Industrial batch packaging equipment for light emitting diodes

A technology of light-emitting diodes and packaging equipment, applied in the directions of packaging, transportation and packaging, multiple packages, etc., can solve the problem of not being able to automatically package light-emitting diodes in batches, achieve intermittent automatic cutting, reduce manual edge sealing operations, Reduce the effect of manual sealing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

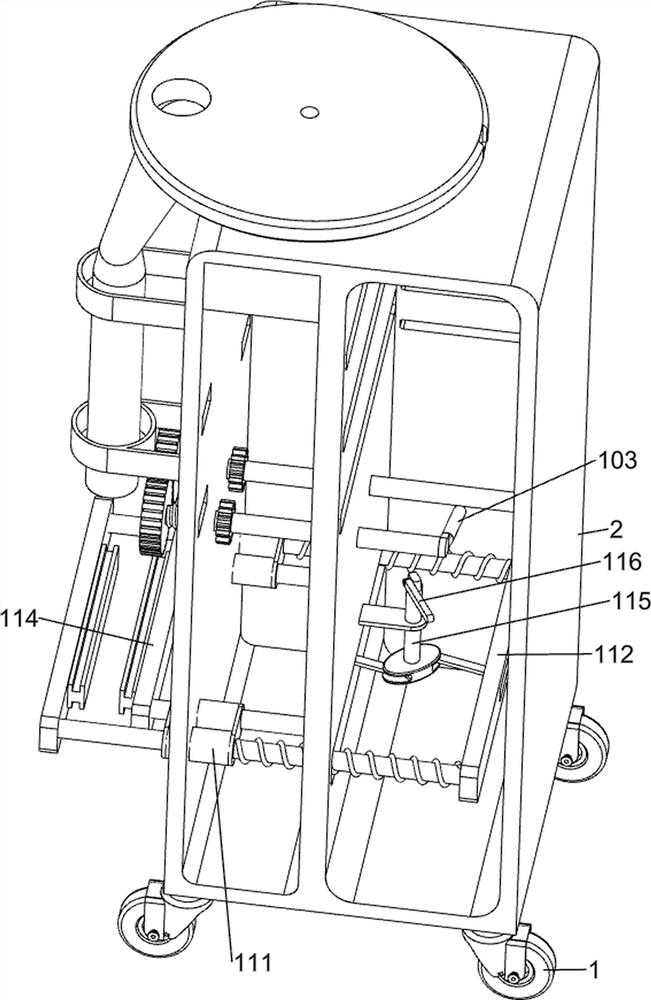

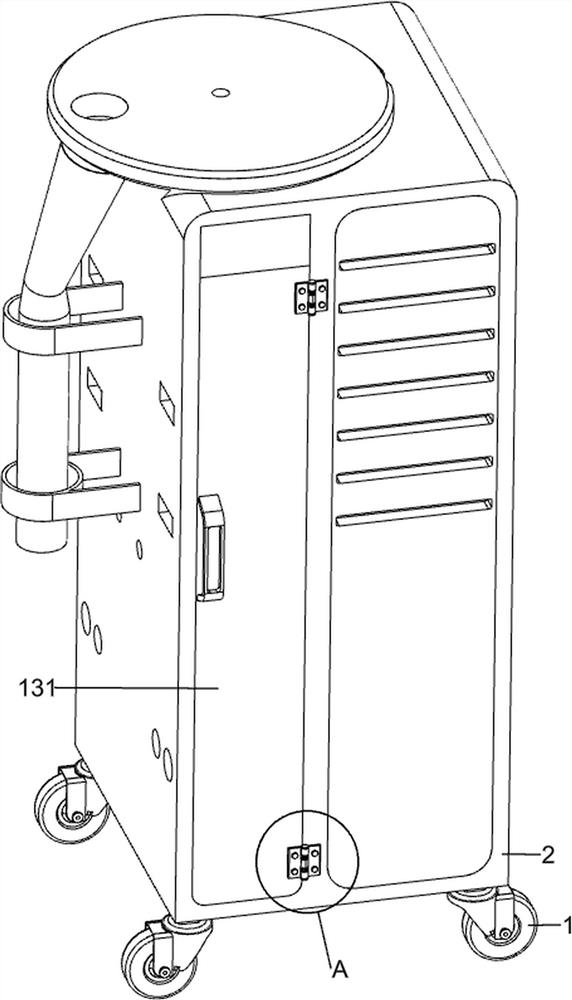

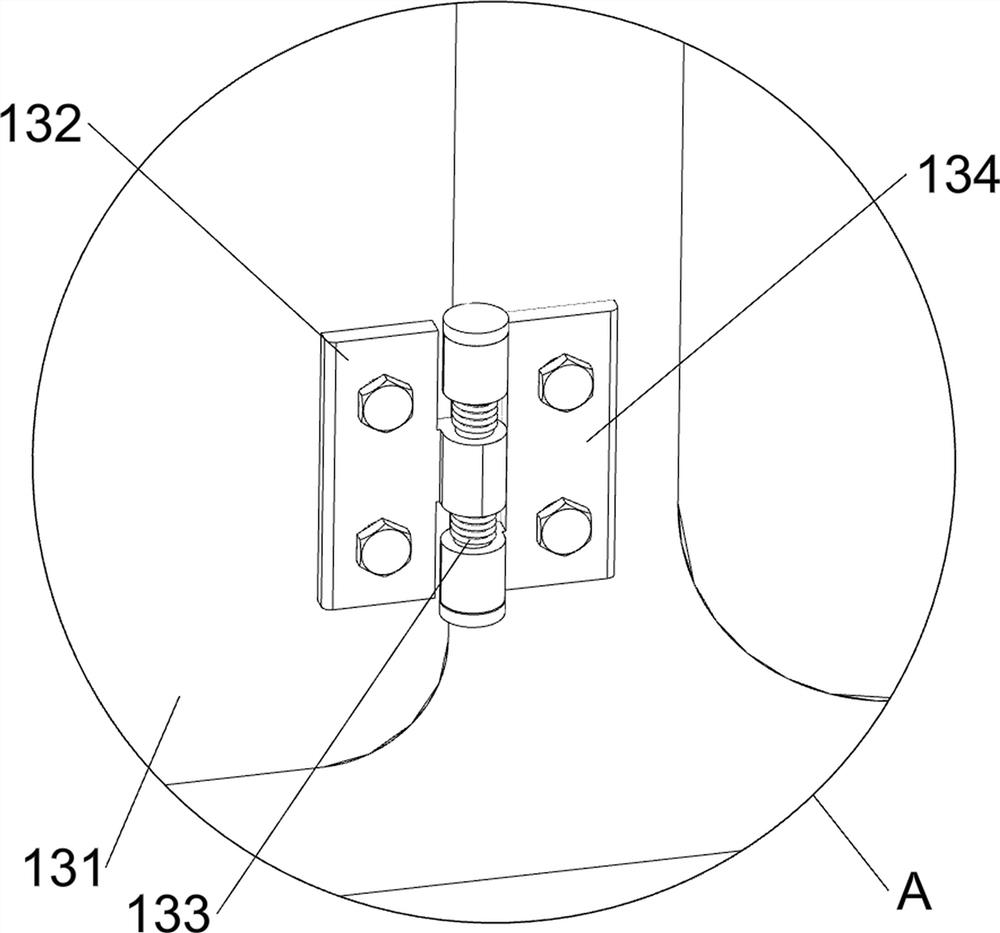

[0035] An industrial batch packaging equipment for light-emitting diodes, such as figure 1 , figure 2 and image 3As shown, it includes a roller 1, a tool box 2, a feeding rack 3, a loader 4, a feeding tube 5, an upper limit frame 6, a lower limit frame 61, a device frame 7, an intermittent diode feeding mechanism 8, and a packaging mechanism 9. The pulling mechanism 10 and the splitting mechanism 11, the left and right sides of the bottom of the toolbox 2 are provided with rollers 1 that rotate symmetrically forward and backward, the top left of the toolbox 2 is provided with a feeding rack 3, and the right side of the top of the feeding rack 3 is connected with a The feeder 4, the bottom of the feeding rack 3 are connected with a lowering pipe 5, the upper left part of the tool box 2 is provided with an upper limit frame 6 and a lower limit frame 61, the lower limit frame 61 is located below the upper limit frame 6, and the upper limit frame 6 is Horizontal N shape, the s...

Embodiment 2

[0042] On the basis of Example 1, as image 3 and Figure 13 As shown, it also includes a toughness increasing mechanism 12. The toughness increasing mechanism 12 includes a sliding frame 121, a fifth fixing frame 122, a third tension spring 123 and a pressing shaft 124. The left part of the device frame 7 is provided with sliding frames on both sides. 121. The lower part of the sliding frame 121 is provided with a fifth fixing frame 122, a lower pressing shaft 124 is slidably connected between the fifth fixing frames 122, and a third tension spring 123 is wound around the lower part of the fifth fixing frame 122, and the third tension spring 123 The two ends are respectively connected with the fifth fixing frame 122 and the pressing shaft 124 .

[0043] The rolled packaging film is sleeved on the left end of the device frame 7, and then the packaging film is pulled out to make it bypass the bottom of the pressing shaft 124, the top of the device frame 7, and the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com