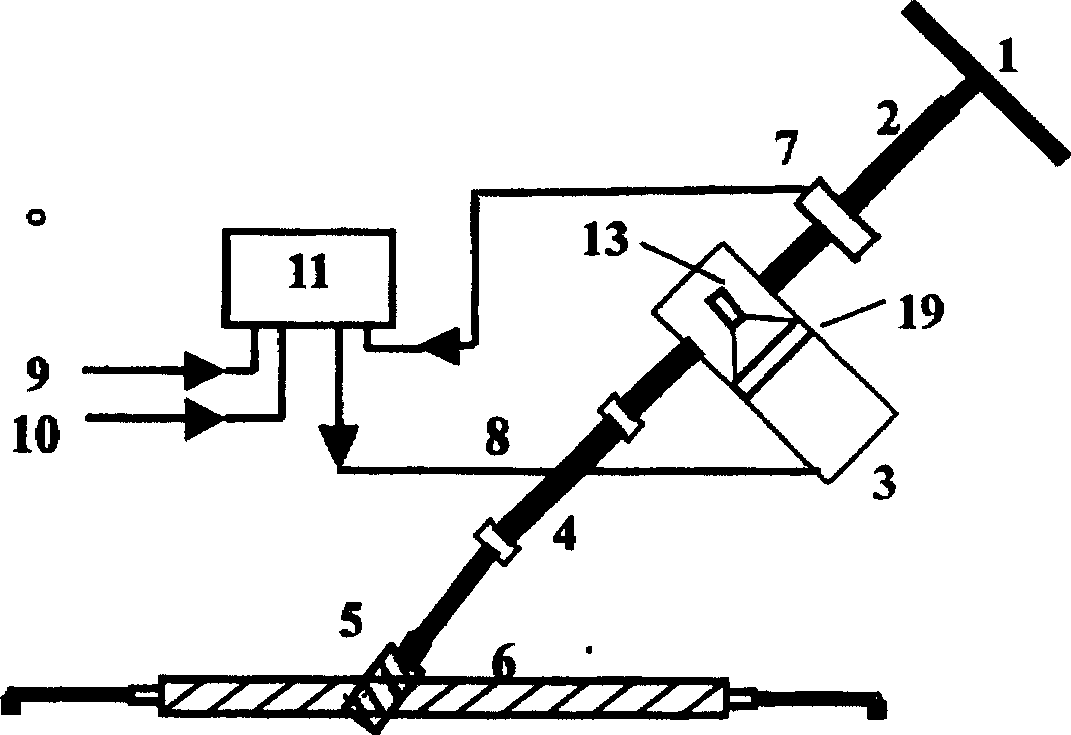

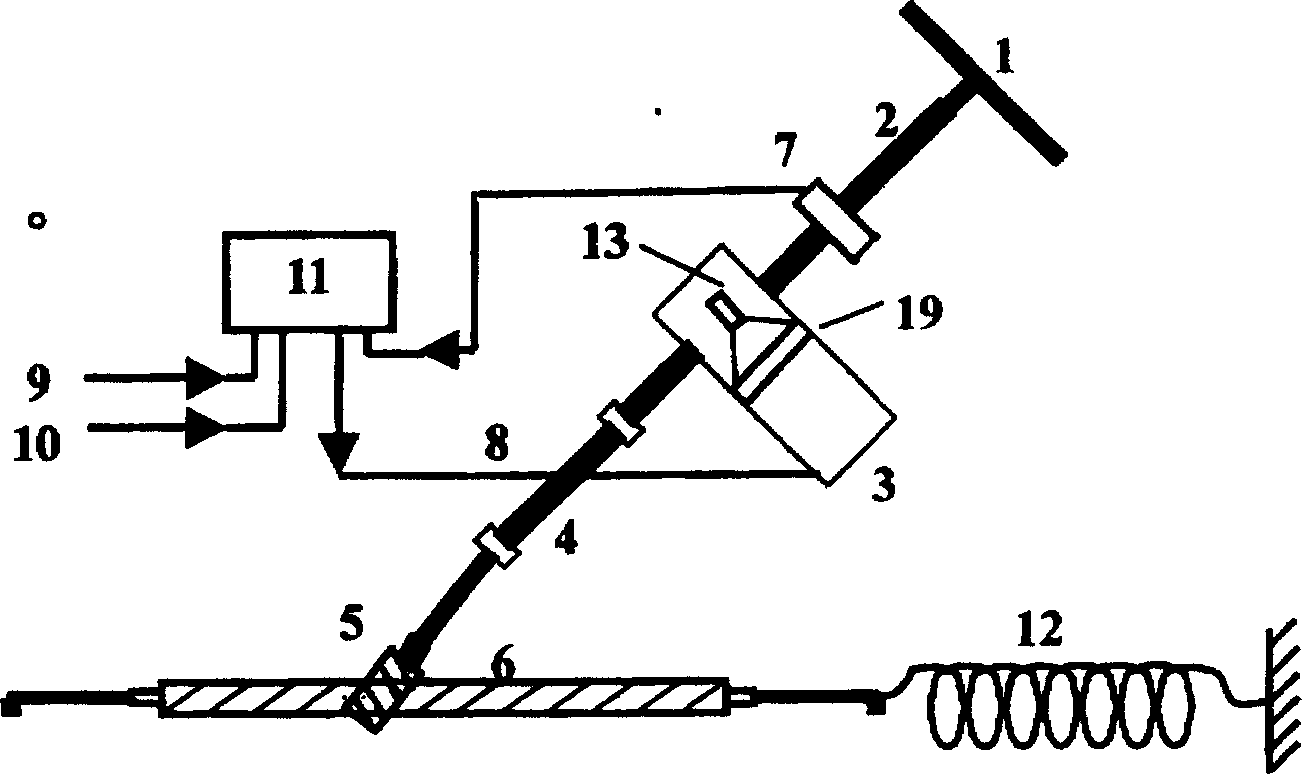

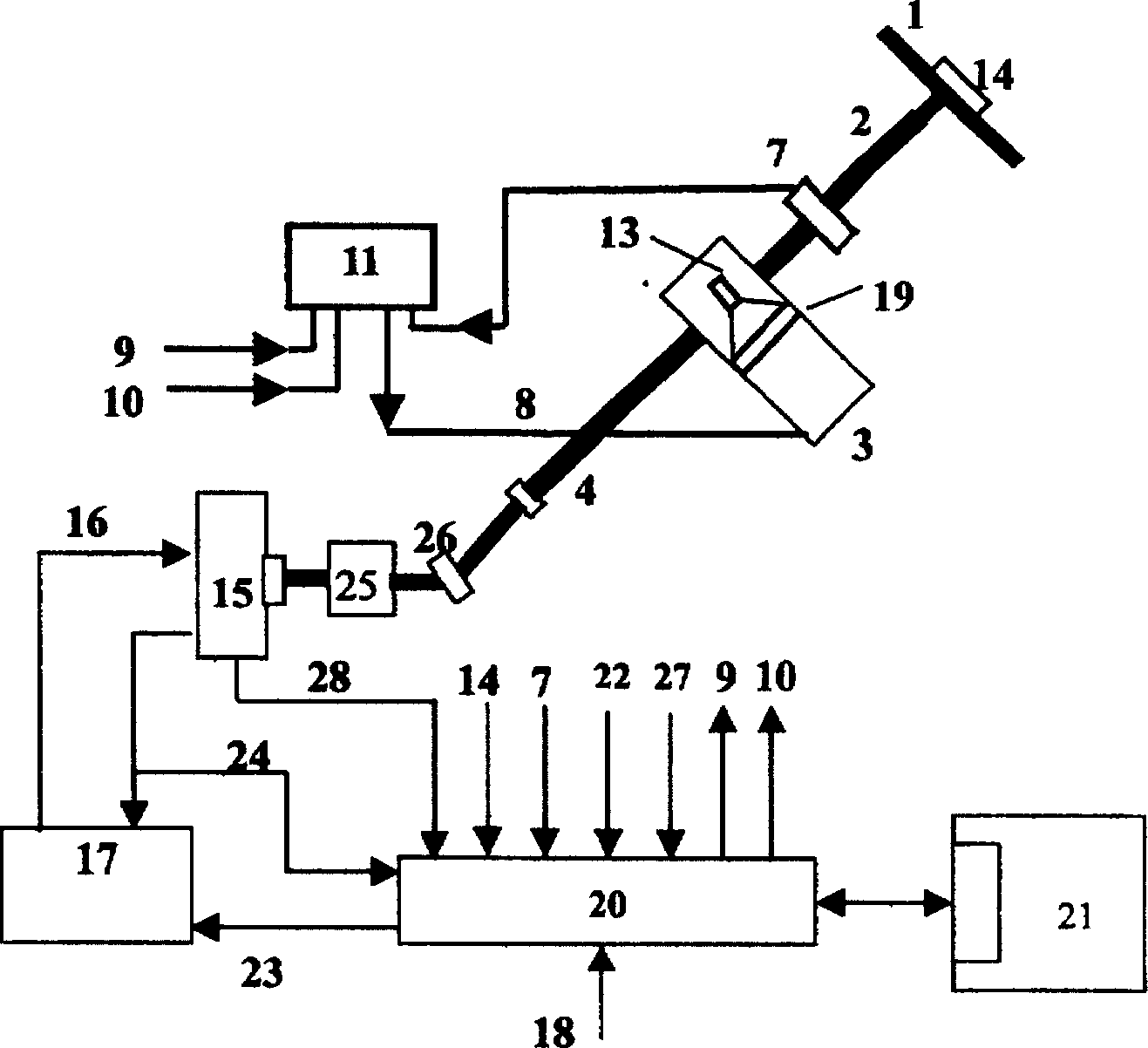

Automobile electric power-assisted steering system simulation testing arrangement

InactiveCN1595091ASpeed up developmentCutting costsVehicle steering/rolling behaviourSteering systemData acquisition

This invention discloses an artificial apparatus of mobile booster steering system which is servo-motor used to mock the resistance force the mobile exerts on the output axis of the steering and to transmit the torque signals to the data collection card. The servo motor controller is connected with the data collection card, which is used to control the torque of the resistance servomotor. The current sensor is used to measure the motor current of the EPS, and provide a proportional voltage signals to the motor current for the data collection card. The angle sensor locates on top of the steering wheel and is used to measure the angle of the wheel and provide angle signals to the data collection card. The computer collects and transmits control orders through the data collection card and processes the data and gets the measurement results.

