Spiral material fishing device

A technology of spiral type and feeder, which is applied in chemical instruments and methods, mobile filter element filters, filtration and separation, etc., can solve the problems of high energy consumption, high cost and complicated process of machinery and equipment, and achieve the effect of convenient operation for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

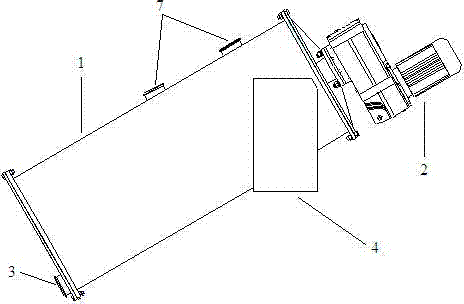

[0016] In some fields that need to use a material extraction device, especially in the pharmaceutical industry, the fresh extraction liquid is generally pure tap water. After the extraction liquid washes away the residue in the previous process, the liquid with the residue is removed from the figure 1 The inlet 3 of the shown screw-type dredger enters the dredger, starts the motor to drive the dredger bar 5 to rotate, and like this, the spiral blade 6 installed on the dredger bar 5 will take the residue out from the bottom of the dredger Go to Exit 4.

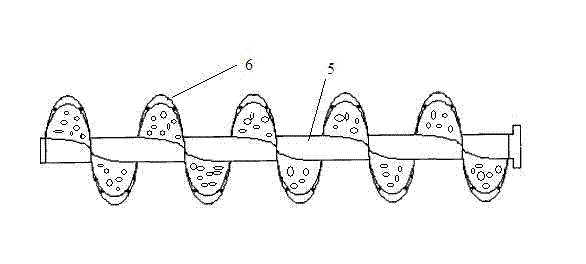

[0017] In the process of taking out the residue, the spiral blade 6 will also squeeze the blade, and then keep the liquid at the bottom of the scraper as much as possible, so that it can enter another process to extract the active ingredients in the raw material to achieve the maximum circulation use. From figure 2 The leaf diameters of the spiral blades shown are equal or unequal, and the leaf diameters gradually de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com