Patents

Literature

143results about How to "Easy for automatic loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic stabilizer for wet-mixed mortar

InactiveCN104556812AImprove performanceShorten the setting timeWater soluble polysaccharidesProcess engineering

The invention discloses a plastic stabilizer for wet-mixed mortar. The plastic stabilizer comprises the following components in parts by weight: 0.1-5 parts of a water retention agent, 0.1-5 parts of an air entraining agent, 0.1-1 part of a defoaming agent, 0.01-1 part of water soluble polysaccharide, 1-10 parts of a special effect retarder, 1-10 parts of a water reducing agent and 68-98 parts of water. The plastic stabilizer for the wet-mixed mortar, provided by the invention, is liquid, is beneficial for automatic feeding and metering, and overcomes the defects that most mortar additives on the market are solid powder products and cannot realize automatic metering. Meanwhile, the water retention rate of the plastic stabilizer for the wet-mixed mortar, provided by the invention, can reach 98%, so that the setting time of the mortar can be deferred to 10-72 hours.

Owner:JIANGSU ZHONGKAI NEW MATERIALS

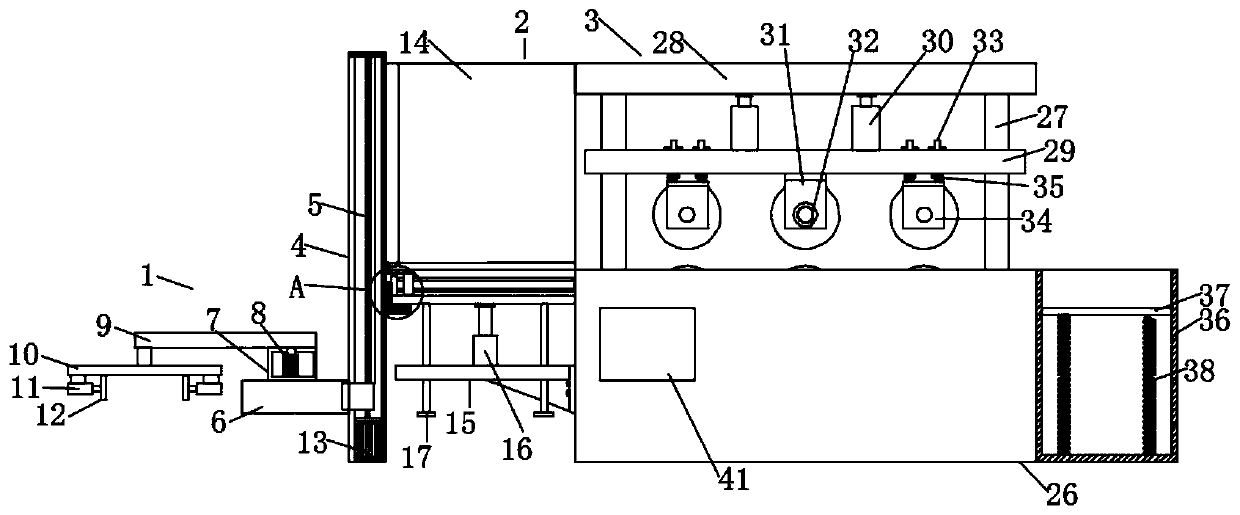

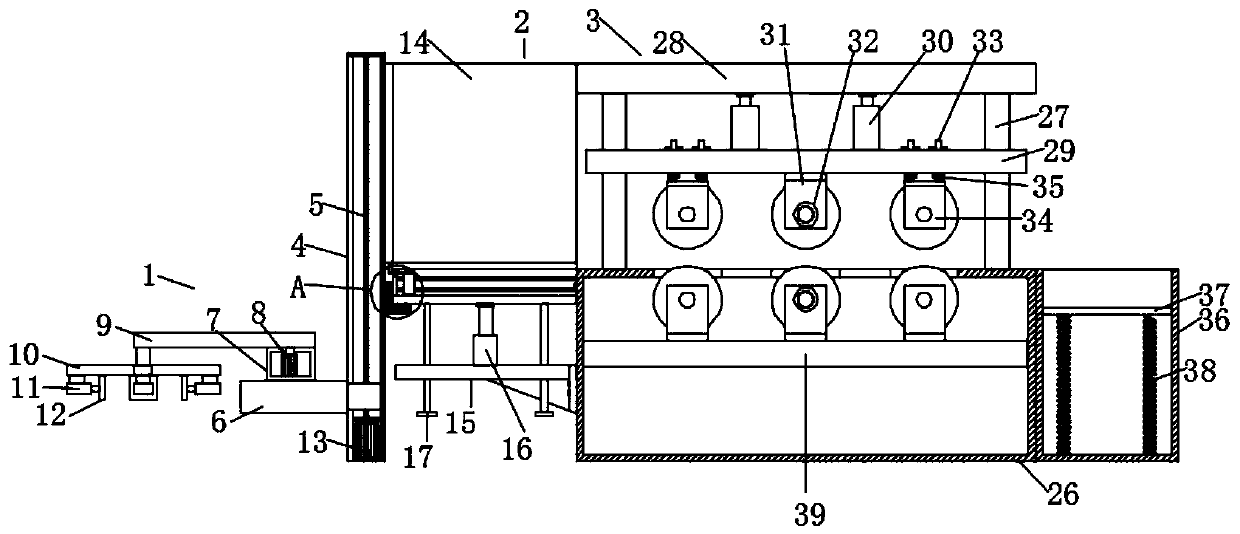

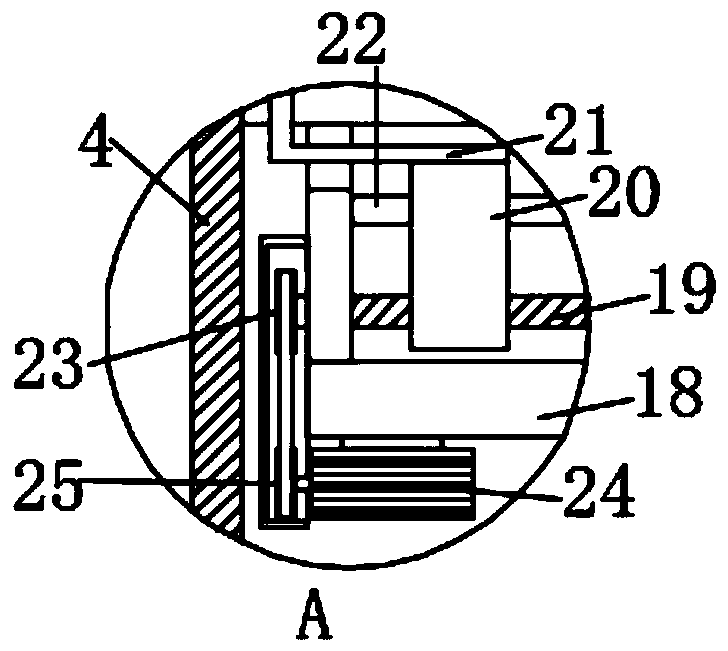

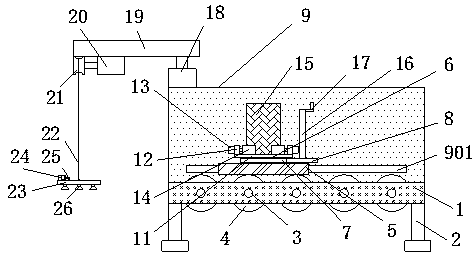

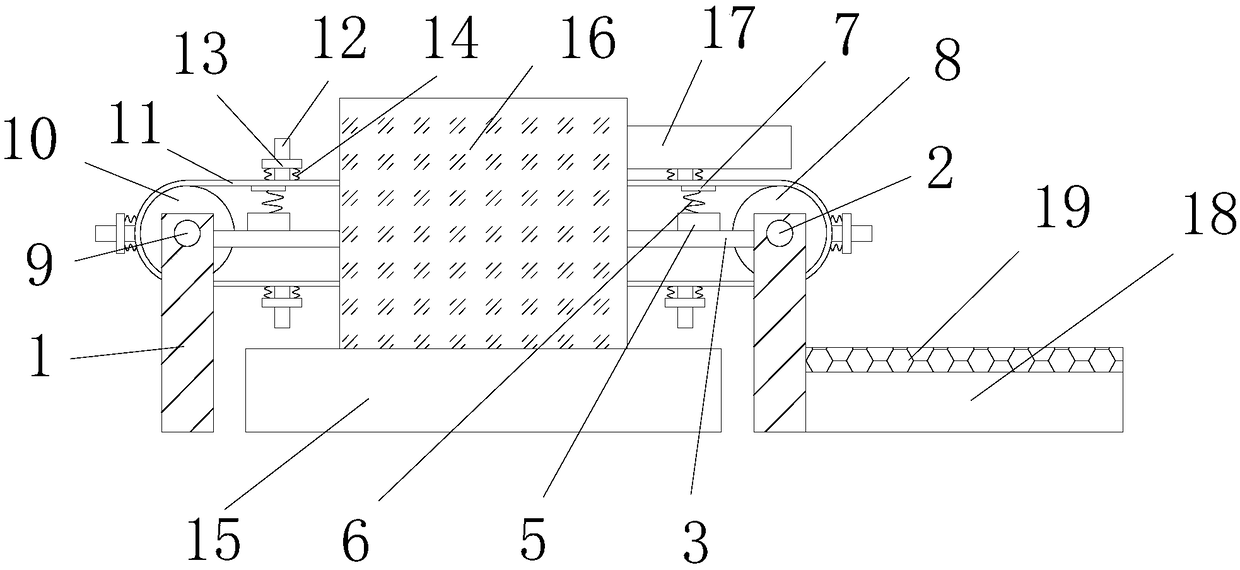

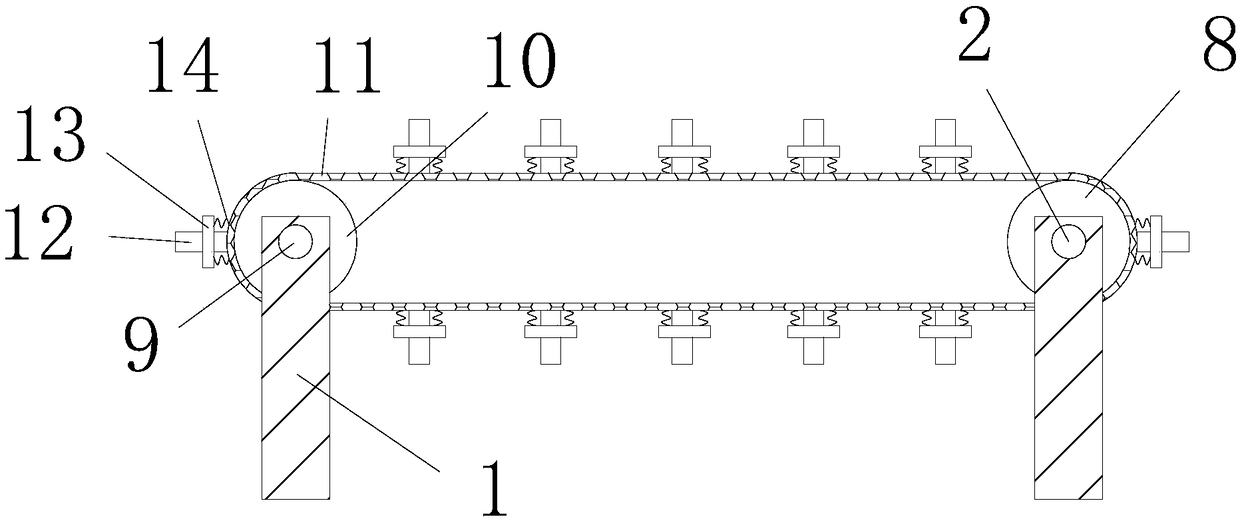

Modified plastic-wood profile embossing device and embossing process thereof

PendingCN110328729AIncrease the scope of applicationAutomateConveyorsWood compressionEngineeringHook plate

The invention discloses a modified plastic-wood profile embossing device and an embossing process thereof. The embossing device comprises a feeding mechanism, a conveying mechanism and an embossing mechanism, wherein the embossing mechanism is composed of a working table, distance adjusting slide rods, a top plate, an adjusting sliding plate, a distance adjusting air cylinder, pressing rollers, adriving motor, a buffering sliding rod, an auxiliary roller, a buffer spring, a collecting box, a material receiving plate and a return spring, wherein the four corners of the top of the working tableare fixedly connected with the distance adjusting slide rods. According to the modified plastic-wood profile embossing device and the embossing process thereof, through arranging the feeding mechanism and under the action of a lifting motor and a clamping air cylinder, profiles can be automatically fed without manual carrying, which leads to the saving of time and labor; in addition, under the action of the distance adjusting air cylinder, distances between the pressing rollers can be flexibly adjusted, so that the device can be applied to the profiles of different thickness, which improves the application range of the device; finally, through setting a storage box and a push hook plate, the automatic conveying and adding of the profiles is facilitated, so that both automation and intelligentization can be realized, thus reducing labor intensity of workers as well as improving embossing processing efficiency of modified plastic-wood profiles.

