Patents

Literature

118results about How to "Flexible adjustment of spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

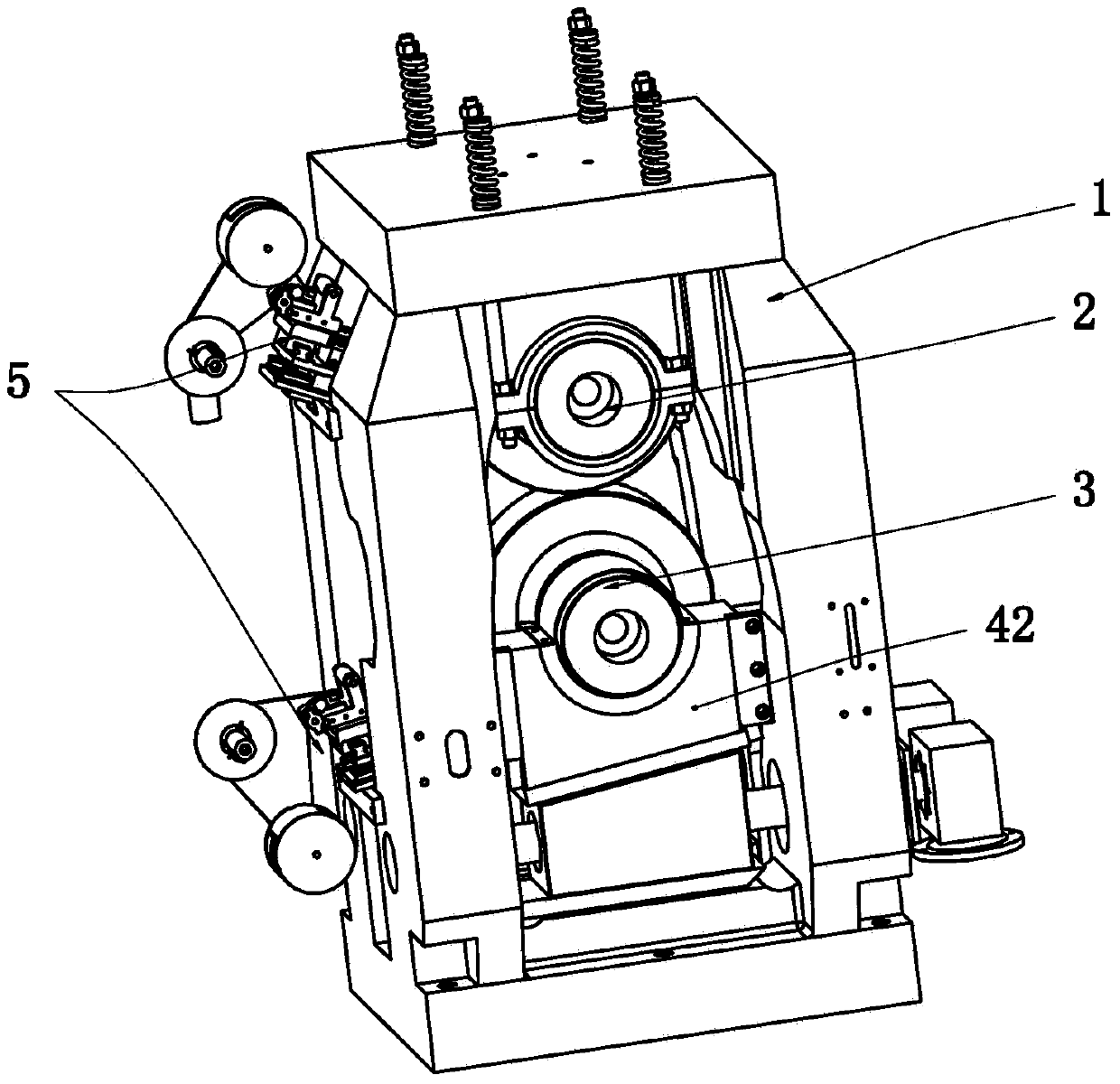

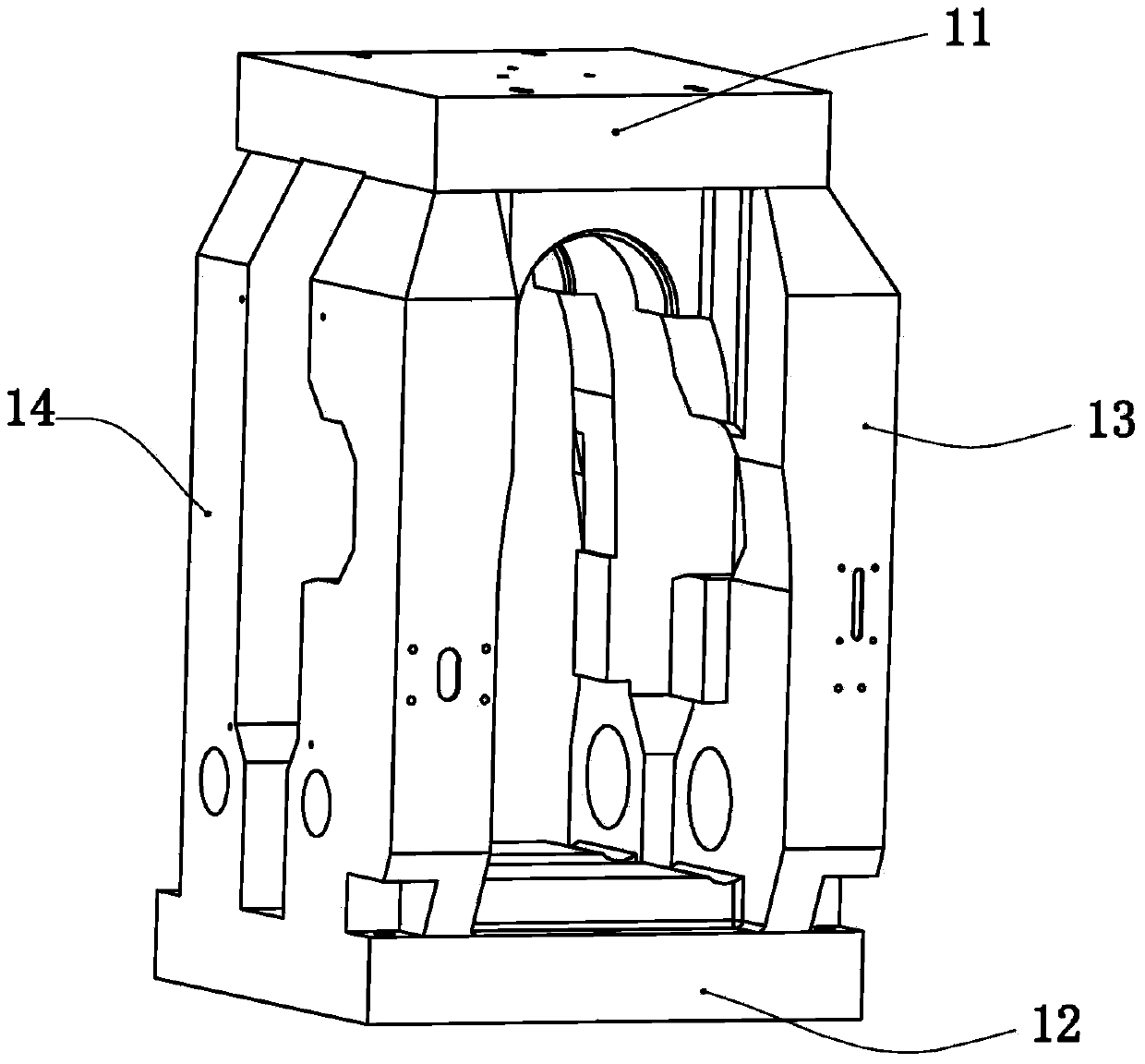

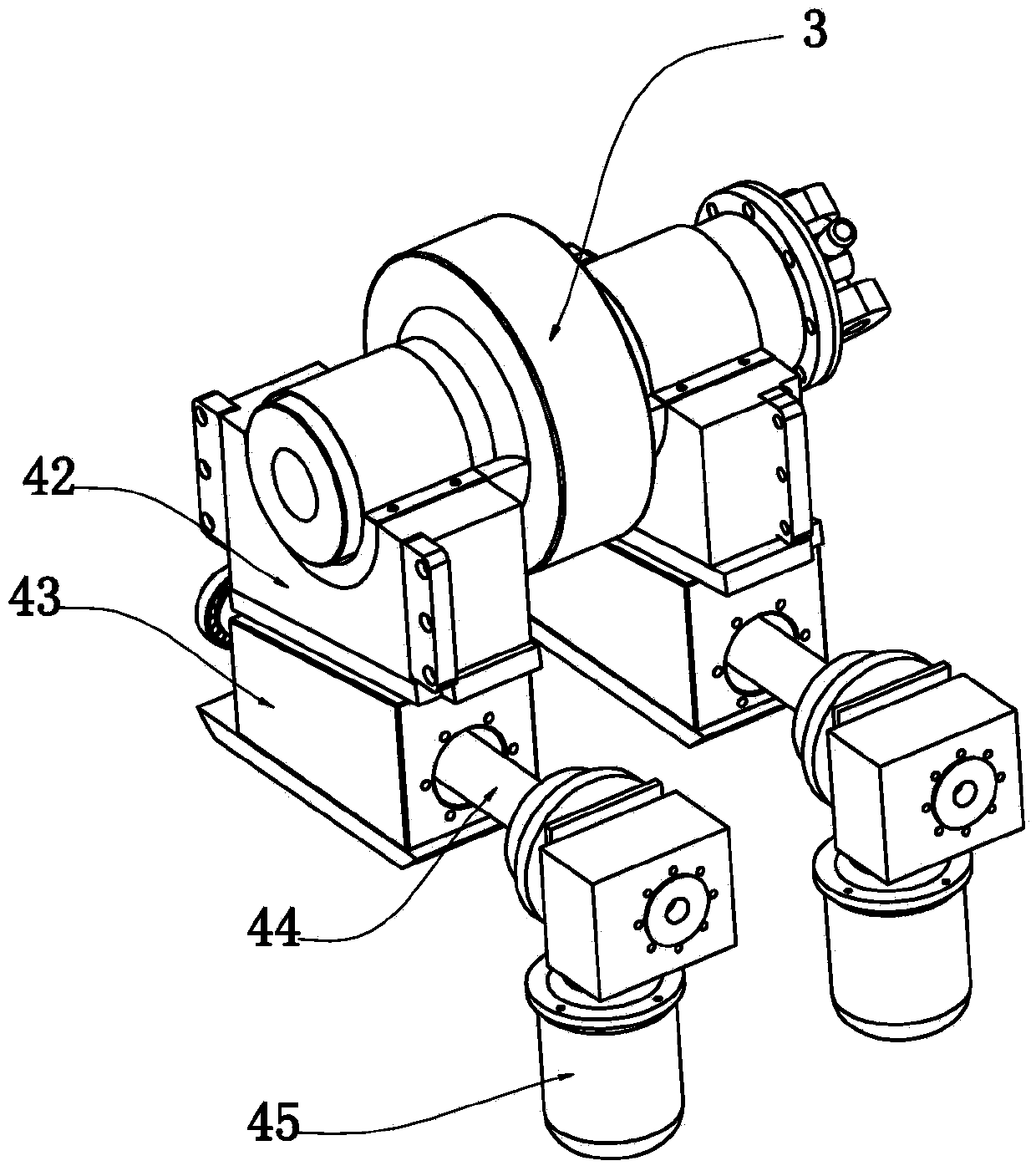

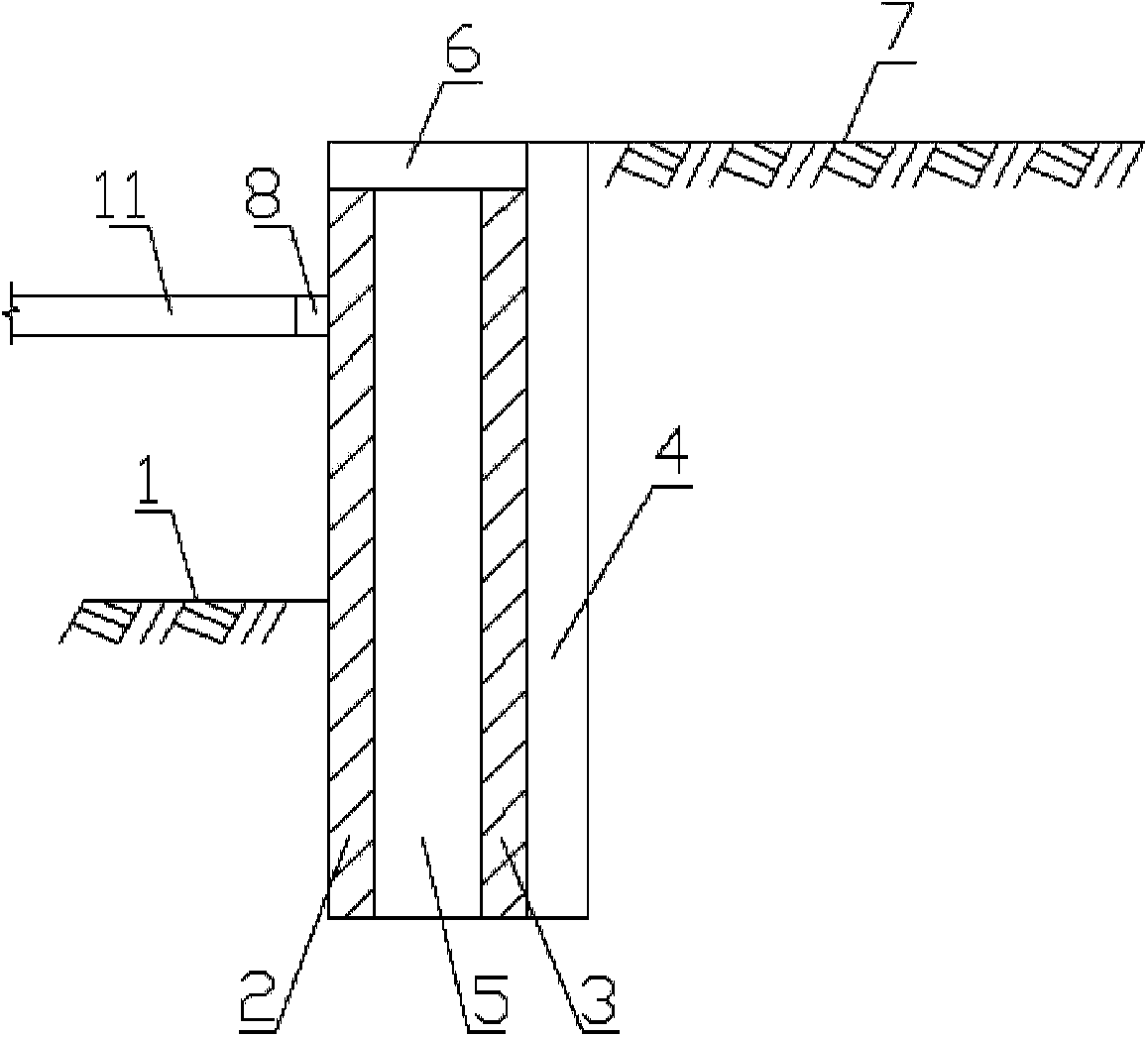

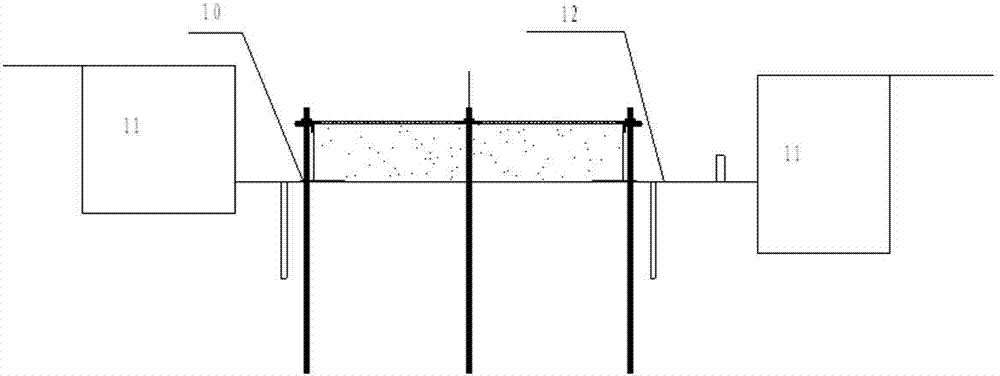

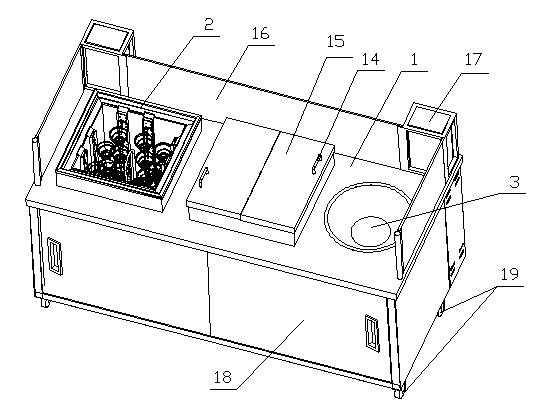

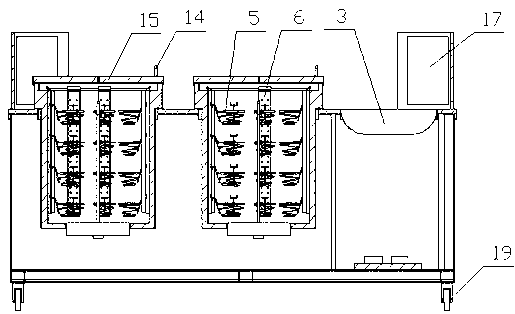

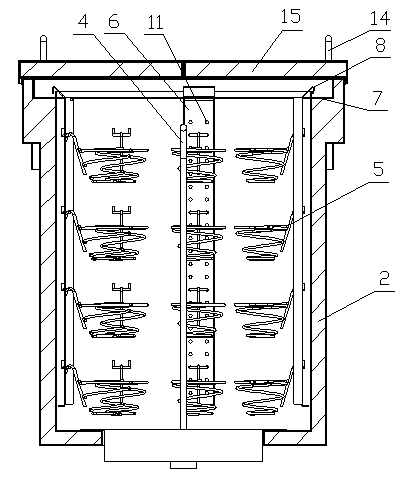

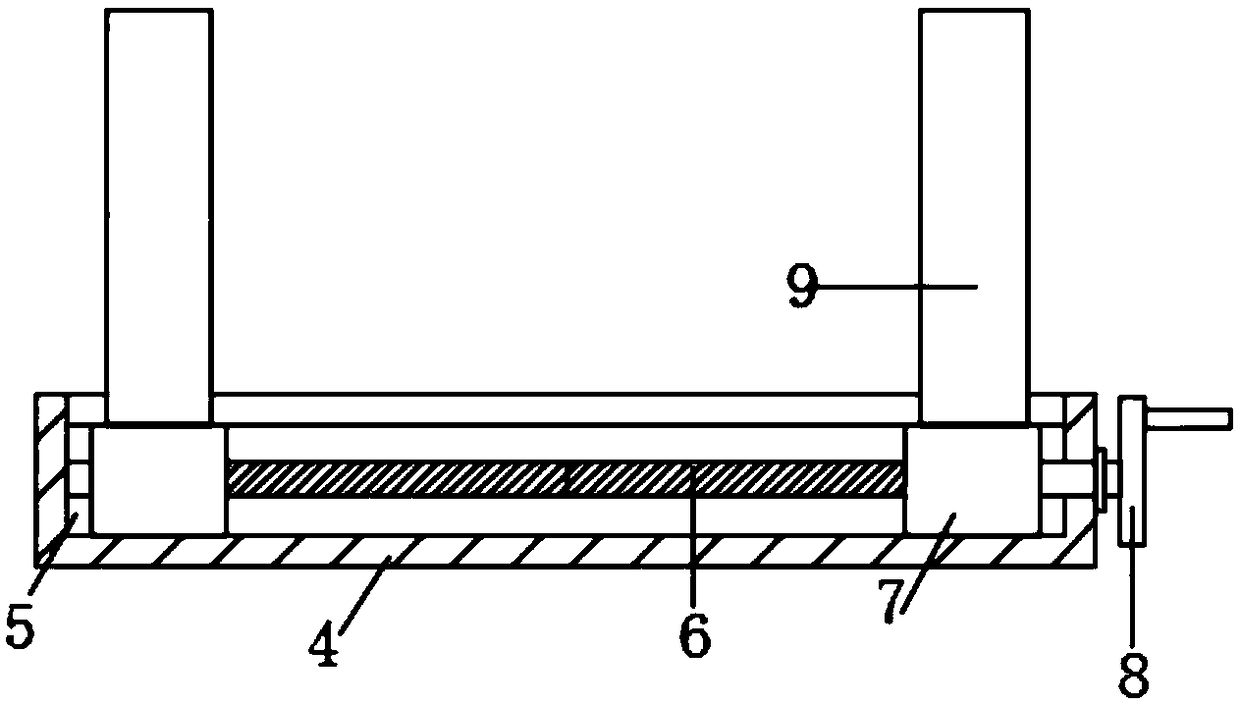

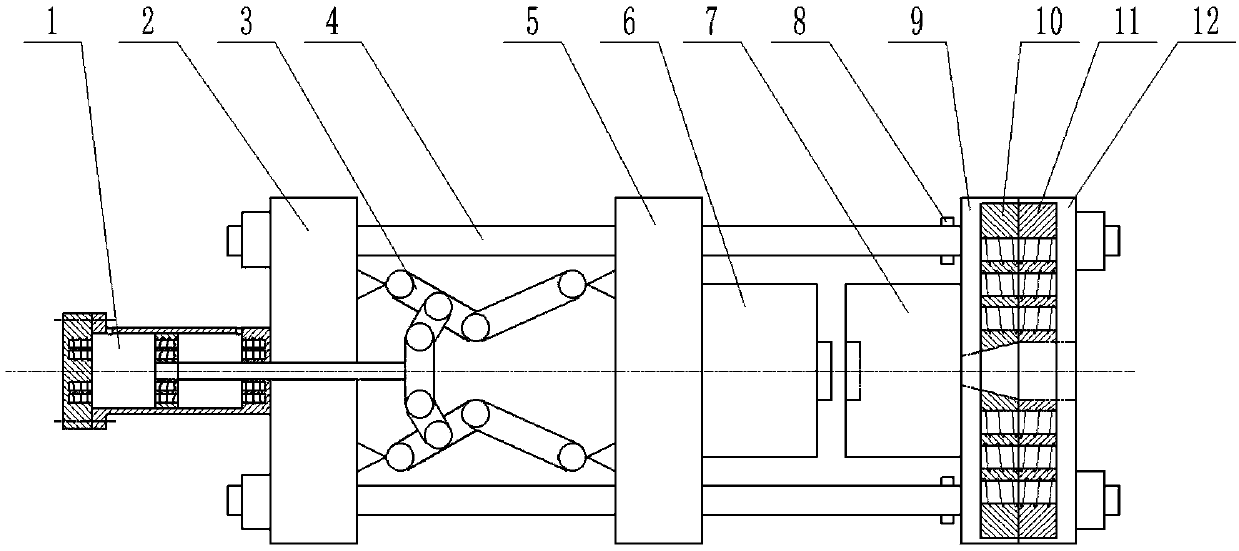

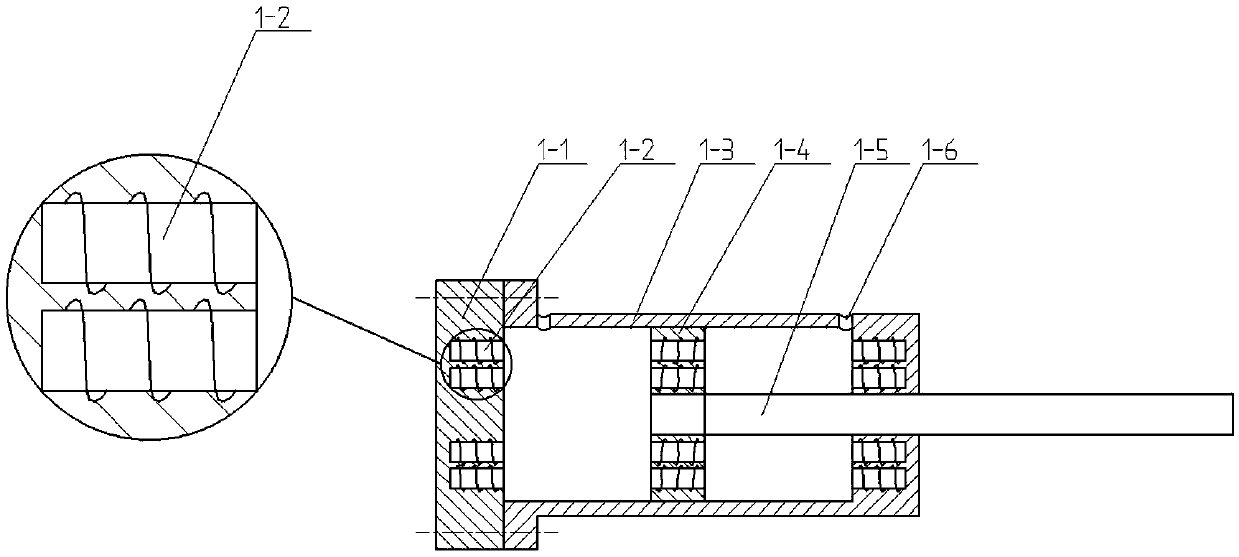

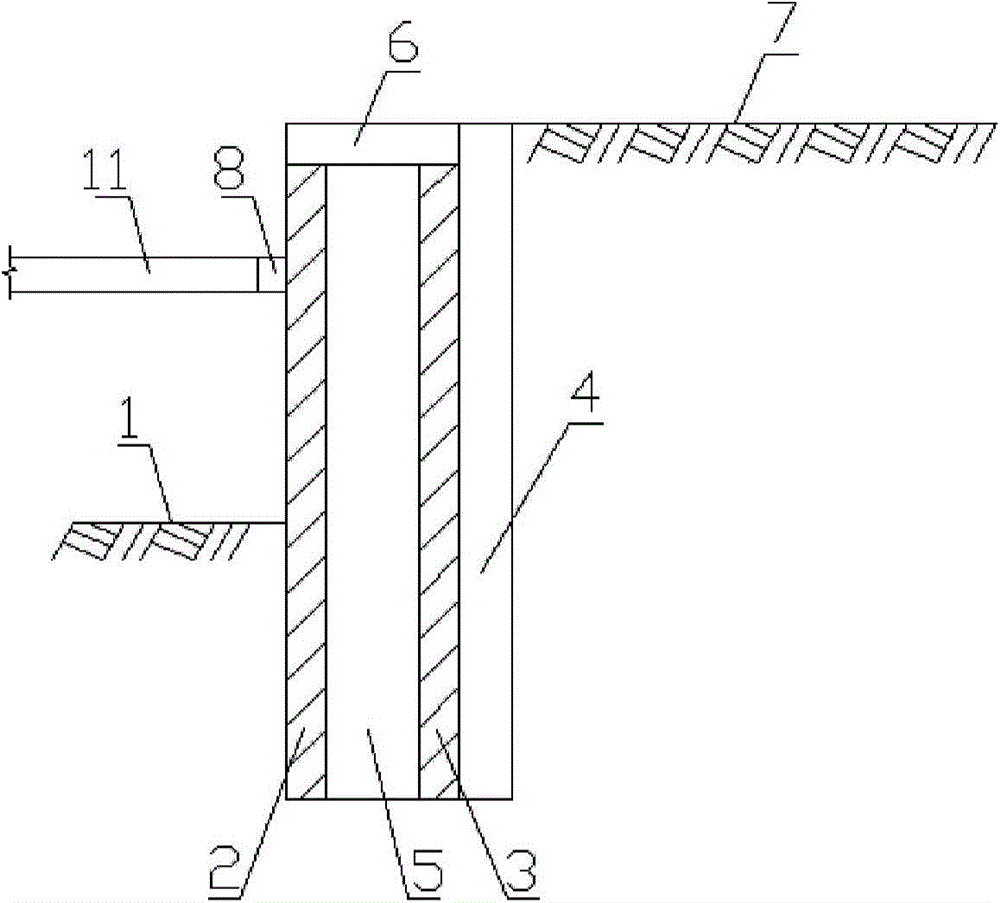

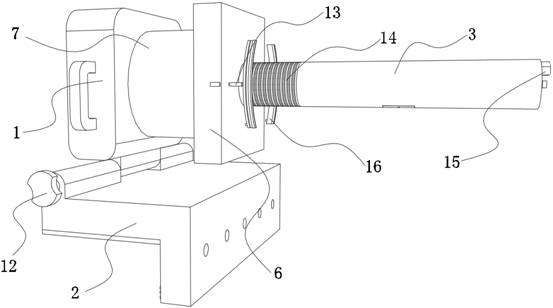

Body of horizontal rolling machine

ActiveCN103464466AEasy to cleanRealize automatic cleaningMetal rolling stand detailsCleaning using toolsEngineeringMechanical engineering

