Waste circuit board conveying and loading device

A waste circuit board and loading device technology, which is applied in packaging and other directions, can solve the problems affecting the loading of waste circuit boards, the box door 6 cannot be opened normally, and the pressure is insufficient, so as to achieve a simple and practical structure, convenient loading, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

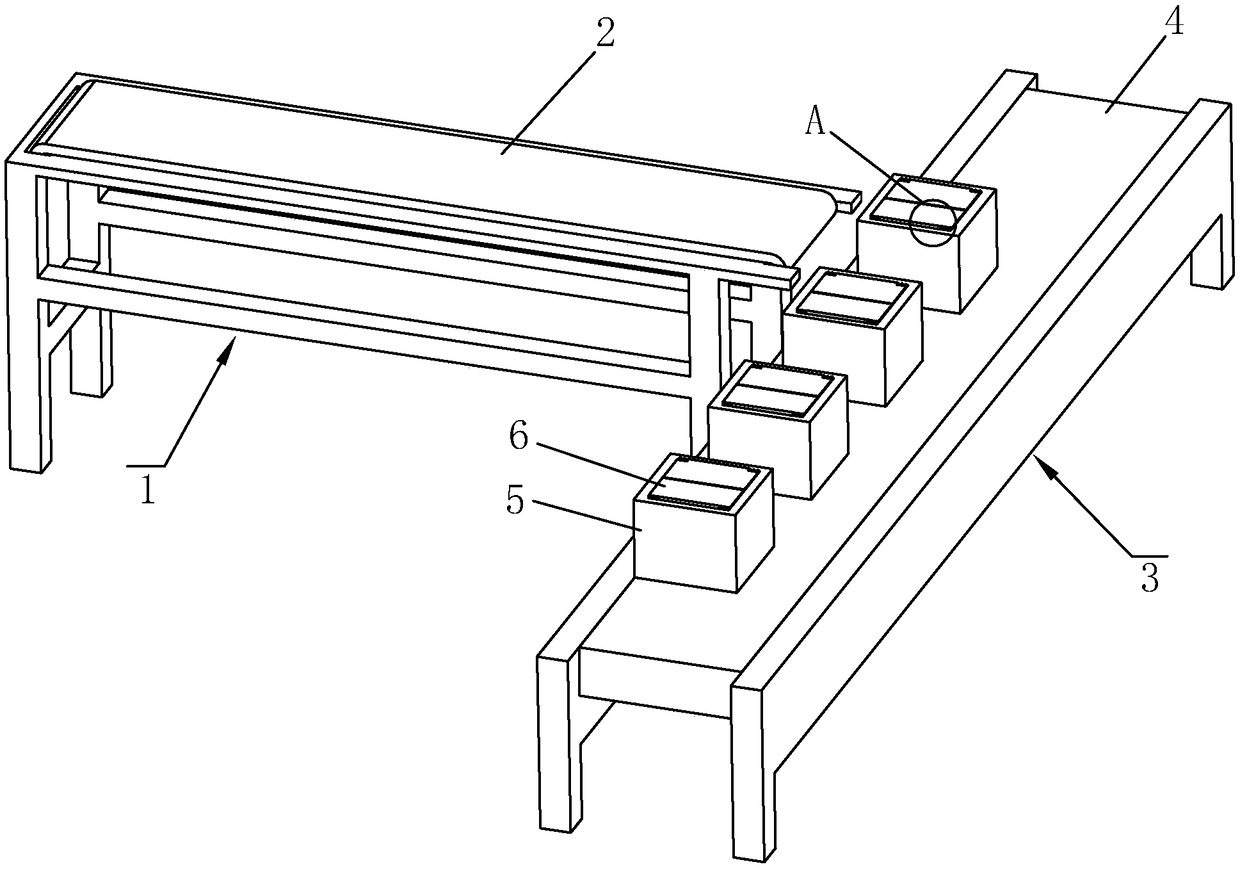

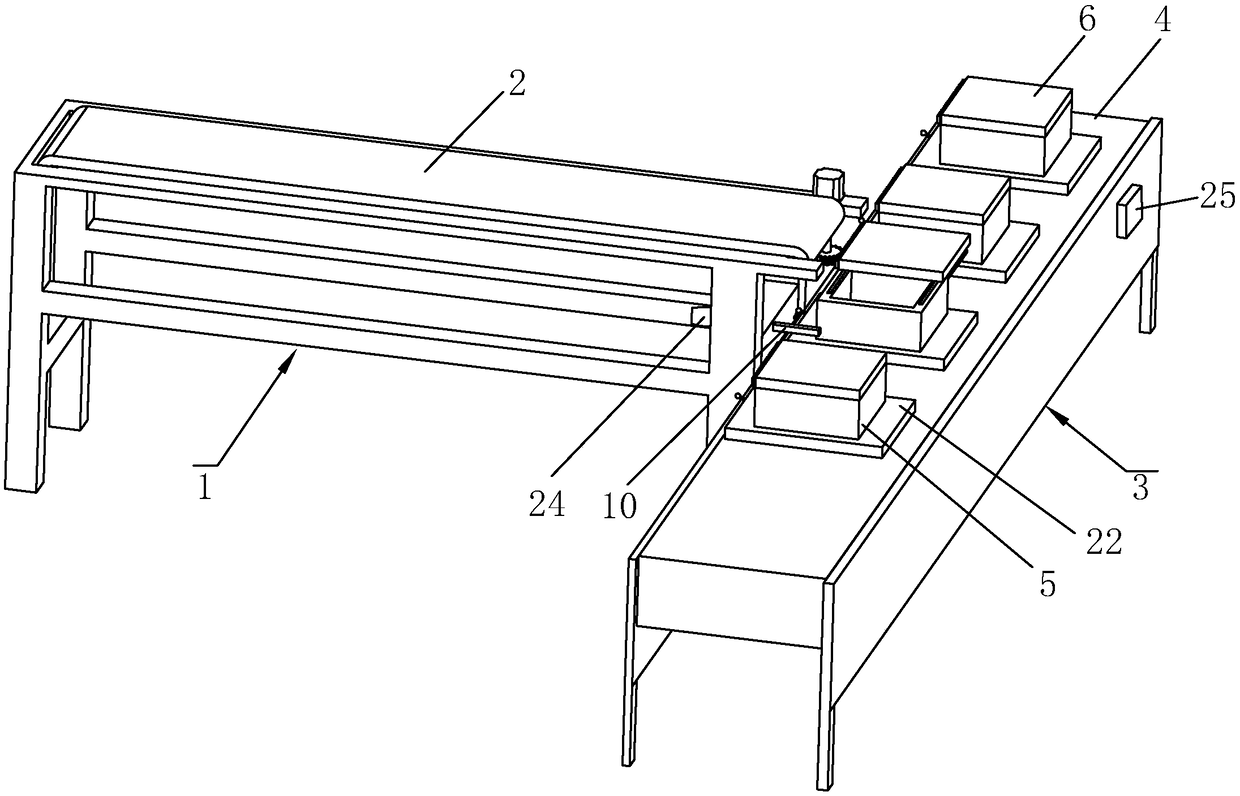

[0041] A waste circuit board conveying and loading device, refer to image 3 , including a frame 1, a conveyor belt 2 fixedly installed on the top of the frame 1, and a fixed table 3 located on one side of the frame 1, the conveyor belt 2 is used to transport waste circuit boards to be loaded, and the fixed table 3 is slidably installed with a cuboid The conveyor plate 4, the conveyor belt 2 and the conveyor plate 4 are all arranged horizontally, the feeding terminal of the conveyor belt 2 is located directly above the conveyor plate 4, and the length direction of the conveyor belt 2 is perpendicular to the length direction of the conveyor plate 4. Simultaneously, the fixed platform 3 is provided with a power part for driving the sliding of the conveying plate 4. In this embodiment, the power part can preferably be a servo motor 27 (refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com