Patents

Literature

78 results about "Tube tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tube tools are tools used to service any tubing (material) in industrial applications including, but not limited to: HVAC or industrial heating and air (hospitals and universities, for example), OEM's(Original equipment manufacturer), defense contractors, the automotive industry, process industries, aluminum smelting facilities, food and sugar production plants, oil refineries, and power plants.

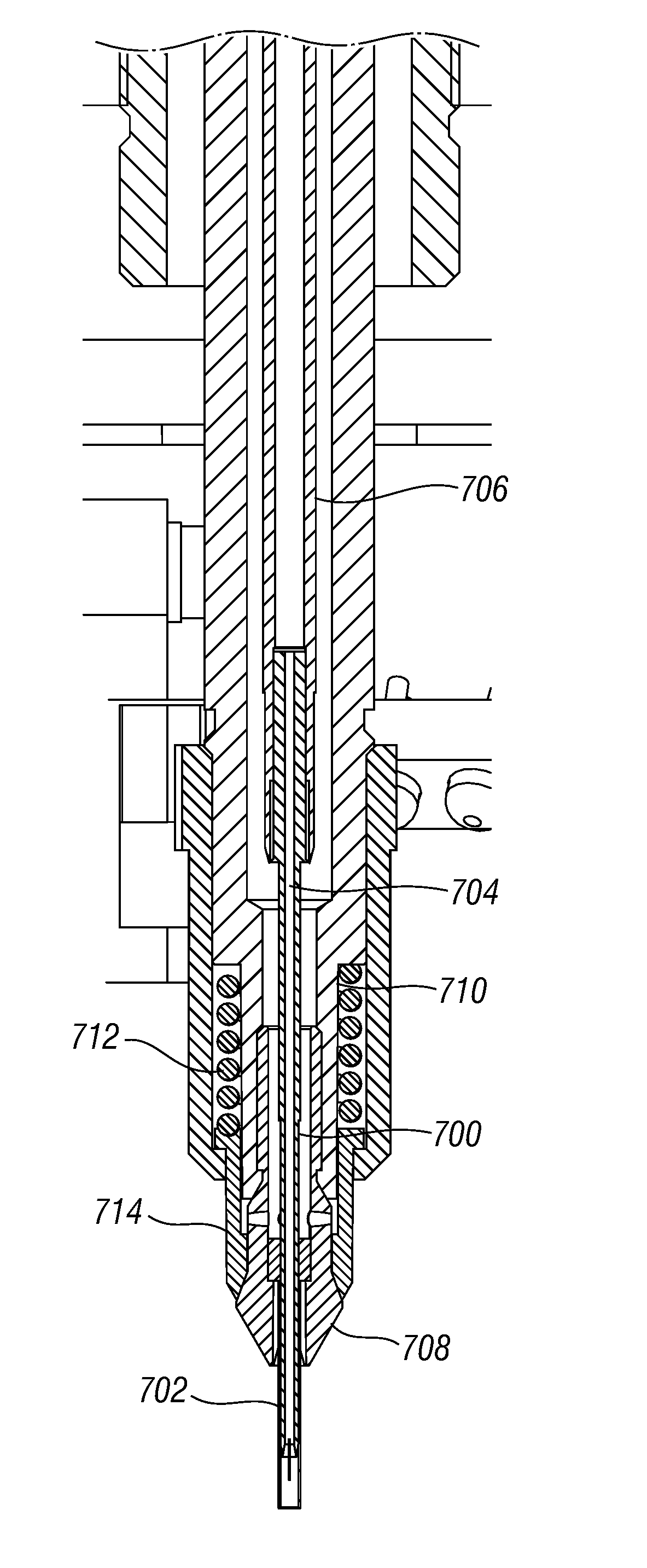

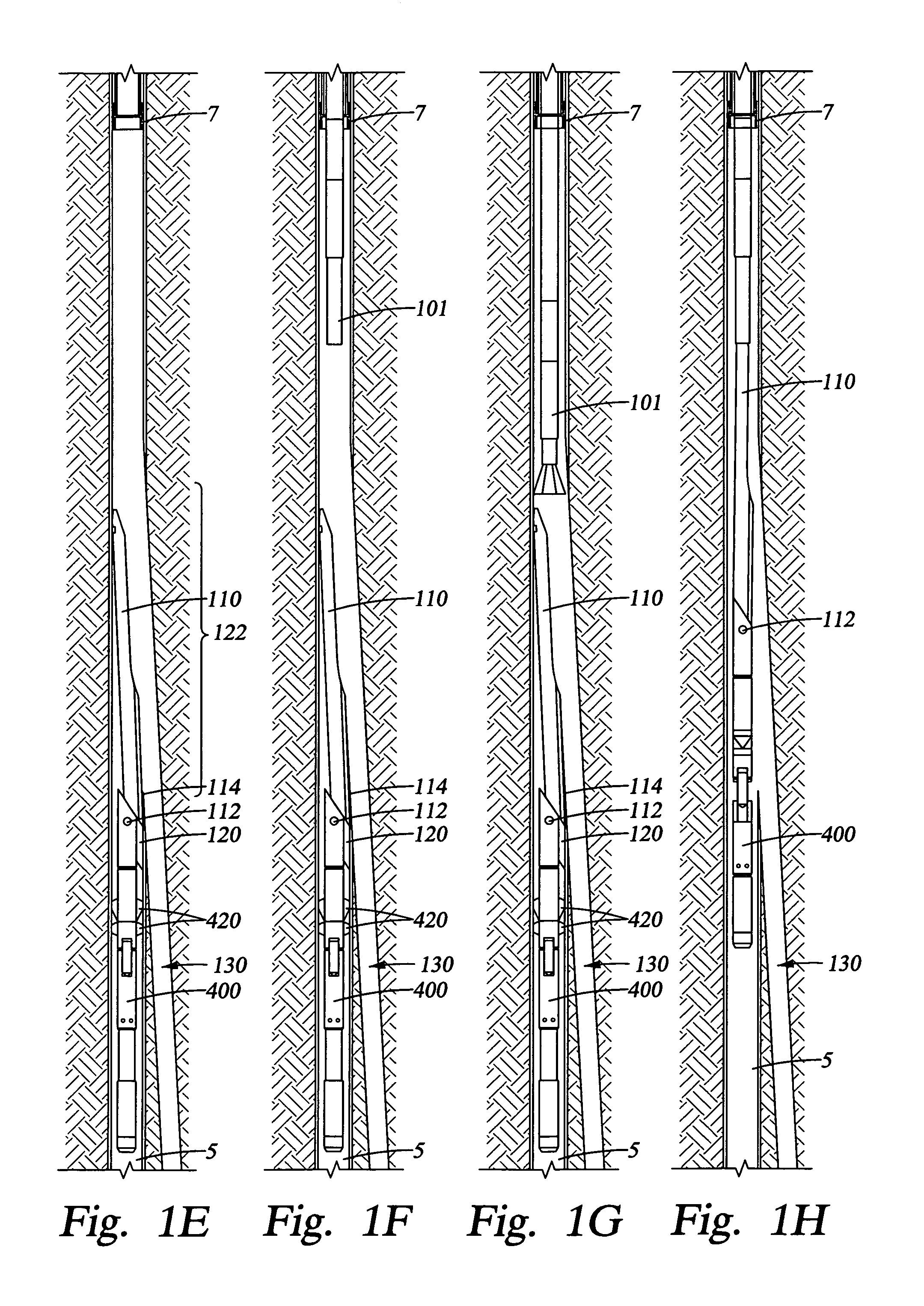

Biological unit removal tools with concentric tubes

ActiveUS20080234699A1Increase productionEffectively penetrate tissueHair-singeingSkin implantsBiological unitBiomedical engineering

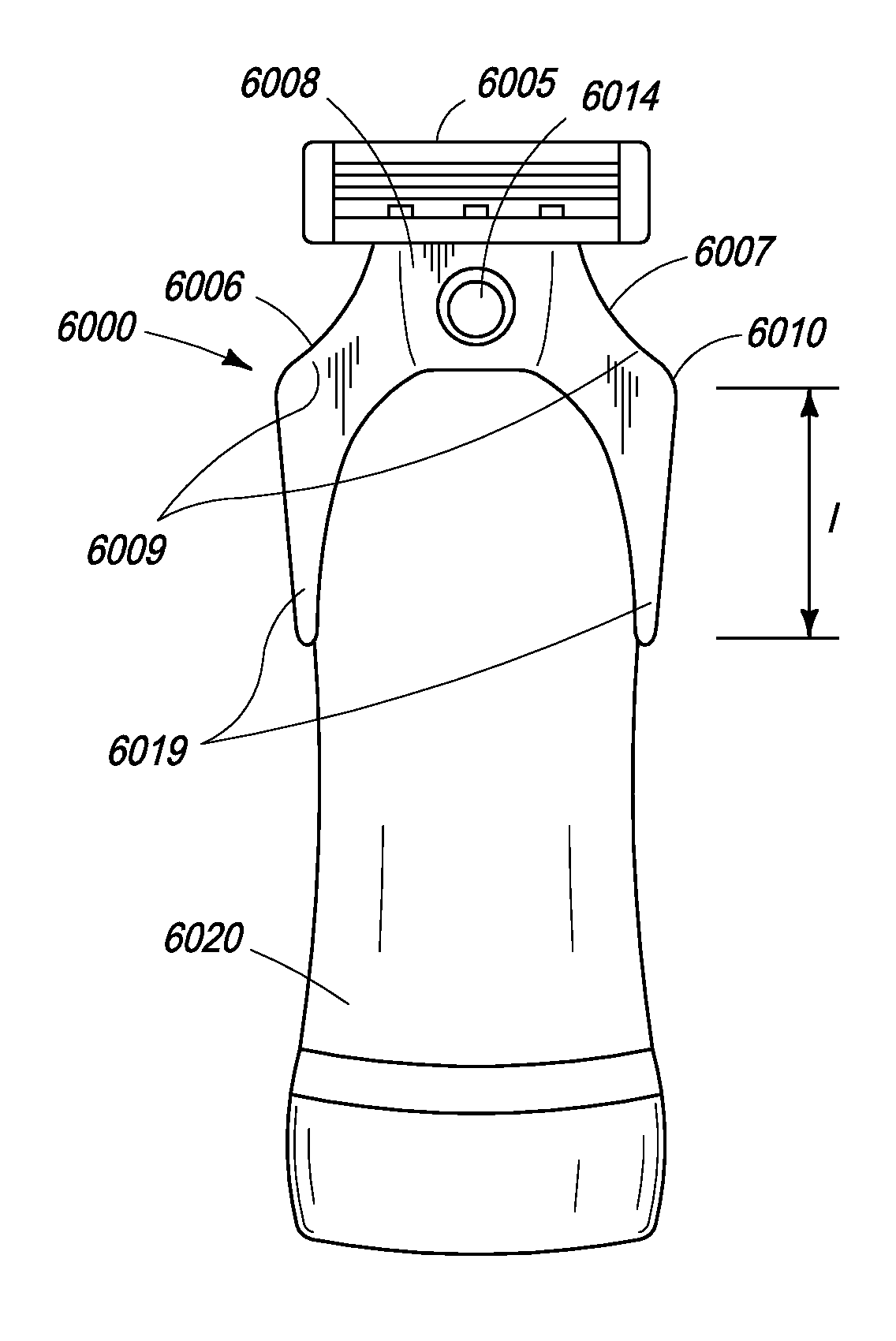

Tools and methods are provided for removing biological units from a body surface utilizing a removal tool. The tools may incorporate retention members and mechanisms configured to impede movement of the biological unit in the direction of a distal end of the tool and to improve retention of the biological unit in the tool. Some of the retention members are stationary and some are movable within the lumen of the biological unit removal tools. The distal tips of the tools are desirably configured to reduce the chance of transection of a biological unit, such as by including both cutting segments and blunt relief segments. A number of dual concentric tube embodiments permit a division of removal functions. Distal fluid or gas delivery may supplement a vacuum in a luminal space to help extract biological units from surrounding tissue.

Owner:VENUS CONCEPT INC

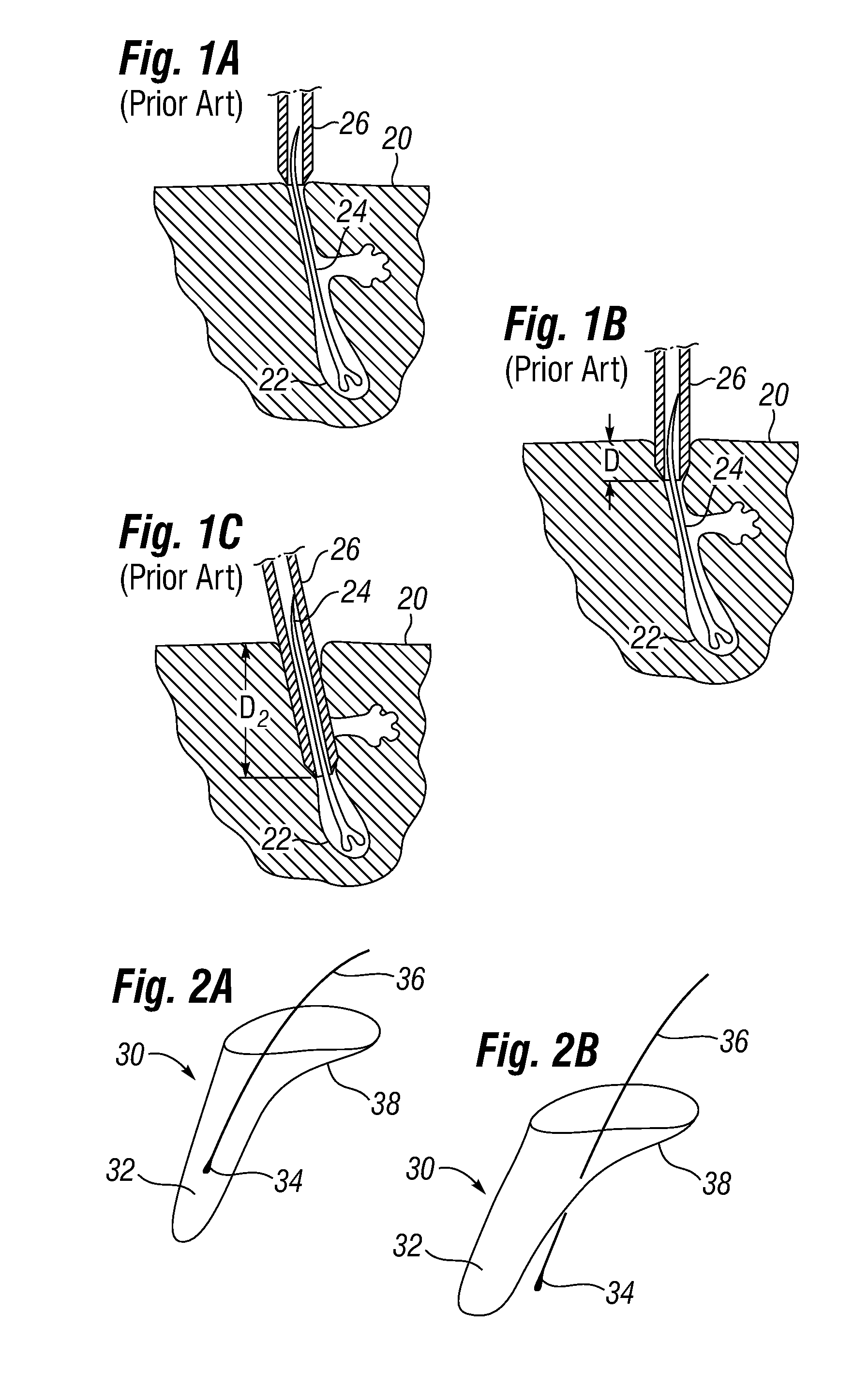

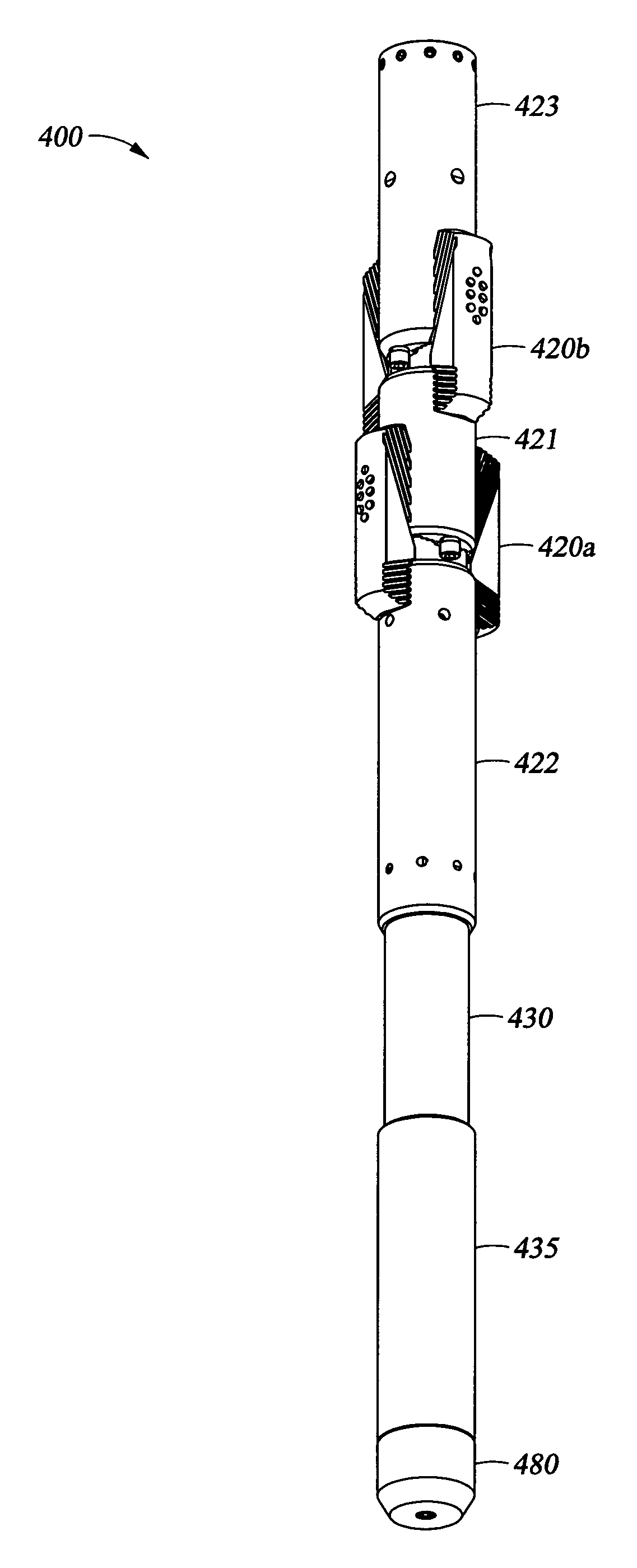

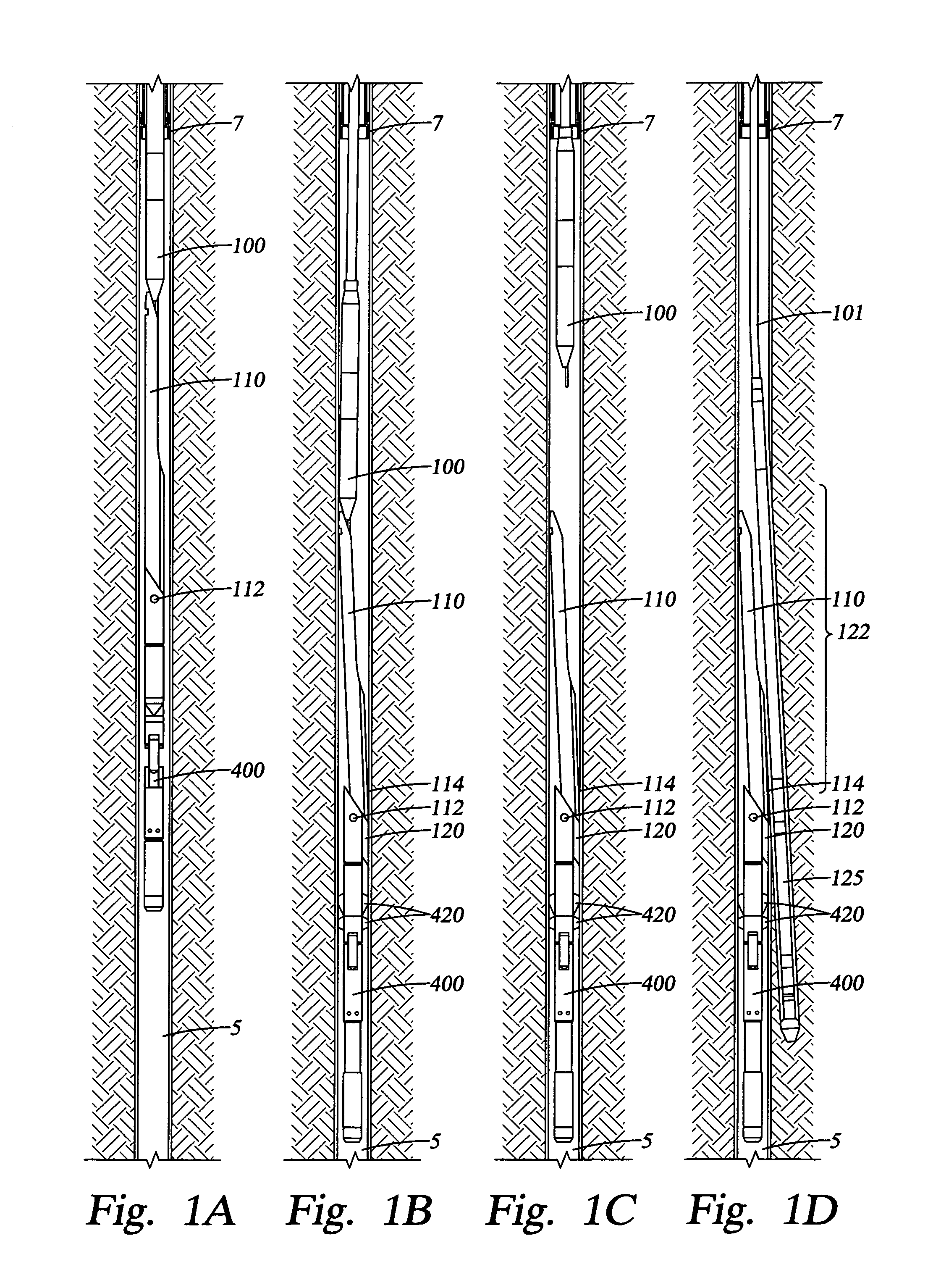

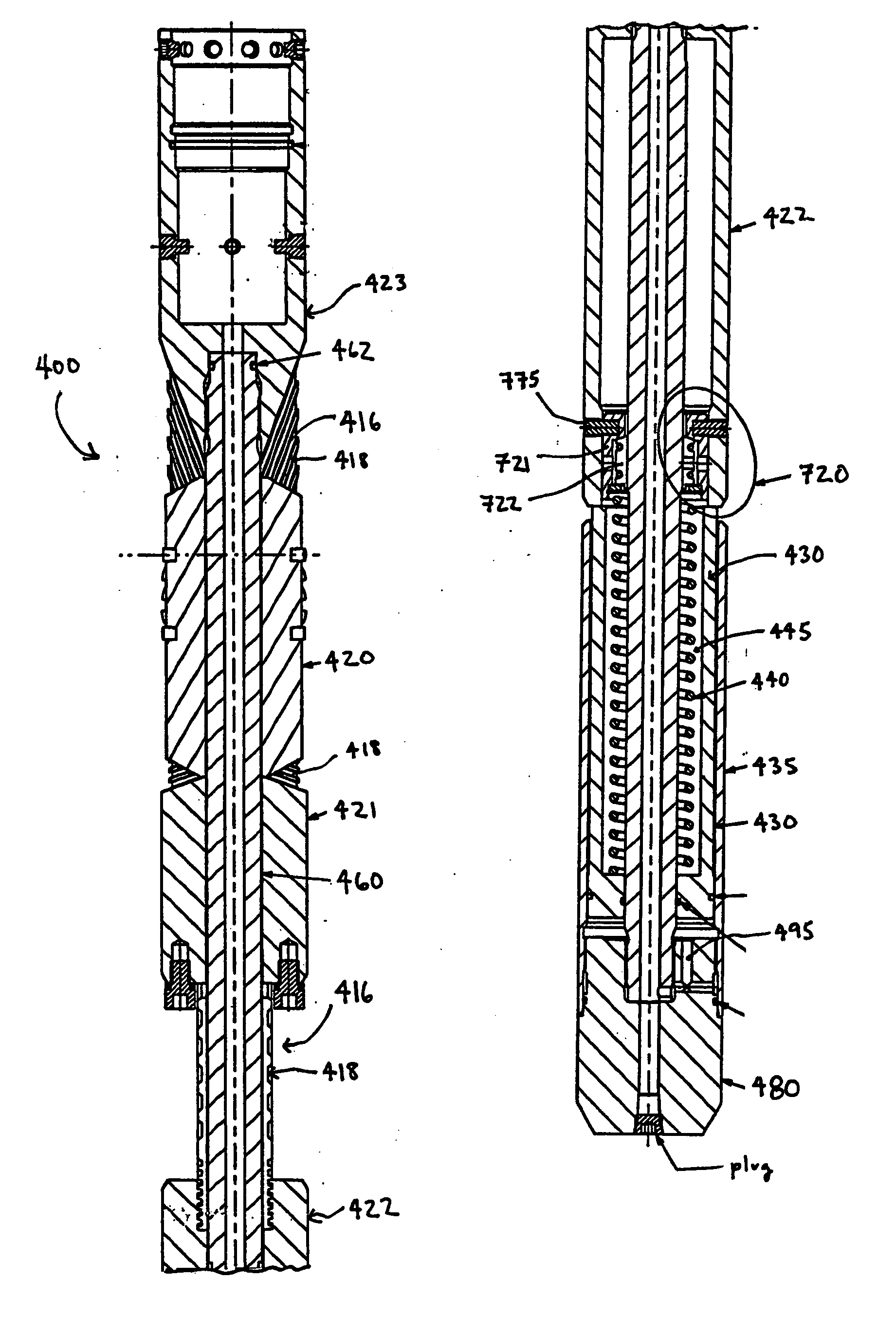

Thru tubing tool and method

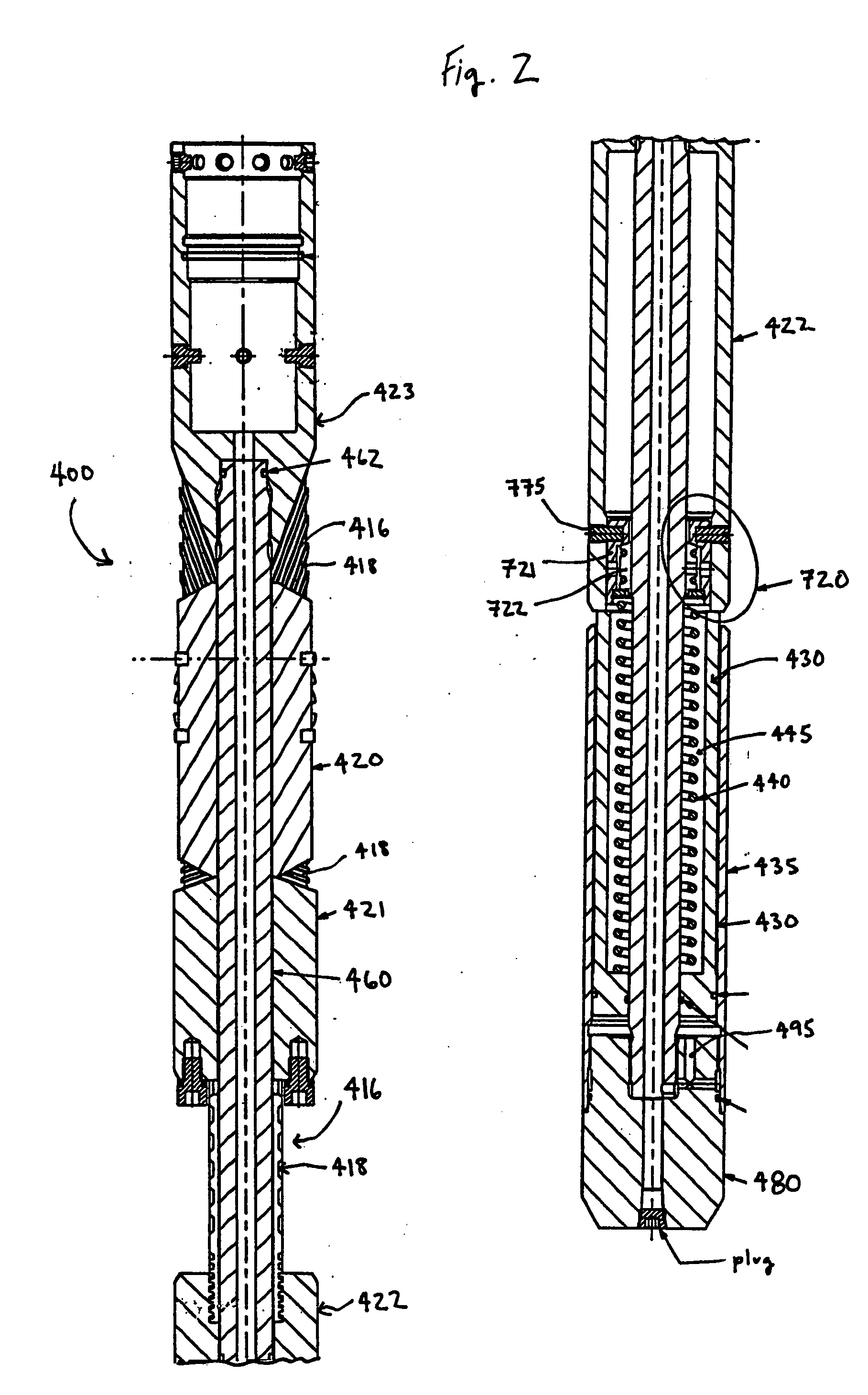

A downhole tool is disclosed that functions as an expandable anchoring tool, capable of passing through a restricted wellbore diameter while in a collapsed position and thereafter translating to an expanded position for grippingly engaging a larger wellbore diameter. An embodiment of the tool includes a body including a plurality of angled channels formed into a wall of the body and a plurality of moveable slips. The plurality of moveable slips translates along the plurality of angled channels between a collapsed position and an expanded position. The slips may include a plurality of extensions corresponding to and engaging the plurality of channels.

Owner:WELLBORE INTEGRITY SOLUTIONS LLC

Tube Tool Device

The present invention is directed to an implement holder and a flexible tube handle that has semi-rigid or flexible walls. The tube handle has a frame adapted to be removably secured to the sealed end of the flexible tube. The frame has an attachment portion and a tool portion. The attachment portion has a first surface adapted to generally encircle and / or grip a portion of the sealed end or body of the flexible tube and the tool portion has a tube holder adapted to receive a tool or having a tool affixed thereto.