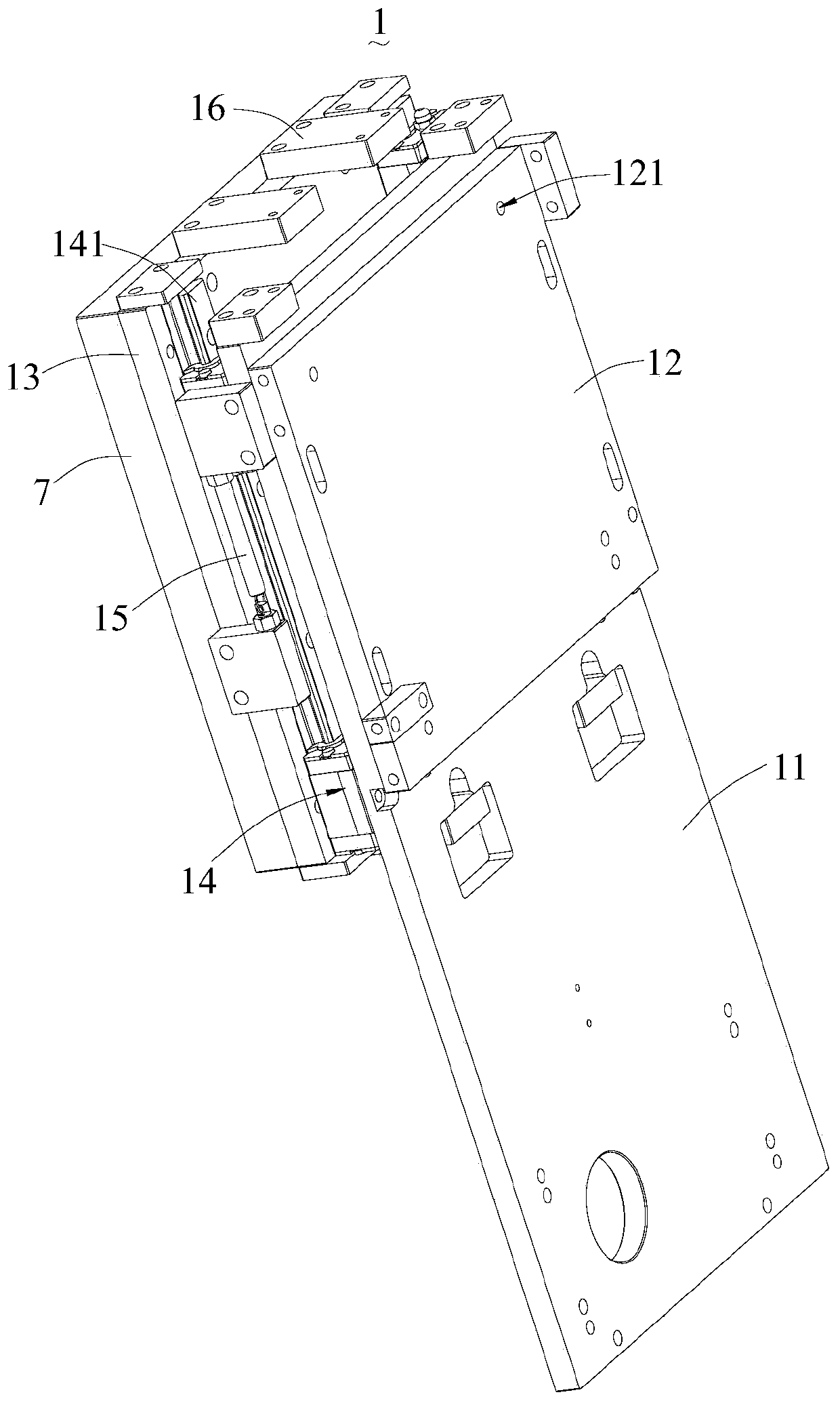

The invention relates to a body of a horizontal rolling machine. The body comprises a frame. The frame comprises a top beam, four vertical posts and a base. A hold-down roll rotating support is disposed inside the frame. The body further comprises a height adjusting mechanism. The height adjusting mechanism comprises a height adjusting base and a height adjusting base transverse drive device. A lower press roll comprises a roll body and a rotating shaft fixedly linked to the roll body. The rotating shaft is rotatably supported on the lower press roll rotating support. The lower press roll rotating support is slidably supported on the height adjusting base, and sliding support faces of the lower press roll rotating support and the height adjusting base are inclined. The body of the horizontal rolling machine has the advantages that the body is high in impact resistance, the height of the lower press roll can be flexibly adjusted during the rolling process of metal workpieces, spacing of top and bottom press rolls is adjusted, a roll cleaning mechanism can be used to clean the rolls effectively, and the rolls can be cleaned automatically.

