Patents

Literature

236results about How to "Easy to undertake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

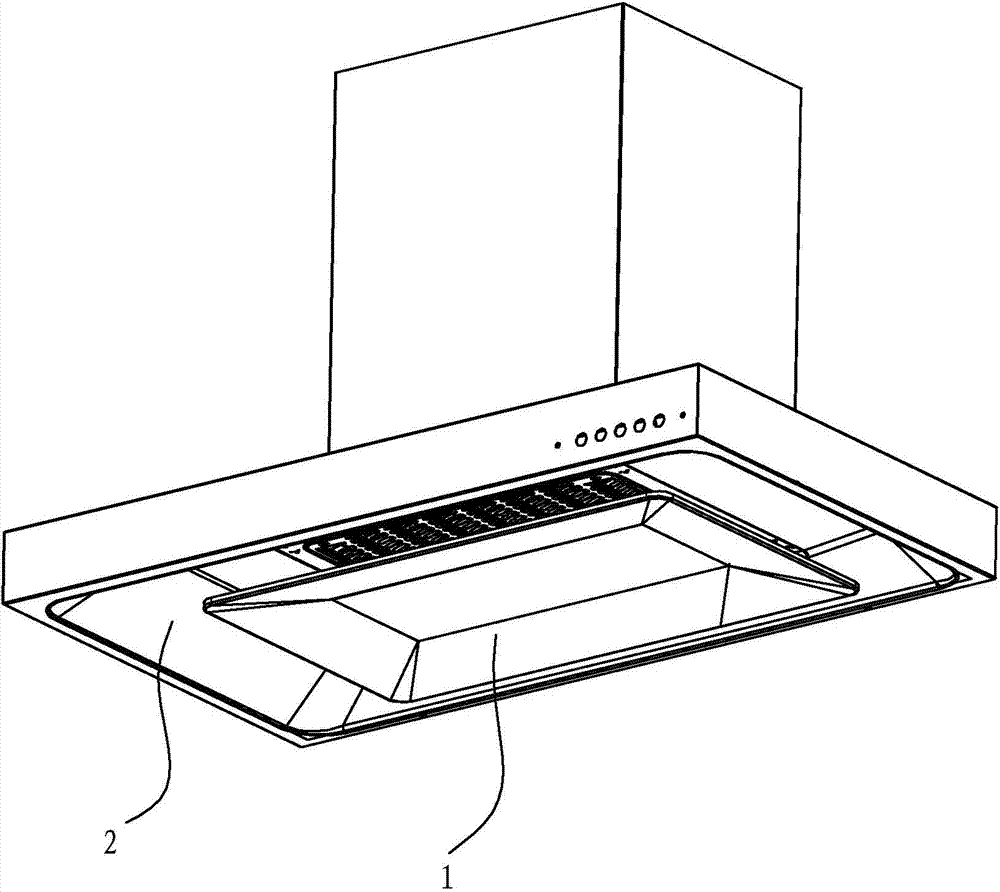

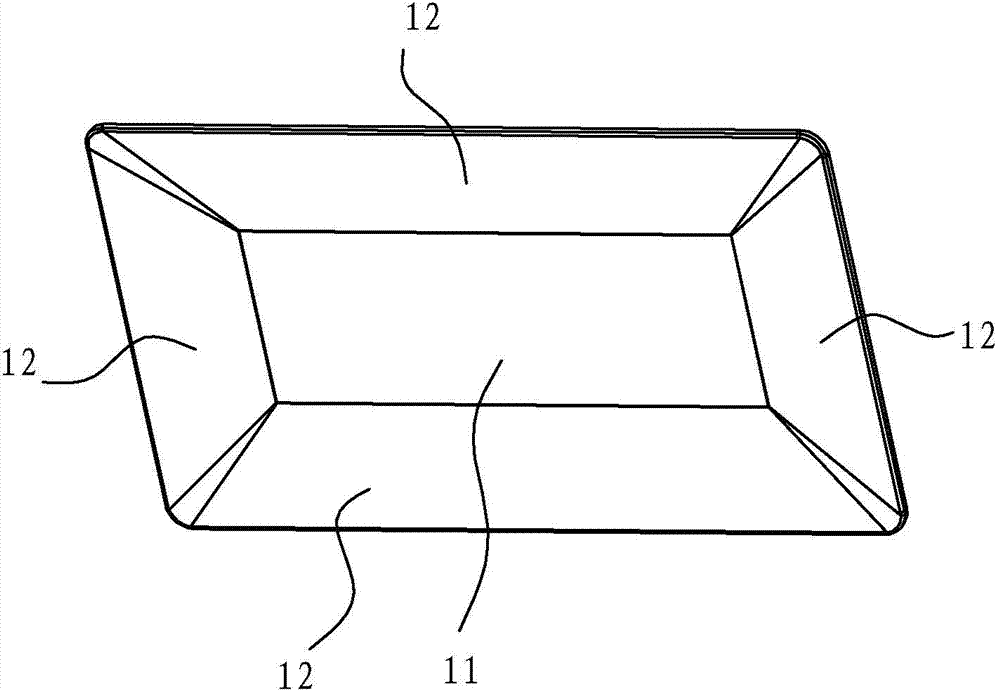

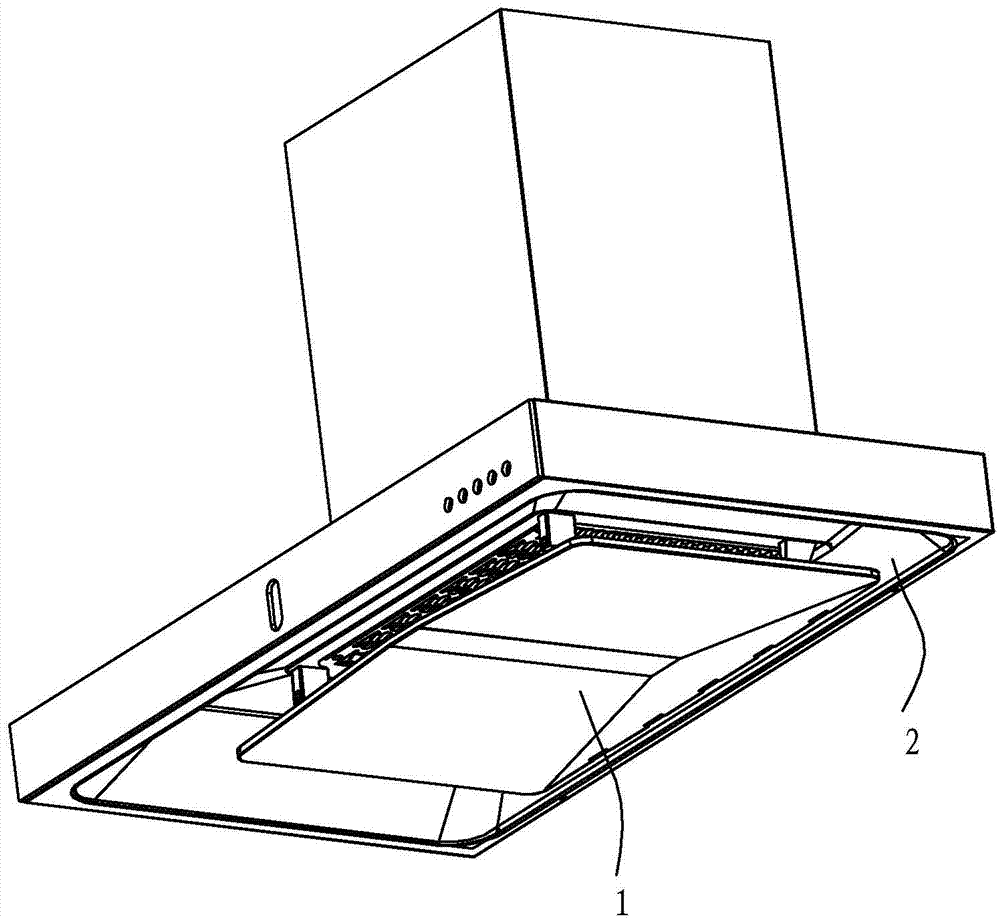

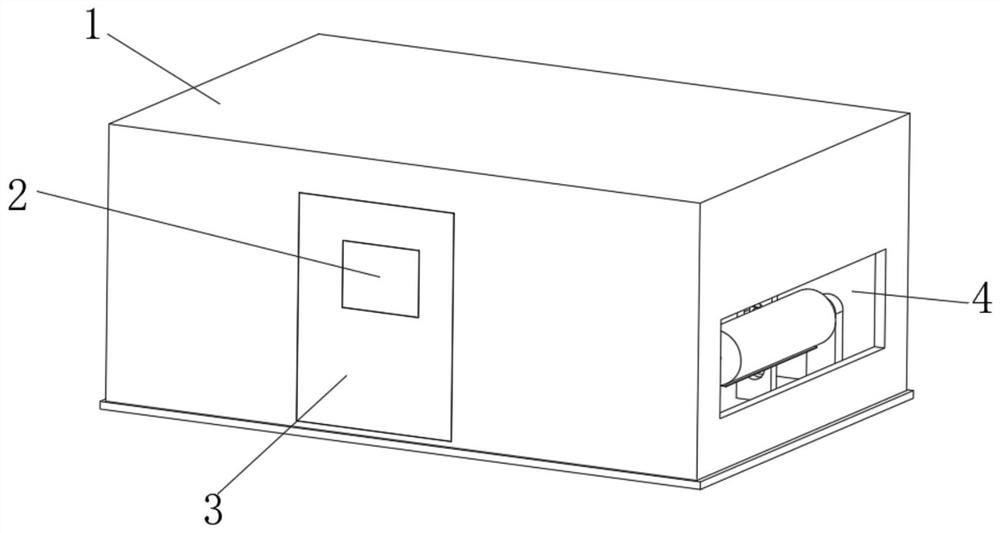

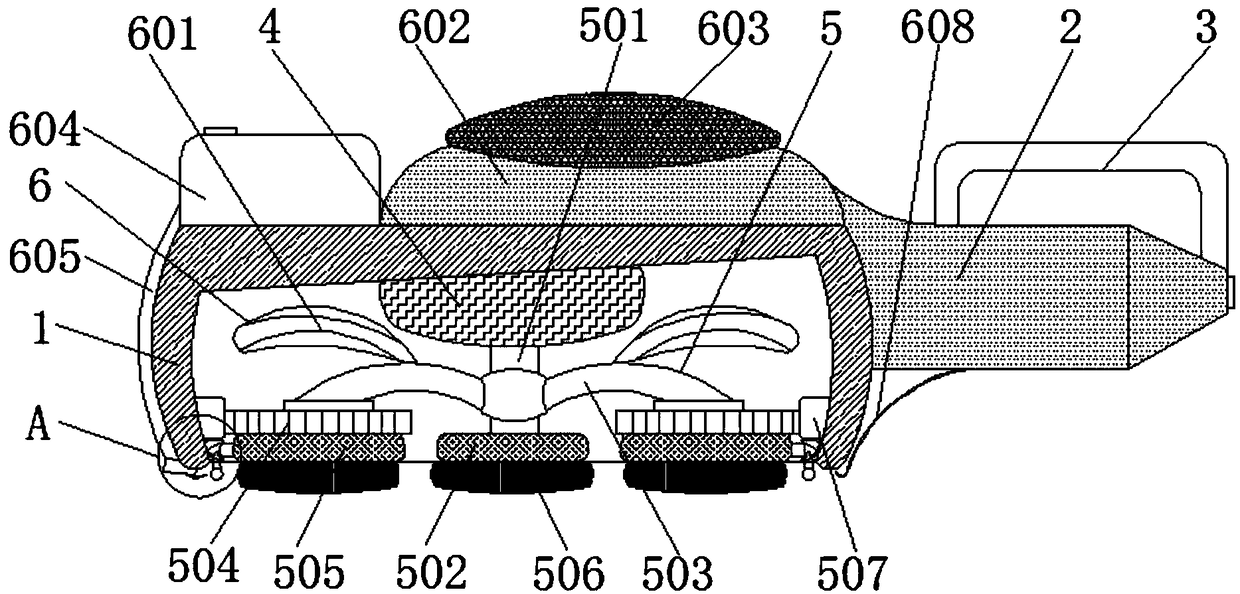

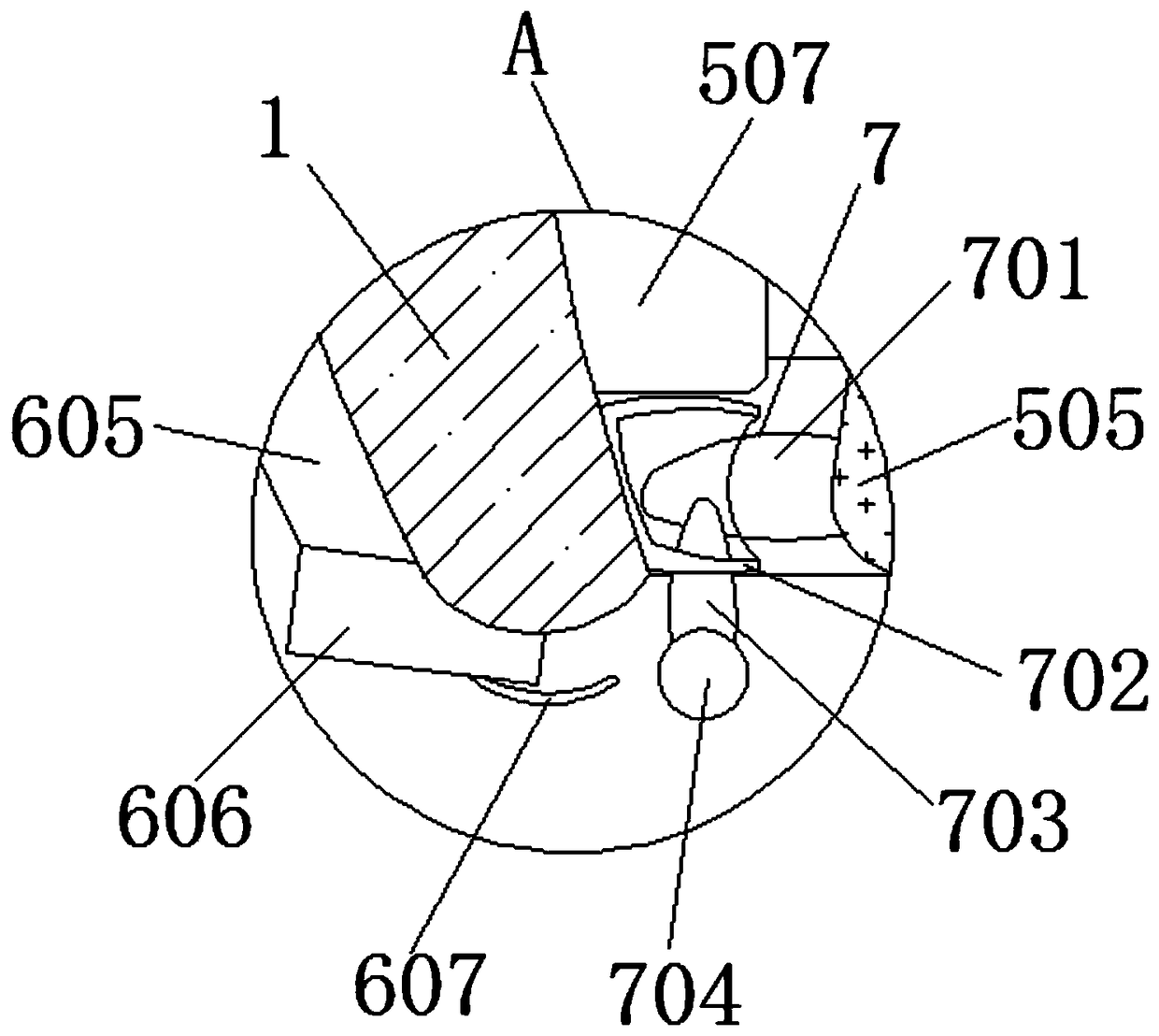

Diffusion drainage device of range hood

ActiveCN103697511AFacilitated DiffusionReduce flowDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

The invention relates to a diffusion drainage device of a range hood. The diffusion drainage device comprises a diffusion drainage smoke control plate which is just opposite to an exhaust fume collecting hood air inlet of the ceiling type range hood, and is characterized in that the diffusion drainage smoke control plate has an inwards concave structure with a high middle part and a low periphery. Compared with the prior art, the diffusion drainage device disclosed by the invention has the advantages that the diffusion drainage smoke control plate having the inwards concave structure with the high middle part and the low periphery can ensure that the pressure distribution on the lower side and the edges of the range hood is improved and reconstructed; compared with a conventional range hood, the range hood has the advantages that the periphery of the diffusion drainage smoke control plate has a venturi effect to ensure that negative pressure is expanded outwards to the edges of the diffusion drainage smoke control plate, and an effective area for sucking oil fume is enlarged by about twice; after oil fume gas rises and contacts the edges of the diffusion drainage smoke control plate, the oil fume gas can move upwards quickly, a negative pressure passage is defined by the diffusion drainage smoke control plate and the inner surface of a smoke collecting cavity at the upper part of the diffusion drainage smoke control plate at the same time, and then the oil fume gas flows inwards to an air inlet of a blower along the negative pressure passage; by virtue of the inwards concave area, the oil smoke diffusion is greatly promoted.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

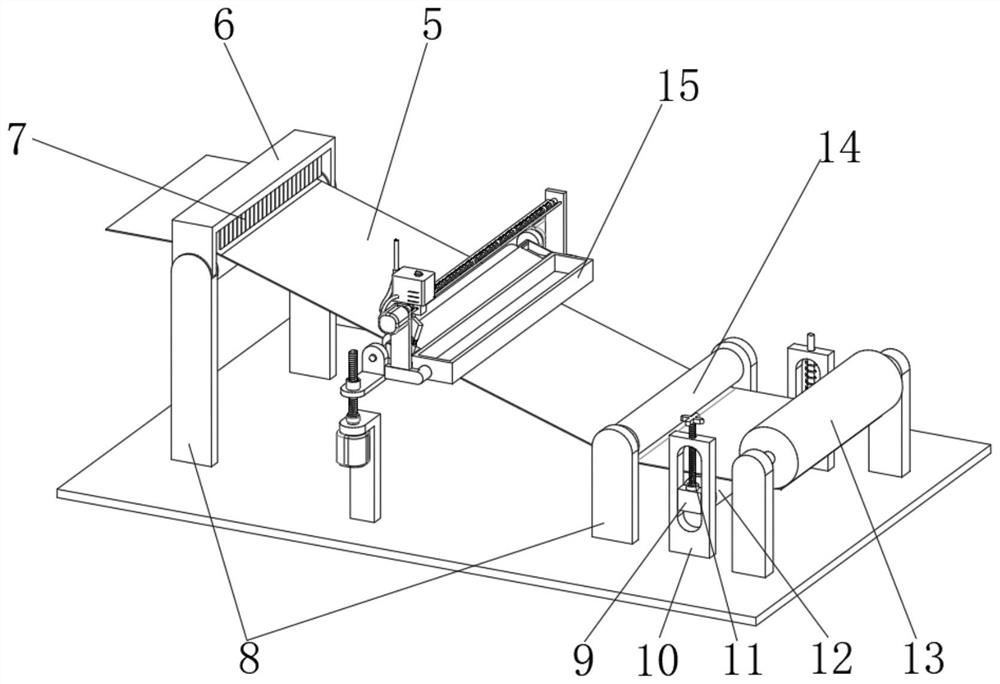

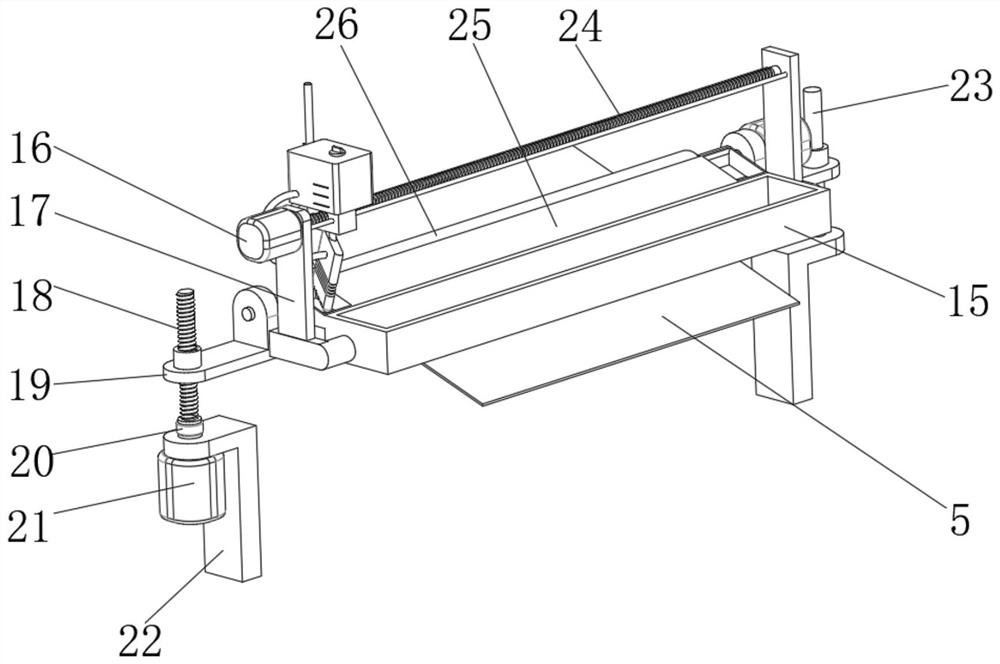

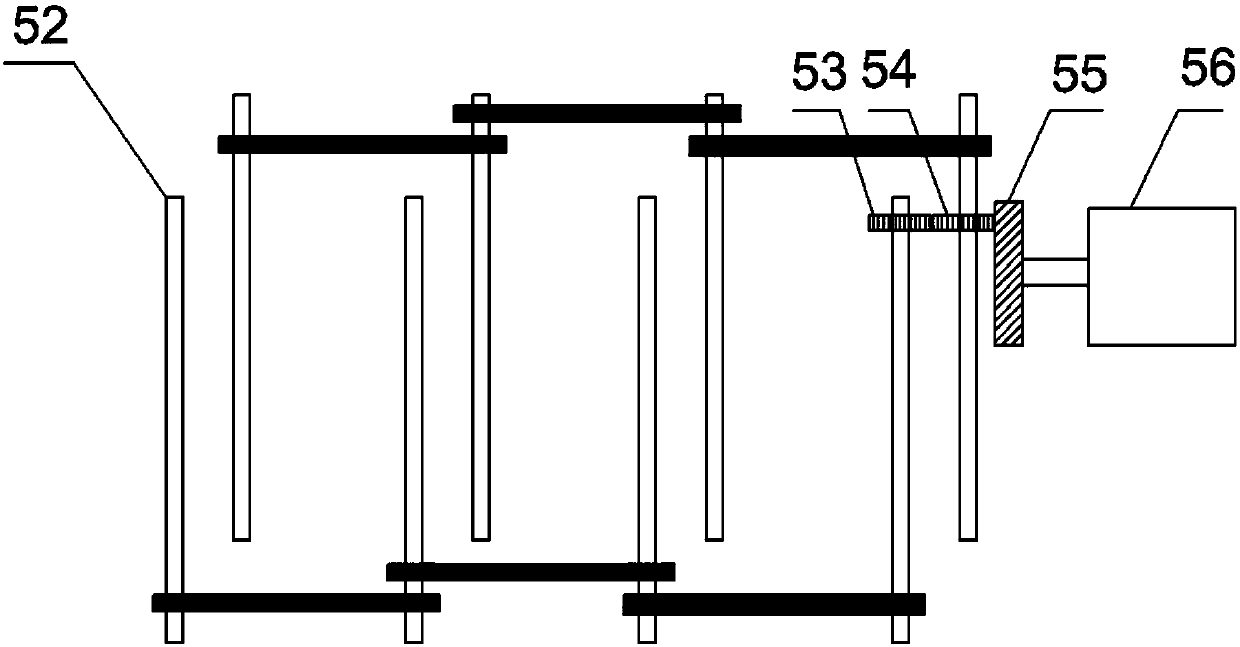

Ultrathin adhesive tape preparation method and thickness adjusting device

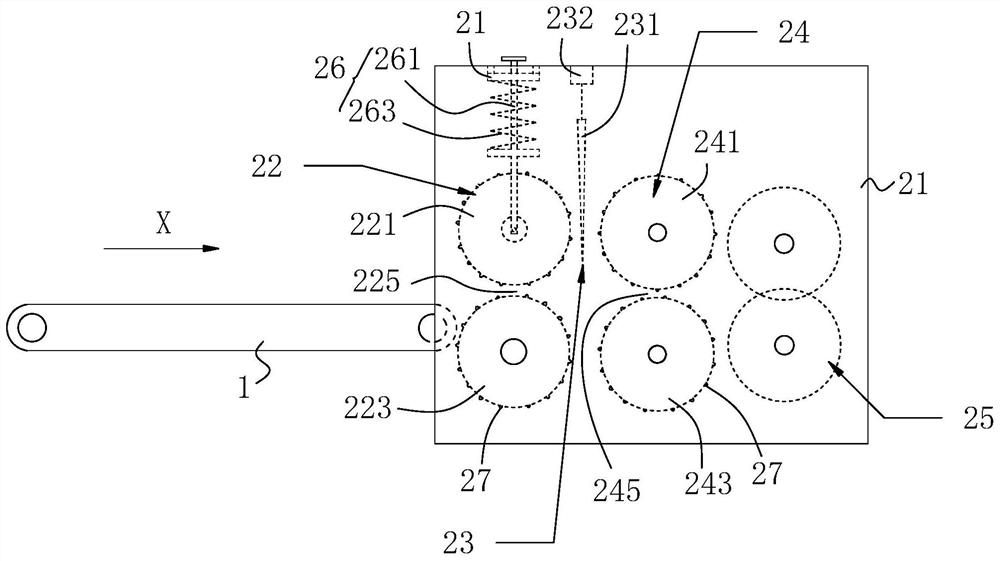

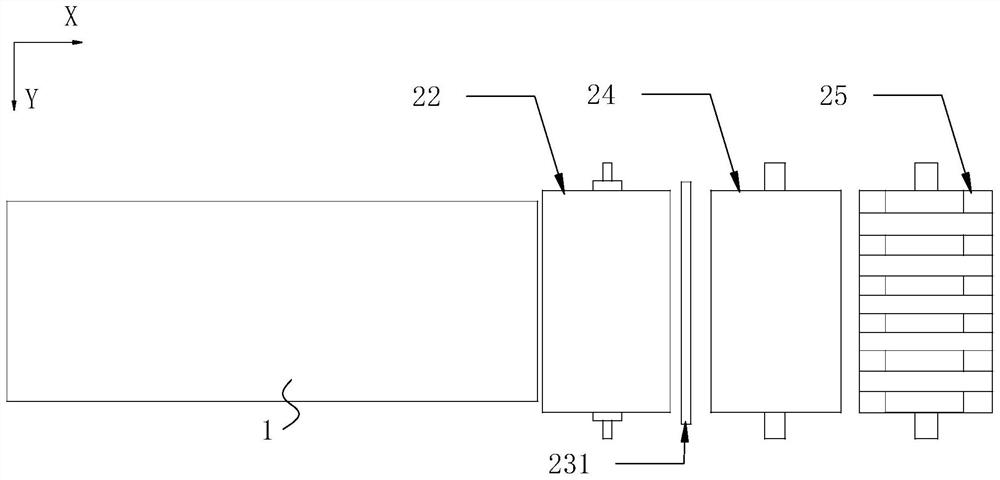

InactiveCN112871584AChange spacingAdjustable thicknessLiquid surface applicatorsSpraying apparatusAdhesiveElectric machinery

The invention discloses an ultrathin adhesive tape preparation method and a thickness adjusting device thereof, and relates to the technical field of ultrathin adhesive tape preparation. The spraying thickness of an adhesive is convenient to control. The ultrathin adhesive tape thickness adjusting device comprises a glue scraping mechanism and two first supporting frames, the glue scraping mechanism and the two first supporting frames are installed in a dust-free chamber, an adjusting stud is rotatably installed on the outer wall of the top of one first supporting frame, an adjusting guide rod is fixed to the outer wall of the top of the other first supporting frame through a screw, and a servo adjusting motor is fixed to one outer wall of the first supporting frame through a screw. The ultrathin adhesive tape preparation method comprises the following steps that one end of an adhesive tape base film is pulled to a winding roller to be fixed; and parameters are adjusted through a control screen, so that the servo adjusting motor controls the adjusting stud to rotate. By arranging a glue scraping roller, an adjusting frame and other structures, the servo adjusting motor can be controlled to work to drive the adjusting stud to rotate, and then the adjusting frame is made to ascend and descend, so that the distance between the glue scraping roller and the adhesive tape base film is changed, and the purpose of adjusting the thickness is achieved.

