Patents

Literature

45results about How to "Exclude in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

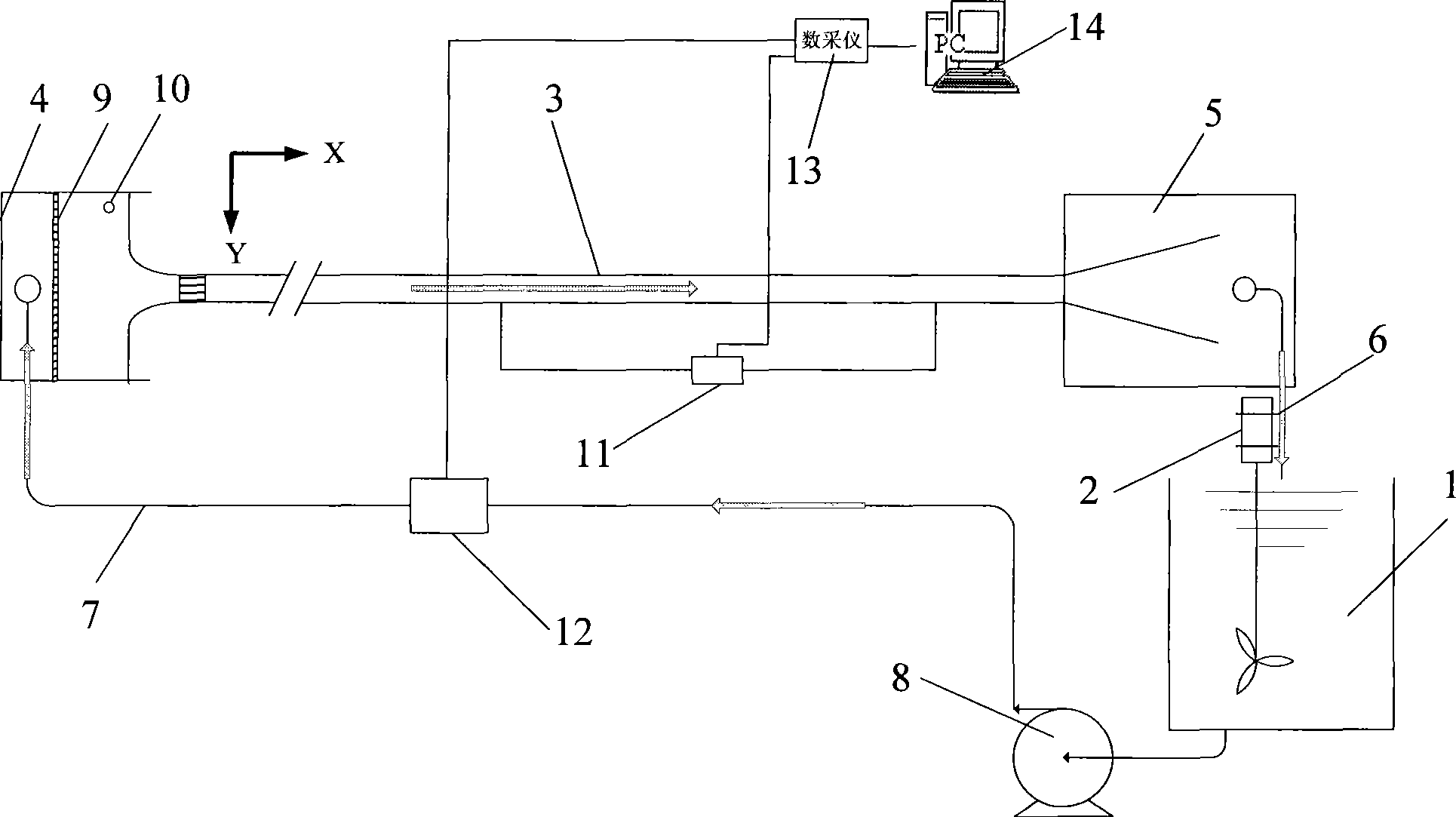

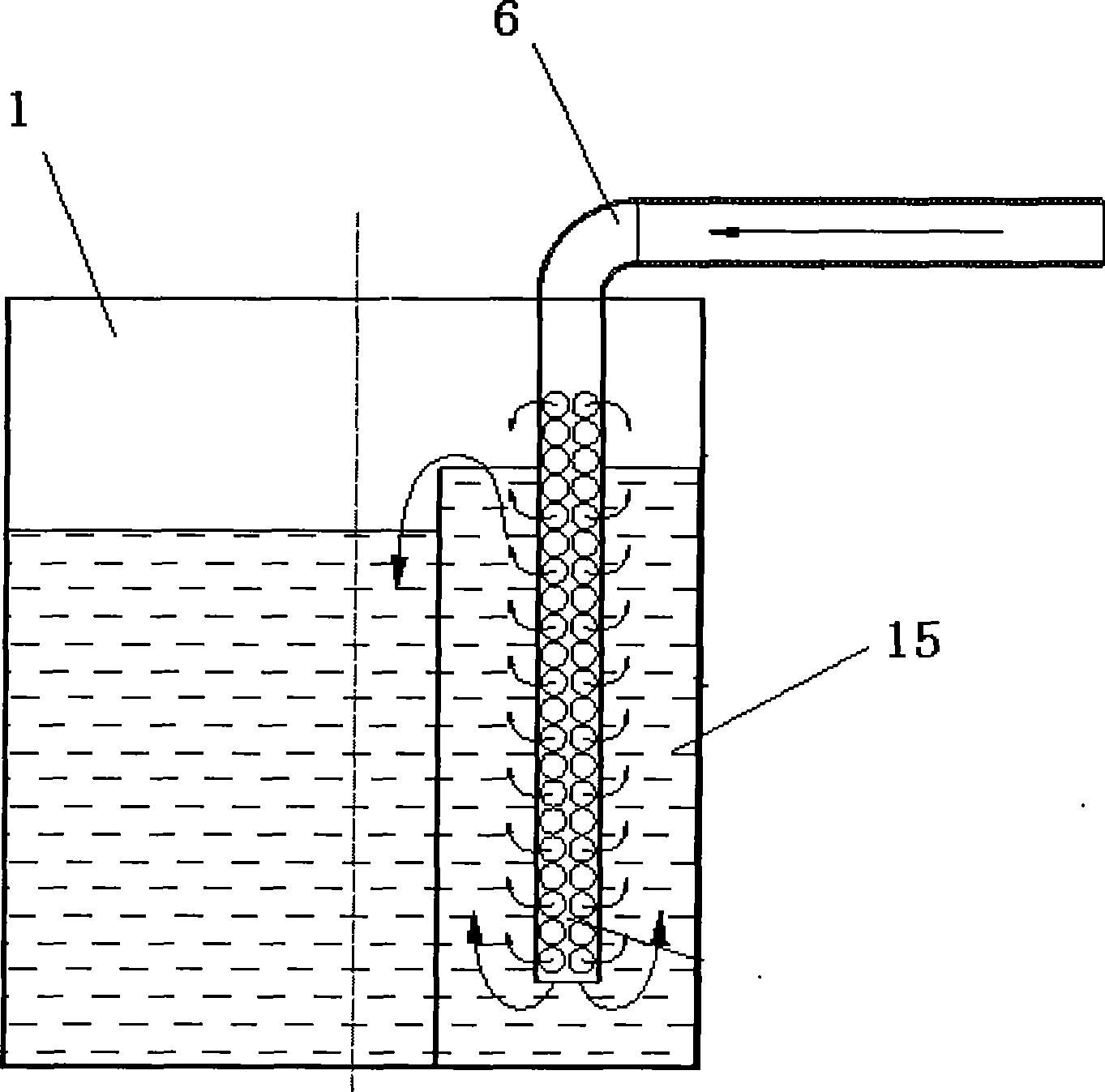

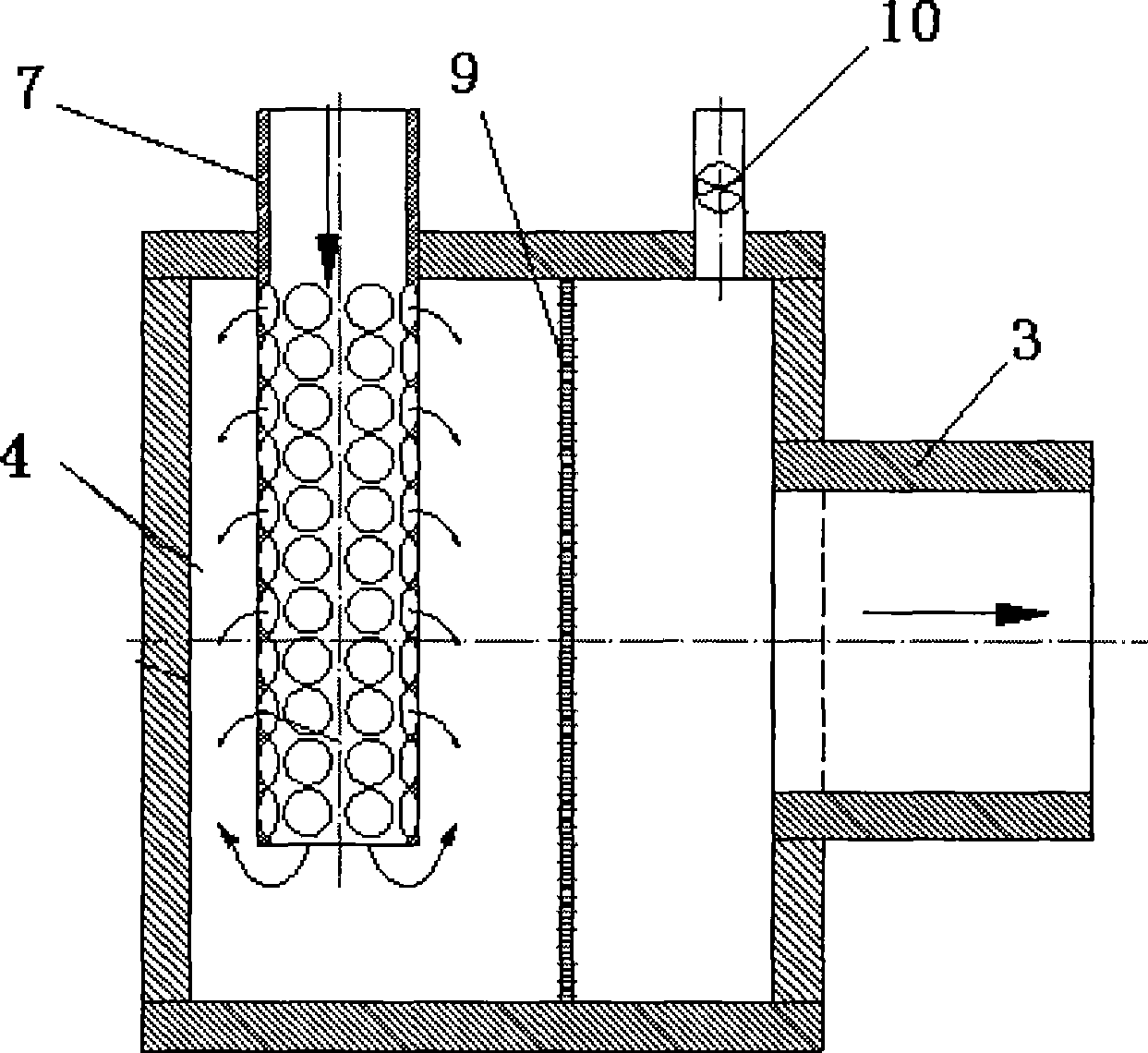

Drag-reduction property experimental apparatus for surfactant solution

InactiveCN101545843AReduce generationSpeed up experimentationFlow propertiesCirculator pumpLiquid storage tank

The invention relates to the field of the research on the drag-reduction property of surfactant solution, in particular to a drag-reduction property experimental apparatus for surfactant solution, comprising a liquid storage tank, a test section, a liquid inlet chamber communicated with the inlet of the test section, a liquid outlet chamber communicated with the outlet of the test section, a liquid outlet pipe communicated with the liquid outlet chamber and the liquid storage tank, a liquid inlet pipe communicated with the liquid storage tank and the liquid inlet chamber and a circulation pump arranged on the liquid inlet pipe. The drag-reduction property experimental apparatus for surfactant solution is characterized in that the liquid outlet pipe extends into the liquid storage tank, and the pipe wall of the extension section of the liquid outlet pipe is provided with a hole.

Owner:XI AN JIAOTONG UNIV

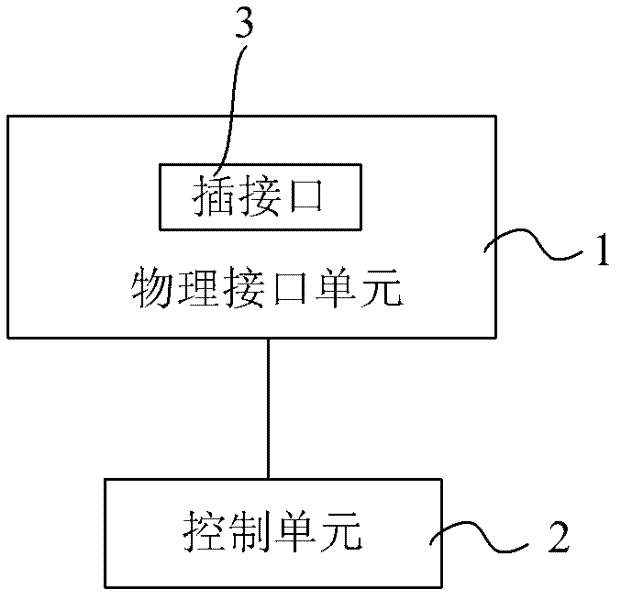

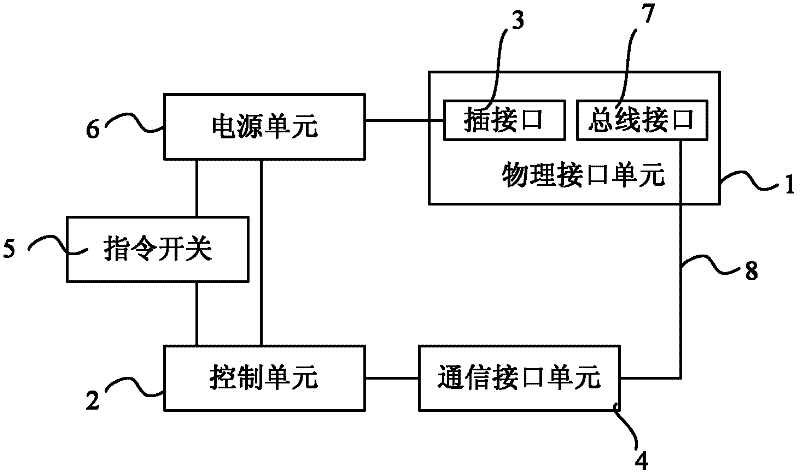

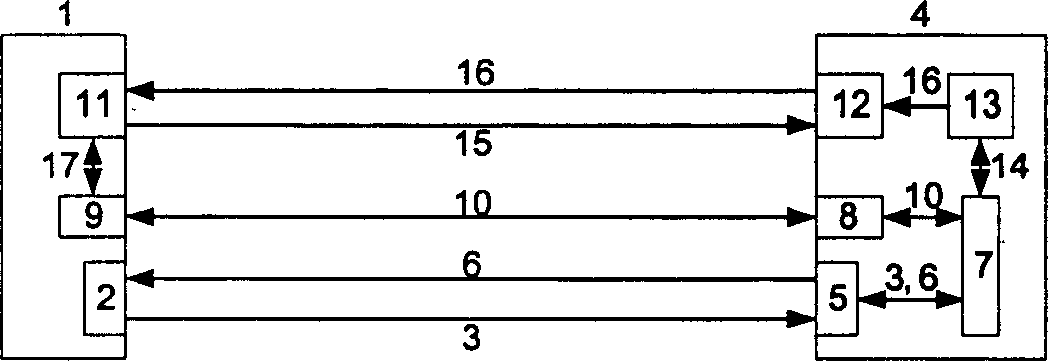

Board card test device

The invention discloses a board card test device, which comprises a physical interface unit and a control unit, wherein an inserting connection hole is formed in the physical interface unit; an insertion core of a board card to be tested is inserted into the inserting connection hole; the control unit is connected with the physical interface unit and used for testing the board card to be tested according to a test program which is locally set; and the control unit is in data communication with the board card to be tested in the test process. The board card test device can be used for testing whether the communication of the board card is normal. The board card test device is easy to operate and particularly applicable to a debugging scene of a railway vehicle so as to test the board card in a network monitoring system in the railway vehicle before energization; complicated equipment is not required; and a simple and effective scene test tool is provided for elimination of faults of the board card before the energization of the network monitoring system.

Owner:CHINA CNR CORPORATION

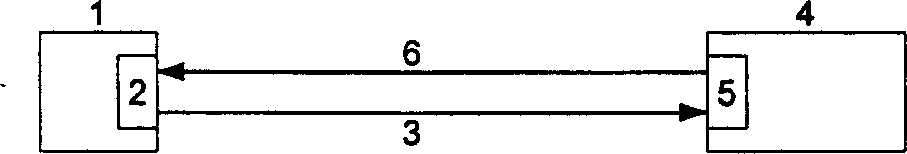

Distributed monitoring method based on bidirectional information flow

InactiveCN1485737AImprove performanceImprove usabilityHardware monitoringConcurrent instruction executionFault analysisReal-time computing

The invention discloses a distributed monitor and control method based on bi-directional information flow which comprises, receiving the monitoring information, receiving the monitoring information and proceeding analysis and decision-making, receiving the accepting file data and control command data, when the monitoring party finds the accident or potential fault on the monitored party, the corresponding processing scheme can be determined according to the different fault and clearing the fault.

Owner:TIANJIN ZHONGKE BLUEWHALE INFORMATION TECH +1

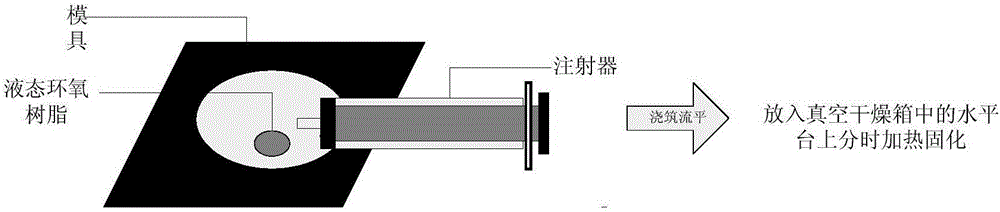

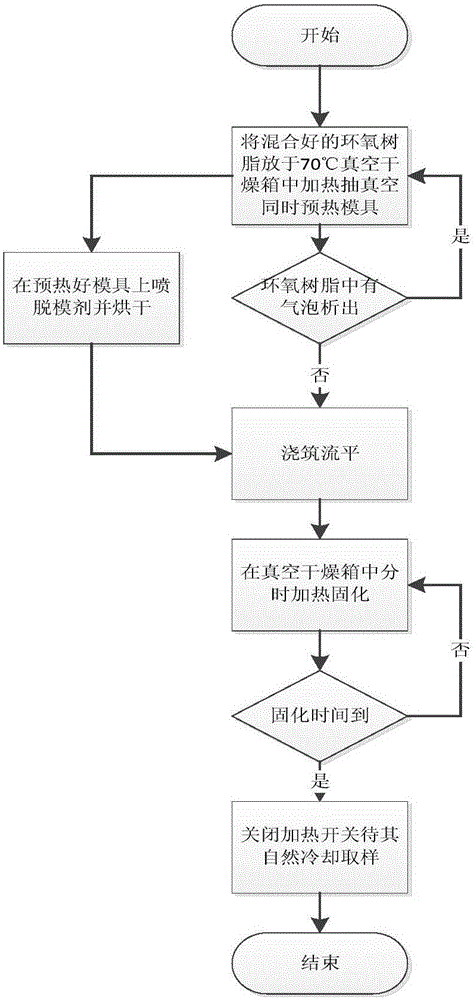

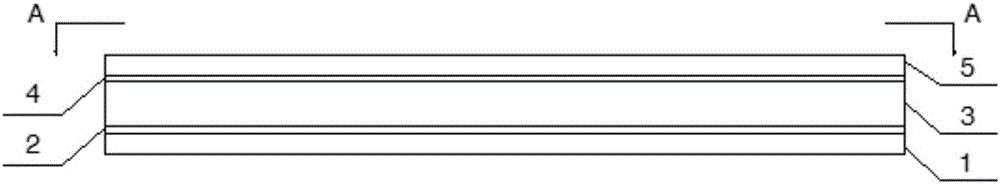

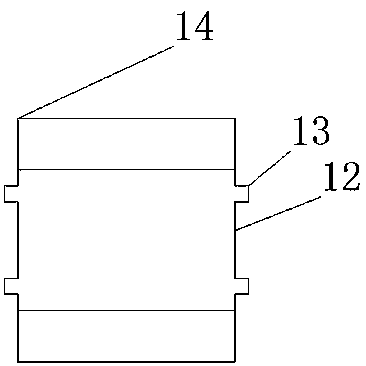

Sandwich tablet sample preparing die for epoxy resin and method

The invention discloses a sandwich pressing sample preparation mold and method for epoxy resin. The sample preparation mold is formed by aligning and stacking a bottom mirror panel, a bottom film, a middle thickness-calibrating mold, an upper film and an upper mirror panel , a cavity is provided in the middle of the intermediate thickness interlayer. Described sample preparation method is as follows: one, the base film is placed on the base mirror panel, and then the intermediate thickness interlayer is placed on the base film; Two, inject epoxy resin in the mold cavity of the intermediate thickness interlayer with a syringe; 1. Cover the upper layer of film, and gradually cover it from one side to the other during the process of covering the film. If there are air bubbles, drive the air bubbles to the edge of the mold to get rid of them; 4. Cover the upper mirror panel; Slowly put it on the preheated flat vulcanizer for pressurized time-sharing solidification, and after it cools down naturally, demould and take out the sample. The samples prepared by the invention have high quality and uniform thickness, and samples with any thickness can be prepared, which greatly reduces the interference factors in the measurement process.