Owner:南京聚锋新材料有限公司 +1

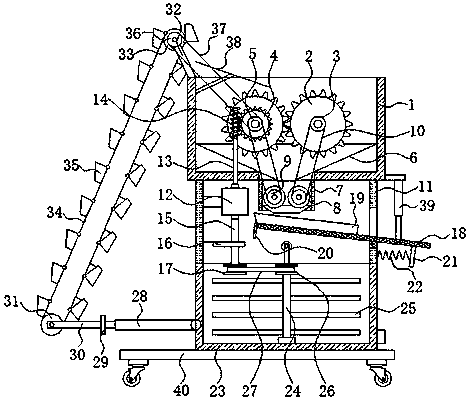

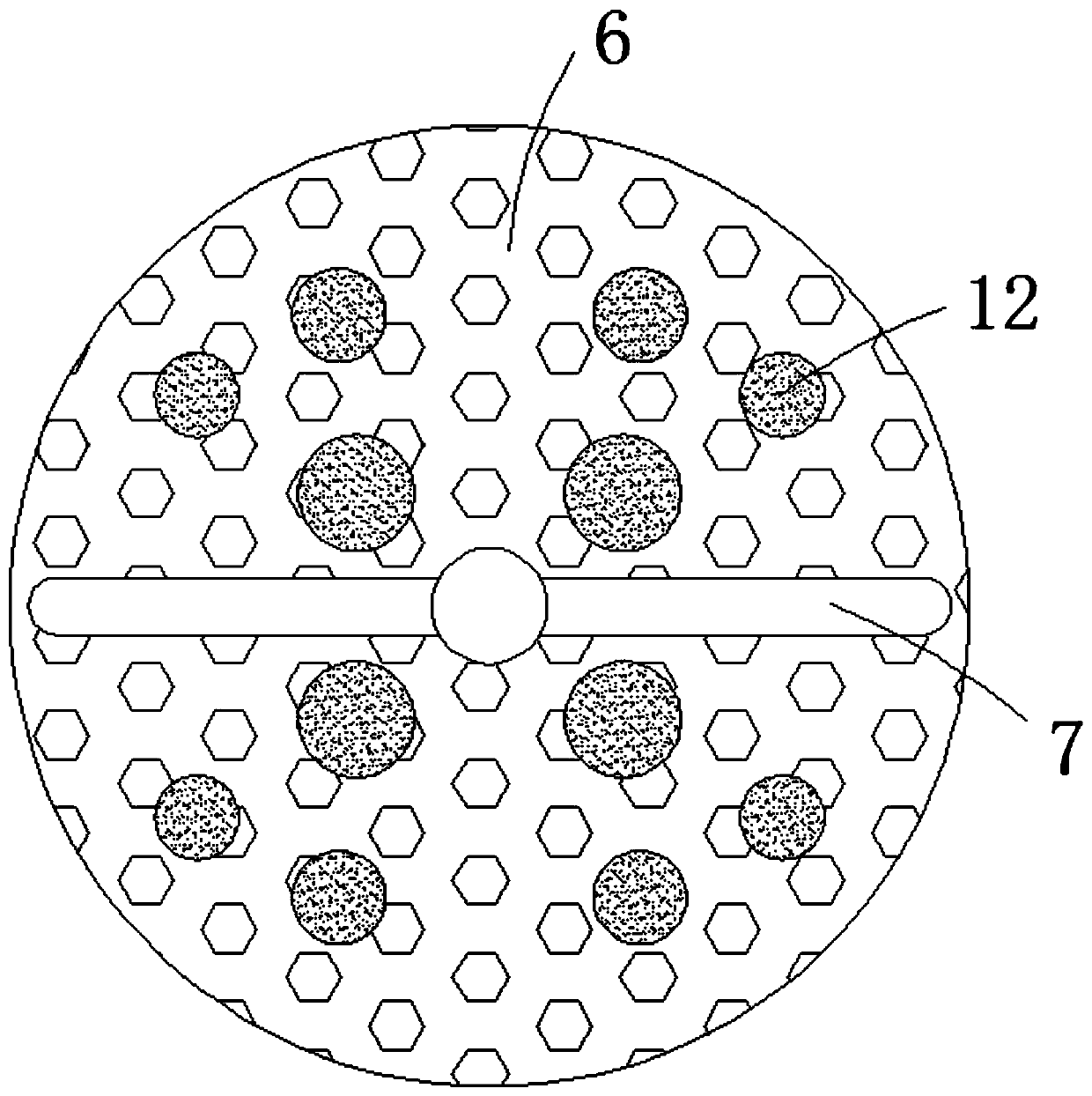

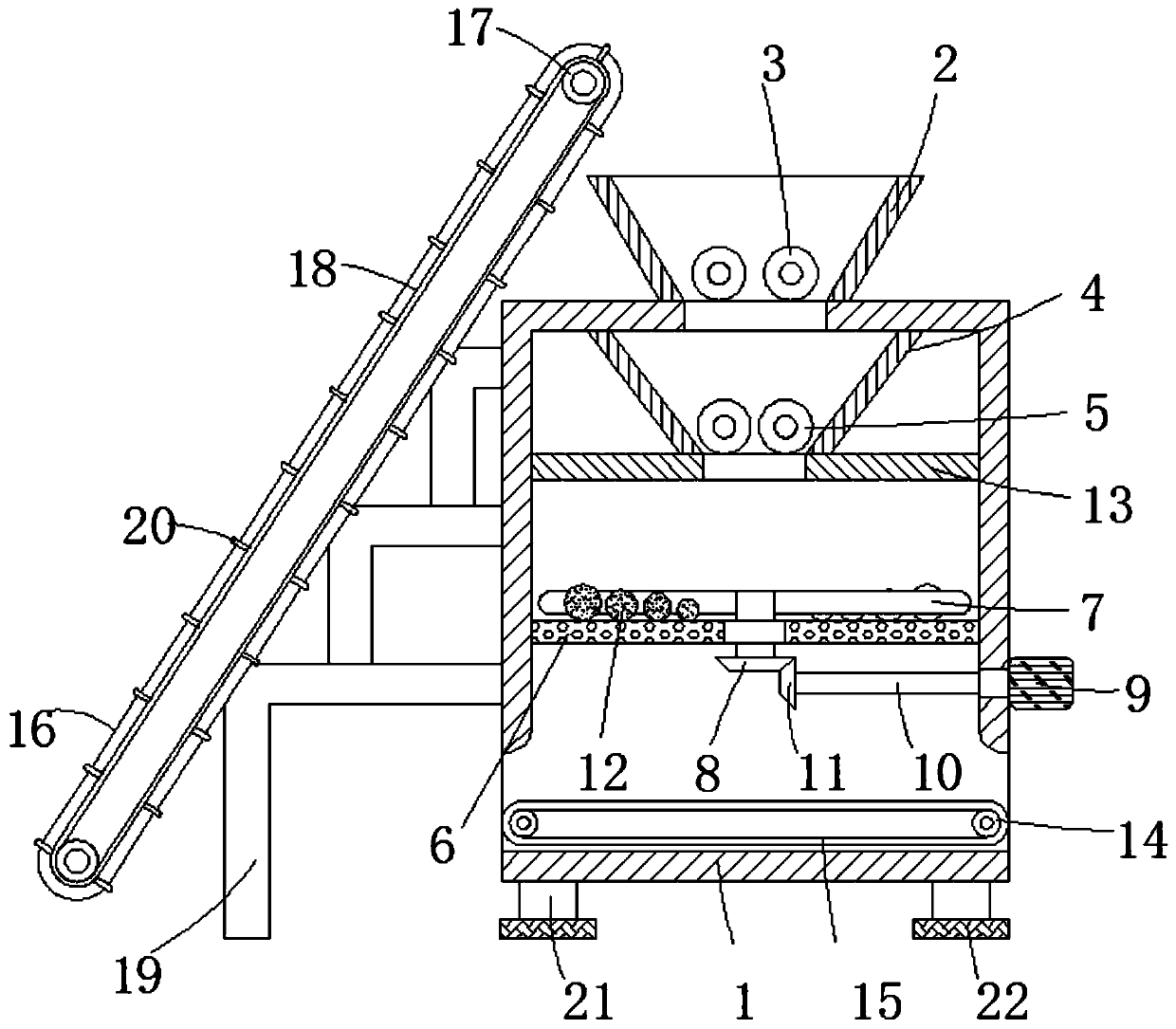

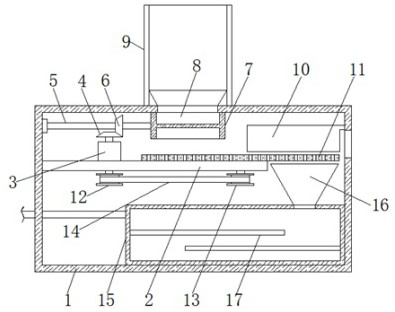

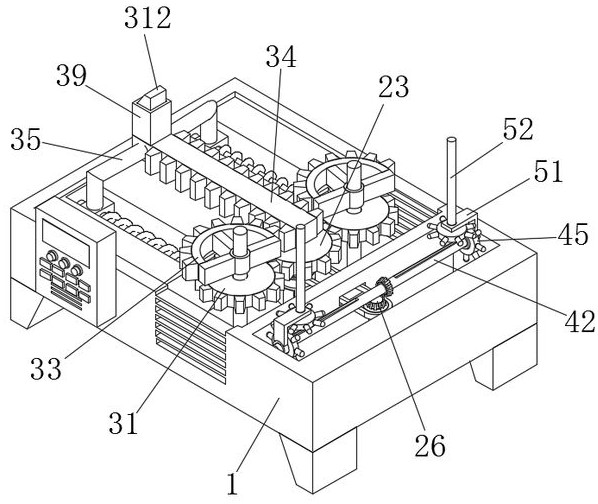

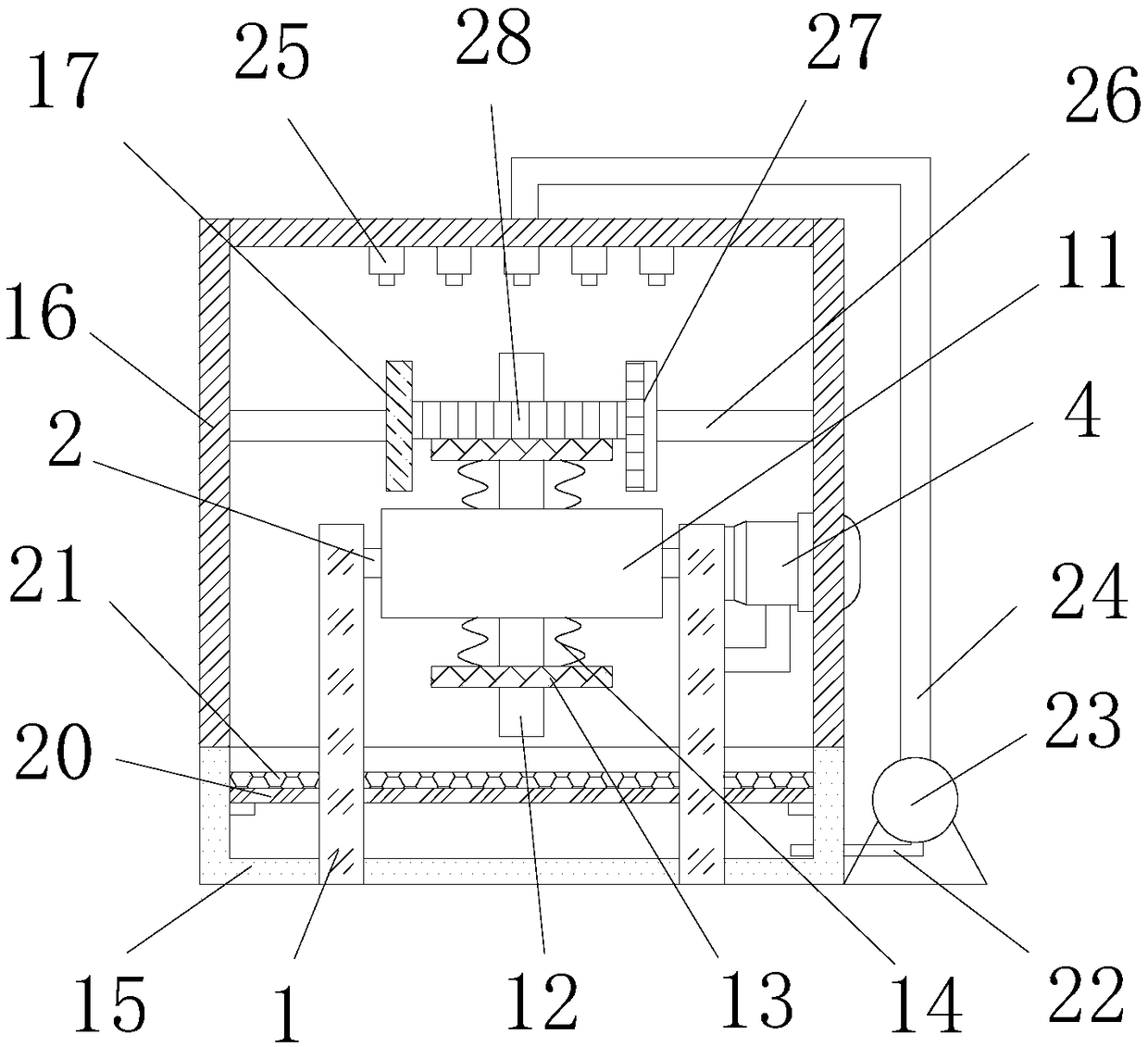

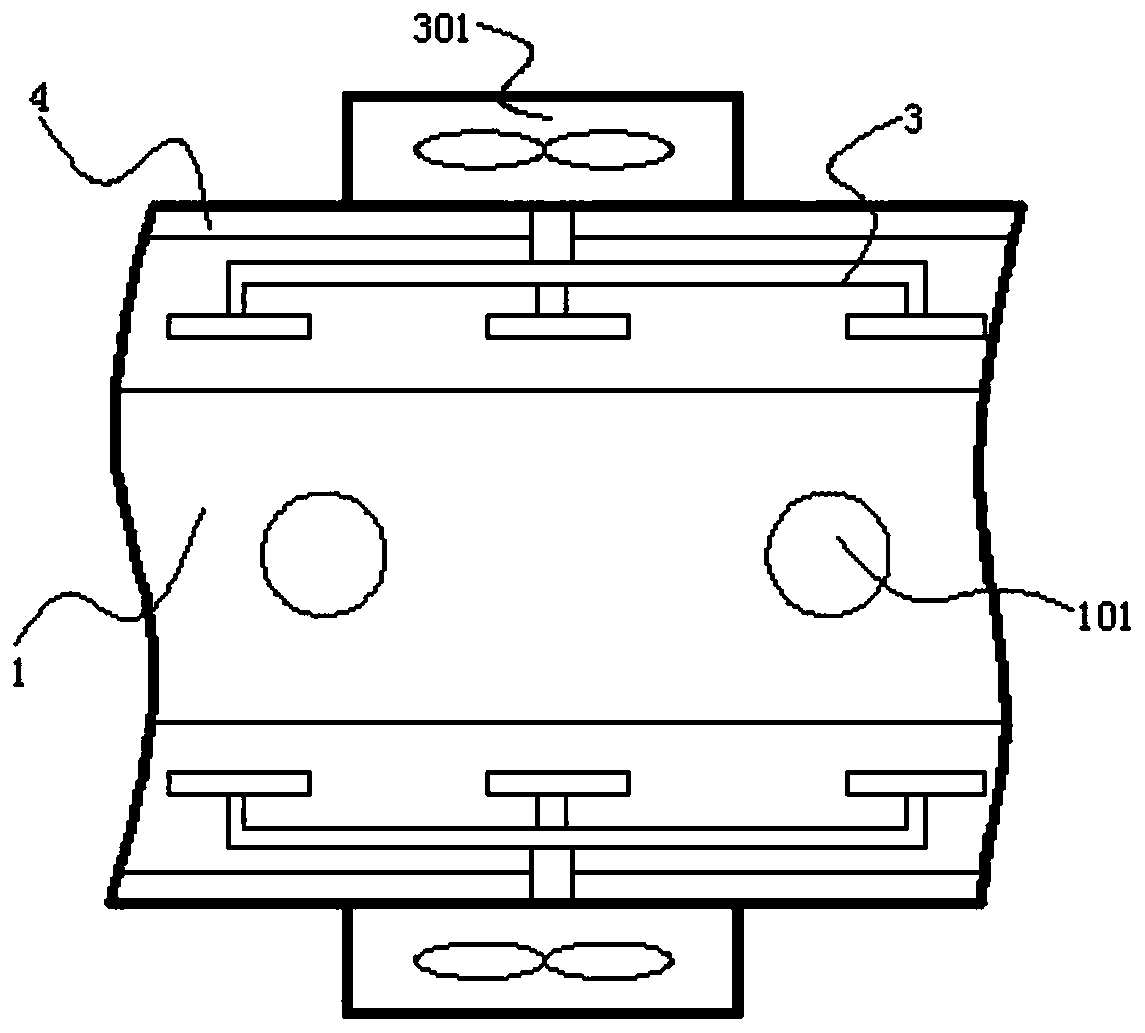

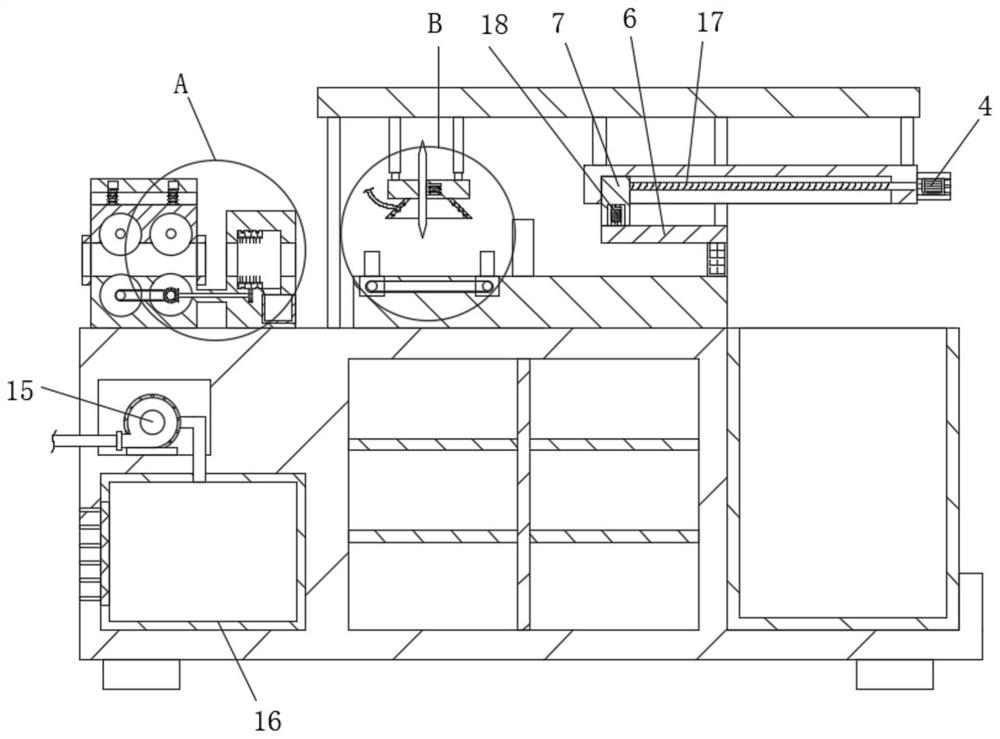

Continuous remediation equipment for remediating heavy metal composite soil based on biomineralization

InactiveCN111420977AEasy to crushConducive to uniform thicknessSievingScreeningSoil remediationEnvironmental engineering

The invention discloses continuous remediation equipment for remediating heavy metal composite soil based on biomineralization. The invention relates to the technical field of soil remediation, existing soil remediation equipment is diverse and messy and large in field occupation, the soil remediation is easily influenced by factors such as soil thickness, humidity and biological content, in orderto solve the problems that an existing grinding and screening device is not beneficial to efficient and rapid repairing, the following scheme is provided, the continuous remediation equipment comprises a smashing mechanism, a grinding mechanism, a screening mechanism, a mixing mechanism, a feeding mechanism and a driving mechanism, the grinding mechanism is located below the smashing mechanism, the screening mechanism is located below the grinding mechanism, and the mixing mechanism is located below the screening mechanism. According to the remediation equipment, automatic soil feeding is facilitated, continuous operation is facilitated, soil is smashed, screened and mixed, the thickness, humidity and biological content of the soil can be kept balanced accordingly, overall efficient remediation of the soil is facilitated, and the equipment is high in integration degree, small in occupied area and high in practicability.

Owner:安徽新之图科技发展有限公司

Environment-friendly building waste processing device

InactiveCN111135926AEasy for multiple shreddingEasy to GrindGrain treatmentsLoading/unloadingWaste processingArchitectural engineering

The invention relates to the technical field of building construction waste processing, and discloses an environment-friendly building waste processing device. The device comprises a crushing box, a feeding hopper is fixedly connected to the upper end of the crushing box, two symmetrically-arranged first crushing rollers are rotationally connected to the interior of the feeding hopper through twofirst rotating shafts, a feeding port corresponding to the feeding hopper in position is formed in the upper side wall of the crushing box, a discharging hopper corresponding to the feeding hopper inposition is arranged at the upper end of the interior of the crushing box, the upper end of the discharging hopper is fixedly connected with the upper inner side wall of the crushing box, second crushing rollers are rotationally connected with the interior of the discharging hopper through two second rotating shafts, and the distance between the two second crushing rollers is smaller than that between the two first crushing rollers. According to the environment-friendly building waste processing device, building waste stone can be subjected to multiple crushing and grinding, so that recyclingis facilitated, the resource waste is avoided, automatic feeding of the waste stone is facilitated, the labor intensity of people is relieved, and the use by people is facilitated.

Owner:南京星佛管业有限公司

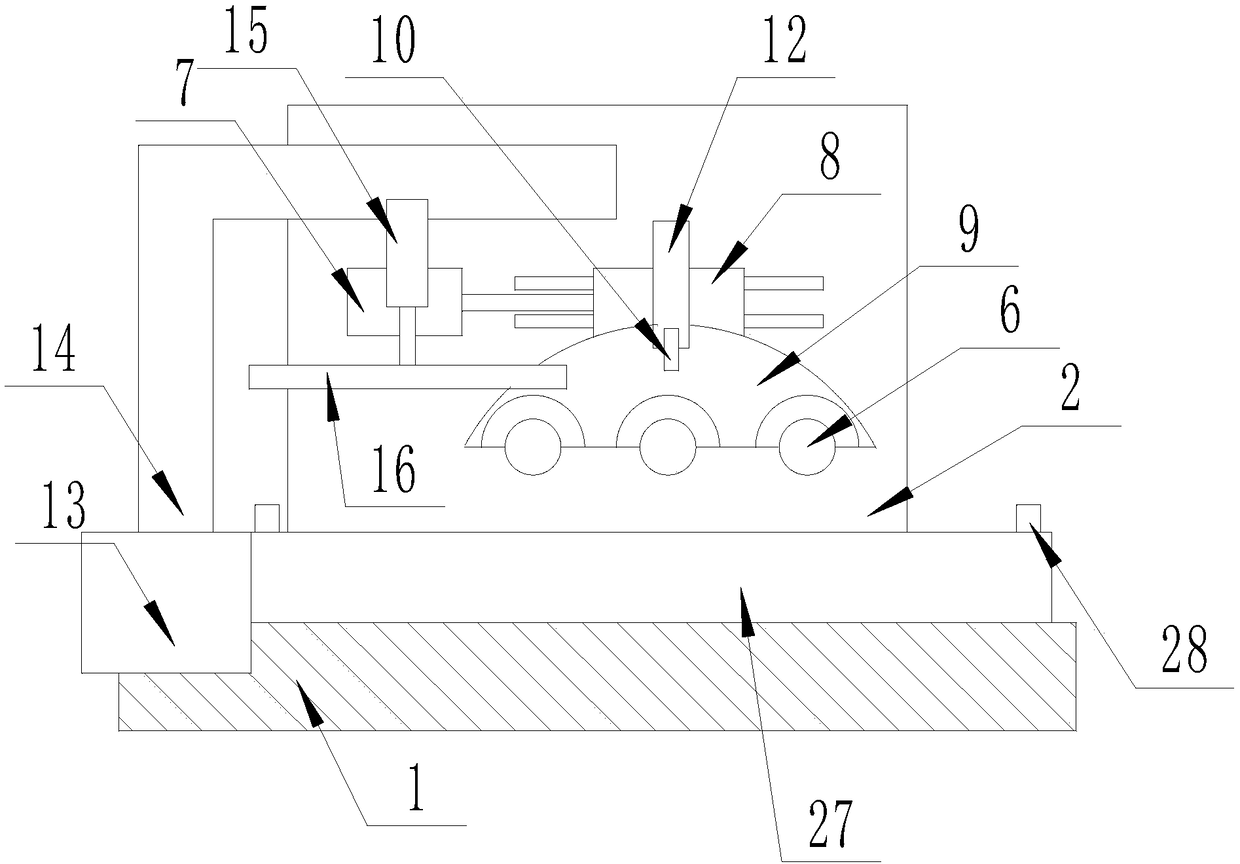

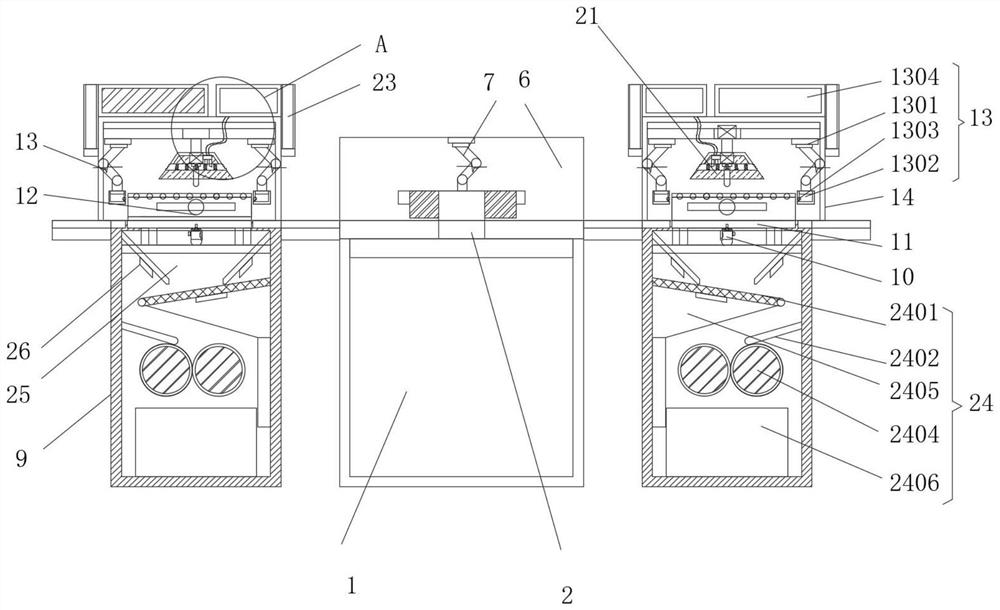

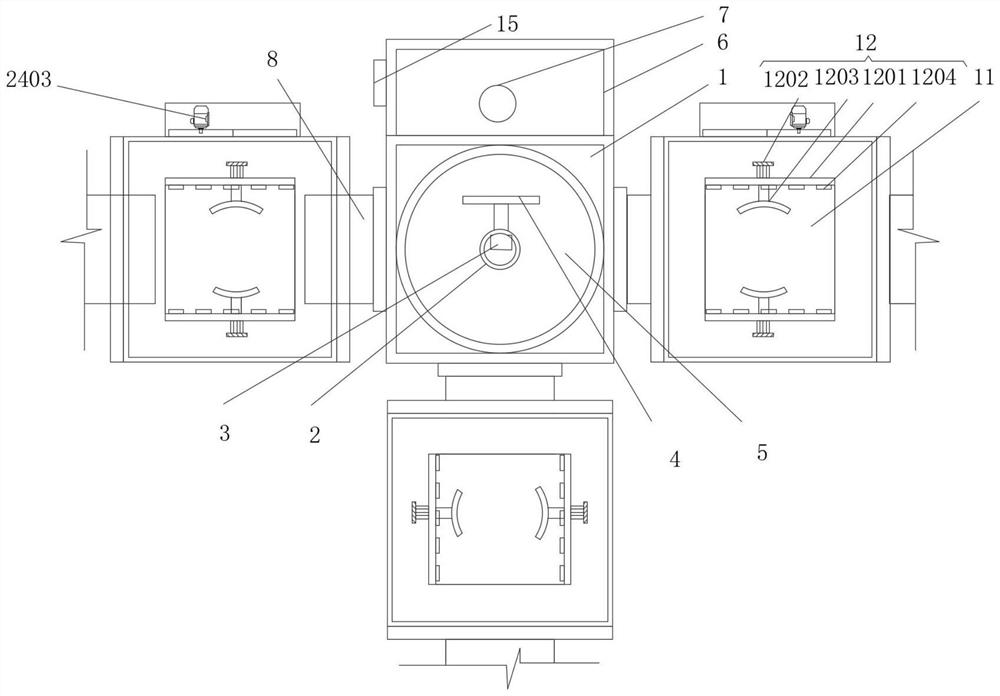

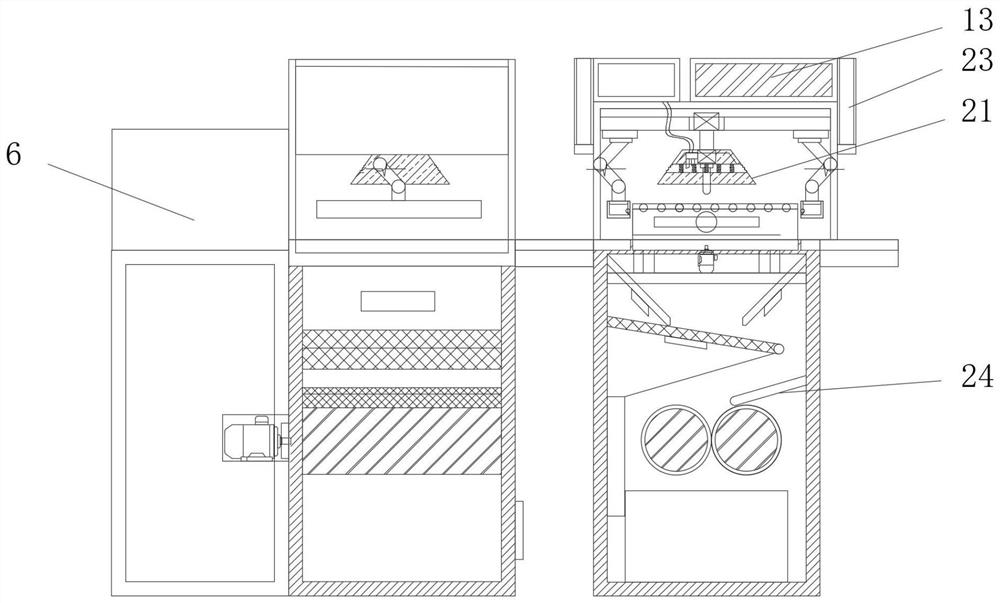

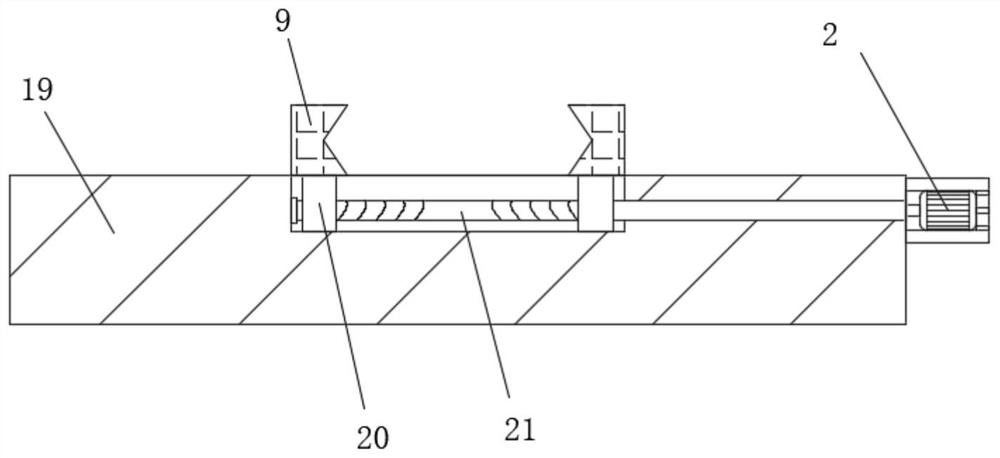

Integrated steel pipe processing equipment and processing method

InactiveCN110142260AEasy surface cleaningEasy for automatic cuttingHollow article cleaningTreatment involving filtrationEngineeringWaste material

The invention discloses integrated steel pipe processing equipment and processing method and belongs to the technical field of steel pipe processing equipment. The integrated steel pipe processing equipment comprises a bracket, a discharging opening formed in the surface middle position of the bracket, feeding devices symmetrically mounted at the two ends of the bracket, a washing pipe fixedly connected to the upper surface of the bracket, a hot air annular pipe located at one side of the washing pipe, a polishing device detachably connected to the middle position of the upper surface of the bracket, a cutting device welded above the bracket and a waste material framework movably placed below the bracket, wherein each feeding device comprises a servo motor I and a feeding roller. Accordingto the embodiment of the invention, the feeding devices, the washing pipe, the hot air annular pipe, the polishing device and the cutting device are sequentially mounted on the bracket from the leftto the right, so that surface washing, pipe wall polishing and automatic cutting can be conveniently carried out on steel pipes, the operation process is ordered, labor is saved, and the production efficiency is increased.