Owner:HUAZHONG UNIV OF SCI & TECH

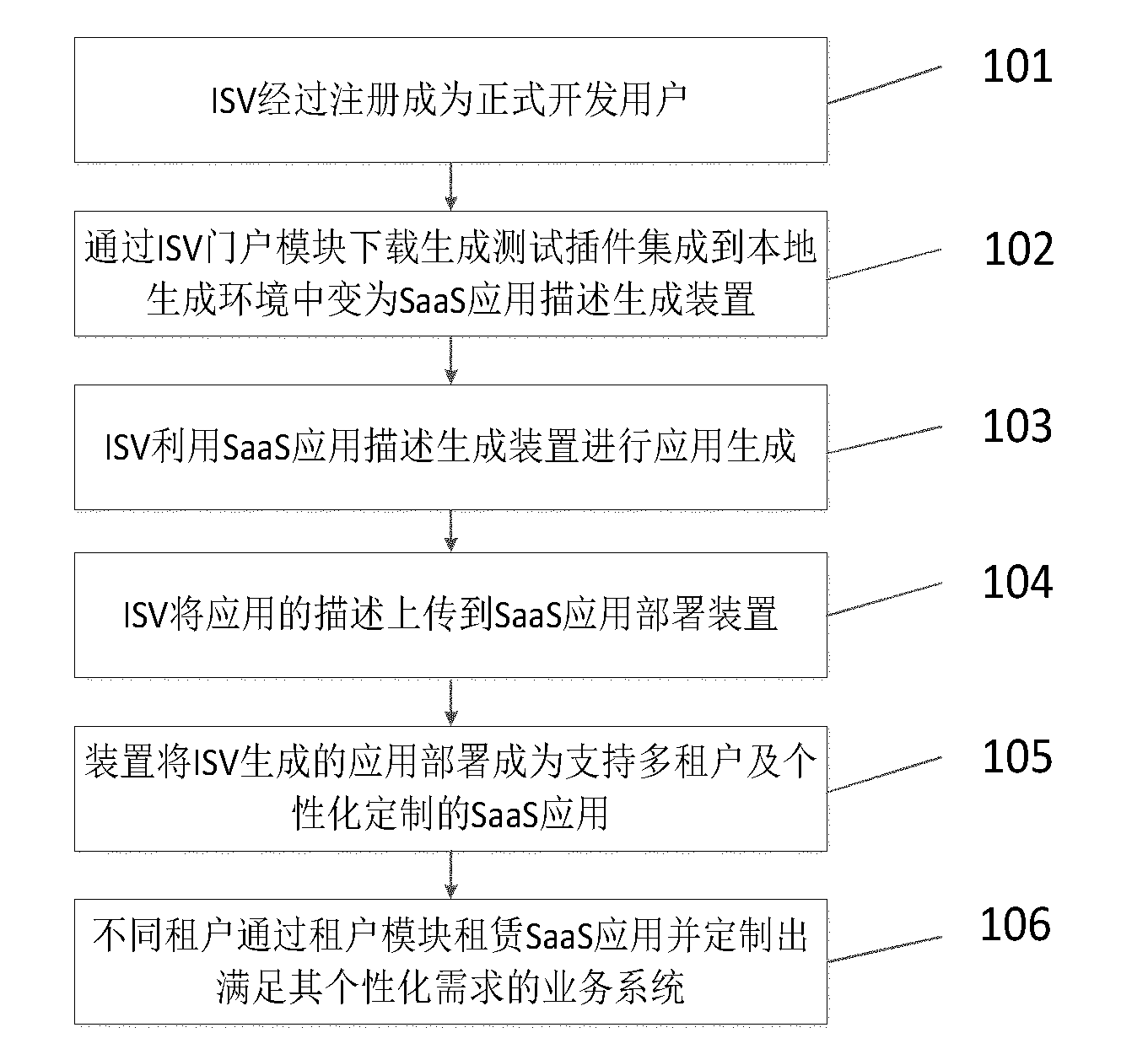

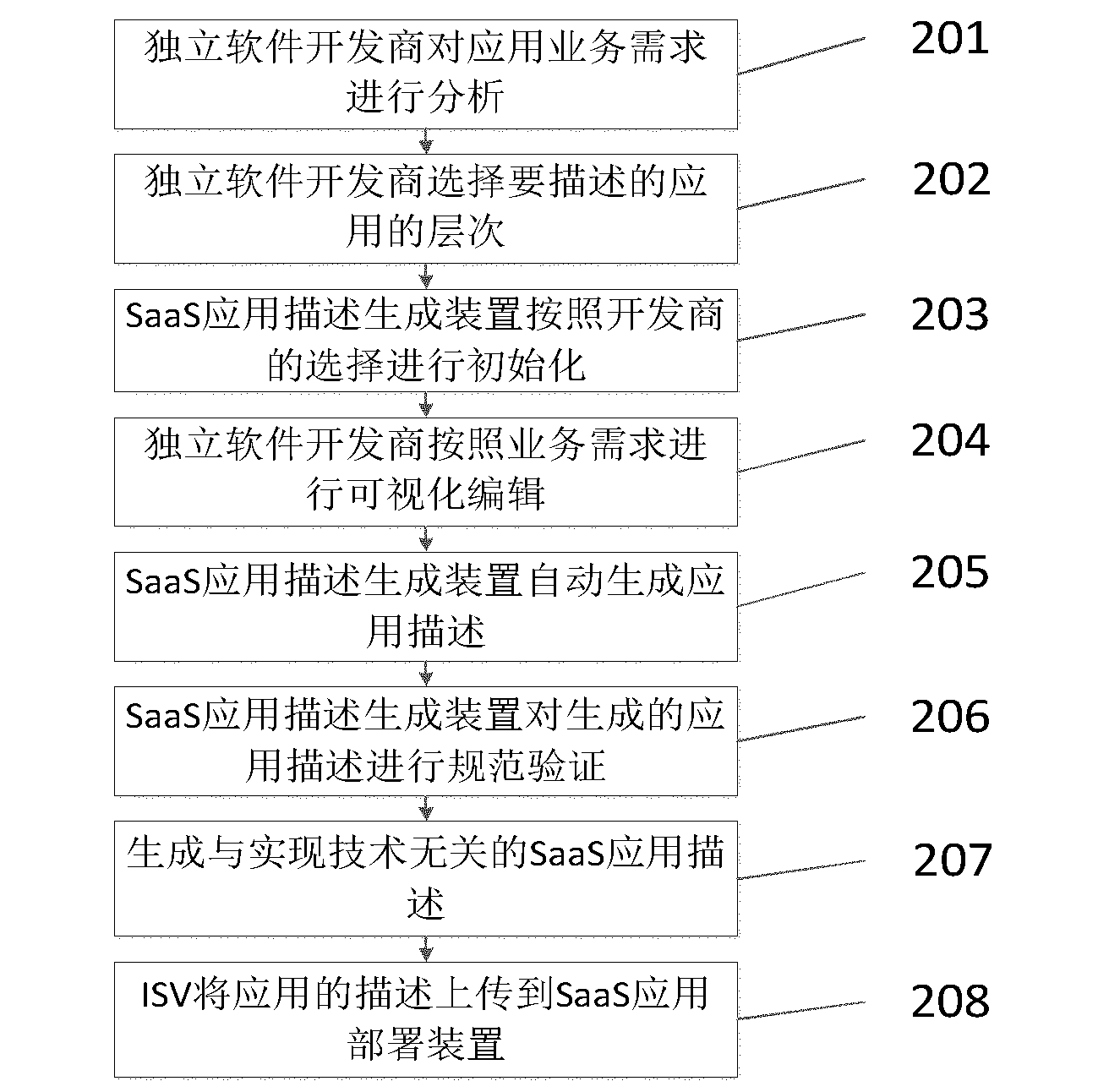

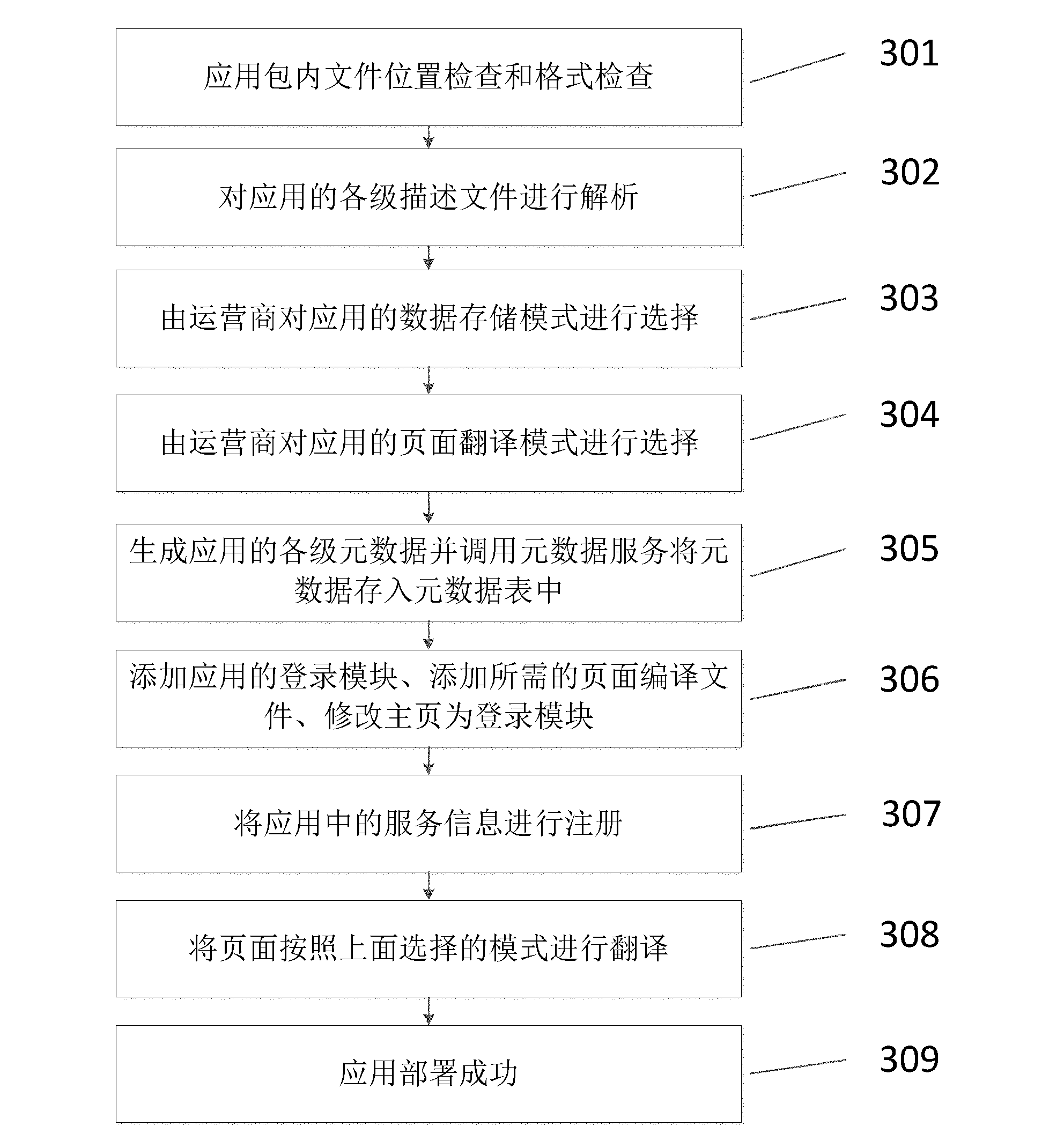

Software-as-a-service (SaaS) application generation and deployment supporting method and device

ActiveCN102135883AStrong development independenceSupport personalized customizationTransmissionSpecific program execution arrangementsPortletSoftware engineering

The invention relates to a software-as-a-service (SaaS) application generation and deployment supporting method and an SaaS application generation and deployment supporting device, which aim to solve the problems of the conventional SaaS software generation and release. The method comprises the following steps that: A, an independent software vendor obtains a development license of an SaaS application generation and deployment device by registration to become an official development user; B, the independent software vendor downloads a generation and testing tool kit by an independent software vendor (ISV) portlet, and integrates the tool kit into a local generation environment to make the local generation environment become an SaaS application description generation device for rapidly generating SaaS application; C, the independent software vendor performs application generation by utilizing the SaaS application description generation device, and uploads the description of the application into an SaaS application deployment device; D, the SaaS application deployment device adds bottom-layer realization to the application generated by the ISV to deploy the application into the SaaS application supporting multiple tenants and personalized customization; and E, the tenants try on, rent and customize the SaaS application.

Owner:SHANDONG UNIV

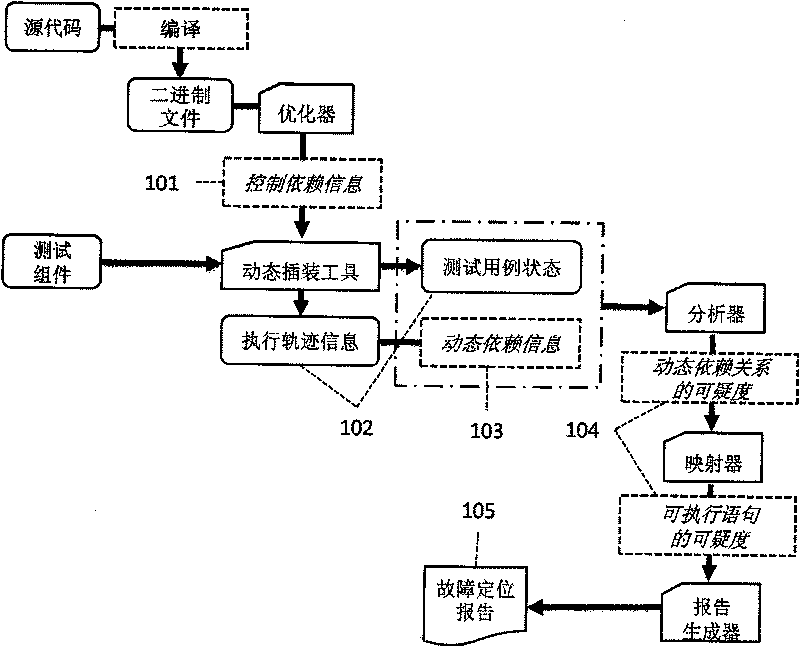

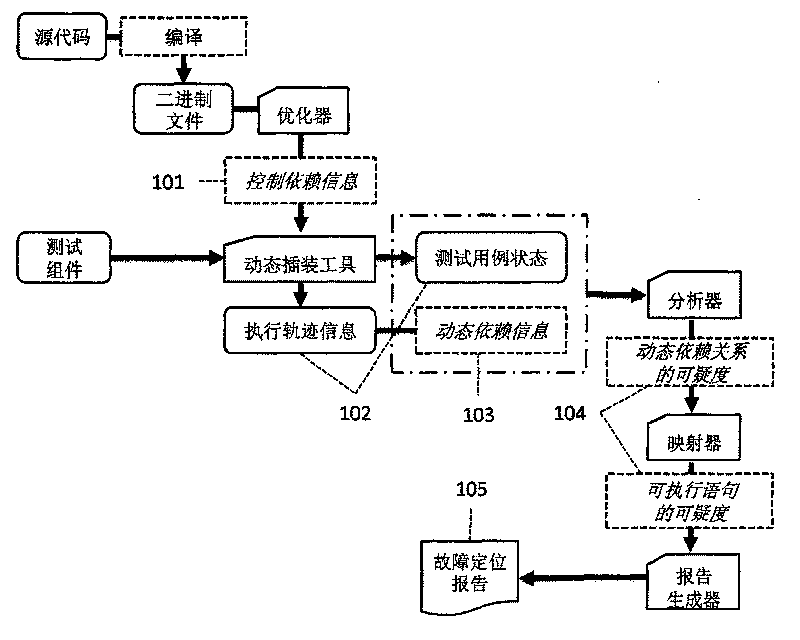

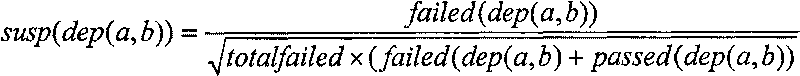

Program dynamic dependency relation-based software fault positioning method

InactiveCN101739339ASpeed up developmentHigh degree of automationSoftware testing/debuggingSoftware faultDependency relation

The invention discloses a program dynamic dependency relation-based software fault positioning method. The method comprises the following steps: acquiring static control dependency information on the basis of an optimizer acting on a link; dynamically plugging an executable program and searching track information of dynamic execution; analyzing the track information to obtain dynamic dependency relations; calculating the suspicious degree of each dynamic dependency relation according to a suspicious degree formula of the dynamic dependency relations; mapping values of the suspicious degree toexecutable sentences of a program; and arranging the sentences in a descending order according to the values of the suspicious degree and outputting a report of software fault positioning. A developer can examine codes according to the order of the suspicious degree from large to small, which reduces the range and the quantity of the codes which must be examined in the phase of program debugging and improves the efficiency for positioning a program fault. The method has the advantages of high degree of automation and high positioning accuracy.

Owner:BEIHANG UNIV

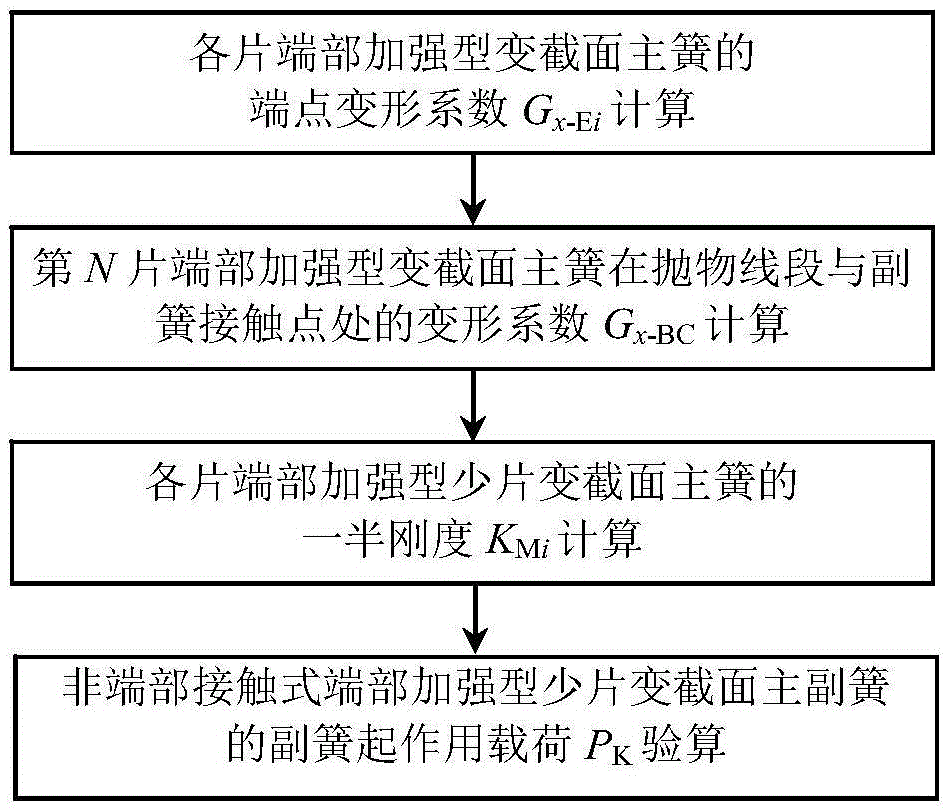

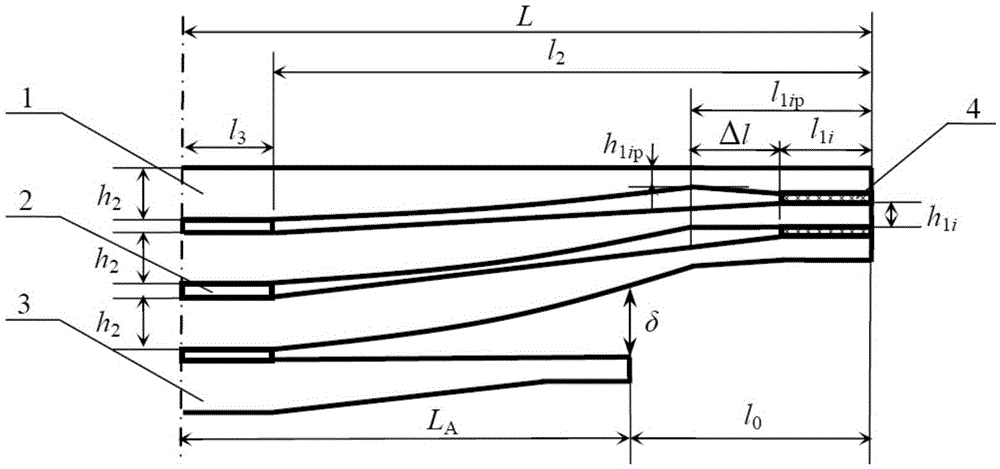

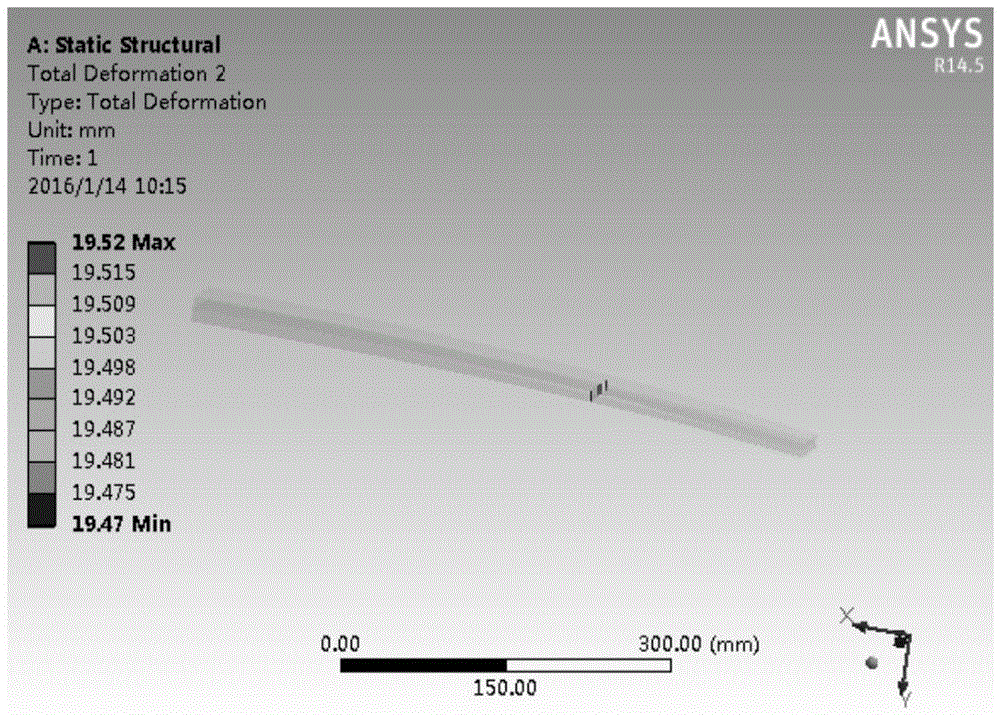

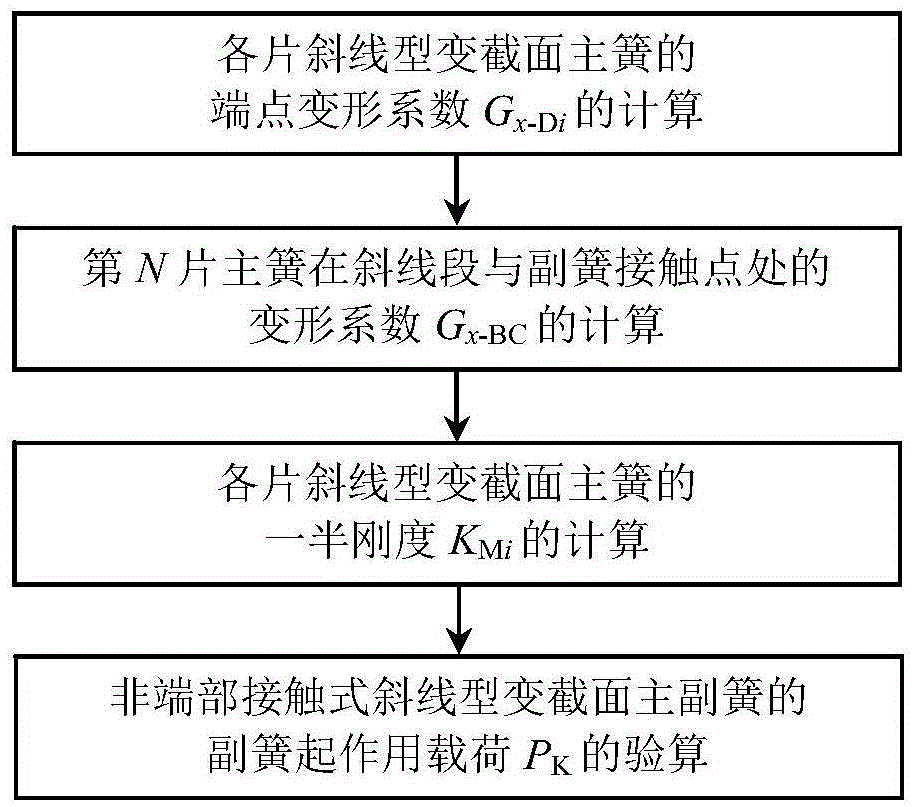

Auxiliary spring work load checking method of non end part contact type end part strengthened few-leaf main and auxiliary springs

ActiveCN105590009AImprove the design levelThe checking method is reliableDesign optimisation/simulationSpecial data processing applicationsContact typeEngineering