Owner:苏州睿泰鑫材料科技有限公司

uv-high leveling sanding primer

InactiveCN102277069AImprove the level ofHigh surface flatnessEpoxy resin coatingsPolyester coatingsSurface finishAcrylic resin

The invention discloses a UV-high leveling sanding primer. The components of the primer and their weight proportions are: 100% UV resin 50%-65%, defoaming agent 0.1%-0.3%, dispersant 1.0%-2%, filler 5%-10%, initiator 3%-5%, leveling agent 0.1%-1%, anti-settling agent 1%-1.5%, and the balance is monomer; the 100% The UV-resin is polyester acrylic resin, modified epoxy acrylic resin or their mixture; the monomer is acrylate, modified acrylate or their mixture; the filler is inorganic powder. The present invention has high surface smoothness, good fullness, good leveling, and is easy to sand, and the formed paint film structure is easy to polish, and can provide a smooth surface in the construction process of wooden furniture, wooden floors and other wooden products, thereby Provides the best assistance for the finish effect of the surface.

Owner:JIANGSU HIMONIA TECH

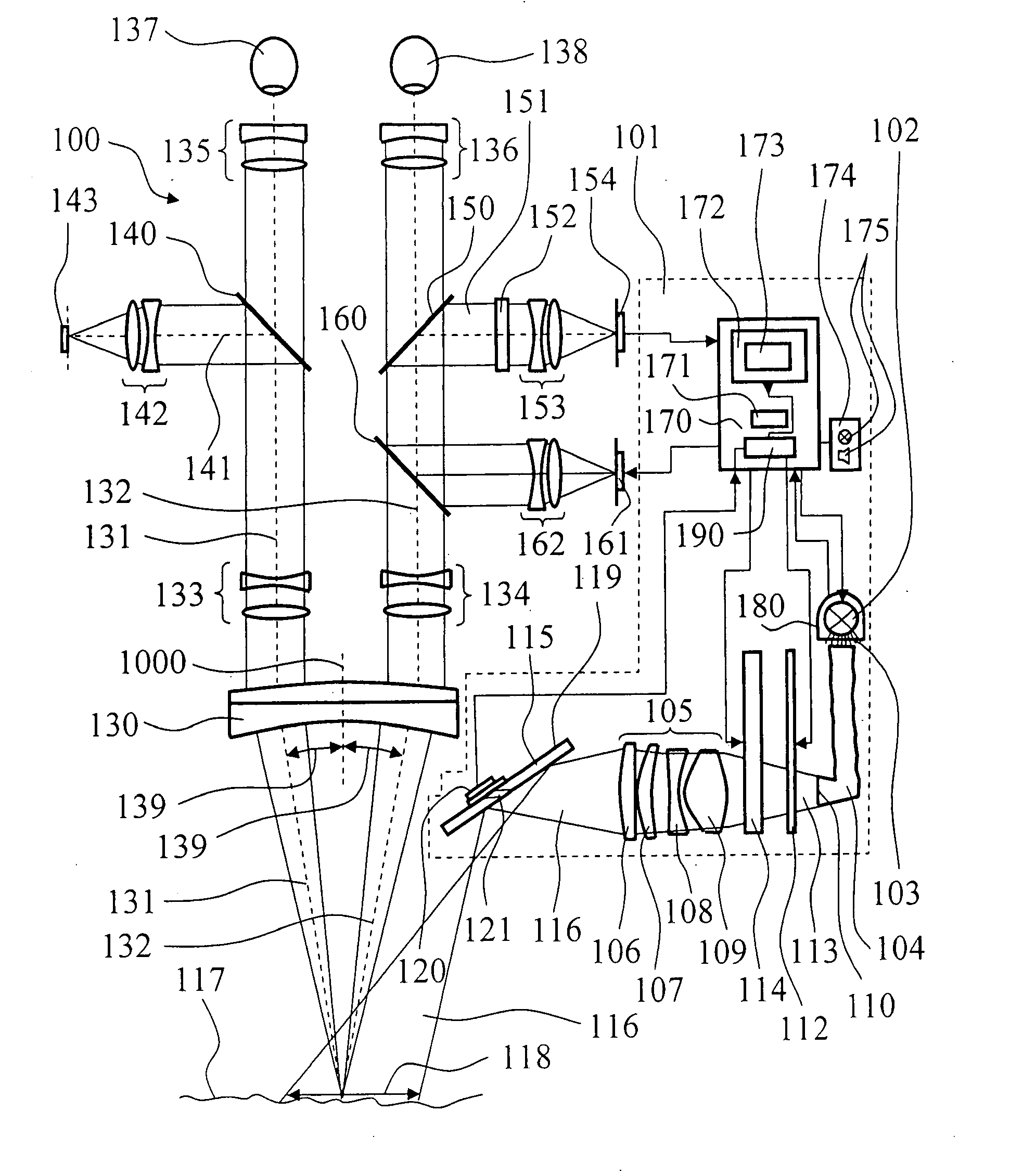

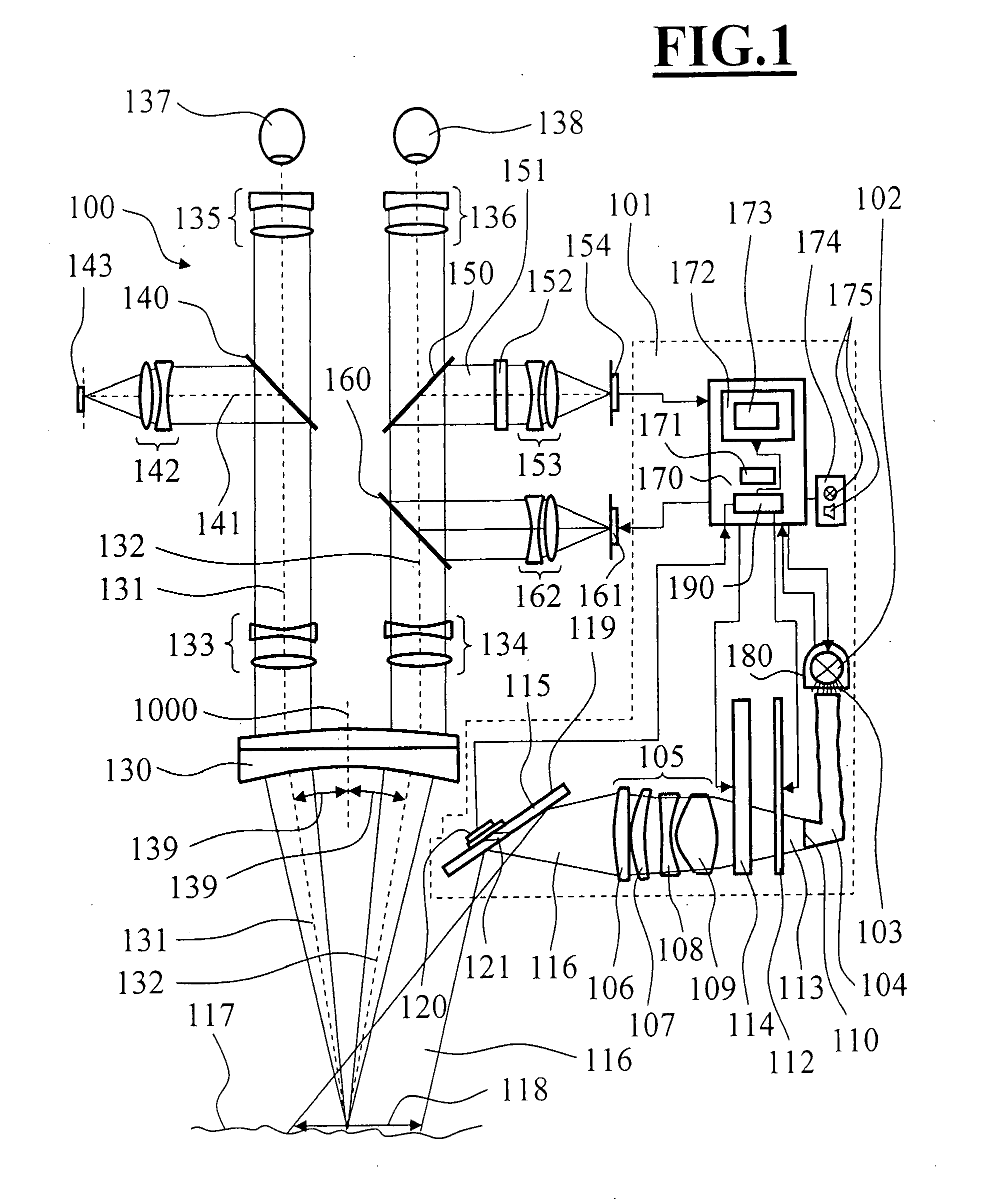

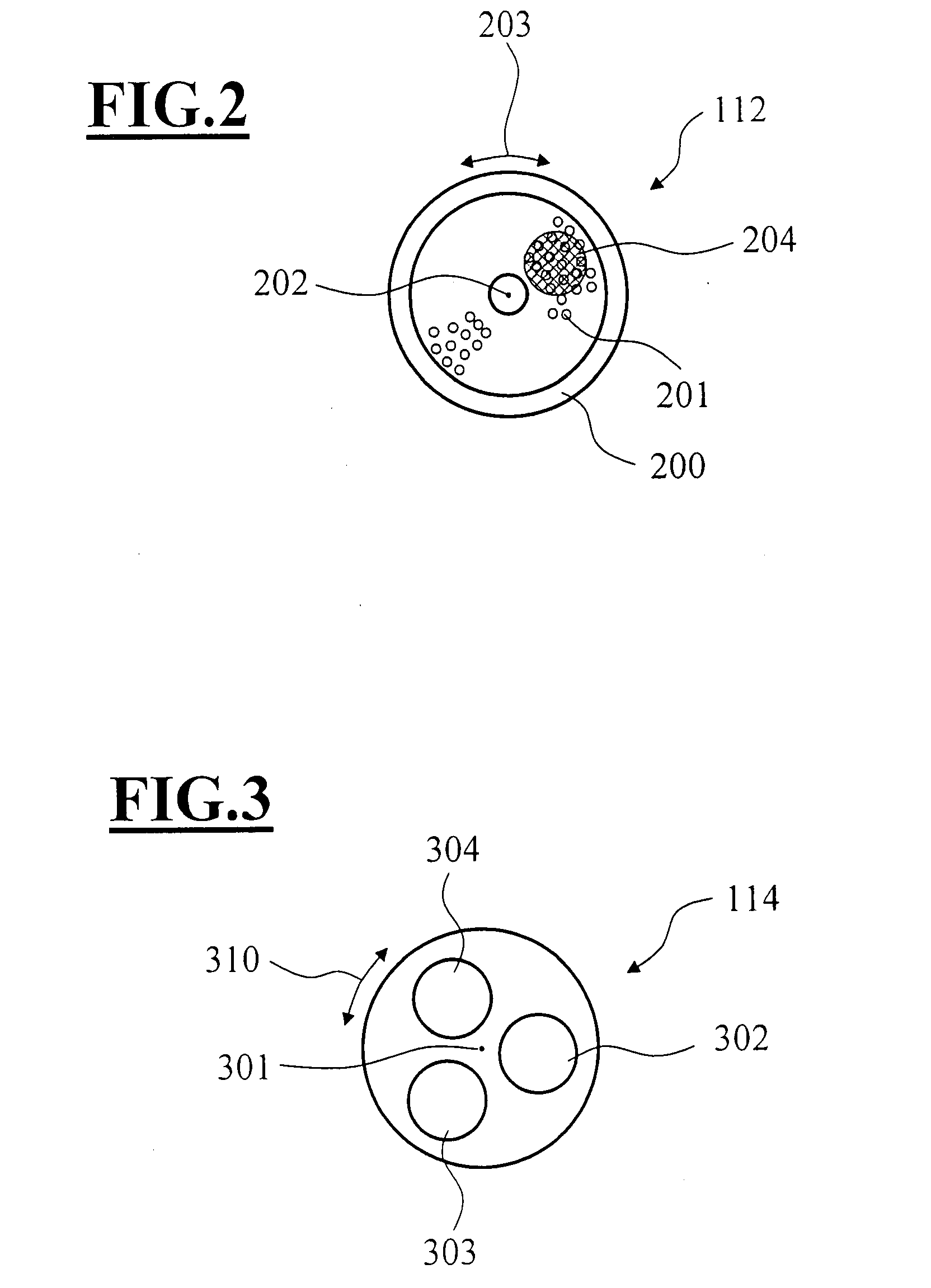

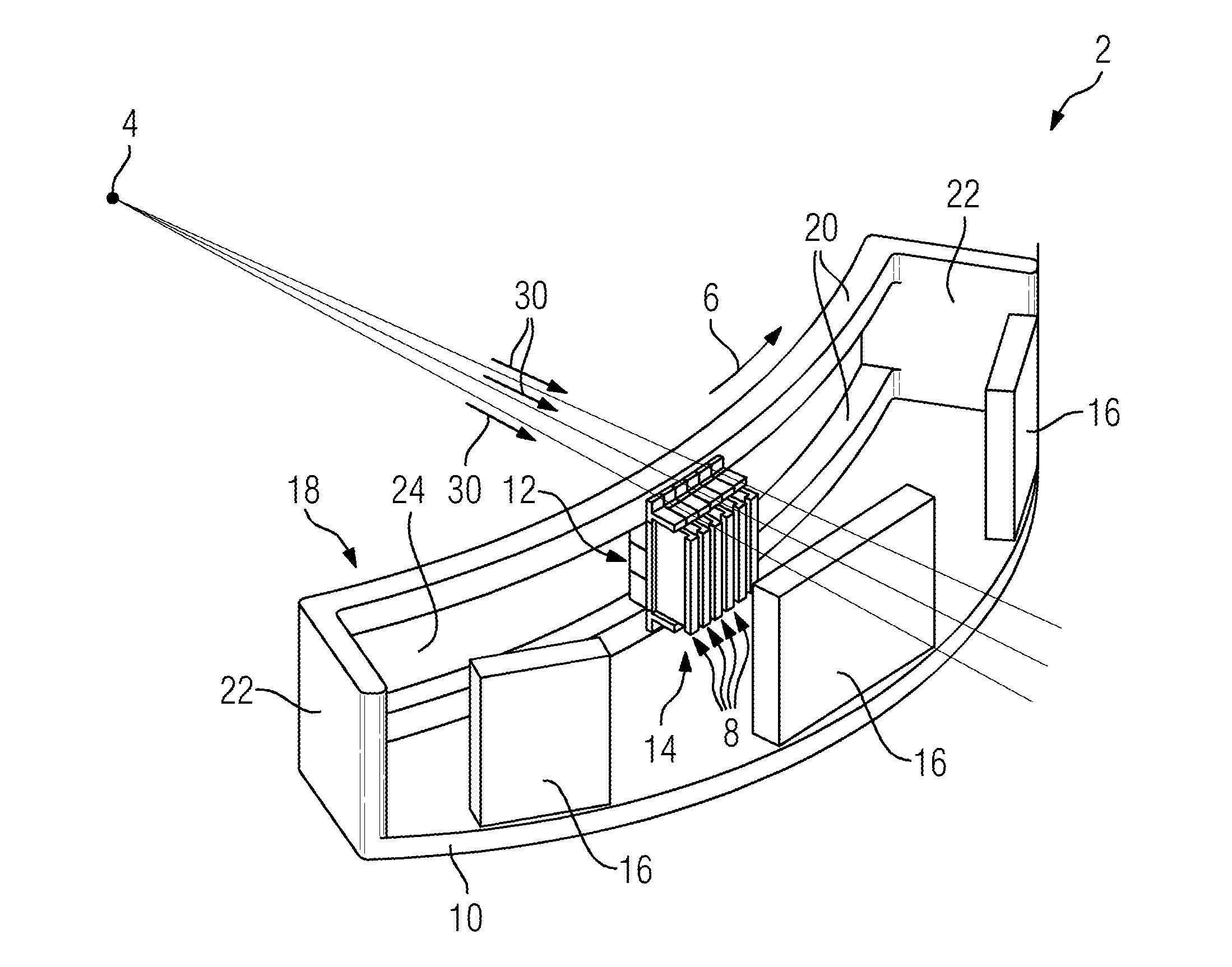

Surgical microscope having an illuminating arrangement

ActiveUS20080049314A1Extend service hoursEasy to undertakeSurgeryMicroscopesSurgical microscopeLimit value

A surgical microscope (100) is especially suited for use in neurosurgery. The surgical microscope has an illuminating arrangement (101) for making available illuminating light in an operating region (117) to be examined with the surgical microscope (100). The illuminating arrangement (101) contains a high-power light source (102) which includes an intensity adjusting device (112). The intensity adjusting device (112) makes possible to adjust the intensity of the illuminating light (116), which is guided to the object region (117), between a maximum value and a minimum value. The surgical microscope (100) has a control unit (170) for the illuminating arrangement (101) which includes an operator-controlled module (172) via which the illuminating arrangement (101) can be activated and controlled. For adjusting the intensity of the illuminating light (116) guided to the operating region (117), the control unit coacts with the adjustable filter unit (112). A signal generator (175) is provided which outputs a warning signal when an intensity of the illuminating light is adjusted via the operator-controlled module (172) which exceeds the safety limit value stored in a memory (171).

Owner:CARL ZEISS MEDITEC AG

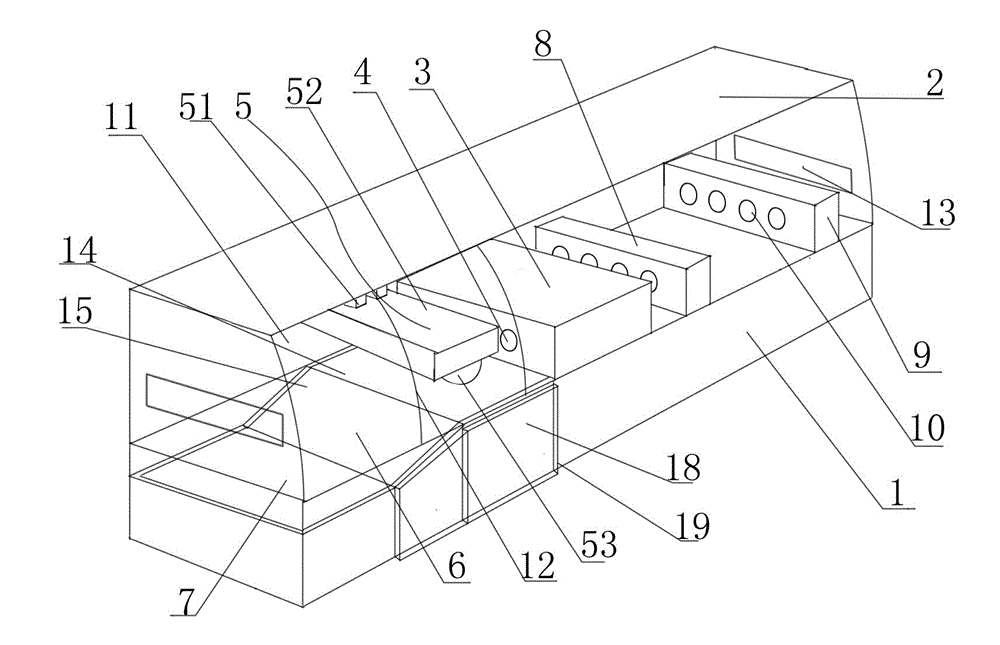

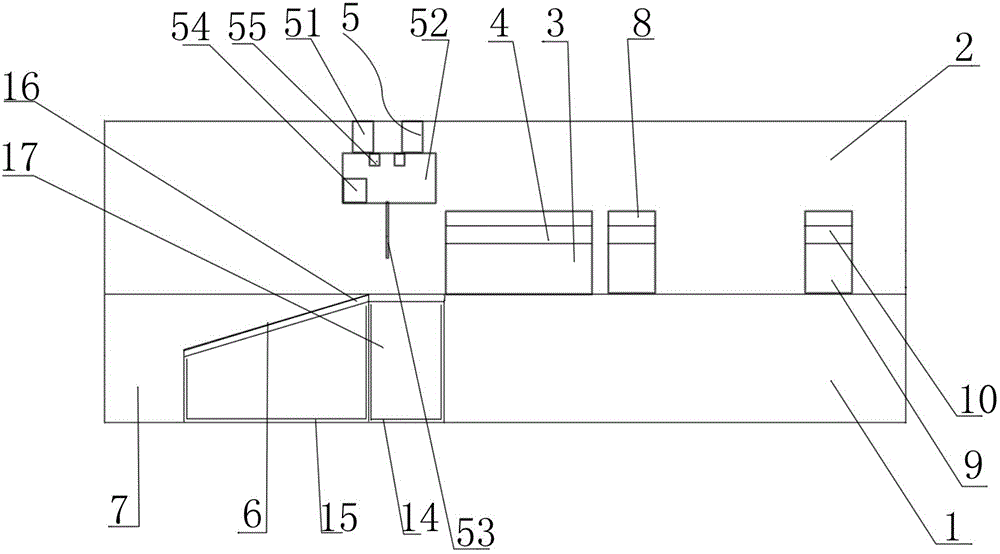

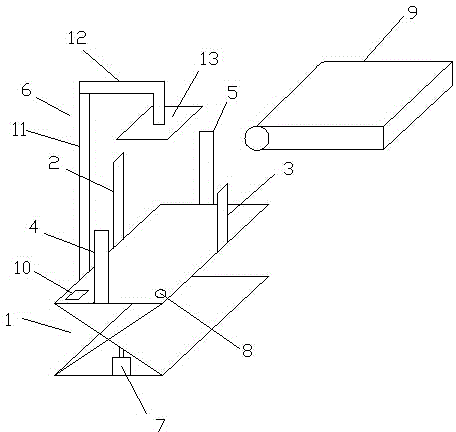

Scrap-collecting metal pipe cutting machine

InactiveCN104096898AEasy accessEasy to undertakeTube shearing machinesMaintainance and safety accessoriesEngineeringClockwise

The invention discloses a scrap-collecting metal pipe cutting machine, which comprises a rectangular block base and a box arranged on the upper part of the base. The scrap-collecting metal pipe cutting machine is characterized in that a clockwise guide device is arranged in the center of the top of the base; a cutting part is arranged on the top of the box, on one side of the clockwise guide device; an inwards-indented first groove is formed in the base, on the lower part of the cutting part; a second groove is arranged on one side of the first groove; a slope is arranged on the top of the second groove; the top of the slope and the top of the first groove are respectively provided with a layer of metal mesh. According to the scrap-collecting metal pipe cutting machine, the first and second grooves are used for collecting the metal scraps, the slope is arranged on the top of the second groove, thus a metal pipe can enter the collecting box besides the second groove, the top of the slope and the top of the first groove are respectively provided with one layer of metal mesh, adapting of the metal pipe is facilitated, and the metal scraps can also enter the grooves. The scrap-collecting metal pipe cutting machine has the advantages of simple structure, convenience in use and the like.