Owner:佛山市南海源金信不锈钢制品有限公司

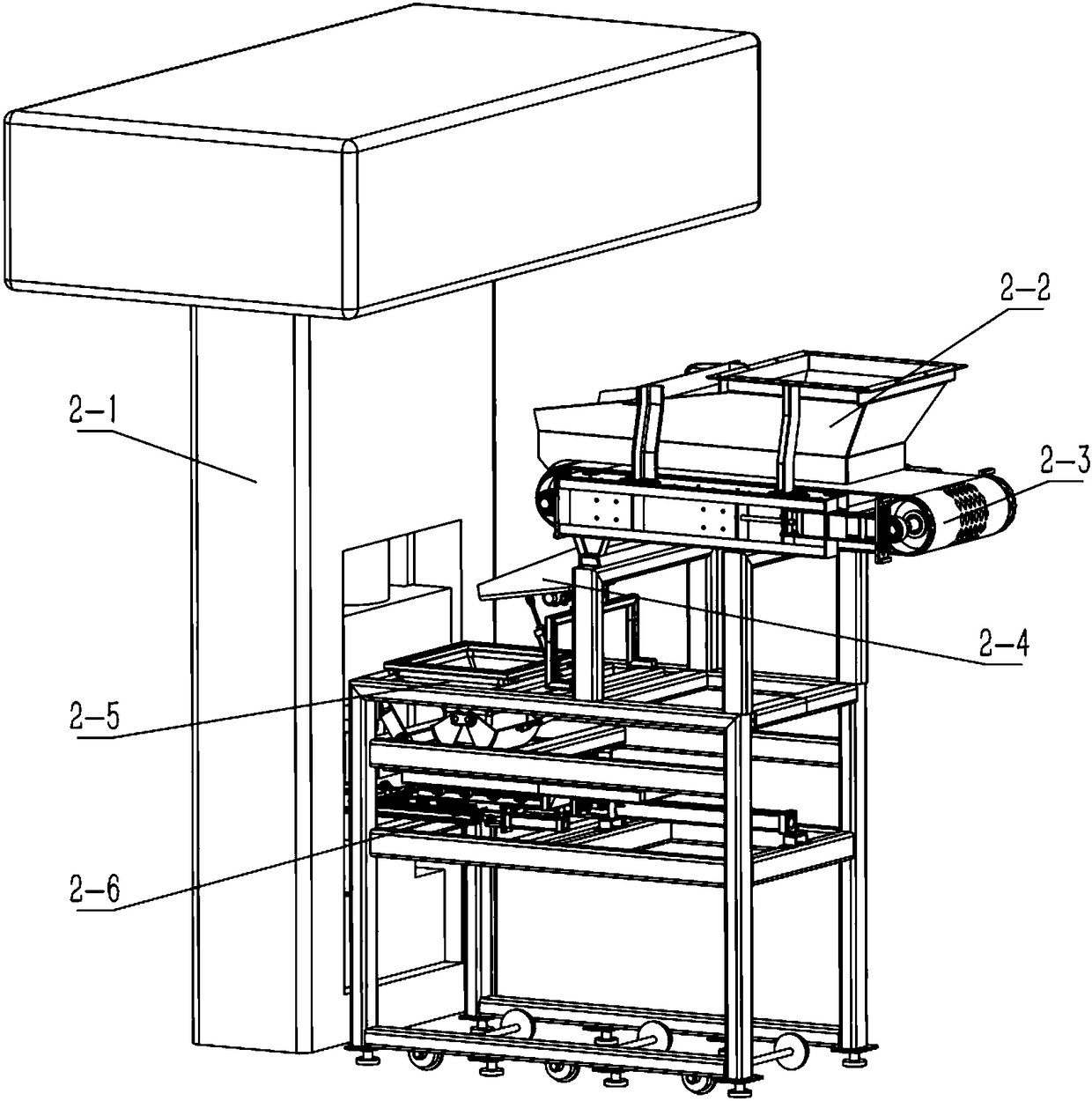

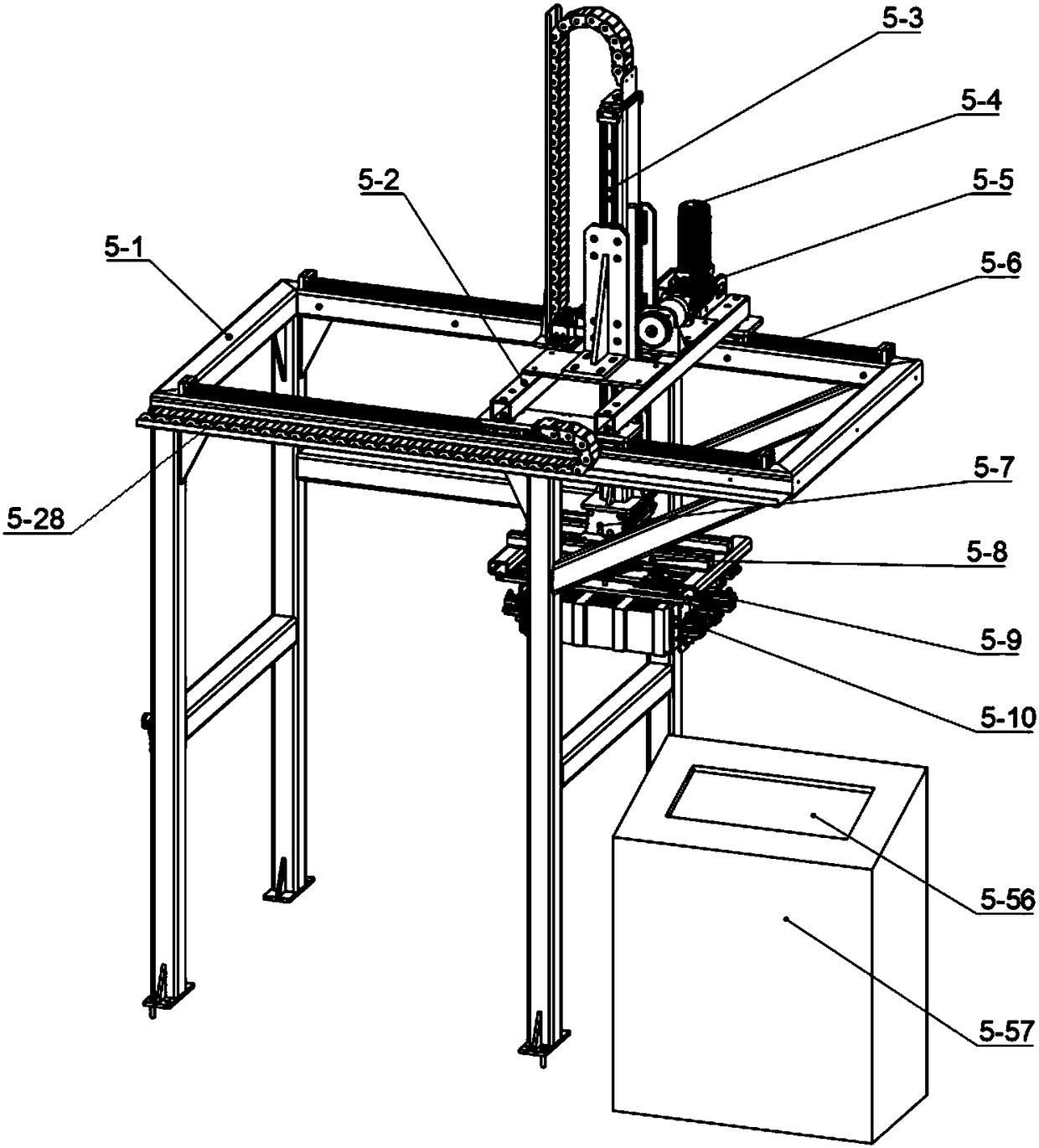

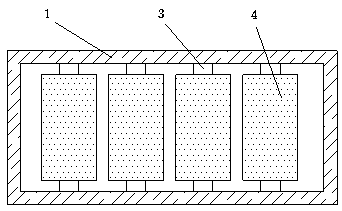

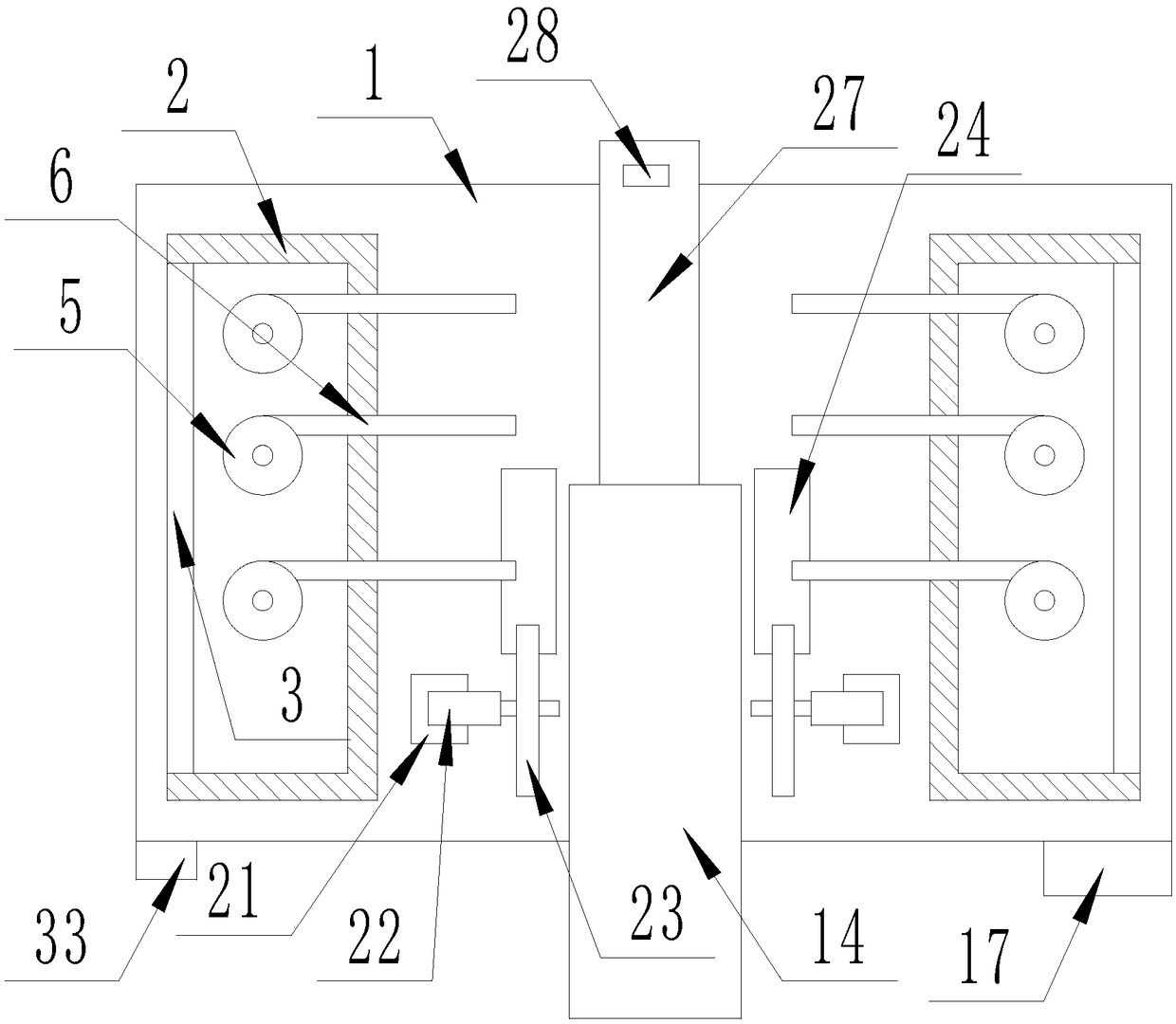

Intelligent manufacturing production-line for refractory bricks

InactiveCN108327060AIncrease productivityReduce investmentCeramic shaping plantsProduction lineBrick

The invention discloses an intelligent manufacturing production-line for refractory bricks, and belongs to the technical field of refractory brick manufacturing. The intelligent manufacturing production-line for the refractory bricks comprises an intelligent control system, a conveying assembly line, an automatic material-distributing and brick-pressing device, an automatic brick-clamping mechanical hand, a visual inspection device, an automatic line-moving device, an automatic plate-superposing device and a circulating vehicle driving device. By digital and automatic facilities being introduced or existing devices being updated intellectually, each process of refractory brick manufacturing can be automatically performed, operating workers are reduced, standardized production is realized,the whole producing process is carried out without artificial participation, and automation operation is completely realized. Further, the refractory bricks are made by using an intelligent assembly line, personal injuries of production process and risks of safety production is greatly reduced, influence of dust on personnel health during brick pressing is reduced, labor intensity is lowered, production efficiency is improved, production capacity is expanded, and great benefits are brought to enterprises and local economy.