Owner:ZHEJIANG KINGSTONE HOUSEWARES

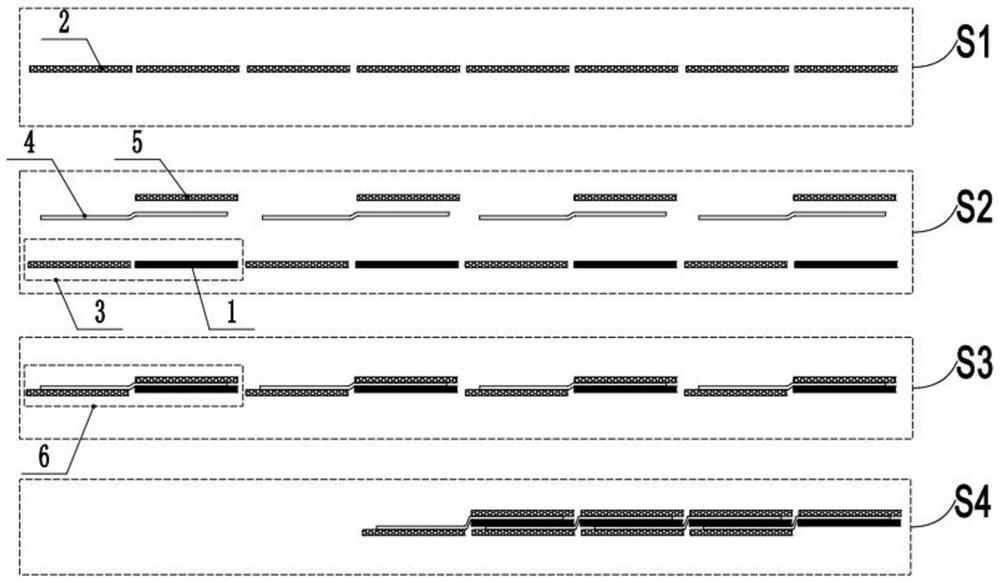

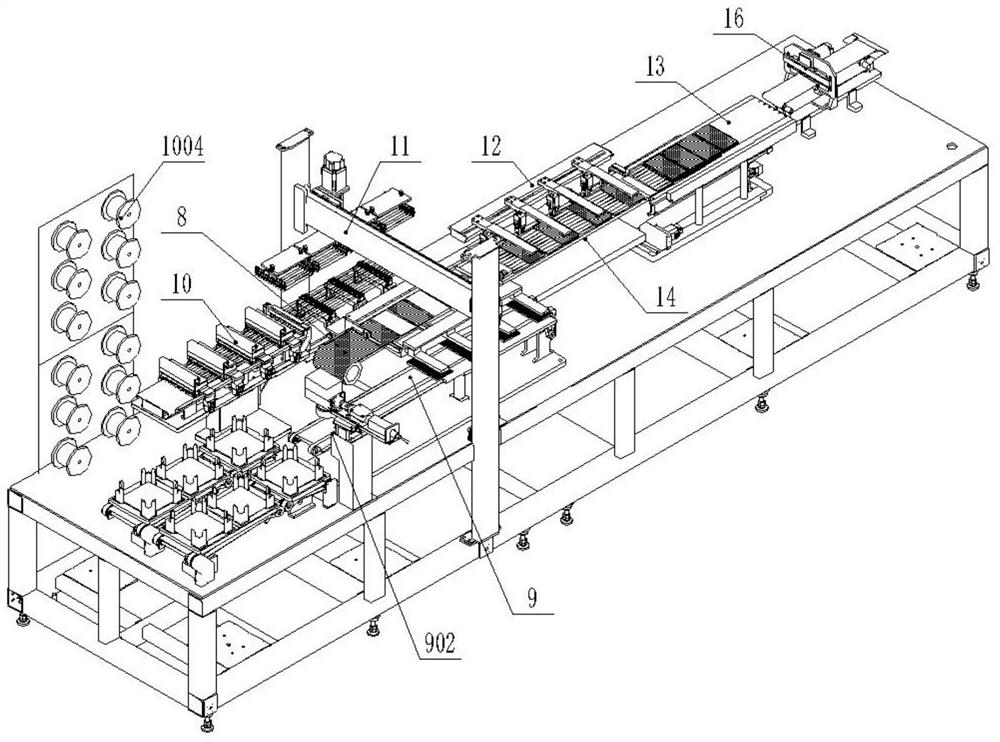

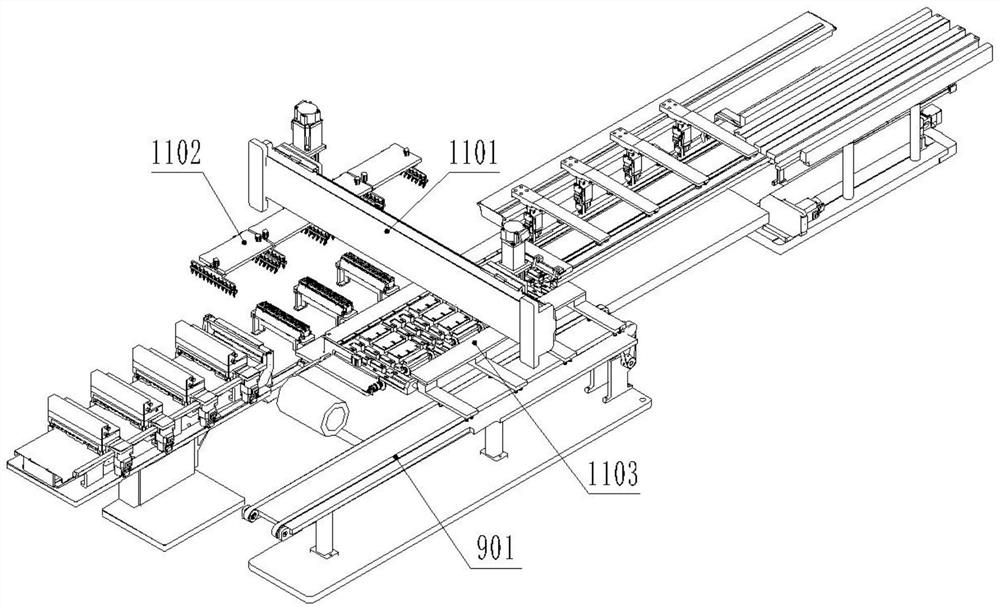

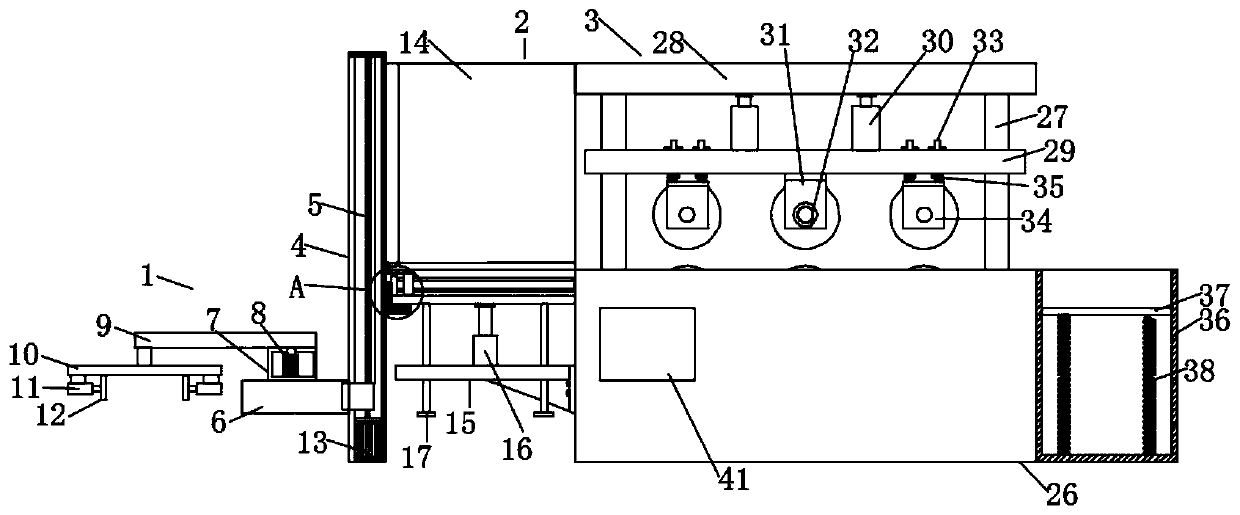

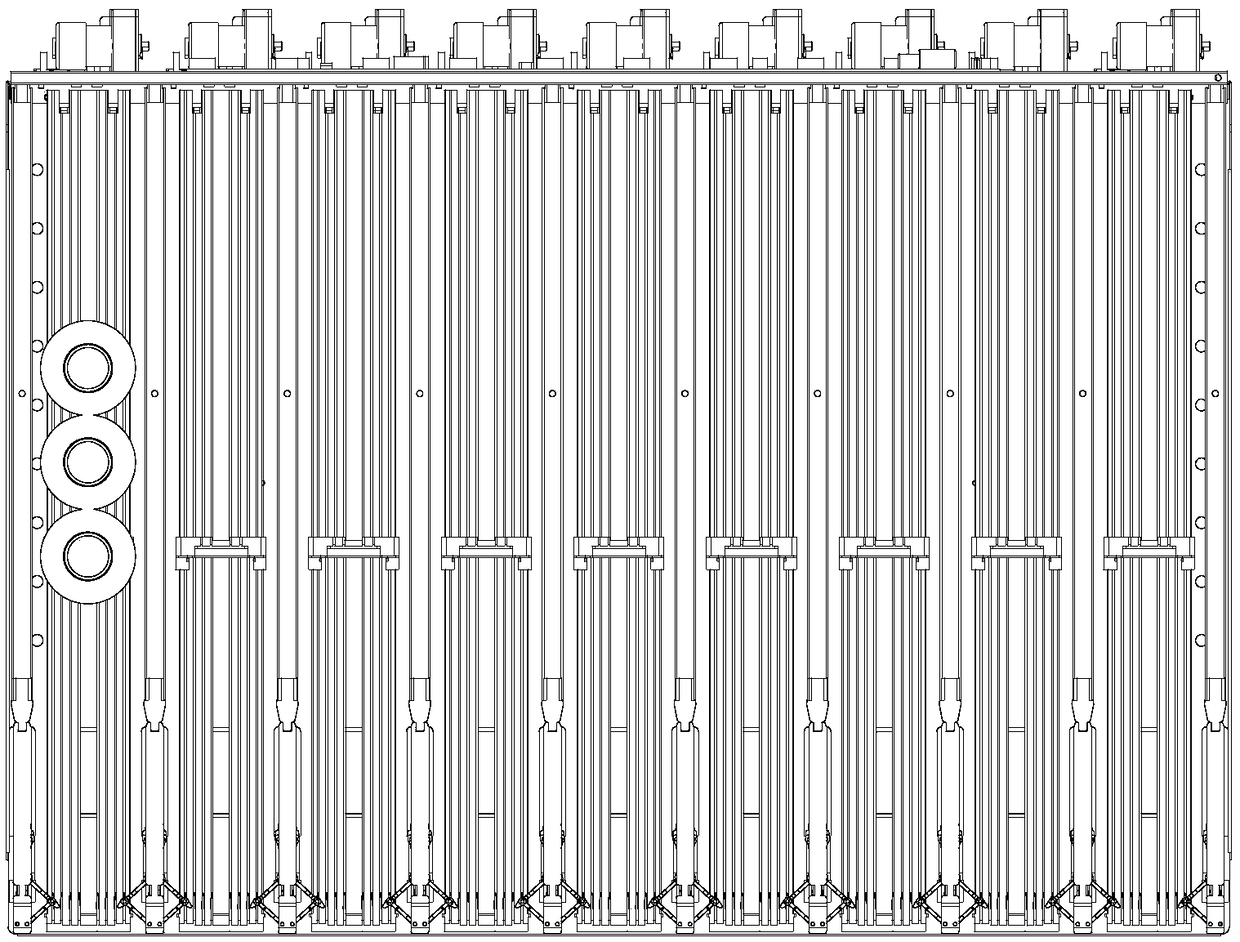

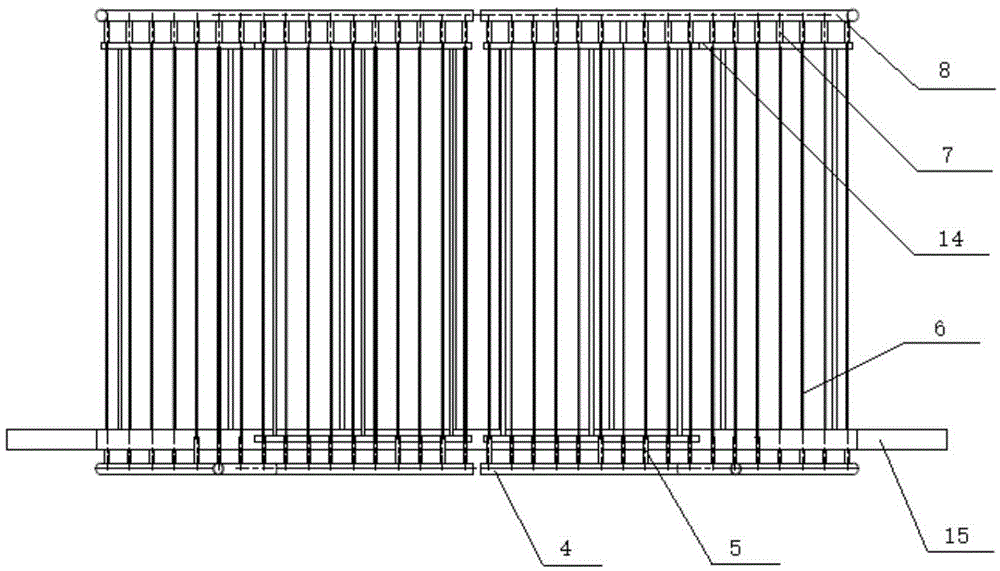

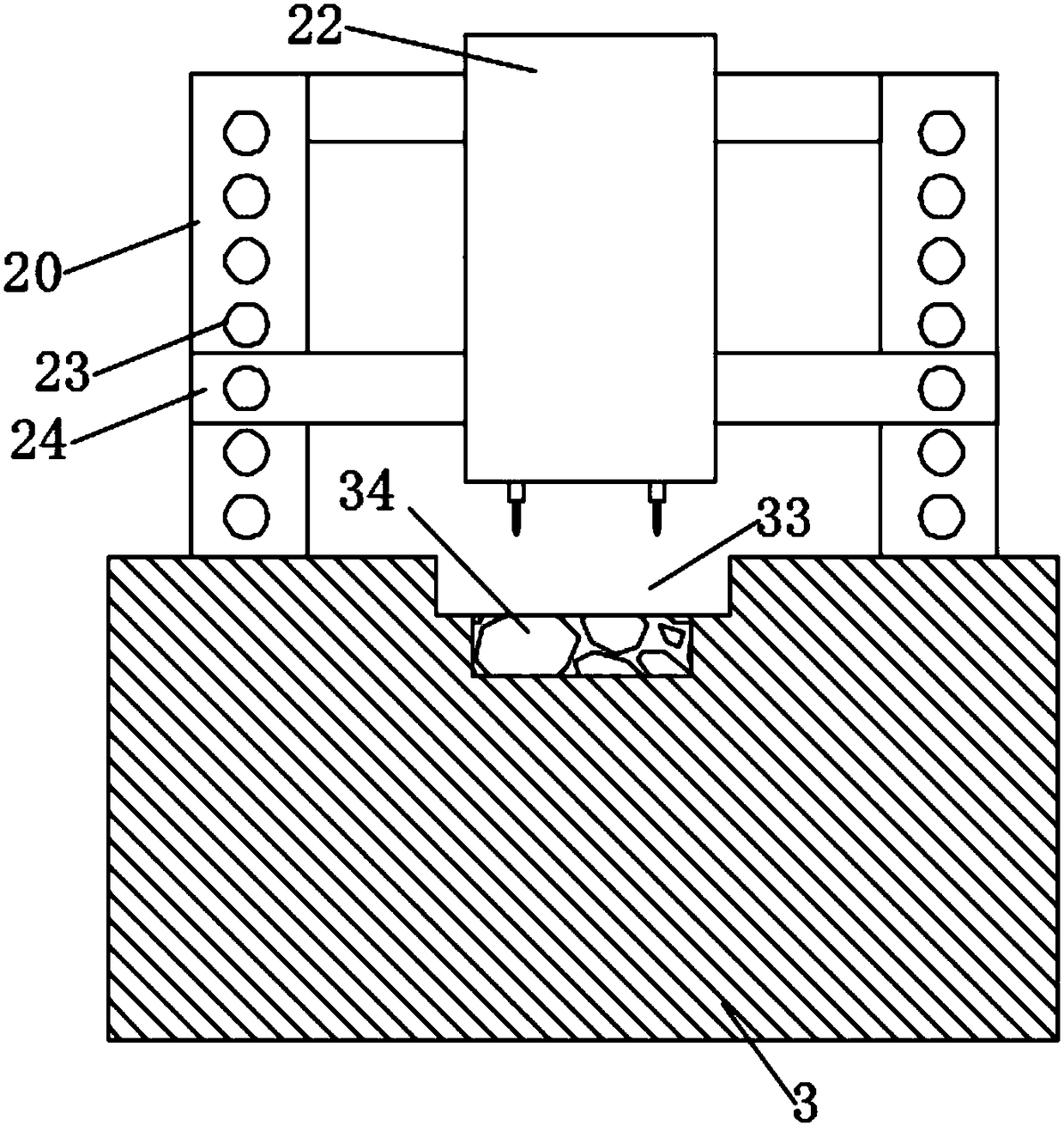

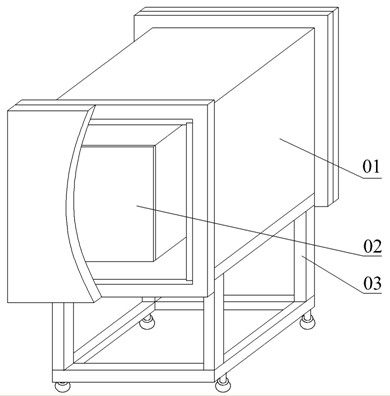

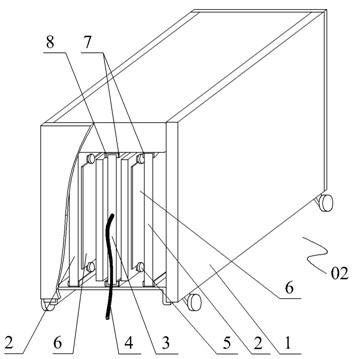

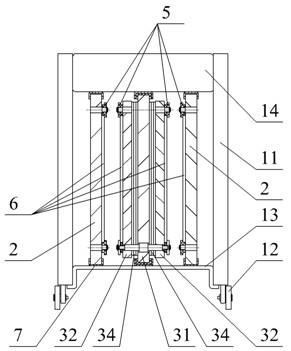

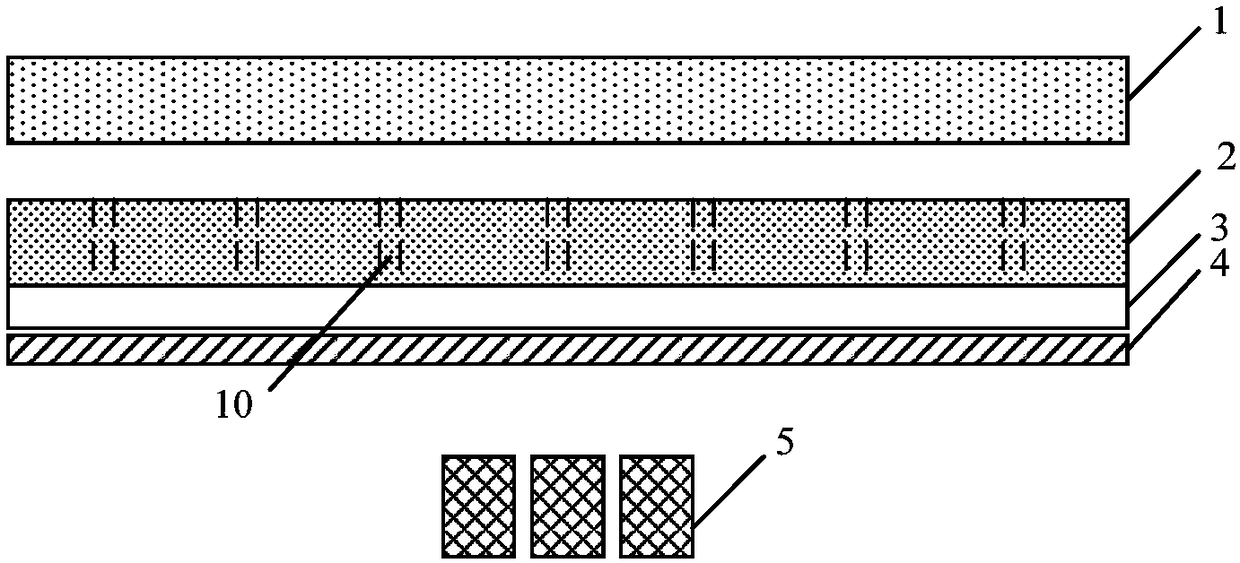

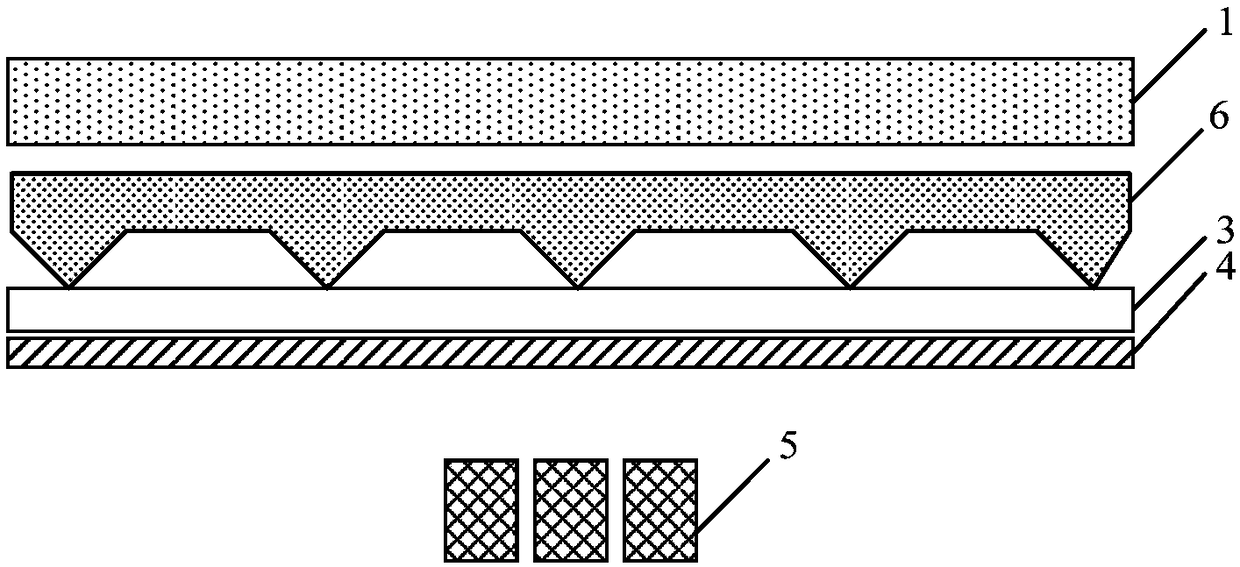

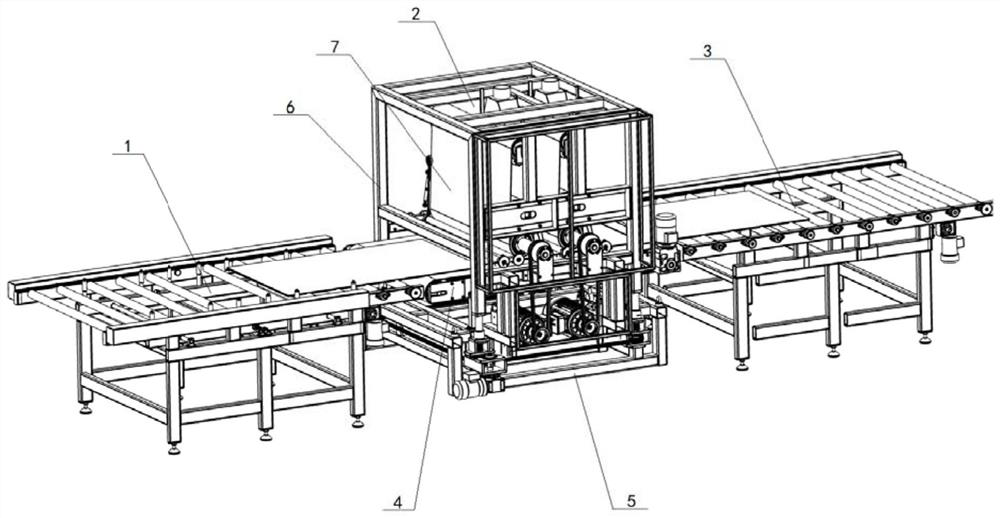

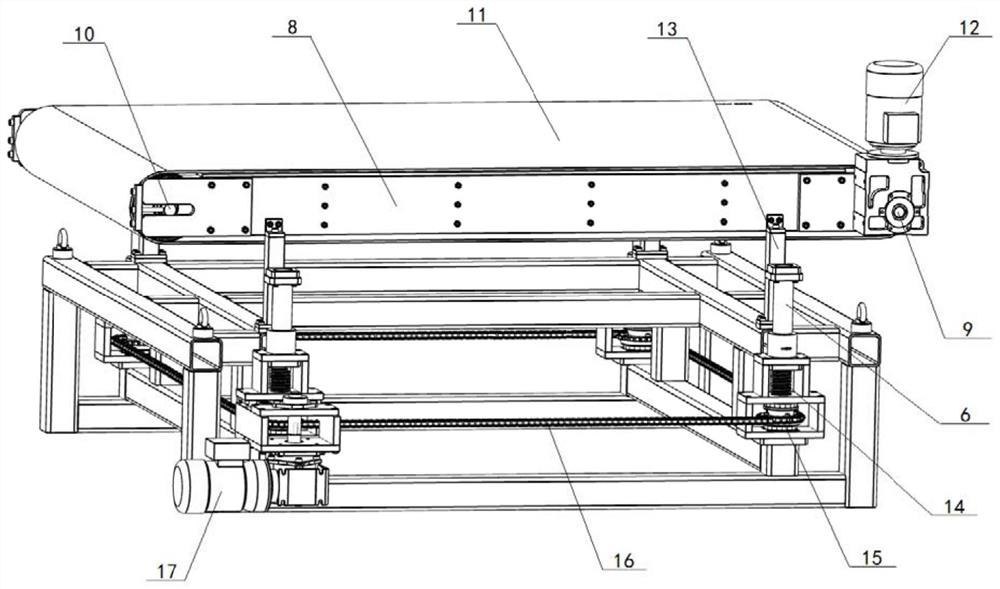

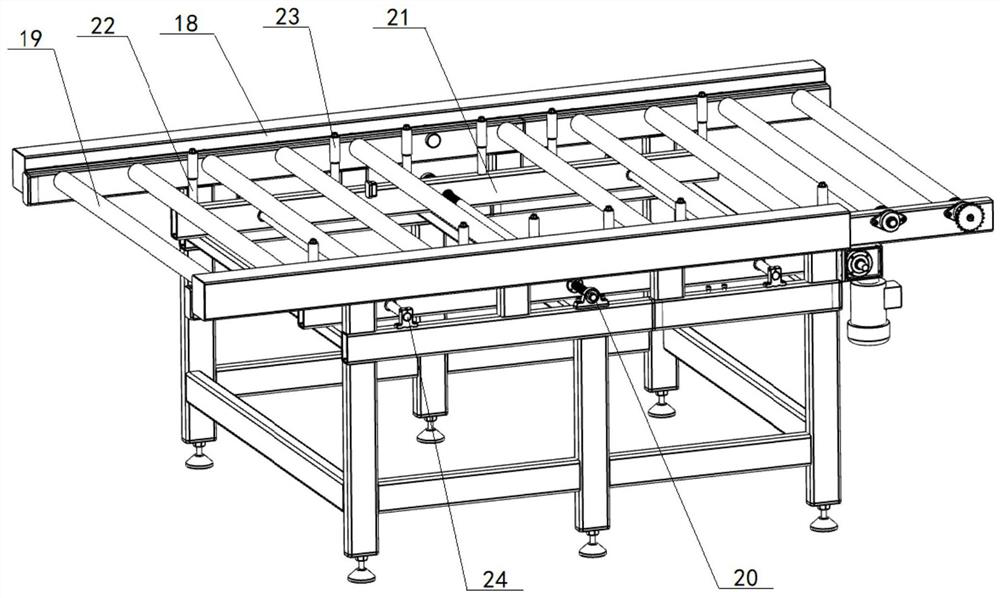

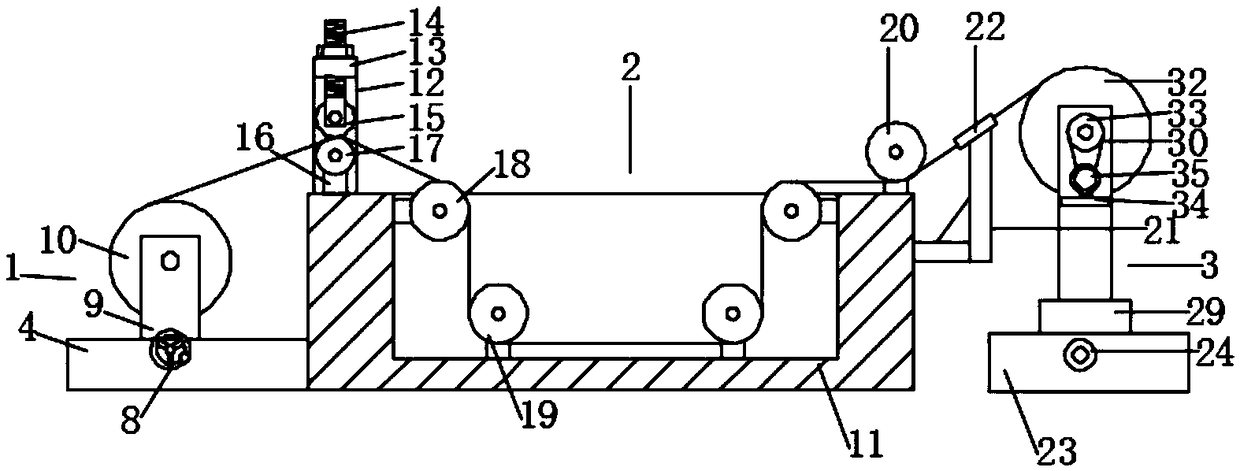

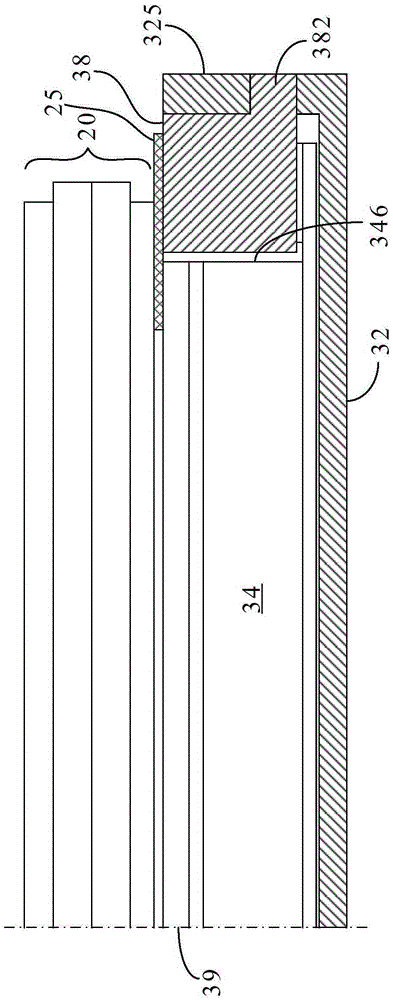

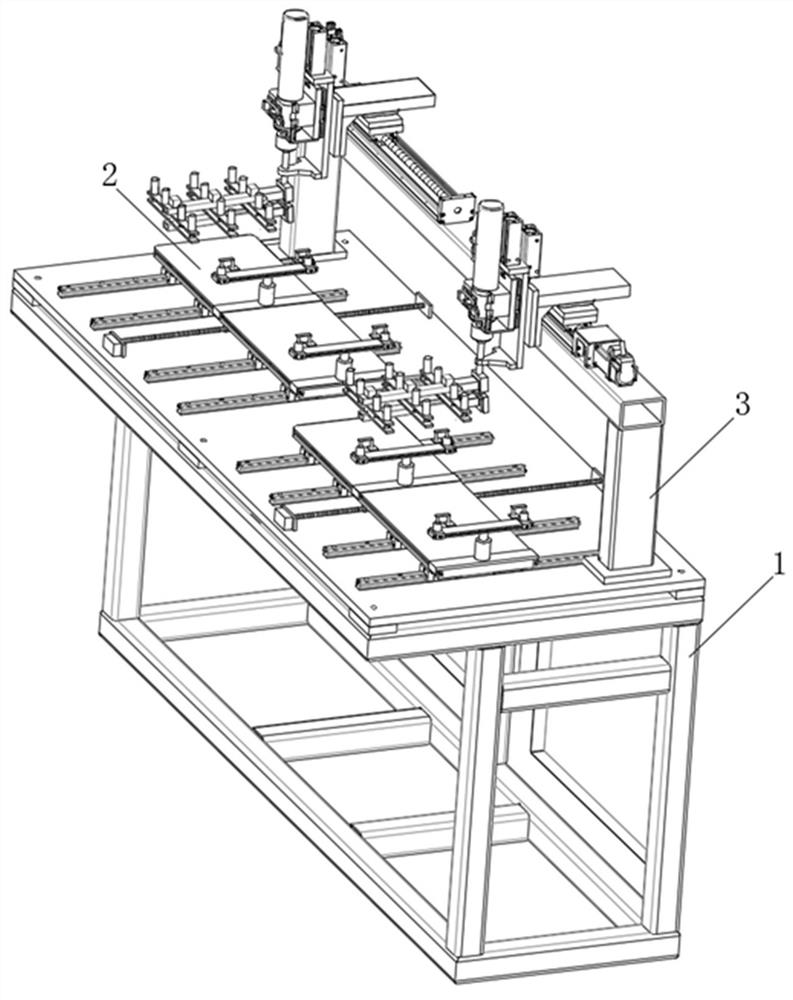

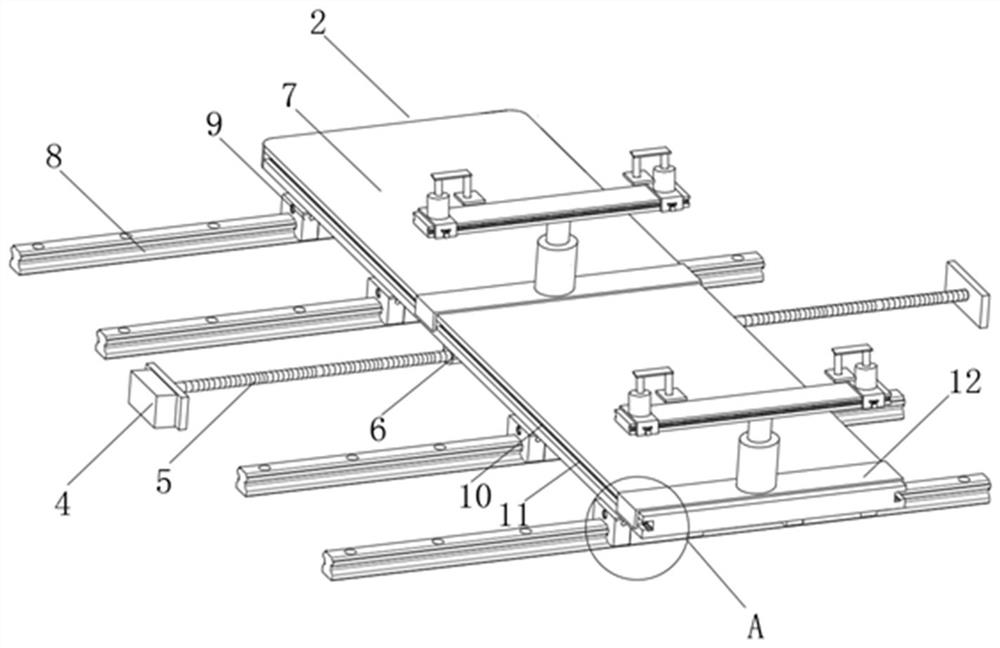

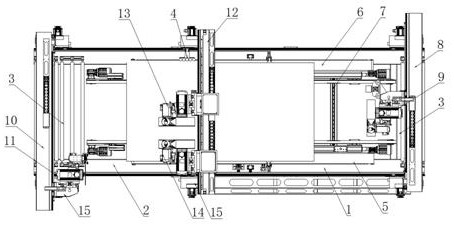

Battery string production method and equipment

ActiveCN113937190ARealize diversified productionFlexible adjustment of spacingFinal product manufacturePhotovoltaic energy generationElectrical batteryMechanical engineering

The invention discloses a battery string production method, which comprises the following steps of: arranging N battery pieces and N back diaphragms at intervals to form N laying units, and laying a welding strip group and a front diaphragm on the laying units, wherein the front diaphragm to be positioned at the top part of the welding strip group; fixedly connecting the welding strip group, the front diaphragm and the laying units into a whole to form battery units; connecting n battery units in series to obtain battery string segments, connecting the battery string segments in series to form a long string, and cutting the long string at cut-off gaps thereof to obtain battery strings. The invention further provides battery string production equipment, which comprises a film making unit, a battery piece supply unit and a solder strip preparation unit, wherein the film making unit, the battery piece supply unit and the solder strip preparation unit can be used for preparing battery pieces, front membranes, back membranes and solder strip groups, the manipulator unit can be used for laying a plurality of solder strip groups and front membranes, meanwhile, a first curing unit works to obtain the battery units, and a transfer unit conveys the multiple groups of battery units to a connecting platform to be connected in series.