Owner:南通市海门江海建设投资有限公司

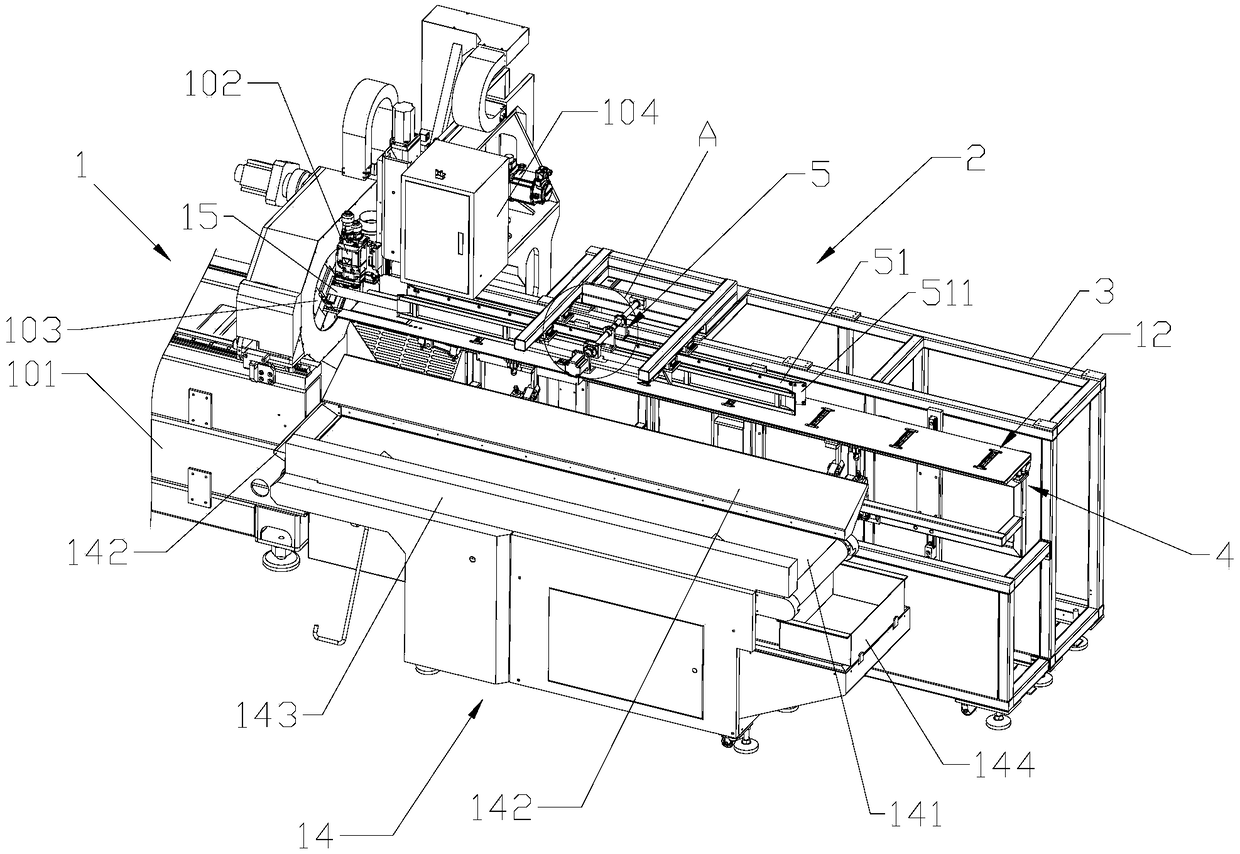

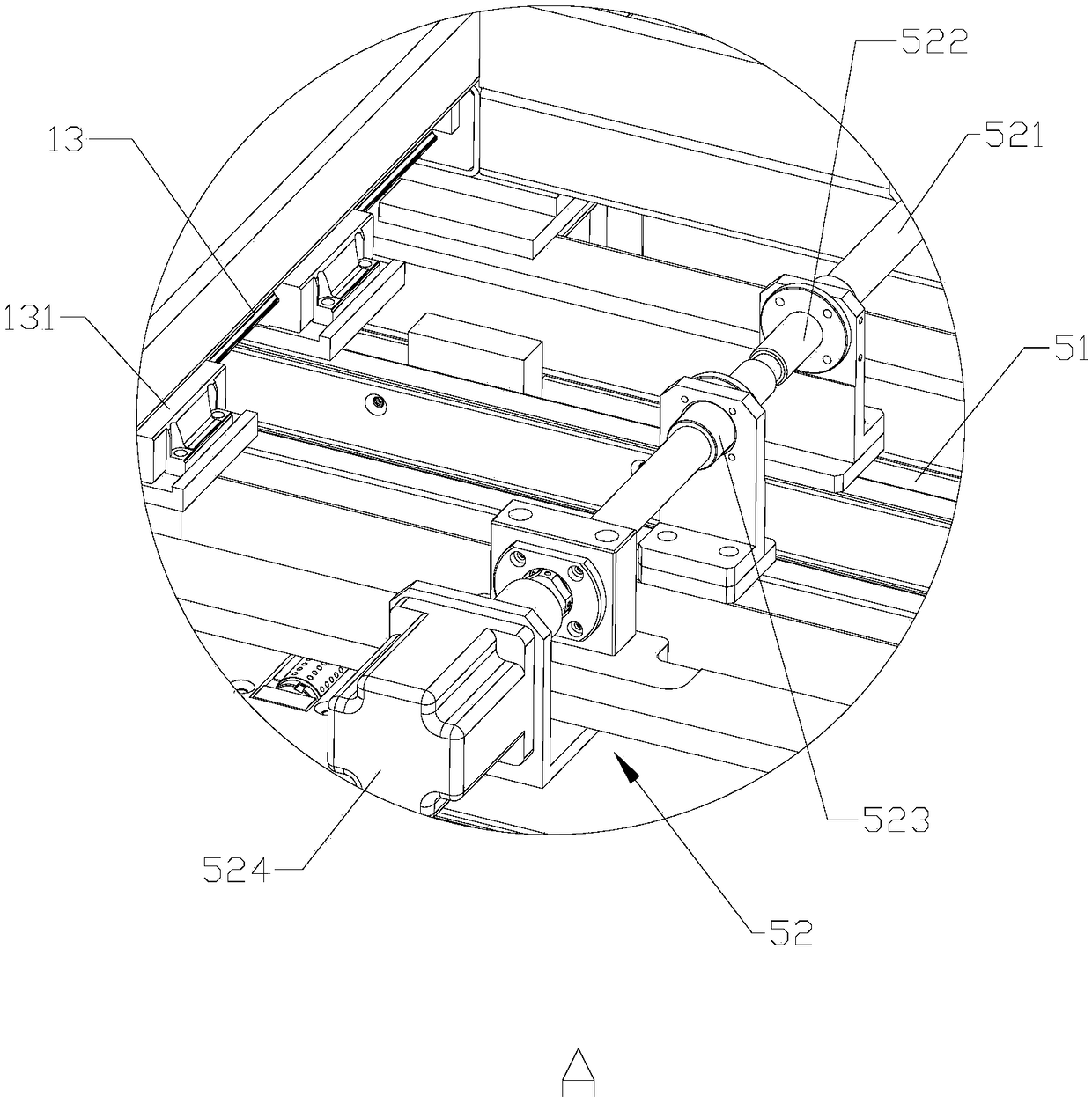

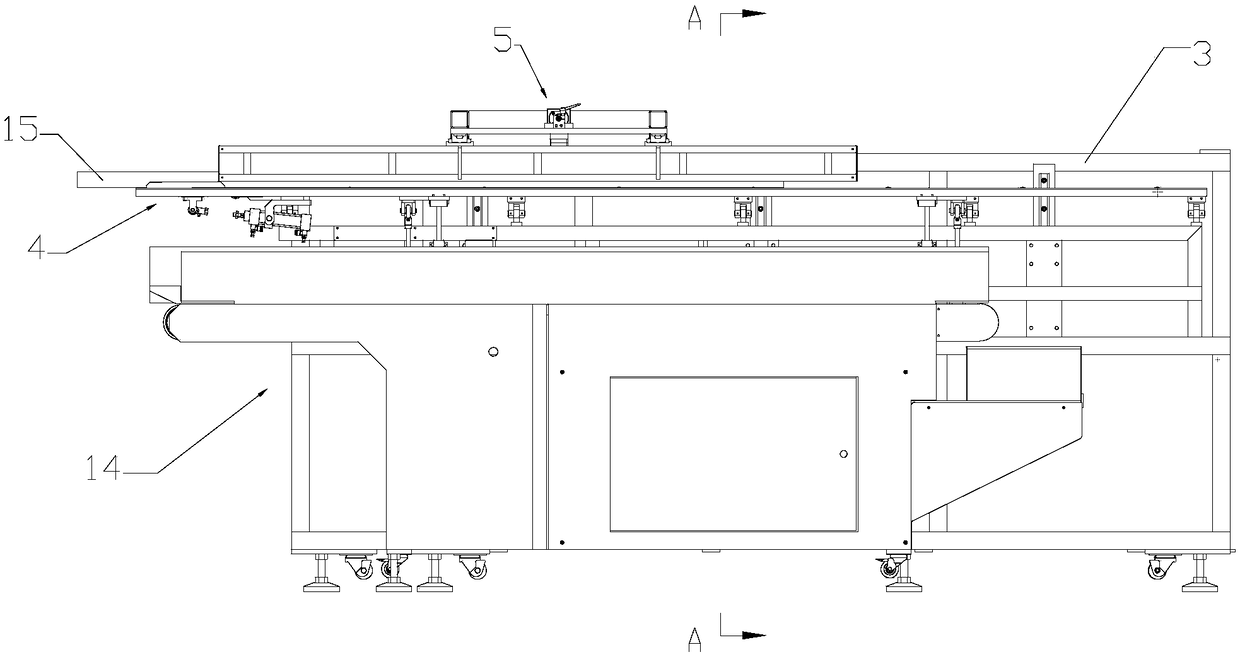

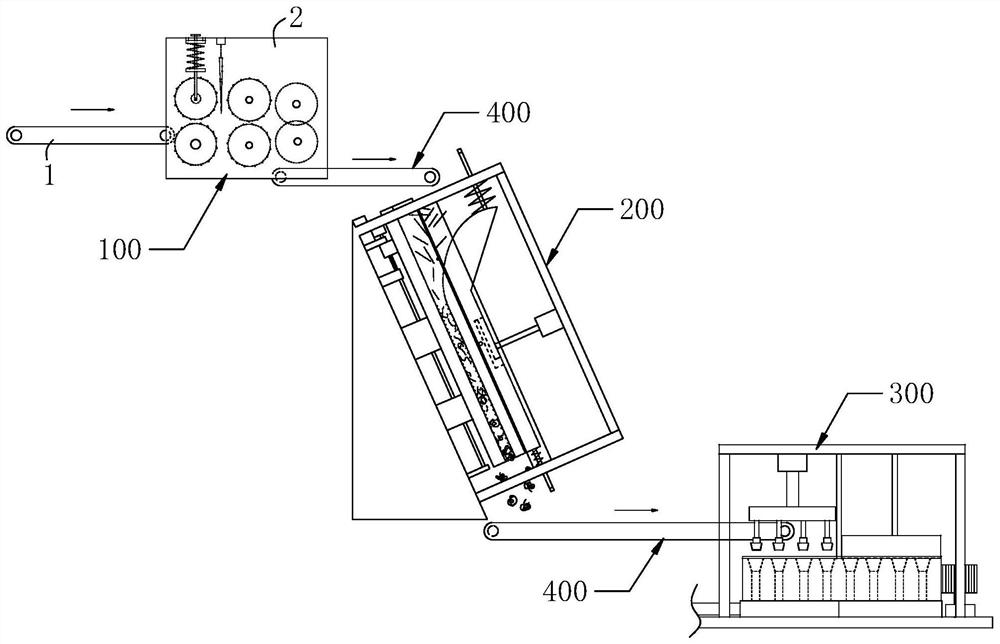

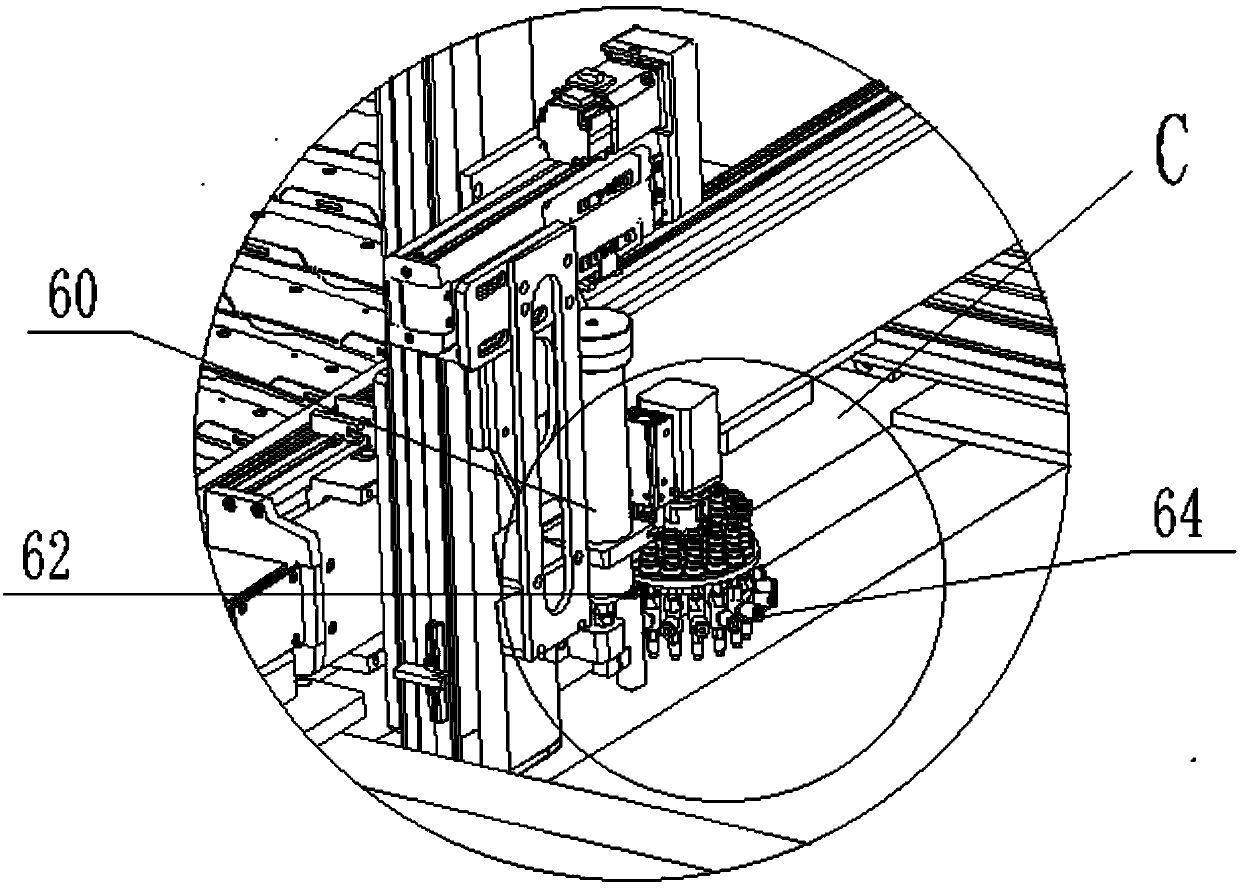

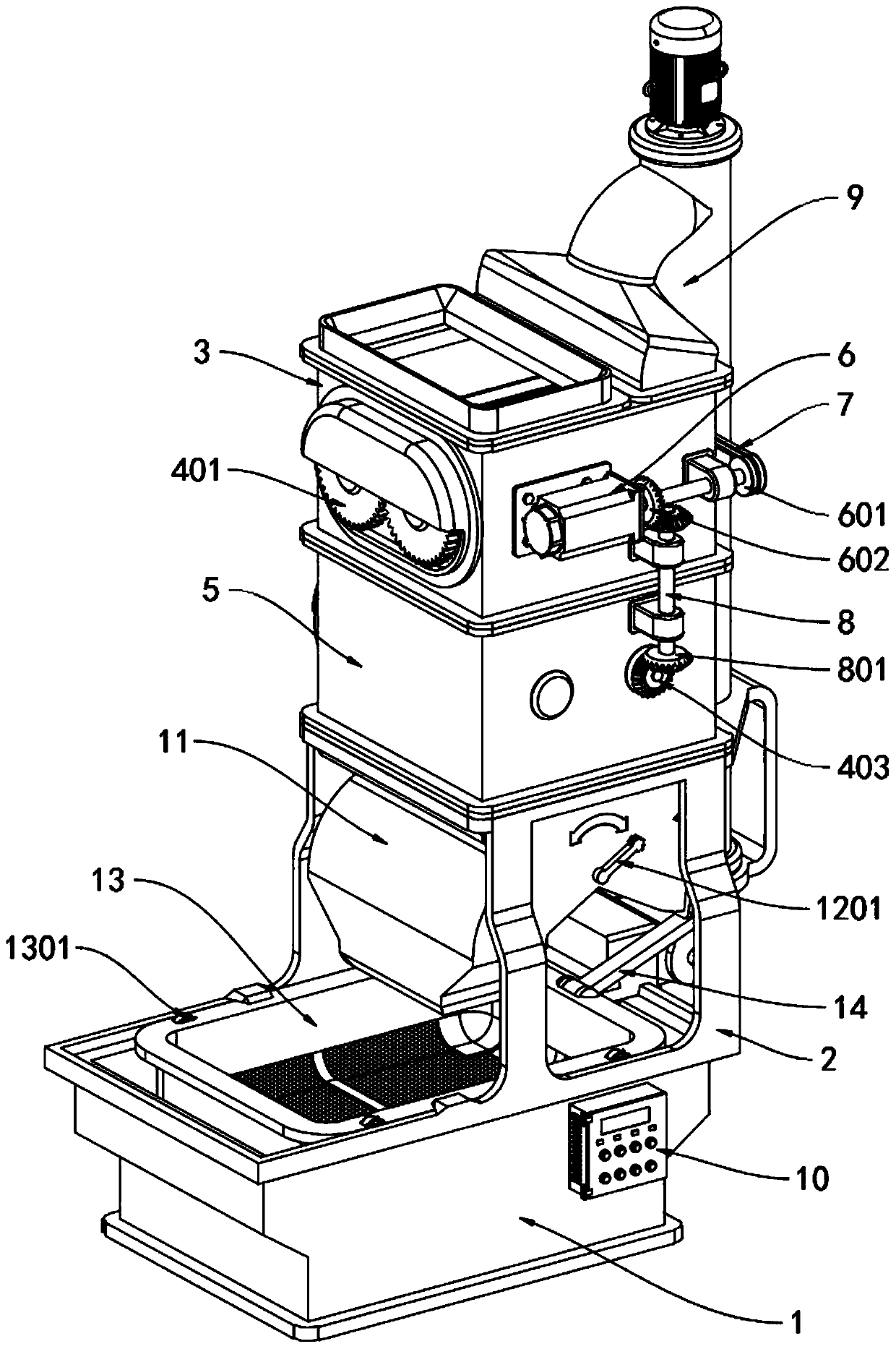

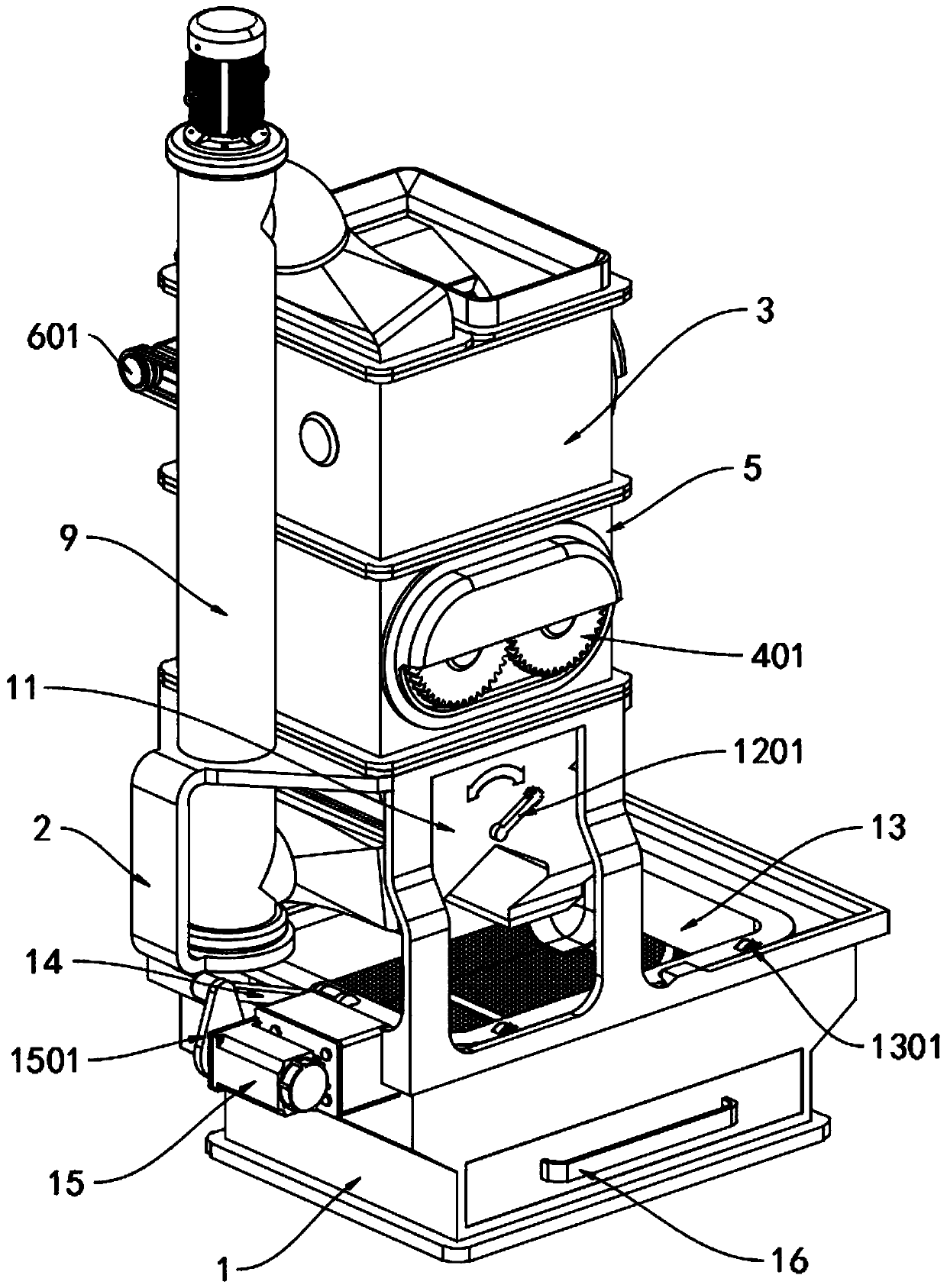

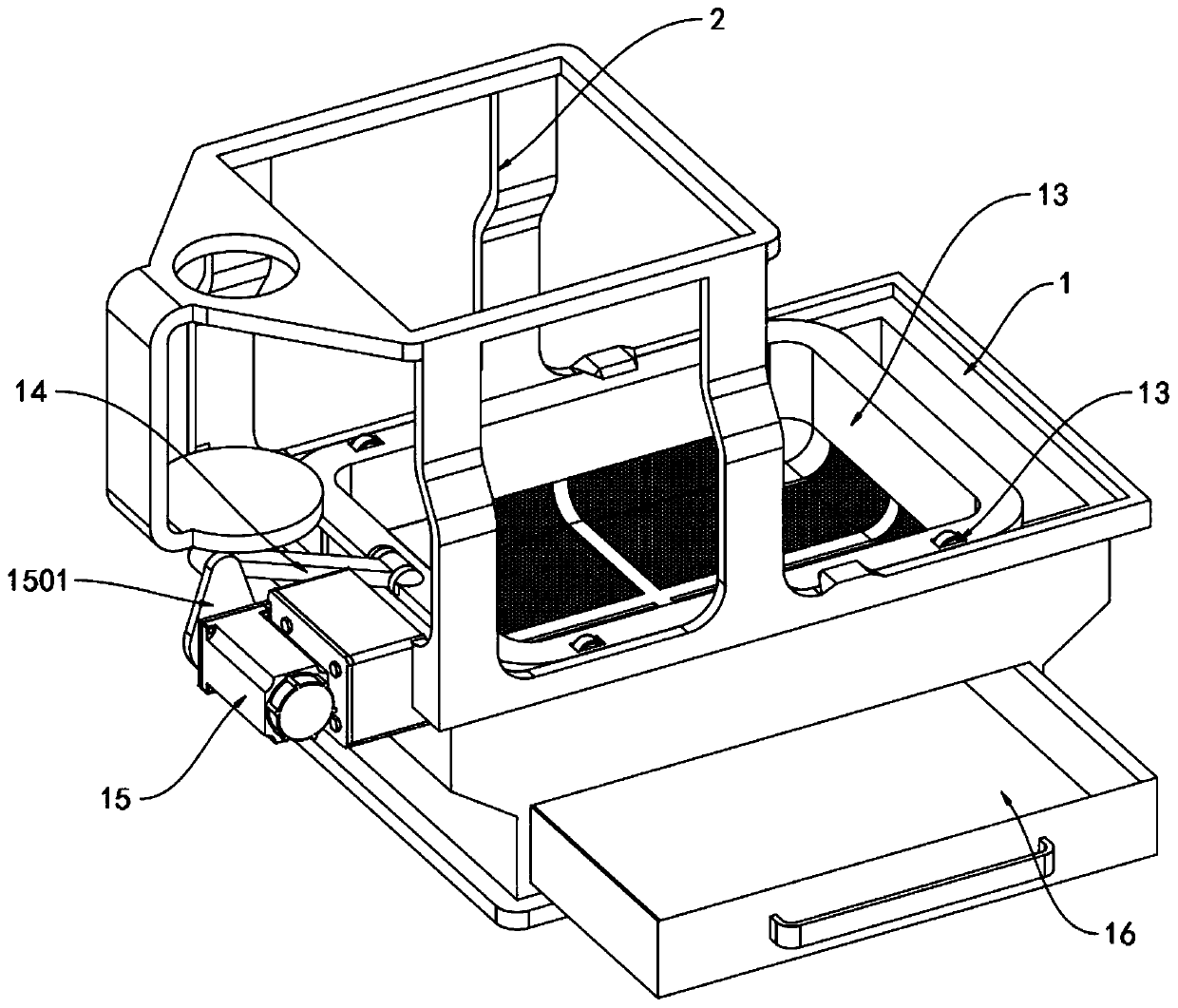

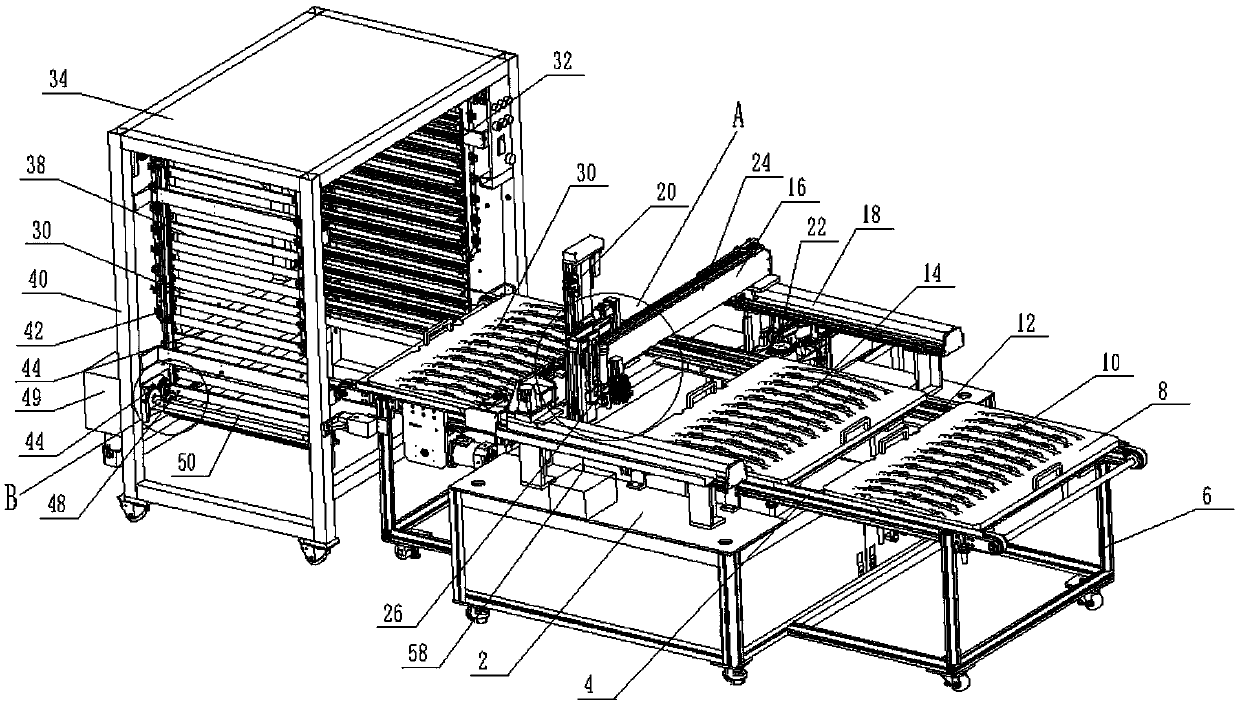

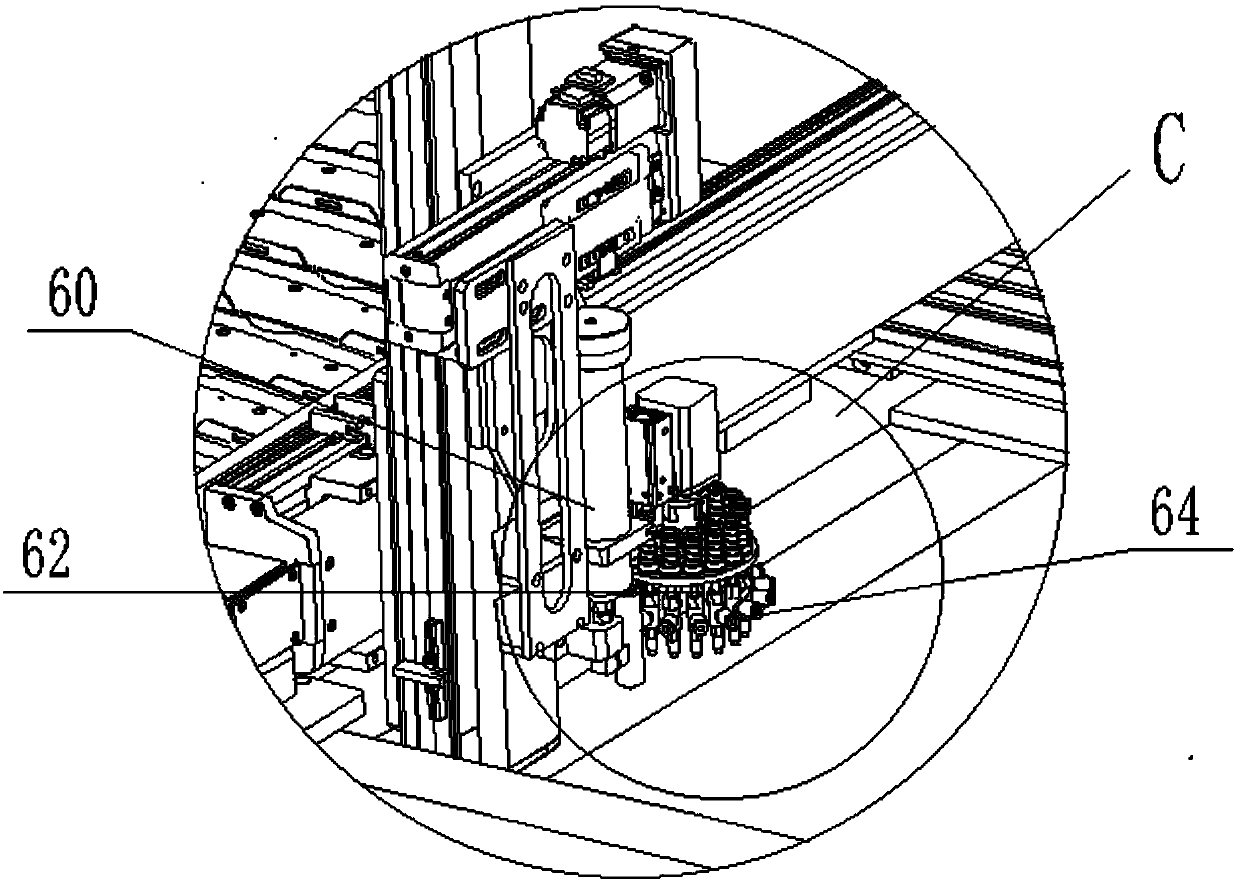

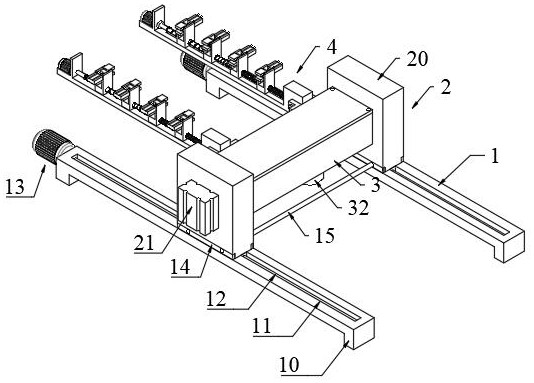

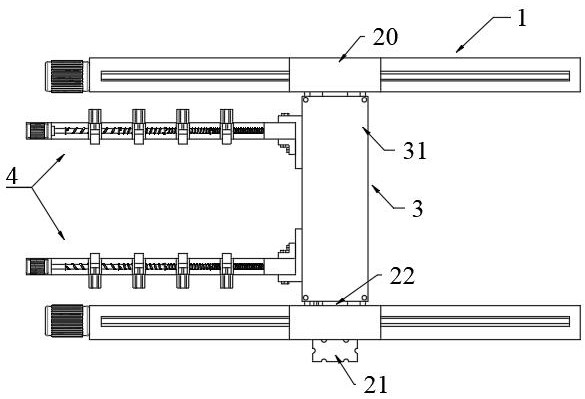

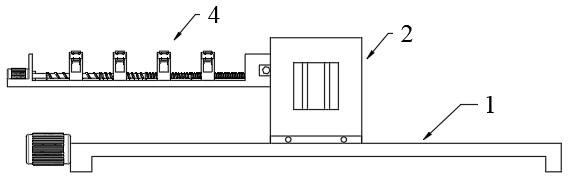

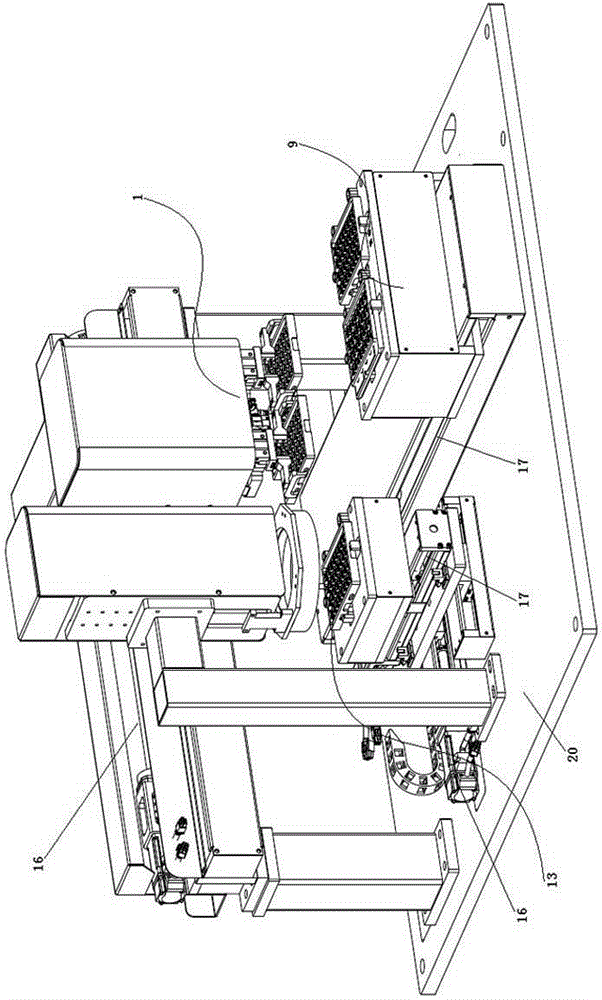

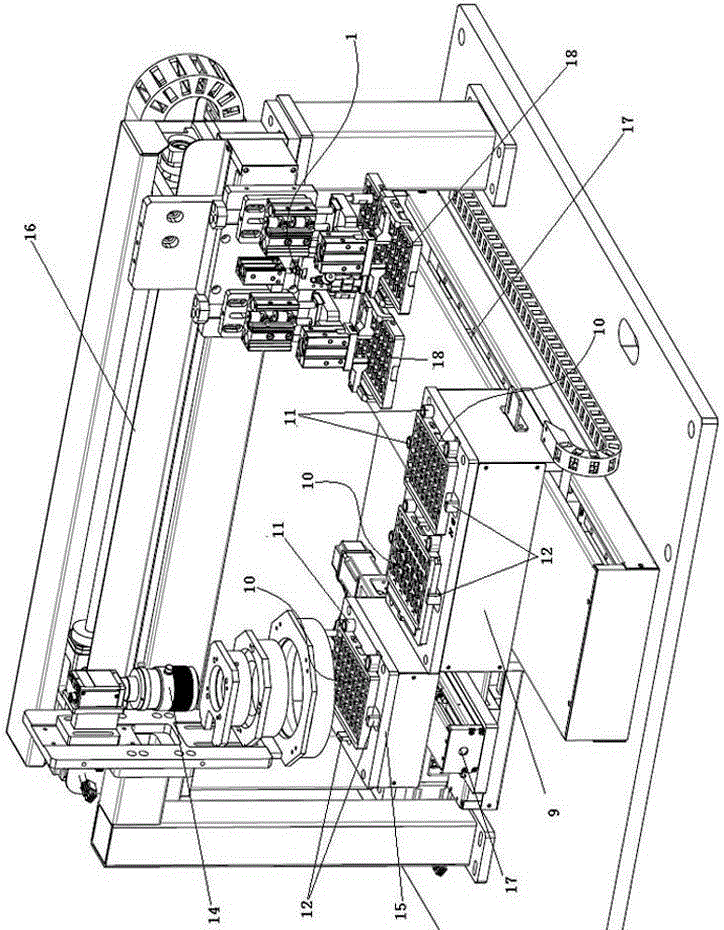

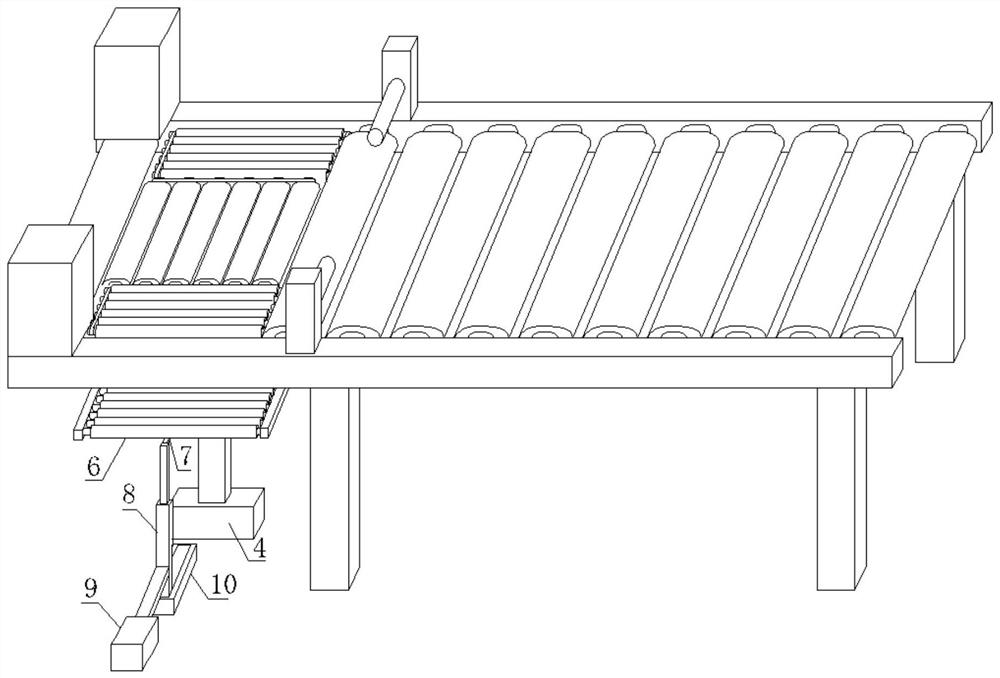

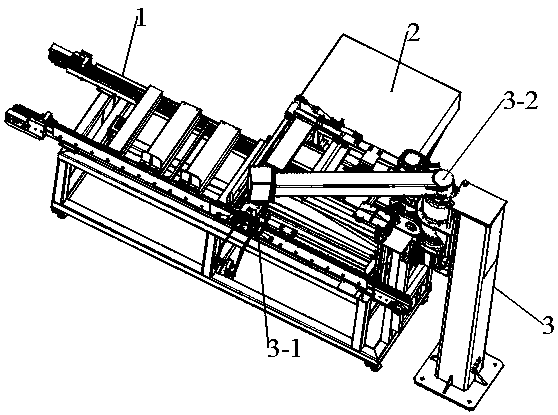

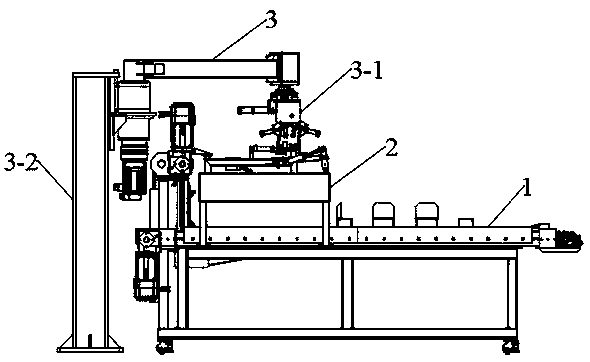

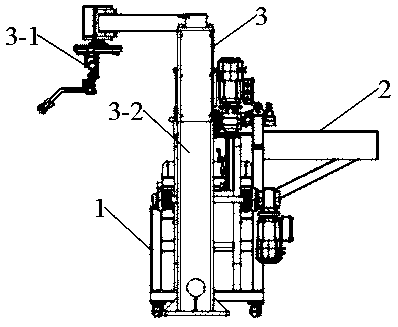

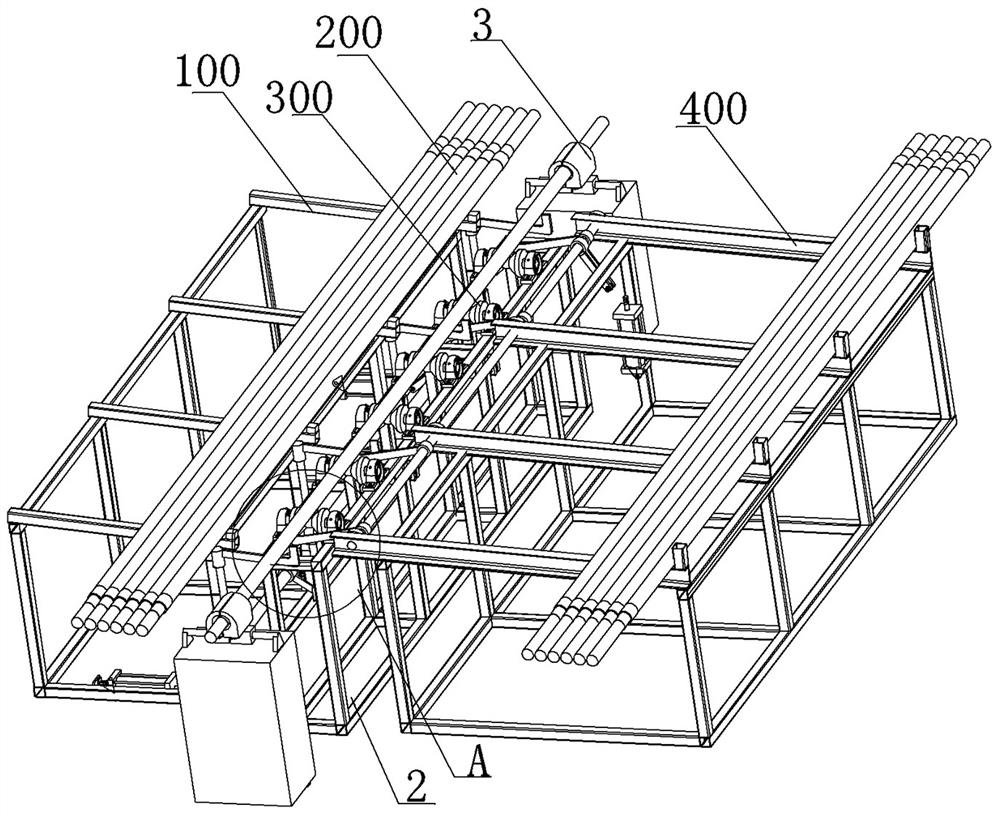

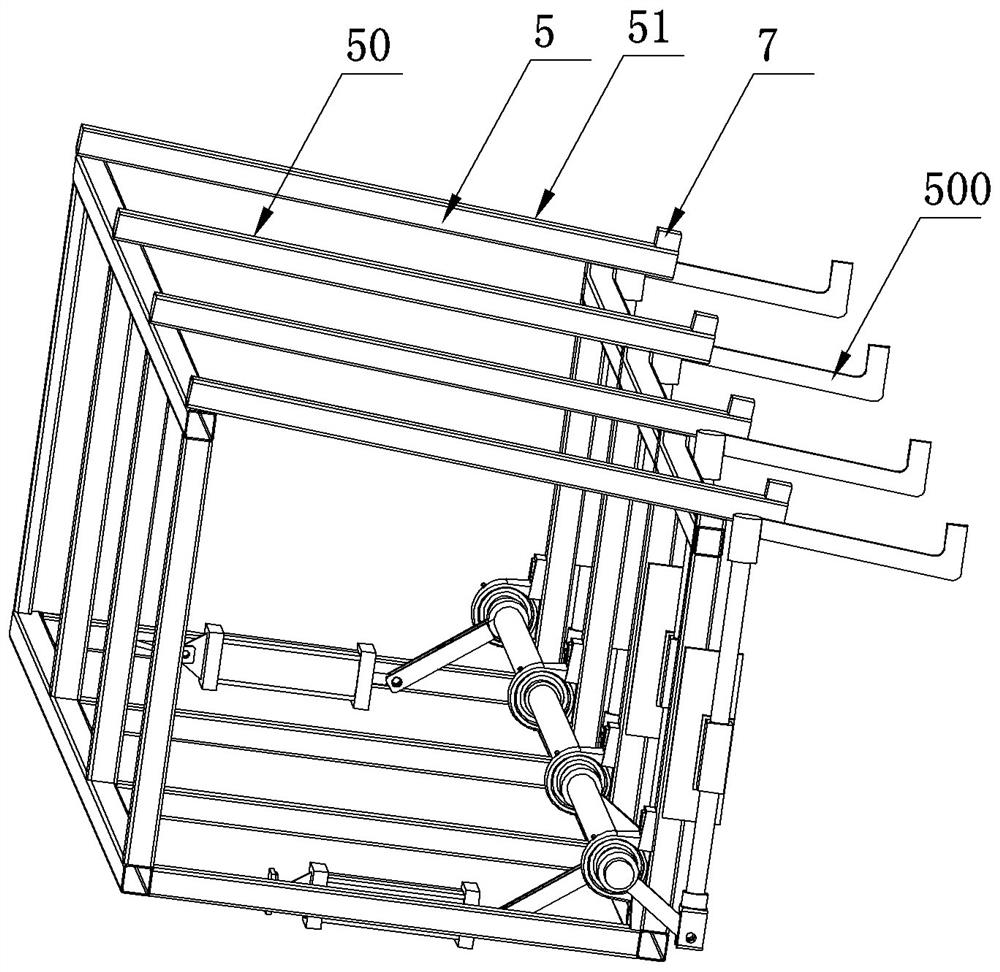

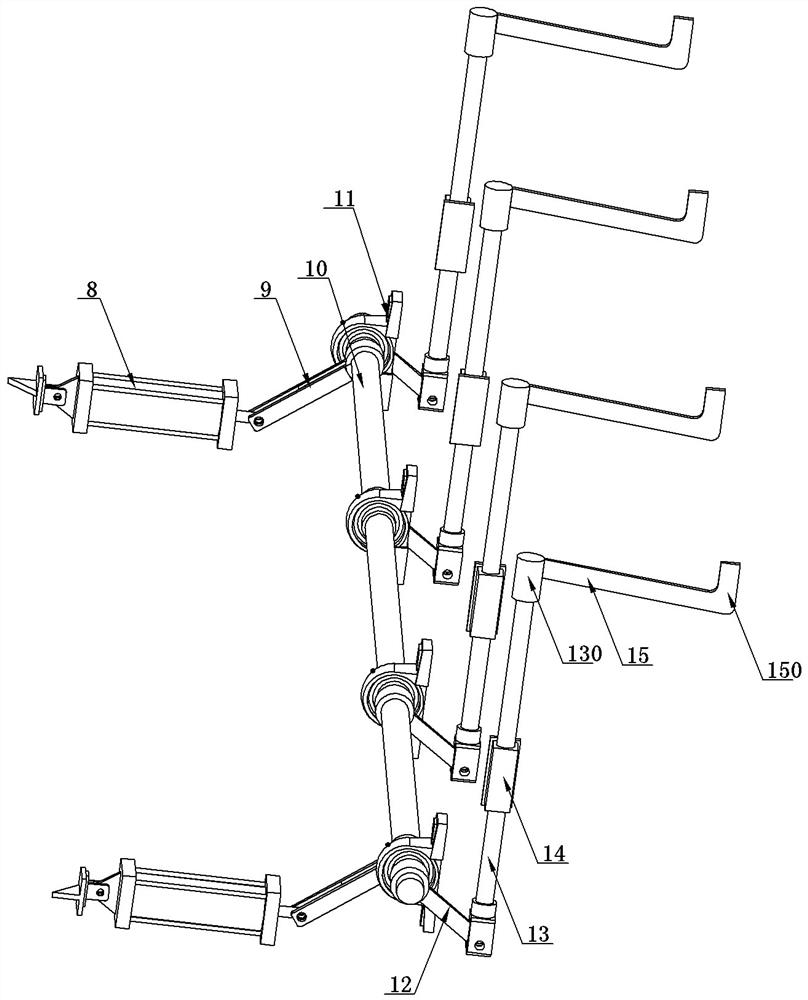

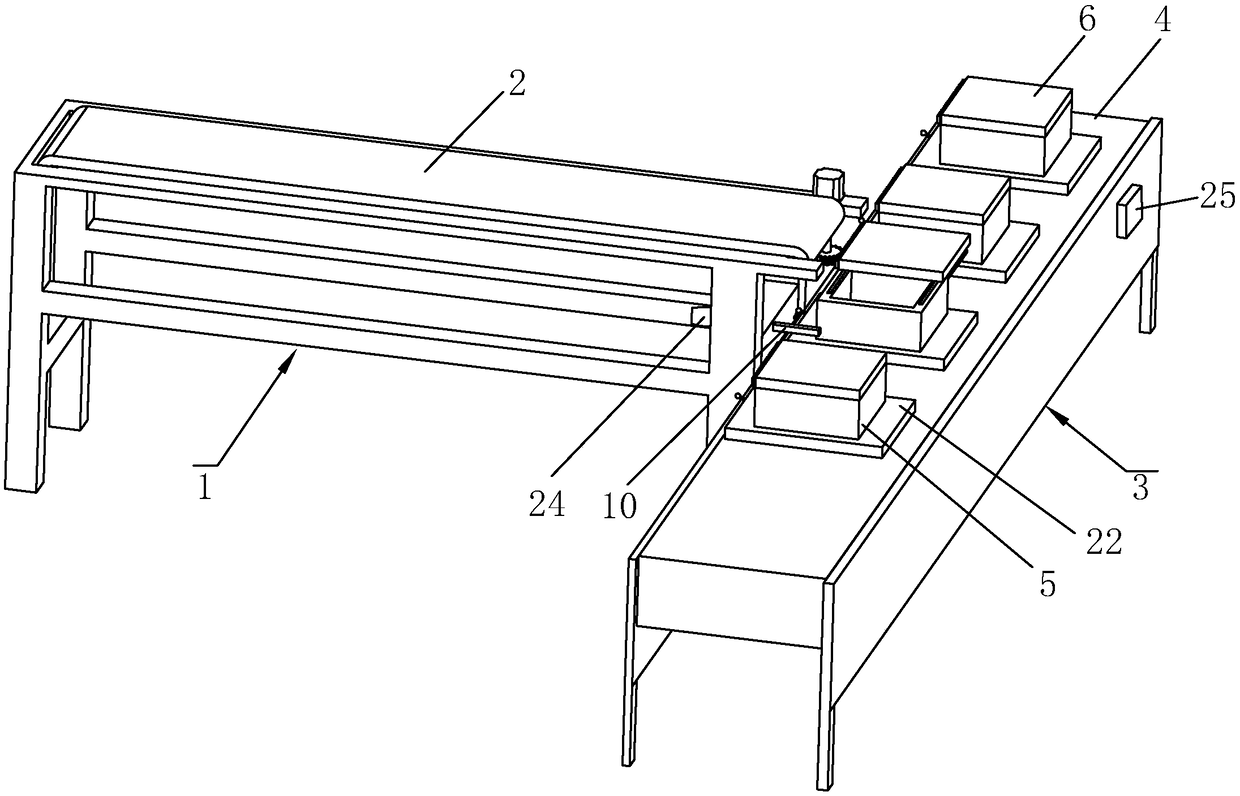

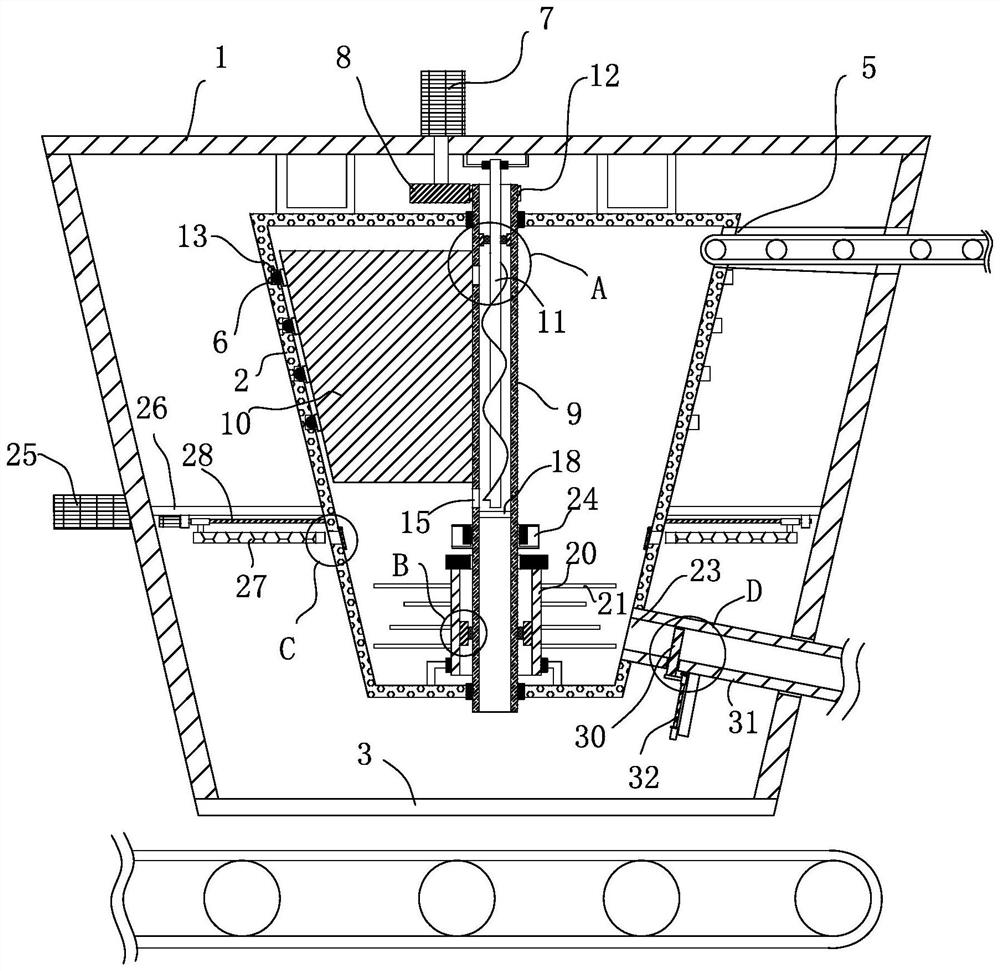

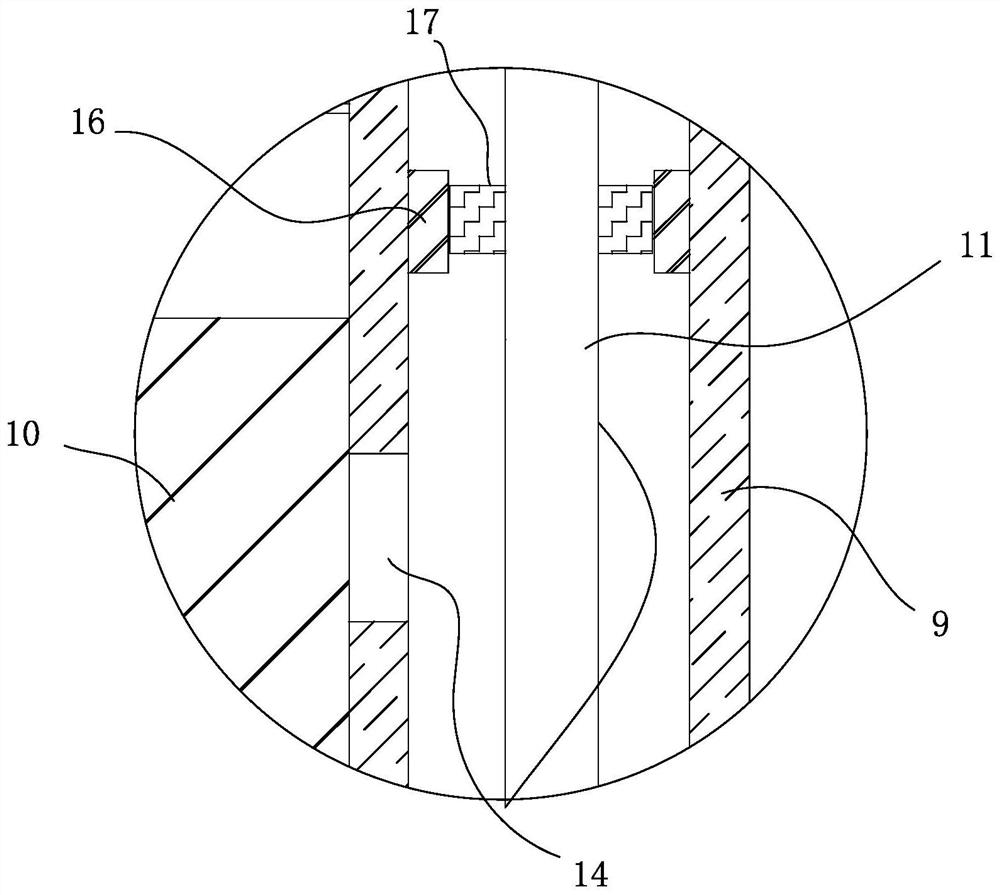

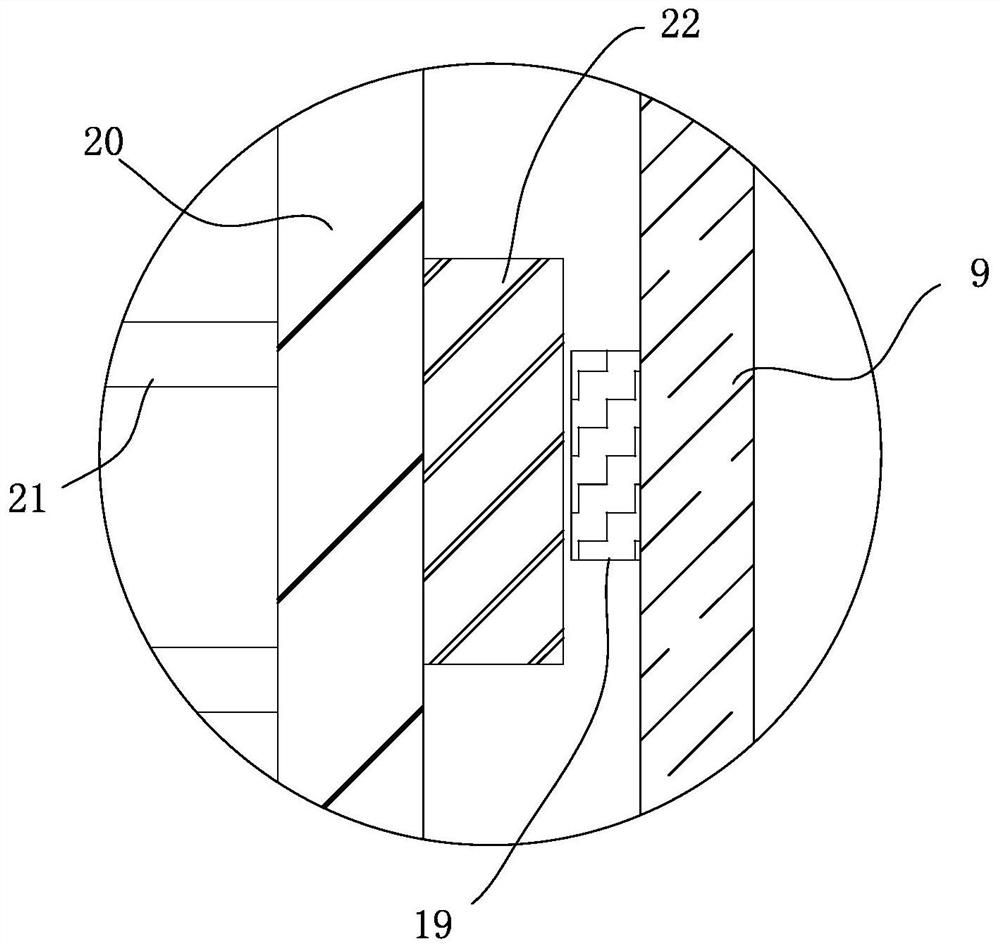

Pipe dropping device for laser pipe cutter

The invention discloses a pipe dropping device for a laser pipe cutter. According to the scheme adopted by the invention, the pipe dropping device comprises a pipe supporting device and a carrying conveying assembly, wherein the pipe supporting device comprises a mounting bracket, a horizontal supporting assembly and an anti-swing assembly; the horizontal supporting assembly comprises a supportingbottom plate and a supporting platform; a lifting drive assembly is arranged on the mounting bracket; the supporting platform is hinged with the supporting bottom plate; a turnover drive assembly isarranged on the supporting bottom plate; the anti-swing assembly comprises two clamping plates and a horizontal drive assembly; the carrying conveying assembly is arranged below the supporting platform and is positioned at one side, away from the mounting bracket, of the supporting platform; the lifting drive assembly drives the horizontal supporting assembly to lift, so that the supporting platform supports pipes; the horizontal drive assembly drives two clamping plates to clamp pipes, so that pipe swing is reduced, and pipe processing precision is improved; and the turnover drive assembly drives the supporting platform to turn over, and the processed pipes drop to the bearing conveying assembly to transmit, so that dropping and transmitting are convenient.

