Patents

Literature

137results about How to "Realize the effect of automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

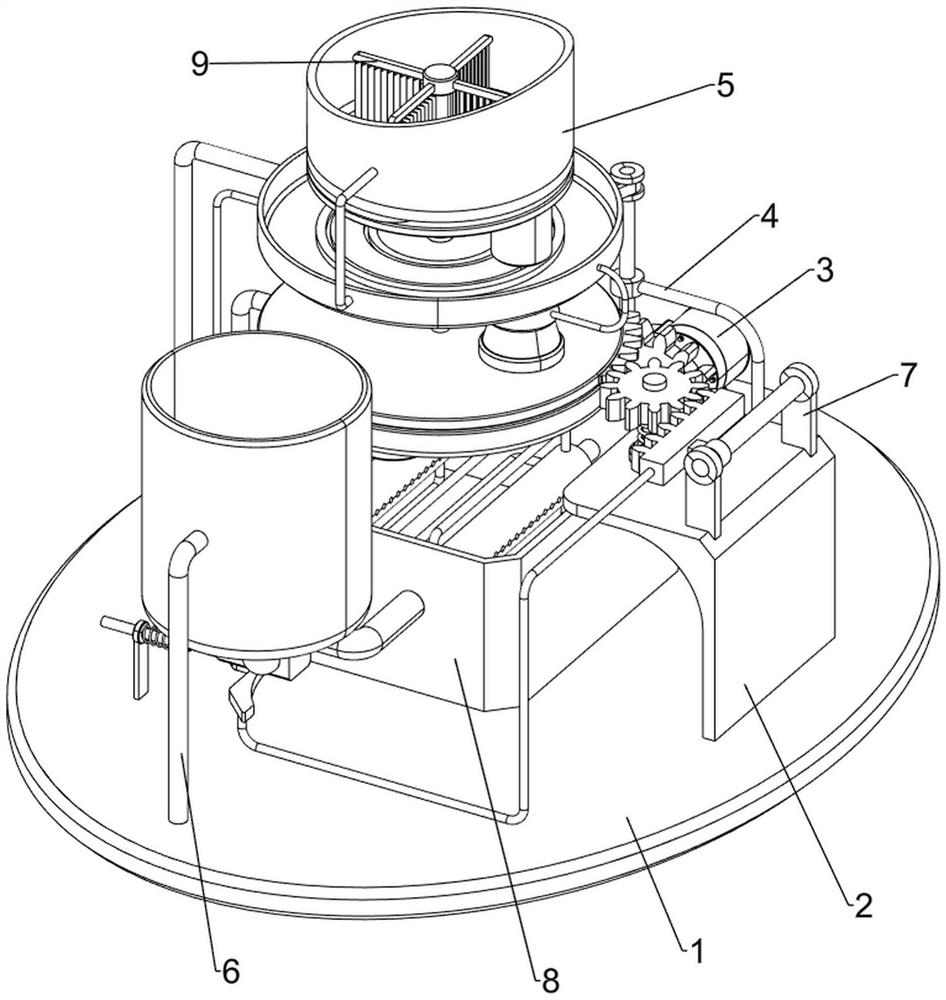

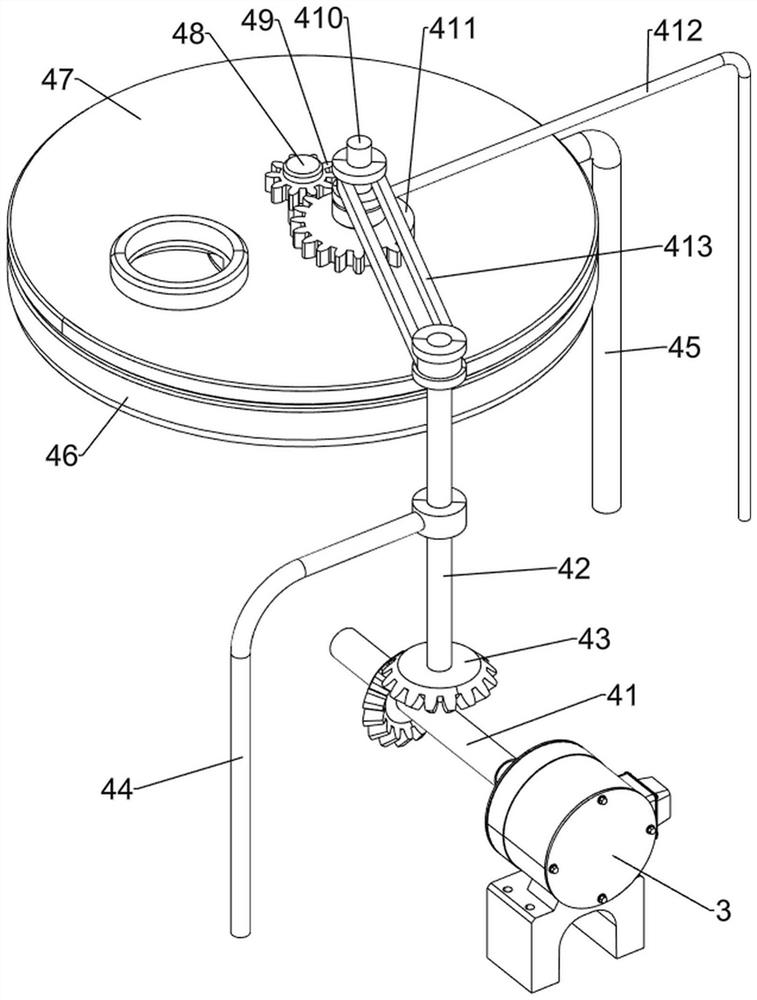

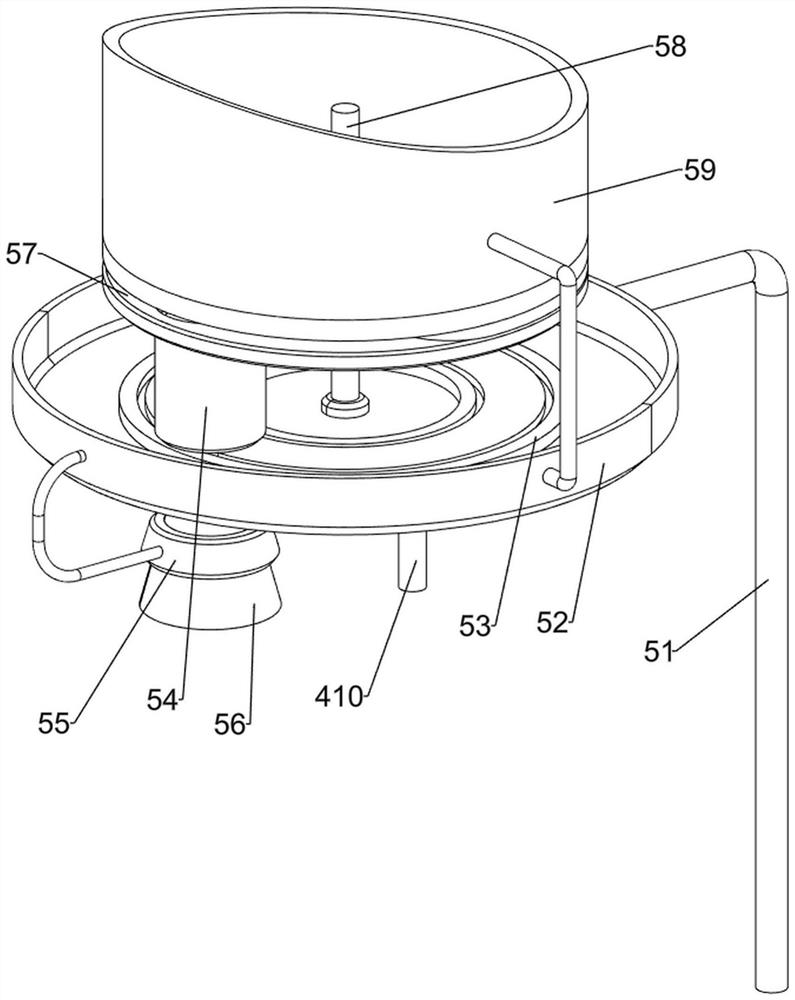

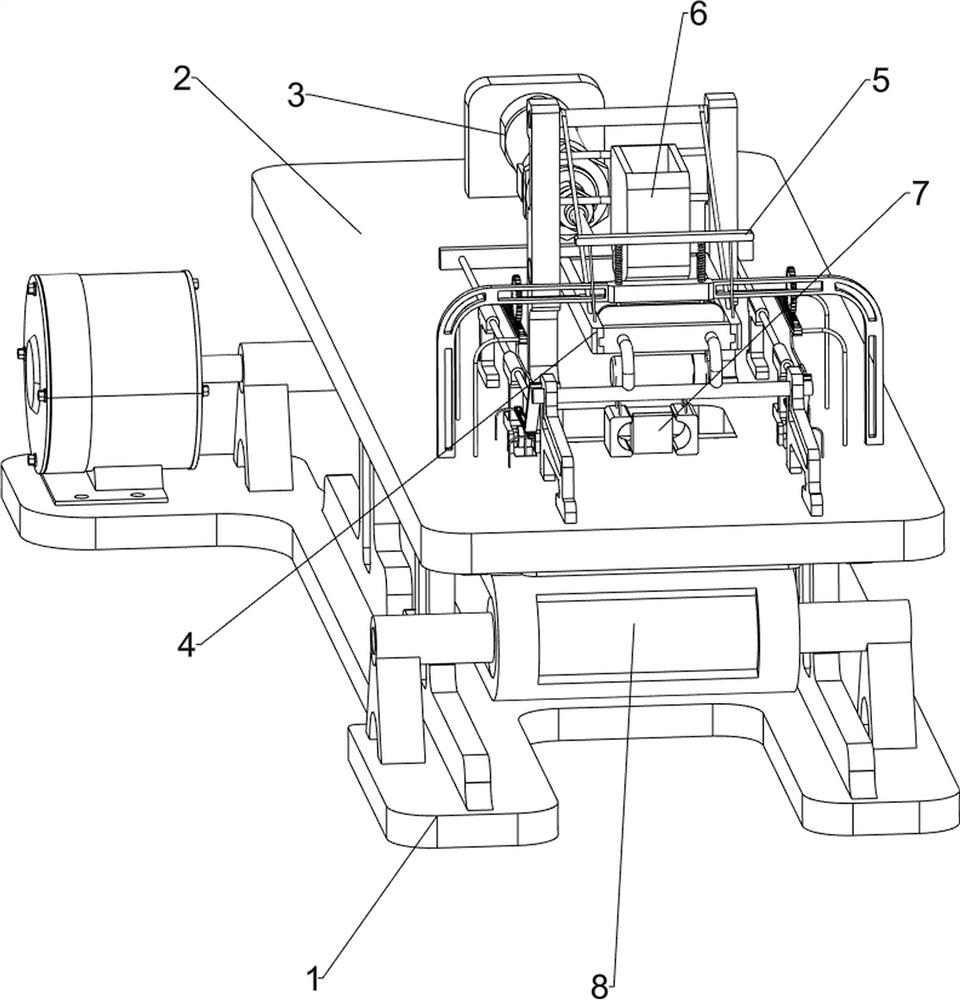

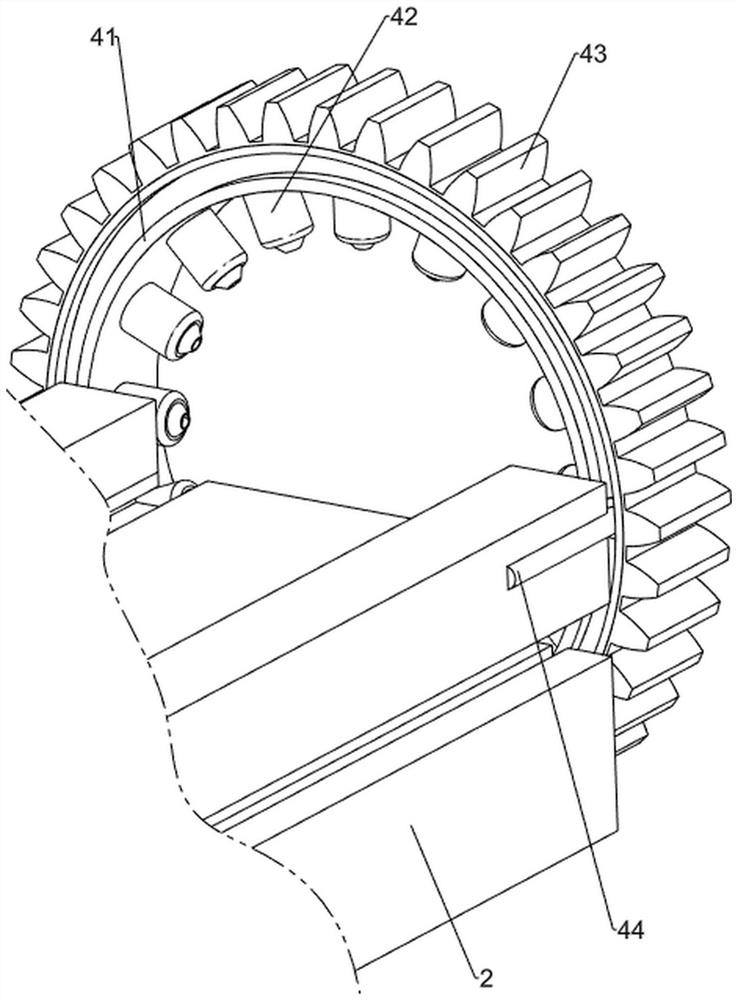

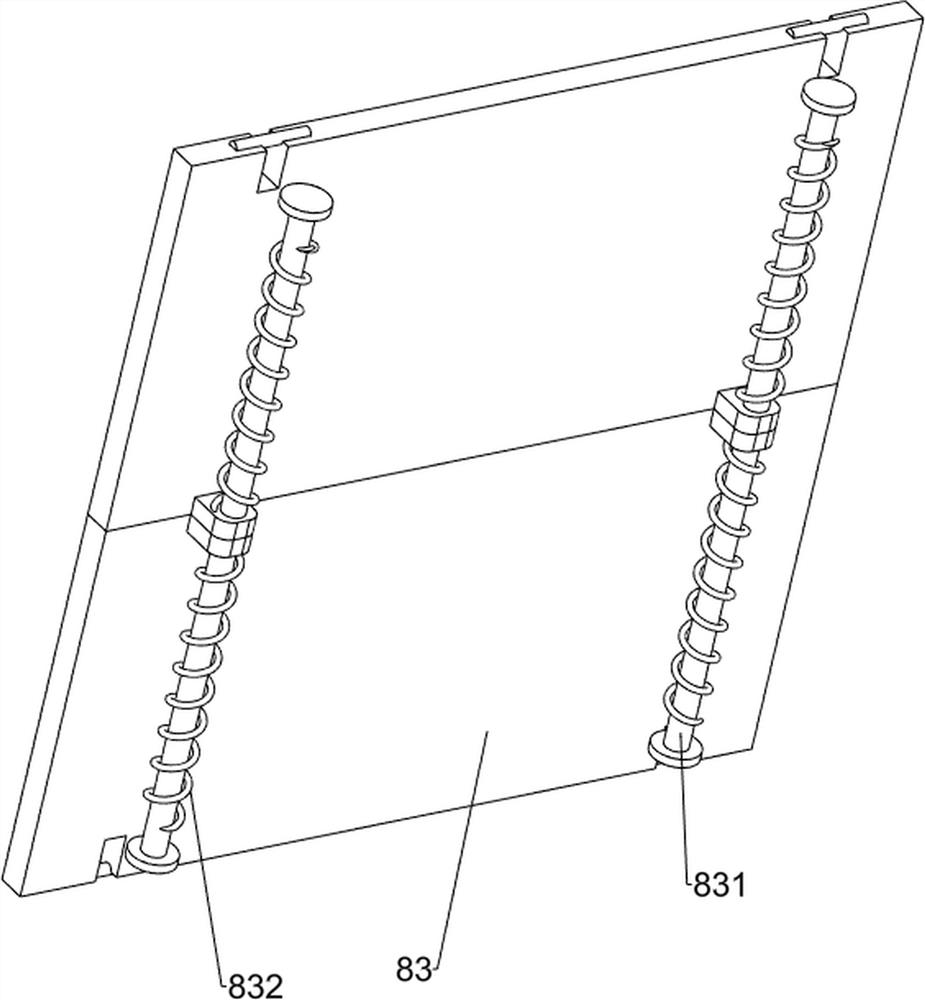

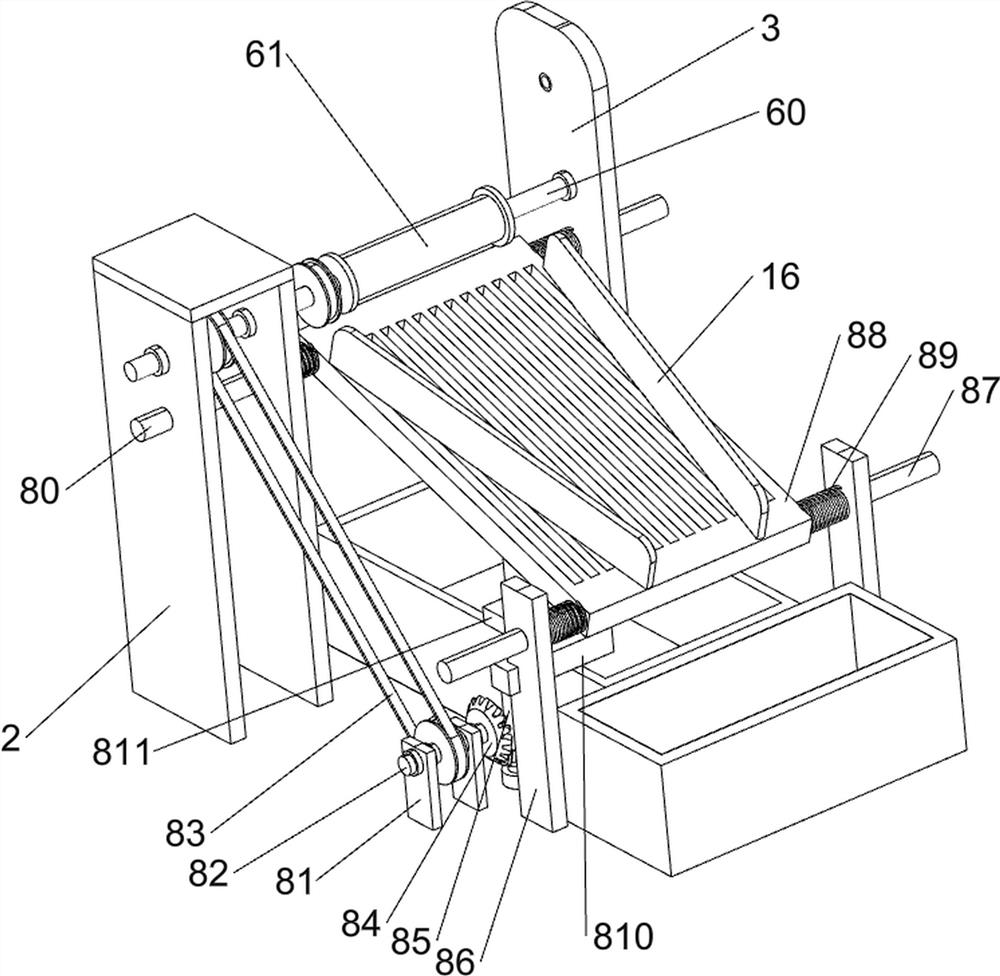

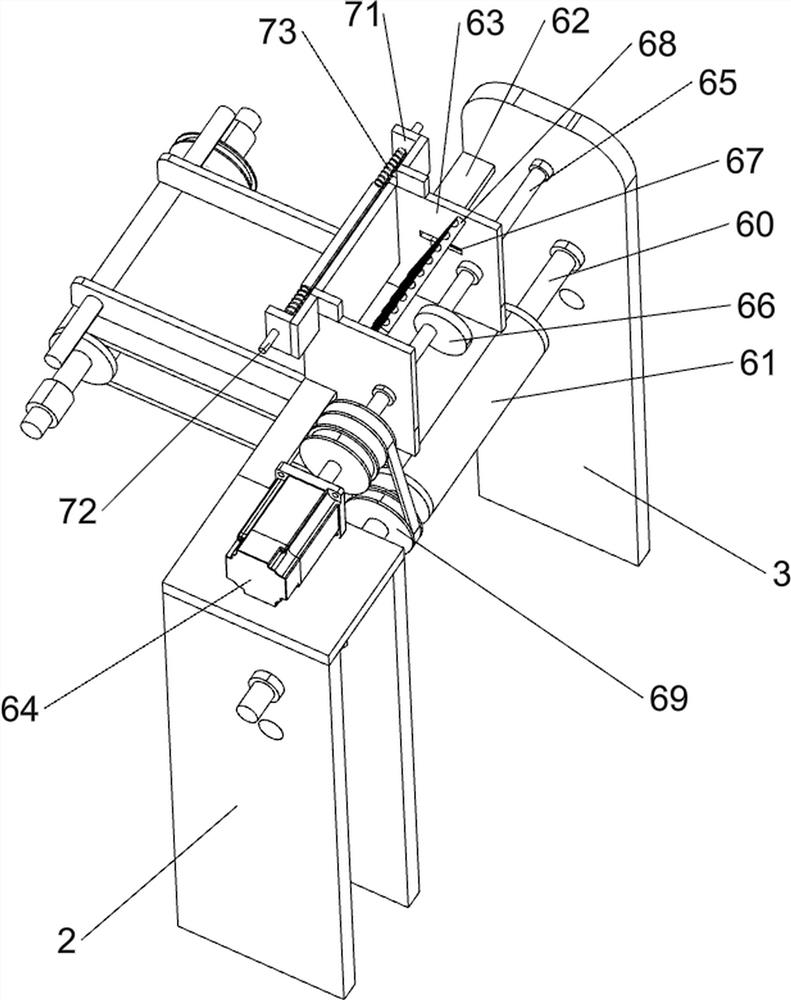

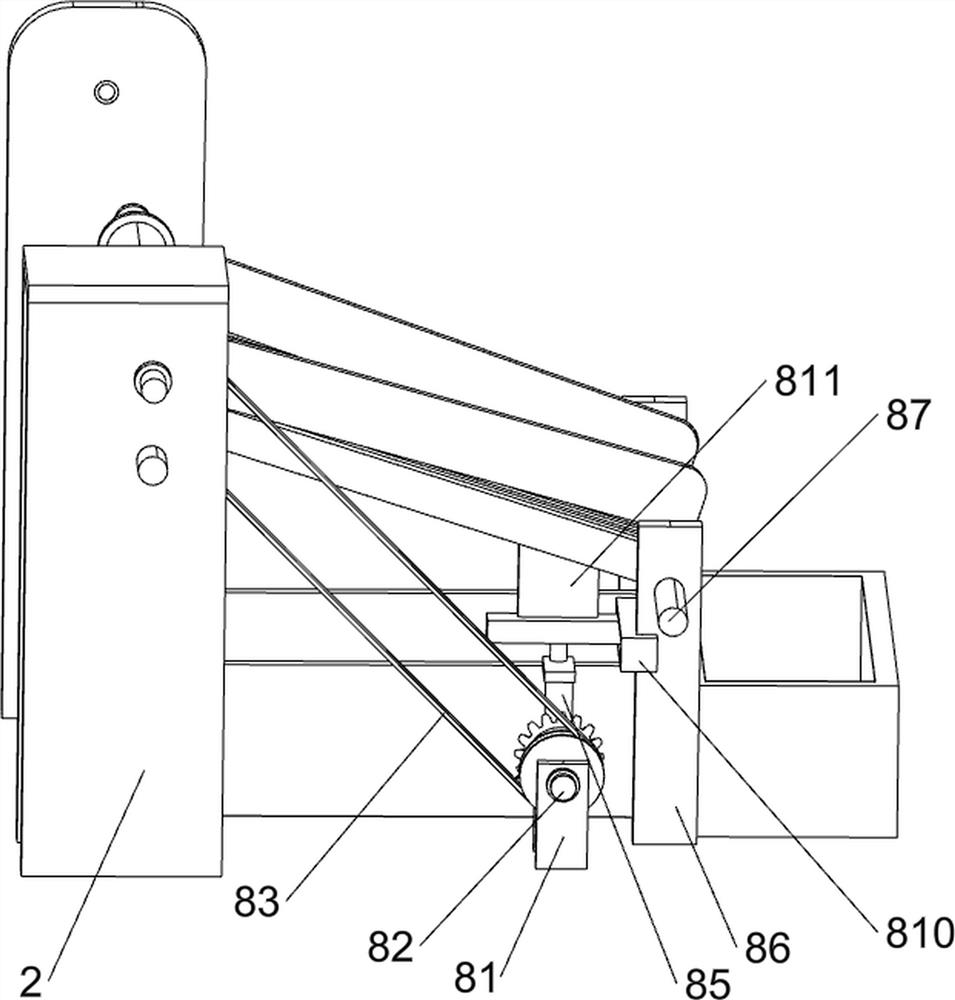

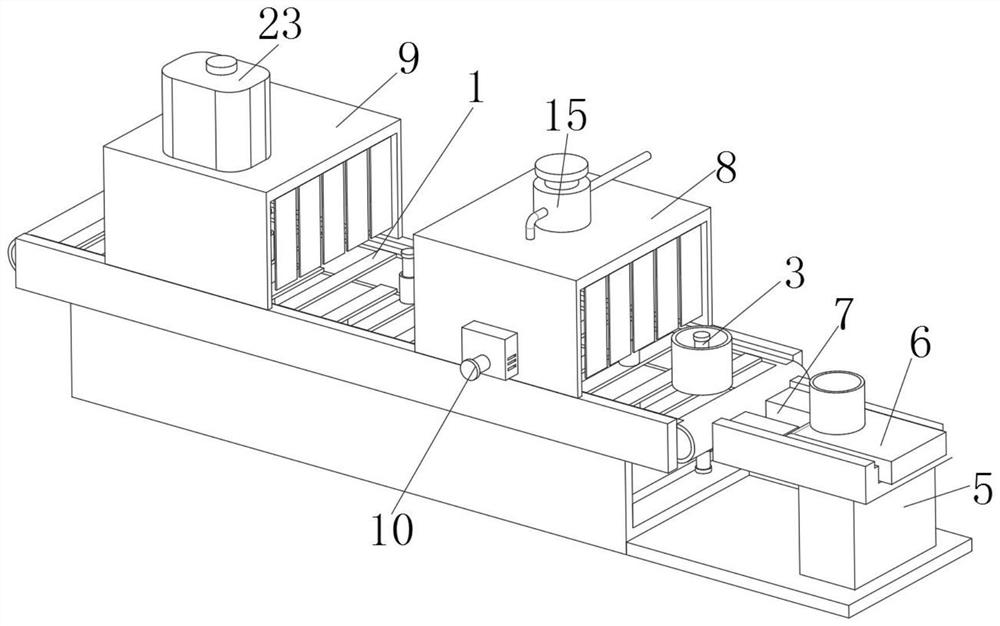

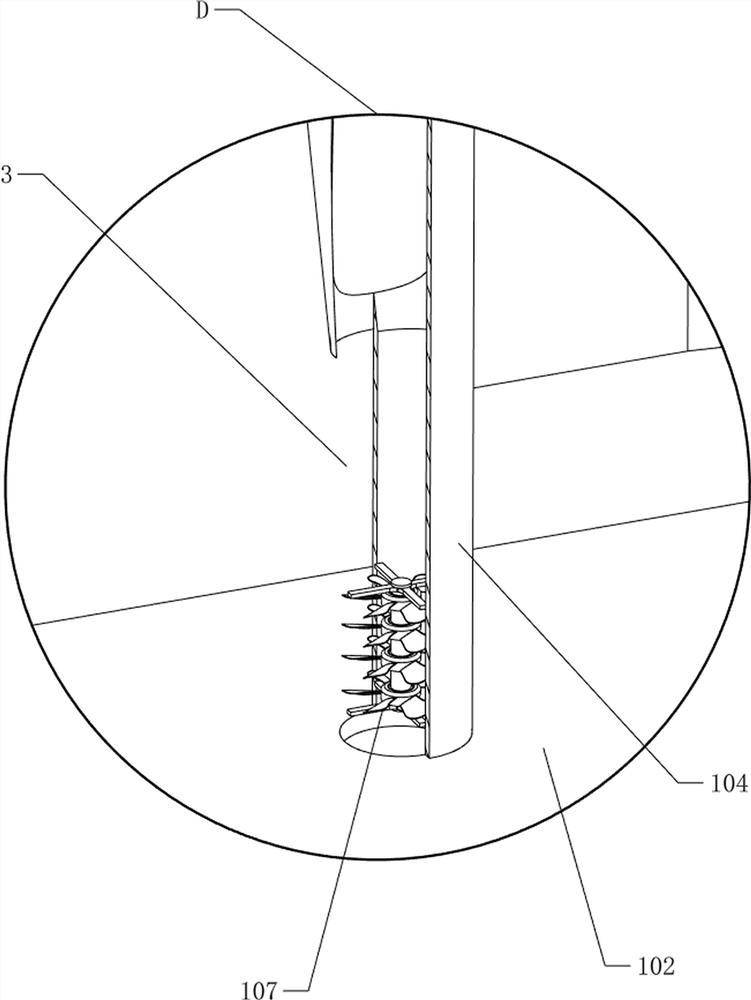

Ceramic production raw material grinding treatment equipment

InactiveCN112452427ARealize the effect of grinding treatmentRealize the effect of automatic feedingMixing operation control apparatusPretreatment controlGear wheelElectric machinery

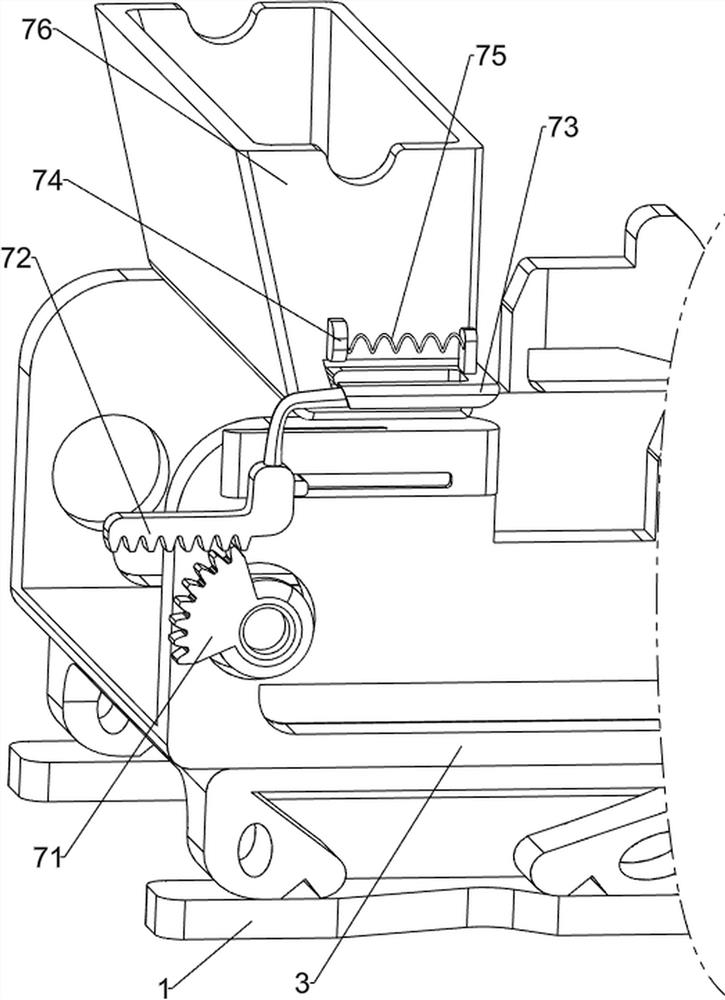

The invention discloses ceramic production raw material grinding treatment equipment. The ceramic production raw material grinding treatment equipment comprises a bottom plate, a motor, a grinding mechanism and a discharging mechanism, wherein a workbench is arranged on the bottom plate; the motor is arranged on the bottom plate, the grinding mechanism is arranged on the bottom plate, and the grinding mechanism is connected with an output shaft of the motor; and the discharging mechanism is arranged on the bottom plate, and the discharging mechanism is connected with the grinding mechanism. According to the ceramic production raw material grinding treatment equipment, a first incomplete gear is intermittently engaged with a first spur gear, so that the first spur gear intermittently rotates to drive a third rotating shaft to rotate, the third rotating shaft drives a grinding plate to rotate, and the effect that the grinding plate grinds mixed production raw materials in a discharging plate is achieved; the grinding mechanism drives the discharging mechanism to operate, and the effect of automatic discharging of the mixed production raw materials is achieved; and two second water pipes are driven to rotate through a first rotating shaft and a seventh rotating shaft, then mud mixing rods are driven to rotate, the mud mixing rods can uniformly stir raw material powder sprayed by water in a mud mixing box, and the mud mixing effect is achieved.