Owner:HARBIN UNIV OF SCI & TECH

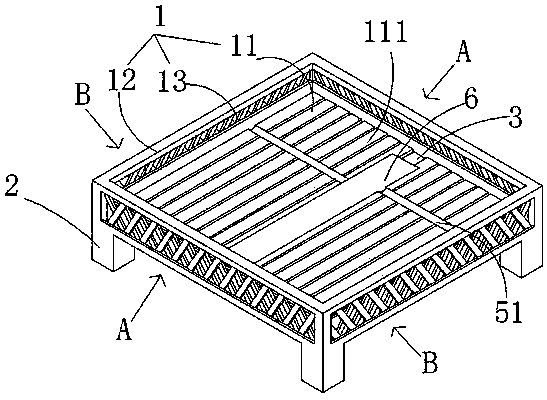

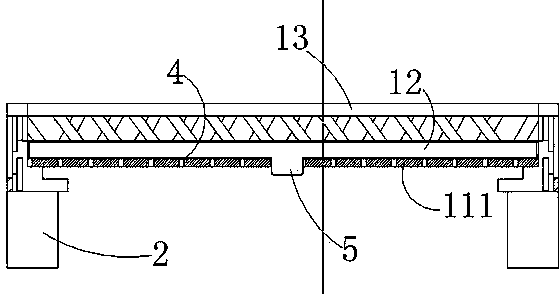

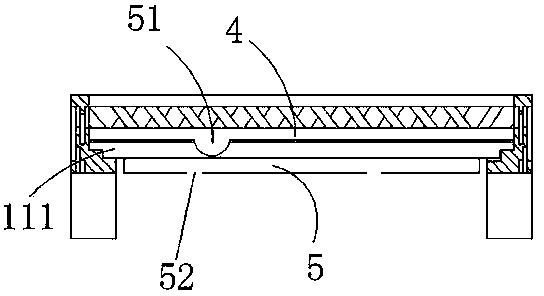

Vegetable planting device

InactiveCN103636423AEasy to excludeExclude in timeReceptacle cultivationAgricultural engineeringDrainage ditch

The invention relates to a vegetable planting device which comprises a planting box. The planting box comprises a box bottom and a box wall. The planting device further comprises supporting components. The planting box is arranged on the supporting components. The box bottom is formed by a plurality of bar-shaped plates. A waterproof membrane is laid at the box bottom. At least one space is reserved among the bar-shaped plates. The waterproof membrane is recessed downwards at the position of the at least one space to form a drainage ditch. The vegetable planting device is simple in structure, needed water in the planting box can be kept, meanwhile, redundant water can be timely removed, the water draining effect is good, the water can also be prevented from making contact with a box body, and therefore the service life of the planting box and the service life of the waterproof membrane are prolonged.

Owner:HUZHOU YIMENG CITY AGRI DEV

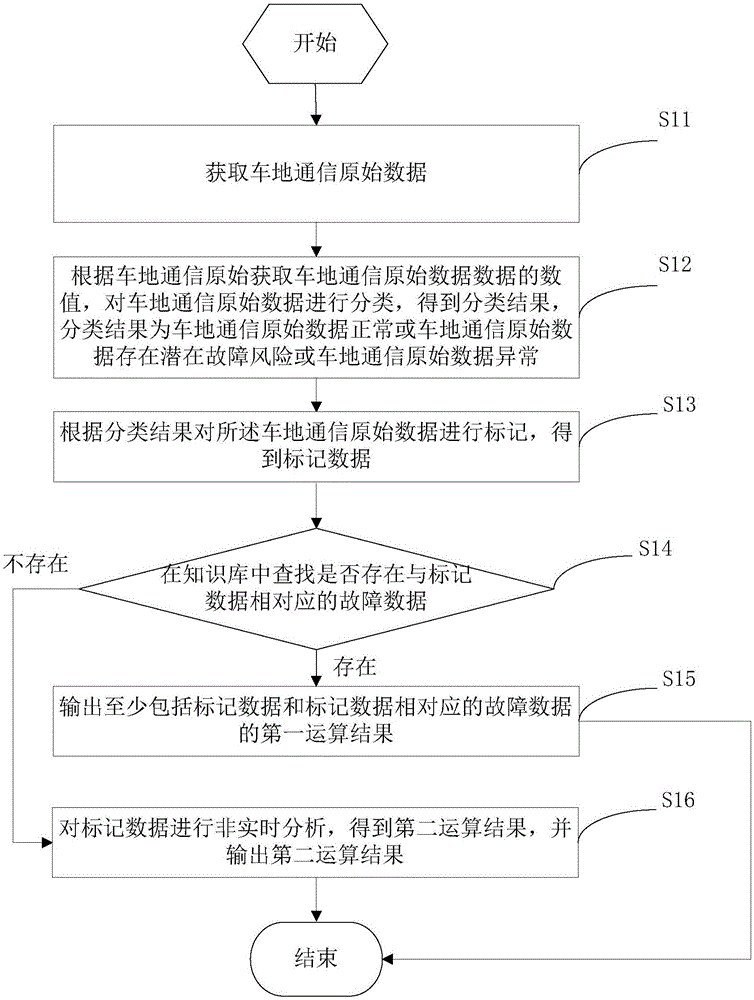

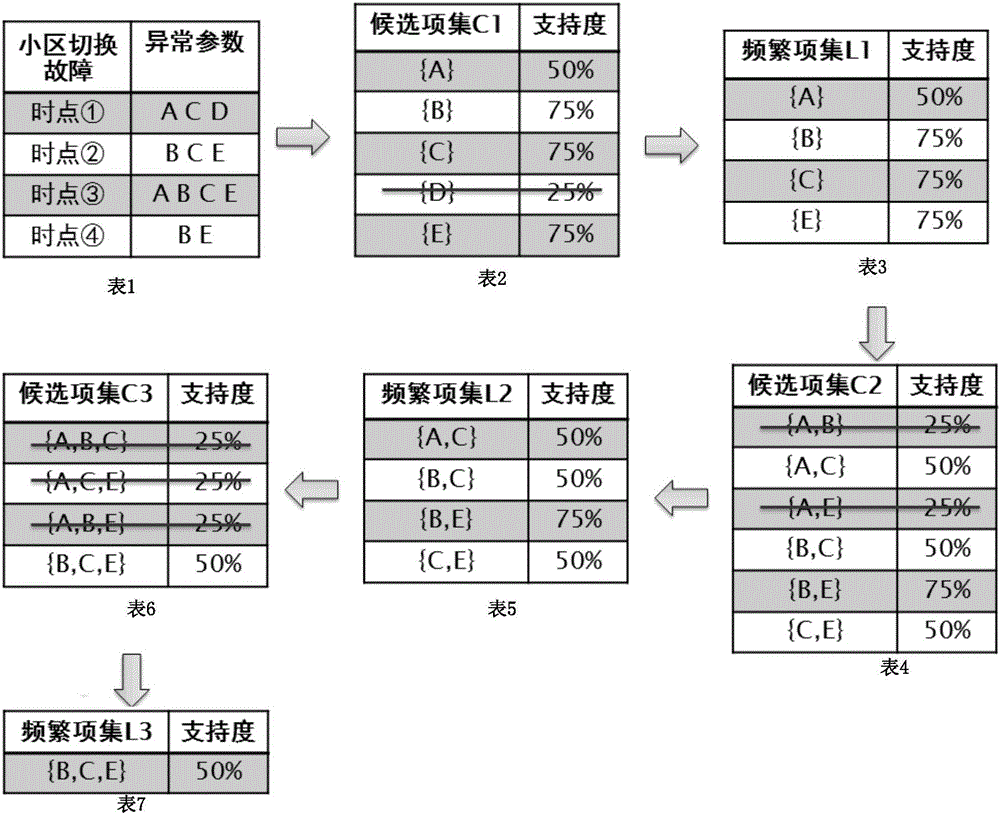

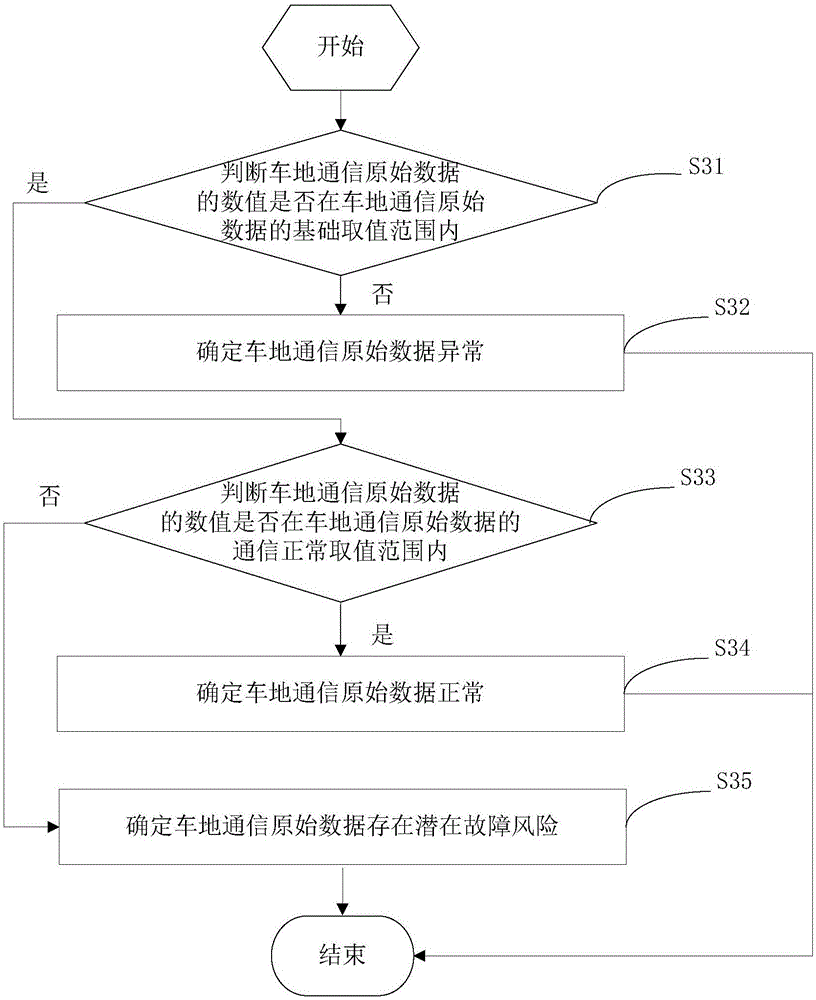

Train-ground communication data processing method and apparatus

InactiveCN106330535AShort detection timeImprove detection efficiencyData switching networksWireless communicationFailure dataReal time analysis

The invention provides a train-ground communication data processing method and apparatus. The train-ground communication data processing method comprises the steps of obtaining train-ground communication original data; obtaining numerical values of the train-ground communication original data according to the train-ground communication originally, and classifying the train-ground communication original data to obtain a classified result; marking the train-ground communication original data according to the classified result to obtain a marked data; finding whether a fault data corresponding to the marked data exists in a knowledge base or not, wherein the fault data is a fault reason or a possibly-caused fault; if the fault data corresponding to the marked data exists in the knowledge base, outputting a first calculation result which at least comprises the marked data and the fault data corresponding to the marked data; and if the fault data corresponding to the marked data does not exist in the knowledge base, performing non-real-time analysis on the marked data to obtain a second calculation result, and outputting the second calculation result. According to the train-ground communication data processing method and apparatus, detection efficiency is improved by virtue of the mode, thereby eliminating faults in time and improving the reliability and safety of the train operation.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD +1

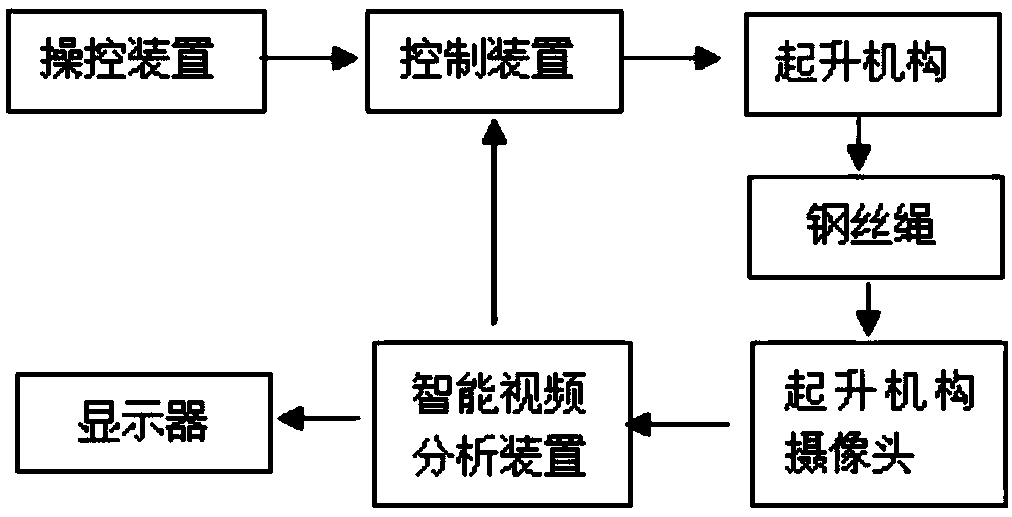

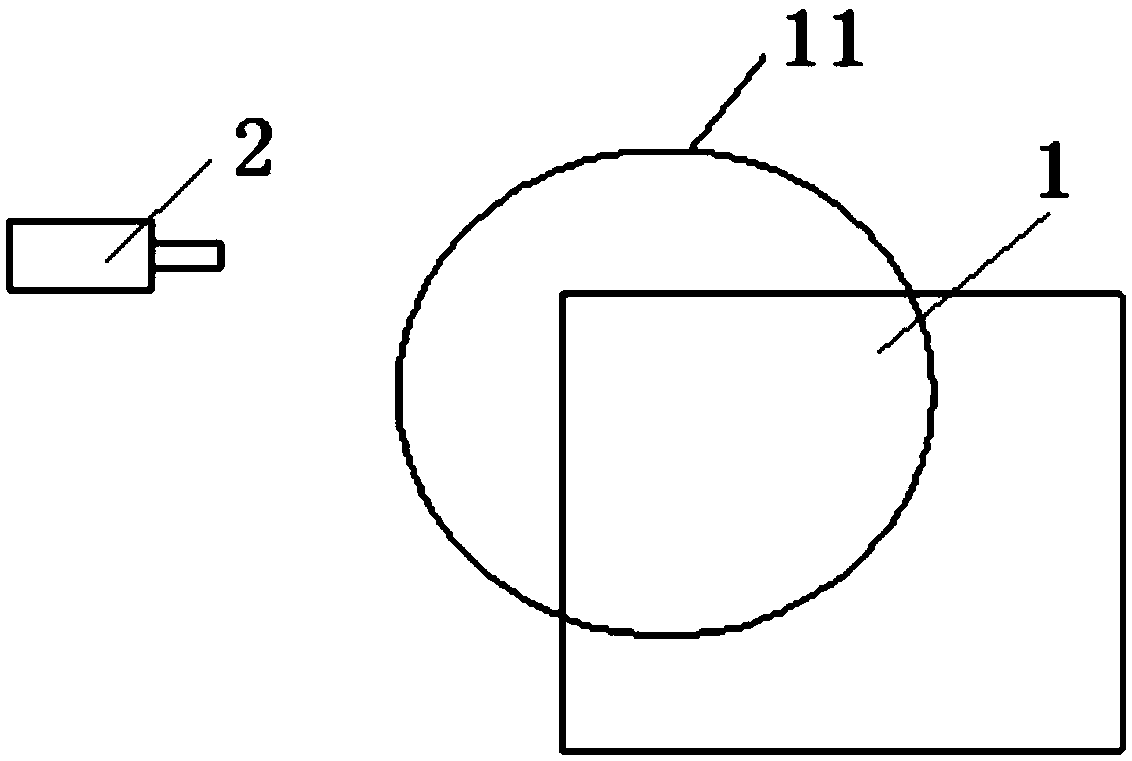

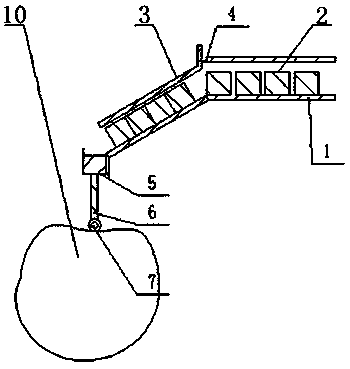

Tower crane safety monitoring system and method

InactiveCN109095376AImprove intelligenceImprove tower crane lifeWinding mechanismsSafety gearWire ropeDisplay device

The invention discloses a tower crane safety monitoring system and method, which can monitor wire rope on the hoisting mechanism coiling block in real time through a camera mounted around the hoistingmechanism focusing on the lifting drum. The intelligent video analyzing device collects and analyzes lifting video image of the camera of the mechanism, confirming whether the hoisted ropes are regularly ordered to perform the detection of the disordered ropes. When the ropes are tangled, the intelligent video analysis device identifies the irregularities of the ropes and displays the alarm information on the operator cab display. At the same time, the chaotic rope signal is sent to the control device, which controls the motor of the hoisting mechanism to reverse and corotate according to therange of the chaotic ropes, and automatically eliminates the disordered rope in time. During the whole process it does not require manual operation and is highly intelligent, which helps to eliminatethe disordered rope in time and improve the service life of the tower crane.

