Aeroplane buffet air tunnel model integration design and manufacturing method

A technology of flutter model and manufacturing method, applied in the field of integrated design and manufacture of full-resin aircraft flutter wind tunnel models, which can solve problems affecting similar quality, loss of overall accuracy, and difficult control of accuracy, so as to improve the development speed , improve manufacturing accuracy, and eliminate the effect of assembly links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

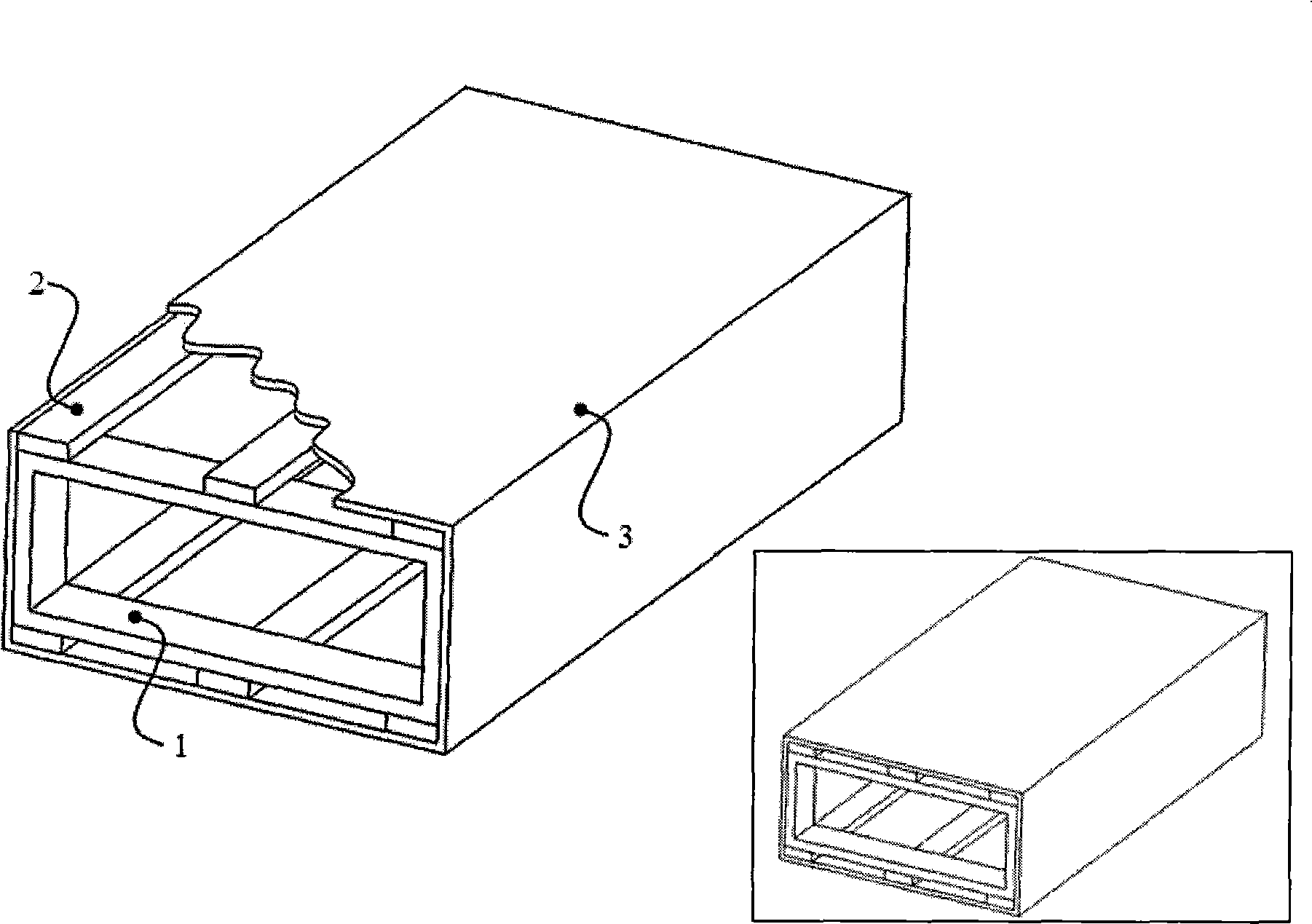

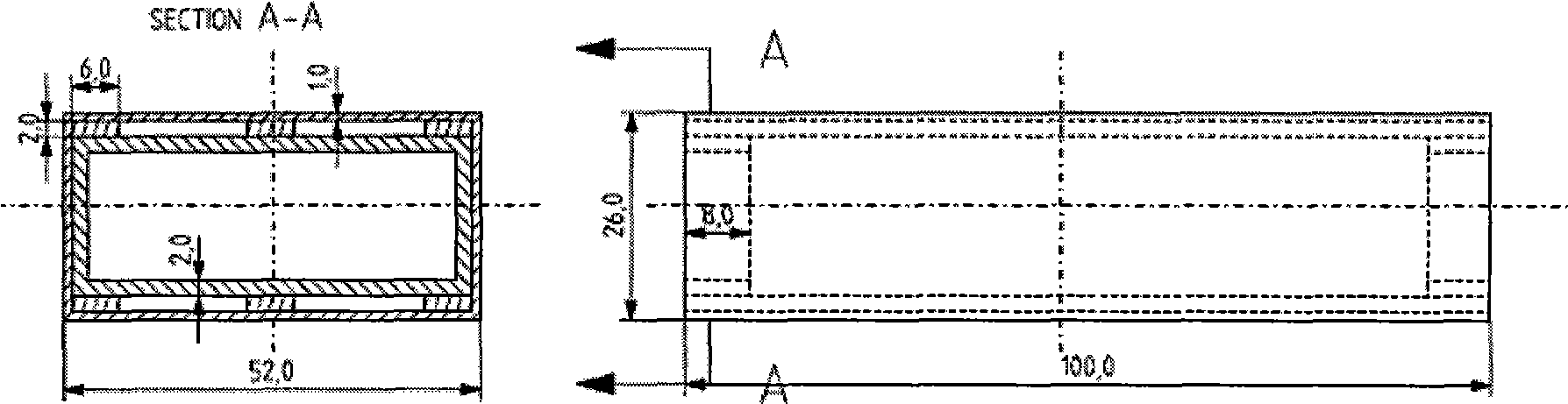

[0038] refer to figure 1 with figure 2 , the object in this example is a typical frame segment structure of an aircraft wing, which consists of frame 1, stringer 2 and skin 3. The frame segment is the basic unit in the aircraft structure, which can be used as a typical case of flutter model design. SPS600B light-curing molding machine (Shaanxi Hengtong Intelligent Machinery Co., Ltd.) is used, and the light-curing resin material is SOMOS 14120 (DSM).

[0039] refer to figure 1 with figure 2 , according to the actual aircraft structure, size reduction factor, critical wind speed reduction factor and light-curing resin material performance parameters, based on the light-curing resin material, the integrated design of the flutter model is carried out; through geometric similarity design, stiffness similarity design and structure The similar design and sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com