Owner:李伟

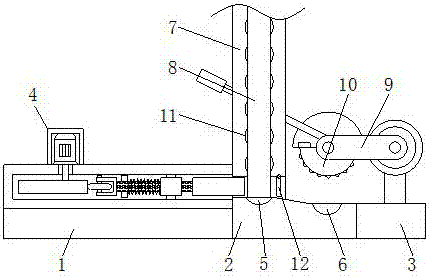

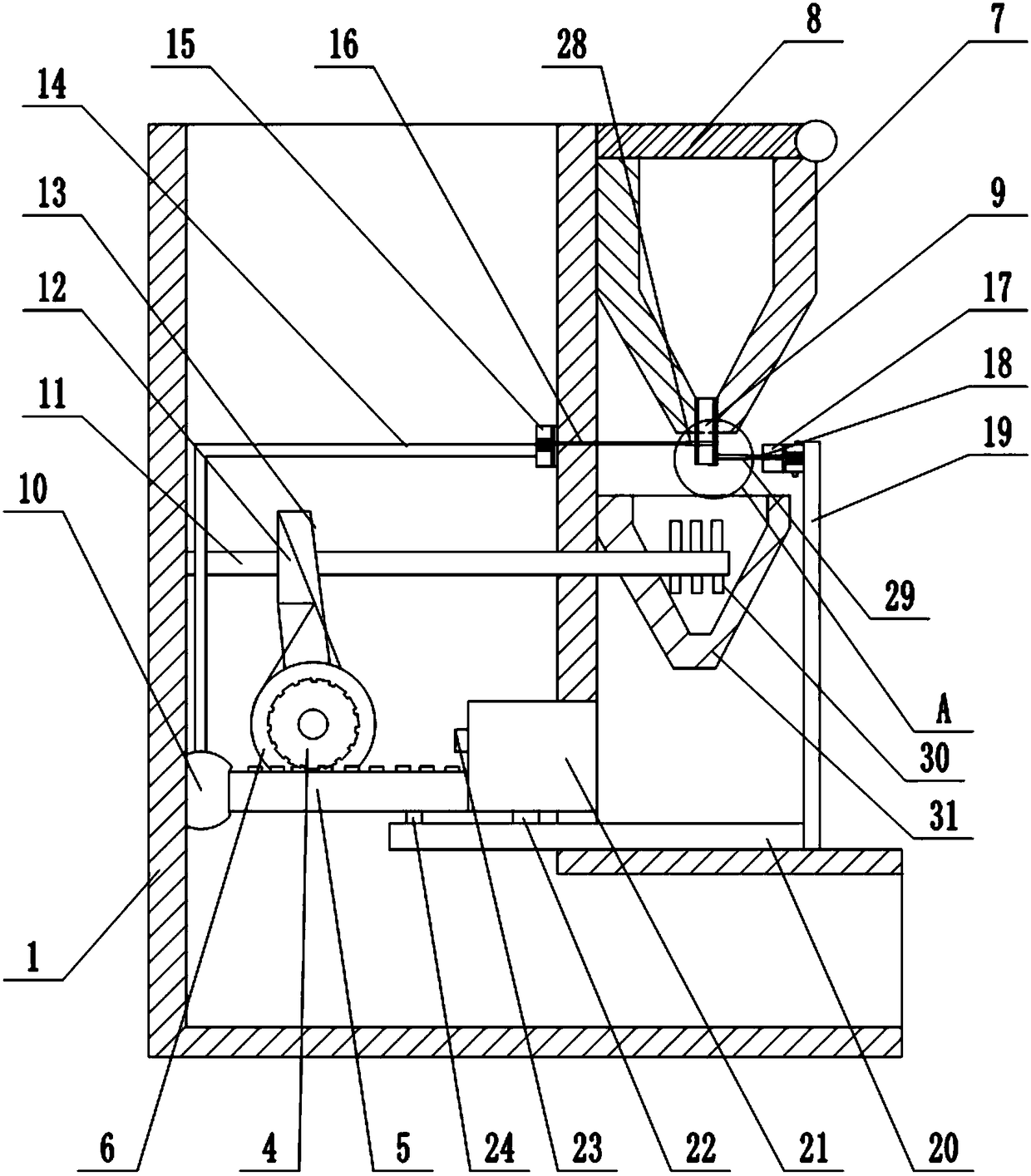

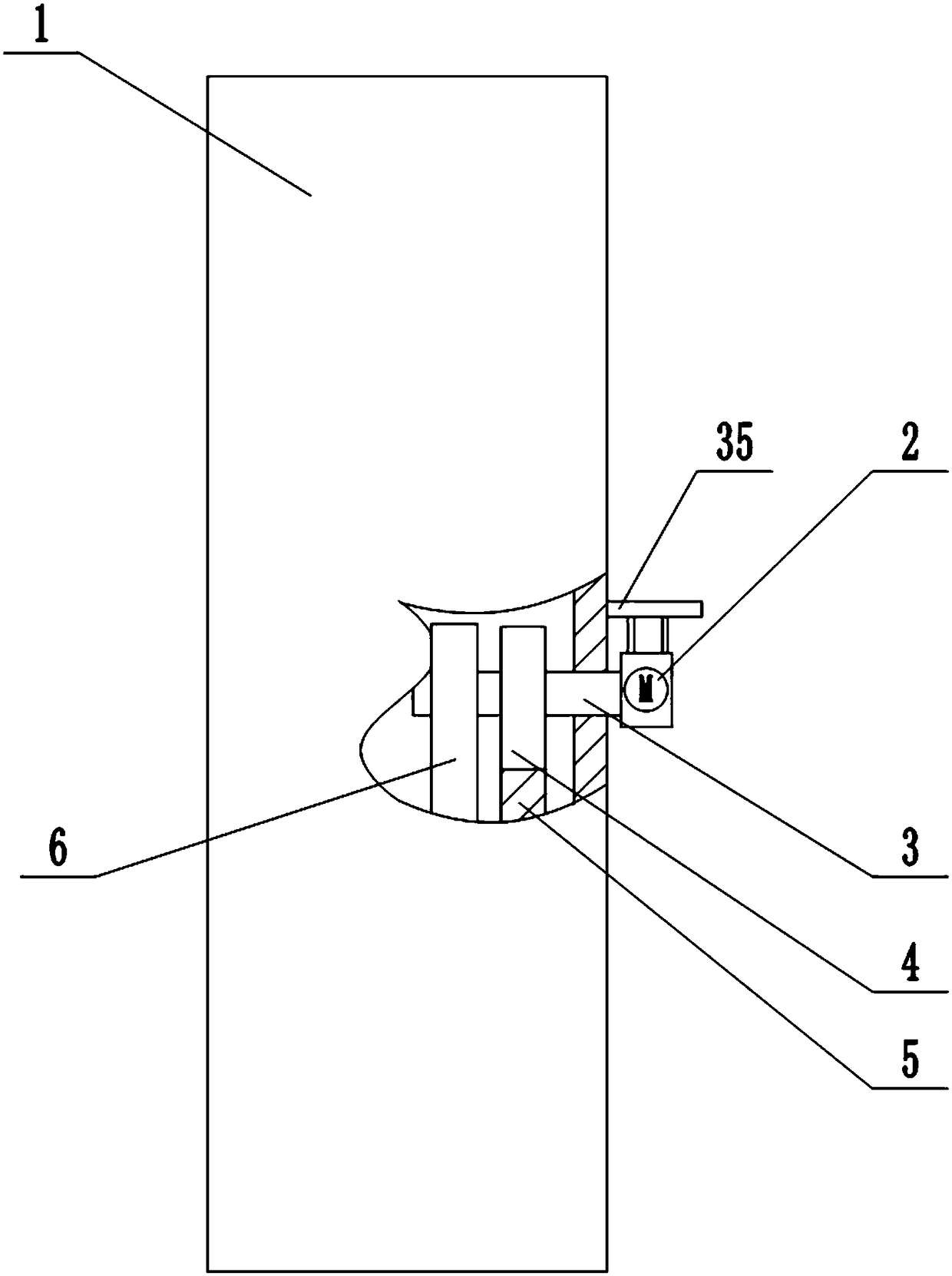

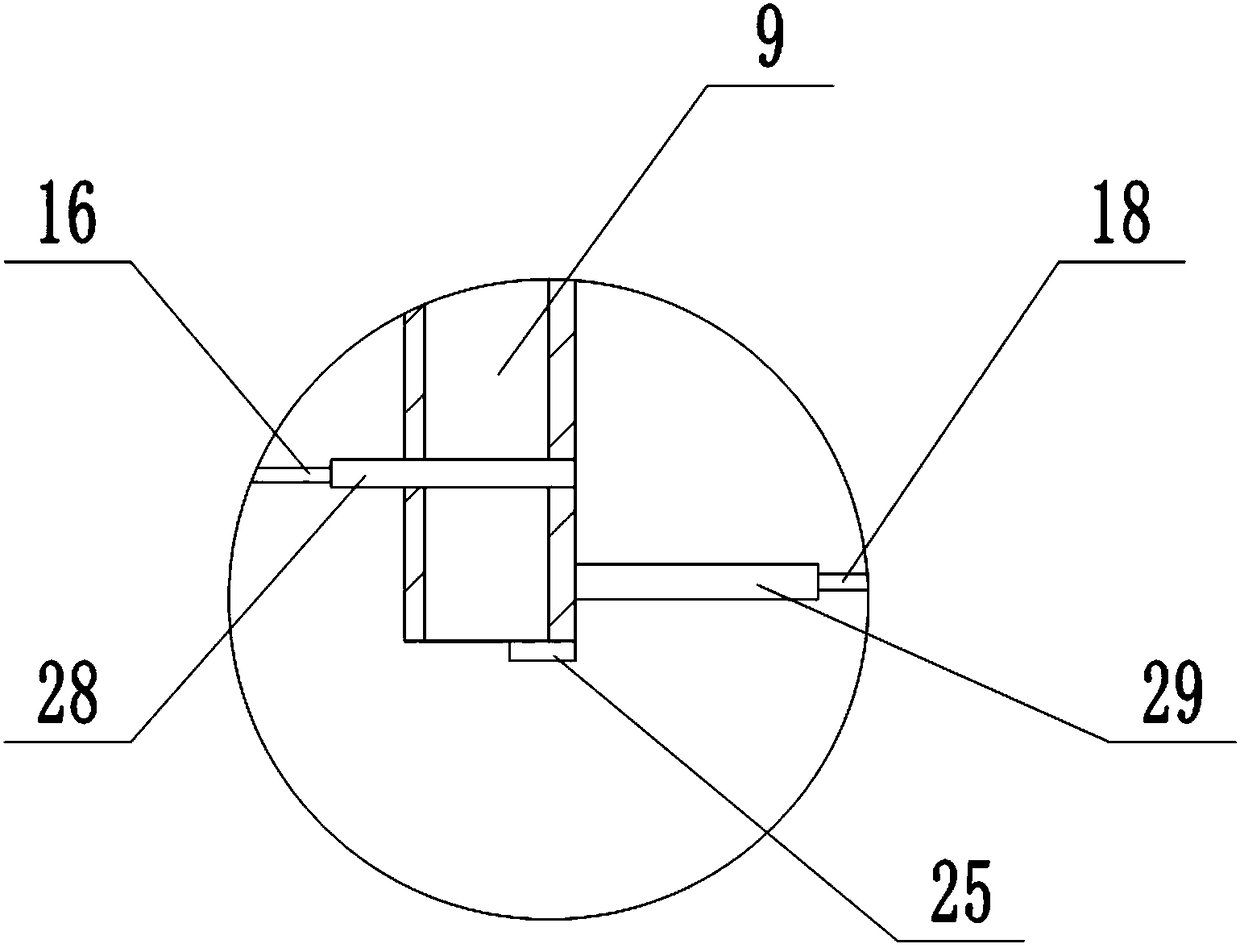

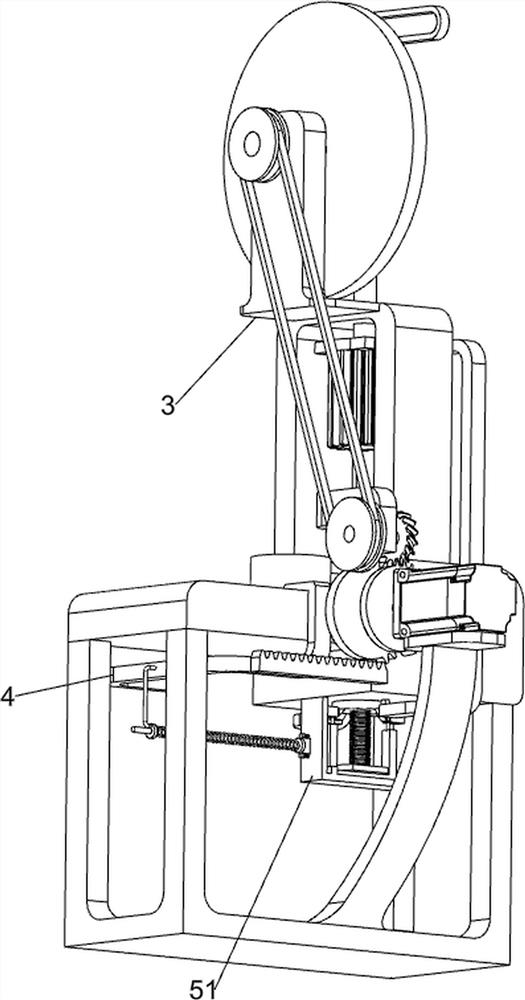

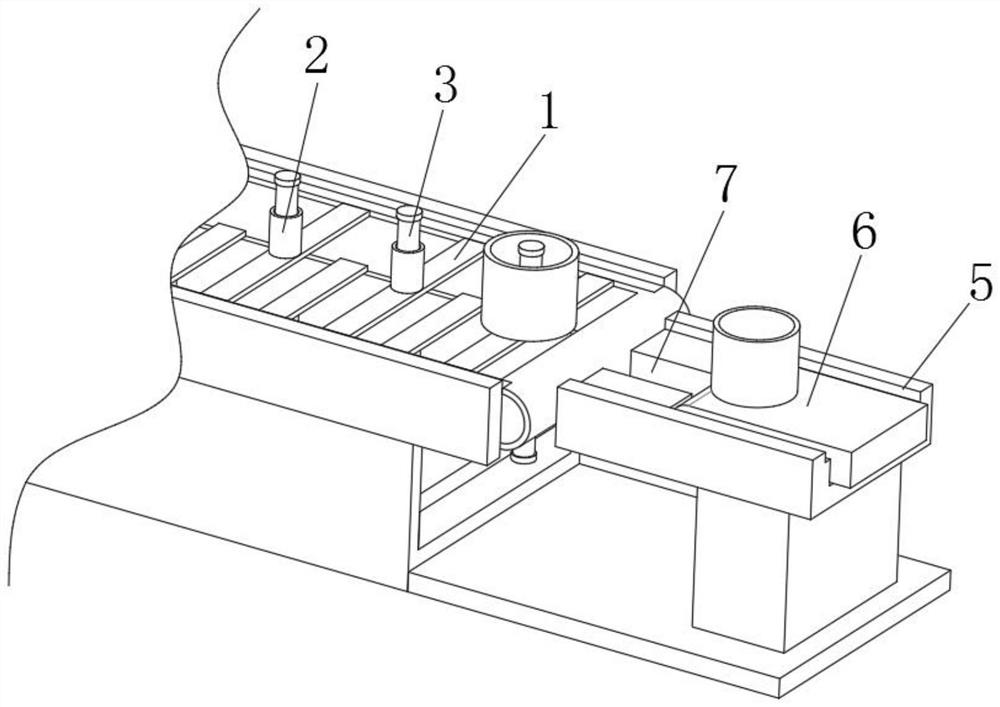

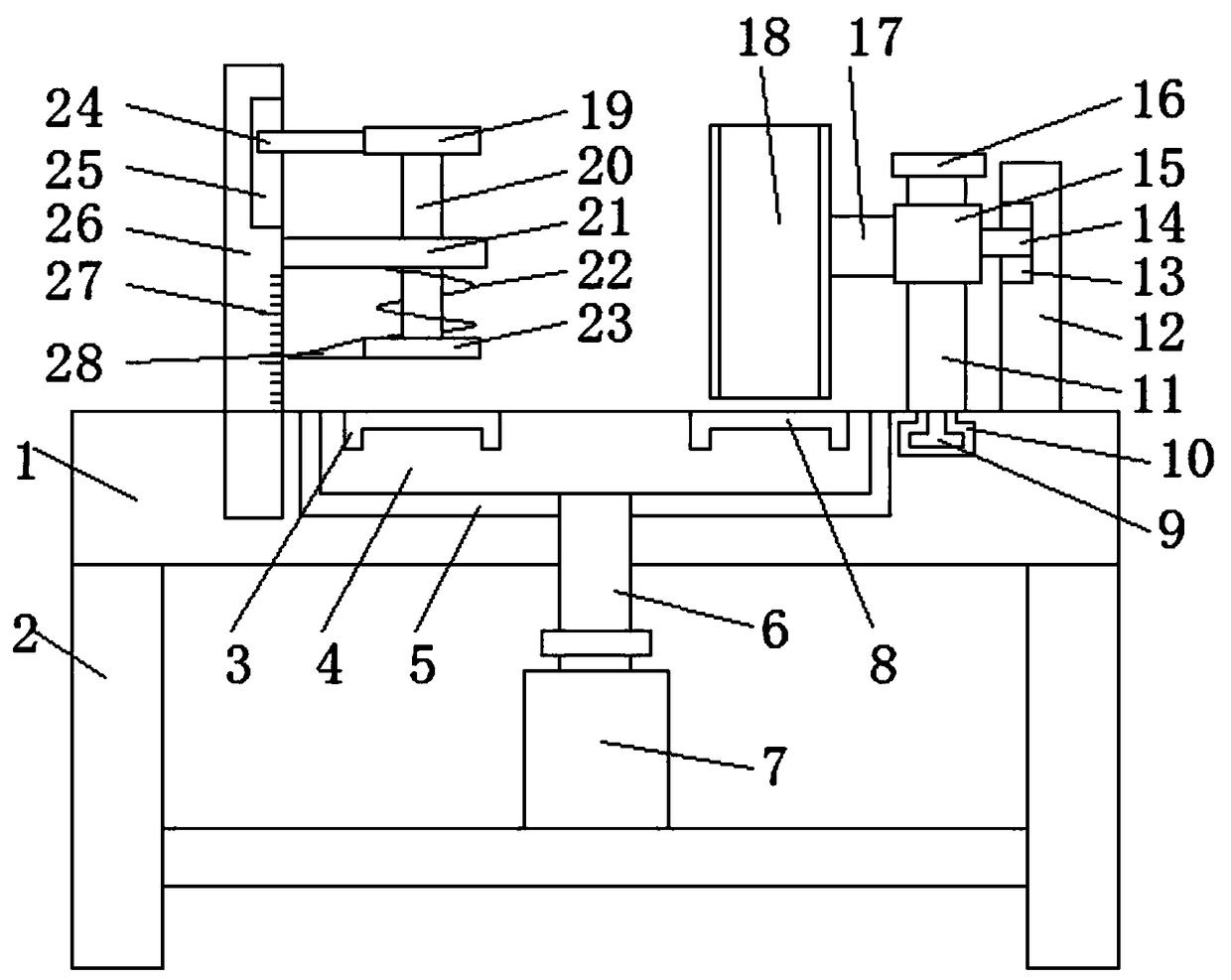

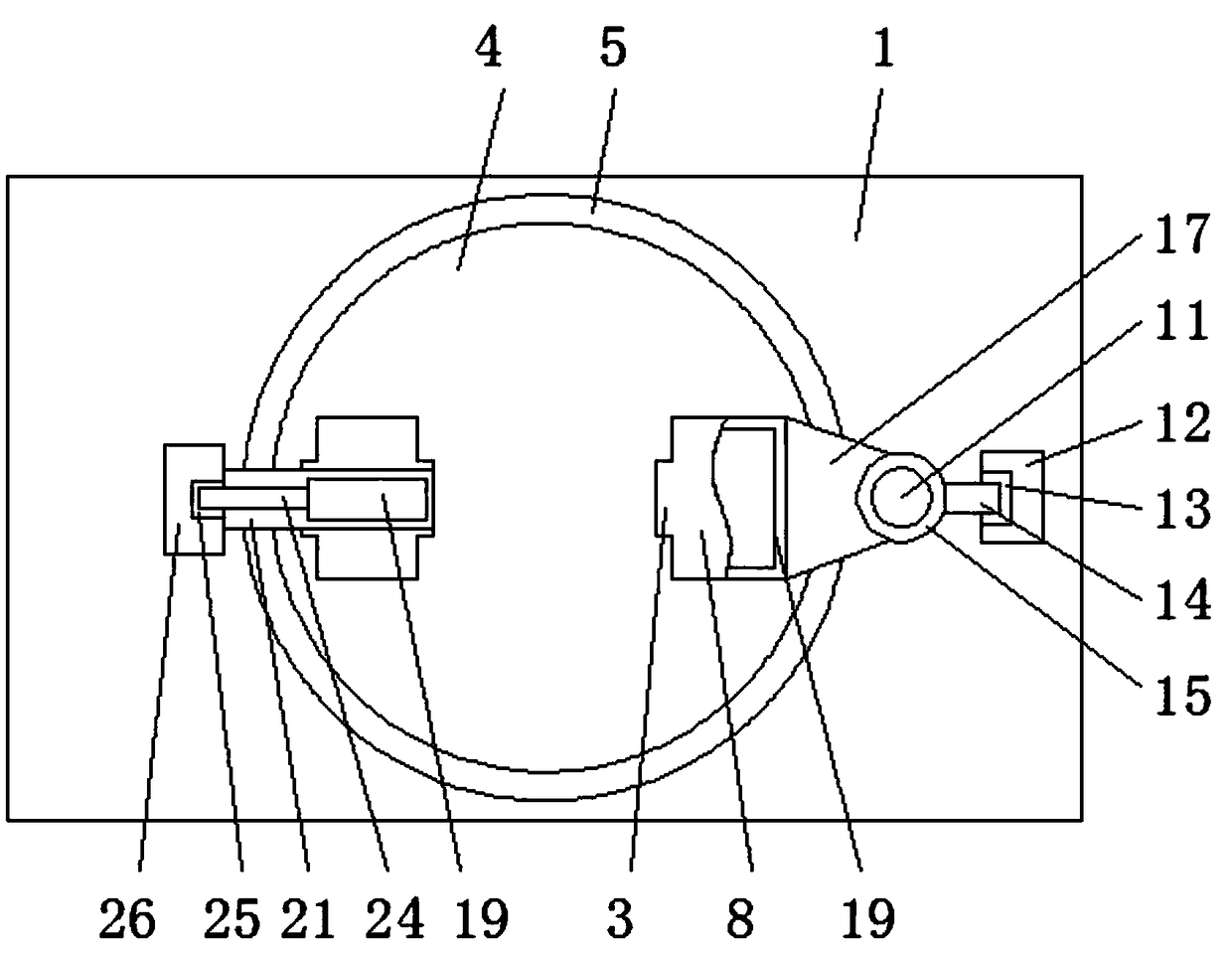

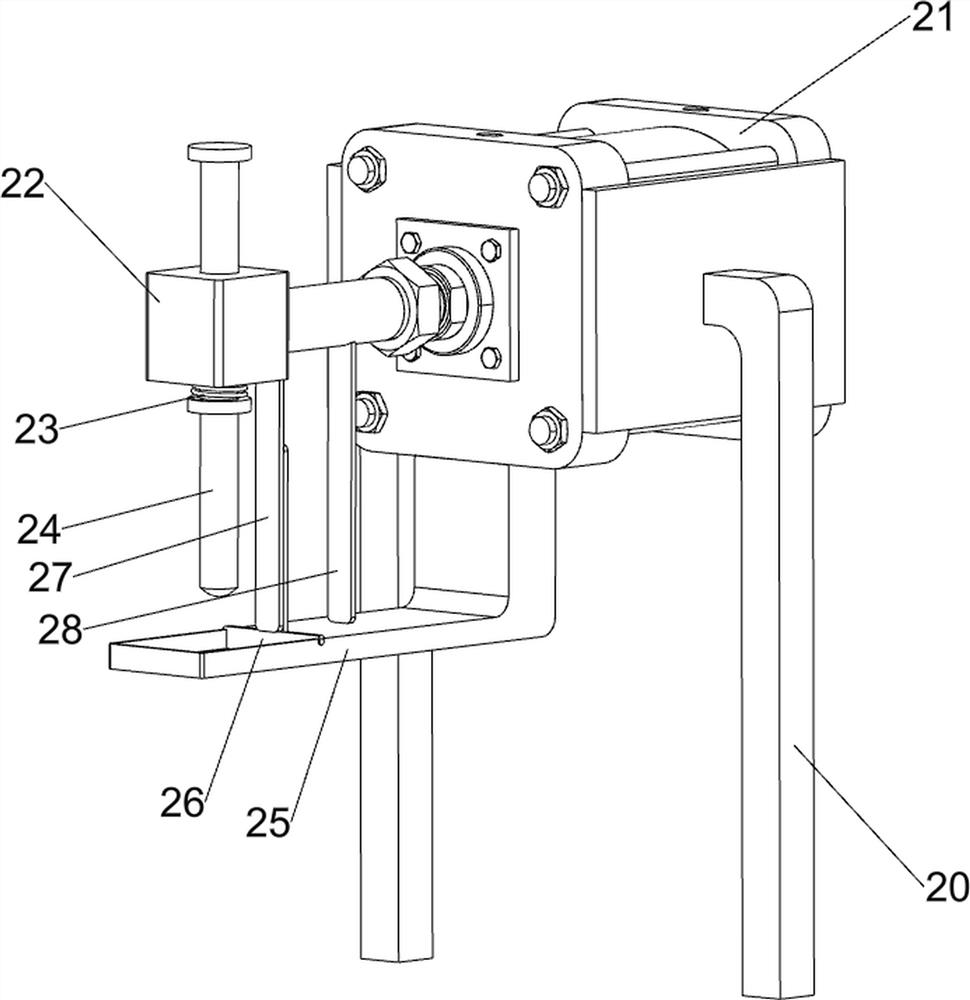

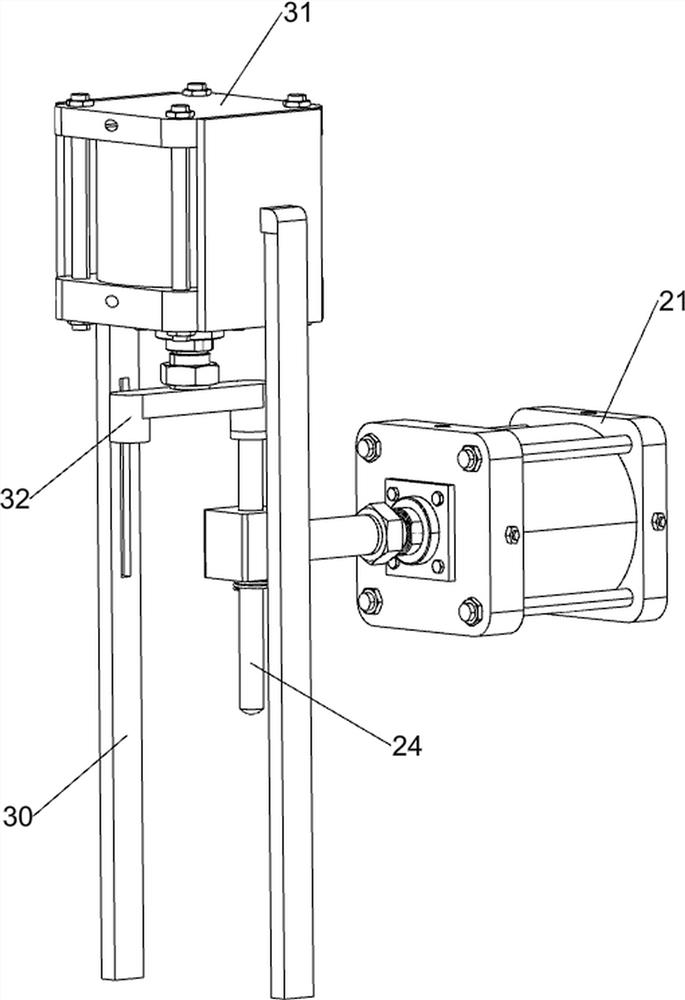

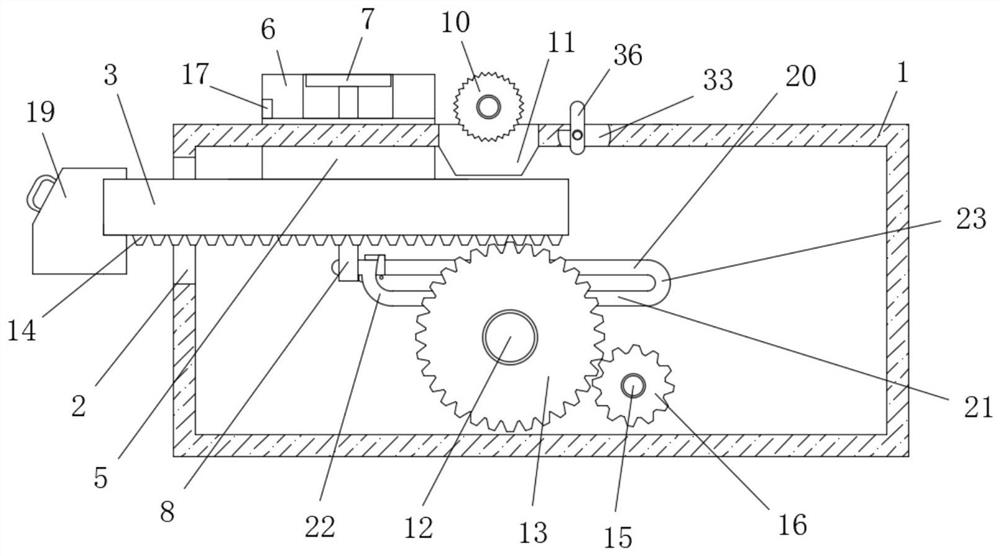

Cutting machine for metal corrugated pipes

InactiveCN107052442ARealize the effect of automatic feedingDoes not affect operationTube shearing machinesShearing machine accessoriesProduction rateEconomic benefits

The invention discloses a cutting machine for metal corrugated pipes. The cutting machine for the metal corrugated pipes comprises a bearing table, a cutting table and a cutting machine base. The top of the bearing table is fixedly connected with a jacking mechanism. The top of the cutting table is provided with a discharging groove and a cutting groove sequentially from left to right. The position, corresponding to the discharging groove, of the top of the cutting table is fixedly connected with a feeding shell. A discharging channel is formed in the bottom of the side, close to the cutting groove, of the feeding shell. The top of the cutting machine base is fixedly connected with a cutting machine body. A cutting wheel is arranged in the position, corresponding to the discharging groove, of the cutting machine body. Through cooperation of the jacking mechanism, the discharging groove, the cutting groove, the feeding shell and the discharging channel, an automatic feeding effect is achieved, manually placing the corrugated pipes to an operating floor is not needed, both time and labor are saved, normal operation is not affected, the working efficiency is improved, the working progress is accelerated, productivity is improved, and accordingly, economic benefits are obtained to a certain extent.