Owner:XUZHOU CONSTR MACHINERY

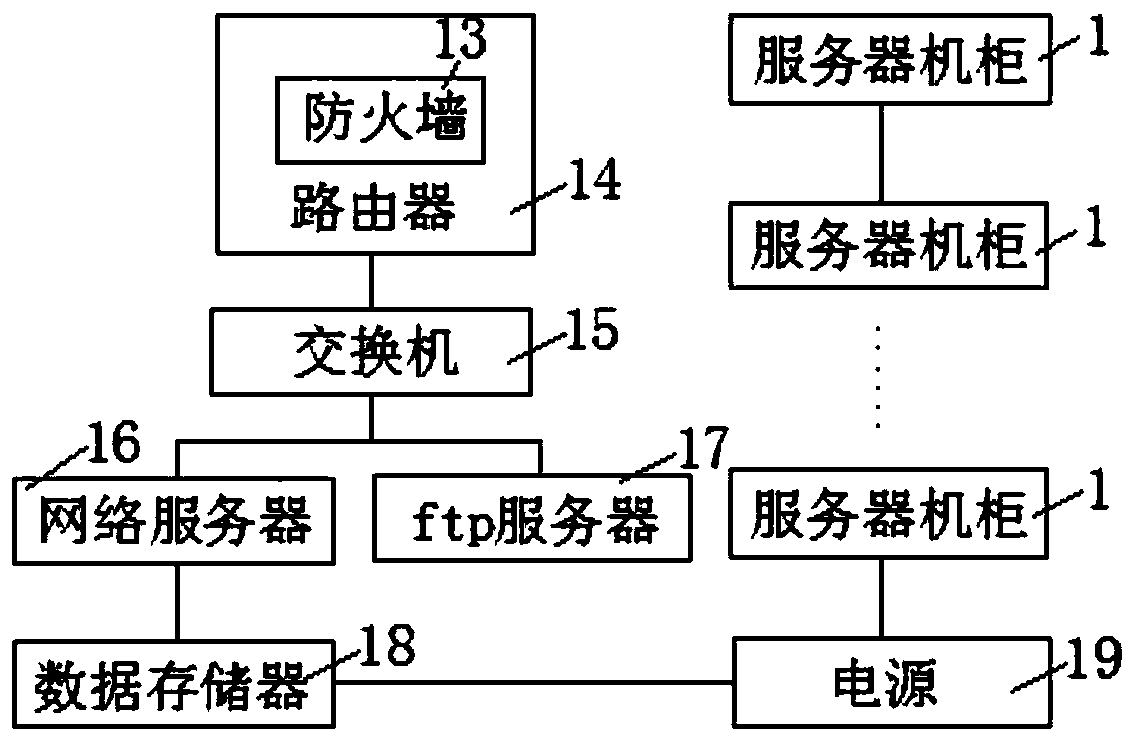

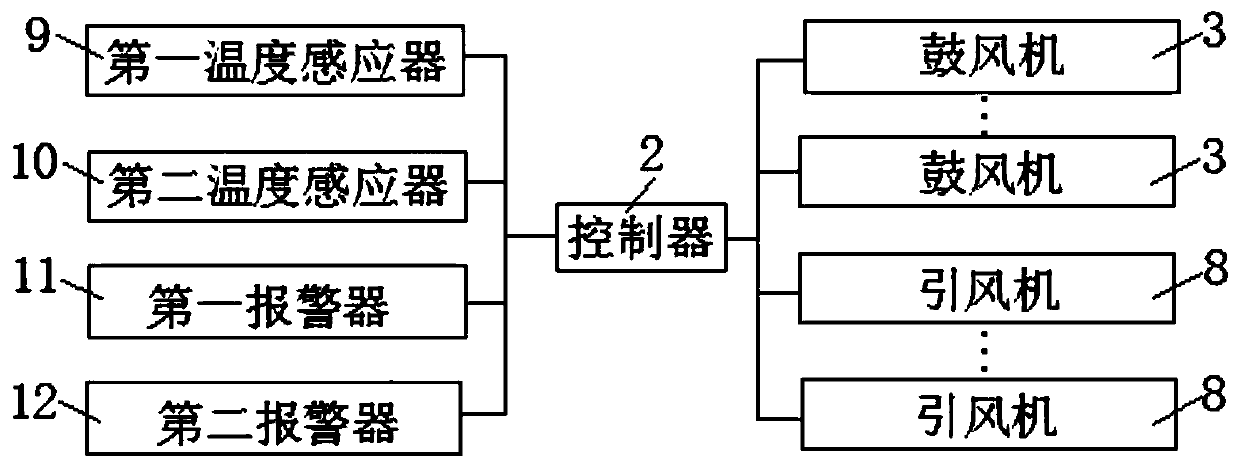

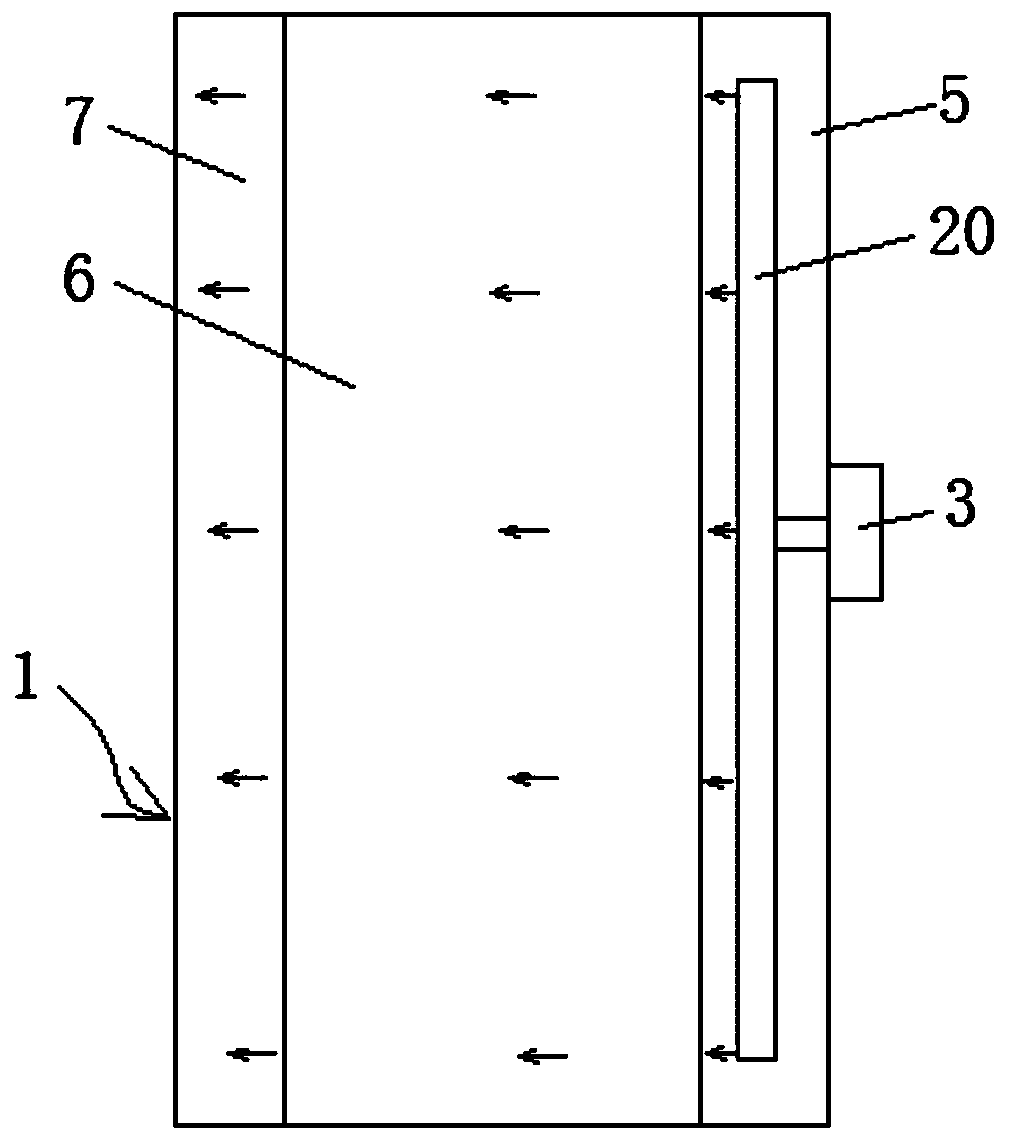

BGP data center security system

InactiveCN110191615AFacilitate timely detection of abnormal situationsDetect abnormalities in timeCooling/ventilation/heating modificationsData centerAlarm device

The invention relates to a BGP data center security system. The system comprises a machine room, and a monitoring device, a heat dissipation device and a plurality of server cabinets which are mountedin the machine room. The monitoring device and the heat dissipation device are in communication connection with a controller of the remote monitoring center. The monitoring device is used for monitoring the real-time temperature in the machine room and sending a temperature signal to the controller. The controller receives the corresponding temperature signal and sends an instruction to the heatdissipation device, and the heat dissipation device receives the instruction and conducts heat dissipation on the machine room and the server cabinets. The invention further comprises an alarm device.The beneficial effects are that the design is reasonable, the structure is simple, the heat dissipation effects of the server cabinets are good, the safety condition of the data center can be remotely monitored, and the system is safe and reliable.

Owner:贵阳忆联网络有限公司

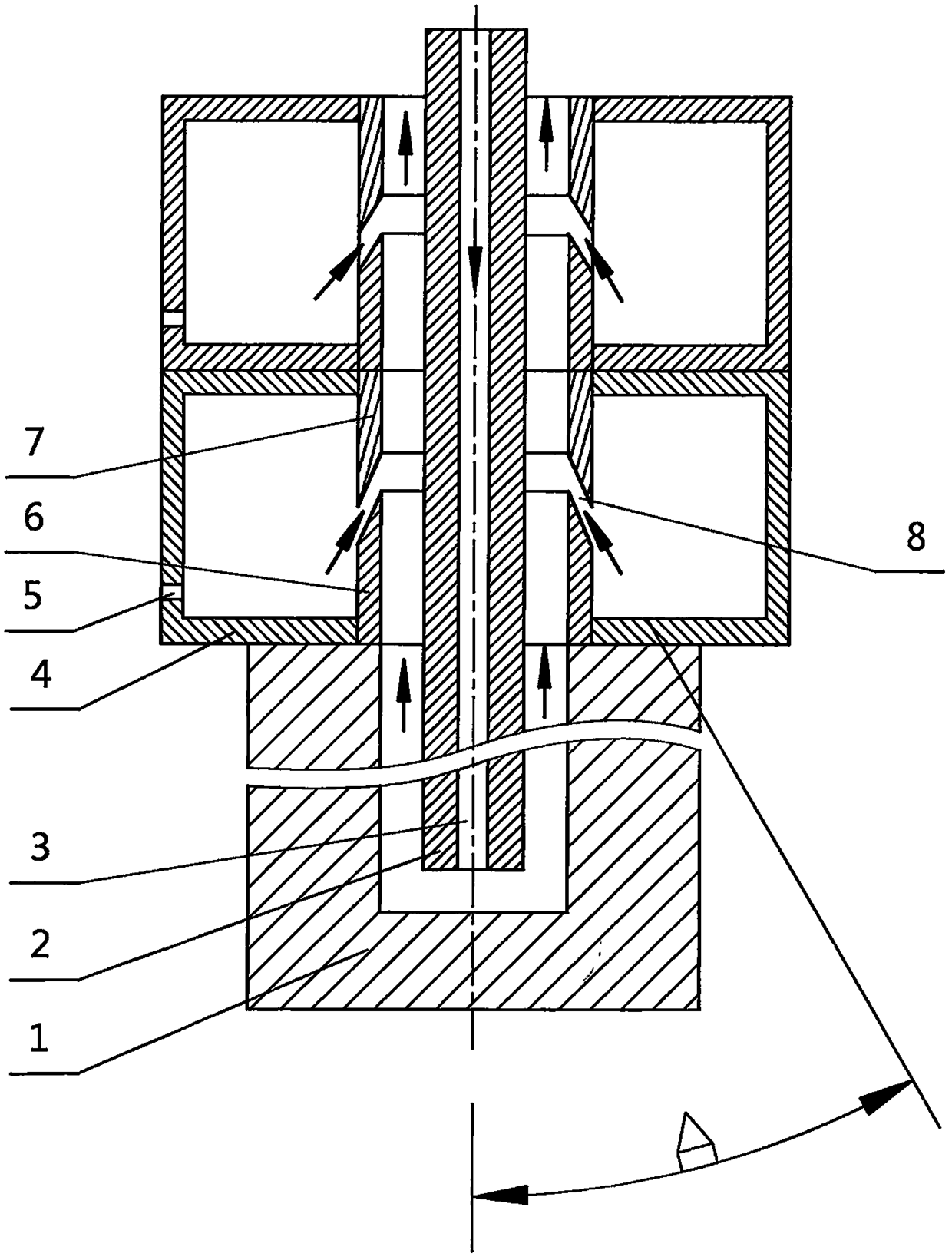

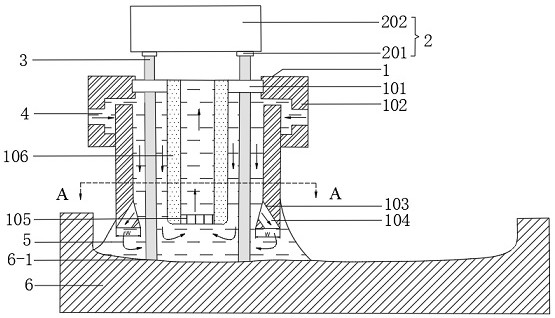

Discharging method for electric corrosion products for electric spark machining

ActiveCN109175551AGuaranteed stabilityGuaranteed machining dimensional accuracyElectricityAcute angle

The invention belongs to the technical field of special machining and particularly relates to a discharging method for electric corrosion products for electric spark machining, and the discharging method is used for discharging the electric corrosion products in the electric spark machining process of deep holes, deep grooves, narrow seams and other structures. The method relates to a hydraulic force discharging device, and the device is composed of a hydraulic force box, an outer cone body, an inner cone body and an annular gap. Liquid with pressure flows into the hydraulic force box and flows out of the annular gap; an included angle A formed between the annular gap and the axis of an electrode is an acute angle; and the hydraulic force discharging device can be in one set, two sets or aplurality of sets. The steps of the discharging method for the electric corrosion products includes that firstly, the electrode and the hydraulic force discharging device are machined; secondly, theelectrode, a workpiece and the hydraulic force discharging device are installed; and thirdly, electric spark discharging machining is performed, and the liquid with the pressure flows into and flows out of a discharging device for the electric corrosion products. Due to a method that flowing liquid is externally added, the electric corrosion products of the machining system are discharged in time,blocking is prevented, the size precision of machining and the shape and position precision are guaranteed, and the machining efficiency is improved.