Owner:希望银蕨智能科技有限公司

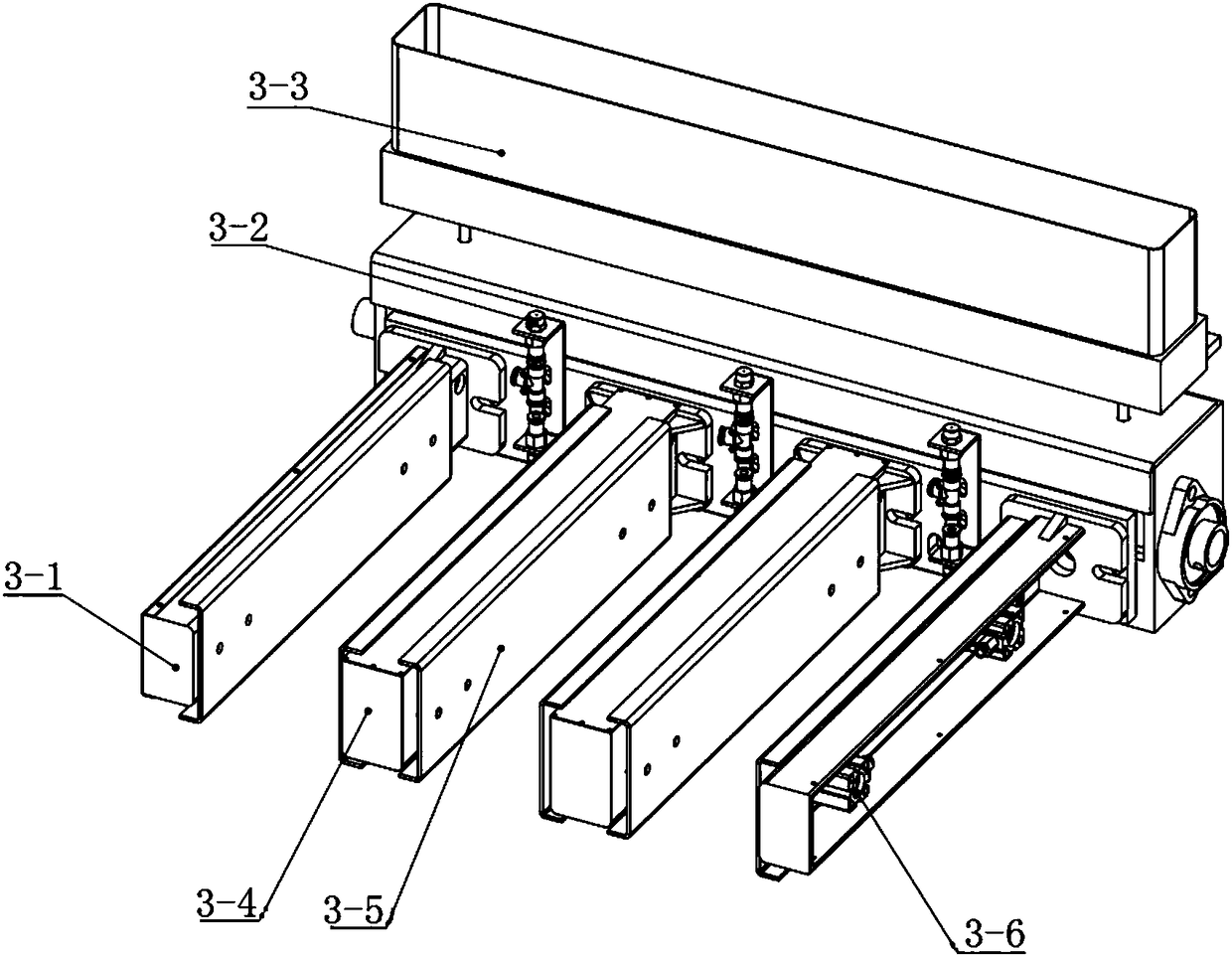

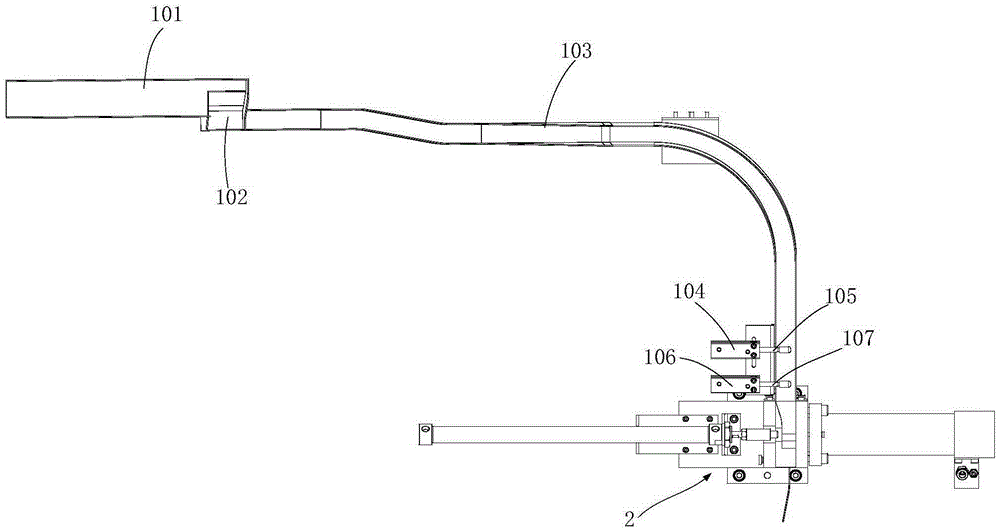

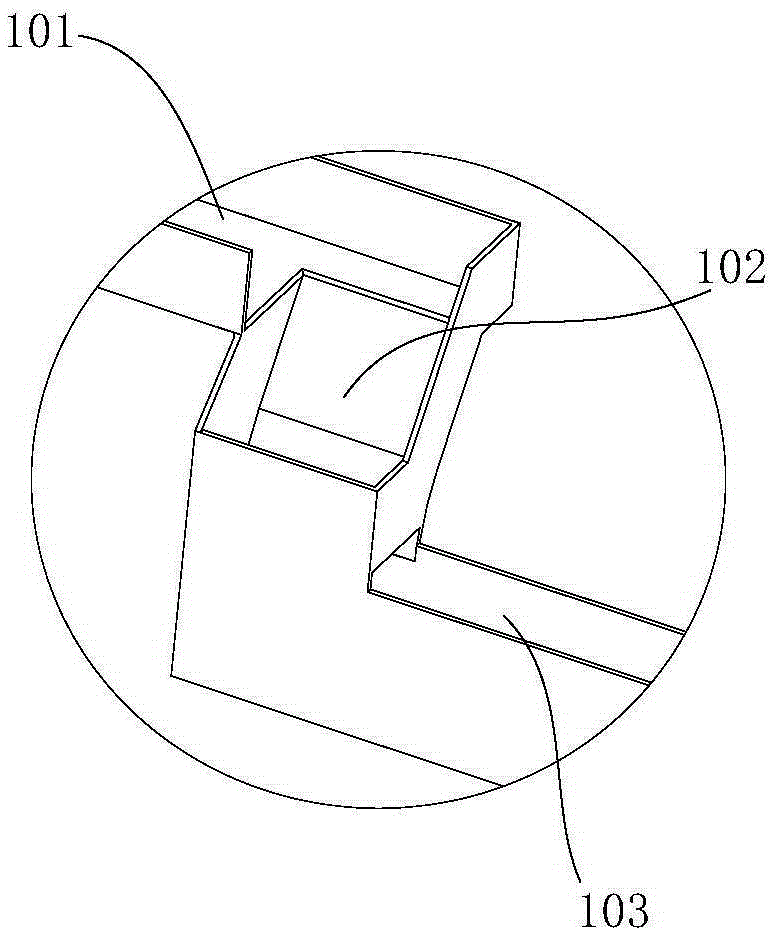

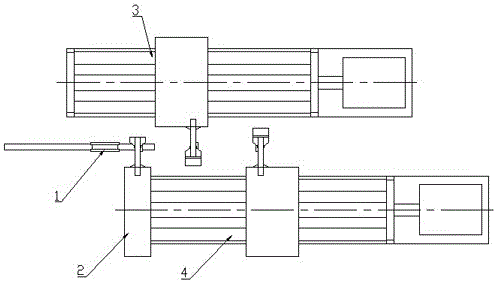

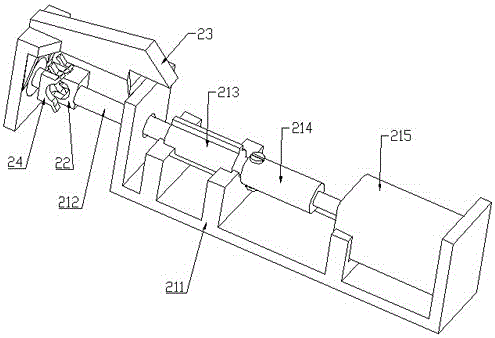

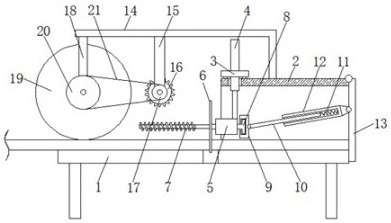

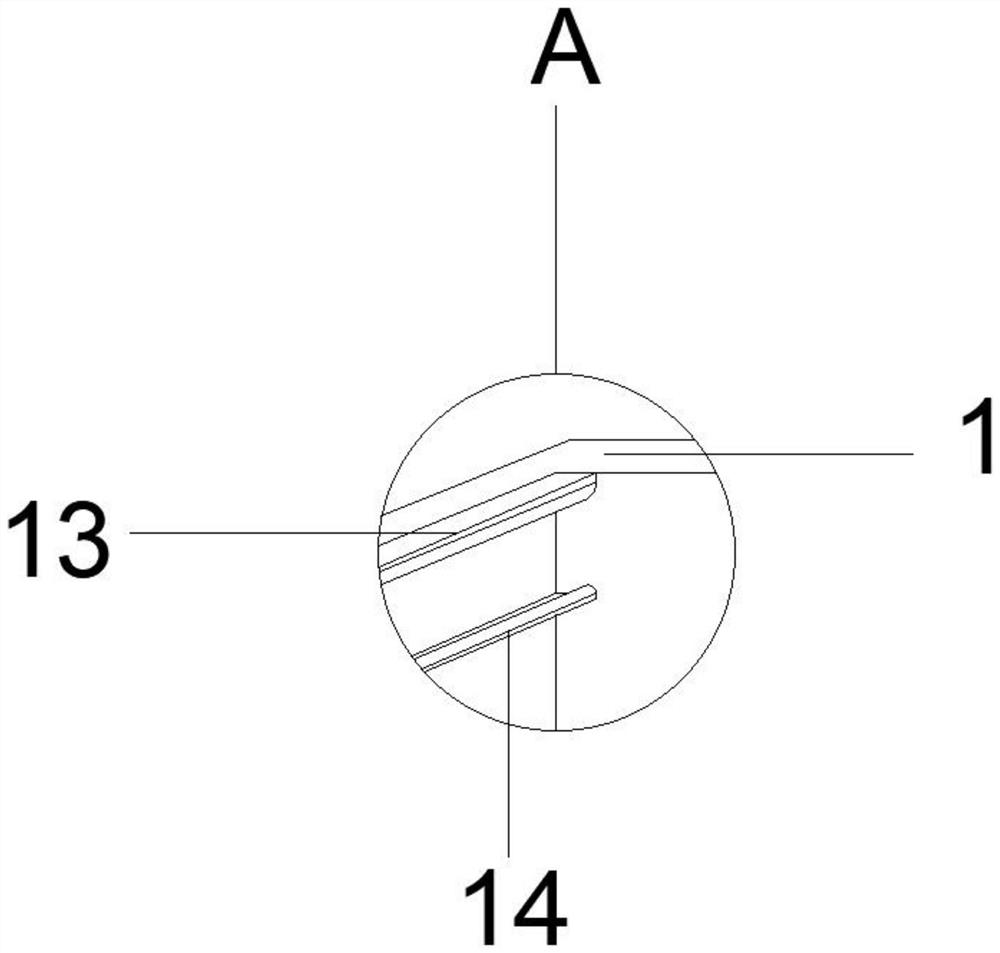

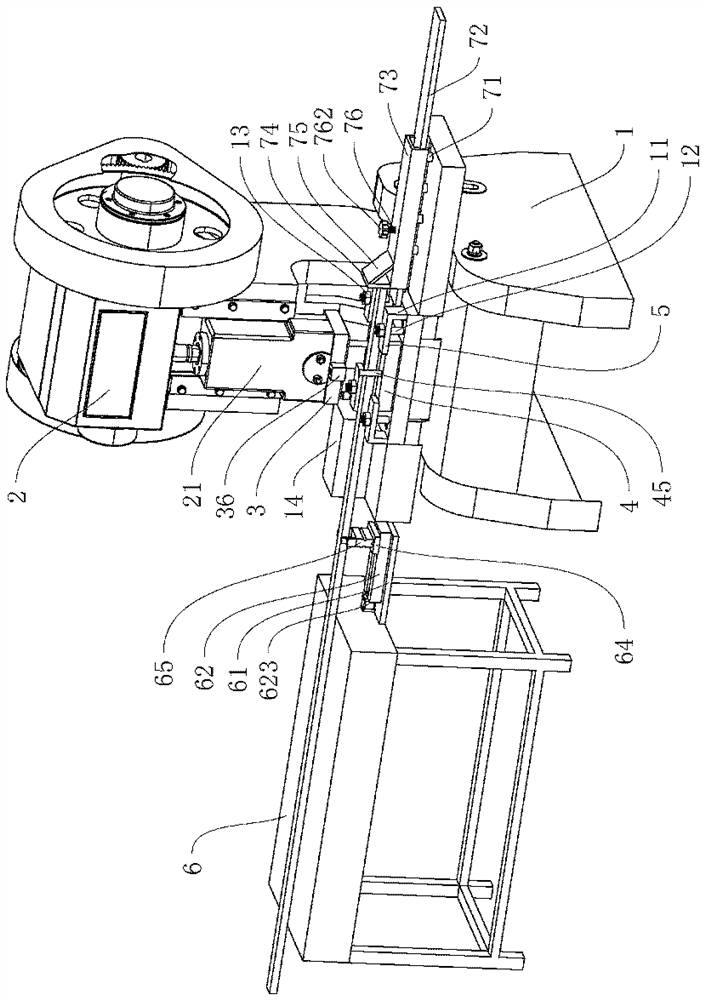

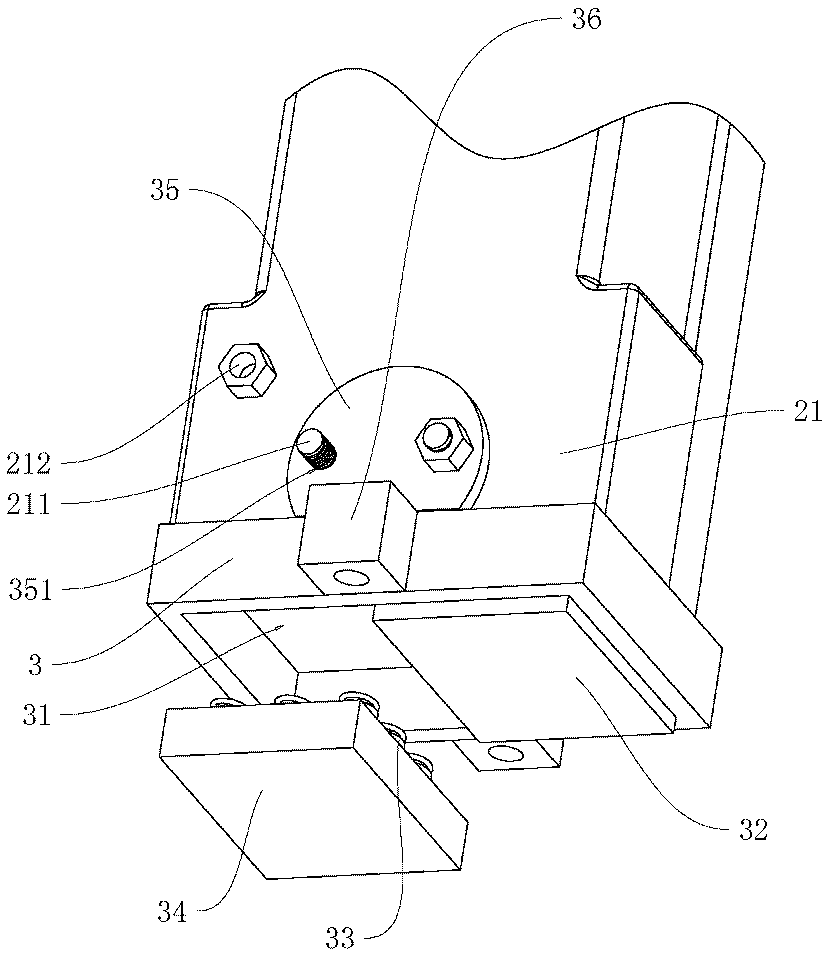

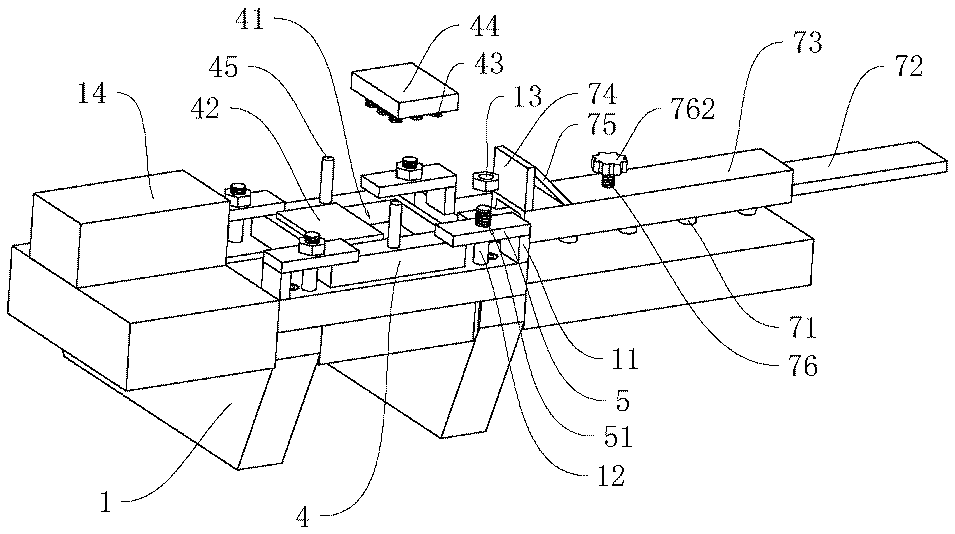

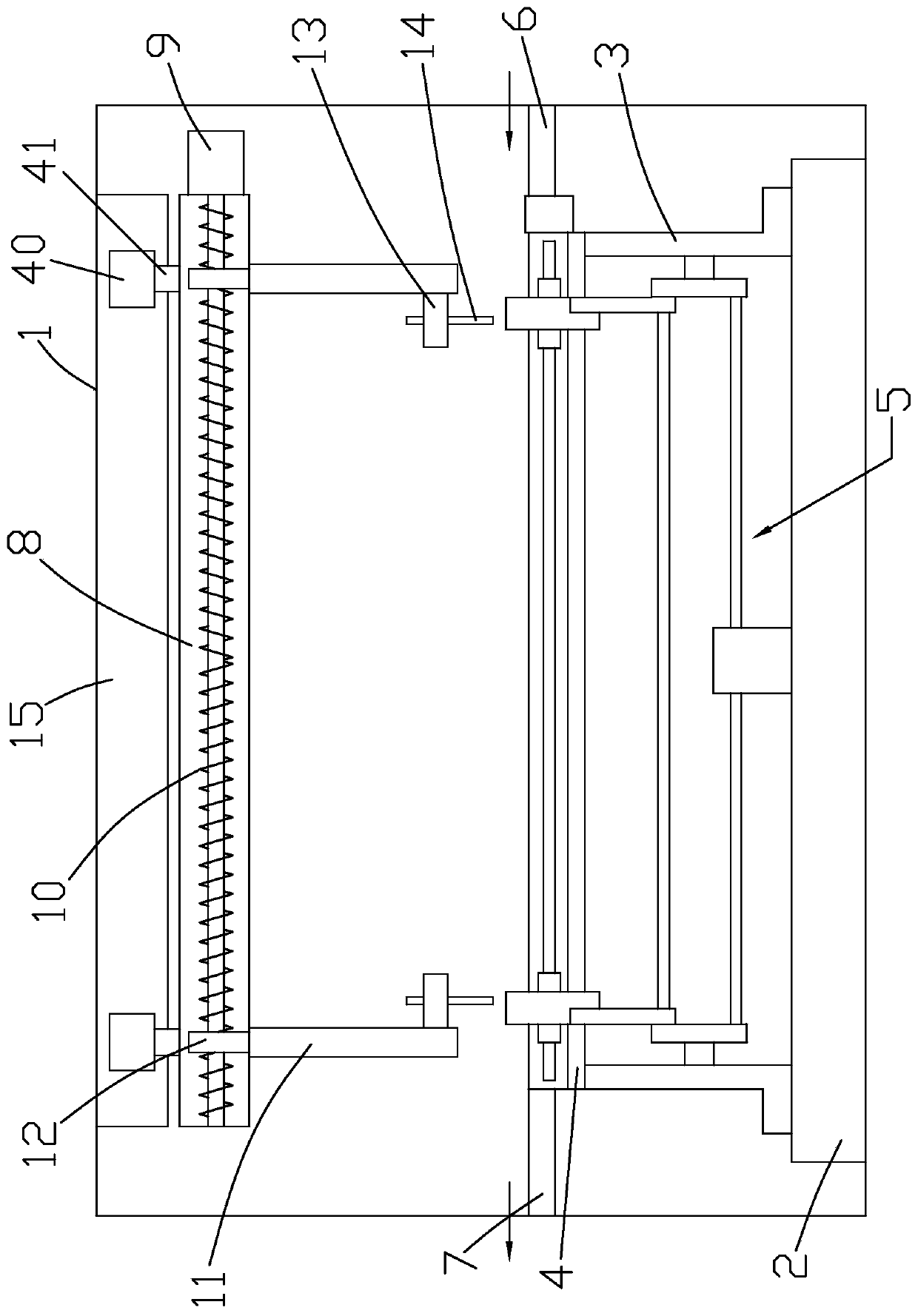

Feeding and splitting system for tool

InactiveCN105252335AEasy for automatic loadingReduce labor intensityMetal working apparatusMachine toolElectrical and Electronics engineering

The invention provides a feeding and splitting system for a tool. The system comprises a track groove which is used for bearing a workpiece; a feeding position is formed at one end of the track groove and a splitting position is formed at the other end of the track groove; two material blocking mechanisms are arranged side by side at the splitting position of the track groove; each material blocking mechanism comprises a splitting air cylinder and a blocking rod connected onto the air cylinder; blocking rods of the two material blocking mechanisms are parallel to each other; sensors are arranged on both two splitting air cylinders; and a conversion device which is used for changing the placing pose of the workpiece is arranged at the position close to the feeding position of the track groove. According to the feeding and splitting system, a workpiece in the former process can be fed to the next process automatically and conveniently; and at the same time, poses can be converted automatically, and only one workpiece is guaranteed to be fed every time through a two-stage splitting mechanism.

Owner:CHONGQING OUBOTE INTELLIGENT ROBOT TECH CO LTD

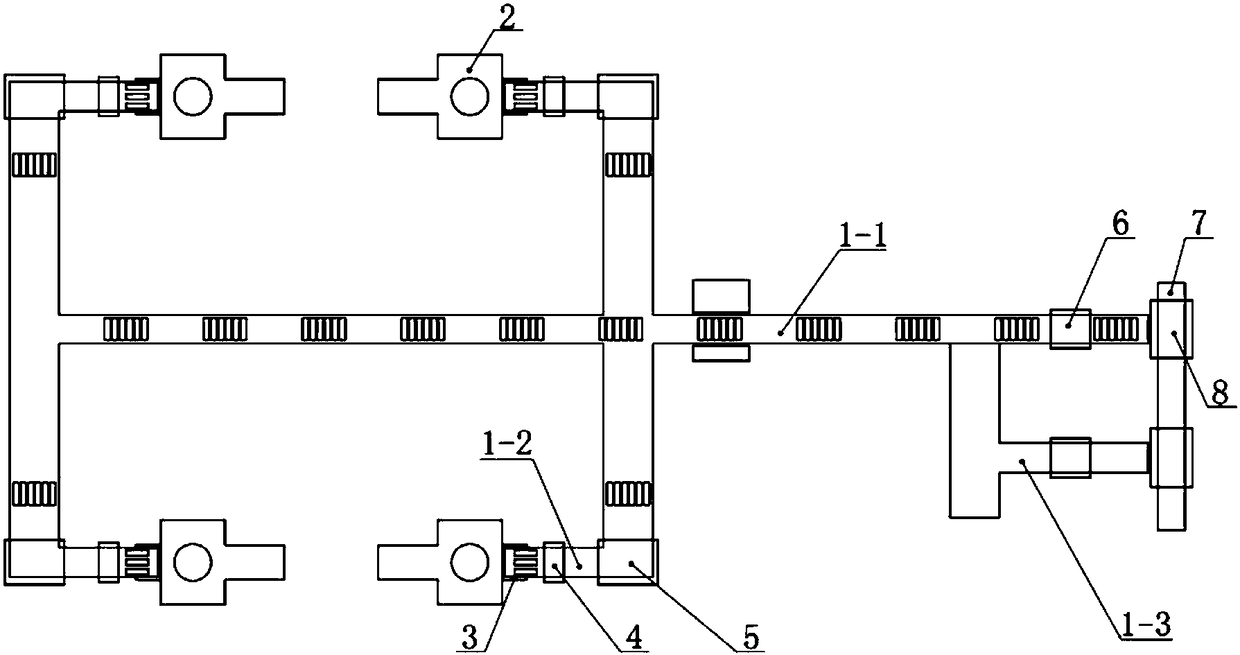

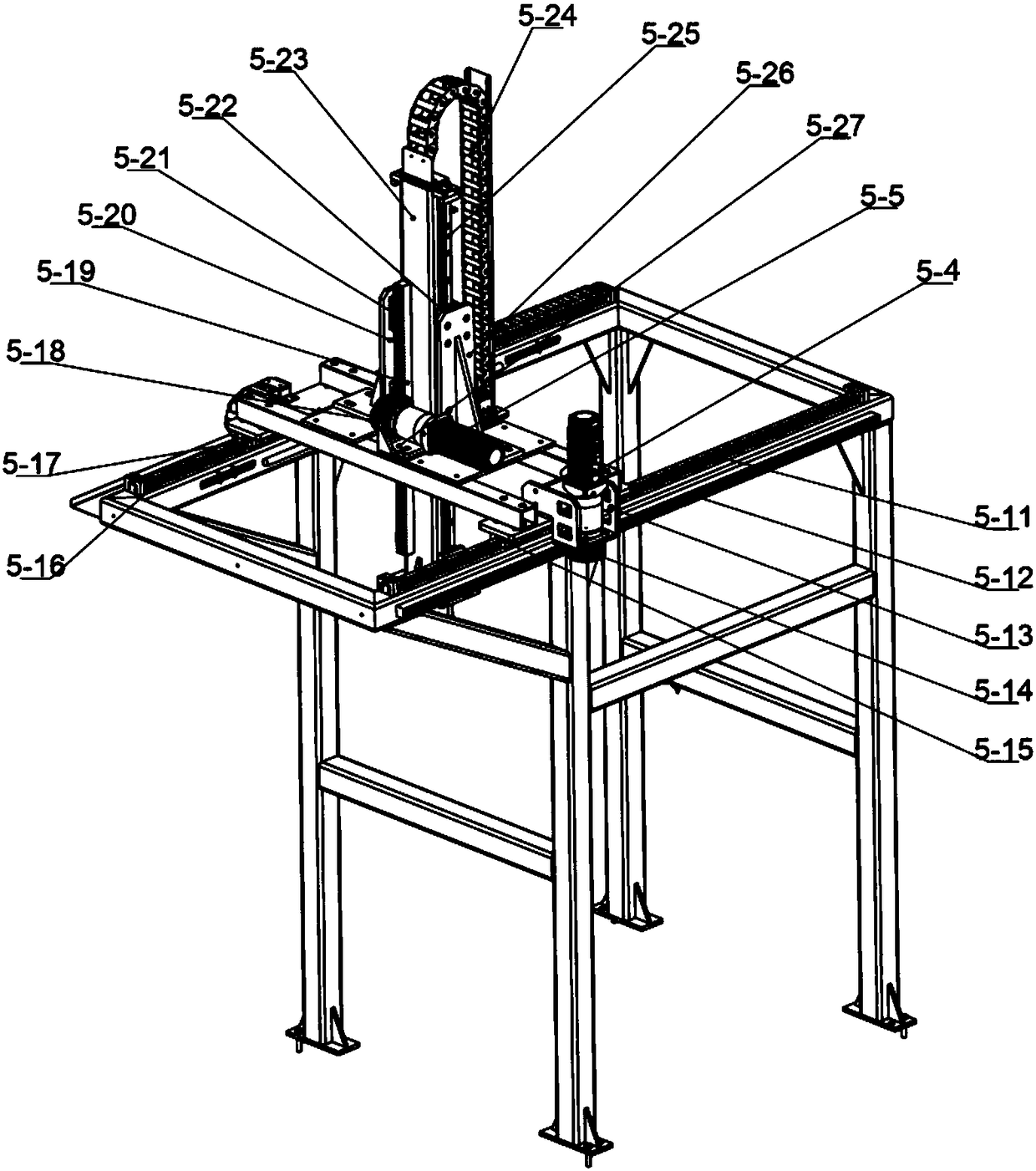

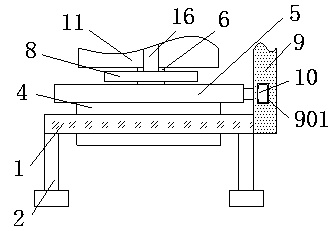

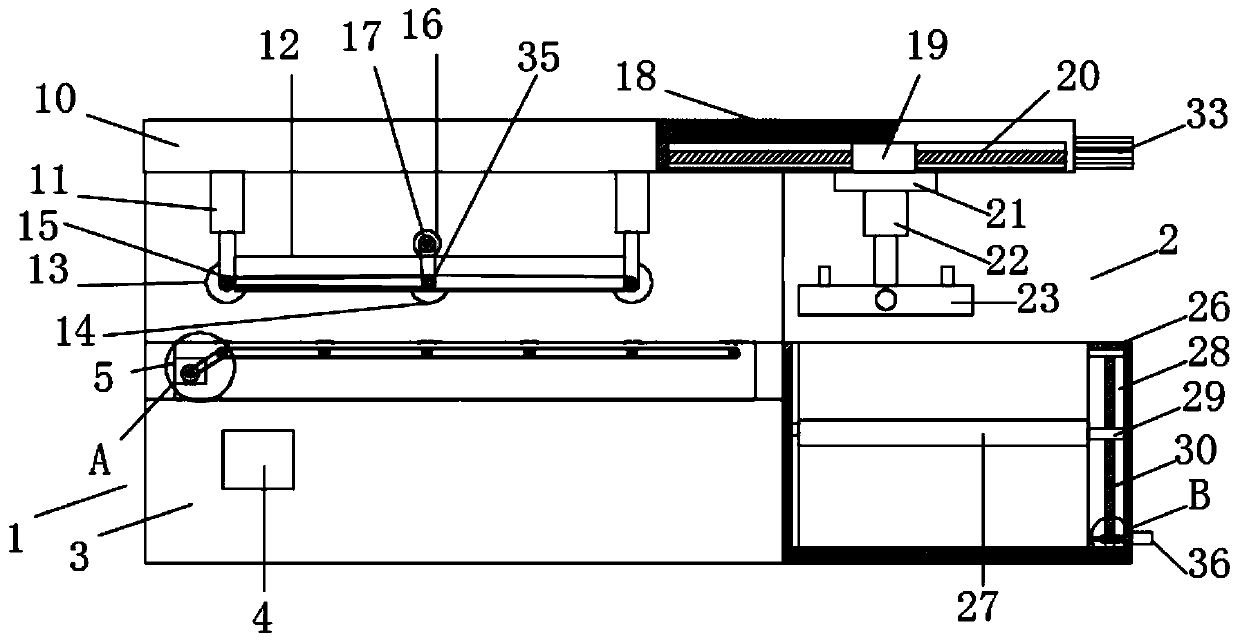

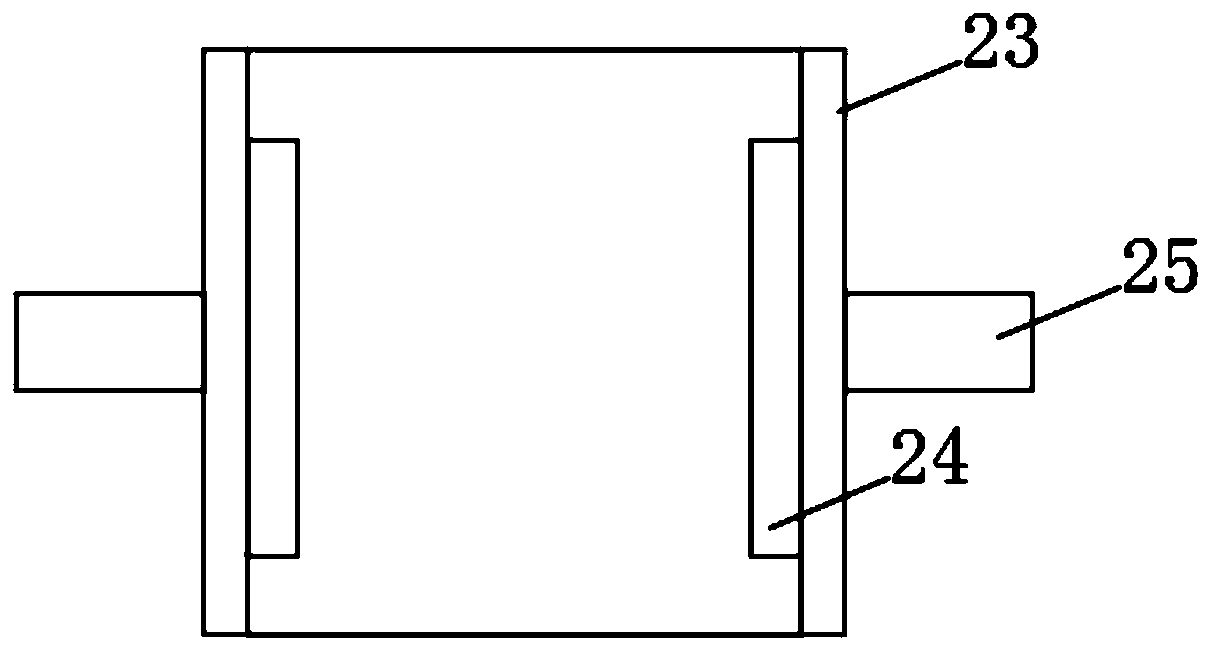

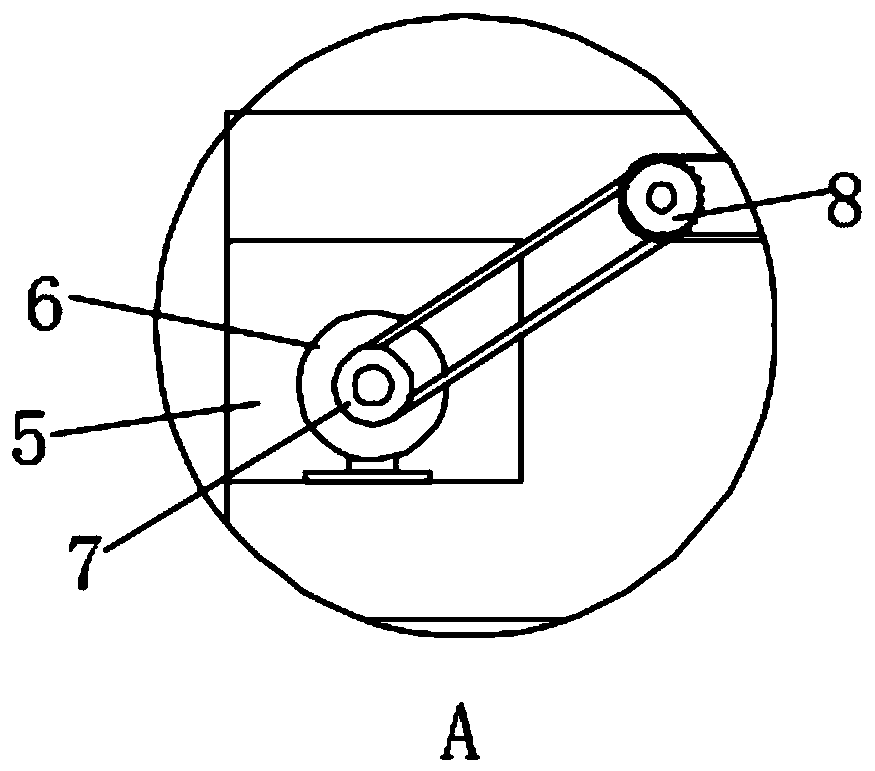

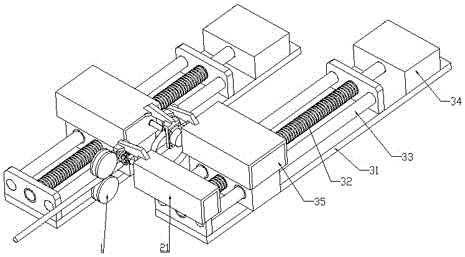

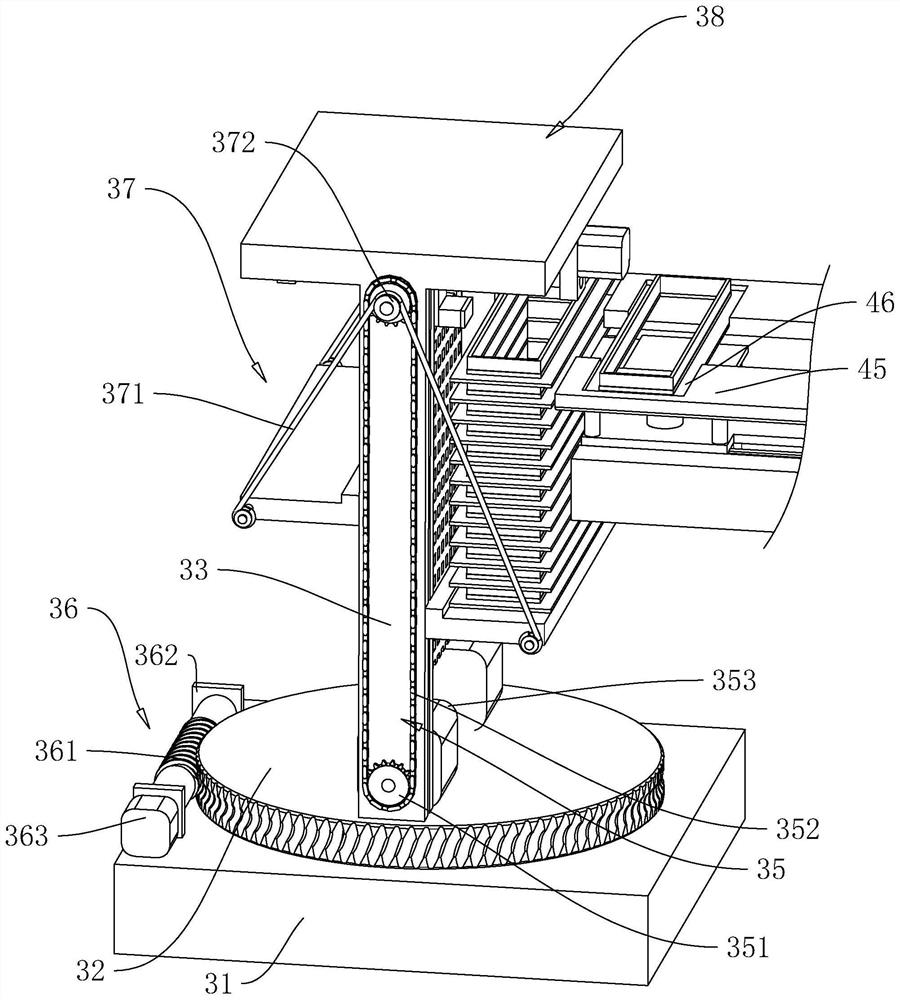

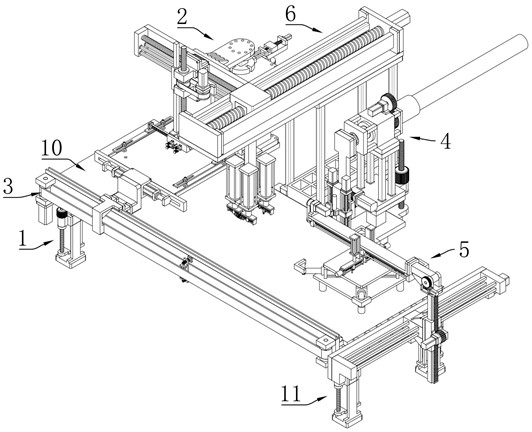

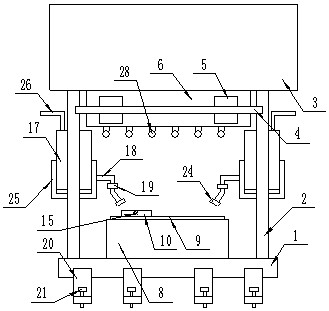

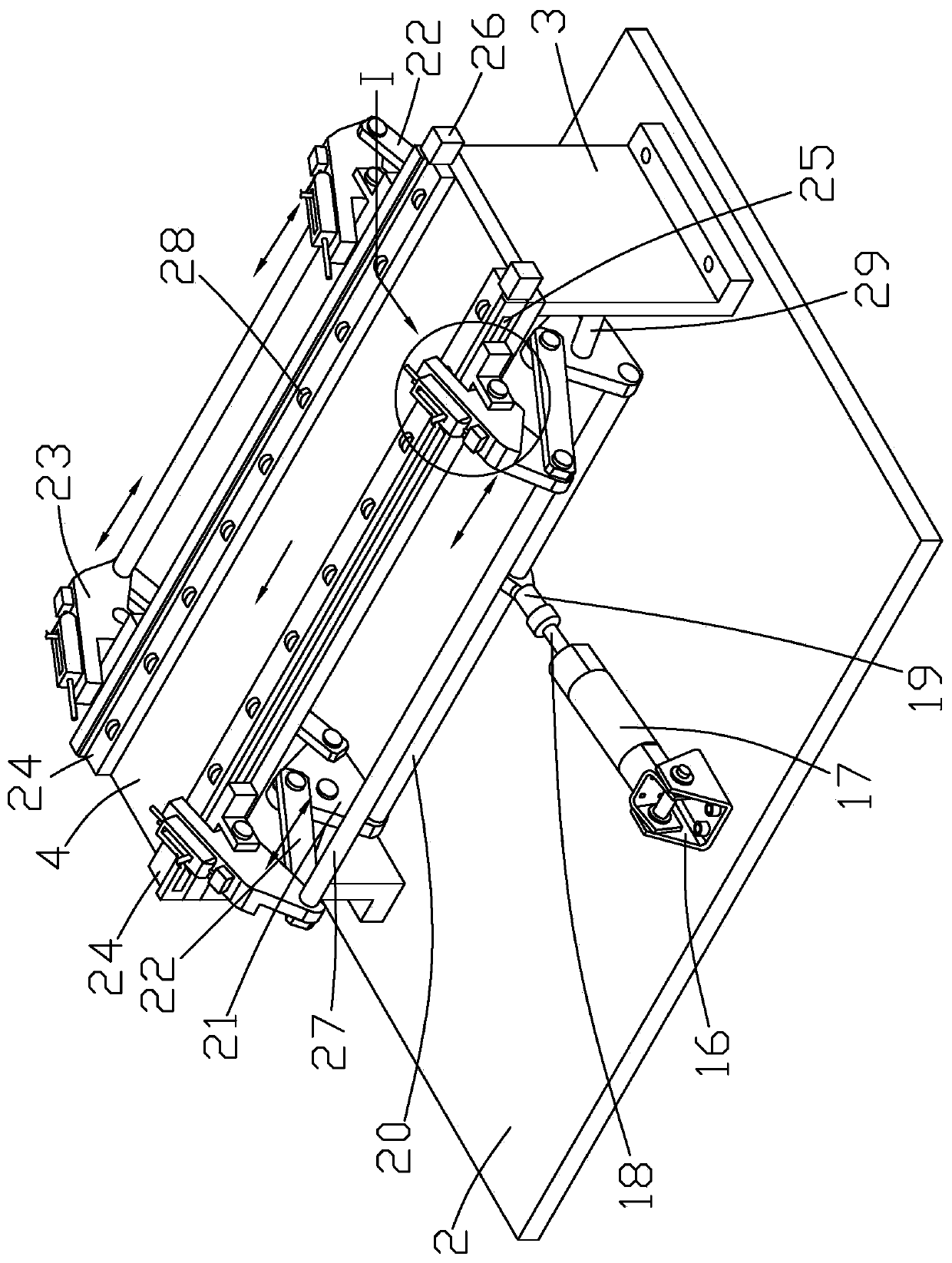

Automatic line shifting device for refractory brick production line

InactiveCN108298309AReduce distanceEasy for automatic loadingConveyorsControl devices for conveyorsAutonomationOccupational disease

The invention discloses an automatic line shifting device for a refractory brick production line, and belongs to the field of refractory brick manufacturing. The automatic line shifting device is usedfor transfering pressed and shaped refractory bricks on conveying lines in different directions, meets the using requirements of an intelligent production line of the refractory bricks, can be automatically folded in the process of transferring refractory brick adobe, reduces the distance between the refractory brick adobe, is convenient for subsequent automatic loading, does not need manual participation in the whole process, and realizes full automatic operation. The intelligent production line is used for making the refractory brick, personal injury and production safety risks in the production process are greatly reduced, the influence of dust on the health of the personnel in the brick pressing process is reduced, the labor intensity is reduced, the problem of difficult employment issolved, the production efficiency is improved, and the production capacity is expanded. The unit land output rate is increased, equipment investment is reduced, personnel investment is reduced, and expenditures in accident and occupational disease expenditures are reduced, and great benefits are brought to enterprises and local economies.