Owner:何朋飞

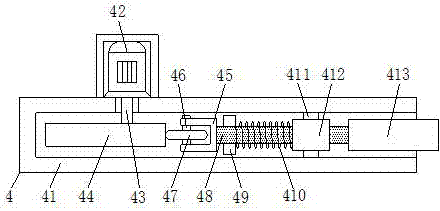

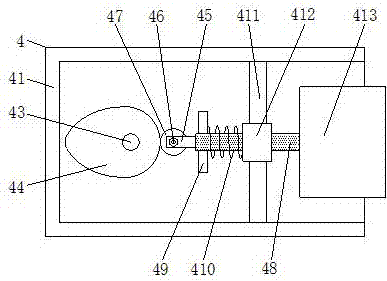

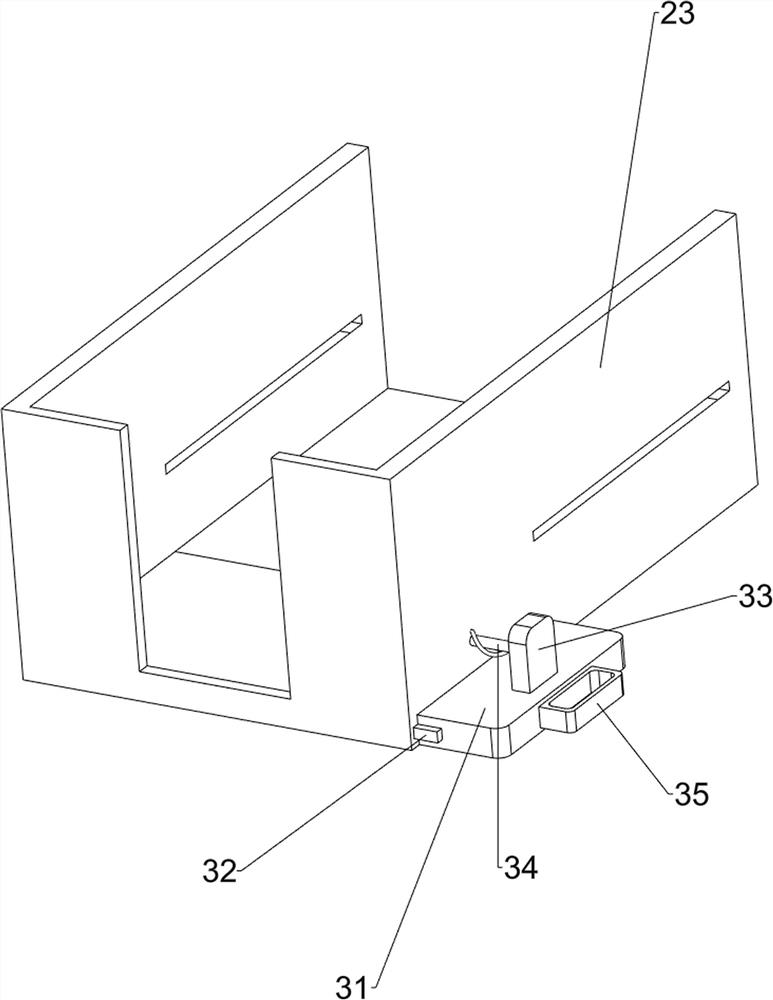

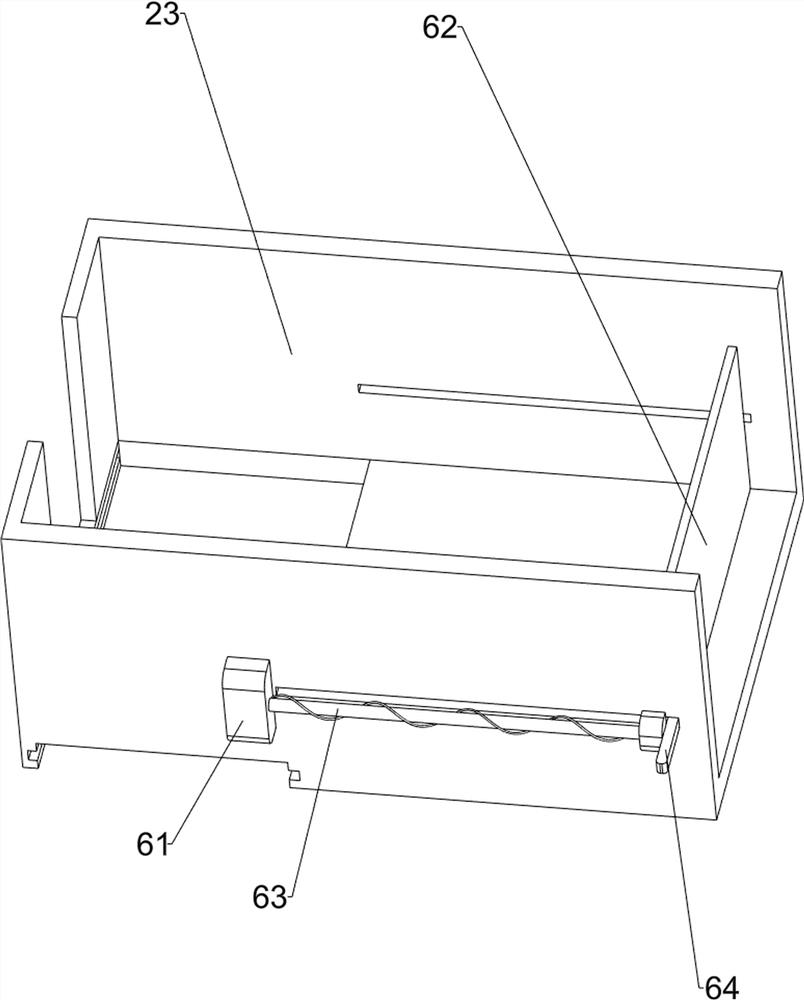

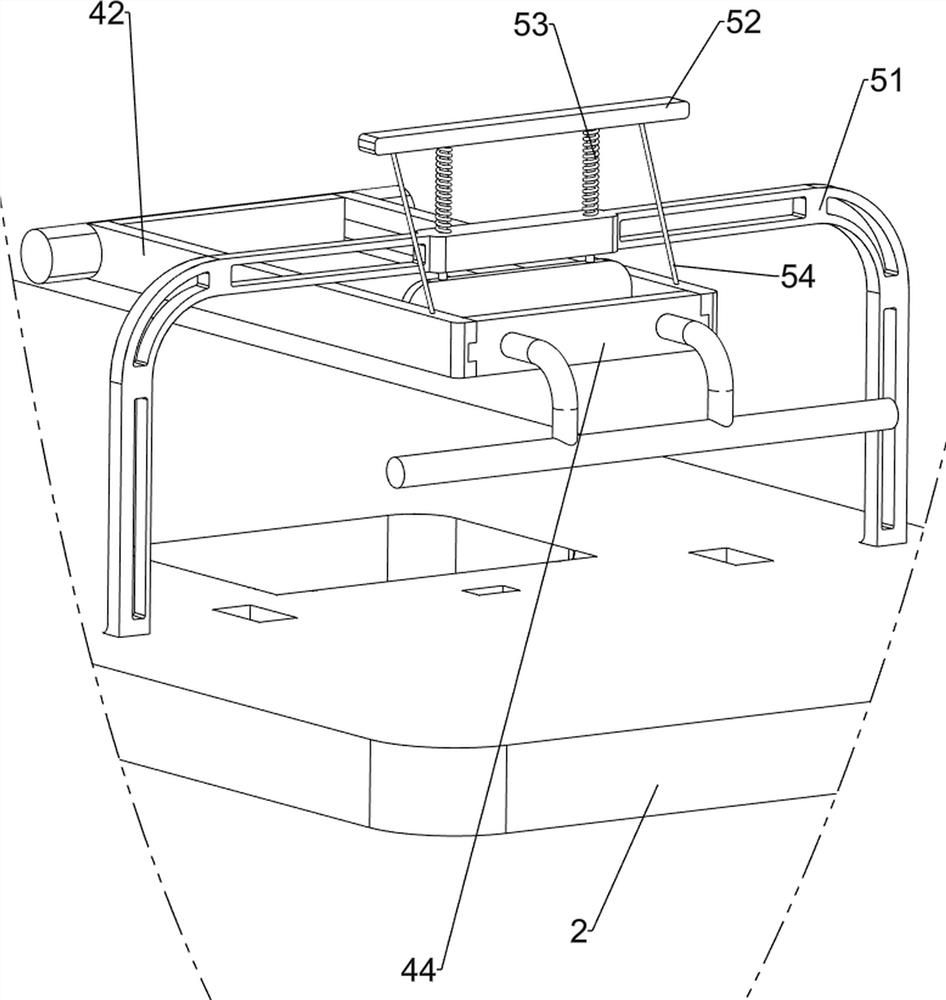

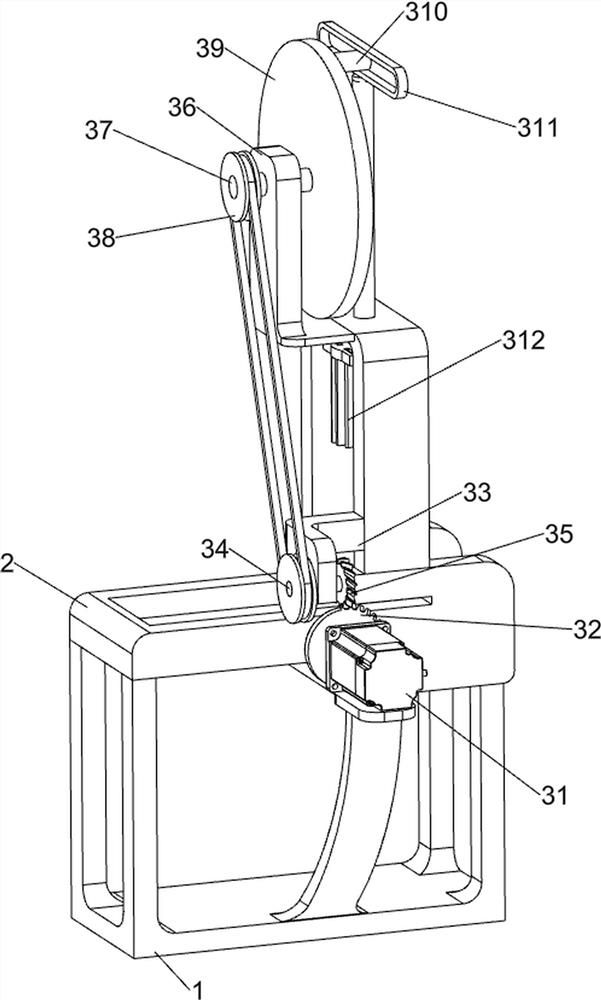

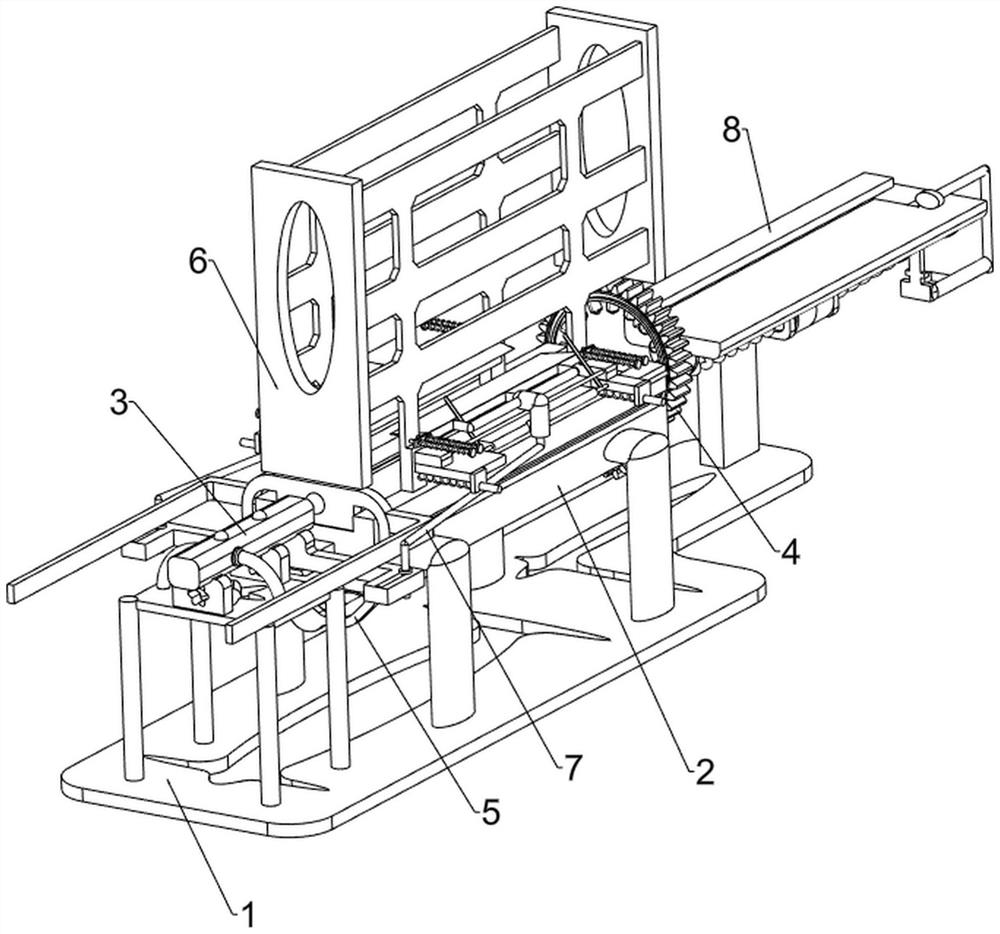

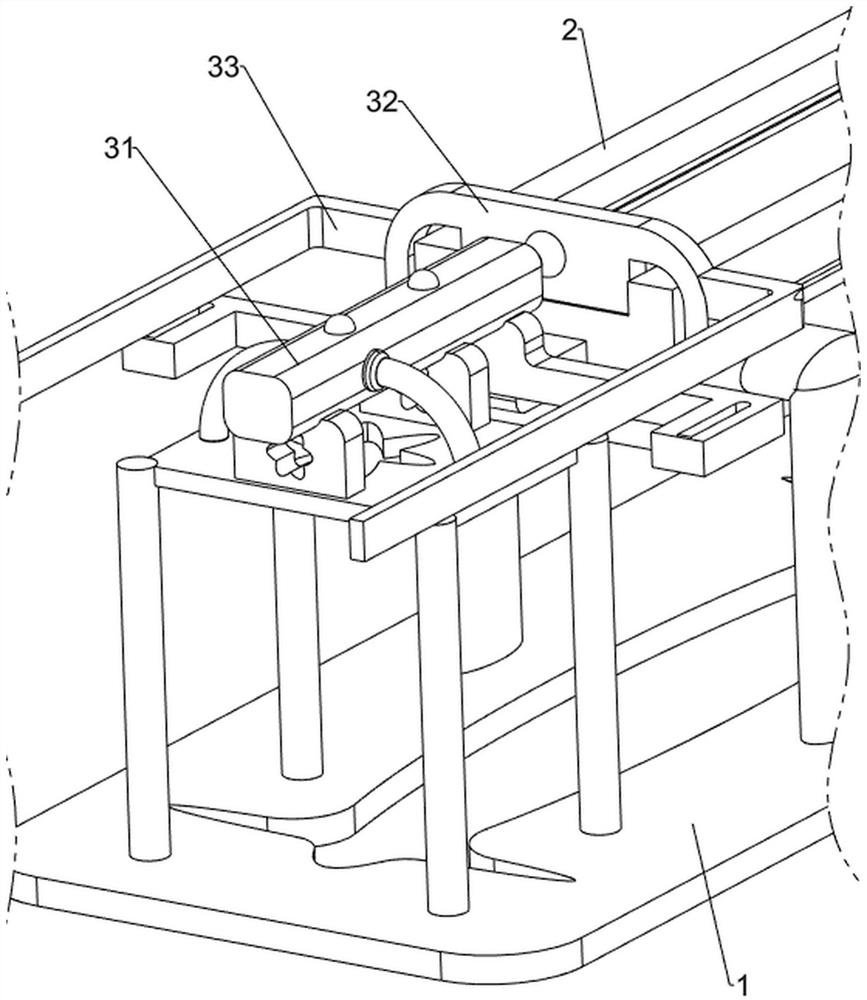

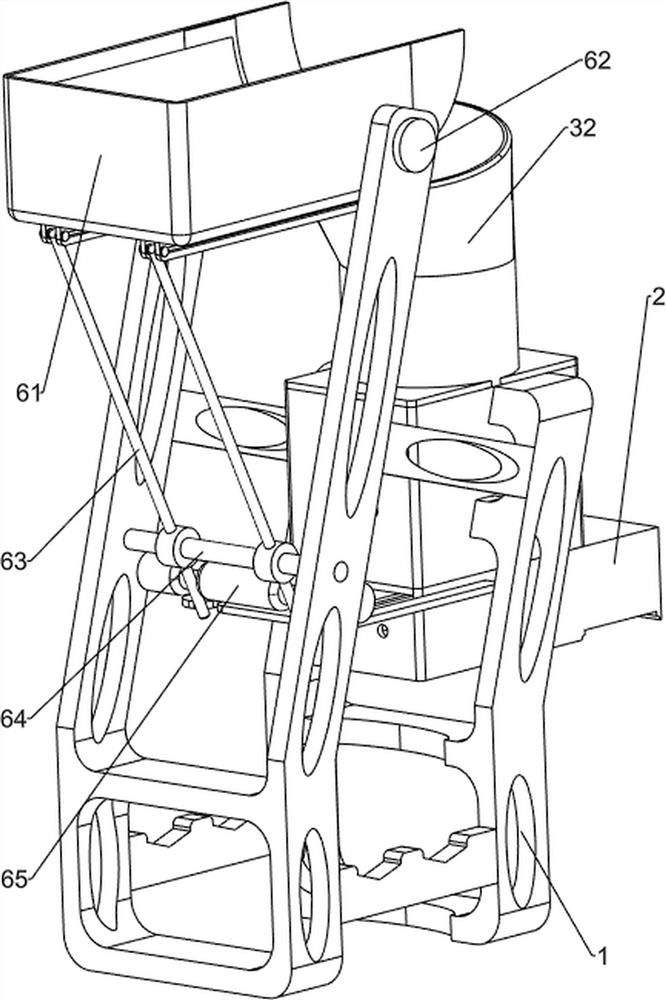

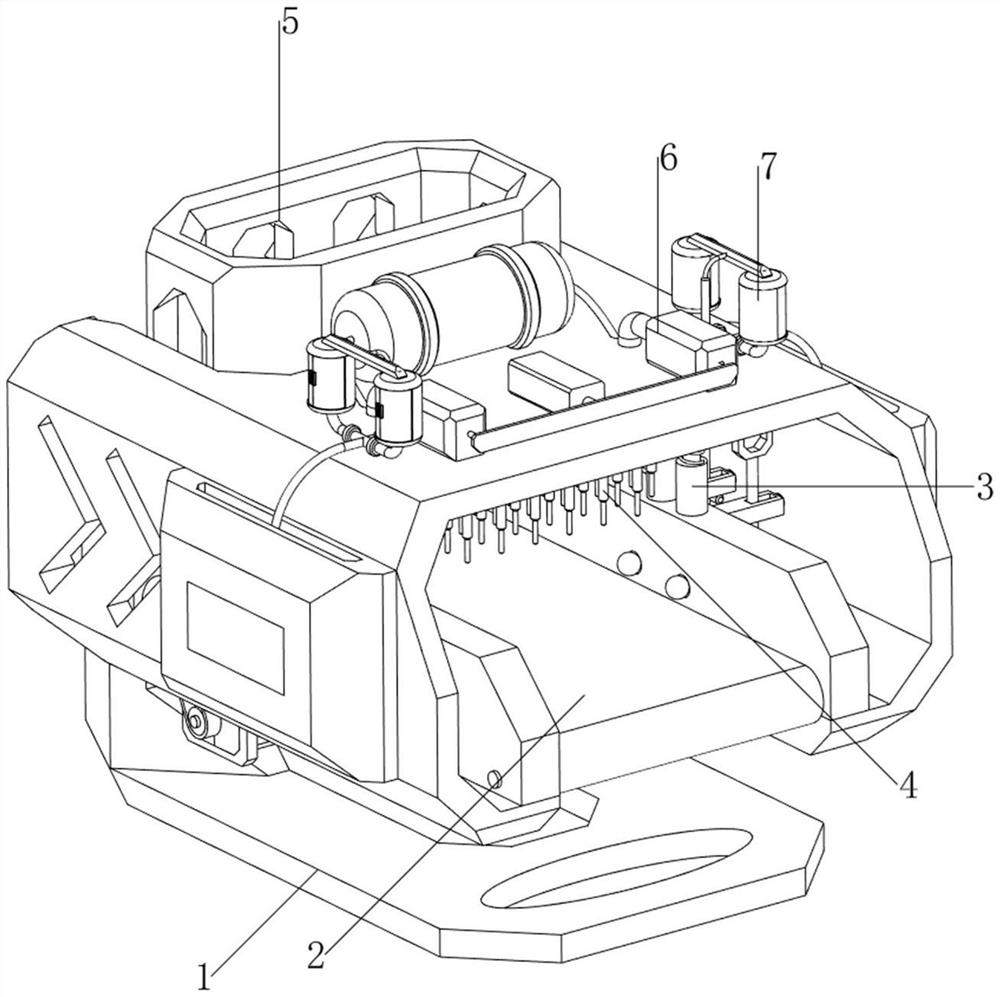

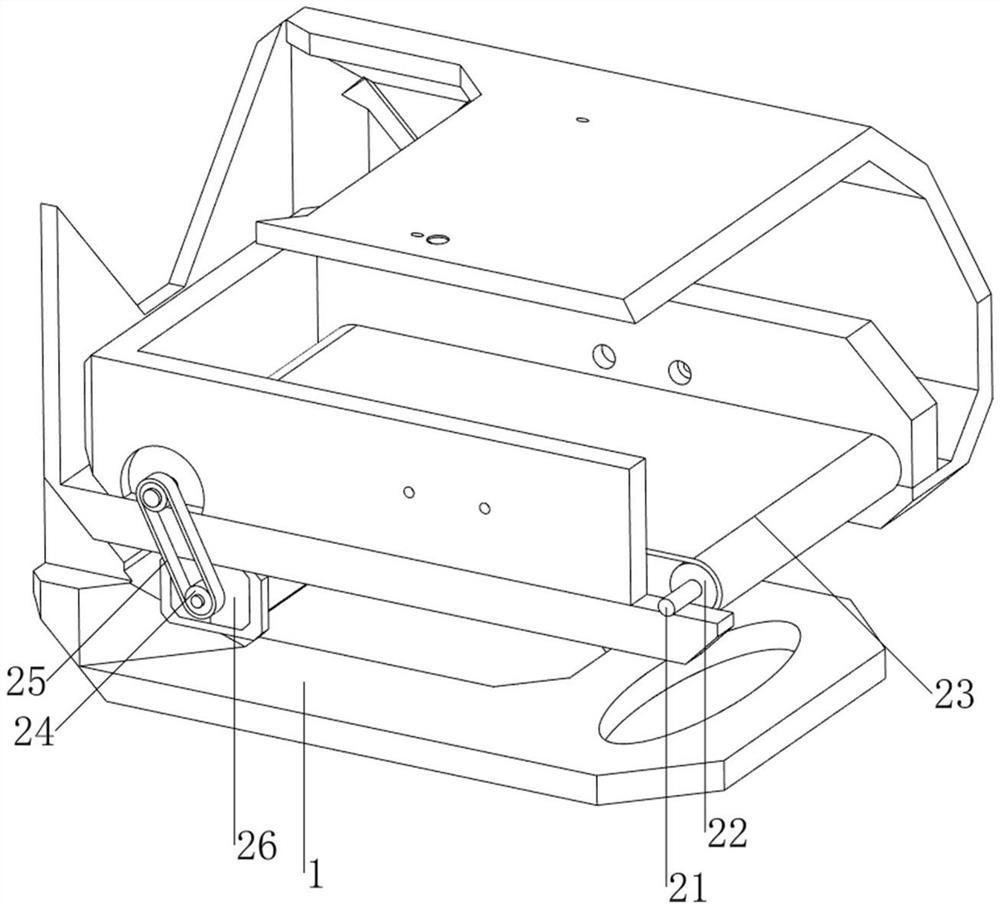

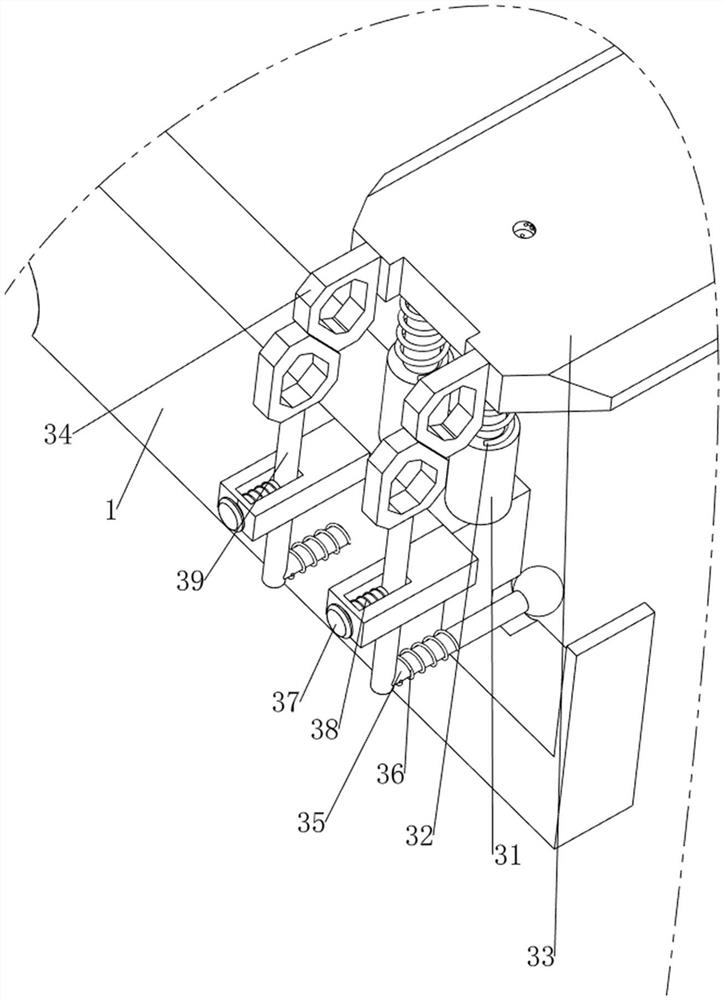

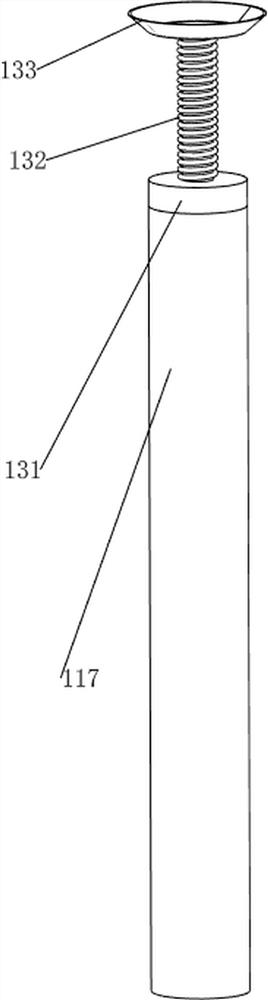

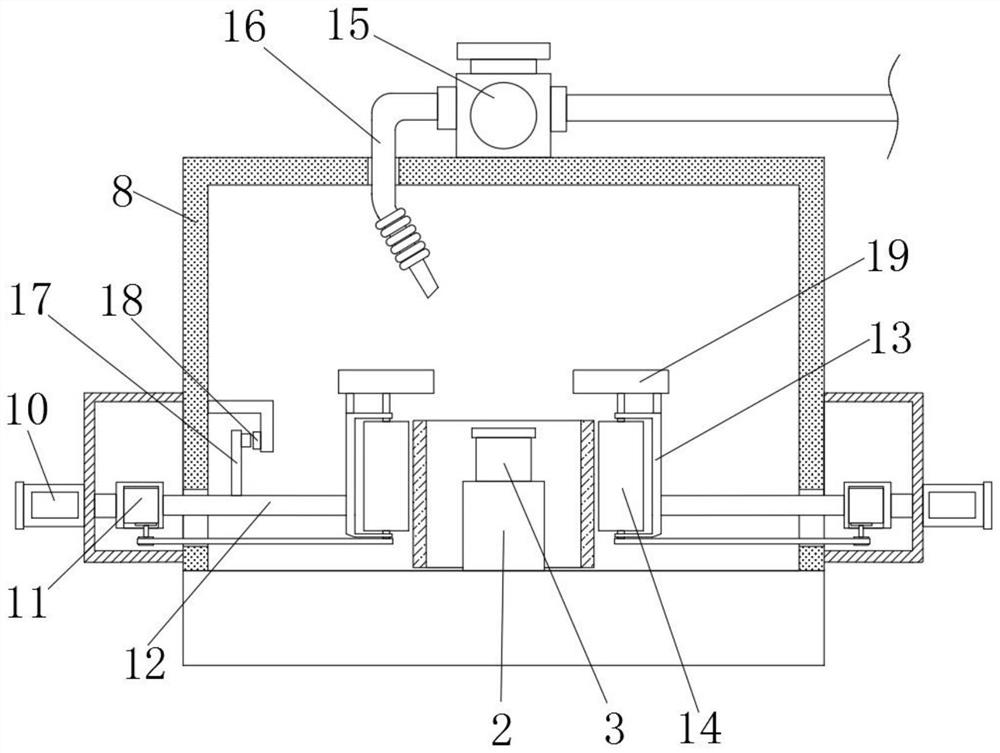

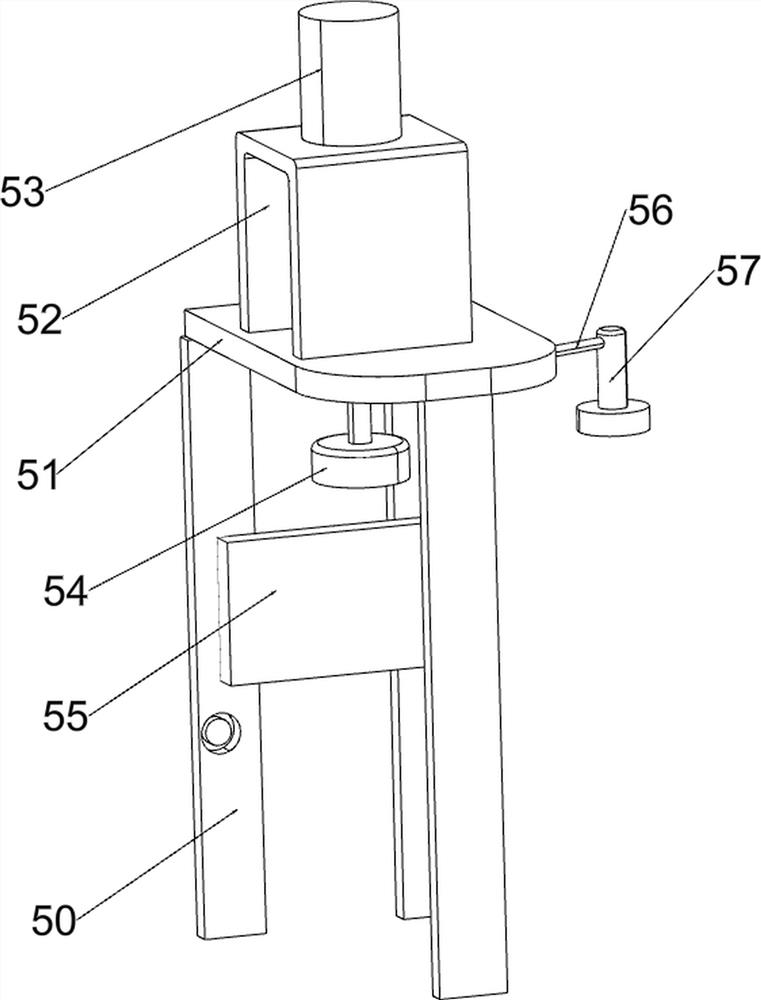

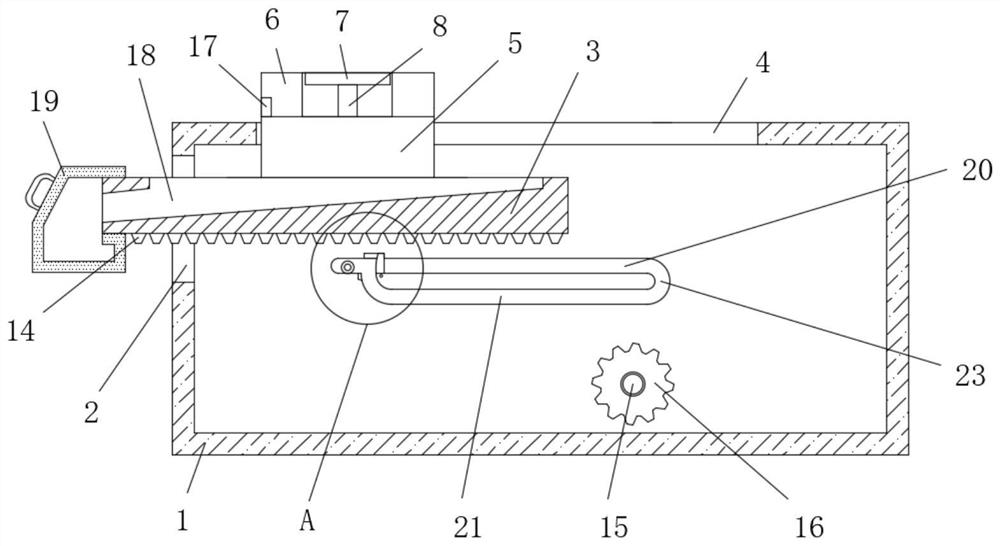

Pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection

PendingCN112477255ARealize the effect of extrusionRealize the blanking effectPressesThermodynamicsEngineering

The invention relates to extrusion forming and recycling equipment, in particular to pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection. The pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection can achieve automatic feeding and discharging and automatic extrusion forming. The pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection comprises a base and a discharging mechanism, and a compression mechanism is arranged on the base; and the discharging mechanism is arranged at the lower part of the compression mechanism. An air cylinder extends to push a push rod backwards, so that an extrusion plate is pushed backwards, the extrusion plate pushes a zip-top can backwards, the zip-top can is clamped between the inner wall of the rear side of an extrusion table and the extrusion plate, and the effect of extrusion forming of the zip-top can isachieved. A first handle is manually pulled leftwards, a first baffle is subjected to leftward pulling force to enable a first sliding block to slide leftwards, a first baffle moves leftwards to drivea first fixing block to move leftwards, and the discharging effect of the zip-top can formed through extrusion is achieved.

Owner:曾鹏

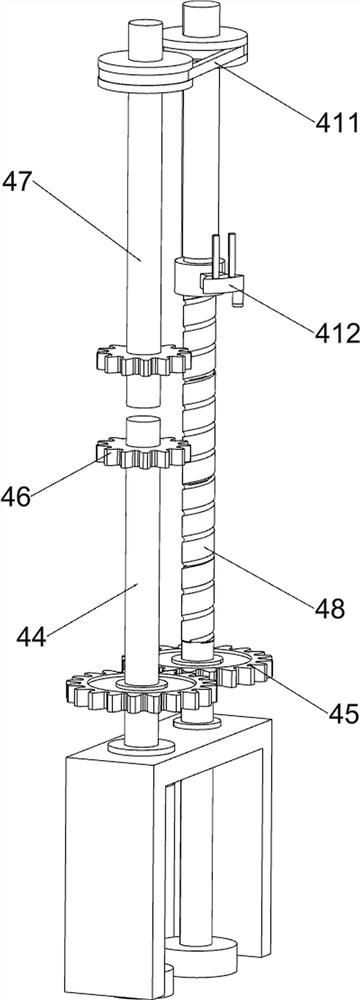

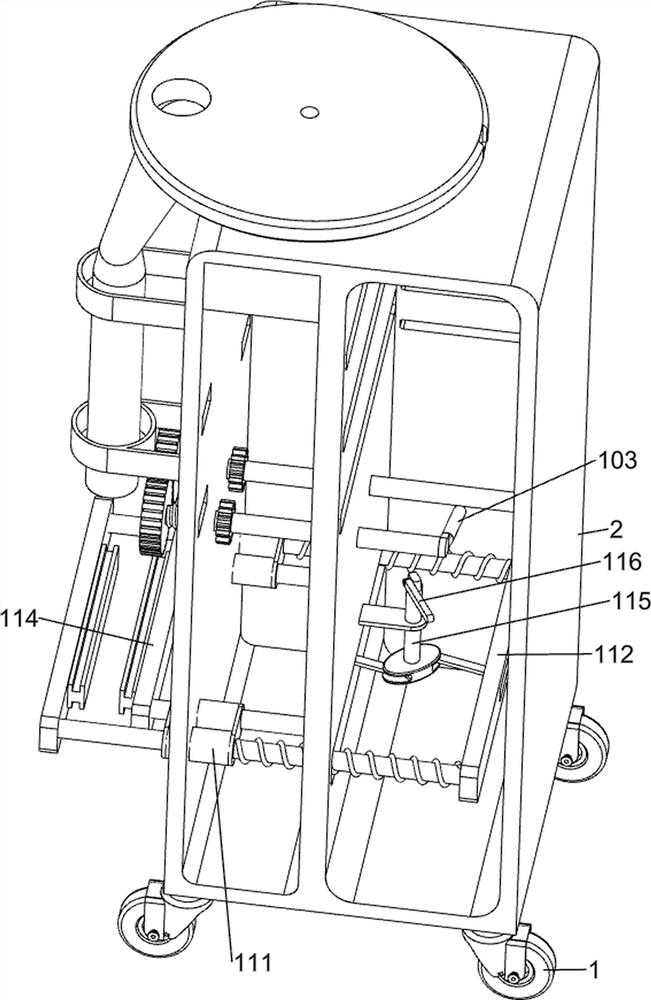

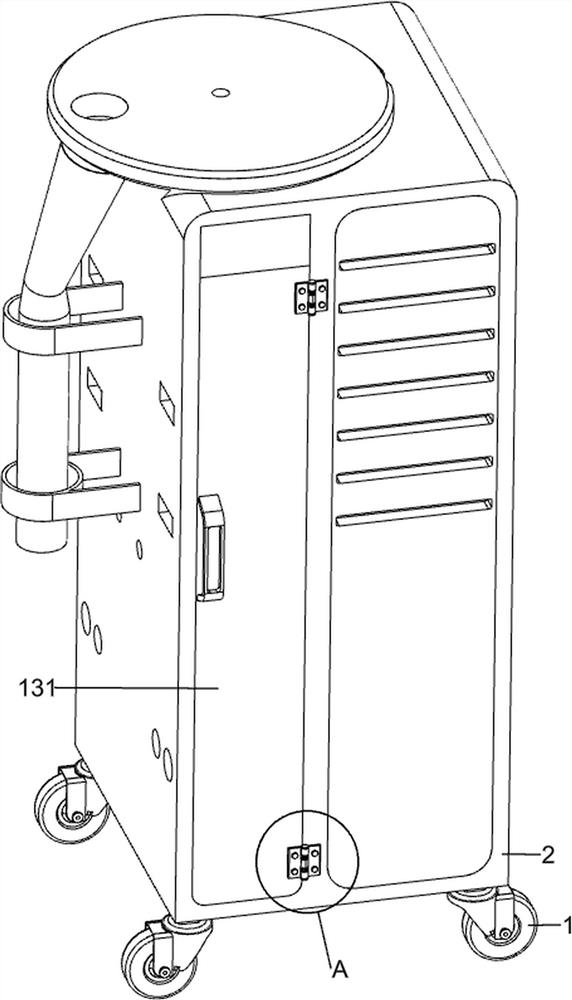

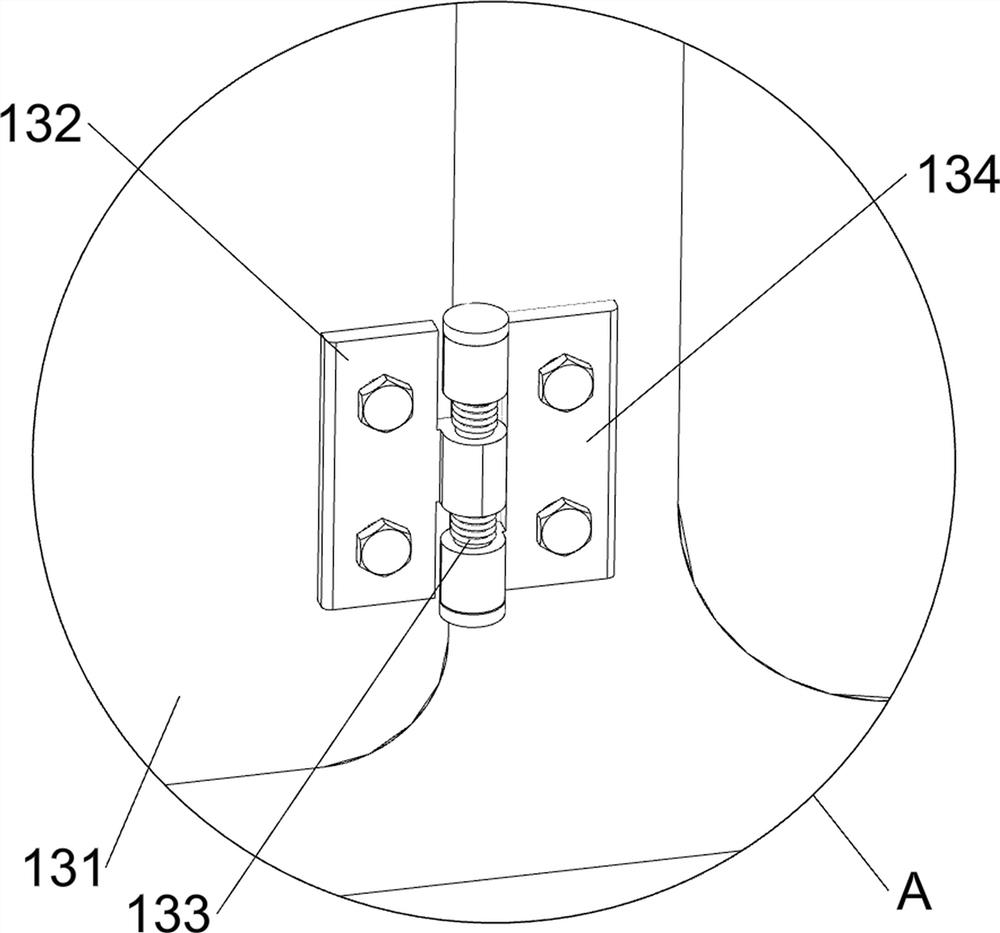

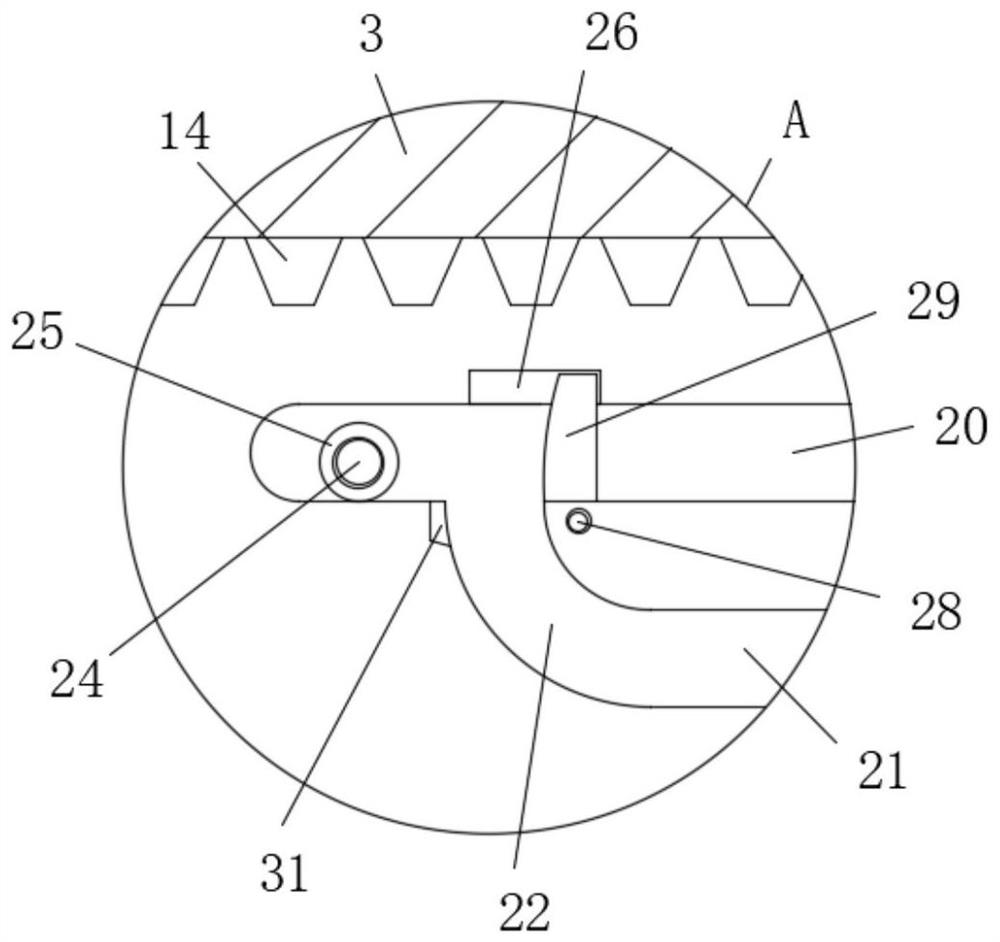

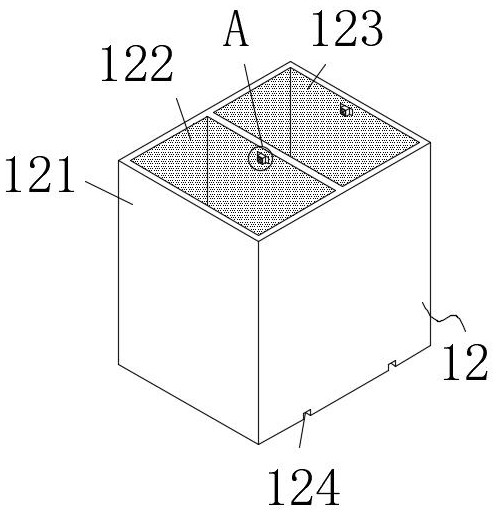

Automatic feeder of pig feed

ActiveCN108371111ASolve the problem of susceptibility to contaminationRealize the effect of automatic feedingAnimal feeding devicesGear wheelFodder