Owner:ZHONGBEI UNIV

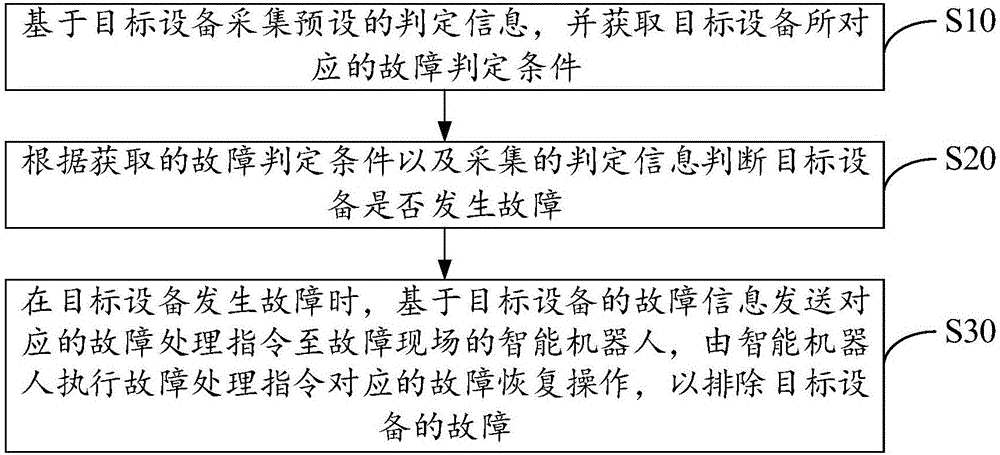

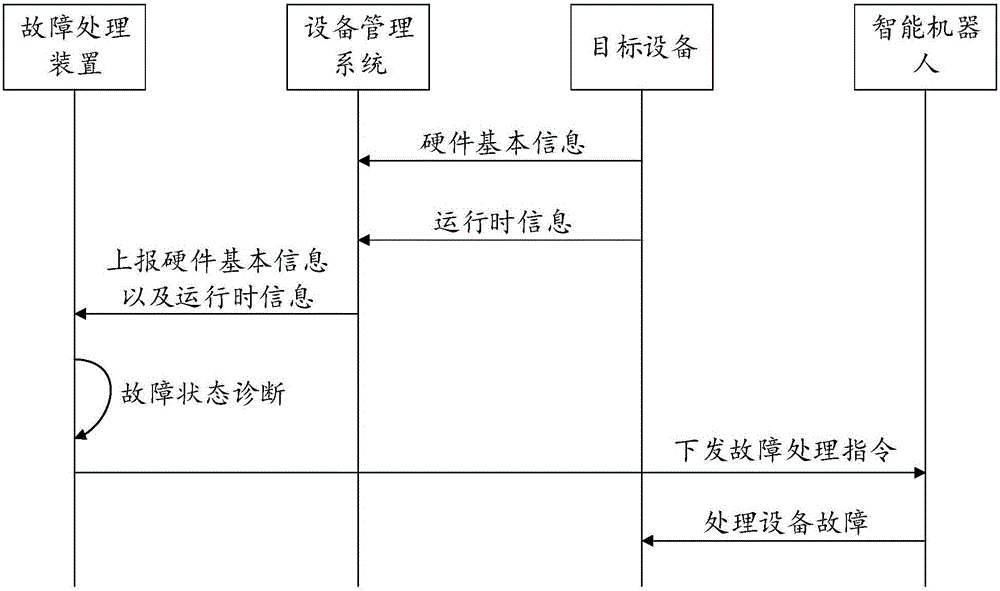

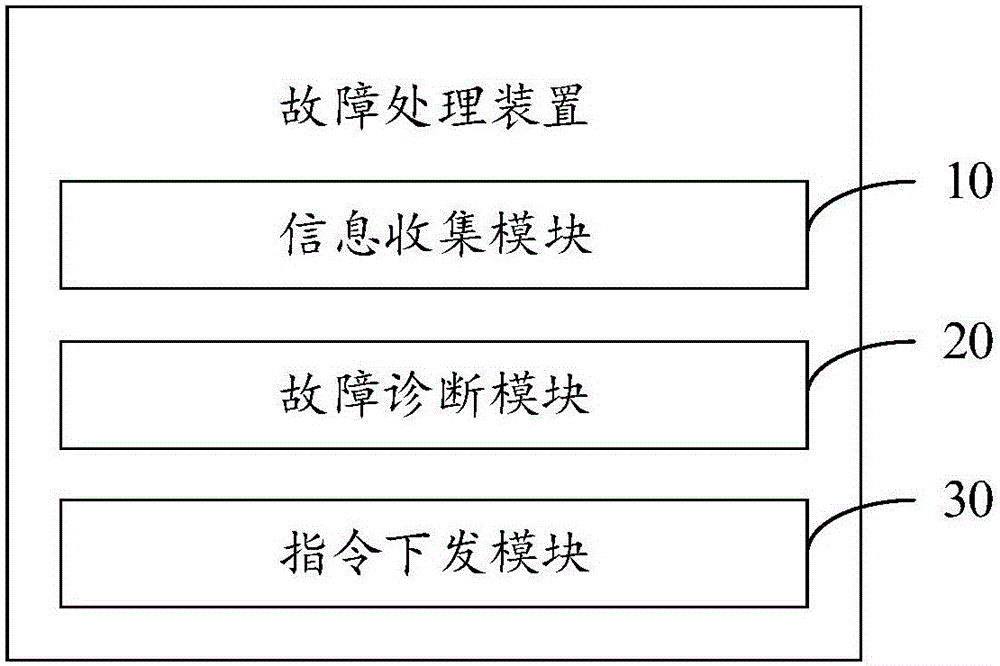

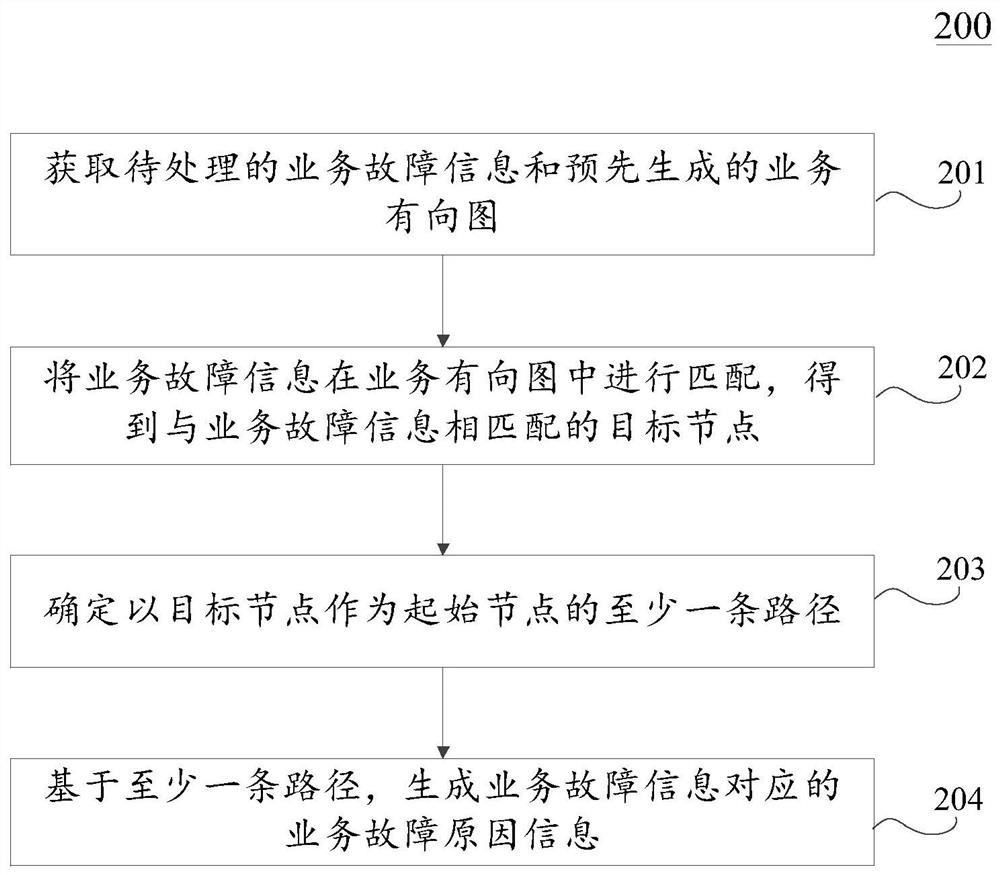

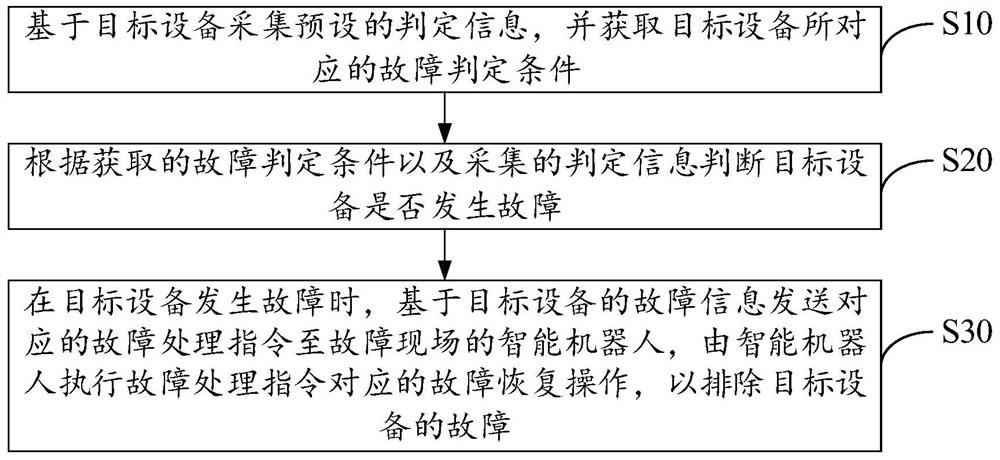

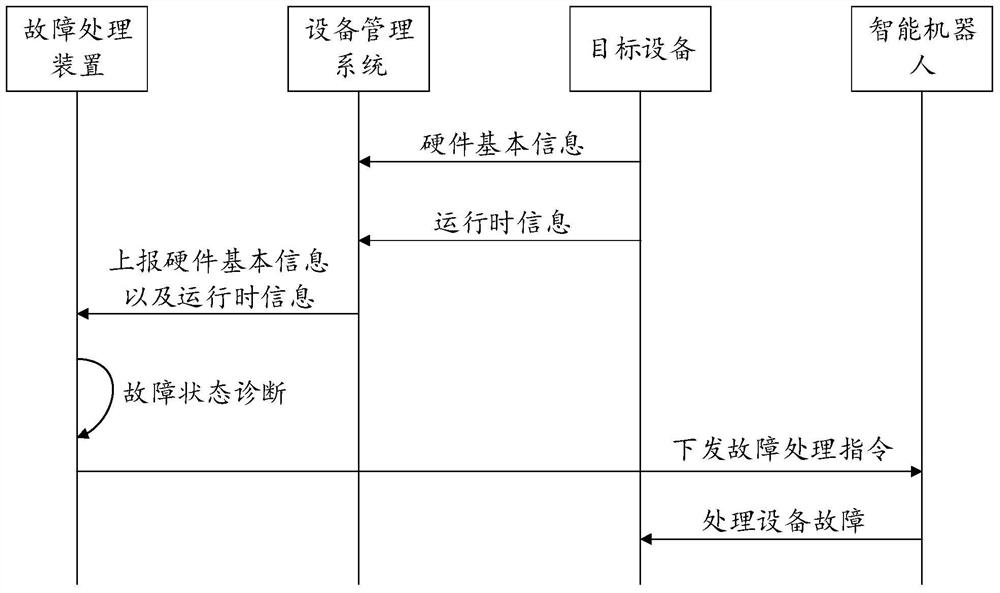

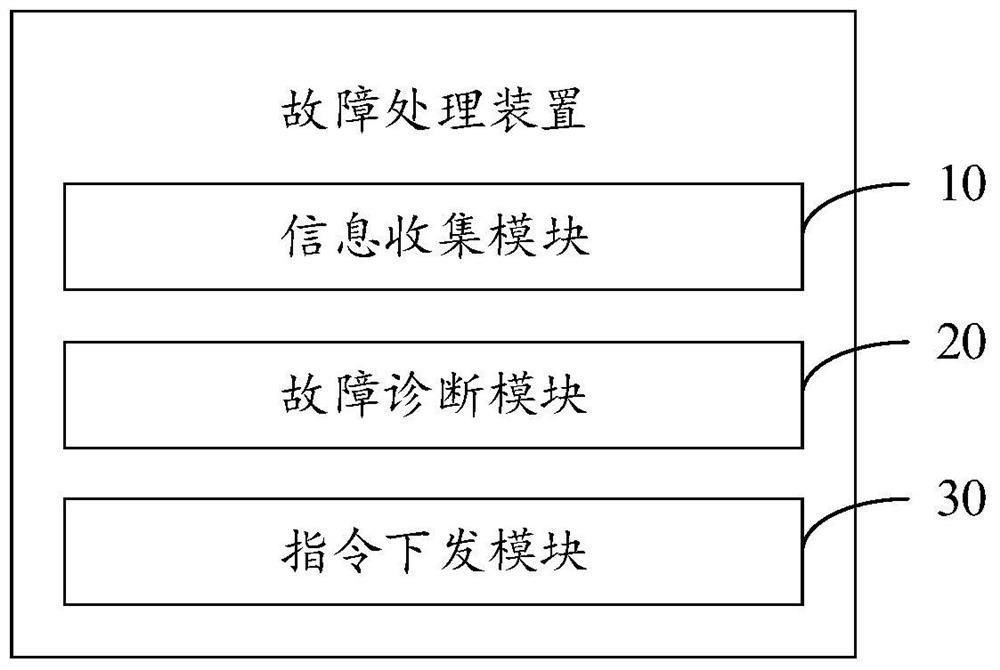

Fault processing method and apparatus

ActiveCN107528705AExclude in timeImprove troubleshooting efficiencyData switching networksProcessing InstructionComputer science

The invention discloses a fault processing method. The fault processing method comprises the following steps: collecting preset judgement information based on a target device, and obtaining a fault judgement condition corresponding to the target device; judging whether the target device is faulty according to the fault judgement condition and the collected judgement information; and when the target device is faulty, sending a corresponding fault processing instruction to an intelligent robot on a fault site based on the fault information of the target device, so that the intelligent robot executes a fault recovery operation corresponding to the fault processing instruction to remove the fault of the target device. The invention further provides a fault processing apparatus. By adoption of the fault processing method and apparatus provided by the invention, the fault processing efficiency of the device can be improved.

Owner:ZTE CORP

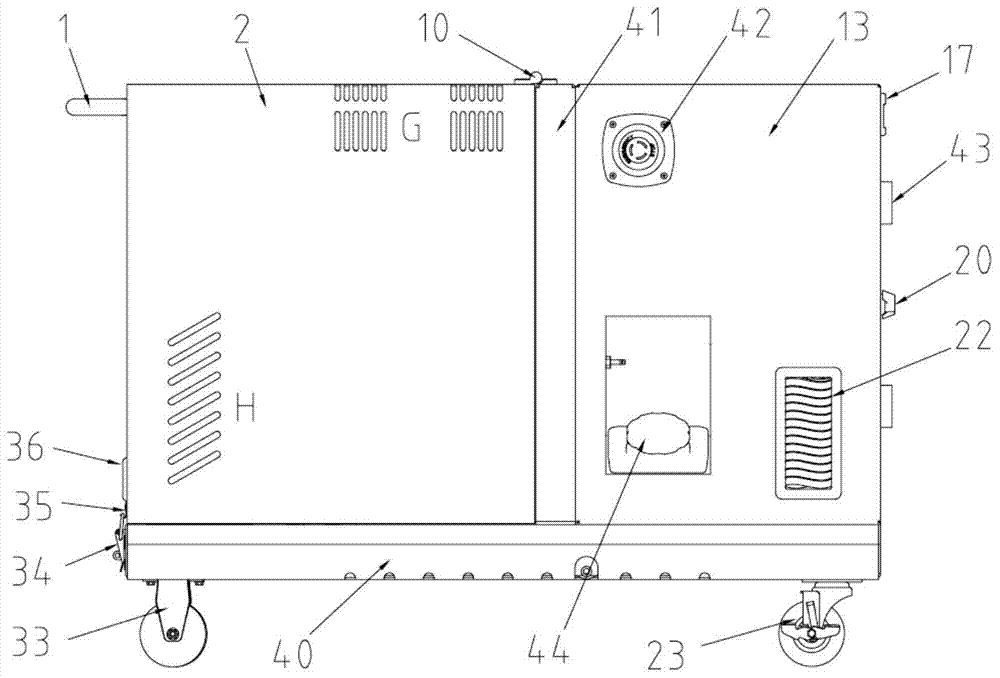

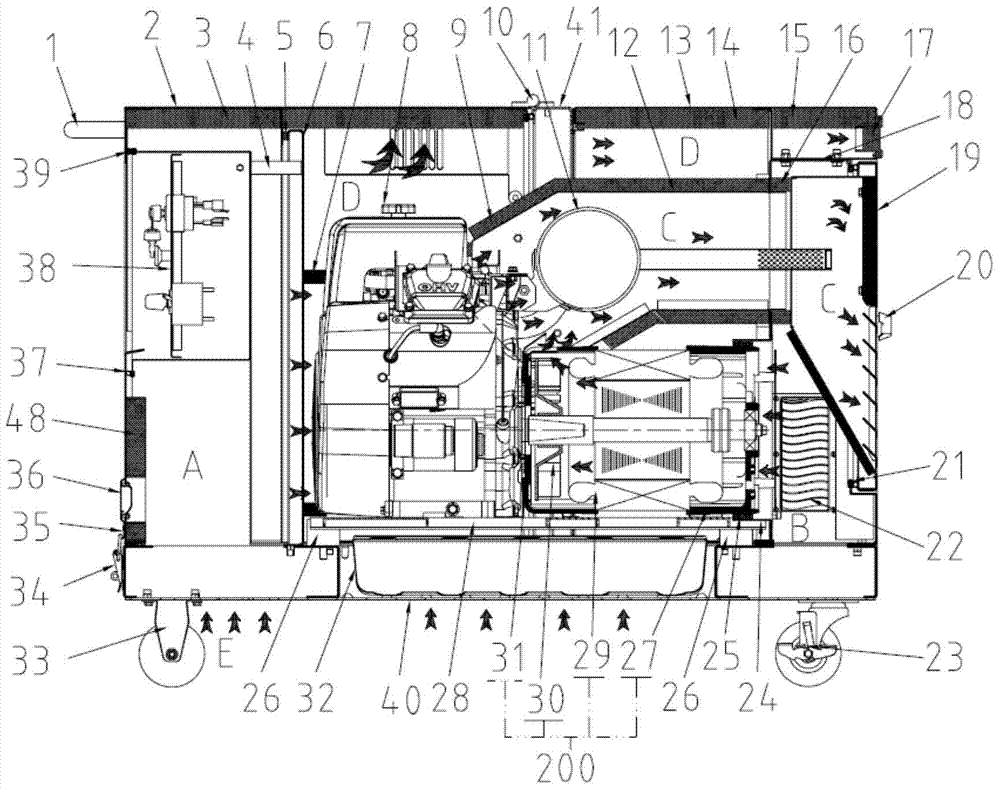

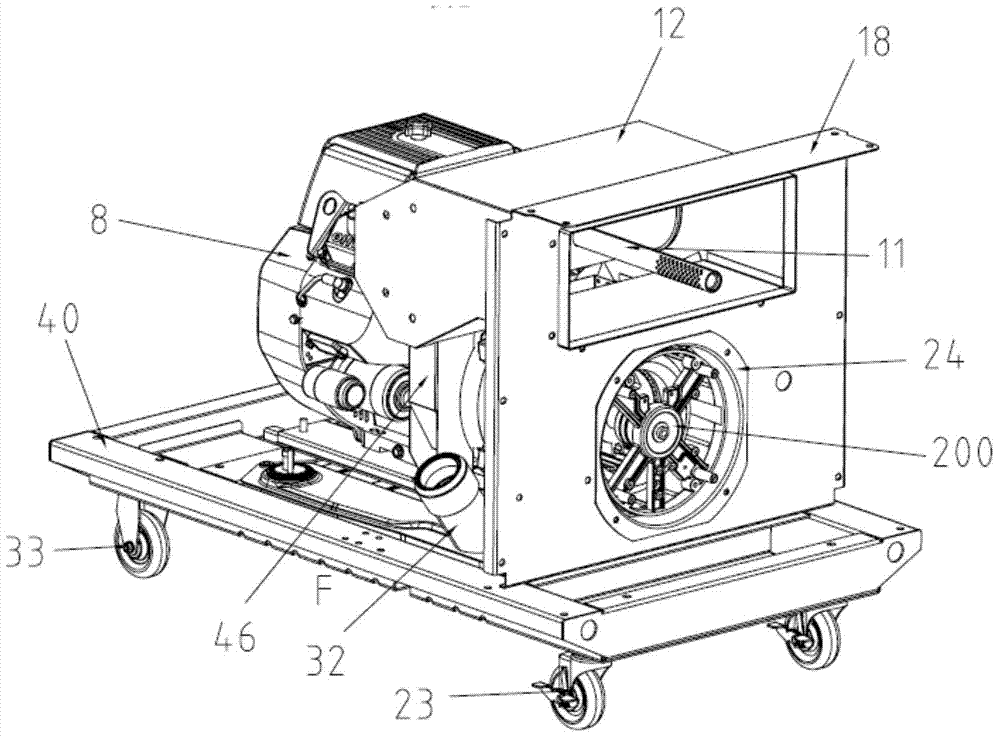

Double-cylinder air-cooled mute gasoline engine generator unit

InactiveCN103939206AReduce the impactReduce noiseAir coolingExhaust apparatusGasolineEngine-generator

The invention discloses a double-cylinder air-cooled mute gasoline engine generator unit. The double-cylinder air-cooled mute gasoline engine generator unit comprises a tank and a chassis, wherein the space defined by the tank and the chassis is internally provided with a double-cylinder engine and an electric generator coaxially connected with the double-cylinder engine. The double-cylinder air-cooled mute gasoline engine generator unit further comprises an exhaust chamber and an exhaust silencer; an exhaust port of the electric generator is upward; the exhaust chamber is arranged above the electric generator and extends in the horizontal direction; the left end and the right end of the exhaust chamber are open; the left-end opening is formed in the upper portion of the engine and the electric generator and covers a cooling air outlet of the engine and a cooling air outlet of the electric generator; the right-end opening is connected with an air hole in a rear cover of the tank; the exhaust silencer is arranged on the position, right opposite to the exhaust port of the electric generator, inside the exhaust chamber; the exhaust silencer is connected with an exhaust port of the double-cylinder engine through two exhaust pipelines. A circulating cooling system is formed inside the unit, and influence on the double-cylinder engine and the electric generator by heat energy is reduced effectively.

Owner:江苏紫睿机电产业有限公司

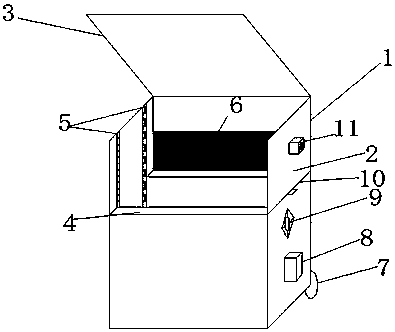

Environmental sanitation garbage can

The invention belongs to the field of environmental sanitation facilities and particularly relates to an environmental sanitation garbage can. A base plate of the environmental sanitation garbage canis composed of two ascending-and-descending plates and a fixing plate, and a gap is formed between every two parts, so that water in garbage is drained through the gaps and prevented from being accumulated in the garbage. In addition, an exhaust opening is formed in one side of a garbage can body, and peculiar smell in the garbage can body can be removed in time. The environmental sanitation garbage can is further provided with electric wheels; sanitation workers do not need to push the environmental sanitation garbage can manually, and manpower is saved; the garbage can body is internally provided with a separating body, and when the garbage falls through the separating body, metal products are attracted by magnetic attraction devices; after a can cap is closed, the attracted metal products fall into containing boxes; when the garbage can body is cleaned, the containing boxes are shielded through a shielding plate, and metal in the containing boxes is prevented from being disposed together with other types of garbage; and after other types of garbage is disposed, the shielding plate is opened, and the metal in the containing boxes is cleaned.

Owner:常州蓝森环保设备有限公司

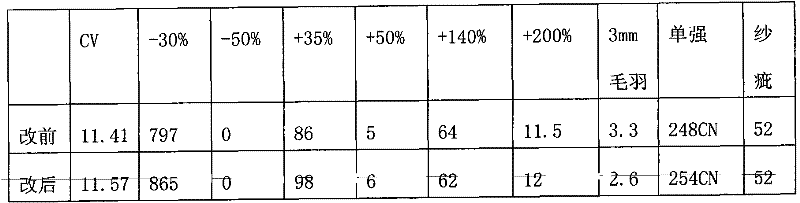

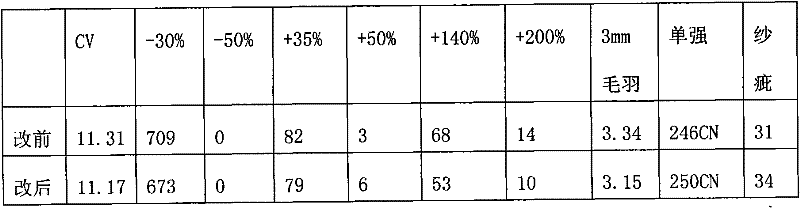

Process for producing high-grade weaving yarns with heavy weight per unit of card silver in a carding machine from Zhengzhou Textile Machinery Co., Ltd

InactiveCN101748518AIncrease speedIncrease productivityContinuous processingCarding machinesYarnCombing

A process for producing high-grade weaving yarns with heavy weight per unit of card silver in a carding machine from Zhengzhou Textile Machinery Co., Ltd relates to the textile technical field, in particular to a process for producing high-grade weaving yarns. The process includes: ZTM blowing-carding process- pre-drawing- lap drawing- combing- drawing (with auto leveling) - roving- cheese winding -bale packing- yarn sales. Under the circumstance of constant card clothing of the carding machine, the linear weight of card silver can be increased to 21g / 5m increased by nearly 17 percent by, increasing the RPM of cubing rolls, cylinders and cover plates, blocking up a support trunnion for feed roller and reducing the spacing between the feed roller and the cubing roll, thus not only increasing the production efficiency and saving the energy consumption but also addressing the problem of dissatisfaction with the supply of card silvers.

