Automatic steel wire rope circular ring welding device

A welding device and steel wire rope technology, which is applied in the field of automatic steel wire rope ring welding device, can solve the problems of unstable joint quality and low efficiency, and achieve the effects of small space occupation, simple overall structure and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

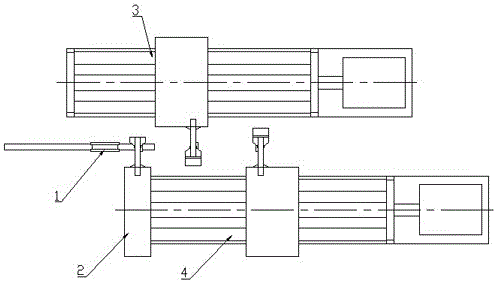

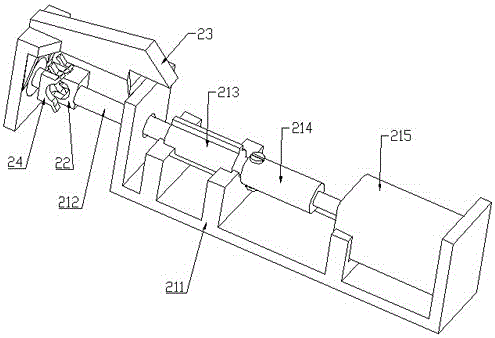

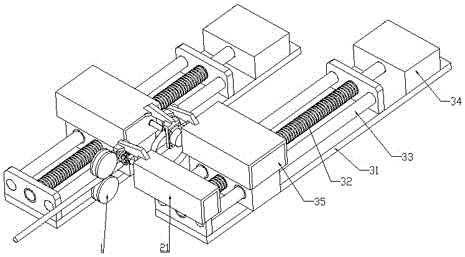

[0020] Such as figure 1 As shown, an automatic steel wire rope ring welding device includes a feeding device 1, a wire rope fusing device 2, a first welding device 3, and a second welding device 4 arranged in sequence; The welding parts in the welding device 3 and the second welding device 4 are as close as possible, and the wire rope fusing device 2 , the first welding device 3 and the second welding device 4 are arranged in a staggered manner. Such as figure 2 As shown, the wire rope fusing device 2 includes a first driving device 21, the output end of the first driving device 21 is provided with a fusing inner clamping claw 22, and the fusing inner clamping claw 22 can realize linear motion through the first driving device 21. A driving device 21 is provided with a first connecting arm 23 and an electric heating device, the other end of the first connecting arm 23 is provided with a fusing outer clamping jaw 24, and the fusing inner clamping jaw 22 and the fusing outer cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com