Owner:希望银蕨智能科技有限公司

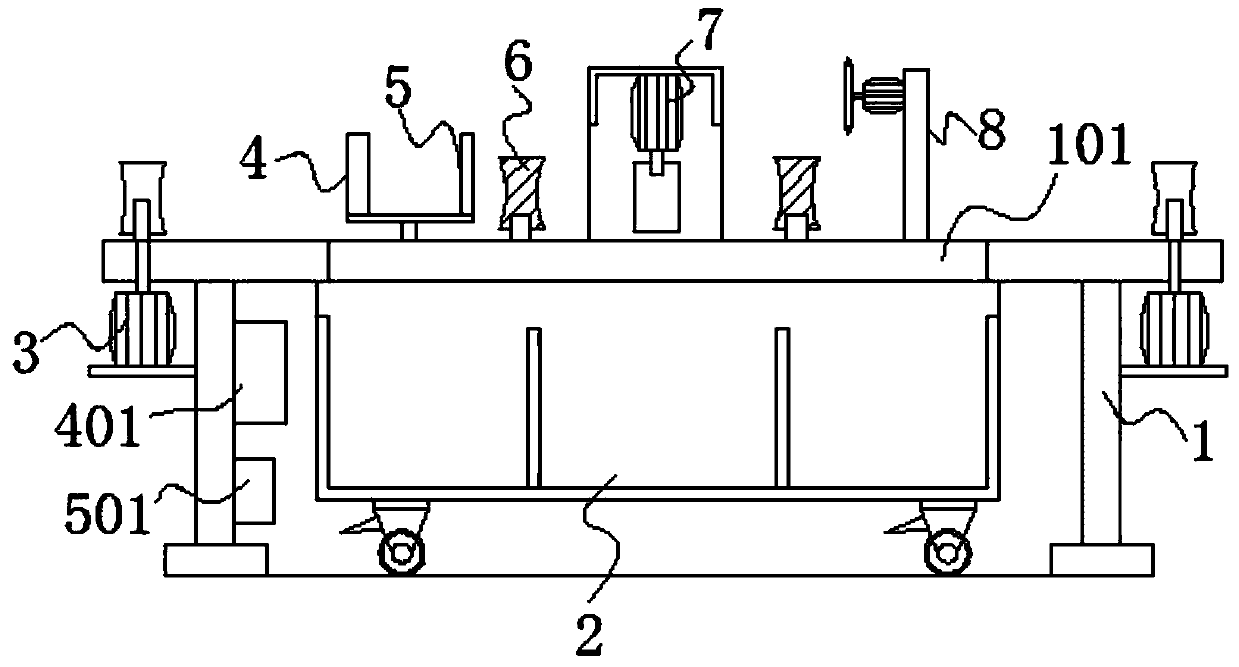

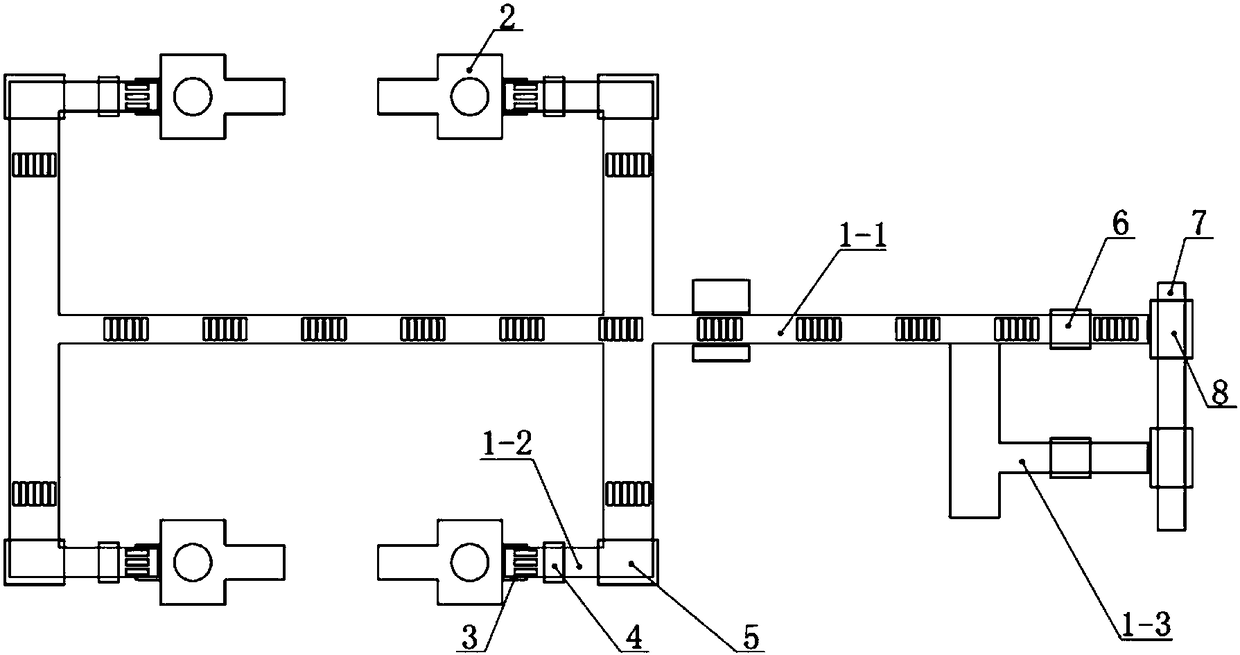

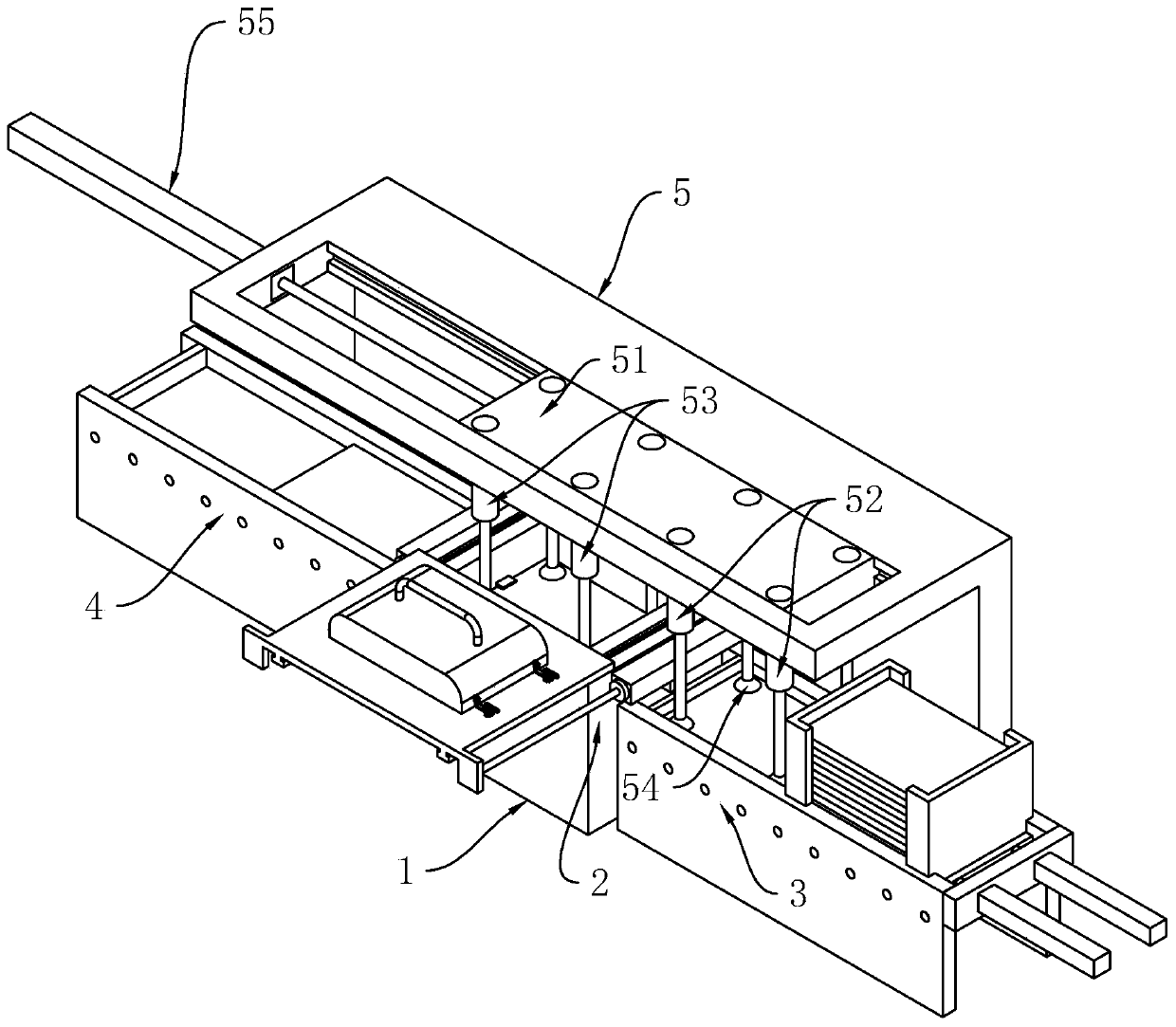

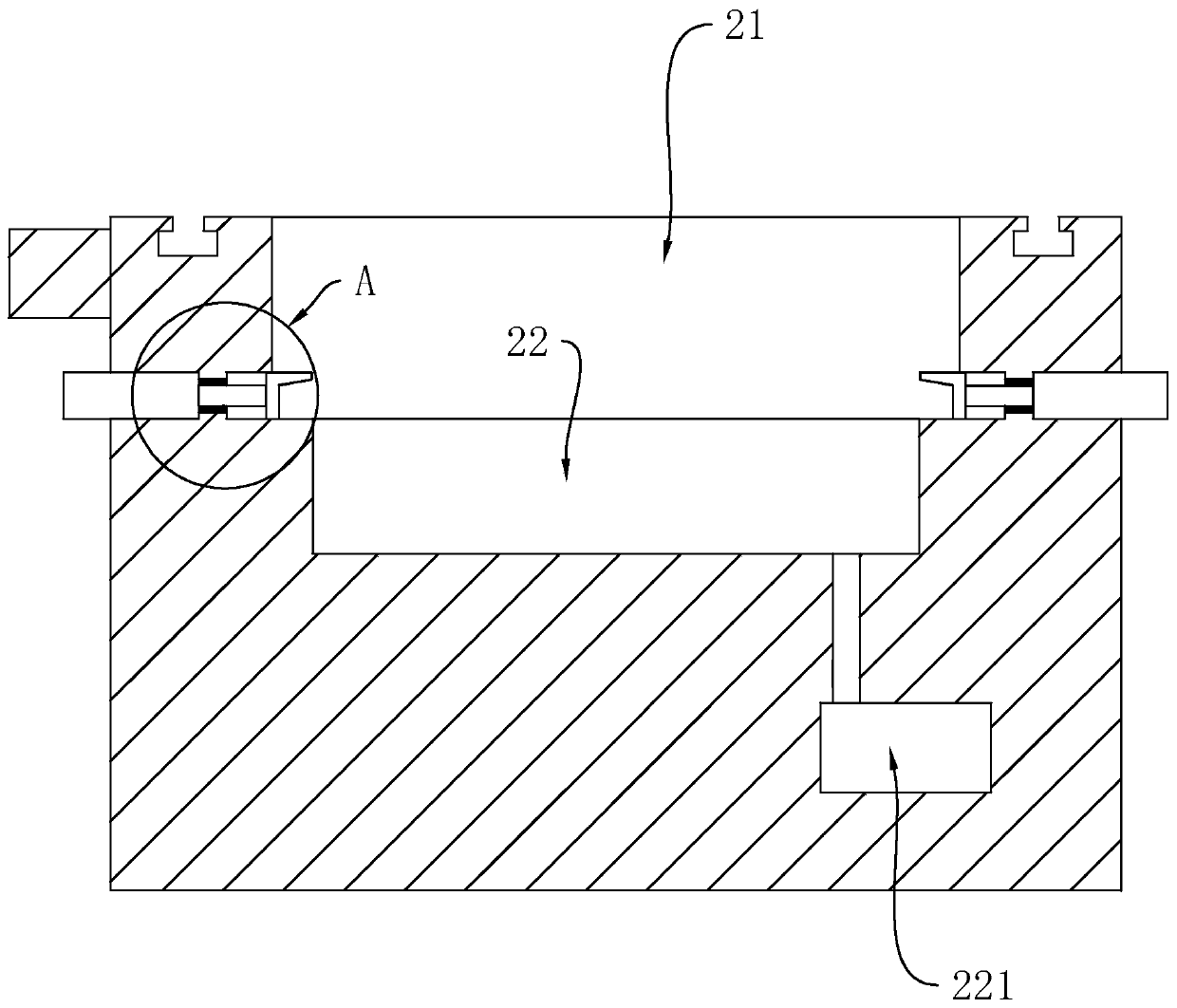

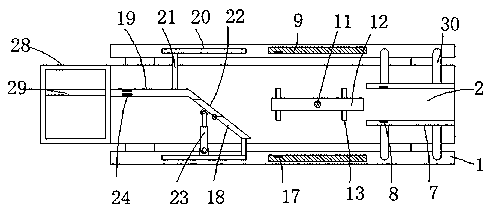

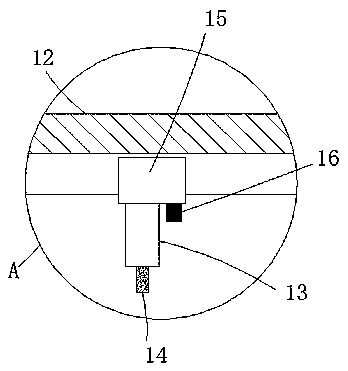

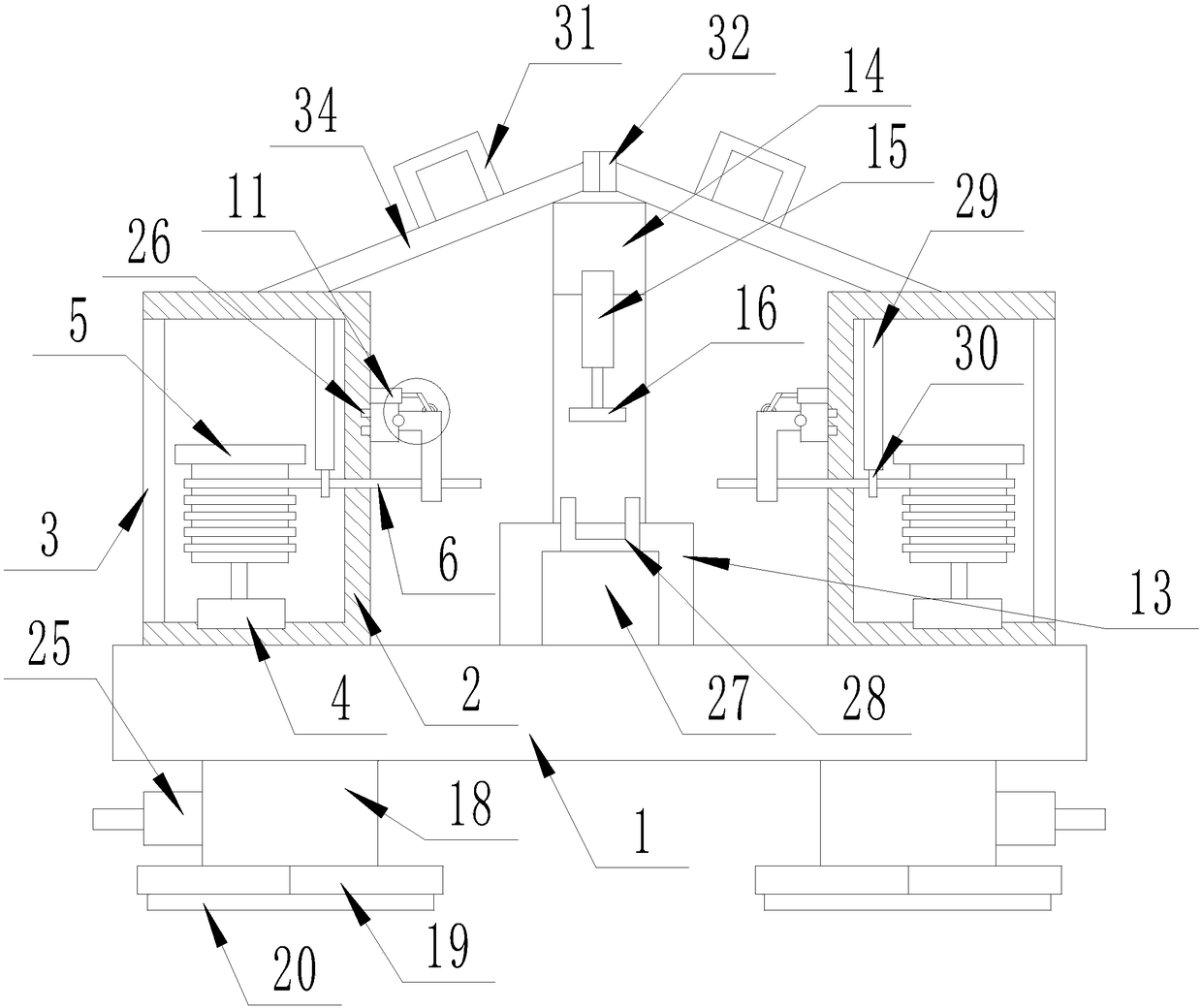

Door and window air tightness detection device

ActiveCN110987327AAir tightness observationEasy for automatic loadingFluid-tightness measurement by detecting dimension changeMachineAir tightness

The invention relates to a door and window air tightness detection device. The door and window air tightness detection includes a base; a detection body is fixedly connected to the middle of the base;a feeding table and a discharging table are arranged at the two ends, corresponding to the detection machine body, of the base. A containing groove is formed in the middle of the upper side of the detection machine body, a clamping device is arranged in the detection machine body, a detection cavity is formed in the lower side of the containing groove, an inflation device is further arranged in the detection machine body, a cover plate is further arranged on the upper side of the detection machine body, and an elastic sealing film is fixedly connected to the middle of the cover plate. The feeding table is fixedly connected with a limiting frame, the upper side of the base is fixedly connected with a supporting frame, the supporting frame is slidably connected with a sliding frame, the twoends of the sliding frame are fixedly connected with a feeding telescopic cylinder and a discharging telescopic cylinder correspondingly, the lower ends of the feeding telescopic cylinder and the discharging telescopic cylinder are both fixedly connected with pneumatic suction cups, and the supporting frame is further provided with a pushing mechanism capable of pushing the sliding frame to reciprocate. The door and window air tightness detection device has the effect that the door and window can be automatically assembled in the detection device for detection.

Owner:深圳市深科工程检测有限公司

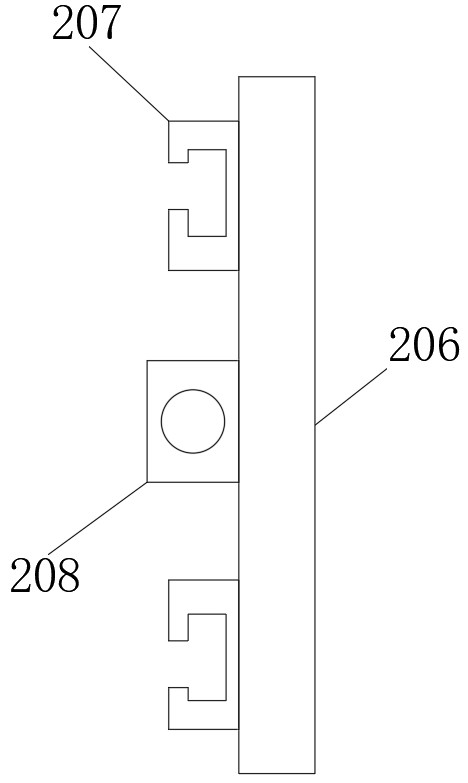

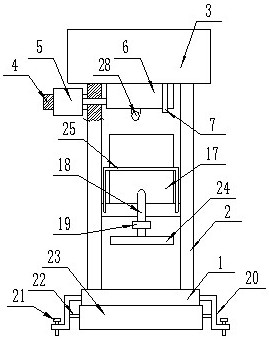

Switch cabinet quick assembling tool

The invention discloses a switch cabinet quick assembling tool. The switch cabinet quick assembling tool comprises a fixed frame, supporting legs, rotation shafts, rollers, a sliding board, supportingcolumns, a first gear, a second gear, a fixed plate, a sliding groove, a sliding block, a rotating plate, connecting plates, an electric push rod, clamping frames, a switch cabinet frame, a rotatingrod, a rocker, a first motor, a moving plate, a second motor, a reel, a connecting rope, an adsorption plate, an air pump, a suction pipe and rubber suction cups. The switch cabinet quick assembling tool is simple in structure and novel in design, facilitates the automatic feeding of side boards which need to be installed to ensure the stability of the side boards in the feeding process, greatly reduces the labor intensity of workers, improves the feeding efficiency of the side boards of a switch cabinet, and facilitates the use of the worker; under the action of arranged fixed clamping mechanisms, the switch cabinet frame which needs to be assembled is stabilized and fixed conveniently to facilitate the stabilization of the side boards in the process of installing the switch cabinet, theinstallation accuracy of the side boards and the switch cabinet is improved, and installation is facilitated.