Owner:江苏省华强纺织有限公司

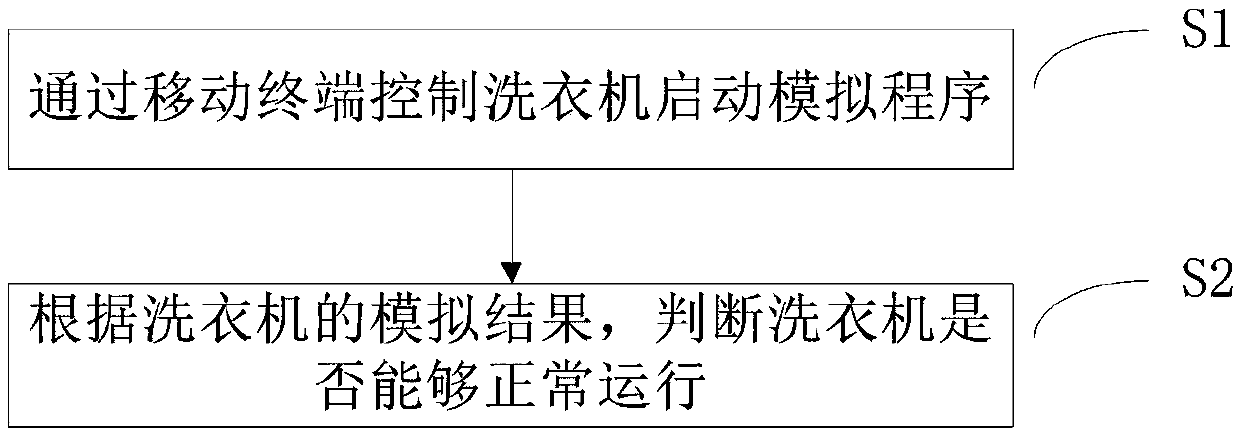

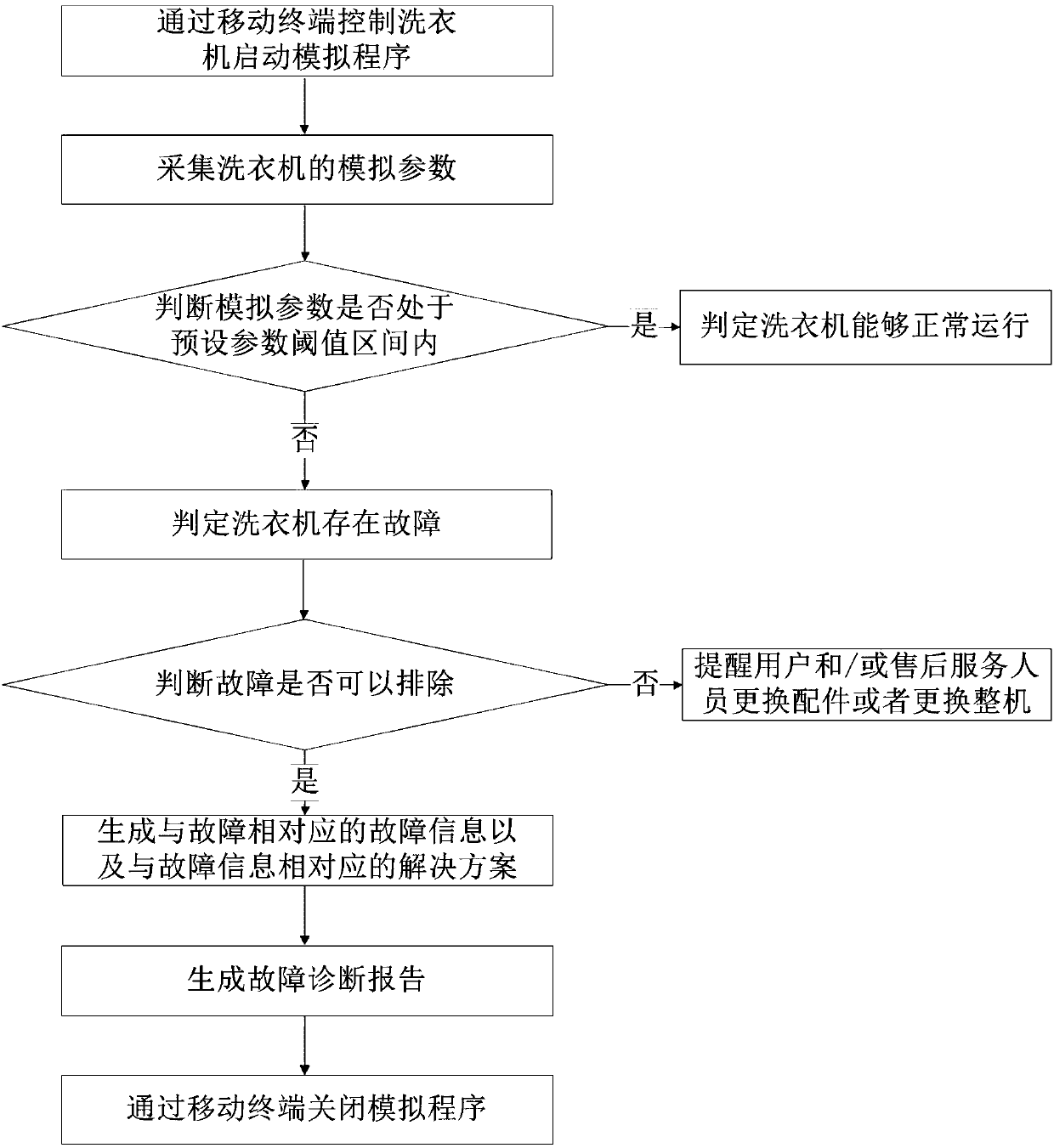

Diagnosis method for clothes treatment equipment

InactiveCN109778490AGuaranteed uptimeKeep abreast of diagnosis resultsControl devices for washing apparatusTextiles and paperService personnelDiagnosis methods

The invention relates to the technical field of clothes treatment equipment, and particularly provides a diagnosis method for clothes treatment equipment. The diagnosis method aims at solving the problems that an existing method for diagnosing whether or not the clothes treatment equipment has a fault consumes long time and cannot accurately judge the cause of the fault. In order to solve the problems, the diagnosis method comprises the following steps of controlling the clothes treatment equipment to start a simulation program through a mobile terminal; judging whether or not the clothes treatment equipment can run normally according to a simulation result of the clothes treatment equipment. The method has the advantages that through the simulation program controlled by the mobile terminal, the time for testing whether or not the clothes treatment equipment can run normally is shortened, the working efficiency of after-sales service personnel is improved accordingly, and the use experience of users is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

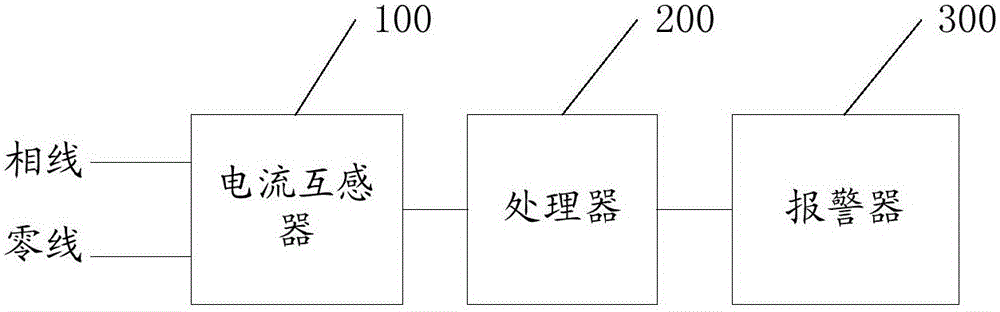

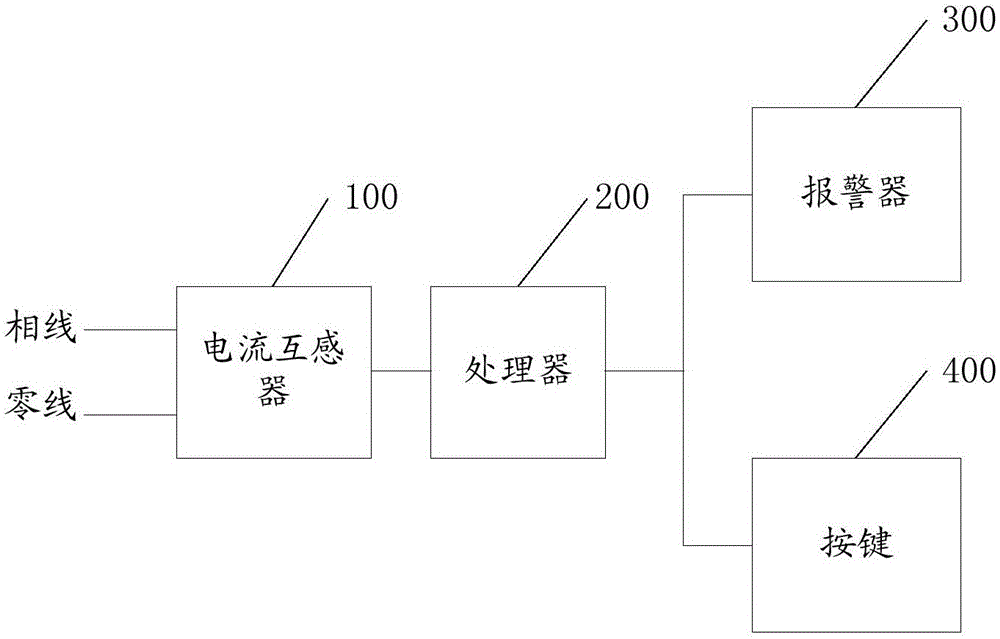

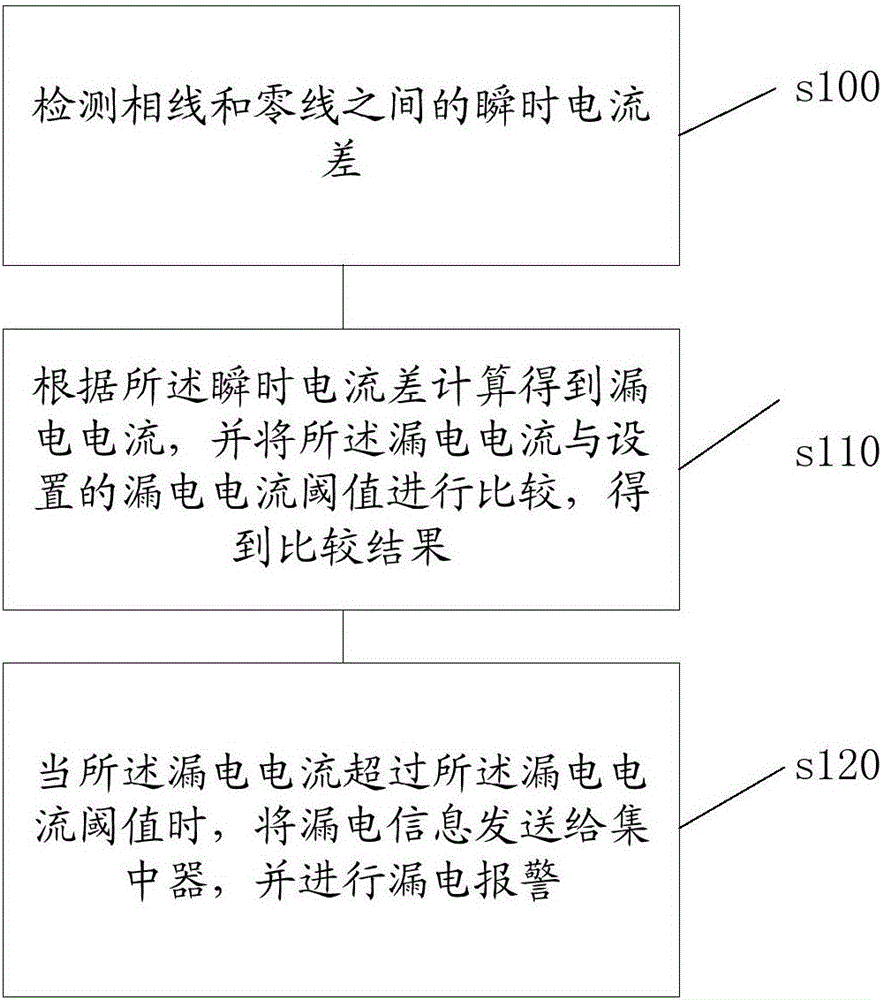

Single-phase residual electricity quantity signal trigger and monitoring method

InactiveCN105067872AGuaranteed normal power consumptionExclude in timeCurrent/voltage measurementElectrical testingElectricityCurrent threshold

The invention discloses a single-phase residual electricity quantity signal trigger, which comprises a current transformer, a processor and an alarm, wherein the current transformer is used for detecting instantaneous current difference between a phase line and a null line; the processor is connected with the current transformer, obtains leakage current through calculation according to the instantaneous current difference, compares the leakage current with a set leakage current threshold value, sends leakage current information to a concentrator when the leakage current exceeds the leakage current threshold value, and sends an alarm command; and the alarm is connected with the processor, and carries out leakage current alarm according to the command of the processor. The single-phase residual electricity quantity signal trigger can help the user to analyze causes of current leakage, so as to perform timely troubleshooting, and protect the normal electricity utilization of the user. The invention further provides a single-phase residual electricity quantity signal monitoring method.

Owner:STATE GRID ZHEJIANG HANGZHOU CITY FUYANG DISTRICT POWER SUPPLY CO LTD +2

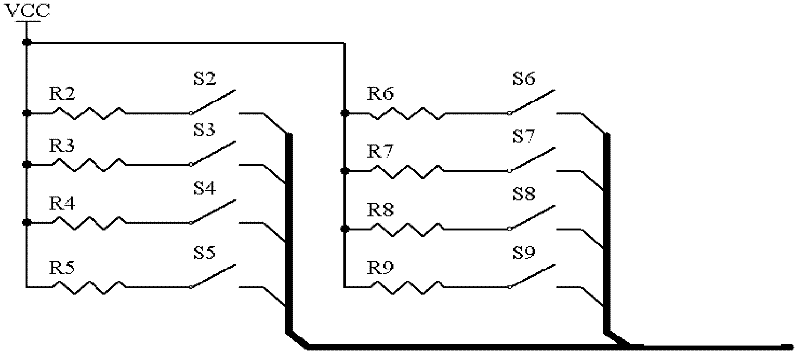

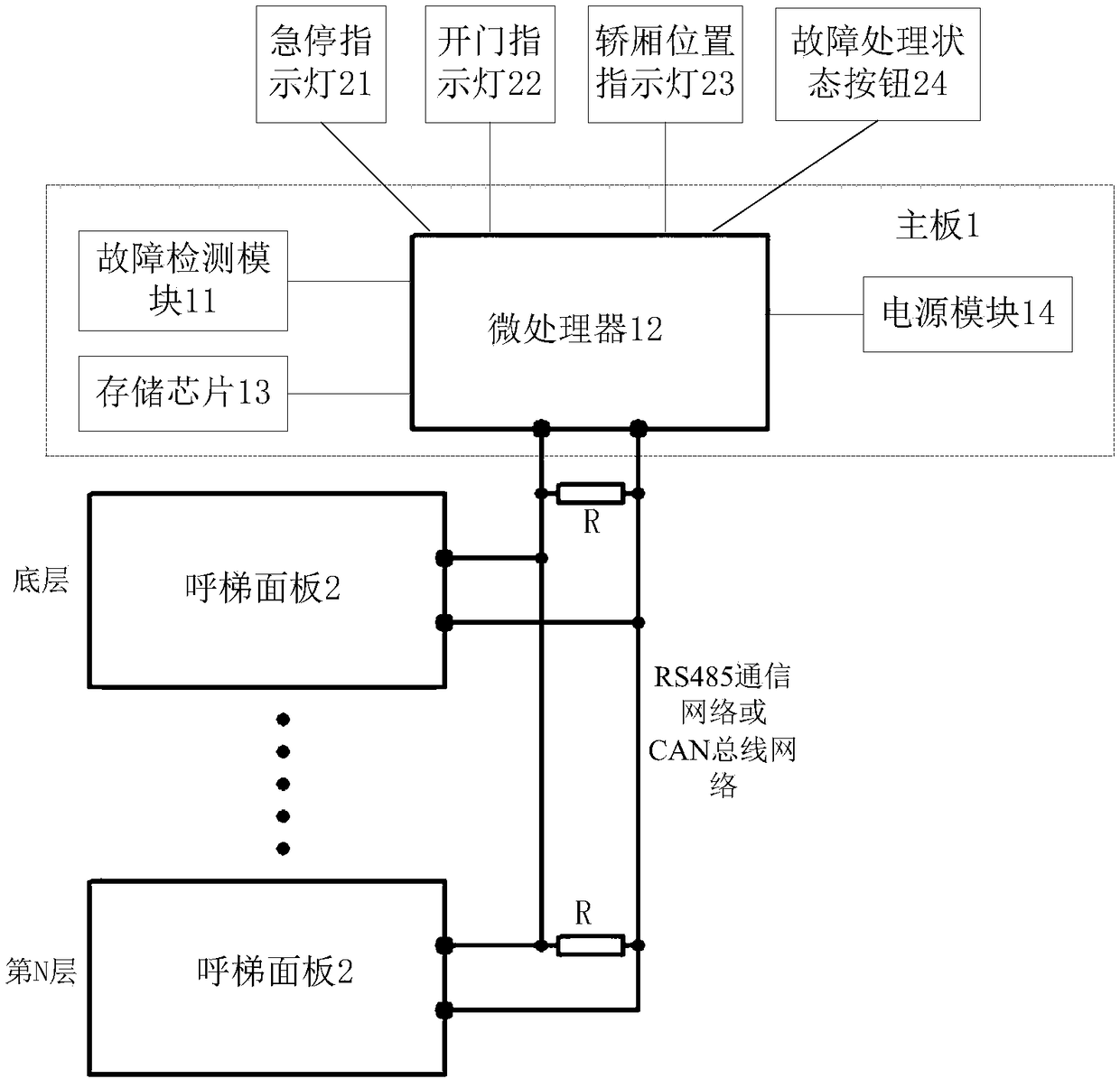

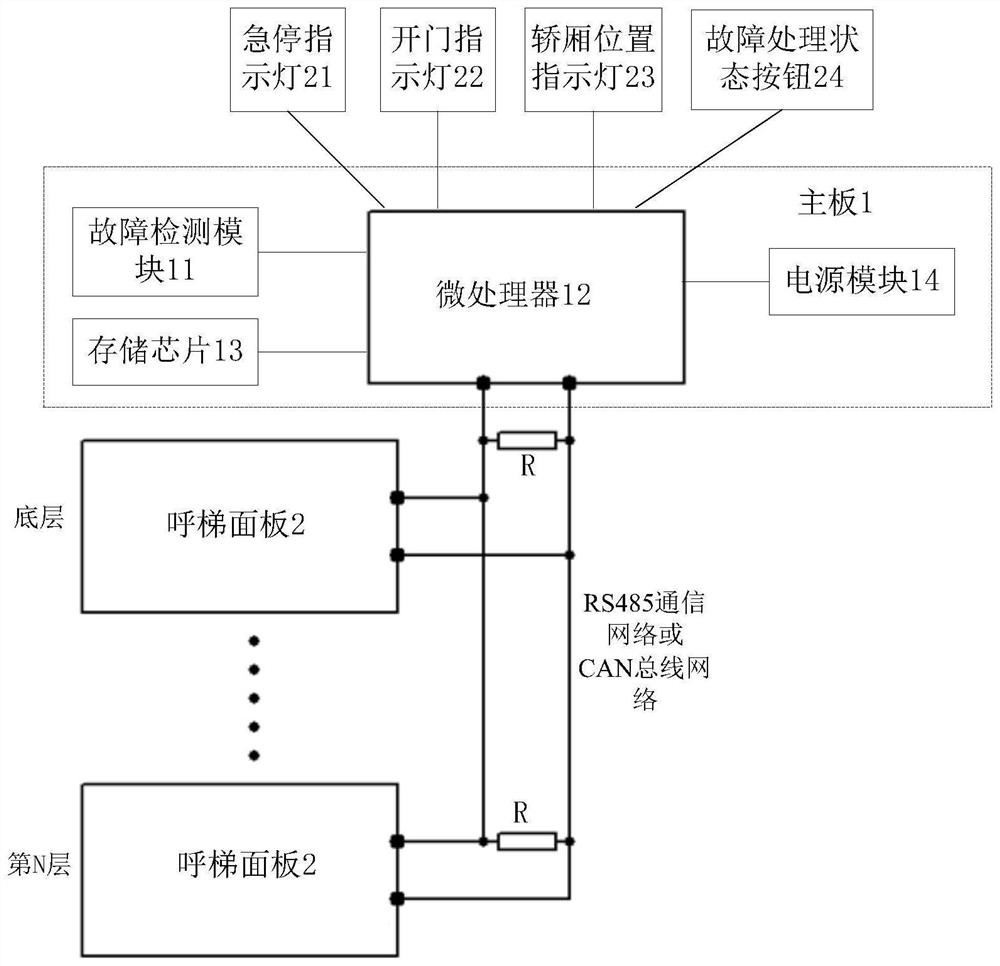

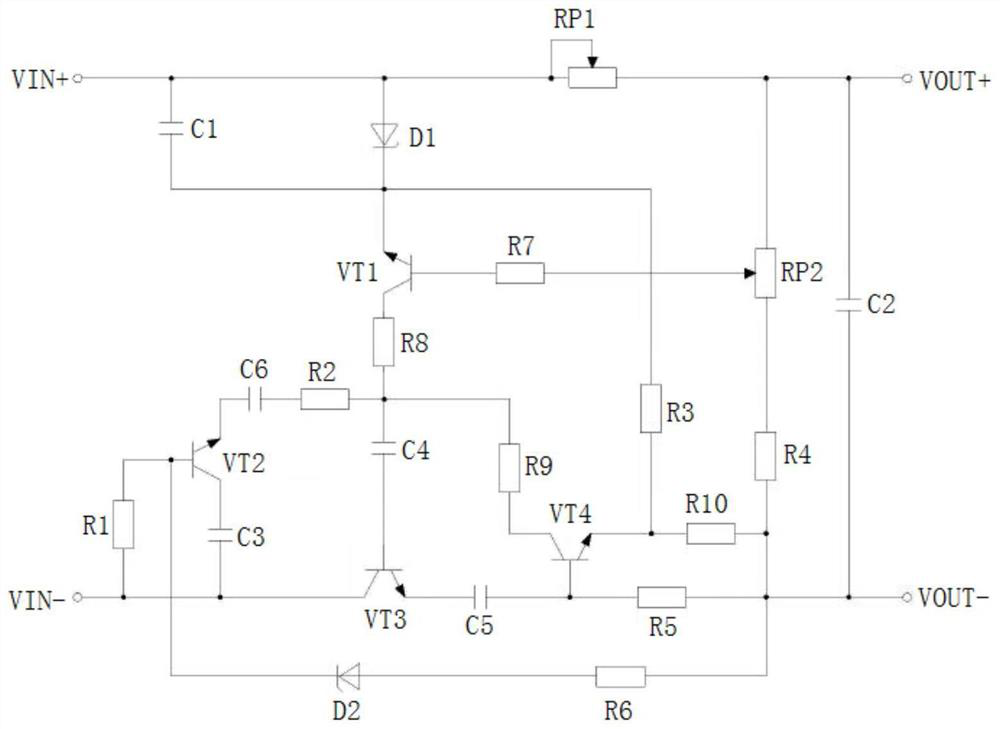

Elevator control system

The invention discloses an elevator control system. The elevator control system comprises a main board and a plurality of elevator calling panels, wherein the elevator calling panel on each layer is equipped with a scrap indicating lamp, a door-opening indicating lamp and a car position indicating lamp; the main board comprises a fault detecting module, a micro processor, a storage chip and a power supply module; after detecting that an elevator has faults, the fault detecting module converts fault information into fault codes and sends the fault codes to the micro processor; the micro processor is used for separately sending the fault codes to the elevator calling panel on each layer to display through an RS485 communication network or a CAN bus communication network; when the fault detecting module detects that the fault does not have faults, the micro processor sends floor display and up-down direction information to the elevator calling panel on each layer to display through the RS485 communication network or the CAN bus network; and the scram indicating lamp, the door-opening indicating lamp and the car position indicating lamp are connected with the micro processor. The elevator control system brings very great convenience to elimination of elevator faults, and is beneficial for maintenance personnel to timely eliminate the elevator faults.