The invention relates to the technical field of livestock raising machines and particularly discloses an automatic feeder of pig feed. The automatic feeder comprises a body and a hopper-shaped feed box fixedly connected to the top of the body, wherein a discharging pipe is communicated under the hopper-shaped feed box; a first valve plate is arranged at the discharging pipe; a forwards-rotating and reversely-rotating motor is arranged on the outer side wall of the body; an output shaft in the forwards-rotating and reversely-rotating motor is connected with a gear by a rotary rod; a sliding guide rail is fixedly connected to a platform of the body and is connected with a rack meshed with the gear in a sliding manner; one end of the rack is fixedly connected with a feed intake groove which is connected with the sliding guide rail in a sliding manner; an elastic air bag is adhered to the inner side wall of the body; the free end of the rack is contacted with the elastic air bag in an extruding manner; the elastic air bag is communicated with a first cylinder by an air transmission pipe; one end of a first piston rod is connected with the first valve plate. The automatic feeder disclosed by the invention has the advantage that the problem that the feed intake groove is exposed outside when being arranged in a piggery and is easily polluted when being not used is solved.

Owner:道真仡佬族苗族自治县兴康生态特种养殖有限公司

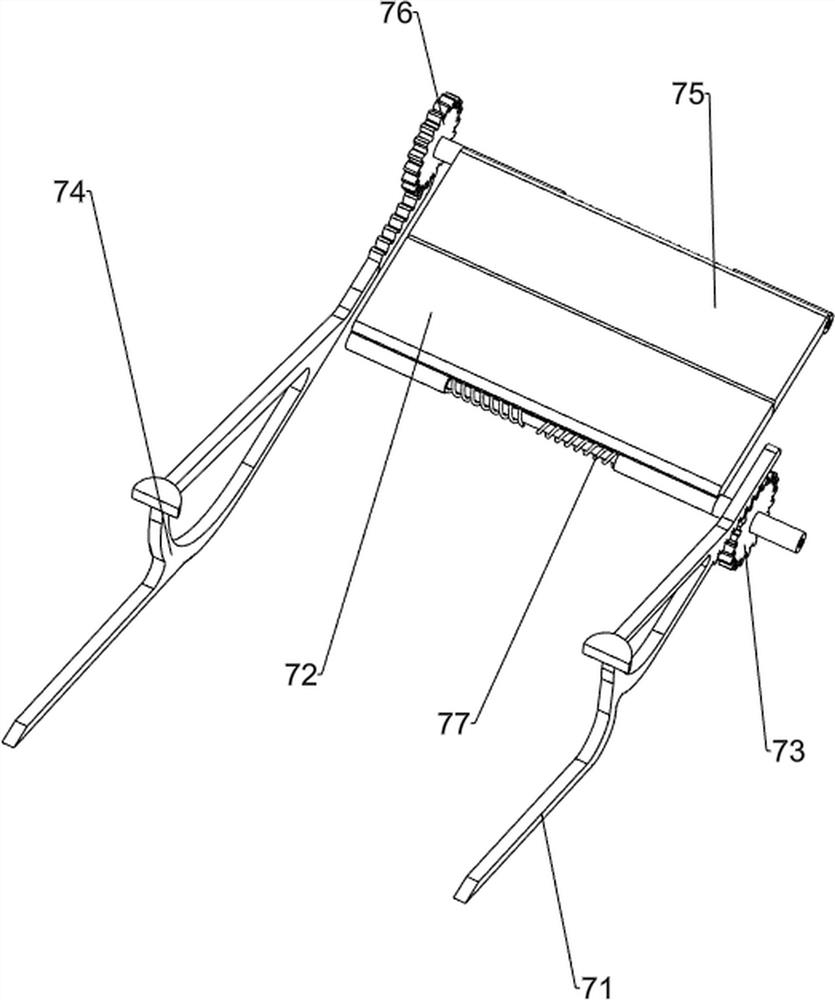

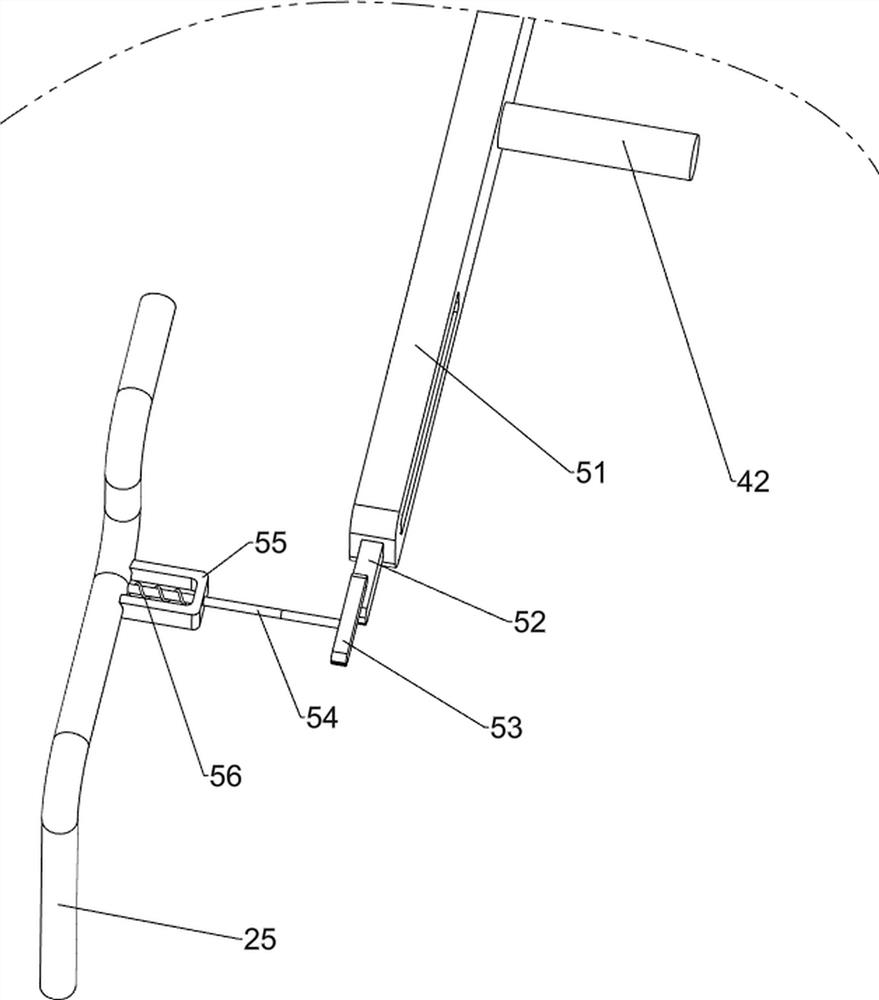

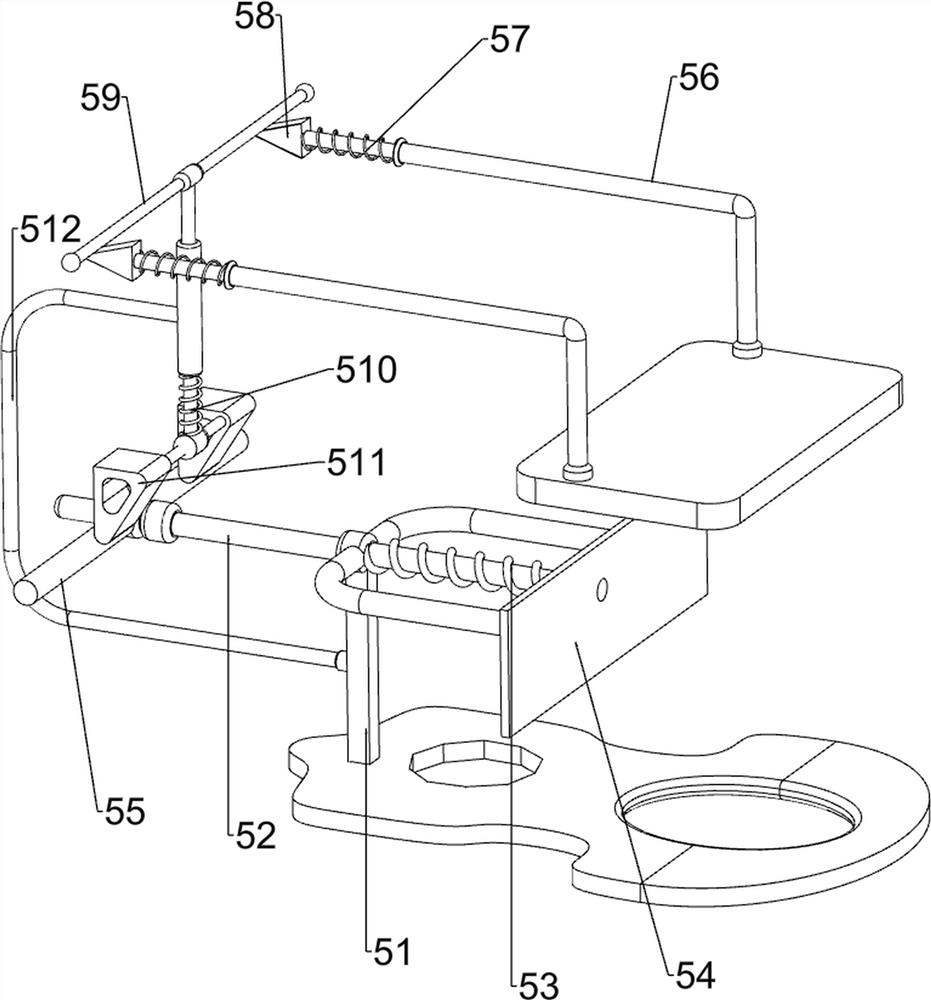

Portable vacuum cup screen printing device

ActiveCN112092493AEffect of contactRealize automatic mud adding effectScreen printersConveyor partsScreen printingEngineering

The invention relates to a screen printing device, in particular to a portable vacuum cup screen printing device. The portable vacuum cup screen printing device reduces manual operation, can achieve automatic screen printing, automatic mud pushing and automatic material receiving, and enhances the screen printing effect. The portable vacuum cup screen printing device comprises a base, an air cylinder, a screen printing mechanism and a mud scraping mechanism, and a placing plate is arranged on the base; the air cylinder is mounted at the top of the placing plate; the screen printing mechanism is arranged at the top of the placing plate, and the screen printing mechanism is connected with the air cylinder; and the mud scraping mechanism connected with the screen printing mechanism is arranged at the top of the placing plate. The air cylinder drives a push rod to slide forwards along a first guide sleeve to be in contact fit with a handle, so that the handle slides forwards and downwardsalong a sliding fixed plate, then a screen printing frame is driven to obliquely slide forwards and downwards, a supporting frame swings downwards, a first elastic pull rope stretches, and the effectthat the bottom of the screen printing frame makes contact with the surface of a vacuum cup is achieved.