Owner:HANDSFREE MARKETING

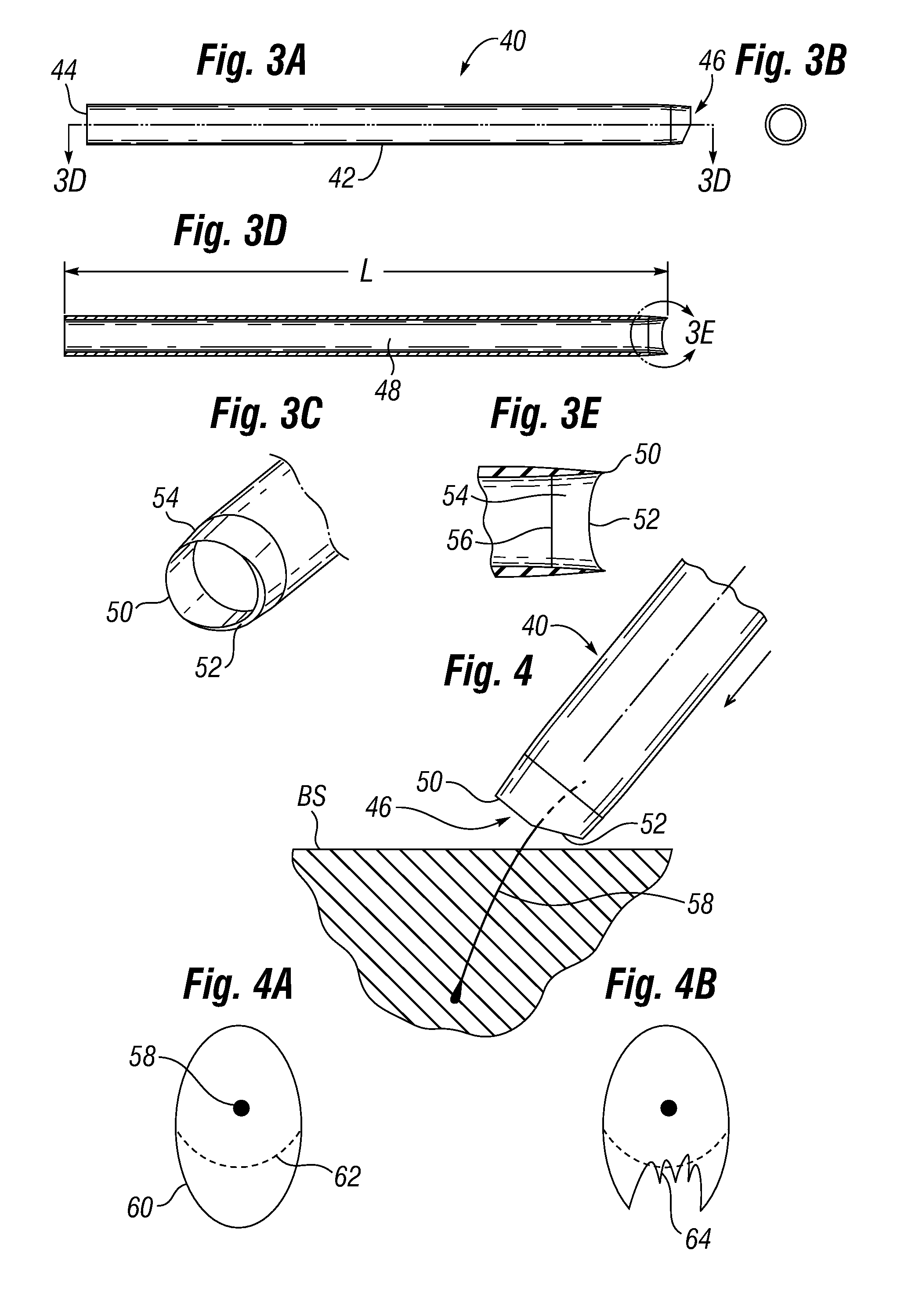

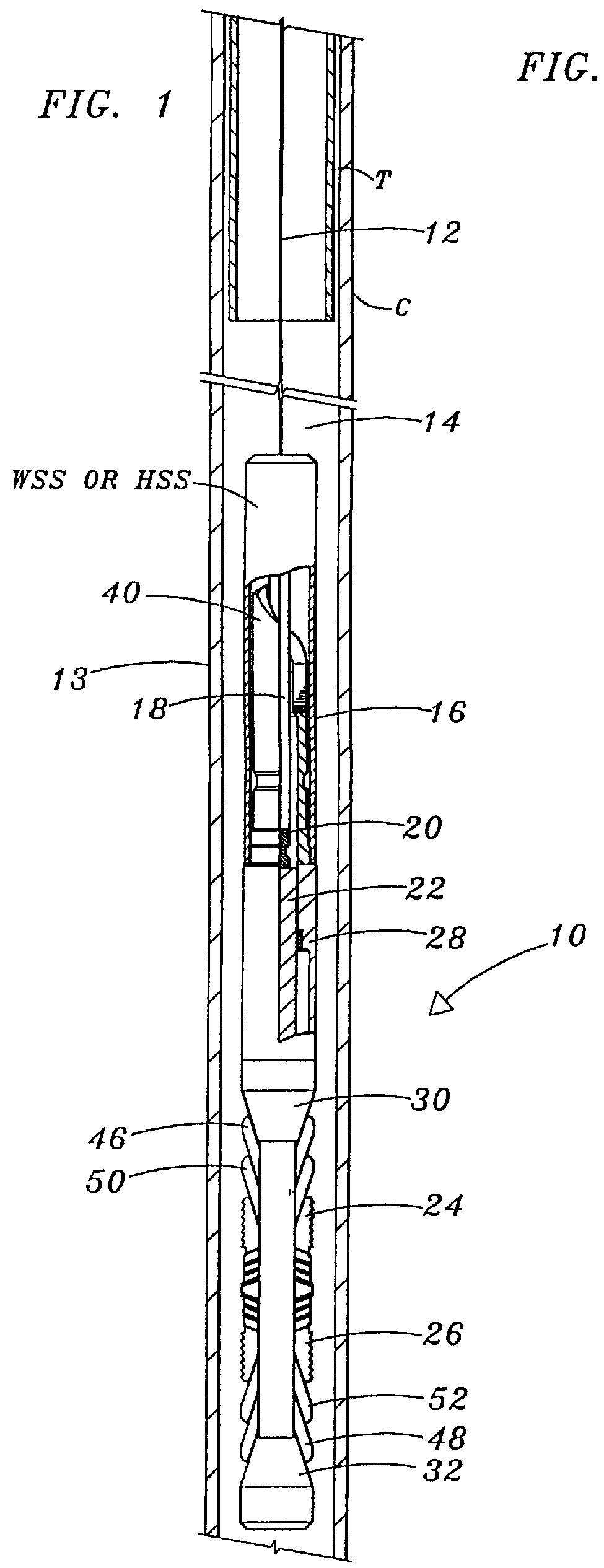

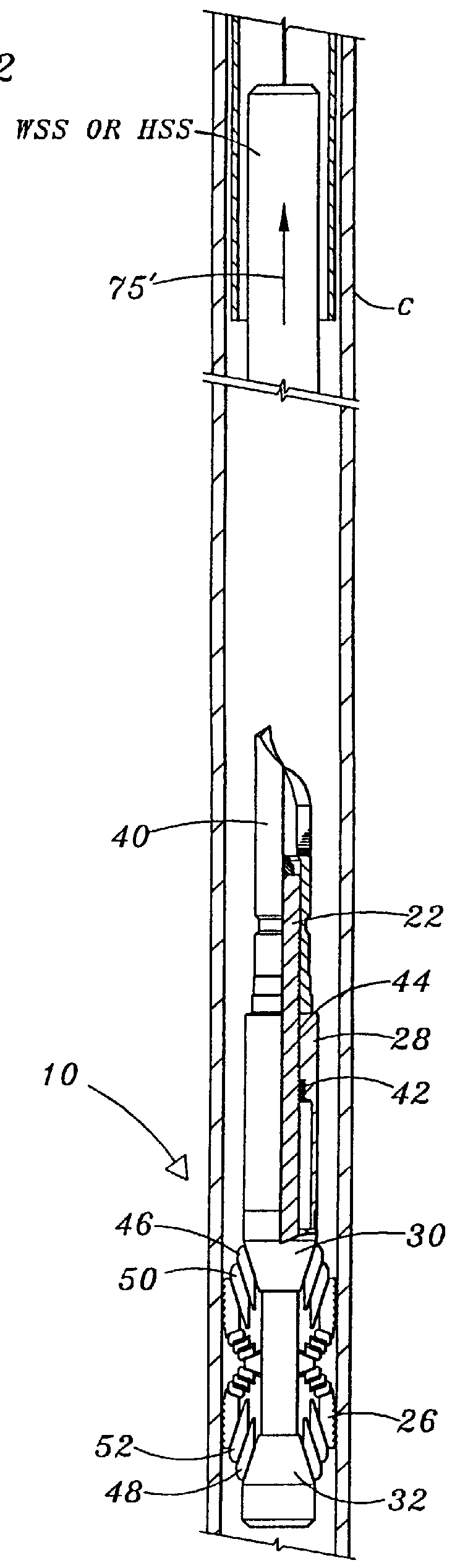

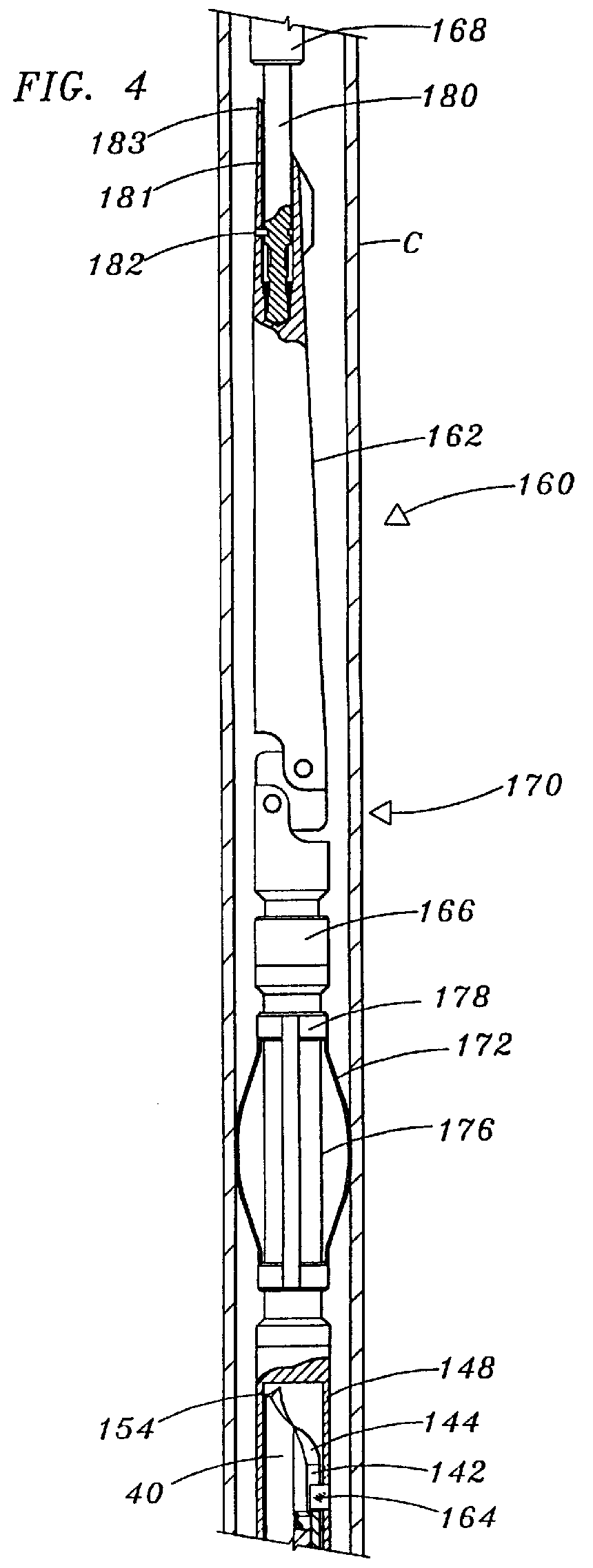

Retrievable through tubing tool and method

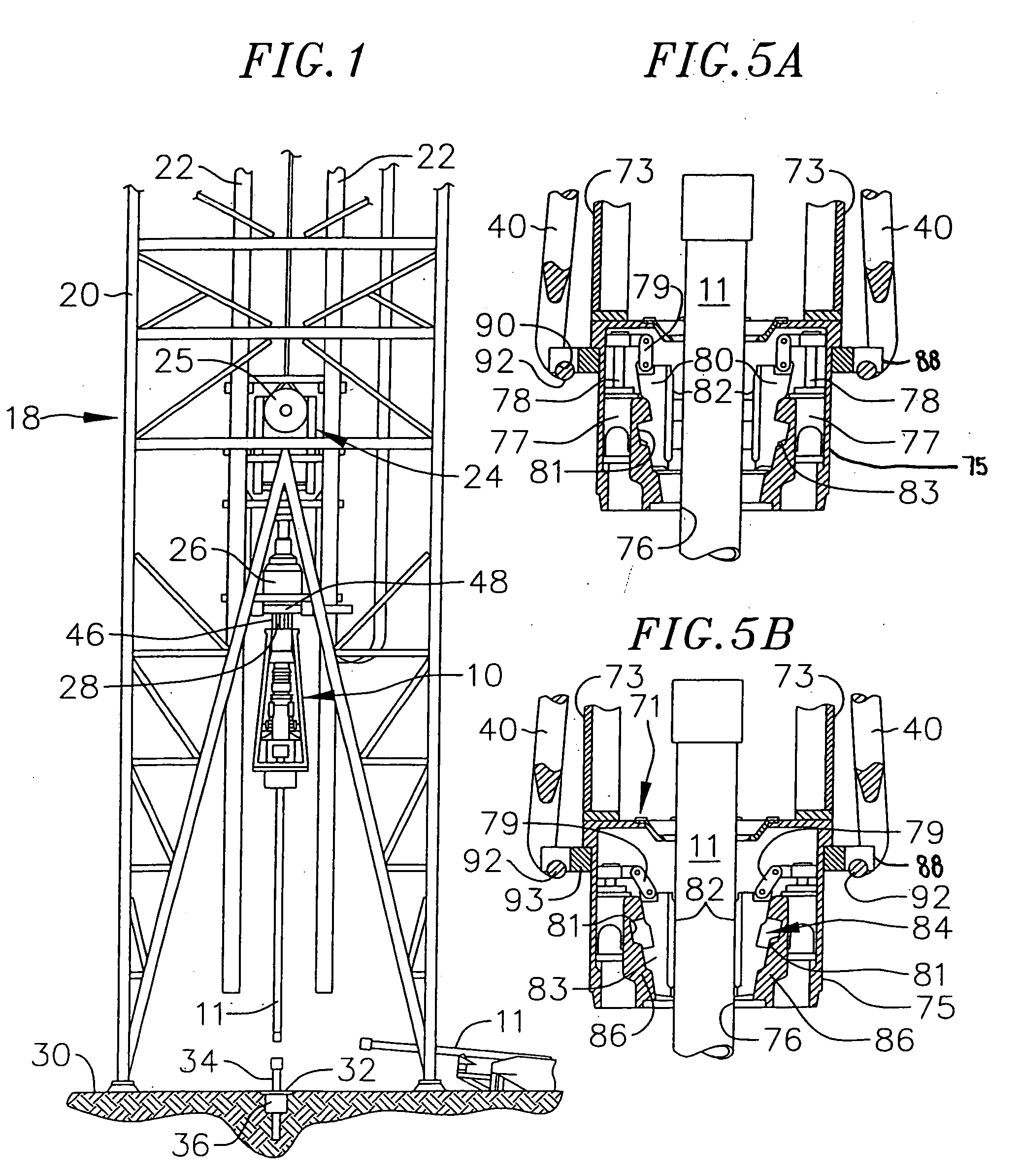

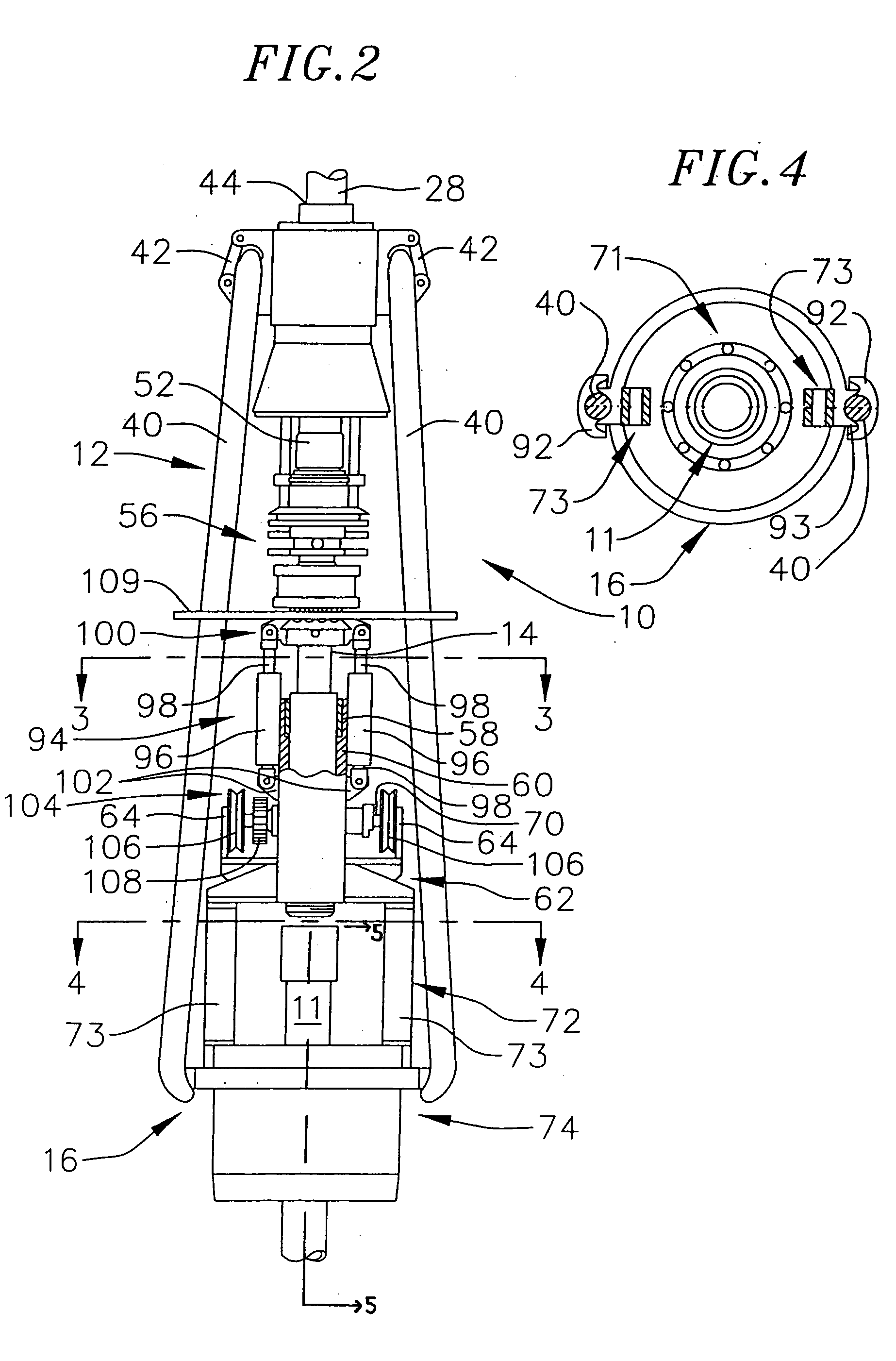

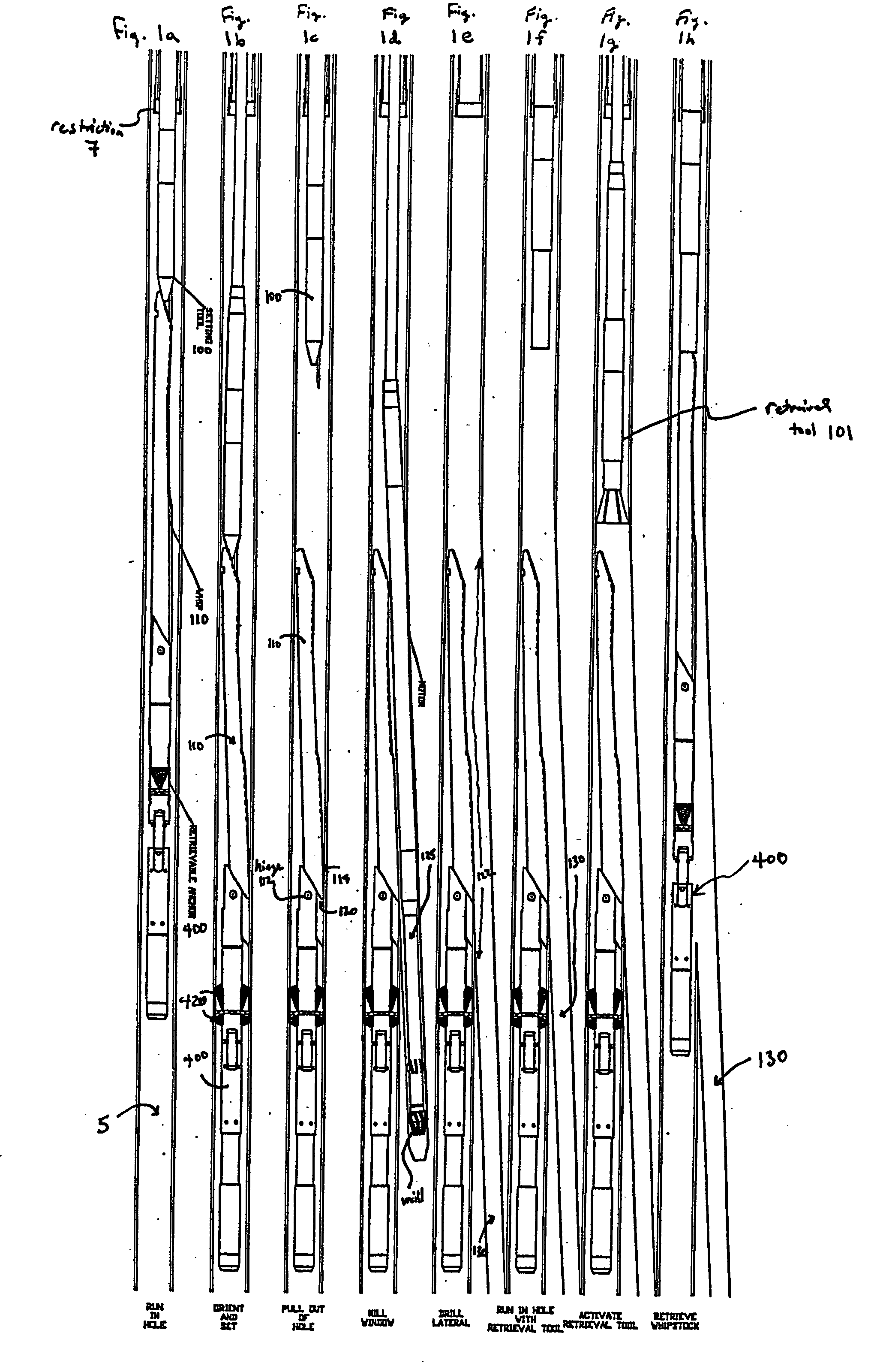

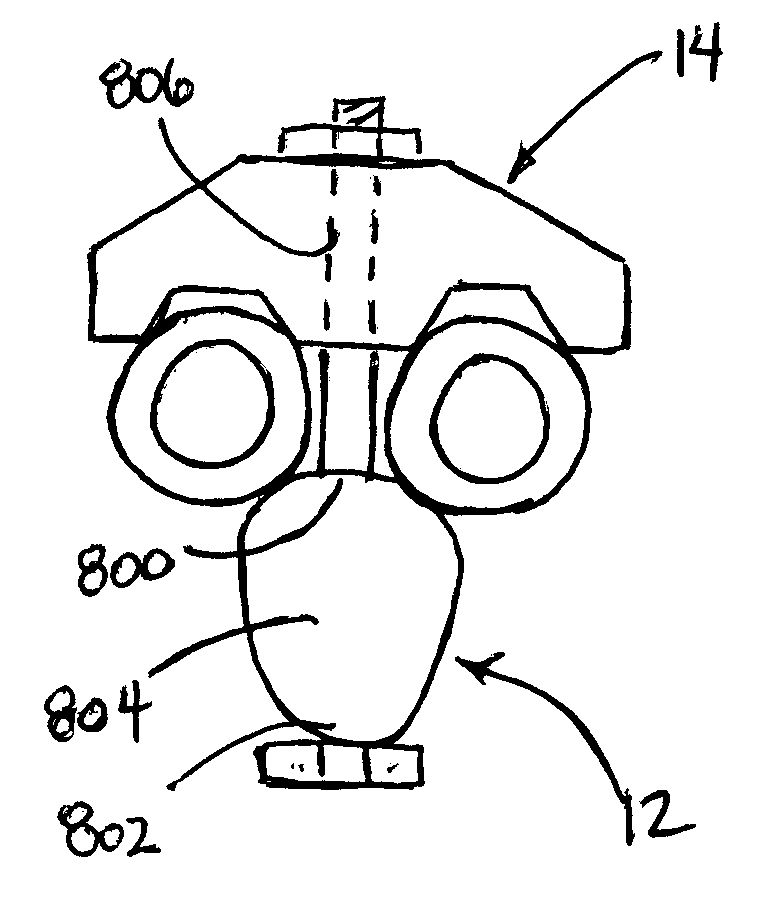

Retrievable window cutting apparatus and method include a whipstock assembly 160 and anchor assembly 10. Whipstock assembly 160 and anchor assembly 10 contract radially inwardly to pass through tubing string T and then expand radially outwardly to operate in casing C. Upper and lower independently moveable slips 24 and 26 engage casing C. Whipstock assembly 160 includes hinge assembly 170 that can be set for operation with a milling assembly 270. Cooperation between shear members in setting tool WSS, working string adaptor 180, hinge assembly 170, and anchor assembly 10 provide for keeping whipstock assembly 160 and anchor assembly 10 in a contracted position for passing downwardly through tubing T, expansion in casing C, and subsequent retrieval through tubing T.

Owner:TIW

Pipe cutting tool

InactiveUS20090049697A1Tube shearing machinesMetal working apparatusEngineeringMechanical engineering

A pipe-cutting tool is provided. This tool includes a body; a track on the middle portion of the body; a first moveable carriage mounted on the track, wherein the first carriage includes first and second rollers mounted therein; a handle mounted in the rear portion of the body, wherein the handle is connected to the first moveable carriage; a second moveable carriage slidably mounted on the track, wherein the second moveable carriage further includes a rotatable cutting blade mounted therein; a carriage stop mounted on or formed integrally with on the front portion of the body, wherein the carriage stop is adapted to receive therein a portion of the second moveable carriage; and a biasing member mounted between the carriage stop and the second moveable carriage, wherein the biasing member exerts substantially continuous force on the second moveable carriage for urging the rotatable cutting blade against a pipe being cut.

Owner:WILLIAMS DENNIS R

Pipe running tool having a cement path

An oil and gas well drilling system is provided that includes a top drive assembly having an output shaft; and a pipe running tool having a top drive extension shaft connected to the top drive output shaft and engageable with a pipe string to transmit translational and rotational forces from the top drive assembly to the pipe string, wherein the pipe running tool further includes a cementing pipe connected to the top drive extension shaft and having a fluid passageway which receives cement during a cementing operation.

Owner:VARCO I P INC

Tube tool device

The present invention is directed to an implement holder and a flexible tube handle that has semi-rigid or flexible walls. The tube handle has a frame adapted to be removably secured to the sealed end of the flexible tube. The frame has an attachment portion and a tool portion. The attachment portion has a first surface adapted to generally encircle and / or grip a portion of the sealed end or body of the flexible tube and the tool portion has a tube holder adapted to receive a tool or having a tool affixed thereto.