The invention relates to an auxiliary spring work load checking method of a non end part contact type end part strengthened few-leaf main and auxiliary springs belonging to the suspension steel plate spring technical field. According to the method of the invention, firstly, according to the structure size and the elastic modulus of each end part strengthened few-leaf cross-section variable main spring, the end point deformation coefficient Gx-Ei and the half rigidity KMi of each main spring, and the deformation coefficient Gx-BC at the contact point of the Nth main spring and an auxiliary spring on a parabolic segment can be determined; then, according to the half rigidity KMi of each main spring, the thickness h2 of a root straight section, the Gx-BC of the Nth main spring and a main and auxiliary spring interval Delta design value, the auxiliary spring work load of the non end part contact type end part strengthened few-leaf cross-section variable main and auxiliary springs is checked. Through the emulation proof, in adoption of the method of the invention, the accurate and reliable auxiliary spring work load checking value can be obtained; therefore, the design levels and performances of the few-leaf cross-section variable main and auxiliary springs and the smoothness of a vehicle are improved; moreover, the design and test cost is saved; and the product development speed is accelerated.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

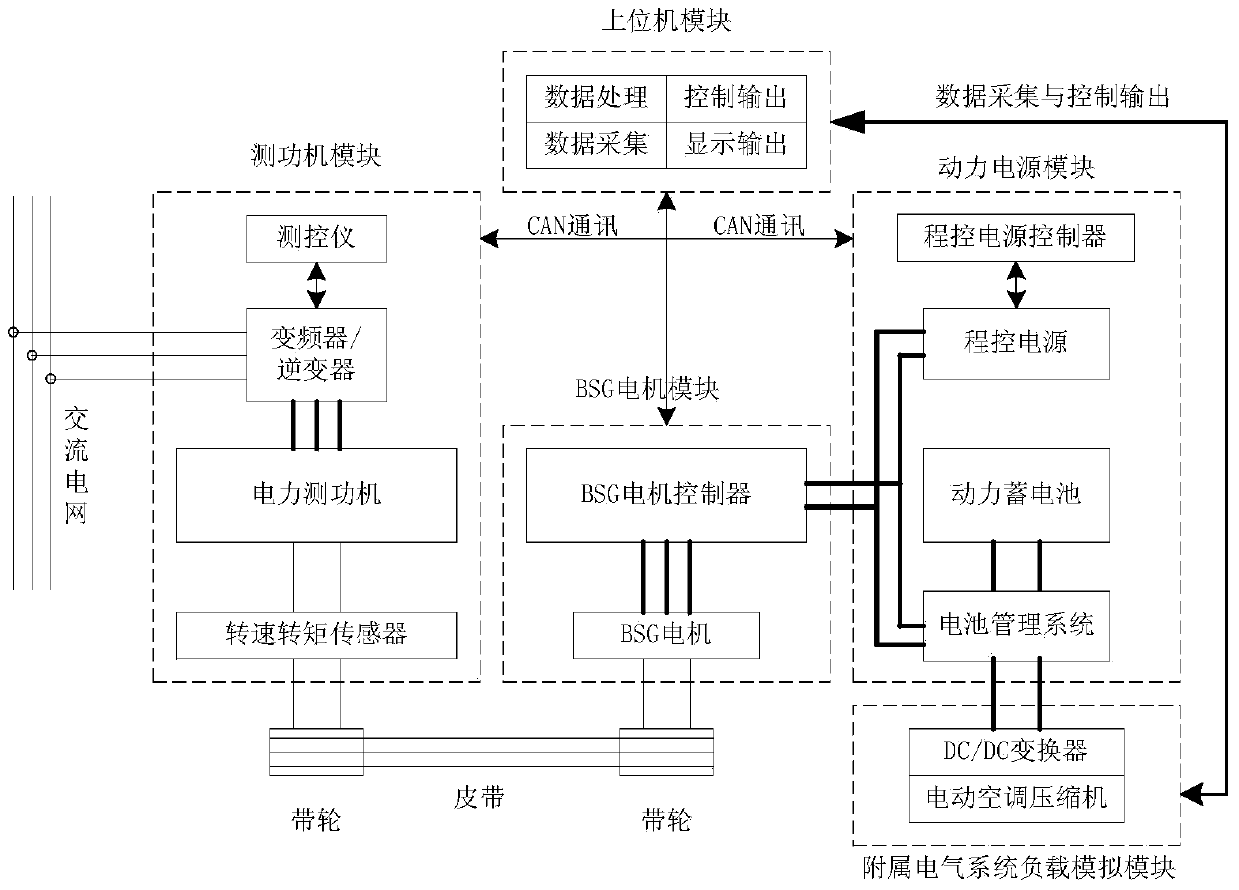

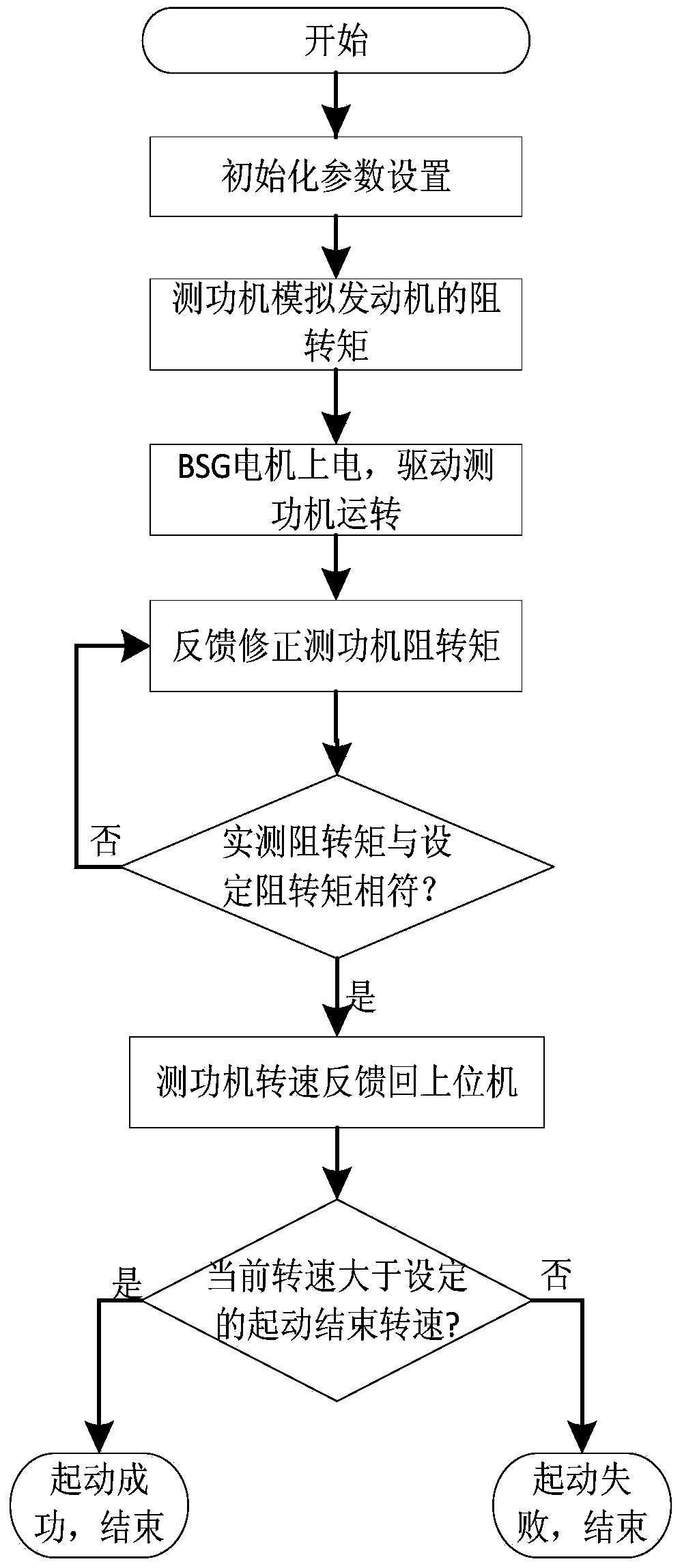

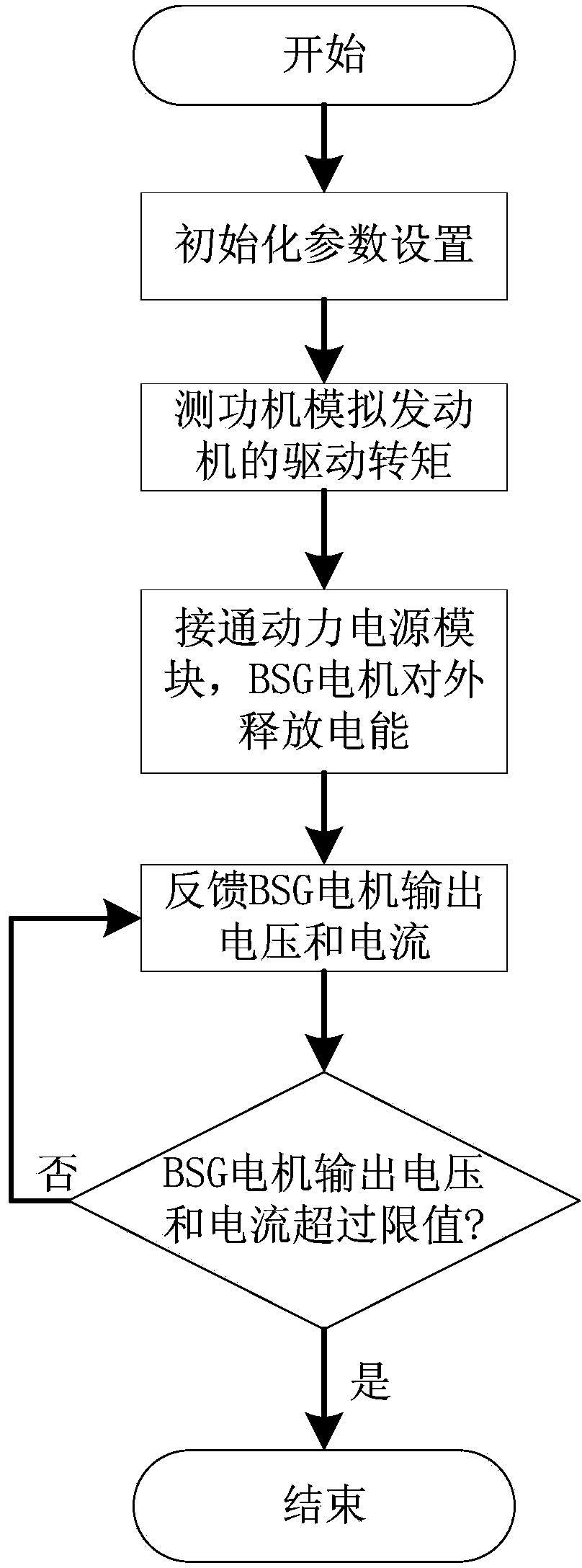

Testing system and method for electric part of power system for weak hybrid electric vehicle

ActiveCN103809120AFull trial testShorten the test cycleElectric testing/monitoringDynamo-electric machine testingElectrical batteryDynamometer

The invention discloses a testing system and a method for electric part of power system for weak hybrid electric vehicle, and the system comprises a BSG motor module provided with a BSG motor and a BSG motor controller; a dynamometer module provided with a dynamometer, a measuring and control instrument and a torque and speed sensor, and a transducer or an inverter; a power module provided with a power storage battery, a battery management system, a program control power supply and a program control power supply controller; an auxiliary electric system load simulation module provided with a DC / DC convertor and an auxiliary electric system load; an upper computer module. The method adopts the half object simulation principle, the dynamometer simulates the engine for doing test to the BSG motor module and does the service life test for the electric part of weak hybrid power system at different working conditions that the BSG motor starts the engine, the engine drives the BSG motor for generating, regenerative braking, idle parking while the battery drives the load, the system and method can reduce the test cost, shorten the test period for vehicle performance and raise the developing speed for product.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

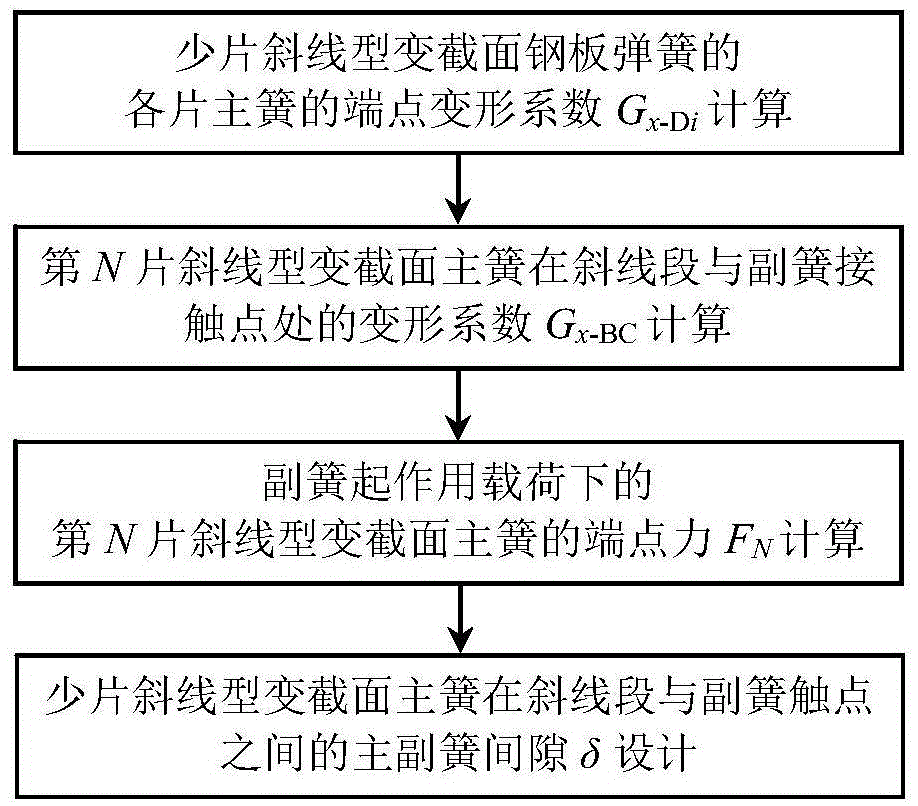

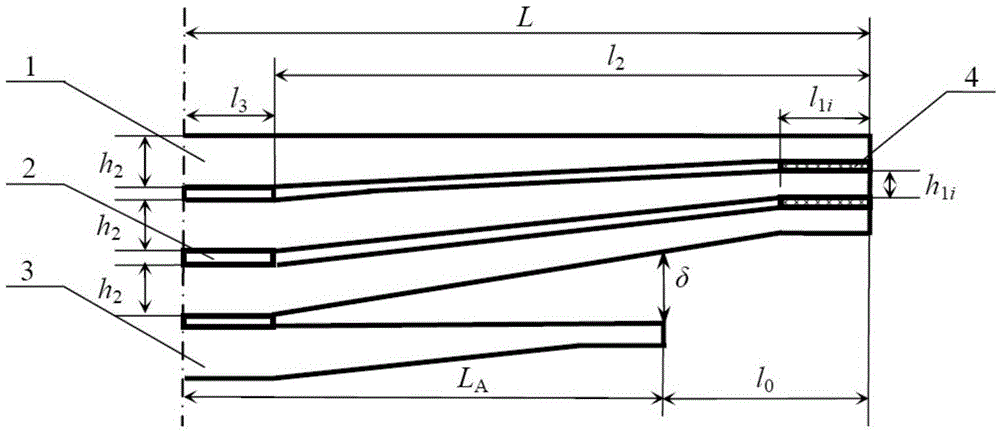

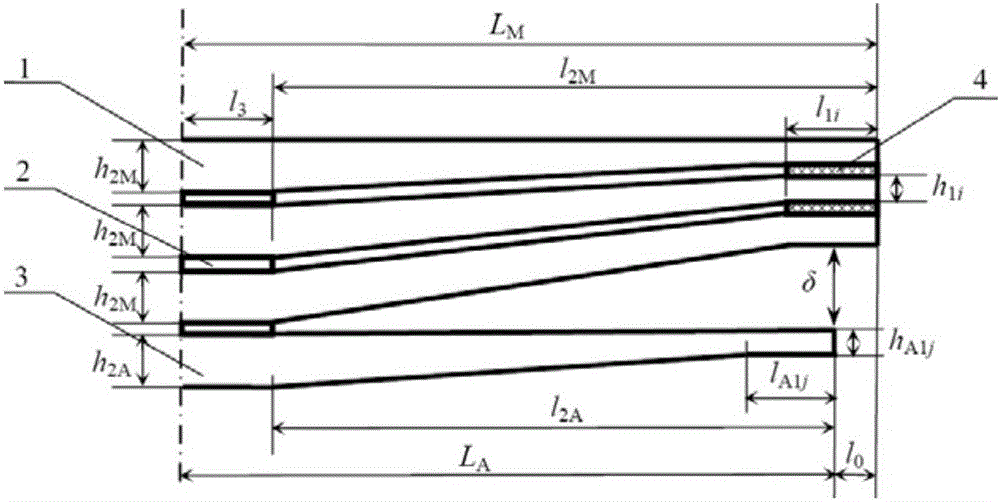

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

ActiveCN105550487AImprove the design levelQuality improvementGeometric CADDesign optimisation/simulationLine segmentOblique line

The invention relates to a method for designing few-leaf oblique line type variable-section main springs in the gaps between oblique line segments and an auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural sizes and the elasticity moduli of the oblique line type variable-section main springs, the endpoint deformation coefficient Gx-Di of each main spring and the deformation coefficient Gx-BC of the Nth main spring at the contact point of the corresponding oblique line segment and the auxiliary spring are determined first; then, according to the required auxiliary spring acting load design value and the endpoint deformation coefficient Gx-Di of each main spring, endpoint force FN of the Nth main spring is obtained; then, according to the thickness h of the root straight section of the Nth main spring, the Gx-BC and the FN, main spring and auxiliary spring gaps between the oblique line segment of the main springs and the contact point of the auxiliary spring are designed. Through simulation verification, it can be known that the main and auxiliary spring gap design value meeting the auxiliary spring acting load requirement can be obtained by means of the method, and the product design level, product performance and vehicle smoothness are improved. Meanwhile, design and testing cost is reduced, and product development speed is increased.