Owner:NINGXIA XN AUTOMATION EQUIP CO LTD

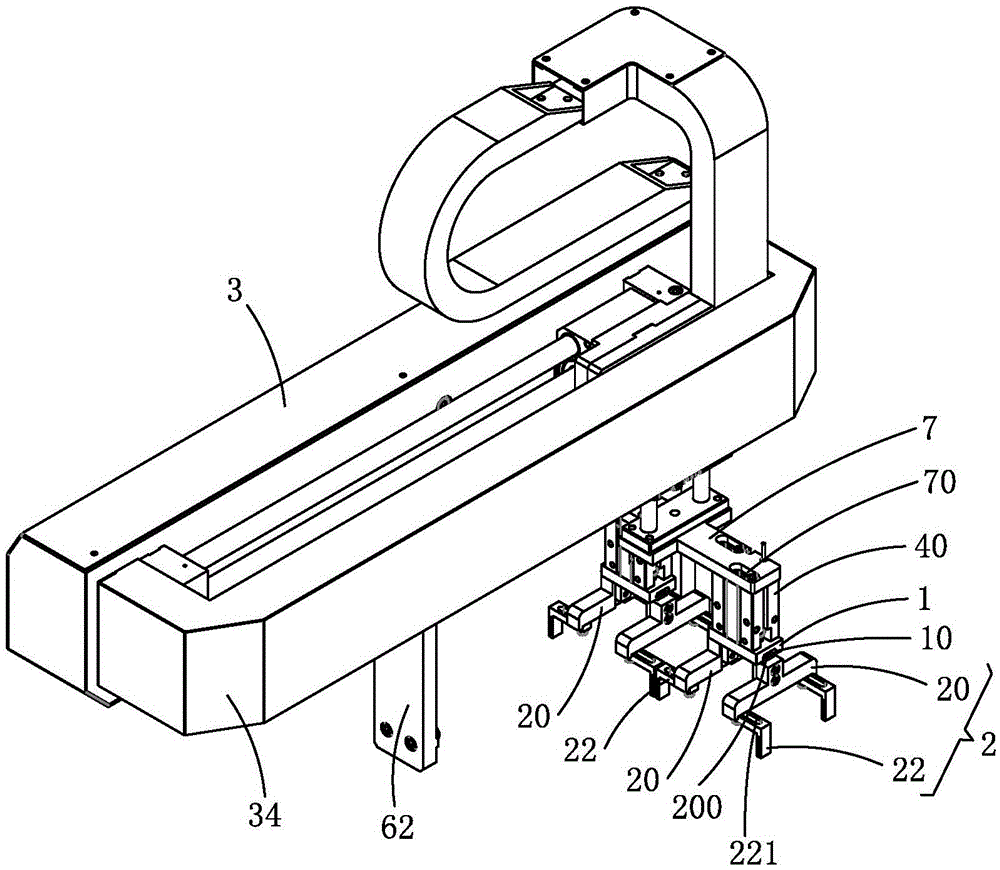

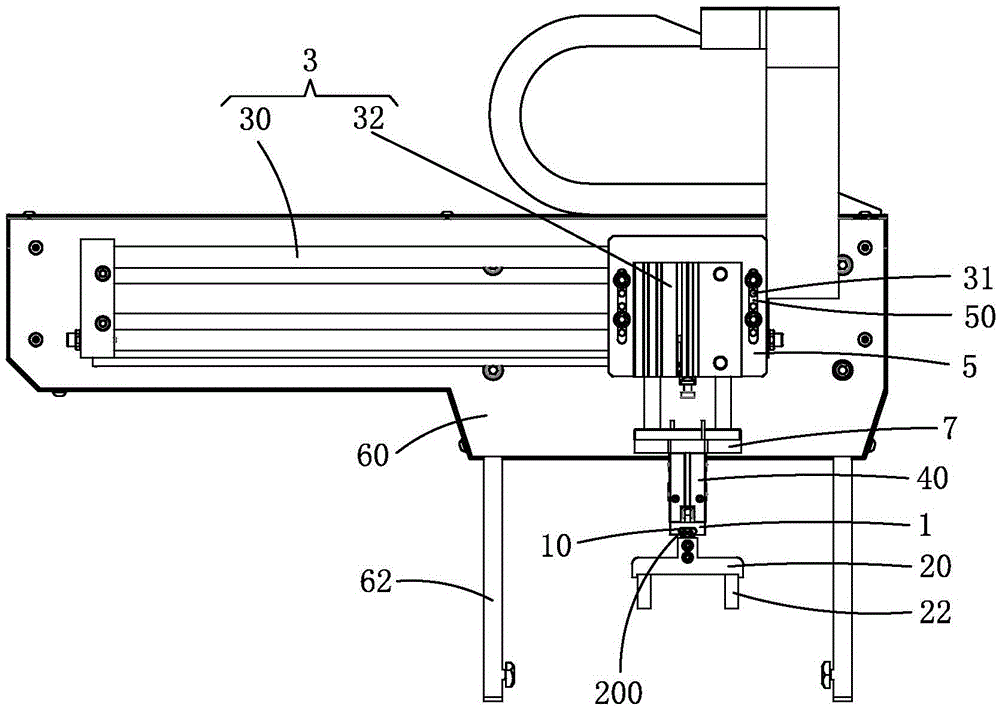

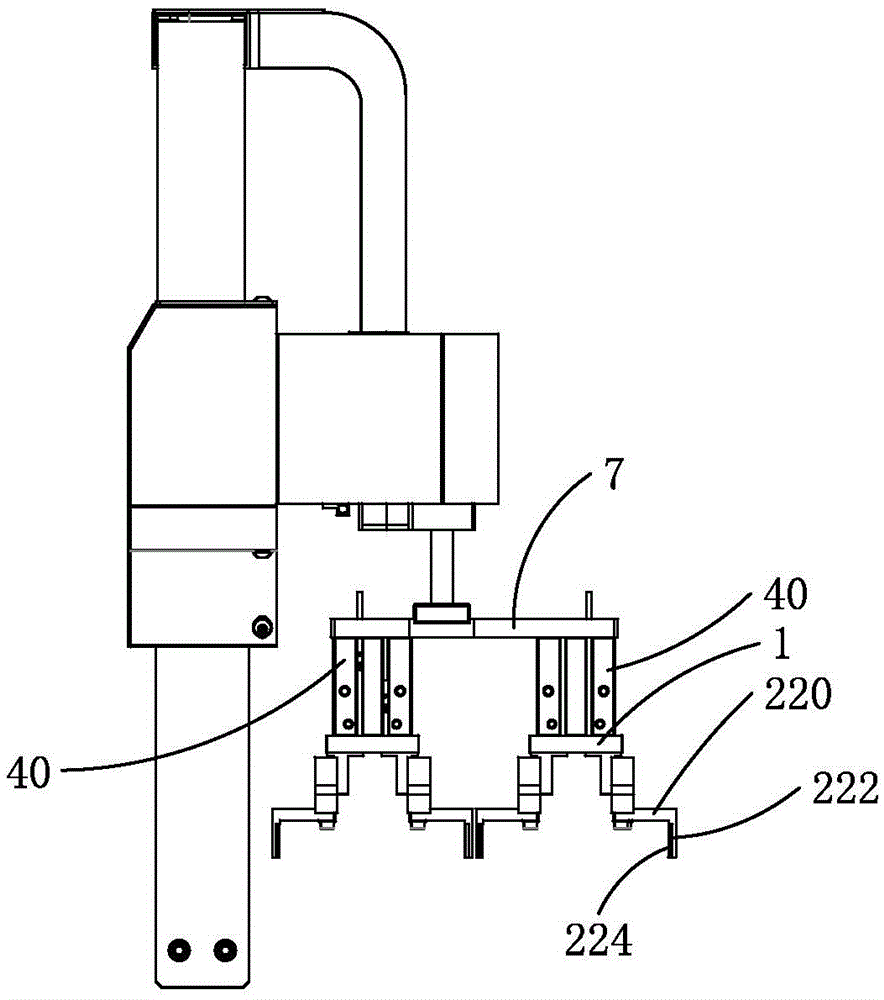

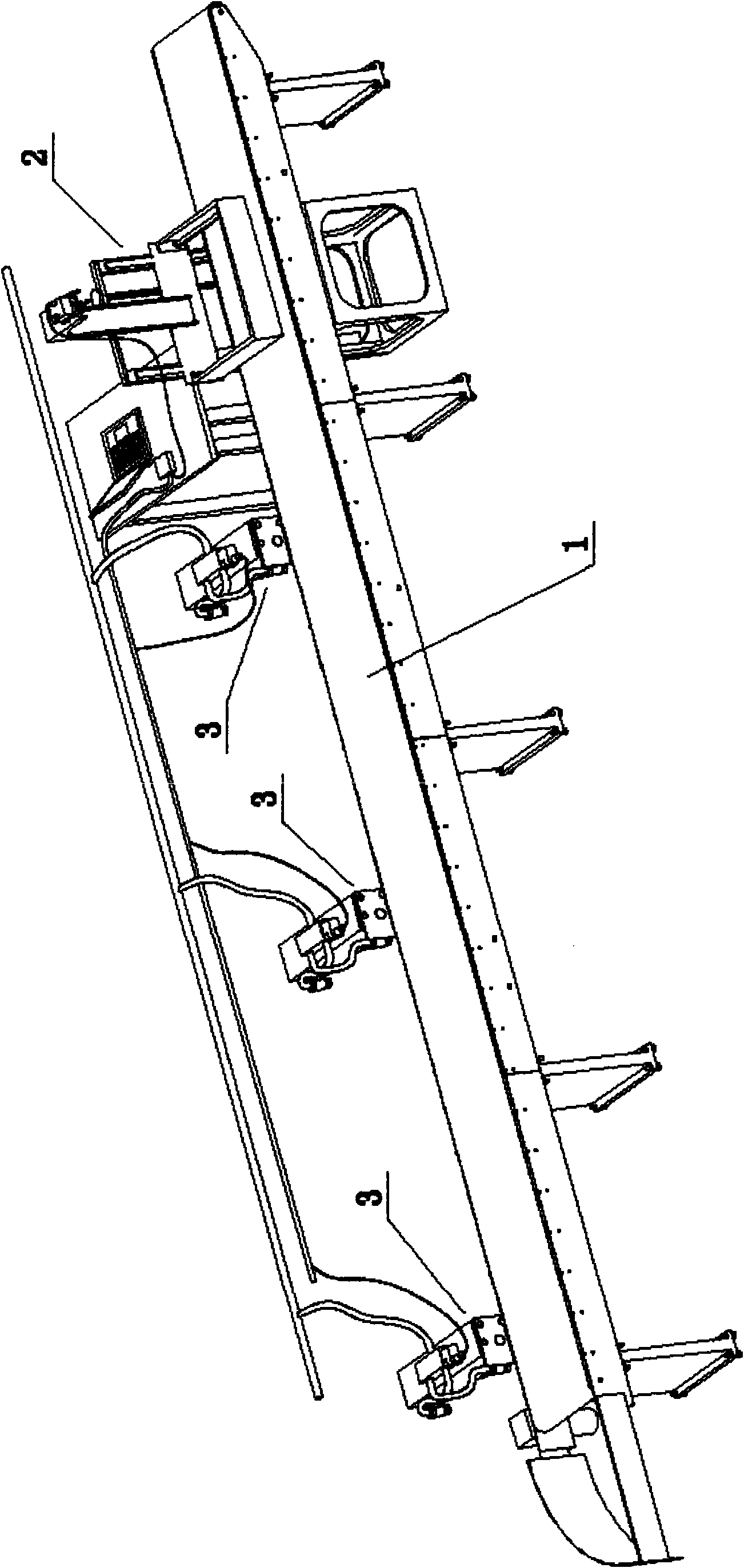

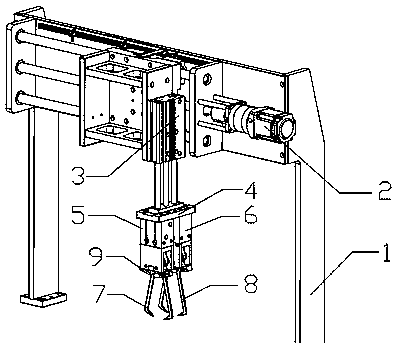

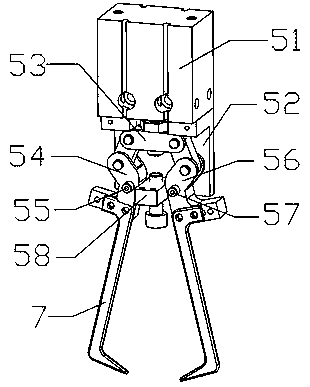

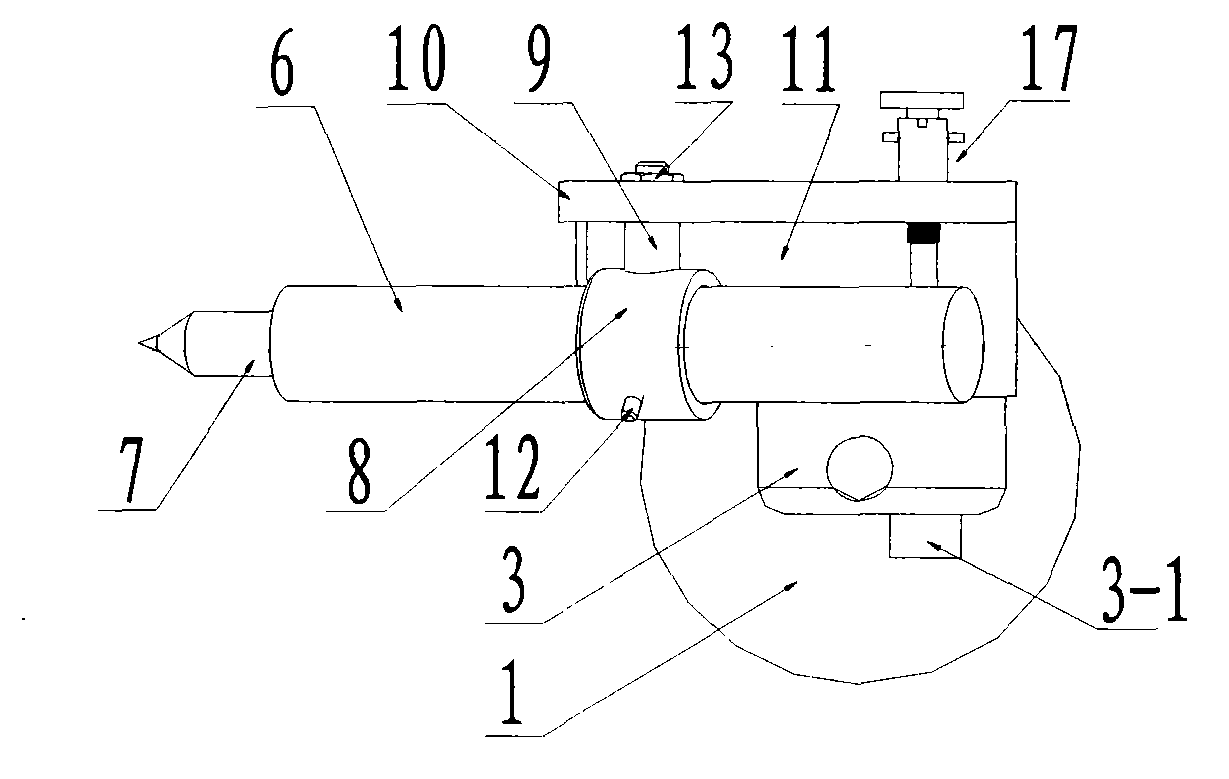

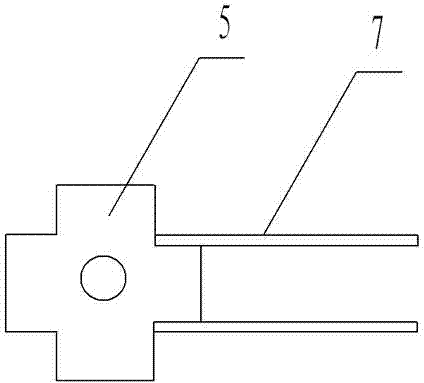

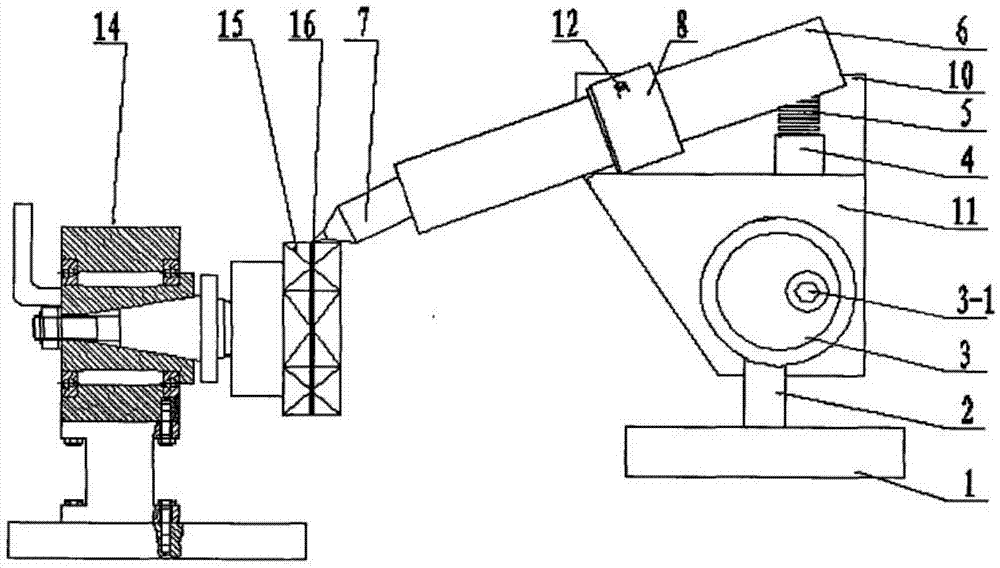

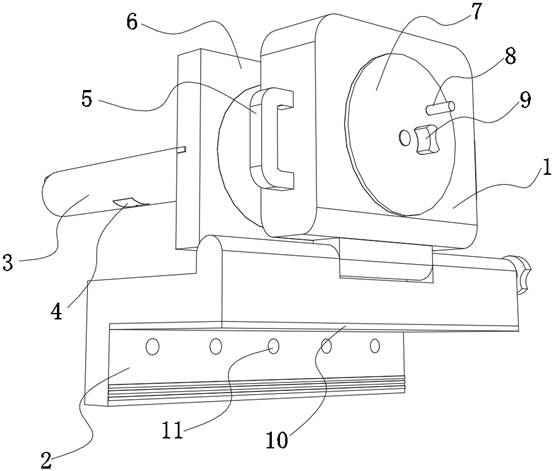

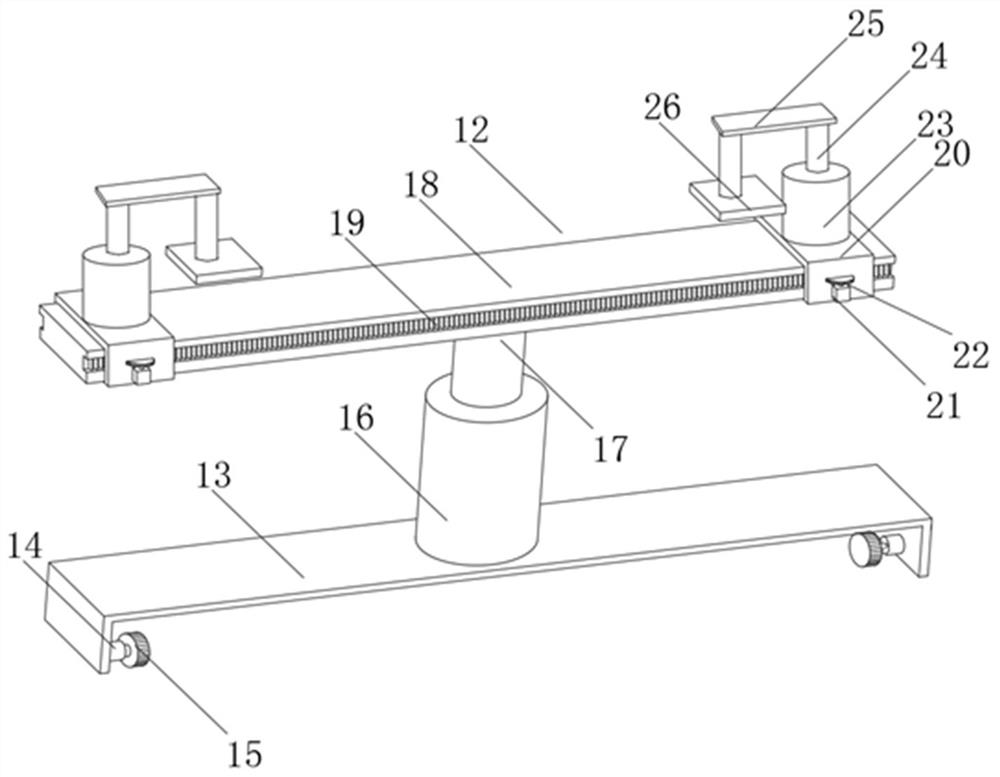

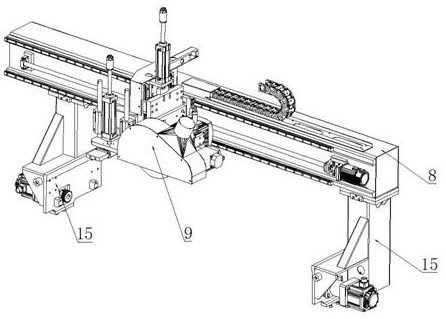

Pneumatic material taking mechanical arm

InactiveCN105563480AFlexible adjustment of spacingAchieve releaseProgramme-controlled manipulatorGripping headsEngineeringManipulator

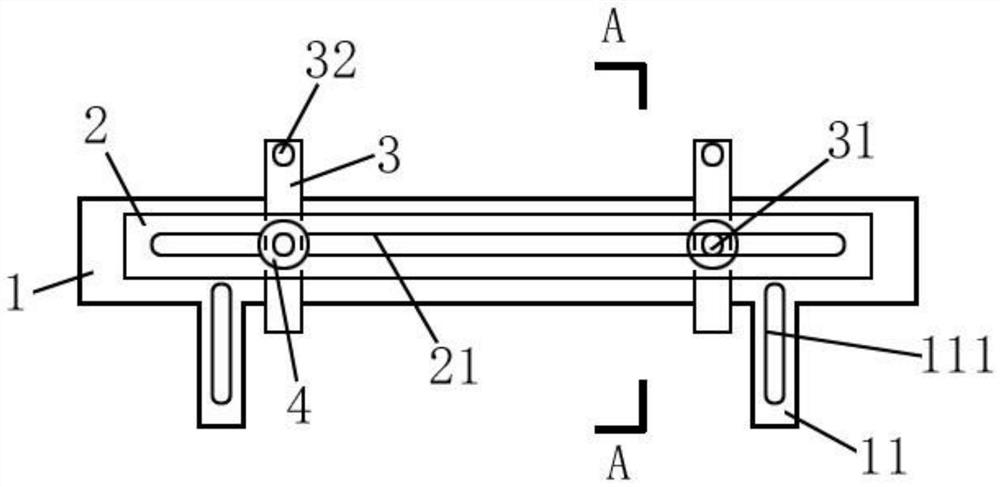

The invention provides a pneumatic material taking mechanical arm. The mechanical arm comprises a base plate, clamping fingers, a displacement mechanism and a clamping driving mechanism for driving the clamping fingers to be opened and closed; the displacement mechanism comprises a rodless air cylinder assembly and a guide rod air cylinder assembly; the rodless air cylinder assembly is arranged in the Y axis direction, and the guide rod air cylinder assembly is arranged on a movable block of the rodless air cylinder assembly and is arranged in the Z-axis direction; the base plate and the movable block of the guide rod air cylinder assembly are relatively fixedly connected, a sliding rail is arranged on the base plate, and each pair of clamping fingers comprises two transverse supports arranged on the sliding rail in a sliding manner; a plurality of mounting holes are formed in each transverse support, two mounting holes are each provided with a clamping finger unit in a locking manner, and the transverse supports of the same pair of clamping fingers and the clamping finger units are symmetrically arranged; and the clamping driving mechanism comprises a clamping air cylinder arranged in the Z axis direction and a transmission assembly which is arranged between the tail end of a piston rod of the clamping air cylinder and the top ends of the transverse supports so as to drive the two transverse supports of each pair of clamping fingers and the clamping finger units on the two transverse supports to synchronously move in an opposite or backing manner. The pneumatic material taking mechanical arm is simple in overall structure and high in applicability.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

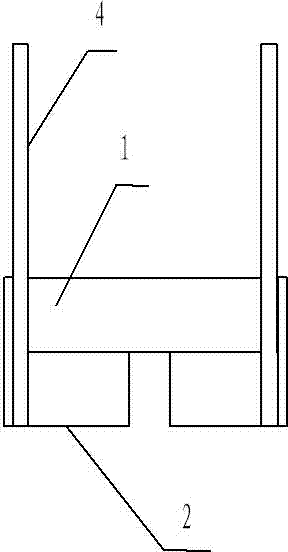

Supporting structure of foundation pit

The invention discloses a supporting structure of a foundation pit. The supporting structure comprises jet grouting piles and a double-row pile structure which is inserted in the jet grouting piles, wherein the jet grouting piles are high-strength cement-soil pile bodies formed on a soil body around the foundation pit, and the multiple jet grouting piles are in mutual lap joint to form a reinforcing region; the double-row pile structure comprises a first row of cast-in-place piles, a second row of cast-in-place piles and connecting beams, the connecting beams are connected with the tops of the first row of cast-in-place piles and the tops of the second row of cast-in-place piles, and the first row of cast-in-place piles, the second row of cast-in-place piles and the connecting beams are all of a reinforced concrete structure. According to the scheme, the supporting structure aims to brace the deep foundation pit under the complicated geological condition with rich water and soft soil and under the condition that complicated barriers cut through the upper portions of the foundation pit; when the barriers such as cables cut through the upper portion of the foundation pit, the intervals between the cast-in-place piles can be flexibly adjusted to avoid the barriers; the large-diameter high-pressure jet grouting piles are in mutual lap joint, can effectively stop water and can control horizontal displacement of the soil body outside the pit along with the double rows of cast-in-place piles; the supporting structure formed by the cast-in-place piles is constructed in the large-diameter jet grouting piles, and therefore construction sites outside the foundation pit are saved.

Owner:CCCC HIGHWAY CONSULTANTS +1

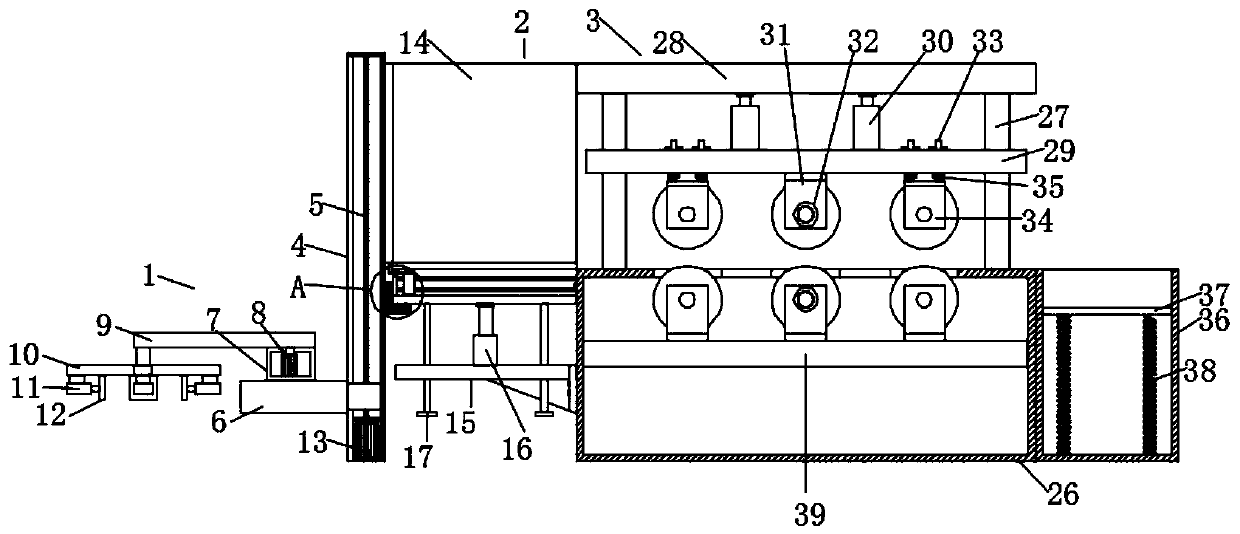

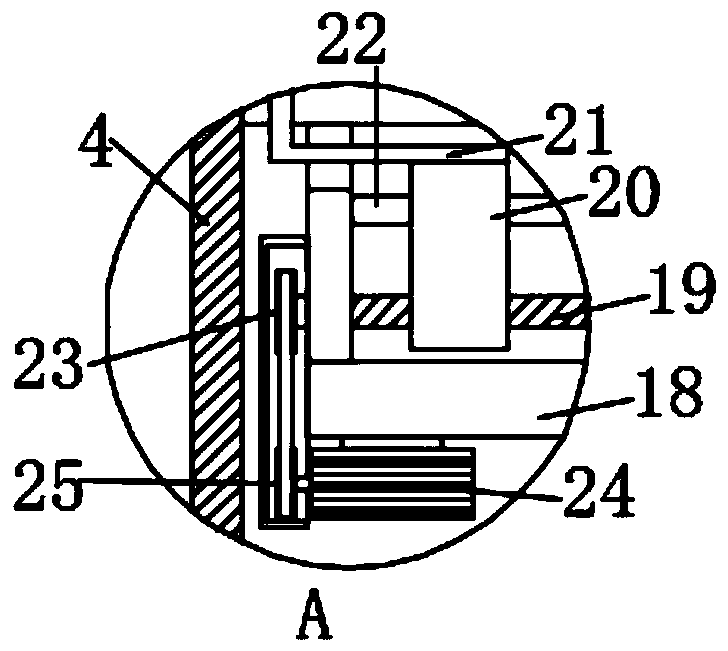

Modified plastic-wood profile embossing device and embossing process thereof

PendingCN110328729AIncrease the scope of applicationAutomateConveyorsWood compressionEngineeringHook plate

The invention discloses a modified plastic-wood profile embossing device and an embossing process thereof. The embossing device comprises a feeding mechanism, a conveying mechanism and an embossing mechanism, wherein the embossing mechanism is composed of a working table, distance adjusting slide rods, a top plate, an adjusting sliding plate, a distance adjusting air cylinder, pressing rollers, adriving motor, a buffering sliding rod, an auxiliary roller, a buffer spring, a collecting box, a material receiving plate and a return spring, wherein the four corners of the top of the working tableare fixedly connected with the distance adjusting slide rods. According to the modified plastic-wood profile embossing device and the embossing process thereof, through arranging the feeding mechanism and under the action of a lifting motor and a clamping air cylinder, profiles can be automatically fed without manual carrying, which leads to the saving of time and labor; in addition, under the action of the distance adjusting air cylinder, distances between the pressing rollers can be flexibly adjusted, so that the device can be applied to the profiles of different thickness, which improves the application range of the device; finally, through setting a storage box and a push hook plate, the automatic conveying and adding of the profiles is facilitated, so that both automation and intelligentization can be realized, thus reducing labor intensity of workers as well as improving embossing processing efficiency of modified plastic-wood profiles.

Owner:南京聚锋新材料有限公司 +1

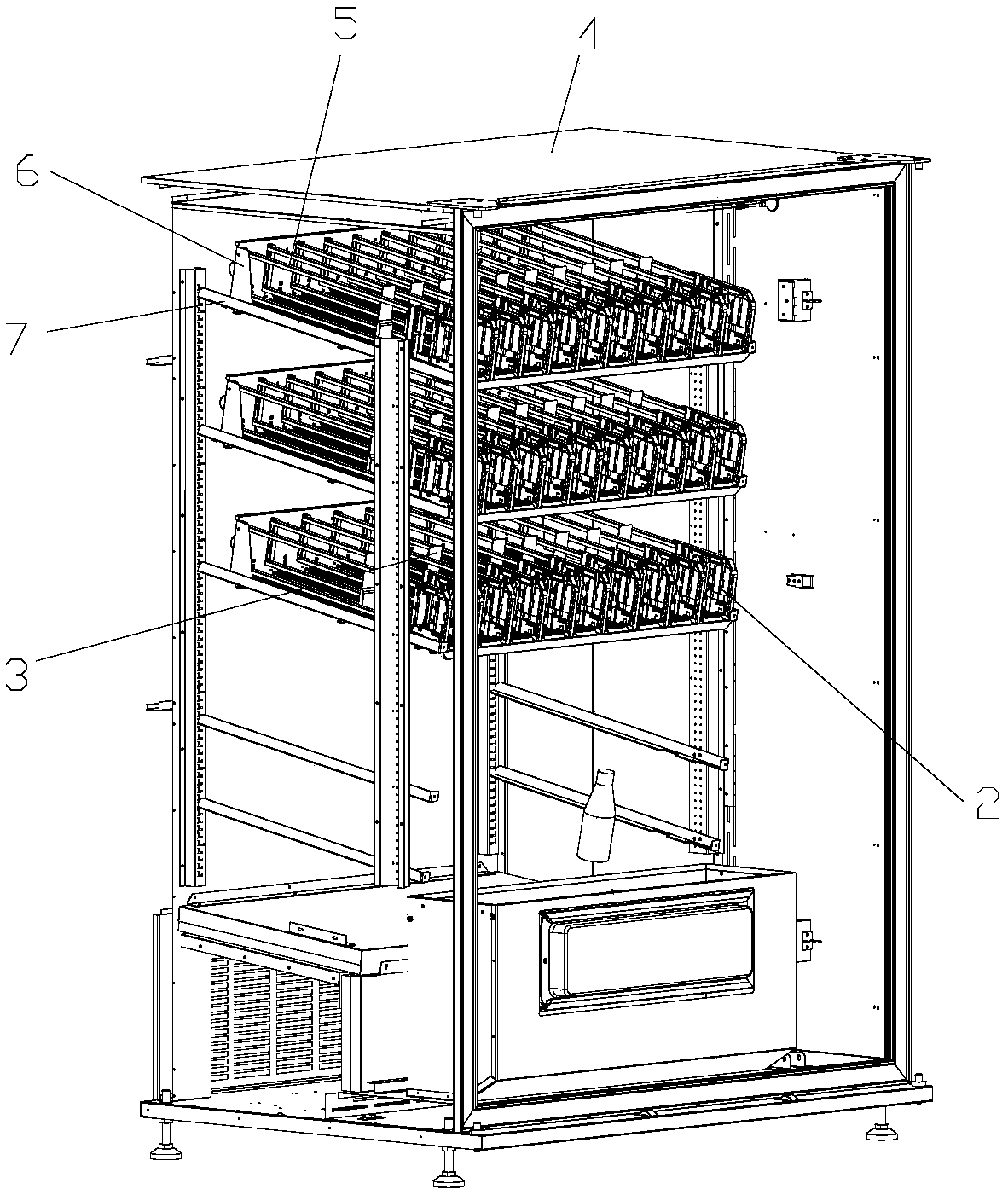

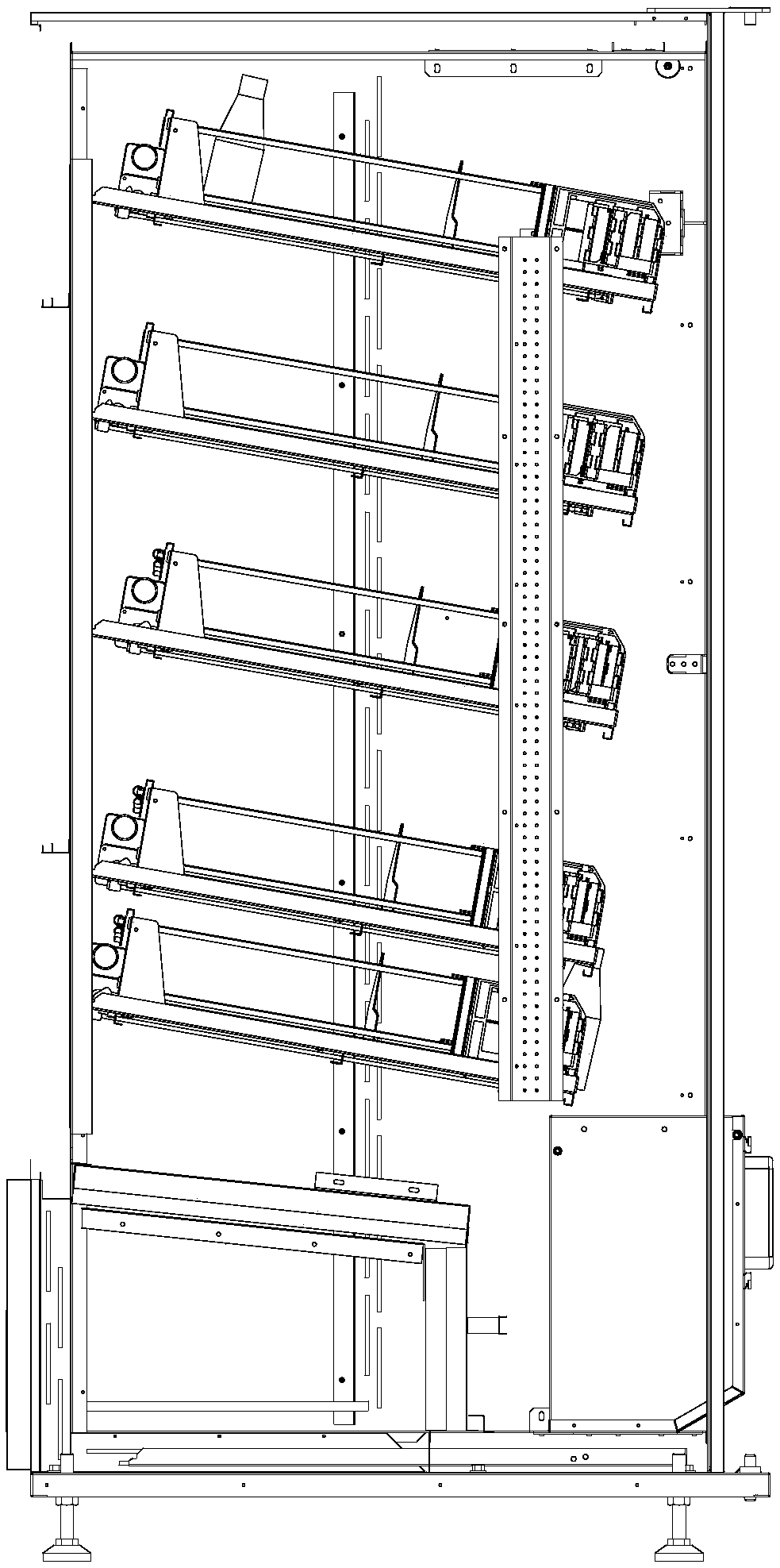

Elastic clip type vending machine discharging device and method

PendingCN108986315AIncrease distanceAchieve replyCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringCam

The invention discloses an elastic clip type vending machine discharging device and method. The elastic clip type vending machine discharging device is characterized in that the device comprises a push plate mechanism, a gate mechanism and a gate driving mechanism, wherein the gate mechanism is a hinge type gate mechanism, the push plate mechanism is used for providing outward thrust for goods ona goods channel, the gate mechanism is arranged at a goods outlet of a goods shelf, is closed to stop goods from being pushed out when the goods are not discharged, and is opened to allow the goods tobe pushed out when the goods are discharged, the gate driving mechanism is used for driving a gate mechanism switch, the gate driving mechanism is an electric driving mechanism, and the gate drivingmechanism adopts the combination of a cam-based driving mechanism and a manual pressing-based driving structure. The elastic clip type vending machine discharging device adopts the hinge gate mechanism and the cam-based driving mechanism, is ingenious in structure, and is easy to implement.

Owner:HUNAN KIMMA INTELLIGENT EQUIP MFR

Method and device for sorting wood according to colors and wood grains

The invention discloses a method and a device for sorting wood according to colors and wood grains. The method comprises the following steps of: establishing categorical data, collecting wood images, confirming wood categories, starting sorting devices, and the like. The device comprises a wood conveying belt, a wood video imaging device, a plurality of wood sorting devices and a program control system, wherein the video imaging device is arranged at the beginning end of the wood conveying belt, the plurality of wood sorting device are arranged at the lateral side of the wood conveying belt at the downstream of the video imaging device in an equidistance way, and the video imaging device and the plurality of wood sorting devices are respectively in circuit connection with the program control system. The invention has accurate sorting and high working efficiency and avoids the individual difference and the inconsistency of manual sorting.