Owner:HANDSFREE MARKETING

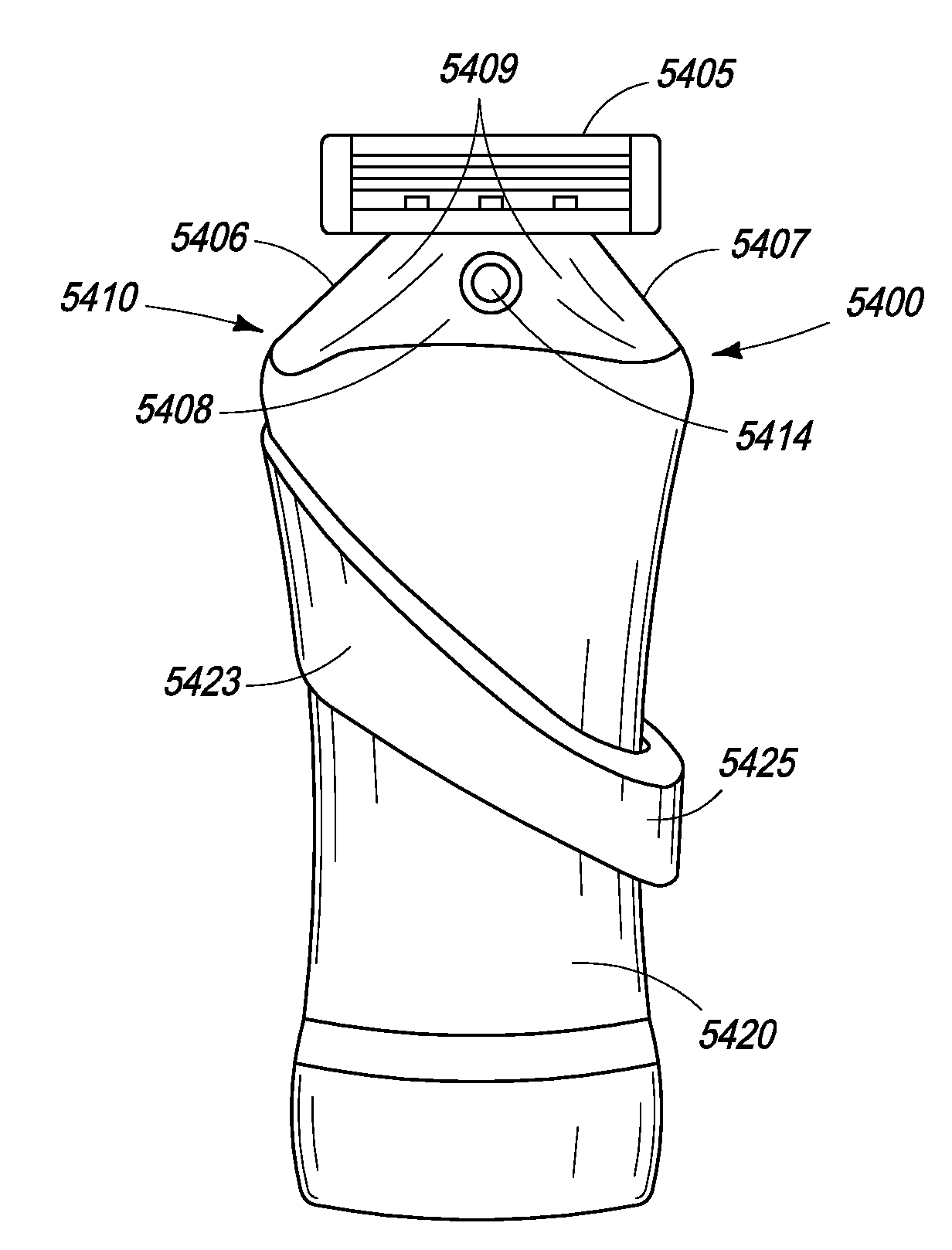

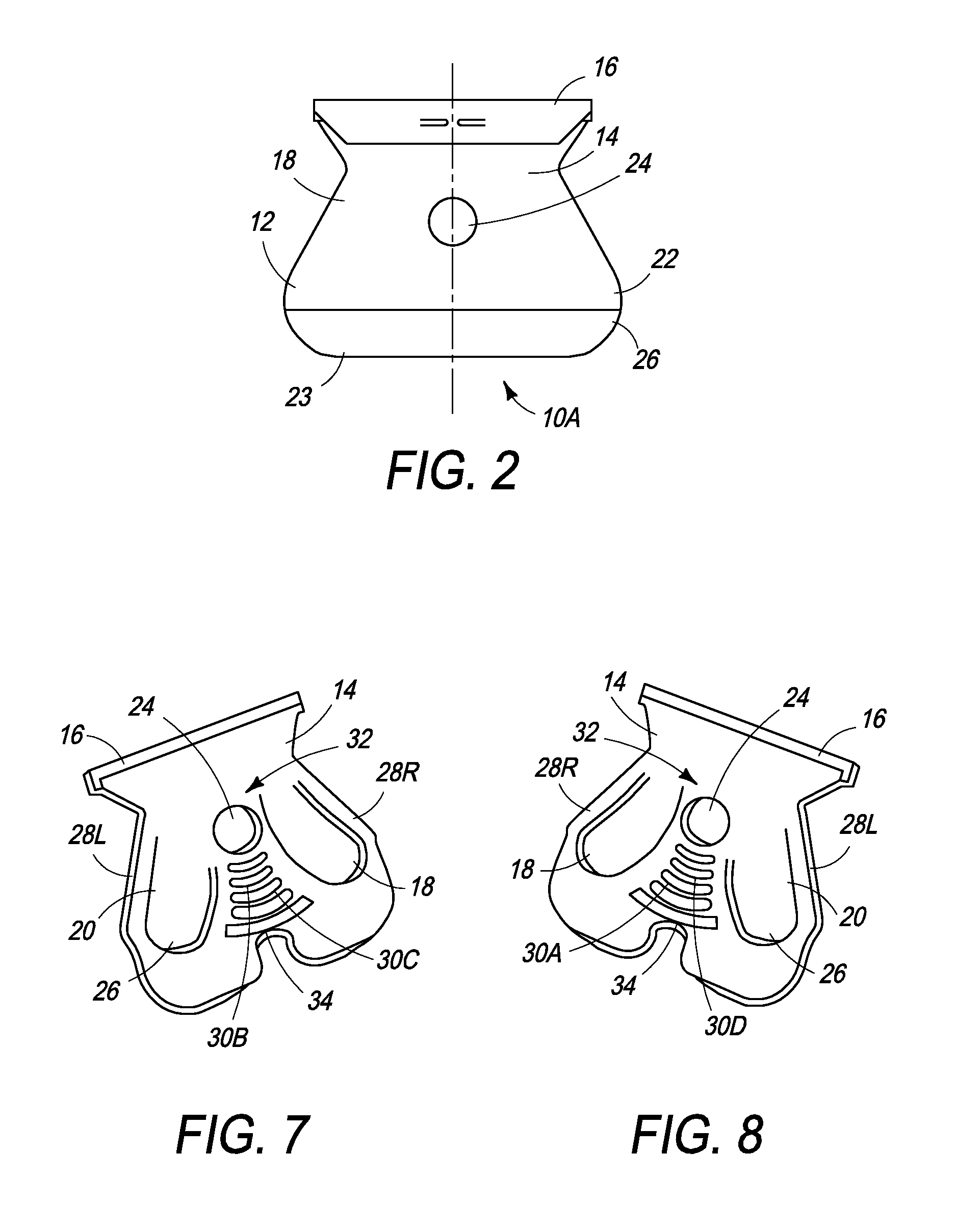

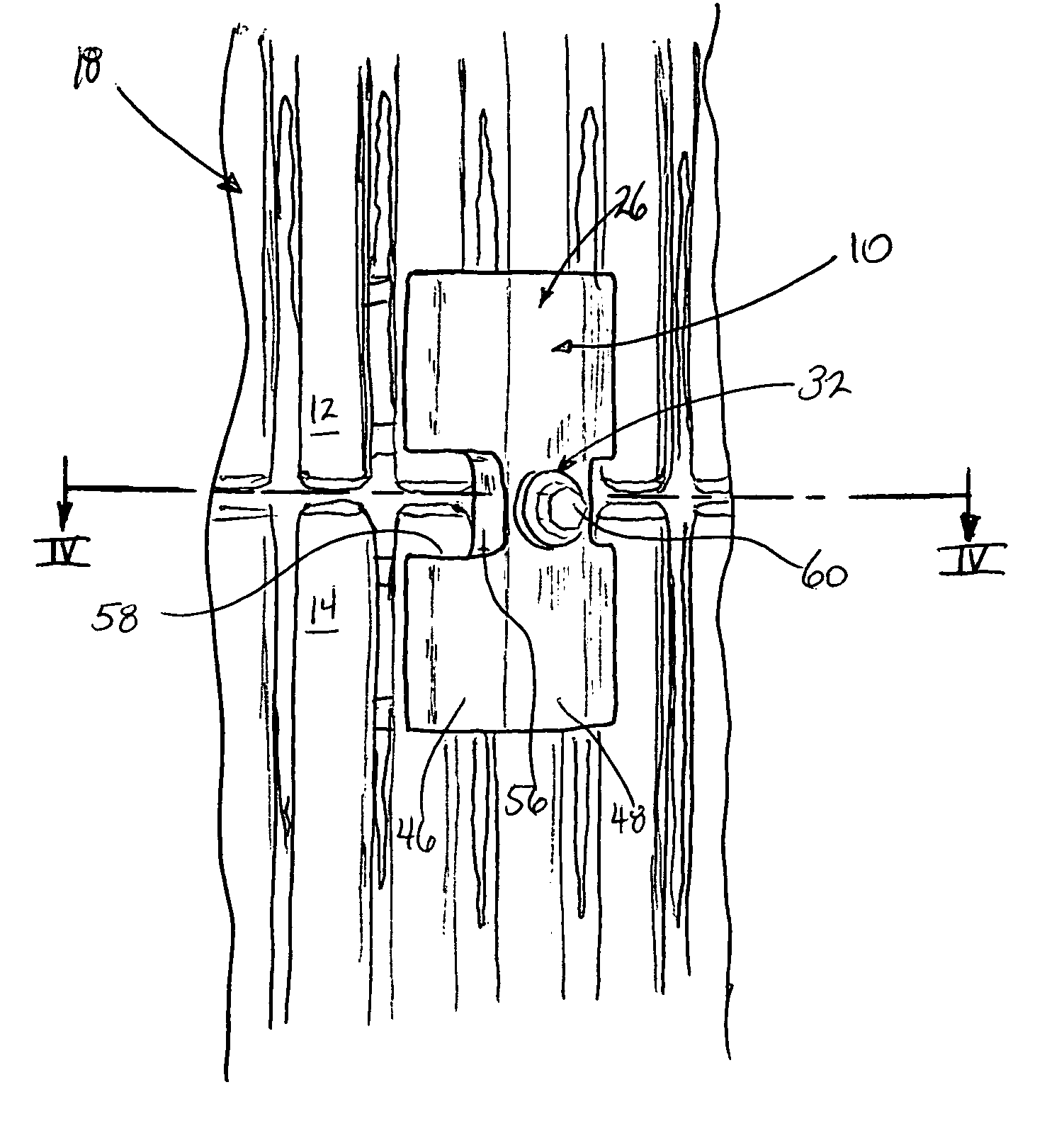

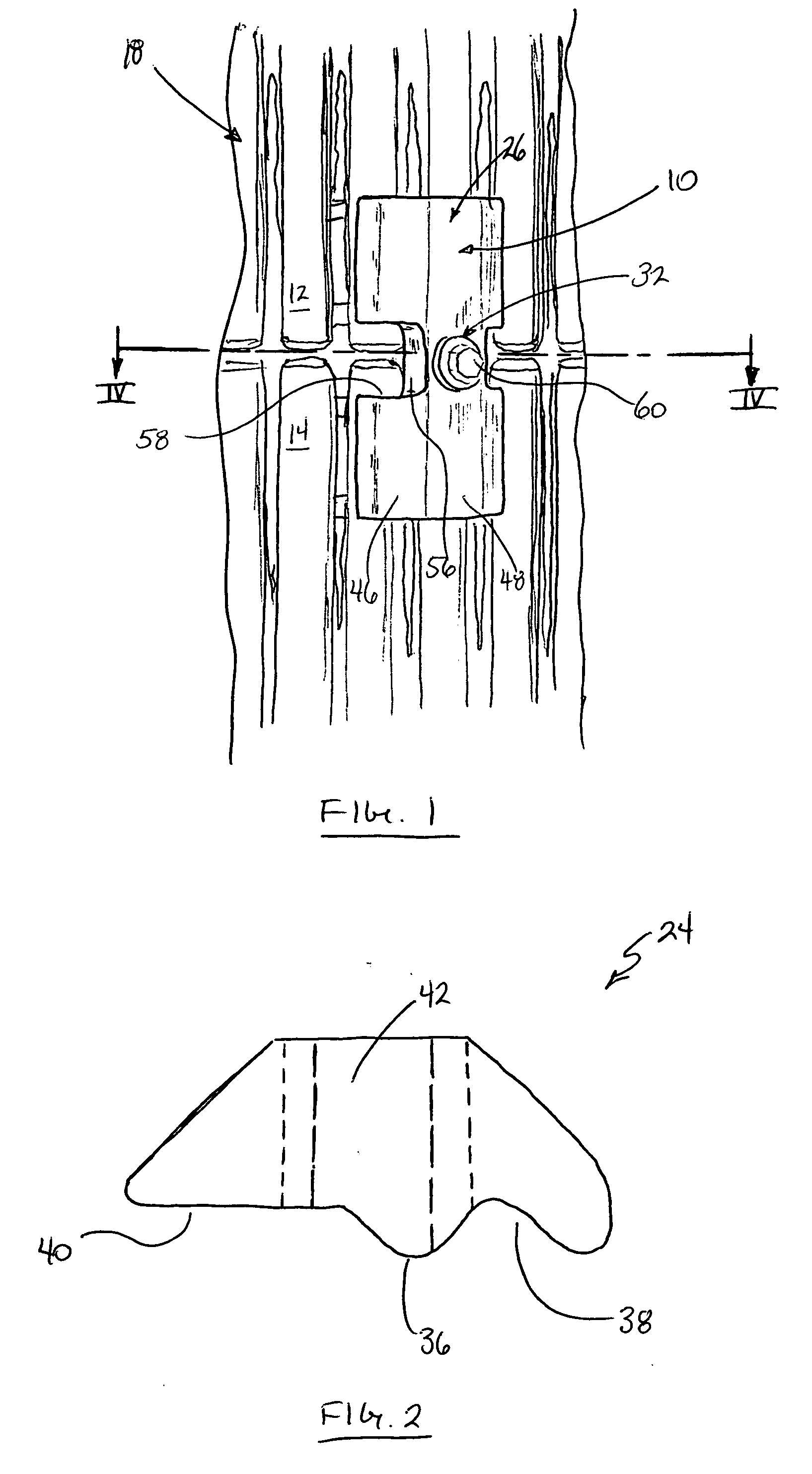

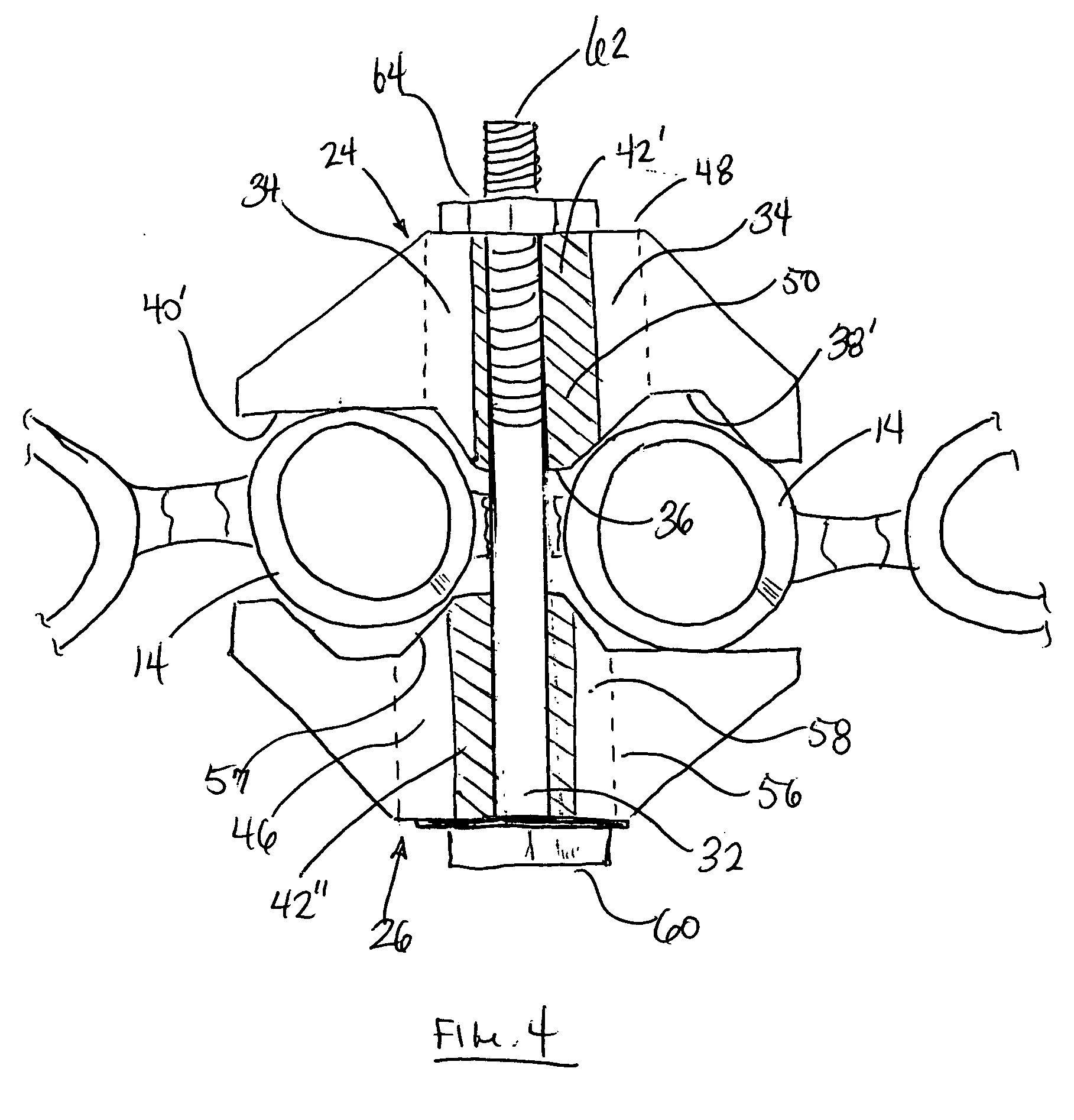

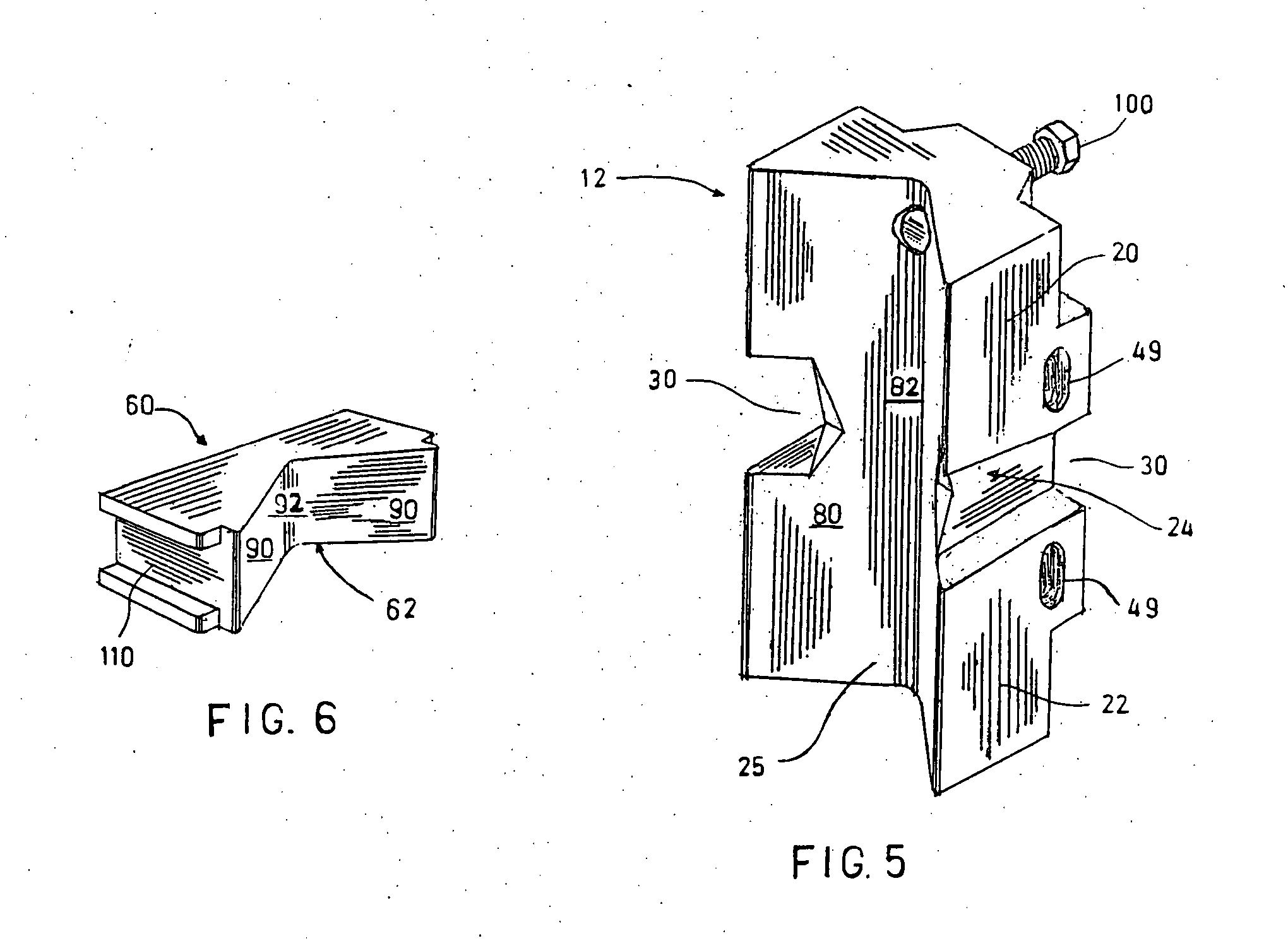

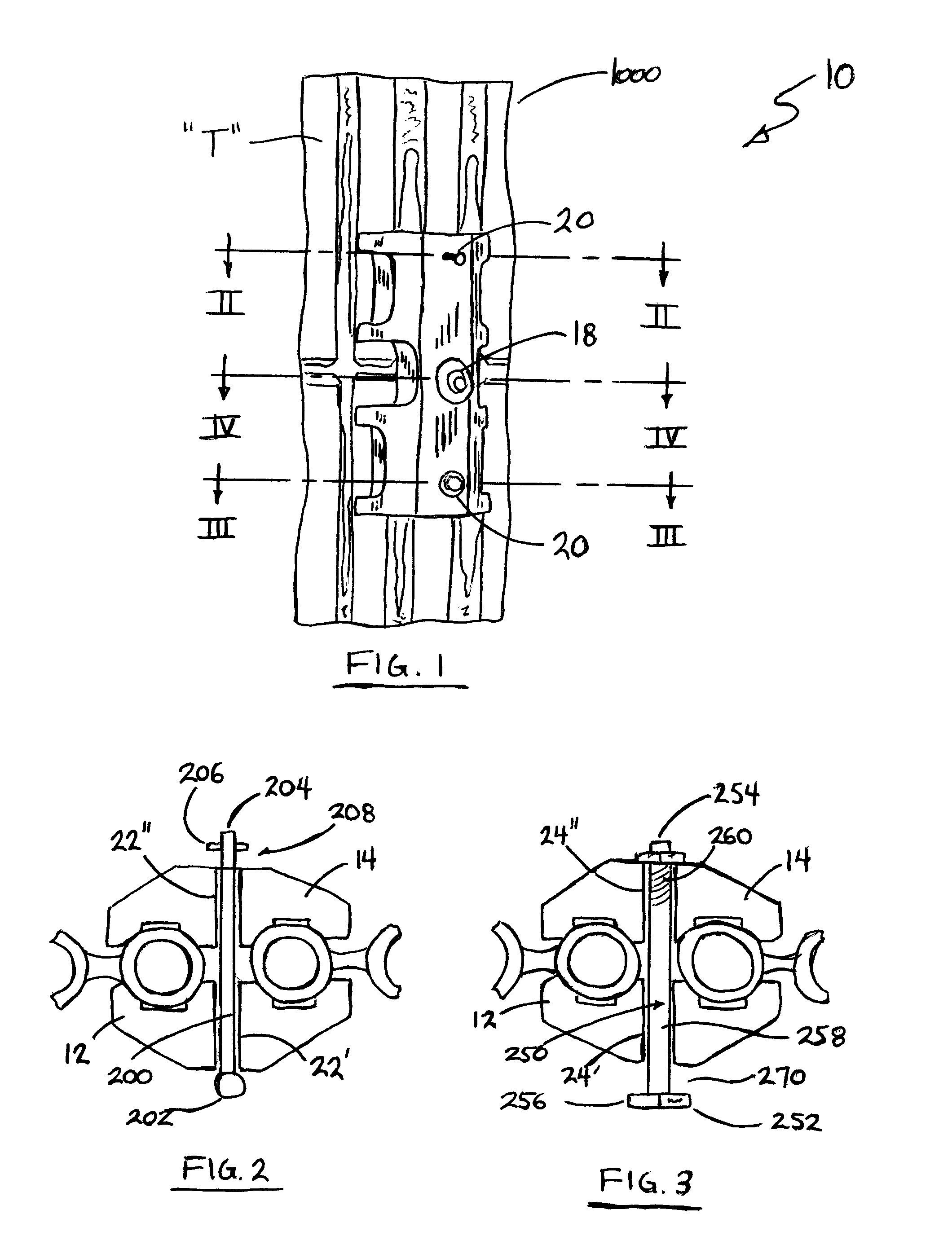

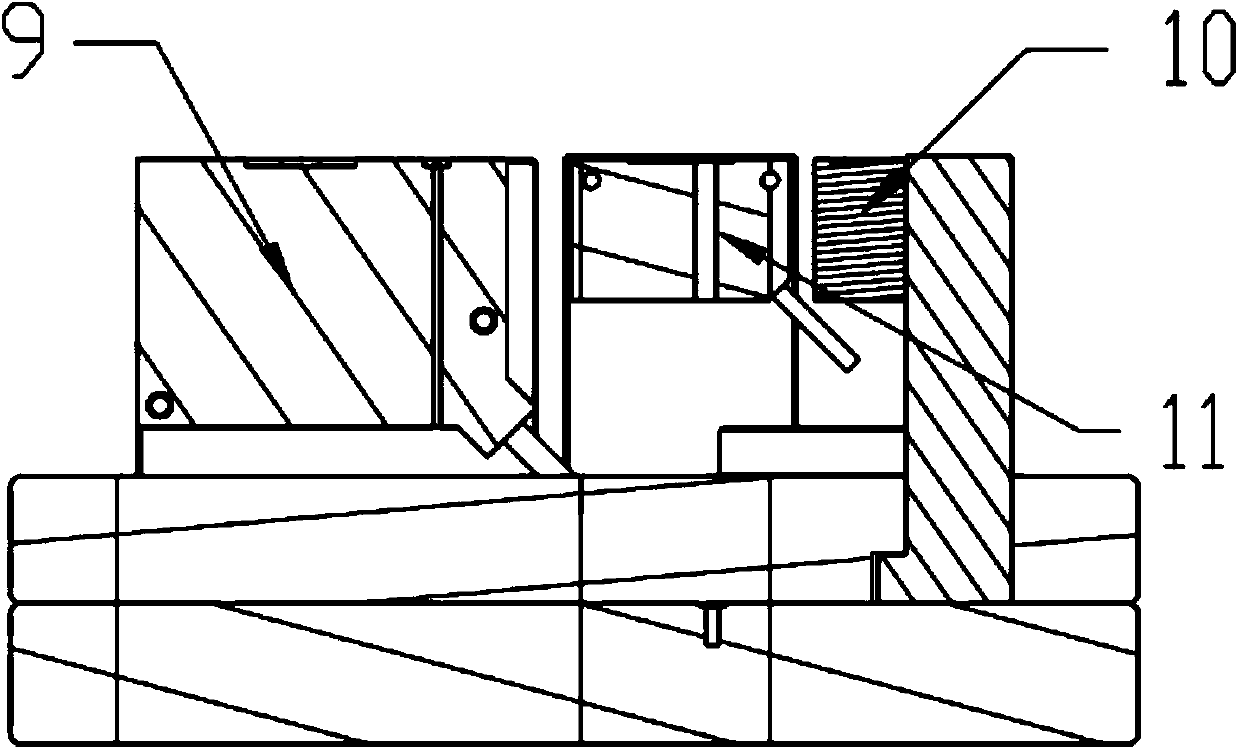

Modified boiler wall tube tool

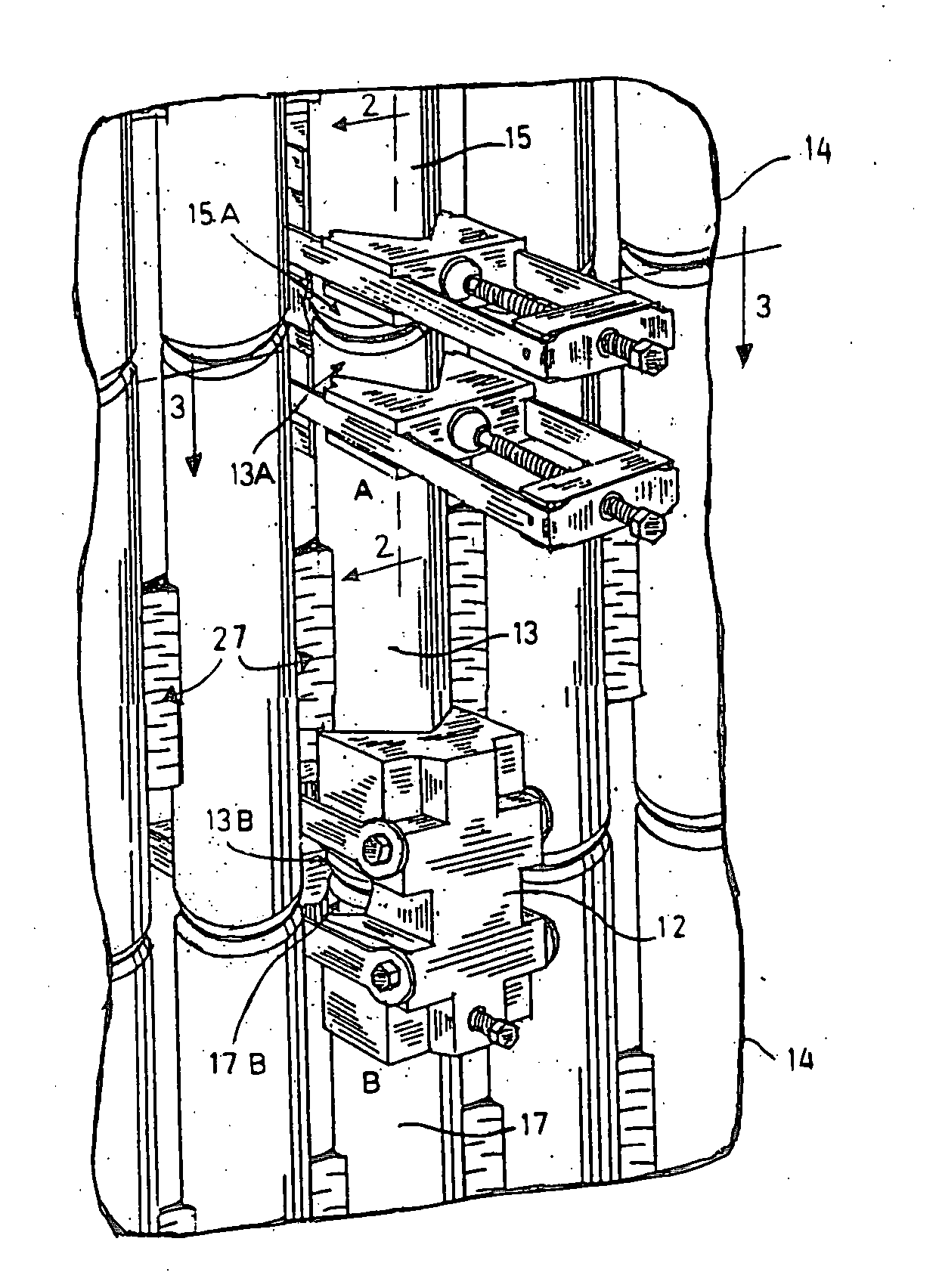

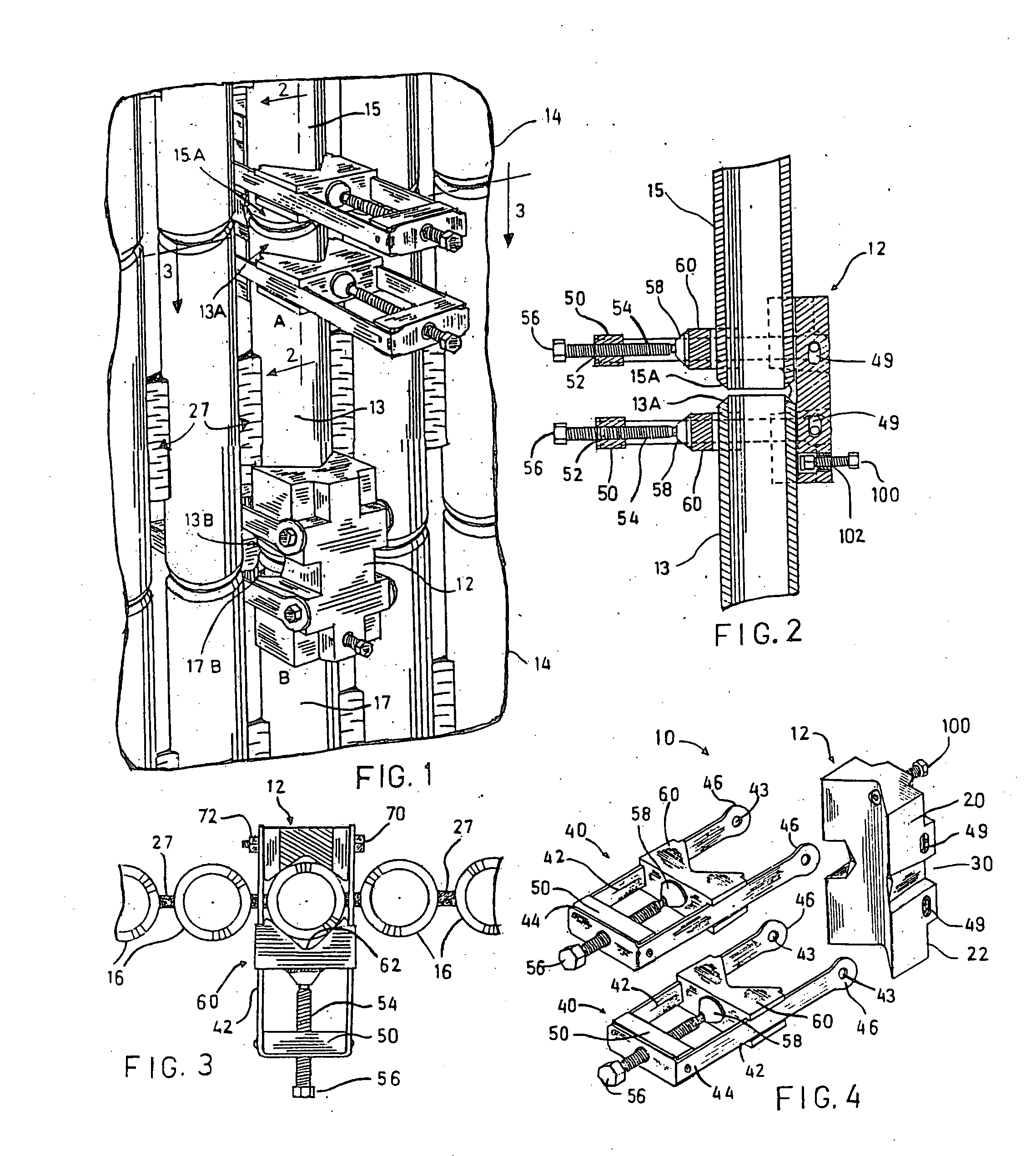

A boiler wall tube tool has a first clamp member positioned about one side of the boiler wall and a second clamp member positioned about the opposite side of the boiler wall. The first clamp member has recess or recesses, each recess receiving one of the tubes therein. The second clamp member has a radius or radiuses abutting against the opposite side of a tube or the tubes. The first clamp member and the second clamp member are coupled to one another about the tube or tubes through slots formed in the first clamp member and the second clamp member.