Owner:南京神雨食品科技有限公司

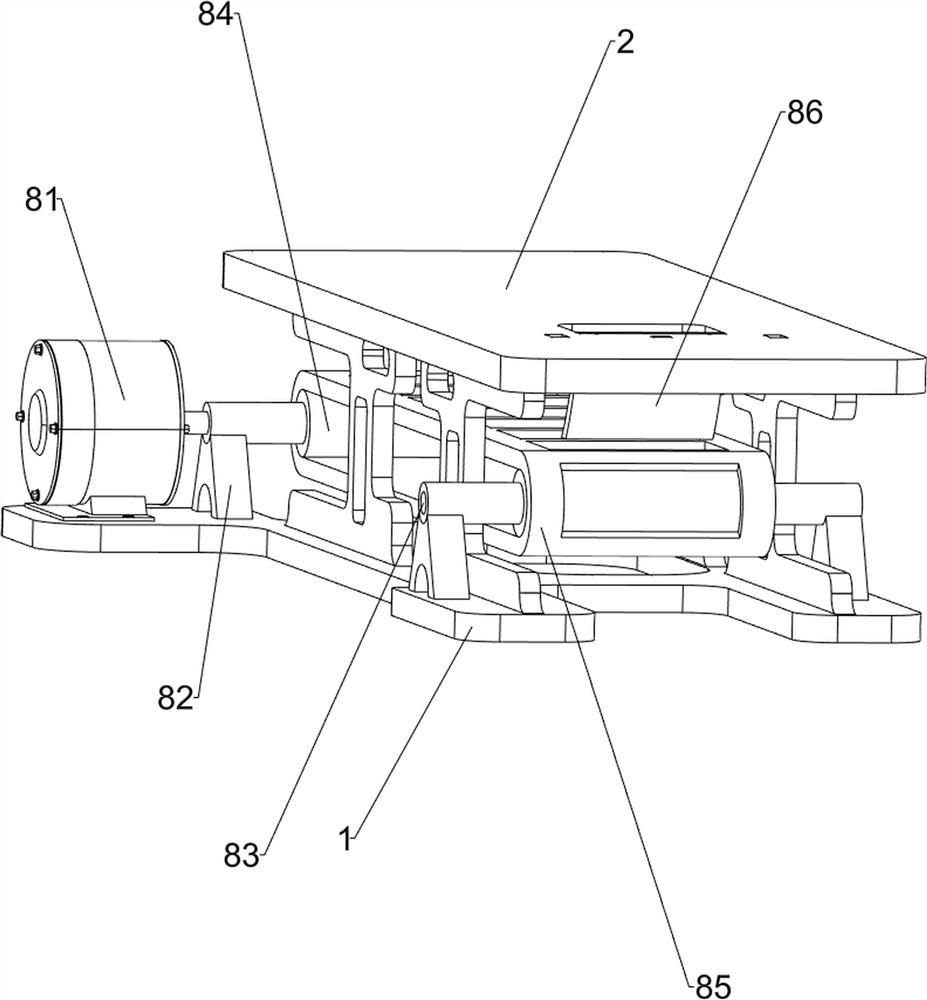

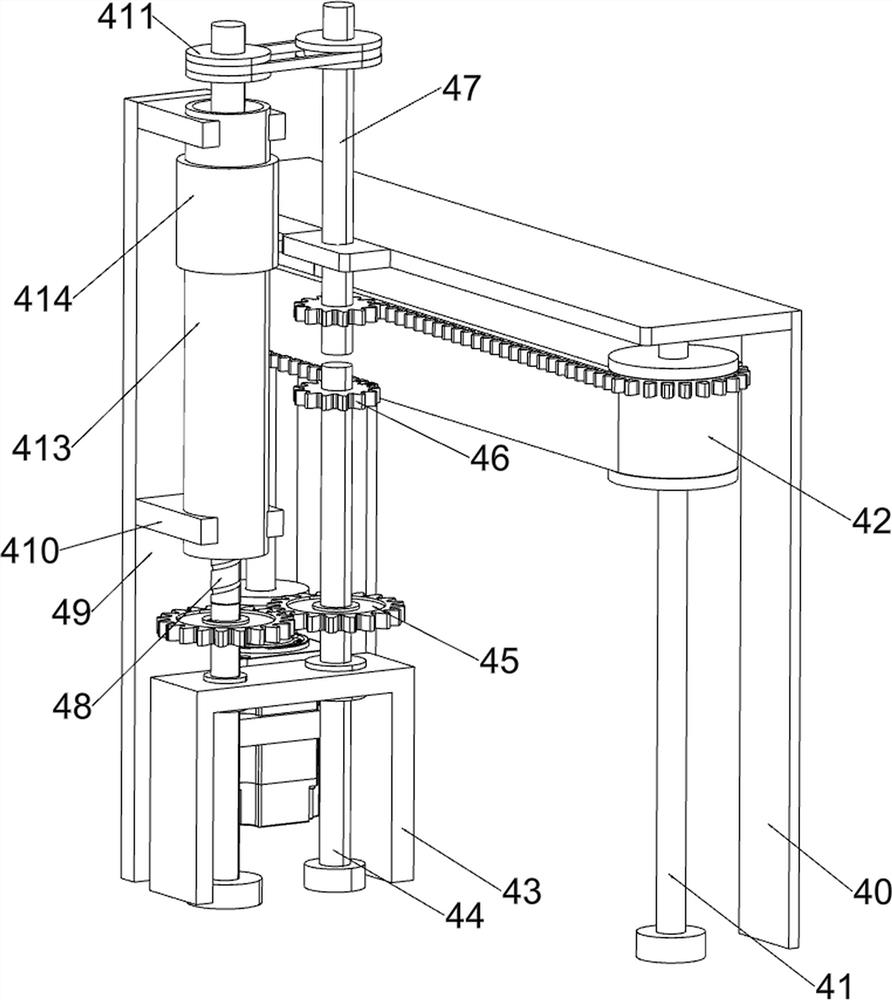

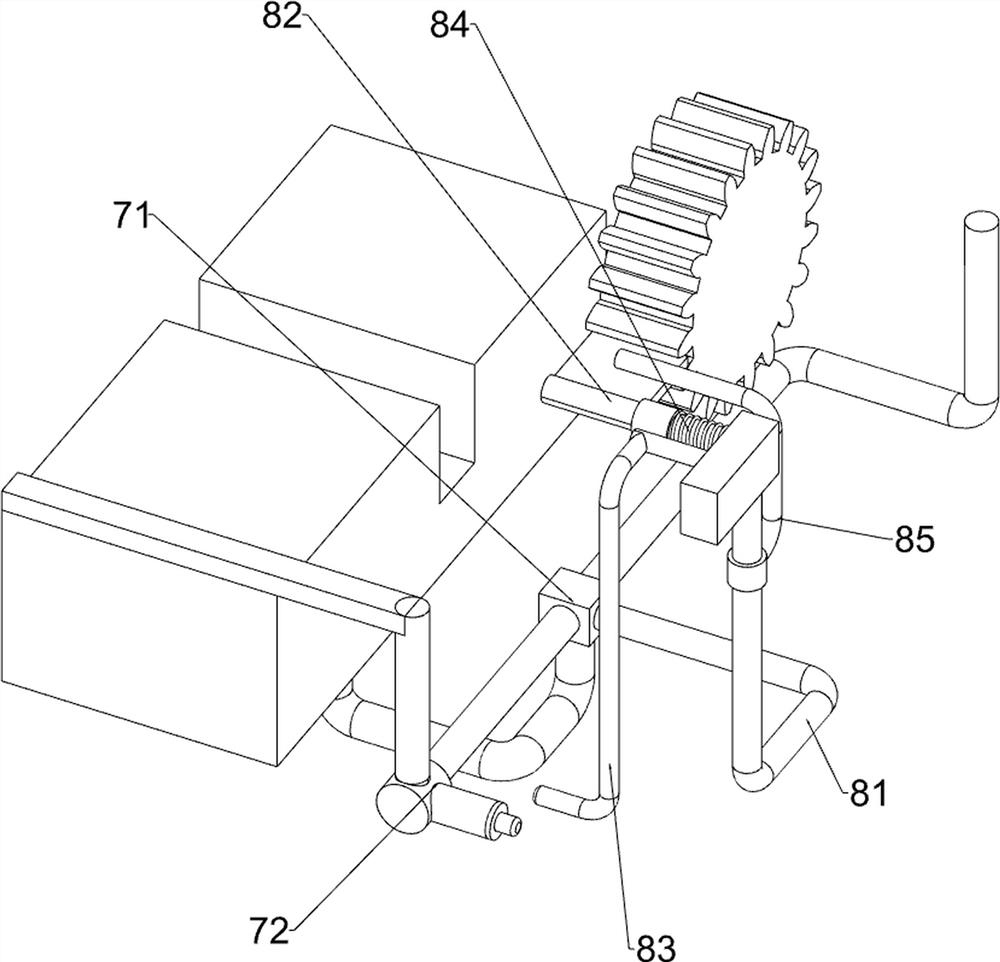

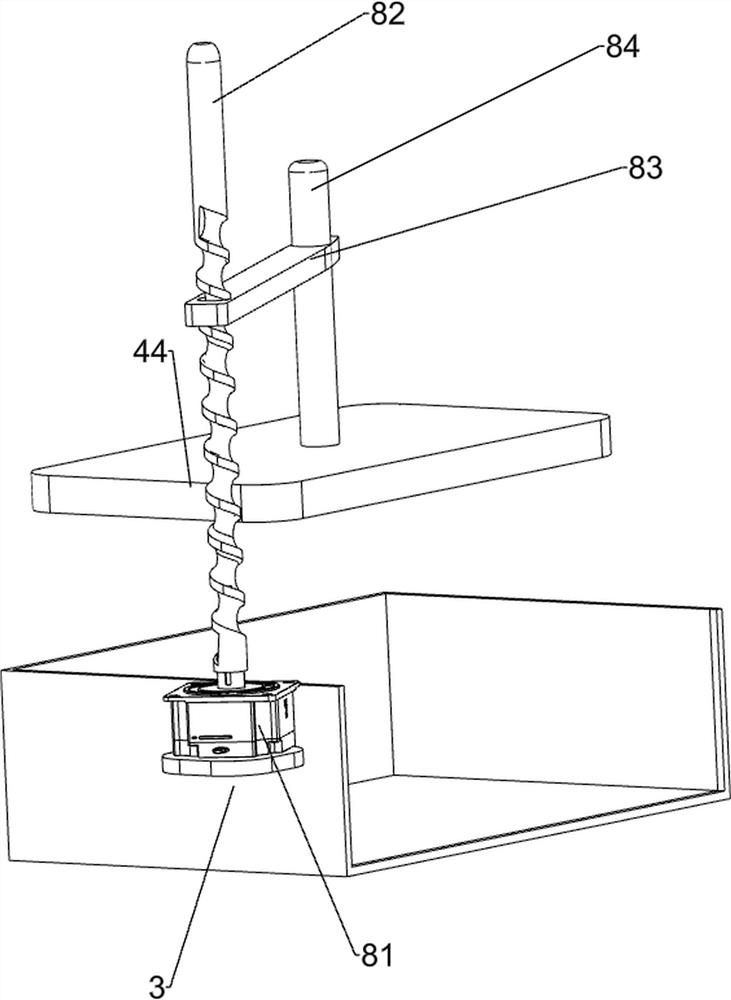

Gear extrusion forming equipment for metal powder metallurgy

PendingCN112387970AAchieve automatic feedingRealize the effect of automatic feedingMolding machineMetal powder

The invention relates to extrusion forming equipment, in particular to gear extrusion forming equipment for metal powder metallurgy. The invention provides the gear extrusion forming equipment for metal powder metallurgy capable of automatically carrying out discharging, and capable of ejecting out metal powder formed through extrusion. The gear extrusion forming equipment for metal powder metallurgy comprises a supporting frame, a die plate, a forming mechanism, a material spreading mechanism and a material ejection mechanism; the supporting frame is used for allowing the whole equipment to be arranged; and the die plate is arranged at the upper portion of the supporting frame; and the forming mechanism is arranged on the die plate, the material spreading mechanism is arranged on the dieplate, and the material ejection mechanism is arranged on the die plate. The gear extrusion forming equipment for metal powder metallurgy achieves the effects that automatic discharging can be achieved, and the metal powder formed through extrusion can be ejected out, the metal powder needing to be subjected to extrusion forming is placed in a discharging pipe, a pressing column moves up and down,the metal powder in the discharging pipe is extruded downwards, and therefore the automatic discharging effect can be achieved.

Owner:韦熙斌

Automatic succulent plant juice extraction equipment

InactiveCN112294079ARealize the effect of automatic feedingStrainersEngineeringMechanical engineering

The invention relates to extraction equipment, in particular to automatic succulent plant juice extraction equipment. According to the automatic succulent plant juice extraction equipment, automatic feeding can be achieved, and residues obtained after juicing are pushed out while juicing is conducted. According to the technical scheme, the automatic succulent plant juice extraction equipment comprises a bottom plate for install the whole equipment; a servo motor arranged on one side of the upper part of the bottom plate; a first storage basket arranged at the upper part of the bottom plate; and a conveying mechanism arranged on the side, close to the servo motor, of the upper portion of the bottom plate. The effects that automatic feeding can be achieved, and residues obtained after juicing are pushed out while juicing is conducted are achieved; succulent plants are placed in a discharging frame and moved into a juicing basket through a second circular pipe, and therefore, the effect of automatic discharging can be achieved.

Owner:李堂海

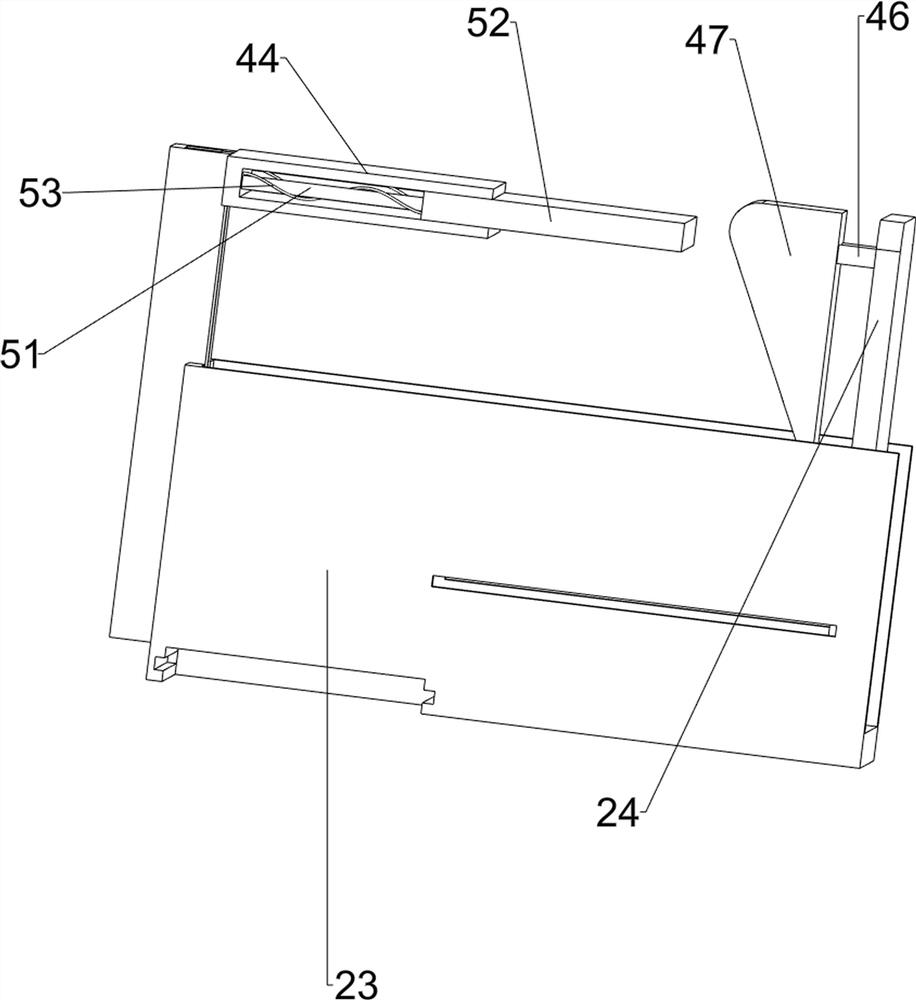

Plate burr removing device for furniture processing

ActiveCN112497401AAchieve effectAchieve the effect of removing burrs from the plateWood charring/burningEngineeringWorkbench

Owner:上犹县广兴木业有限公司

Crushing treatment equipment for medical waste garbage

InactiveCN112705304ARealize the effect of primary crushing garbageRealize the effect of automatic feedingGrain treatmentsPressesMedical wasteProcess engineering

The invention relates to garbage crushing treatment equipment, in particular to crushing treatment equipment for medical waste garbage. The crushing treatment equipment for the medical waste garbage is good in crushing effect and capable of achieving automatic feeding and discharging. The crushing treatment equipment for medical waste garbage comprises a supporting frame, a working frame, a crushing mechanism and a compression mechanism, and the working frame is arranged in the middle of the supporting frame; the crushing mechanism is arranged at the top of the supporting frame; and the compression mechanism is arranged on the supporting frame. A second transmission shaft rotates to drive a second belt wheel assembly to transmit, so that a cutting assembly is driven to rotate, the cutting assembly stirs and crushes garbage, and the effect of primary garbage crushing is achieved.

Owner:李静

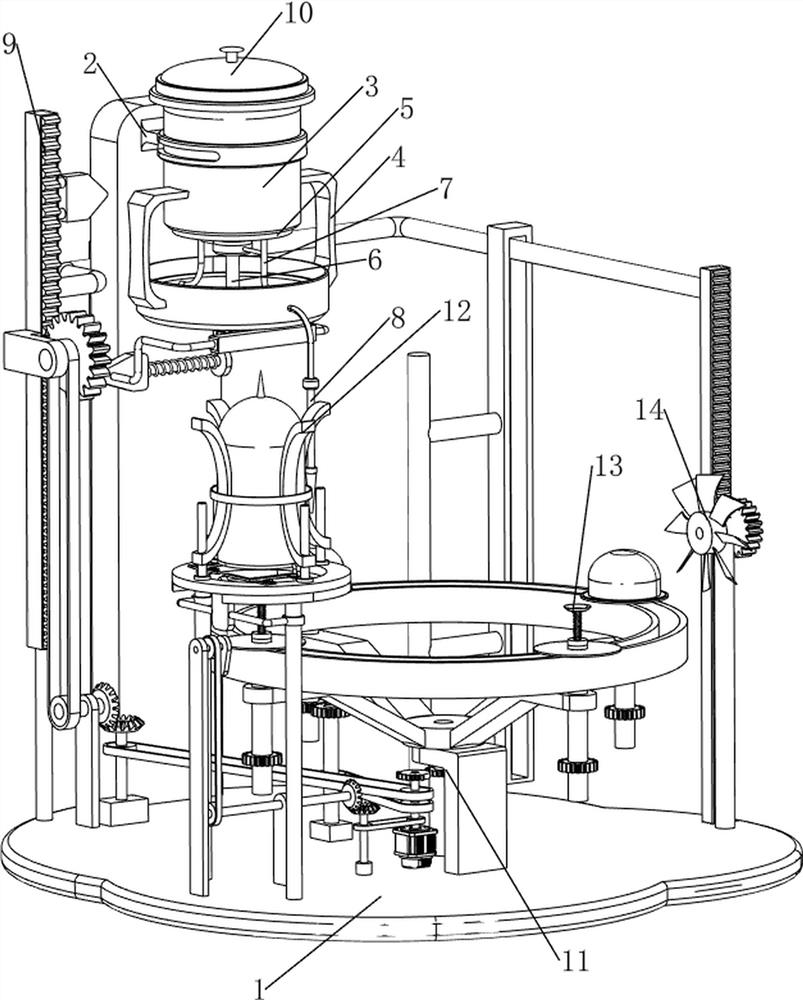

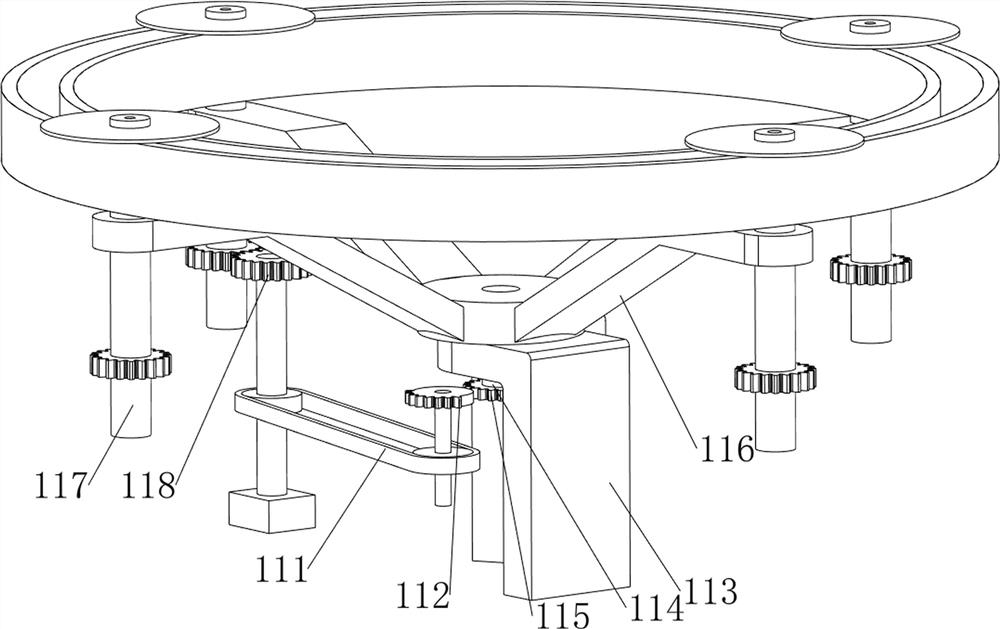

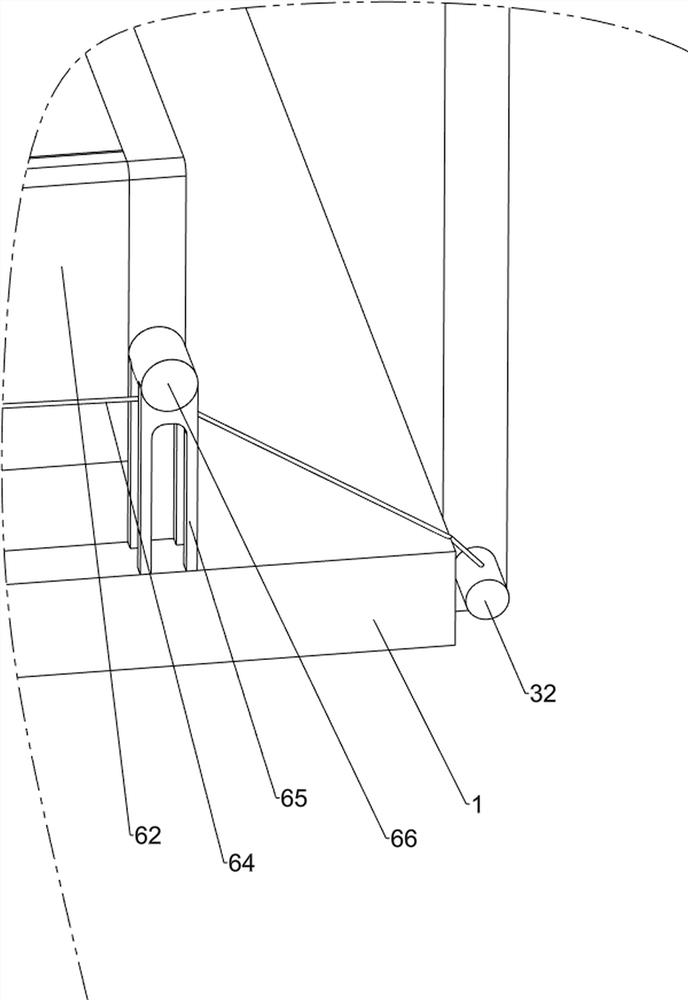

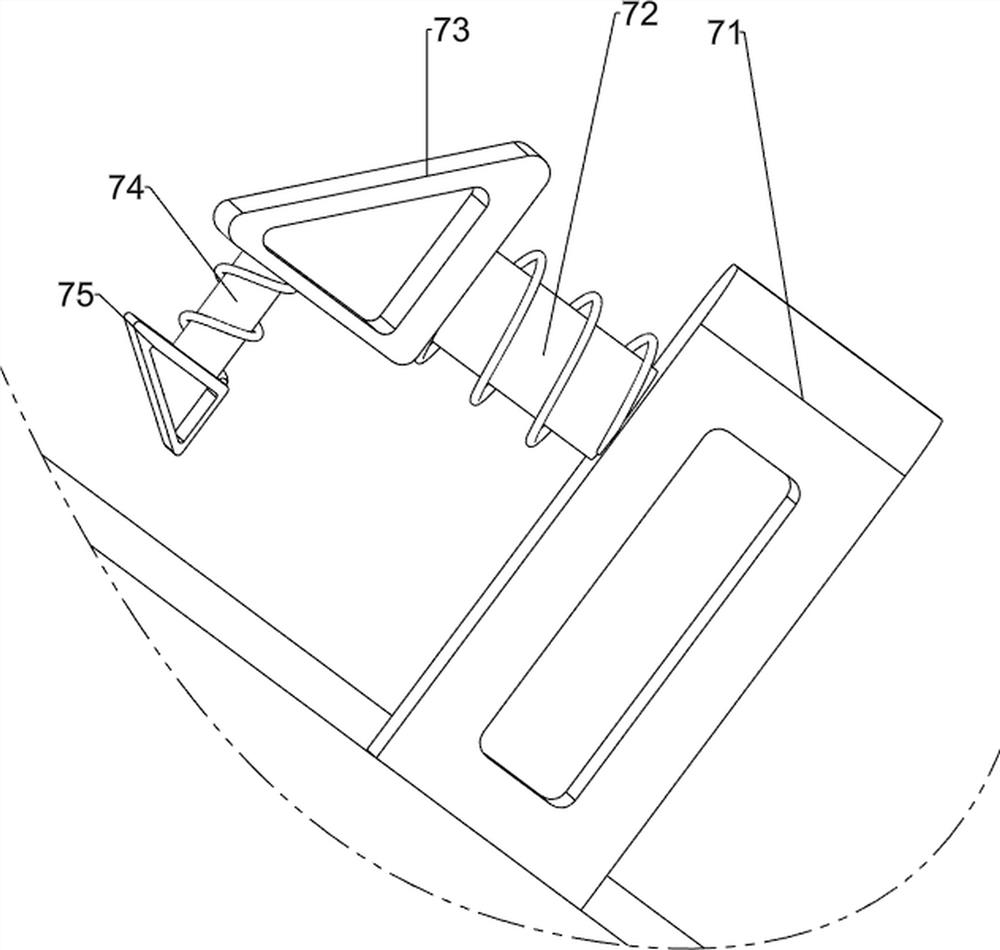

Machine for processing and making ball-shaped food

ActiveCN112244342ATo achieve the cutting effectNo manual placement requiredFood shapingProcess engineeringIndustrial engineering

The invention relates to a food processing and making machine, and particularly relates to a machine for processing and making ball-shaped food. The invention provides the machine for processing and making the ball-shaped food, which can increase the safety factor of food making, increase the aesthetic degree of balls and improve the making efficiency. The machine for processing and making the ball-shaped food comprises a supporting rod, a second fixing column and a discharging mechanism, wherein a first fixing column is arranged on the supporting rod; the second fixing column is arranged on the supporting rod; and the discharging mechanism is arranged on the supporting rod. According to the machine disclosed by the invention, through the opposite movement of a material pushing plate and amaterial bearing pushing plate, the effects that the lower half part of a mold in a first material loading frame is pushed to the front side of a placing table, and the upper half part of a mold in asecond material loading frame is brought to a position just under the rear side of a discharging pipe are realized, and the molds do not need to be manually placed and made.