Owner:FOSHAN HONGSHI LASER TECH

High-accuracy paper catching device

InactiveCN104528445AGood for neat stackingNeatly stackedPile receiversArticle deliveryPulp and paper industry

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

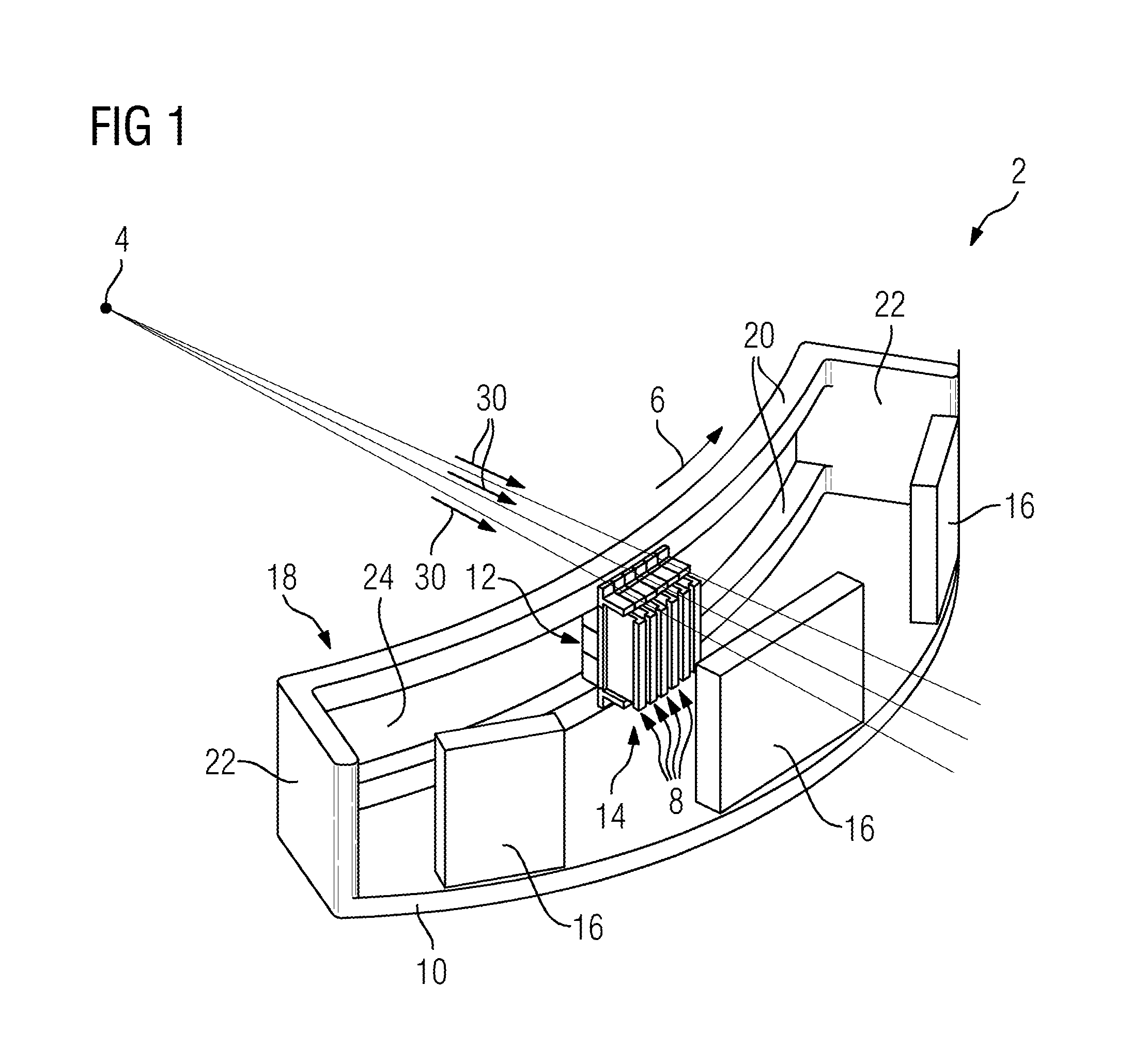

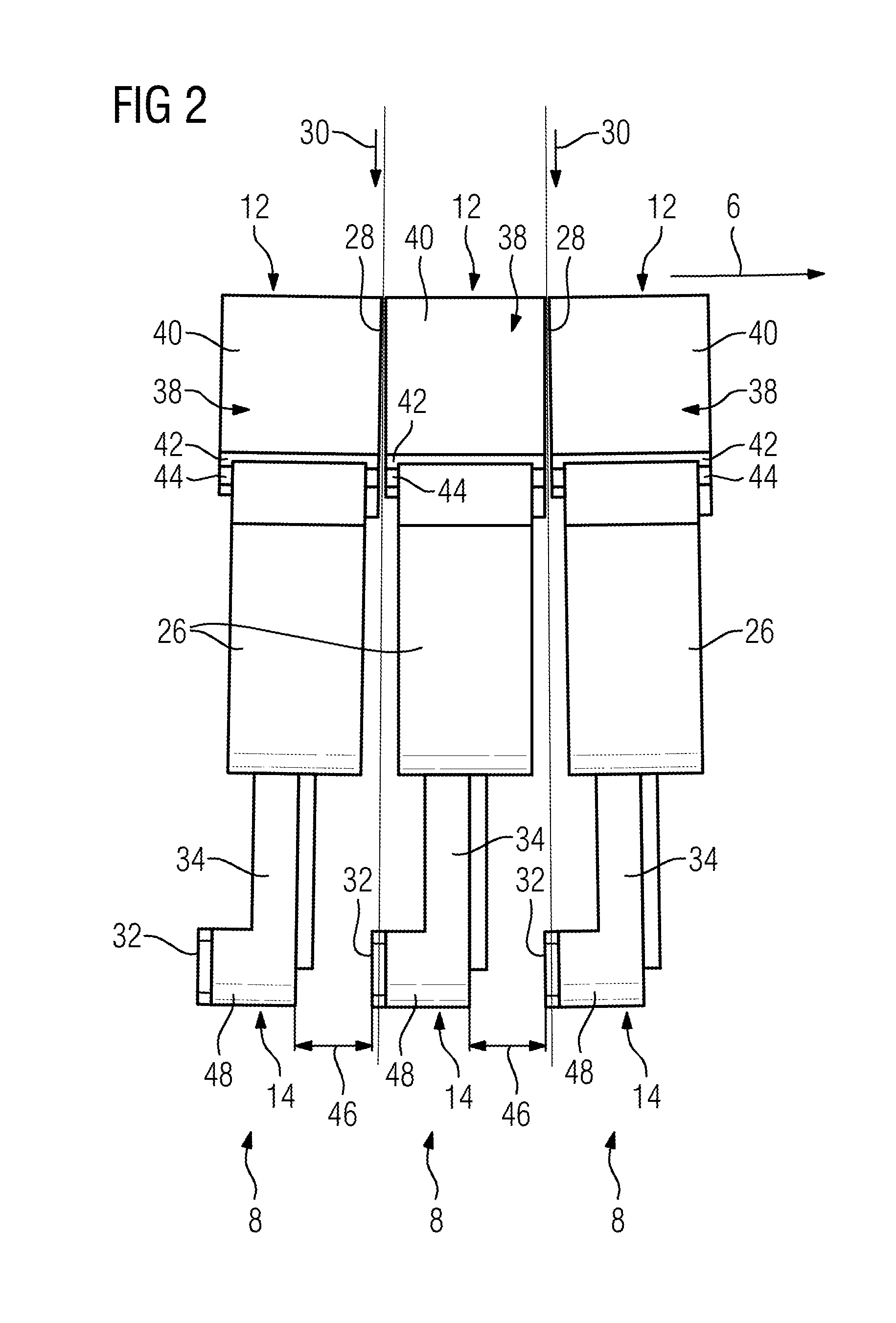

X-ray detector

InactiveUS20130306877A1Small installation space requirementEasy to undertakeMaterial analysis by optical meansPhotometry using electric radiation detectorsSide lyingX-ray

An x-ray detector, especially for a computed tomograph, includes a number of detector modules arranged next to one another in a stacking direction with a front side, which during operation is oriented towards an x-ray source, and with a rear side lying opposite the front side. For screening against x-rays which pass during operation through an installation between two adjacent detector modules, an absorption element is positioned on the rear side of the two adjacent detector modules.

Owner:SIEMENS HEALTHCARE GMBH

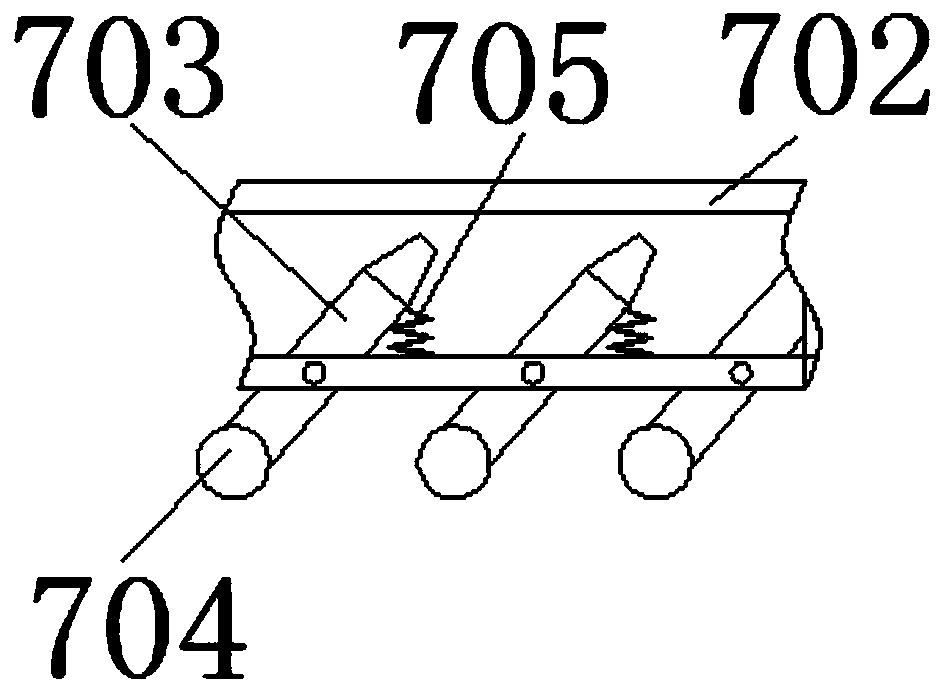

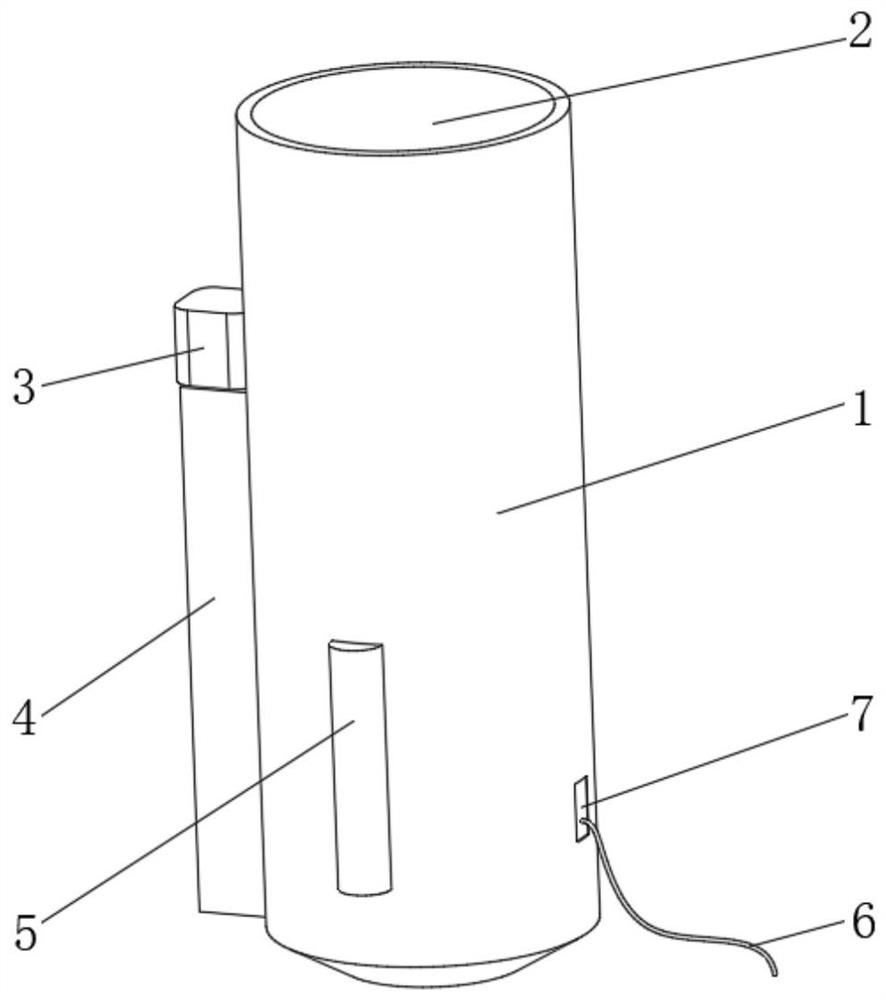

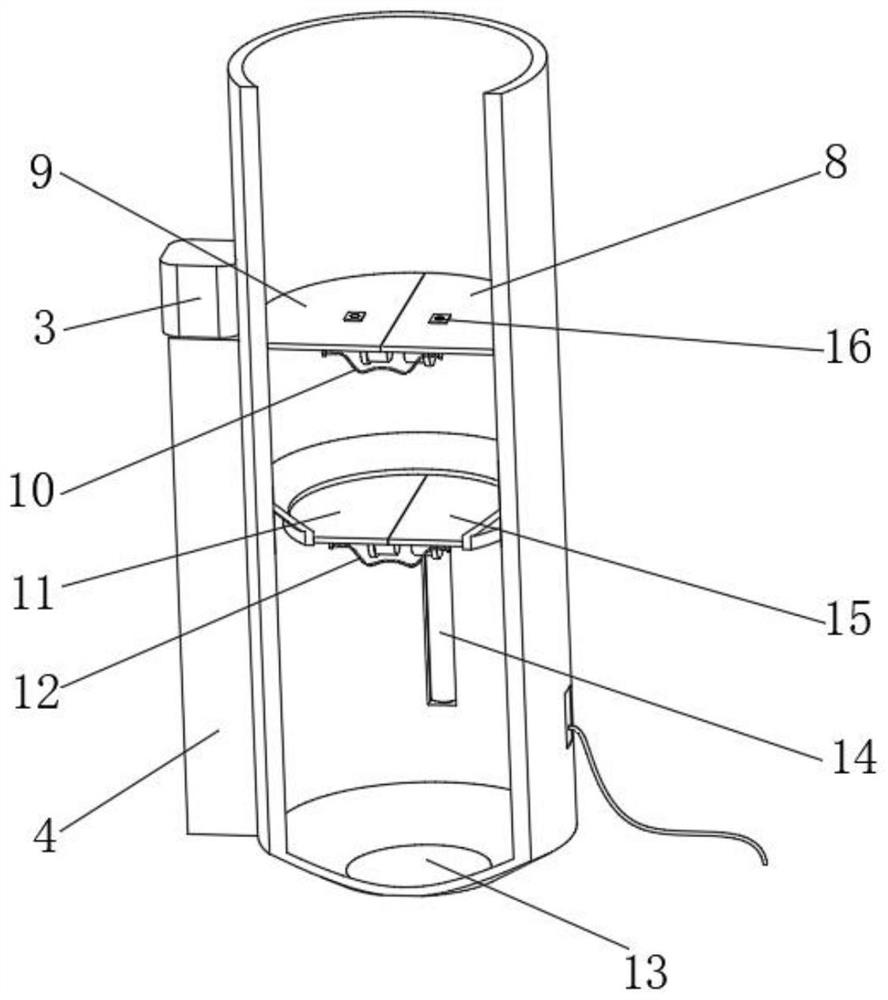

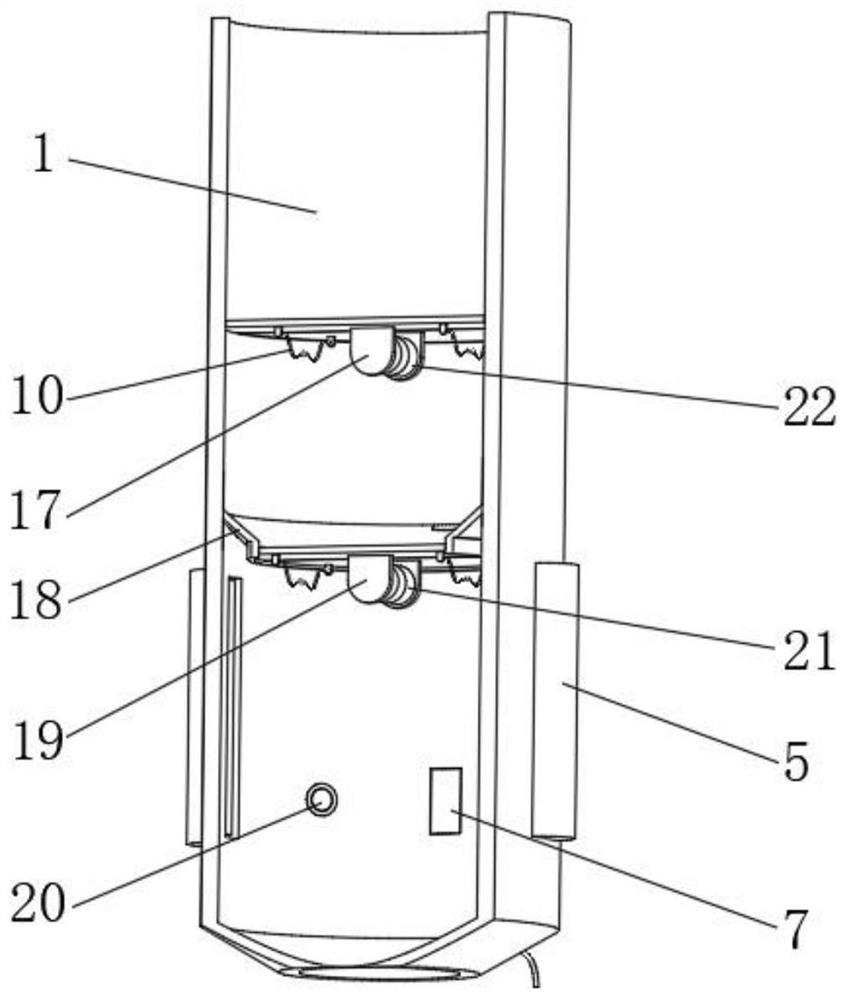

Loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection

ActiveCN108970281AImprove cleaning qualityEasy to wipeDispersed particle filtrationTransportation and packagingDrive motorEngineering

The invention provides a loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection, and relates to the field of loudspeaker box cleaning equipment. The loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection comprises a supporting fixed housing, wherein the sidewall of the supporting fixed housing is spliced with a holding internal hollow fixing barrel; the side wall of the holding internal hollow fixing barrel is spliced with a lateral grip; the top of theinner wall of the supporting fixed housing is spliced with a dust-proof moisture-proof protecting case; the top of the supporting fixed housing is provided with a floating dust cleaning and removal mechanism. According to the loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection, one end of a rotary sliding rod is controlledby a driving motor to slide in a concave sliding ring to enable the rotary sliding rod to incline to one side of a jacking spring; after sliding, an overturning linkage rod is jacked under the elasticfunction of the jacking spring to drive a round knocking ball on the end part of the overturning linkage rod to knock the loudspeaker box dust screen, dust is separated from the dust screen due to the influence of inertia, and the dust removal efficiency of the loudspeaker box dust screen is effectively improved.

Owner:临沭县济才人力资源服务有限公司

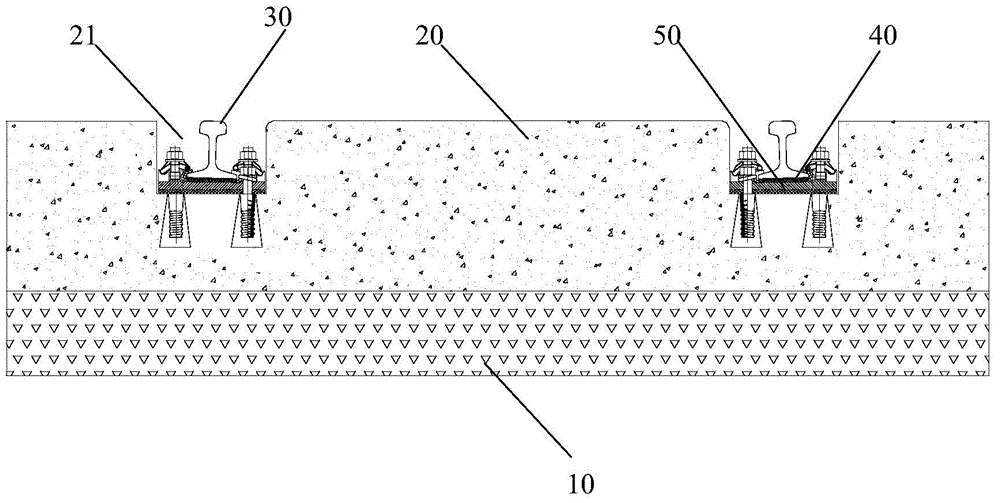

Assembled grade crossing

InactiveCN104947566AReduce the number of potting jointsImprove stabilityTemporary pavingsBuilding construction

The invention provides an assembled grade crossing with compact structure, good integrity, stress uniformity, simplicity in construction, long maintenance cycle and low maintenance cost. The assembled grade crossing comprises a graded broken stone layer, an integral road bed and a track, wherein the graded broken stone layer is laid on a foundation of the railroad grade crossing; the integral road bed is arranged on the graded broken stone layer, and two grooves used for mounting the track are formed in the upper surface of the integral road bed; and the track is mounted in the grooves used for mounting the track. The assembled grade crossing is simple to construct, construction speed is high, construction time is shortened, normal traffic can be restored in the shortest time, and construction cost is reduced; meanwhile, the problems that a circuit is hung on a plate, mud pumping is caused and a grade crossing plate is broken can be solved.

Owner:TIANJIN PORT FACILITIES MANAGEMENT SERVICE

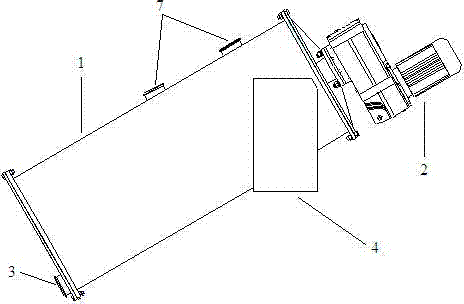

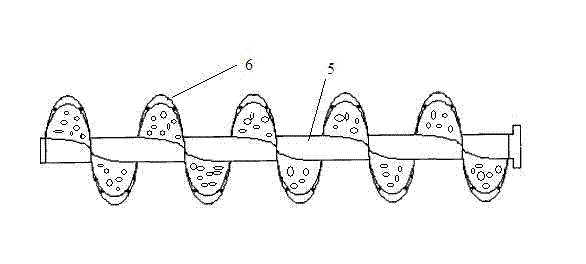

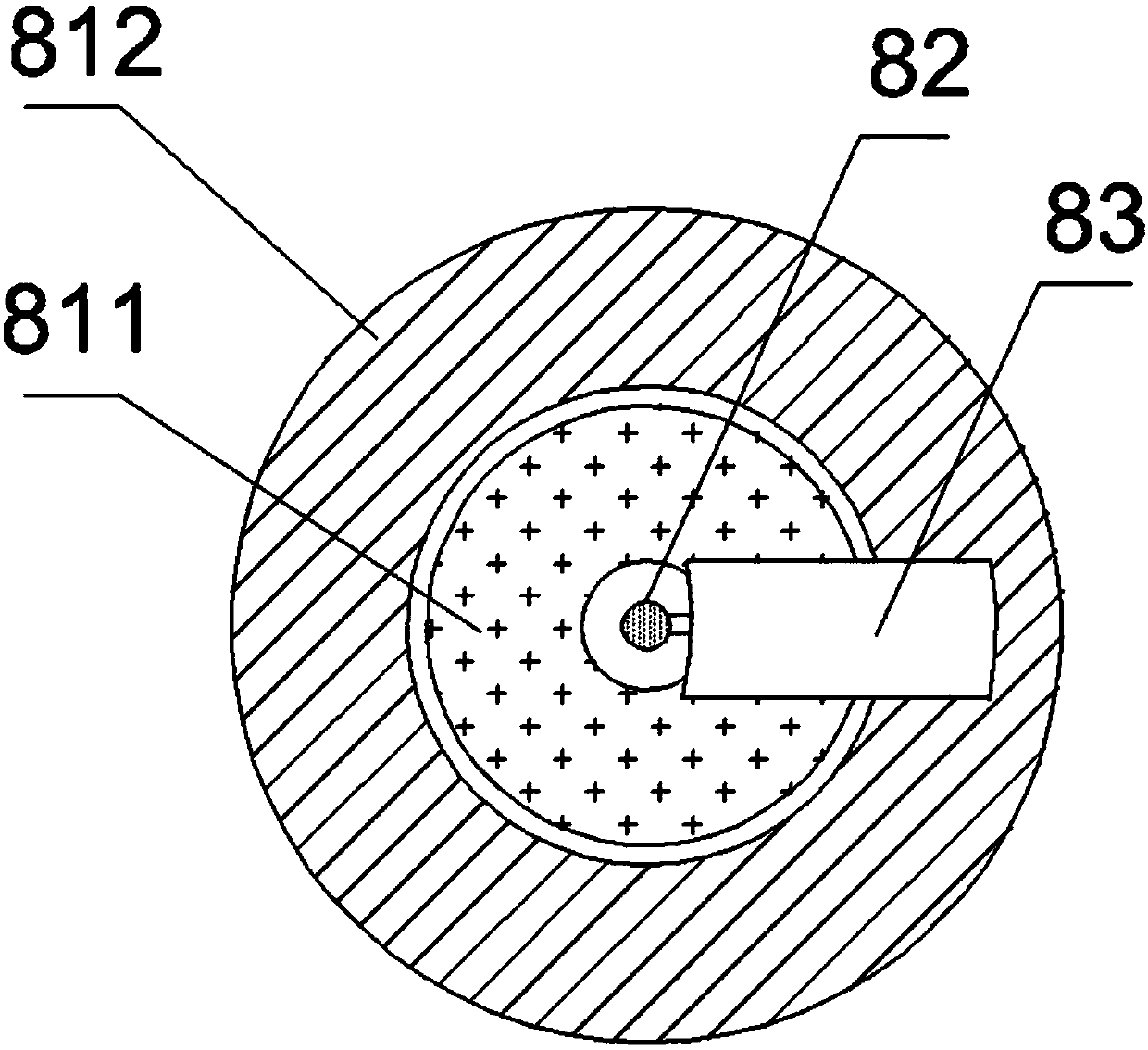

Spiral material fishing device

ActiveCN102921222AEasy to operateSmooth material removalMoving filtering element filtersSpiral bladeEngineering

The invention discloses a spiral material fishing device, which comprises a shell with a feeding hole and a discharge hole and a power source, wherein a material fishing rod is supported near the discharge hole of the shell; the power source is connected with the material fishing rod; and spiral blades are arranged on the material fishing rod. According to the technical scheme, the spiral material fishing device can fish residues out continuously from a solid-liquid mixture in quantity; and an operation method is simple, low in cost and high in efficiency. The blade diameters of the optimized spiral blades are reduced sequentially from the discharge hole to the feeding hole. The spiral material fishing device has the advantages that the process of fishing residues out is progressive, and the residues are fished out smoothly. According to the other technical scheme, meshes are distributed in the spiral blades, so that the spiral material fishing device has the advantages that liquid formed by extruding the residues in the fishing process can flow out conveniently, materials are saved due to the arrangement of the meshes, and the blades are attractive in appearance.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