Owner:MCCLURE MARK W

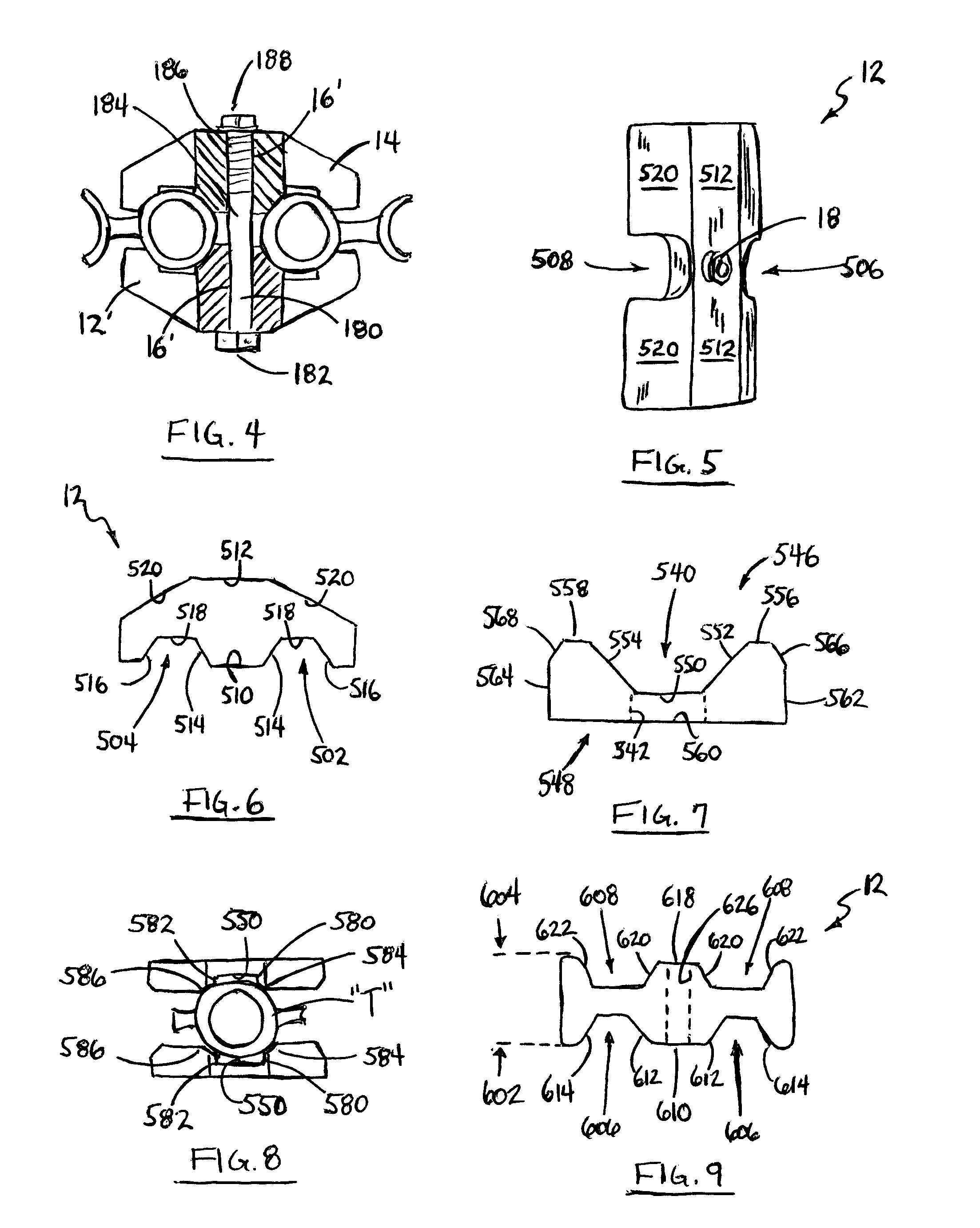

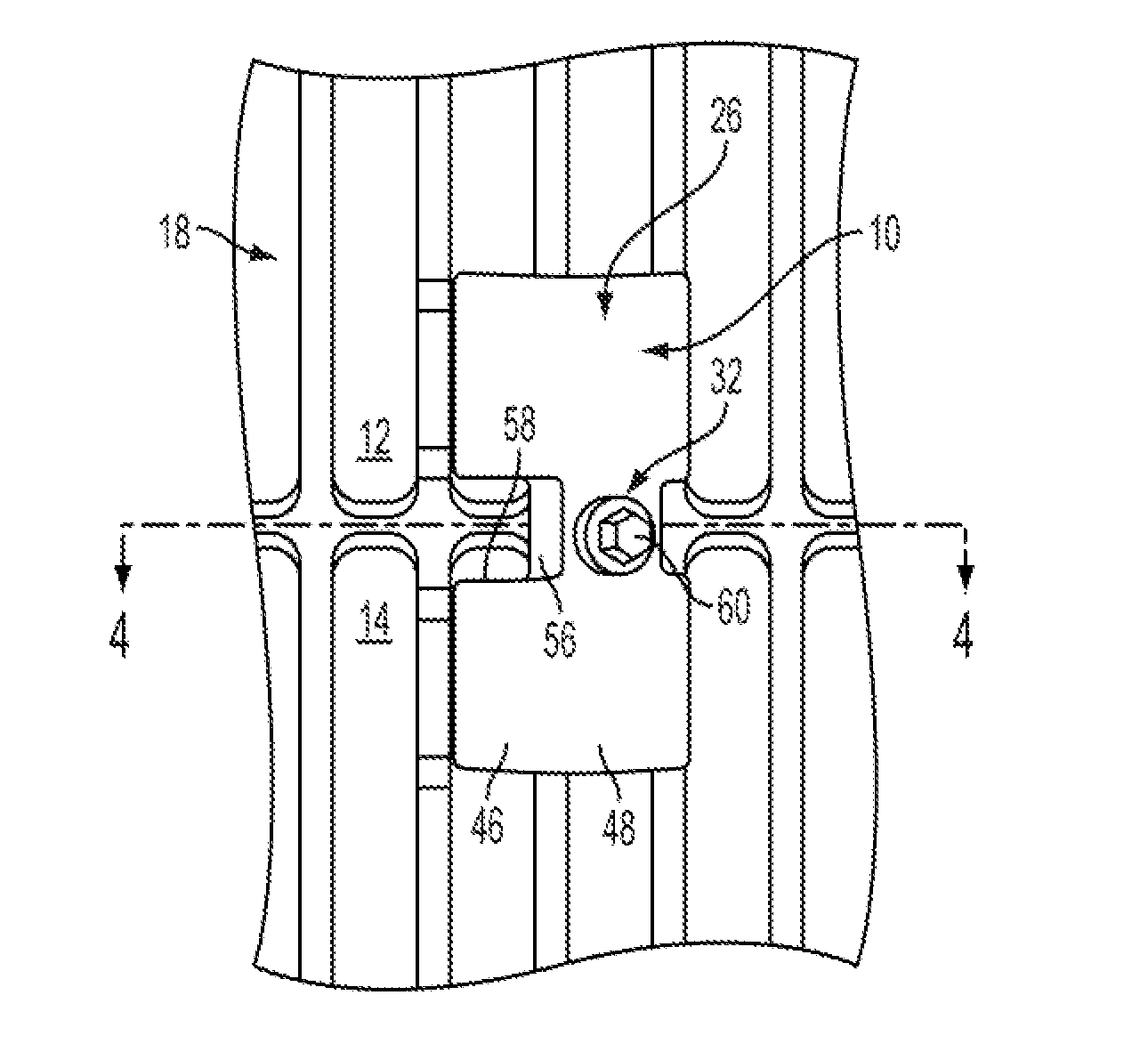

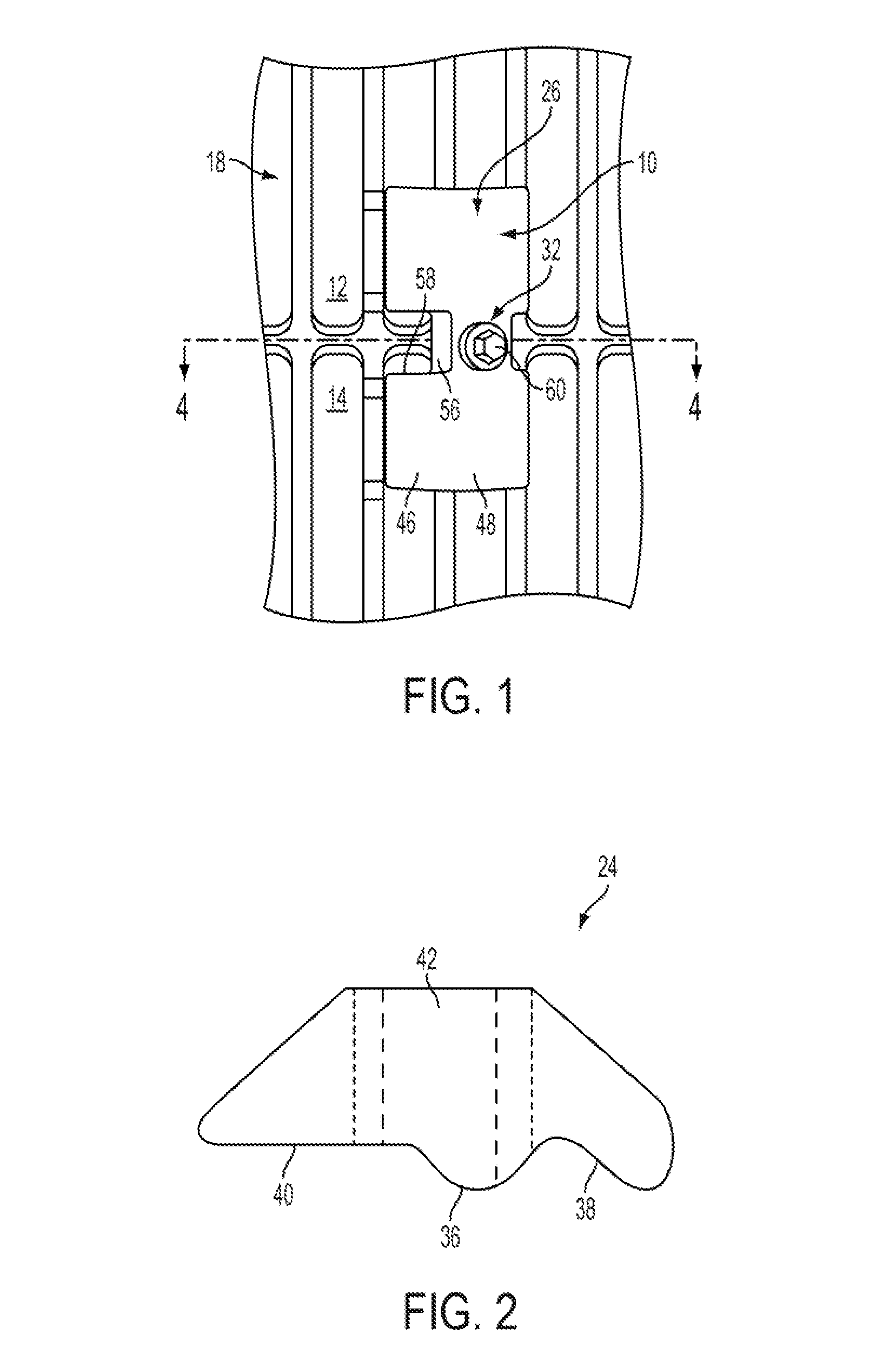

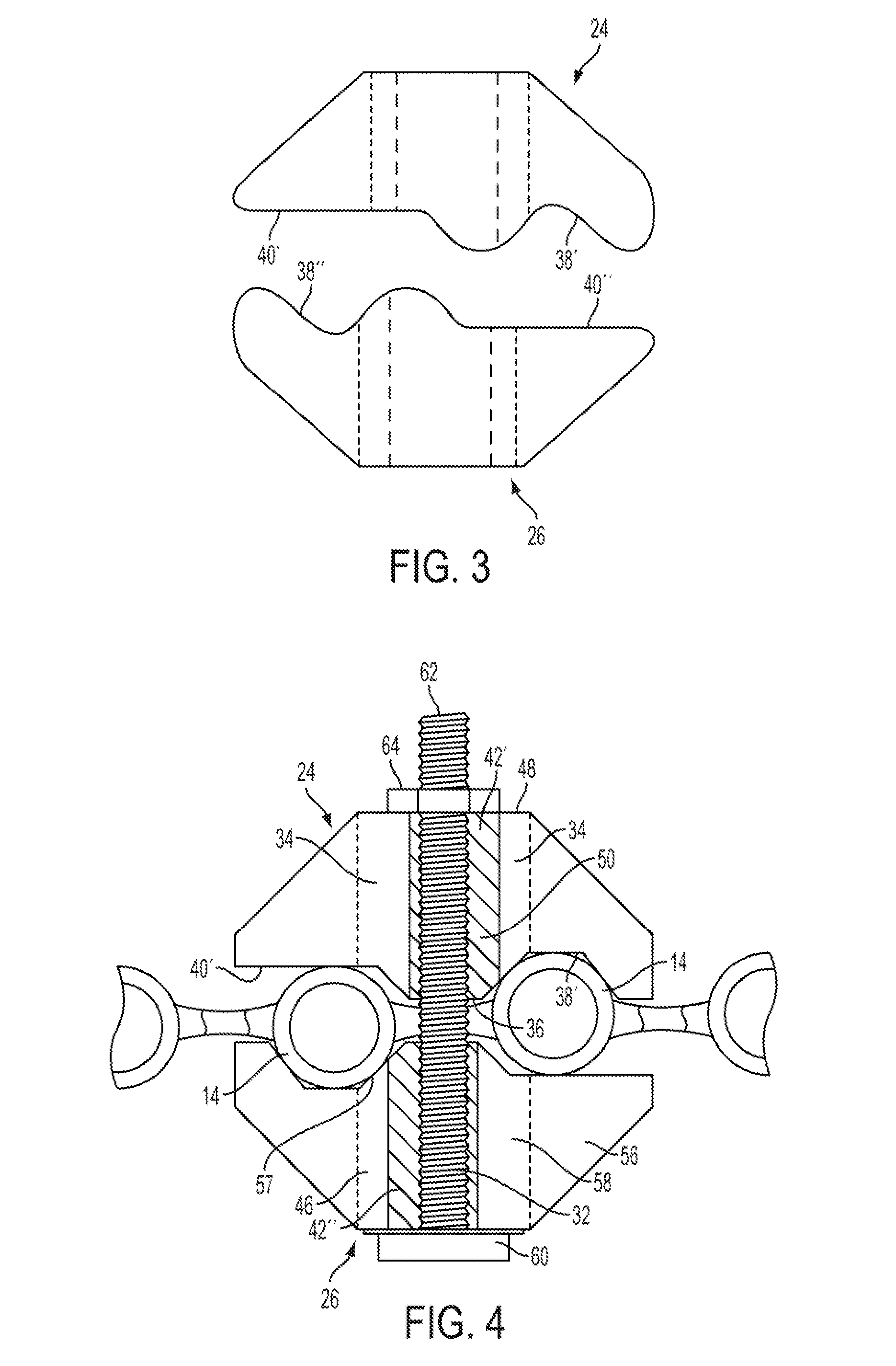

Modified boiler wall tube tool

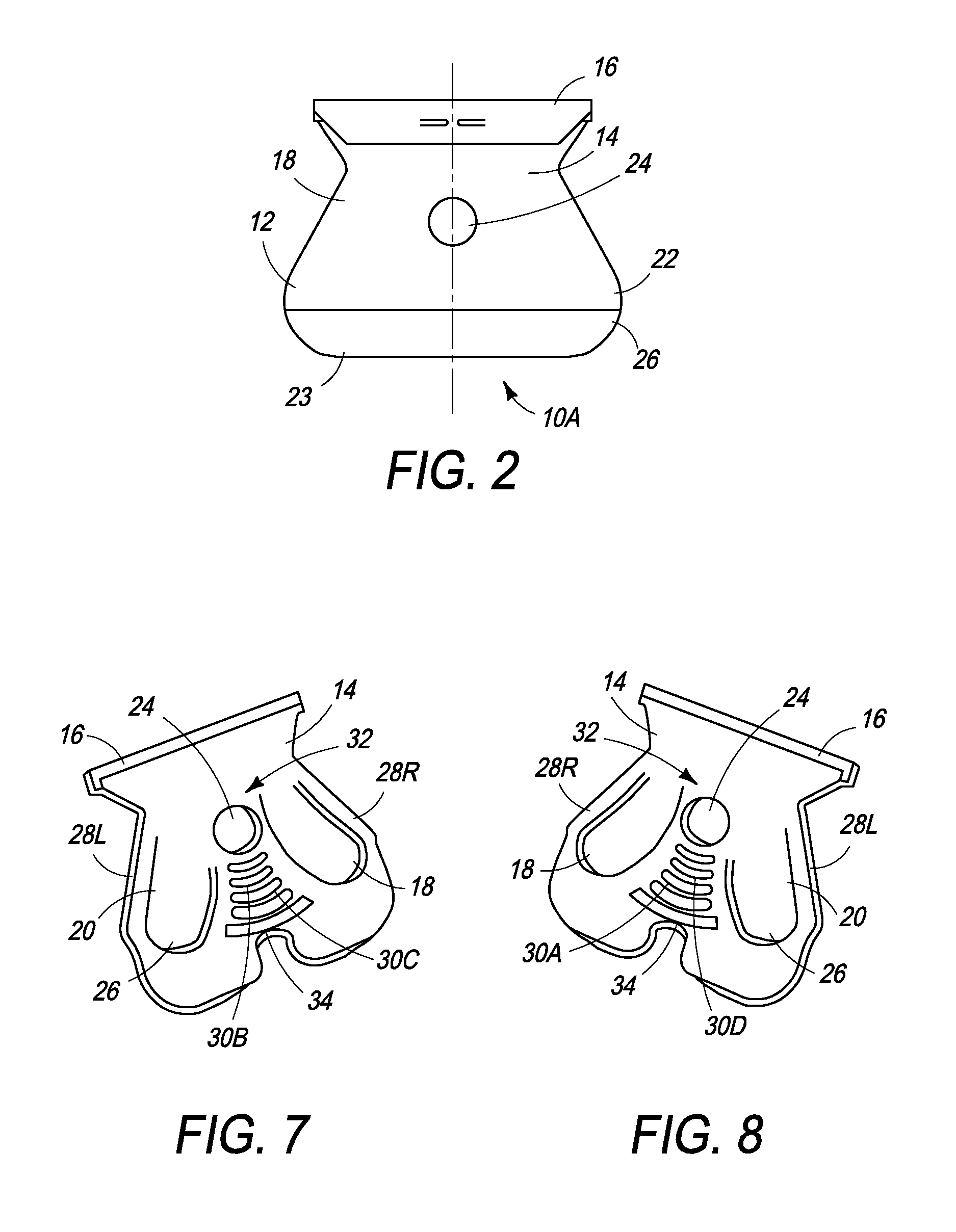

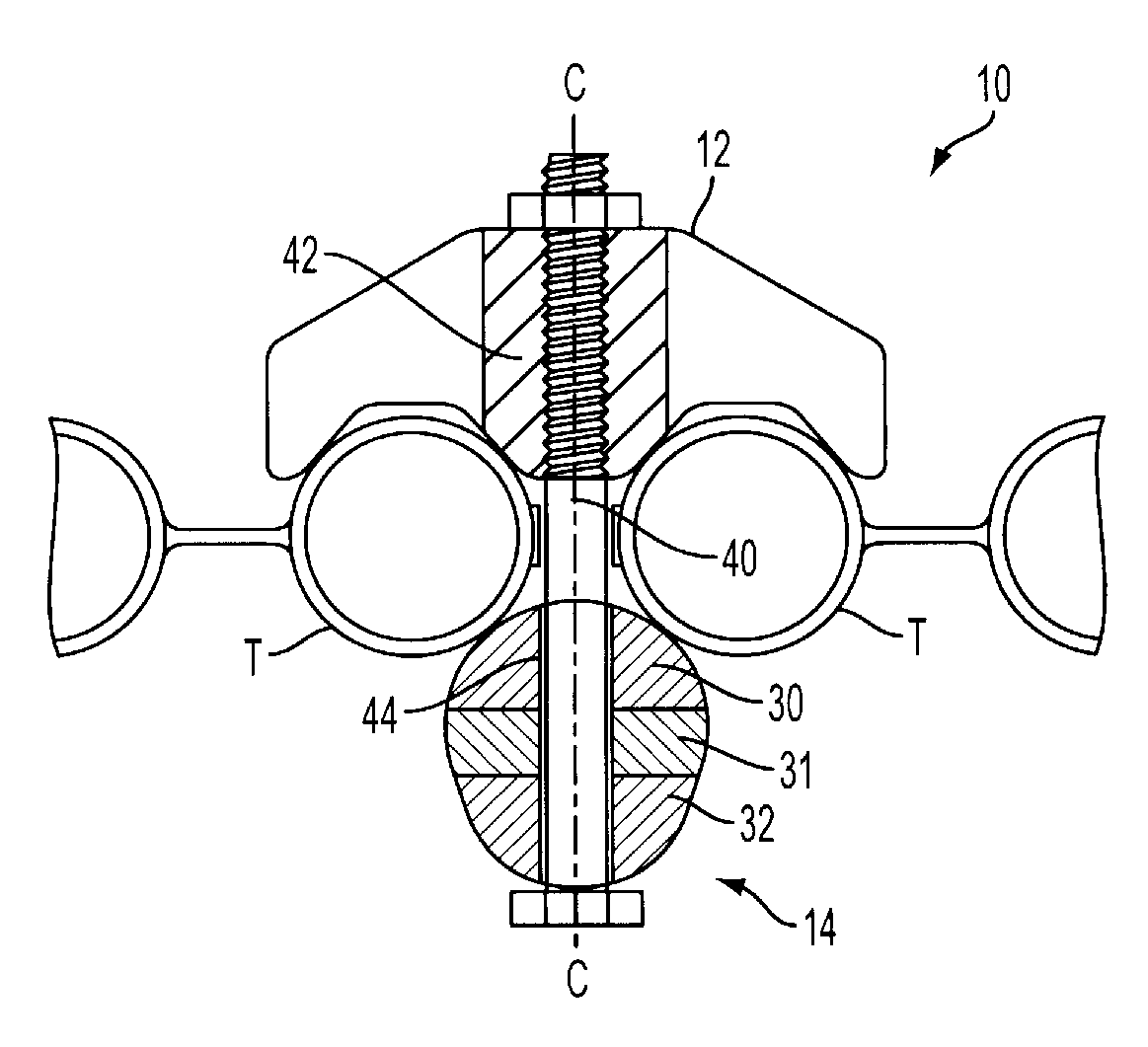

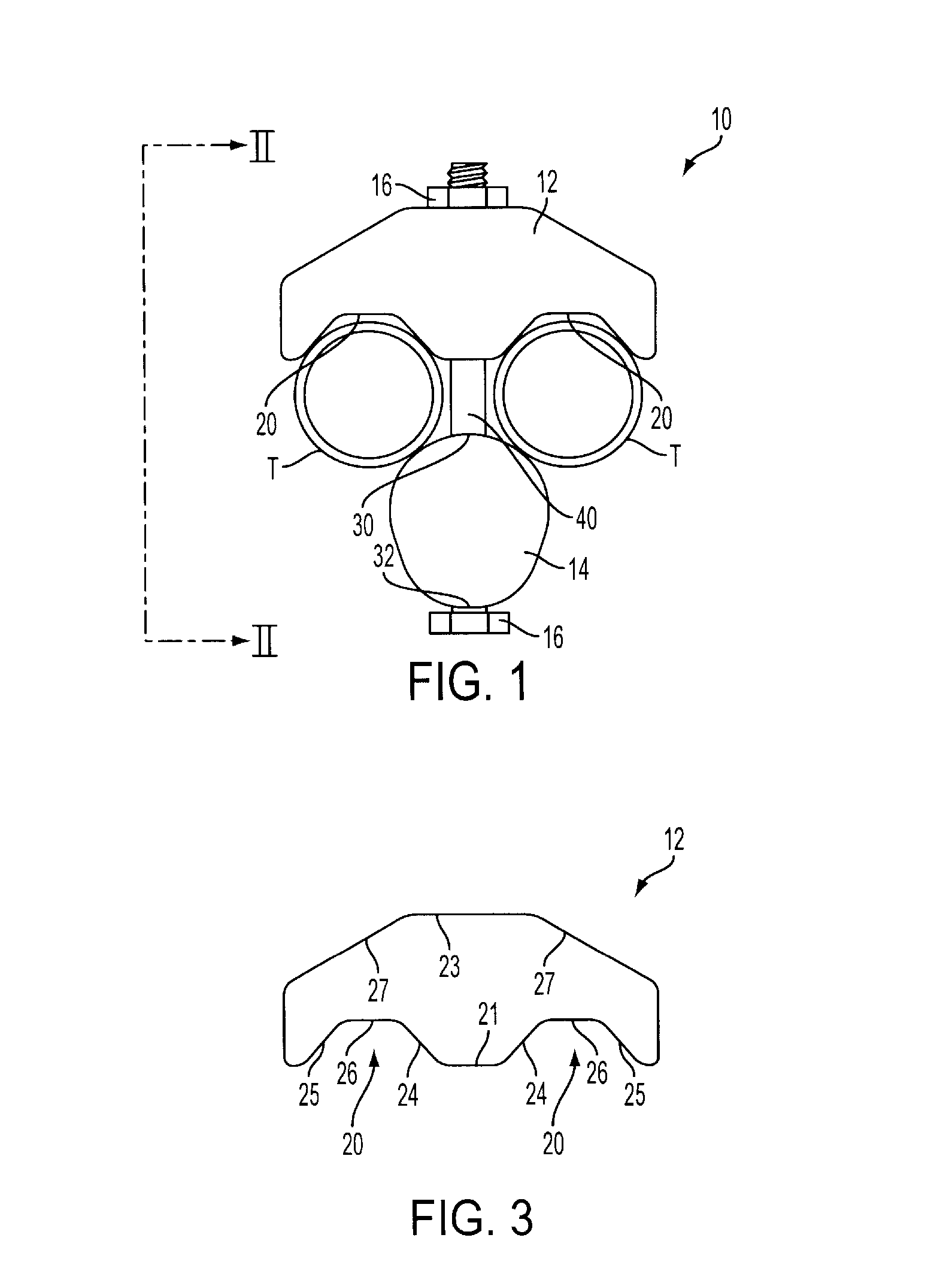

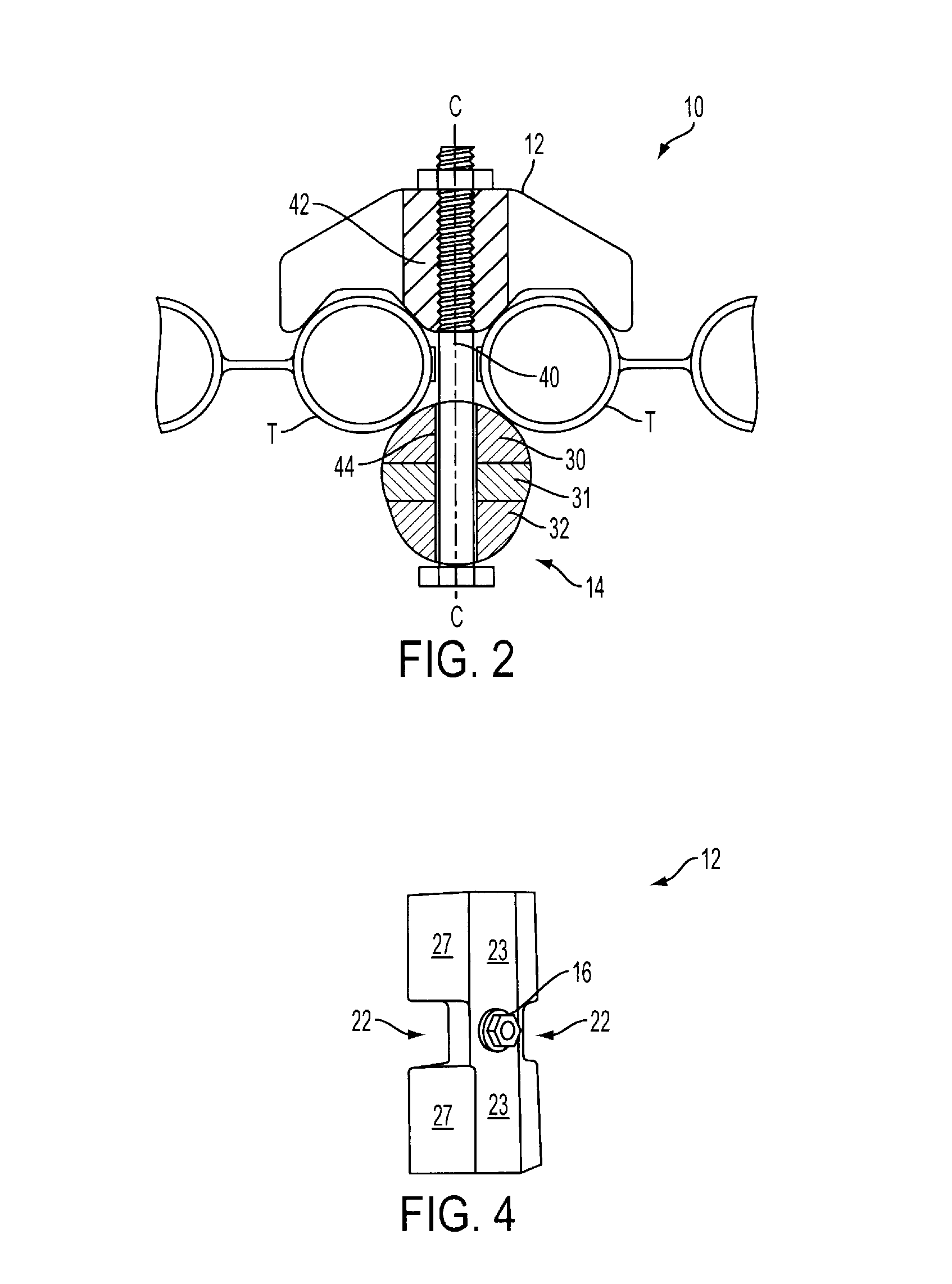

InactiveUS20070210498A1Improve versatilityMaintain alignmentWelding/cutting auxillary devicesAuxillary welding devicesTube toolTroffer

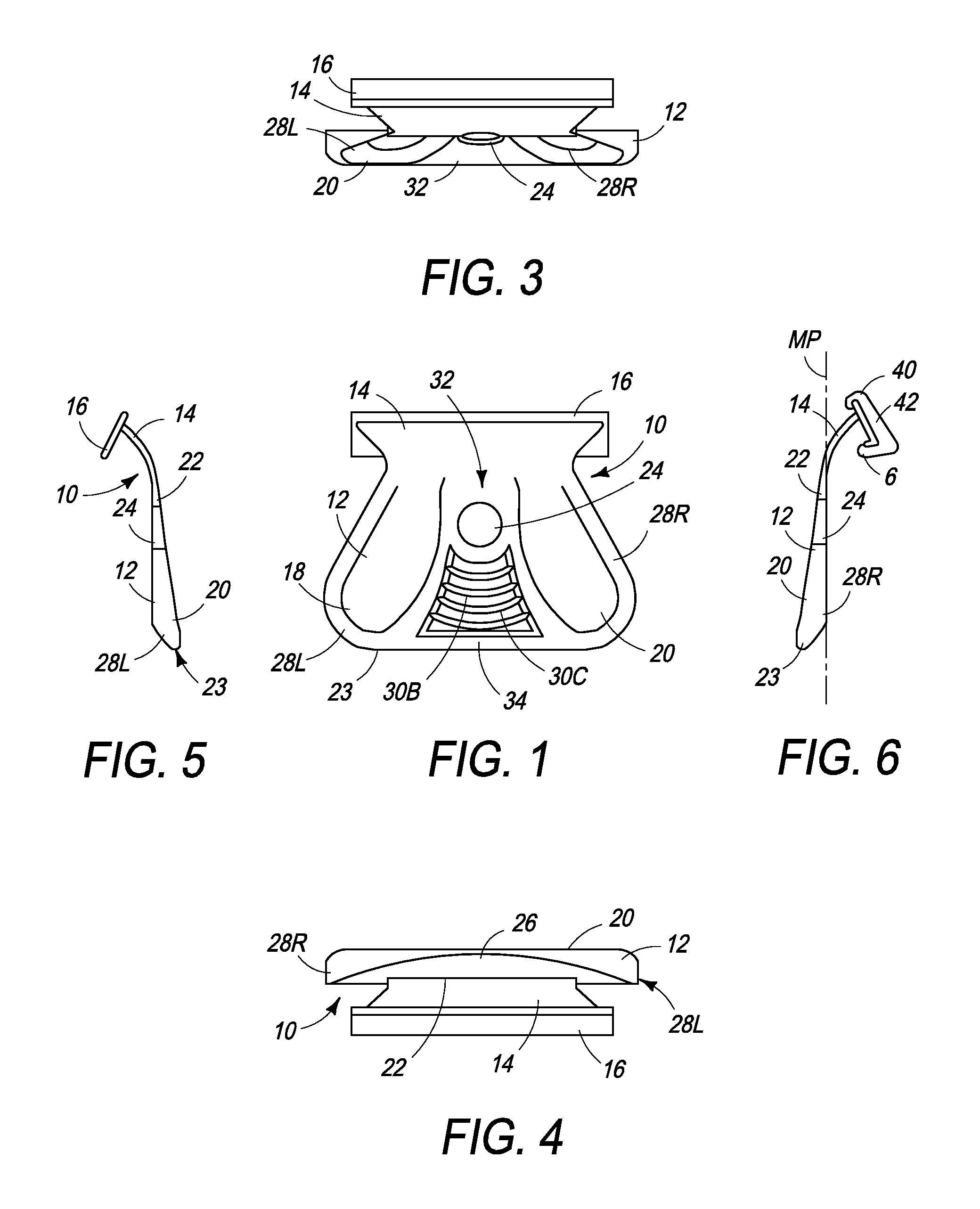

A boiler wall tube tool comprises a pair of opposed clamp members, each one of the clamp members having a nose intermediately disposed between a recess and a planar or inclined wall, and an aperture formed centrally through the clamp member. The clamp members oriented so that the recess of one of the clamp members is substantially aligned with the planar wall of the remaining clamp member for engaging a boiler wall tube therebetween. The aperture of one clamp member is substantially aligned with the aperture of the remaining clamp member. Means for moving the clamp members toward each other for secure clamping engagement of the tubes for maintaining the clamp members in alignment while connecting the ends of the tubes by welding is also provided.

Owner:MCCLURE MARK W

Thru tubing tool and method

Owner:WELLBORE INTEGRITY SOLUTIONS LLC

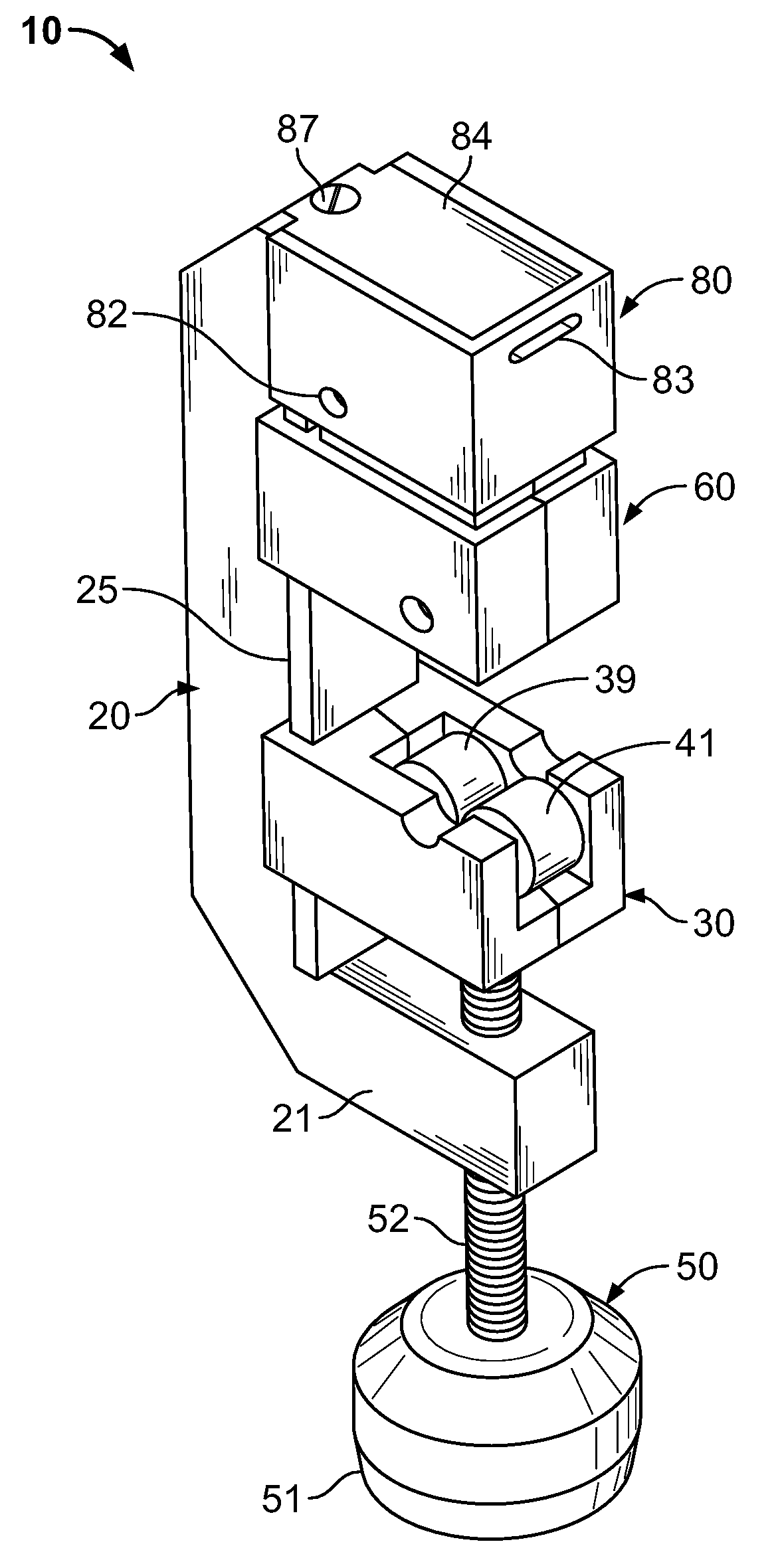

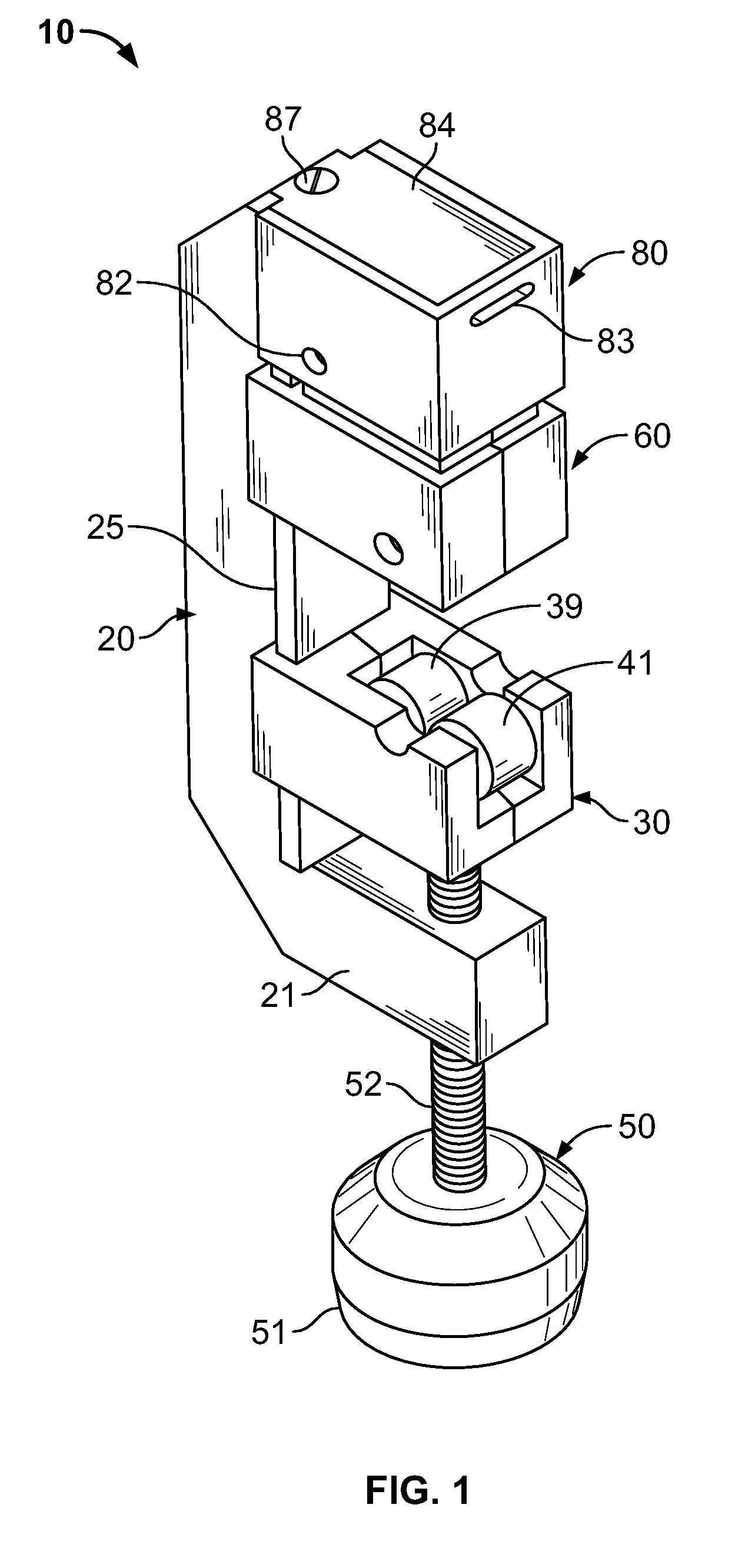

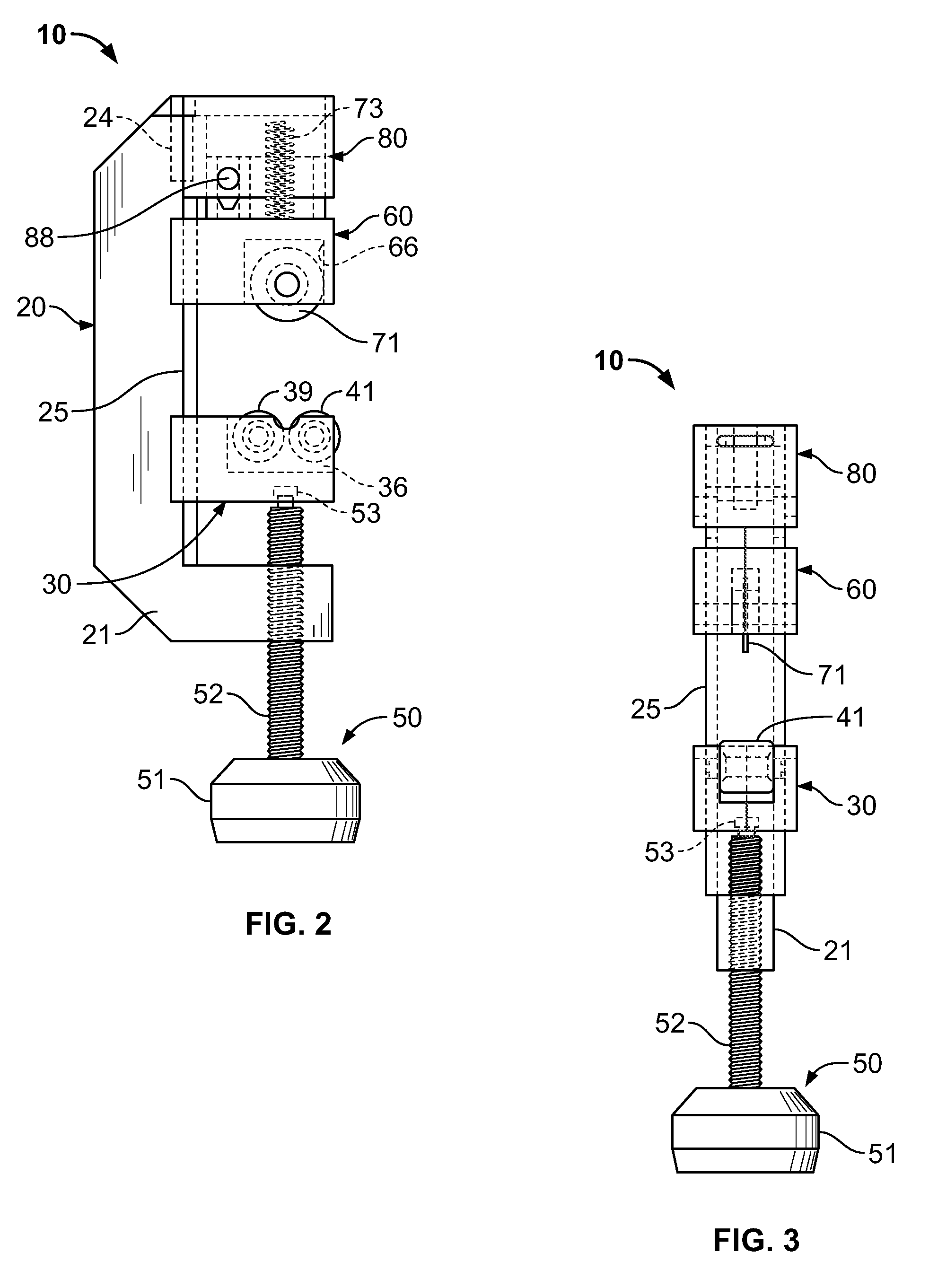

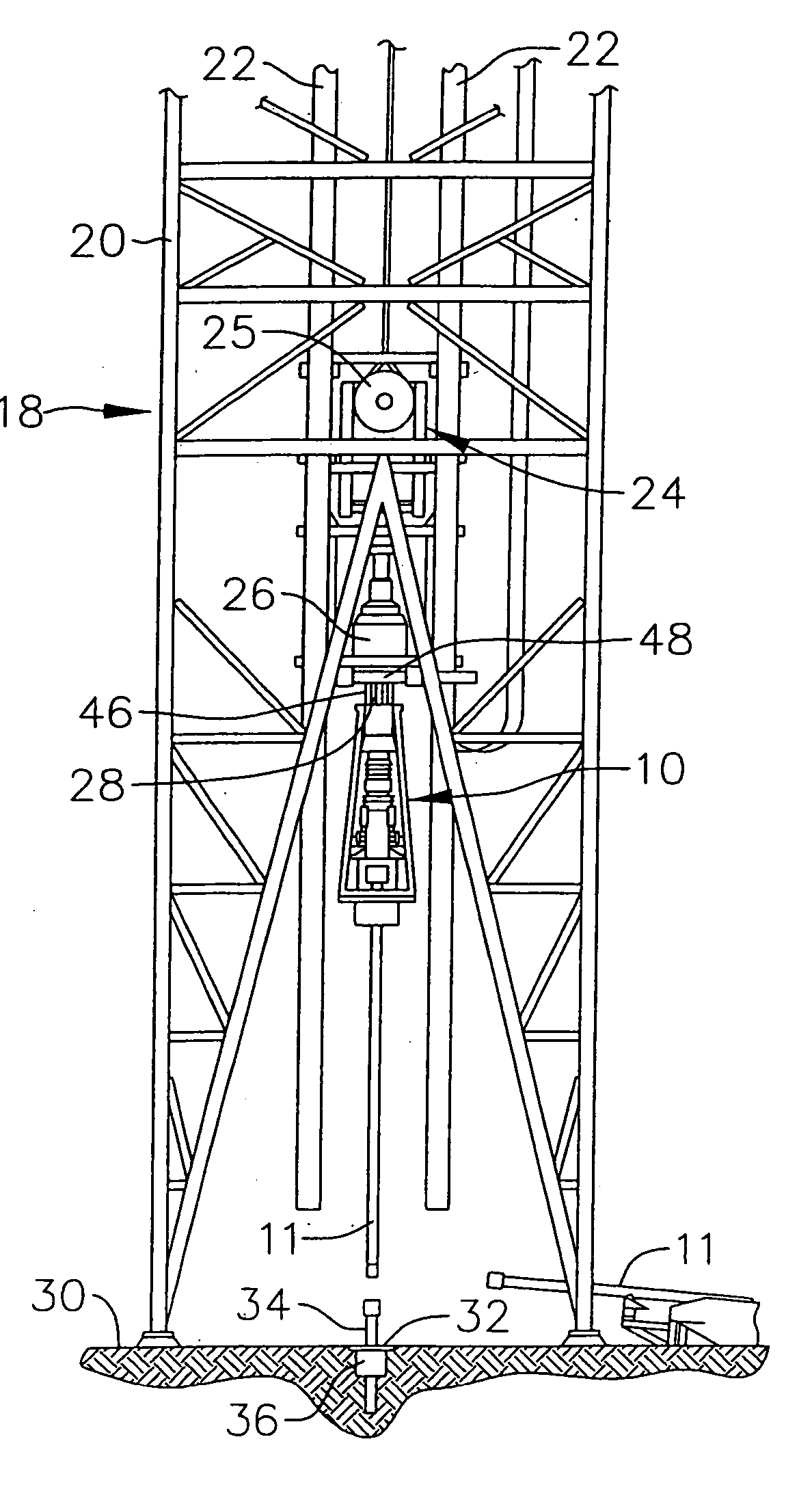

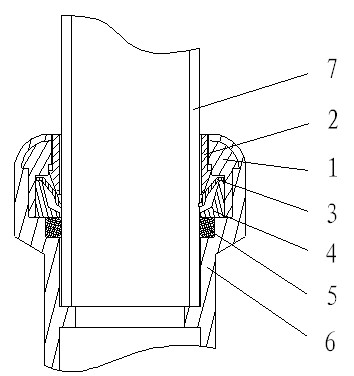

Boiler wall tube welding tool

InactiveUS20060196043A1Easy for visual observationLimited spaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

A boiler wall tube tool for clamping together for welding adjacent ends of boiler wall tube segments in a boiler wall having narrowly spaced apart tubes. The tool includes a base with a tube engaging recess, and a pair of clamp members that attach to the base. The base has cutouts and notches to facilitate a welder's observation of the welding process. Each of the pipe clamp members includes a parallel pair of guides that are insertable between adjacent tubes of a boiler wall and are attachable by nuts and bolts to opposite sides of the base. A header that joins the guides has a threaded bore. A saddle block mounted for sliding movement between the guides is attached by a swivel nut to a clamp screw that is mounted within the threaded bore. Each saddle block is recessed for engaging an exterior surface of one of two aligned tube segments. The tool clamps aligned segments together by rotation of the clamp screws in a first direction; rotation of the screws in an opposite direction permits detaching the tool from the pipe segments. A lateral adjustment screw is provided for adjusting the tool for snug fit to adjacent, aligned tube segments.

