High-precision sealing ring thickness detector

A technology for thickness detection and sealing rings, which is applied in the field of high-precision sealing ring thickness detectors, can solve the problems of aggravating the labor intensity of the staff and low measurement efficiency, and achieve the effects of improving measurement efficiency, reducing labor intensity, and facilitating effective replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

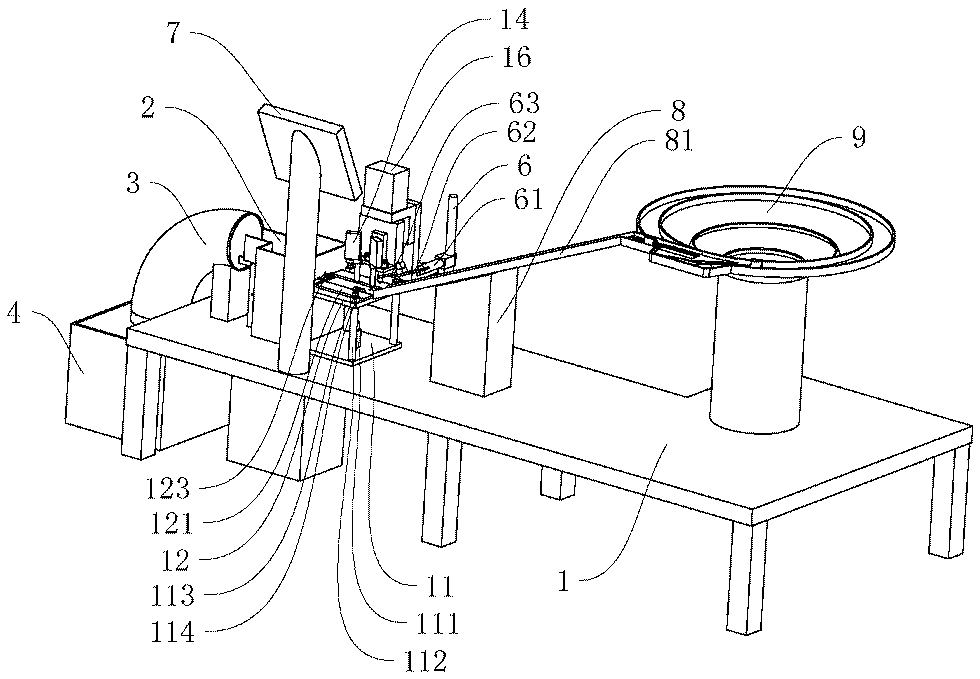

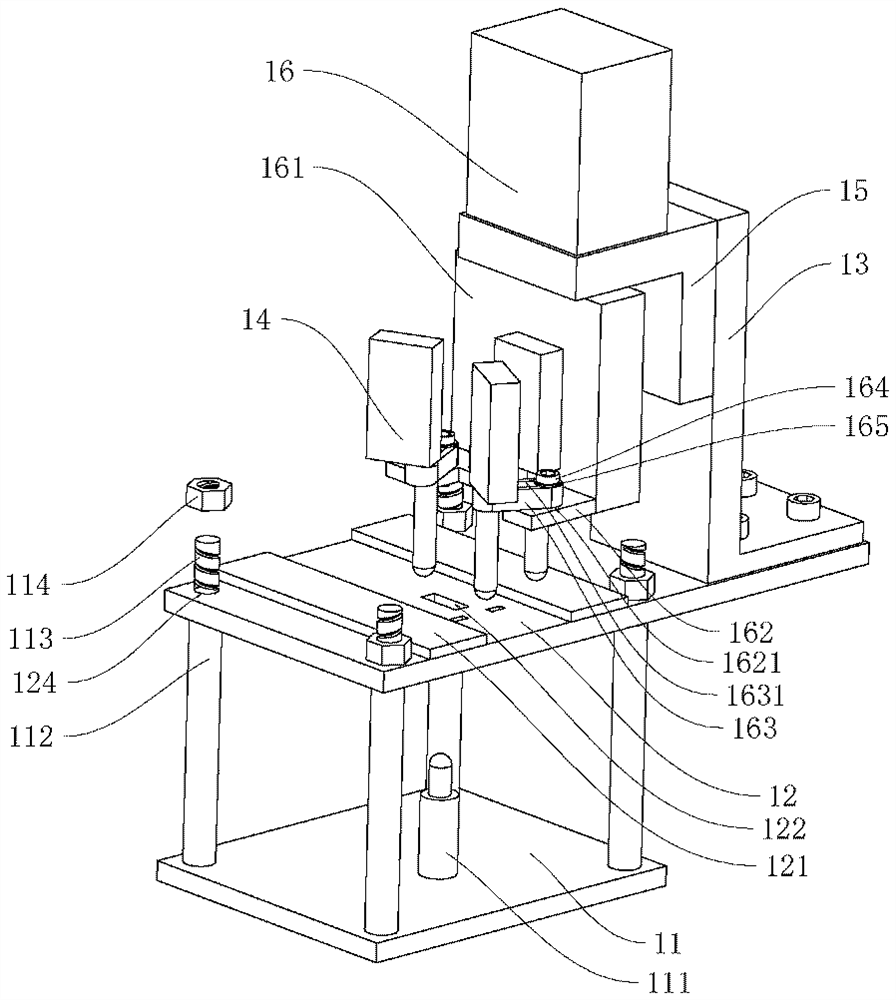

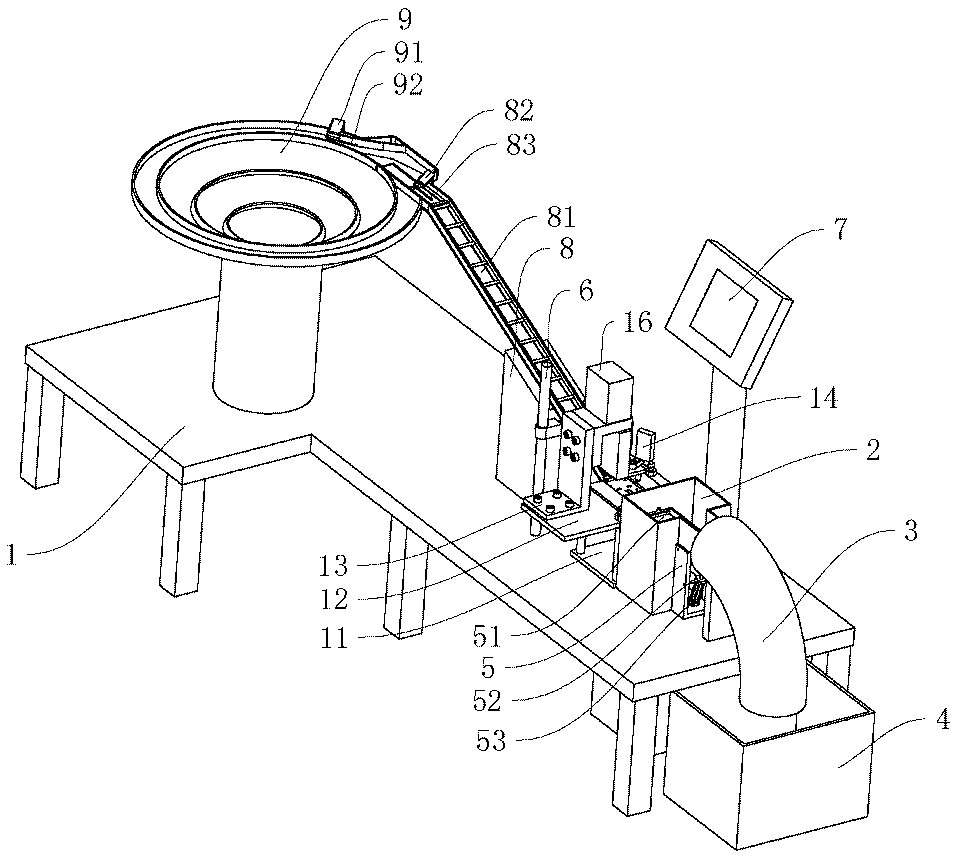

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] The embodiment of the present application discloses a high-precision sealing ring thickness detector. refer to figure 1 , The thickness detector includes a base 1, on which a detection device is arranged, and the detection device is used to effectively detect the thickness of the sealing ring. Specifically, the detection device includes a base plate 11, the base plate 11 is fixedly installed on the bearing surface of the base 1, and a detection board 12 is fixedly installed on the base plate 11 through a bearing assembly, and the bearing surface of the detection board 12 is fixedly installed with two One guide plate 121, the two guide plates 121 and the detection plate 12 enclose a detection area, and the detection area is used to place the sealing ring to be tested.

[0037] More specifically, refer to figure 2 , in this embodiment, the carrying assembly includes a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com