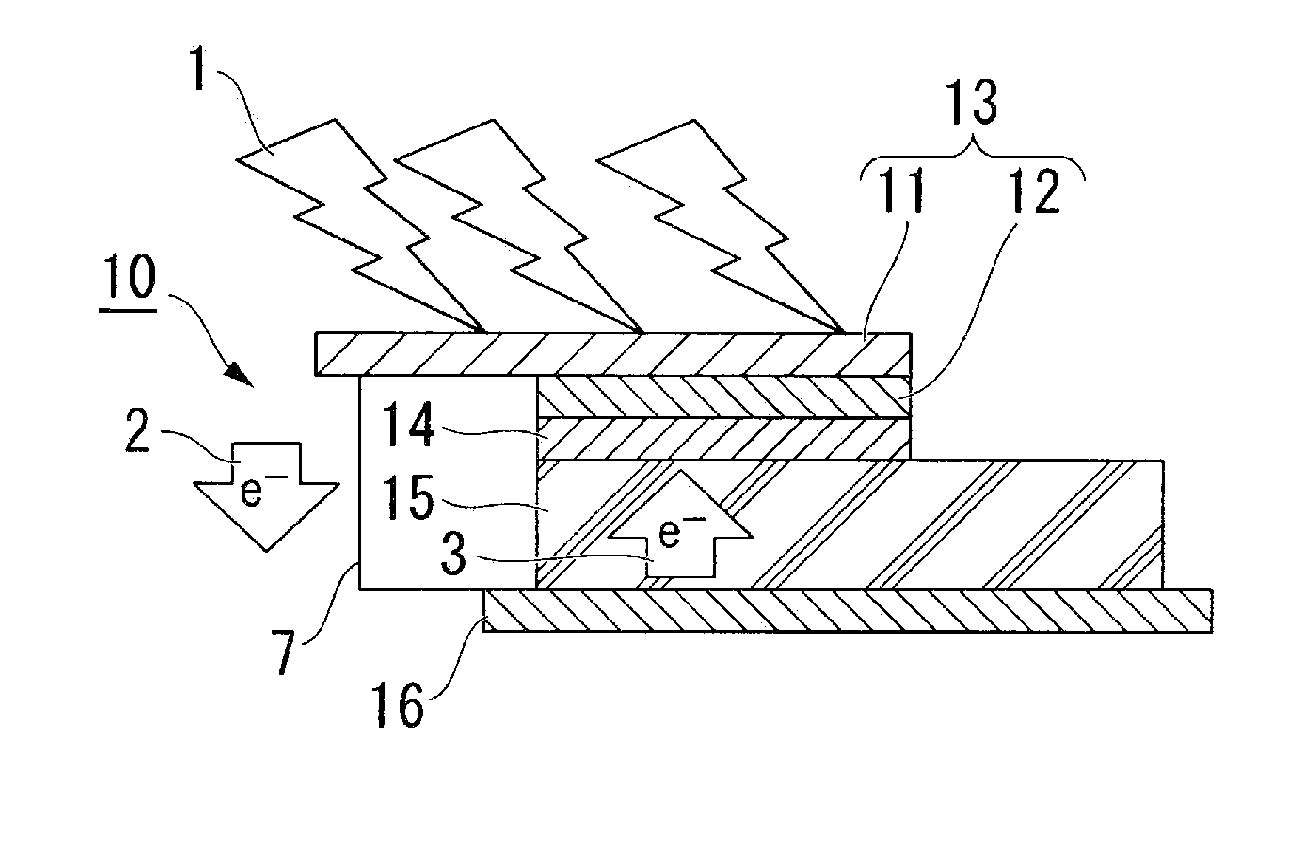

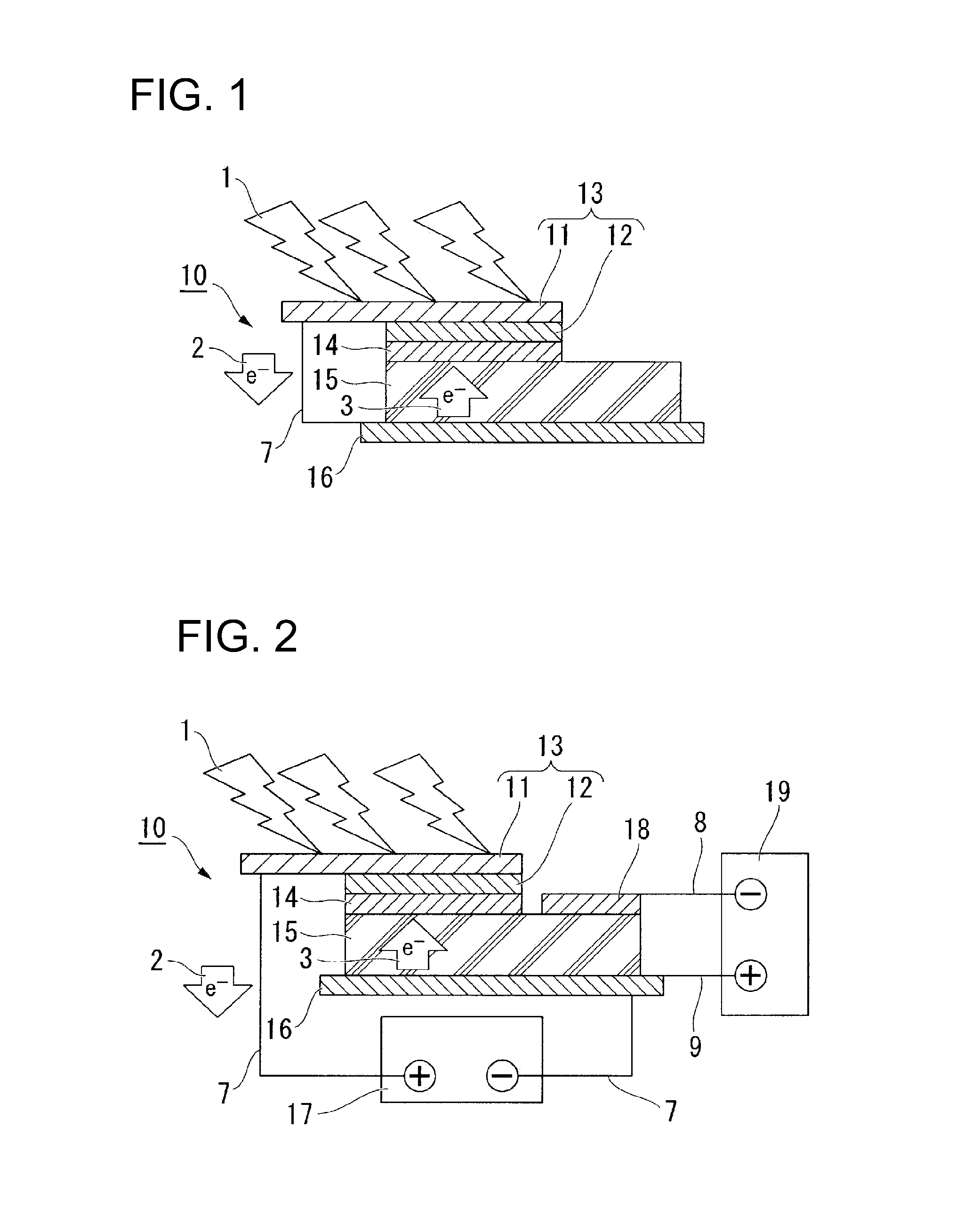

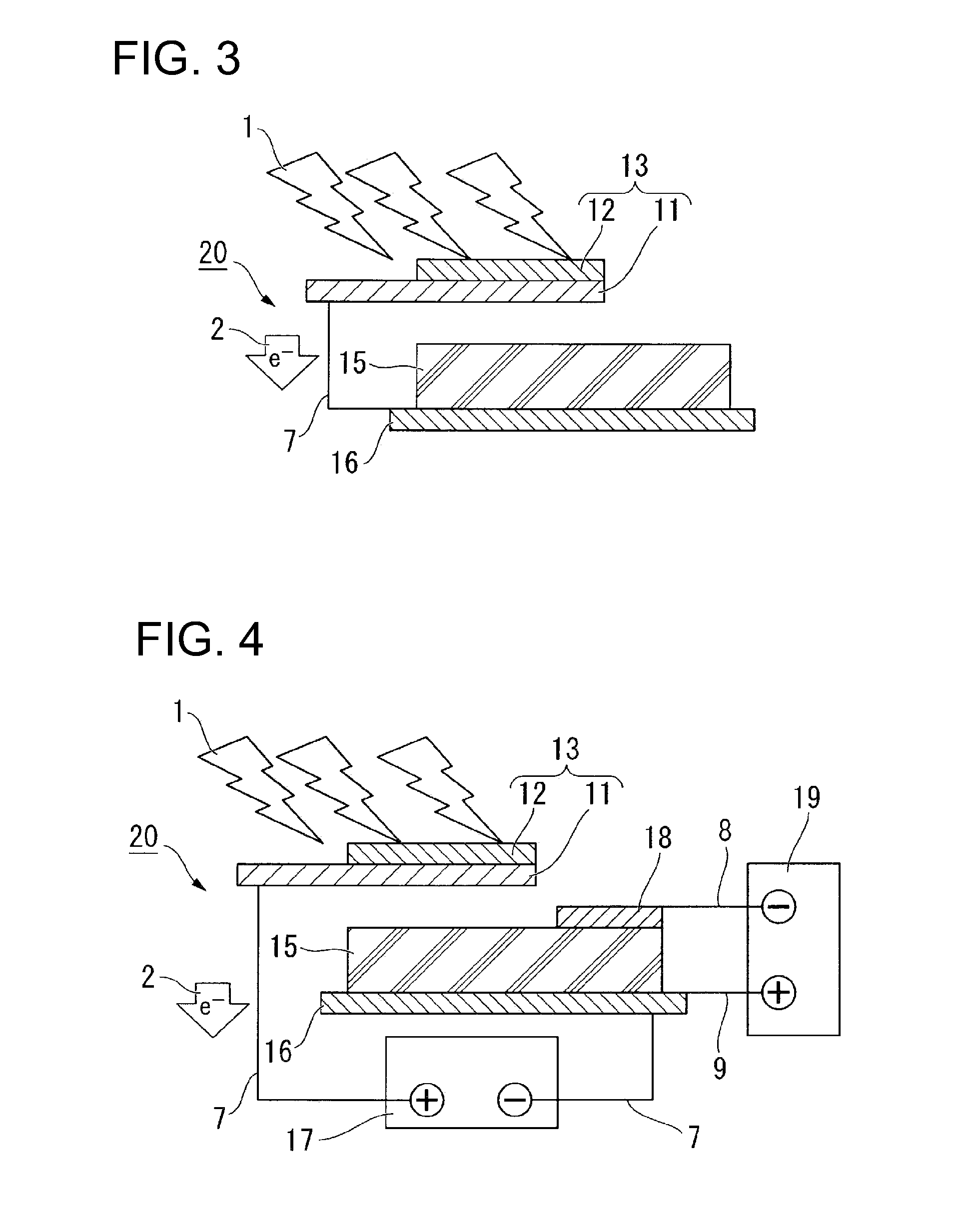

Corrosion Protection Method And Corrosion Protection Structure

InactiveUS20120018312A1Increase freedomEffective corrosion protection treatmentElectrically-conductive paintsRebarSemiconductor

A semiconductor layer (12) is caused to receive electromagnetic waves (1) to emit electrons; the emitted electrons are collected and supplied to an object to be protected against corrosion; and the electrons (3) are returned from the object to be protected against corrosion (16), to which the electrons (2) are supplied, to the semiconductor layer (12) via an electrolytic layer (14), to thereby cause an electric current to flow to the object to be protected against corrosion (16) to make a potential of the object to be protected against corrosion (16) low. In a corrosion protection structure (10), an electron supplier (13) is electrically connected to a object to be protected against corrosion (16), to thereby provide corrosion protection, the electron supplier (13) being made of a semiconductor layer (12) formed on a supporting member (11) that is capable of transmitting electromagnetic waves and has electrical conductivity. In addition, the electron supplier (13) is electrically connected to an object to be protected against corrosion (16) via an electrolytic layer (14) that is at least in contact with the semiconductor layer (12). According to the present invention, even if an object to be protected against corrosion is coated with a coating layer such as a rebar in concrete, it is possible to provide a corrosion protection method and a corrosion protection structure that can obtain a sufficient corrosion protection effect.

Owner:FUJIMORI KOGYO CO LTD +1

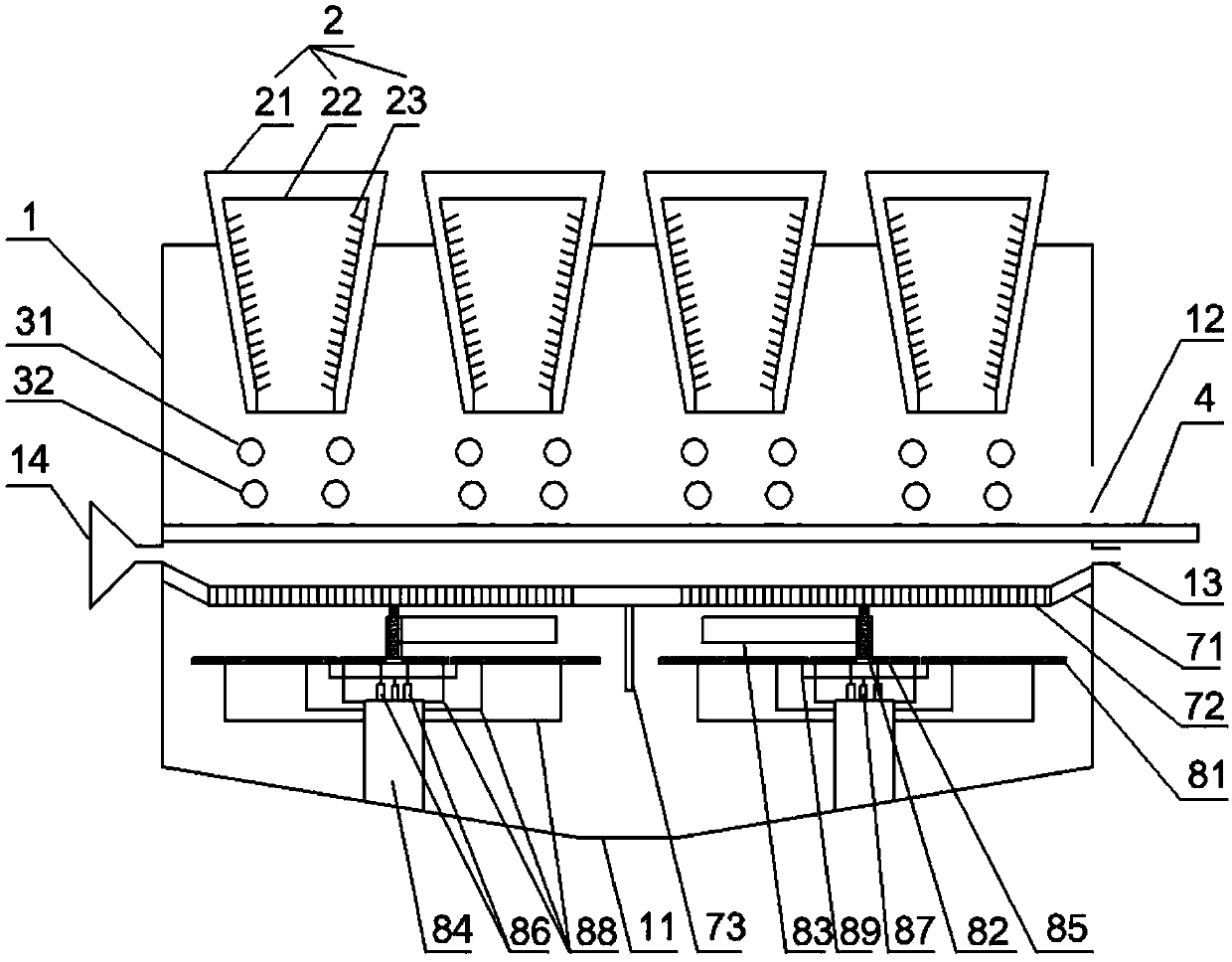

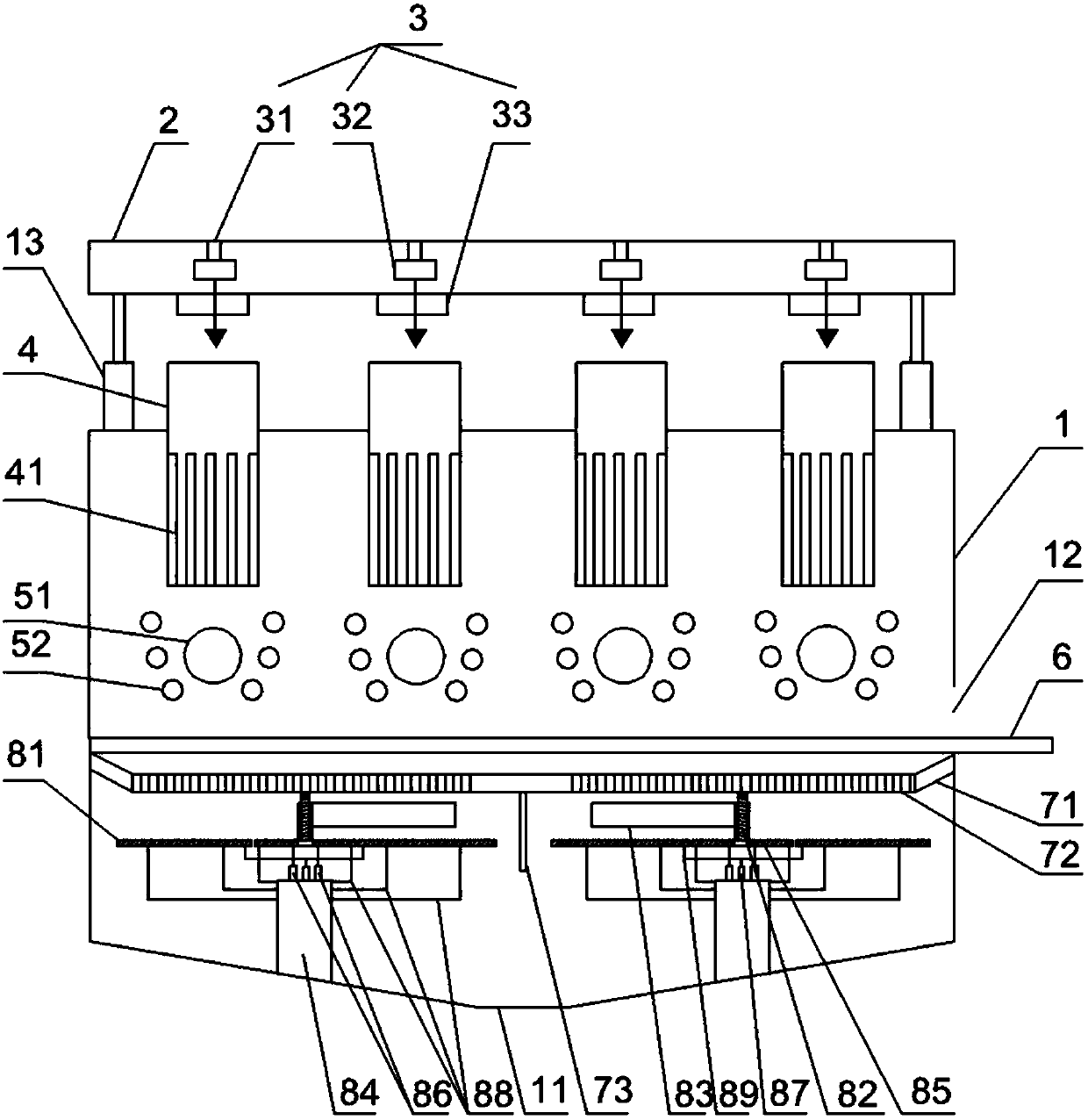

Forage ball kneading device, ruminant pellet feed production line and preparation method

PendingCN111671112AGuaranteed palatabilitySatisfy digestive needsFeeding-stuffCrop conditionersFiberRuminant animal

The invention provides a forage ball kneading device. The forage ball kneading device comprises a rack, a bottom plate, a kneading plate and a kneading driving piece, wherein the bottom plate is connected with the rack; the kneading plate is located above the bottom plate and a kneading space with a feeding opening and a discharging opening is commonly defined by the kneading plate and the bottomplate; the feeding opening and the discharging opening are oppositely arranged; the bottom plate and the kneading plate are obliquely arranged so that the feeding opening is located above the discharging opening; and the kneading driving piece is mounted on the rack and is connected with the kneading plate so as to drive the kneading plate to revolve around a revolution shaft parallel to the normal direction of the kneading plate. The forage ball kneading device can be used for preparing long-strip-shaped forage into forage balls so that forage feed has palatability; and meanwhile, the forageballs have long fibers so that the digestion requirements of ruminants are met. The invention further provides a ruminant pellet feed production line adopting the forage ball kneading device and a ruminant pellet feed preparation method.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION INST OF ANIMAL HUSBANDRY