Owner:JIANGSU HAIHONG MACHINERY MFG

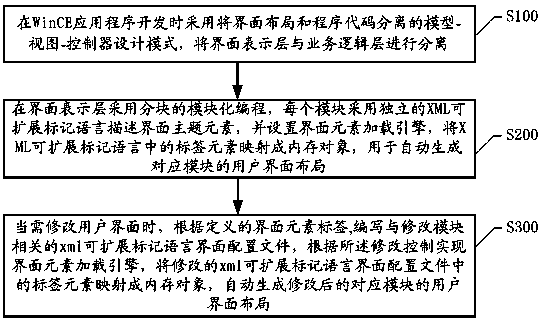

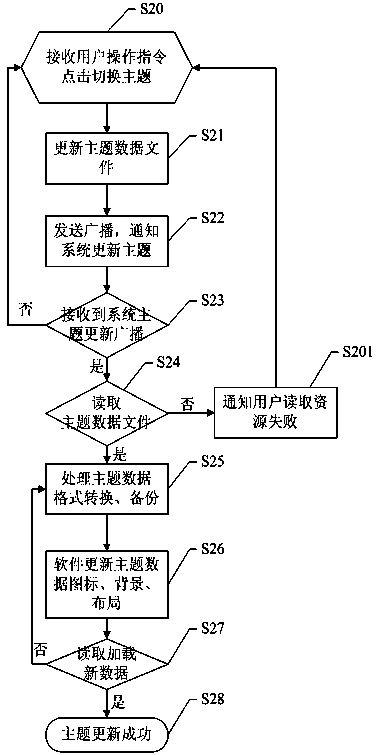

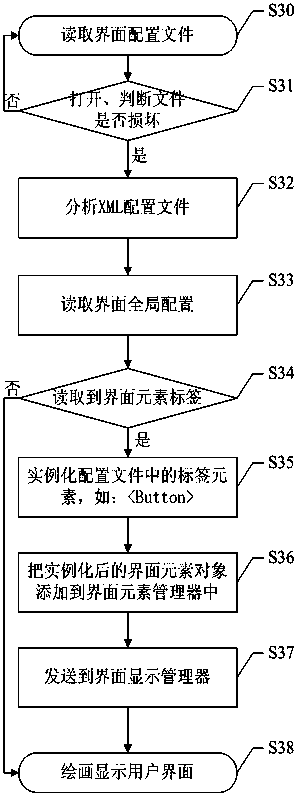

Processing method and system for updating and changing interface theme of WinCE product

ActiveCN104090749AEasy to operateEasy to implementSpecific program execution arrangementsBusiness logicDesign pattern

The invention discloses a processing method and system for updating and changing the interface theme of a WinCE product. The method comprises the following steps: when the WinCE application program is developed, separating an interface presentation layer from a business logic layer by adopting a design mode of separating interface layout from program codes, adopting segmented modular programming in the interface presentation layer, and adopting independent XML extensible markup language to describe the elements of the interface theme for each module; when a user interface is required to be amended, writing and amending xml (extensible markup language) interface configuration files relevant to the modules, controlling and realizing the loading engine of the interface element according to the amended contents, mapping the label elements in the amended xml (extensible markup language) interface configuration files into internal storage objects, and automatically generating the user interface layout of the corresponding amended modules. The interface layout and the program codes are separated, so that the problem that the application program interface cannot be freely customized by a client is solved, and simultaneously, the development efficiency of the application program is improved.

Owner:SHENZHEN APICAL TECH CO LTD

Development, testing, operation and maintenance integration system, deployment and full-quantity and incremental updating method

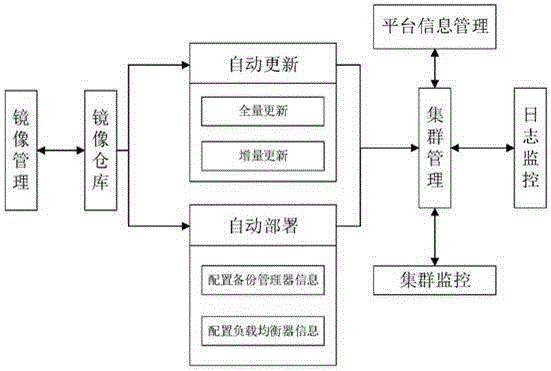

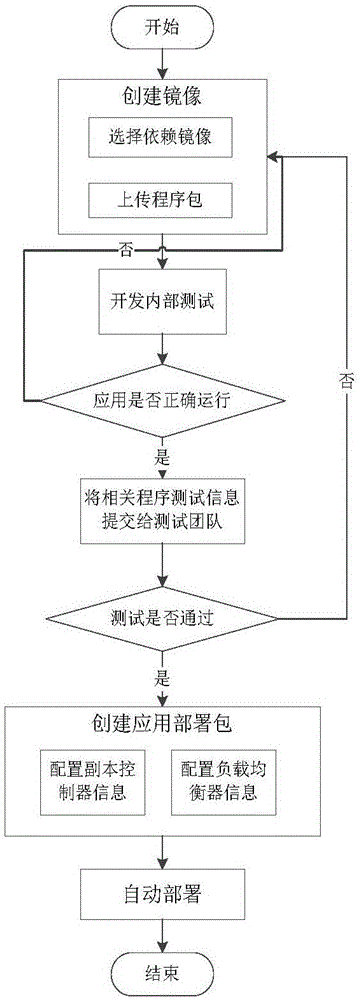

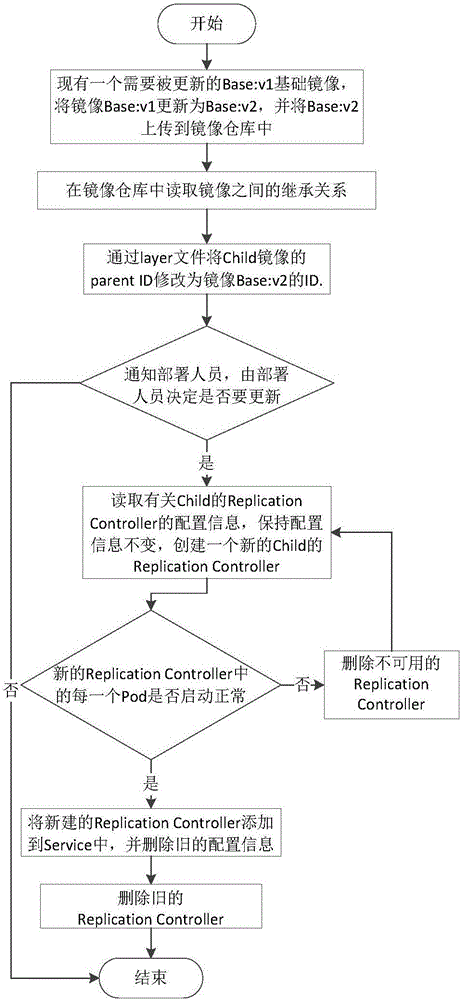

ActiveCN106293820ARealize integrationImplement automatic deploymentSoftware testing/debuggingProgram loading/initiatingApplication softwareMirror image

The invention discloses a development, testing, operation and maintenance integration system, deployment and a full-quantity and incremental updating method. The system comprises an automatic deployment module and an automatic updating module, wherein the automatic deployment module configures corresponding backup controller information and load balancer information according to mirror images in a mirror image warehouse at a developer end, automatically generates an application deployment script, and automatically / manually spreads the application deployment script to a testing deployment end; the testing deployment end automatically deploys an application to the testing, operation and maintenance environment by executing an application deployment script file, the automatic updating module updates an application program according to the mirror images in the mirror image warehouse at the developer end, generates an update pack file in a full-quantity or incremental updating mode and automatically / manually spreads the update pack file to the testing deployment end; the testing deployment end automatically deploys the updated application to the testing, operation and maintenance environment by executing the update pack file. Cooperation obstacles among development, testing, operation and maintenance are reduced, the cooperation efficiency is improved, application deployment processes are simplified, a developer pays close attention to business flows, and the requirement for technological levels of operation and maintenance staffs is lowered.

Owner:SHANDONG UNIV

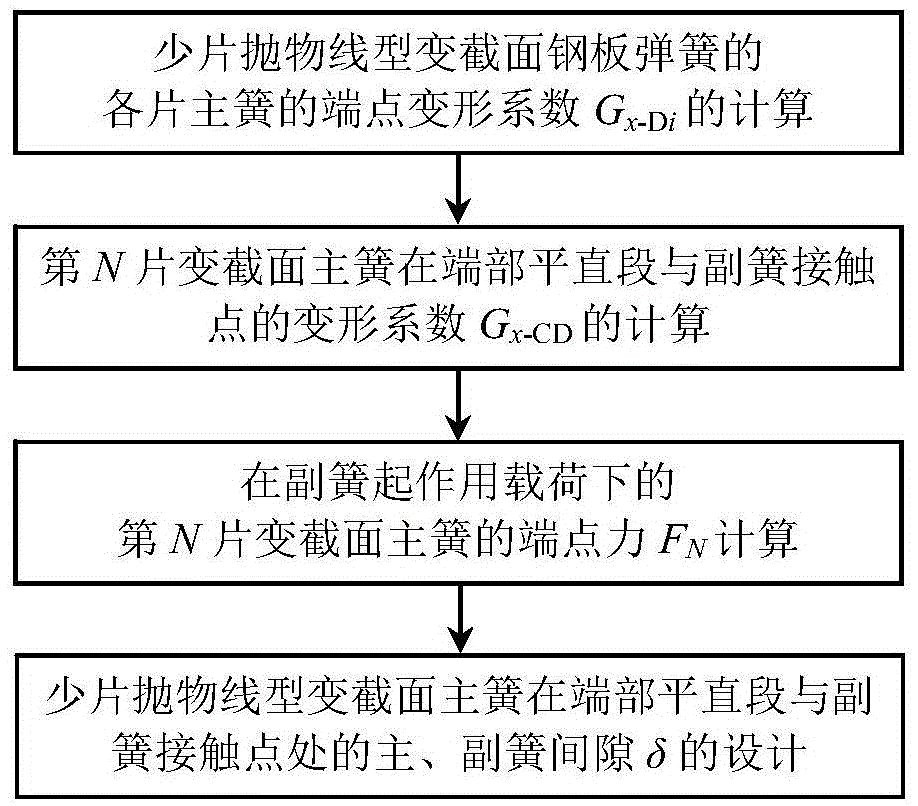

Design method for few parabolic type variable cross-section main spring end and auxiliary spring gaps

ActiveCN105608300AImprove the design levelQuality improvementDesign optimisation/simulationSpecial data processing applicationsSteel platesElastic modulus

The invention relates to a design method for few parabolic type variable cross-section main spring end and auxiliary spring gaps, and belongs to the technical field of suspension steel plate springs. The method comprises the steps that according to the structural size and elastic modulus of each parabolic type variable cross-section main spring, an end point deformation coefficient of each main spring and a deformation coefficient Gx-CD of the Nth main spring on the contact point of an auxiliary spring and the end straight section; then, according to the auxiliary spring acting load design requirement value and the end point deformation coefficient of each main spring, the endpoint force FN of the Nth main spring is obtained; then, according to the thickness h2 of the straight section at the root of the Nth main spring, the FN and the Gx-CD, the main and auxiliary gaps between the contact points of the auxiliary springs and the end straight sections of the main springs are designed. According to simulation verification, the accurate and reliable main and auxiliary spring gap design values can be obtained by means of the method, the auxiliary spring acting load design requirement is met, and the product design level and performance and the vehicle ride comfort are improved; meanwhile, the product development speed is increased, and the design and testing expenses are lowered.

Owner:慕贝尔汽车部件(太仓)有限公司

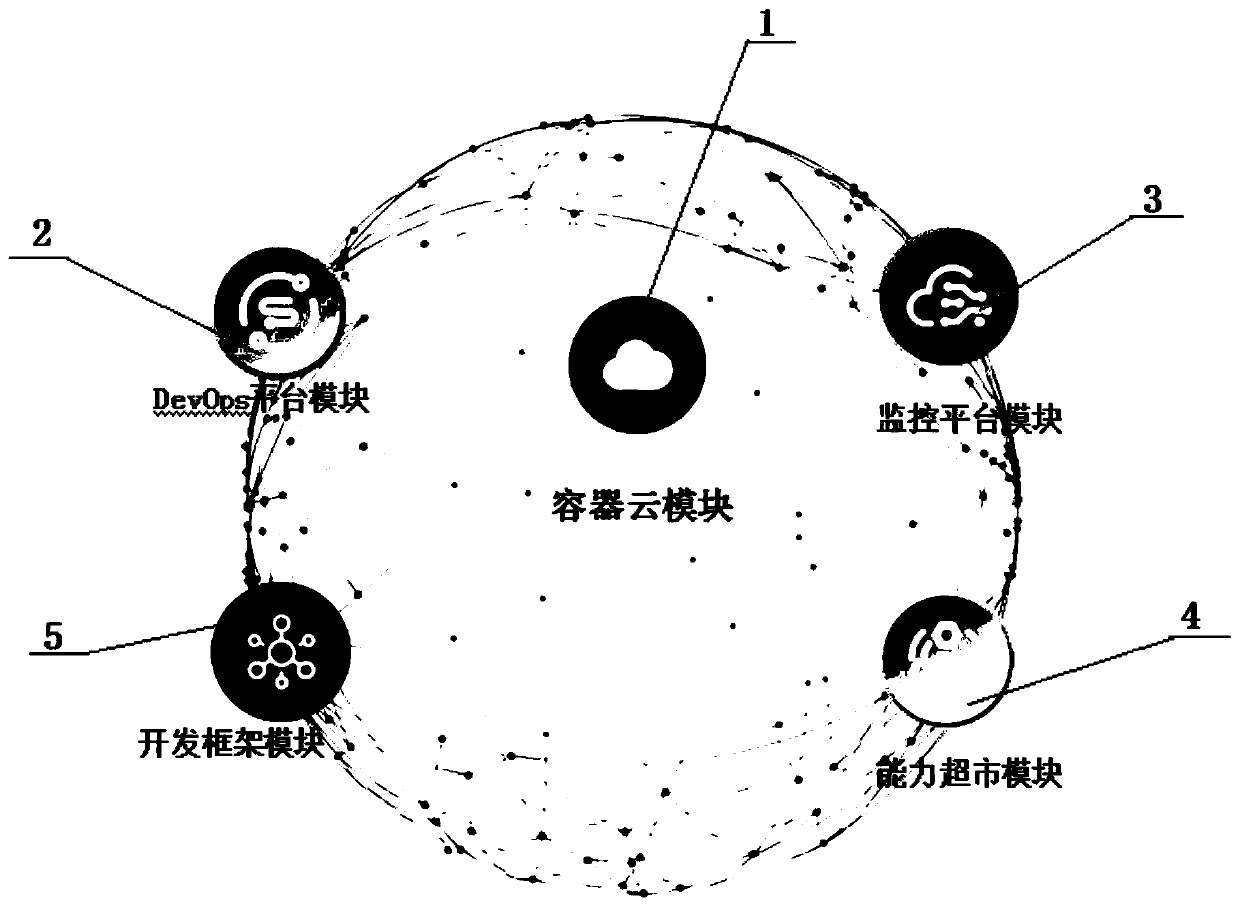

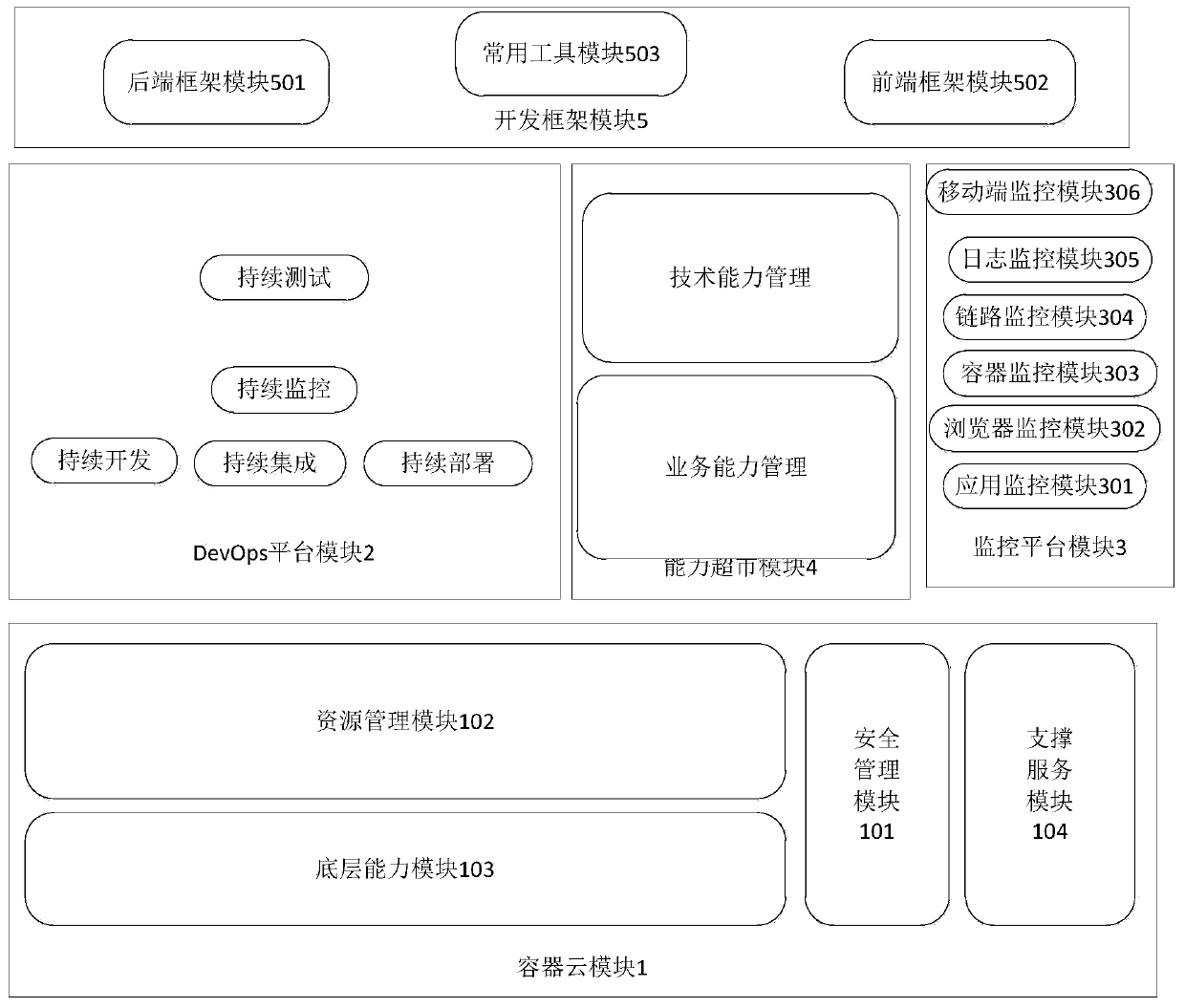

Software development platform

ActiveCN110321152ASpeed up developmentQuality improvementSoftware maintainance/managementEnergy efficient computingThe InternetAgile software development

The invention discloses a software development platform, which belongs to the technical field of software development. The platform is a PaaS platform of an enterprise level. Enterprises can be helpedto go to DevOps practice. A business capability supermarket is constructed, an enterprise is enabled to get rid of complex infrastructure management and more concentrate on business research and development and delivery, an internet distributed architecture is adopted for design and development, normalization, standardization and internet technicalization of development and operation and maintenance processes are realized through a PaaS platform, and the development efficiency and the operation and maintenance capability are improved; design is carried out based on a micro-service architecture, high reliability and high expansion capability are taken as basic attributes, and use scenes such as single-point faults and large concurrency are dealt with; pROVIDING AUTOMATED DEPLOYMENT OF STANDS, rapid iteration and automatic operation and maintenance are used as basic attributes; the software development platform supports scenes of rapid development, smooth upgrading and the like, so thatthe user experience of the software development platform can be improved, the software development speed and the software quality are improved, one-stop service is provided for the software development process, smooth and continuous development of software and dynamic analysis and positioning during operation are facilitated, and the customer satisfaction is improved.