Owner:荣成东荣食品有限公司

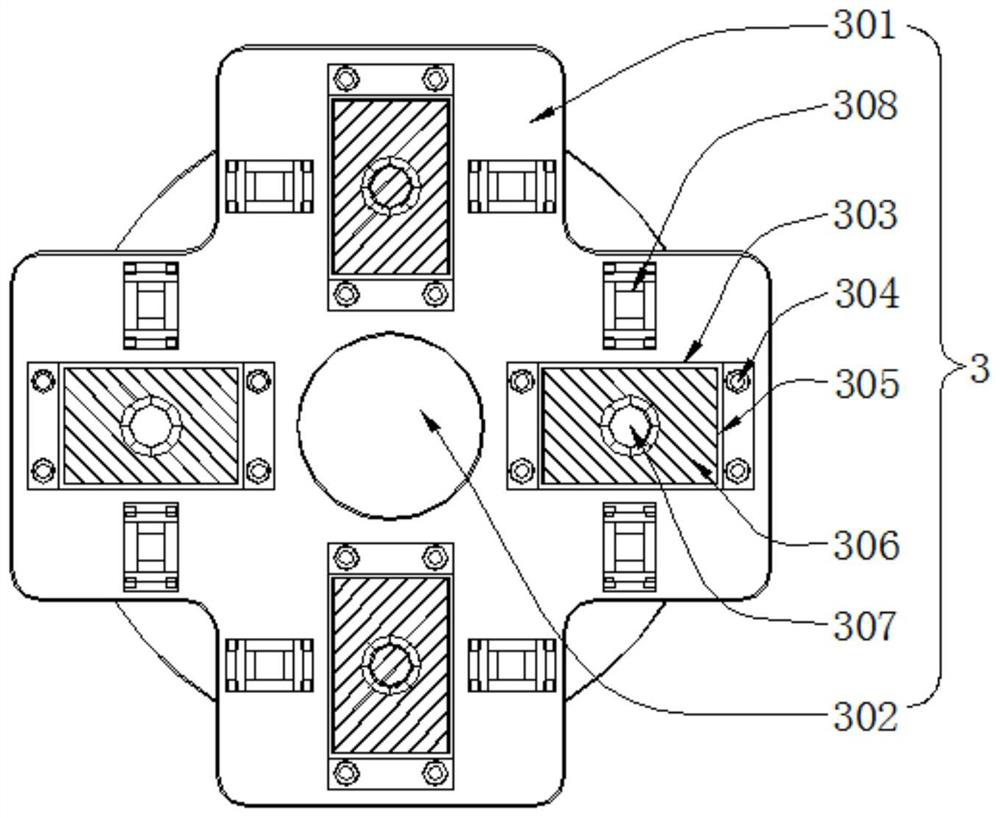

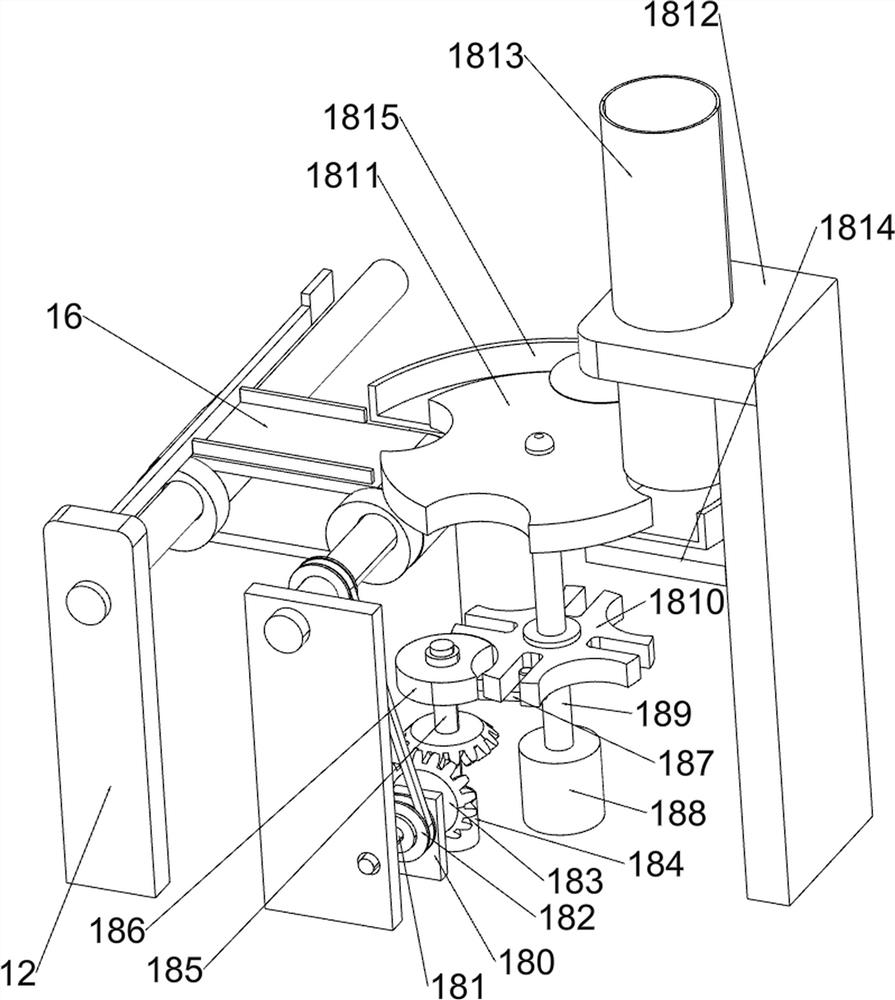

Candy can bottle cap packaging equipment for food processing

InactiveCN112340085AAchieve the effect of twist capAchieve orientationPackagingEngineeringBottle cap

The invention relates to candy can bottle cap packaging equipment, in particular to candy can bottle cap packaging equipment for food processing. The candy can bottle cap packaging equipment for foodprocessing is provided, wherein the candy can bottle cap packaging equipment automatically feeds bottle caps and bottle bodies, reinforces the bottle bodies, simplifies manual operation steps, and improves the cap packaging efficiency. The candy can bottle cap packaging equipment for food processing comprises a base, and a cap twisting mechanism, wherein a material rotating mechanism is arranged in the middle of the lower portion of the base, and the cap twisting mechanism is arranged at the upper portion of the base and is matched with the material rotating mechanism. According to the candy can bottle cap packaging equipment, a first arc-shaped block is driven not to be clamped any more after rotating by 90 degrees through clamping of a shifting block and the first arc-shaped block, so that a second rotating shaft is driven to rotate by 90 degrees, then a second rotating disc is driven to intermittently rotate by 90 degrees, and then candy tanks intermittently rotate by 90 degrees, sothat the effect of intermittently rotating one candy can to be cap-twisted to the position below the cap twisting mechanism is achieved.

Owner:杨兴丽

Building material strength detection device

PendingCN111678792AEasy to detectRealize the effect of automatic feedingMaterial strength using tensile/compressive forcesArchitectural engineeringStructural engineering

The invention relates to the field of building material detection. The invention discloses a building material strength detection device. The device comprises a support plate, and a detection unit fordetecting a sample is arranged on the support plate. The support plate is connected with two guide plates which are arranged in parallel, and a moving channel is formed between the two guide plates.A storage frame perpendicular to the guide plates is arranged on the support plate, one end of the storage frame is communicated with the moving channel, a sliding plate for pushing a sample to the detection unit is arranged in the moving channel in a sliding fit mode, and a driving unit for driving the sliding plate to slide in a reciprocating mode is arranged on one side of the sliding plate. Asliding block is arranged on the support plate in a sliding fit mode in the direction perpendicular to the guide plates, a tension spring is fixedly connected between the sliding block and the storageframe, a pushing rod is perpendicularly connected to the sliding block, and the end, away from the sliding block, of the pushing rod perpendicularly penetrates into the storage frame. According to the invention, a sample can be automatically pushed below the detection unit for detection, so that the detection efficiency is improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

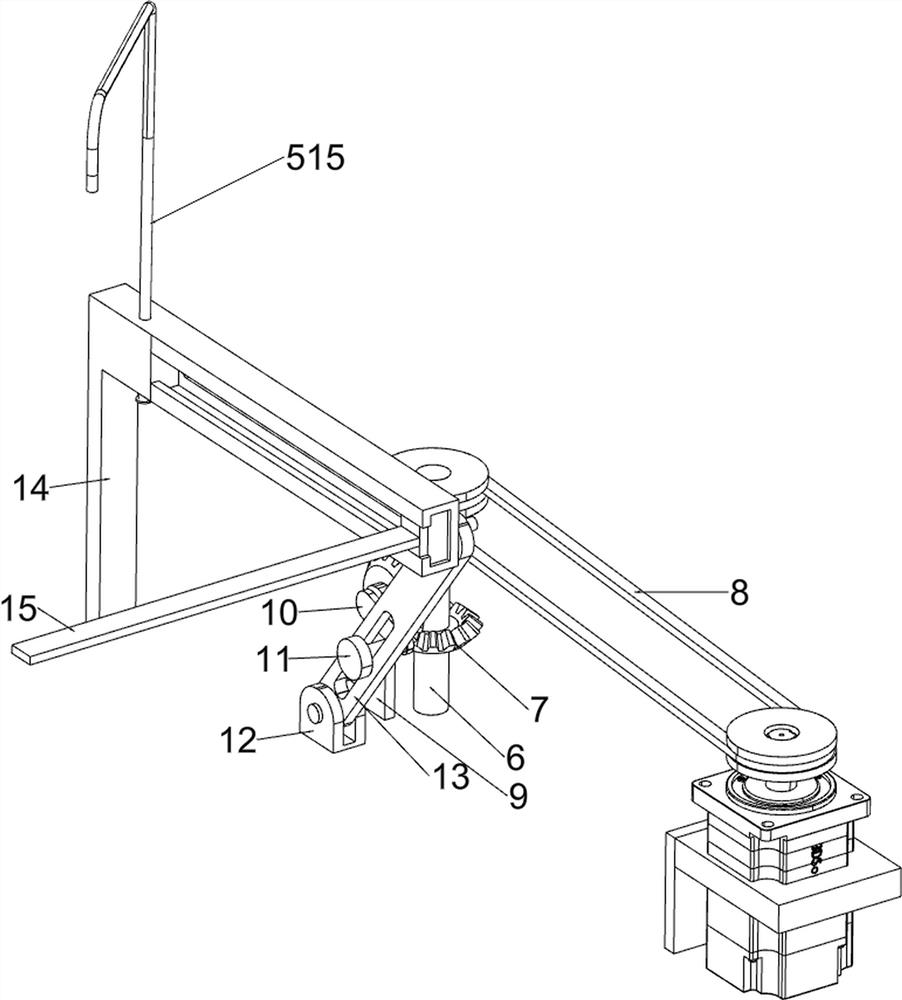

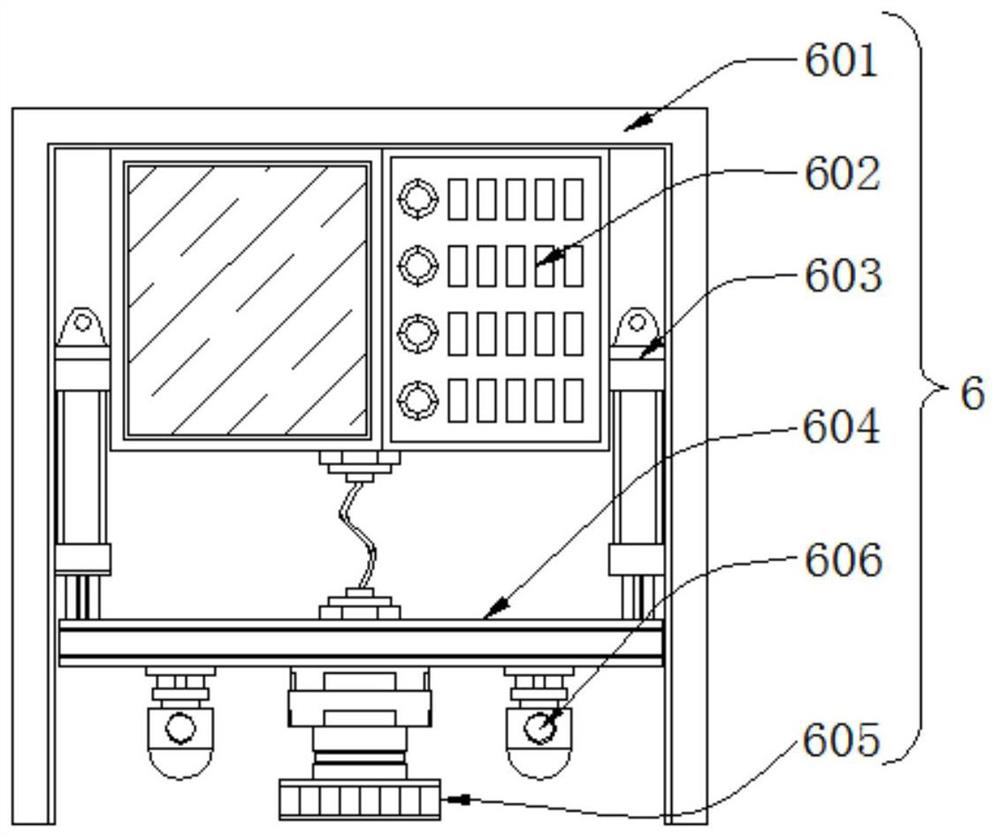

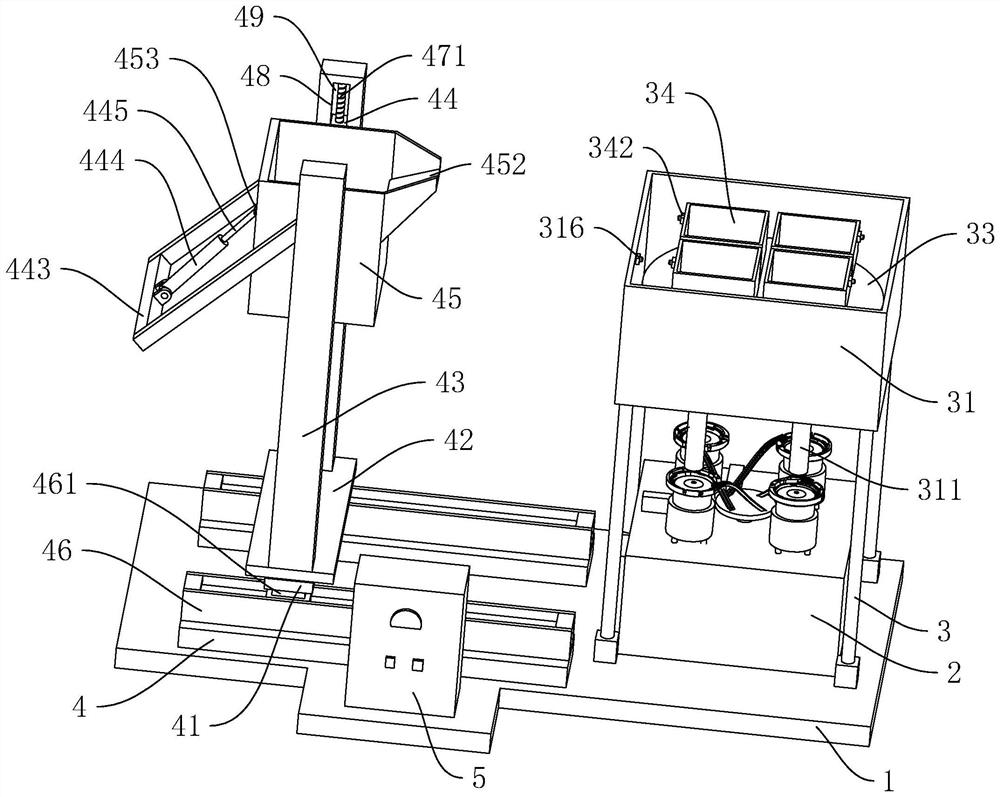

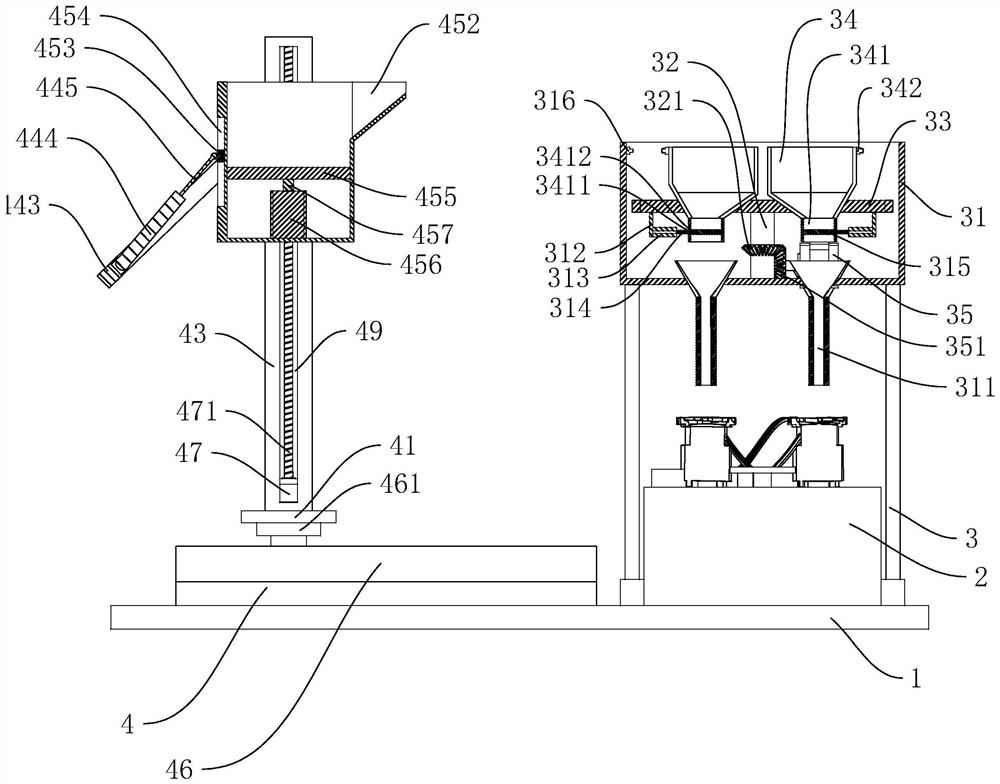

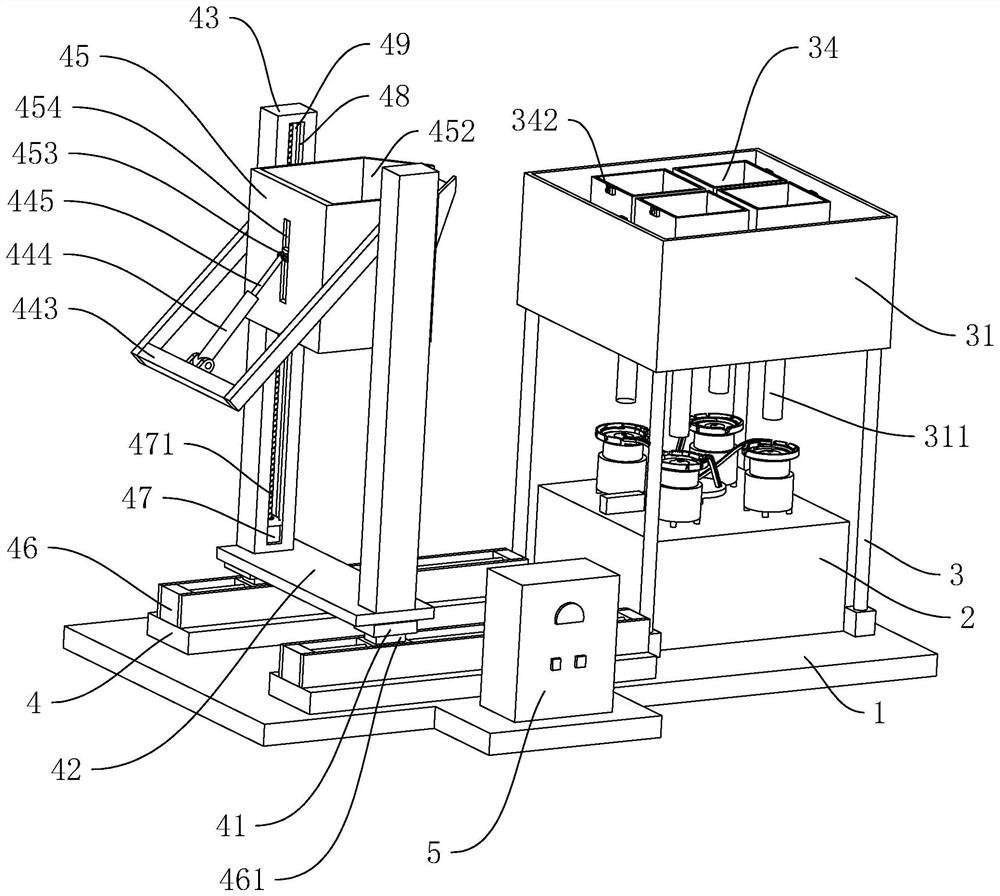

Liquid injection equipment for manufacturing circular lithium battery of new energy automobile

ActiveCN112635932AEasy to unloadRealize automatic material transferFinal product manufactureCell component detailsNew energyLithium battery

The invention relates to liquid injection equipment, in particular to liquid injection equipment for manufacturing a circular lithium battery of a new energy automobile. The liquid injection equipment for manufacturing the circular lithium battery of the new energy automobile provided by the invention is capable of automatically loading and unloading the lithium battery, shunting and injecting liquid and improving the safety. The liquid injection equipment for manufacturing the circular lithium battery of the new energy automobile comprises a supporting frame; a conveying mechanism is arranged in the supporting frame; a pressing mechanism is arranged in the middle of the interior of the supporting frame; a liquid injection mechanism is arranged at the top of the supporting frame and located above the pressing mechanism. Through the arrangement of the conveying mechanism, lithium batteries subjected to liquid injection are intermittently conveyed forwards to be unloaded through the conveying mechanism, meanwhile, the next lithium battery to be subjected to liquid injection is conveyed forwards to the position below the pressing mechanism to be subjected to liquid injection; and therefore, the effects of automatic lithium battery conveying and convenient unloading are achieved.

Owner:YICHUN JINHUI NEW ENERGY MATERIALS

Building safety helmet paint spraying device

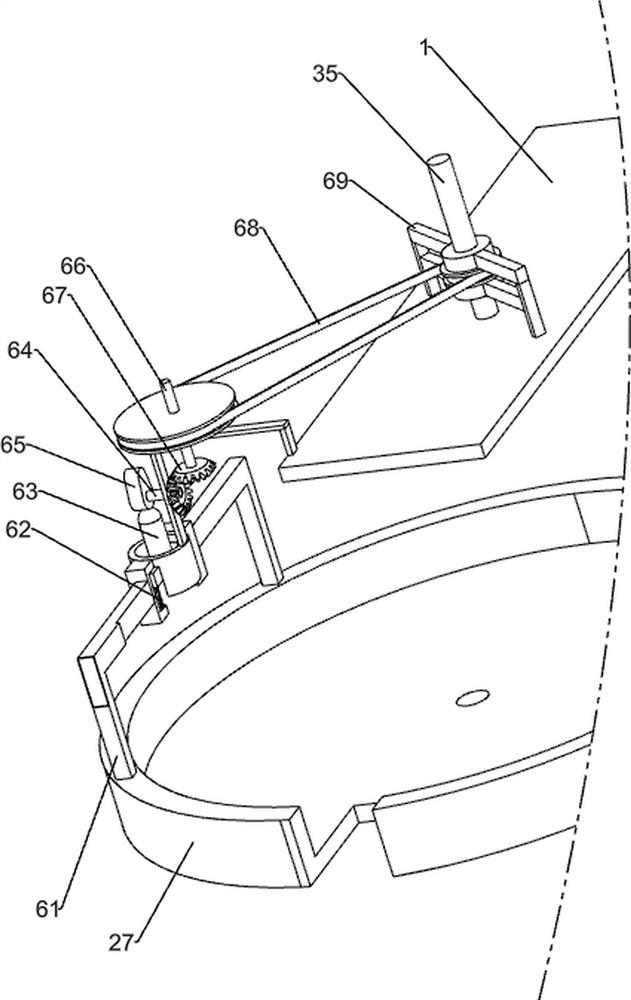

ActiveCN113304906ATo achieve the effect of imprintingRealize the effect of automatic feedingPretreated surfacesLiquid spraying apparatusEngineeringWater pipe

The invention relates to a paint spraying device, in particular to a building safety helmet paint spraying device. The technical problem to be solved is to provide the building safety helmet paint spraying device capable of automatically feeding safety helmets and stamping the safety helmets. The building safety helmet paint spraying device comprises a bottom plate, a first support frame, a paint storage bucket, a tray, and a first rotating shaft, a third rotating rod is rotationally arranged in the middle of the upper portion of the bottom plate, the first support frame is arranged on one side of the upper part of the bottom plate; the paint storage bucket is arranged on the first supporting frame; the tray is arranged on the lower side of the paint storage bucket; the first baffle is arranged on the first rotating shaft; and the first rotating shaft is rotationally arranged at the bottom of the paint storage bucket. According to the building safety helmet paint spraying device, the effects that the safety helmets can be automatically fed, and the safety helmets can be stamped are achieved; and the first rotating shaft intermittently rotates, so that a water pipe communicates with a hose, and the paint storage bucket can automatically spray paint on the safety helmets.

Owner:广东欣禄工程建设有限公司

Hamster feeding and storing equipment for pet feeding

PendingCN112715393AAchieve the effect of feedingRealize the operationAnimal watering devicesAnimal feeding devicesAnimal scienceMedicine

The invention relates to a storing equipment, in particular to a hamster feeding and storing equipment for pet feeding. The invention provides a hamster feeding and storing equipment for pet feeding which is large in space and capable of achieving automatic feeding and automatic locking. The hamster feeding and storing equipment for pet feeding comprises a box body and a feeding mechanism, the feeding mechanism is arranged on the upper portion in the box body, and the door opening mechanism is arranged on the box body in a sliding manner. According to the device, a rotating plate is moved upwards, so that a first rotating shaft rotates, then people pour water and feed into a storage box, the water and the feed enter a feeding basin through pipelines correspondingly, and the feeding effect is achieved. People manually pull the handle upwards, so that a movable plate drives a limiting block to move upwards, which realizes the operation of opening the door.

Owner:南京中枢讯飞信息技术有限公司

Rare earth ore block crushing equipment

ActiveCN112156828AQuick breakRealize the effect of automatic feedingGrain treatmentsMineralogyMining engineering

The invention relates to crushing equipment, in particular to rare earth ore block crushing equipment. According to the rare earth ore block crushing equipment, rare earth ore can be rapidly crushed,and automatic discharging can be achieved. The rare earth ore block crushing equipment comprises a bottom plate, a first support and a first supporting plate. The bottom plate is used for mounting ofthe whole equipment. The first support is arranged in the middle of one side of the upper part of the bottom plate; the first supporting plate is arranged at the side, close to the first support, of the upper portion of the bottom plate; according to the rare earth ore crushing equipment, the effects that rare earth ore can be rapidly crushed, and automatic discharging can be achieved are achieved; and the rare earth ore is moved into a crushing box, an eccentric wheel is driven to rotate through a second rotating shaft, and when the eccentric wheel rotates to make contact with a crushing block, the crushing block can be driven to move, so that the crushing block can crush the rare earth ore.

Owner:青岛凯祥机械科技有限公司

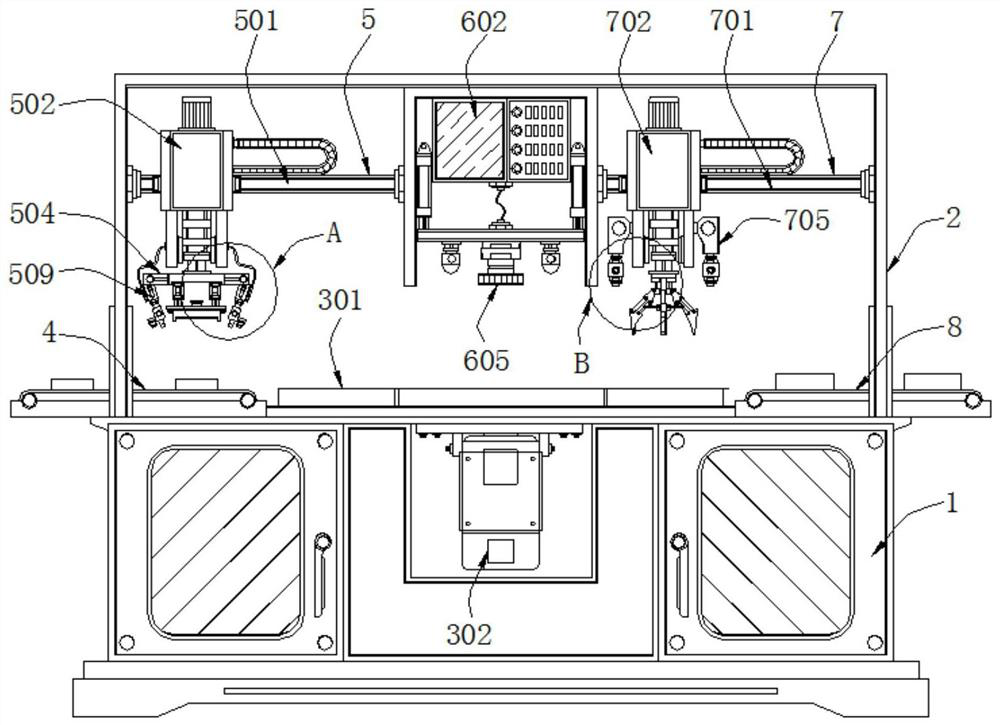

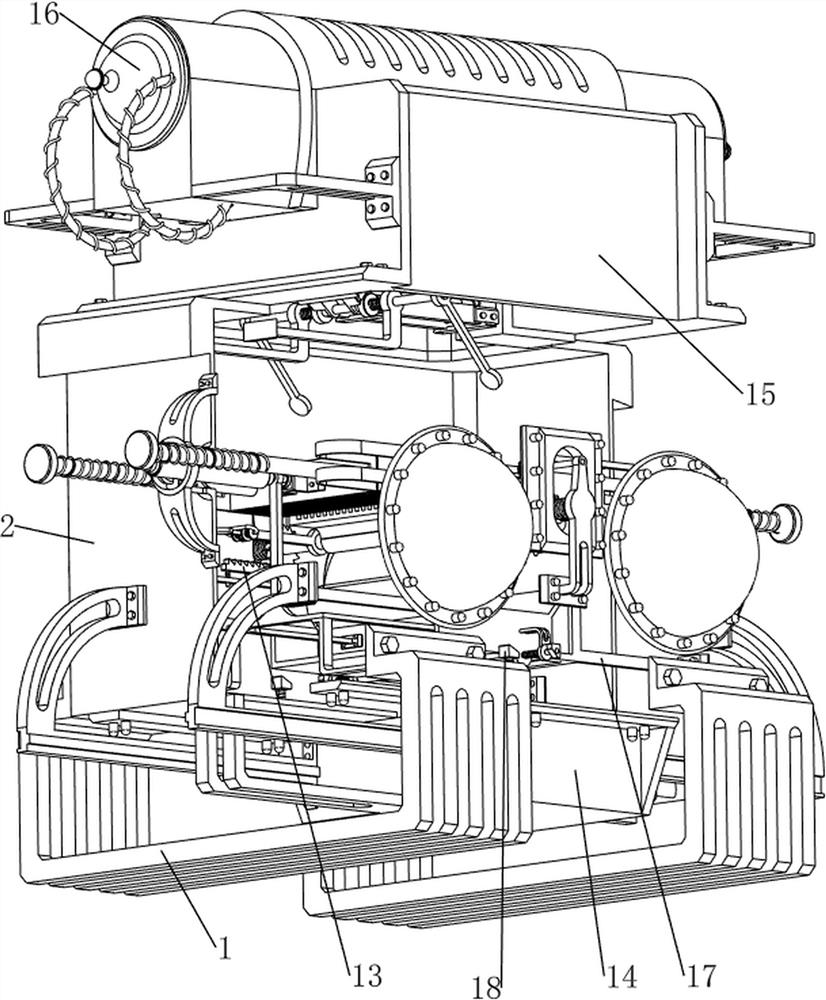

Automatically-assembled high-precision laser welding equipment

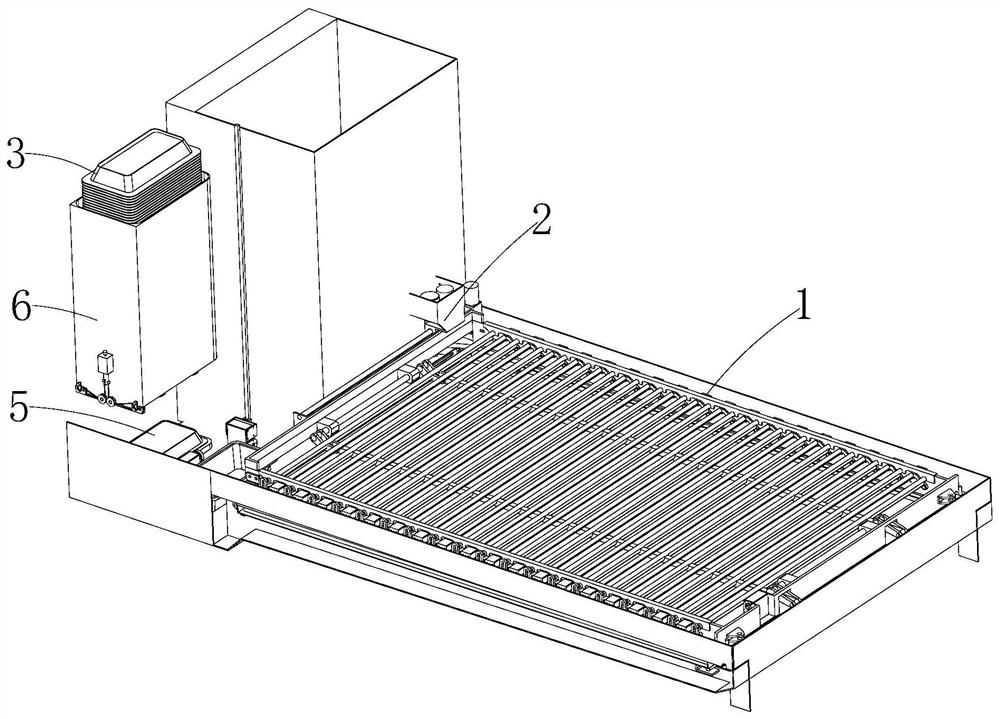

ActiveCN113751873ARealize automatic continuous welding workGuarantee welding qualityLaser beam welding apparatusMobile phoneLaser soldering

The invention discloses automatically-assembled high-precision laser welding equipment, and relates to the technical field of mobile phone automatic assembly. The automatically-assembled high-precision laser welding equipment comprises a bearing seat and a welding assembly, a placement frame is arranged at the position, close to the edge, of the upper end of the bearing seat, a transfer assembly used for transferring a mobile phone shell is arranged at the center position of the upper end of the bearing seat, an accessory conveying belt is arranged in the middle of the left side of the upper end of the bearing seat, and the welding assembly used for metal part welding is arranged on the left side in the placement frame. By means of adsorption clamping blocks and connecting flange blocks which are distributed in parallel, the precision of adsorbing and clamping small metal parts conveyed at the upper end of the accessory conveying belt through the adsorption clamping blocks is guaranteed, the adsorption clamping blocks connected with the connecting flange blocks through fastening bolts are conveniently matched with the replacement progress of bearing blocks for corresponding replacement, so as to ensure the actual using effect of the welding equipment. The exposed area of the small metal parts is larger in an adsorption clamping mode, welding work can be conveniently conducted on the small metal parts through a laser welding head, and the welding precision is improved.