Owner:上电电气(江苏)有限公司

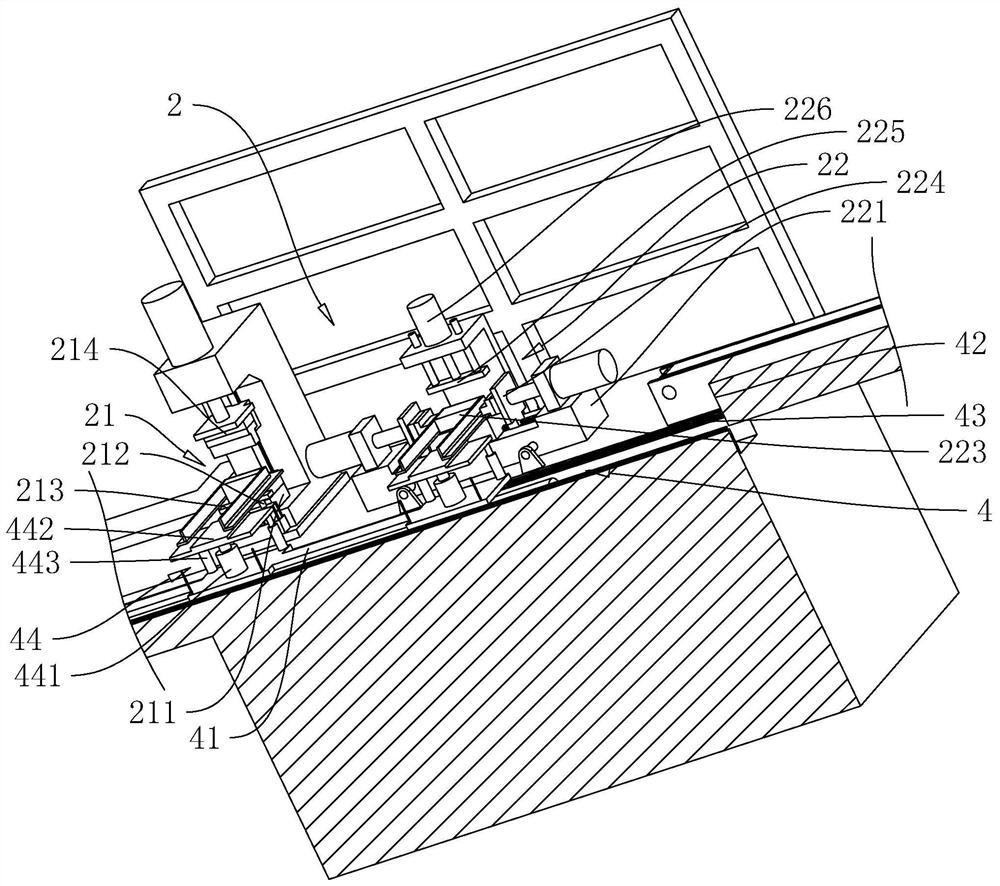

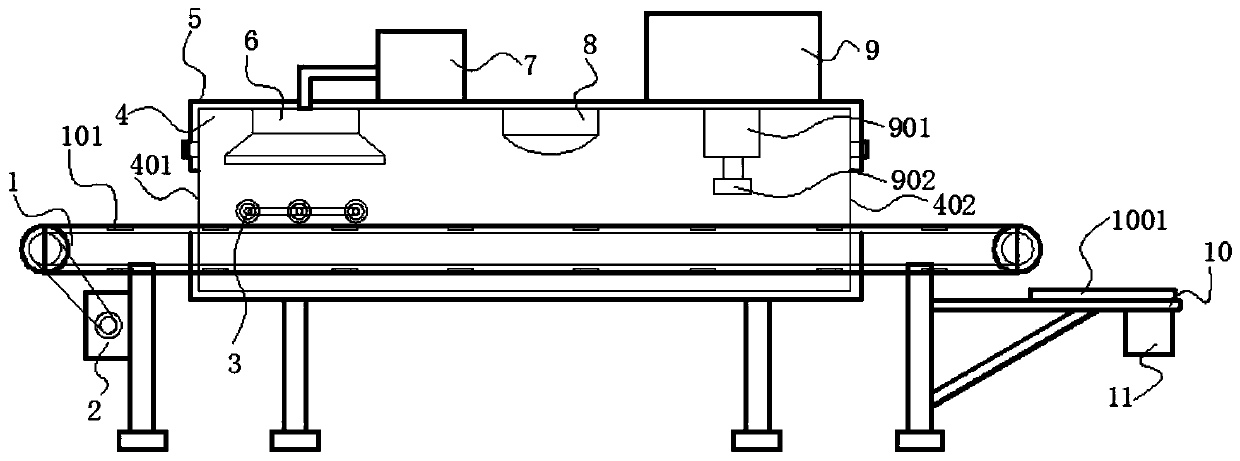

Pressing buckle type flat cable detection device

InactiveCN110935654AFacilitate automatic intermittent feedingFacilitates automatic position detectionPrinted circuit testingSortingStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of flat cable detection, and discloses a pressing buckle type flat cable detection device. The pressing buckle type flat cable detection device comprises adetection table, a feeding mechanism, a detection mechanism, a sorting mechanism and a discharging mechanism, wherein a detection conveying belt is arranged at the upper end of the detection table, the feeding mechanism is arranged on the right side of the detection table; the feeding mechanism comprises a feeding box; the upper end of the feeding box extends to the upper part of the detection conveying belt, and the lower end of the feeding box extends to the lower part of the detection conveying belt; a feeding conveying belt is arranged below the interior of the feeding box; a spring is fixedly connected to the upper inner side wall of the feeding box; the lower end of the spring is fixedly connected with a lower pressing plate; a feeding port is formed in the lower part of the side wall of one side, close to the detection conveying belt, of the feeding box; and the feeding conveying belt and the upper side wall of the detection conveying belt are arranged at the same height. According to the pressing buckle type flat cable detection device, to-be-detected flat cables with different lengths can be automatically fed, detected, sorted and collected, the automation degree is high,the detection efficiency is improved, the labor force is saved, and the use by people is facilitated.

Owner:惠州硕贝德电子有限公司

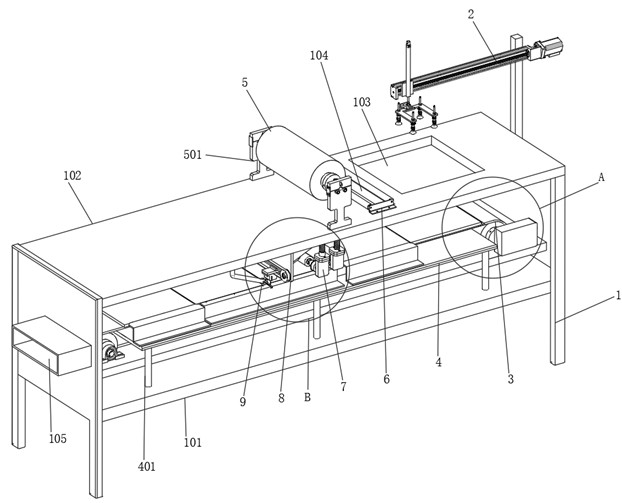

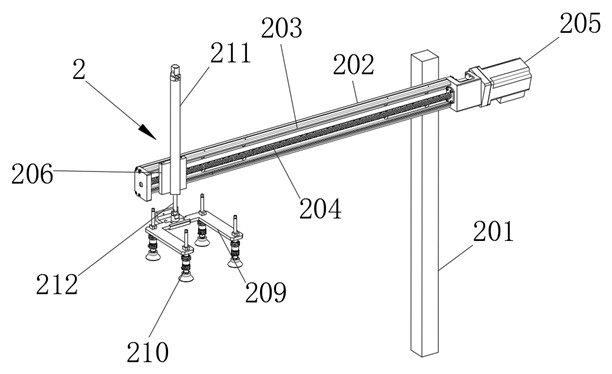

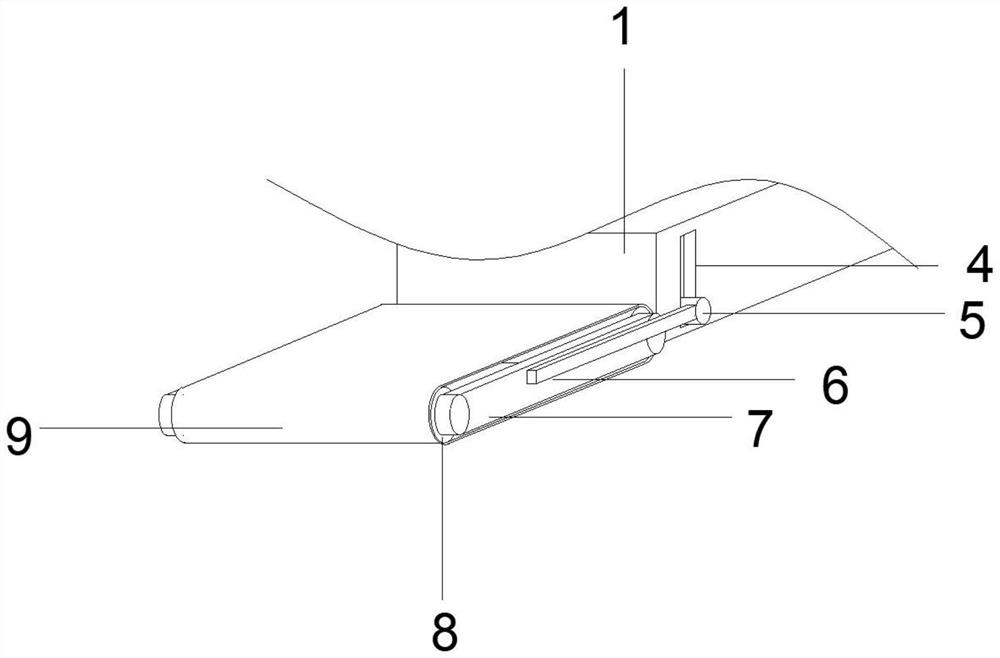

Film coating equipment for photovoltaic solar module production and working method thereof

ActiveCN114311644AHigh degree of automationAvoid injuryFinal product manufacturePhotovoltaic energy generationPhotovoltaic solar energyEngineering physics

The invention relates to the technical field of photovoltaic solar module film covering, in particular to film covering equipment for photovoltaic solar module production and a working method thereof.The film covering equipment comprises a supporting frame, a feeding assembly, a conveying assembly, a film covering roller, a film covering assembly, a film cutting assembly and a film pressing wheel; according to the film laminating equipment, the film laminating roller and the film laminating assembly are used for laminating in the conveying process, and the connected film is cut by the film cutting assembly, so that the film laminating equipment can be used for automatically laminating the photovoltaic solar panel in a streamlined manner, and all links of the film laminating equipment do not need to be manually operated by automatically laminating the film, so that the labor intensity of workers is reduced, and the production efficiency is improved. Compared with the prior art, labor is saved, meanwhile, the situation that personnel are hurt by the equipment or the photovoltaic solar panel in the manual operation process is avoided, and meanwhile, through film laminating streamline of the equipment, all links of film laminating of the equipment are matched more tightly, and the film laminating speed is higher.

Owner:ANHUI GUOCHENG PHOTOELECTRIC TECH CO LTD

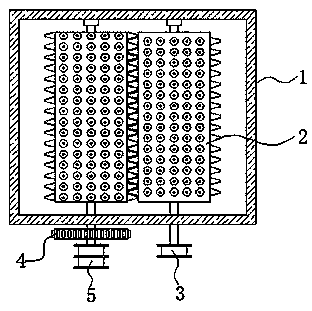

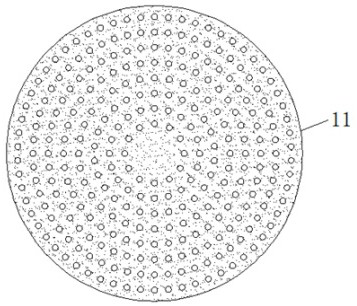

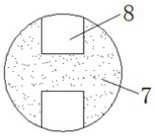

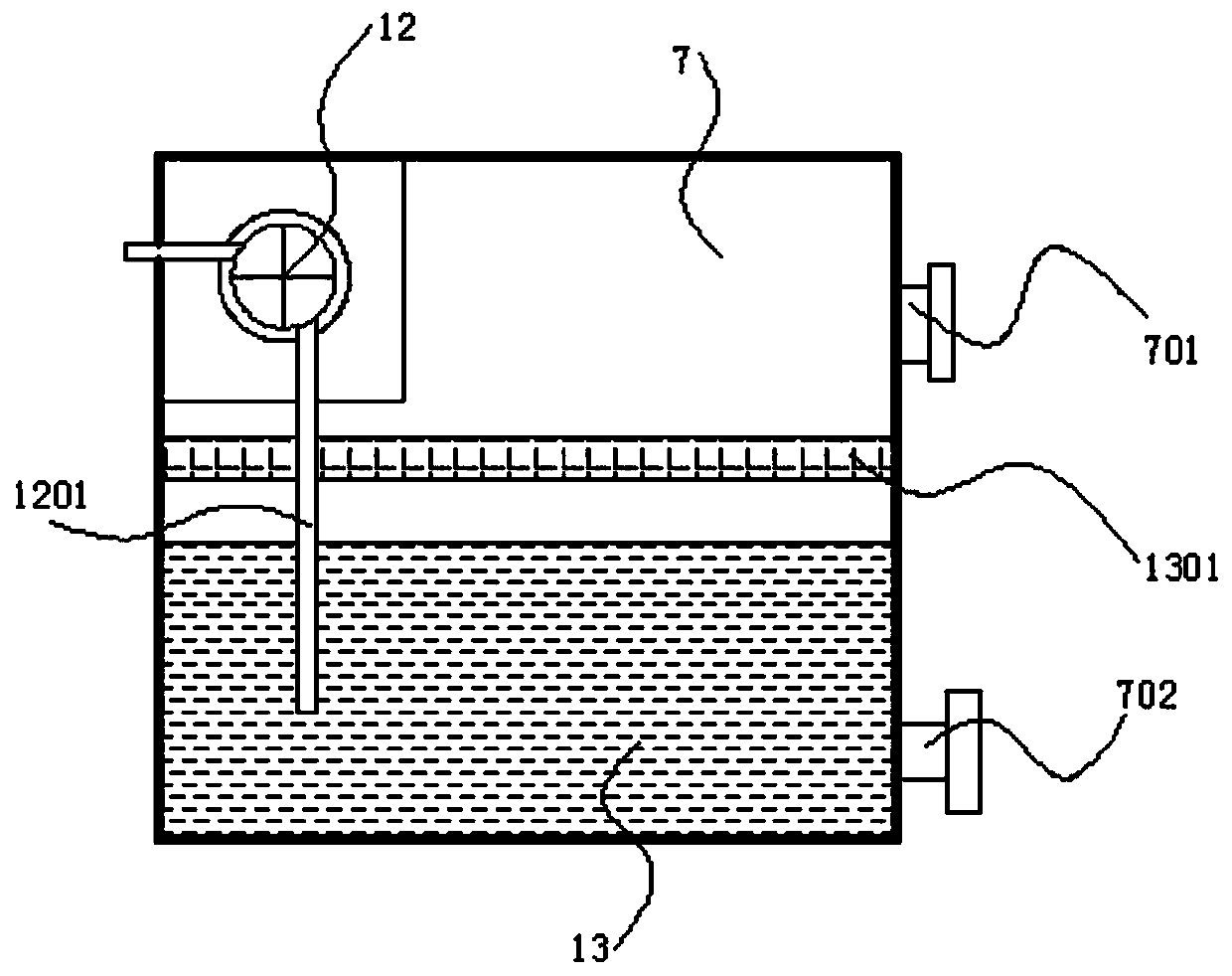

High-temperature sterilization device for fresh corn packaging

InactiveCN112042737ADoes not cause buildupIt will not cause the problem of being piled up and unable to be completely sterilizedSeed preservation by heatingMaterial storageElectrical and Electronics engineering

The invention discloses a high-temperature sterilization device for fresh corn packaging, relates to the technical field of corn processing, and provides the following scheme for solving the problem that existing high-temperature sterilization equipment cannot thoroughly sterilize stacked corn: the high-temperature sterilization device comprises a box body, and a supporting plate is fixedly connected to the inner wall of the left side of the box body; the top of the supporting plate is fixedly connected with a driving feeding mechanism; the outer wall of the top of the box body is fixedly connected with a material storage barrel; the inner wall of the right side of the box body is fixedly connected with a material pushing baffle; a disc rotationally connected to the supporting plate is arranged below the material pushing baffle; a plurality of air holes are formed in the disc in an array mode; and a transmission mechanism is arranged between the disc and the driving feeding mechanism.According to the high-temperature sterilization device, automatic feeding is facilitated, corns are conveniently and uniformly distributed and prevented from being stacked together, continuous sterilization is facilitated, the sterilization efficiency and quality are guaranteed, automatic discharging can be achieved, manual taking is not needed, and workers are prevented from being scalded.

Owner:濉溪县双兴农产品种植专业合作社

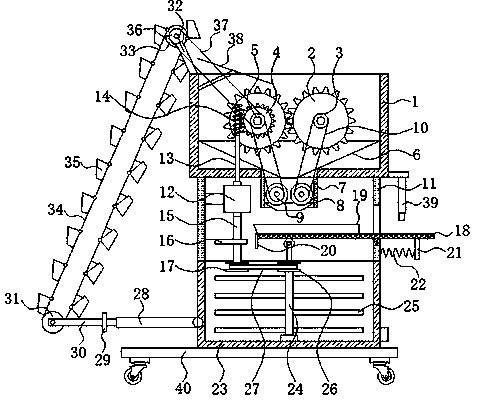

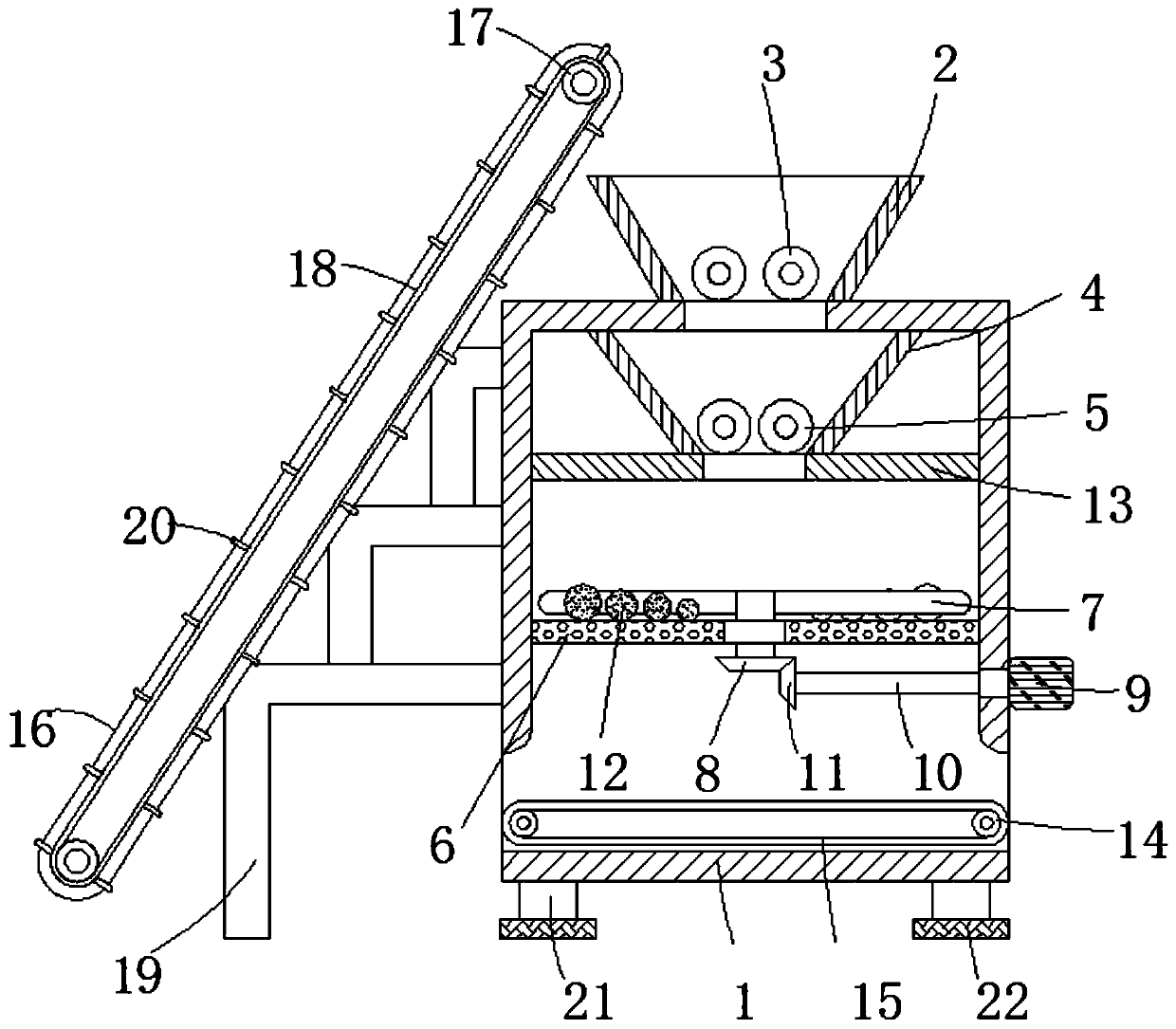

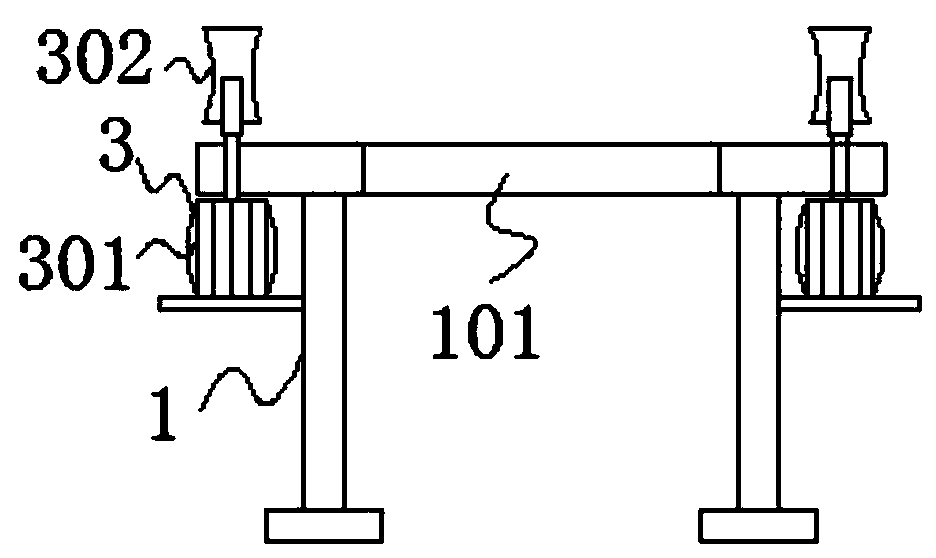

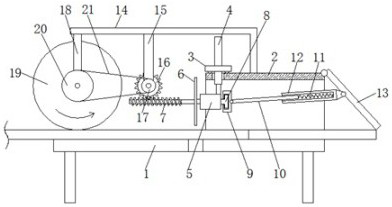

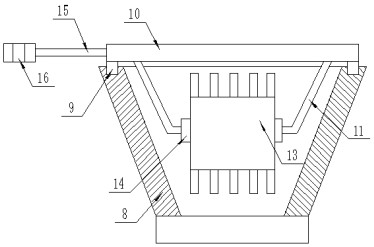

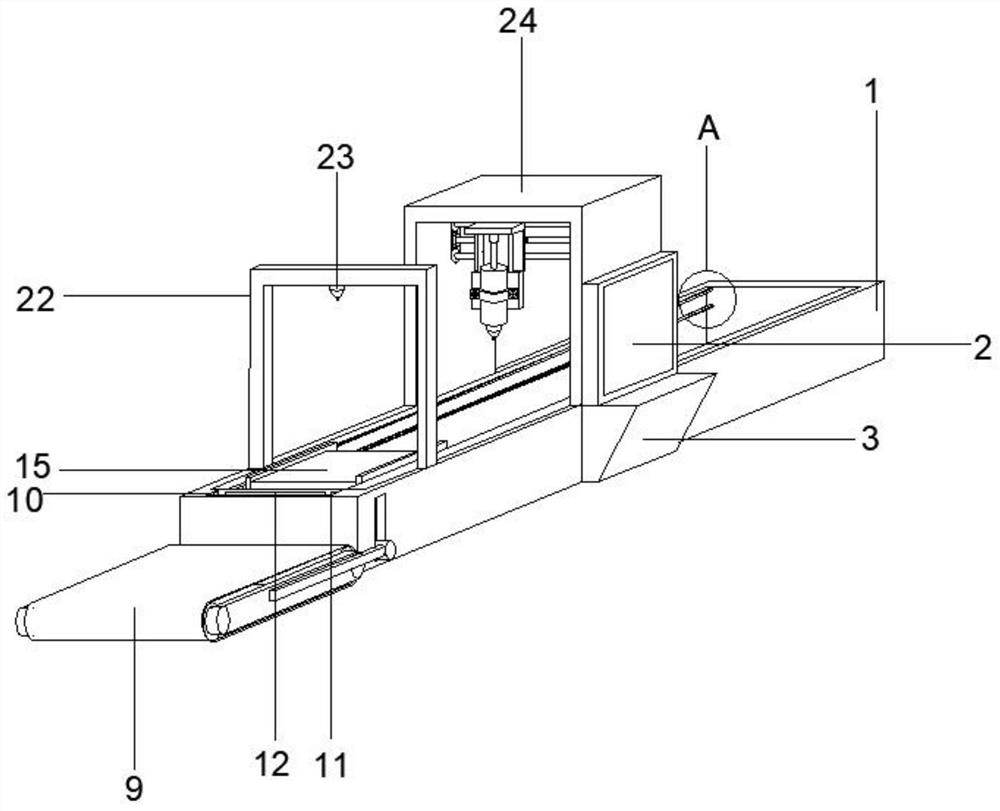

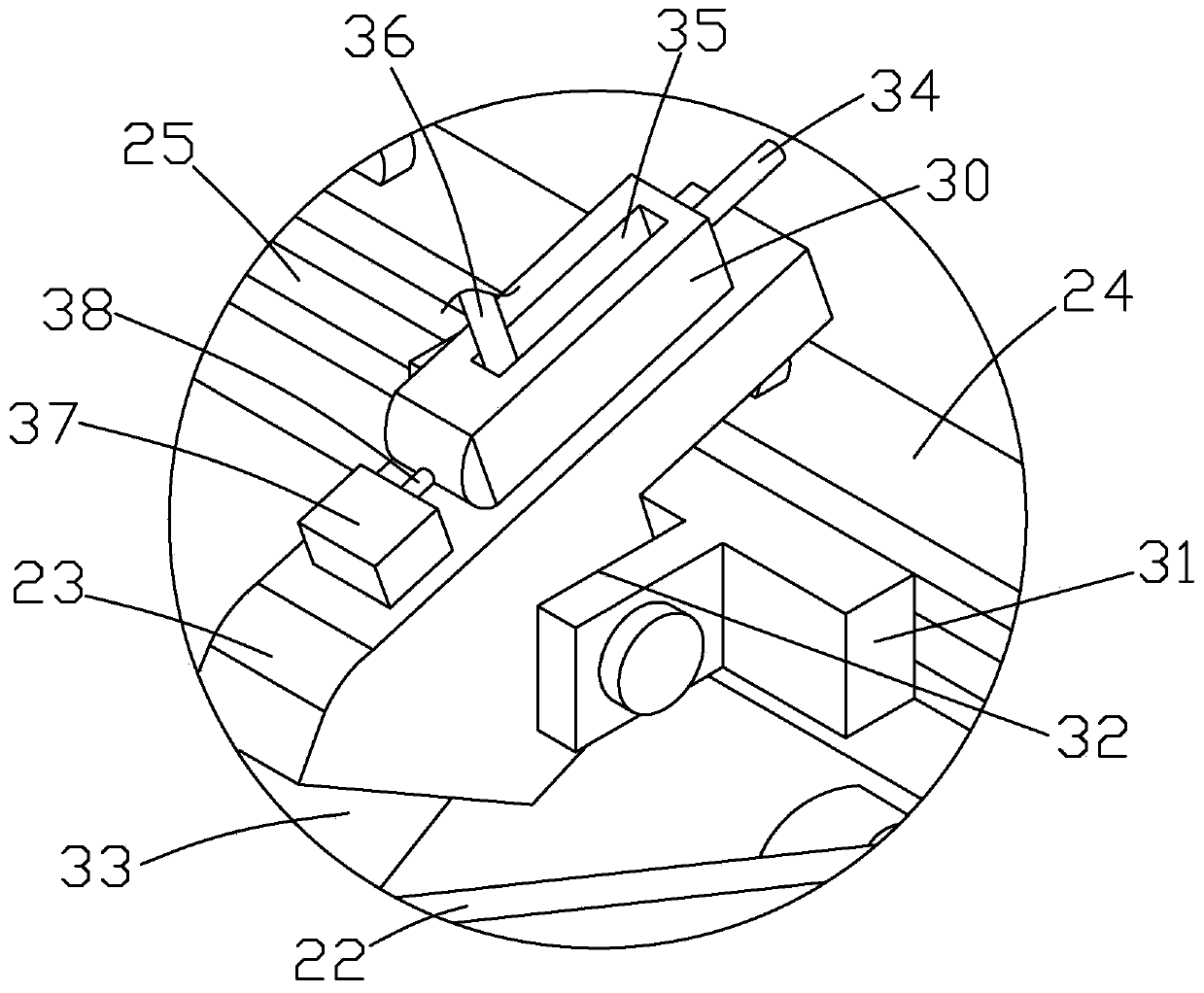

Efficient multi-sawtooth thicknessing machine for trees

InactiveCN111391026AEasy for automatic loadingReduce labor intensityThicknessing machinesElectric machineryEngineering

The invention discloses an efficient multi-sawtooth thicknessing machine for trees. The efficient multi-sawtooth thicknessing machine comprises a machining mechanism and a feeding mechanism, the machining mechanism is composed of a workbench, a control panel, a mounting groove, a first servo motor, a driving chain wheel, a driven chain wheel, cutting rollers, a supporting frame, a pressing air cylinder, a fixing frame, a driven pressing roller, a driving pressing roller, a first driven belt wheel, a second servo motor and a driving belt wheel, and a material conveying groove is formed in the top of the workbench. According to the efficient multi-sawtooth thicknessing machine for the trees, the structure is simple and flexible; through the arrangement of a feeding motor and a conveying motor, during work, automatically feeding on materials can be conveniently carried out through a clamping plate and a lifting electric telescopic rod, manual feeding is avoided, the labor intensity of workers is reduced, the feeding speed is increased; and through the arrangement of the pressing rollers and the plurality of cutting rollers, under the condition that the plurality of cutting rollers work at the same time, the cutting speed is greatly increased, the machining time is shortened, and the machining efficiency is greatly improved.