Owner:青岛华正信息技术股份有限公司

Aeroplane buffet air tunnel model integration design and manufacturing method

InactiveCN101509825ASpeed up developmentImprove manufacturing precisionAerodynamic testingJet aeroplaneIntegrated design

The invention relates to an integrated design and manufacture method of a full resin airplane low-velocity flutter wind tunnel model based on photocuring rapid prototyping. The method first conducts the integrated design of the flutter model according to the actual structure of an airplane, the requirement of a wind tunnel experiment and the parameters of photocuring resin material and based on the photocuring resin material, and makes the full resin flutter model in an integrated way on the basis of the optimization of the photocuring rapid process. The method proposes a new design and manufacture concept of the flutter model of low modulus material, gets rid of unnecessary assembly links by the use of the advantages of accuracy, quickness and low cost of the photocuring rapid prototyping technology, the uniformity of the model material, the low modulus of the resin material and isotropy characteristic, and designs and manufactures the full resin flutter wind tunnel model meeting the full dynamic similarity. The method overcomes the defects of traditional technologies, improves the manufacture precision of the wind tunnel model, reduces cost, shortens the period and realizes structural similarity, thus boosting the development speed of an airplane.

Owner:XI AN JIAOTONG UNIV

Method for checking useful load of auxiliary springs of non-end contact diagonal main and auxiliary spring

ActiveCN105653883AImprove transportation efficiencyImprove securityInformaticsSpecial data processing applicationsEngineeringOblique line

The invention relates to a method for checking a useful load of auxiliary springs of a non-end contact diagonal primary and auxiliary spring, and belongs to the technical field of suspension steel plate springs. The method comprises the following steps: firstly, determining an endpoint deformation coefficient and the half rigidity of each main spring, as well as a deformation coefficient Gx-CB of the contact point between an Nth main spring and the auxiliary spring at an oblique line segment according to a structural dimension and an elastic modulus of the diagonal variable cross-section main spring with non-isostructural end parts; then, checking the useful load of the auxiliary springs of the non-end contact few-leaf diagonal variable cross-section main and auxiliary spring according to the thicknesses of root straight sections of the main springs, Gx-CB of the Nth main spring, the half rigidity of each main spring and a design value of the clearance Delta between the main springs and the auxiliary springs. The simulated verification shows that an accurate checking value of the useful load of the auxiliary springs of the non-end contact diagonal main and auxiliary spring can be obtained by using the method, the design level and performance of products are improved, the vehicle running smoothness is improved, meanwhile, the design, manufacturing and test costs are reduced, and the product development speed is increased.

Owner:平邑经济开发区投资发展有限公司

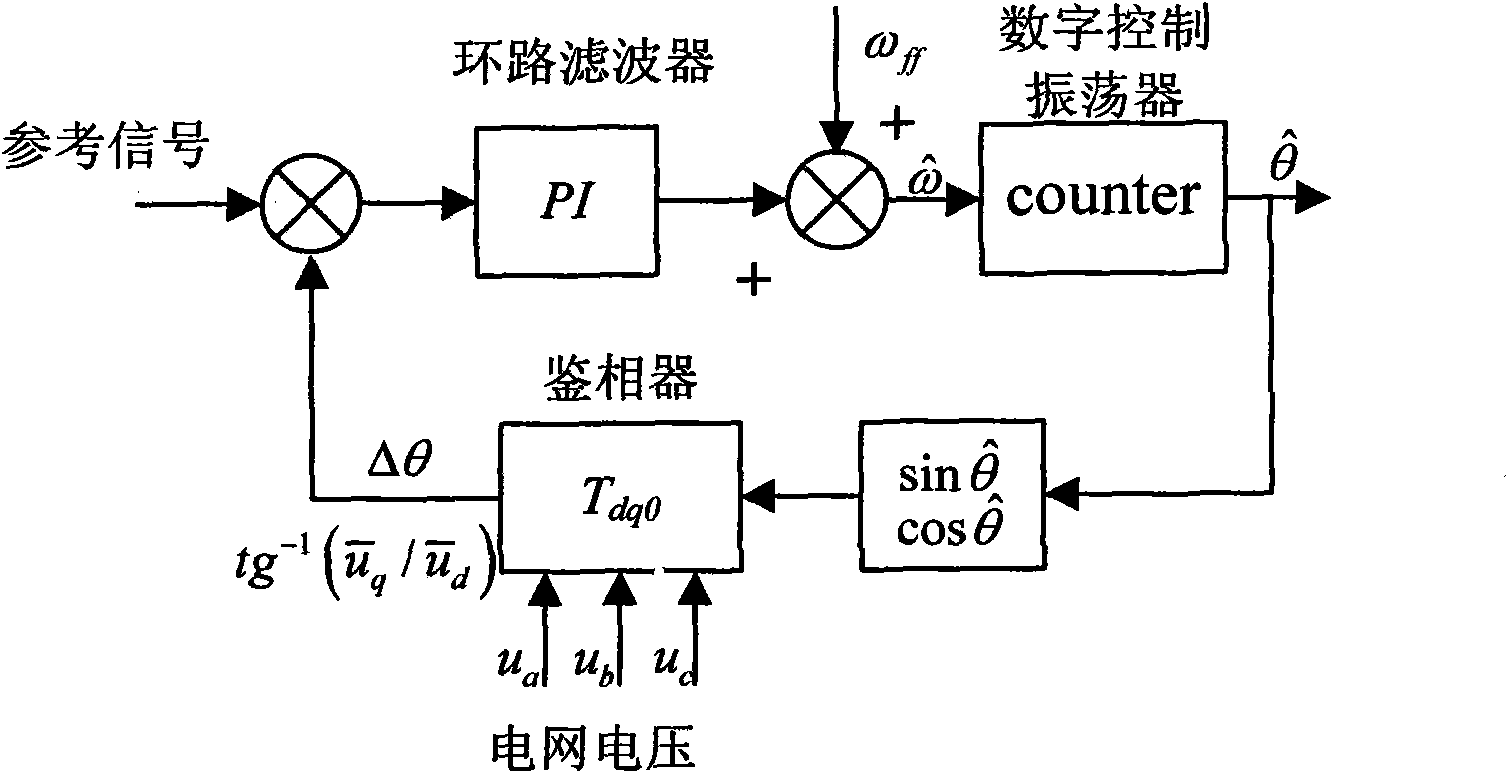

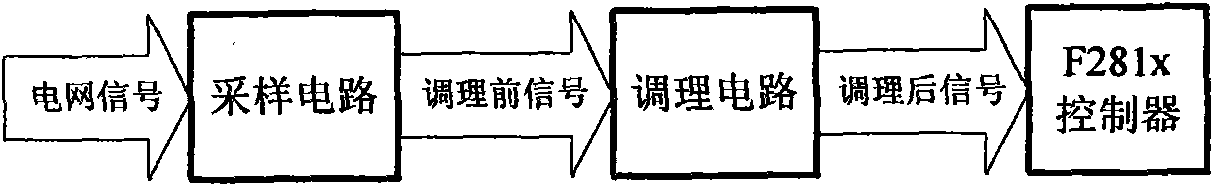

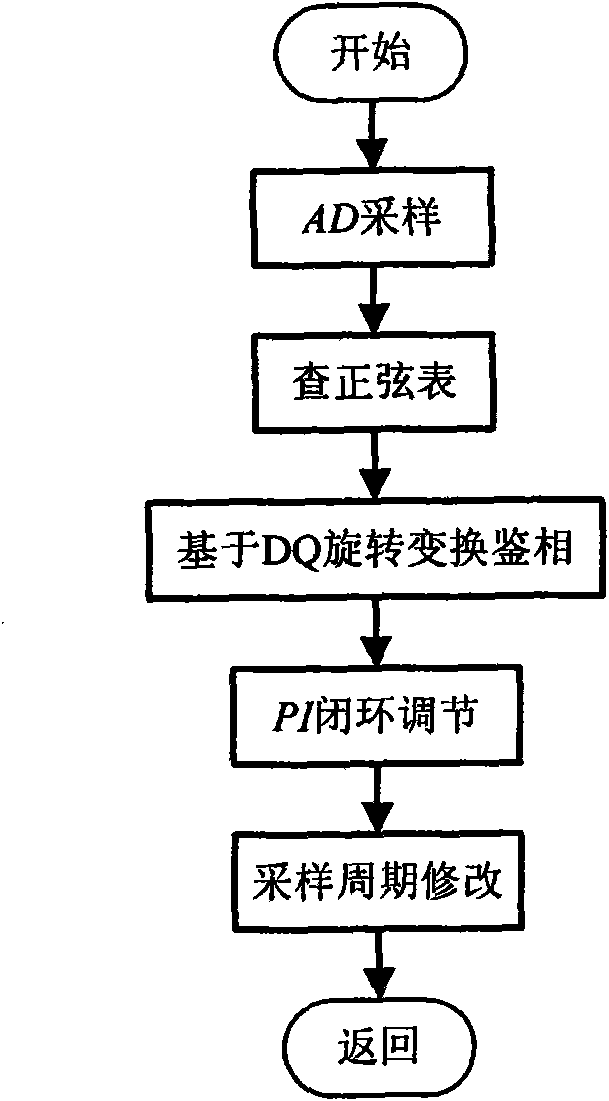

Method for realizing software phase-locked loop with unfixed sampling frequency

InactiveCN101777912ASpeed up developmentImprove calculation accuracyPulse automatic controlNew energyNumerically controlled oscillator

The invention discloses a method for realizing a software phase-locked loop with an unfixed sampling frequency. The method comprises the following steps: firstly adopting an analog phase-locked loop digital controlled oscillator of the DSP period counter to obtain digital controlled oscillator output signals; then working out the phase error between the mains voltage and a reference signals in the DQ-transformation phase demodulation mode by using the digital controlled oscillator output signals as the reference signals; and establishing a closed loop transfer function secular equation of a phase-locked loop system and determining the parameters of the designed loop filter based on the digital controlled oscillator output signals and the phase error between the mains voltage and the reference signals. The invention can maintain the fixed number of the sampling points in the primitive period, and is used for repeatedly controlling various grid-connected converting devices, such as active electric filters, new energy-powered grid-connected converters and the like. By adopting the DQ-transformation phase demodulation mode, the invention can well inhibit the harmonic and unbalanced mains, resist the fluctuation of the mains voltage, and ensure the reliable operation of the phase-locked loop under the conditions of multiple mains voltage zero passage, voltage harmonics, voltage fluctuation and mains voltage imbalance.

Owner:ZHEJIANG UNIV

Electronic map capable of uploading or downloading local photos

InactiveCN101127109AVirtuous business development cycleSpeed up developmentSpecial data processing applicationsMarketingEconomic benefitsThe Internet

The utility model relates to an internet technique, in particular to an electronic map applied in internet environment, which is characterized in that providing an electronic map where a plurality of designated-position field photos can be uploaded and downloaded and user integral and photo sorting function are provided. Besides the functions of the prior general electronic map, a photo upload module, a photo download module, a user integral module and a photo sorting module are added. All modules can exchange information and are connected tightly on the functions. The utility model has the advantages that the system provides the field image of each detailed geographic location, simultaneously as the user integral and photo sorting functions are realized, each network browser can participate in the construction of the electronic map, so as to accelerate the development speed of the electronic map and increase the economic benefit.

Owner:冯志刚

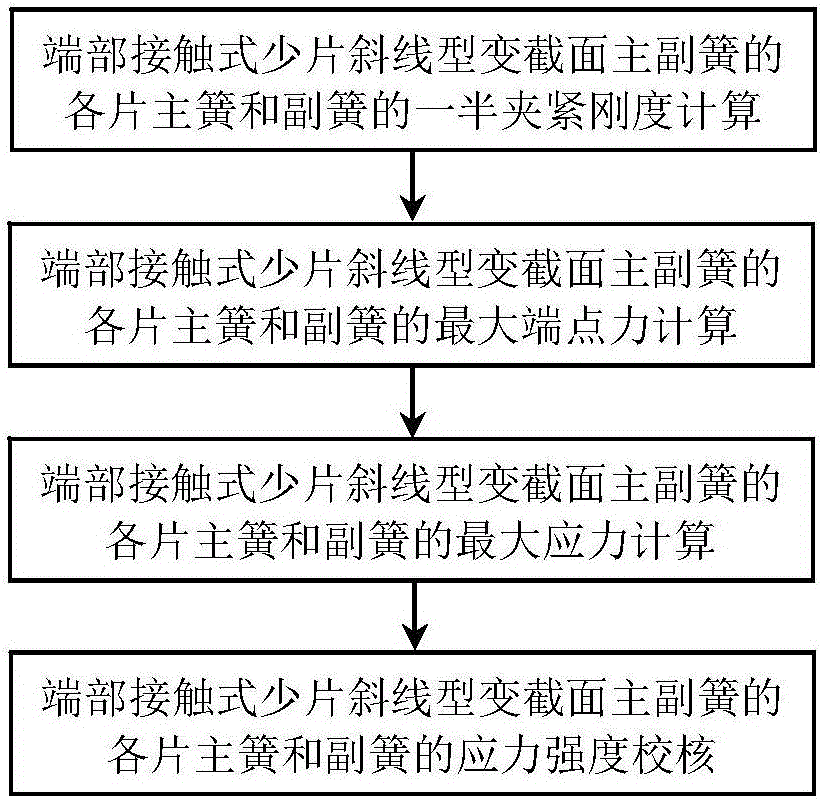

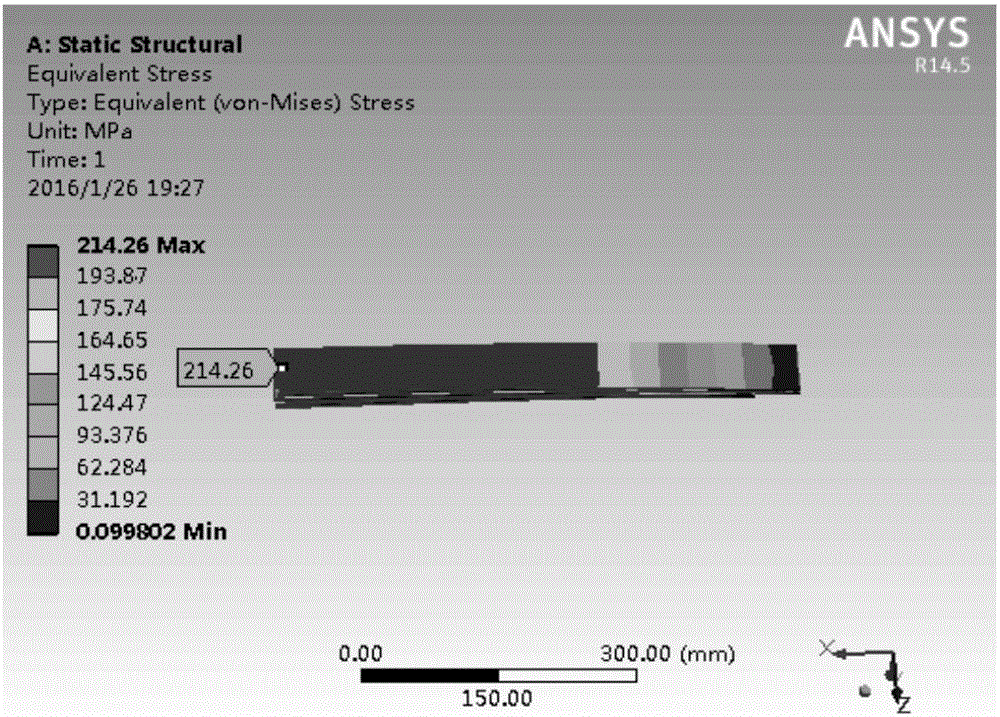

Method for verifying strength of each leaf of end contact type few-leaf oblique main and auxiliary springs

InactiveCN105740591AThe calculation value of the maximum stress check is accurate and reliableImprove the design levelDesign optimisation/simulationSpecial data processing applicationsEngineeringStress strength

The invention relates to a method for verifying strength of each leaf of end contact type few-leaf oblique main and auxiliary springs and belongs to the technical field of suspension leaf springs. It is possible to verify and calculate stress strength of each of main and auxiliary leaves according to structural parameters, elastic model and allowable stress of all main and auxiliary leaves of the end contact type few-leaf oblique variable-section main and auxiliary springs, acting load of each auxiliary spring and maximum load bearable by a main spring. Experiments and simulation tests show that this method is correct, maximum stress verification calculations of all main and auxiliary leaves are accurate and reliable, the design level, product quality and life of the end contact type few-leaf oblique variable-section main and auxiliary leaf springs as well as vehicle driving smoothness may be improved; meanwhile, it is also possible to reduce designing and testing cost and increase product development speed.