Owner:苏州派富特智能制造科技有限公司

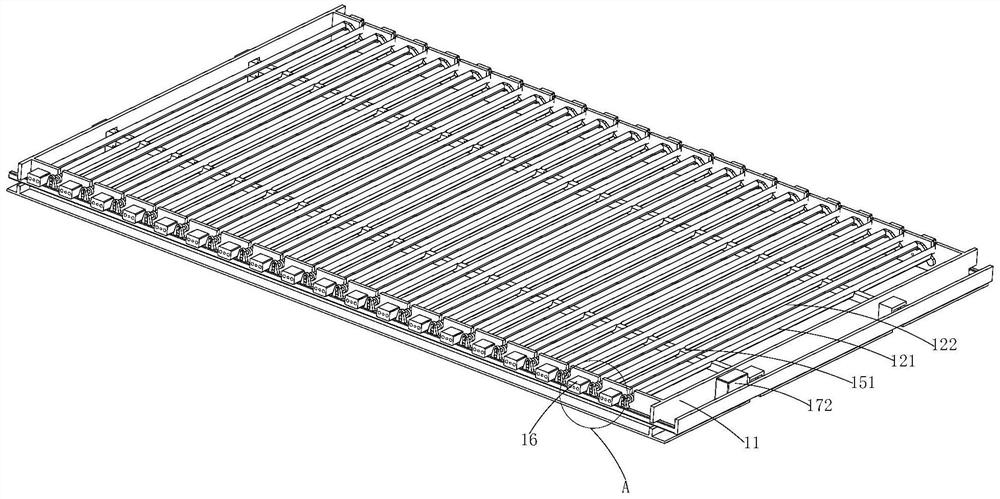

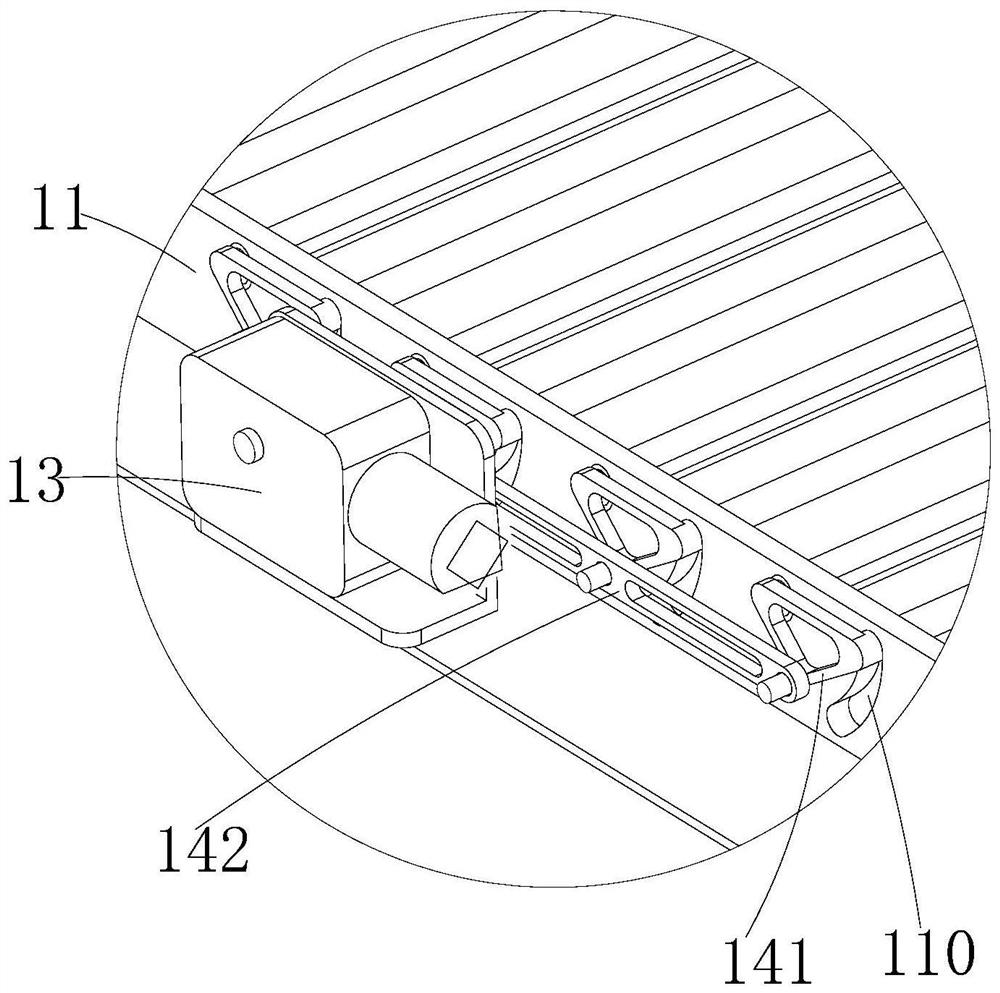

Automatic pump production line

PendingCN114131497AEasy to follow upAvoid displacementPolishing machinesGrinding drivesEngineeringMachining process

The automatic pump production line comprises a workbench, a conveying assembly is arranged on the upper surface of the workbench, the conveying assembly is composed of a plurality of conveying plates and a conveying belt, the conveying plates form a conveying belt with the hollow surface, and sleeves are fixedly connected to the upper surfaces of the conveying plates. According to the automatic pump production line, the conveying plate, the sleeve and the feeding column are arranged and matched with the feeding opening in the surface of the feeding table, the feeding column can be driven to rotate and penetrate through the feeding opening in the moving process of the conveying plate, and meanwhile the feeding column is inserted into a water pump shell from the lower portion; and the water pump shell is fixed to the surface of the conveying belt through the sleeve and the feeding column, subsequent machining treatment on the water pump shell is facilitated, displacement of the water pump shell in the machining process is prevented, the machining stability is improved, and the machining efficiency is improved. And the processing efficiency can be improved.

Owner:安徽岳泉泵业制造有限公司

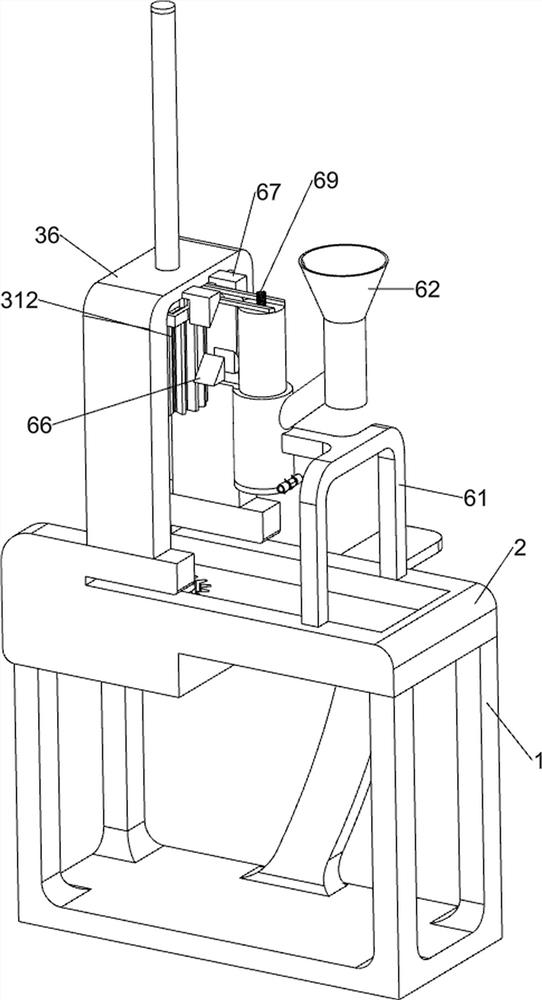

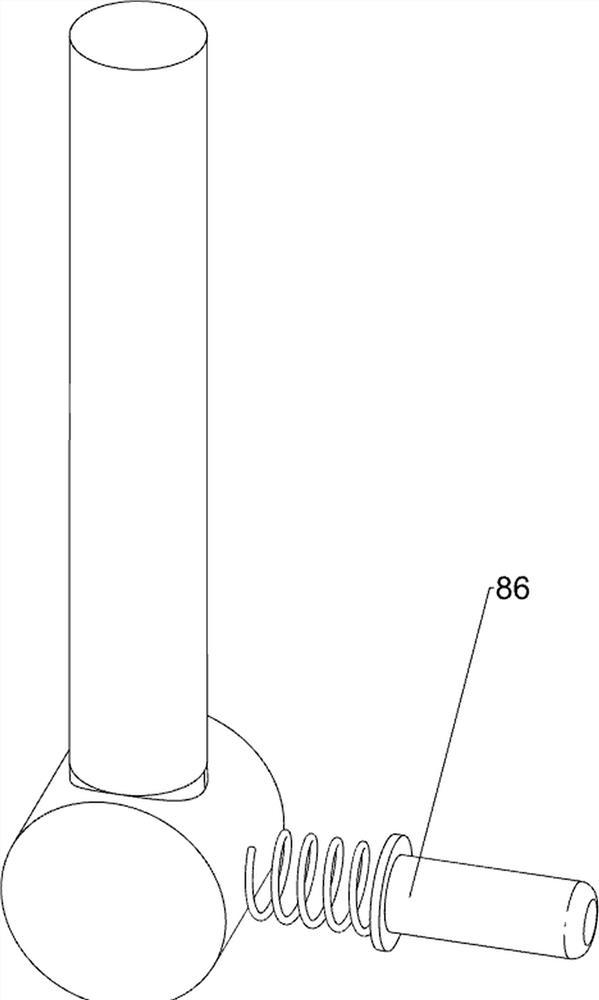

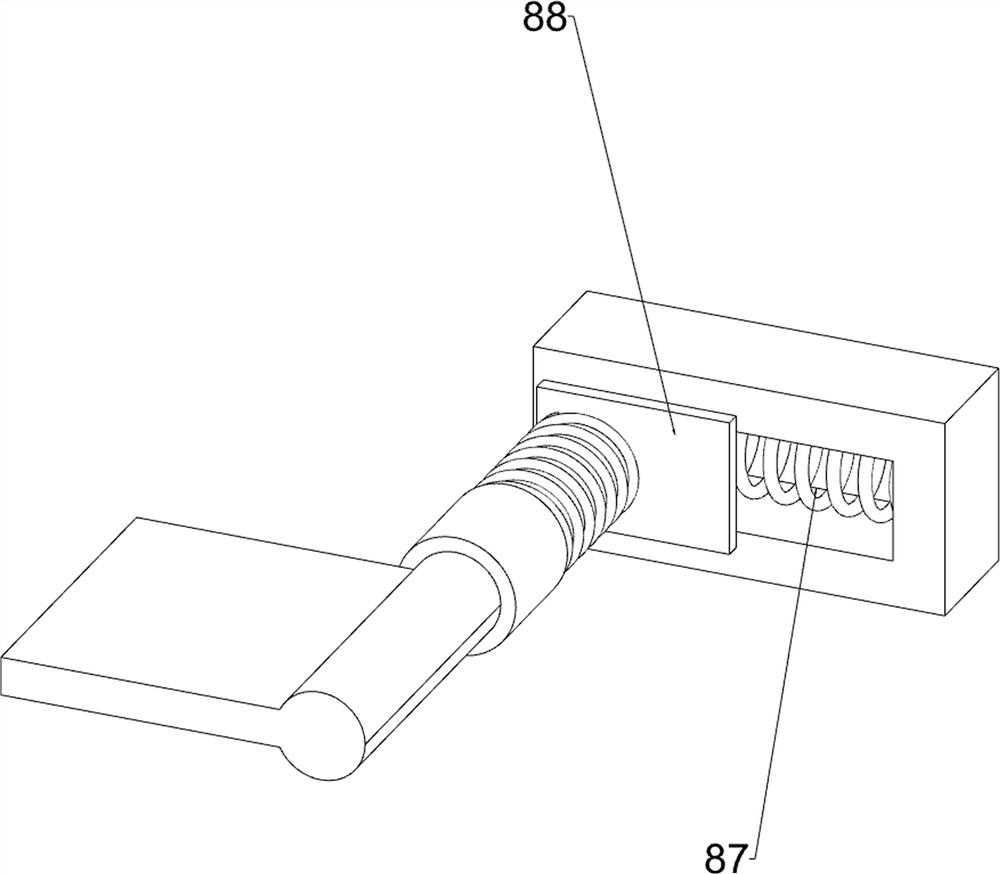

Granular medicine crushing equipment for endocrinology department

ActiveCN113385249AAutomatic grinding effectRealize the effect of automatic feedingOral administration deviceGrain treatmentsEndocrinology departmentPharmacy medicine

The invention relates to crushing equipment, in particular to granular medicine crushing equipment for the endocrinology department. The granular medicine crushing equipment for the endocrinology department aims at achieving the technical effects that automatic discharging can be achieved, and tablets can be automatically ground. The granular medicine crushing equipment for the endocrinology department comprises supporting frames, a first outer frame, a first fixing column, an air cylinder, cutting knives and first springs, wherein the supporting frames are symmetrically arranged on the first outer frame; the first fixing column is arranged on one side of the first outer frame; the air cylinder is arranged on the first fixing column; the cutting knives are arranged on the two sides of the first outer frame in a sliding mode, and the air cylinders are connected with the adjacent cutting knives; and the first springs are connected between the cutting knives and the first outer frame. According to the equipment, the effects that automatic discharging can be achieved, and tablets can be automatically ground are achieved; and the cutting knives on the front side and the rear side move towards the inner side, so that the effect of automatically crushing the tablets can be achieved.

Owner:QINGDAO CENT HOSPITAL

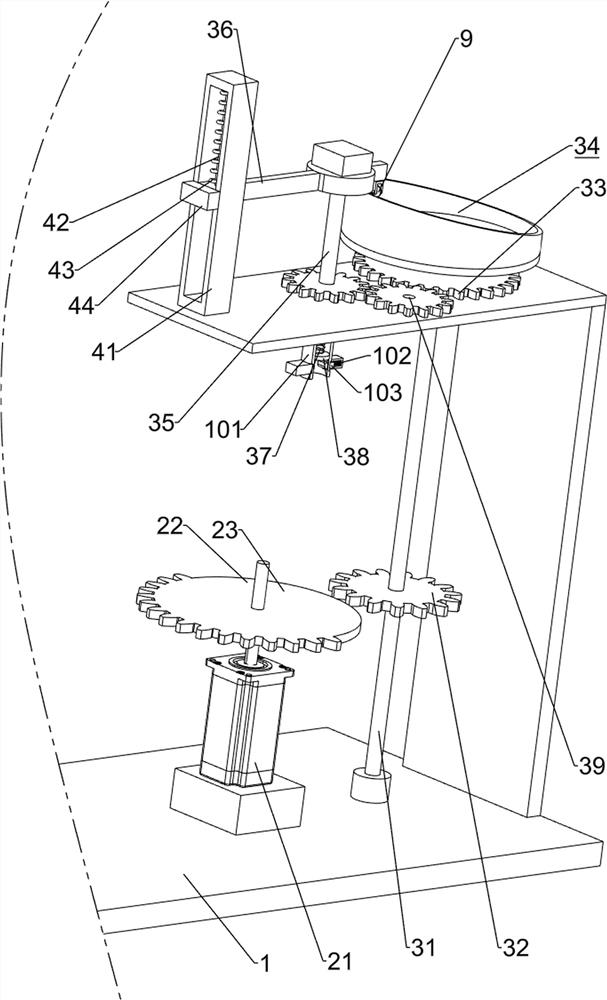

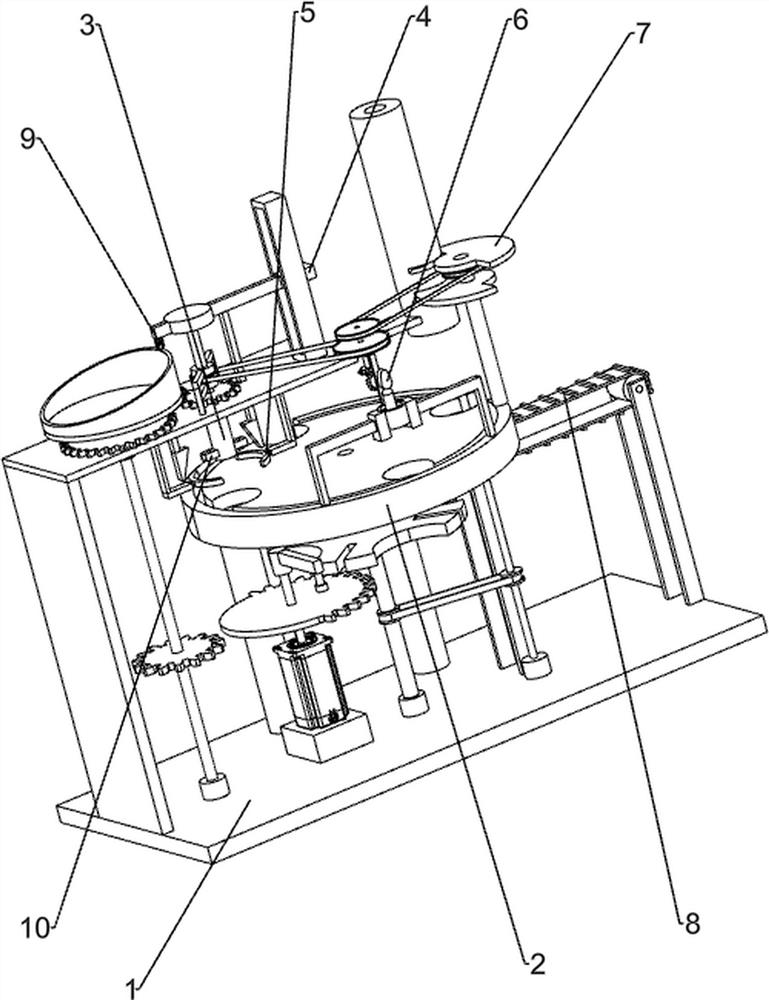

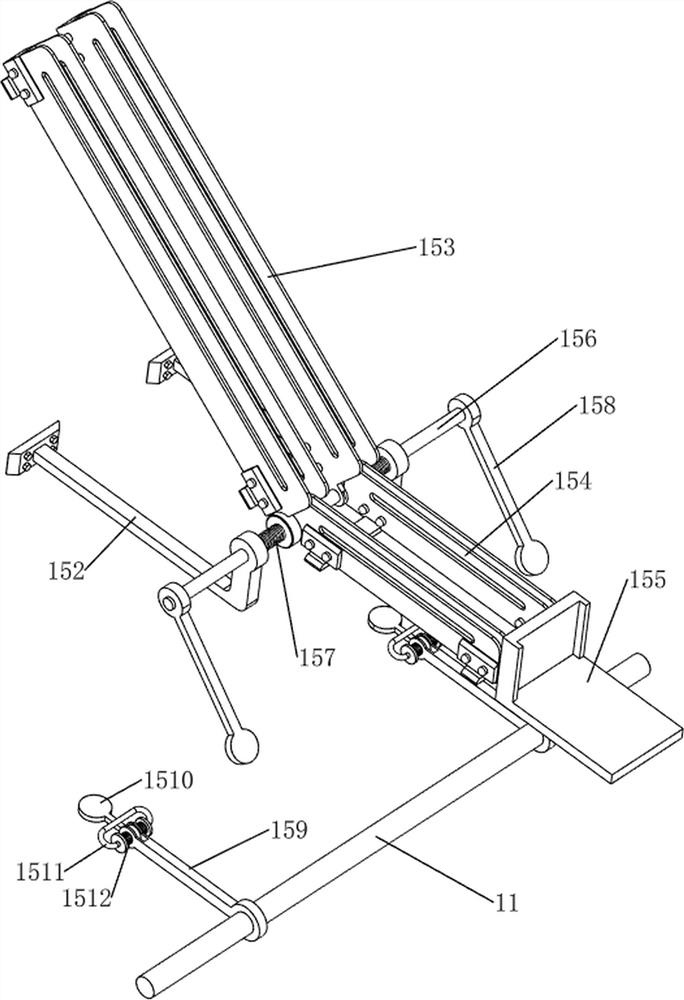

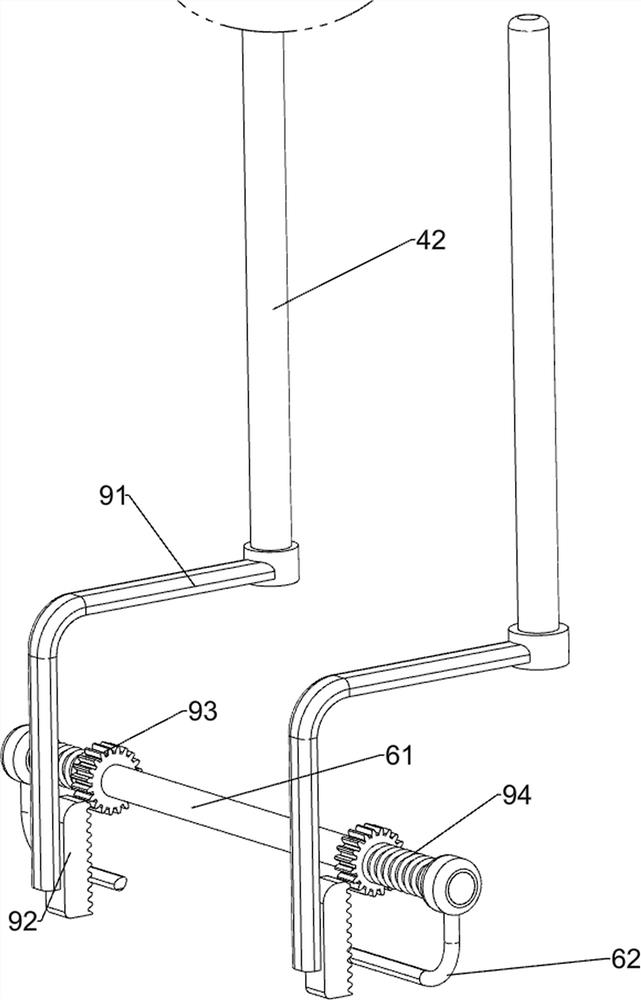

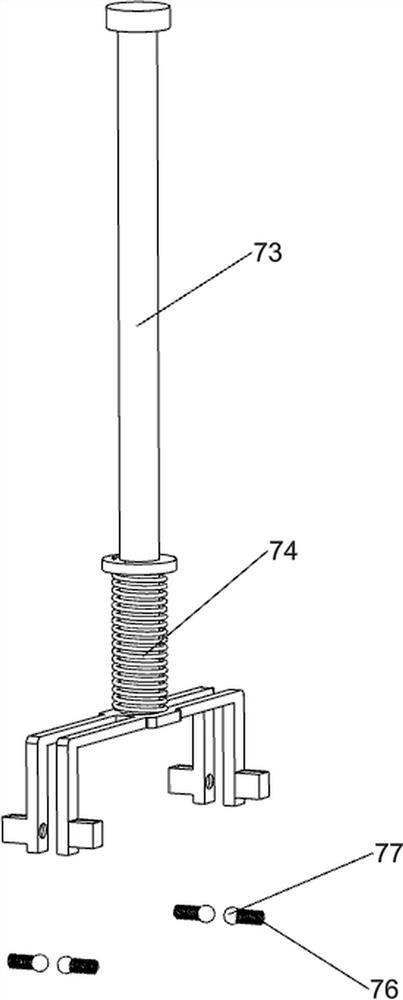

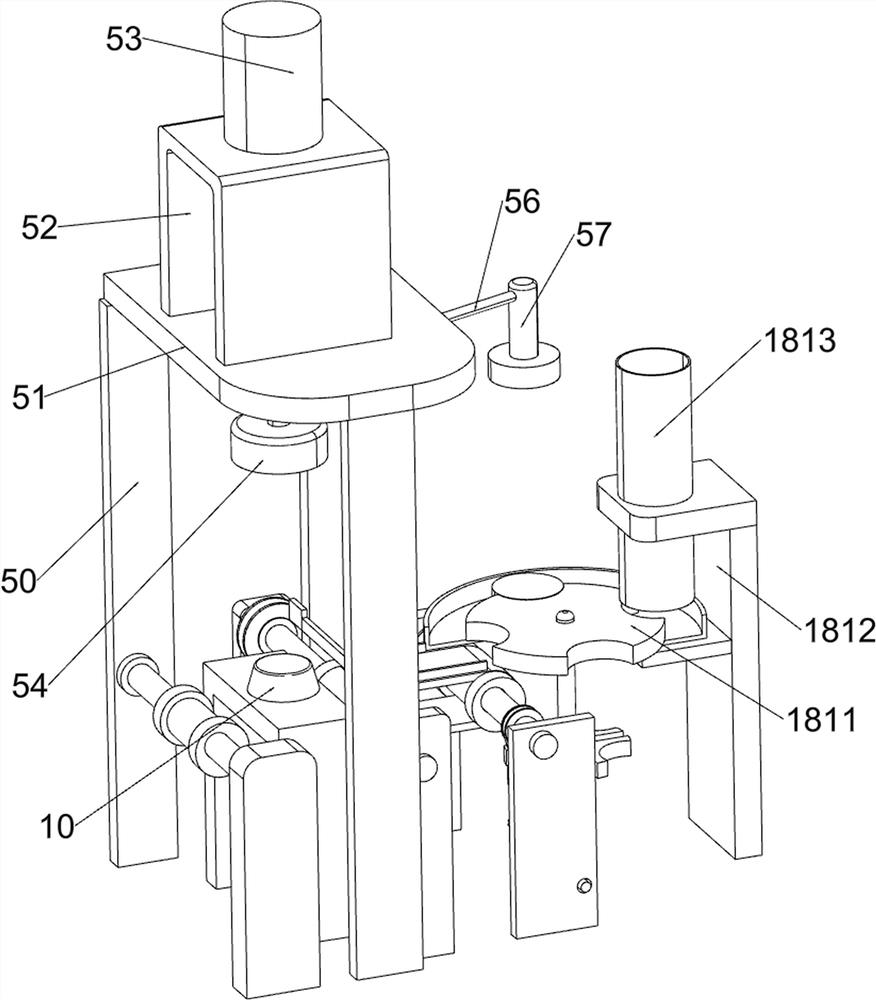

Full-automatic four-point assembling machine

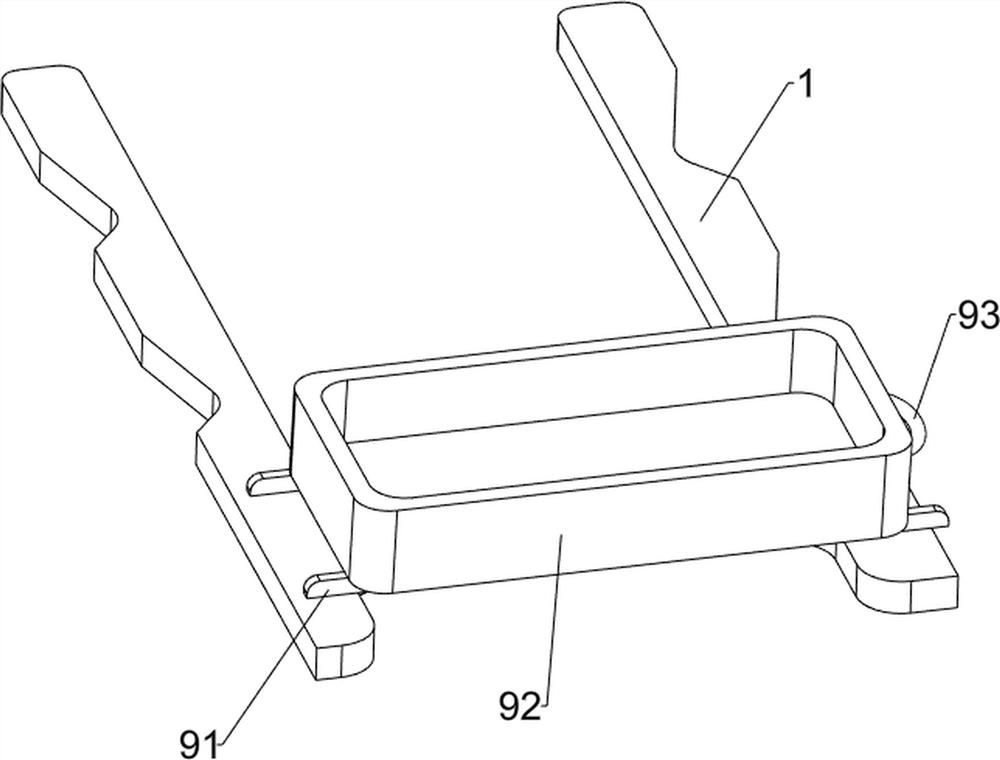

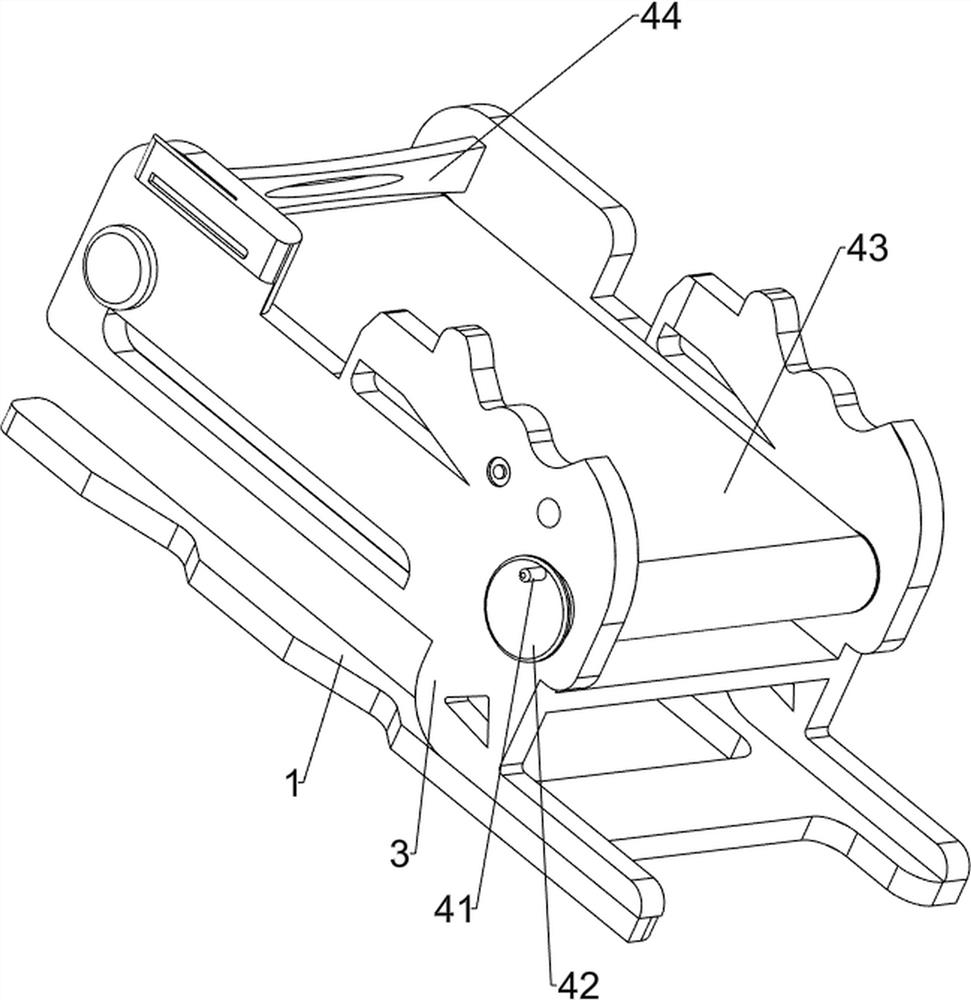

ActiveCN111906535AEasy for automatic loadingRealize the effect of automatic feedingAssembly machinesMetal working apparatusCircular discMachine