Owner:WENZHOU CHUYING TECH CO LTD

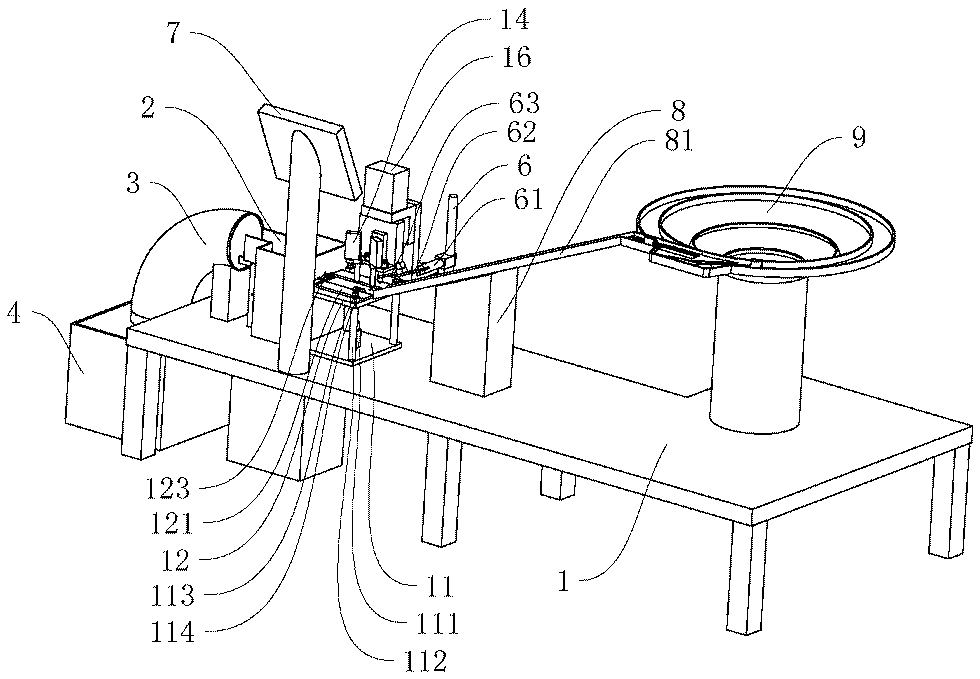

Automatic steel wire rope circular ring welding device

ActiveCN106466755AHas a guiding roleEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterial supply

The invention discloses an automatic steel wire rope circular ring welding device which comprises a material supply device, a steel wire rope fusing device, a first welding device and a second welding device which are arranged in sequence, wherein a fusing inner clamping claw and a fusing outer clamping claw in the steel wire rope fusing device are combined together to form a fusing opening; inner clamping claws and outer clamping claws in the first welding device and the second welding device are combined together to form welding openings; the fusing opening and the welding openings are concentrically and correspondingly arrayed; a driving wheel and a driven wheel in the material supply device supply one end of a steel wire rope into the steel wire rope fusing device, the first welding device and the second welding device in sequence; the fusing opening in the steel wire rope fusing device and the welding openings in the first welding device and the second welding device respectively clamp the steel wire rope; and after the fusing inner clamping claw and the fusing outer clamping claw fuse the other end of the steel wire rope through an electric heating device, the inner clamping claws and the outer clamping claws respectively carry out rotating, butt jointing and welding operation on two ends of the steel wire rope. The device is high in working efficiency and high in product quality.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

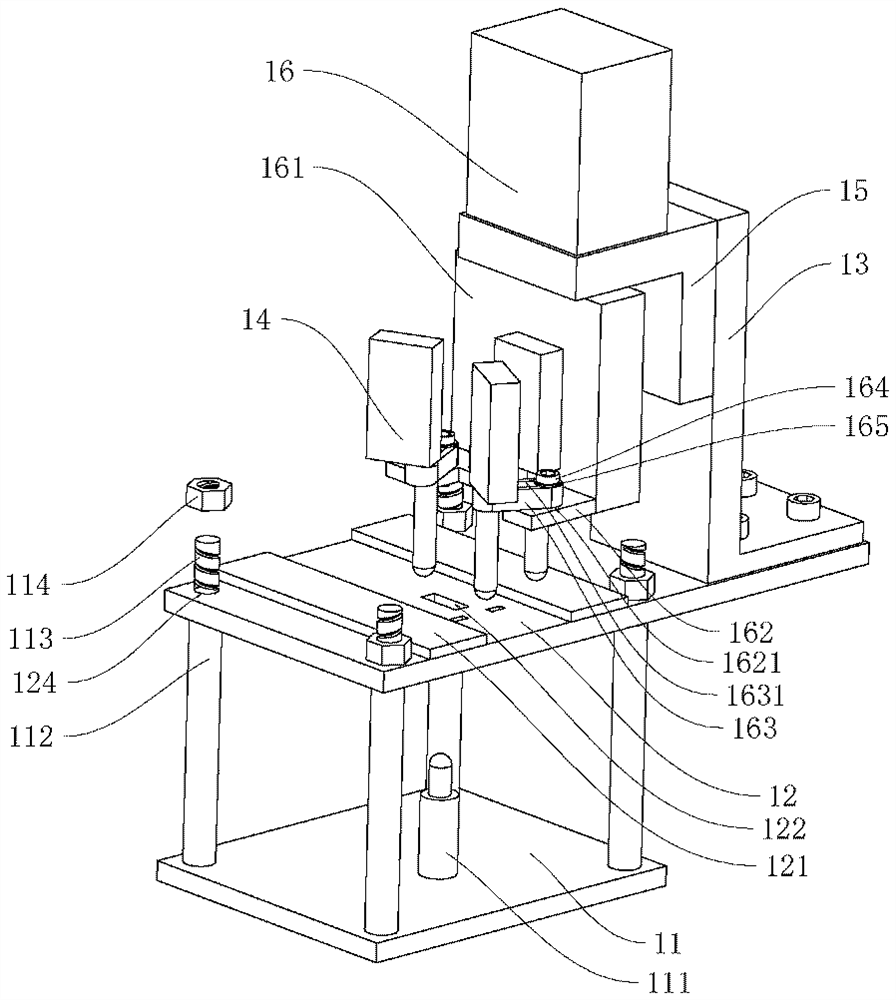

Automatic riveting device

The invention relates to an automatic riveting device. The automatic riveting device comprises a workbench; a feeding end and a discharging end are arranged on the workbench; a riveting mechanism is arranged on the workbench and used for riveting and fastening sheet metal parts; the feeding end is provided with a feeding mechanism, and the feeding mechanism is used for pushing the sheet metal parts to the workbench one by one for riveting; a material receiving mechanism is arranged at the discharging end and used for collecting and stacking the riveted sheet metal parts; a pushing mechanism isarranged in the position, below the riveting mechanism, of the workbench; and the pushing mechanism is used for transferring the riveted sheet metal parts to the material receiving mechanism, transferring to-be-riveted sheet metal parts on the feeding mechanism to the riveting mechanism and conveying the riveted sheet metal parts to the material receiving mechanism. The automatic riveting devicehas the effects of conveniently and automatically feeding materials and reducing the labor force of workers.

Owner:湖南泰川宏业有限公司

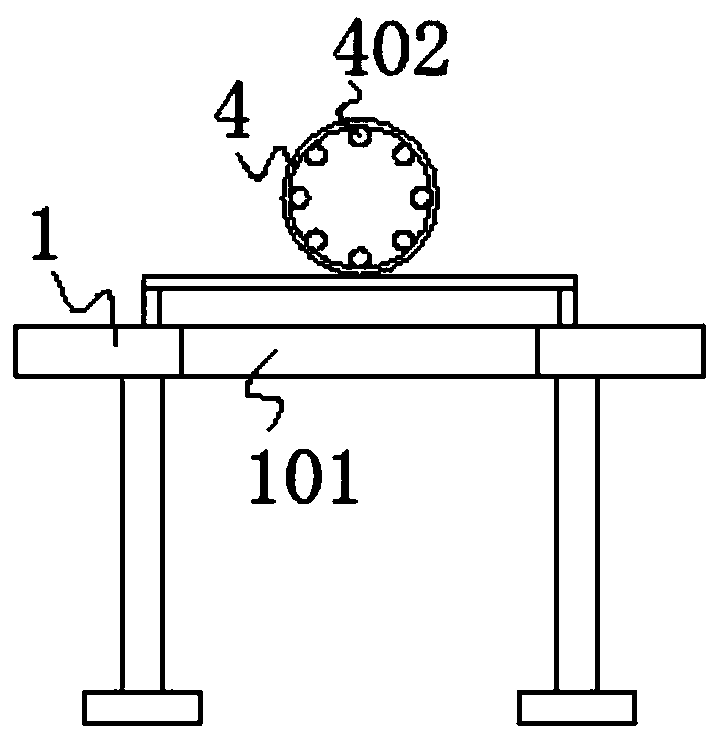

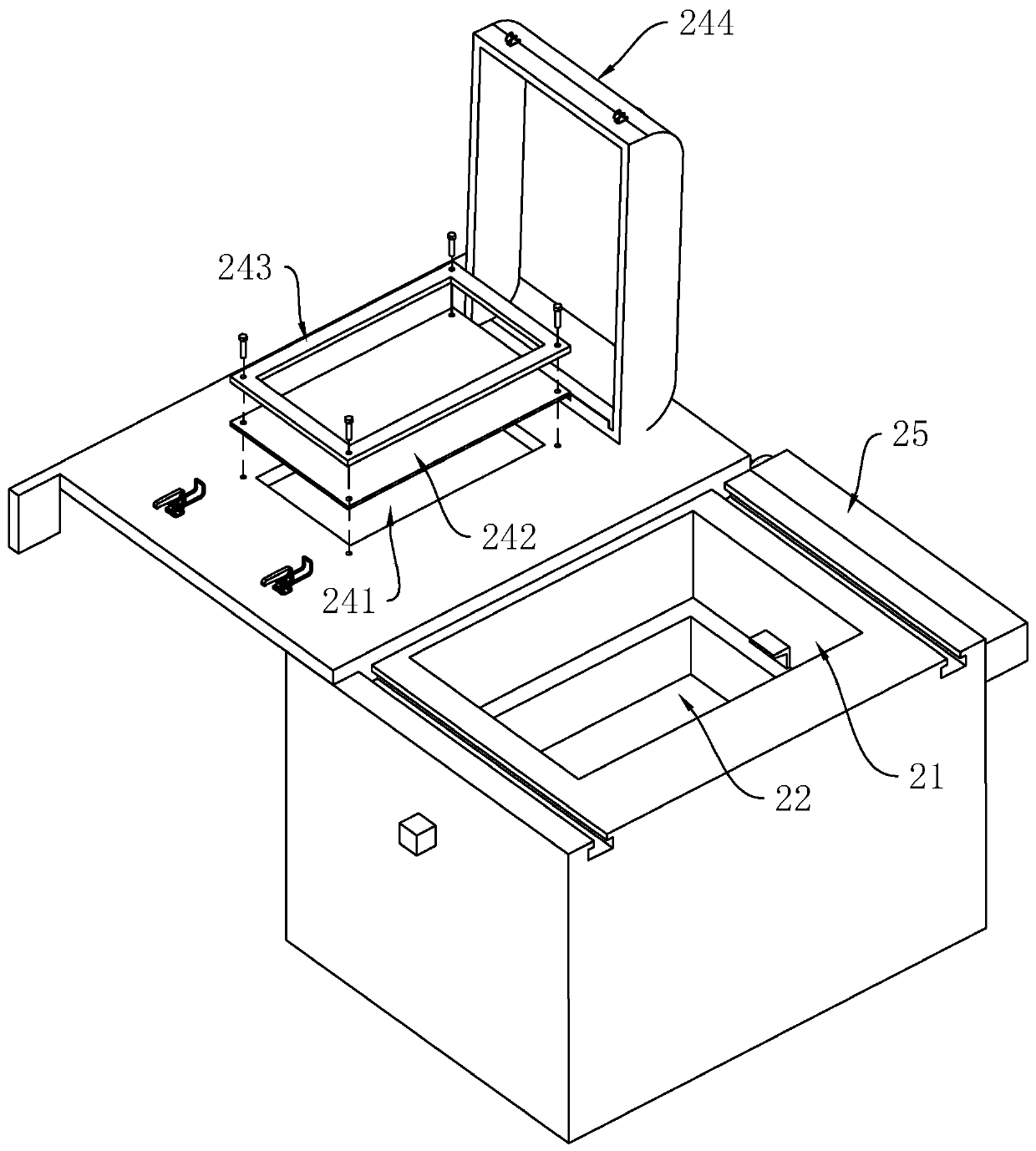

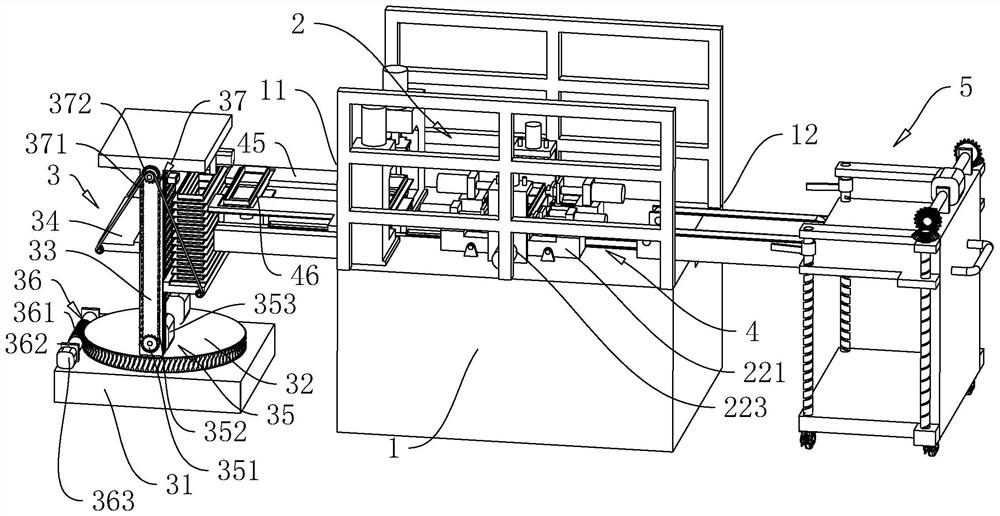

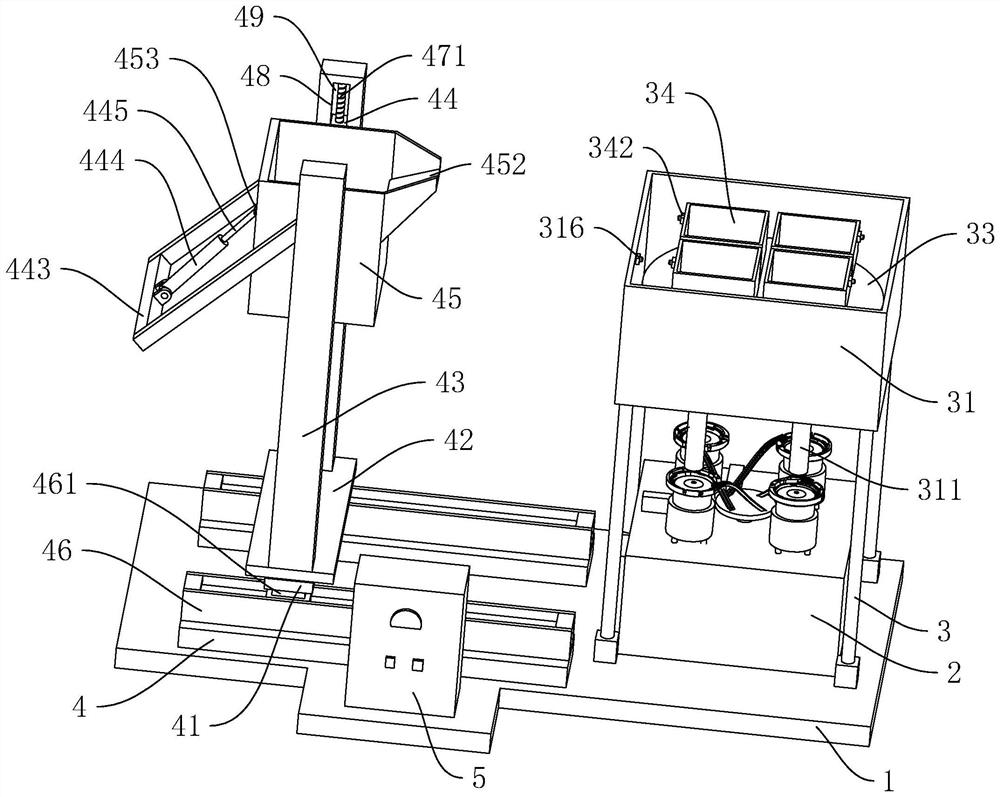

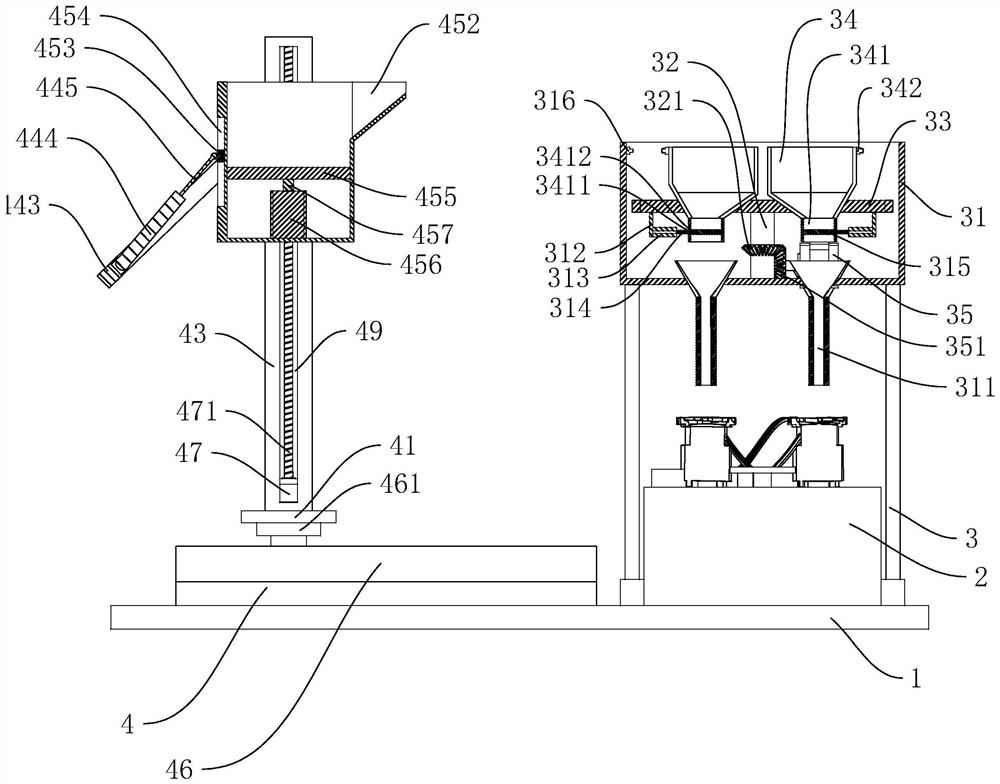

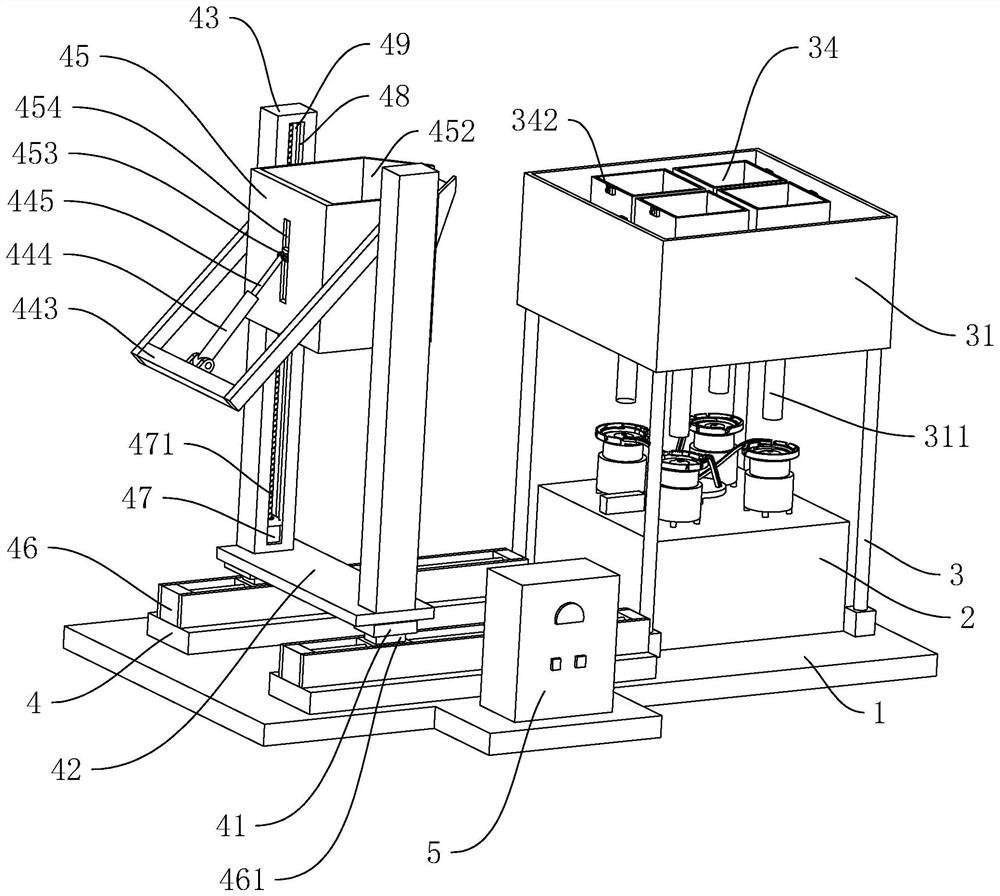

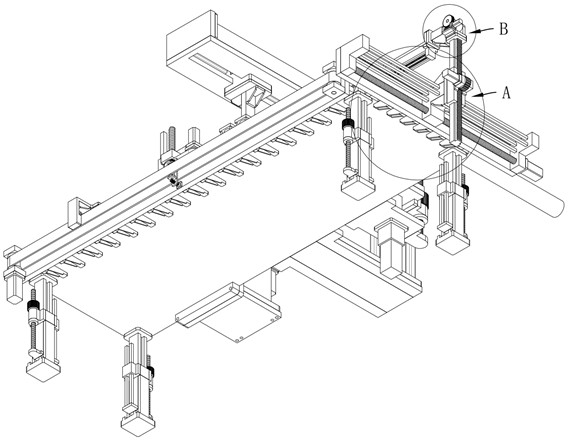

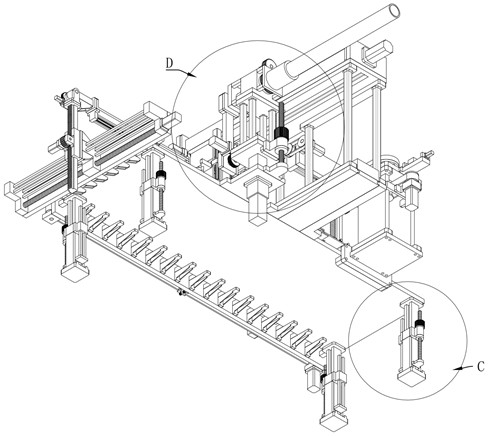

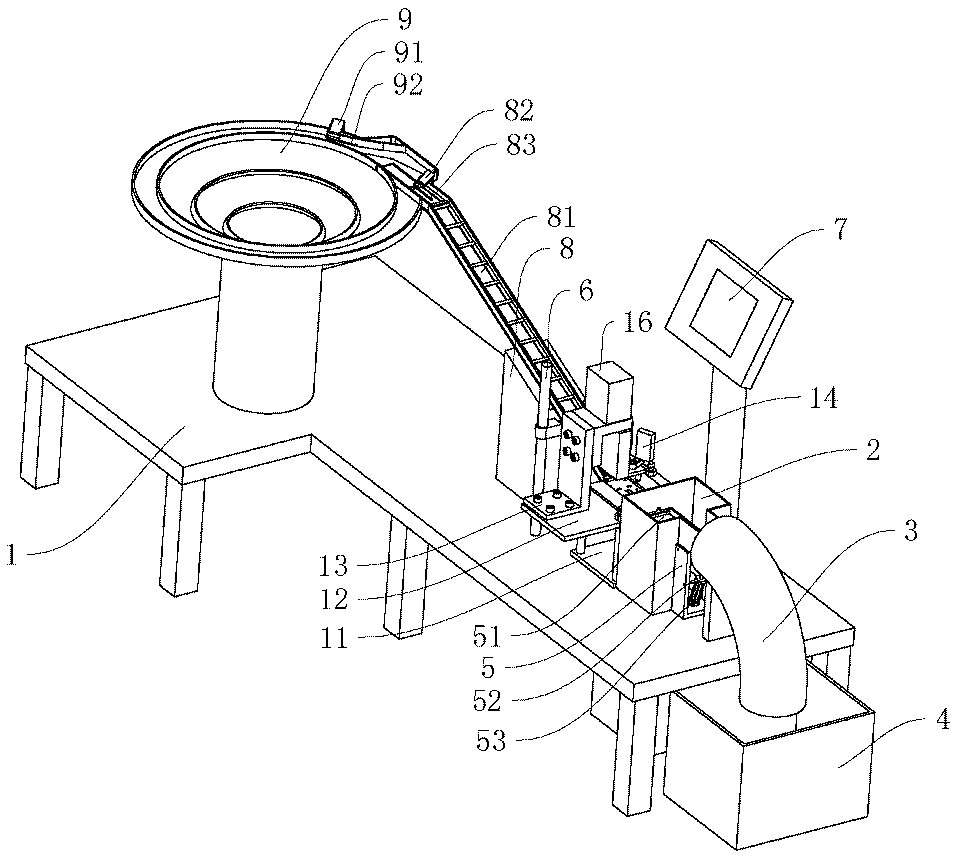

Full-automatic four-point assembling machine

ActiveCN111906535AEasy for automatic loadingRealize the effect of automatic feedingAssembly machinesMetal working apparatusCircular discMachine