Owner:UNION BROTHER (SHANGHAI) MACHINREY CO LTD

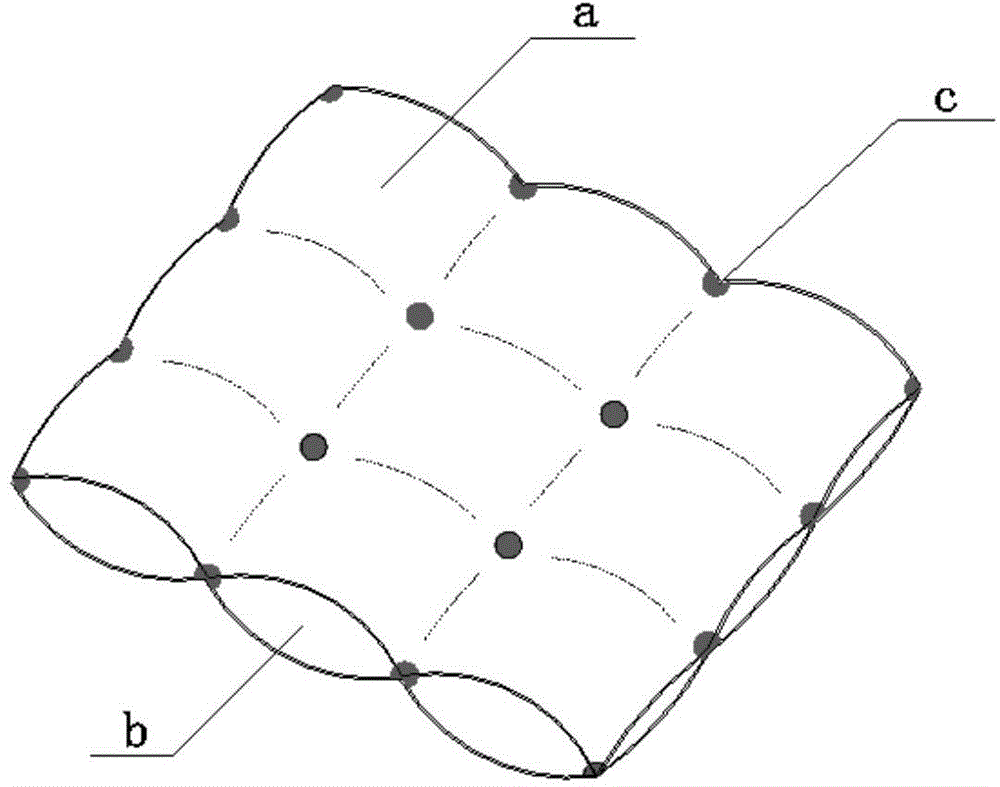

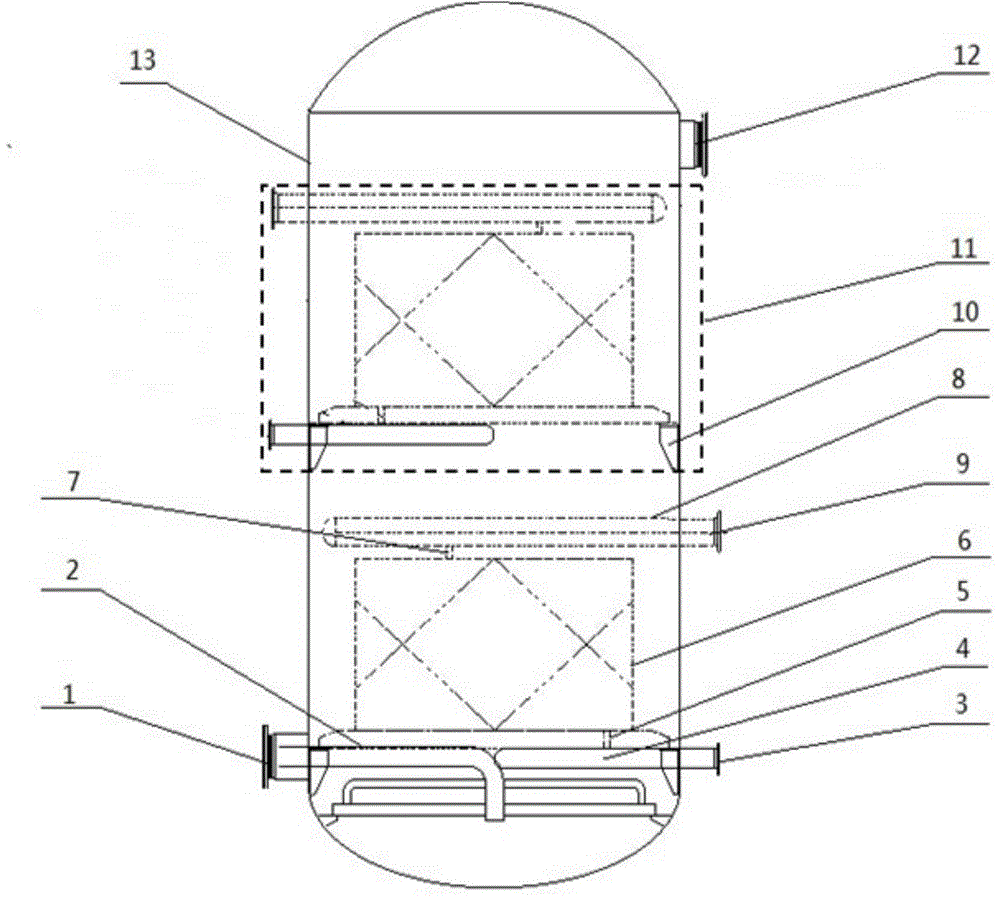

Plate type heat exchange reactor

ActiveCN104801240AImprove heat transfer effectNo short circuitChemical/physical/physico-chemical processesEngineeringDistributor

The invention relates to a plate type heat exchange reactor which comprises a reactor shell, a material distributor and plate type heat exchange elements, wherein the reactor shell comprises at least one reaction material inlet and one reaction material outlet as well as at least one heat exchange medium inlet and one heat exchange medium outlet; the material distributor is arranged at the top or the bottom of the reactor according to the reaction property; each plate type heat exchange element comprises multiple heat exchange plate pairs, heat exchange medium inlet and outlet coil pipes and distribution pipes, two ends of each heat exchange plate pair are connected with the heat exchange medium inlet and outlet coil pipes through the distribution pipes, the heat exchange medium inlet and outlet coil pipes are connected with the heat exchange medium inlet and outlet, a plate-side pass cavity for medium circulation is formed in each heat exchange plate pair, and shell-side pass cavities for reaction material circulation are formed between adjacent heat exchange plate pairs as well as between each heat exchange plate pair and the reaction shell. Compared with the prior art, the plate type heat exchange reactor has the advantages of flexible structural adjustment, high heat exchange efficiency, low cost, convenience in cleaning and the like.

Owner:ATHCO ENG SHANGHAI CO LTD

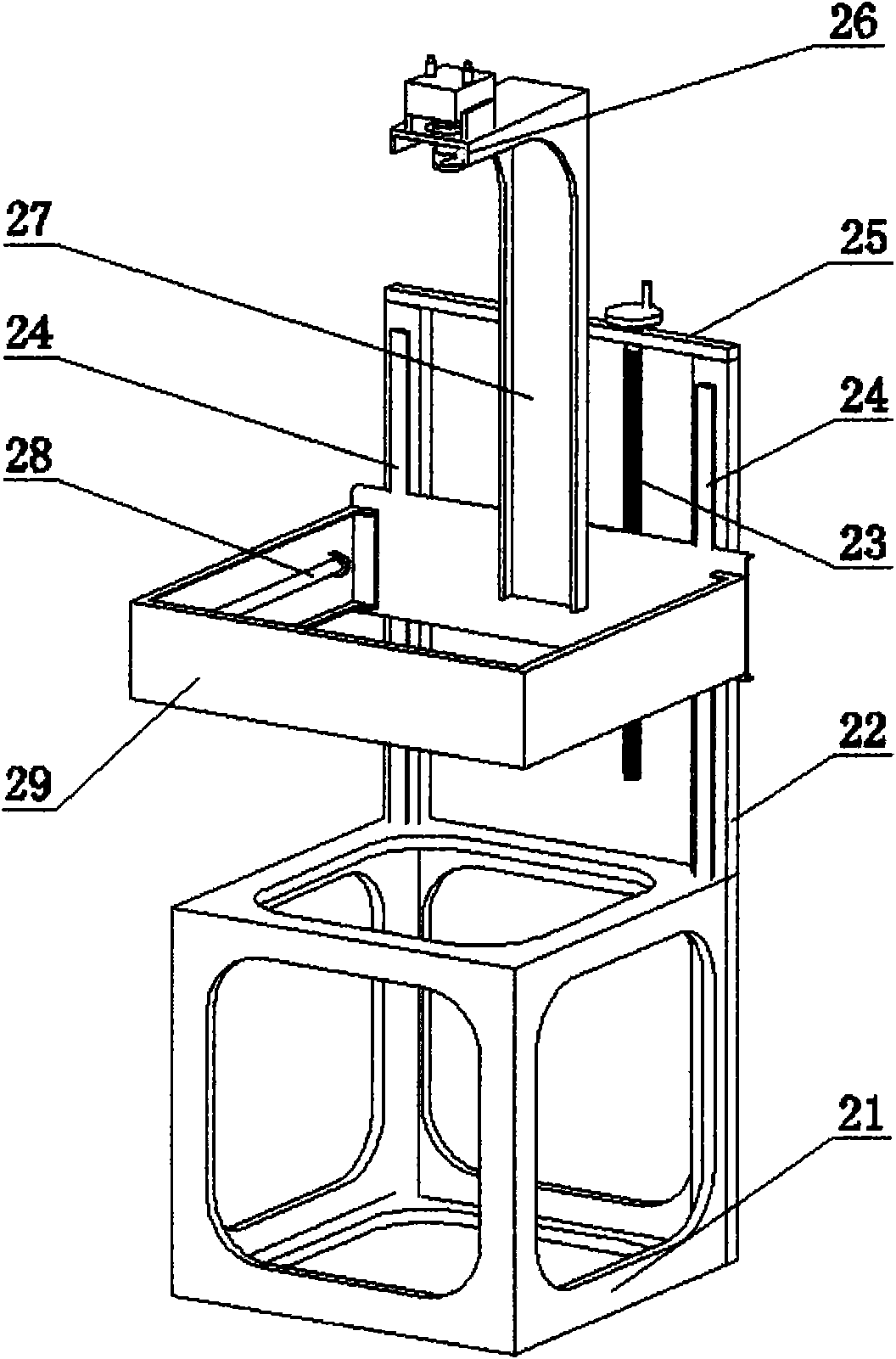

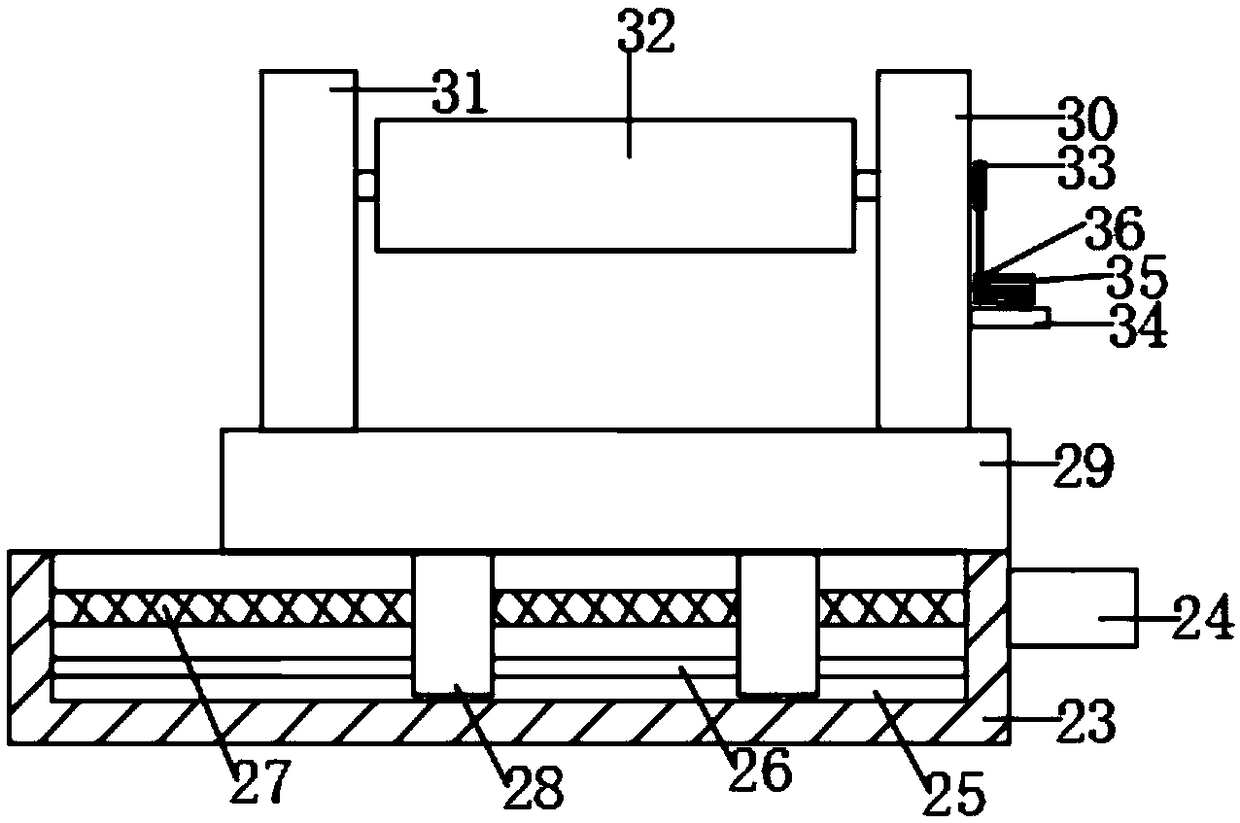

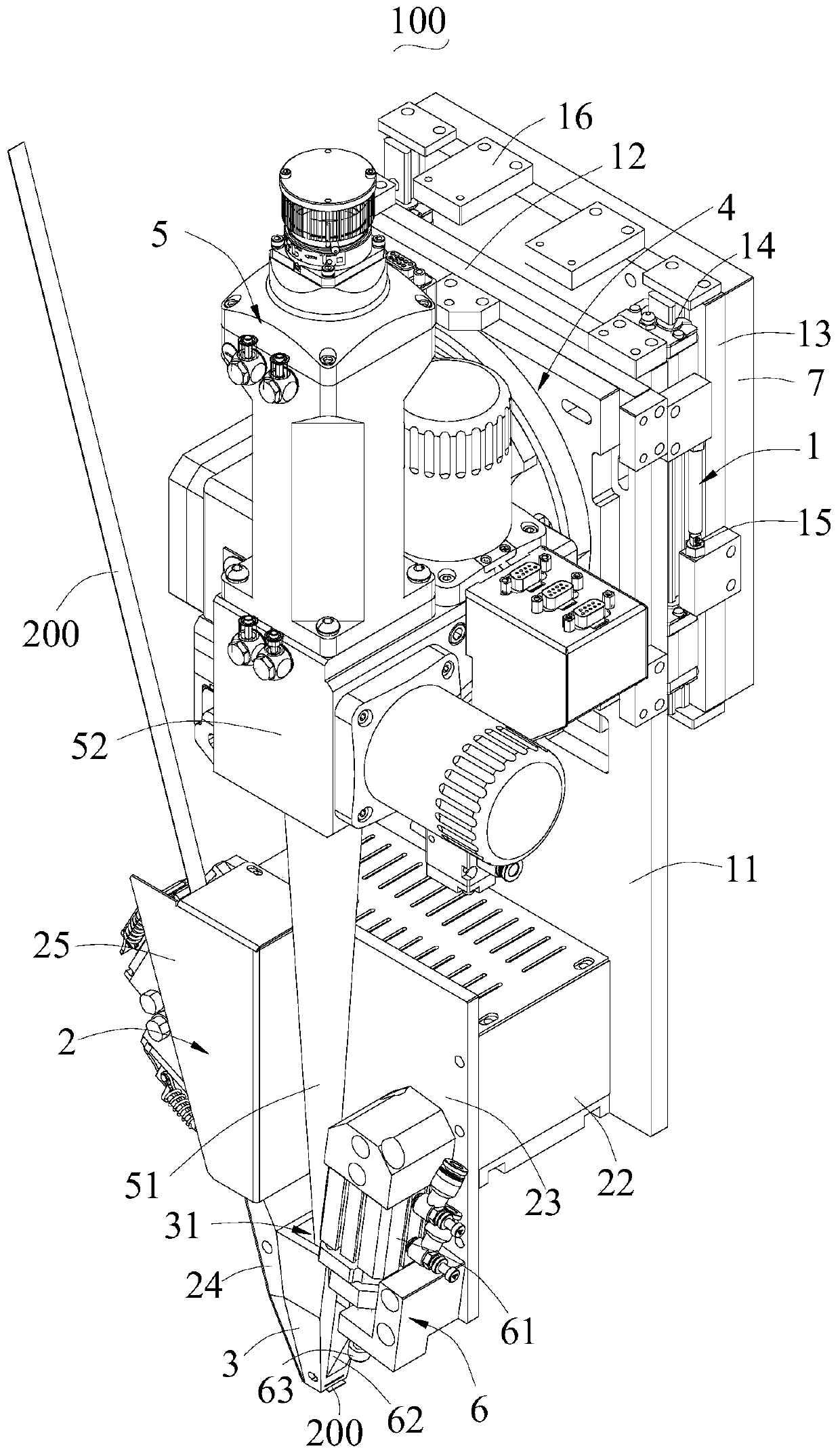

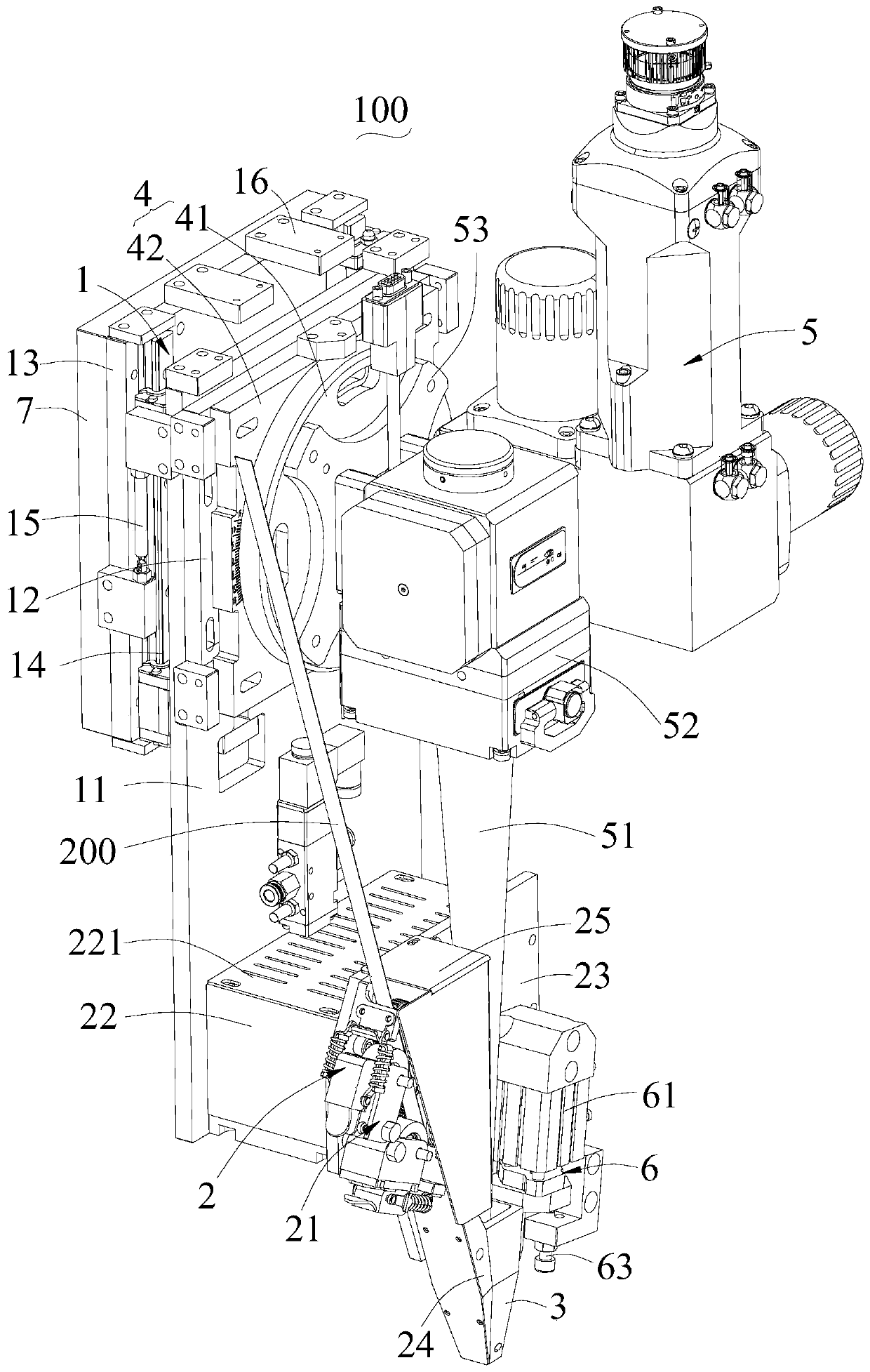

Novel type gripping mechanism with interval size being adjustable

InactiveCN109648547AFlexible adjustment of spacingFlexible spacing adjustmentProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

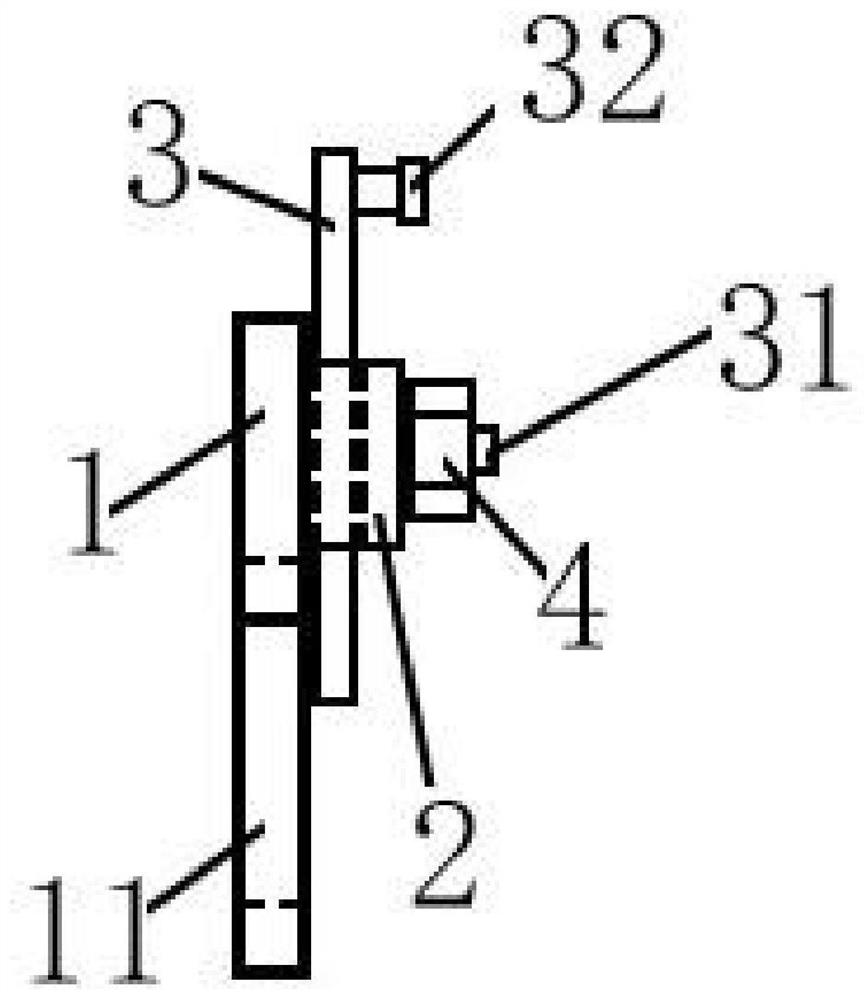

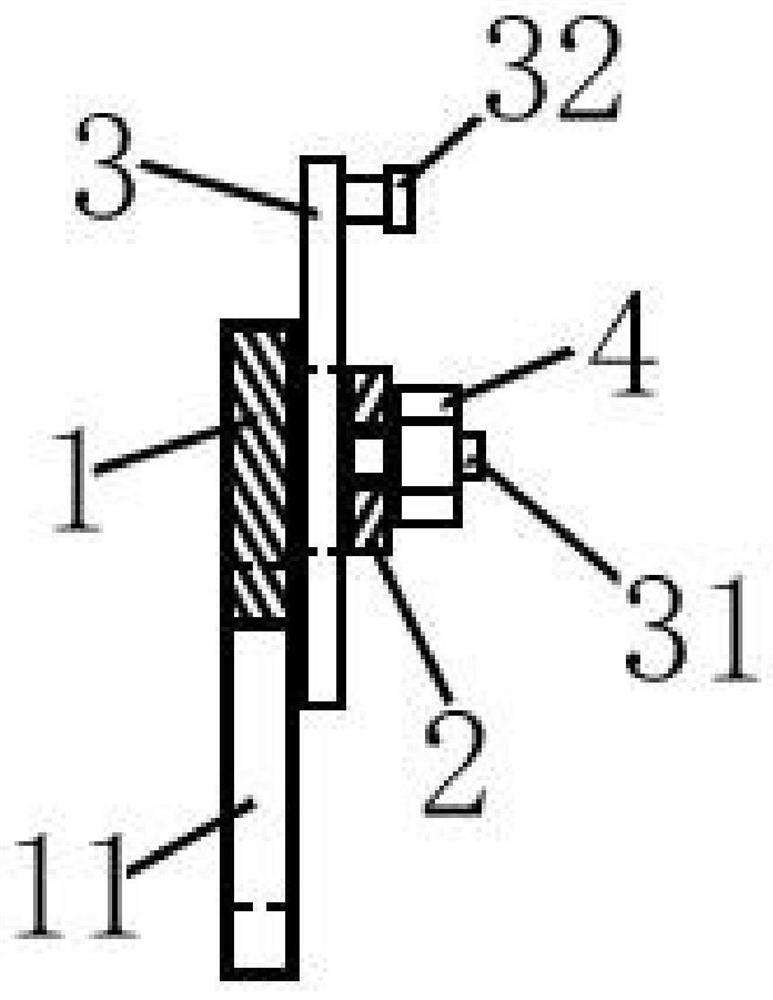

The invention relates to a novel type gripping mechanism with interval size being adjustable. The novel type gripping mechanism with interval size being adjustable comprises a supporting frame and further comprises a horizontal translocation assembly, an assembly lifting cylinder, an assembly installation plate, a first gripping power assembly, a first positioning assembly, a second gripping powerassembly, a second positioning assembly, a first clamping jaw set and a second clamping jaw set. A working end of the horizontal translocation assembly is connected with a fixed end of the assembly lifting cylinder. A working end of the assembly lifting cylinder is connected with the upper wall of the assembly installation plate. Both the first gripping power assembly and the second gripping power assembly are installed in the lower portion of the assembly installation plate and are arranged front and back. A working end of the first gripping power assembly is connected with the first clamping jaw set through the first positioning assembly. A working end of the second gripping power assembly is connected with the second clamping jaw set through the second positioning assembly. According to the novel type gripping mechanism with interval size being adjustable, the interval between the first clamping jaw set and the second clamping jaw set can be adjusted so that products of different sizes can be conveniently clamped; the application range is wide; the structure is compact; practicability is high; and the gripping mechanism has good market application value.