Owner:HOLLOWAY SCOTT

Modified Boiler Wall Tube Tool Having Inhibiting Means

A boiler wall tube tool is disclosed and comprises a pair of opposed clamp members, means for securing the members to a boiler wall, and means for inhibiting ejection of the members from the boiler wall. Each one of the members comprises an aperture formed centrally therethrough for receiving securing means that is inserted through each of the apertures. Securing means may comprise a threaded bolt and a threaded nut, wherein the nut may be fixed or floating. Inhibiting means may comprise a pin having a stop formed at an end thereof, or a bolt having a threaded end formed at an end thereof. In the bolt type inhibiting means, the threaded end is threadably coupled to a nut, wherein the nut may be fixed or floating.

Owner:MCCLURE MARK W

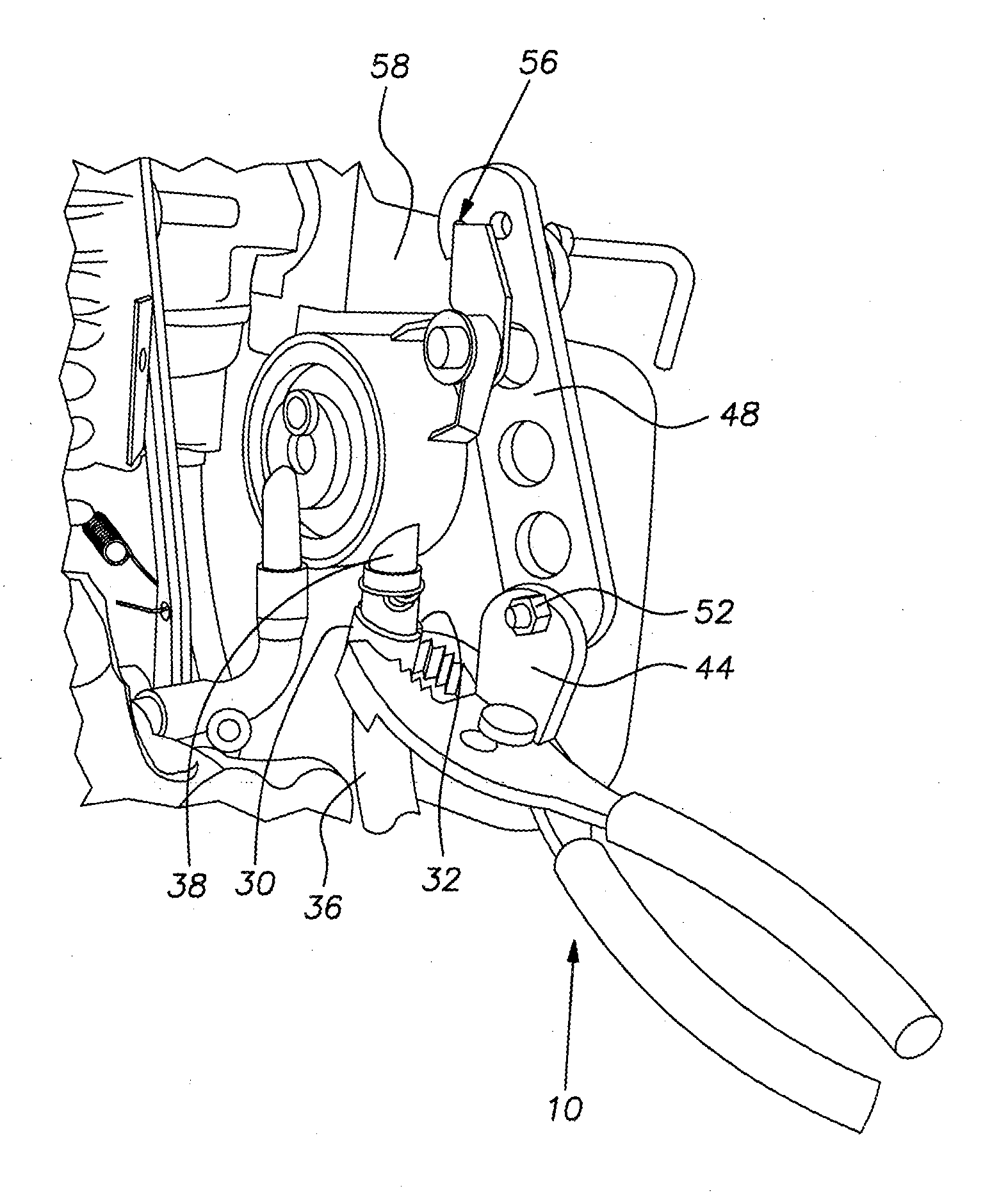

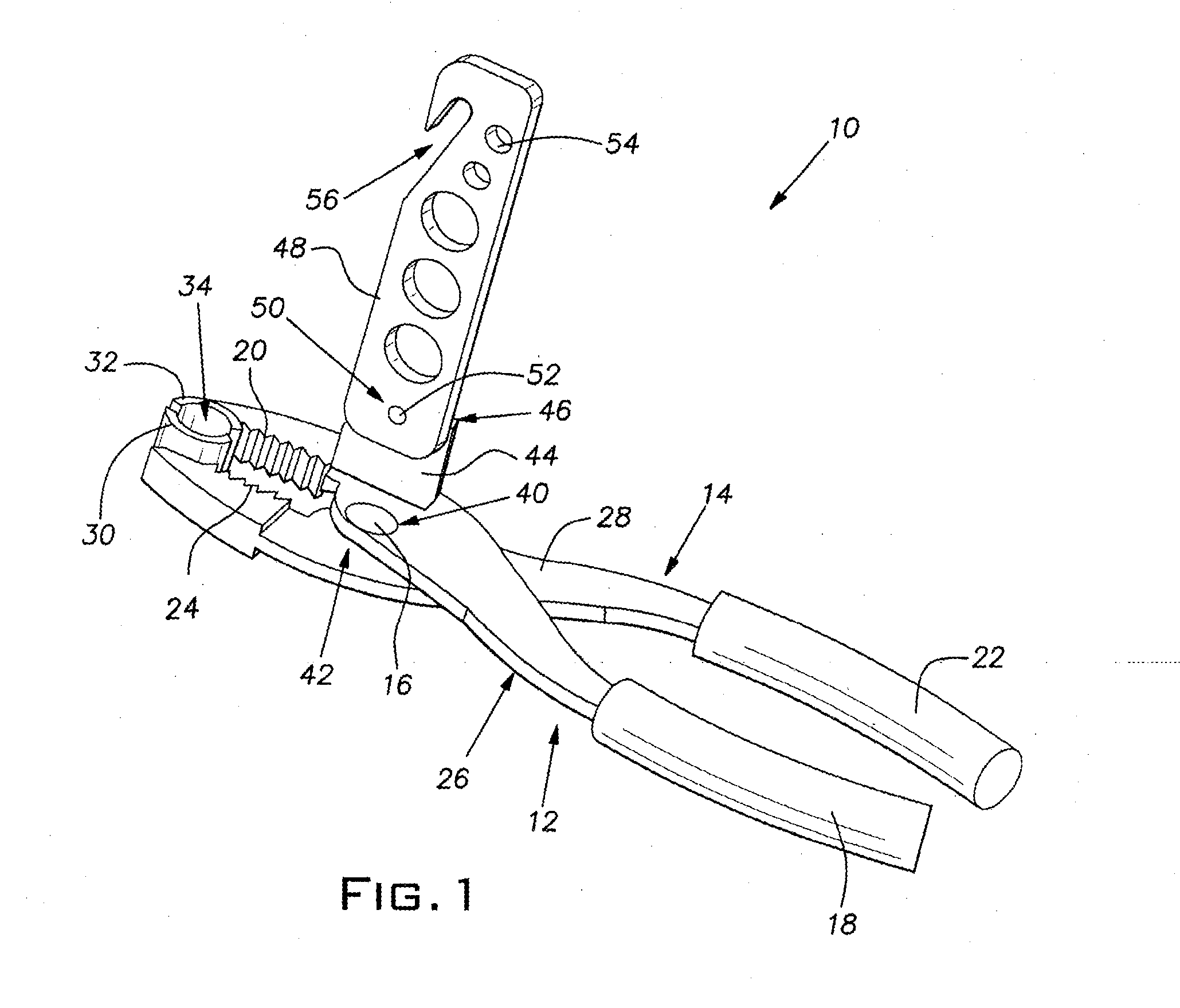

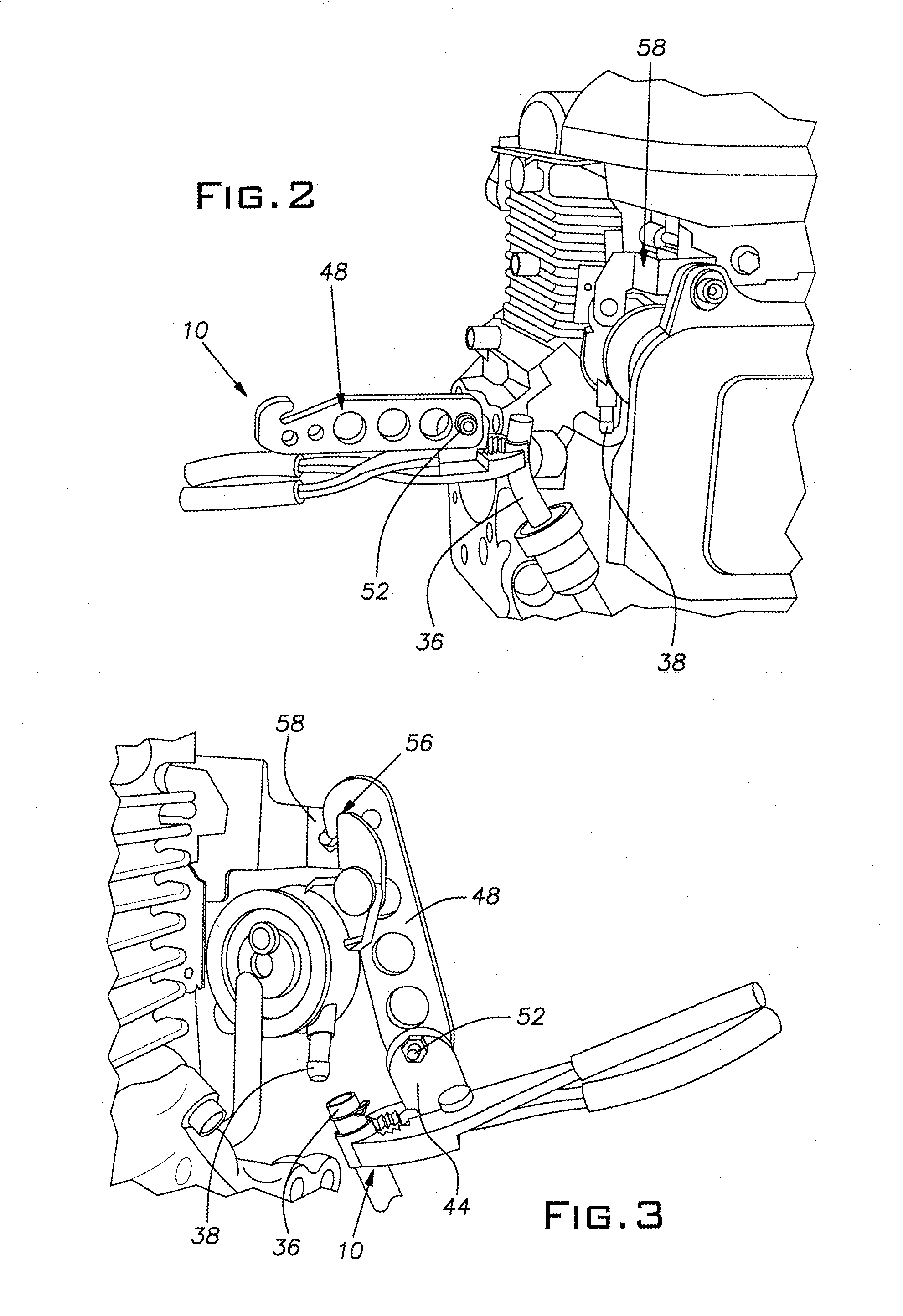

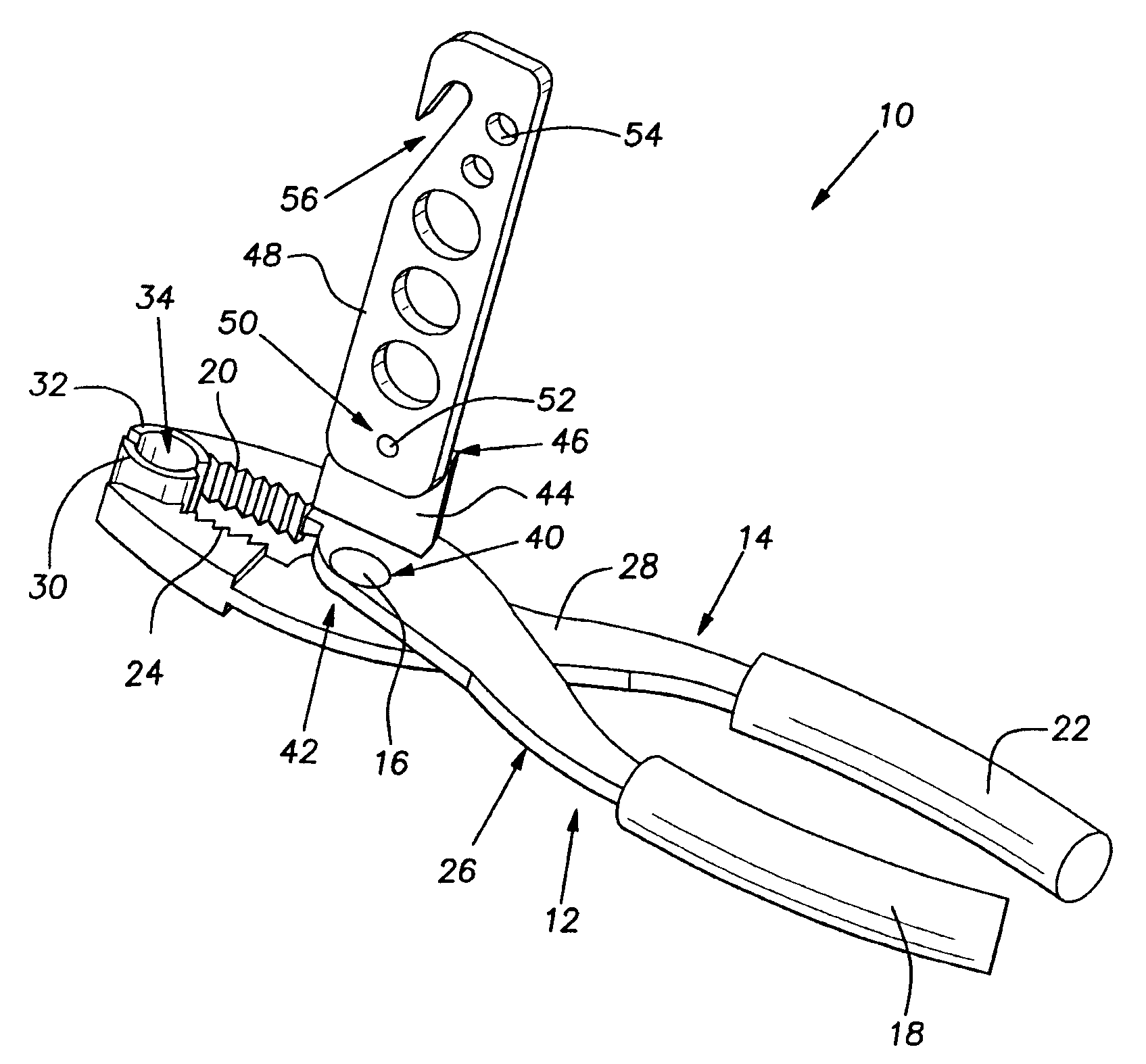

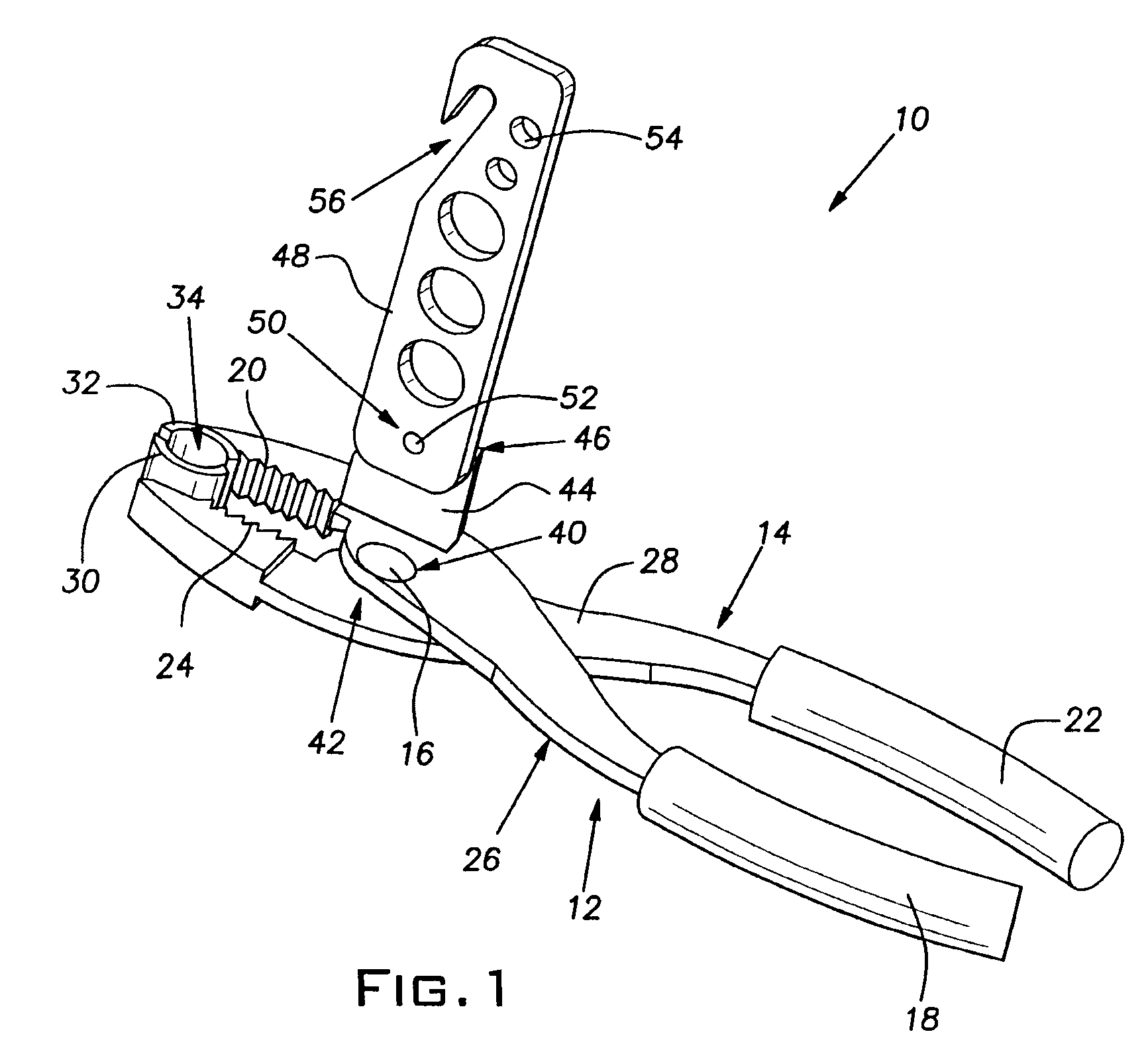

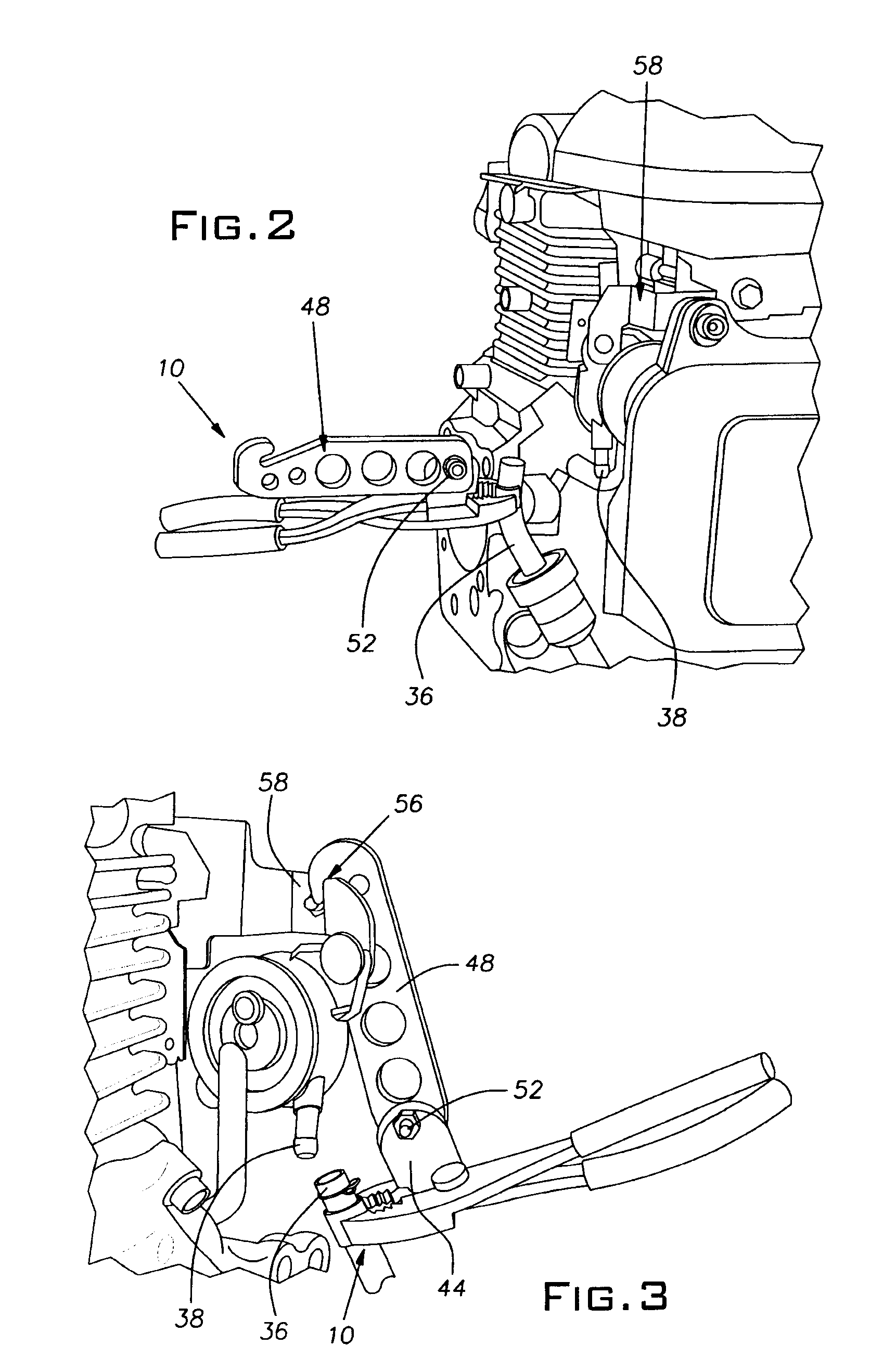

Tool for inserting fuel tubes

A fuel insertion tube tool for installing a fuel tube on a barb. The tool has first and second arms that are pivotably attached through an arm pivot axis. Each arm has a grip to engage the fuel tube. A tab extends from the first arm and is pivotably attached to a proximal end of a bar with a pivot pin that defines a bar axis. The bar axis and the arm axis are perpendicular to each other. A hook is disposed at a distal end of the bar for engagement with an attachment site. The tab functions as a fulcrum to reduce the amount of force required to install the fuel tube on the barb. The bar has weight reducing holes and the grips have straight knurls for frictional engagement with the fuel tube.