The invention relates to a full-automatic four-point assembling machine. The full-automatic four-point assembling machine comprises a base and an assembling machine body, wherein a feeding device is arranged on the base; the feeding device comprises a plurality of bearing rods arranged on the base, a bearing box arranged on the bearing rods, a plurality of falling channels communicated to the periphery of the bottom of the bearing box, a rotating shaft rotationally connected to the bottom of the bearing box, a bearing disc arranged at the end, away from the bottom of the bearing box, of the rotating shaft, a plurality of material collecting bins connected to the bearing surface of the bearing disc, discharging pipelines communicated to the bottoms of the material collecting bins and communicated with the falling channels, a driving assembly arranged at the bottom of the bearing box, and a feeding mechanism arranged on one side of the assembling machine body and used for automatically feeding to the material collecting bins. According to the full-automatic four-point assembling machine, the effect of automatically feeding to the assembling machine body can be achieved, so that the labor intensity of workers can be relieved, the situation that wrists of the workers are injured can be reduced, and then the production efficiency of sliders of zipper fasteners can be improved.

Owner:广州品晶五金实业有限公司

Intelligent electric welding device for industrial production

The invention discloses an intelligent electric welding device for industrial production. The device comprises a strip-shaped bearing base, wherein an intelligent electric welding mechanism is arranged on the upper surface of the strip-shaped bearing base, and a fixing mechanism is arranged on the lower surface of the strip-shaped bearing base. The device has the beneficial effects that the use isconvenient, the automatic feeding is facilitated, the welding shape can be adjusted conveniently through control, the multiple welding can be carried out simultaneously, and the efficiency is improved.

Owner:江门市新会区泓安家居用品有限公司

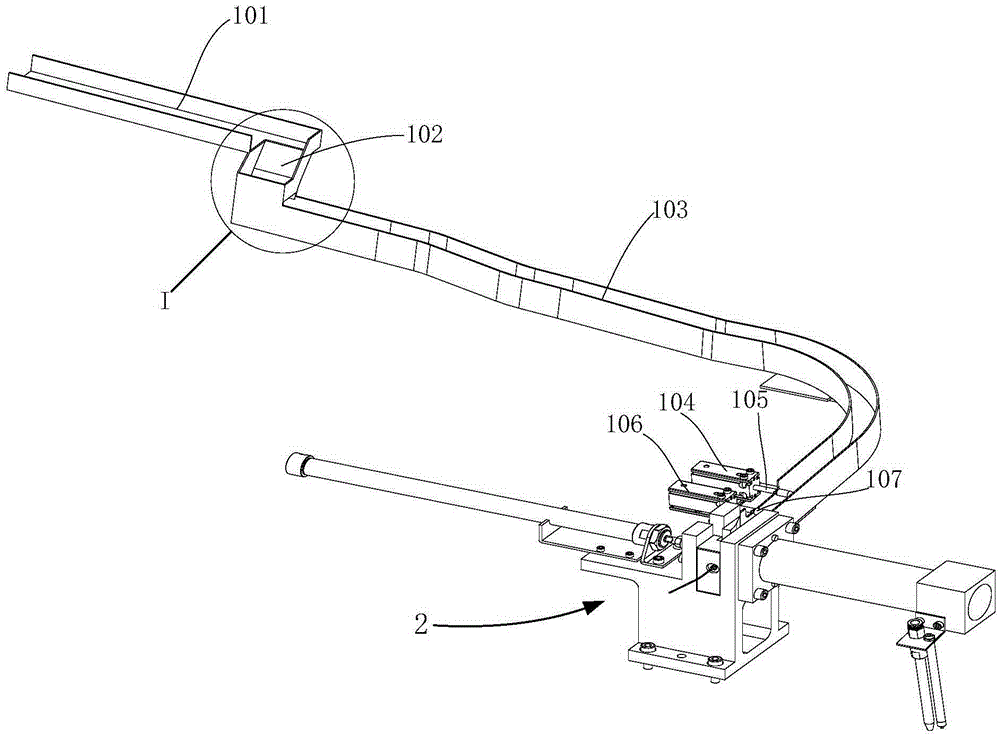

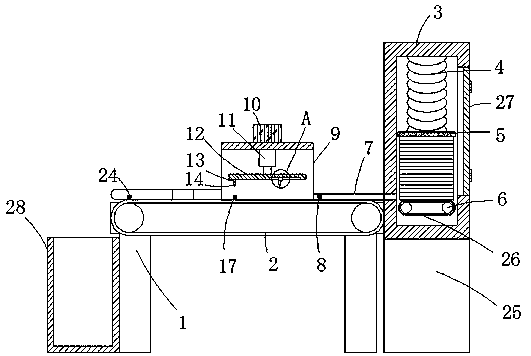

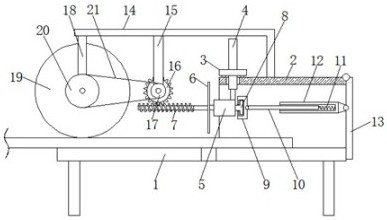

Cutting mechanism used for aluminium product production

InactiveCN111843018AGuaranteed fixed lengthInnovative designShearing machinesShearing machine accessoriesAluminium preparationsElectric machinery

The invention discloses a cutting mechanism used for aluminium product production and relates to the technical field of aluminium product production. For problems that the determining of the cut length of an existing aluminium product is inconvenient during cutting the existing aluminium product and automatic material loading is also inconvenient after cutting is finished, the following scheme isprovided; the cutting mechanism used for aluminium product production comprises a placing plate; a fixing frame is fixedly connected to the right side of the top of the placing plate; a push rod motoris movably arranged at the top of the fixing frame in a sleeving manner; a driving motor is fixedly connected to an output shaft of the push rod motor; a cutting wheel is fixedly connected to an output shaft at the left end of the driving motor; a transmission screw rod is fixedly connected to an output shaft of the cutting wheel; a limiting mechanism is connected to the right side of the drivingmotor; a mounting plate is welded at the top of the fixing frame; and a material feeding mechanism is arranged on the left side of the bottom of the mounting plate. The cutting mechanism used for aluminium product production has the advantages that the cutting mechanism used for aluminium product production is not only convenient to determine the cut length but also convenient to automatic unloadand load materials after the cutting is finished, the machining efficiency is enhanced, and the cutting mechanism used for aluminium product production is suitable for market promotion.

Owner:安徽省裕康铝业有限公司

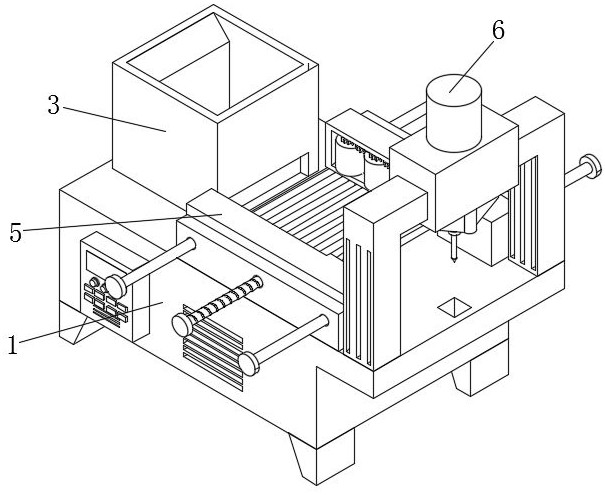

Circuit board drilling machining equipment with guide structure

ActiveCN112776076AEasy for automatic loadingAvoid loading operationsPrinted circuit manufactureMetal working apparatusPunchingGear wheel

The invention relates to the technical field of circuit board machining, in particular to circuit board drilling machining equipment with a guide structure. The equipment comprises a punching device main body and a puncher, a driving mechanism is arranged in the punching device main body, a feeding mechanism is arranged on the surface of the driving mechanism, the feeding mechanism comprises a second gear, and the surface of the driving mechanism abuts against the surface of the second gear. According to the equipment, a driving ring and a pushing block are arranged, through rotation of the driving ring, a transmission rod can reciprocate in the punching device main body, so that the effect of driving a fixing frame to integrally move is achieved, and circuit boards are collected and stacked in a collecting bin; the pushing block is driven by the fixing frame to reciprocate, the circuit boards on the bottommost layer of the collecting bin can be pushed to the surfaces of conveying rollers, so that the circuit boards can be fed effectively, conveniently and automatically, the labor intensity of workers can be greatly reduced, and the punching production efficiency of the circuit boards is improved.

Owner:福建省唯正智能科技有限公司

Environment monitoring equipment circuit board testing device

ActiveCN113702809AEasy for automatic loadingEasy to operateGeneral water supply conservationPrinted circuit testingElectronic componentMonitor equipment

An environment monitoring equipment circuit board testing device comprises an operation platform, a feeding assembly, a conveying mechanism, a chip mounting assembly, a welding assembly and a spot measurement assembly. The feeding assembly is arranged at one end of the operation platform. The conveying mechanism is arranged on one side of the operation platform. The chip mounting assembly is arranged on the operation platform and located on one side of the feeding assembly. The welding assembly is arranged on the operation platform. The spot measurement assembly is arranged at the other end of the operation platform. When environment monitoring equipment is processed, automatic feeding and conveying operation of a circuit board are facilitated, the automation degree of feeding and transferring is improved, automatic chip mounting operation can be carried out, the precision and efficiency during chip mounting are improved, welding operation of electronic components can be automatically and efficiently carried out with high precision, the circuit board can be automatically tested, the testing efficiency and the automation degree are improved, the automation degree of control board card processing is realized, and the circuit board testing device has strong practicability.

Owner:四川久环环境技术有限责任公司

Drilling device capable of carrying out auxiliary fixation on flanges with different diameters for flange machining

PendingCN113731915APrevent splashImprove processing efficiencyCleaning using liquidsPressesThermodynamicsMachining

The invention discloses a drilling device capable of carrying out auxiliary fixation on flanges with different diameters for flange machining. The drilling device comprises a base, a conveying belt and a waste storage box, a first rotating mechanism is fixedly arranged on the base, a rotating disc is located on the lower side of a pushing plate, the conveying belt is located between the base and the storage box, a second rotating mechanism is fixedly arranged on the upper side of the interior of the storage box, a rotating supporting plate is fixedly arranged on the second rotating mechanism, a U-shaped plate is fixedly arranged on the upper side of the storage box, a sliding way is formed in the upper side of the interior of the U-shaped plate, a second fixing plate is fixedly arranged on the lower side of a height adjusting mechanism, a flushing assembly is fixedly arranged on a drilling mechanism, and a waste recovery assembly is located in the storage box and located on the upper side of a material guide plate. The drilling device capable of carrying out auxiliary fixation on the flanges with the different diameters for flange machining has the advantages that the whole machining efficiency can be improved, waste can be prevented from splashing, extrusion can be carried out on large waste, and auxiliary fixing can be carried out on the flanges with the different diameters.

Owner:建湖中恒机械有限公司

Gear surface cleaning device

InactiveCN109499968ARealize automatic feeding processEasy for automatic loadingMultistage water/sewage treatmentCleaning using toolsDrive wheelFixed frame

The invention discloses a gear surface cleaning device which comprises supporting legs, a driving shaft, a connecting frame, a motor, a vibration motor, a first spring, a sliding plate, a driving wheel, a driven shaft, a driven wheel, a conveyor belt, a fixing column, a lantern ring, a second spring, a water storage shell, a fixed frame, a rack, a material receiving plate, a sponge block, a filterresidue filter net, a sponge pad, a water pumping pipe, a water pump, a water drainage pipe, a spraying nozzle, a connecting rod, a cleaning hairbrush and gears. The gear surface cleaning device is novel in design, automatic feeding of the cleaned gears is achieved, it is guaranteed that the gears are orderly placed on the surface of the conveyor belt, automatic cleaning of the gear surfaces is facilitated, the labor intensity of the automatic feeding by a worker is reduced, the labor efficiency of the worker is improved, and use by the worker is facilitated; and the conveyor belt is arrangedto drive the gears to rotate under the effect of the rack, meanwhile, the matching action of the cleaning hairbrush is used for cleaning the gear surfaces, the cleaning effect of the gear surface isimproved, and the gear surfaces are conveniently and effectively cleaned thoroughly.

Owner:南京壹久软件科技有限公司

Full-automatic feed feeding device for animal husbandry

InactiveCN112772435AEasy for automatic loadingEasy to feed in large quantitiesAnimal feeding devicesAnimal scienceZoology

The invention discloses a full-automatic feed feeding device for animal husbandry. The device comprises a strip-shaped fixing base, an automatic feeding mechanism is arranged on the upper surface of the strip-shaped fixing base, and a fixing mechanism is arranged on the side surface of the strip-shaped fixing base. The device has the beneficial effects that automatic feeding and automatic stirring are facilitated, adhesion is prevented, the food state can be conveniently adjusted according to the feeding condition, manpower is saved, and large-scale feeding is facilitated.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

Loudspeaker magnetizing equipment convenient for improving magnetizing quality and use method

InactiveCN110446153AEasy for automatic loadingImprove the quality of magnetizationElectrical transducersMagnetic bodiesGlass coverMagnetic poles

The invention discloses loudspeaker magnetizing equipment convenient for improving magnetizing quality and a use method, and belongs to the technical field of loudspeaker production equipment. The equipment comprises a conveyor belt, a stepping motor and a magnetizer, the transmission output end of the stepping motor is in transmission connection with the conveying belt; the magnetizer is locatedabove the conveying belt. Material grooves are uniformly distributed in the surface of the conveying belt; a tempered glass cover is installed outside the conveying belt. A metal shielding net is riveted to the outer wall of the tempered glass cover and used for shielding an external magnetic field, air blowing covers are symmetrically installed on the inner side wall of the tempered glass cover and used for blowing air to remove dust, and a dust suction cover is inserted into the top end of the interior of the tempered glass cover and used for sucking away blown-away dust. The air blowing cover and the dust suction cover are installed in the tempered glass cover, dust removal operation on the loudspeaker is facilitated, static electricity is removed through the ion fan, magnetizing operation is conducted through an additional magnetic pole of the magnetizer, and the magnetizing quality is improved.

Owner:梁志宇

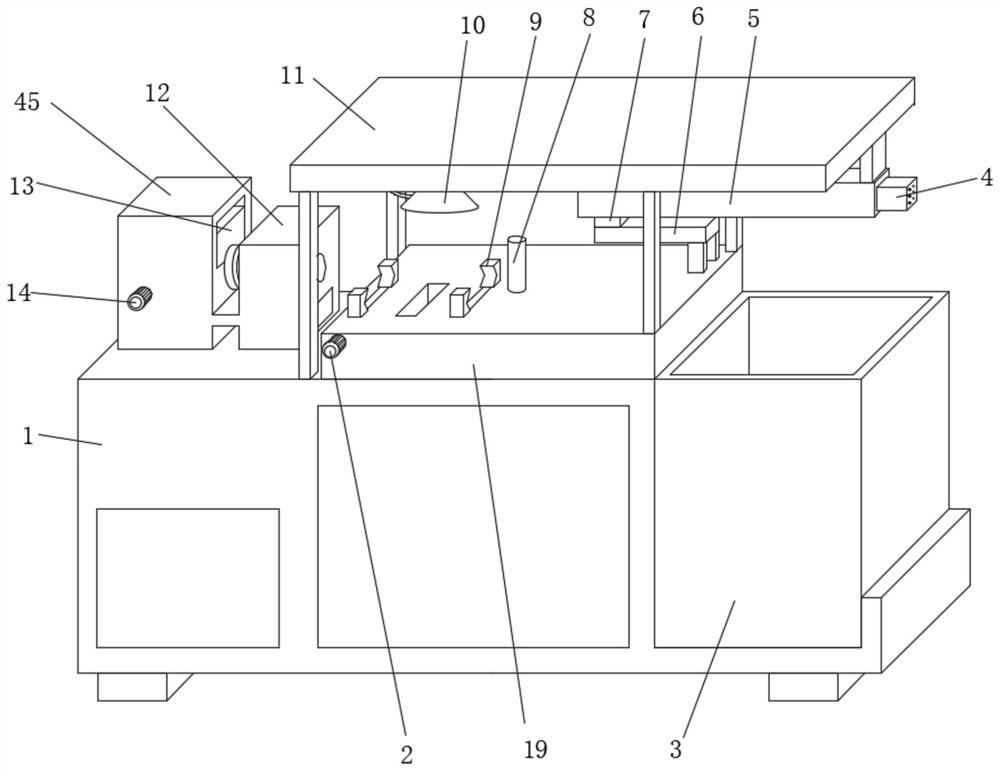

High-precision sealing ring thickness detector

ActiveCN112246670AEasy for automatic loadingPlay the effect of automatic unloadingSortingEngineeringMechanical engineering

The invention relates to a high-precision sealing ring thickness detector and belongs to the technical field of sealing ring thickness detection equipment. The high-precision sealing ring thickness detector comprises a base, a detection device is arranged on the base, the detection device comprises a bottom plate arranged on the base, a detection plate is arranged on the bottom plate through a bearing assembly, a bearing plate is arranged on the detection plate, the bearing plate is provided with a plurality of detection equipment used for measuring the thickness of the sealing ring through alifting assembly, the base is provided with a feeding mechanism used for automatically feeding the sealing ring to the detection plate, and the base is further provided with a discharging mechanism used for automatically discharging the sealing ring. According to the high-precision sealing ring thickness detector, the sealing rings can be conveniently and automatically fed onto the detection platein sequence, so that the detection equipment can accurately detect the thickness of the sealing rings; and moreover, the detected sealing ring can be automatically unloaded conveniently, so that themeasuring efficiency of the sealing ring can be improved, and the labor intensity of workers can be effectively reduced.

Owner:FOSHAN NANHAI HEFENG RUBBER WARE

Machining platform for machining high-strength steel bars and using method of machining platform

InactiveCN114406140AEasy for automatic loadingEasy to cleanDirt cleaningCleaning using toolsElectric machineryRebar

The machining platform comprises a machining table, the top of the machining table is sequentially and fixedly connected with a limiting seat and a fixing seat, the outer side of the limiting seat is slidably connected with a lifting seat, and guide rollers are sequentially arranged at the bottom of the lifting seat; the steel bar feeding device has the beneficial effects that by arranging the limiting base, the fixing base, the first conveying roller, the second conveying roller and the guide roller, the function of conveniently and automatically feeding steel bars is achieved; by arranging a cleaning cylinder and a cleaning brush, the function of conveniently cleaning the reinforcing steel bars is achieved; a rotating rod, a fixing block, a pressing block, a fixing rod and a clamping block are arranged, so that the function of bending the reinforcing steel bars conveniently is achieved; a cutting disc, a dust suction cover, a fan and a dust collection box are arranged, so that the function of conveniently cutting the reinforcing steel bars is realized; and a second motor and a sliding seat are arranged, so that the function of conveniently collecting the cut reinforcing steel bars is achieved, and the practicability is high.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Carbon dioxide laser cutting machine rack with automatic feeding mechanism

InactiveCN111975224AEasy for automatic loadingAchieve the purpose of free cuttingWelding/cutting auxillary devicesAuxillary welding devicesCarbon dioxide laser lightEngineering

The invention discloses a carbon dioxide laser cutting machine rack with an automatic feeding mechanism. The carbon dioxide laser cutting machine rack comprises a cutting machine body, wherein a conveying belt is movably arranged on the front portion of the cutting machine body; a containing plate is movably installed inside the cutting machine body; the corresponding containing plate is arrangedon the front portion of the upper surface of the cutting machine body; a red point positioning device is fixedly installed above the upper surface of the containing plate; and a cutting support is movably installed in the middle of the upper surface of the cutting machine body. The carbon dioxide laser cutting machine rack with the automatic feeding mechanism belongs to the technical field of laser cutting, a lifting groove, a movable rod and a fixed rod are arranged to be matched so that the whole conveying belt device can move up and down, and automatic feeding of the cutting machine body isfacilitated; and an arranged abutting block enables a sliding shaft to help the conveying belt to transfer materials needing to be cut to the containing plate, and the red point positioning device isarranged to determine the material position, and then movable fixing plates on the left side and the right side of the containing plate are used for fixing and adjusting the material position.

Owner:苏州刘氏钣金科技有限公司

Punching equipment capable of accurately cutting steel plate

InactiveCN112317597AEasy for automatic loadingEffective positioningShaping toolsPunchingStructural engineering

The invention relates to punching equipment capable of accurately cutting a steel plate, and belongs to the technical field of punching equipment. The punching equipment comprises a rack and a stamping machine body arranged on the rack, wherein the punching machine body is slidably connected with a mounting base through a driving piece, an upper die set is arranged at the bottom of the mounting base, a lower die set is arranged on the bearing surface of the rack, the upper die set is matched with the lower die set, a positioning mechanism for positioning a workpiece is arranged on one side ofthe rack, and a feeding mechanism for feeding the workpiece is arranged on the side, away from the positioning mechanism, of the rack. According to the punching equipment, the steel plate workpiece can be automatically fed and can be effectively positioned so that the steel plate workpieces can be effectively punched and cut, the cutting efficiency of the steel plate workpiece can be improved, andthe quality of a cut steel plate finished product can be improved.

Owner:佛山市中得文仪家具制造有限公司

Welding device for hardware fitting production

ActiveCN110421282AImprove welding efficiencyAchieve weldingWelding/cutting auxillary devicesAuxillary welding devicesWelding

The invention discloses a welding device for hardware fitting production. The welding device for hardware fitting production comprises a box body, wherein a welding rod conveying mechanism, a bottom plate, a welding table, a welding mechanism and a driving mechanism are arranged in the box body; the welding rod conveying mechanism is connected to the top of the box body; the bottom plate is fixedly connected to the bottom of the box body; two sides of the welding table are fixedly connected above the bottom plate through supporting plates; a feeding plate and a discharging plate are respectively arranged on the two sides of the welding table; the welding mechanism is arranged on the side surface of the welding table; and the welding mechanism is connected with the bottom plate through thedriving mechanism. The invention has the simple structure and strong practicability, not only improves the welding efficiency of hardware fittings, but also can carry out high-precision welding and realize the pipeline welding of the hardware fittings; and meanwhile, thewelding device can adjust the space between the welding components and realize the continuous welding processing of hardware fittings with different sizes and specifications.

Owner:嵊州市非标链轮有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com