The invention relates to a full-automatic four-point assembling machine. The full-automatic four-point assembling machine comprises a base and an assembling machine body, wherein a feeding device is arranged on the base; the feeding device comprises a plurality of bearing rods arranged on the base, a bearing box arranged on the bearing rods, a plurality of falling channels communicated to the periphery of the bottom of the bearing box, a rotating shaft rotationally connected to the bottom of the bearing box, a bearing disc arranged at the end, away from the bottom of the bearing box, of the rotating shaft, a plurality of material collecting bins connected to the bearing surface of the bearing disc, discharging pipelines communicated to the bottoms of the material collecting bins and communicated with the falling channels, a driving assembly arranged at the bottom of the bearing box, and a feeding mechanism arranged on one side of the assembling machine body and used for automatically feeding to the material collecting bins. According to the full-automatic four-point assembling machine, the effect of automatically feeding to the assembling machine body can be achieved, so that the labor intensity of workers can be relieved, the situation that wrists of the workers are injured can be reduced, and then the production efficiency of sliders of zipper fasteners can be improved.

Owner:广州品晶五金实业有限公司

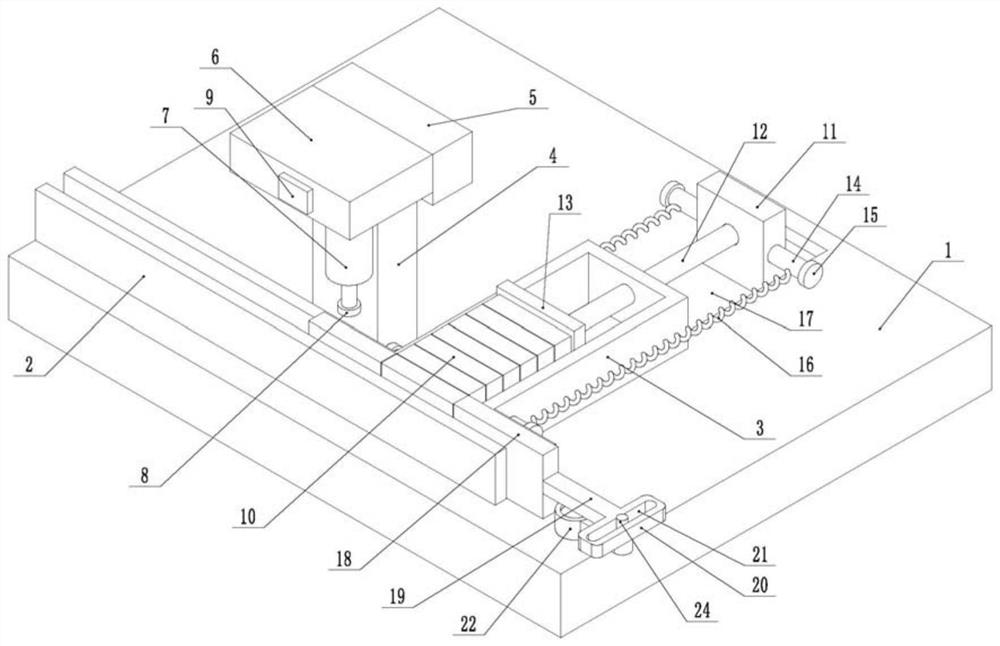

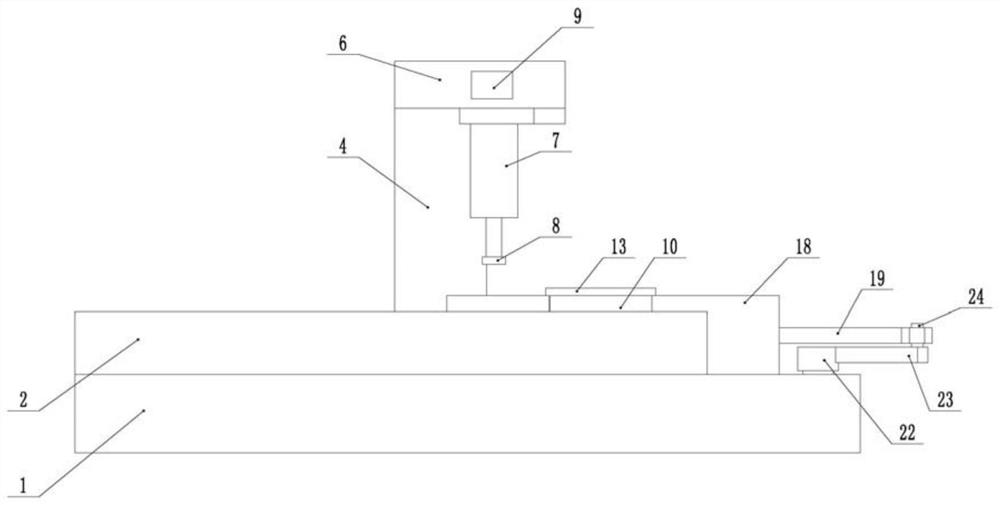

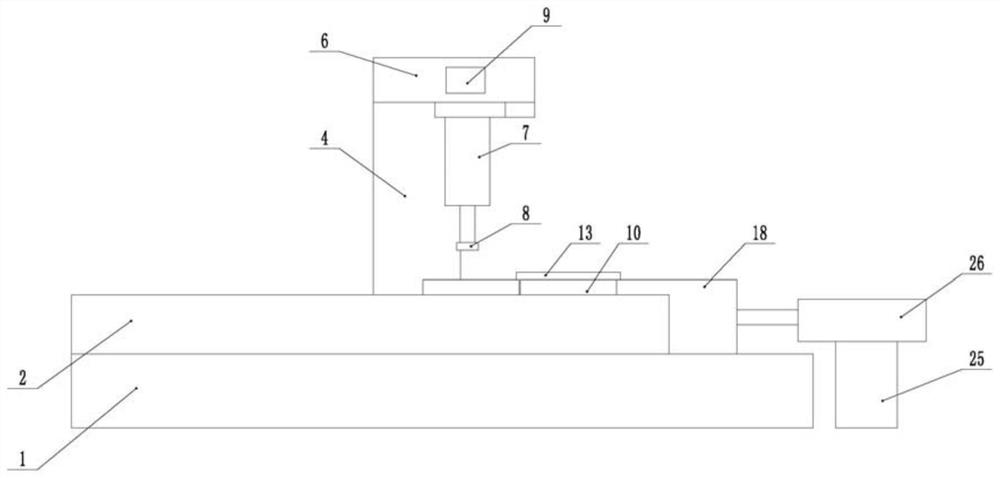

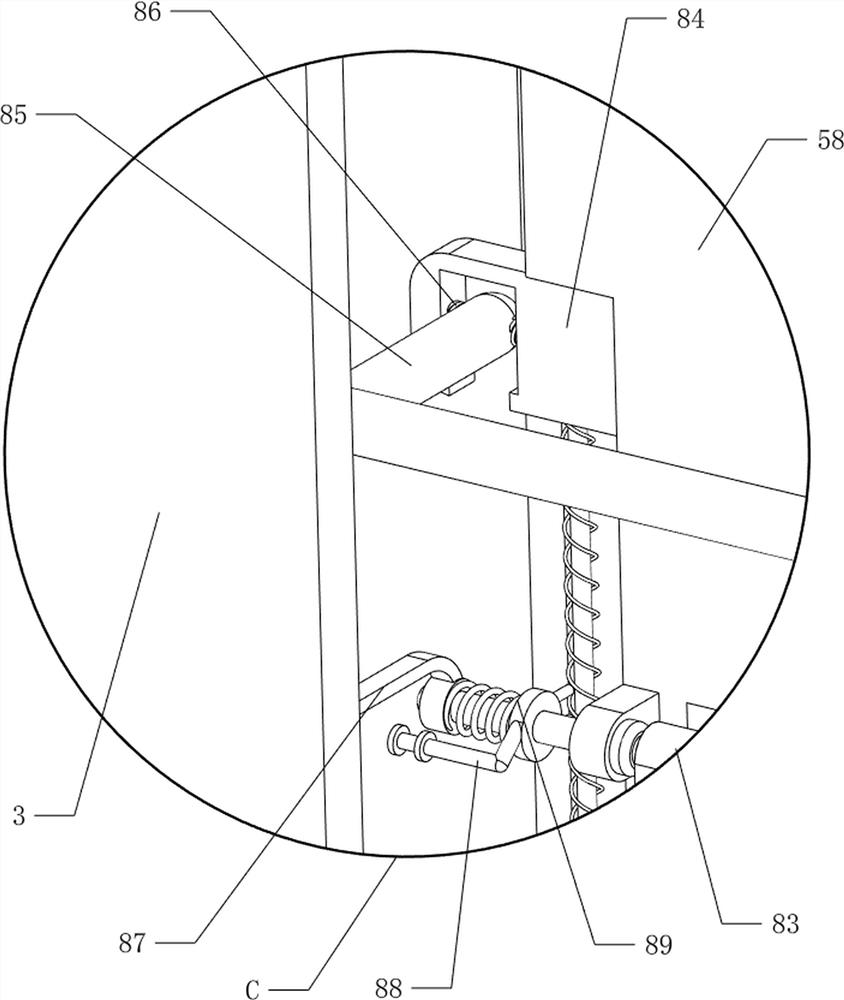

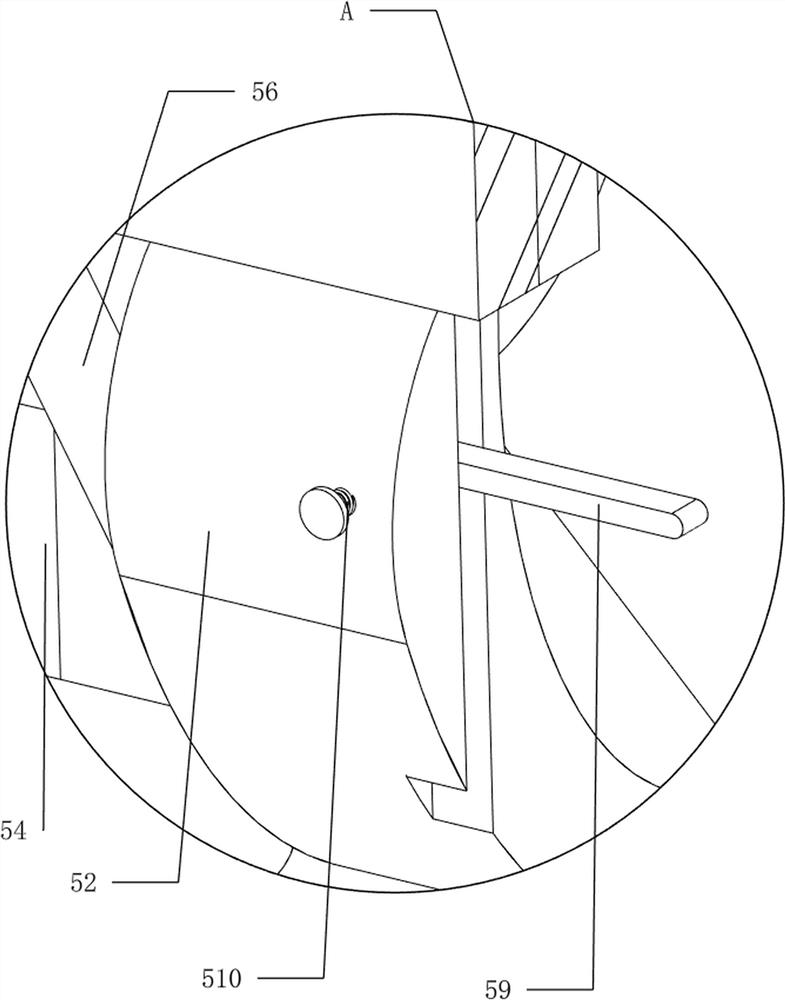

Thickness detection device for car brake pads

ActiveCN109029205AImprove detection accuracyFast efficiencyMechanical thickness measurementsThreaded pipeEngineering

The invention relates to the technical field of detection devices, in particular to a thickness detection device for car brake pads. The device comprises an operation table, wherein support legs are mounted at the four corners of the lower end of the operation table; a circular groove is formed on the upper side of the operation table; a circular rotation block is rotationally arranged in the circular groove; grooves are formed at both ends of the upper side of the circular rotation block; a motor is mounted on the inner sides of the support legs through a bracket; an output shaft of the motoris connected with a rotation shaft; the rotation shaft is connected to the center of the lower side of the circular rotation block after penetrating the operation table; a threaded rod is connected to one end of the upper side of the operation table through a rotation mechanism; the outer side of the threaded rod is sleeved by a threaded pipe; the threaded pipe is limited through a first limitingmechanism; a rectangular feeding barrel is mounted on the threaded pipe and located on one side of the circular groove, and the feeding barrel and one of the grooves are located on a same vertical line; and a measurement mechanism is arranged at the other end of the upper side of the operation table. The device provided by the invention has the effects of high convenience in operation, high detection efficiency, and high detection accuracy.

Owner:重庆磊飞机械制造有限责任公司

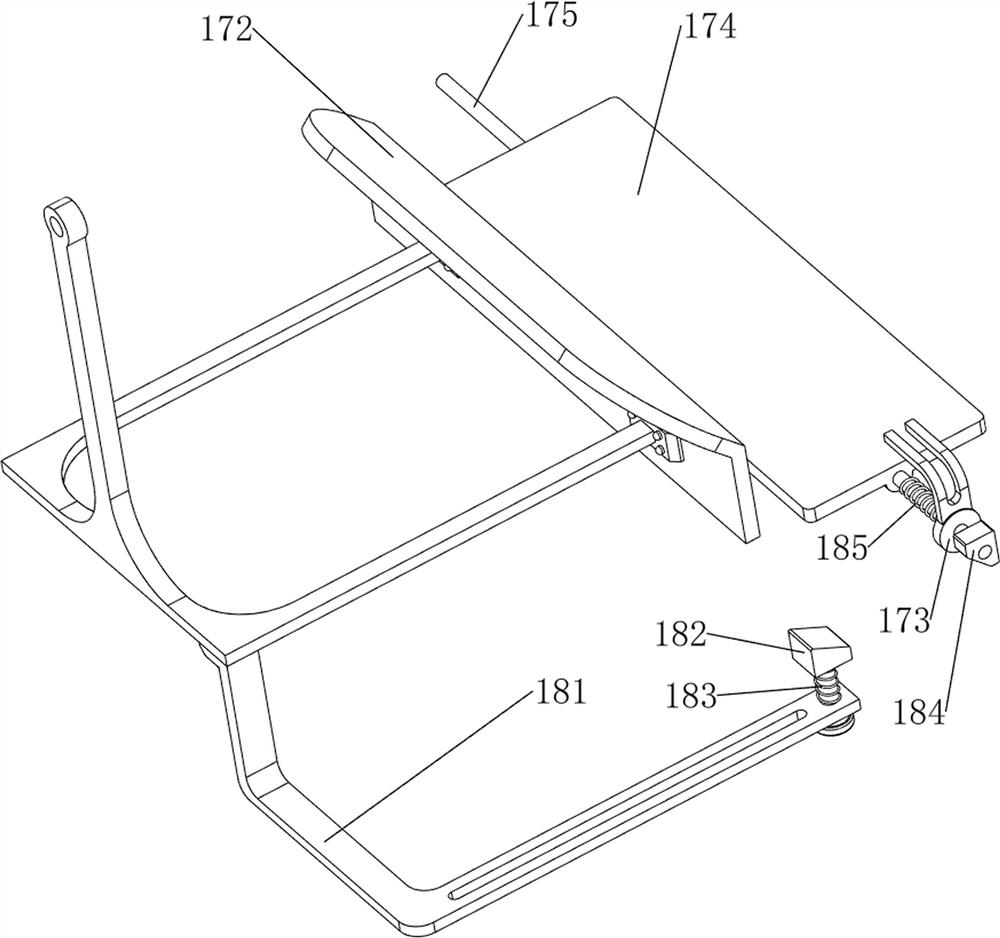

PPC pipe excess material processing device

PendingCN114523387AThe effect of automatic transportAutomatic grindingGrinding carriagesGrinding drivesMaterials processingIndustrial engineering

The invention relates to a processing device, in particular to a PPC pipe excess material processing device. The technical problem to be solved is to provide the PPC pipe excess material processing device which can support irregular PPC pipe excess materials and can automatically transport the PPC pipe excess materials at the same time. According to the technical scheme, the PPC pipe excess material processing device comprises a bottom plate, a lower half body frame, a main body frame, an upper half body frame and a lifting mechanism, the lower half body frame is arranged on the front side of the upper portion of the bottom plate, the main body frame is arranged in the lower half body frame, the upper half body frame is arranged on the outer side of the upper portion of the main body frame, and the lifting mechanism is arranged between the lower half body frame and the bottom plate. According to the PPC pipe excess material conveying device, the telescopic rod of the air cylinder extends to drive the oval corner to move upwards, PPC pipe excess materials can be lifted upwards in the upward moving process of the oval corner, and therefore the effect of automatically conveying the PPC pipe excess materials can be achieved.

Owner:邹昌全

Extrusion type modified starch grinding device

PendingCN113083414ARealize the effect of pressing down and crushingGrind evenlyGrain treatmentsComposite materialManufacturing engineering

The invention relates to a grinding device, in particular to an extrusion type modified starch grinding device. The extrusion type modified starch grinding device can improve the production efficiency and has the function of grinding while extruding. The extrusion type modified starch grinding device comprises a first fixing plate, a first supporting plate, a first discharging frame, a pressing mechanism and a material pushing mechanism; the first fixing plate is provided with the first supporting plate; the first discharging frame is arranged on the first supporting plate; the pressing mechanism is arranged on the first discharging frame; and the material pushing mechanism is arranged on the first fixing plate. According to the extrusion type modified starch grinding device, when first connecting rods are pushed by hands to move downwards, first springs are driven to be stretched, and then a grinding plate is driven to move downwards, so that modified starch in the first discharging frame is extruded and ground, and the effects of pressing and grinding are achieved.

Owner:吁红

Industrial automatic part cleaning device

PendingCN113319038ARealize the transfer functionAchieve cleaningConveyorsCleaning using toolsLeather beltManufacturing engineering

Owner:罗丽珍

Management equipment for pet life

ActiveCN111955360AImplement collection processingWon't hurtAnimal housingEngineeringCompanion animal

The invention discloses a management device for pet life. The device comprises a shell, a bed body device arranged in the shell, a cleaning device used for cleaning excrement falling onto the bed bodydevice, a material box used for containing the excrement, a lower box device and a boxing device arranged below the lower box device. The bed body device comprises a frame body, a plurality of rod bodies arranged on the frame body, supporting rods arranged at intervals with the rod bodies and supporting parts used for supporting the supporting rods. After the supporting parts release supporting of the supporting rods, the supporting rods move downwards to increase the interval L. According to the invention, pets can live in the management device for a long time, excrement of the pets can be collected and treated, the invention guarantees that the pets do not have peculiar smells in the management device, the pet excrement is boxed and collected, the pet excrement can be treated conveniently, and therefore the pets can live in the management device for a long time.

Owner:杭州宿元兽科技有限公司

LOGO code printing equipment for information technology chip processor

ActiveCN112158420ANo manual operationAchieve fixationRotary pressesPackagingSoftware engineeringManual handling

The invention relates to printing equipment, in particular to LOGO code printing equipment for an information technology chip processor. The invention aims to provide the LOGO code printing equipmentfor the information technology chip processor, and the LOGO code printing equipment can realize automatic chip transmission and automatic printing. The LOGO code printing equipment for the informationtechnology chip processor comprises a base and a telescopic mechanism, and the telescopic mechanism is arranged at one side of the top of the base; and an up-down mechanism is also included, and thebase is provided with the up-down mechanism. Through cooperation of the telescopic mechanism, the up-down mechanism and a control mechanism, LOGO codes can be automatically printed on chips, manual operation is not needed, and time and labor are saved.

Owner:广州好未来科技研究有限公司

Equipment for printing and stamping bottle caps

InactiveCN111922164ARealize the effect of automatic feedingImprove the efficiency of printing stampingMetal-working feeding devicesClosure capsStamping processBottle cap

The invention relates to stamping equipment, in particular to equipment for printing and stamping bottle caps. The technical problem to be solved is to provide the equipment for printing and stampingthe bottle caps, which can automatically discharge in the printing and stamping process. The equipment for printing and stamping the bottle caps comprises a bottom plate, a first supporting frame, a servo motor and a first bearing seat, wherein the bottom plate is used for mounting the whole equipment; the first supporting frame is arranged on one side of the upper part of the bottom plate; the servo motor is arranged on the first supporting frame; and the first bearing seat is arranged on the side, close to the first supporting frame, of the upper portion of the bottom plate. According to theequipment, the effect of automatic discharging in the printing and stamping process is achieved, bottle caps to be printed and stamped are placed in a discharging pipe, then a third rotating disc rotates continuously, the bottle caps at the bottommost end in the discharging pipe are moved to a second conveying belt, and therefore the effect of automatic discharging can be achieved.

Owner:黄春燕

Industrial batch packaging equipment for light emitting diodes

PendingCN114537740AReduce stepsReduce manual sealing operationsSuccessive articlesEngineeringToolbox

The invention relates to industrial batch packaging equipment, in particular to industrial batch packaging equipment for light emitting diodes. The invention provides industrial batch packaging equipment for light-emitting diodes with automatic loading and edge sealing functions. Industrial batch packaging equipment for light-emitting diodes comprises idler wheels, a tool box, a feeding frame, a loading device, a discharging pipe, an upper limiting frame, a lower limiting frame, a device frame and the like, the idler wheels are rotationally arranged on the left side and the right side of the bottom of the tool box in a front-back symmetrical mode, the feeding frame is arranged on the left side of the top of the tool box, and the right side of the top of the feeding frame communicates with the loading device; the bottom of the feeding frame communicates with a discharging pipe, an upper limiting frame and a lower limiting frame are arranged on the upper left portion of the tool box, and a device frame is arranged on the upper left portion of the tool box. And the third packaging device and the second packaging device can intermittently and transversely clamp and package the middle of the packaging film, the effect of automatically packaging the top and bottom edges of the packaging bag is achieved, and manual sealing operation is reduced.

Owner:深圳市荣晟泰科技有限公司

An automatic metal cutting device

ActiveCN112276644BRealize the effect of automatic cuttingPlay the effect of resisting pushMetal working apparatusPositioning apparatusEngineeringLever pressing

The invention belongs to the technical field of metal cutting devices, especially an automatic metal cutting device. Aiming at the problems of low cutting efficiency, low precision, high labor intensity, high risk and low degree of automation in the prior art, the following proposals are now made: The scheme includes a cutting table, and the cutting table is a hollow structure. A through hole is opened on the top of one side of the cutting table, and a moving plate is slidably connected in the through hole. Two moving holes are symmetrically opened on the top of the cutting table. In the invention, starting the servo motor can not only drive the moving plate to move to realize the effect of automatic feeding, but also realize the effect of automatic clamping of the plate through the cooperation of the pressing rod and the pressing plate during the feeding process, and realize the automatic clamping effect by rotating the block. The effect of unloading, the whole process is highly automated, the operation is simple, no manual feeding is required, the labor intensity is low, the safety is high, and the cutting efficiency and cutting accuracy are greatly improved.

Owner:WENZHOU UNIV

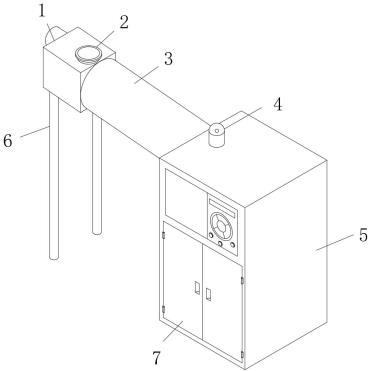

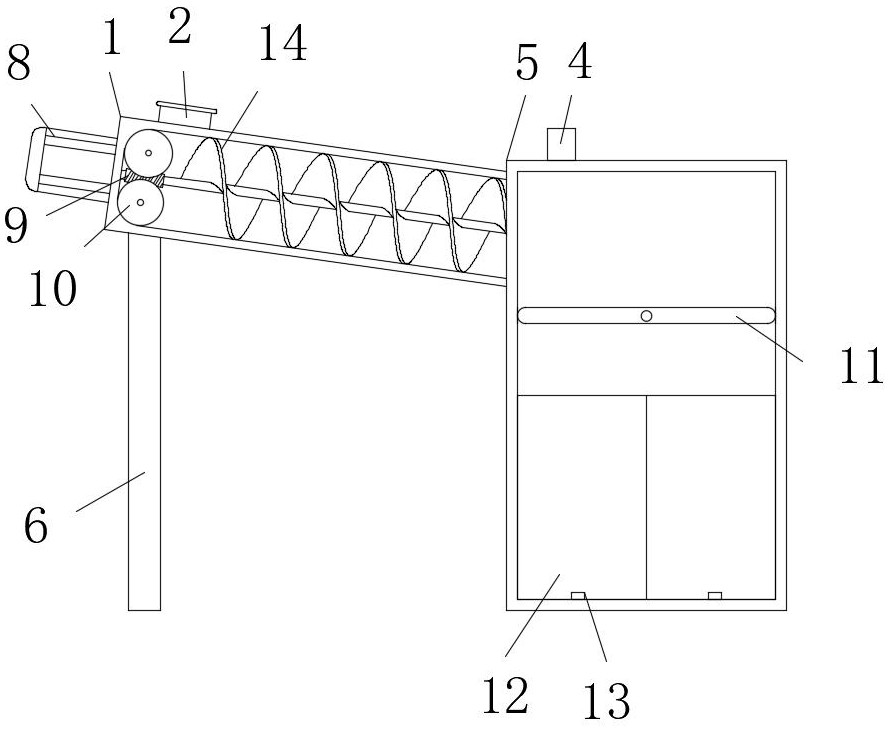

Intelligent environment-friendly dry-wet separation device with feeding structure

InactiveCN113500007AAvoid residueAvoid miss deliveryHollow article cleaningSortingSeparation technologyElectric machinery

The invention discloses an intelligent environment-friendly dry-wet separation device with a feeding structure, and belongs to the technical field of dry-wet separation. The device comprises a side shell, a material conveying barrel and a classification box, wherein the material conveying barrel is fixedly mounted on the outer wall of one side of the upper end of the classification box, and the side shell is fixedly mounted on the side wall of the material conveying barrel. According to the device, the material conveying barrel is mounted in a matched mode, when materials are fed, the materials can be put into the side shell through a feeding opening, a side motor is started, the side motor can drive a material conveying screw to feed the materials, an automatic feeding effect can be achieved, when the material conveying screw rotates, through a linkage effect, a grinding and cleaning assembly with a transmission worm wheel can be driven to rotate, the rotating grinding and cleaning assembly can synchronously clean corners in the side shell, the materials are effectively prevented from being left at the corners, missing feeding of the materials is avoided, meanwhile, the materials can be synchronously ground, the fineness of the materials is guaranteed, and blocking in a feeding process is avoided.

Owner:马鞍山市数知物联科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com