Owner:王炳超

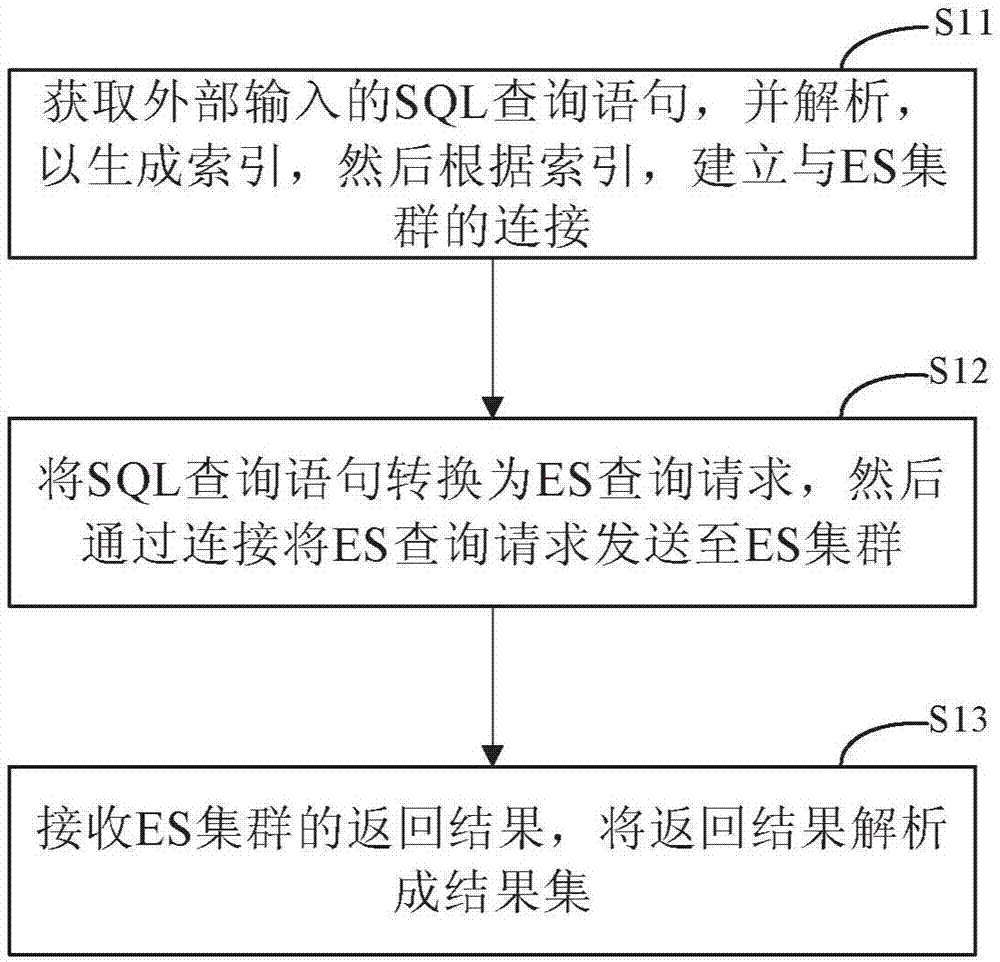

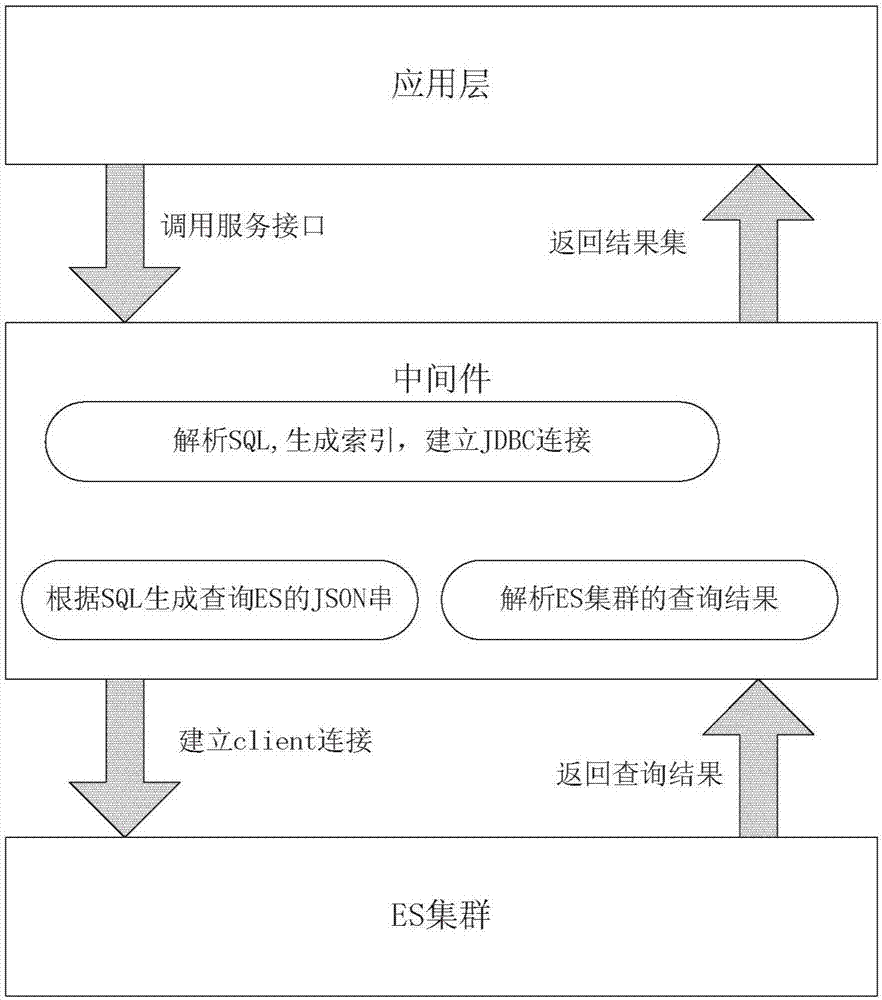

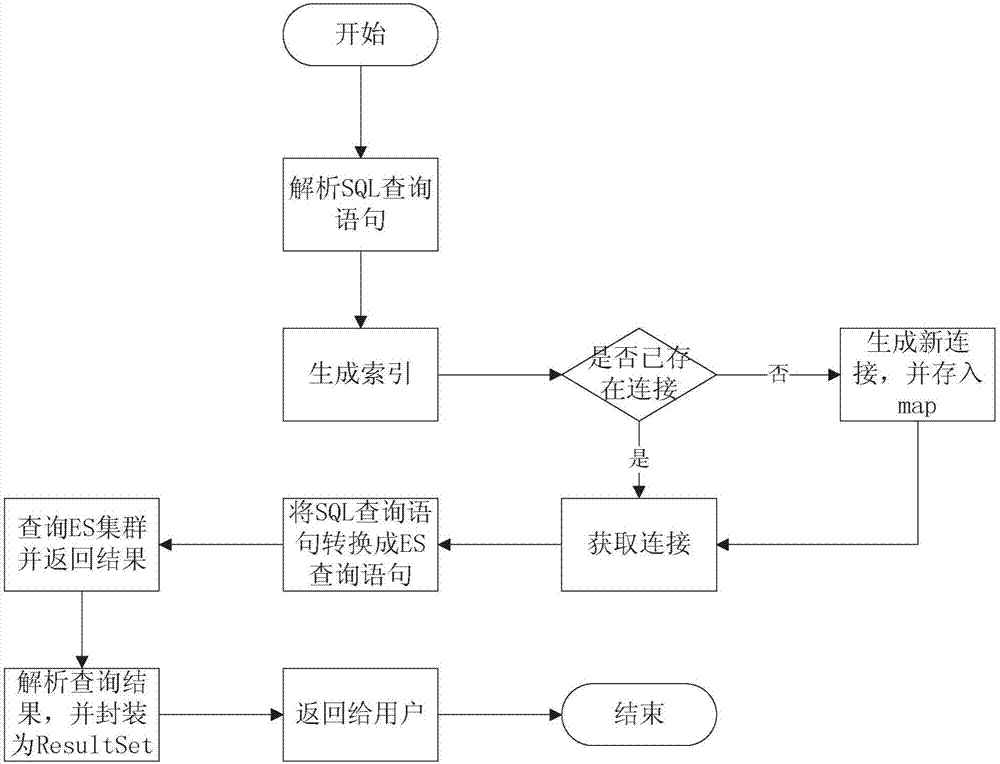

Method and device for inquiring elasticsearch cluster, electronic device and readable storage medium

ActiveCN107133267ASpeed up developmentFree and personalized developmentRelational databasesSpecial data processing applicationsResult setEnd user

The embodiment of the invention provides a method and device for inquiring an elasticsearch cluster, an electronic device and a readable storage medium. A front end user can conveniently inquire and use an ES cluster by compiling SQL statements under the situation that the ES cluster is unknown and JDBC connection does not need to be established. The method comprises the steps that an SQL inquiring statement input externally is obtained and analyzed to generate an index, and then connection with the ES cluster is established according to the index; the SQL inquiring statement is transformed into an ES inquiring request, and then the ES inquiring request is sent to the ES cluster through the connection; return results of the ES cluster are received and analyzed into a result set.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

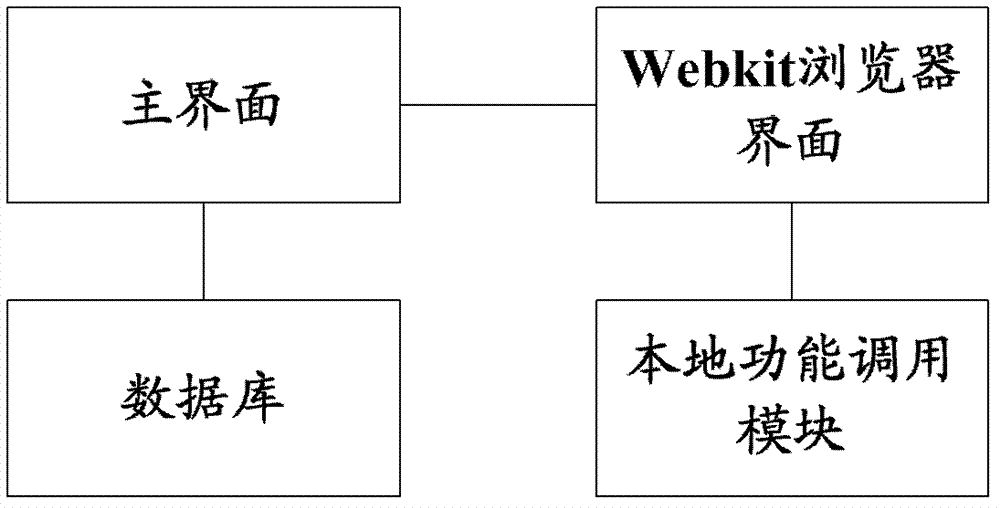

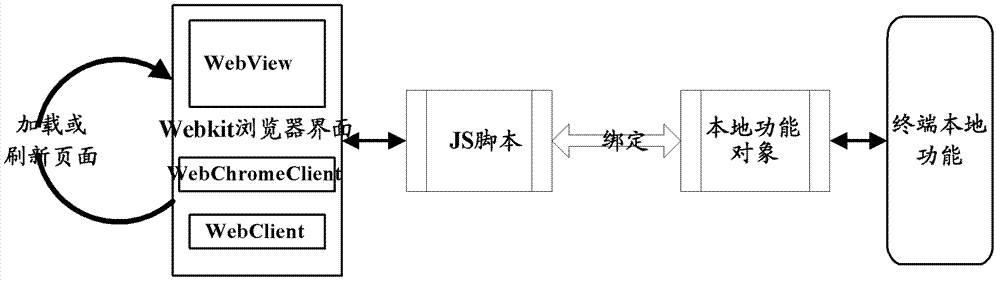

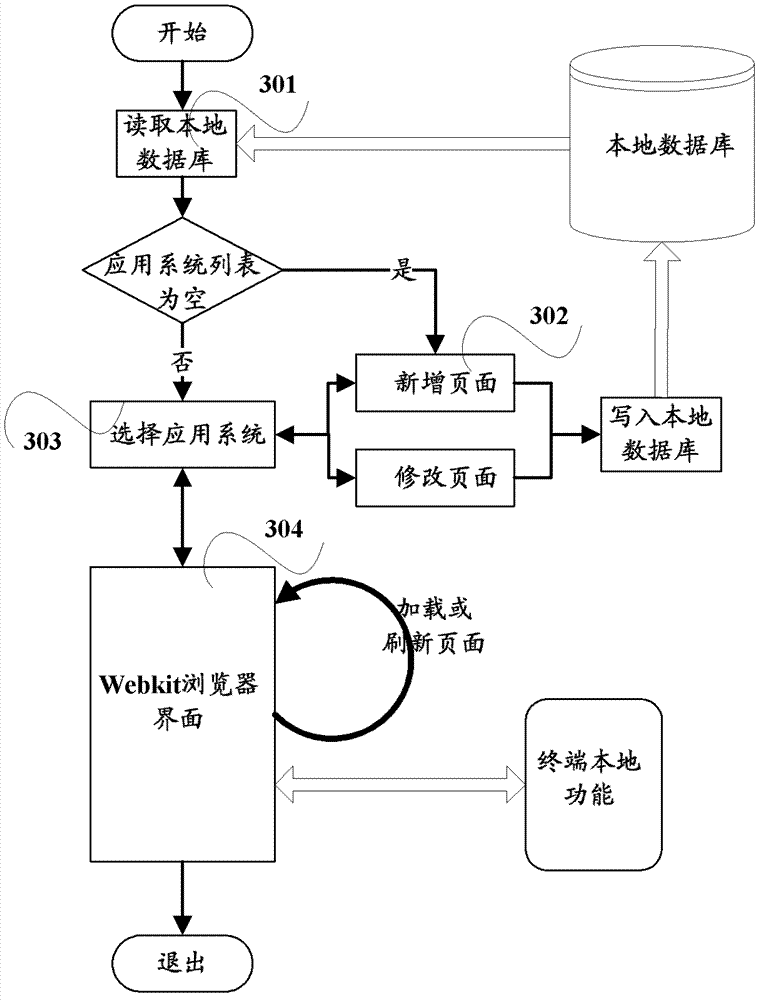

Client implementation method based on WebKit browser and client

ActiveCN102955694ASimplify the development processLower technical barriersSpecific program execution arrangementsSpecial data processing applicationsWeb browserWeb application

The invention proposes a client implementation method based on a WebKit browser and a client. The client implementation method comprises the steps of: entering a main interface in a clicking manner; reading application system data from a local database, entering an application system list interface to select an application system; loading a URL (uniform resource locator) page of the selected application system, wherein a JS (javascript) script of the application system is bounded to a local object of a terminal; and clicking a URL of the application system, transferring the local object of the terminal through the JS script to transfer the data. According to client implementation method, the development process of the client based on an Android platform is simplified; rapid development and adaptation of a single Android smart client butted with a plurality of Web application systems are adapted, and the velocity of the Android platform client butted with the Web system is improved.

Owner:CHINA TELECOM CORP LTD

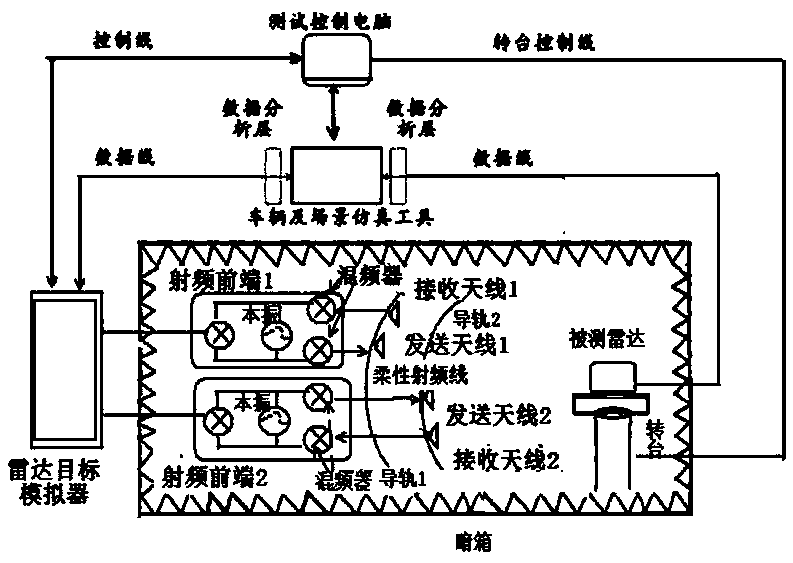

Automatic test system and method of vehicle millimeter wave radar

InactiveCN110133607AImprove R&D efficiencyImprove securityWave based measurement systemsControl systemRadar

The invention relates to an automatic test system and method of a vehicle millimeter wave radar simulation scene. The automatic test system of the vehicle millimeter wave radar simulation scene includes a test control computer, vehicles and scene simulation tools, a radar target simulator and radar to be tested; and a control system is arranged in the test control computer. The test method performed by using the automatic test system of the vehicle millimeter wave radar simulation scene comprises the following steps: combining the vehicles and scene simulation tools and the system, and using the vehicles and scene simulation tools to perform simulation and construction on vehicle types, road environments, weather conditions and the like; using the target simulator and the radar to be tested to perform transmission and reception on target information; and using the control system to perform real-time collection and saving on the target information, perform comparison, judgment, analysisand process with the working condition scene information constructed by the simulation tools, and automatically output a detection report. The invention integrates the vehicles and scene simulation tools and the system to form a complete, effective and integrated millimeter wave radar automatic test system.