Owner:石家庄松达电子科技有限公司

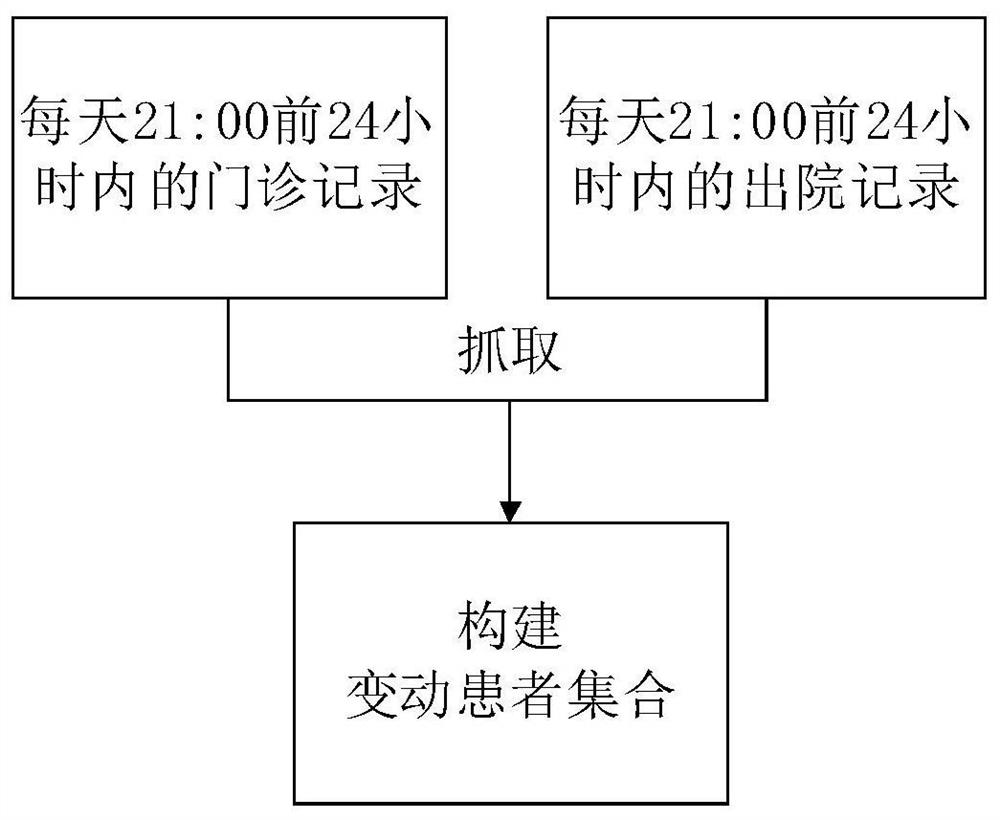

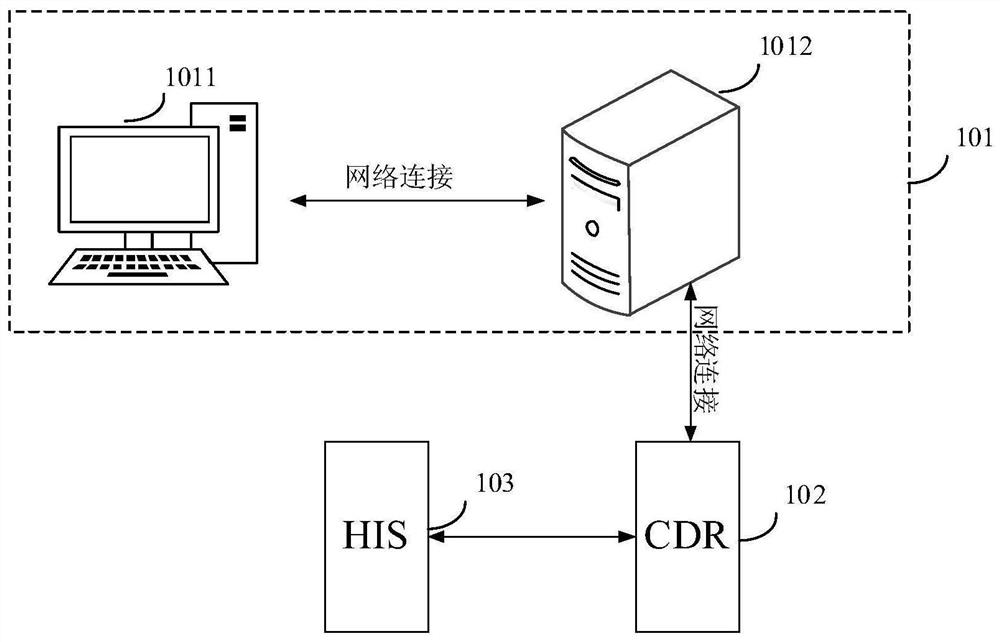

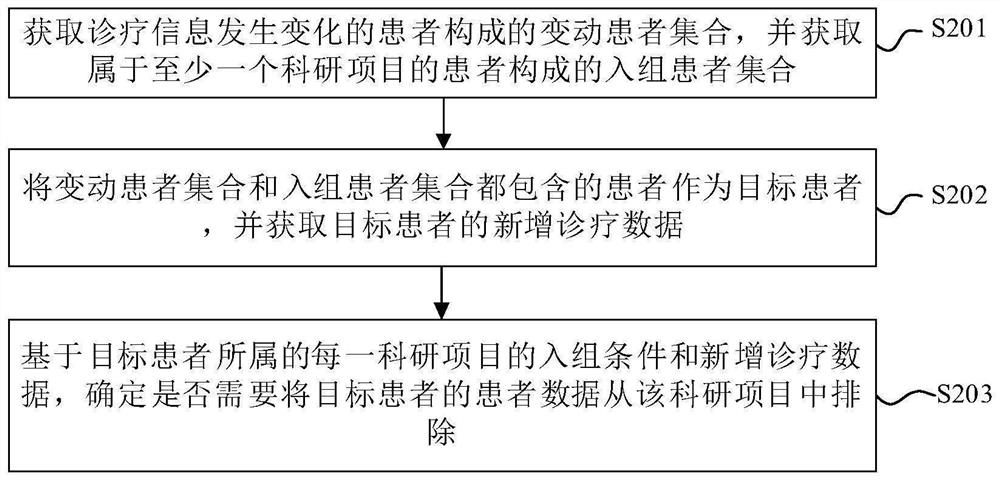

Clinical research patient screening method and corresponding device

PendingCN113889205AExclude in timeFast screeningMedical automated diagnosisPatient-specific dataPatient needClinical research

The embodiment of the invention provides a clinical research patient screening method and a corresponding device, and the method comprises the steps: obtaining a changing patient set composed of patients whose diagnosis and treatment information changes, and obtaining an in-group patient set composed of patients belonging to at least one scientific research project; taking patients contained in the changed patient set and the in-group patient set as target patients, and obtaining newly added diagnosis and treatment data of the target patients; and determining whether the patient data of the target patient needs to be excluded from the scientific research project or not based on the group entering condition of each scientific research project to which the target patient belongs and the newly added diagnosis and treatment data. According to the scheme, only part of data of part of patients need to be screened, compared with full-amount screening, the screening speed is higher, and the in-group patients not meeting the group entering requirement can be eliminated in time.

Owner:上海柯林布瑞信息技术有限公司

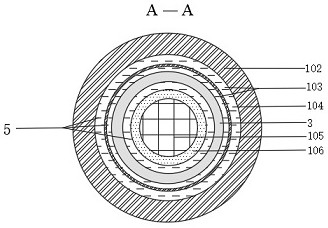

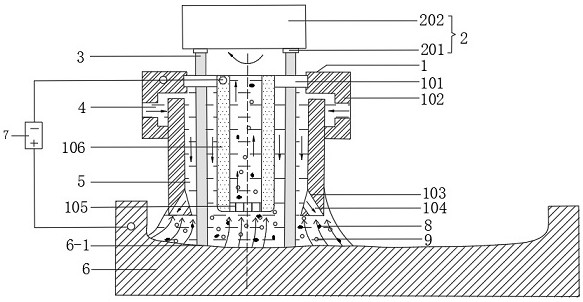

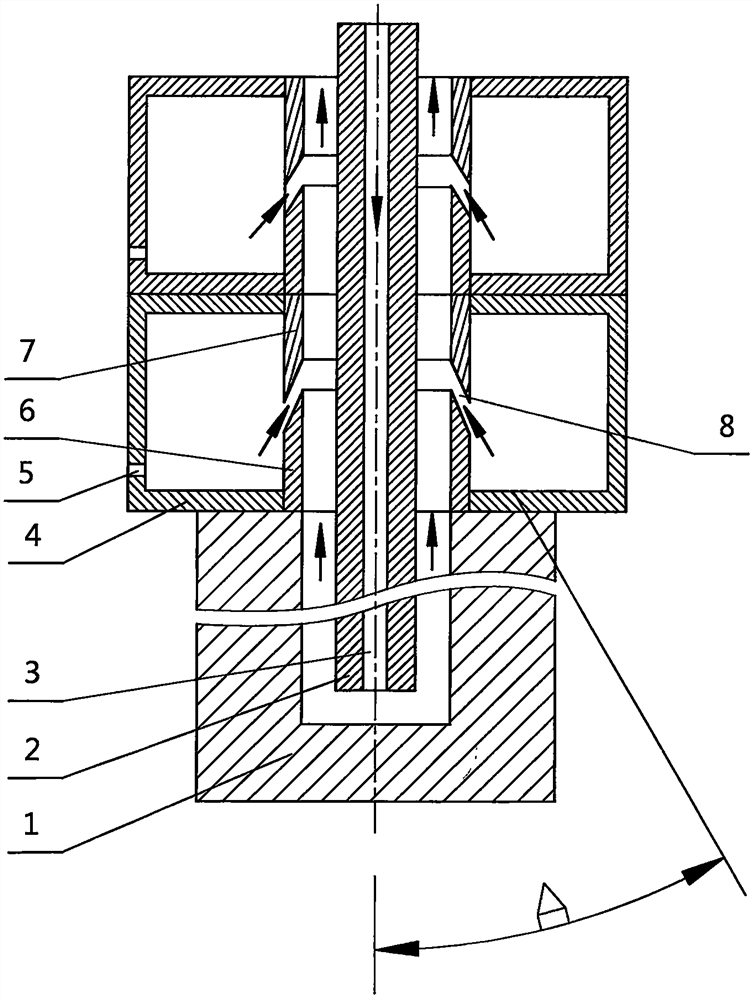

Laser-jet electrolysis combined machining double-pipe tool electrode and milling machining method

PendingCN114850596ASmall sizeLarge milling area in one scanProcess efficiency improvementLaser beam welding apparatusElectrolytic agentDouble tube

The invention discloses a laser-jet flow electrolysis combined machining double-pipe tool electrode and a milling machining method, and belongs to the field of laser-electrolysis combined machining. The double-tube tool electrode comprises an optical lens, an outer cathode tube, an inner inclined convex ring, an array outer inclined hole, a mesh, an inner cathode tube and an annular laser beam. The outer cathode tube is coaxially sleeved outside the inner cathode tube, an annular laser beam is adopted, an inner inclined convex ring is arranged at the lower end of the outer cathode tube, and a mesh is arranged at the lower end of the inner cathode tube. In the milling process, the annular band laser is started, and a power supply is switched on. A workpiece to be machined is corroded to form a groove under the synergistic effect of a laser irradiation thermal field, an electric field, an electrochemical field, a flow field and the like, and electrolyte is supplied in a spraying and sucking mode, so that the annular cavity is filled with the electrolyte, and machined products and bubbles are taken away in time. The outer diameter of the double-tube tool electrode reaches the centimeter level, large-area milling of a metal component can be achieved, the machining process is stable, and efficient and high-precision machining can be achieved.

Owner:HENAN POLYTECHNIC UNIV

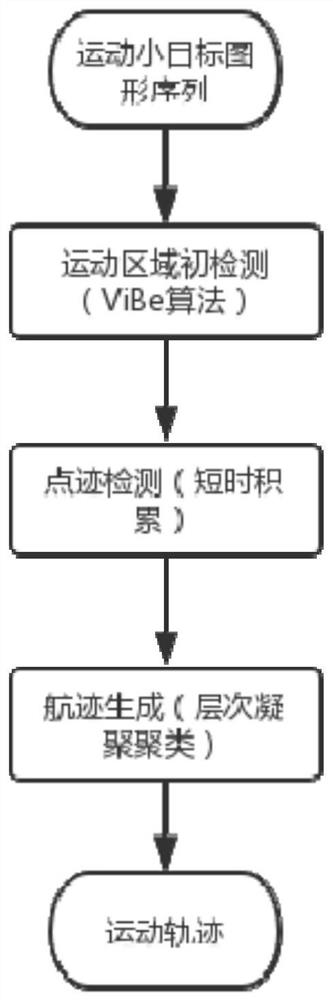

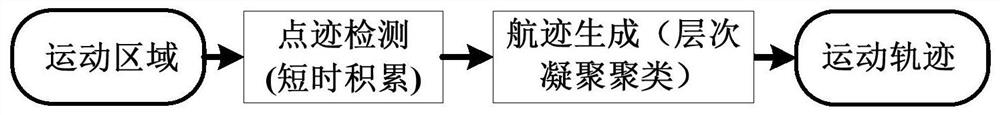

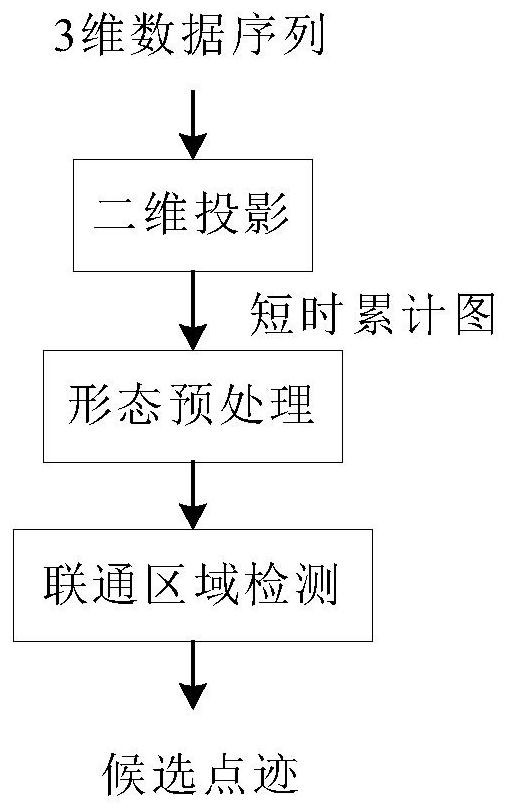

Moving small target detection method based on TBD complex environment

PendingCN111833377AImprove performanceReduce false alarm rateImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention discloses a moving small target detection method based on a TBD complex environment. According to the invention, on the basis of the basic thought of the TBD (tracking before detection)technology, image video processing algorithms such as background modeling, morphological processing and the like and a point / extended point target detection tracking algorithm are subjected to deep fusion, and a two-stage fast TBD algorithm is provided. According to the invention, the background noise environment is considered, the motion characteristics of a moving target are utilized, and a ViBealgorithm is used for carrying out initial detection on a motion area; then, trace point detection is carried out in a short-time accumulation mode; and the moving target track is generated in a long-term accumulation mode, so that the performance of the detection algorithm is improved, the false alarm rate is reduced, and the detection speed is increased.

Owner:HANGZHOU DIANZI UNIV

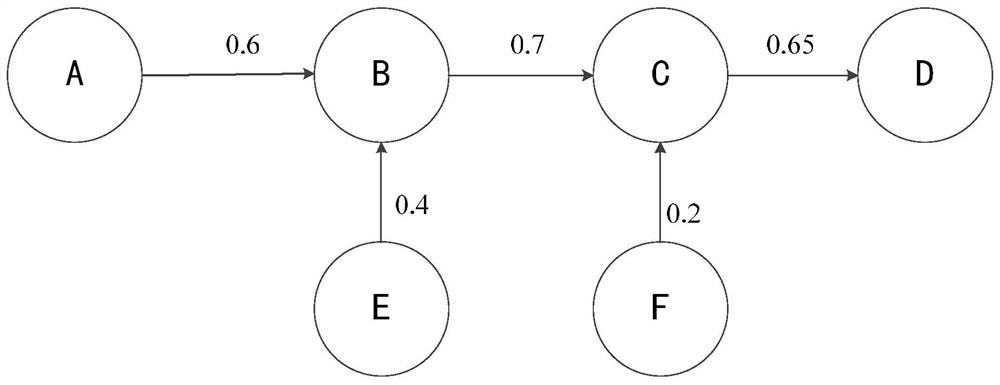

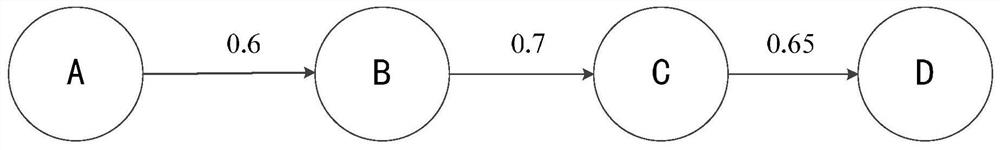

Service fault reason information generation method and device, equipment and computer readable medium

PendingCN113793128AAccurately determineTroubleshoot in timeMathematical modelsOffice automationService informationPathPing

The embodiment of the invention discloses a service fault reason information generation method and device, electronic equipment and a computer readable medium. According to one specific embodiment, the method comprises the steps: obtaining to-be-processed service fault information and a pre-generated service directed graph, wherein each node of the service directed graph corresponds to one piece of service information, and a weight value is set between every two nodes connected through a directed line; matching the service fault information in a service directed graph to obtain a target node matched with the service fault information; determining at least one path taking the target node as an initial node; and based on the at least one path, generating service fault reason information corresponding to the service fault information. According to the embodiment, the service fault reason information can be determined more accurately.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

Troubleshooting method and device

ActiveCN107528705BExclude in timeImprove troubleshooting efficiencyData switching networksIntelligent robotsReal-time computing

The invention discloses a fault processing method. The fault processing method includes: collecting preset judgment information based on a target device, and acquiring fault judgment conditions corresponding to the target device; information to determine whether the target device is faulty; when the target device is faulty, based on the fault information of the target device, a corresponding fault handling instruction is sent to the intelligent robot at the fault site, and the intelligent robot executes the fault processing instruction corresponding to the fault Resume operations to troubleshoot the target device. The invention also discloses a fault processing device. The invention can improve the failure handling efficiency of equipment.