Owner:HONDA MOTOR CO LTD

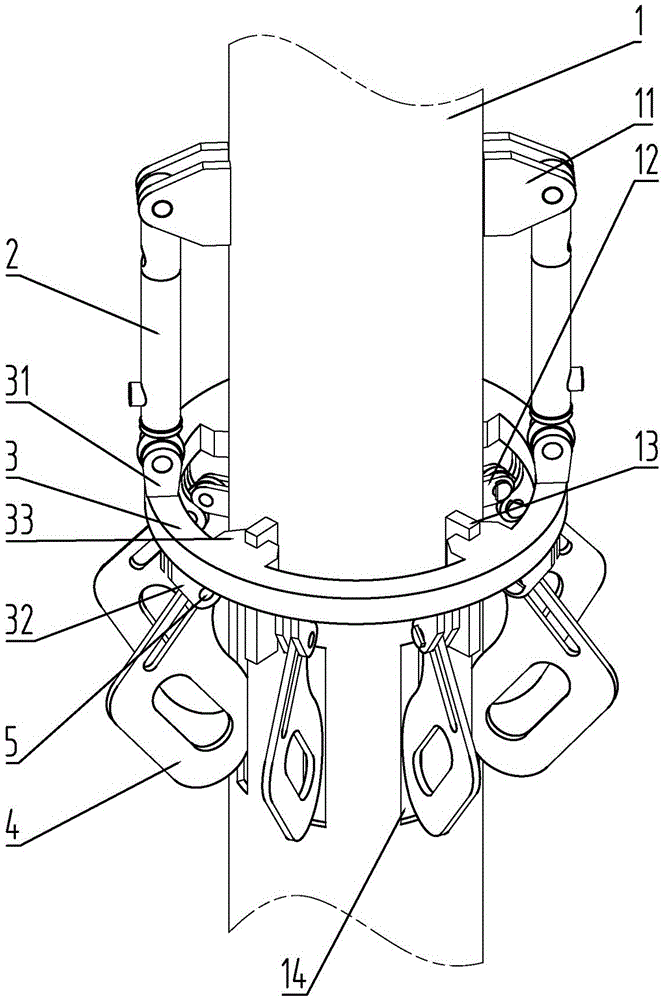

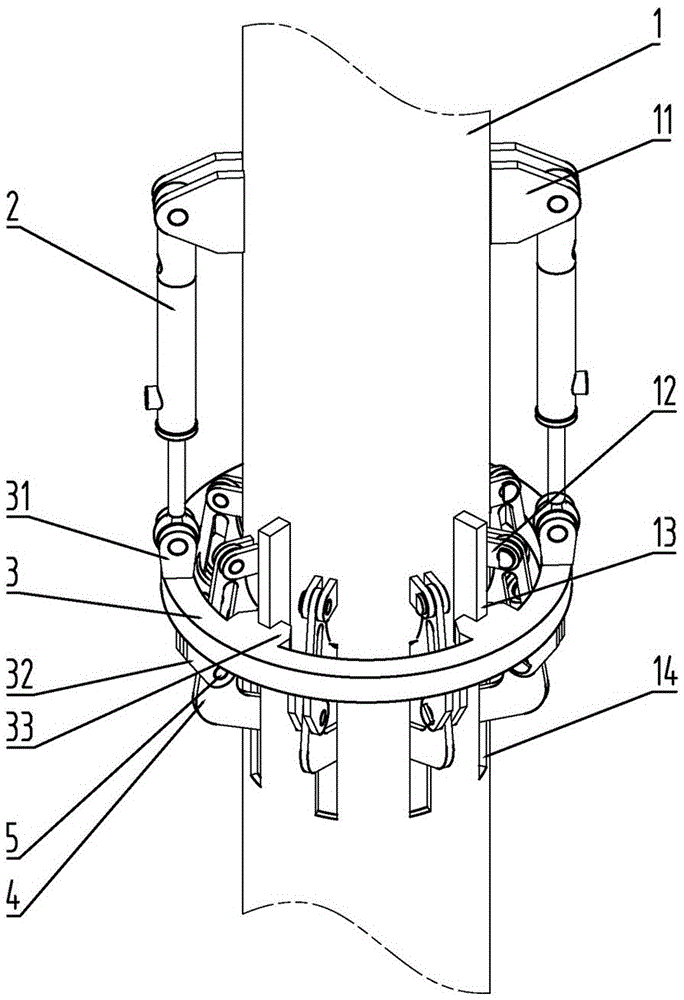

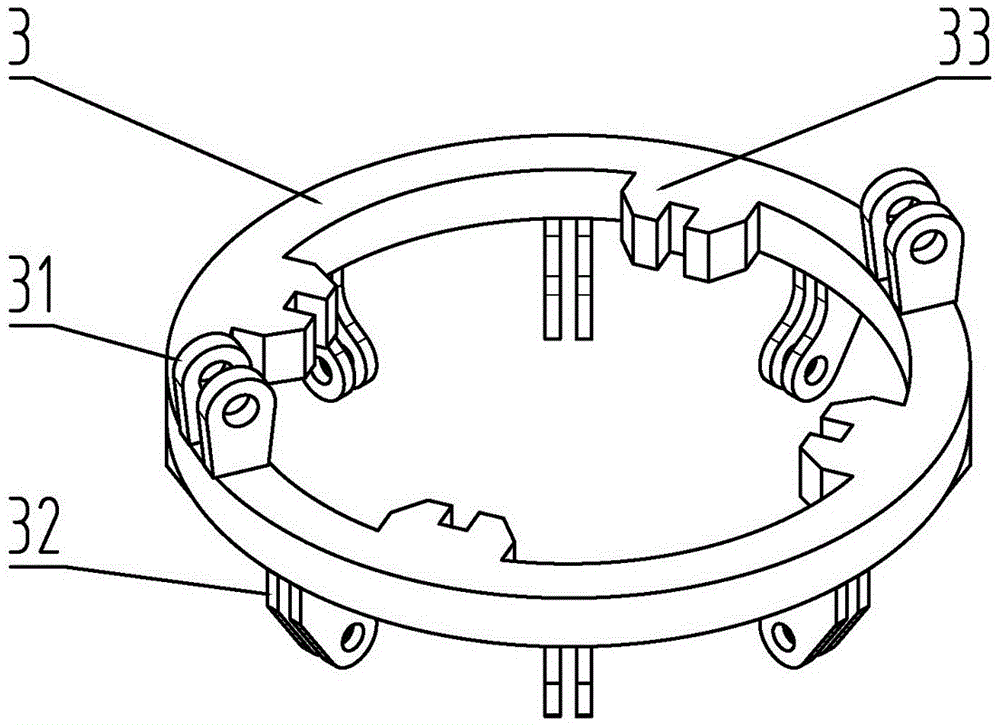

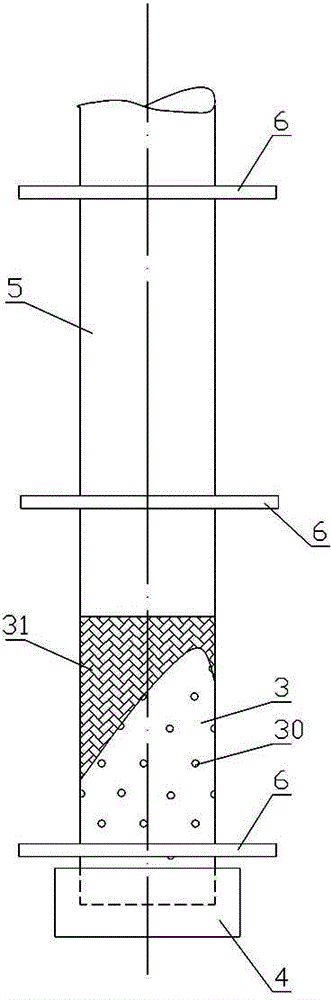

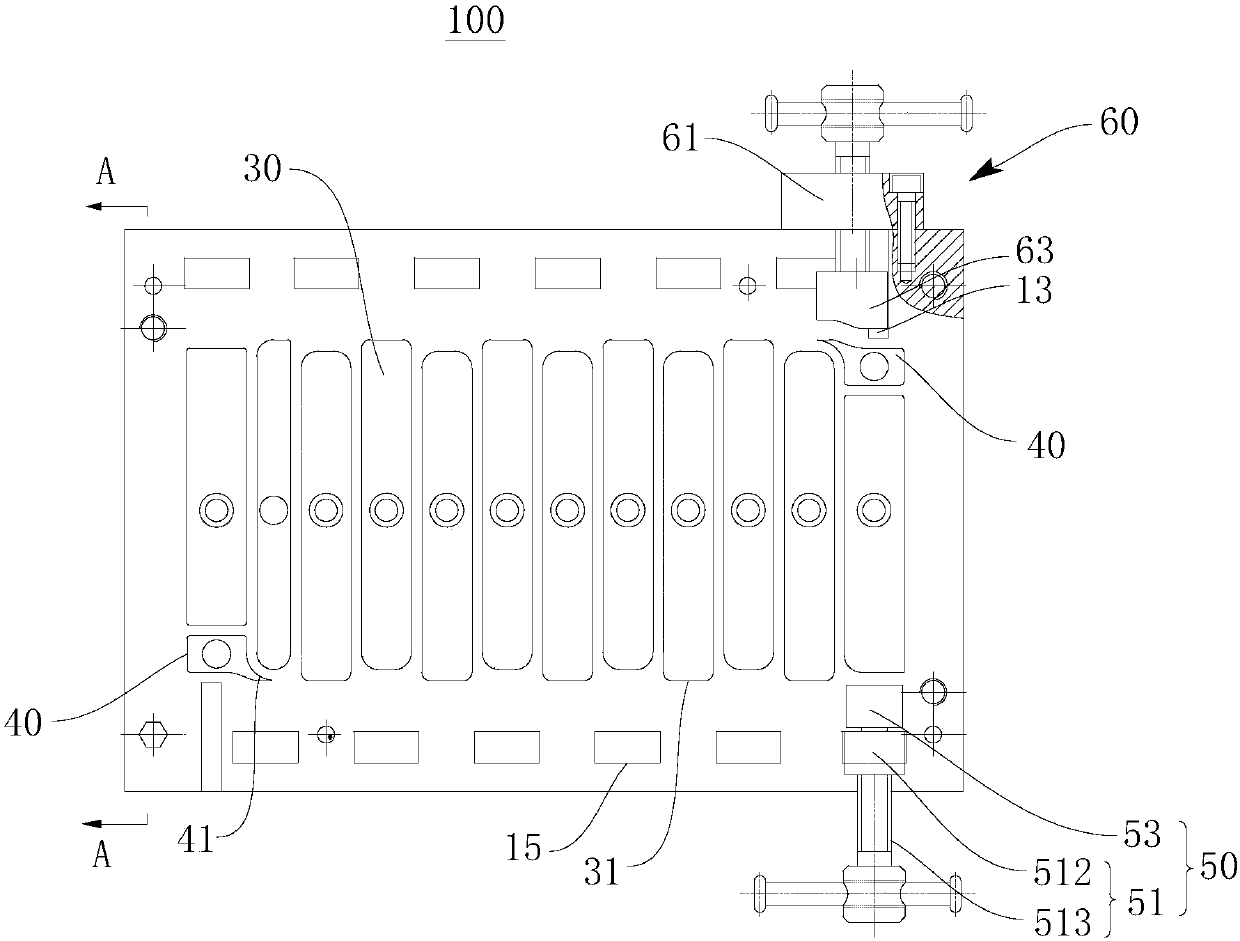

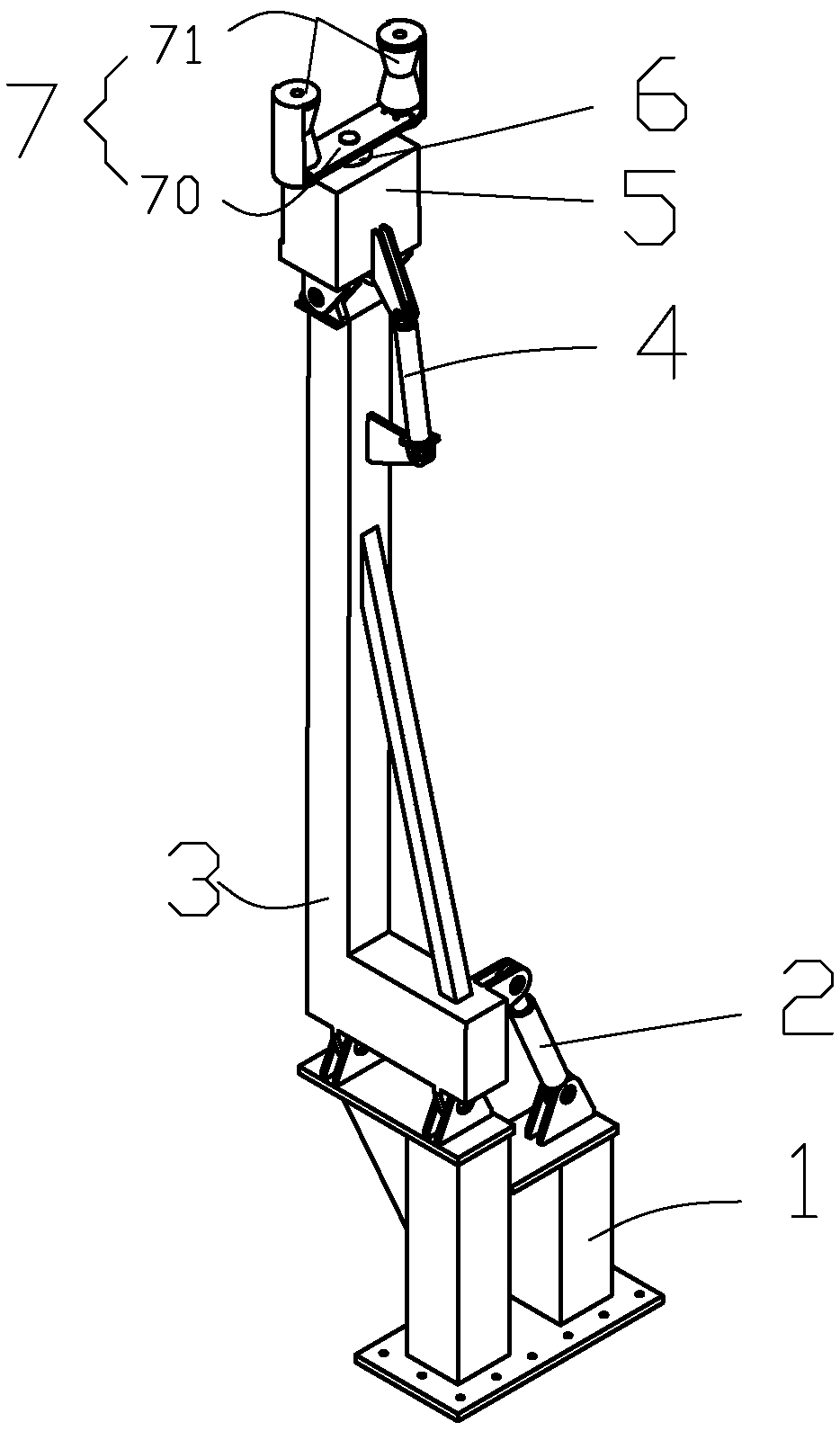

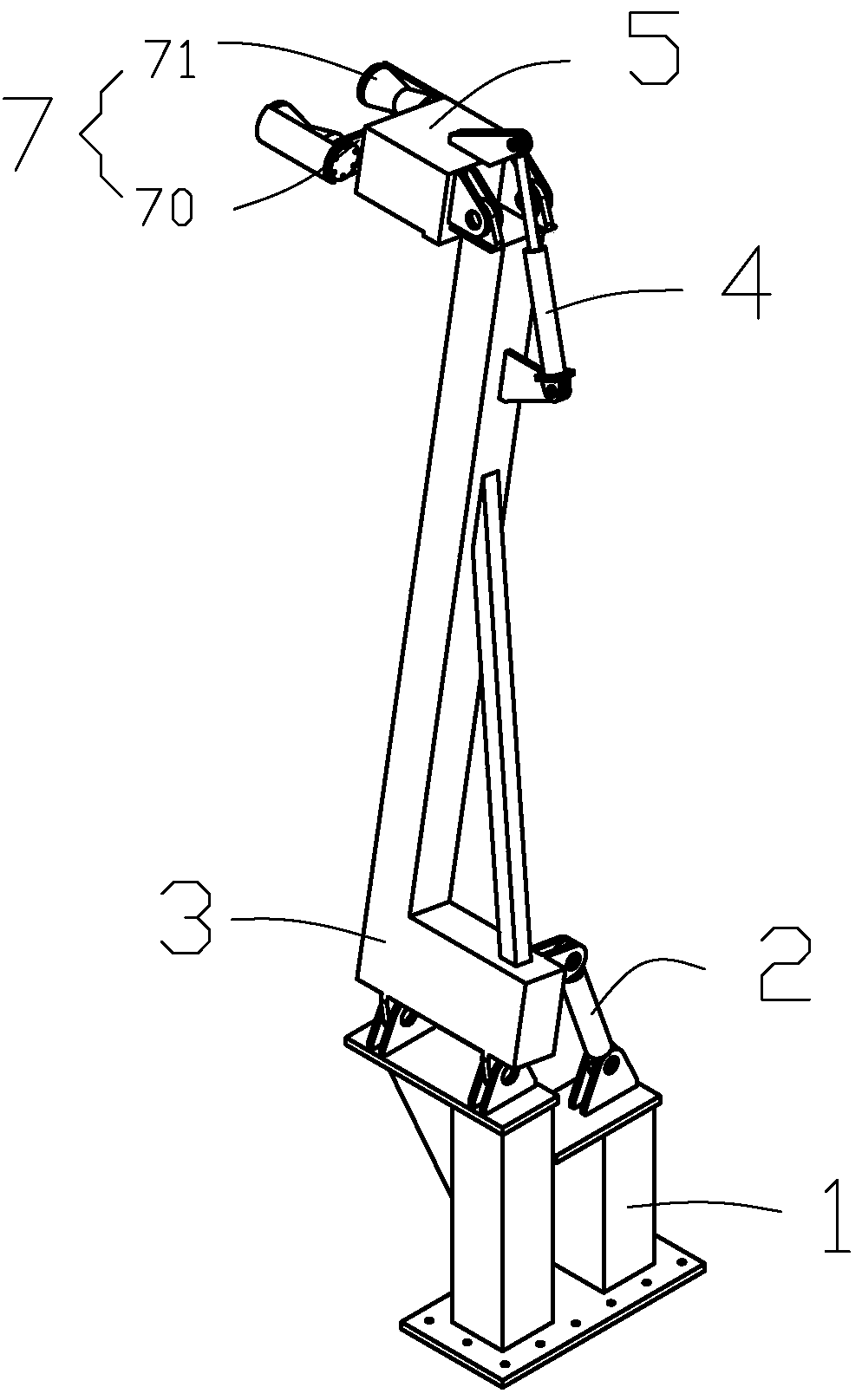

Tube tool centering device

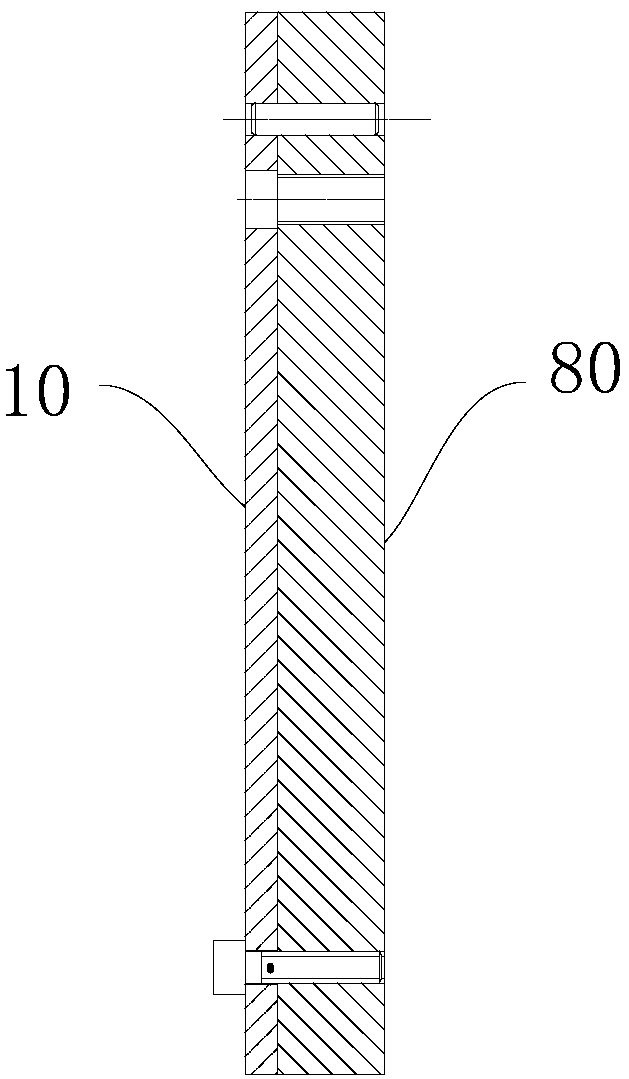

ActiveCN105937374ARealize the centering functionGood centering and reliableDrilling rodsDrilling casingsOil and natural gasTube tool

The invention relates to the technical field of oil and natural gas drilling, in particular to a tube tool centering device. The tube tool centering device comprises a foundation support fixedly connected with a mounting foundation, drive oil cylinders movably connected with the foundation support through support lugs on the foundation support, a transition bracket movably connected with the drive oil cylinders and the foundation support and centering plates movably connected with the foundation support and the transition bracket respectively. The tube tool centering device is simple in structure, small in size and high in centering accuracy.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

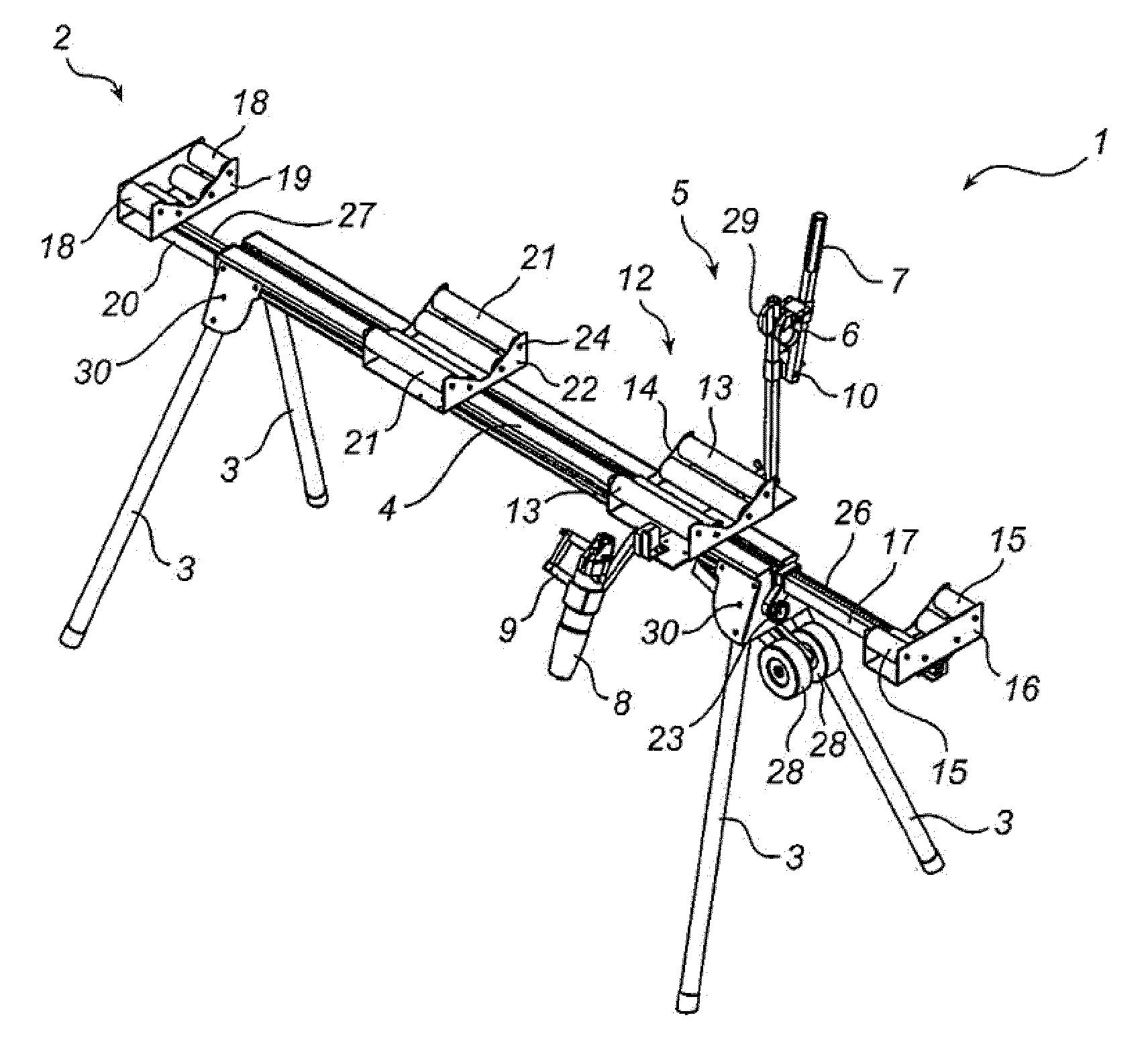

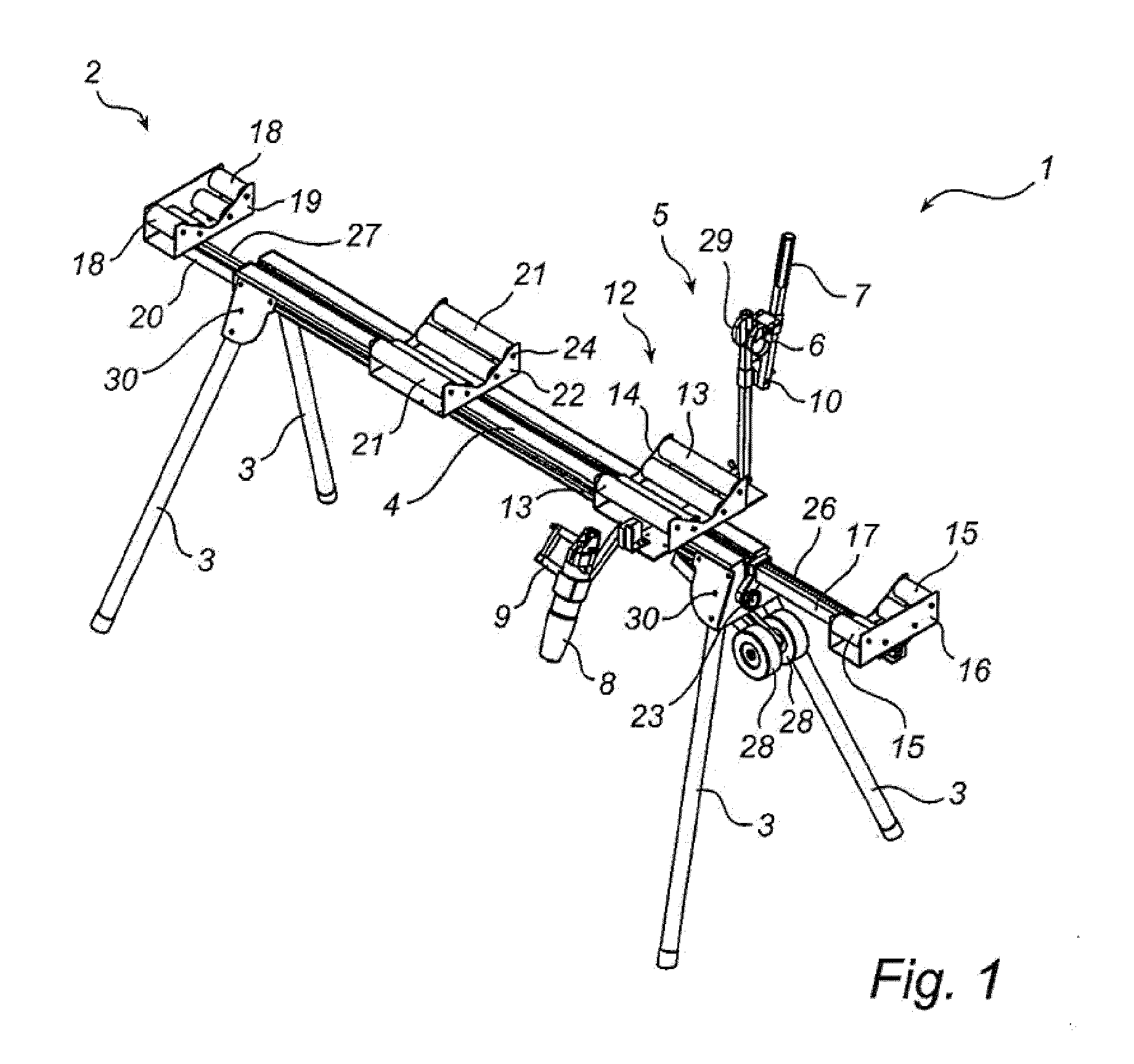

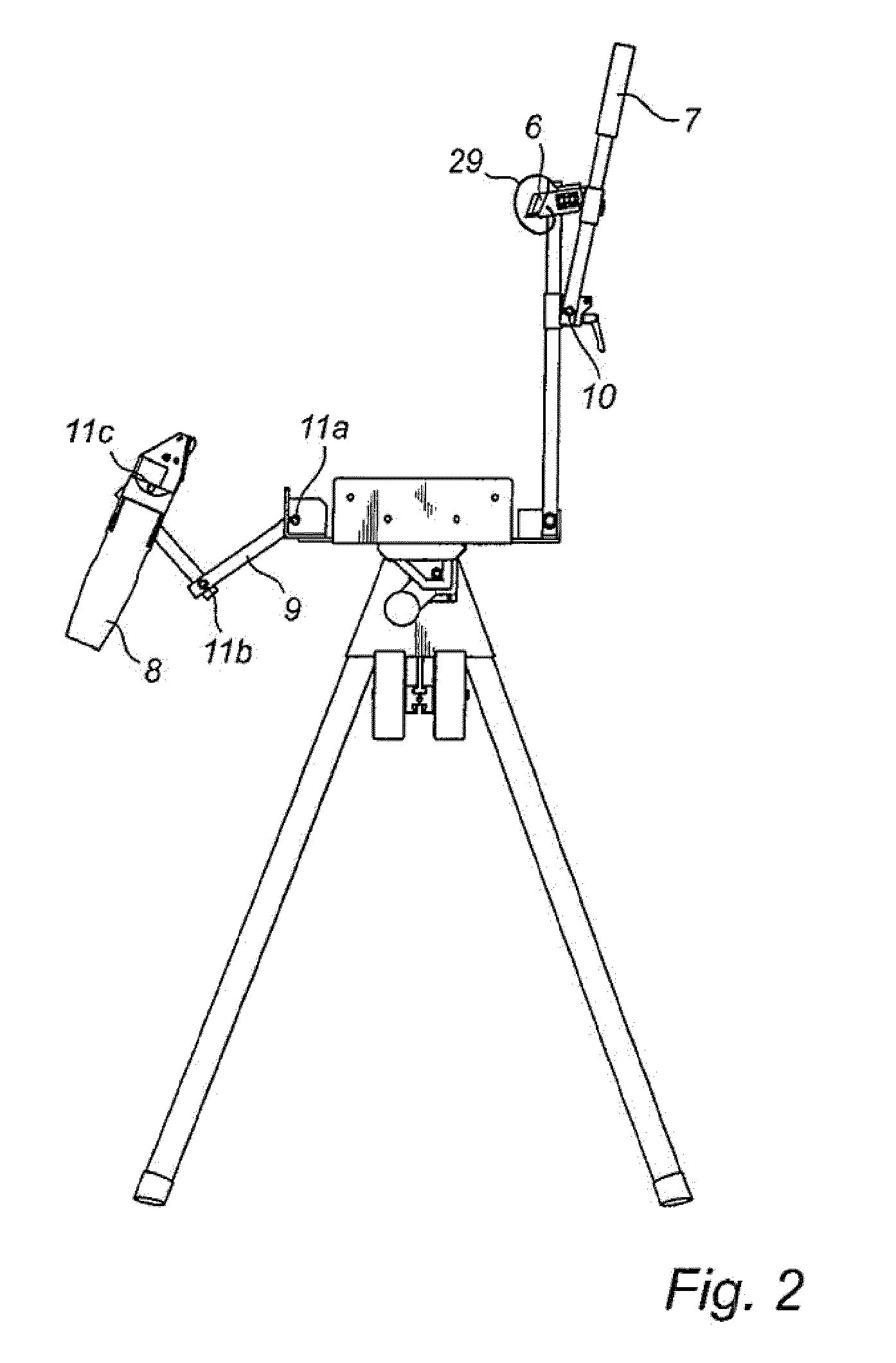

Work bench for cutting a tube and method using such work bench

InactiveUS20100107838A1Easy to insertEliminates creationWork benchesTube shearing machinesAbutmentEngineering

A work bench for cutting a tube comprises a support structure (2) for supporting the tube, a holder assembly (12) for holding the tube and a tool assembly (5) for cutting the tube (34). The tool assembly (5) comprises a cutting tool (8) which is restrained to move only in a plane perpendicular to a longitudinal direction of the tube (34), and that the holder assembly (12) comprises an abutment (16, 19) for an end of the tube (34). The abutment is movable in relation to the cutting tool (8) for setting a desired length of the tube (34) to be cut, and fixable to fix the position of the end of the tube (34) in relation to the cutting tool (8). A method for cutting a tube is also disclosed.

Owner:LINDAB

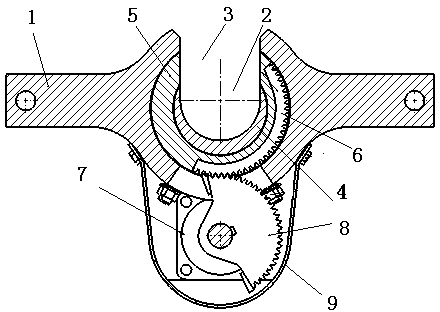

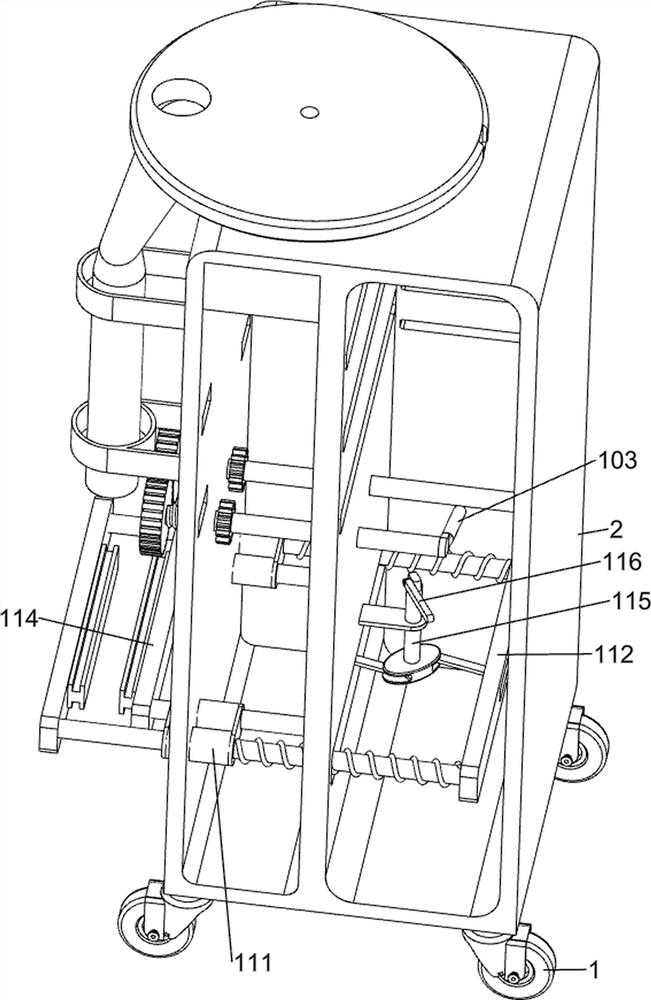

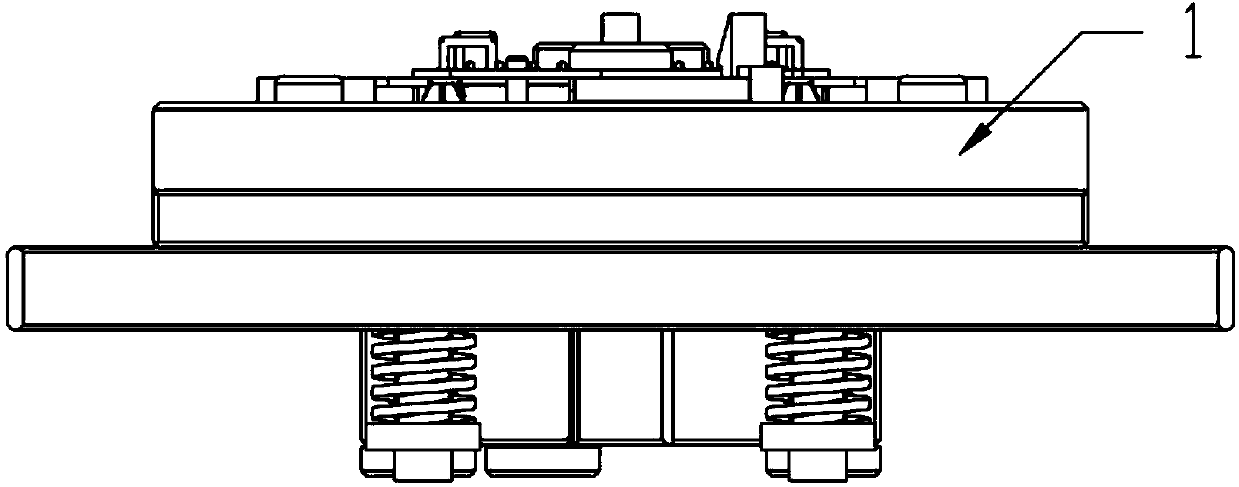

Hydraulic drive oil tube elevator

InactiveCN103590762ARealize remote controlEasy to operateDrilling rodsDrilling casingsHydraulic motorGear drive

The invention relates to ascending or descending oil tube tools in oil field petroleum drilling and production operations, in particular to a hydraulic drive oil tube elevator. The hydraulic drive oil tube elevator is suitable for the lifting operation of suspending an oil tube with a tube diameter of 1.9''-41 / 2'' and an external upset oil tube. The hydraulic drive oil tube elevator comprises an elevator body and a central hole which is formed in the middle of the elevator body and used for clamping the oil tube, an opening allowing the oil tube to pass through is formed in one side of the central hole, and an open thread ring and a locking ring capable of rotating and moving are arranged in the central hole in a lining mode. An arc-shaped gear rack is embedded in the outer surface of the locking ring, and a sector gear driven by a hydraulic motor is arranged outside the elevator body and penetrates through the elevator body to be meshed and connected with the arc-shaped gear rack of the locking ring. A protection cover is arranged outside the hydraulic motor. Hydraulic driving is adopted, operating personnel can be reduced, and the hydraulic drive oil tube elevator is a key component for achieving well repair automation. The hydraulic control locking structure is adopted, the hydraulic drive oil tube elevator is suitable for oil field intelligent control, remote control is achieved, the operation is convenient, and locking is safe and reliable.

Owner:TONGHUA CITY FORWARD GASOLINEEUM MACHINERY

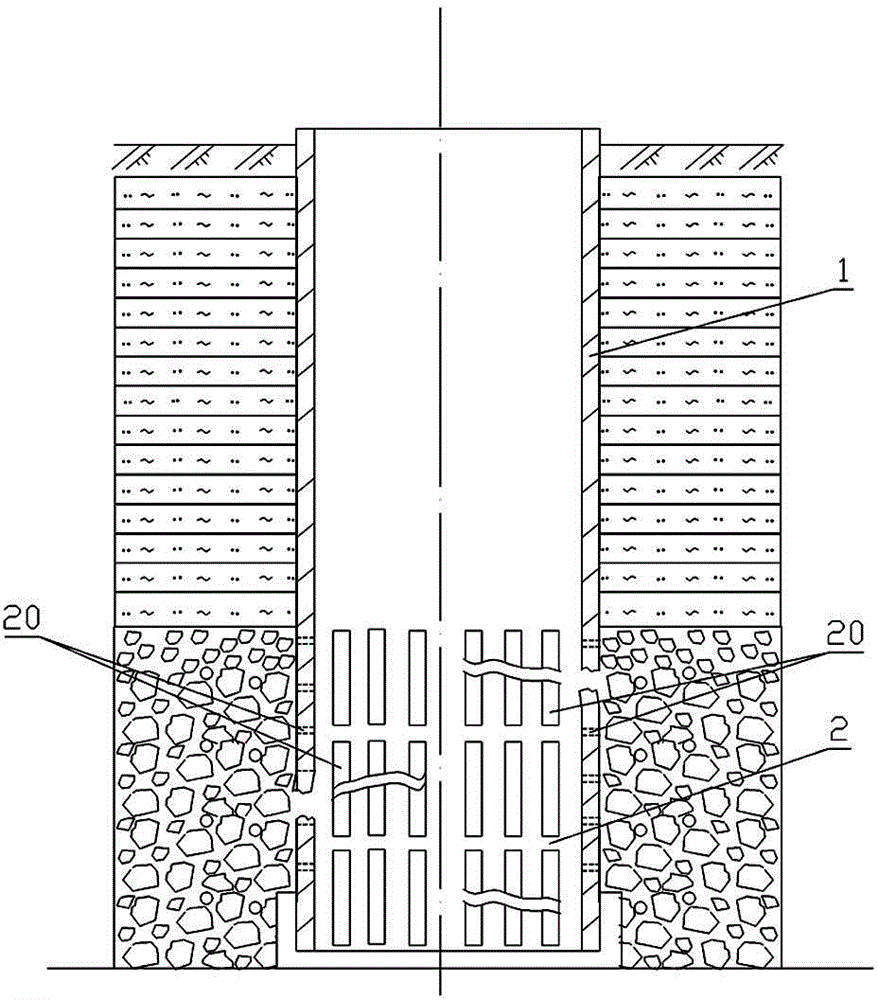

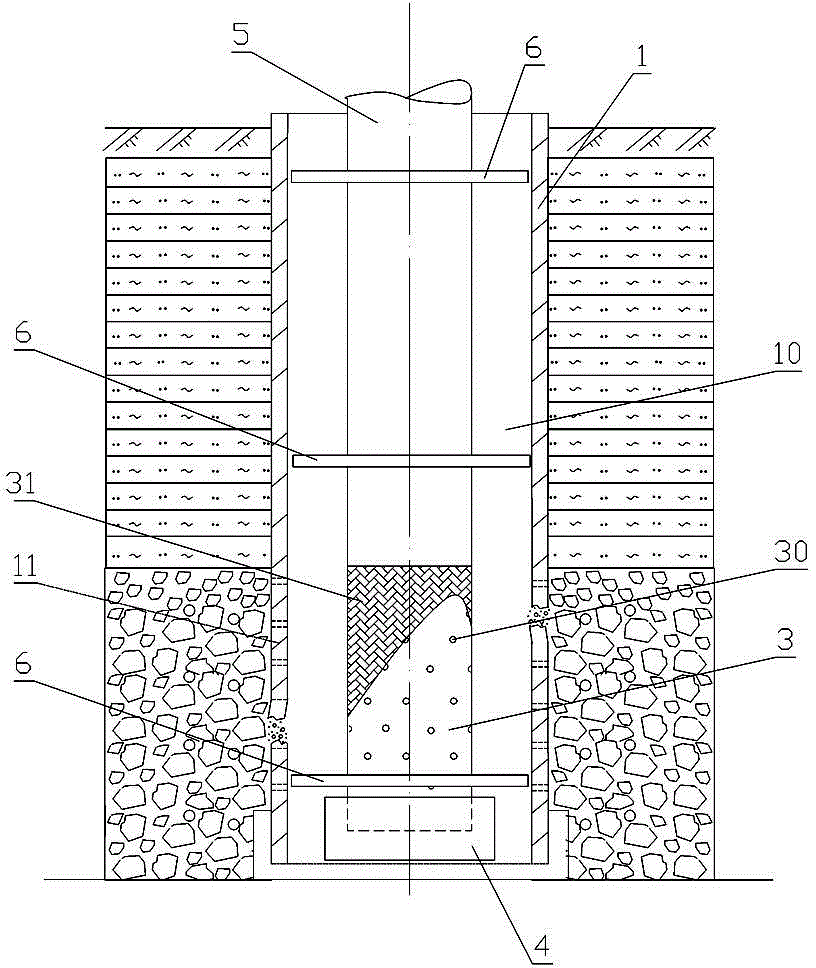

Repair technology for drainage pressure reducing well

ActiveCN104452664AAvoid deformation damagePrevent diffusion and seepageDamsFoundation engineeringFiberEngineering

The invention provides a repair technology for a drainage pressure reducing well. The repair technology includes the steps that first, cleaning is conducted in an original well; second, inserting tube tools are prepared, the inserting tube tools comprise a filter tube and steel retaining devices, the length of the filter tube is 0.5-1 meter larger than the length of a filter tube of a well tube of the original pressure reducing well, filter holes are evenly distributed in the outer wall of the fiber tube, the outer wall of the filter tube is coated with a filter net, a tube plug is arranged at the bottom end of the filter tube, the top end of the filter tube and the bottom end of a water rising tube are connected to form an inserting tube with the length being larger than the depth of the original pressure reducing well, the steel retaining devices are round pieces with inserting holes formed in the middles, and the diameter of the outer edge of each steel retaining device is equal to the inner diameter of the well tube of the original pressure reducing well; third, the inserting tube tools are inserted into the well tube of the original pressure reducing well in a downward mode, and the filling space of at least 80 mm is reserved between the inserting tube tools and the well tube of the original pressure reducing well; fourth, fifth, sixth and seventh, filter materials are evenly backfilled to the filter tube along the filling space so that the filter tube is full of the filter materials, coarse sand is backfilled to the position 1-1.2 meters higher than the bottom of the water rising tube, clay is backfilled to the position 2-2.2 meters lower than the top of the water rising tube, and concrete is backfilled to the position on the top of the water rising tube; eighth, a wellhead is manufactured. The pressure reducing well repaired through the method has an original drainage function, the phenomenon that a waste well is subjected to landfill treatment and is shifted again to build the pressure reducing well is avoided, and the project cost is lowered.