Owner:HUIZHOU DESAY SV INTELLIGENT TRANSPORTATION TECH INST CO LTD

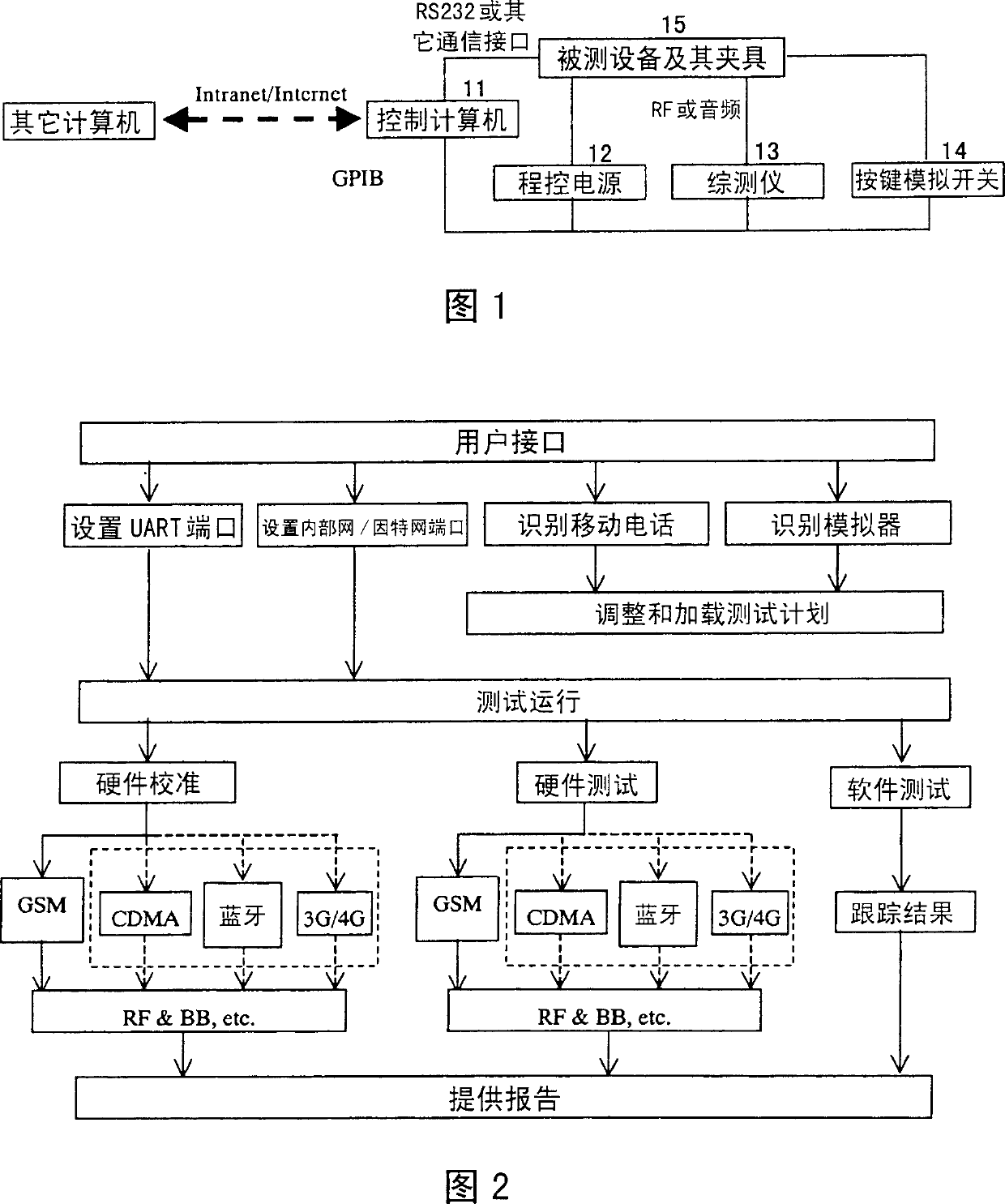

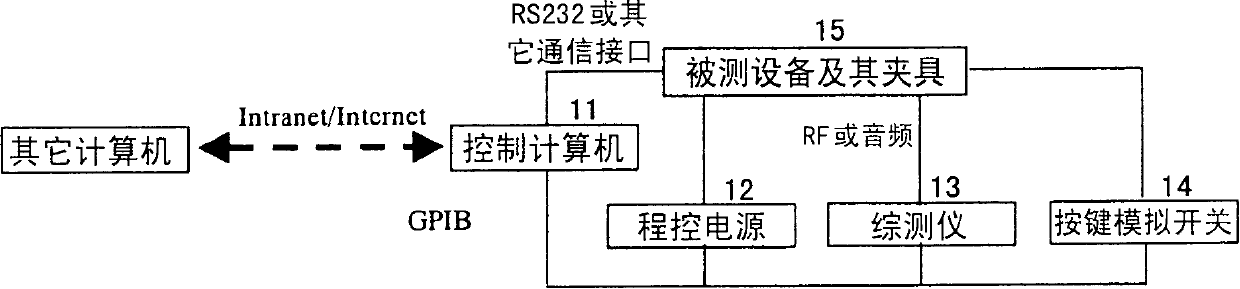

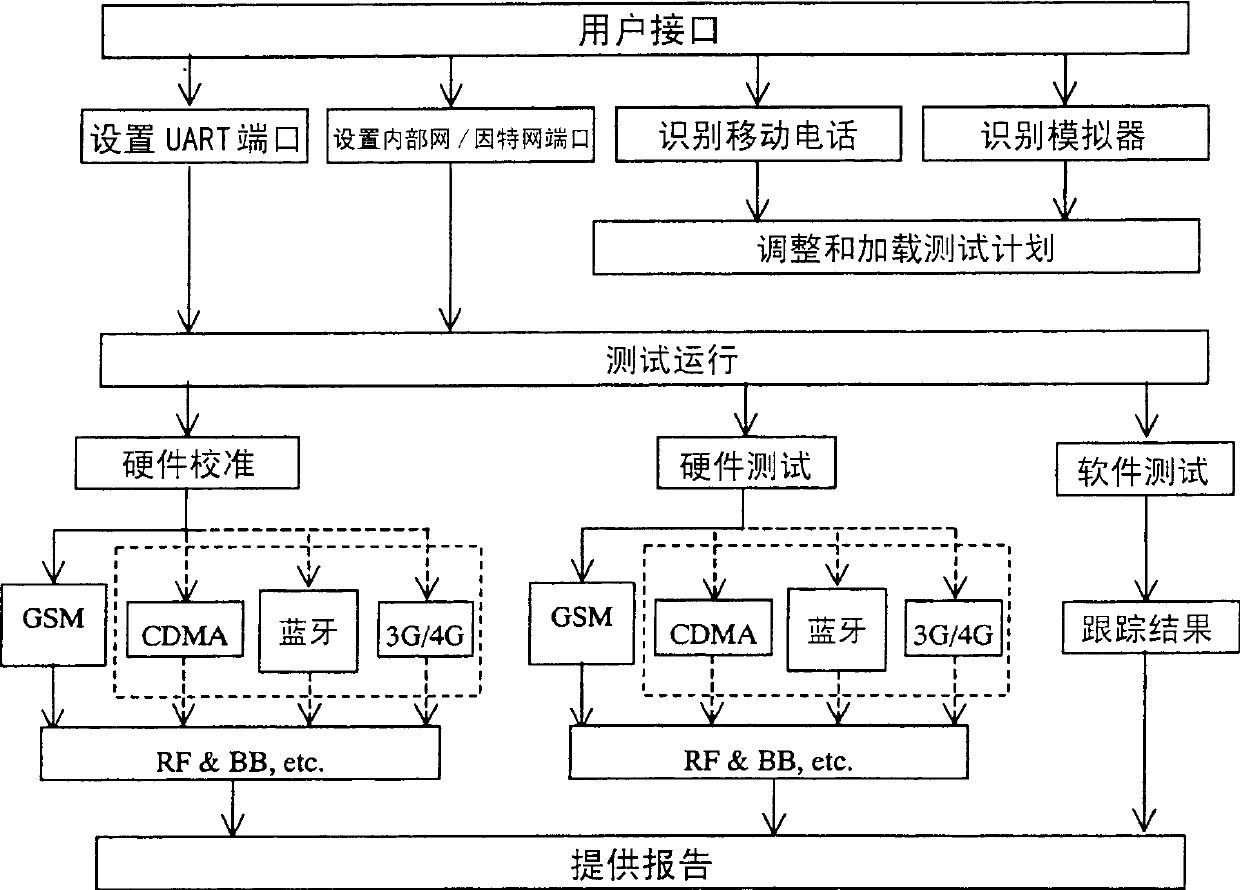

Testing system and method for mobile telephones

The system consist of: integrated tester used to generate and calculate testing signal and execute calibrating run; programmable power supply used to supply power to the tested mobile phone, to record current of mobile phone and to charge the tested mobile phone; keystroke analog switch used to made keystroke simulation in order to execute test related to keystroke operation; the holder of tested device used to install tested mobile phone; and control unit connecting to the holder of tested device, integrated tester, programmable power supply and keystroke simulation switch, and to be used to store control program, to control operation of test system and to receive result of test.

Owner:乐知新创(北京)咨询服务有限公司

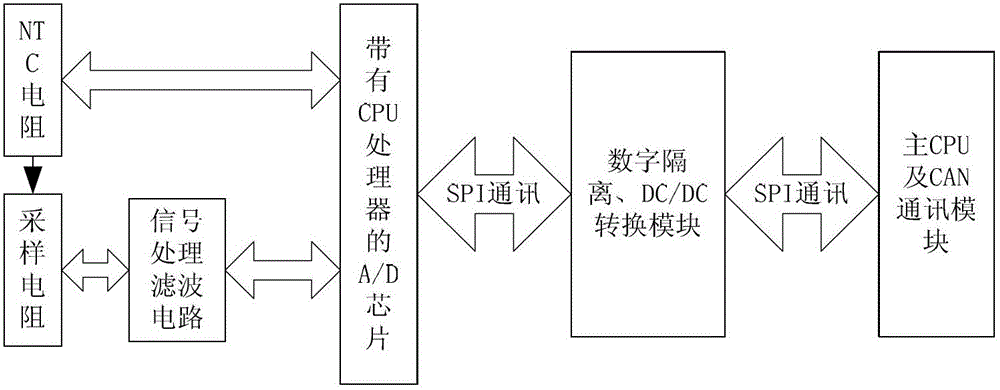

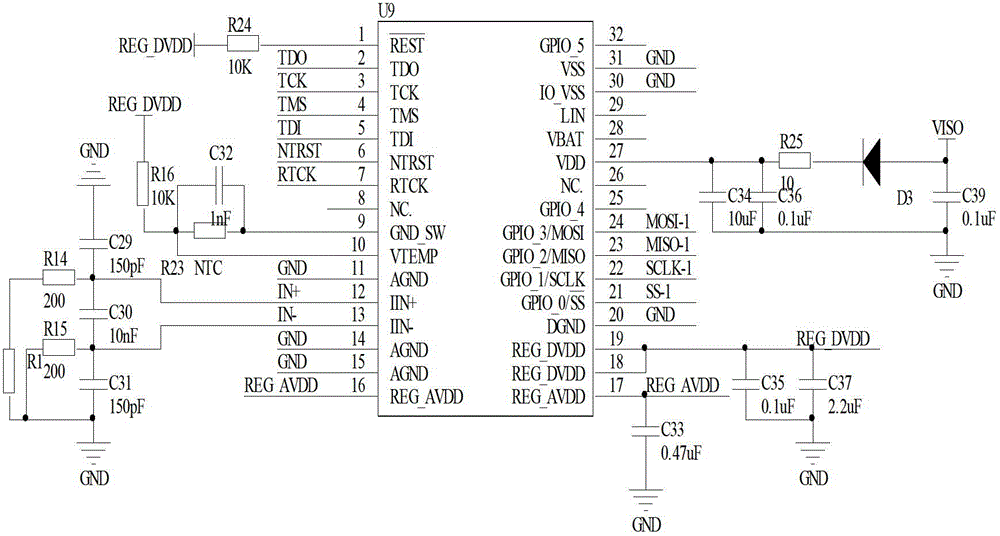

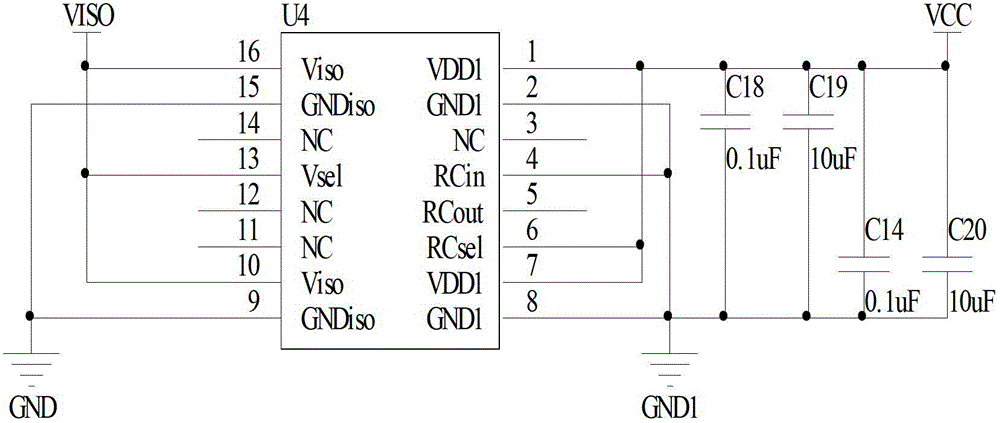

Intelligent sensor for measuring high current

ActiveCN102944737AReduce design difficultyOvercoming the technical shortcomings of measuring large currentsTemperature compensation modificationElectrical testingDigital signal processingArea network

Provided is an intelligent sensor for measuring high current. A large-power sampling resistor (R1) of the intelligent sensor converts current signals into voltage signals. Converted voltage signals are processed and filtered through a signal processing filter circuit and fed to an AD chip (U9). A negative temperature coefficient (NTC) thermal resistor (R23) is adopted by a temperature measurement module to measure the temperature of the large-power sampling resistor so as to be used for temperature compensation for the large-power sampling resistor. The AD chip converts output voltage of the measuring signal processing filter circuit and the temperature value of the NTC thermal resistor into digital signals, digital filtering processing is performed, and digital signals of voltage and the temperature are sent to an external main central processing unit (CPU) through a serial peripheral interface (SPI) communication interface isolated through an optocoupler. Isolation of the SPI communication digital signals is achieved through a digital isolation and direct current (DC) / DC conversion module, and the digital isolation and DC / DC conversion module supplies power to the signal processing filter circuit, the temperature measurement module and an analog to digital (A / D) conversion chip with a CPU processor. The main CPU and a controller area network (CAN) communication module receive external instructions and send digital signals of current measurement values.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