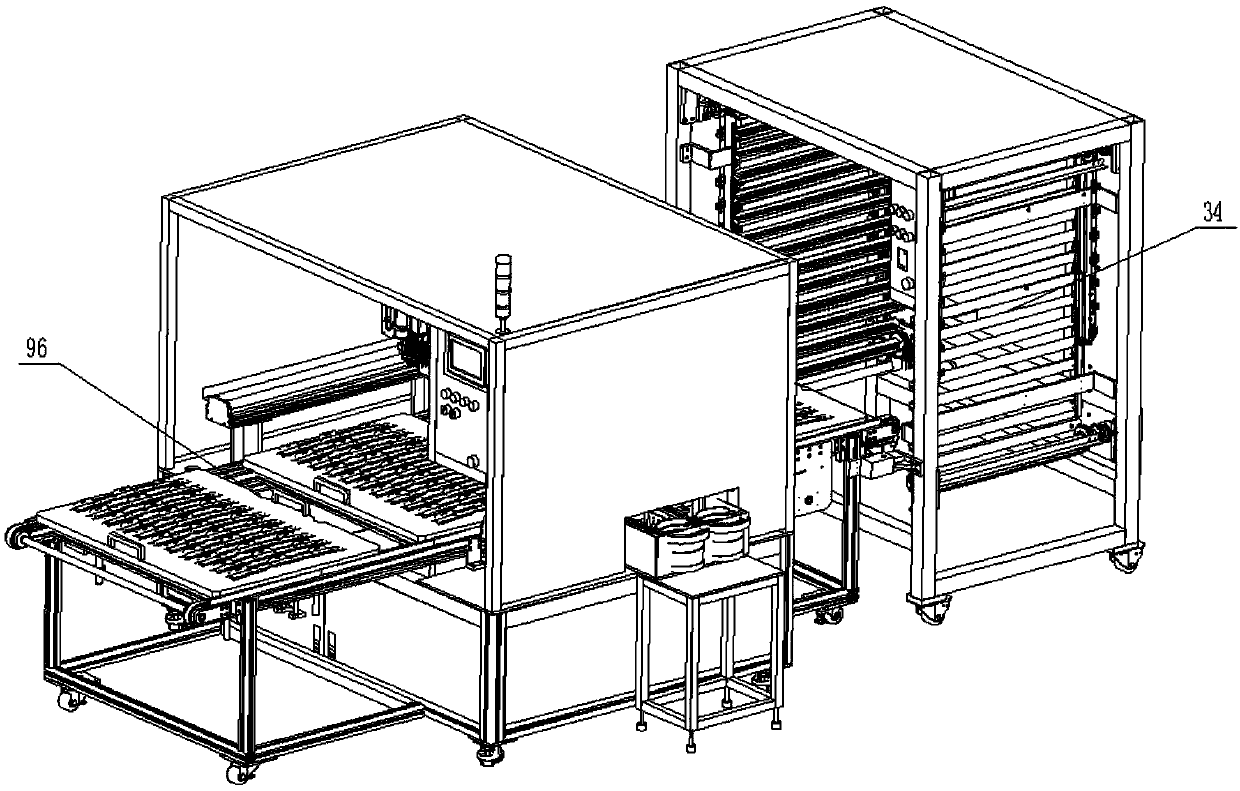

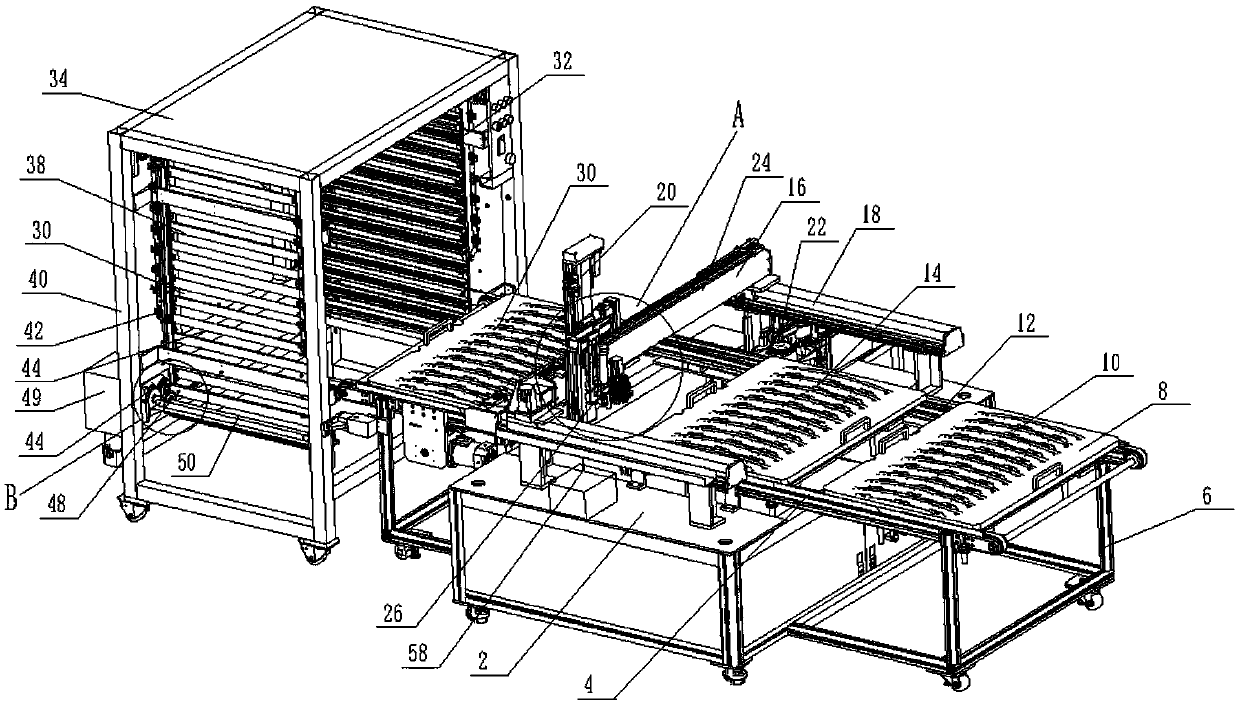

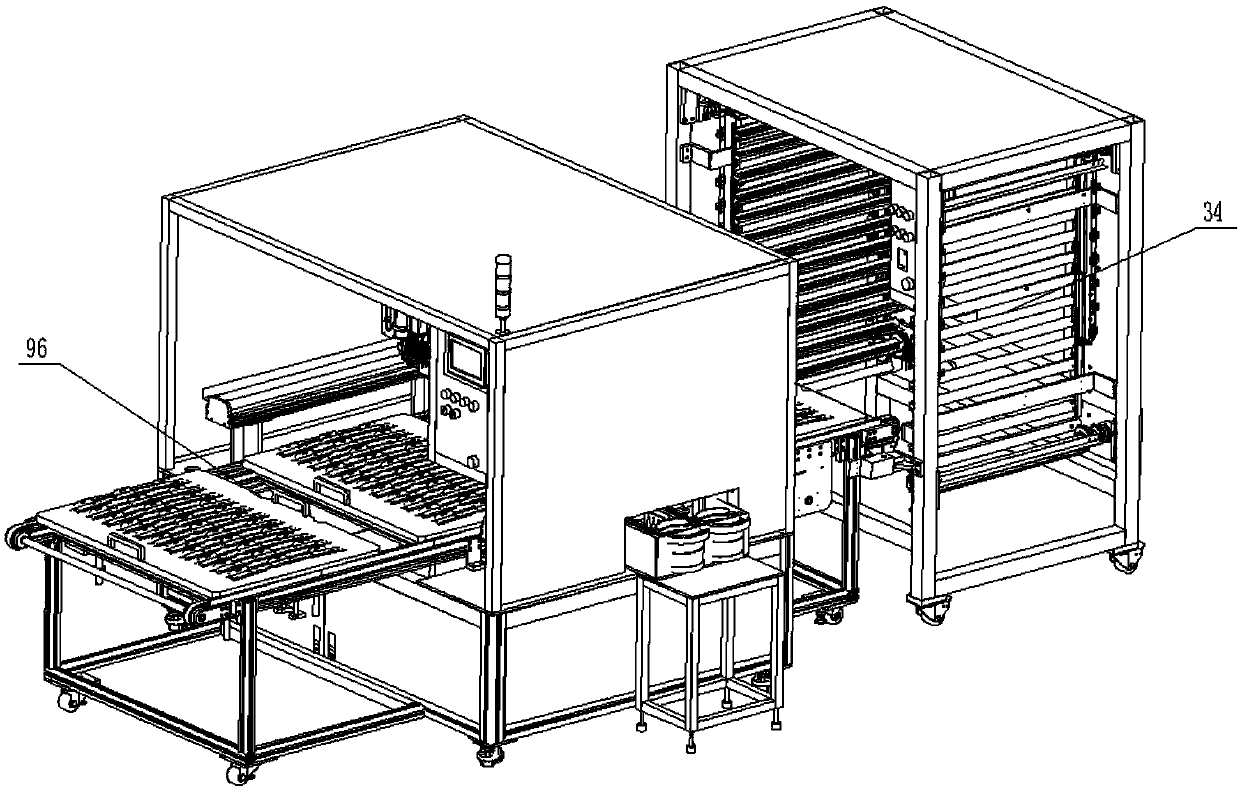

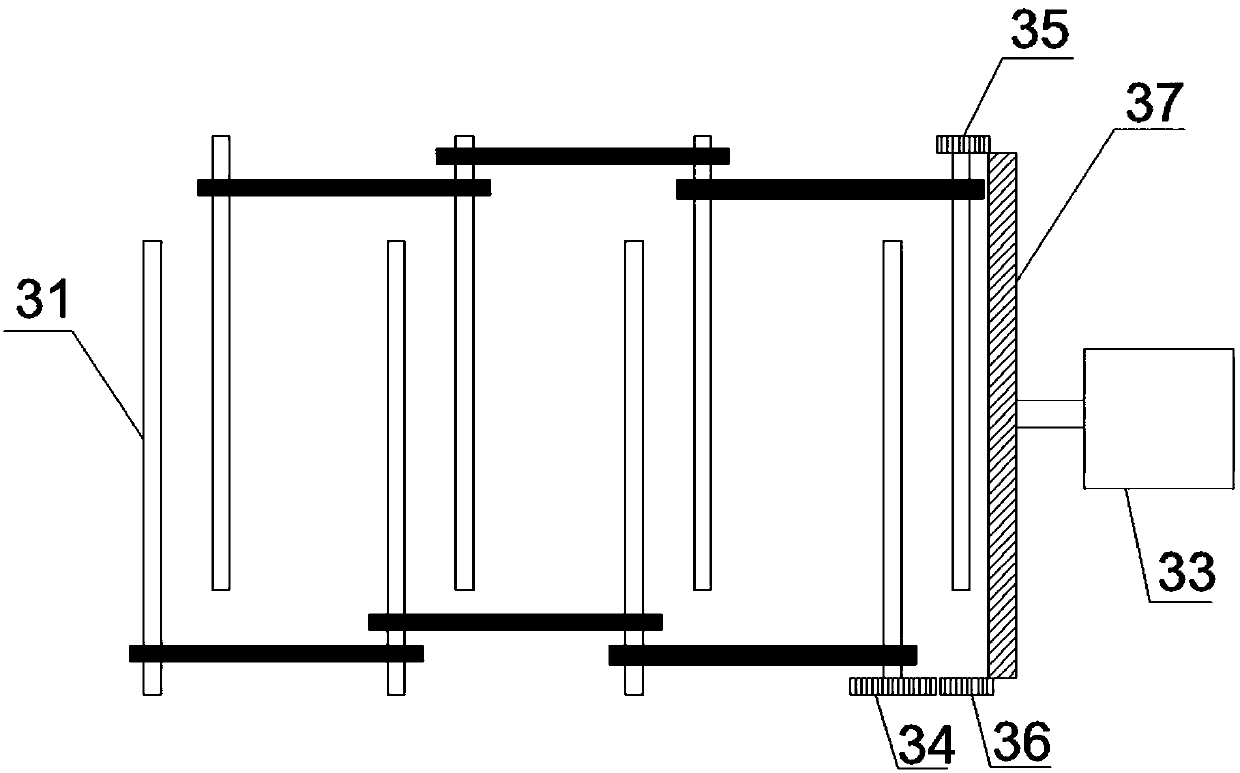

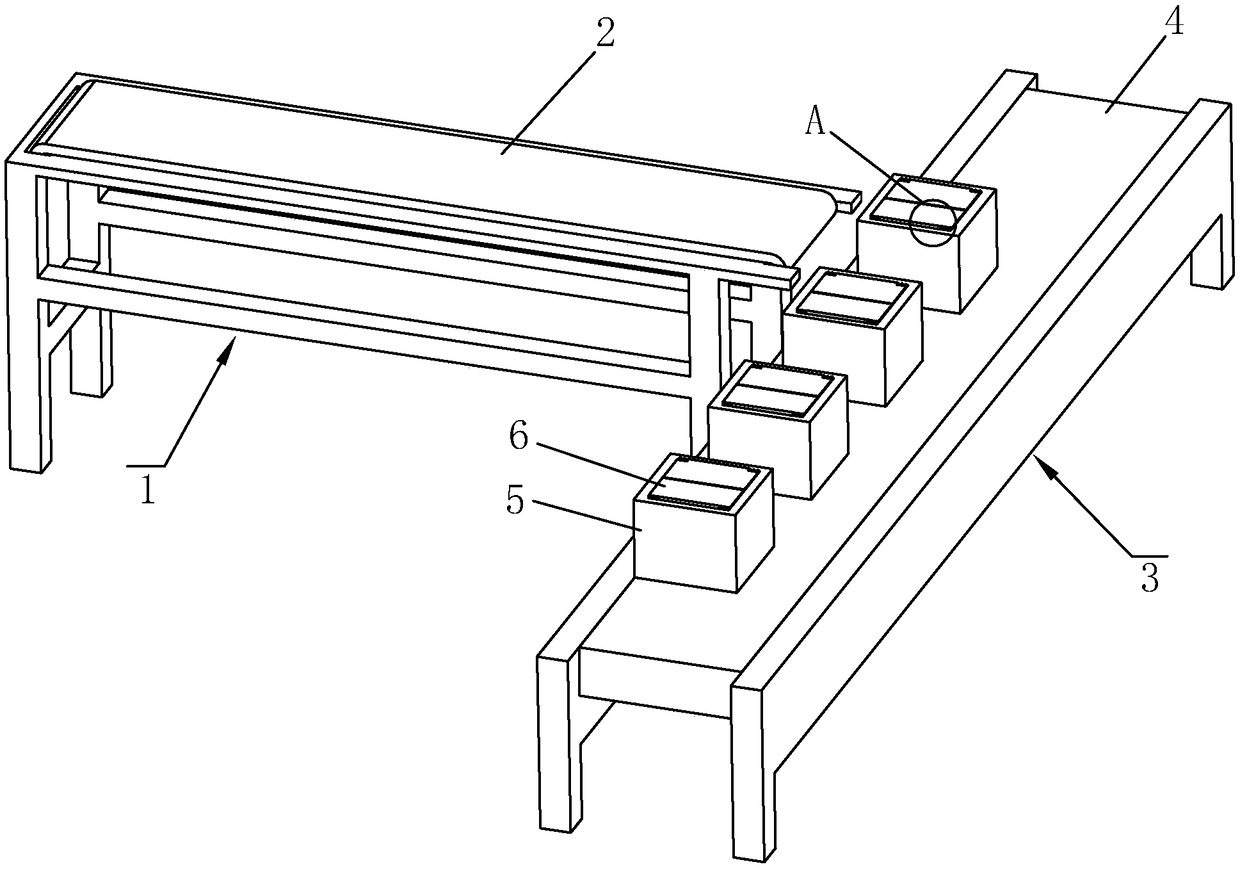

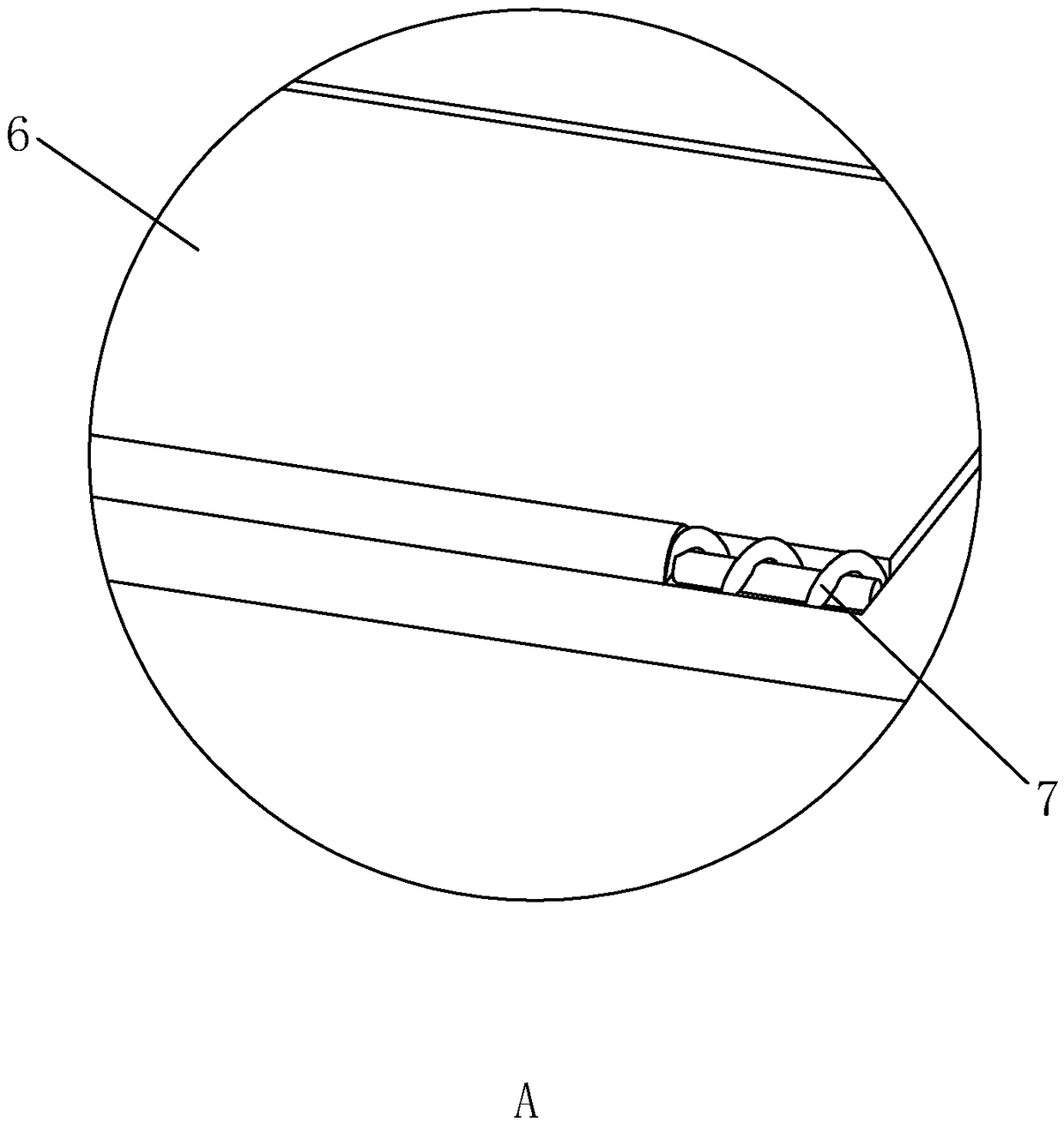

Gasket gluing equipment

The invention discloses gasket gluing equipment. The gasket gluing equipment comprises a tray and a conveying mechanism for conveying products; the products are placed on the tray; the conveying mechanism is provided with a loading station, a glue dispensing station and an unloading station in a conveying direction; a laminator for bearing the tray is arranged on the side near the unloading station; the laminator comprises a laminating frame, and a first shelf set and a second shelf set arranged on the laminating frame; the first shelf set and the second shelf set are oppositely arranged, andrespectively comprise multiple support units; the support units on the first shelf set and the support units on the second shelf set are correspondingly arranged for supporting the same tray; each support unit comprises an U-shaped groove and multiple strips arranged in the U-shaped groove; and the strips are arranged in the conveying direction of the conveying mechanism. The gasket gluing equipment can realize glue dispensing to improve the working efficiency.

Owner:苏州工业园区多司电子科技有限公司

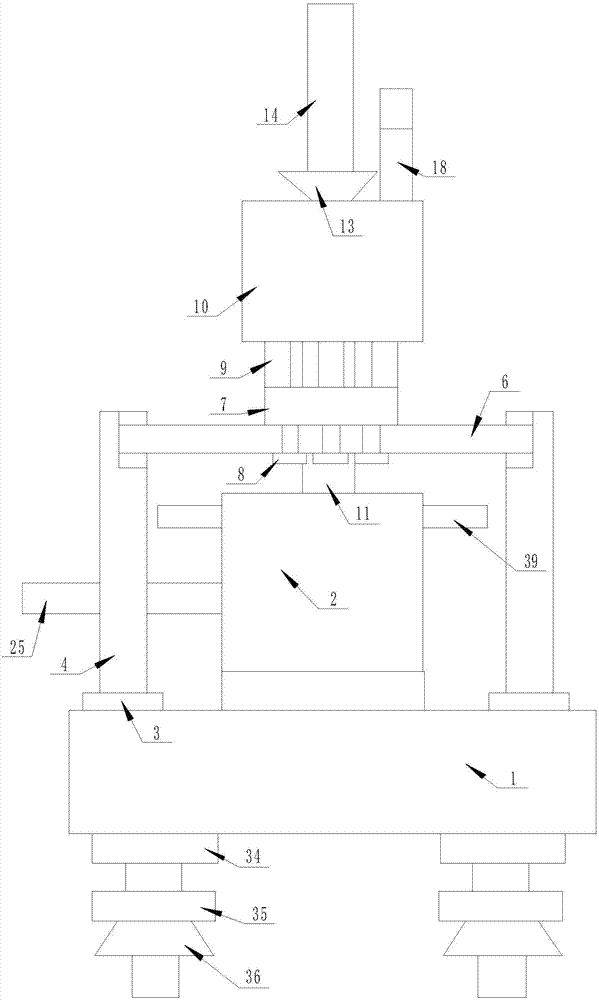

Reciprocating type crushing device for medicinal material processing

InactiveCN111570004AImprove crushing effectImprove the effect of rolling and refiningGrain treatmentsMedicinal herbsScrew conveyor

The invention provides a reciprocating type crushing device for medicinal material processing, and relates to the field of traditional Chinese medicinal material processing. The reciprocating type crushing device solves the problems that when a traditional crushing device for medicinal material processing is used, the traditional Chinese medicinal material crushing and refining efficiency is low,only part of medicinal materials can be crushed and refined when passing through the device, residual medicinal materials which are not crushed and refined and discharged need to be manually put intoan operation device by personnel, operation is tedious, and the medicinal material processing progress is prone to being influenced. The reciprocating type crushing device comprises an upper crushingbox and a lower crushing box, the interior of a body is of a hollow structure, and a supporting frame is installed at the top of the body; the upper crushing box is of a square box structure, and a crushing roller is located in the upper crushing box; when medicinal material particles are too large and cannot be sufficiently crushed, a reversing funnel conveys medicinal materials to the bottom ofa spiral conveyor, the medicinal materials are conveyed into the top of the upper crushing box through the spiral conveyor, so that the medicinal materials are crushed through the crushing roller rotationally running in the upper crushing box and the lower crushing box again, and the medicinal material grinding and refining effect is improved.

Owner:牟振豪

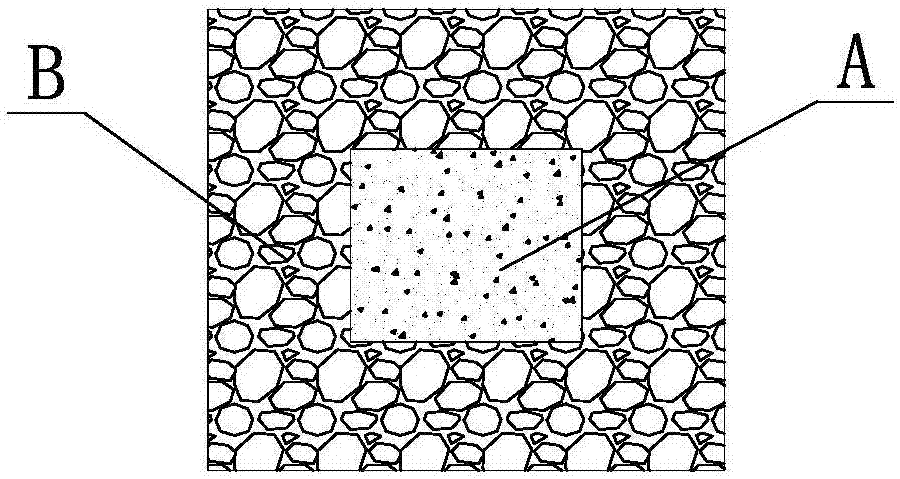

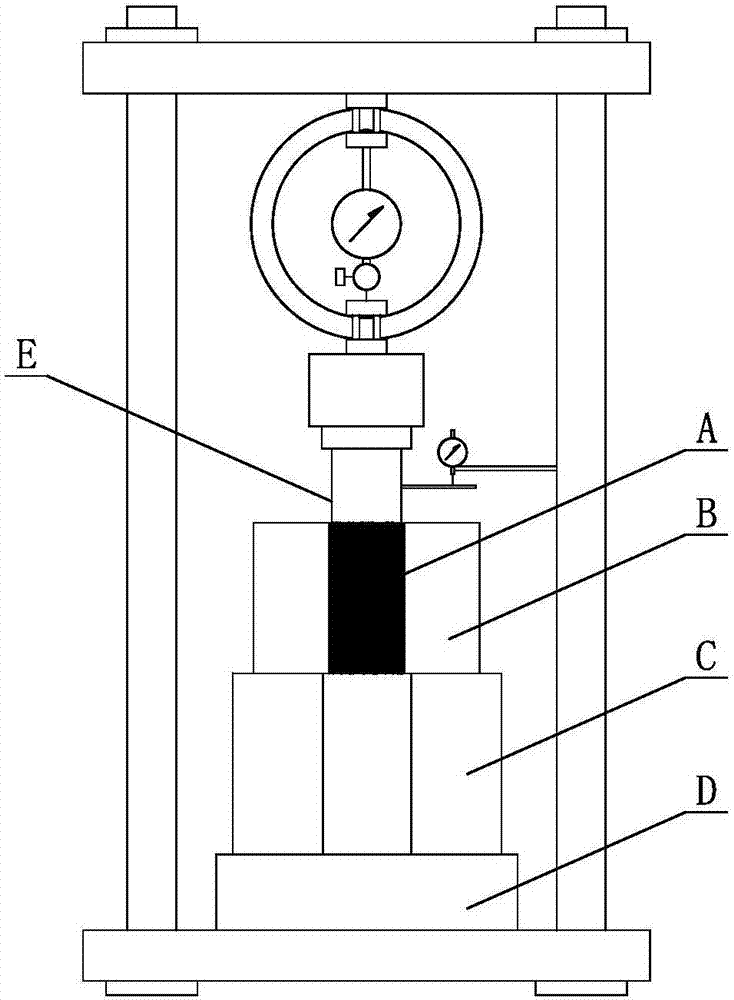

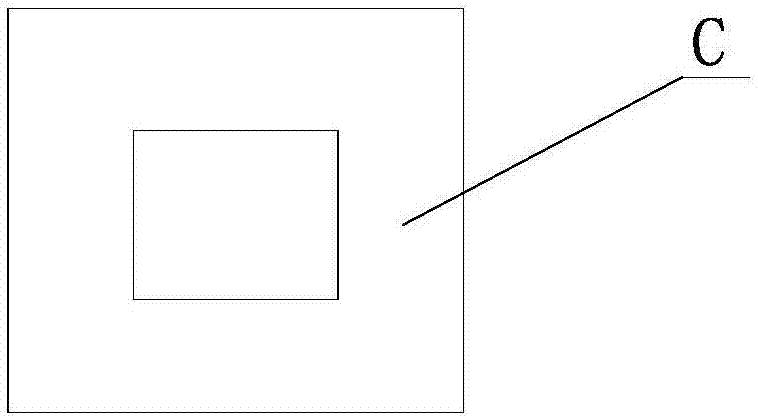

Test method of bonding characteristic of disintegrated soft rock and concrete and test sample

ActiveCN107063791AAvoid breakingComplete structurePreparing sample for investigationUsing mechanical meansTest sampleData treatment

The invention relates to a test method of the bonding characteristic of disintegrated soft rock and concrete and a test sample. The test method comprises the following steps of: manufacturing the test sample, mounting the test sample and an instrument, carrying out test loading and data processing, and the like. The test sample is obtained by pouring a concrete block adhered to a soft rock block integrally around the cuboid or cylindrical soft rock block. The test method comprises the followings steps of: putting the test sample through drying treatment or water-saturation treatment on a carrying gasket; then applying a load through a loading column; and recording the loading values P at different moments and a bonding sliding displacement value S of the soft rock block and the concrete block till the interface of the soft rock block and the concrete block is sheared and destroyed, so as to acquire the bonding characteristic and shear strength data of the soft rock block and the concrete after the soft rock is disintegrated. The test method provided by the invention effectively solves the problem of an indoor test of the bonding characteristic of easily softened or disintegrated soft rock and concrete. In addition, the test is easy to operate, high in sample manufacturing success rate, and objective and accurate in test data.

Owner:HEFEI UNIV OF TECH

Automatic dispensing mechanism

PendingCN109550646ALabor savingSave energyLiquid surface applicatorsCoatingsEngineeringAutomatic Dispensing

The invention discloses an automatic dispensing mechanism. The mechanism comprises a workbench; a feeding mechanism and a material taking and placing mechanism are arranged on the workbench, the material taking and placing mechanism is arranged on a moving assembly, the moving assembly drives the material taking and placing mechanism to move, and the feeding mechanism comprises a stock bin and atleast one vibrating disc; and the stock bin comprises a material distributing disc and a first driving mechanism for driving the material distributing disc to rotate, the material distributing disc isprovided with a plurality of object placing tables used for containing gaskets, each containing table is provided with a notch allowing the gasket to pass through, and the material distributing discis provided with feeding positions which are used for receiving materials from discharge ends of the vibrating discs. The dispensing can be realized, and the working efficiency is improved.

Owner:苏州工业园区多司电子科技有限公司

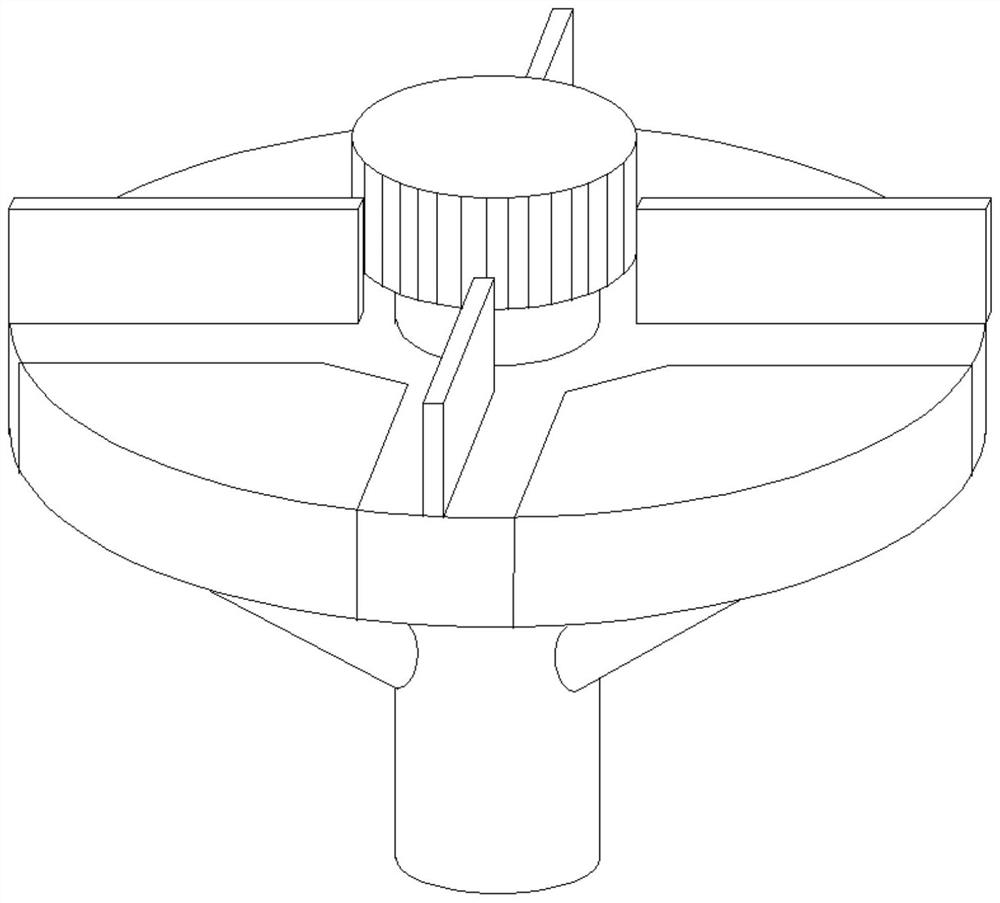

Centrifugal type threshing and grinding machine

InactiveCN107736138AImprove threshing effectAvoid wastingThreshersGrain treatmentsEngineeringPower unit

The invention discloses a centrifugal threshing grinder, comprising: a shell, the bottom surface of which forms a powder outlet, one side is provided with a core body outlet and an air inlet, and the other side is provided with an air outlet; A threshing cylinder, which includes a guide cylinder, a tooth cylinder, and a first motor; a first pair of roller layers and a second pair of roller layers; a conveyor belt assembly that guides the corncobs out of the housing; a blower and an exhaust fan; a vibration assembly , which includes a fixed plate and a pair of vibrating screens; a pair of grinding components, which include a grinding plate, a screw and a grinding stone, a support table, and a power unit. The invention can be fast, efficient, line-type threshing and grinding, effectively separate corn kernels, corn cobs and dust, reduce procedures, improve work efficiency, and facilitate maintenance and maintenance.

Owner:李斌施

Automatic turnover device for printed circuit board

ActiveCN112996256AHigh flexibilityImprove practicalityPrinted circuit manufactureElectric machineryPrinted circuit board

The invention provides an automatic turnover device for a printed circuit board, and belongs to the technical field of printed circuit board preparation. The device comprises a linear mechanism, a rotating mechanism, a width adjusting mechanism and a clamping mechanism; the rotating mechanism comprises a seat body arranged on the linear mechanism and a rotating air cylinder arranged on the seat body; the width adjusting mechanism comprises a shell, a gear, a width adjusting motor and a rack, the shell is connected with a rotating shaft of the rotating air cylinder, two strip-shaped through holes are formed in one side face of the shell, the rack is in sliding fit with a horizontal guide rod, the horizontal guide rod is arranged on the inner wall of the shell, connecting strips are arranged on the top face of the rack, and penetrating rods are connected to the connecting strips, the two penetrating rods extend out of the strip-shaped through holes respectively and are connected with L-shaped frames located outside the shell respectively; the clamping mechanism is installed on the L-shaped frames. According to the automatic turnover device, automatic turnover is achieved to replace manual operation, conveying of a front silk-screen procedure and a rear silk-screen procedure is carried out; the automatic turnover device is high in flexibility and can adapt to circuit boards of different sizes and can adapt to the situation that conveying slightly deviates and is high in practicability.

Owner:四川英创力电子科技股份有限公司

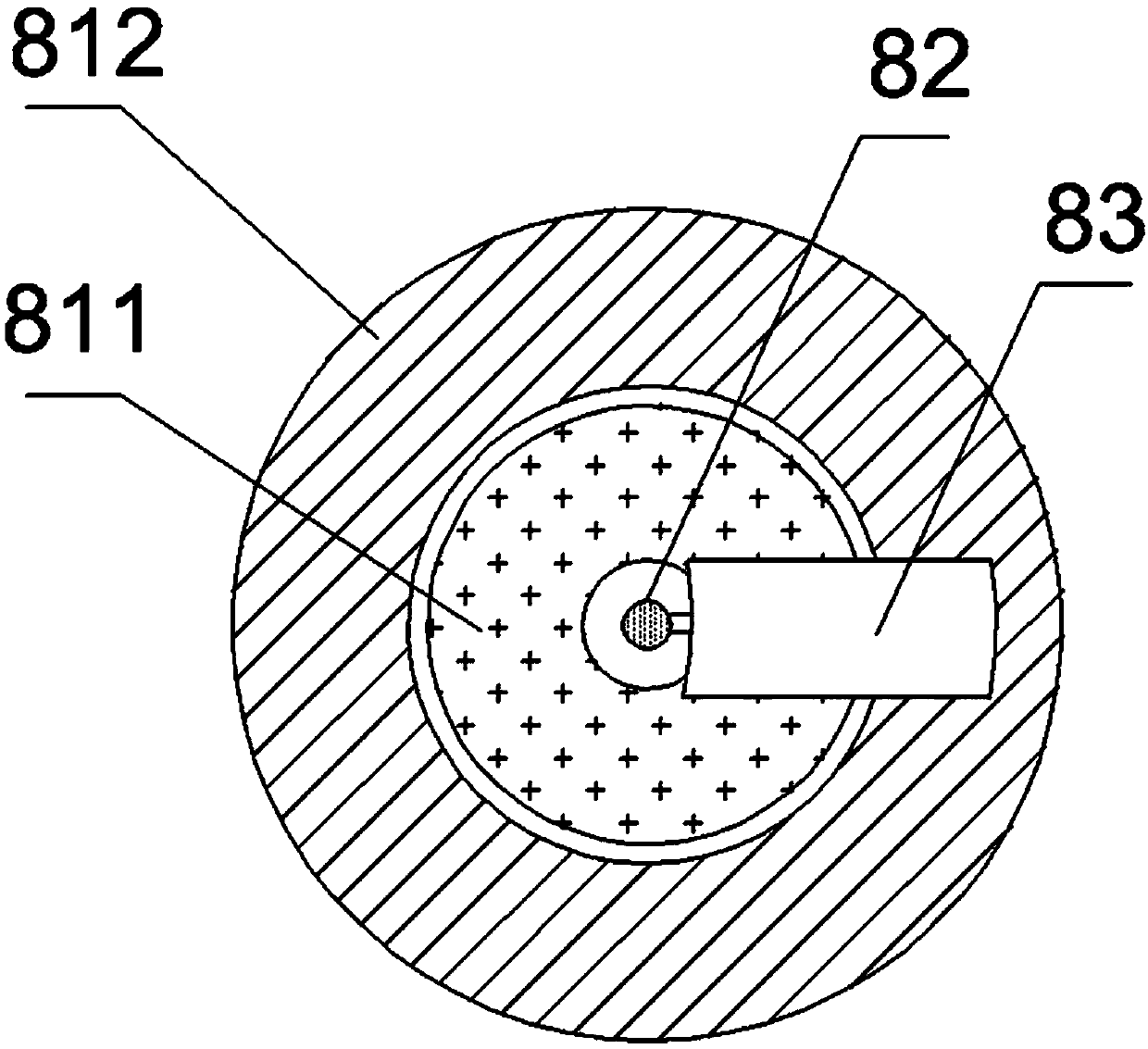

Anti-blocking dust restraining device for limestone powder blanking

PendingCN111646251AAvoid it happening againEasy to undertakeConveyorsControl devices for conveyorsElectric machineStructural engineering

The invention discloses an anti-blocking dust restraining device for limestone powder blanking, and relates to the technical field of producing and processing of limestone powder. In order to take account of functions of guaranteeing quality and restraining dust, the anti-blocking dust restraining device specifically comprises a main body, a blocking mechanism and a transporting mechanism, whereina feeding opening is formed in the top of the main body; a discharging opening is formed in the bottom of the main body; the blocking mechanism is arranged between the feeding opening and the transporting mechanism; the transporting mechanism comprises a static electricity discharging seat, a transporting power chamber and a motor; the transporting power chamber and the main body are integrally designed, the outer wall of the bottom of the motor is fixed to the outer wall of the top of the transporting power chamber through screws; and the output end of the motor is rotatably connected to a threaded pillar through a coupling. According to the anti-blocking dust restraining device disclosed by the invention, a first supporting door, a second supporting door, the static electricity discharging seat and the transporting power chamber are arranged, so that the effect of transporting limestone powder can be achieved, and the situation that a great deal of blowing dust is produced caused bydirect blanking is avoided; and besides, the static electricity discharging seat is electrified to adsorb the part of the blown limestone powder, so that blowing dust is further reduced, and the environmentally-friendly performance is promoted.