Owner:GUANGDONG YUANTIAN ENG

Modified boiler wall tube tool

InactiveUS8348253B2Improve versatilityMaintain alignmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTroffer

A boiler wall tube tool comprises a pair of opposed clamp members, each one of the clamp members having a nose intermediately disposed between a recess and a planar or inclined wall, and an aperture formed centrally through the clamp member. The clamp members oriented so that the recess of one of the clamp members is substantially aligned with the planar wall of the remaining clamp member for engaging a boiler wall tube therebetween. The aperture of one clamp member is substantially aligned with the aperture of the remaining clamp member. Means for moving the clamp members toward each other for secure clamping engagement of the tubes for maintaining the clamp members in alignment while connecting the ends of the tubes by welding is also provided.

Owner:MCCLURE MARK W

Tool for inserting fuel tubes

A fuel insertion tube tool for installing a fuel tube on a barb. The tool has first and second arms that are pivotably attached through an arm pivot axis. Each arm has a grip to engage the fuel tube. A tab extends from the first arm and is pivotably attached to a proximal end of a bar with a pivot pin that defines a bar axis. The bar axis and the arm axis are perpendicular to each other. A hook is disposed at a distal end of the bar for engagement with an attachment site. The tab functions as a fulcrum to reduce the amount of force required to install the fuel tube on the barb. The bar has weight reducing holes and the grips have straight knurls for frictional engagement with the fuel tube.

Owner:HONDA MOTOR CO LTD

Pipe bending tool and pipe bending method

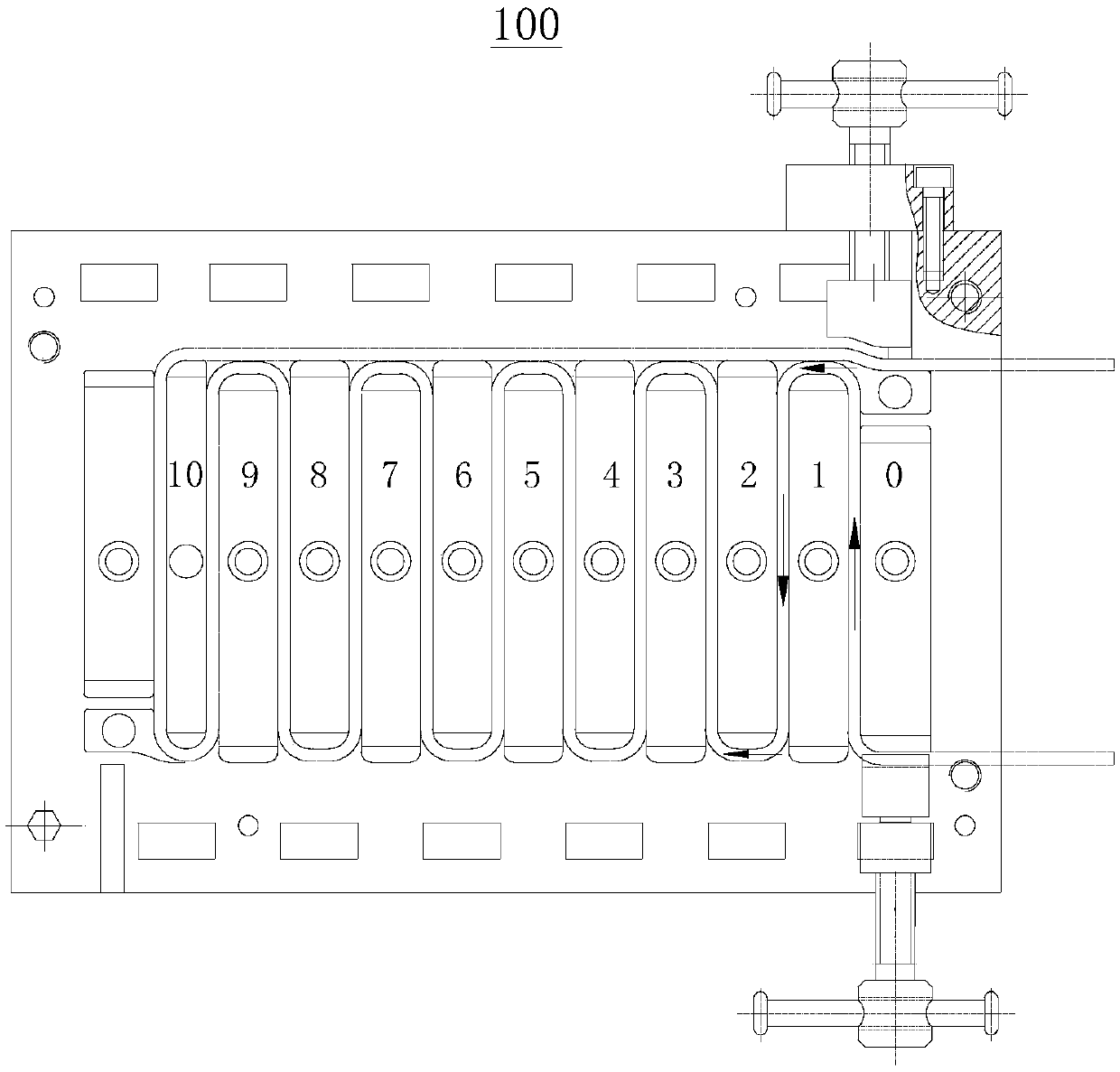

PendingCN107671151ASmooth bendingGuaranteed accuracyShaping toolsMetal-working feeding devicesProduct baseTube forming

The invention provides a pipe bending tool and a pipe bending method, and relates to the technical field of pipe fitting machining. The pipe bending tool comprises a positioning plate, first mold cores, second mold cores and a fastening device, wherein the positioning plate is provided with a concave groove; the length and the width of the concave groove are set according to the size requirementsof products to be bent; the first mold cores are matched with the concave groove, and are detachably connected with the positioning plate; the first mold cores comprise pipe bending parts; the shapesof the pipe bending parts are set according to the shapes of the bent places of the products to be bent; the second mold cores comprise guide parts for limiting the directions of thin-wall pipes; thefastening device is used for pushing the thin-wall pipes to enable the thin-wall pipes to bond with the pipe bending parts of the first mold cores; first molding channels for molding the products areformed among multiple first mold cores and between part of the first mold cores and part of the second mold cores; and the widths of the first molding channels are equal to the thicknesses of the thin-wall pipes. The pipe bending method can guarantee high-precision production of the thin-wall pipes without damage through using the pipe bending tool.

Owner:NEW UNITED RAIL TRANSIT TECH

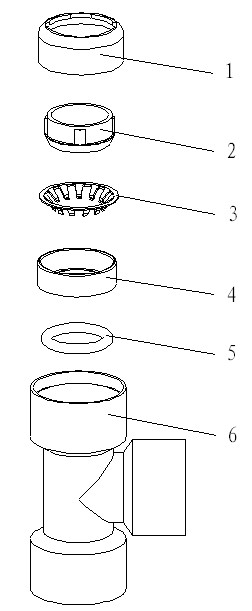

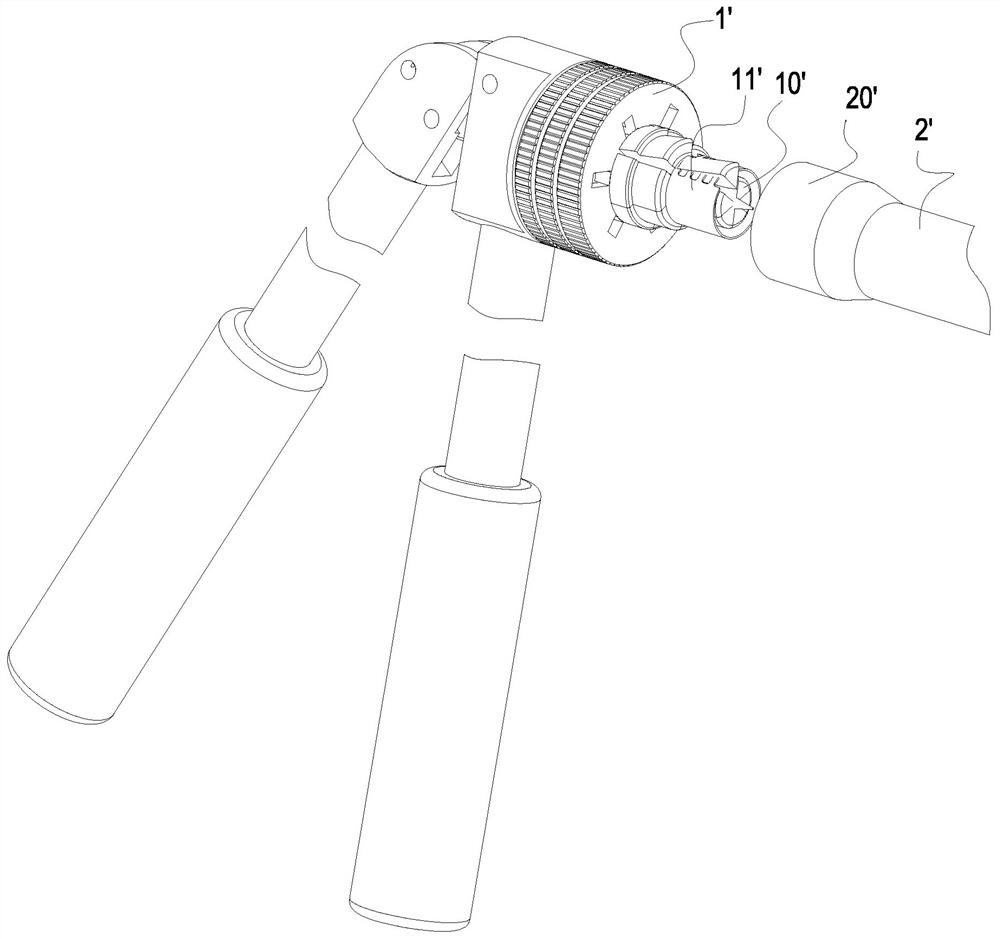

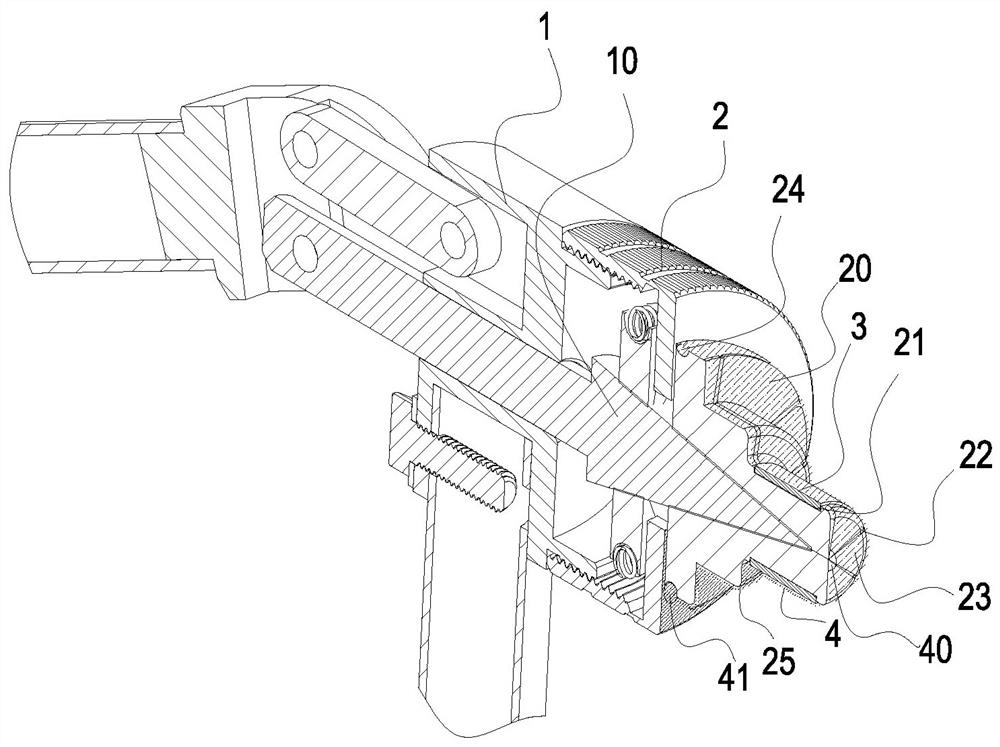

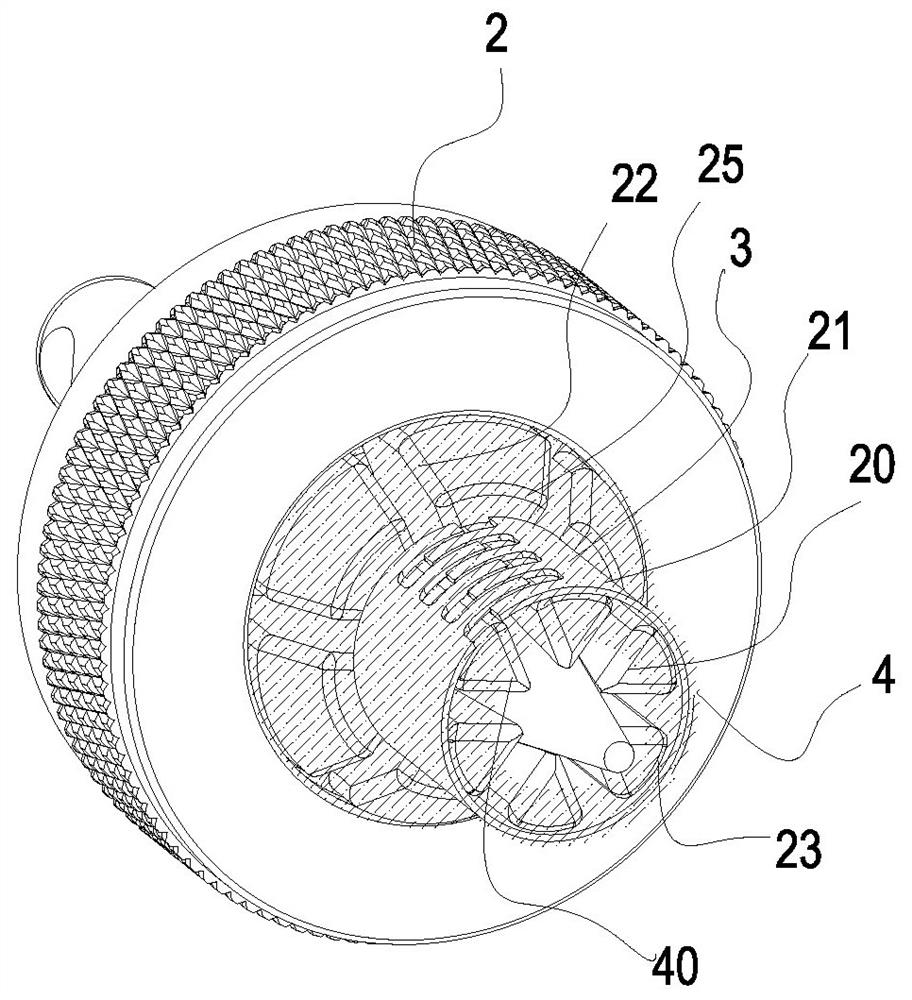

Fluid pipe connection device and supporting pipe demolition tool thereof

InactiveCN102635747ASimple and fast operationNot easy to wearCouplingsBranching pipesEngineeringMechanical engineering

The invention provides a fluid pipe connection device, aiming to solve the problems that the pipe demolition is troublesome and the top part of the pushing gear ring can be easily worn and damaged. The fluid pipe connection device comprises a pipe connector, and an inner gear clamping ring and a pushing gear ring are arranged in the pipe connector and a plug sleeve via the plug sleeve arranged fixedly on the pipe connector. When a pipe is butted, the pipe penetrates through the plug sleeve, the pushing gear ring and the inner gear clamping ring, and the wall of the pipe is tightly clamped by the inner gear clamping ring; and when the pipe is removed, and an inner gear is pushed by the pushing gear ring along the pipe insertion direction so that the wall of the pipe is not clamped by the inner gear clamping ring. The fluid pipe connection device is characterized in that the pushing gear ring and the plug sleeve are contacted in a sliding way; and the top end of the pushing gear ring is basically flush with the plug sleeve or is contracted into the plug sleeve when the pipe is butted. The invention also provides a supporting pipe demolition tool, which comprises a handle, the handle is connected with an ejection block, and the ejection block can extend into a clearance between the plug sleeve and the wall of the pipe to push the pushing gear ring.

Owner:MUCH RISE INVESTMENT

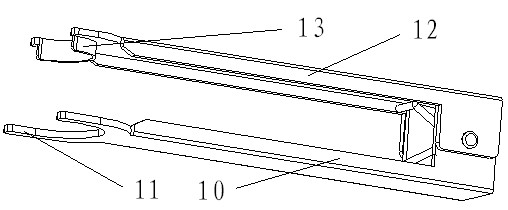

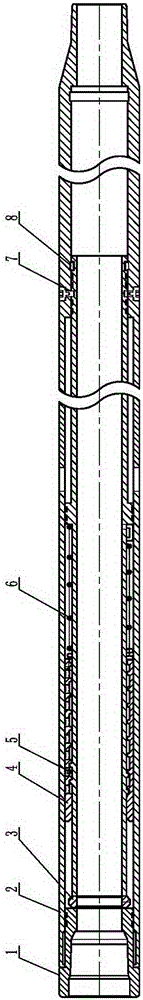

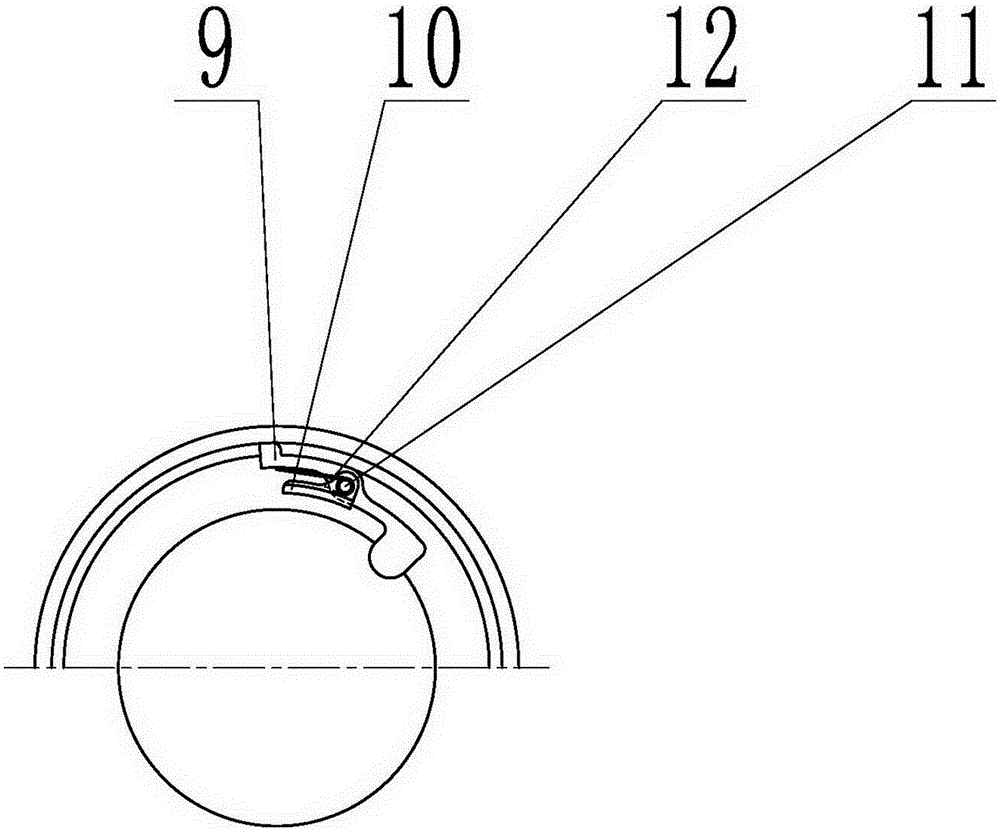

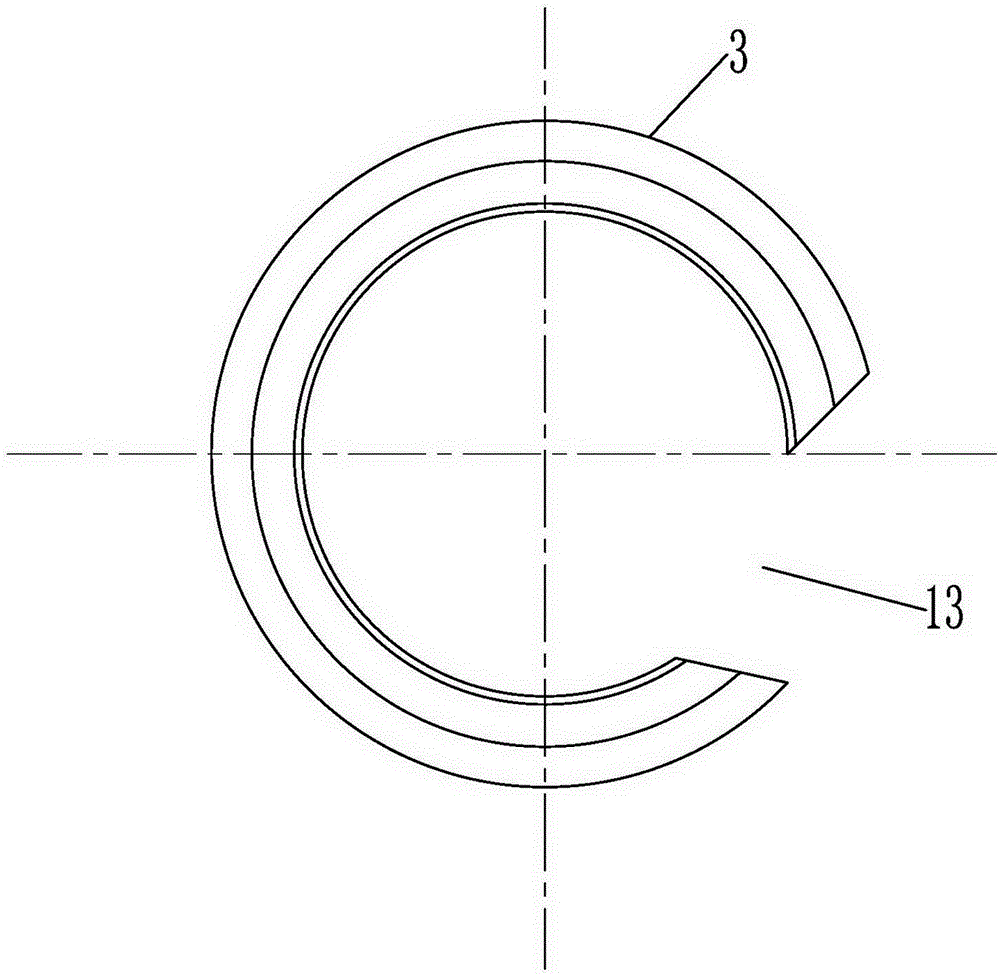

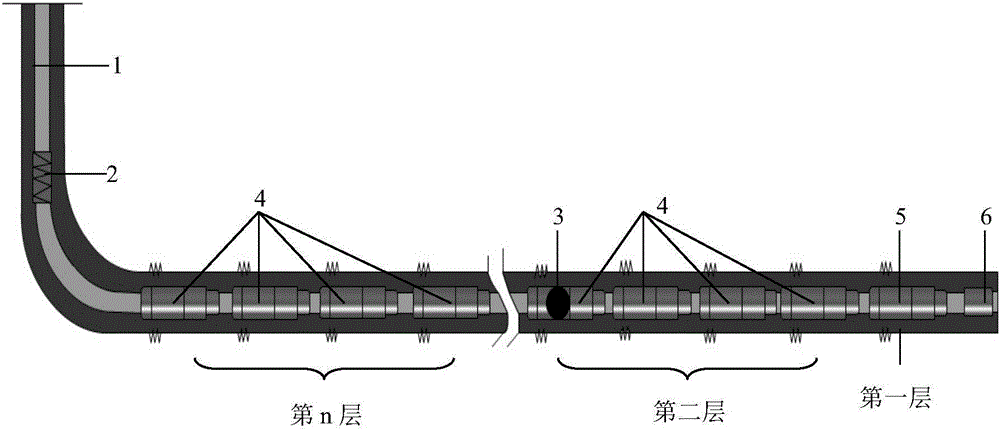

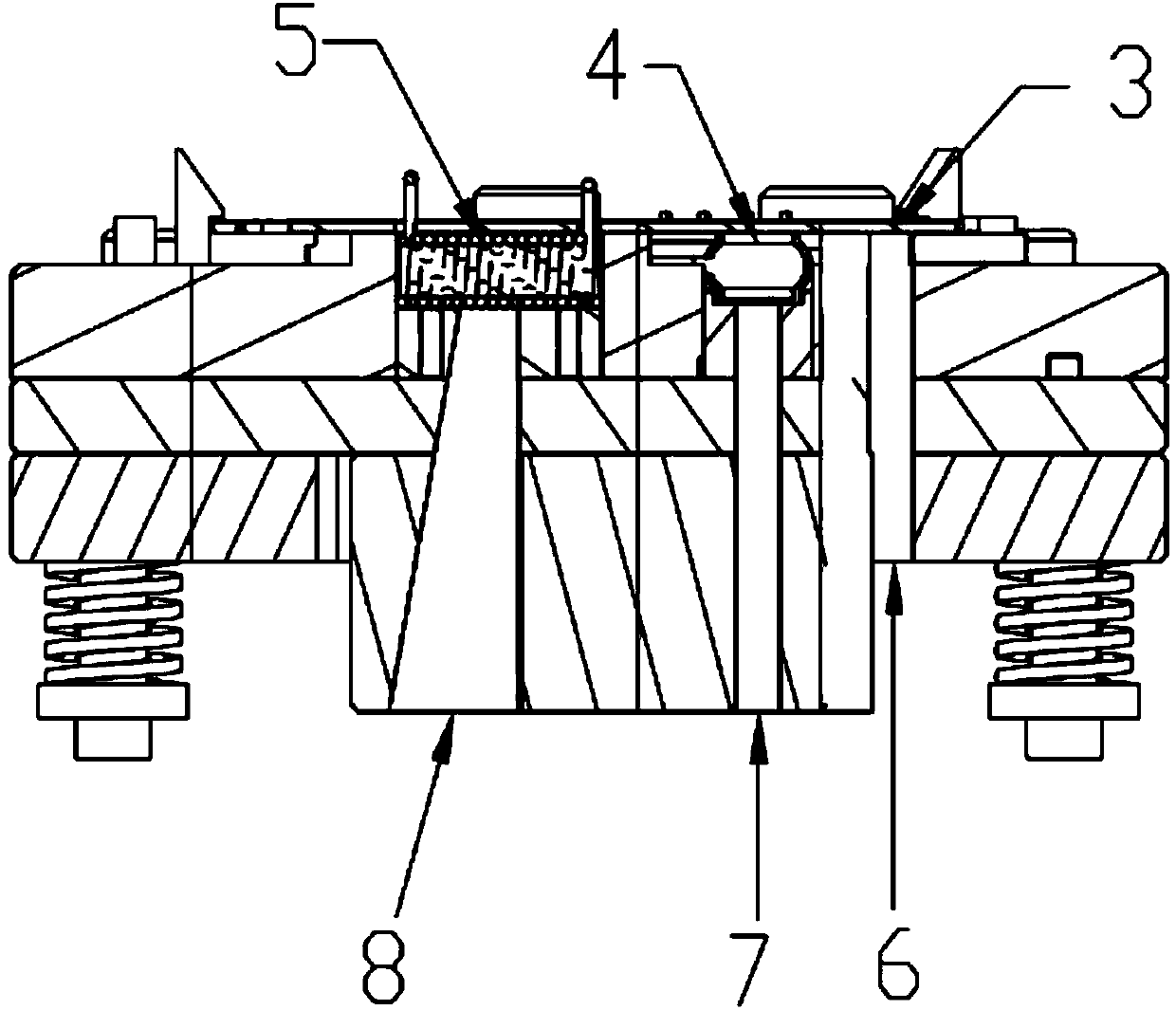

Guide rail type intelligent sliding sleeve sieve tube tool

ActiveCN105134161AImprove opening rateSimple designFluid removalWell/borehole valve arrangementsAcid fracturingTube tool

The invention belongs to the field of full-bore segmented acid fracturing in mining well-completion practice of oil and gas wells, and in particular relates to a guide rail type sliding sleeve sieve tube tool which comprises a lifted joint and a shell, wherein the shell is provided with a retractable C ring ball seat, a counting sleeve, a locating sleeve, a spring, a shear pin and a spacing ring. In an operation process, balls with the same size are always thrown to trigger an ejection device and seal the ball seat. The pressure grade for opening a sieve pore shear pin can not be changed with the change of the segmented grade of acid fracturing, and the pressure of each segment of the shear pin subjected to acid fracturing is same, so that the open rate of a sliding sleeve is increased, the acid fracturing efficiency is increased, and the well control risk and operation cost are further reduced. The tool is simple in design structure, has few components, is convenient to install, relatively saves trouble and labor, and is worthy of being popularized and used in oil and gas fields in China.

Owner:XINJIANG GANGTUO ENERGY TECH

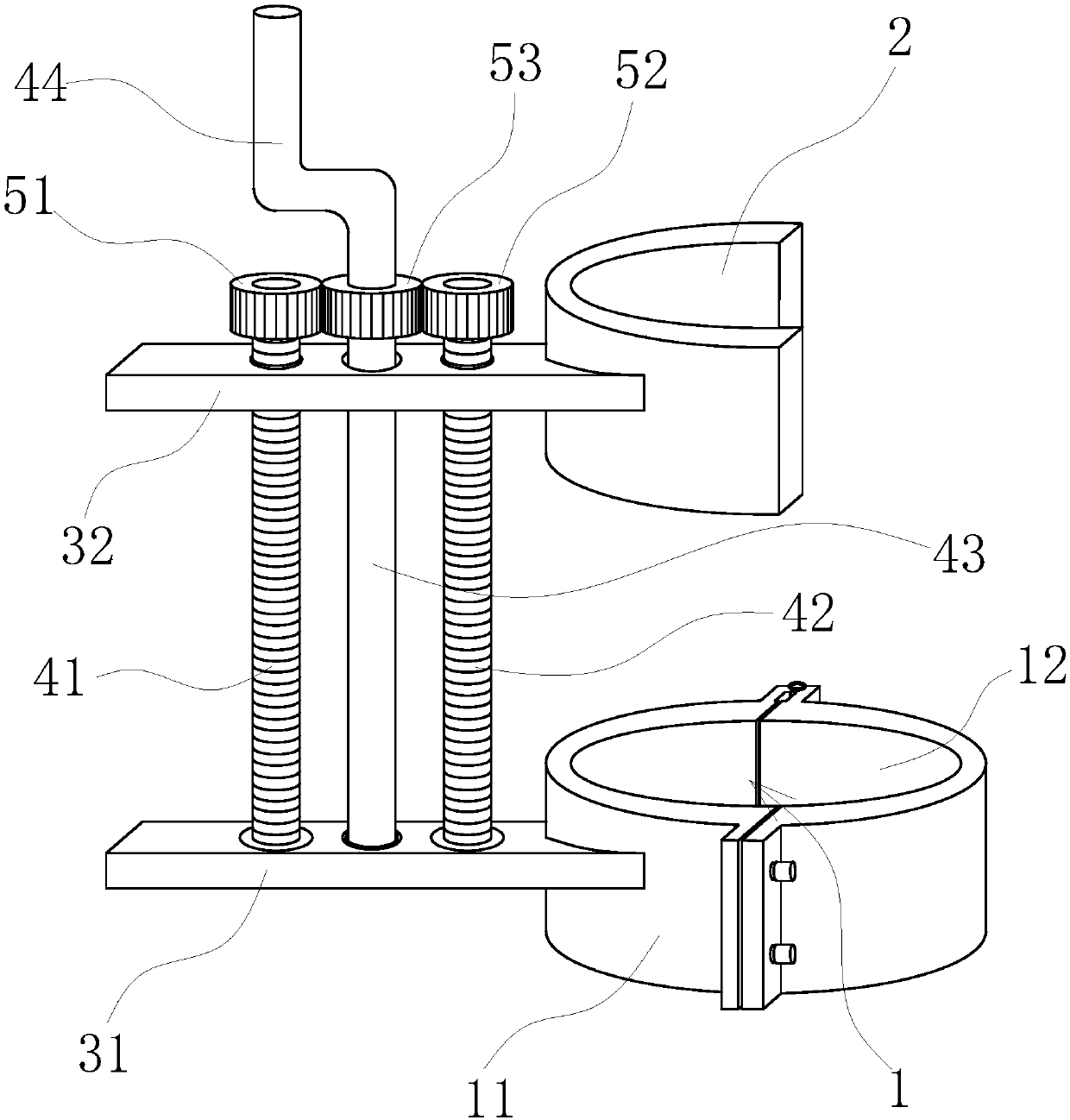

Quick pipe connecting tool

PendingCN107781547ALabor-saving operationQuickly take over jobsSleeve/socket jointsMetal-working hand toolsEngineeringScrew thread

The invention provides a quick pipe connecting tool. The pipe connecting tool comprises a hoop and a pressure clamp, wherein a first connecting plate is fixedly arranged on the hoop, a second connecting plate parallel with the first connecting plate is fixedly arranged on the outer side wall of the pressure clamp, a first screw, a second screw and a drive rod which are parallel with the axis of the hoop are arranged between the first connecting plate and the second connecting plate, lower ends of the first screw and the second screw are connected with the first connecting plate through bearings, a first gear and a second gear are fixedly arranged at upper ends of the first screw and the second screw respectively, the lower end of the drive rod is connected with the first connecting plate through a bearing, a rocking handle is connected with the upper end of the drive rod, an intermediate gear meshed with the first gear and the second gear simultaneously is also fixedly arranged on thedrive rod, the first screw and the second screw are in threaded connection with the second connecting plate, the drive rod is arranged on the second connecting plate in a penetrating manner, and a gapexists between the drive rod and the second connecting plate. The quick pipe connecting tool has the advantages of being simple in structure, time-saving and labor-saving.