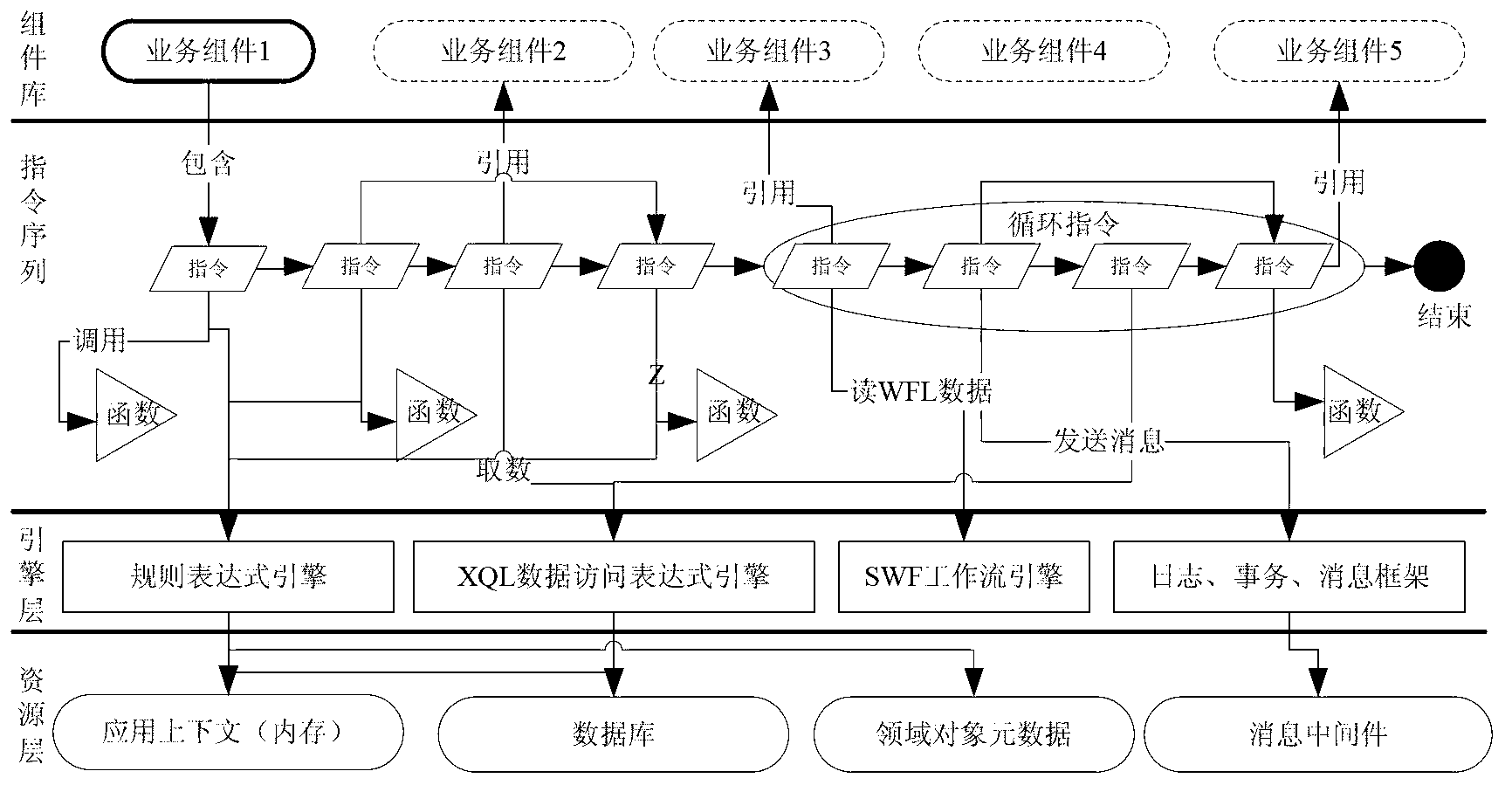

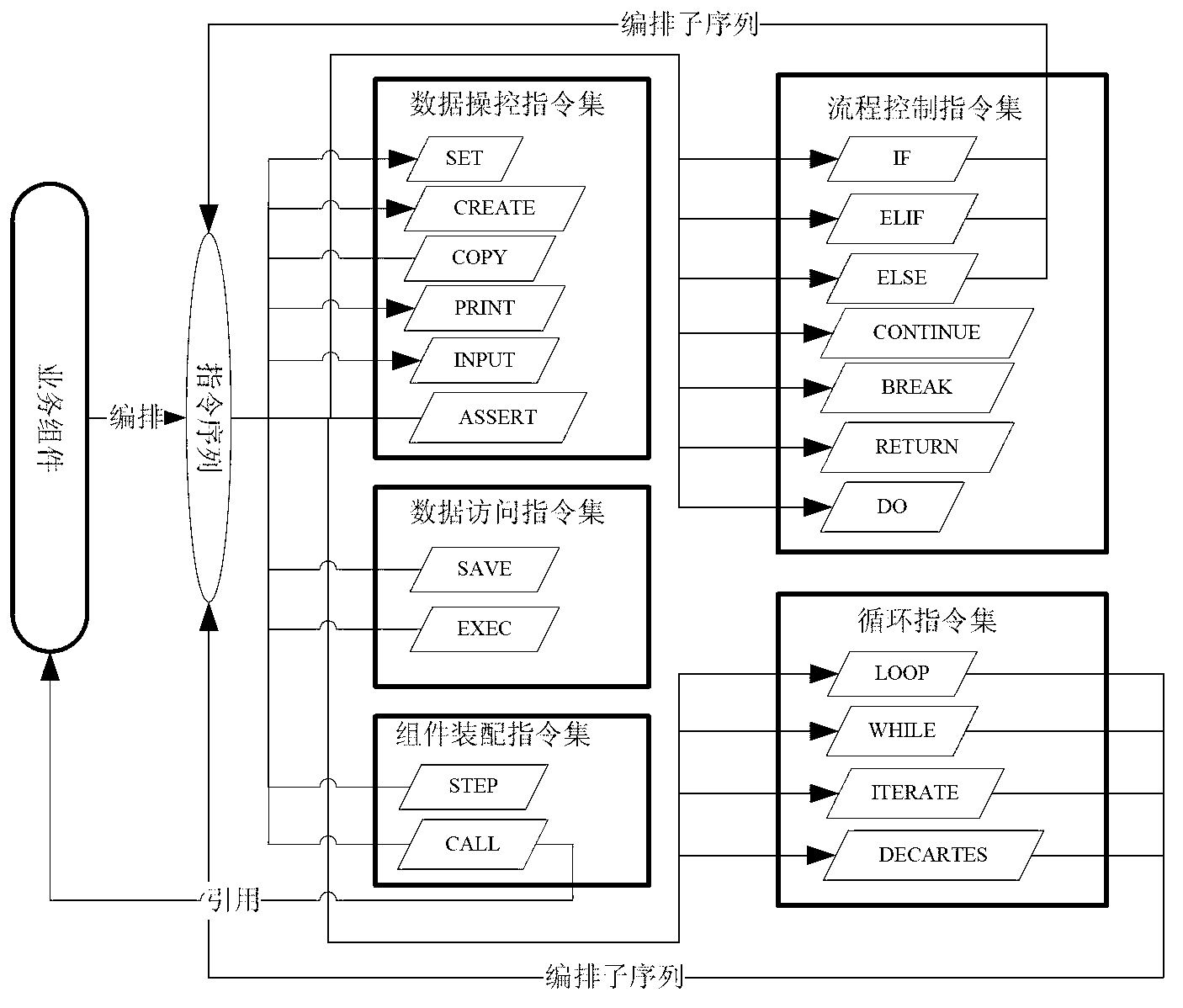

Interpreted dynamic business component construction method for industrial applications

ActiveCN103279358ASpecification operation logRapid positioningSpecific program execution arrangementsData accessBusiness requirements

The invention relates to an interpreted dynamic business component construction method for industrial applications and belongs to the field of technology platforms of computer systems. An instruction set mode similar to machine languages is adopted to solidify atomic business operations of business requirements, technologies of log, business, data access, data operation, massage handling and the like in application development are packaged, then, modularization is achieved through dynamic assembly of finite instruction sets, developers can focus on business logic realization itself instead of technological realization details, learning curves are shortened, the development is simplified, and the efficiency and the service capacity of rapid response to user needs are improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

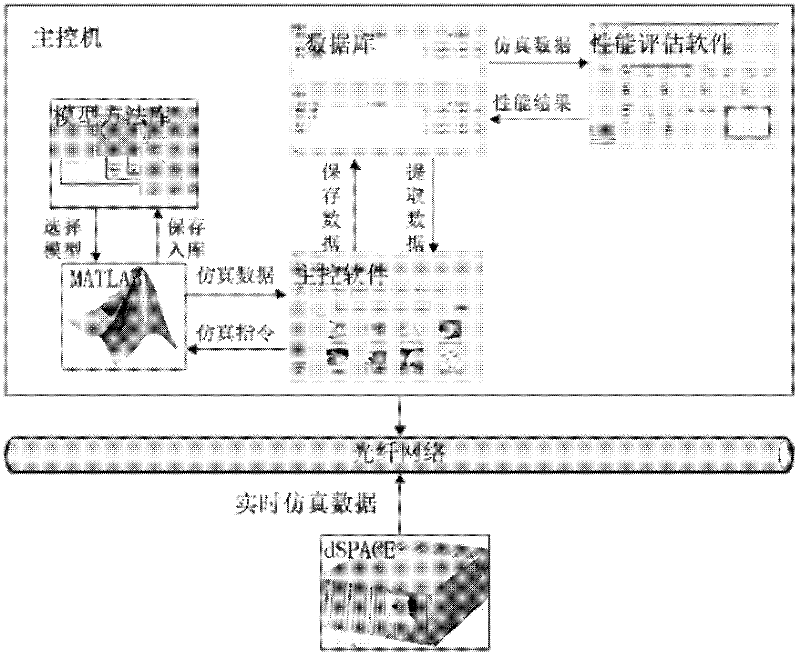

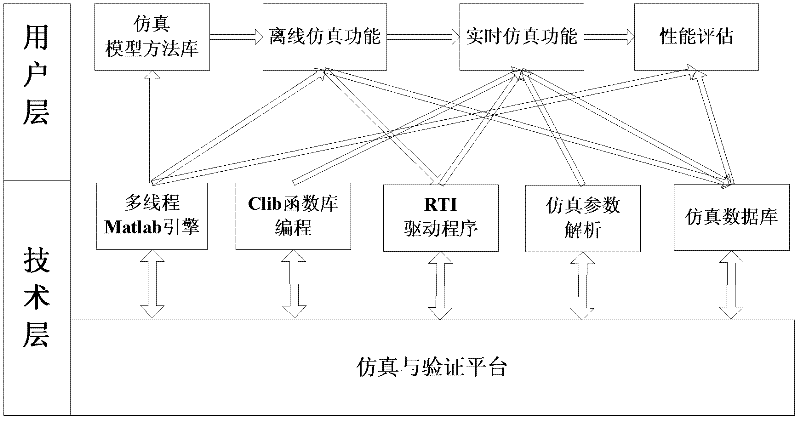

Simulation and verification method of control method of near space aircraft

ActiveCN102508692AStrong computing powerSpeed up developmentSoftware simulation/interpretation/emulationCommunication interfaceReal-time simulation

The invention relates to the simulation and the verification of a control method in the field of aerospace. In order to provide a simulation and verification platform capable of supporting a near space aircraft to real-time simulation tests and performance evaluation from the design of a flight control system, the technical scheme adopted by the invention is as follows: a simulation and verification method of the control method of the near space aircraft is realized by virtue of the following devices: a simulation master control machine and a dSPACE real-time simulation machine, wherein the simulation master control machine is provided with a DS817 high-speed serial communication interface plate; and the simulation master control machine is communicated with the DS814 high-speed serial communication interface plate of the dSPACE real-time simulation machine through an optical fiber. The method comprises the following steps of: operating master control software; dividing a whole evaluation process into two parts, namely a control system efficiency evaluation process and an evaluation confirmation process, by performance evaluation software; and obtaining data, which is needed by control system efficiency evaluation, by the control system efficiency evaluation process through three steps. The simulation and verification method of the control method of the near space aircraft is mainly applied to simulation and verification in the field of aerospace.

Owner:TIANJIN UNIV

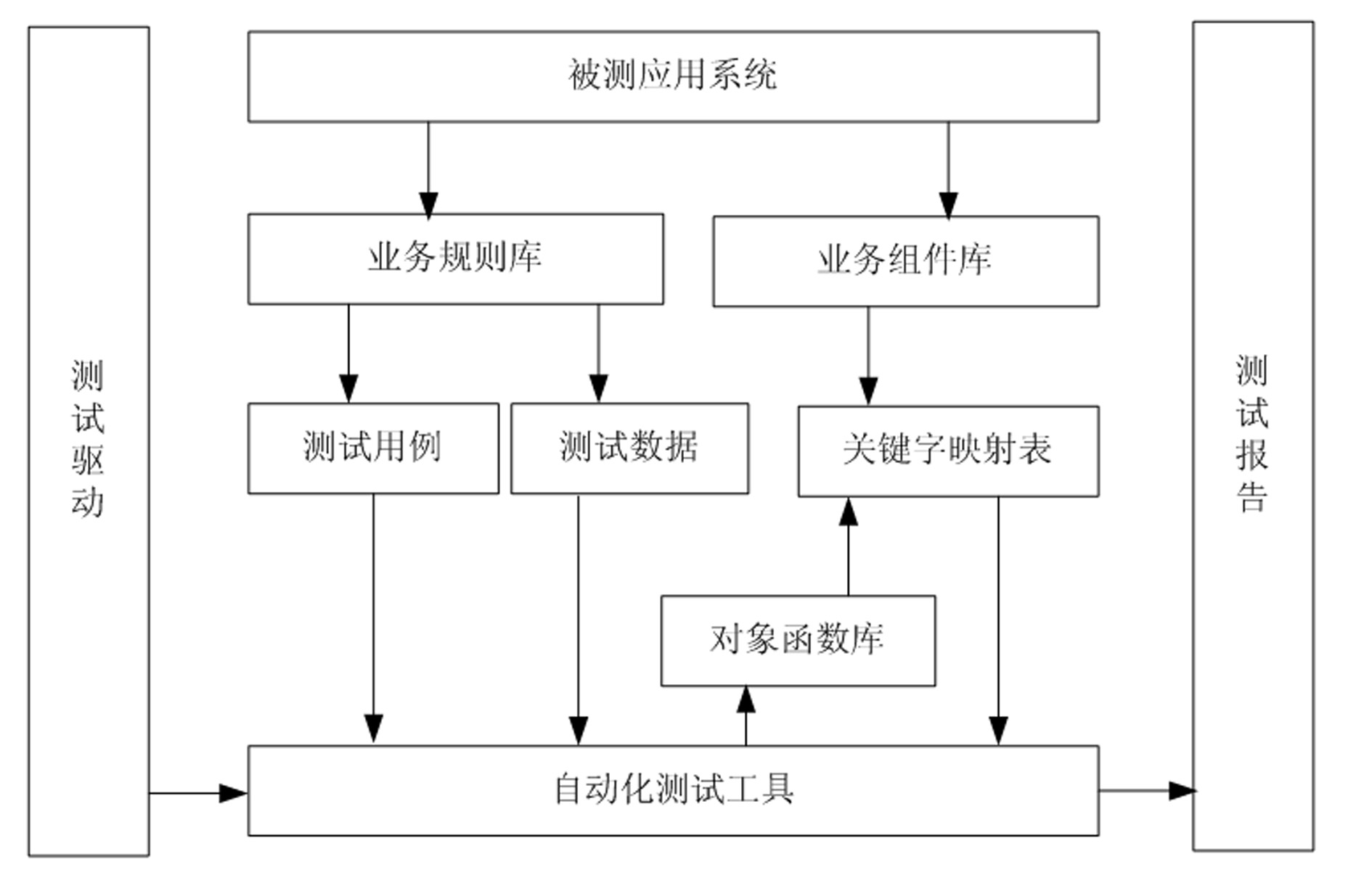

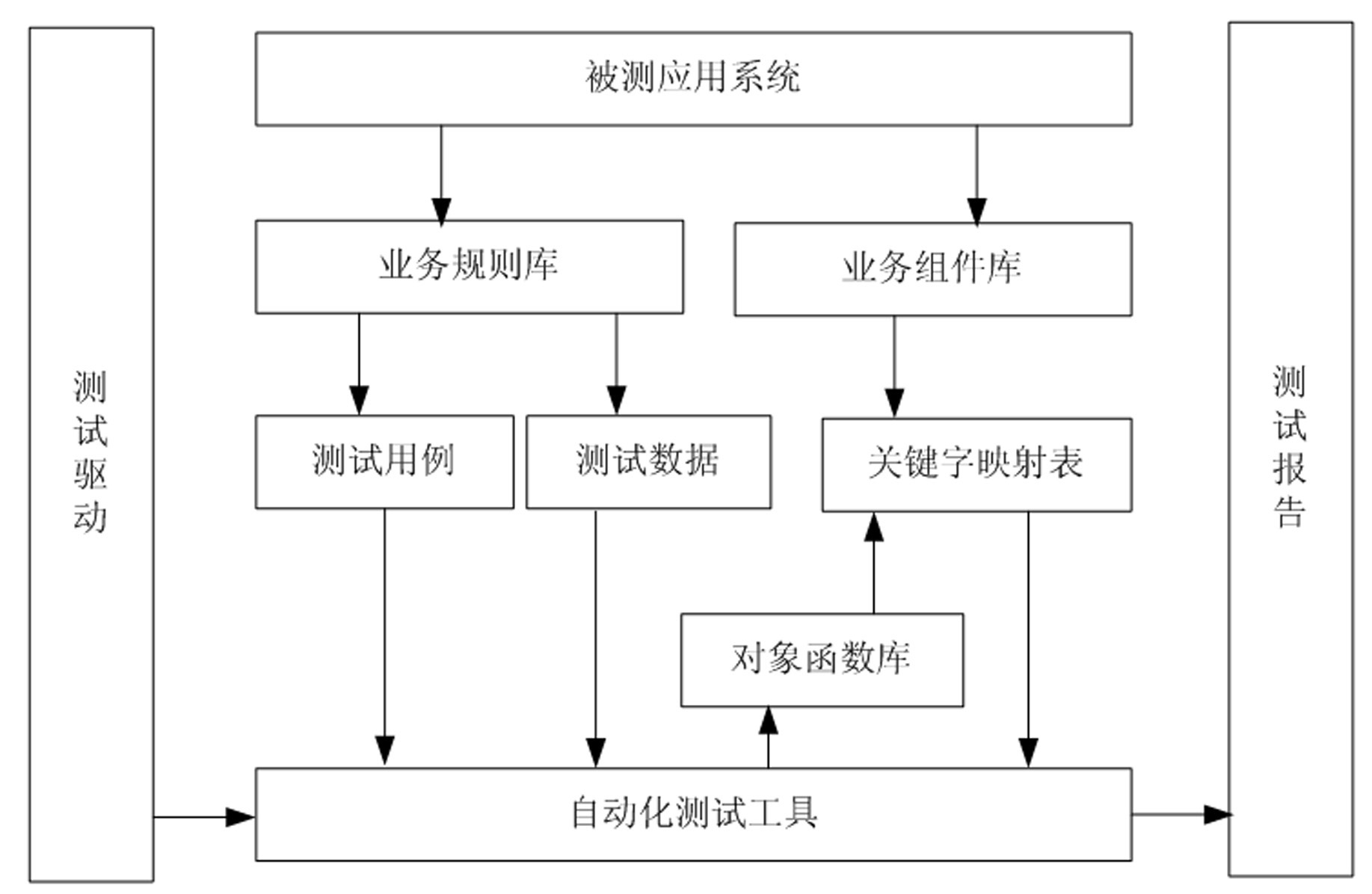

Automatic software testing method based on business driving

InactiveCN102043716AGuaranteed reasonable testingReduce business capability requirementsSoftware testing/debuggingData fileSingle type

The invention relates to an automatic software testing method based on business driving. Driven by business logic, business modularization is carried out on a tested software object, automated software testing function points are refined to business components and a method for testing business modularization is formed; a single type component is used on the basis of minimal granularity; a combination type component is used on the basis of a page area; hypertext markup language (HTML) codes of the combination component are realized in a component template; the combination type component comprises the component template, components and component regulation to form a business component library; an automated software testing tool tests the components of the business component library, and packages testing logic in data files in a form of keyword mapping table; explanation and use are carried out on keywords by the automated software testing tool; and the automated software testing tool calls an object function library to obtain the keyword mapping table, and the business component library carries out testing with the automated software testing tool by the keyword mapping table.

Owner:LINKAGE SYST INTEGRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com