Owner:阳泉市泰耀工贸有限公司

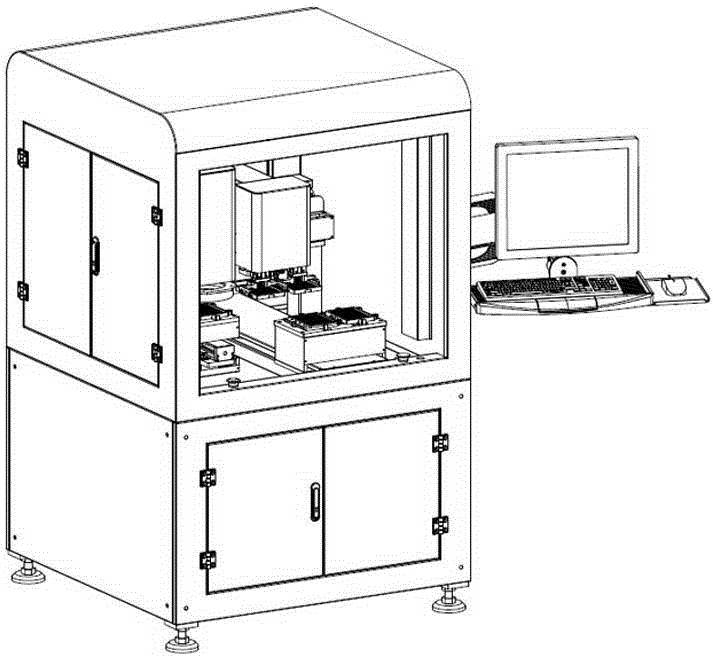

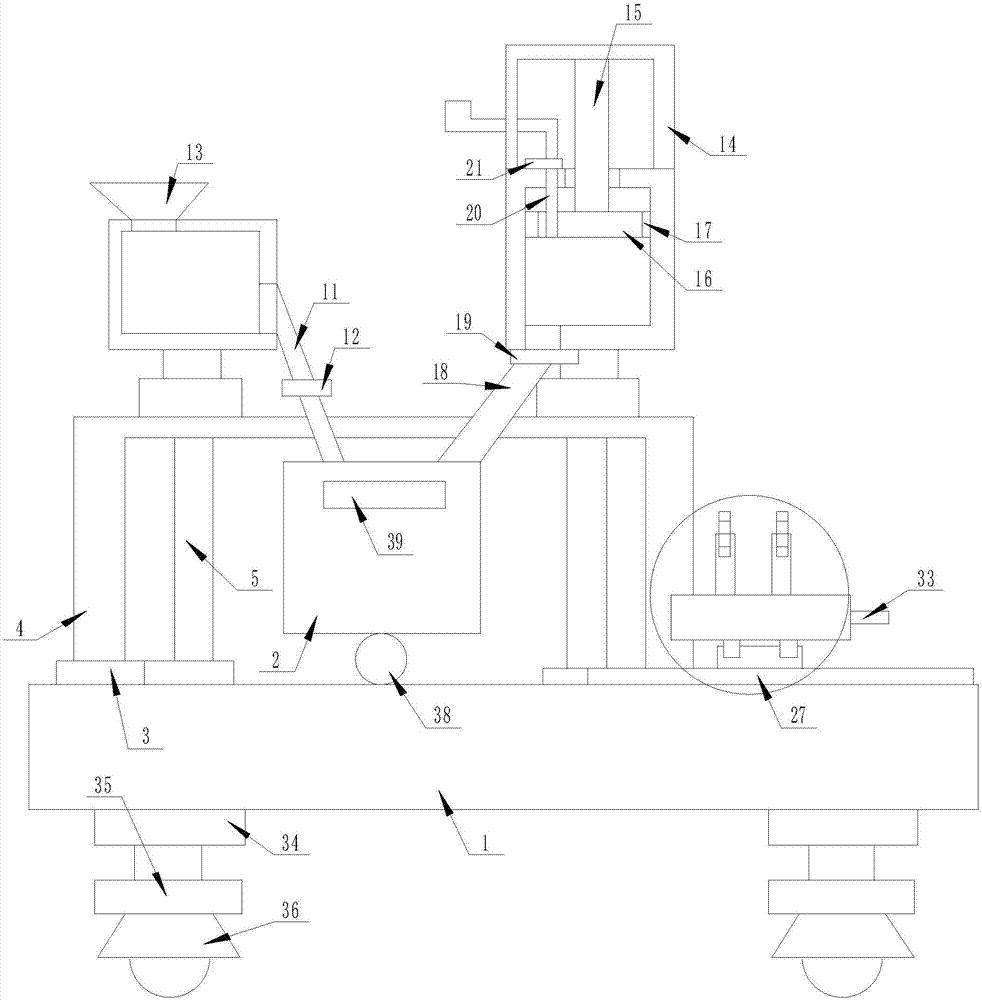

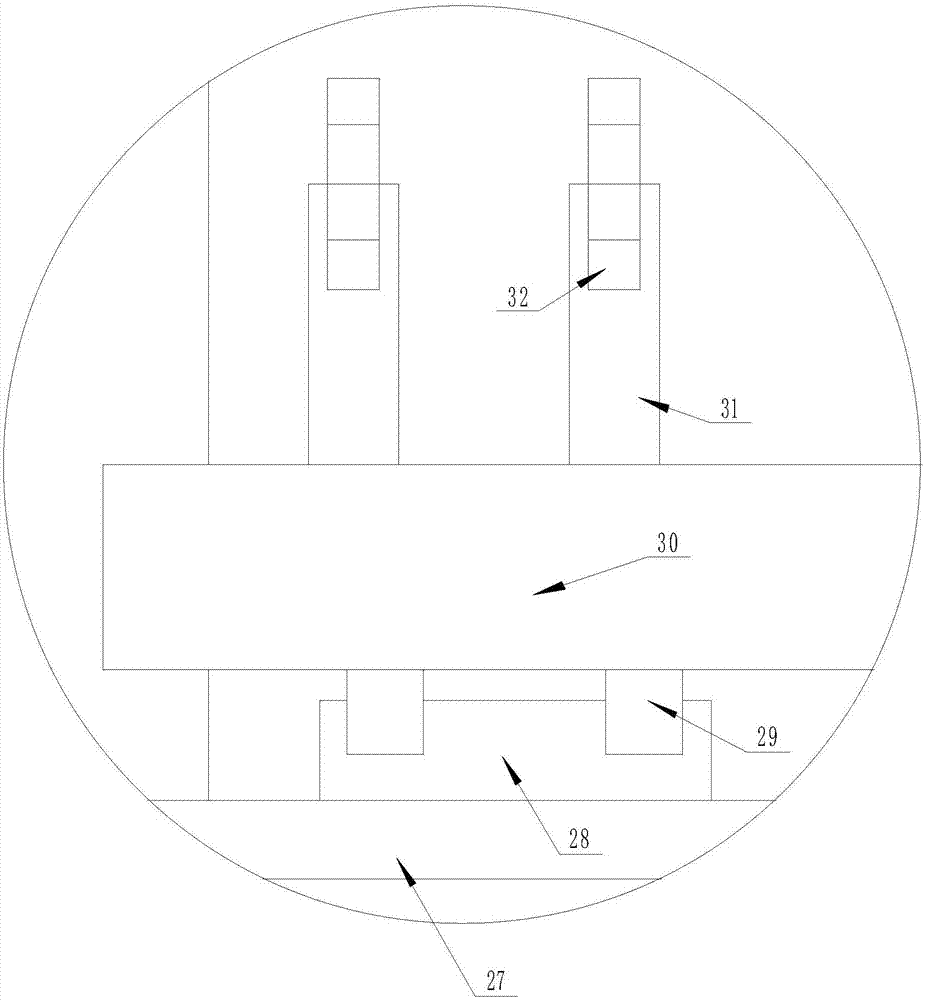

Material appearance automatic detecting device

ActiveCN105181703ASatisfy the location requirements of the inspectionRealize random transferOptically investigating flaws/contaminationTransfer mechanismTesting equipment

Owner:苏州佳祺仕科技股份有限公司

Automatic feeding flour mixing device

ActiveCN107047673AEasy to operateEasy to useMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsUltimate tensile strengthMechanical engineering

The invention discloses an automatic feeding flour mixing device. The device comprises a strip-shaped bearing base, an automatic feeding mechanism is arranged above the strip-shaped bearing base, a mixing bearing barrel is arranged at the center of the upper surface of the strip-shaped bearing base, and a moving mechanism is arranged on the lower surface of the strip-shaped bearing base. A stirring mechanism is arranged in the mixing bearing barrel, and a bearing mechanism is arranged on the upper surface of the strip-shaped bearing base and located on the right side of the mixing bearing barrel. The device has the advantages of being very convenient to operate, good in using effect, uniform in proportional mixing, uniform in stirring, good in collecting property, capable of reducing the labor intensity and convenient to move.

Owner:安徽正宇面粉有限公司

Logistics conveying and distributing device

ActiveCN112357448AImplement interception and steeringMeet the needs of production and transportationConveyor partsRoller-waysProduction lineLogistics management

The invention discloses a logistics conveying and distributing device. The logistics conveying and distributing device is connected with a previous production line and comprises a conveying section, asteering section and a distributing section. The conveying section comprises a first electric roller conveyor. The steering section is adjacently arranged on the downstream side of the conveying section in the conveying direction, the steering section comprises a pair of positioning air cylinders, a conveying roller assembly, a steering roller assembly and a pair of limiting blocks, and the conveying roller assembly comprises a longitudinal electric roller and a first lifting air cylinder. The steering roller assembly comprises a pair of transverse mechanical rollers located on the two sidesof the longitudinal electric roller, a pair of transverse electric rollers, a pair of L-shaped swing arms, a pair of second lifting air cylinders, a pair of third telescopic air cylinders and a pair of sliding grooves. The distributing section is located on one side of the steering section and comprises a second electric roller conveyor, a bearing assembly, a scanner and a plurality of third electric roller conveyors. Distributing can be carried out according to the size specifications of goods and destinations or goods attributes, the working efficiency is high, human interference is reduced,the intelligent degree is high, and the requirements of general flow production and transportation are met.

Owner:BEIJING UNIV OF POSTS & TELECOMM

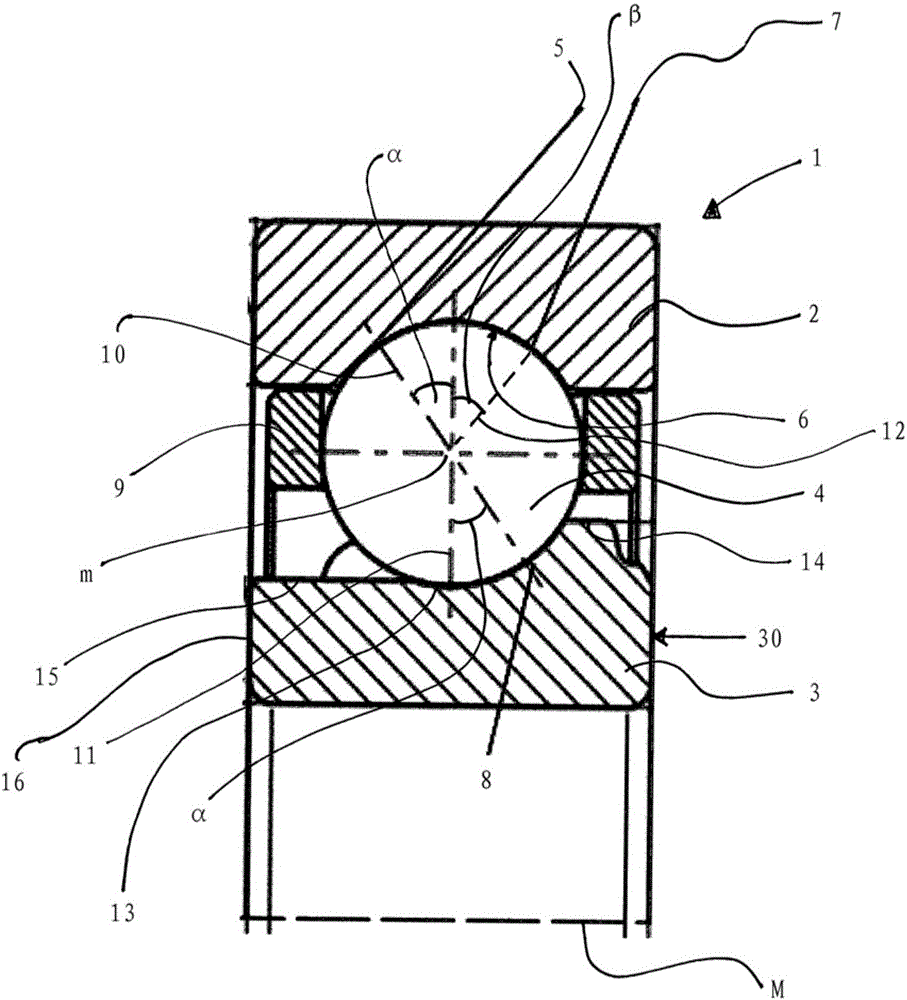

Rolling bearing, high-speed bearing device and compressor

InactiveCN106065899AAvoid or at least minimize changeEasy to undertakeShaftsBall bearingsEngineeringMechanical engineering

An embodiment relates to a rolling bearing (1) having at least one outer ring (2) and at least one inner ring (3). A plurality of rolling bodies (4) is provided between the outer ring and the inner ring to support the inner ring (3) in a rotary mode with respect to the outer ring (2). The outer ring (2) has at least one more rollaway nest (5, 7) for the plurality of rolling bodies (4) than the inner race (3).

Owner:AB SKF

Control method of automatic material charging bag applicator

ActiveCN108773527AImprove work efficiencyImprove practicalityPackagingEngineeringMechanical engineering

The invention discloses a control method of an automatic material charging bag applicator. The control method is characterized in that the material charging bag applicator is adopted to pick up and open a packaging bag, the packaging bag is transversely placed on a bag placing tray of an X-axis conveying device for conveying, the X-axis conveying device conveys the packaging bag to an operation station of a remaining bag supporting mechanism, and a remaining bag tray of a Y-axis supporting device moves outwards in the Y-axis direction and is connected into the bottom of the packaging bag in aninserting mode; and the packaging bag is transversely placed on the remaining bag tray of the Y-axis supporting device, a guide suction bag mechanism is used for upwards lifting the side edge of thepackaging bag, a bag taking device of a bag grabbing mechanical arm clamps the side edge of the lifted packaging bag, and a bag opening device is used for adsorbing and opening the opening of the packaging bag so as to enable the packaging bag to receive materials. According to the control method of the automatic material charging bag applicator, conveying, bag taking and bag opening of the packaging bag are effectively achieved, the working efficiency is improved, and relatively good practicability is achieved.

Owner:成都鸿源锦程机器人有限公司

Integrated device for corn aftertreatment

The invention discloses an integrated device for corn aftertreatment. The integrated device comprises a shell body, a cover body, a plurality of needle pricking assemblies, a plurality of threshing drums, a plurality of roller shaft assemblies, a conveying belt assembly, a vibration assembly and a pair of grinding assemblies, wherein a powder discharging opening and a first air cylinder are formedon the bottom face of the shell body, and a cob discharging opening is formed in one side of the shell body; each needle pricking assembly comprises a first motor, a second air cylinder and a push cylinder; multiple columns of [-shaped rasps are uniformly distributed on the internal wall of each threshing drum; each roller shaft assembly comprises a first roller shaft and multiple pairs of secondroller shafts; the conveying belt assembly is used for leading out corncobs from the shell body; the vibration assembly comprises a fixing plate and a pair of vibration screens; and the grinding assemblies comprise grinding plates, screws, grinding stones, supporting tables and power units. According to the integrated device for corn aftertreatment, threshing and grinding can be carried out in arapid, efficient and assembly-line manner, corn kernels, corncobs and fugitive dust are effectively separated, procedures are reduced, the working efficiency is increased, and the maintenance and servicing are convenient.

Owner:李斌施

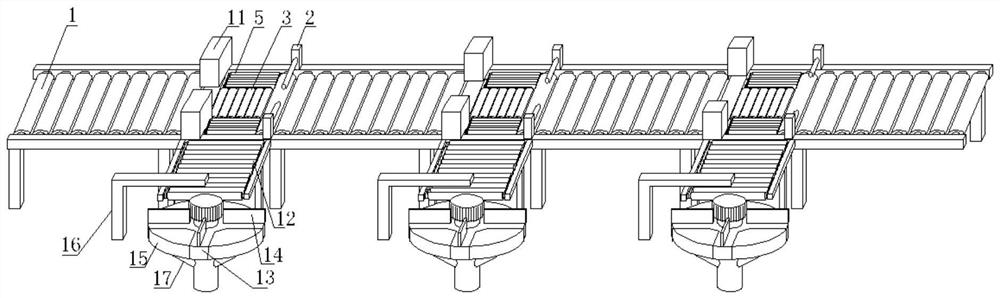

Automatic anchor bolt thermal shrinkage production line

PendingCN113320739AConvenient automatic heat shrink processingReduce labor intensityWrappers shrinkageRod-shaped articlesAnchor boltThermal shrinkage

The invention relates to an automatic anchor bolt thermal shrinkage production line. The automatic anchor bolt thermal shrinkage production line comprises a feeding unit, a thermal shrinkage unit and a material receiving unit; the feeding unit is used for storing anchor bolts to be subjected to thermal shrinkage processing; the thermal shrinkage unit comprises a thermal shrinkage rack and a heating device; the thermal shrinkage rack is provided with a single anchor bolt processing position; the single anchor bolt processing position is used for supporting and placing a single anchor bolt; the heating device is used for heating thermal shrinkage pipes at the two ends of the single anchor bolt to achieve thermal shrinkage processing; the material receiving unit is used for collecting anchor bolts subjected to thermal shrinkage processing; a feeding mechanism is arranged at the rear end of the feeding unit and is used for conveying the anchor bolts to the single anchor bolt processing position one by one; and a discharging mechanism is arranged at the front end of the material receiving unit and is used for transferring the anchor bolts subjected to thermal shrinkage processing to the material receiving unit from the single anchor bolt processing position. The single anchor bolt is conveyed to the single anchor bolt processing position of the thermal shrinkage unit through a feeding structure, the thermal shrinkage pipes on the two sides of the anchor bolt are correspondingly heated through the heating device, and after heating is completed, the anchor bolt is transferred to the receiving unit through the discharging mechanism, so automatic thermal shrinkage processing of the anchor bolt is conveniently achieved.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD +1

Waste circuit board conveying and loading device

The invention relates to the technical field of waste electric appliance recovery processing equipment, in particular to a waste circuit board conveying and loading device. According to the technicalscheme, the device is characterized by comprising a conveying mechanism and a machine frame, the conveying mechanism comprises a fixed table, a conveying plate, a power piece and a conveying belt, theconveying belt is arranged on the machine frame, the conveying plate is provided with a storage box, the storage box is in sliding connection with a box door, a rack is arranged on the box door, themachine frame is provided with a gear meshed with the rack, and the gear is fixedly connected with a motor. According to the waste circuit board conveying and loading device, the storage box moves along with sliding of the conveying plate, when the storage box moves close to the conveying direction of the conveying belt, the gear is meshed with the rack, the motor is not started at the moment, thegear is used for limiting the rack, and the box door moves relative to the storage box, so that the box door is conveniently and rapidly opened, and a waste circuit board on the conveying belt can smoothly enter the storage box for loading; and after loading is completed, the motor is started, the gear rotates to drive the rack to move, then the box door is closed, so that the structure is simpleand practical.

Owner:厦门绿洲环保产业有限公司

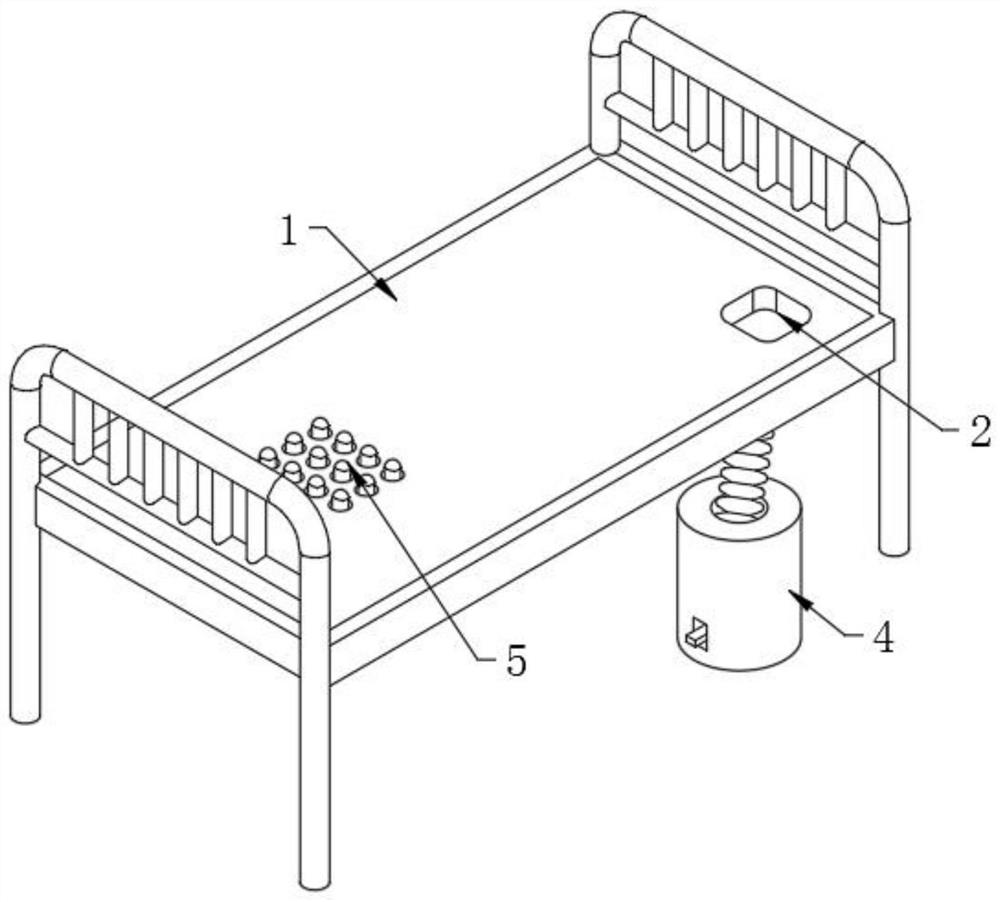

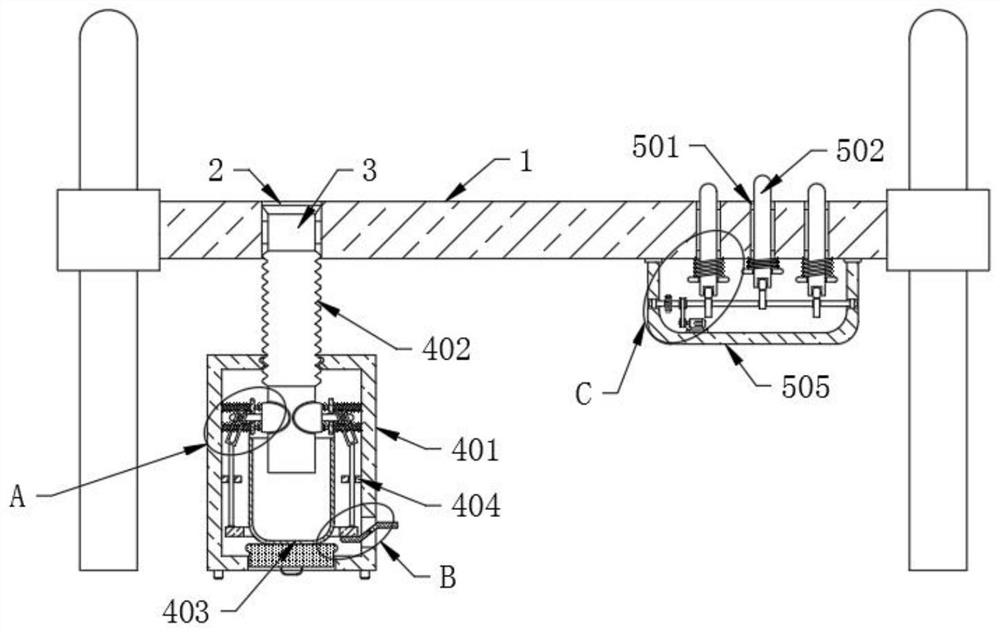

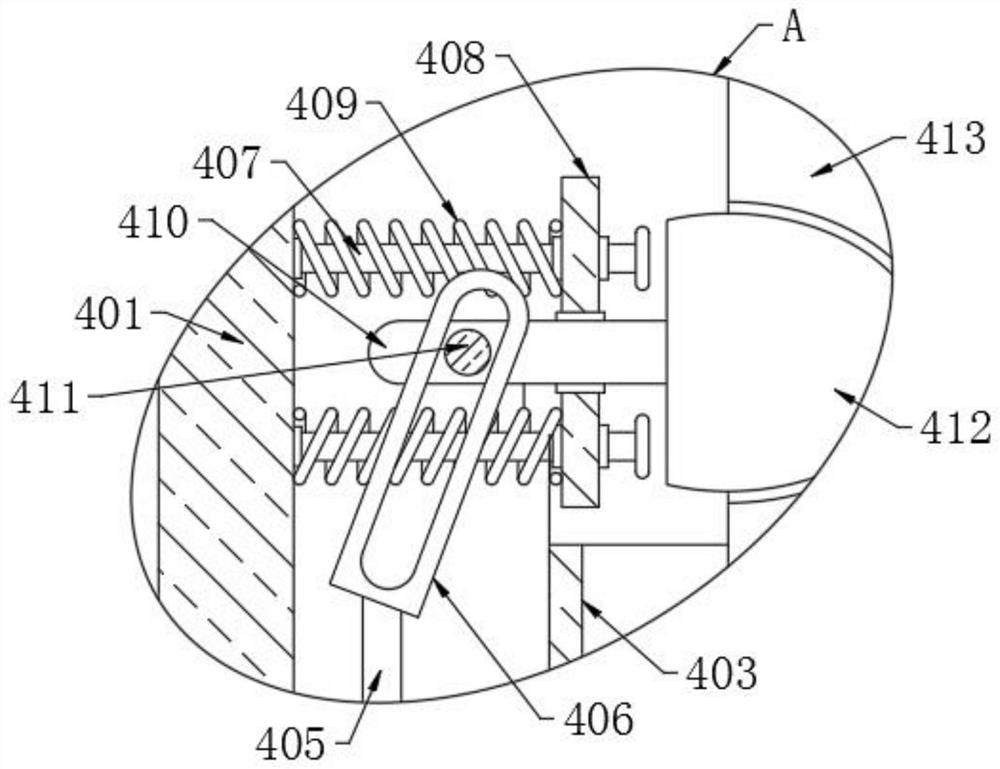

Chemotherapy nursing device for medical oncology

InactiveCN111904745AReduce numbnessEasy to undertakeNursing bedsSpittle receiving devicesNursing careMassage

The invention belongs to the technical field of medical instruments, and particularly relates to a chemotherapy nursing device for medical oncology. The chemotherapy nursing device comprises a nursingbed body, wherein a sewage draining opening is formed in the nursing bed body, a wide-mouth funnel is fixedly mounted in the sewage draining opening, and a storage device is arranged below the nursing bed body, and comprises a cylinder; a corrugated pipe is arranged at the top of the cylinder, the top end of the corrugated pipe extends into the sewage draining opening and is fixedly connected with the wide-mouth funnel, the corrugated pipe penetrates through the cylinder and extends into the cylinder, a containing groove is formed in the bottom of the cylinder, and a massage mechanism is arranged on the nursing bed body; and the massage mechanism comprises nine sliding holes formed in the nursing bed body. The nursing bed is novel in design and simple to operate, vomit of a patient can beconveniently received and sealed, smell is prevented from being emitted, legs of the patient can be massaged, and leg numbness caused by long-time lying of the patient is prevented.

Owner:杨静

Concrete material screening device

InactiveCN112138979AImprove filtration efficiencyWon't affect landingSievingScreeningStructural engineeringMechanical engineering

The invention aims to provide a concrete material screening device to achieve the technical purpose of screening concrete materials. The concrete material screening device comprises a screen body mechanism and a stirring mechanism. The screen body mechanism comprises an outer screen shell and an inner screen body, wherein the inner screen body is installed in the outer screen shell, and a space allowing screened concrete to pass through is formed between the inner screen body and the outer screen shell. A discharging opening is formed in the bottom end of the outer screen shell, and a feedingcavity is formed in one side of the upper portions of the outer screen shell and the inner screen body. The inner screen body is of a conical cavity structure. The stirring mechanism comprises a stirring cavity and a stirring plate, wherein the stirring cavity is rotatably mounted in the inner screen body, and the stirring plate is mounted on the stirring cavity.

Owner:孔庆珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com