Owner:深圳市欧达斯科技有限公司

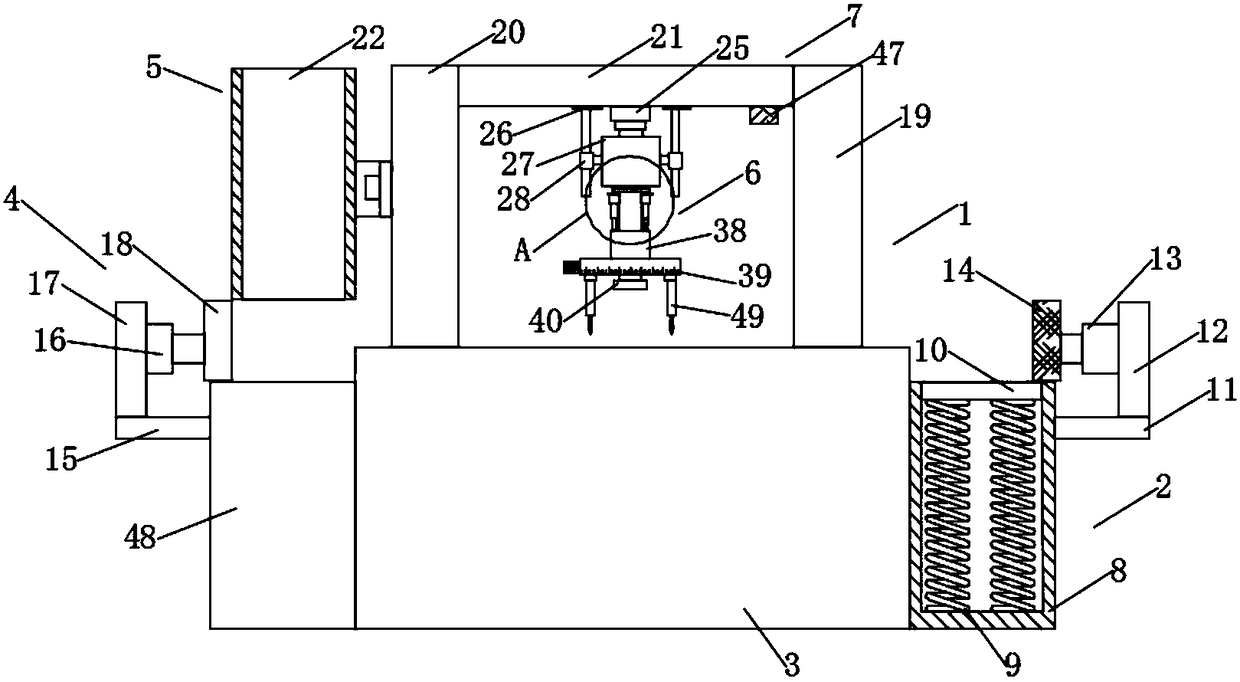

Automatic spot welding device for metal machining

InactiveCN108544158AEasy to use for processingFeeding for processing does not requireWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderMetal machining

The invention discloses an automatic spot welding device for metal machining. The automatic spot welding device comprises a spot welding device body, the spot welding device body consists of a material receiving mechanism, a worktable, a feeding mechanism, a material storage mechanism, a spot welding mechanism and a supporting mechanism, wherein one end of the worktable is fixedly connected with the material receiving mechanism, the other end which is relatively to the material receiving mechanism of the worktable is fixedly connected with the feeding mechanism. According to the device, the structure is compact, the feeding usage of the metal machining is facilitated, through the arrangement of the feeding mechanism, a material is pushed to the right lower part of a pressing block througha feeding hydraulic cylinder during use, so that manual operation is not needed, the device is simple and convenient, the labor intensity is reduced, the inaccurate spot welding position caused by inaccurate feeding position is avoided, and the accuracy of the spot welding device is improved; and through the arrangement of a rotating box and a distance adjusting motor, the distance between weldingheads can be flexibly adjusted according to the position where the spot welding is needed by the spot welding device, so that the structure of the spot welding device is flexible and adjustable, thepracticability of the spot welding device is improved, and the production efficiency is improved.

Owner:刘道灵

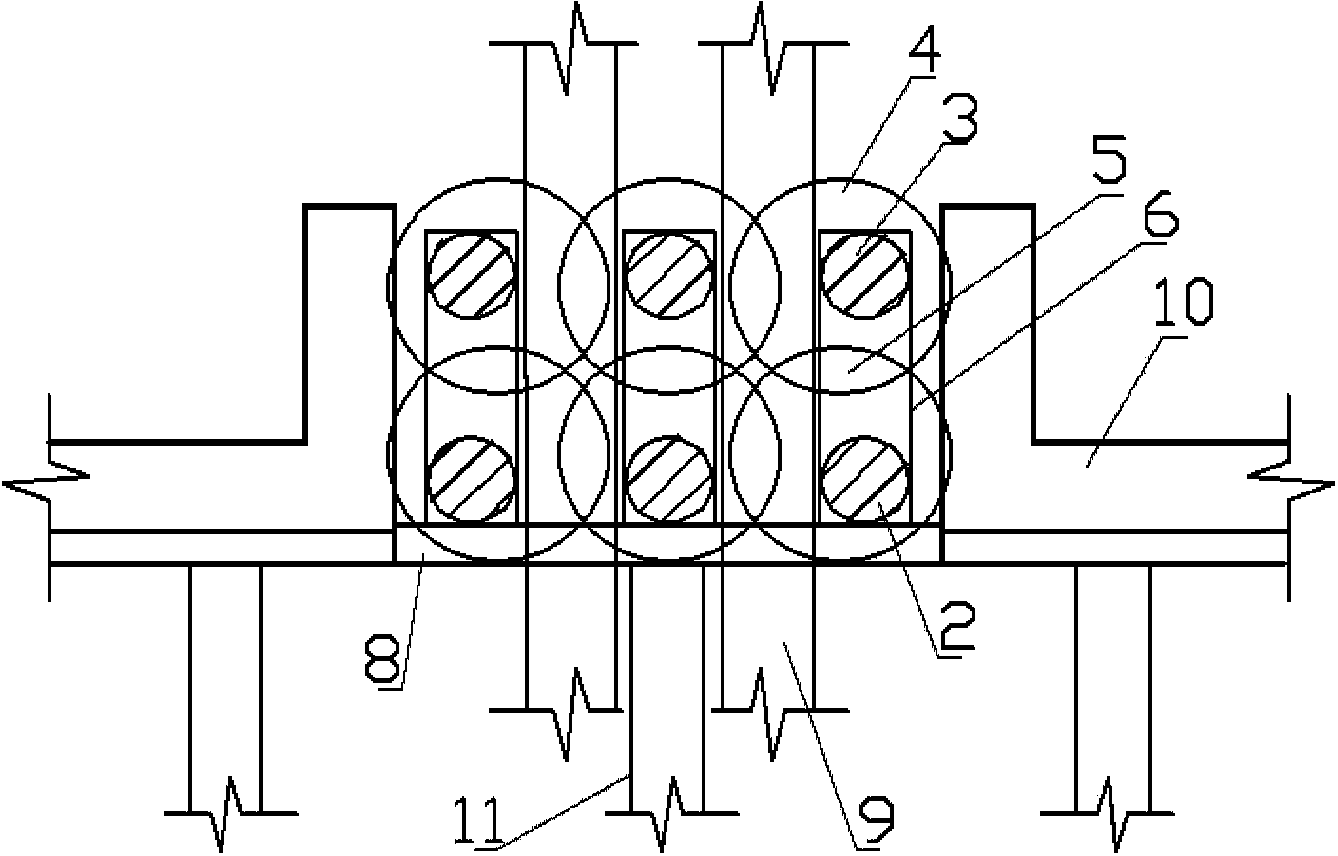

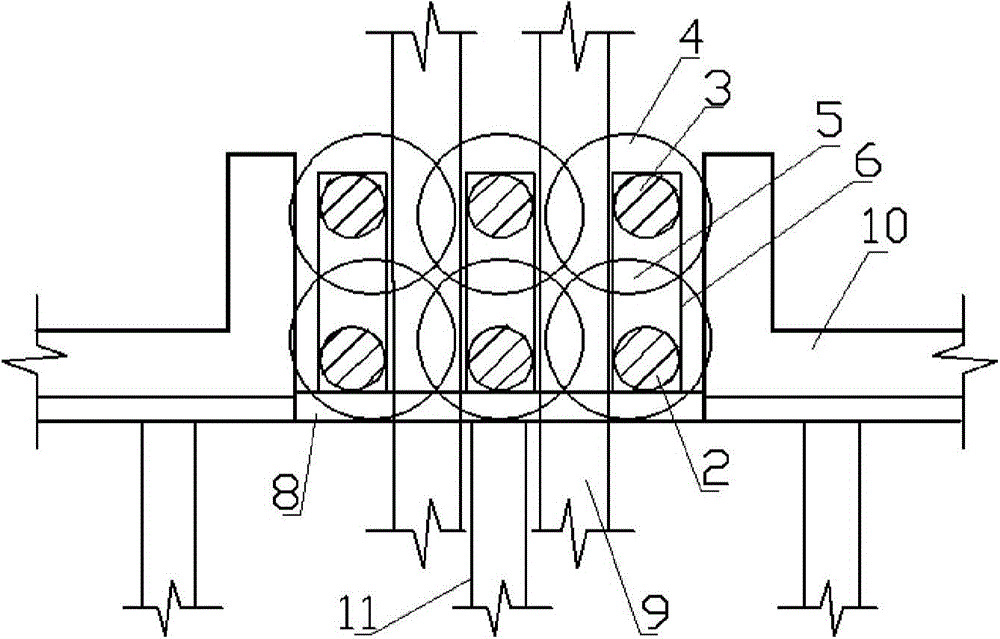

Compound electrode plate and PECVD deposition box and PECVD system

ActiveCN101988192AFlexible adjustment of spacingUniform dischargeChemical vapor deposition coatingEngineeringElectrode

The invention provides a compound electrode plate. The invention is characterized in that the compound electrode plate comprises a fixed plate and two movable plates; wherein the movable plates are arranged at the two sides of the fixed plate, and the distance between the movable plates and the fixed plate can be adjusted. The movable plates can be parallel with the fixed plate or can not be parallel with the fixed plate. The invention also provides a PECVD deposition box and a PECVD system which apply the compound electrode plate. The PECVD system applying the compound electrode plate can flexibly adjust the space of electrode plates, and uniform discharge between electrode plates is realized.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

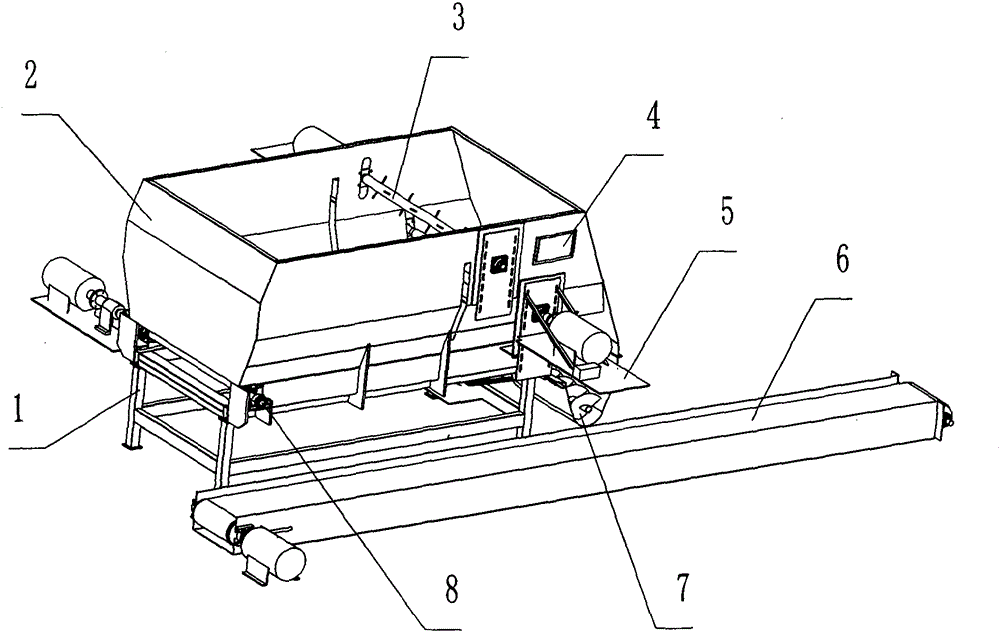

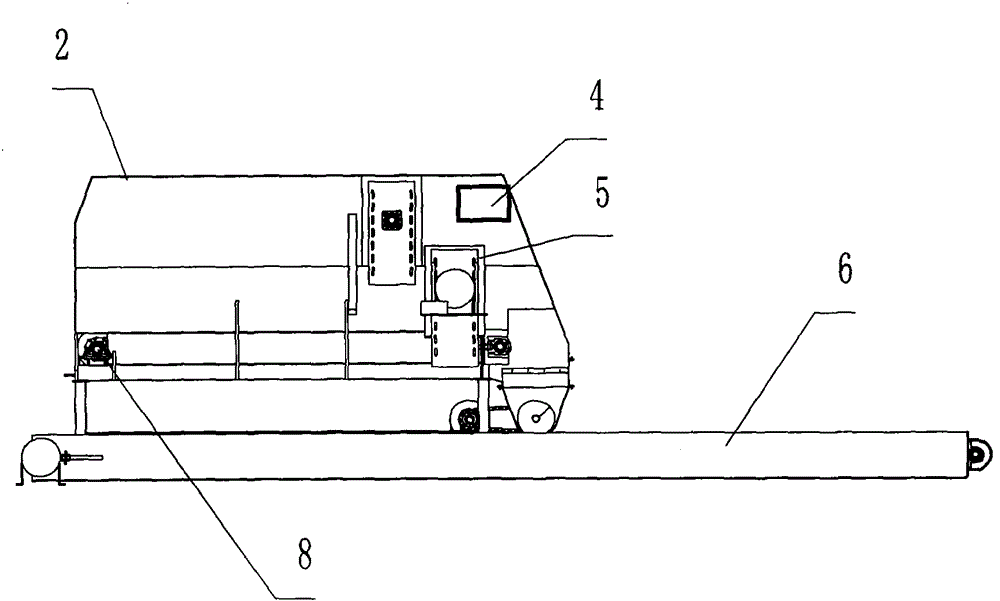

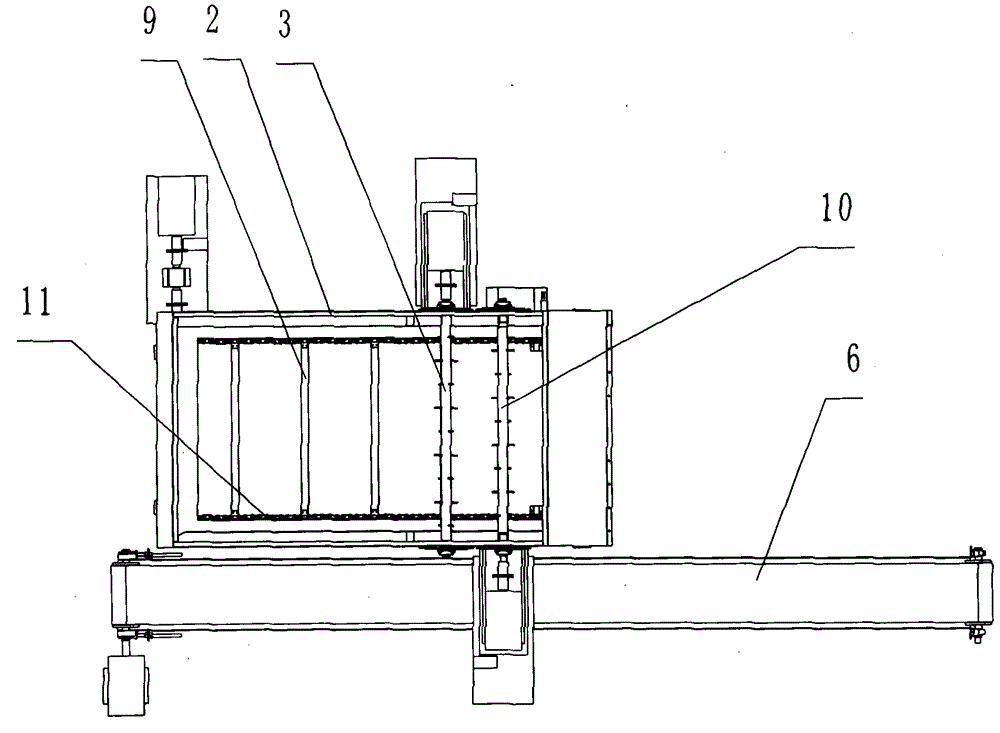

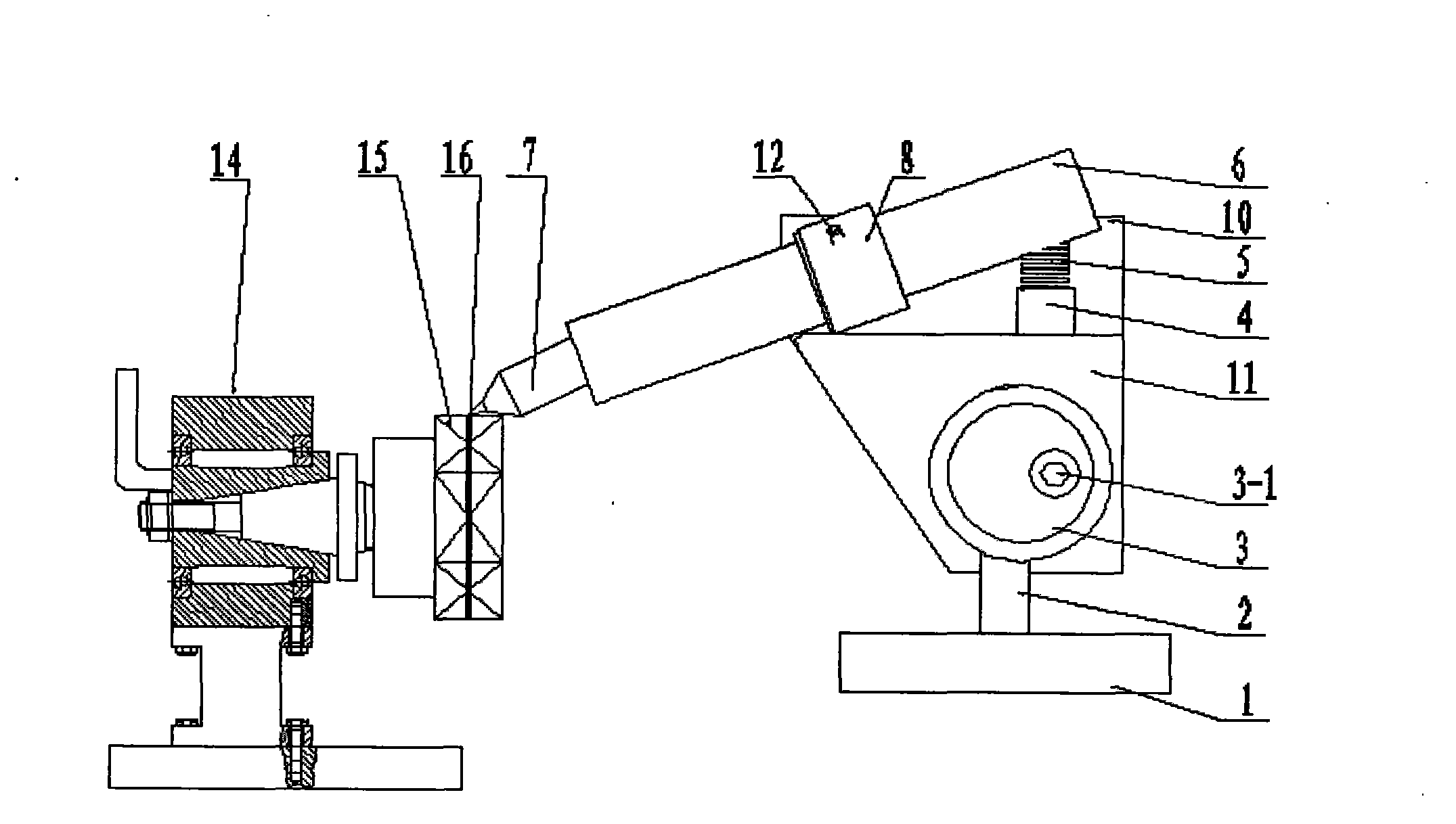

Livestock feed casting test stand

InactiveCN105059962AFlexible speed adjustmentFlexible adjustment of spacingConveyorsLoading/unloadingHeifer calfRelative motion

The invention relates to a livestock feed casting test stand. The livestock feed casting test stand is characterized in that the test stand comprises a support; a material box is arranged on the support; scrapers are arranged inside the material box; a driving chain is arranged at the two ends of the scrapers; the rear part of the inside of the material box is provided with a baffle roller, a shifting roller and a feed casting auger sequentially from top to bottom; a weighing sensor is arranged between the support and the material box; a weighing display screen is disposed on the wall of the material box. The livestock feed casting test stand is a feed casting test stand of a cattle and sheep feeding car; the test stand can flexibly adjust rotating speeds of a scraper conveyor spindle, a feeding auger, the baffle roller and the shifting roller through a frequency converter; the interval of the scrapers can be adjusted through selection of different chain lugs; the position height of the baffle roller and the shifting roller of a feed casting car can be flexibly adjusted through moving of a device support; traveling feed casting of the feed casting car is simulated through relative motion of a static rack and belt conveyor driving.

Owner:SHIHEZI UNIVERSITY +1

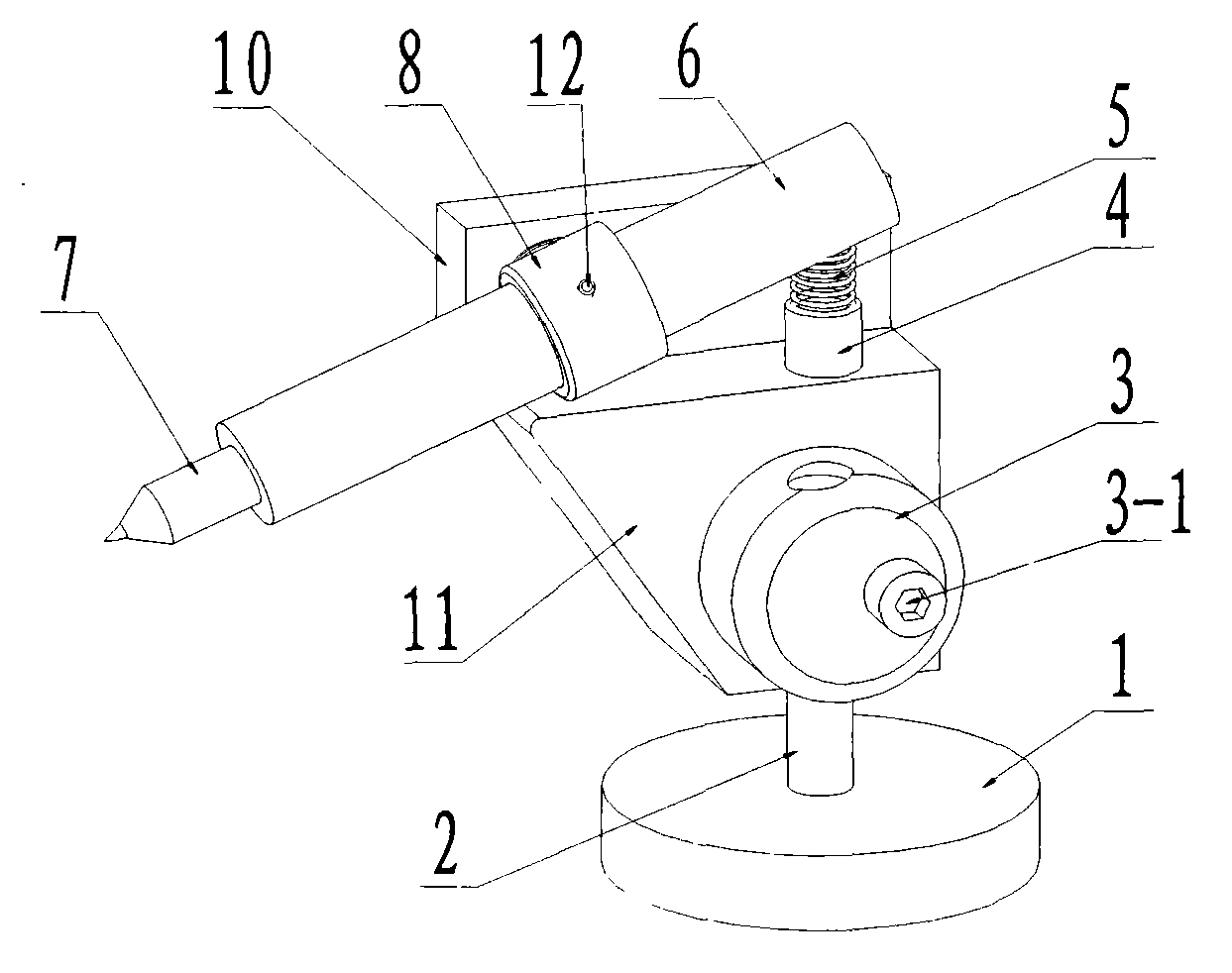

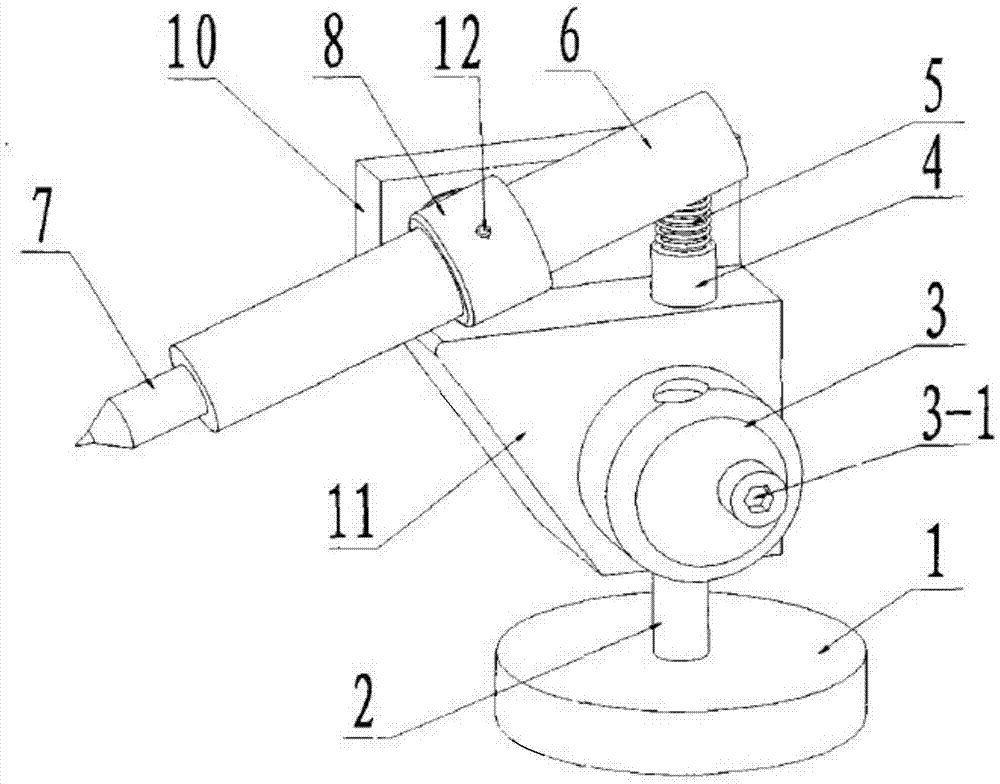

Marking device

InactiveCN103158144ASame contact forceGood line positionOther workshop equipmentEngineeringMechanical engineering

The invention relates to a marking device and belongs to the field of workpiece machining The marking device comprises a base, a support placed on the base and a marking penholder and is characterized by further comprising a second supporting seat movably connected with the support and a first supporting seat fixedly connected with one side of the second supporting seat; a spring is arranged on the second supporting seat; a rotary rod is inserted in the first supporting seat; the marking penholder is connected with the first supporting seat through the rotary rod; a pen core is inserted at the front end of the marking penholder and the rear end of the marking penholder is supported on the second supporting seat through the spring. The marking device has the advantages that according to dual match of the spring and the rotary rod, the marking pen core is capable of automatically moving vertically according to a machined workpiece so that contacting force of the marking pen core and the workpiece is equal and an even marking line can be drawn.

Owner:张瀛元

Ballast bed and tunnel bottom defect regulating and constructing method as well as anchoring device

The invention discloses a ballast bed and tunnel bottom defect regulating and constructing method as well as an anchoring device. The anchoring device comprises anchor rod and ballast bed slab anchoring ends and ballast bed slab middle anchoring ends, wherein each anchor rod and ballast bed slab anchoring end comprises a combination end, an anchor rod I and deformed steel bars I, the combination end is welded by two pieces of anchor rod clamp-fixing angle steel and a piece of ballast bed slab clamp-fixing angle steel, the two pieces of anchor rod clamp-fixing angle steel are welded on the same surface of the ballast bed slab clamp-fixing angle steel, and an interval allowing the anchor rod I to pass is reserved between the two pieces of angle steel, and the deformed steel bars I are welded on two sides of the combination end respectively; and each ballast bed slab middle anchoring end comprises a bearing plate, an anchor rod II and deformed steel bars II, the bearing plate adopts a crossed steel plate provided with a hole which is formed in the middle and allows the anchor rod II to pass, and the deformed steel bars II are welded on two sides of the bearing plate respectively. According to the ballast bed and tunnel bottom defect regulating and constructing method as well as the anchoring device, the structure is simple, the processing is easy, the problems of baseplate reinforcement and controlling and blocking of opening and closing cracks between the ballast bed slab and the baseplate can be solved effectively, and the purpose of quick, effective and comprehensive regulation of the ballast bed slab and tunnel bottom defects is achieved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

Contact plate and evaporation equipment

ActiveCN108220904AFlexible adjustment of spacingHeat dissipation fastVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention provides a contact plate and evaporation equipment and belongs to the technical field of display. The contact plate is applied to the evaporation equipment and is used for supporting a to-be-evaporated substrate; the contact plate comprises a bottom plate and a plurality of support parts at the same height on the bottom plate. By means of the technical scheme, poor white dot displaycan be relieved on the premise that good heat dissipation of the to-be-evaporated substrate is guaranteed in the heating process of an evaporation source.