Owner:HUBEI UNIV OF SCI & TECH

Industrial batch packaging equipment for light emitting diodes

PendingCN114537740AReduce stepsReduce manual sealing operationsSuccessive articlesEngineeringToolbox

The invention relates to industrial batch packaging equipment, in particular to industrial batch packaging equipment for light emitting diodes. The invention provides industrial batch packaging equipment for light-emitting diodes with automatic loading and edge sealing functions. Industrial batch packaging equipment for light-emitting diodes comprises idler wheels, a tool box, a feeding frame, a loading device, a discharging pipe, an upper limiting frame, a lower limiting frame, a device frame and the like, the idler wheels are rotationally arranged on the left side and the right side of the bottom of the tool box in a front-back symmetrical mode, the feeding frame is arranged on the left side of the top of the tool box, and the right side of the top of the feeding frame communicates with the loading device; the bottom of the feeding frame communicates with a discharging pipe, an upper limiting frame and a lower limiting frame are arranged on the upper left portion of the tool box, and a device frame is arranged on the upper left portion of the tool box. And the third packaging device and the second packaging device can intermittently and transversely clamp and package the middle of the packaging film, the effect of automatically packaging the top and bottom edges of the packaging bag is achieved, and manual sealing operation is reduced.

Owner:深圳市荣晟泰科技有限公司

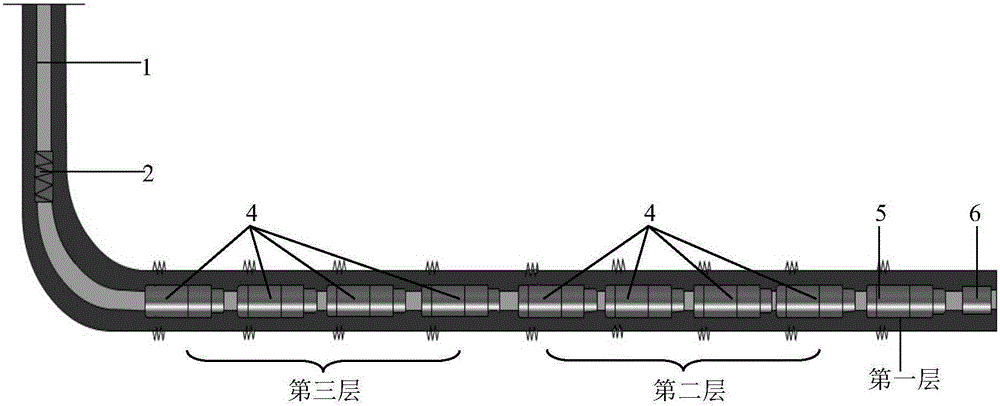

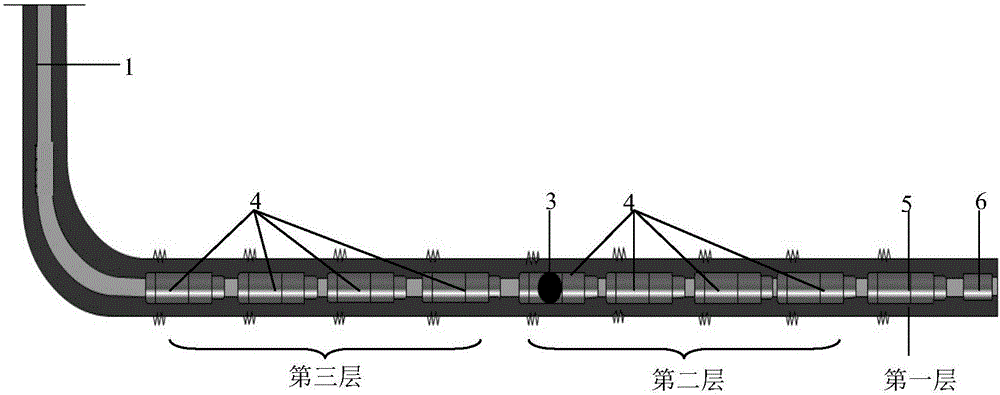

Horizontal well cementation segmented multi-cluster volume fracturing technology

InactiveCN105937389AIncrease productionReduce processing costsFluid removalThermodynamicsHorizontal wells

The invention relates to the technical field of oil field oil production engineering, and belongs to a horizontal well cementation segmented multi-cluster volume fracturing technology. The problems that when ball putting is adopted in a horizontal well cementation sliding sleeve fracturing technology for fracturing construction, each segment of fracturing ball can only open one stage of sliding sleeve, and consequently construction is complex, and cost is high are effectively solved. According to the technology, a horizontal well cementation cluster type sliding sleeve (4), a pressure sliding sleeve (5) and a bump-pressure seat (6) are firstly put down into a well along with a sleeve pipe (1) to design depth; well cementation is carried out, a pipe cleaning tool (2) is put down to scrape away cement in the pipe, the pipe cleaning tool (2) is put down directly to the bump-pressure seat (6) and matched with the bump pressure seat (6) to achieve locking, the cement is returned to a well mouth, and well shut-in and cement setting waiting are carried out pressure bumping; after pump pressure is added to the well mouth to open the pressure sliding sleeve (5), fracturing is carried out on the first layer; a ball (3) is fed to the second layer, and then the ball is sequentially fed to the third layer to the nth layer in sequence for multi-layer-segment fracturing construction. The technology has the advantages of increasing single-well yield, reducing cost, achieving effective development and the like.

Owner:PETROCHINA CO LTD +1

Material missed-arrangement detection device

ActiveCN103744118ASolve the leakElectric/magnetic detectionAcoustic wave reradiationEngineeringTube tool

The invention relates to a material missed-arrangement detection device which includes detection sensors and a support board and the like. Through holes are arranged in a tube tool and the through holes are corresponding to different kinds of sensors. When material parts are not placed on installation locations above the through holes, an alarm notification is performed. Through installation of the detection sensors at corresponding material positions of a support and through hole detection on the positions where the materials are placed on a multifunctional pipe,, the detection device is applicable to an automation device and capable of solving a material missed-arrangement problem and the device is controlled to stop operation after missed arrangement of the material happens.

Owner:NINGBO TIANLONG ELECTRONICS

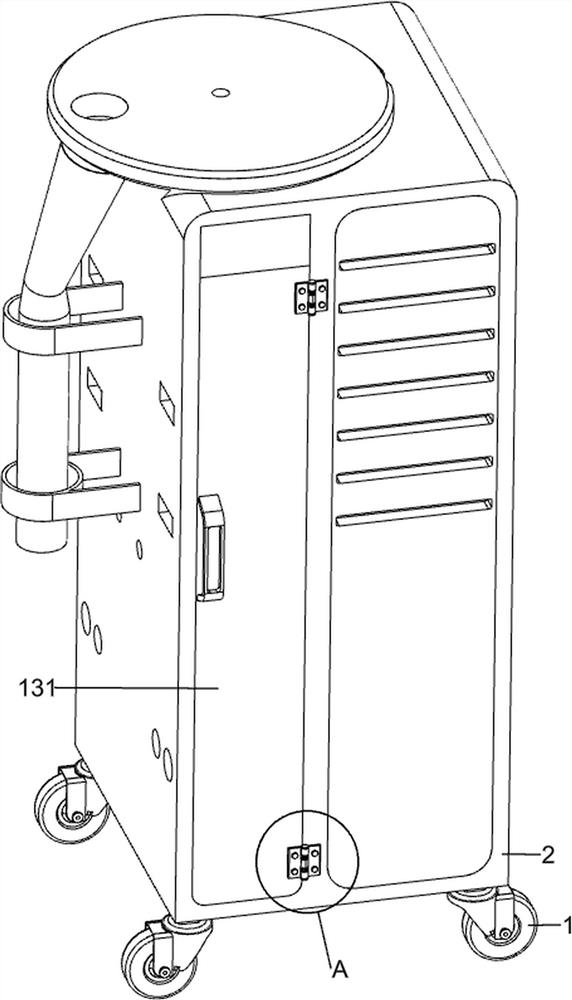

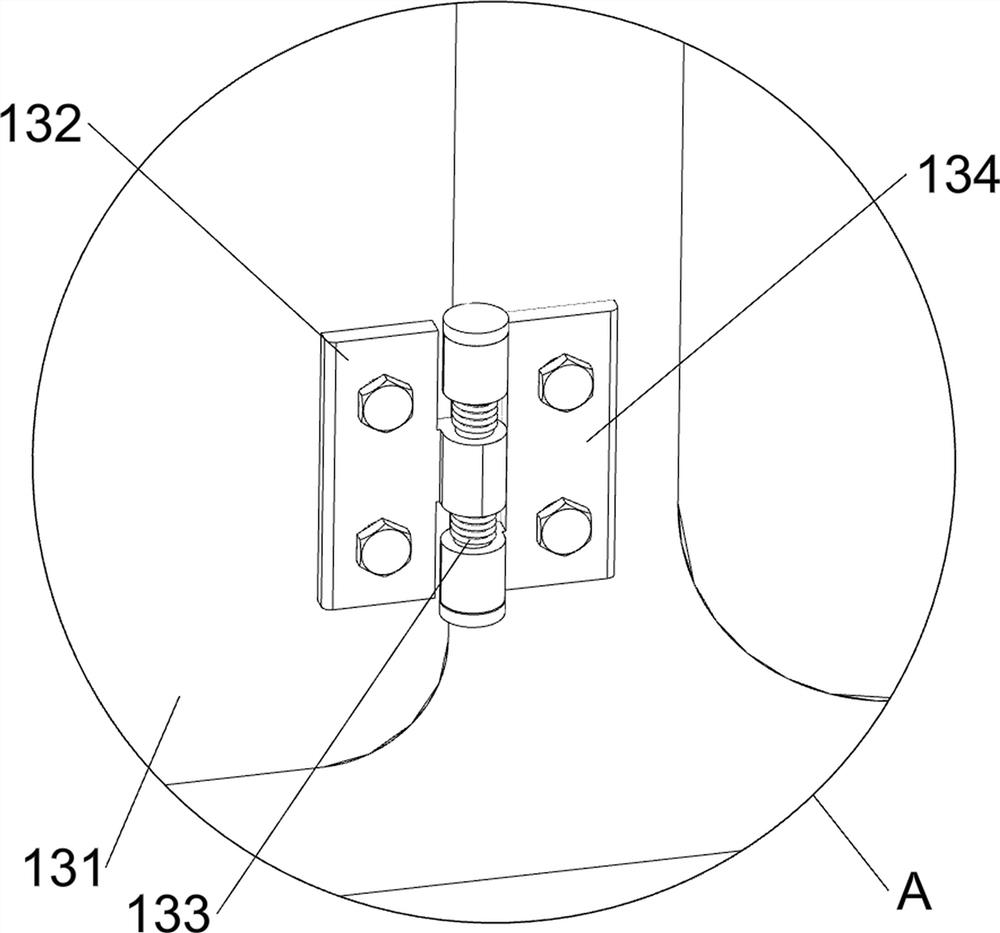

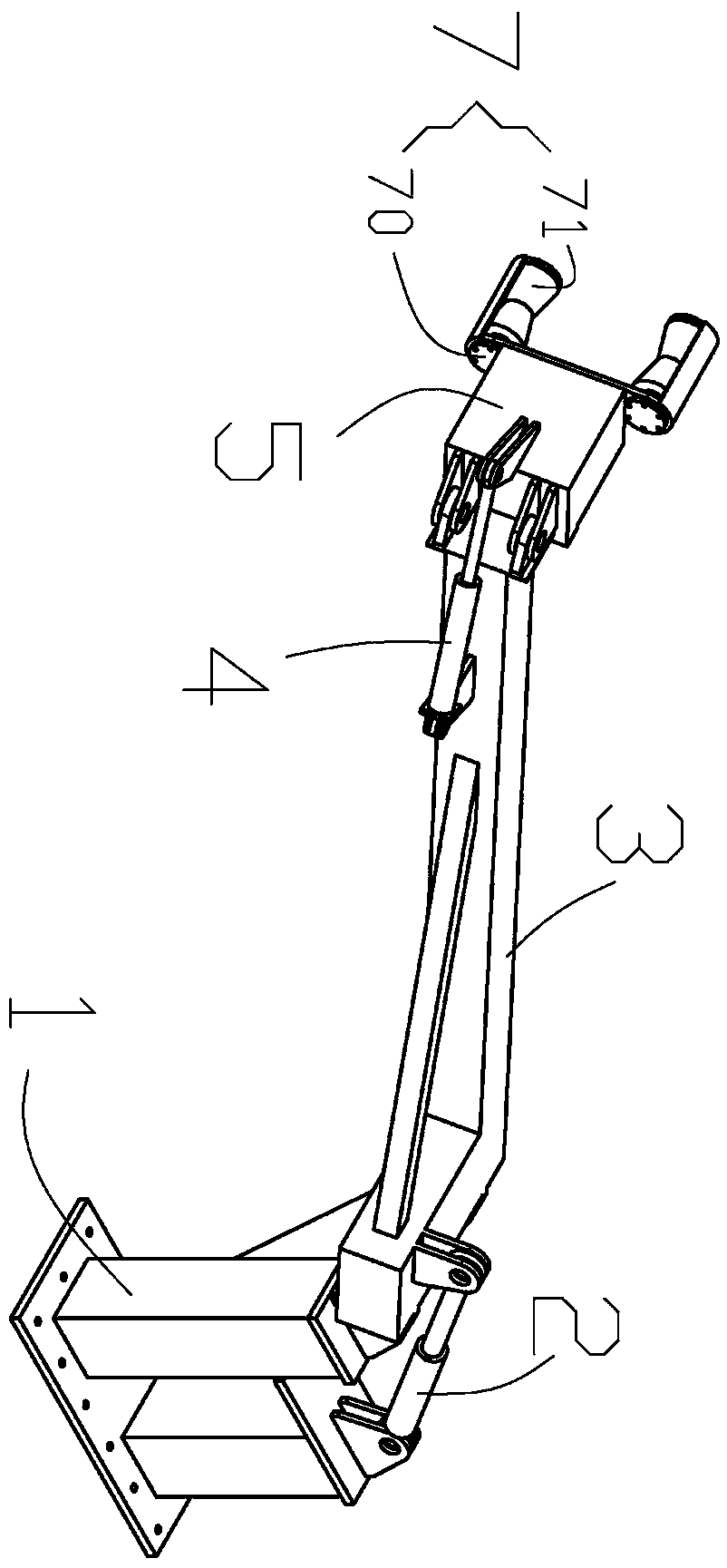

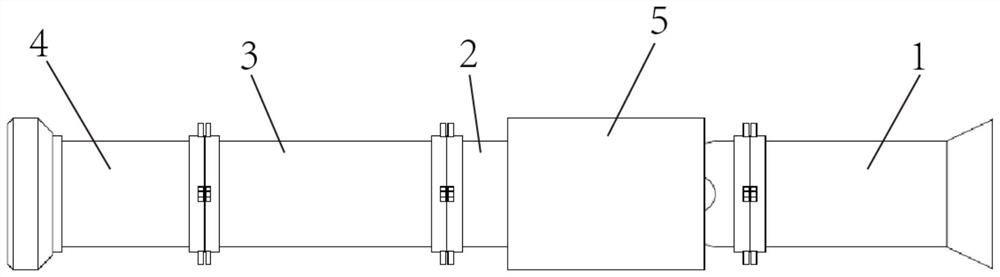

Tube tool centering device

PendingCN110005347ARealize the centering functionIncrease contactDrilling rodsDrilling casingsPosition-sensing hydraulic cylinderTube tool

The invention relates to the field of engineering equipment, in particular to a tube tool centering device. The tube tool centering device comprises a base, a swinging hydraulic cylinder, a swinging arm, a guide arm, a guide hydraulic cylinder, a rotary motor and a centering mechanism, the swinging arm is hinged to the base, one end of the swinging hydraulic cylinder is hinged to the base, the other end of the swinging hydraulic cylinder is hinged to the swinging arm, the guide arm is hinged to the swinging arm, one end of the guide hydraulic cylinder is hinged to the swinging arm, the other end of the guide hydraulic cylinder is hinged to the guide arm, one end of the rotary motor is hinged to the guide arm, and the other end of the rotary motor is hinged to the centering mechanism. The rotary motor can drive the centering mechanism to rotate to adjust the centering angle, and the centering mechanism is ensured to be in good contact with tube tools to adapt the tube tools with different diameters; and the guide hydraulic cylinder extends and shrinks to realize the conversion of the working attitude and the waiting attitude, the swinging hydraulic cylinder shrinks to adjust the position, so that the tube tools are centered to another position from one position, as position adjustment is realized through hinged rotation, the size is small, the operation is stable, the precisionis high, the efficiency is high, and the purposes of reducing the cost and improving the efficiency are achieved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

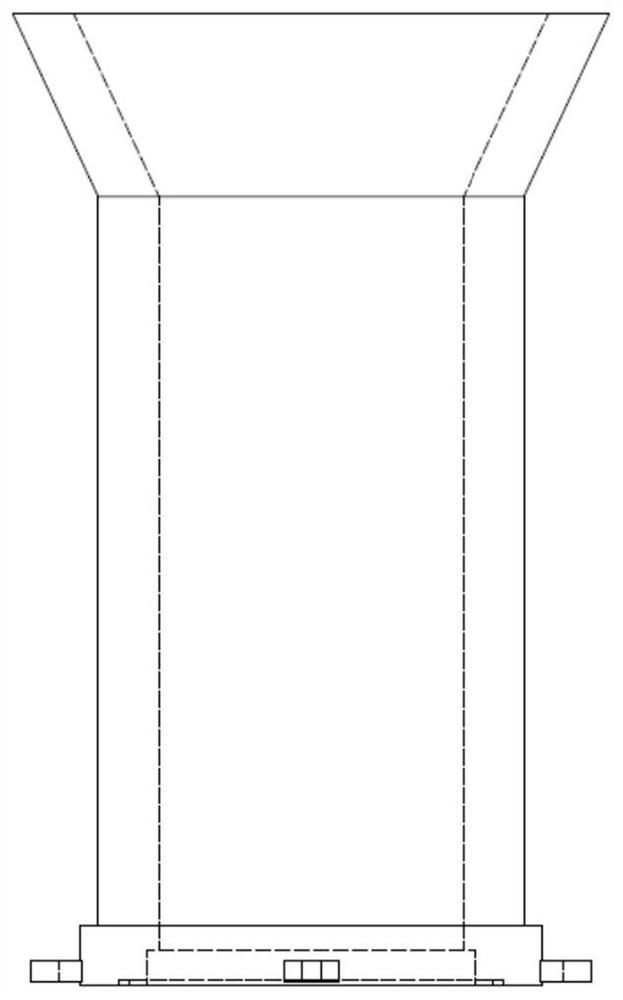

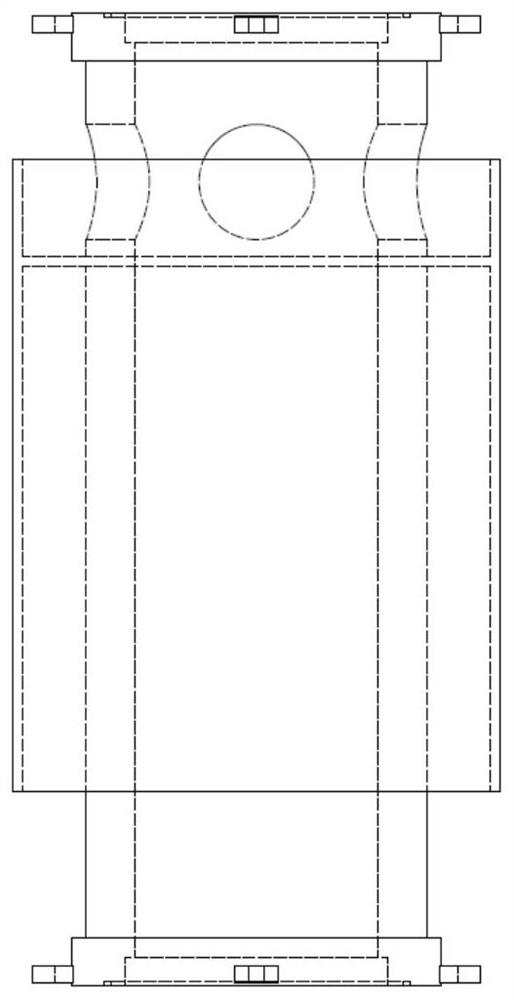

Adjustable flow guide pipe tool for installing rotary blowout preventer at wellhead of flow divider of offshore platform

PendingCN114542004AAchieving Zero Emissions RequirementsShorten working timeSealing/packingUpper jointBlowout preventer

The invention provides an adjustable flow guide pipe tool for installing a rotary blowout preventer at a wellhead of a flow divider of an offshore platform, which is characterized in that a flow guide pipe adopts a tubular structure with a funnel-shaped upper part, a flow guide pipe quick joint is formed at the tail end of the flow guide pipe, a clamping pipe upper joint is formed at the head end of a clamping pipe, and the tail end of the flow guide pipe is connected with the head end of the clamping pipe; an outer-layer sleeve is connected to the middle of the clamping pipe in a sleeved mode, reinforcing ribs are evenly distributed between the outer wall of the clamping pipe and the inner wall of the outer-layer sleeve, a drainage hole penetrating through the clamping pipe is formed in the position, at the connecting position of the clamping pipe and the outer-layer sleeve, of the clamping pipe, and a clamping pipe lower connector is formed at the tail end of the clamping pipe. A base tool quick connector is formed at the head end of the base tool, and the tail end of the clamping pipe is connected with the head end of the base tool. According to the flow guide pipe tool, under the condition that a flow divider wellhead is not disassembled, a flow guide pipe is put down, connection and disconnection with the flow divider wellhead are achieved, operation efficiency is improved, zero discharge of the wellhead is achieved, and it is guaranteed that the wellhead is fixed firmly.

Owner:CNOOC ENERGY TECH & SERVICES

Pipe expansion installation tool

The invention relates to the field of installation of construction pipelines, in particular to an installation tool for expansion of pipeline nozzles. A pipe expansion installation tool, including a pipe expansion head installed at the front end of the pipe expansion tool. The pipe expansion head extends from the inside to the outside with more than four expansion pipe splits. The elastic ring also includes a stretchable rubber sleeve, and the rubber sleeve wraps and limits all the expansion tube splits; the surface of the expansion tube splits is provided with a chamfer structure and a rounded corner structure. On the basis of the prior art, the present invention wraps the limited expansion tube split valves with rubber sleeves, adjusts the expansion tube split structure, solves the problem of the expansion tube split valves warping and detachment at the expander head, and greatly improves the performance of the expansion tubes. The service life and durability of the head are improved, and the uniformity of pipe expansion is further improved, the beneficial effect is obvious, and it has market promotion value.

Owner:TAIZHOU BANCHENG HVAC TECH CO LTD

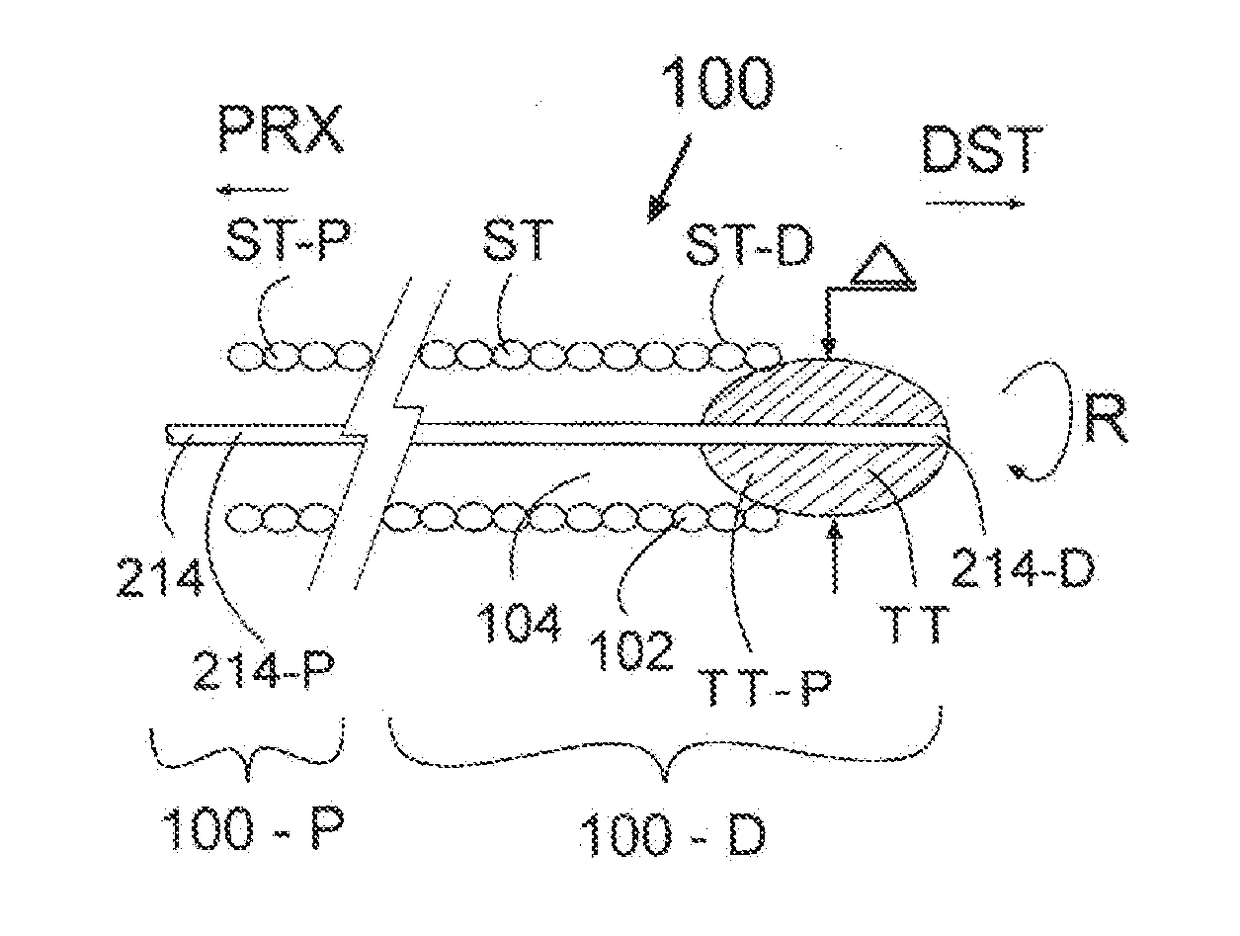

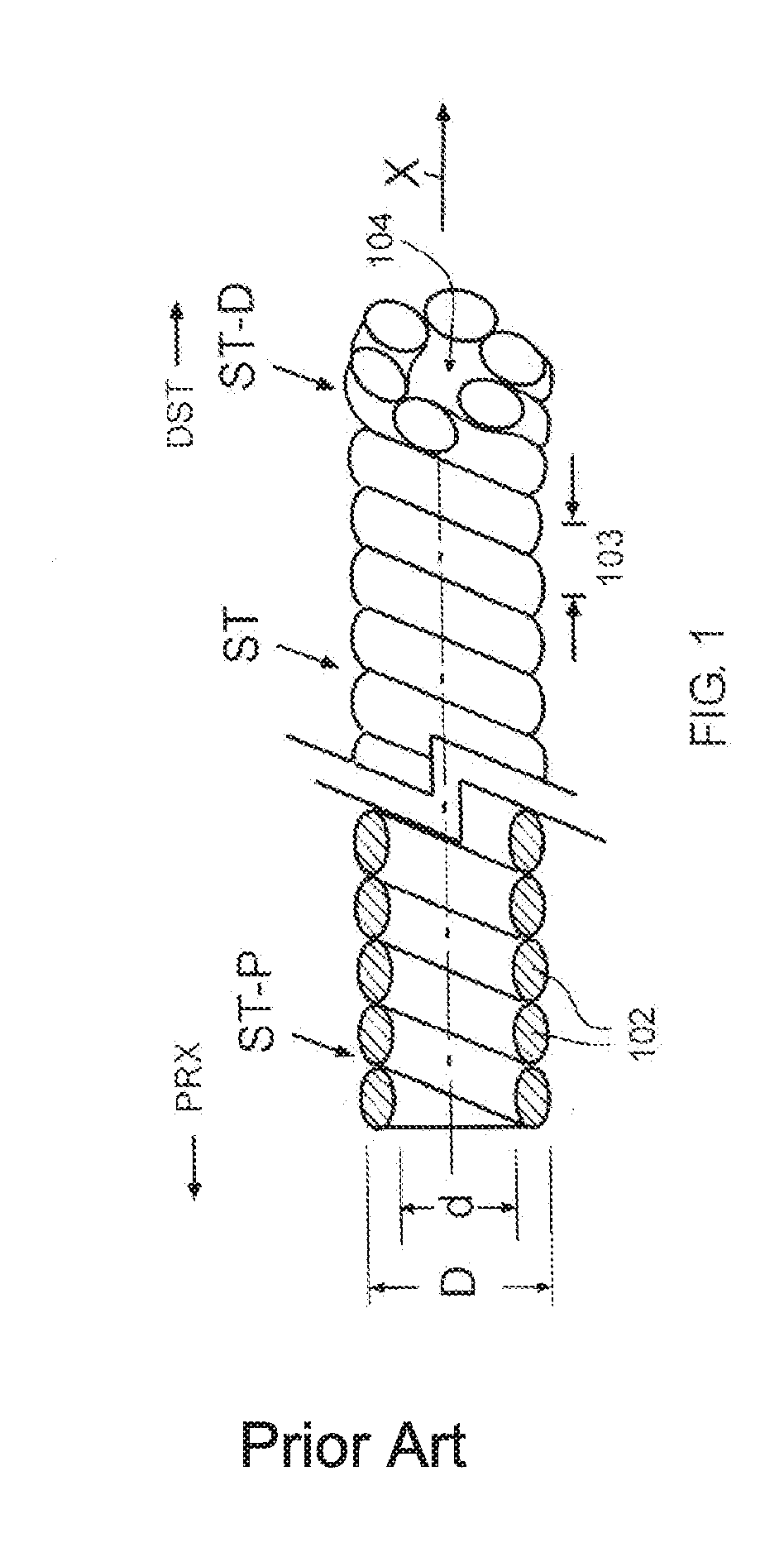

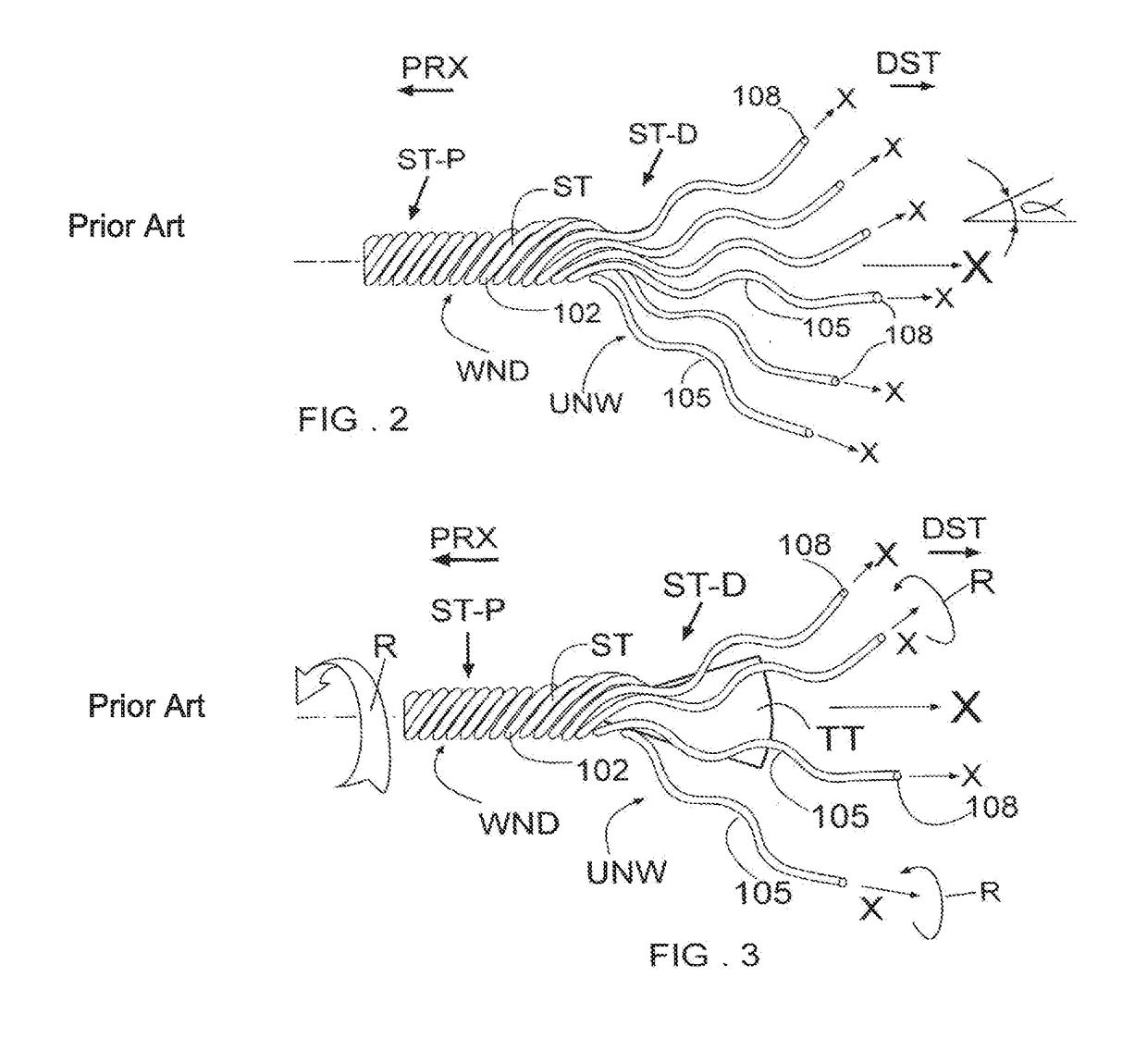

Method system and fastener for anchoring a corpu

There is described a method, a system, and a device for the anchoring of and into a corpus disposed distally in a conduit by engaging a stranded tube with the corpus and unwinding the wound threads of the stranded tube into unwound threads. Engagement includes the use of handling and manipulation shaft to dispose the stranded tube proximally, distally, or in the interior to the corpus. Unwinding, of the stranded tube is achieved by rotating a tube tool against the stranded tube. Unwinding liberates the helically coiled unwound strands in “corkscrew” rotation into the corpus. Proximal retrieval of a corpus is achieved by proximal retrieval of the stranded tube anchoring the corpus. An unwound stranded tube is operable as a fastener, as an electrical lead, and as a support for a device.

Owner:MAJIPA MED LTD ISRAEL CO REGISTRATION NO 515701555

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com