Reciprocating type crushing device for medicinal material processing

A reciprocating technology for medicinal material processing, which is applied in the direction of grain processing, etc., can solve the problems of low crushing and refining efficiency of Chinese medicinal materials, affecting the processing efficiency of medicinal materials, and cumbersome process, so as to improve the effect of rolling and refining, and improve the rolling effect Fragmentation effect, effect of guarantee connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

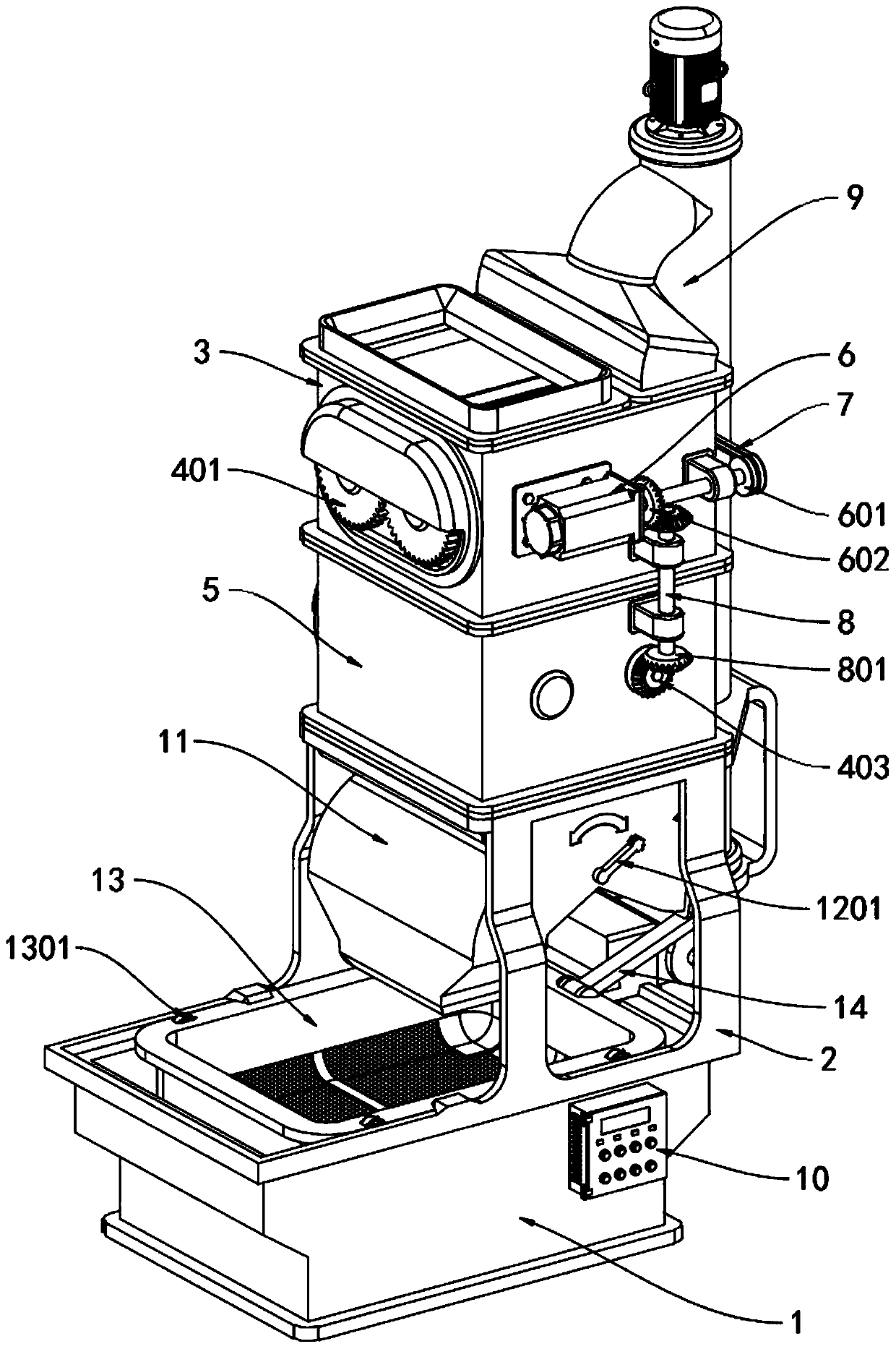

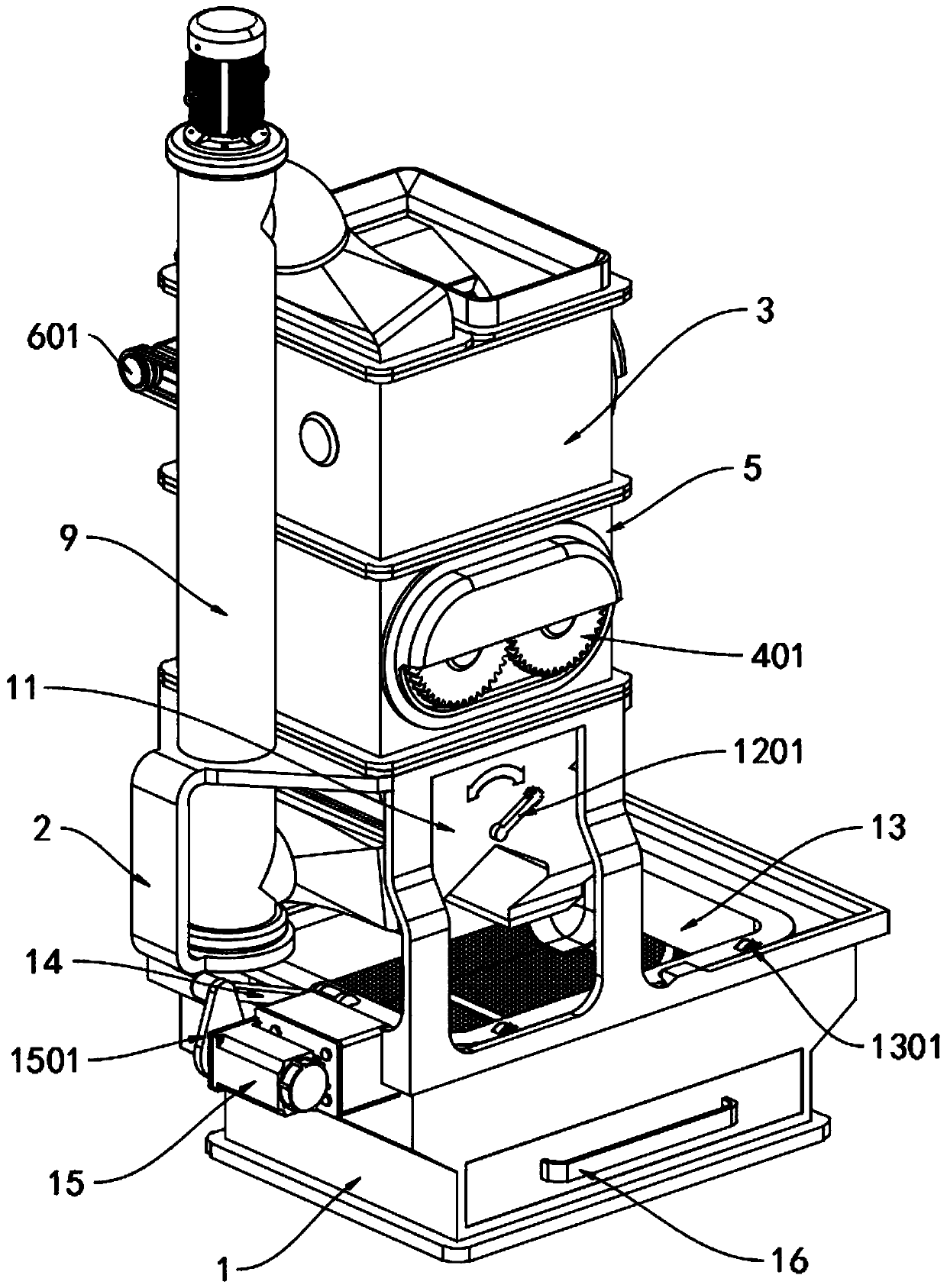

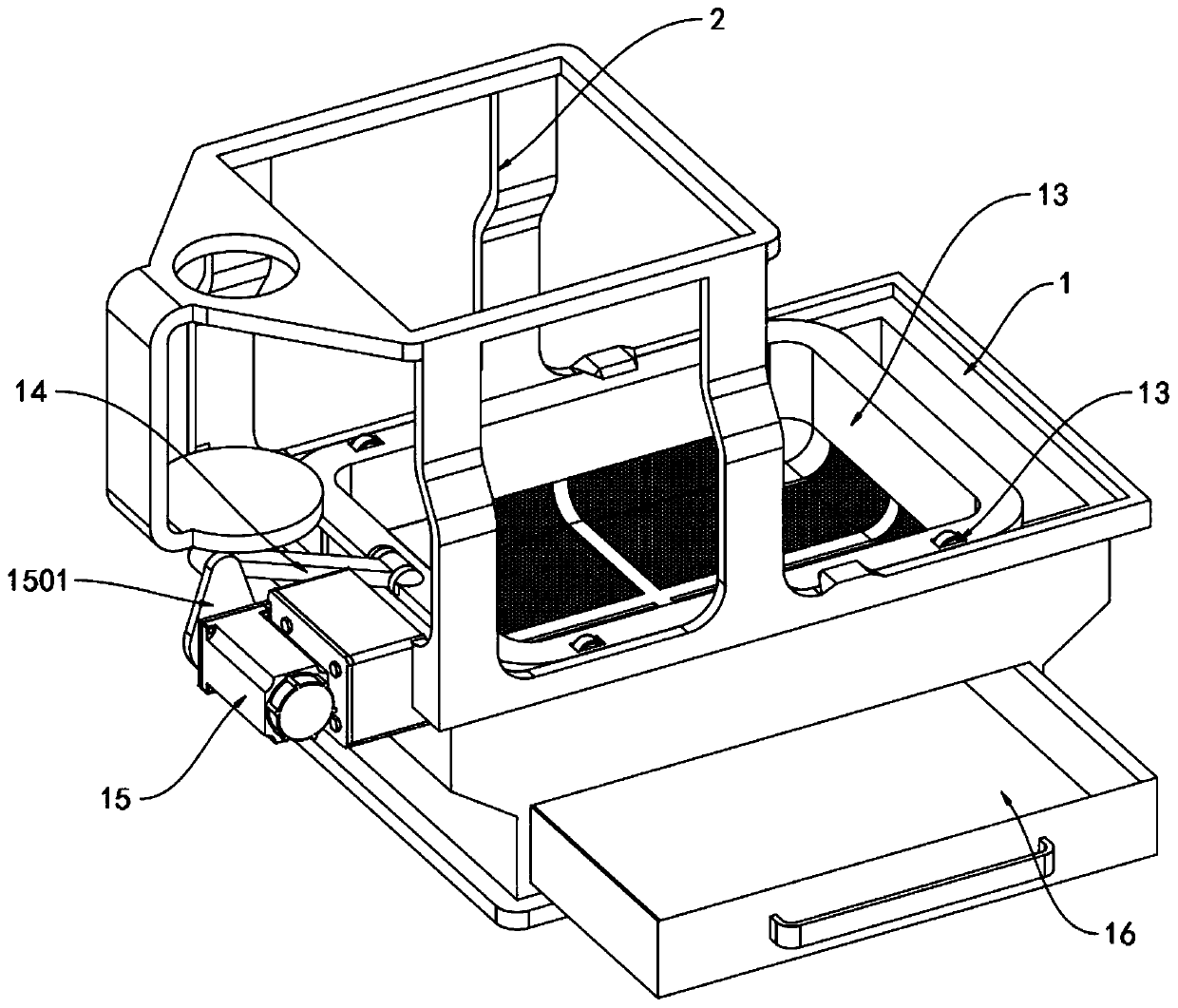

[0033] as attached figure 1 To attach Figure 9 Shown:

[0034]The invention provides a reciprocating crushing device for processing medicinal materials, which includes a main body 1, an upper crushing box 3, a lower crushing box 5, a driving motor 6, a linkage rod 8, a screw conveyor 9, a screen basket 13 and a storage The material drawer 16; the inside of the main body 1 is a hollow structure, and the support frame 2 is installed on the top of the main body 1; the upper crushing box 3 is a square box structure, and the crushing roller 4 is located inside the upper crushing box 3; the lower crushing box 5 is Square box structure, the lower crushing box 5 is located at the top of the upper crushing box 3, and the crushing roller 4 is located inside the lower crushing box 5; the drive motor 6 is electrically connected with the control electric box 10 through a line, and the control electric box 10 is installed on the On the outer wall of the main body 1, and the control elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com