Owner:ZTE CORP

elevator control system

The invention discloses an elevator control system, which comprises a main board and a plurality of call panels, each floor's call panel is equipped with an emergency stop indicator light, a door opening indicator light and a car position indicator light, the main board includes a fault detection module, Microprocessor, storage chip and power supply module, after the fault detection module detects that the elevator is faulty, it converts the fault information into a fault code and sends it to the microprocessor, and the microprocessor transmits the fault code respectively through the RS485 or CAN bus communication network It is sent to the call panel of each floor for display. When the fault detection module detects that the elevator is not faulty, the microprocessor sends the floor display and up and down direction information to the call panel of each floor for display through the RS485 communication network or CAN bus network. The emergency stop indicator light, the door open indicator light and the car position indicator light are all connected with the microprocessor. The invention brings great convenience to the elimination of elevator faults, and is beneficial for maintenance personnel to eliminate elevator faults in time.

Owner:石家庄松达电子科技有限公司

An ornamental pool for cleaning floating objects

ActiveCN111576603BEasy to cleanReal-time processingWater cleaningSewerage structuresElectric machineryDrive motor

The invention discloses an ornamental pond which is convenient for cleaning floating objects, and relates to the technical field of ornamental ponds. The ornamental pool for easy cleaning of floating objects includes a base and a pool. The pool is fixedly installed in the middle of the top of the base. Limiting plates are fixedly installed on both sides of the inside of the pool. The limiting plate is in the shape of a rectangular plate. The length is the same as the width inside the pool. In the present invention, the drive motor inside the decoration box is started to drive the drive shaft to rotate at a low speed, so that the shaft plate slowly pushes the inside of the pool at a low speed. The water flow fluctuates through the through groove on the isolation plate, so that the surface of the water flow oscillates, so that the floating objects on the surface of the water flow move to the corresponding position of the rubber plate through the shock waves, so that the water waves generated by the water flow shock drive the floating objects It falls into the gap between the limiting plate and the pool, so as to achieve the effect of real-time treatment of floating objects on the ornamental pool.

Owner:WUCHANG UNIV OF TECH

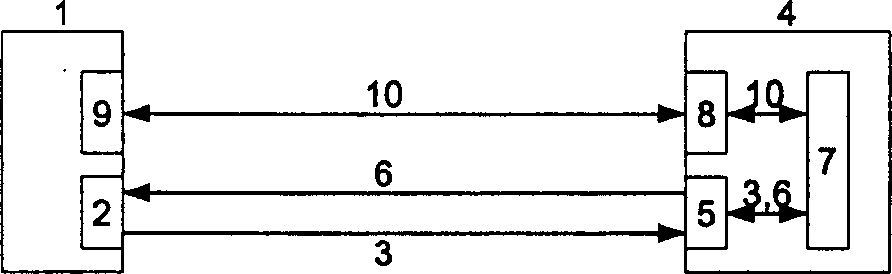

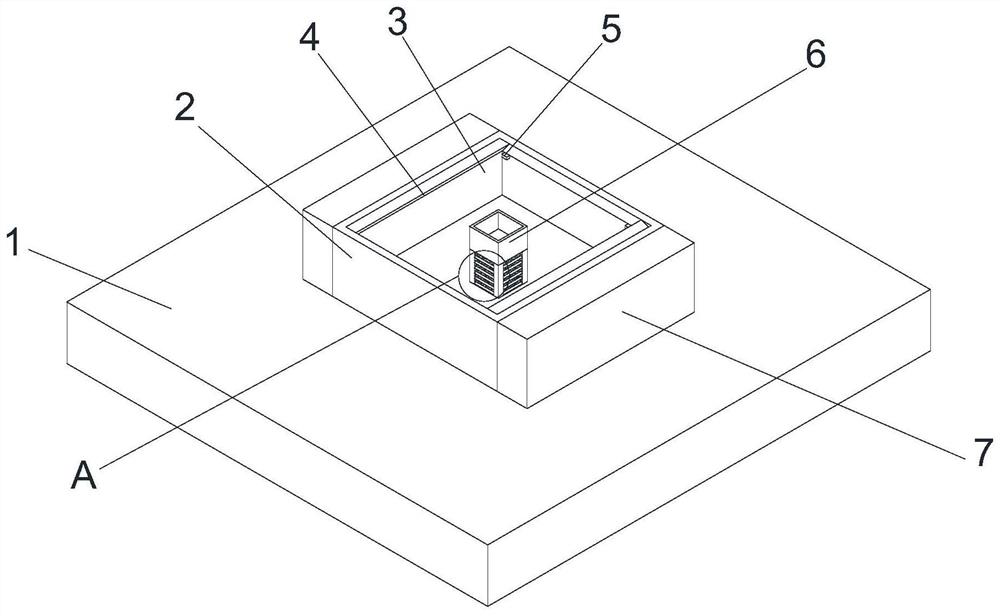

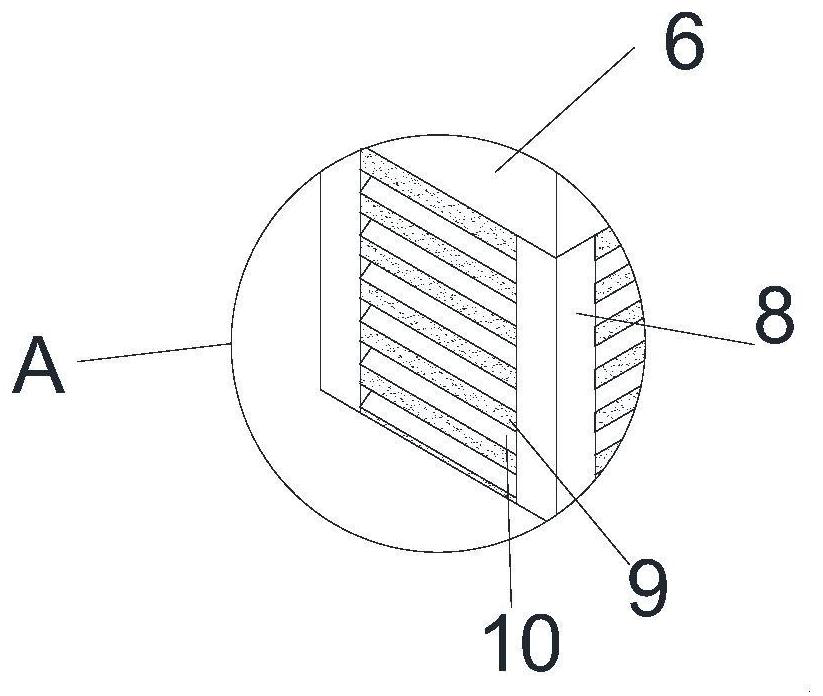

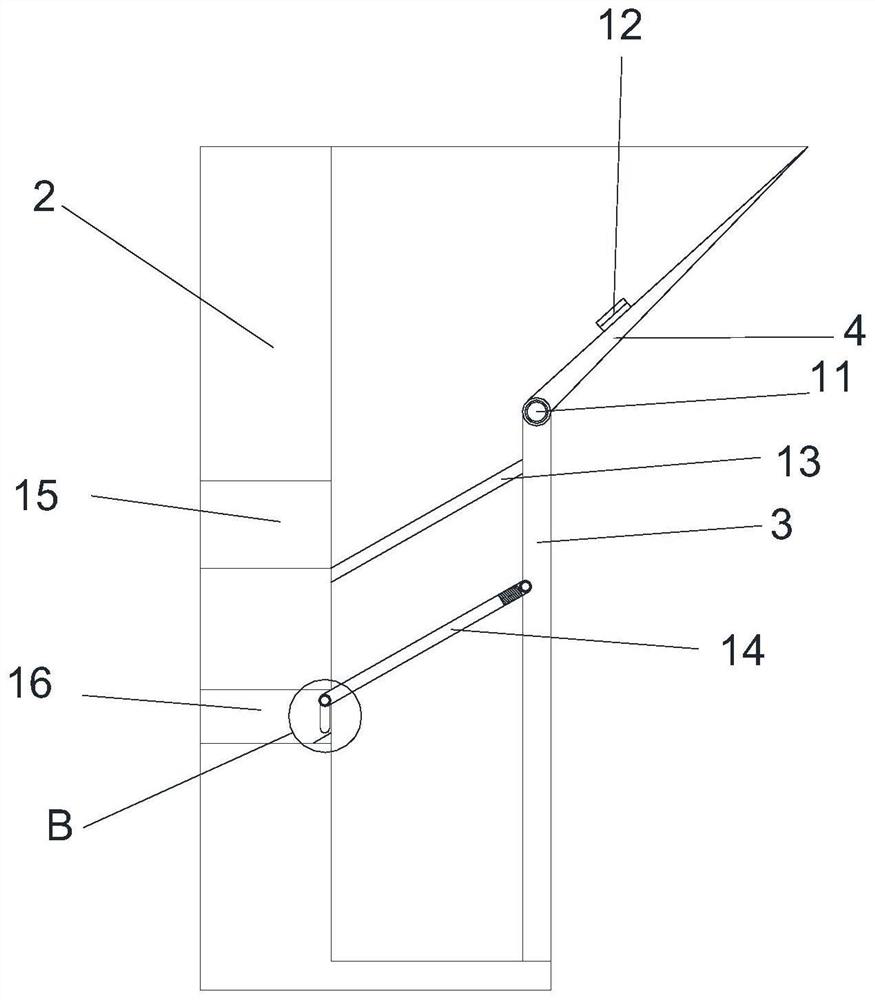

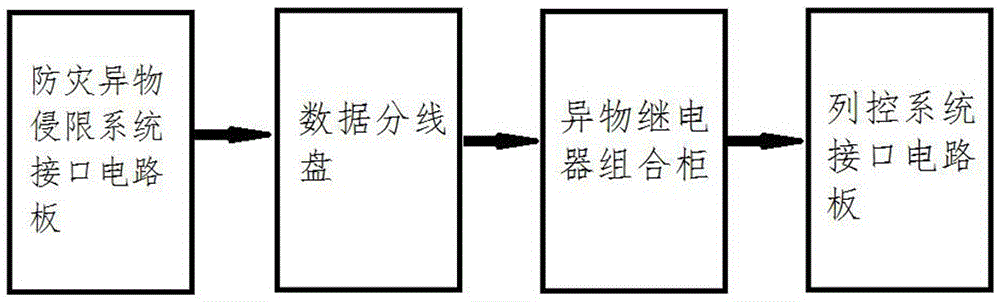

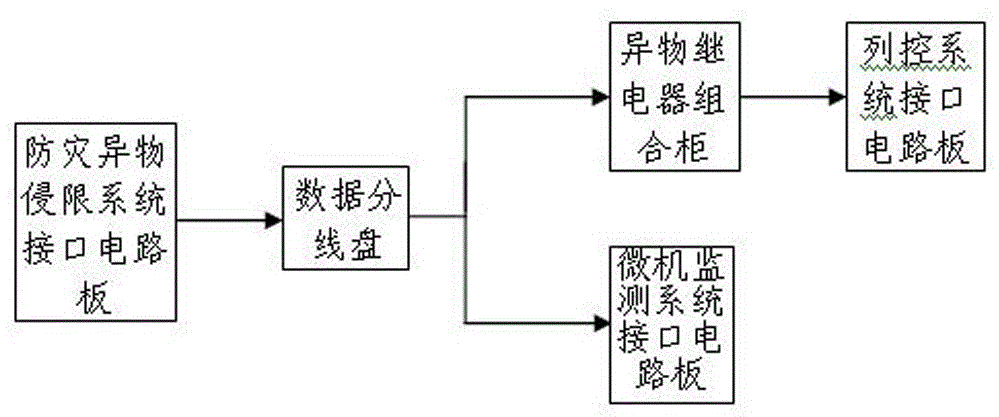

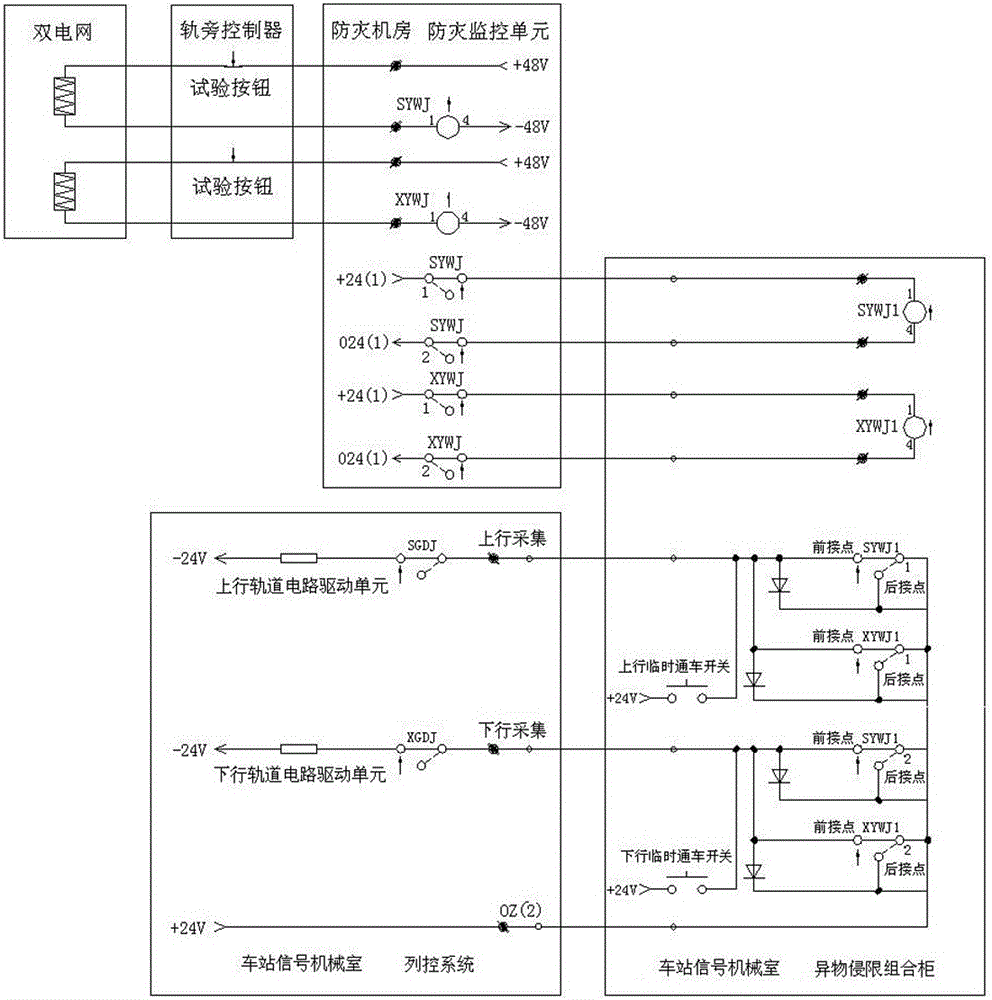

The interface structure and method between the high-speed rail disaster prevention and foreign object intrusion control system and the signal system

ActiveCN105172843BFix false positivesGuaranteed operational safetyRailway signalling and safetyForeign matterMicrocomputer

The invention relates to the field of signal systems of high-speed rails, in particular to an interface structure between a disaster-preventing foreign matter invasion limiting system and a signal system of a high-speed rail and a method of the interface structure. The interface structure is characterized in that a set of acquisition lines are added to rear contacts of an uplink foreign matter invasion limiting relay and a downlink foreign matter invasion limiting relay and connected to an interface circuit board of a microcomputer monitoring system of a signal computer room; inspection relays, an uplink foreign matter invasion limiting relay front-contact alarm lamp and a downlink foreign matter invasion limiting relay front-contact alarm lamp are additionally arranged on the interface circuit board of the microcomputer monitoring system; a set of alarm circuit is formed by the contacts of the uplink inspection relay and the downlink inspection relay, the uplink foreign matter invasion limiting relay front-contact alarm lamp and the downlink foreign matter invasion limiting relay front-contact alarm lamp, and the circuit is used for comparing information acquired by the rear contacts of the uplink foreign matter invasion limiting relay and the downlink foreign matter invasion limiting relay with information sent by field monitoring points and giving an alarm. The interface structure between the disaster-preventing foreign matter invasion limiting system and the signal system of the high-speed rail and the method of the interface structure have the advantages that the problem of misinformation caused after the disaster-preventing foreign matter invasion limiting system of the high-speed rail is connected to an interface of a train control system is solved, the reason for faults can be judged out by electric service maintenance personnel by means of a microcomputer monitoring system analysis technique, and fault removal time is shortened.

Owner:中铁二十四局集团上海电务电化有限公司 +1

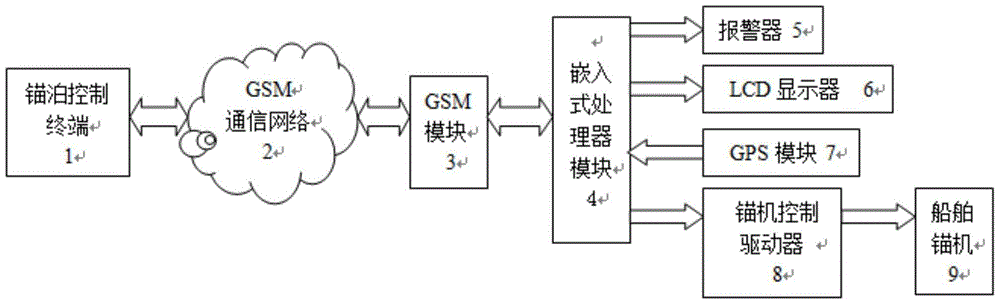

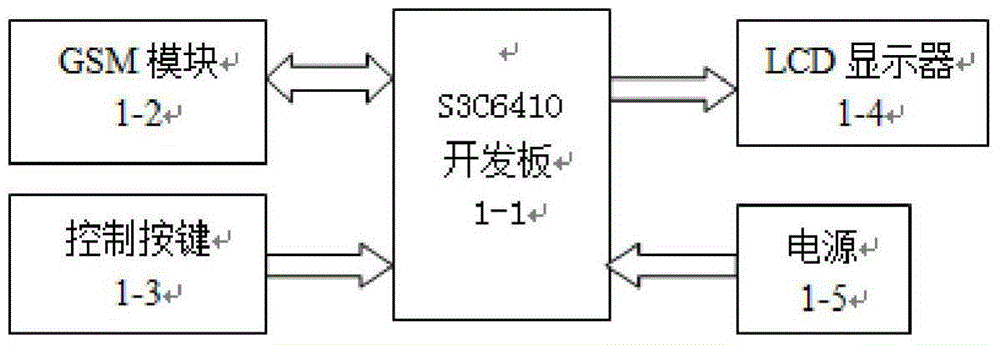

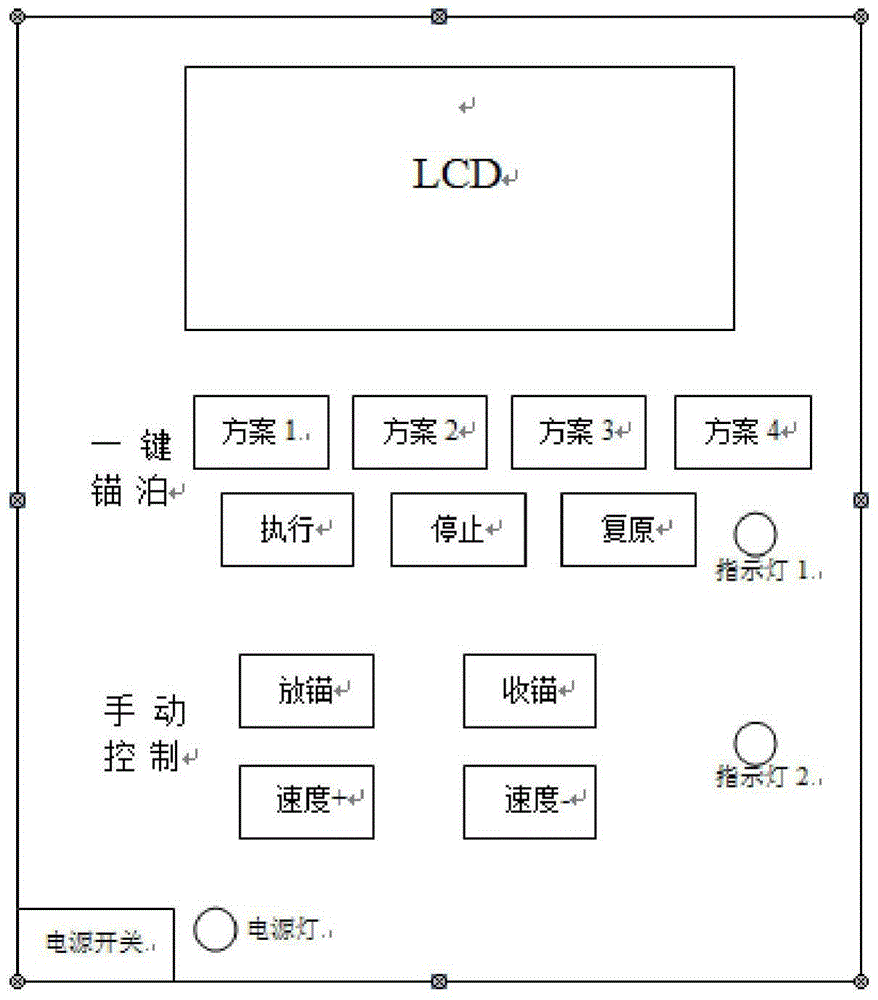

A ship anchor remote alarm control device and method

ActiveCN104485024BEasy to operateShorten the timeMarine craft traffic controlMachine controlMarine engineering

The invention discloses a ship dragging remote alarm control device. The ship dragging remote alarm control device comprises an anchoring control terminal, an embedded processor module, a first GSM (Global System for Mobile) module, a GPS (Global Positioning System) module, a first LCD, an alarm apparatus, an anchor machine control driver and a ship anchor machine, wherein the GPS module, the first GSM module, the first LCD, the alarm apparatus and the anchor machine control driver are connected with the embedded processor module; the anchor machine control driver is connected with the anchor machine. The anchoring control terminal is connected with the first GSM module on a ship through a GSM communication network. The alarm control device disclosed by the invention has an active detection effect for ship dragging, remote anchoring operation can be realized through the anchoring control terminal, the restriction of communication distance is broken by utilizing the GSM network, the anchoring control terminal can bring convenience for operators by adopting a one-key anchoring mode or a manual control mode, and meanwhile the time for eliminating dragging risks is reduced. The invention further discloses an alarm control method of the ship dragging remote alarm control device.