Owner:BOE TECH GRP CO LTD +1

Mobile type food-baking vending vehicle

ActiveCN103169254AFlexible adjustment of spacingEasy to placeRoasting apparatusServing tablesHazardous substanceProcess engineering

The invention discloses a mobile type food-baking vending vehicle which comprises a cooking bench (1), a baking oven (2) embedded in the cooking bench (1) and a seasoning bowl (3). An electric heating tube (4) is arranged in an inner cavity of the baking oven (2), a food shelf (5) is movably hanged on a hanger (6) in the inner cavity of the baking oven (2), and a thermal reflective layer is arranged on the outer surface of the inner wall of the baking oven (2). The vending vehicle further comprises a plurality of braking frame units which surround the electric heating tube and are hanged on the inner wall of the baking oven, and thus temperature in the baking oven is uniform, and food can be uniform in cooked degree of each face without being turned in baking. When the process of baking finishes, all the baking frame units are taken out, the roasted food is taken out and unbaked food is put into the baking oven (2). The mobile type food-baking vending vehicle is convenient to use, food is prevented from being polluted by harmful substances by using the electric heating tube as a heating source and is environmental friendly and beneficial to health.

Owner:成都索拉泰克精密机械有限公司

Steel plate polishing equipment suitable for multiple sizes

PendingCN113523977AImprove polishing efficiency and qualityPrevents deviation of conveying directionBelt grinding machinesGrinding feedersSteel platesPolishing

The invention provides steel plate polishing equipment suitable for multiple sizes. Steel plates are conveyed to a polishing conveying assembly through a feeding conveying assembly, the polishing conveying assembly polishes the surfaces of the steel plates and enables the steel plates to be conveyed to a discharging conveying assembly, and the discharging conveying assembly discharges and conveys the steel plates. The polishing conveying assembly comprises a conveying belt mechanism. The bottom end of the conveying belt mechanism is connected with a mounting table, the mounting table is connected with a mounting frame, the mounting frame is erected above the conveying belt mechanism, the mounting frame is connected with a polishing mechanism for polishing the steel plates on the conveying belt mechanism, the distance between the polishing mechanism and the conveying belt mechanism can be flexibly adjusted, and therefore the position of the polishing mechanism relative to the polished faces of the steel plates is controlled; and the steel plate polishing equipment flexibly adapts to steel plates of different sizes and specifications, guarantees smooth polishing operation of the steel plates of different sizes and specifications, and improves the polishing efficiency and quality of the steel plates.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

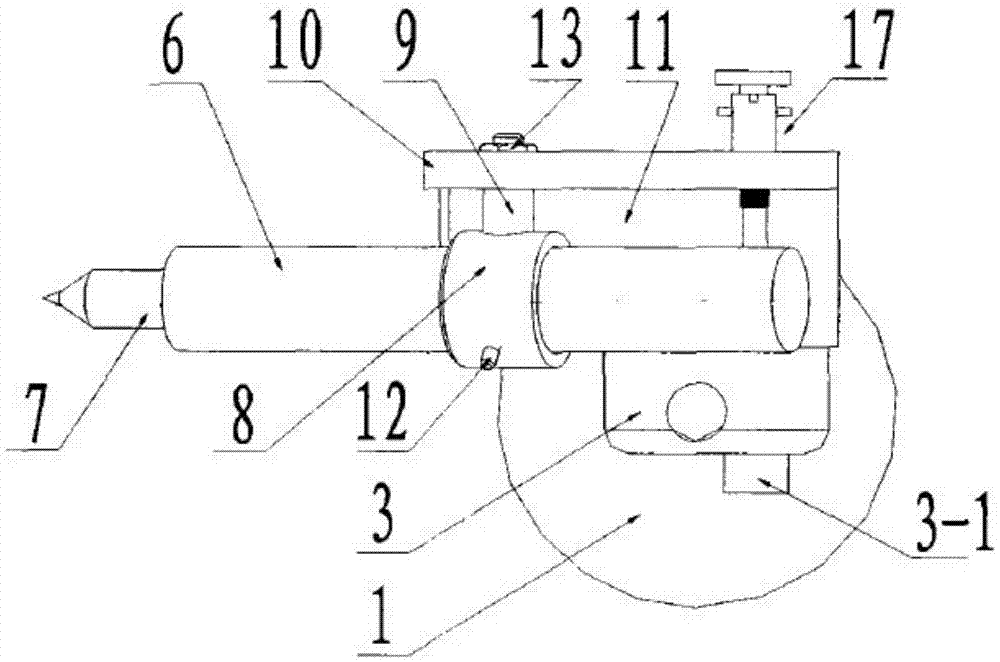

Scribing device

InactiveCN106891317ASame contact forceGood line positionOther workshop equipmentEngineeringMachining

The invention relates to a scribing device and belongs to the field of workpiece machining. The scribing device comprises a base, a support located on the base and a scribing penholder. The scribing device is characterized in that the scribing device further comprises a second supporting seat movably connected with the support and a first supporting seat fixedly connected to one side of the second supporting seat, a spring is installed on the second supporting seat, a rotary rod is inserted into the first supporting seat, and the scribing penholder is connected with the first supporting seat through the rotary rod; and a scribing pen refill is installed at the front end of the scribing penholder in an inserted mode, and the rear end of the scribing penholder is supported on the second supporting seat through the spring. The scribing device has the beneficial effects that through double cooperation of the spring and the rotary rod, the scribing pen refill can automatically and vertically move very well according to a machined workpiece, so that the scribing pen refill is the same as the workpiece in contact intensity, and accordingly an even marking line is drawn.

Owner:BADONG FENGTAI AGRI SPECIALIZED COOP

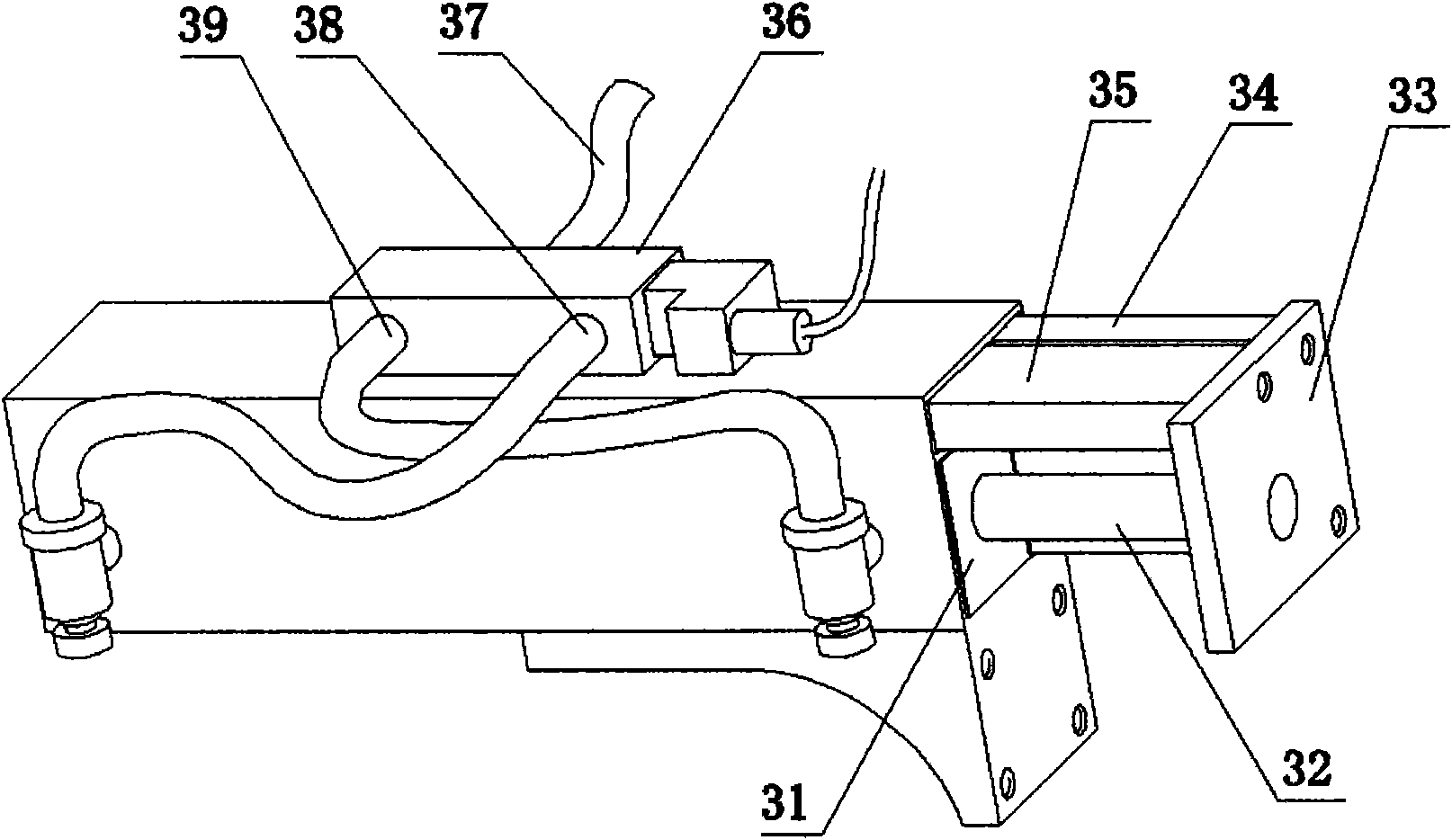

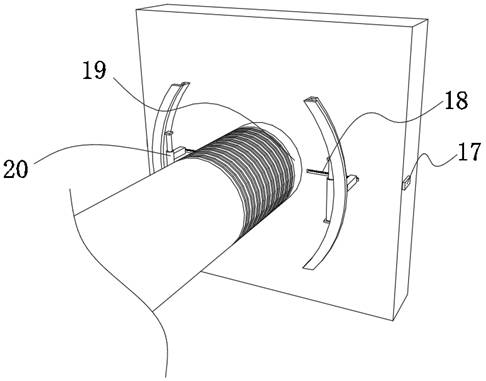

Steel wire drawing and winding mechanism

The invention discloses a steel wire drawing and winding mechanism. The steel wire drawing and winding mechanism comprises a wire unwinding mechanism, a drawing mechanism and a wire winding mechanism,wherein one side of the wire unwinding mechanism is provided with the drawing mechanism, the side, away from the wire unwinding mechanism, of the drawing mechanism is provided with the wire winding mechanism, and the wire unwinding mechanism is composed of a first fixed seat, a distance adjusting sliding groove, a distance adjusting screw rod, distance adjusting sliding blocks, a distance adjusting hand wheel, fixed supporting columns and a wire unwinding roller. According to the steel wire drawing and winding mechanism, by means of the arrangements of the distance adjusting screw rod and thedistance adjusting hand wheel, the separation distance between the fixed supporting columns can be flexibly adjusted according to the wire unwinding rollers of different specifications, and the practicality range of the steel wire drawing and winding mechanism is broadened; by means of the arrangements of a first pressing wheel and a second pressing wheel, squeezing and drawing on steel wires arerealized; and the steel wires are winded through a wire winding roller, under the action of a reciprocating screw rod, the wire winding roller is made to perform reciprocating motions, arranging of the steel wires in the winding process is realized, the steel wires are prevented from being wound in one place, and the machining efficiency of the steel wires is greatly improved.

Owner:王嘉政

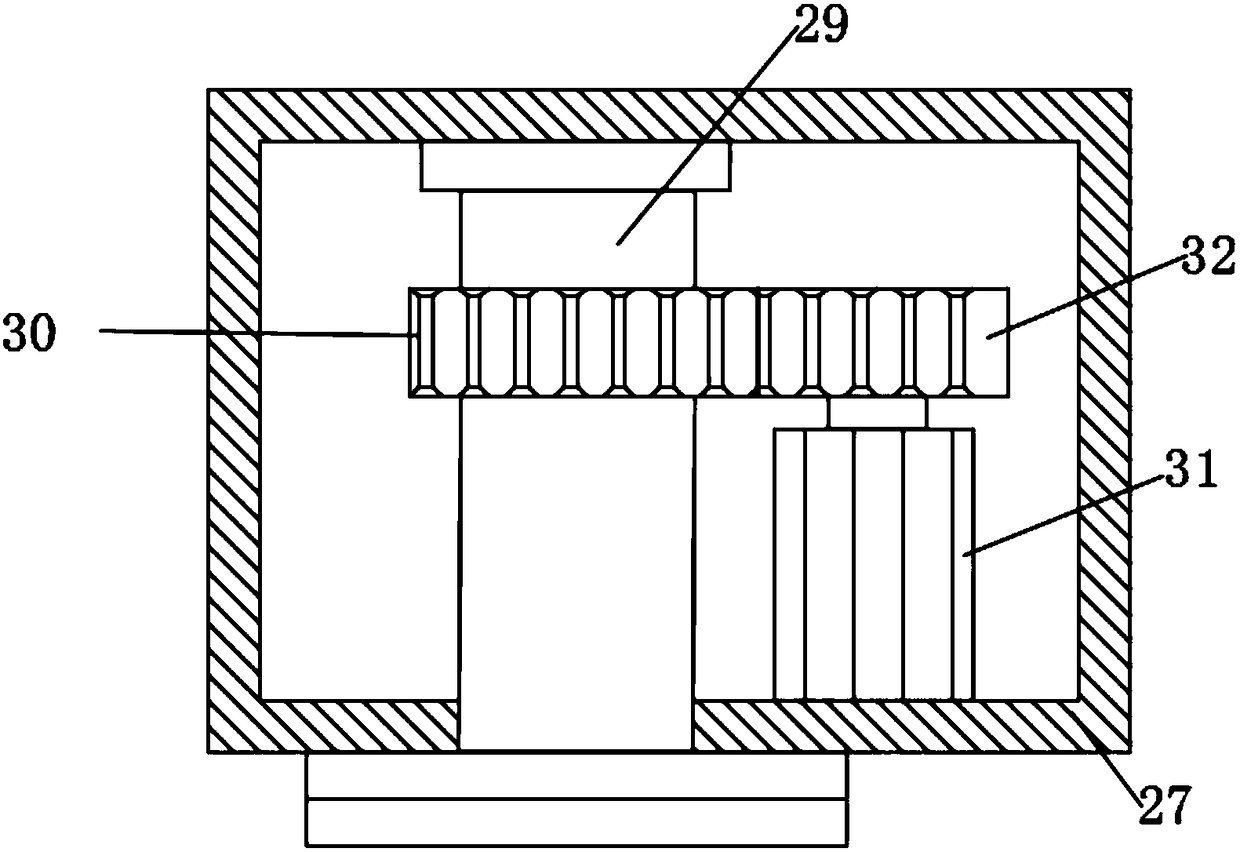

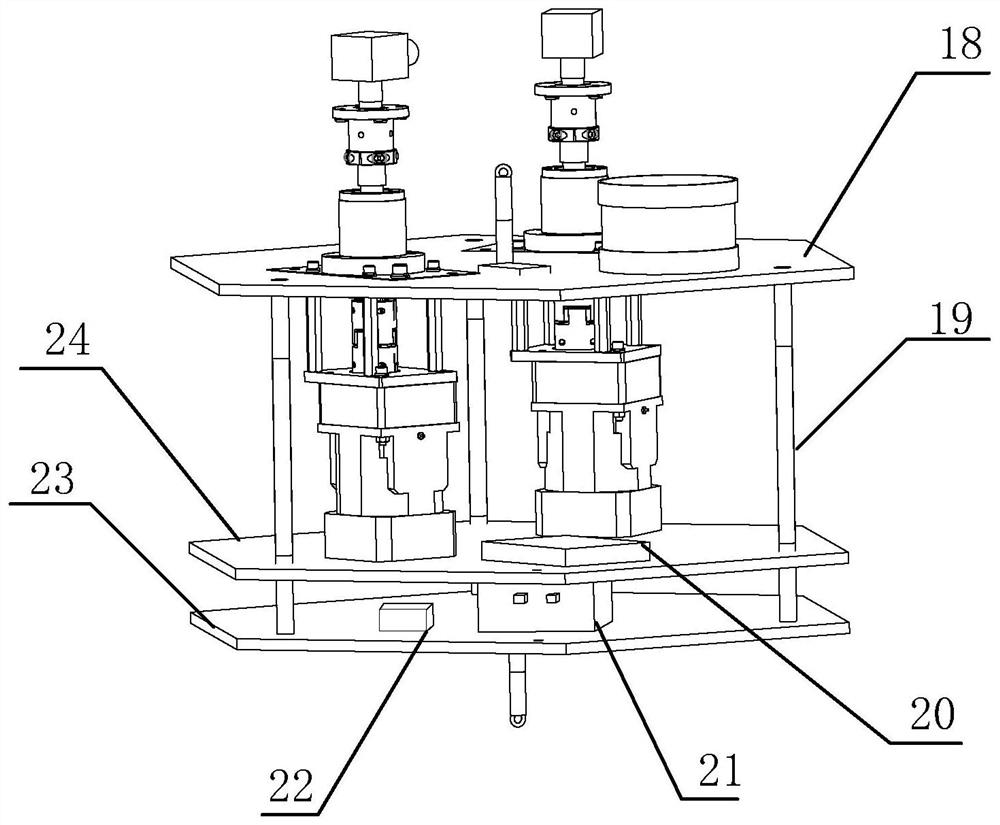

Electromagnetic mold locking and transferring device for injection molding machine

The invention relates to an electromagnetic mold locking and transferring device for an injection molding machine. The electromagnetic mold locking and transferring device for the injection molding machine mainly comprises a mold transferring cylinder, a rear mold plate, a toggle rod mechanism, a pull rod, a movable mold plate, a movable mold, a fixed mold, a fixed mold limiting device, a fixed mold rear plate, a fixed mold front plate, a front electromagnetic mold plate and a rear electromagnetic mold plate. Each of the rear electromagnetic mold plate and the front electromagnetic mold platemainly comprises a magnetic conductive back plate and an electromagnet, each electromagnet is arranged in the corresponding magnetic conductive back plate, each electromagnet consists of an iron coreand a magnet exciting coil which is wound on the iron core, and a magnetic system of each electromagnet has a circular structure, and is arranged as concentric circles. An electromagnetic mold transferring cylinder or a gear and rack mold transferring device replaces a hydraulic cylinder, a complicated lubricating system or a hydraulic sealing requirement is not required, and oil pollution does not exist; the electromagnetic mold locking force is uniform, the magnetic systems are uniformly distributed on the mold plates, and therefore, the generated mold locking force is uniform; and the application range is wide, and the reciprocating motion and the mold transferring speed of the mold transferring electromagnetic cylinder can be realized by only needing to control the direction and magnitude of current of the magnet exciting coil in the electromagnetic cylinder; and the electromagnetic mold locking and transferring device for the injection molding machine is clean and environmentallyfriendly, and is wide in application range.

Owner:TEDERIC MACHINERY

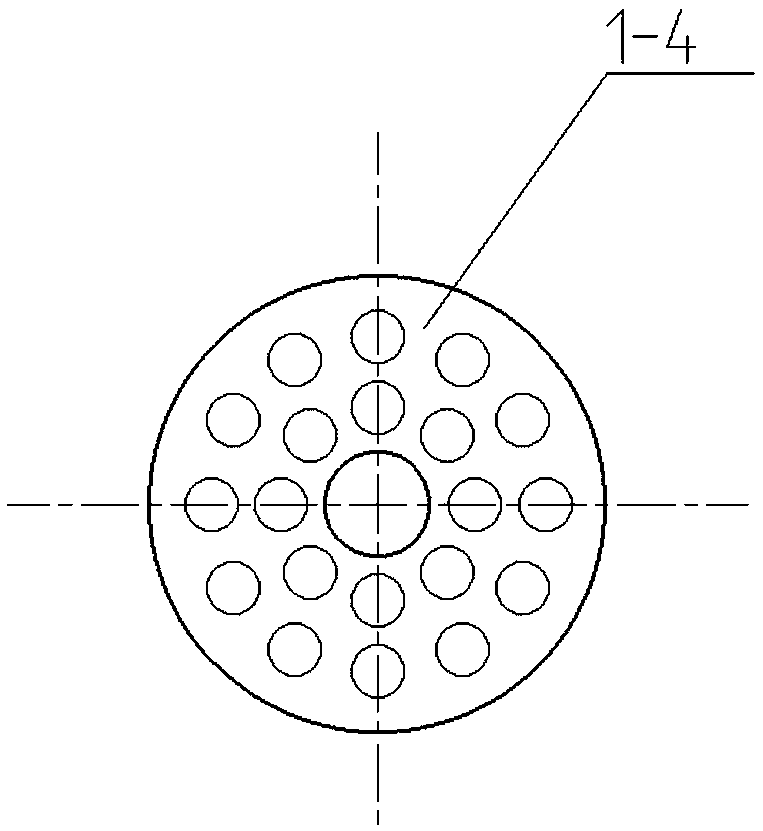

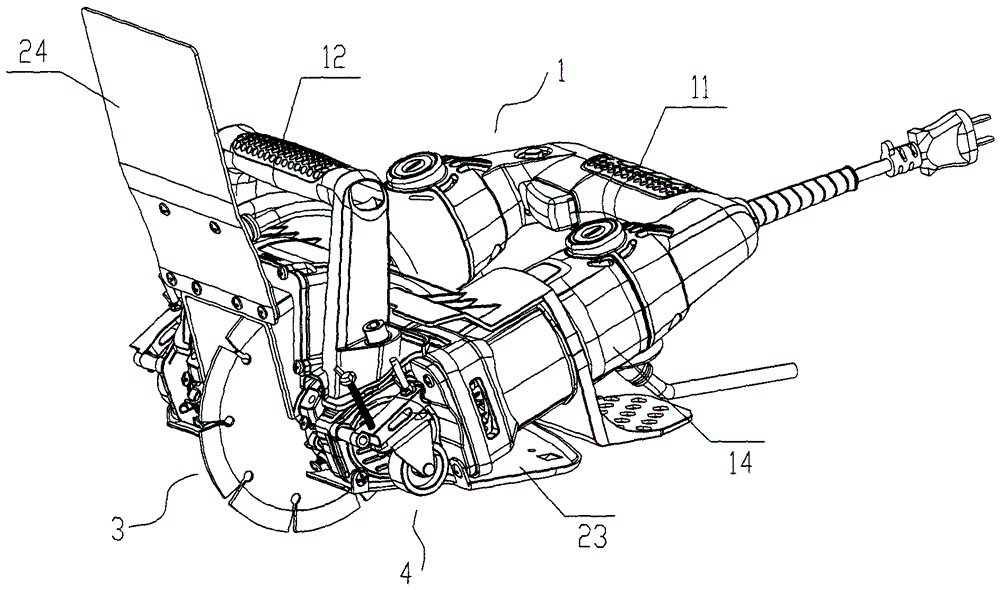

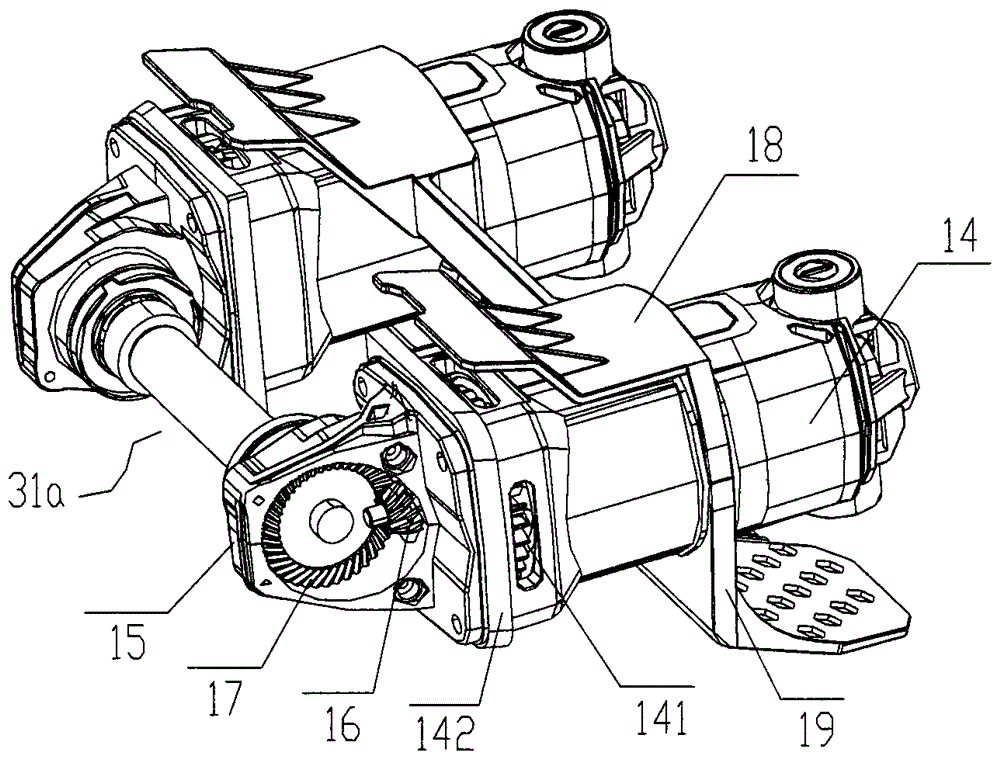

Dual-power one-stage molding wall grooving machine

InactiveCN105178572AStrong cutting powerReduce loadBuilding constructionsTerrainAgricultural engineering

The invention discloses a dual-power one-stage molding wall grooving machine which comprises two motor covers, wherein the two motor covers are parallel left and right and spaced, and a motor is arranged in each motor cover; the tails of the motor covers are connected through horizontal grips, a front cover is arranged at the front end of each motor cover, and a shaft seat is arranged on the front cover. The two ends of a cutter shaft are rotationally arranged on the left and right shaft seats respectively, and the upper ends of the left and right shaft seats are connected through vertical grips. A dead-corner-free waterproof structure is arranged on the front cover of each motor cover, and the upper half of each blade on the cutter shaft is positioned in the dead-corner-free waterproof structure. When the dual-power one-stage molding wall grooving machine grooves a non-planar wall, the dead-corner-free waterproof structures can be adjusted, so that the front end part of each blade is exposed out to groove the wall on the vertical direction. Groove depth adjustment mechanisms are fixedly arranged on the outer sides of the left and right shaft seats. The dual-power one-stage molding wall grooving machine can stably and powerfully output power to the two ends of the cutter shaft, so that the cutting strength of all blades on the cutter shaft keeps consistent. The adaptability to the grooving terrain is wide, the grooving depth can be flexibly adjusted, and the hand-holding pressure of the grooving machine is reduced.

