Modified plastic-wood profile embossing device and embossing process thereof

An improved embossing technology, applied in the direction of wood compression, transportation and packaging, conveyors, etc., can solve the problems of difficult operation, complex structure, slow start, etc., and achieve the effect of improving efficiency, reducing labor intensity, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

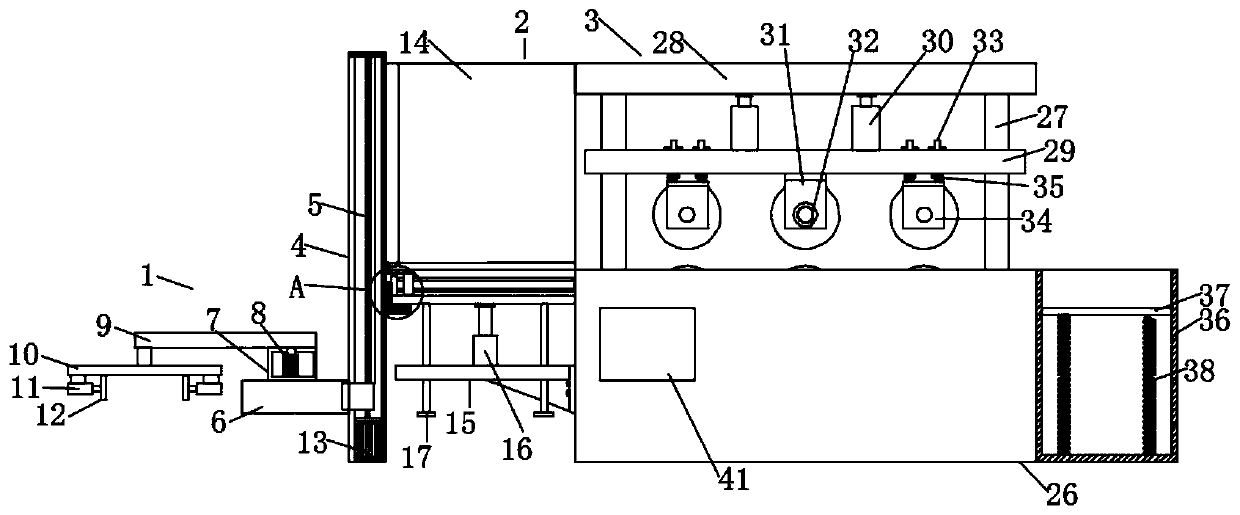

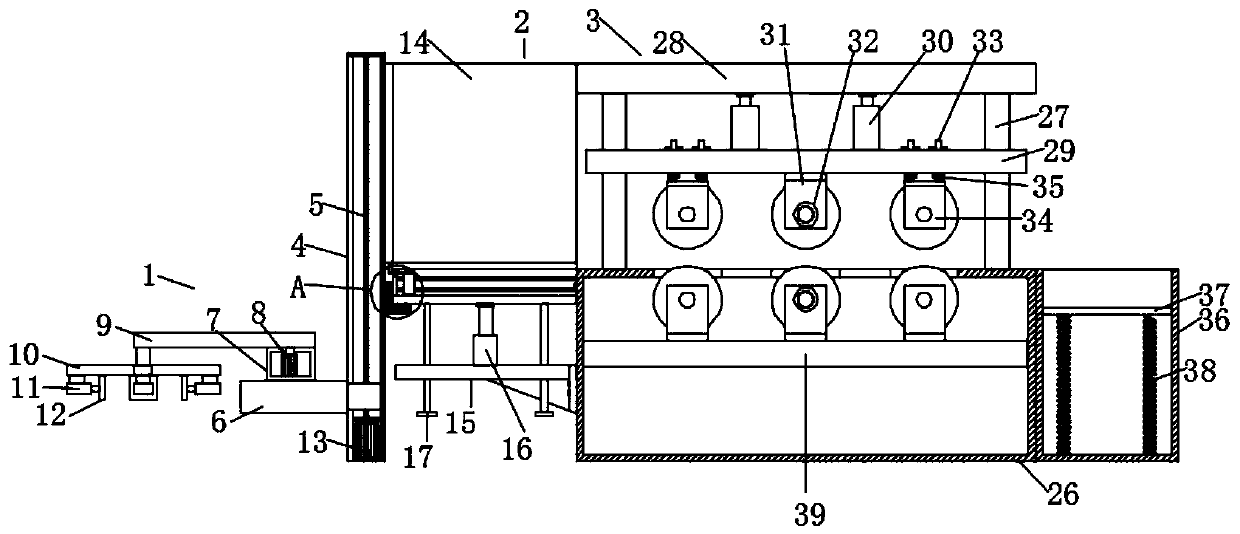

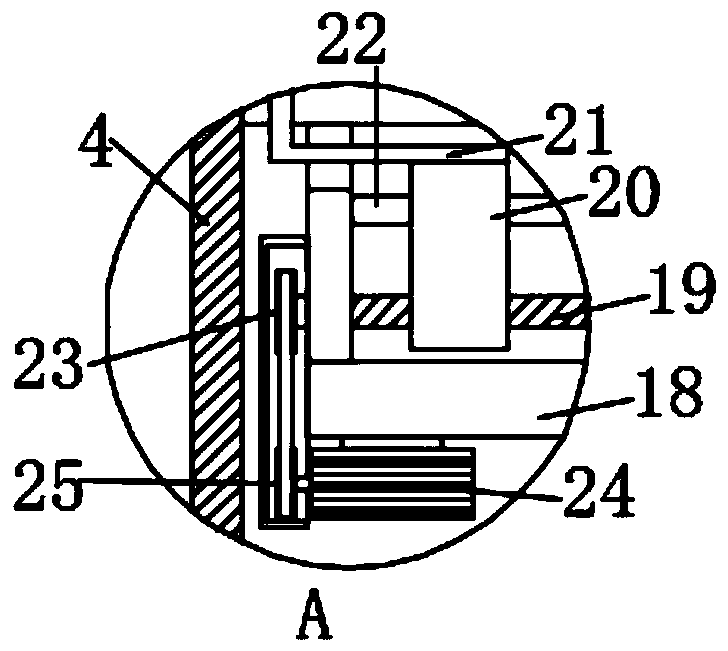

[0023] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: an improved plastic wood profile embossing device, including a feeding mechanism 1, a feeding mechanism 2 and an embossing mechanism 3, and the embossing mechanism 3 is composed of a workbench 26, an adjustable Distance slide bar 27, top plate 28, adjustment slide plate 29, distance adjustment cylinder 30, press roller 31, drive motor 32, buffer slide bar 33, auxiliary roller 34, buffer spring 35, collection box 36, receiving slide plate 37 and return spring 38 The four corners of the top of the workbench 26 are fixedly connected with a distance-adjusting slide bar 27, and the top of the distance-adjusting slide bar 27 is fixedly connected with a top plate 28, and the outer side of the distance-adjusting slide bar 27 is located between the top plate 28 and the working An adjustment slide plate 29 is slidingly connected between the platforms 26, and the top of the adjustment sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com