Owner:江苏金马云物流科技有限公司

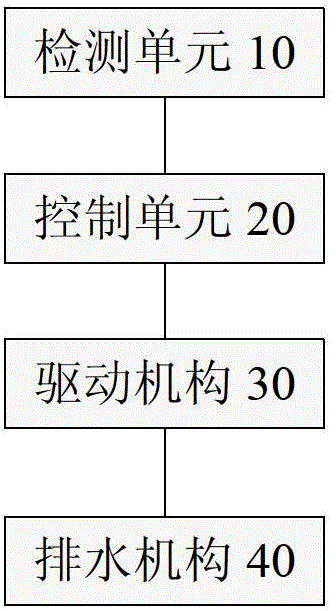

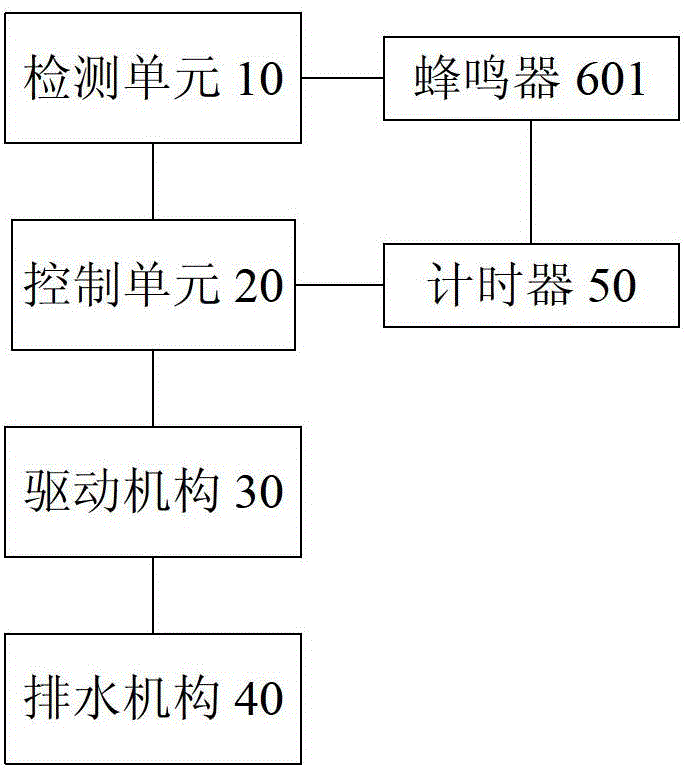

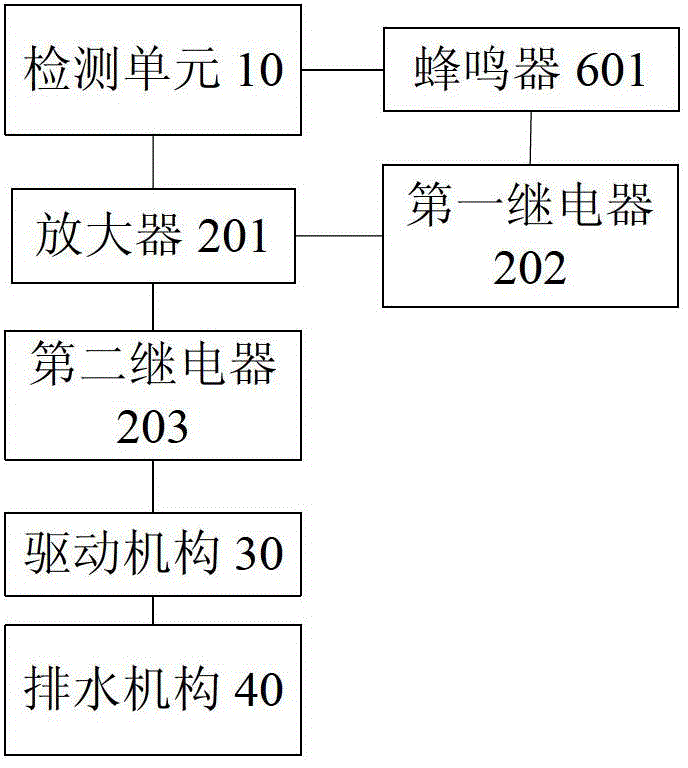

Drainage device for cable interlayer

InactiveCN104375423AExclude in timeProgramme control in sequence/logic controllersEngineeringControl unit

The invention discloses a drainage device for a cable interlayer. The device comprises a detection unit arranged in the cable interlayer to detect whether water is accumulated in the cable interlayer and generate a detection signal when water accumulation is detected, a control unit connected with the detection unit to receive the detection signal from the detection unit, a drainage mechanism, and a driving mechanism connected with the control unit and the drainage mechanism to drive the drainage mechanism to drain accumulated water in the cable interlayer under the control of the control unit. By the adoption of the device, accumulated water in the cable interlayer can be drained in time.

Owner:STATE GRID CORP OF CHINA +1

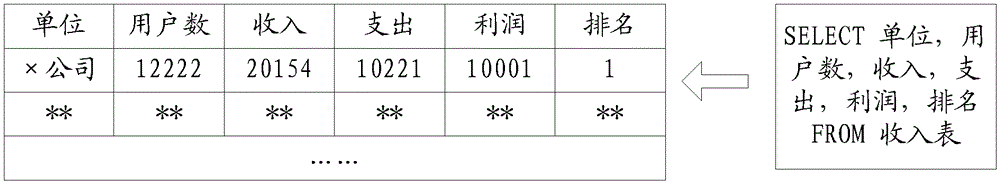

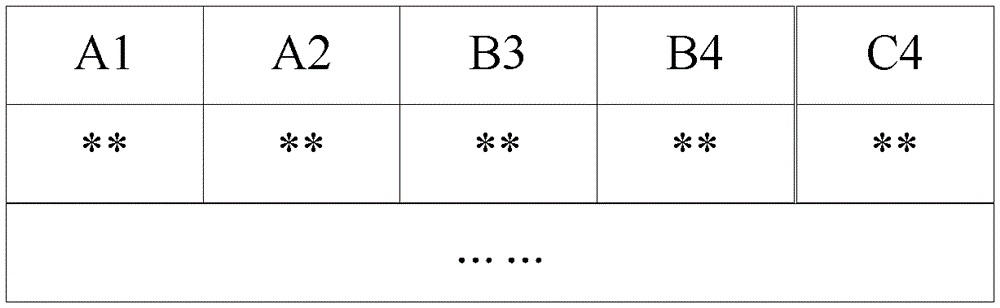

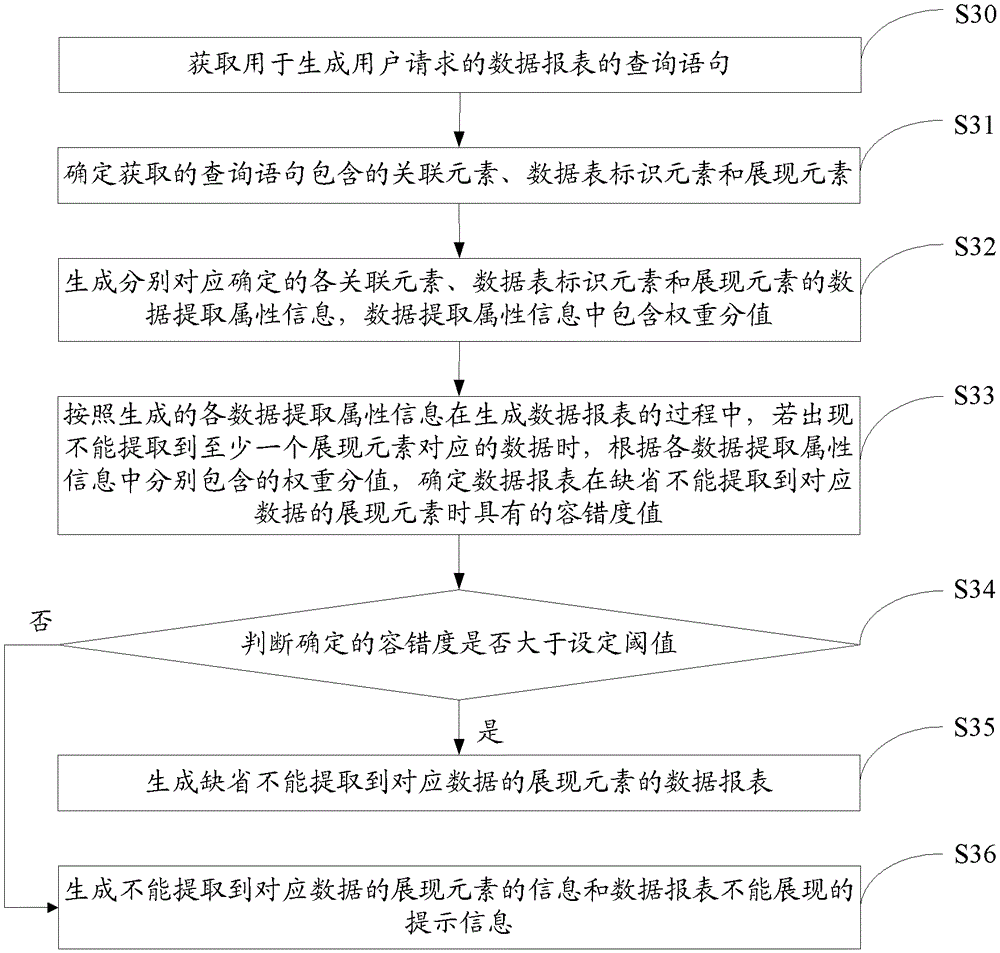

Method and device for generating data report

ActiveCN103198071BExclude in timeAccurate exclusionSpecial data processing applicationsData ingestionFault tolerance

The invention discloses a data report generation method and a device adopting same. The method comprises the following steps: acquiring inquire statements used for generating a data report required by a user; determining associated elements, data sheet identification elements and display elements in the inquire statements; generating data extraction attribute information respectively corresponding to the associated statements, the data sheet identification elements and display elements, wherein the data extraction attribute information contains weighting scores; and if data corresponding to at least one display element can not be extracted in the data report generation processes of all generated data extraction attribute information, according to weighting scores in all data extraction attribute information, when the situation that the fault tolerance is larger than the set threshold when the data report defaults the display element which can not extract the corresponding data is determined, generating a data report of the default display element. According to the scheme, the data report not containing default display elements can be generated, and causes which lead to failures in generating the required data report are immediately and accurately located.

Owner:CHINA MOBILE GROUP SHANDONG

Discharge method of electro-corrosion products in EDM

ActiveCN109175551BGuaranteed stabilityGuaranteed machining dimensional accuracyAcute angleElectrical discharge machining

Owner:ZHONGBEI UNIV

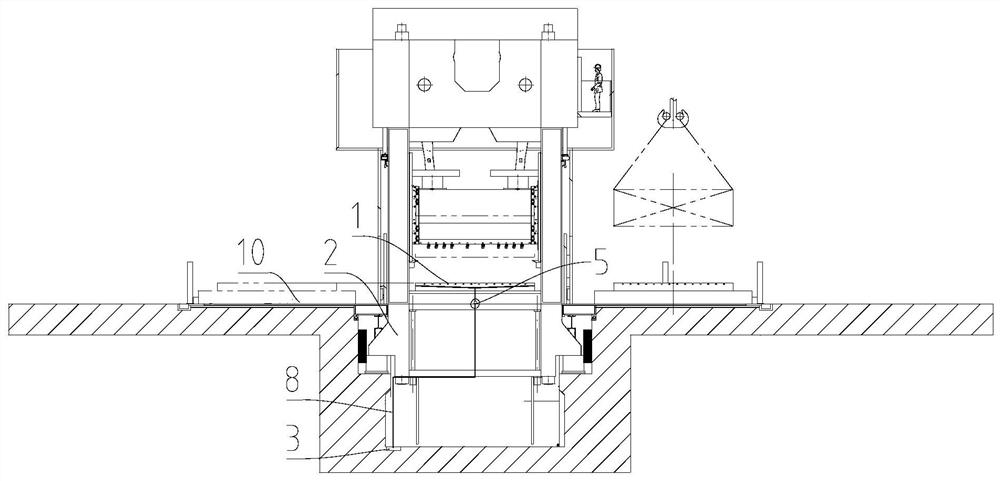

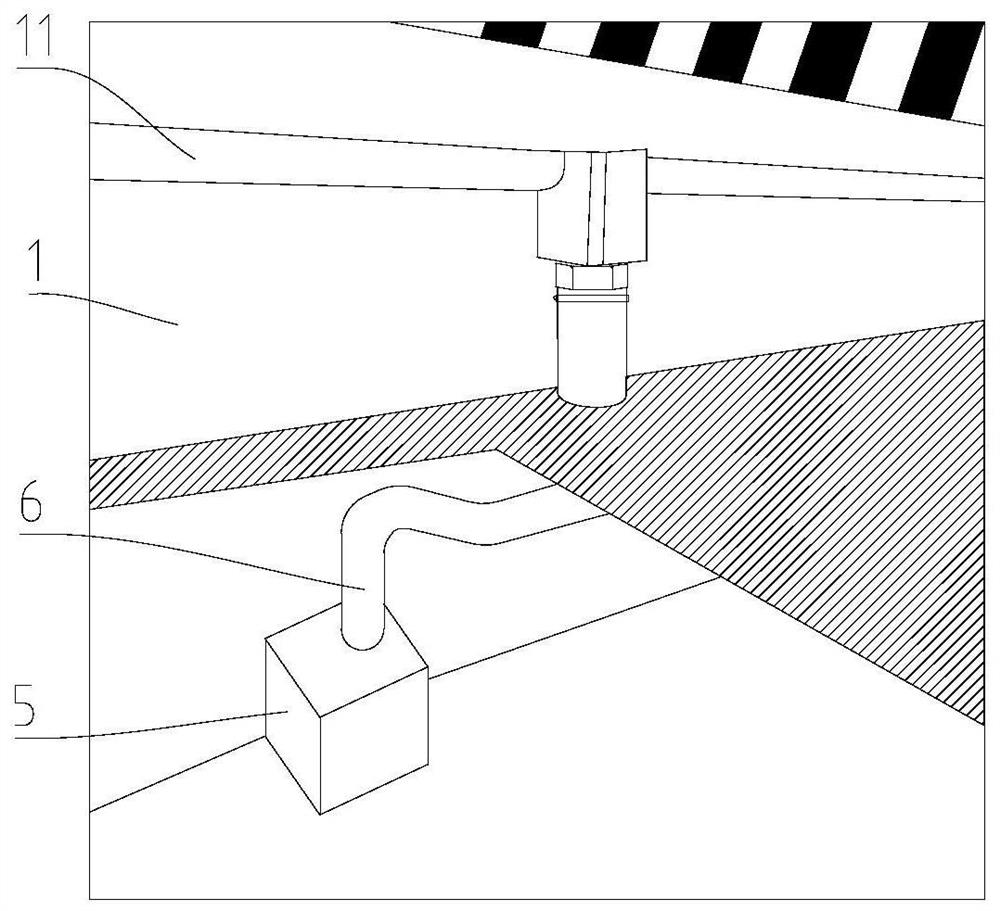

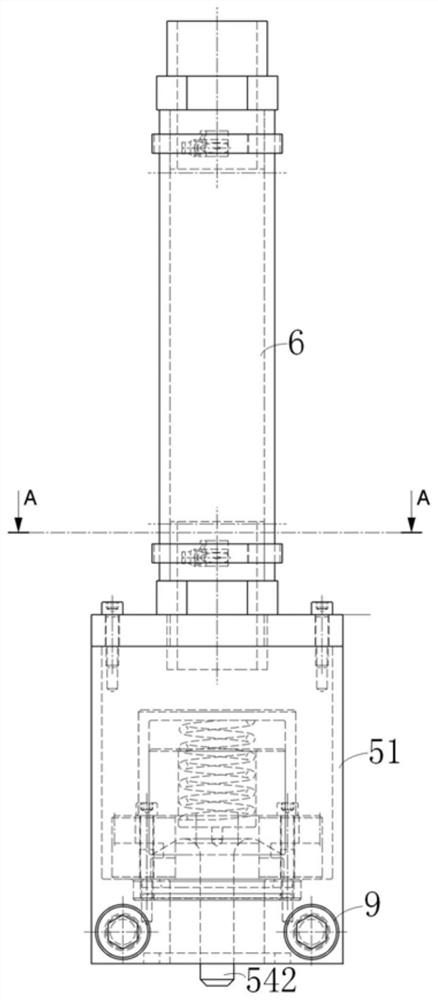

Press oil recovery system and check valve for removing press oil

The disclosure relates to a press dirty oil recovery system and a check valve for removing press dirty oil. The press dirty oil recovery system includes an oil guide groove formed on the workbench of the press, and a The oil storage device connected to the base of the base, and the conduction member that can selectively conduct the oil guide groove and the base. When the worktable and the base are in contact, the conduction member is in an open state, and the dirty oil flows It flows through the conduction piece and the base successively and enters the oil storage device; when the workbench and the base are separated, the conduction piece is in a closed state, and the dirty oil is located in the oil guide groove. The press dirty oil recovery system provided by the present disclosure can automatically and timely remove the dirty oil on the workbench during the working process of the press, eliminating the need for manual processing and avoiding damage to the production environment due to untimely manual processing. Pollution.

Owner:BEIQI FOTON MOTOR CO LTD

Anti-blockage angle conveying belt

InactiveCN107826605AReduce machine idlingReduce cargo accumulationConveyorsConveyor partsEngineeringLateral projection

This solution relates to the field of automation, specifically an anti-blocking angled conveyor belt, including a horizontal conveyor belt channel, characterized in that an oblique conveyor belt channel is connected below the end of the horizontal conveyor belt channel, and a shelf protrusion is provided above the oblique conveyor belt channel , a square peephole is provided between the protrusion of the shelf and the channel of the transverse conveyor belt. This solution has the function of eliminating stuck objects. When there are stuck objects, they can be found through the peephole in time and removed in time to reduce machine idling.

Owner:济宁诺轩矿山设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com