Owner:ZHEJIANG KWSM ELECTRICAL CO LTD

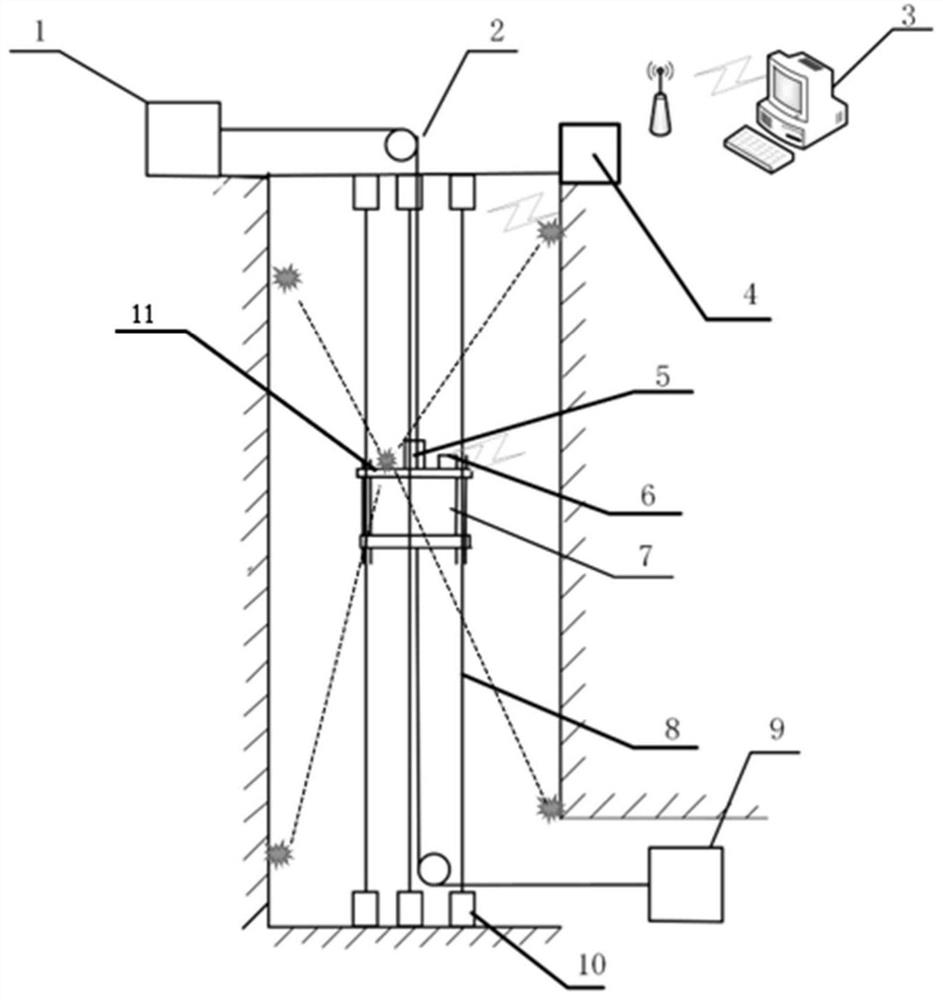

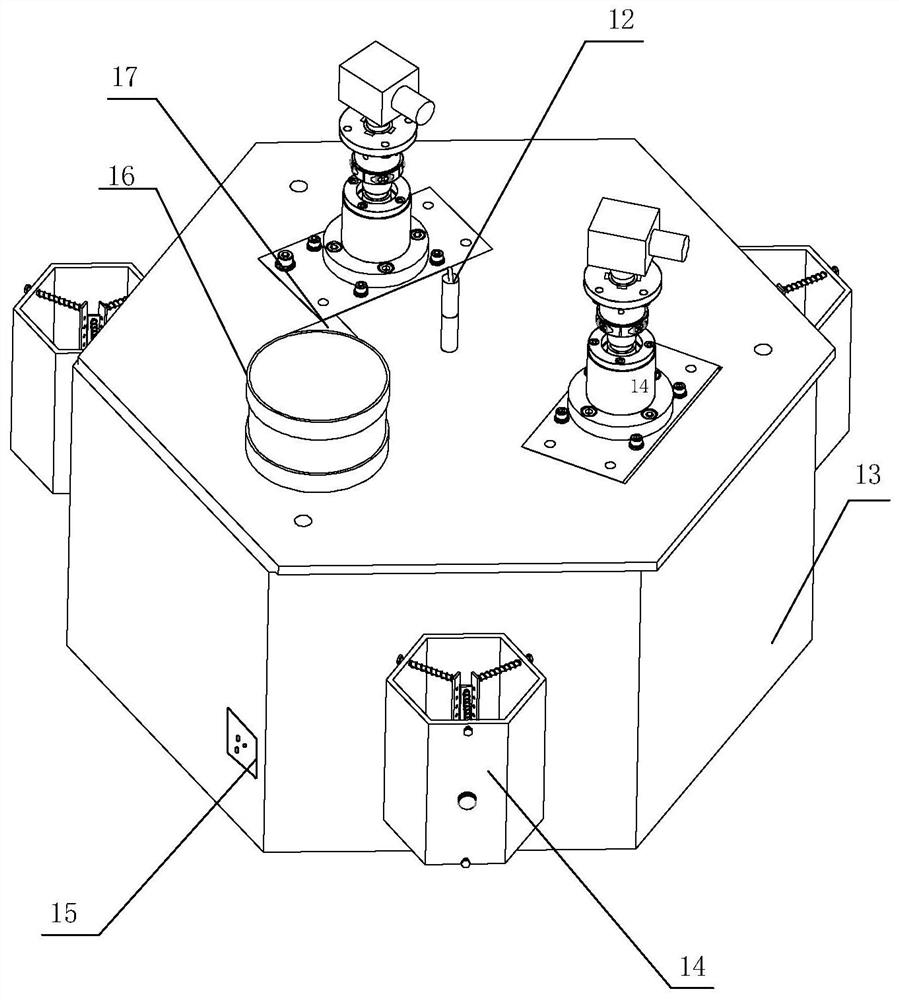

Coal mine vertical shaft inspection device and laser scanning defect detection method

ActiveCN112924463ALifting and moving smoothlyAvoid deflectionOptically investigating flaws/contaminationUsing optical meansLaser scanningEngineering

The invention relates to a coal mine shaft inspection device and a laser scanning defect detection method, and the device comprises: an inspection device body which is arranged in a shaft and moves up and down in the shaft; an external driving device which is used for driving the inspection device body to move up and down; a guide steel wire rope which is vertically erected between the two corresponding tensioning devices; body guide devices which are uniformly distributed and fixed on the side wall of the inspection device body in the circumferential direction, wherein the guide steel wire ropes penetrate through the body guide devices in a sliding manner; a positioning system which comprises a plurality of UWB nodes arranged on the inner wall of the shaft and a UWB node arranged on the inspection device body. An energy supply battery pack, a wireless communication module, a laser radar and the image acquisition platform which are mounted on the inspection device body; the energy supply battery pack is used for supplying power to the wireless communication module, the laser radar and the image acquisition platform; and the wireless communication module has a wireless communication function and a UWB node-based positioning function. According to the invention, the current situation that the existing manual inspection efficiency is low and potential safety hazards exist can be effectively changed.

Owner:CHINA UNIV OF MINING & TECH

A foundation pit support structure

ActiveCN103806449BReduce lateral deformationIncrease lateral stiffnessExcavationsReinforced concreteEngineering

The invention discloses a supporting structure of a foundation pit. The supporting structure comprises jet grouting piles and a double-row pile structure which is inserted in the jet grouting piles, wherein the jet grouting piles are high-strength cement-soil pile bodies formed on a soil body around the foundation pit, and the multiple jet grouting piles are in mutual lap joint to form a reinforcing region; the double-row pile structure comprises a first row of cast-in-place piles, a second row of cast-in-place piles and connecting beams, the connecting beams are connected with the tops of the first row of cast-in-place piles and the tops of the second row of cast-in-place piles, and the first row of cast-in-place piles, the second row of cast-in-place piles and the connecting beams are all of a reinforced concrete structure. According to the scheme, the supporting structure aims to brace the deep foundation pit under the complicated geological condition with rich water and soft soil and under the condition that complicated barriers cut through the upper portions of the foundation pit; when the barriers such as cables cut through the upper portion of the foundation pit, the intervals between the cast-in-place piles can be flexibly adjusted to avoid the barriers; the large-diameter high-pressure jet grouting piles are in mutual lap joint, can effectively stop water and can control horizontal displacement of the soil body outside the pit along with the double rows of cast-in-place piles; the supporting structure formed by the cast-in-place piles is constructed in the large-diameter jet grouting piles, and therefore construction sites outside the foundation pit are saved.

Owner:CCCC HIGHWAY CONSULTANTS +1

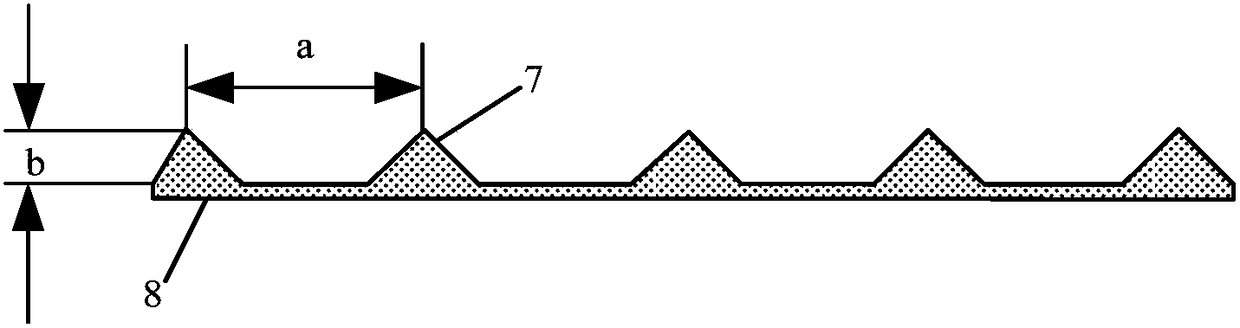

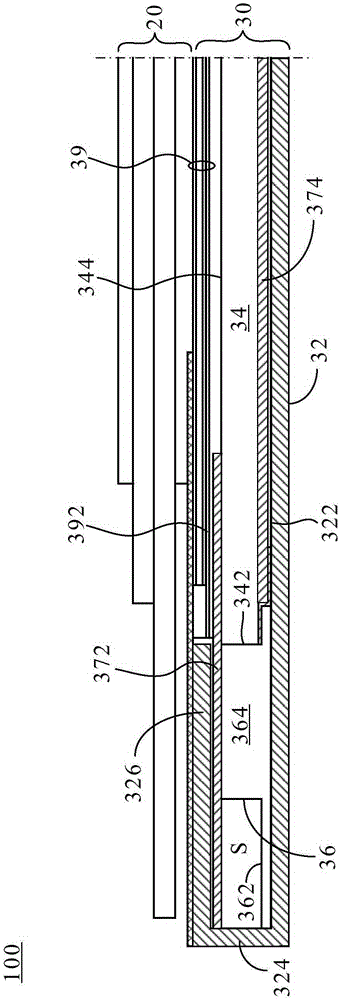

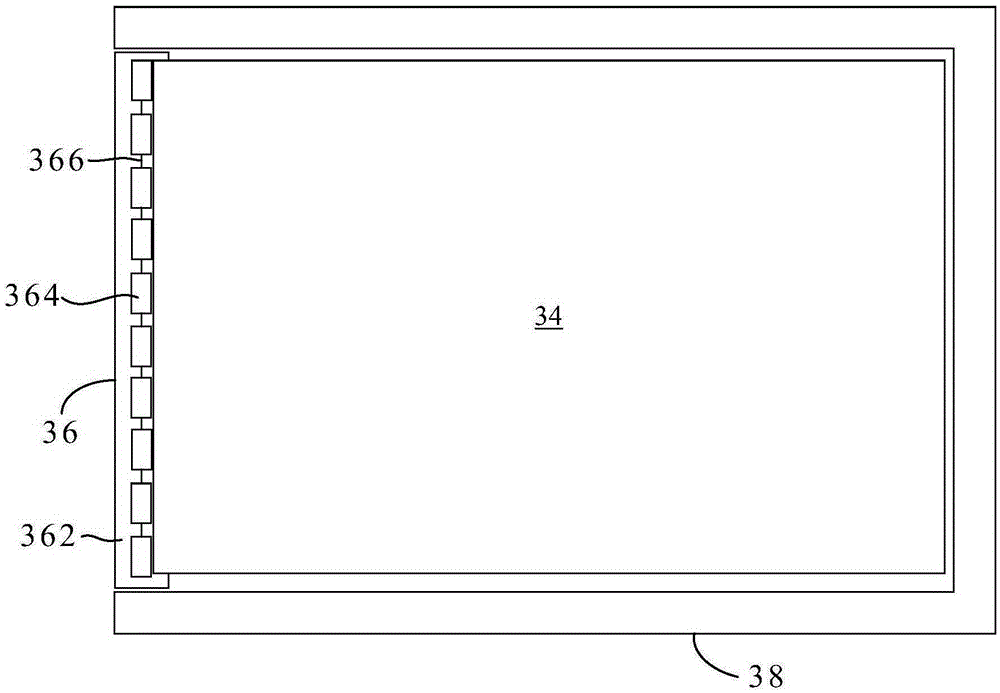

Laterally-incident-type backlight module and liquid crystal display device

InactiveCN105334668AFlexible adjustment of spacingIncrease the number ofNon-linear opticsLiquid-crystal displayLight guide

The invention provides a laterally-incident-type backlight module and a liquid crystal display device. The laterally-incident-type backlight module comprises a back plate, a light guide plate, a light bar and rubber frames. The back plate comprises a bottom wall; the light guide plate is arranged on the bottom wall and comprises a first side face, a light outgoing surface and a second side face corresponding to the first side face; the light bar is arranged on the bottom wall and located on the first side face of the light guide plate; the rubber frames are arranged at the three edges, without the light bar, of the periphery of the light guide plate; the light bar comprises a sapphire substrate, a plurality of LED chips formed on the sapphire substrate and a circuit for driving the multiple LED chips, wherein the circuit is formed on the sapphire substrate. The distance between the LED chips can be flexibly adjusted so that the effect of increasing the number of LED chips can be achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Intestinal polyp excision device for enterosurgery department

PendingCN114451964AImprove surgical efficiencyReduce surgical riskCannulasEnemata/irrigatorsSurgical riskIntestinal polyp

The invention discloses an intestinal polyp excision device for the enterosurgery department, and relates to the technical field of medical instruments. The problem that polyps easily fall into intestinal tracts in an operation is solved. The device specifically comprises a connecting base, a connecting column is rotationally connected to the inner wall of the connecting base, a supporting plate is rotationally connected to one end of the connecting column, an expanding and supporting part is arranged on the outer wall of one side of the supporting plate, a connecting plate is rotationally connected to the outer wall of one side of the supporting plate, and one end of the connecting plate is connected with one end of the connecting column through a coupler; one end of the connecting plate is connected with a sleeve through a length adjusting part, the sleeve is composed of a flushing part, a cutting part and a polyp recycling part, the polyp recycling part comprises two extrusion blocks, a through hole located under the extrusion blocks, a material collecting chamber and a sealing baffle, and the outer walls of one sides of the two extrusion blocks are fixedly connected to the outer walls of the opposite sides of the tool pliers respectively; the material collecting chamber is arranged on the inner wall of the sleeve; and the through holes are formed in the circumferential inner wall of the sleeve. Operation efficiency is improved, and operation risks are reduced.

Owner:谭霖欢

Tapping equipment for machining automobile oil pan guard plate, and working method thereof

InactiveCN112157457AGuaranteed tightnessHigh precisionFeeding apparatusPositioning apparatusElectric machineryDrill floor

The invention discloses tapping equipment for machining an automobile oil pan guard plate, and a working method thereof. The tapping equipment comprises a supporting frame, two supporting tables and adrill moving table; the two supporting tables are arranged on the two sides of the top of the supporting frame separately, and the drill moving table is arranged at one end of the top of the supporting frame; each supporting table comprises a motor I, a sleeve rail and a sliding disc I; and the motor I is arranged at one end of the middle part of the supporting table, and one end of the motor I is rotatably connected with a lead screw I through an output shaft. The tapping equipment has the beneficial effects that four drilling bases are arranged on each rotary disc, and drill bits in different sizes and models can be installed on each drilling base; it is guaranteed that the equipment can be used for rapidly drilling holes in different diameters in an oil pan guard plate, and the use diversity of the equipment and the efficiency of drilling holes in different oil pan guard plates are improved; the equipment is higher in tapping precision and efficiency for oil pan guard plates in different sizes; and the equipment is high in working automation degree, has good social benefits, and is suitable for popularization and application.

Owner:马鞍山贺辉信息科技有限公司

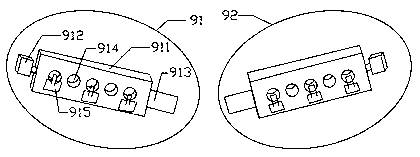

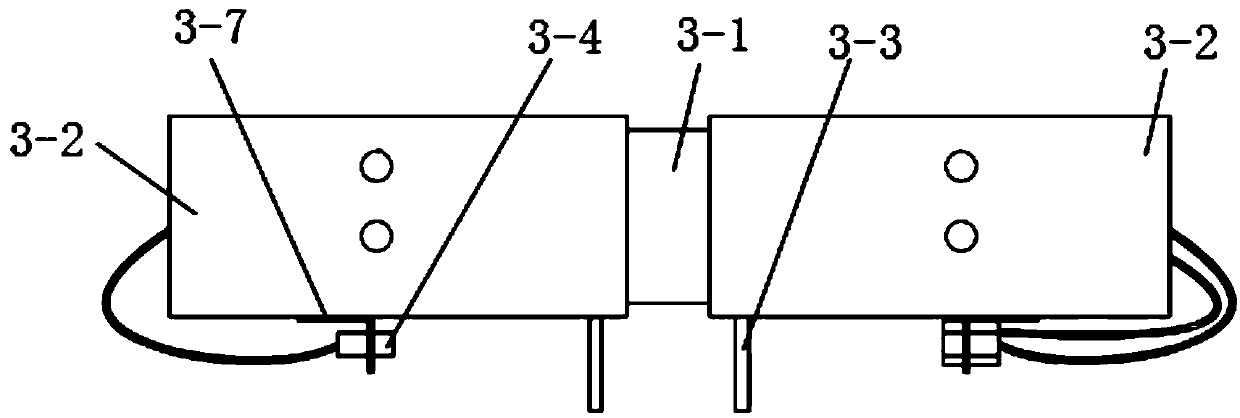

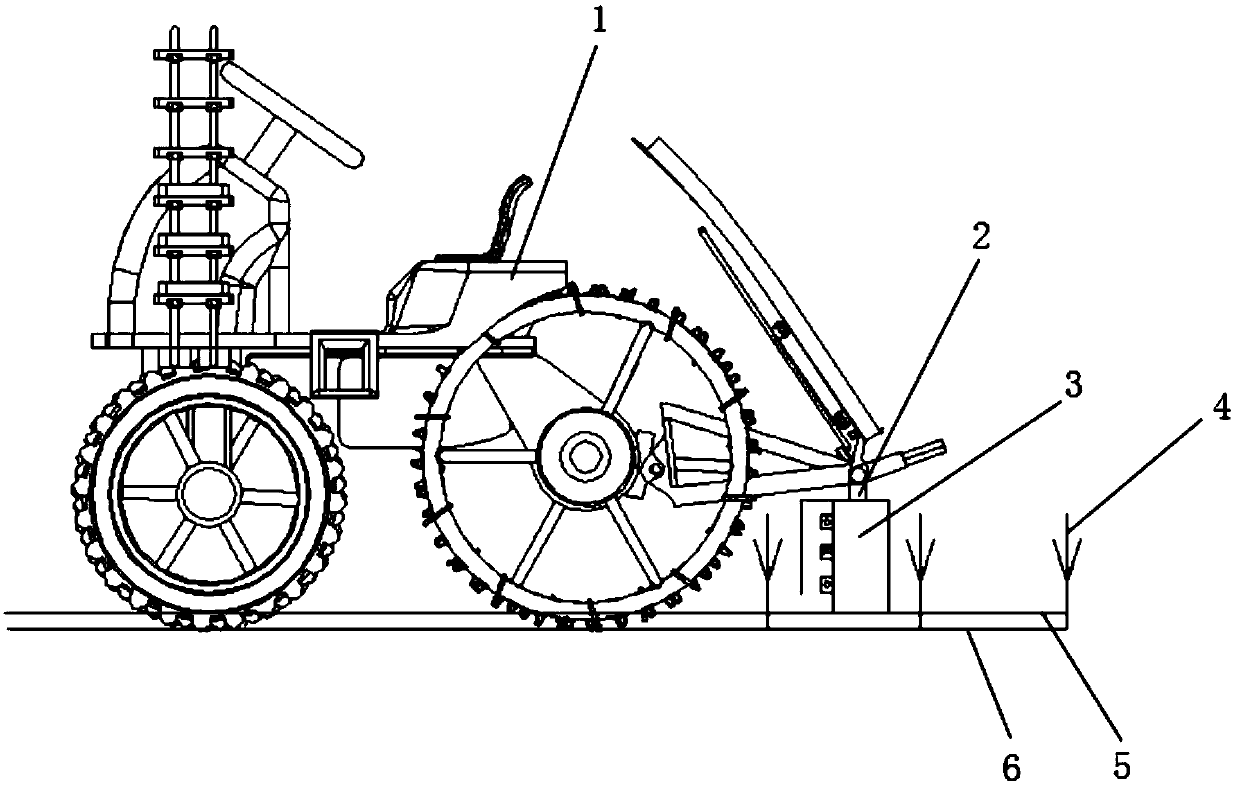

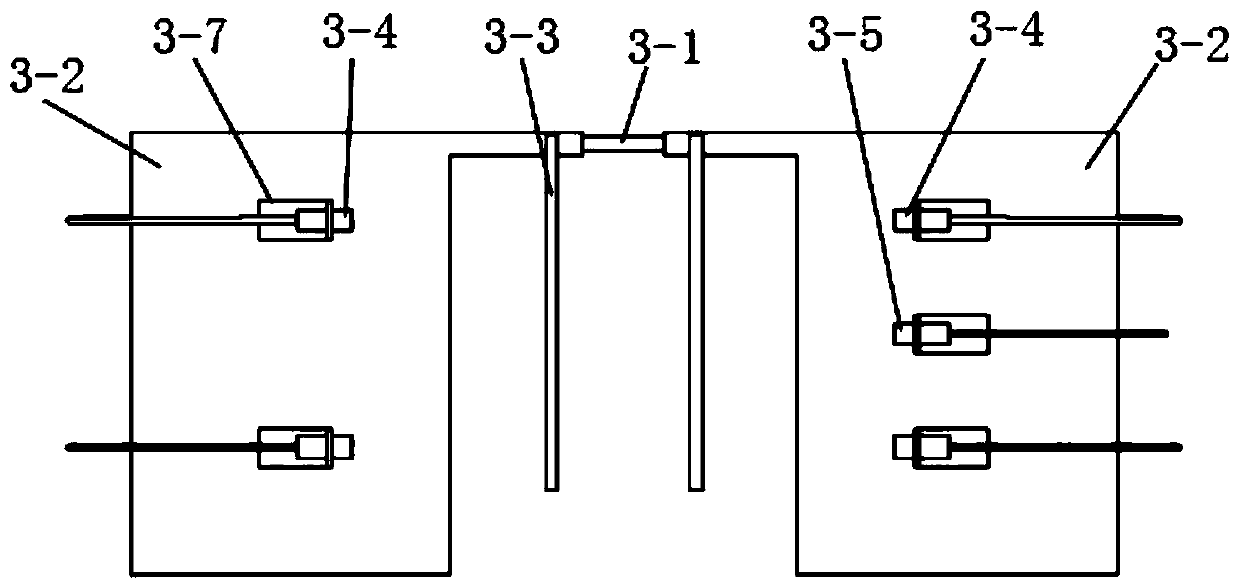

Rice plant identifying and positioning device and method based on infrared sensors

InactiveCN109539984AAccurate identificationAccurate identification and positioningUsing optical meansTransplantingData processing systemRadiation sensor

The invention relates to a rice plant identifying and positioning device based on infrared sensors. The device comprises a connecting part, two mounting boxes, two seedling shifting parts, two sets ofinfrared radiation sensors, an infrared distance measuring sensor, a data processing system, and a power supply. The two mounting boxes are mounted on the left end and the right end of the connectingpart in a left-right symmetry mode. The two seedling shifting parts are fixed in the inner sides of the fronts of the two mounting boxes in a left-right symmetry mode. Each infrared radiation sensorcomprises a transmitting end and a receiving end which are separately mounted on the front side of one of the two mounting boxes. The infrared distance measuring sensor is mounted on the front side ofone of the mounting boxes. One set of infrared radiation sensors, the infrared distance measuring sensor, and the other set of infrared radiation sensors are sequentially arranged in order of high and low in the vertical direction. The invention further relates to a rice plant identifying and positioning method based on the infrared sensors. The device and method can accurately identify and position rice plants, have real-time and accuracy, and belong to the mechanical design and intelligent control technology of agricultural equipment.

Owner:SOUTH CHINA AGRI UNIV

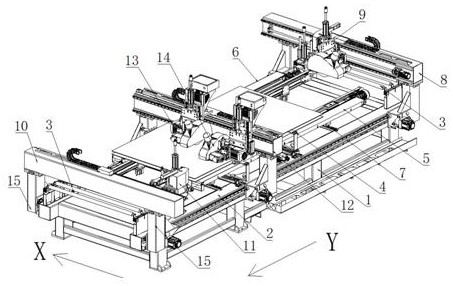

Four-side saw and door plank cutting method thereof

PendingCN114346311AImprove processing efficiencyImprove versatilityMetal sawing devicesMetal sawing accessoriesStructural engineeringMechanical engineering

The invention discloses a four-edge saw and a door plate cutting method thereof, and relates to the field of plate machining. The four-side saw comprises a lathe bed assembly, a first transverse cutting unit, a second transverse cutting unit and a longitudinal cutting unit. The first transverse cutting unit, the second transverse cutting unit and the longitudinal cutting unit are all arranged on the lathe bed assembly and can translate in the Y direction of the lathe bed assembly. The first transverse cutting unit and the second transverse cutting unit can be used for conducting X-direction cutting on the two ends of a plate. The longitudinal cutting unit is arranged between the first transverse cutting unit and the second transverse cutting unit, the longitudinal cutting unit comprises two longitudinal cutting saws, and the two longitudinal cutting saws can be used for conducting Y-direction cutting on the two sides of a plate correspondingly; according to the four-side saw, the machining universality of door plates of different sizes is improved, and the cutting efficiency is improved; the adjustable supporting mechanisms arranged on the lathe bed can flexibly adjust the distance between the supporting mechanisms according to the sizes of plate blanks to adapt to transportation of plates of different sizes.

Owner:山东速雕智能装备有限公司

Integrated laser continuous welding device and battery assembling equipment

ActiveCN111112836AQuickly modify the series and parallel modeFlexible adjustment of spacingOther manufacturing equipments/toolsCell component detailsEngineeringBattery pack

The invention belongs to the technical field of laser welding, and particularly relates to an integrated laser continuous welding device and battery assembling equipment. The integrated laser continuous welding device comprises a down-pressing buffering device and a tape feeding device, a pressing head, a rotating device, a laser welding swinging head and a cutting device which are driven to movein the vertical direction by the down-pressing buffering device; the down-pressing buffering device is connected to a moving device and comprises a sliding plate which is arranged vertically and can slide in the vertical direction; the tape feeding device is arranged on the front surface of the sliding plate; the pressing head and the cutting device are both arranged at the bottom end of the tapefeeding device; a light through hole is formed in the centre of the pressing head; a tape feeding component of the tape feeding device, the pressing head and the cutting device are arranged side by side in the transverse direction in sequence; one side of the rotating device is arranged on the front surface of the sliding plate; the laser welding swinging head is arranged on the other side of therotating device; and a laser beam emitted from the laser welding swinging head can penetrate through the light through hole. In a word, the device and the battery assembling equipment are simple in structure, good in compatibility, low in remodeling cost, short in assembling and debugging time, low in assembling cost and high in production efficiency.

Owner:深圳市大族锂电智能装备有限公司

Novel picture frame hanging rack

PendingCN111603009AFlexible adjustment of spacingNovel structurePicture framesDomestic mirrorsEngineeringStructural engineering

The invention provides a novel picture frame hanging rack, a left vertical adjusting piece and a right vertical adjusting piece are integrally formed at the bottom of a rectangular seat piece throughstamping, and a vertical long-strip-shaped through hole is formed in the middle of each vertical adjusting piece in a stamping mode; an arched sliding sheet is welded to the middle of the front side face of the rectangular seat piece, and a transverse long-strip-shaped sliding hole is punched in the middle of the arched sliding sheet; the left transverse moving piece and the right transverse moving piece are embedded into sliding cavities respectively, the middle of the front side face of each transverse moving piece is connected with a threaded rod in a screwed mode, and each threaded rod isforwards embedded into the transverse long-strip-shaped sliding hole of the corresponding arch sliding sheet. The upper end of the front side face of each transverse moving piece is connected with a hanging nail in a screwed mode. The transverse moving piece can transversely move along the transverse long-strip-shaped sliding hole through the threaded rod, and a tightening nut can be screwed in from the front end of the threaded rod and can fasten the transverse moving piece. The novel picture frame hanging rack has the characteristics of being novel in structure, flexible in adjustment and higher in practicability.

Owner:王宝珠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com