Four-side saw and door plank cutting method thereof

A four-sided sawing and cross-cutting technology, applied in the field of sheet metal processing, can solve the problems of poor suitability of door panels, difficult placement and processing of door panels, poor applicability of door panels of different widths, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

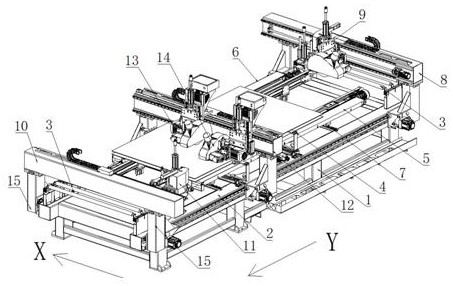

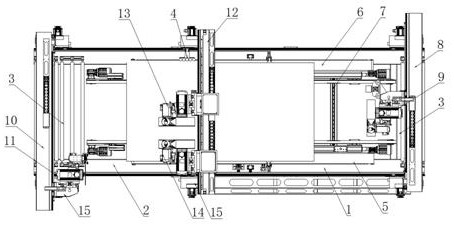

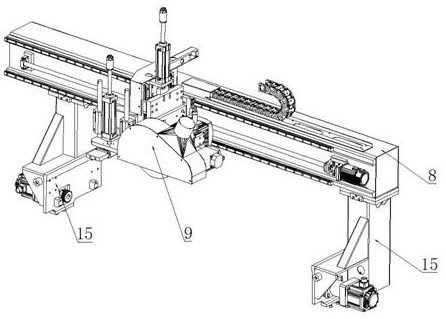

[0060] The present application will be further described in detail below in conjunction with the accompanying drawings. refer to Figure 1-17 , the application discloses a four-sided saw, including

[0061] bed assembly;

[0062] The first cross-cutting unit;

[0063] The second cross-cutting unit;

[0064] Slitting unit.

[0065] Such as Figure 1-2 As shown, the first cross-cutting unit, the second cross-cutting unit and the longitudinal cutting unit are all arranged on the bed assembly and can translate along the Y direction of the bed assembly; the first cross-cutting unit and the second cross-cutting unit The cutting unit can be used to cut the two ends of the plate in the X direction; the slitting unit is arranged between the first cross-cutting unit and the second cross-cutting unit, and the slitting unit includes two slitting saws, and the two slitting saws The chop saw can be used separately to make Y-cuts on both sides of the board.

[0066] The first cross-cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com