Hydraulic drive oil tube elevator

A technology of elevators and oil pipes, which is applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve the problems of not being able to meet the needs of intelligent control in oilfields, poor locking effects, and potential safety hazards, and achieve convenient operation, reduce operators, Safe and reliable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

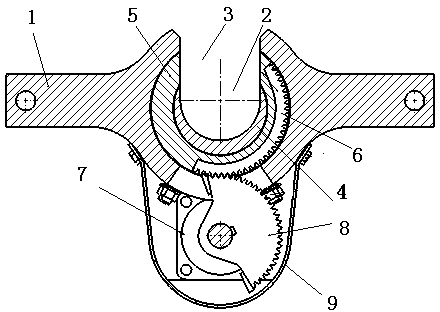

[0010] see figure 1 , The names of the parts are as follows: Elevator body 1, central hole 2, gap 3, open tooth ring 4, locking ring 5, arc-shaped rack 6, hydraulic motor 7, sector gear 8, shield 9.

[0011] see figure 1 , a hydraulically driven oil pipe elevator includes an elevator body 1, a center hole 2 for holding the oil pipe in the middle of the elevator body 1, a gap 3 for the oil supply pipe to enter and exit on one side of the center hole 2, and a crescent in the center hole 2 Shaped open tooth ring 4 and coaxial rotatable locking ring 5. One side of the outer surface of the locking ring 5 is inlaid with an arc-shaped rack 6, and there is a sector gear 8 driven by a hydraulic motor 7 outside the elevator body 1, which passes through the elevator body and meshes with the arc-shaped rack 6 of the locking ring to drive the arc-shaped rack 6 Rotate to seal the gap 3. The hydraulic motor 7 is fixed on the outer surface of the elevator body 1 by bolts and has a shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com